Page 1

SL-OCT

Slitlamp- OCT

Installation Instructions

Version 001, February 2009

© Heidelberg Engineering GmbH 2009

Art. No 18107

QM-Nr. 97 201-001

Page 2

SL-OCT Installation Manual

Art. No.: 18107 Page 2 of 42

Corporate Headquarters

Heidelberg Engineering GmbH • Tiergartenstr. 15 • 69121 Heidelberg • Germany

Phone +49 6221 6463-0 • Fax +49 6221 646362 • www.HeidelbergEngineering.de

US Main Office

Heidelberg Engineering, Inc. • 1499 Poinsettia Avenue, Suite 160 • Vista, CA 92081

Phone 760 598-3770 • Fax 760 598-3060 • www.HeidelbergEngineering.com

US Service Center

Heidelberg Engineering, Inc. • 410 Harris Road • Smithfield, RI 02917

Phone 401 349-0500 • Fax 401 349-0504 • www.HeidelbergEngineering.com

Page 3

SL-OCT Installation Manual

Art. No.: 18107 Page 3 of 42

Contents

1 INTRODUCTION 4

2 SCOPE 6

3 TOOLS 7

4 UNPACKING THE SYSTEM 8

4.1 Lift table 8

4.2 OCT-box 8

4.3 Slit lamp 8

5 INSTALLATION 9

5.1 Lift table 9

5.2 Optional printer table 16

5.3 OCT-box 19

5.4 Slit lamp 25

5.5 Electrical and fiber connections to the slit lamp 26

5.6 Electrical connections to the OCT-box 28

5.7 AC connections 29

5.8 Cleaning 30

6 TEST MEASUREMENT 31

7 DISASSEMBLY OF A SL-OCT UNIT 33

8 APPENDIX A: TROUBLESHOOTING 35

9 APPENDIX B: LIST OF SCREWS 37

10 APPENDIX C: PACKING LISTS 38

10.1 Lift table 38

10.2 OCT-box 39

10.3 Slit lamp 40

10.4 Optional printer table 42

Page 4

SL-OCT Installation Manual

Art. No.: 18107 Page 4 of 42

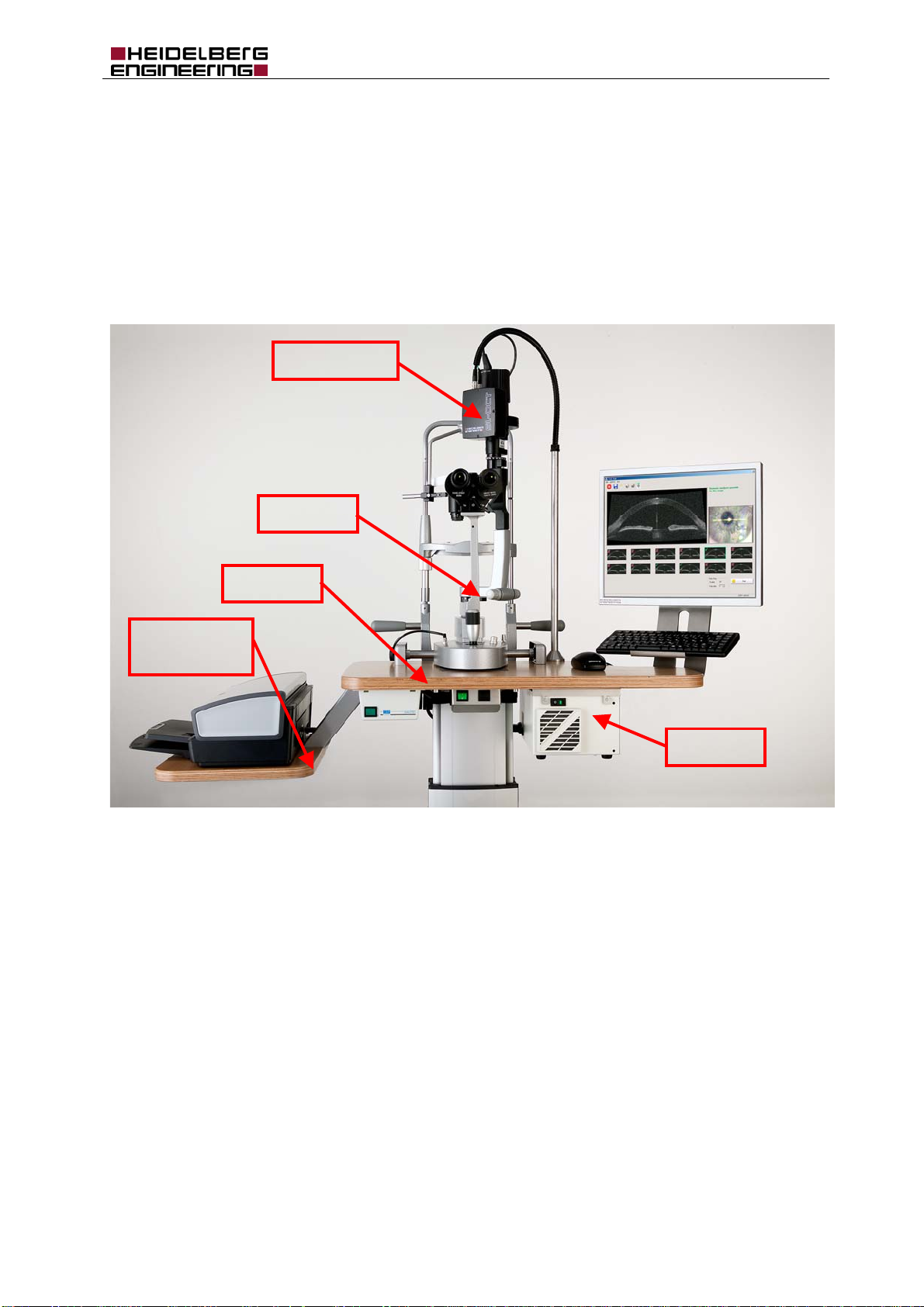

1 Introduction

The SL-OCT is a tomographic device for the viewing and axial, cross sectional imaging of anterior ocular

structures. It is used for the in vivo imaging and measurement of the anterior segment structures of the

eye.

This document describes the installation of the SL-OCT device. It also contains important safety

information.

NOTE: To ensure the overall safety of the system, the SL-OCT must be installed by certified staff

of your local Heidelberg Engineering distributor.

Scanner-box

Slit lamp

Printer table

(optional)

Lift table

OCT-box

Pic. 1 SL-OCT with optional printer table

Page 5

SL-OCT Installation Manual

Art. No.: 18107 Page 5 of 42

1.4 Cautions, Warnings, and Contraindications

WARNING Carefully read the operation manual before operating the device. Misuse of the device

may lead to incorrect diagnostic results.

WARNING Do not open the device component housings. Doing so may result in electrical shock and

laser radiation.

WARNING Do not use the device outside the scope of its “Intended use”. Doing so may lead to

malfunctions or damage of the device.

WARNING Do not use PCs, components or accessories that have not been approved by Heidelberg

Engineering. Do not install other software as this may interfere with the functionality of the

Heidelberg Engineering software or equipment. This could include damage to the system

as well as incorrect measurement results.

WARNING Do not use a network connection without network isolation in accordance with

IEC 60601-1. In the event of a failure in the network, user and patient could be at risk of

electrical shock.

WARNING Make sure that the environmental requirements are met when the system is operated.

Exceeding environmental conditions may damage the system or lead to incorrect

measuring results.

WARNING Make sure the patient is correctly positioned in front of the device before starting the

examination. Wrong positioning may lead to poor images and incorrect diagnostic results.

WARNING Artifacts on the images could falsify the measured results. Do not use the measured

results for further treatment if there are artefacts in the images.

WARNING Do not make a diagnostic decision on the basis of one single examination. The device is

not clinically evaluated for the diagnosis of specific pathologies. So always use alternative

information; history data etc. to assist in a final diagnostic determination.

WARNING Do not use the analysis results from patients with pathological eyes without an inspection

of the segmentation. In case of pathological eyes, the segmentation might be incorrect,

and lead to wrong calculations of the analysis results.

WARNING Prepare safeguards to ensure that only authorized personnel can access the patient

data. Data loss impedes follow-up analyses and may result in inappropriate diagnostic

decisions.

WARNING Be sure to perform periodic data backup procedures. Check the success of the backup to

avoid data loss caused by backup errors.

WARNING To avoid the risk of electric shock, this equipment must only be connected to a grounded

power supply.

WARNING To avoid the risk of electric shock, do not touch conductive parts of connectors and the

patient simultaneously.

WARNING Do not operate the system directly after large temperature changes. Let the device

acclimatize itself for a minimum of 2 hours to avoid device damage or incorrect

measurement results.

CAUTION Never leave the patient alone with the instrument during the examination!

CAUTION The instrument must not be used under any circumstances if mechanical, optical or

electrical faults occur. Any change or addition to the system must comply with the

relevant legal guidelines. Repairs, particularly to the electronic and optical components,

must be carried out only by Heidelberg engineering authorized, trained personnel.

CAUTION Unusual noises and/or vibrations can indicate a fault. Should this happen, please turn the

instrument off immediately and contact the technical support center responsible for your

area. Do not attempt to repair the instrument yourself in the event of a fault.

CAUTION This instrument contains a diode laser and emits invisible laser light through the slit lamp.

The Heidelberg SL-OCT is a Class I laser system. The laser does not pose any safety

hazard.

CAUTION This equipment was tested in accordance to IEC 60601-1-2, Electromagnetic

Compatibility (EMC). Nevertheless, it might be affected by strong electromagnetic fields.

Portable high frequency communication devices may affect the device.

CAUTION The operator must be sure that the device settings and adjustments are correct before

starting an examination and making any diagnostic decision. Wrong settings and

adjustments may lead to poor image quality or incorrect examination information.

CAUTION The physician must be sure to have the correct patient data before making a diagnostic

decision. Mismatched patient data may lead to inappropriate diagnostic decisions.

Page 6

SL-OCT Installation Manual

Art. No.: 18107 Page 6 of 42

CAUTION Read subsection “Imaging Process” of the Operation Instructions carefully before starting

the examination. Incorrect preparation of the patient may lead to poor image quality and

incorrect diagnoses.

CAUTION Do not start an examination without informing the patient about the examination

procedure. Inappropriate patient behavior during the examination may lead to poor image

quality and incorrect diagnoses.

CAUTION Read subsection “Service Maintenance and Cleaning” of the Operation Instructions

carefully. A failure to carry out maintenance or incorrect adjustment of the device may

lead to poor image quality and incorrect diagnoses.

CAUTION Before starting the system check the regional power supply specifications to verify that

they comply with the required tolerances (100V < U < 240V; 50Hz < f < 60Hz). Wrong

power supply conditions may lead to malfunctions of the system.

CAUTION A computer failure during image acquisition or analysis could lead to incorrect results.

CAUTION United States of America:

Federal law restricts this device to sale by or on the order of a Physician or Practitioner.

CAUTION While printing using the optinal printer table, it is not possible to take measurements due

to the vibrations of the printer

CONTRAINDICATIONS No contraindications are known.

For the United States of America only:

The laser class label “Laser Class 1” is located on the rear of the OCT housing.

The Laser safety class is approved and defined in accordance to IEC 60825 part

1 and part 2 and in accordance to the 21 CFR Part 1040 “Performance Standard

for Light emitting Products”.

2 Scope

This installation instruction is referring to model SL-OCT Ver. B01.

Page 7

SL-OCT Installation Manual

Art. No.: 18107 Page 7 of 42

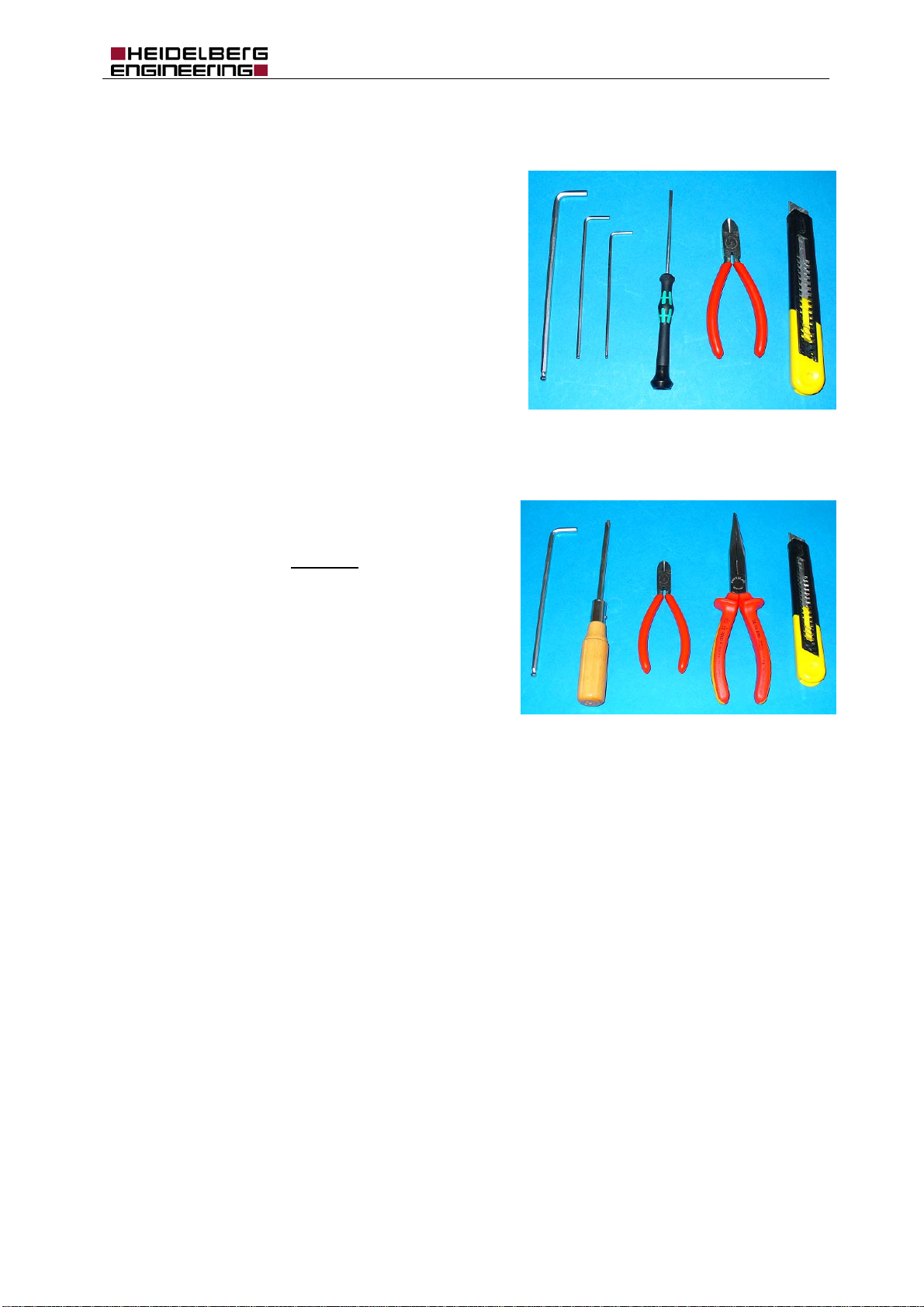

3 Tools

The following tools are required:

Allen wrenches

o 5 mm

o 3 mm

o 2.5 mm

Screwdriver for slotted head screws 3 mm

Wire cutter

Cutter.

For the assembly of the optional printer table, following

the tools are required:

Allen wrench with ball head

5 mm

Screwdriver for recessed head screws

Wire cutter

Long nose pliers

Cutter.

Pic. 2 Tools for installation of SL-OCT

Pic. 3 Tools for the assembly of the printer table

Page 8

SL-OCT Installation Manual

Art. No.: 18107 Page 8 of 42

4 Unpacking the system

The SL-OCT is delivered in three cardboard boxes – lift table, OCT-box, and slit lamp. The packing lists

for each box are listed in section 10 Appendix C.

4.1 Lift table

The lift table package contains three layers:

1. Cable conduit, column, keyboard fixation

arm, and monitor fixation arm.

2. Cables, wheels, and table top.

3. Foot.

Pic. 4 Cardboard box containing the lift table

4.2 OCT-box

The OCT-box package contains two layers:

1. Folder with operating instructions etc., and

mouse pad.

2. Cables, mouse, dust cover, protective caps,

replacement fuses, OCT-box.

4.3 Slit lamp

The slit lamp package contains two layers:

1. Head rest in a separate cardboard box.

2. Monitor, slit lamp with permanently mounted

scanner-box, slit lamp accessories in a

separate cardboard box, eyepieces for the

microscope, and keyboard.

Pic. 5 Cardboard box containing OCT-box

Pic. 6 Cardboard box containing slit lamp

Page 9

SL-OCT Installation Manual

Art. No.: 18107 Page 9 of 42

5 Installation

The installation of the SL-OCT unit is started with the build up of the lift table. The next part is the

assembly of the OCT-box onto the lift table. Afterwards, the slit lamp including the permanently mounted

scanner-box is installed onto the lift table. At the end of the installation procedure, test measurements

are carried out to ensure correct operation of the device.

5.1 Lift table

The first step is the assembly of foot and column. Take

the column out of its package and place it on top onto

e.g. a cellular plastic backing (see Pic. 7).

cellular plastic backing

Pic. 7 Column prepared for assembly of foot

Remove the four Allen screws (M6 x 40) and spring washers needed for

the assembly of the foot.

All screws and washers necessary for assembly are provided,

slightly screwed into their respective screw holes!

Control the cable laying. The mains cable of the column must lay in

the slit (see Pic. 9).

Pic. 8 Premounted screws for

assembly of the foot

Pic. 9 Cable laying of mains cable

Page 10

SL-OCT Installation Manual

Art. No.: 18107 Page 10 of 42

Mount the foot onto the column (see Pic. 10). The

longer part of the foot must be oriented towards the the

cable outlet of the column. The computer screen will

later be mounted onto this side of the table. Therefore,

the correct orientation of the foot is essential for the

stability of the table.

Pic. 10 Foot onto column mounted

Now clip in the four wheels onto the foot.

Pic. 11a Wheels

Pic. 11 Clip in the wheel

Turn around column and mounted foot (see Pic. 12a). Then, connect mains and lift the column until the

stop at end (see Pic. 12).

Attention: Be very careful not to touch the cables in the open

control console as they are alive! As soon as the column is

lifted, disconnect the mains!

Pic. 12a Column not lifted

Pic. 12 Column lifted till stop at end

Page 11

SL-OCT Installation Manual

Art. No.: 18107 Page 11 of 42

After disconnecting mains, the tabletop is prepared. Remove the screws and washers from the screw

holes for the column (M6 x 25 and spring washers) and control console (M6 x 16 and spring washers)

(see Pic. 13 red and green).

Multible power

socket

Assembly of

head rest

Assembly of

control console

Assembly of

column

Pic. 13 Table top (bottom) with premounted screws and washers

Mount the tabletop onto the column. Use the short

Allen screws for the console and the long ones for

the column.

Assembly of

monitor fixation

Pic. 14 Mounting of table top onto the column

If there is an optional printer arm delivered with the SL-OCT, it can be assembled at this state of the

installation or at the end of the assembly procedure. Please refer to section 5.2.

Page 12

SL-OCT Installation Manual

Art. No.: 18107 Page 12 of 42

Pic. 15a rear side of mounted monitor unit

Pic. 15 Mounted monitor including keyboard

fixation arm

The computer screen is mounted together with the keyboard fixa tion arm on its fixation arm. The other

end of the monitor fixation arm is mounted beneath the tabletop (see Pic. 15a and Pic. 15).

There are two possible ways for mounting the monitor unit onto the table:

1. Premounting of monitor arm, keyboard arm, and monitor before assembly of the whole unit onto

the lift table.

This is recommended if several persons are installing the device together.

2. Premounting of monitor arm and lift table before assembly of keyboard arm and monitor.

This might be more comfortable if there is a single person installing the device. It is easy to

adjust the monitor fixation arm with one hand while looking beneath the tabletop and mounting

the screws. Handling the whole premounted unit with one hand while adjusting the screws

beneath the table needs more strength.

Avoid touching the surface of the screen.

Pic. 16a Monitor arm and keyboard arm

Pic. 16 Rear side computer screen with its screws

Page 13

SL-OCT Installation Manual

Art. No.: 18107 Page 13 of 42

1. Premounting of monitor unit

Put the computer screen with the screen facing downwards

onto a table parallel to the table’s edge (see Pic. 16).

Remove the screws (Allen screws M4 x 20). Place the

keyboard arm onto the monitor with the angled part

hanging down. Now place the monitor arm on top and

screw all parts together (see Pic. 17).

Pic. 17 Mounted monitor unit

Remove the screws from the tabletop (see magenta arrow in Pic. 13 and

Pic. 18).

Pic. 18 rear side of tabletop in detail

Place the monitor unit so that the keyboard arm is on top of the lift table and

the angled part of the monitor arm is beneath the table (see Pic. 15a).

Assembly the 4 Allen screws (M6 x 20). Adjust the computer screen into the

right position by turning it slightly around the middle screw before fastening

the screws.

2. Premounting of the monitor arm

Remove the screws from the tabletop (see Pic. 13 magenta

and Pic. 18). Assemble the monitor arm (see Pic. 16a) at the

lift table (see Pic. 20).

Do not fully fasten the screws (M6 x 20) until the computer

screen is mounted and adjusted.

Plug in mains and lower the lift table to a convenient height.

Pic. 19 Mounted monitor arm

Pic. 20 Mounted monitor arm

Page 14

SL-OCT Installation Manual

Art. No.: 18107 Page 14 of 42

Remove the screws from the rear side of the monitor (see Pic. 16).

Place the keyboard arm in front of the monitor arm and stick the

screws (M4 x 20) through the holes (see Pic. 21) so that it is hanging

on the screws.

Pic. 21 Keyboard arm hanging on screws

Now carefully place the monitor in front of the keyboard arm and fasten the screws (M4 x 20). Adjust the

computer screen to the right position by turning it slightly around the middle screw before fastening the

screws beneath the table.

Now continue with the installation of the headrest.

If necessary, plug in mains and lift the table to comfortable height.

Remove the two Allen screws (M6 x 20) of the headrest assembly from

the edge of tabletop (see turquoise arrow in Pic. 13 and Pic. 22). Loosen

one of the knurled screws and remove the second. Swing the protective

cover aside (see Pic. 22a).

Pic. 22a Protective cover of headrest’s

electrical plug

Pic. 22 Assembly of headrest beneath table

Page 15

SL-OCT Installation Manual

Art. No.: 18107 Page 15 of 42

Connect the electrical plug of the headrest and assemble

the headrest onto the lift table.

Swing back the protective cover (see Pic. 22b) and fasten

the knurled screws again.

Grab handles

and locking

screws

Pic. 22b Protective cover of the

headrest’s electrical plug

Pic. 23 Headrest

Loosen the locking screws at the inner side of the headrest a bit, screw in the grab handles, and fasten

the locking screws again (see Pic. 23 red).

Pic. 24 Rail covers

Pic. 24a Rail cover on the right side

Fit the rail covers onto the rails (see Pic. 24 and Pic. 24a). The rail cover with the cable bracket is on the

left side from operator’s view.

The rail cover at the cable conduit’s side (right) must be mounted before the cable conduit is

assembled! (See section 5.3 below)

Page 16

SL-OCT Installation Manual

Art. No.: 18107 Page 16 of 42

5.2 Optional printer table

Heidelberg Engineering recommends placing the

printer on a separate table near the SL-OCT

unit.

If this is not possible, the optional printer table

can be assembled to the unit with a fixation arm

(see Pic. 25).

Note: While printing using the optinal printer

table, it is not possible to take

measurements due to the vibrations of

the printer.

Pic. 25 Optional printer table with printer

Heidelberg Engineering recommends using the following printer types:

Hewlett Packard D4200 family

Hewlett Packard 5900 family.

For both printer series, the software drivers are preinstalled on the SL-OCT built-in computer.

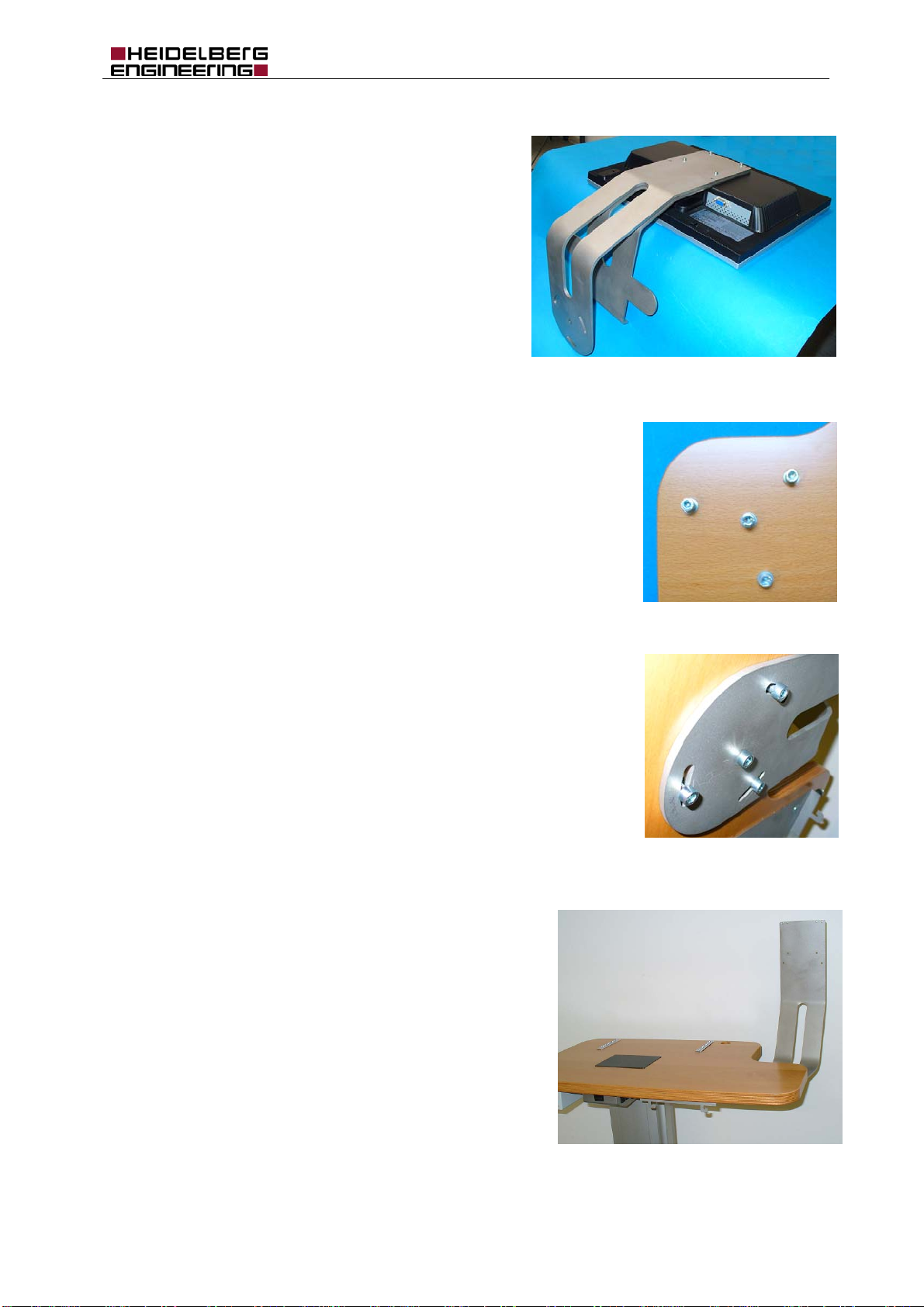

First, the fixation arm is mounted onto the

printer tabletop (see Pic. 26 and Pic. 27).

Pic. 26 Printer table fixation arm

The image to the right (Pic. 27) shows the rear side of

the printer table with premounted cable brackets for the

assembly of the printer’s power supply and premounted

recessed countersunk flat head wood screws (4 x 16

mm) for the assembly of the arm.

Remove the four recessed head screws and mount the

arm onto the table (see Pic. 28).

Pic. 27 Rear side of the printer tabletop

Page 17

SL-OCT Installation Manual

Art. No.: 18107 Page 17 of 42

Pic. 28 Rear side of the printer table with fixation arm

The fixation arm is assembled onto the SL-OCT lift table

with three Allen screws (M6 x 12). Pic. 29 shows the

screw holes beneath the SL-OCT tabletop near the slit

lamp power supply.

Pic. 29 Detail of SL-OCT table top with screw holes for the

printer fixation arm

The assembly must start with the single screw near the

table’s edge. Screw in this screw first without fastening it,

then mount the other two screws.

After adjusting the table, fasten at first the single screw

(see Pic. 30 and Pic. 31) then the others.

Note: The single screw near the table’s edge can only be

fastened with an Allen screwdriver with ball head

.

Pic. 31 Detail of the single screw near the table’s edge

Pic. 30 Assembly of the printer fixation arm

Page 18

SL-OCT Installation Manual

Art. No.: 18107 Page 18 of 42

Now place the printer on the table as shown in Pic. 25.

Install the printer’s power supply beneath the printer

table using the premounted cable brackets and the long

cable ties (see Pic. 32).

Pic. 32 Power supply printer

Thread the USB cable and

the printer’s power cord

through the printer arm (see

Pic. 33a and b) - long nose

pliers may be helpful.

Pic. 33a Printer cable at the SL-

OCT table

Pic. 33b Cable of the printer

Connect the USB cable to the SL-OCT computer and the power cord to the multiple power socket. Use

the short cable ties for a proper cord placing.

If necessary the mains connector of the printer must be replaced by an

IEC60 320-2-2 connector. The connector is delivered with the printer table.

Only a qualified person is allowed to replace the plug.

Pic. 34 IEC60 320 power plug

Page 19

SL-OCT Installation Manual

Art. No.: 18107 Page 19 of 42

5.3 OCT-box

Attention: A glass fiber is permanently connected to the OCT-box – handle the unit with care!

Do not buckle the glass fiber!

Before taking the OCT-box out of the

package, remove the cellular plastic

stopper from the glass fiber packaging

(see Pic. 35).

Pic. 35 OCT-box in the package with stopper in the hole for the glass fiber

Check if the fuses are correctly dimensioned

for the used mains voltage (see Pic. 36). The

default built in fuses (T 2.5A /250V) are for

230Vac.

For the use with 110Vac the needed 5A fuses

(T 5,0A / 250V) are in the package (see

section 10.2 Appendix C Packing lists).

Pic. 36 Fuses of the OCT-box

Replace the fuses (see Pic. 37a and b).

Unscrew the carriers from the fuse bases and

pull out the fuses.

Stick the 5A fuses into the carriers and screw them

into the fuse bases of the OCT-box.

Pic. 37a Removal of a fuse

Pic. 37b Fuse in fuse carrier

Page 20

SL-OCT Installation Manual

w

Art. No.: 18107 Page 20 of 42

The Allen screws in the OCT-box (M3 x 10) should show 6 – 8 mm thread as shown in Pic. 38a.

Pic. 38a OCT-Box with premounted screws

Pic. 38b Hook for hanging the OCT-box

beneath the table

Hang the OCT-box onto the hooks. The switch must be on the operator’s side of the table. Fasten the

four Allen screws (M3 x 10) (see Pic. 38 a-d).

Pic. 38c OCT-Box hanging beneath the table

Pic. 38d OCT-Box with fastened scre

Page 21

SL-OCT Installation Manual

r

Art. No.: 18107 Page 21 of 42

Pic. 39a Scanner cable

The next step is the installation of the scanner cable (see

Pic. 39a).

When looking from the patients side of the device, the

connectors of the OCT-box are located at the left side of the

box (see Pic. 60). All connectors are labeled.

The sub-D connector of the cable is connected to the OCTbox (see Pic. 39b). The other end of the cable is pushed

through the hole in the tabletop together with the fiber plug

(see Pic. 40).

Remove the Allen screws

(M4 x 35) and washers from

the cable conduit (see Pic.

41a).

Pic. 39b Scanner cable connected to OCT-box

Pic. 40 Scanner cable and glass fiber are pushed

through the hole in the tabletop

Pic. 41a Cable conduit

Pic. 41b Fiber and electrical connecto

Pic. 41c Put first fiber and second electrical

connector into the conduit

Both fiber and scanner cable together are threaded through the cable conduit (see Pic. 41b). The fiber

connector must pass the tube first (see Pic. 41b and c). The scanner cable is stiff enough to be pushed

through the tube taking the fiber with it.

Page 22

SL-OCT Installation Manual

Art. No.: 18107 Page 22 of 42

Stick the cable conduit into the hole in the table (see Pic. 42). Do not screw it at

this point of time.

Pic. 42 Cable conduit mounted onto the table

First mount the black plastic flexible tube onto fiber and scanner cable (see Pic. 43a and b).

Pic. 43a Plastic tube and clip

Pic. 43b Two parts of plastic tube

The flexible tube consists of two parts, which are clipped together (see Pic. 43b). Part it and fit in fiber

and scanner cable near the connectors into the slit of the inner tube (see Pic. 44). The more flexible,

thinner glass fiber must be at the inner side of the tube.

Pic. 44 Fit in glass fiber and scanner cable into the slit of the tube

Now carefully pull the connectors and the tube in the directions indicated in picture 45 in order to slide the

cables into the tube (see Pic. 45).

Page 23

SL-OCT Installation Manual

Art. No.: 18107 Page 23 of 42

Pic. 45 Glass fiber and scanner cable are sliding into the tube

Clip the outer part of the plastic tube (see Pic. 43) onto the

inner part which is assembled on the cables (see Pic. 46).

Pic. 46 Closing the flexible tube

Assemble the clip (see Pic. 43a) at the end of the flexible tube (see

Pic. 47).

Pic. 47 Clip at the end of the flexible tube

Page 24

SL-OCT Installation Manual

Art. No.: 18107 Page 24 of 42

The clip is screwed into the conduit by turning

the conduit

around (see Pic. 48a).

Attention: Do not rotate the clip! If the clip

and flexible tube are rotated, the glass fiber

will be drilled. This will cause a loss of

signal quality!

Pic. 48a Screwing of the clip

into the conduit

Pic. 48b Mounted clip

Pic. 49 Flexible tube and clip assembled

When the flexible tube and the clip are mounted (see Pic. 48b and Pic. 49) the cable conduit must be

fixed.

The rail cover must be at its

place before assembling the

cable conduit!

Lift the basis of the conduit

about 2 or 3 mm from the

tabletop (see Pic. 50a).

Now it is possible to see the

screw holes for adjusting

and fastening the screws

(see Pic. 50b)

Pic. 50a Assembly of cable conduit

Pic. 50b Tightened cable conduit

Page 25

SL-OCT Installation Manual

r

Art. No.: 18107 Page 25 of 42

5.4 Slit lamp

Swing the right rail cover to the side as shown in Pic. 51. Take

the slit lamp out of its package and place it on the tabletop so that

the wheels fit onto the rails.

Take the two eyepieces out of the package and push them into

their holders in the microscope arm.

Cover the rails with the rail covers.

Pic. 51 Slit lamp standing onto the table

Remove the transport dust cover from the slit lamp’s mirror (see Pic. 52

red).

Attention: Do not touch the mirror!

Remove the transport protection shown in Pic. 52 yellow. Use the slit width

control to loosen the protection piece and remove it.

Take the protective cover (see Pic. 52a) out of the box containing the slit

lamp accessories and put it onto the basis of the slit lamp arm (see magenta

arrow in Pic. 52).

Protective

cover

Pic. 52a Protective cove

Slit width

control

Pic. 52 Slit lamp’s arm with

transport protections

Page 26

SL-OCT Installation Manual

Art. No.: 18107 Page 26 of 42

5.5 Electrical and fiber connections to the slit lamp

Three connectors are located on the head of the slit lamp (see

Pic. 53):

1. The glass fiber is connected to the scanner-box.

2. The scanner cable is also connected to the scanner-box.

3. The lamp cable from the headrest is connected to the

illumination unit.

Attention: Do not touch the head of the fiber!

Handle the fiber with care.

Pic. 53 connectors of the scanner-box

Remove the protective caps from the

connectors on top of the scanner-box

(see Pic. 54a and b).

The connector next to the illumination

unit of the slit lamp is a fiber socket with

a notch (see also Pic. 56). The

electrical connector for the scanner

cable next to the fiber socket has a

nose.

Pic. 54a connector on top of

scanner box with protective

caps

Pic. 54b Left: electrical socket, right: fiber socket

Remove the protective

cap from the glass

fiber plug (see Pic.

55a and b).

The fiber plug has a

nose (see also

Pic. 55a fiber plug with protective cap

Pic. 55b fiber plug without protective cap

Attention: Do not touch the head of the fiber! Dirt on the head of the fiber will cause a lost of signal

quality!

Page 27

SL-OCT Installation Manual

r

Art. No.: 18107 Page 27 of 42

Plug in the glass fiber as shown in Pic. 56. Fit the nose of the fiber plug into the notch of the socket. Try

to slightly turn the plug in the socket, to check if nose and notch are correctly placed. Be careful not to

twist the glass fiber, as rotating the glass fiber may damage it. If it is not possible to rotate the plug,

fasten the clamping nut.

nose

notch

Pic. 56 Nose and notch of the fiber connection

Attention: Do not buckle the glass fiber!

A kink in the glass fiber will lead to a

loss of signal quality! A break of the

fiber will lead to a breakdown of the

device.

Pic. 57a buckled fibe

Pic. 57b Glass fiber well guided

Connect the scanner cable to the scanner-box. The little nose of the socket (see Pic. 54a and b) must fit

into the notch of the plug. Fasten the clamping nut of the plug.

Connect the power for the slit lamp illumination to the head of the slit lamp (see Pic. 53).

Connect the power of the slit lamp to the slit lamp basis.

Remove the cable bracket from the rail cover with a screwdriver

for slotted head screws. Fix the cable with the bracket (see Pic.

58).

Pic. 58 Power supply for the slit lamp

Page 28

SL-OCT Installation Manual

y

Art. No.: 18107 Page 28 of 42

5.6 Electrical connections to the OCT-box

Place the keyboard onto the keyboard fixation arm, the

mouse pad onto the table, and the mouse onto the

mouse pad (see Pic. 59).

Pic. 59 Keyboard and mouse

When looking from the patients side of the

device, the connectors of the OCT-box are

located at the left side of the box (see Pic.

60). All connectors are labeled.

The scanner is already connected (see Pic.

39).

Connect monitor, keyboard, and mouse.

If the monitor needs dc voltage, the 12V

connector is used. If the monitor needs ac

voltage refer to next section 5.7.

Pic. 60 Connectors of the OCT-box

USB, LAN, and RS232 are optional connectors for computer periphery.

The following images show the connections of the monitor on the rear side. In case of dc power refer to

Pic. 61a. In case of ac power supply refer to Pic. 61b.

Pic. 61a Monitor with dc power suppl

(bottom) and VGA connection (top)

Pic. 61b Monitor with ac power supply (left) and

VGA connection (right)

Page 29

SL-OCT Installation Manual

Art. No.: 18107 Page 29 of 42

5.7 AC connections

The sockets for ac power are located on both sides of the

lift table’s control console (see Pic. 62).

Pic. 62 AC socket at control console

The following ac cables are needed:

1. Power-in to multiple socket (length 0.35 m)

2. Power to power supply slit lamp (length 0.30 m)

3. Power to OCT-box (length 0.32 m)

4. Power to monitor if monitor needs ac power

(length 1.05 m)

5. Optional: power to printer (refer to section 5.2).

Pic. 63 AC cables

The image to the right (Pic. 64) shows the power supply

of the multiple power socket. The mains cord is

connected to the console (see Pic. 62) and to the input of

the multiple socket.

The multiple power socket provides four equal outputs.

Power in

Pic. 64 Multiple power socket with power-in connection

The image to the right (see Pic. 65) illustrates the power

distribution with the multiple power socket. The optional power

connection to the printer is not shown.

to control console of column

Pic. 65 Power distribution with multiple socket

Page 30

SL-OCT Installation Manual

Art. No.: 18107 Page 30 of 42

Use the protective cover

of the headrest and the

premounted cable

bracket with a cable tie

for a proper placement

of the cables (see Pic.

66a and b).

Pic. 66a cable bracket

Pic. 66b placement of cables

5.8 Cleaning

If necessary, clean the mirror of the slit lamp

.

We recommend to remove dust using compressed air, which is commercially available in aerosol cans.

Fingerprints can be removed with a small amount of ethanol and lens cleaning tissue. Contact

Heidelberg Engineering support for a detailed description for the cleaning of mirror and glass fiber head.

If necessary, clean the computer monitor

.

Again, the best way to remove dust is compressed air. In order to remove fingerprints use special

cleaners for TFT computer screens, e.g. a special tissue with alcohol free cleaning fluid.

For information on maintenance, please refer to the SL-OCT Operation Instructions.

Page 31

SL-OCT Installation Manual

Art. No.: 18107 Page 31 of 42

6 Test measurement

Start up the system as described in the SL-OCT Operating Instructions. Wait about 10 minutes until the

device has warmed up. Start the Heidelberg Eye Explorer program and open the acquisition window.

Pic. 67a protective cover

Remove the protective cover from the slit lamp and fit in the test rod of the

slit lamp (see Pic. 67 and Pic. 68).

The test rod is an accessory of the slit lamp and can be found in the

accessories box.

Pic. 67b Slit lamp’s rod

Pic. 68 Installation of the slit lamp’s test rod

Page 32

SL-OCT Installation Manual

Art. No.: 18107 Page 32 of 42

Start the acquisition. Adjust the rod until a horizontal bright white line is visible in the upper third of the

OCT display (see Pic. 69).

If the OCT image of the rod is not shining bright or located at a wrong position in the B-scan, refer to

section 8 Appendix A Troubleshoot.

Pic. 69 Measuring the slit lamp’s test rod

When the test image of the rod is correct, stop the data acquisition and remove the test rod from the slit

lamp. Cover the holding of the rod with the protective cover again.

Now the installation process of the SL-OCT device is finished.

Page 33

SL-OCT Installation Manual

Art. No.: 18107 Page 33 of 42

7 Disassembly of a SL-OCT unit

This section contains special notes for the disassembly of the SL-OCT unit. Basically the disassembly is

the installation procedure in backwards order.

If packages for the unit are lost, contact Heidelberg Engineering for replacement. In any case the original

cardboard boxes must be used for transportation of the SL-OCT unit.

Please slightly screw all screws and washers after disassembly in their screw holes again. Loose screws

in the cardboard boxes may damage the SL-OCT unit!

Removing the fiber connection

Attention: Do not buckle the glass fiber!

Do not touch the head of the fiber!

Before opening the fiber connection on top of the scanner-box, be sure that the protection cap for the

fiber plug is ready to hand. As soon as the plug is disconnected, protect the fiber head with the cap (see

Pic. 55a).

If necessary there are replacement caps in the package of the OCT-box.

Packaging the slit lamp into the cardboard box

Attention: Do not touch the mirror!

First, remove the eyepieces from the slit lamp’s microscope.

Mount the protective caps onto the connectors on top of the scanner-box. If necessary, there are

replacement caps in the package of the OCT-box.

Protect the slit lamps mirror with a lens cleaning tissue as shown in Pic. 52.

Protect the slit lamp against vibrations with the transport protection also shown in Pic. 52.

Lower the slit lamp as low as possible by turning around the control lever.

Opening the plastic clip

Use a screwdriver for slotted head screws for opening

the clip as shown in Pic. 70. Block the locking

mechanism with the screwdriver and part the slit of

the clip.

Pic. 70 Opening the plastic clip

Page 34

SL-OCT Installation Manual

Art. No.: 18107 Page 34 of 42

Removing the flexible plastic tube

Attention: Do not buckle the glass fiber! Handle the fiber with care.

The flexible plastic tube consists of two pieces that are clipped together. First remove the outer part.

Then take both cables – glass fiber and scanner cable – in one hand and pull them out of the slit of the

inner tube.

Putting the column into the cardboard box

After the tabletop is removed from the column, connect mains and lower the column as low as possible.

Attention: Be very careful because cables in the open control console are alive!

The column must be telescoped to the lowest position before it can be put into the cardboard box.

Removing the wheels from the foot

First disassemble the column from the foot.

For removing the wheels from the foot, a solid screwdriver for slotted head

screws at least 6 mm is required. Place the foot on a table near the table’s

edge. Insert the screwdriver between nut and top of the wheel as shown in Pic.

71 and lever the wheel from the pin (see arrow).

Pic. 71 Disassembly of wheel

Page 35

SL-OCT Installation Manual

Art. No.: 18107 Page 35 of 42

8 Appendix A: Troubleshooting

If parts are missing, contact Heidelberg Engineering. For missing screws, please refer to section 9

Problem Cause Measures / Solution

The tube of the cable conduit in

the base is loose.

The lift column is not working.

The Allen set screw holding the

tube is loose.

Tighten the screw in the base with

an Allen key 2 mm.

Mains are not properly connected. Check the mains connection.

Mains cord is defect.

Check the mains cord.

Mains voltage differs from the

specified voltage for the column.

Check the column specifications.

Contact Heidelberg Engineering.

Other cause. Contact Heidelberg Engineering.

Device is switched on and the

green power switch is not

shining.

Device is switched on and

monitor stays dark

Device not connected or

connection with mains is

defective.

Check mains connectors.

Is the multiple socket connected to

the column?

Is the main switch at the control

console of the column switched

on?

Cable connections between

Check the cable connection.

monitor and OCT-box are

defective.

Monitor is switched off. Use the power switch of the

monitor to turn on the screen.

Other cause. Contact Heidelberg Engineering.

Page 36

SL-OCT Installation Manual

Art. No.: 18107 Page 36 of 42

Computer is booted but mouse /

keyboard does not work.

The test measurement is

Connection of mouse / keyboard

is defective.

SL-OCT is not scanning.

strange.

Glass fiber is not properly

connected.

Check the connection of the

mouse / keyboard plug at the

OCT-box and reboot the

computer.

Shut down the computer and

check scanner cable. Reboot the

computer and start measurement.

Check the fiber connection, see

section 5.4 Pic. 56.

Page 37

SL-OCT Installation Manual

Art. No.: 18107 Page 37 of 42

9 Appendix B: List of screws

All screws required are delivered with the system and premounted in their screw holes.

Allen screw

metric thread

length in mm

M3 x 10 4 - OCT-box - table

M4 x 20 4 - Monitor- and keyboard arm - monitor

M4 x 30 3 Flat washer Cable conduit - table

M6 x 12 optional 4 - Optional printer arm - table

M6 x 16 4

M6 x 20 4 - Monitor arm - table

M6 x 25

M6 x 40 4

Recessed

countersunk flat

head wood screws

4 x 16 optional

All used screws are commercially available.

Quantity Washer Position

Spring

washer

Control console column - tabletop

2 - Headrest - table

4

Spring

washer

Spring

washer

Column - tabletop

Foot - column

4 - Optional printer arm – printer tabletop

Page 38

SL-OCT Installation Manual

Art. No.: 18107 Page 38 of 42

10 Appendix C: Packing lists

10.1 Lift table

Part

Foot 1

Wheel 4

Column 1

Tabletop 1

Fixation arm for monitor 1

Fixation arm for keyboard 1

Cable conduit 1

Quantity

Page 39

SL-OCT Installation Manual

Art. No.: 18107 Page 39 of 42

Cable 0.30 m power supply slit lamp

Cable 0.32 m power supply OCT-box

Cable 1.05 m power supply monitor

Cable 0.35 m power supply multiple socket

Flexible plastic tube

1

1

1

1

1

Plastic clip 1

Rail cover 2

10.2 OCT-box

Part

Quantity

OCT-box 1

Protection cap mounted on fiber plug 1

Mouse 1

Mouse pad 1

Scanner cable 1

Signal cable monitor (VGA) 1

Page 40

SL-OCT Installation Manual

Art. No.: 18107 Page 40 of 42

Folder SL-OCT operating instructions 1

Dust cover 1

Replacement protection cap scanner plug-in

Replacement protection cap glass fiber plug

Replacement protection cap fiber plug-in

1

1

1

Replacement fuse 5.0 A 2

10.3 Slit lamp

Part

Quantity

Slit lamp 1

Eye piece 2

Headrest 1

Page 41

SL-OCT Installation Manual

Art. No.: 18107 Page 41 of 42

Headrest handles 2

Keyboard 1

Monitor 1

Dust cover slit lamp 1

Test rod 1

Protective cover 1

Breath-shield 1

Chinrest papers 1 package

Page 42

SL-OCT Installation Manual

Art. No.: 18107 Page 42 of 42

10.4 Optional printer table

Part

Quantity

Tabletop 1

Fixation arm 1

Cable tie 14 mm 2

Cable tie 37 mm 2

Screw M5 x 12 3

Plug IEC60 320 1

Loading...

Loading...