HEIDELBERG Suprasetter 145, Suprasetter 162, Suprasetter 190 User Manual

Suprasetter 145/162/190

User’s Guide

02/2019

Order No. PG.999.0005

ABC

Imprint/Company Address

Copyright © 2019 Heidelberger

Druckmaschinen AG.

No part of this book may be reproduced without prior written permission.

Heidelberger Druckmaschinen AG

Dr.-Hell-Straße

24107 Kiel

Germany

Phone +49 431 386-0

Fax +49 431 386-1380

www.heidelberg.com

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Heidelberg and the Heidelberg logo

are registered trademarks of Heidelberger Druckmaschinen AG.

Suprasetter is a trademark of Heidelberger Druckmaschinen AG.

Other company names, product

names and trademarks not expressly

mentioned in this manual are trademarks or registered trademarks of

the corresponding manufacturers

and fall within the regulations

regarding the protection of trademarks.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Important notice:

We are dedicated to improving and

enhancing our products. Consequently, the information in this

manual is subject to change without

notice.

Heidelberger Druckmaschinen AG

assumes no responsibility for information and description as far as

third-party products are concerned.

The information contained in this

manual about performance and

speed as well as technical data concerning application of our products

is not legally binding as it does not

constitute a written contract of features.

If any problems occur with the product described in this manual, please

contact the agency which is responsible for you.

Translation of Original operating

manual

Order No. PG.999.0005

02/2019

Printed in Germany.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

Table of Co nte nts

Table of Contents

3

Before you start ...

Safety Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Device Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Correct Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Avoid Misuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Qualification of the Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Power Switch with Emergency Cutoff Function . . . . . . . . . . . . . . 11

Emergency Stop Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

On/Off button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Laser Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Service and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Safety Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Check of the safety loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Automatic check of the safety loop . . . . . . . . . . . . . . . . . . . . . . 14

Manual check of the safety loop . . . . . . . . . . . . . . . . . . . . . . . . 15

ESD Protective Measures for Prepress Systems and Operators . . . 16

Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Formation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Practical Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Standards/Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Disposal of the Suprasetter 145/162/190 . . . . . . . . . . . . . . . . . . . . 18

Converting the Suprasetter 145/162/190 . . . . . . . . . . . . . . . . . . . . . 18

About This Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

What You Should Already Know . . . . . . . . . . . . . . . . . . . . . . . . . 19

Further Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Symbols and Styles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Suprasetter 145/162/190 – User’s Guide 3

Table of Contents

Important Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Heidelberg online . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Introduction

Description of the Unit and its Functions . . . . . . . . . . . . . . . . . . . . 23

Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Power switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

On/Off button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Keeping Access Routes Clear . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Notes on the Use of Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Notes on Installation

Notes on Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Transport of the Suprasetter 145/162/190 . . . . . . . . . . . . . . . . . . 29

Installing the Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Automatic Cutouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Software Installation (Container Version) . . . . . . . . . . . . . . . . . . 30

Saving a Backup of the Recorder Configuration . . . . . . . . . . . . . . 31

Selecting the User Interface Language . . . . . . . . . . . . . . . . . . . . 31

Operation

Power-on and Power-off Rules for Recorders with a Linux

Operating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Power-on order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Shutdown order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Switching on the Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Manual Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Automatic Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Switching Off the Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4Version 2019

Table of Contents

Shutdown using the User Interface on the Workstation . . . . . . . 37

Shutdown with the On/Off Button on the Device . . . . . . . . . . . . 37

Quick Shutdown with the On/Off button on the Suprasetter. . . . 38

Material Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Material storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Loading Plates on the Manual Device and on the Semi-automatic

Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Unloading the Plates on a Manual Device . . . . . . . . . . . . . . . . . . . 45

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Loading Plates on a Fully Automated Device . . . . . . . . . . . . . . . . . 46

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Empty waste box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Fixing Jamming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Switching on an Automatic Cutout . . . . . . . . . . . . . . . . . . . . . . 56

Service and Maintenance

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Safety Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Qualification of the Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Maintenance by the User . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Cleaning the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Cleaning the Cleaning Roller on a Manual Device and on a

Semi-automatic Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Suprasetter 145/162/190 – User’s Guide 5

Table of Contents

Cleaning the Cleaning Roller on a Fully Automated Device with a

Cross Conveyor or OLP Table . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Removing Punch Waste on a Manual Device and on a

Semi-automatic Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Removing Punch Waste on a Fully Automated Device with a

Cross Conveyor or OLP Table . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Changing the Filter Kit in the Suction Device . . . . . . . . . . . . . . . 71

Technical Data

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Protection and Safety Requirements . . . . . . . . . . . . . . . . . . . . . . . 78

Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Mechanical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Electrical safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Electromagnetic compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . 80

Interference Emission (Stray Radiation and Interference Voltage) 80

Interference immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Radio Interference Suppression . . . . . . . . . . . . . . . . . . . . . . . . . 81

Approvals and Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

CE-Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Labels on the Suprasetter 145/162/190 . . . . . . . . . . . . . . . . . . . 83

Disposal

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Disposal of the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Disposal of the Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Harmful Substances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Recyclable Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Dismantling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

6Version 2019

Table of Contents

Disposal of the Loader/Unloader . . . . . . . . . . . . . . . . . . . . . . . . 120

Harmful Substances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Recyclable Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Dismantling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Disposal of the Separator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Harmful Substances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Recyclable Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Dismantling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Disposal of the Tray Loader . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Harmful Substances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Recyclable Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Dismantling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Disposal of the Magazine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Recyclable Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Dismantling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Suprasetter 145/162/190 – User’s Guide 7

Before you start ...

Before you start ...

Safety Notes

The Suprasetter complies with the safety regulations of the standards and

specifications listed in the "Technical Data" chapter.

Device Names

Sales designation Type designation

Suprasetter 145/162/190 PG.010.000B

Separator PG.050.000B

Tray loader PG.090.000B

Cassette magazine PG.030.000B

I/O table PG.021.000B

Correct Use

The Suprasetter is a laser imagesetter for imaging offset printing plates and

may only be used for this purpose as described in the customer documentation.

All other use that does not comply with the correct use is prohibited.

Avoid Misuse

Do not place any objects or liquids on the Suprasetter.

Ventilation outlets must be kept clear at all times.

Do not use the Suprasetter as a seat.

Suprasetter 145/162/190 – User’s Guide 9

Before you start ...

Qualification of the Users

After installation, users will be instructed in the operation and service and

maintenance of the Suprasetter by Heidelberg service personnel. Further

instruction, for example, for new staff employed subsequently, must be

ensured by the operator of the Suprasetter.

General

The Suprasetter may be installed only by authorized service personnel. The

ambient conditions must be observed.

For the operating company of a print shop, it is important that the exposure

limits regarding the breathable air in the work area, where the Suprasetter is

located, are adhered to. The air exchange must be arranged in such a way that

the measured dust particles are regularly below the exposure limit values. In

accordance with the state of the art, this can be achieved with an 8 to 10 air

change rate per hour. If this is not the case at the installation site, the operating company should install an additional exhaust system.

Warning: Unauthorized opening of any parts of the casing not specifically referred to in the operating manual and inexpert repairs can lead

to considerable danger for the user.

Servicing

this purpose. The relevant accident prevention regulations must be

observed at all times.

Non-observance of accident prevention regulations can lead to the loss

of accident insurance cover.

Warning: Plate edges can be sharp. You can injure your hands if you do

not wear protective gloves.

10 Version 2019

may only be performed by authorized personnel trained for

Before you start ...

Warning: The following loads should not be exceeded: women 15 kg,

men 25 kg.

Warning: The key-operated switch that can be seen after the top right

side panel is opened may be operated only by service personnel and not

by the operator.

The key-operated switch bypasses the safety loop.

The following risks can occur:

- Hazard of being crushed by moving parts.

- Injury from electric shock.

Warning: If cleaning the Suprasetter involves the use of liquids, discon-

nect it from the power supply beforehand. Do this by pulling out the

power connector on the service tap or by switching it off with the power

switch.

Warning: You run the risk of injuring your fingers on the sharp edges of

the printing plates if your fingers are between the insertion/ejection

table and the cross conveyor of the Suprasetter. The protective cover is

used to avoid this.

Warning: Wear disposable gloves and light dust mask We recom-

mend that you wear the disposable gloves and light dust mask included

in the kit when you are changing the filters. After you remove the filters,

clean the casing with a vacuum cleaner. Place the used filters, dispos-

able gloves, dust mask and vacuum cleaner bag in a plastic bag, tie the

bag up and dispose of it as general commercial waste. If you are not

sure about disposal procedures, contact your local waste disposal com-

pany for details.

Power Switch with Emergency Cutoff Function

The Suprasetter is fully cut off from the power supply by the power switch (red

rotary switch).

Suprasetter 145/162/190 – User’s Guide 11

Before you start ...

The power switch (red rotary switch) separates the Suprasetter's four poles

from the power supply. In an emergency, this power switch is used as an emergency stop switch for the Suprasetter.

Emergency Stop Switch

All mechanical motions in the device are stopped and the invisible laser beam

is switched off when the emergency stop switches (fully automated device: 8

units, semi-automated device: 4 units) are used.

Use these switches in cases of emergency only. They are located behind the

panels of the device. They are designed for an emergency during servicing.

On/Off button

The Suprasetter is only de-energized by the On/Off button.

The CEE or Nema outlets of the service line must be easily accessible at all

times.

To fully separate the Suprasetter from mains, e.g. in case of danger, the device

must be de-energized by actuating the power switch or unplugging the CEE or

Nema plug if applicable.

When connecting or disconnecting the power cable, make sure that your

hands are not wet and only hold the cable at the connector, if the cable has

one. A damaged power cable can cause leakage currents and electric shocks.

Protect the power cable from being damaged. Never place any heavy objects

upon it and do not allow it to get jammed.

Laser Safety

The laser imagesetter is a Class 1 laser product.

This means that the invisible

shielded by means of protective covers.

12 Version 2019

laser radiation produced in the Suprasetter is

Before you start ...

If used as directed, the user is never exposed to danger from the laser beam.

The laser systems used in the Suprasetter are Class 4 products (> 500 mW).

Companies servicing the equipment in Germany must appoint a laser protection officer in compliance with the Accident Prevention Regulations (BGV B2) of

the Professional Trade Association.

Servicing may only be carried out by Heidelberg personnel who have

been trained by appropriate laser protection officers for this purpose.

Service and Maintenance

Servicing may be done solely by persons who are authorized by Heidelberg to

do so.

The relevant accident prevention regulations must be observed at all times.

Warning: Never remove covers or any other parts of the casing except

for the work described in the "Service and Maintenance" and "Trouble-

shooting" chapters. Keep exactly to the procedures laid down when

doing this.

If you do not, the invisible

skin and/or you may suffer a fatal electric shock.

Warning: You may be exposed to dangerous radiation by the invisible

laser beams if you use operating or adjustment equipment other than

those mentioned in this document or if you follow other working proce-

dures.

When carrying out work as described in the customer documentation,

the user must always adhere to the operating process stipulated. Pro-

tection from invisible

loops.

The use of laser protection glasses is not intended as correct operation

eliminates the need for these.

Suprasetter 145/162/190 – User’s Guide 13

laser beam may cause injuries to eyes and

laser radiation is ensured by covers and safety

Before you start ...

Safety Loop

For your safety, the Suprasetter is equipped with a safety loop. If the safety

loop is interrupted, e.g. by removing the insertion table, all mechanical

motions are stopped and the invisible

sure head.

Warning: The safety loop must never be bridged as otherwise you are

in danger of being injured by the invisible

by moving parts or being fatally injured by an electric shock.

laser beam is switched off in the expo-

laser beam, of being crushed

Check of the safety loop

For the safety of the users, EN ISO 13849-1 requires that the safety function of

the Suprasetters is checked at regular intervals.

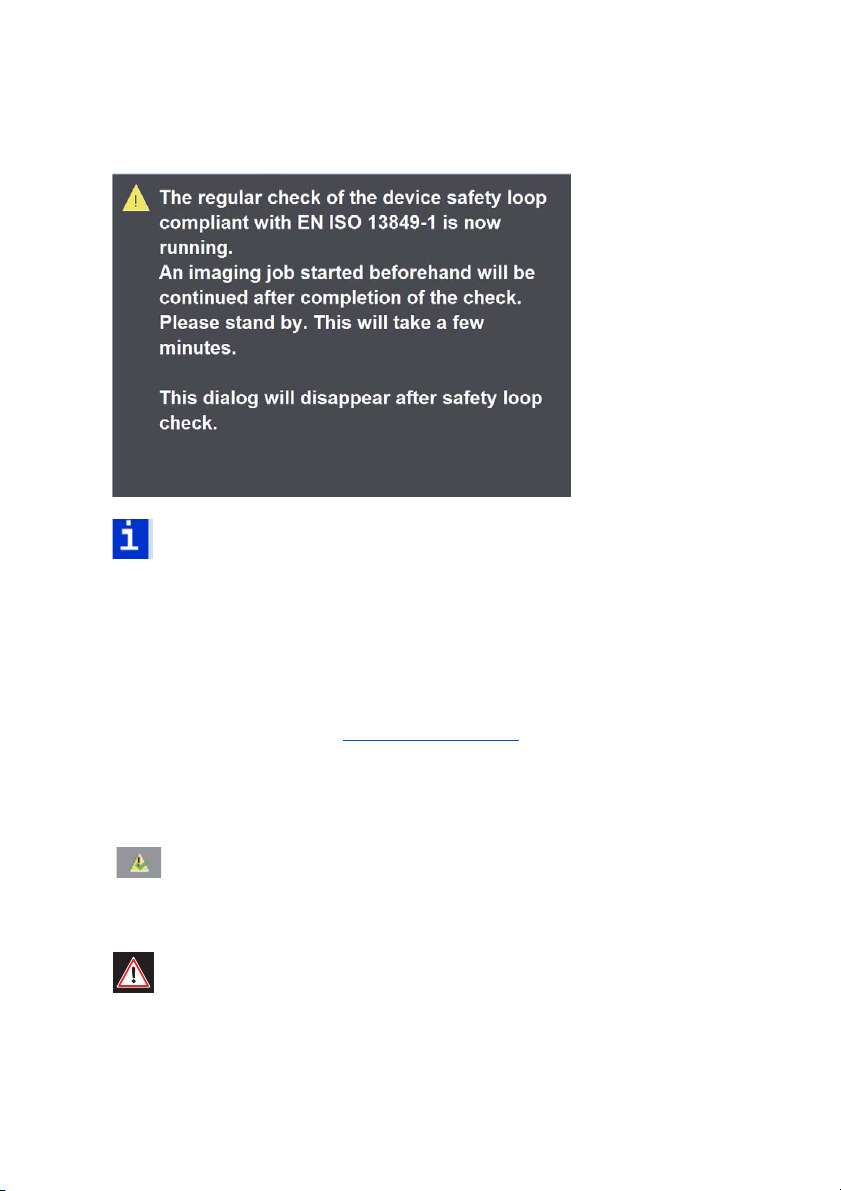

Automatic check of the safety loop

This regular check is triggered automatically after the following criteria:

• When switching on the Suprasetters

• When running certain error corrections

• When the machine is running after a period of 24 hours before the start

of a new plate sequence and a brief waiting period.

During the startup, a window displays on the CTP User Interface, pointing out

the check of the safety loop.

14 Version 2019

Before you start ...

Note: During the check of the safety loop, it is not possible to image

plates.

The window closes automatically as soon as the check is finished (this can take

some minutes).

Manual check of the safety loop

The user can run an early check of the safety loop at any time before the 24hour time limit expires (see

moment in production allows this.

Start check of safety loop

The check of the safety loop starts after you click this button in the

user interface and confirm again.

Caution: During the test no imaging jobs may be processed! In other

words, no plates must be in the device and no jobs are waiting for processing. You must stop processing beforehand.

Suprasetter 145/162/190 – User’s Guide 15

"Timeframe", page 16) if, for example, a suitable

Before you start ...

Timeframe

This displays the interval until the next regular safety loop

test.

ESD Protective Measures for Prepress Systems and Operators

Basics

Devices from Heidelberger Druckmaschinen AG are resistant to electrostatic

discharges (within the limits of EN 55024:2001).

In order to protect devices and users from being unnecessarily exposed to such

discharges, we have listed a few tips below that will help reduce the frequency

and intensity of the discharges.

Formation

In a prepress environment, this physical phenomenon occurs most frequently

as a result of triboelectricity. In such cases, electrostatic charges are generated

when bodies that have close contact are separated.

16 Version 2019

Before you start ...

Examples:

• Walking across non-conductive (insulating) flooring (e.g. synthetic floor

covering)

• Removing the slip sheet from the plate

• Getting up off a seat

The intensity of these charges is determined basically by the following parameters:

• Humidity

• Roughness of the material surface

• Pressure/space when in contact

• Conductivity of the materials

Practical Tips

The following practical tips are to help reduce the number and intensity of electrostatic discharges when handling the devices:

• Install the devices in rooms that have conductive floor covering.

• Resistance to ground < 1x10

ing does not comply with this requirement in the majority of cases. Pure

concrete flooring generally has a low volume resistance. If you have nonconductive floor covering, the use of ESD mats placed on the operator

side of the devices is recommended. These mats can be obtained from

suppliers. However, in such a case, existing charges are only slowly

reduced depending on the shoes that the personnel wear. For personal

safety, the resistance of floor to ground should not fall below 105 ohms.

9

ohms (IEC/EN 61340-5). Synthetic carpet-

• The humidity at the installation site should not fall below 45% relative

humidity. High air humidity is a decisive factor in preventing the formation of electrostatic charges. For example, a relative humidity of 10 - 20%

will produce 35,000 V when crossing a carpet. This value drops to 1,500

V with a relative air humidity of 65 - 90%.

Suprasetter 145/162/190 – User’s Guide 17

Before you start ...

• Clothing where cotton material is >50%.

• Conductive seating.

• ESD shoes that can be obtained from suppliers and are used on conductive flooring help further to reduce charges when walking across floor

coverings.

Standards/Sources

More details on this subject can be found in the following sources:

• IEC / EN 61340-5 (Protection of electronic devices from electrostatic

phenomena - General Requirements)

• Electrostatic Discharge Association

http://www.esda.org/

• Electrostatic Society of America

http//www.electrostatics.org

Disposal of the Suprasetter 145/162/190

The disposal of the Suprasetter 145/162/190 is described in chapter Disposal.

Converting the Suprasetter 145/162/190

Any conversion work on the Suprasetter 145/162/190 may be performed only

by Heidelberg service personnel.

18 Version 2019

Before you start ...

i

i

About This Documentation

This documentation is intended as a reference work for the operator during

training courses and in operation.

Note: The documentation must be kept safely for future use right up to

the disposal of the Suprasetter.

What You Should Already Know

The user, having attended a training course, should be familiar with the Suprasetter.

Further Documentation

You can find more information in the following documentation:

• Prinect MetaDimension - User's Guide/Workflow

• Prinect Integration Manager - User's Guide/Workflow

Suprasetter 145/162/190 – User’s Guide 19

Symbols and Styles

The following typographical conventions are used in this manual:

• References to other chapters and sections are

underlined.

blue (on the screen) and

Example: See

• Quotes are used to indicate menus, folders, functions, hardware conditions, switch settings, system messages, etc.

Example: Set the switch to "off".

• Menus, functions and sub-functions are separated by ">".

Example: Select "File > Open...".

• Buttons which you should hold down simultaneously are connected with

a plus character.

Example: Press Alt+A.

section "Symbols and Styles", page 20.

Before you start ...

i

i

Important Information

Important information in the text is indicated by symbols at the side which are

used as follows:

Warning: Contains information that must be taken into consideration to

protect the user from injury.

Caution: Contains information that must be taken into consideration to

prevent damage to hardware or software.

Note: Contains important general or additional information on a specific topic.

Prerequisite: Lists requirements which must be fulfilled before the

steps which follow can be performed.

Heidelberg online

Do you have questions concerning our products?

Do you want to improve your workflows?

Then visit us on the Internet. You can find us at:

http://www.heidelberg.com/

Suprasetter 145/162/190 – User’s Guide 21

Introduction

Introduction

Description of the Unit and its Functions

The Suprasetter is a high-speed computer-to-plate imaging device for large-format plates.

It images thermal printing plates in daylight operation. The Suprasetter

receives screened data from the RIP for imaging onto printing plates. On a

manual device or semi-automatic device, the plates are placed manually onto

the insertion table or, in the case of a fully automated device, they are loaded

by the cassette magazine. The Suprasetter automatically loads the plate onto

the drum, images it, punches it (option) and conveys the imaged plate back to

the insertion table or to the connected ejection table.

The Suprasetter can be shipped and installed in various versions:

• As a manual device. The plates are inserted and ejected at the front of the

device.

• As a semi-automatic device with manual plate feed at the front. The

plates are ejected at the rear of the device to an ejection table that conveys them straight ahead, to the right or to the left.

• As a fully automated device, with the plates ejected at the front of the

device to an ejection table that conveys them straight ahead, to the right

or to the left.

Suprasetter 145/162/190 – User’s Guide 23

Introduction

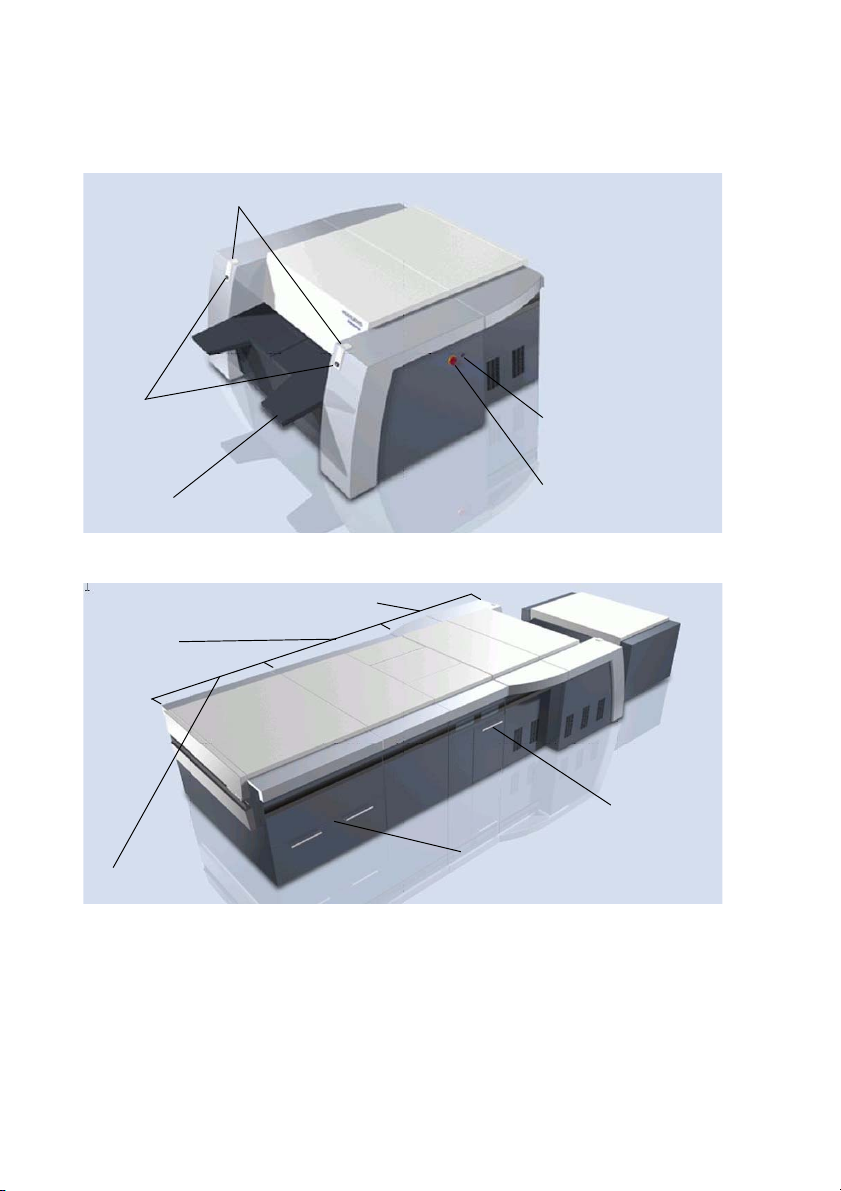

Status LEDs

Load buttons

Insertion table

On/Off button

Power switch

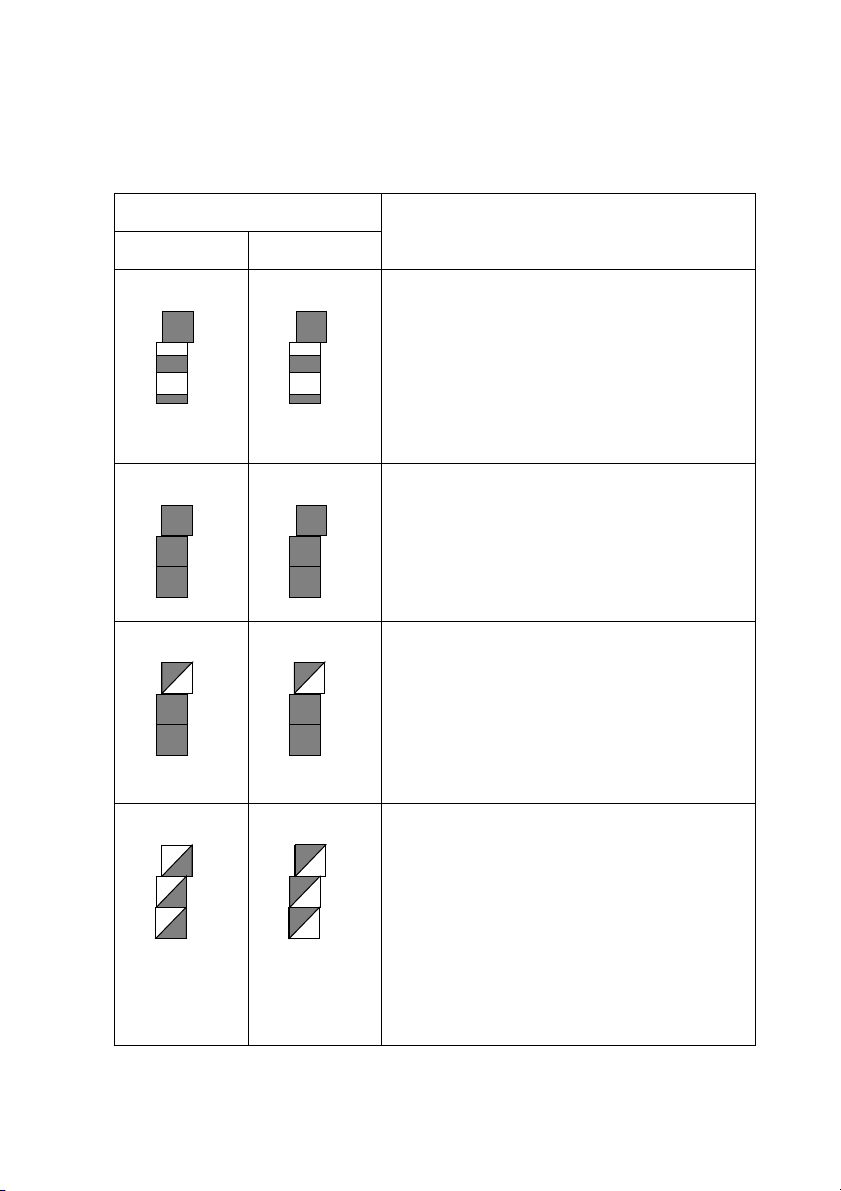

Separator

Recorder

OLP

Cassette magazine

Drawer for plate trays

Waste box

Operating elements on the manual device and on the semi-automatic device

Additional functional groups and operating units on the fully automated device

Status LEDs

The following actions of the Suprasetter are indicated by the status LEDs:

24 Version 2019

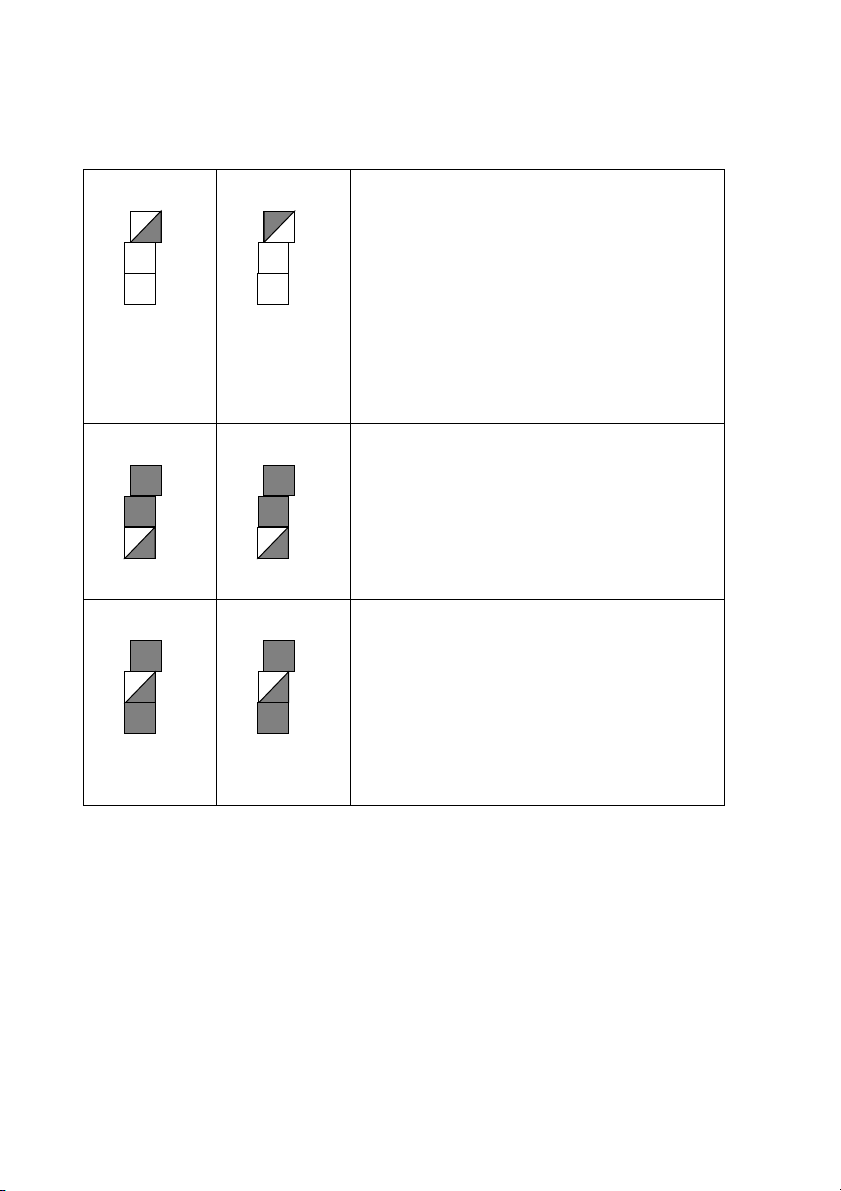

Status Panel Event

Left half Right half

Startup:

The Suprasetter starts the software and initializes the hardware.

The status LEDS are like level indicators filling up from bottom to top, running parallel

on both sides, until normal operation is

reached.

Standby:

The Suprasetter is ready to image a plate but

is not busy imaging at that moment.

All LEDs light up.

Normal operation:

Introduction

The Suprasetter is presently imaging a plate

or otherwise busy, for example, it is unloading a plate to the online processor or loading

a plate from the Autoloader.

The top LEDs flash synchronously.

Error:

An error occurred that must be eliminated by

the user.

The LEDs on each level flash, alternating

between left and right. A beep also indicates

the error status.

The user must go to the GUI of the Suprasetter to learn more details about the error.

Suprasetter 145/162/190 – User’s Guide 25

Introduction

Waiting:

The Suprasetter is waiting for something

within it (e.g. until the operating temperature

is reached) or is waiting for a connected

device (online processor or the cassette

loader).

The top LEDs flash alternately. A brief beep is

also heard if an operator intervention is

required.

Waiting for a plate:

The user is prompted to insert the required

plate.

The bottom LEDs flash synchronously. A brief

beep is also heard.

Plate ready to be removed:

You will hear a beep approx. 3 seconds

before an imaged plate appears. In addition,

the middle LEDs flash synchronously.

When the plate is output, you will hear a

brief beep again, indicating that the plate

can now be removed.

Power switch

You can disconnect the device fully from the power supply with the power

switch, for example, for maintenance work. You can switch on the device only

when the power switch is set to 'I'.

26 Version 2019

On/Off button

i

i

The On/Off button allows you to:

• switch on the Suprasetter, see

34.

Introduction

section "Switching on the Device", page

• switch off the Suprasetter, see

36.

• switch off the beep that sounds, for example, after a malfunction occurs.

section "Switching Off the Device", page

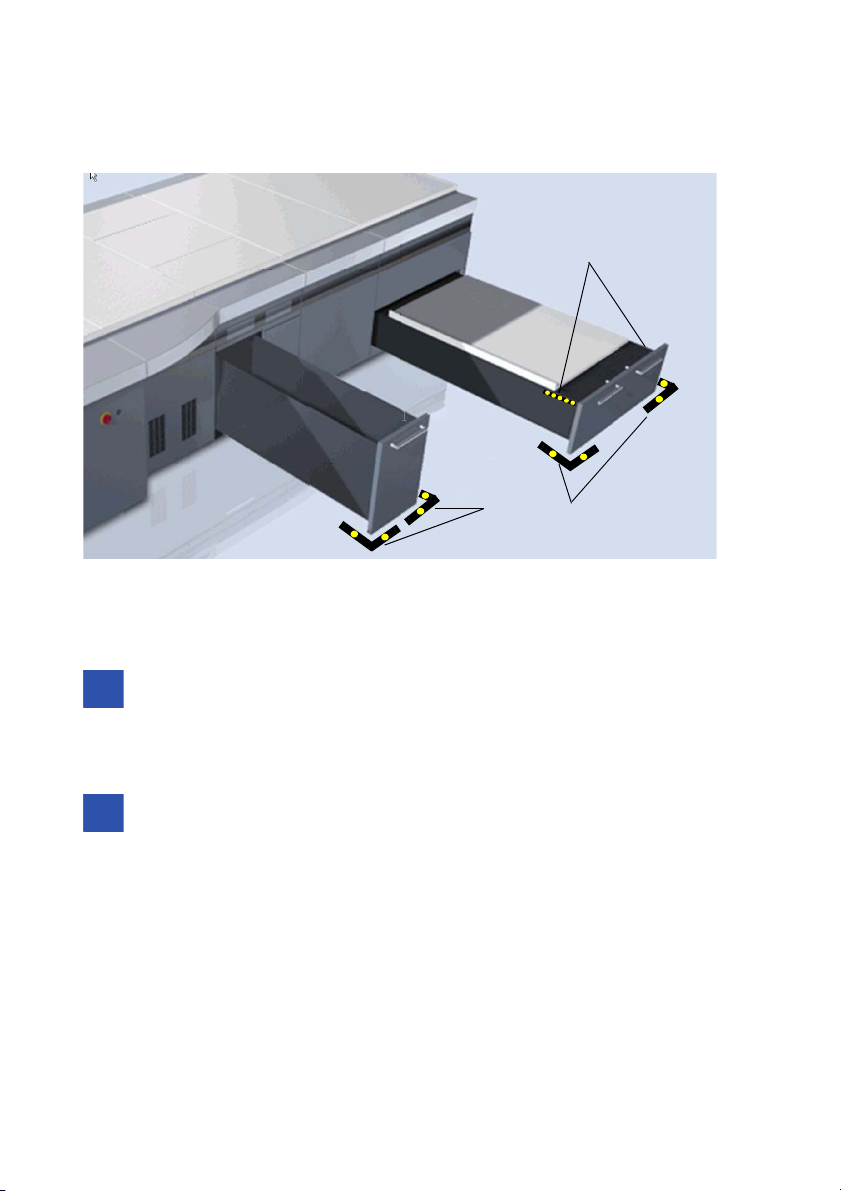

Keeping Access Routes Clear

If an access route runs parallel to the device, with staff passing by the device

several times a day, then the end of the required floor space is to be marked

off by black-and-yellow tape to keep this space clear.

Note: Local regulations on keeping access routes clear must also be

complied with.

Suprasetter 145/162/190 – User’s Guide 27

Introduction

Marking indicating the end

of the required floor space

Markings on both sides of

the magazine drawer

i

i

i

i

Notes on the Use of Plates

Note: Only printing plates and slip sheets approved by Heidelberg may

be used in the Suprasetter as only these produce the specified results.

The use of unapproved plates and slip sheets can result in malfunctions.

Note: It is essential that the Suprasetter is fitted with a suction device

(debris removal system) if plates requiring a suction device are to be

used in the Suprasetter.

28 Version 2019

Notes on Installation

i

i

Notes on Installation

Notes on Installation

Transport of the Suprasetter 145/162/190

The Suprasetter 145/162/190 is to be transported solely by companies that are

authorized by Heidelberg to do so. Transport may be done only by qualified

persons. The appropriate transport regulations must be observed during transport..

Installing the Device

The Suprasetter may be installed only by authorized service personnel. The

ambient conditions must be observed.

Warning: In compliance with standard EN 1010-2:2003 # 5.2.1 and

because the installation site must have clean conditions, the

Suprasetter may not be operated in sites where paper is being printed

or paper finishing devices are running.

Note: Initial installation is performed by service personnel. This

includes lifting the unit off the palette and removing the transport safeguards.

Automatic Cutouts

The automatic cutouts are located behind the right side panel. When an automatic cutout is triggered, please proceed as described in the section "Switching on an Automatic Cutout" (page 61). Repairs may be done only by service

personnel.

Suprasetter 145/162/190 – User’s Guide 29

Notes on Installation

Software Installation (Container Version)

Prerequisite:

· The Suprasetter is switched off.

· The workstation is switched on and ready for operation.

· All Windows applications were run down.

· A backup of the recorder configuration is saved, see the section

"Saving a Backup of the Recorder Configuration" (page 41).

· A buffer plate named "Pagebuff" is available and formatted.

Operation:

1. Insert the Suprasetter installation CD into the CD-ROM drive. Setup

starts automatically if Autorun is activated.

2. If Autorun is disabled, you can start the setup by double-clicking

"Setup.exe". The "CTP User Interface Setup" window displays.

3. Click "Next". The "LicenseAgreement" window displays.

4. Accept the licensing agreement and click "Next". The "Choose Destination Location" window displays.

5. Use the suggested path or select the path you want by clicking the

"Browse" button.

6. Click "Next". The "Select Program Folder" window displays.

7. Use the suggested folder or select one from the list or enter a new folder

name.

8. Click "Next", the "Ethernet Address" window displays.

9. Accept the Ethernet address (172.16.0.2) by clicking "Next". The "Start

Copying Files" window displays.

10. Click "Next". The installation procedure is executed. You will see the

"Install Shield Wizard Complete" window at the end of the installation

procedure.

30 Version 2019

Loading...

Loading...