HEIDELBERG Suprasetter 145, Suprasetter 162, Suprasetter 190 Installation Manual

Suprasetter 145/162/190 - Installation

Suprasetter 145/162/190

Suprasetter 145/162/190

Installation

10/2019

Order No. PG.999.0101

ABC

Copyright © 10/2019

Heidelberger Druckmaschinen AG.

No part of this book may be reproduced

without prior written permission.

.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Important notice:

We are dedicated to improving and

enhancing our products. Consequently,

the information in this manual is subject

to technical modifications and other

changes without notice.

Heidelberger Druckmaschinen AG.

Kurfürsten-Anlage 52-60

69115 Heidelberg

Germany

Phone +49 6221 92-00

Telefax +49 6221 92-6999

www.heidelberg.com

Heidelberger Druckmaschinen AG

assumes no responsibility for information and description as far as third-party

products are concerned.

The information contained in this manual about performance and speed as

well as technical data concerning application of our products is not legally

binding as it does not constitute a written contract of features.

If any problems occur with the product

described in this manual, please contact

the Heidelberg agency which is responsible for you.

Order No. PG.999.0101

Printed in Germany.

Table of Contents

Table o f Con tent s

Prinect Signa Station 1

Suprasetter 145/162/190 1

Table of Contents

1

Before you start ...

About This Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Symbols and Styles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Important Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety

Safety with Suprasetter 145/162/190 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety Notes on Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Additional Protective Conductor Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Power Switch with Emergency Stop Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Automatic Cutouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Mechanical Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Laser safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Laser Standards and Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Service and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Laser Safety Goggles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Radio Interference Suppression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Approvals and Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Safety Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Hold-to-Run Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Service Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Harmful Substances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Glycol coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Closed Refrigerant Circuit in the Chiller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Overview of Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Mounting locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Suprasetter 145/162/190 – Installation 1

Table of Contents

Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Safety with Heidelberg Remote Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Heidelberg Remote Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Safety Precautions During Remote Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Remote Control Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Access to Machine Components

Machine Components Suprasetter 145/162/190 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Suprasetter 145/162/190 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Access to the Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Installation Preparation

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Floor Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Machine's Arrival at the Customer's . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Protection Against Corrosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Provision of a Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Plate Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Special-Purpose Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Installation

Overview: Chassis Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Setting up the Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Setting up the Imaging Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Remove the remaining transport safeguards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Plate Loader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Chiller Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Establish connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

EMC and Ground Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Data cable to plate loader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Plate loader power connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Lexium 05 (3-phase) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Lexium 32 (3-phase) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Lexium 32 (3-phase + N) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Secure the cover plate above the power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

2

Table of Contents

Plate loader compressed air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Data cable to imaging unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Imaging unit power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Plate Loader Opto Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

External Compressed Air Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Laser Module Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Hose connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Imaging Unit: Laser Module Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

PC Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

External Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Network Adapter Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Installing recorder software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Filling the Chiller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Configuring and testing the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Configure the System and set Installation-specific Parameters . . . . . . . . . . . . . . . . . . . 107

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Concluding Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Check Tension of Drive Toothed Belt on Imaging Unit . . . . . . . . . . . . . . . . . . . . . . . . . 110

Optional Components

OLP Conveyor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Cross Conveyor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Suprasetter 145/162/190 with APL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Technical Data

Technical Data of Suprasetter 145/162/190 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Index

Suprasetter 145/162/190 – Installation 3

Before you start ...

Before you start ...

About This Documentation

This documentation applies to Suprasetter 145/162/190.

The Suprasetter 145/162/190 is a laser imagesetter for imaging offset printing plates.

Symbols and Styles

The following typographical conventions are used in this manual:

• References to other chapters and sections are blue (on the screen) and underlined.

Example: See section "Symbols and Styles", page 5.

• Quotes are used to indicate menus, folders, functions, hardware conditions, switch settings, system messages, etc.

Example: Set the switch to "off".

• Menus, functions and sub-functions are separated by ">".

Example: Select "File > Open...".

• A plus sign is used to indicate that several keys have to be pressed at the same time.

Example: Press Alt+A.

Suprasetter 145/162/190 – Installation 5

Before you start ...

i

i

Important Information

Important information in the text is indicated by symbols at the side which are used as follows:

DANGER

The "DANGER" signal word indicates a hazard with a high risk which, if not

avoided, will result in death or severe injury.

WARNING

The "WARNING" signal word indicates a hazard with a medium risk which, if not

avoided, can result in death or severe injury.

CAUTION

The "CAUTION" signal word indicates a hazard with a low risk which, if not

avoided, can result in minor or moderate injury.

NOTICE

The "NOTICE" signal word indicates possible material damage. Non-observance

of this notice can cause damage to the machine.

Note: Contains important general or supplementary information about a specific topic.

Prerequisite: Lists requirements which must be fulfilled before the steps which follow can

be performed.

6

Safety

Safety

Safety with Suprasetter 145/162/190

Intended Use

The Suprasetter is a laser imagesetter with an optional fully automatic loader and transport table to

the on-line processor, for imaging offset printing plates and may only be used for this purpose as

described in the operating instructions.

Heed the safety notes in the related documentations when you connect optional components.

Do not place any objects or liquids on the device.

Ventilation outlets must be kept clear at all times.

General

Service work may be performed only by authorized personnel specialized in this field. The respective

accident prevention regulations must be observed.

Failure to observe the safety regulations may result in the loss of accident insurance!

Unauthorized opening of housing parts and improper repairs not expressly described in the operating

instructions or service documentation can lead to considerable danger for the user (crushing by mov

ing parts or injuries by electric shocks or, in the case of the Suprasetter, injuries through invisible

high-power laser radiation).

Follow the specified operational sequence when removing covers or other housing parts.

Risk of injury from sharp edges

Plate edges can be sharp. You can injure your hands if you do not wear protective gloves. Put on protective gloves!

Safety Notes on Installation

The Suprasetter, including the fully automatic loader and transport table to the processor when they

are used, may only be installed by authorized service personnel. The ambient conditions must be

observed in this process.

Connectors and outlets of the house installation must be easily accessible so that, in the event of an

emergency, for example, the unit can be completely disconnected from the power supply by switching

off the main switch or by pulling out the power plug (if present).

-

The unit must be in a de-energized state when connecting the data cables. Connect the power cables

of

all other devices only after the data cables are connected. This will protect you from a fatal electric shock. It will also protect the electronics of the units from failure caused by voltage impulses following potential differences.

Make sure to lay cables and hoses so no-one can trip over them!

Suprasetter 145/162/190 – Installation 7

Safety

i

i

For the operating company of a print shop, it is important that the exposure limits regarding breathable air in the work area (where the platesetter is located) are adhered to. The air exchange must be

arranged in such a way that the measured dust particles are regularly below the exposure limit val

ues. In accordance with the state of the art, this can be achieved with an 8 to 10 air change rate per

hour. If this is not the case at the installation site, the operating company should install an additional

exhaust system.

When installing the machine, pay attention to the information in the "Installation" and "Technical

Data" chapters.

In order to provide proper ventilation, ensure that there is sufficient distance between the machine

and the wall or between the machine sides and other equipment when the equipment is installed.

The machine

- should not be installed in the proximity of air conditioning facilities,

- must be protected against direct sunlight or spotlights fitted in the room,

- must be protected against moisture.

In order to meet radio interference suppression requirements, only screened data cables may be

used.

-

Because of product safety requirements and because the installation site must have clean conditions,

the Suprasetter may not be operated in sites where paper is being printed or paper finishing devices

are running.

The Suprasetter may be switched on only if the ambient temperature is higher than 15 °C. Temperatures lower than this can cause damage to the components!

The required ambient conditions (see "Technical Data", page 125 chapter) must be observed for at

least 12 hours after power-off so that the Suprasetter is not damaged by condensation.

Power Supply

The Suprasetter is connected to the inhouse power supply either permanently with terminal block X1

and the 5-wire power cable or with a 5-pin connector that must be designed for connection to 400V/

16A (USA: 400V/15A) AC.

The respective national regulations must be observed if power cables are used that were not supplied

by Heidelberger Druckmaschinen AG or if connectors are modified. In the EU and in the extended

area of validity of IEC 60204-1 (for latest version, see

tion of the protective conductor must be 10 mm² for a leakage current of 10 mA and higher. The protective conductor current of this device is approx. 70 mA.

Table Electrical Safety), the minimum cross sec-

Additional Protective Conductor Terminal

Note: After installation, the protective earth connection must be tested.

8

Fig. 1 PE terminal

Safety

Since the leakage current is >10 mA, it is mandatory to connect the protective earth (PE) wire in

the power cable

conductor cable. A separate PE cable (green-andyellow or only green) with a cable cross-section of

at least 6 mm² must be routed parallel to the

power cable.

On the Suprasetter, it must be connected to the

power supply group at its designated PE2 terminal

(

Fig. 2/1).

and the additional protective

Fig. 2 Power supply group PE2

At the service tap, it must be connected to a separate PE terminal (Fig. 1/1). In addition, you must

make sure that the PE is routed further in the service tap with a cable cross section of at least

10

mm².

Suprasetter 145/162/190 – Installation 9

Safety

Power Switch with Emergency Stop Function

The power switch (Fig. 3) triggers an all-pole cutoff of the Suprasetter and the fully automatic

loader from the power supply. In an emergency,

this power switch is used as an emergency stop

switch for the Suprasetter and the automatic

loader. The power switch with emergency stop

function is located on the right side of the Supra

setter.

-

Fig. 3 Suprasetter

WARNING

Risk of injury from improper operation during an emergency stop

The emergency stop circuits of Suprasetter machines are not connected to the

emergency stop circuit of the online processor!

Press the emergency stop on the online processor to stop the online processor.

WARNING

Danger! High Voltage!

The 4 impact buttons with red caps in the Suprasetter are emergency stop buttons. They stop all movements but do not cut off the electric power.

Do not touch any live parts.

10

Automatic Cutouts

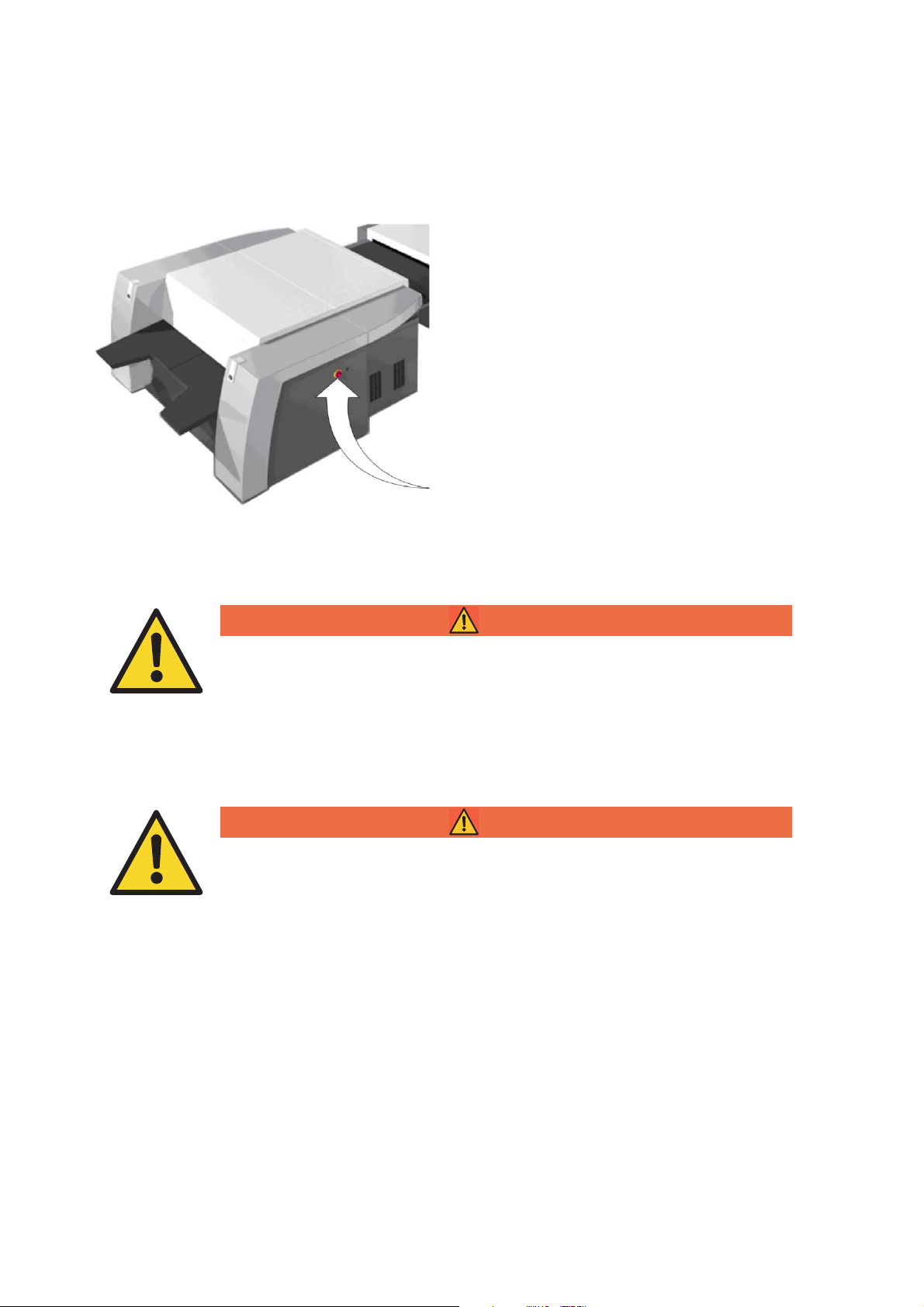

Fig. 4 Automatic cutouts

Safety

The automatic cutouts are located near the main

switch behind the right cover.

F100 1x 3A Electronics box (standby)

F101 3x 6A Electronics box, imaging unit

F102 3x 13A Chiller

F103 3x 10A Power connection for optional Autoloader

F104 3x 10A Plate Loader

F110 3x 15A Main drive (plate cylinder)

F160 3x 6A Laser system

F190 2x 6A Suction device

Tab. Assignment of automatic cutouts

Mechanical Hazards

CAUTION

Beware of moving parts in the Suprasetter

Risk of squeezing in the area of the lifting tables traveling up and down, in the

path traveled by the laser carriage and by the rotating drum when the covering is

open and the safety loop is bridged by the key-operated switch and the hold-torun button has been pressed.

Switch off Suprasetter during work in these areas.

Suprasetter 145/162/190 – Installation 11

Safety

i

i

Laser safety

Definitions

Laser equipment (product) Equipment with a laser system

Laser device (system) Laser with laser power supply module

Tab. Laser definitions

General

The present laser imagesetter is a Class 1 laser product. This means that the invisible laser radiation

generated in the unit is screened by protective covers. When used correctly, users and Service per

sonnel are never subjected to a risk due to laser beams.

The laser systems used in the Suprasetter are Class 4 products (> 500 mW). Companies servicing the

equipment in Germany must appoint a laser protection officer in compliance with the Accident Pre

vention Regulations (BGV B2) of the Professional Trade Association.

-

-

Note: Servicing may only be carried out by Heidelberg personnel who have been trained by

appropriate laser protection officers for this purpose.

WARNING

Risk of injury from laser radiation

You may be exposed to dangerous radiation by the invisible high-power laser

beams if you use operating or adjustment equipment other than those mentioned

in this document or if you follow other working procedures.

Keep exactly to the described procedures.

Laser Standards and Regulations

The Suprasetter complies with the applicable safety regulations. It is manufactured in accordance

with the German Accident Prevention Regulations (BGV B2) and the EN 60825-1, IEC 60825-1 ("Radi

ation safety of laser equipment") and 21 CFR 1040 (USA) standards.

Service and Maintenance

-

Service work may be performed solely by persons authorized by Heidelberg to do so. When performing the work described in the operating instructions and service manual, the service personnel must

adhere to the described work sequence under any circumstances. Protection from invisible laser radi

ation is ensured by covers or safety loops. Never bypass the laser safety loop (see also section "Safety

Loop", page 15)!

Upon completion of the repair, the functionality of the safety circuits must be checked.

12

-

Safety

i

i

i

i

During reassembly, the protective covers must be checked for completeness. Make sure that these

covers do not show any cracks or other damages.

Note: When the safety switches are open, the key switch can only bypass the safety loop

for the powered movements. The laser safety loop is not bridged as this is not necessary.

Note: A hold-to-run button is also required for operating the drives for the imaging cylinder

and the lift tables when the key-operated switch is activated (see also section "Hold-to-Run

Button", page 16).

WARNING

Caution: Remote Control

If Remote Control is run when the key-operated switch is actuated, make sure to

follow the information about

"Heidelberg Remote Service", page 34.

Laser Safety Goggles

Laser safety goggles do not have to be worn as this is not necessary. Laser adjustments are not to be

made on the Suprasetter as the modules are adjusted at the factory and are to be used without any

additional adjusting.

Standards

This device complies with the safety regulations of the standards listed below.

Product Safety

Act

2006/95/EC Low-voltage directive Europe

2006/42/EC EC directive relating to machinery Europe

2004/108/EC EMC directive Europe

EMVG Act on the electromagnetic compatibility of manufacturing

Tab. General safety

Product Safety Act (2011) Germany

Europe

equipment (2008)

Suprasetter 145/162/190 – Installation 13

Safety

EN ISO 12100 Safety of machines Europe

EN 1010-2 Safety of prepress machines Europe

2006/42/EC EC directive relating to machinery Europe

UVV Accident prevention regulation Germany

IEC 68-2-6 Shock test International

IEC 68-2-27 Shock test International

Tab. Mechanical Safety

EN ISO 13849-1:2008 Europe

EN 60204-1: 2006 Europe

IEC 60204-1: 2005 International

EN 60950-1: 2006 Europe

IEC 60950-1: 2005 International

UL 60950-1: 2007 USA

CSA C22.2 No. 60950-1: 2007 Canada

Tab. Electrical Safety

EN 61000-6-4:2007 Europe

EN 61000-3-2: 2006 Europe

EN 61000-3-3:1995 + A1:2001 + A2:2005 Europe

FCC CFR 47, Part 15, Subpart B, Class A USA

ICES-003, Class A Canada

CISPR 22:2006 Australia/New Zealand

Tab. Interference emission (stray radiation and interference voltage)

EN 61000-6-2: 2005 Europe

Tab. Interference immunity

BGV B2 Germany

EN 60825-1: 2007 Europe

IEC 60825-1: 2007 International

21 CFR 1040 USA

Tab. Laser Safety

14

Safety

Radio Interference Suppression

To comply with directive 2004/108/EC on electromagnetic compatibility, the unit is to be operated

only with all covers correctly installed.

When you connect other electrical equipment to this unit by following the instructions given by the

manufacturer of this equipment, follow the regulations regarding correct installation and mainte

nance to ensure compliance with the radio interference suppression regulations.

Compliance with radio interference suppression regulations can be assumed when the equipment in

question is marked with the European Union mark of conformity (CE) and the instructions for instal

lation, operation and servicing are followed.

-

Approvals and Conformity

GS certified Germany

CE Declaration of Conformity Europe

cETLus certified USA / Canada

CDRH Accession-No. (submitted) USA

FCC CFR 47 Part 15,

Subpart B, Class A

GOST-R certified Russia

ACN 004 395 779 Australia

Tab. Approvals and conformity

USA

-

Safety Loop

The Suprasetter is equipped with a safety loop. If the safety loop is interrupted by opening a cover,

for example, all mechanical motions are stopped and the laser is switched off.

Suprasetter 145/162/190 – Installation 15

Safety

WARNING

Risk of injury if safety system bypassed

The safety system must never be bridged because this could lead to eye

and skin injuries due to the invisible high power laser beam, bruising

caused by the optics or plate carriage, the lifting tables and the drum or

critical injuries caused by electric shocks.

We expressly point out that you must not remove the actuators for the

safety switches installed on the panels because of the hazards generated

by moving parts. For this reason, the fastening screws have been secured

with varnish. When you need to readjust any of the actuators, you must

finally seal the screw heads with securing varnish (HD order No.

00.590.0719 for 50 ml of securing varnish, gray).

We also expressly refer to Management Information MMI 00-996-8007

dated March 31, 2005. Never insert actuators into the safety switches in

order to bypass the safety loop while panels are removed.

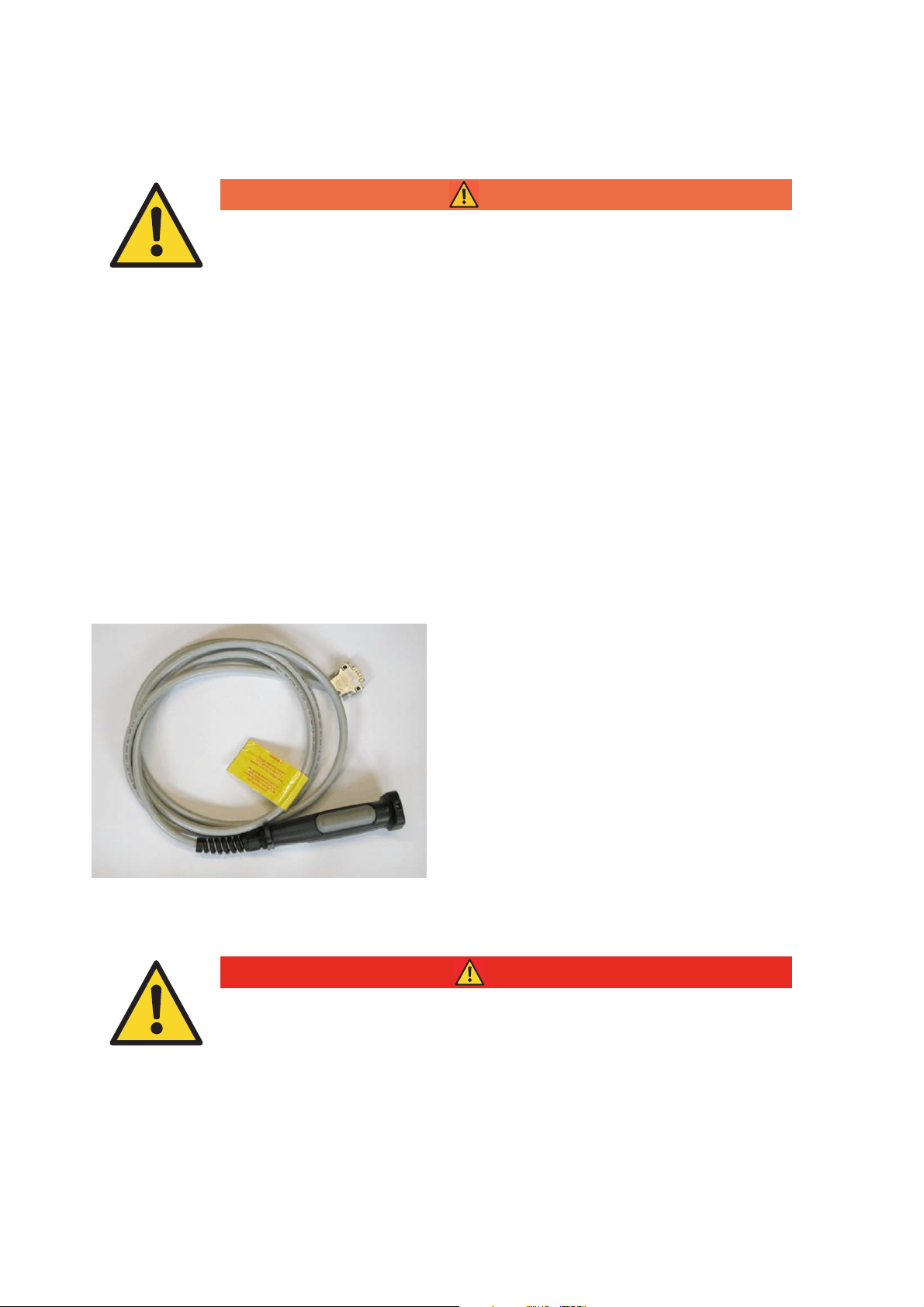

Hold-to-Run Button

Fig. 5 Hold-to-Run Button

Danger! Beware of moving parts! High Voltage!

Never initiate any movements when someone is in the danger area. There must

not be anybody in the machine. No-one must hold his or her head or arm into the

machine. Do not extend the cable of the hold-to-run button to have a better view

of the movement.

Because of the considerable hazard involved,

movements of the imaging cylinder and lift table

are to be enabled only after actuating the hold-torun button as well (for example, to view the move

ments from the outside while the panel is

removed). Releasing or fully pressing down the

button (hand spasm) will immediately stop the

movement.

DANGER

-

16

Safety

i

i

Procedure

You should always heed the following procedure when you want to start mechanical movements with

the hold-to-run button pressed:

1. To move the exposure drum or the lifting tables while the machine is open, you must select this

function via GUI, DIAG or terminal.

2. When prompted to press the Enter key, you must do this within 2 minutes. This will open a 5minute time slot. A single acoustic signal prompts you to press the hold-to-run button now.

3. A double warning signal sounds before the exposure drum or a lifting table start moving. Releasing or fully pressing down the hold-to-run button (hand spasm) or pressing an emergency stop

button will immediately stop the movement. You must then restart the procedure.

4. You must first press the Enter key again if you want to start further mechanical movements after

more than 5 minutes. This is to ensure that at least one person is at the open machine while

movements are running.

Note: The hold-to-run button must always remain with the service staff and must not be

made available to operators.

Service Switch

The service technicians switch the Suprasetter to

the Service mode with the service switch (

for testing and maintenance work. This switch is

located on the left-hand side of the Suprasetter

and is only accessible after removing the side

panel on the unit.

The key for this service switch may only be

accessed by authorized service personnel. The

laser is not active in the Service mode; all other

Suprasetter functions are enabled.

Fig. 6/1)

Fig. 6 Service switch in the Suprasetter

Suprasetter 145/162/190 – Installation 17

Safety

WARNING

Risk of injury from improper operation

Only ONE routine cycle may run at a time when you actuate the service switch. A

continuous test must not be carried out. A new procedure must be started sepa

rately and manually.

You cannot remove the keys while the machine is in the service mode. For that reason, it is not possible to refit the side panel as long as the device is in this mode.

WARNING

Risk of injury from improper operation

Only service staff may actuate the service switch and the hold-to-run button.

-

WARNING

Caution: Remote Control

If Remote Control is run when the key-operated switch is actuated, make sure to

follow the information about

Beware of moving parts in the Suprasetter

Pressing the service switch and the hold-to-run button will close the safety loop

that shuts down the mechanical movements. In the service mode, there is a risk

of being crushed in the area around the lift tables traveling up and down, in the

path traveled by the laser carriage and by the rotating drum.

Switch off Suprasetter during work in these areas.

Upon completion of the work, the covers must be refitted to the unit and screwed down.

"Heidelberg Remote Service", page 34.

CAUTION

Cleaning

Always disconnect the Suprasetter by switching off the main switch if liquid cleaning agents are used.

The surfaces of the Suprasetter can be cleaned using a dry cloth. If it is very dirty, it can be cleaned

with a damp cloth which has been dipped in dish-washing liquid and well wrung.

Ensure that no fluids enter the interior of the Suprasetter and keep moisture away from the connector

sockets on the right side of the Suprasetter.

18

Safety

Do not use any abrasive cleaning agents or solvents.

Harmful Substances

When using cleaning and lubricating agents, observe the manufacturer's instructions. If necessary,

consider the safety data sheets, and for Germany the List of Threshold Values quoting the maximum

permissible concentrations (List of Threshold Values issued by the Federal Ministry of Labor and

Social Affairs) as well as the appropriate local regulations.

Disposal

The Suprasetter must be disposed of in compliance with the relevant national regulations. The Suprasetter contains harmful substances. It may not be disposed of together with household waste and

must be handed over to an approved waste disposal company. Addresses can be obtained from the

relevant environmental office.

Glycol coolant

Containers with coolant residues and material used to bind spilled coolant may be incinerated with

household waste.

Waste coolant with an ethylene glycol content of 40-50% must not reach the surface water or the

groundwater.

Undiluted liquids with an ethylene glycol content of ca. 90% must be treated as hazardous waste and

can be incinerated in hazardous waste facilities under consideration of local regulatory stipulations.

See also the "Disposal" chapter in the Suprasetter 145/162/190 - Operation manual.

Closed Refrigerant Circuit in the Chiller

CAUTION

Risk of injury from liquid hazardous to health

The closed refrigerant circuit of the chiller contains the harmful R134a refrigerant

at a maximum pressure of 18.5 bar.

Servicing the refrigerant circuit is permitted in exceptional cases and after con-

sulting the Service in Kiel and even then by specially trained refrigerant technicians. The entire chiller must be replaced if a hot gas valve should be defective.

Suprasetter 145/162/190 – Installation 19

Safety

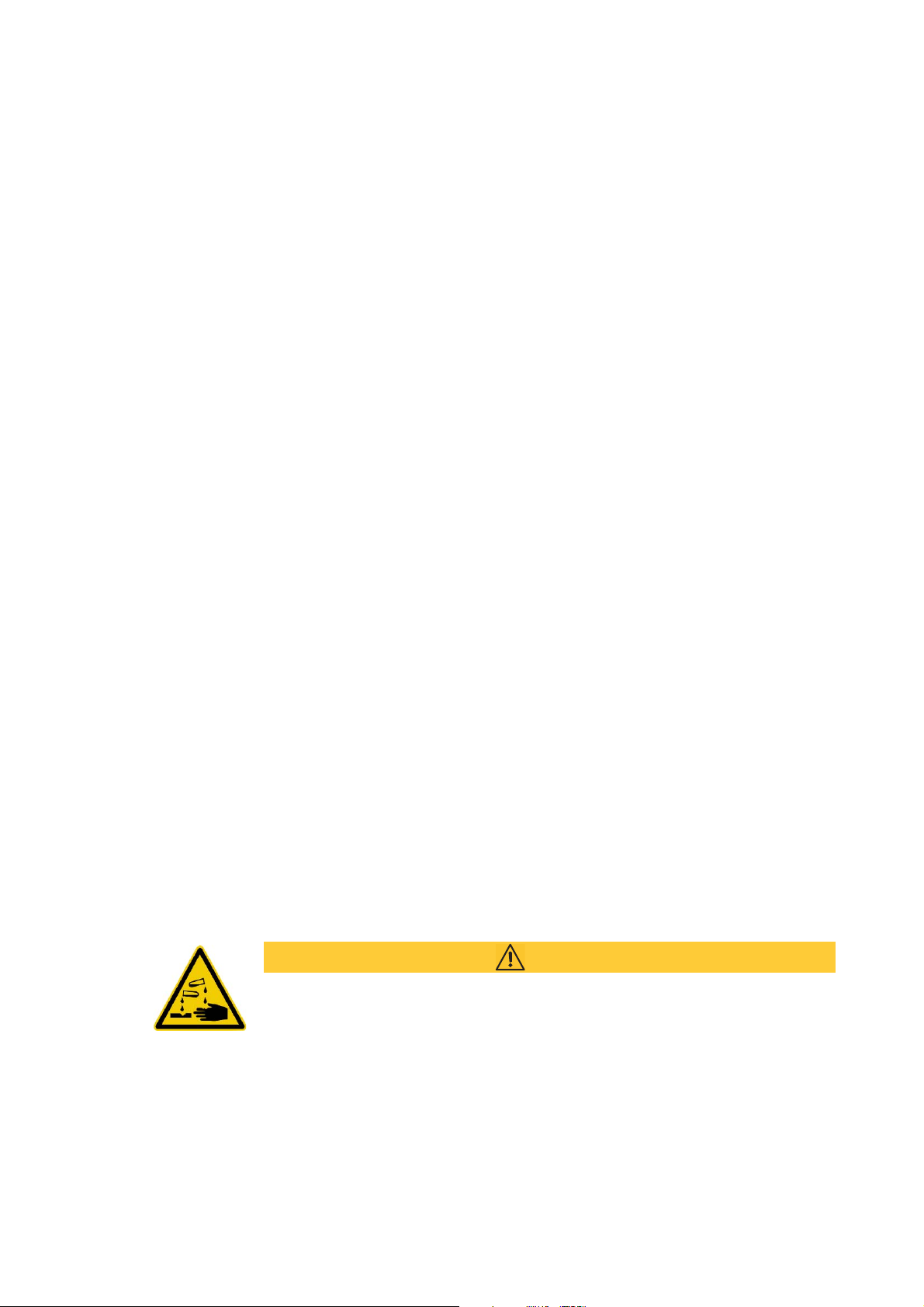

Overview of Labels

Mounting locations

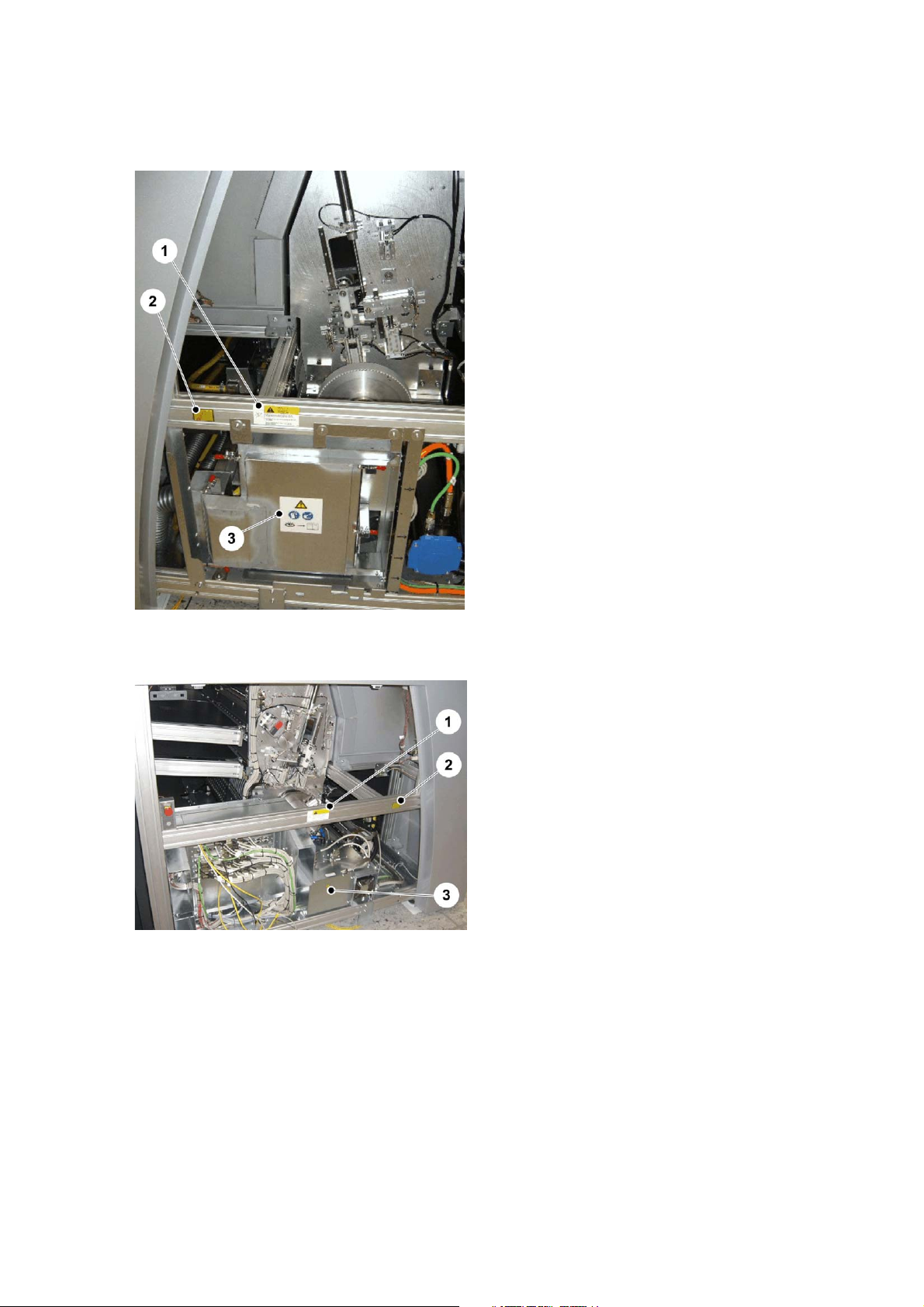

Fig. 7/1: Type label of plate loader

Fig. 7/2: Laser Product Class 1

Fig. 7/3: Note on conformance (USA)

Fig. 7/4: Type label

Fig. 7/5: CE Mark of conformity (Europe)

Fig. 7/6: EAC label (Russia)

Fig. 7 Imaging unit with plate loader

20

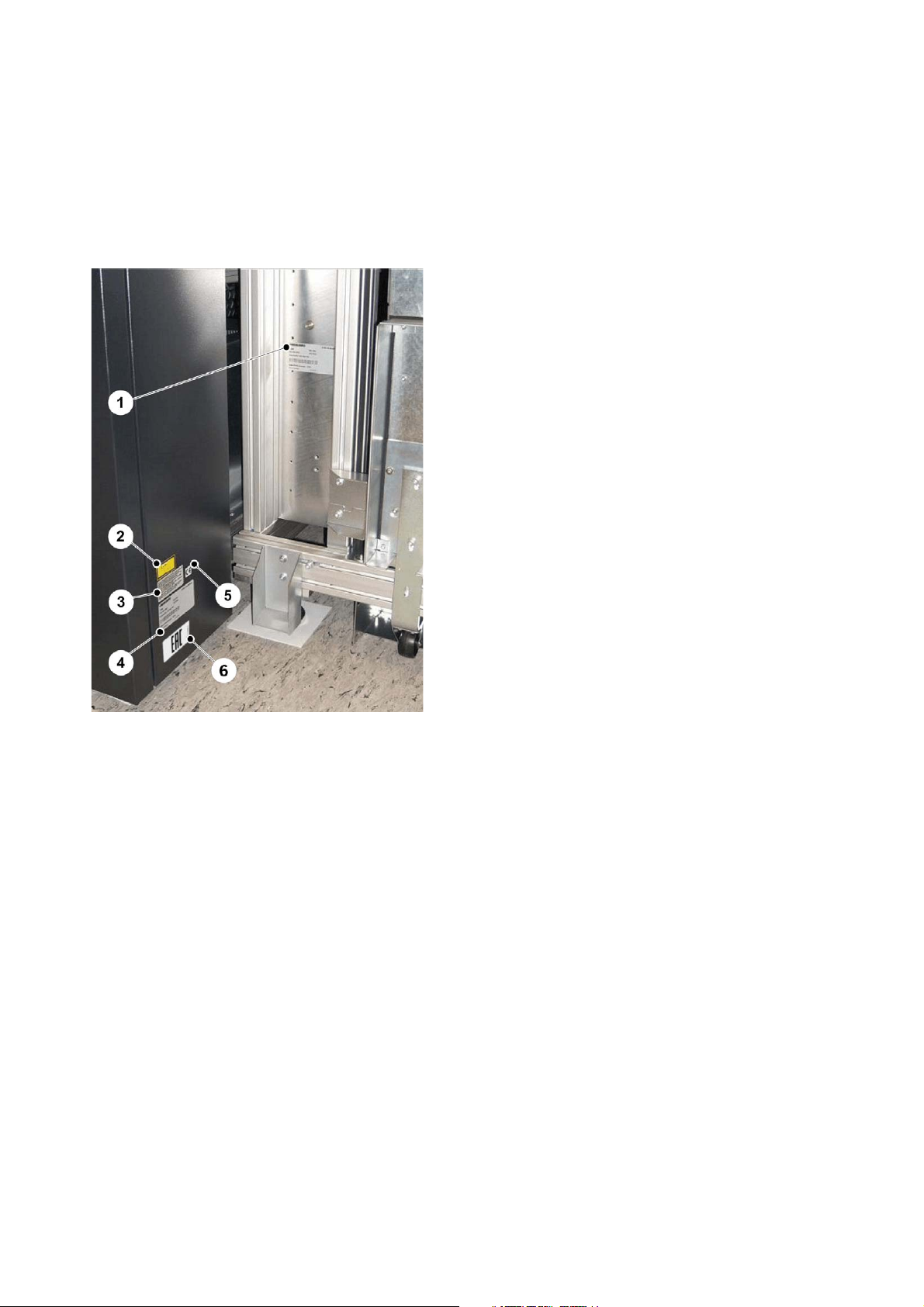

Fig. 8/1: Flash: Beware of high voltage

Safety

Fig. 8 Imaging unit, power connection and fuses

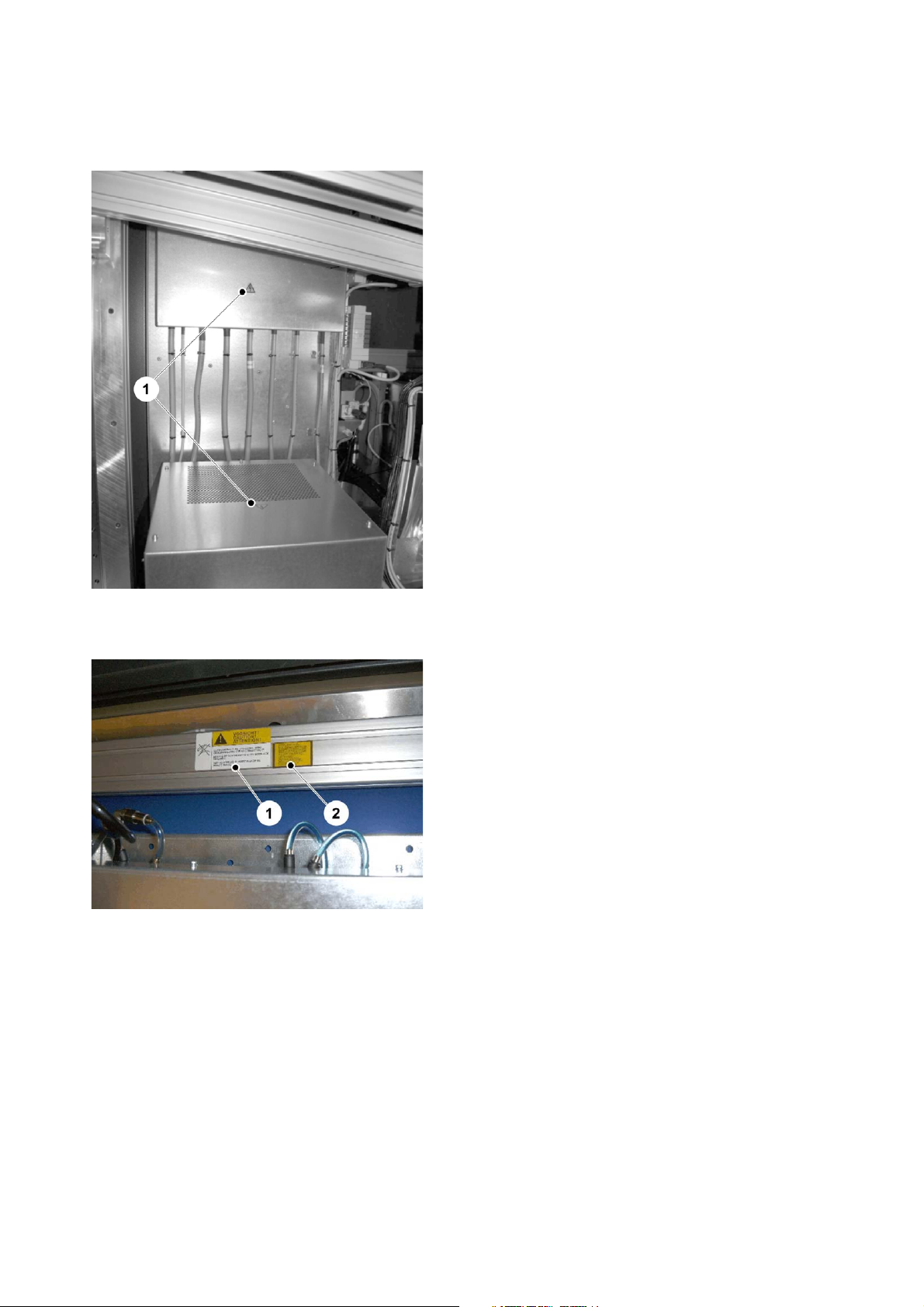

Fig. 9/1: Air Inlet

Fig. 9/2: High leakage current

Fig. 9/3: Heed installation instructions

Fig. 9/4: Flash: Beware of high voltage

Fig. 9 Imaging unit power supply box, outside

Suprasetter 145/162/190 – Installation 21

Safety

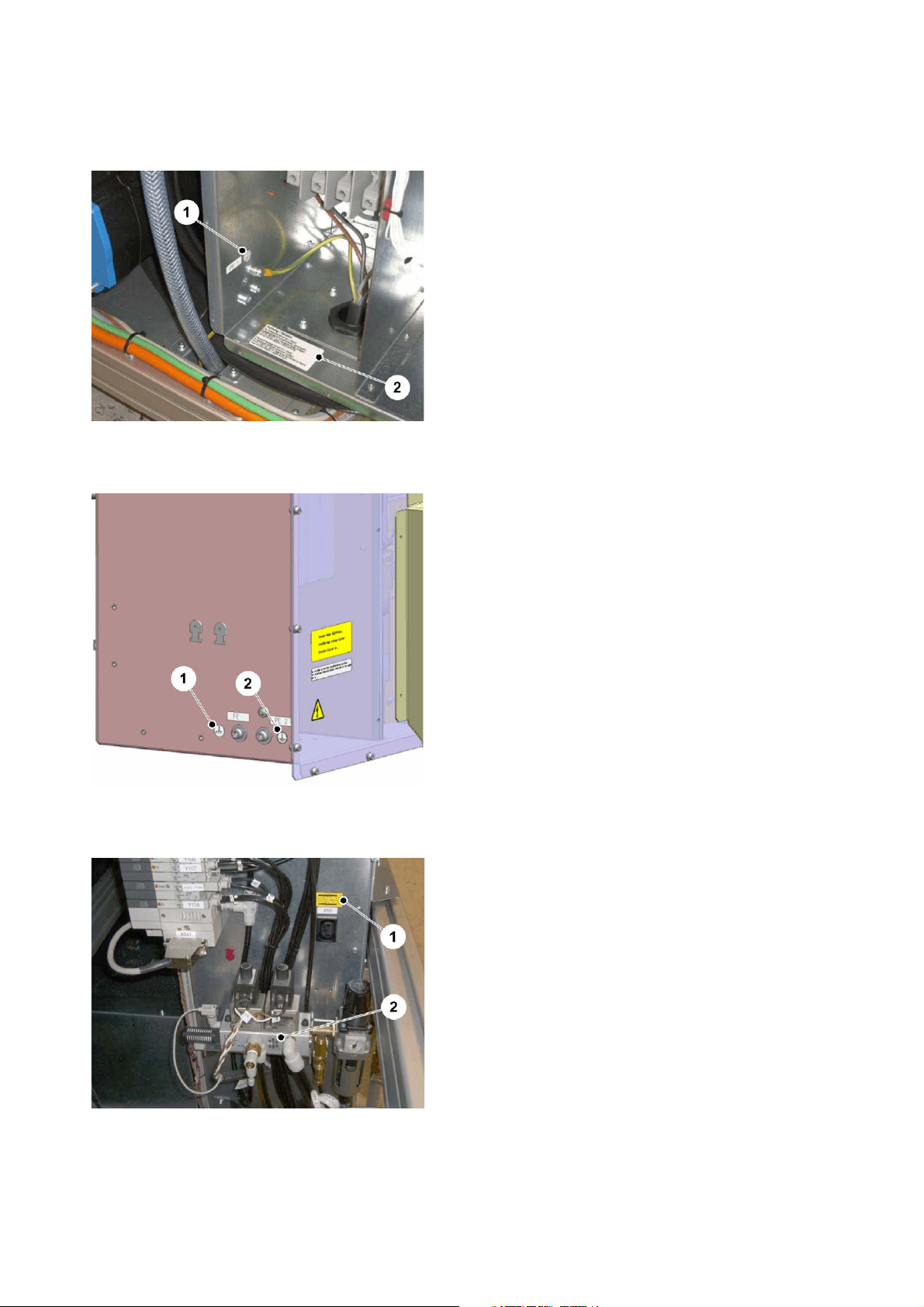

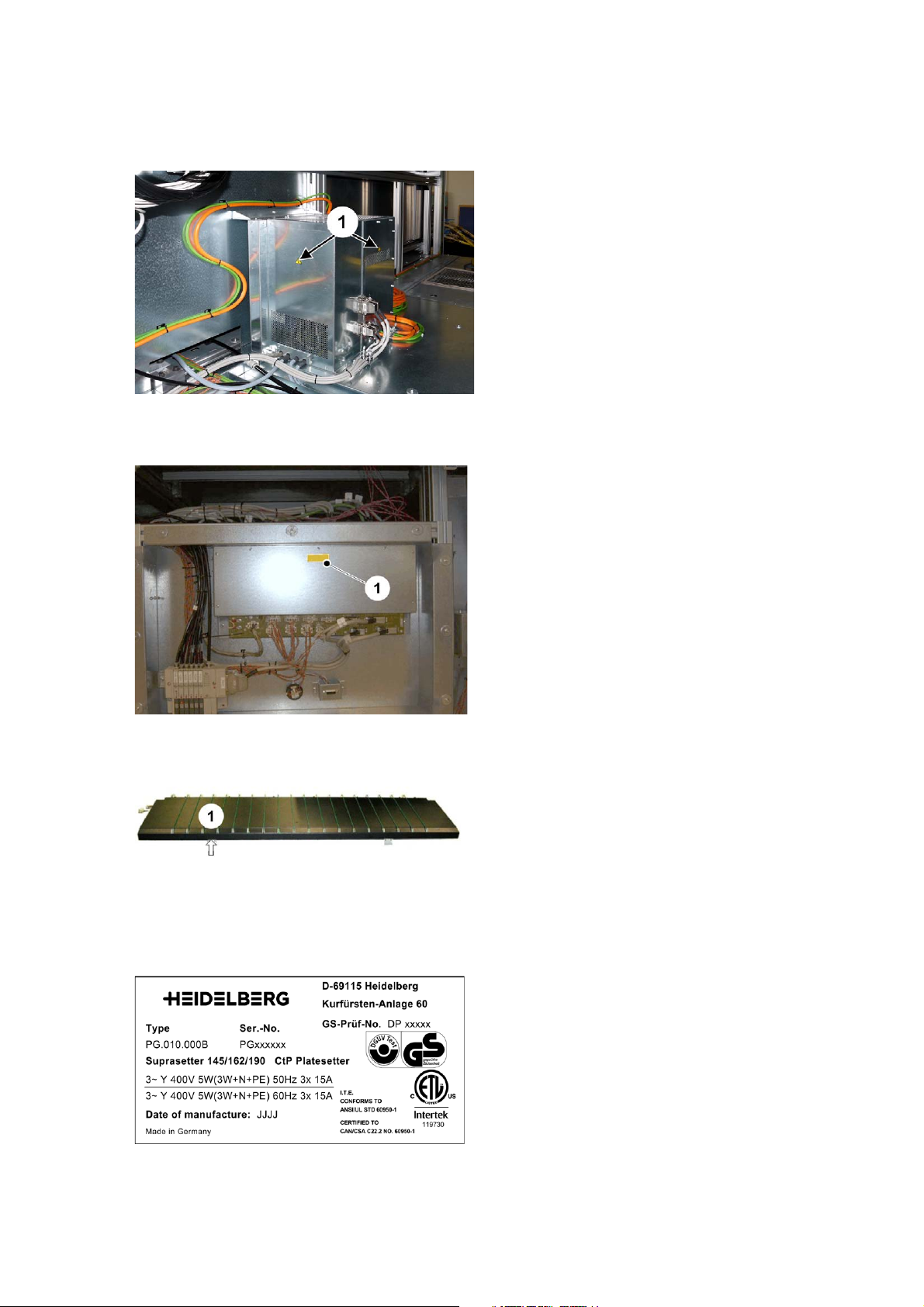

Fig. 10 Imaging unit power supply box, inside

Fig. 10/1: Symbol for protective conductor terminal (PE)

Fig. 10/2: Note on additional PE cable

Fig. 11/1: Symbol for functional earthing (FE)

Fig. 11 Power supply box, on side

Fig. 11/2: Symbol for additional protective conductor terminal (PE)

Fig. 12/1: AC outlet: Supply voltage for cross conveyor

Fig. 12/2: Air outlet: Compressed air connector for

separator

Fig. 12 SuprasetterComp. air

22

Safety

Fig. 13/1: Beware of moving parts

Fig. 13/2: Invisible Class 4 Laser Radiation

Fig. 13/3: Warning/information label on exhaust

(option)

Fig. 13 Imaging unit, right side

Fig. 14 Imaging unit, left side

Fig. 14/1: Beware of moving parts

Fig. 14/2: Invisible Class 4 Laser Radiation

Fig. 14/3: Flash: Beware of high voltage

Suprasetter 145/162/190 – Installation 23

Safety

Fig. 15/1: Flash: Beware of high voltage

Fig. 15 Imaging unit, choke housing

Fig. 16 Imaging unit, strut in front of drum

Fig. 16/1: Beware of moving parts

Fig. 16/2: Invisible Class 4 Laser Radiation

24

Safety

Fig. 17/1: Beware of moving parts (on both sides

of the upper bracing on the double lift table in the

plate loader)

Fig. 17 Lift table of plate loader

Fig. 18 Imaging unit, laser carriage electronics

Fig. 18/1: Warning label "Connect data cable only

when machine is switched off" on the cover of the

electronics on the laser carriage.

Suprasetter 145/162/190 – Installation 25

Safety

Fig. 19/1: Flash: Beware of high voltage

Fig. 19 Central unit, rear

Fig. 20 Electronics unit

Fig. 20/1: Warning label: Data cable

Fig. 20/2: Flash: Beware of high voltage

26

Fig. 21 Servo drive in plate loader

Safety

Fig. 21/1: Flash: Beware of high voltage

Fig. 22/1: Warning label: Data cable

Fig. 22 Electronics door of plate loader

Fig. 23 Input/output table (option)

Labels

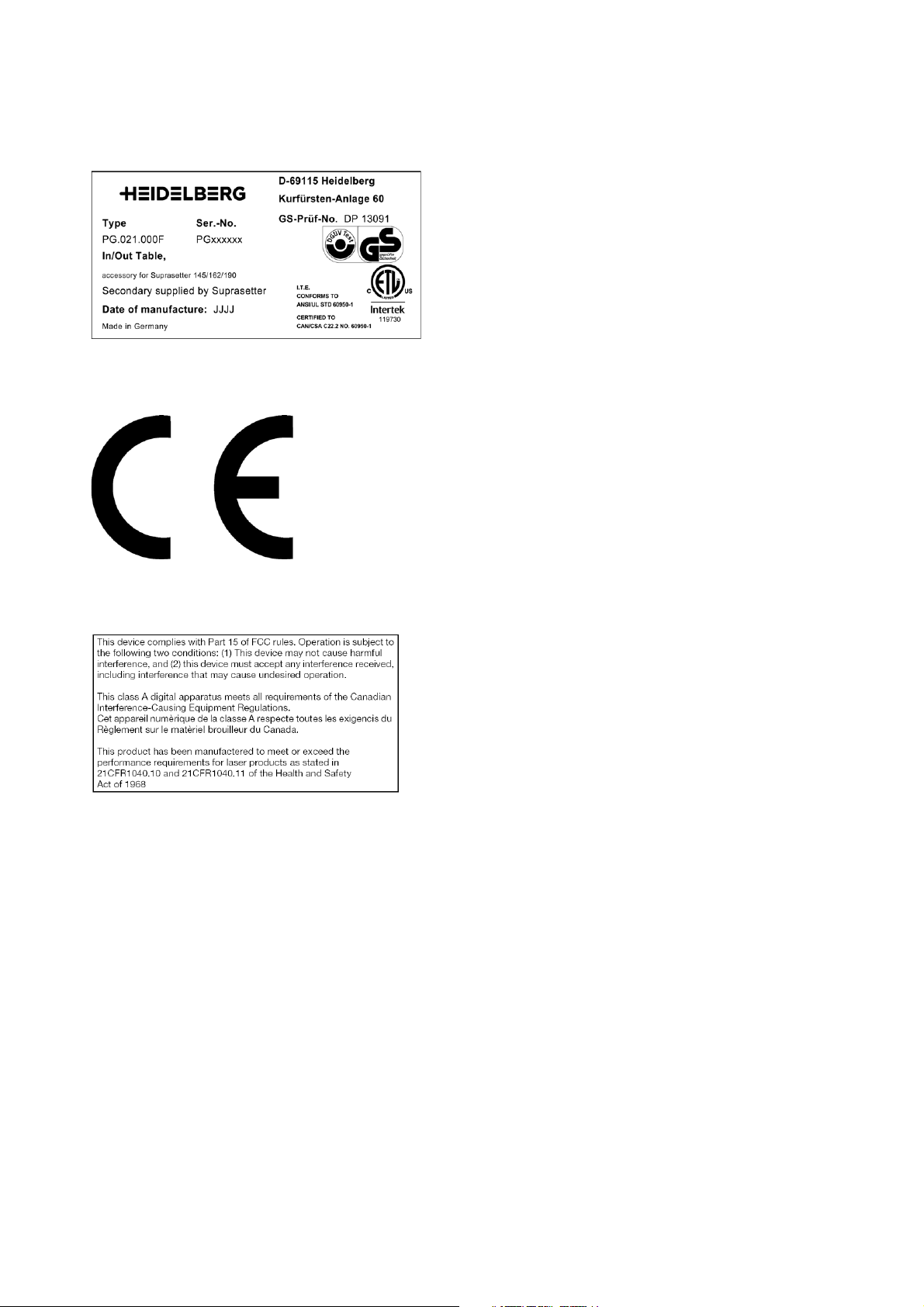

Fig. 24 Type label Suprasetter 145/162/190

Fig. 23/1: Type label under the input/output table

Location:

Fig. 7/4: On the recorder outside

Fig. 7/1: Inside on the chassis of the plate loader

Suprasetter 145/162/190 – Installation 27

Safety

Fig. 25 Type label input/output table

Location:

Fig. 23/1: under the input/output table (option)

Location:

Fig. 7/5: On the Suprasetter outside:

Fig. 26 CE mark of conformity

Fig. 27 Note on conformance

FCC, CDRH note on conformance (USA)

Location: on the Suprasetter outside (Fig. 7/3)

28

Loading...

Loading...