Page 1

User Guide

MLA150

Maskless Aligner

Page 2

MLA150

ii User Guide

Doc. No.: DWL-HI-062

Revision: 1 (July 2016)

Copyright © 2016 by Heidelberg Instruments

Page 3

MLA150

Table of Contents

User Guide i

Table of Contents

Table of Contents ........................................................................................................... i

List of Figures ............................................................................................................... iv

List of Tables ................................................................................................................ iv

1 Introduction ........................................................................................................... 1

1.1 About this User Guide ............................................................................................. 1

1.2 Contact .................................................................................................................... 2

1.3 Related Documentation ........................................................................................... 3

2 Safety ..................................................................................................................... 5

2.1 Intended Use and Limitations .................................................................................. 5

2.2 Conventions ............................................................................................................ 6

2.3 Laser Safety ............................................................................................................ 6

2.4 Electrical Safety ...................................................................................................... 8

2.5 Other Risks during Operation .................................................................................. 9

2.6 Interlock .................................................................................................................. 9

2.7 Labels ................................................................................................................... 10

3 System Description ............................................................................................. 13

3.1 Lithography Main Unit ........................................................................................... 14

3.1.1 Flowbox ................................................................................................... 14

3.1.2 System Components ............................................................................... 17

3.1.3 Optics System ......................................................................................... 20

3.2 Electronics Rack ................................................................................................... 22

3.3 Orientation of Stage and Design ........................................................................... 23

4 Wizard Description .............................................................................................. 25

4.1 Overview: Exposure Wizard .................................................................................. 25

4.2 Static Wizard Elements ......................................................................................... 27

Page 4

MLA150

Table of Contents

ii User Guide

4.2.1 Menu Bar ................................................................................................. 27

4.2.2 Tab Section .............................................................................................. 27

4.2.3 Info Section .............................................................................................. 28

4.3 Substrate Representation ...................................................................................... 31

5 System Startup .................................................................................................... 33

5.1 Powering Up .......................................................................................................... 33

5.2 Powering Down ................................................................................................ ..... 34

6 Job Setup ............................................................................................................. 35

6.1 Select Job .............................................................................................................. 36

6.2 Select Substrate Template .................................................................................... 37

6.3 Load Design .......................................................................................................... 38

6.3.1 Standard: First Exposure ................................................................ ......... 38

6.3.2 Standard: Alignment ................................................................................ 39

6.3.3 Series ....................................................................................................... 40

6.4 Convert Design ...................................................................................................... 41

6.5 Load Substrate ................................................................................................ ...... 43

6.6 Draw Structures ..................................................................................................... 46

6.6.1 Draw Image ............................................................................................. 47

6.6.2 Draw Line or Polygon ............................................................................... 48

6.6.3 Expose Crosses in Draw Mode ................................................................ 49

6.7 Setup Overlay Alignment ....................................................................................... 50

6.8 Expose Design ...................................................................................................... 54

6.8.1 First Exposure Procedure ................................ ................................ ........ 54

6.8.2 Overlay Exposure Procedure ................................................................... 55

6.8.3 Series Exposure Procedure ..................................................................... 57

6.8.4 Draw Mode Exposure Procedure ............................................................. 59

6.9 Unload Substrate ................................................................................................... 60

7 System Utilities and Tools .................................................................................. 63

Page 5

MLA150

Table of Contents

User Guide iii

7.1 Control Panel ........................................................................................................ 63

7.2 Camera Window .................................................................................................... 65

7.3 Optimizing Alignment and Exposure Results ........................................................ 66

7.3.1 Unsatisfying Alignment Measurements .................................................... 66

7.3.2 Unsatisfying Exposure Results ................................................................ 67

7.4 Back Side Alignment ............................................................................................. 68

7.4.1 Overview of BSA Marker Zones .............................................................. 68

7.4.2 BSA Exposure Preparation ...................................................................... 70

8 Operator Maintenance and Troubleshooting .................................................... 71

8.1 Operator Maintenance .......................................................................................... 71

8.2 Troubleshooting .................................................................................................... 72

8.3 TeamViewer Software ........................................................................................... 73

Page 6

MLA150

List of Figures

iv User Guide

List of Figures

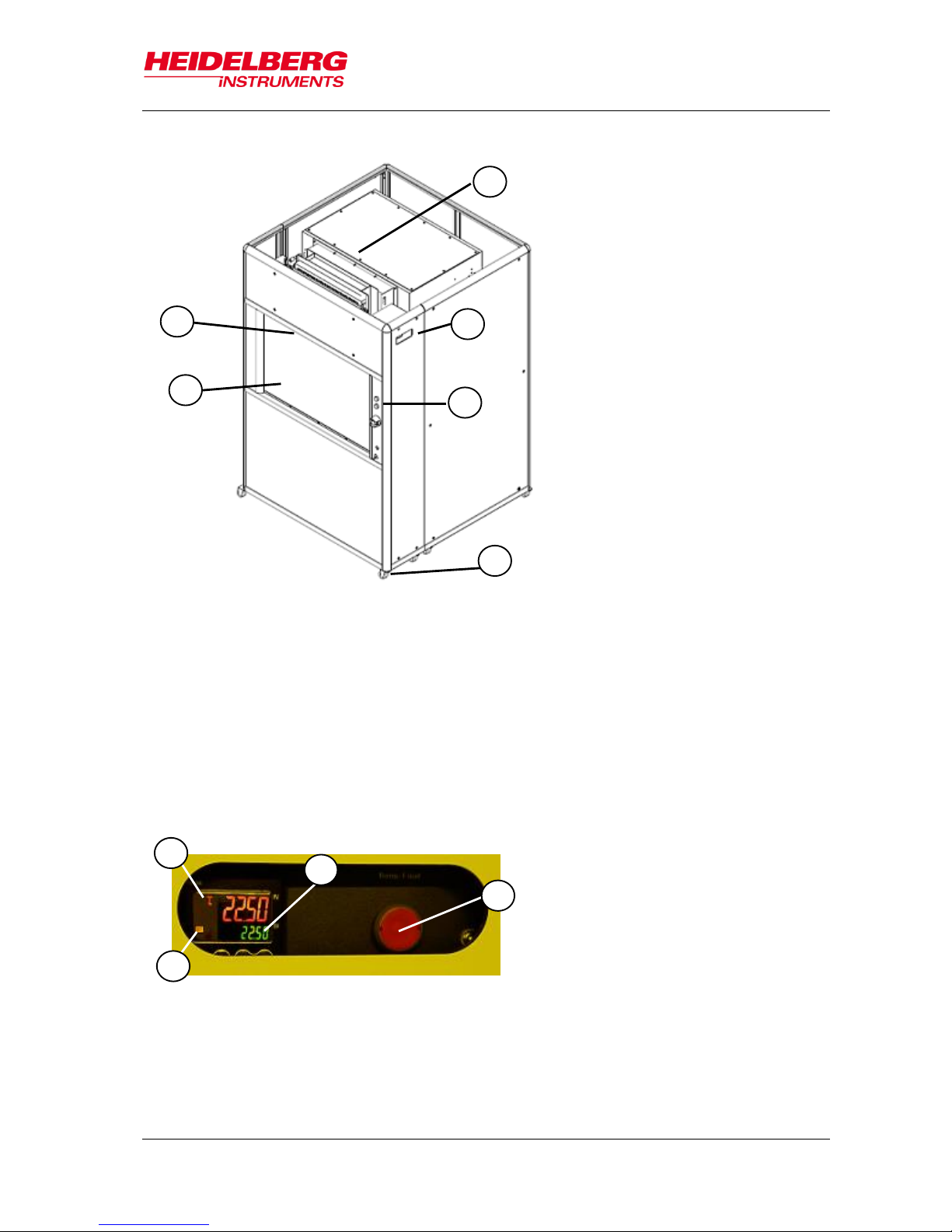

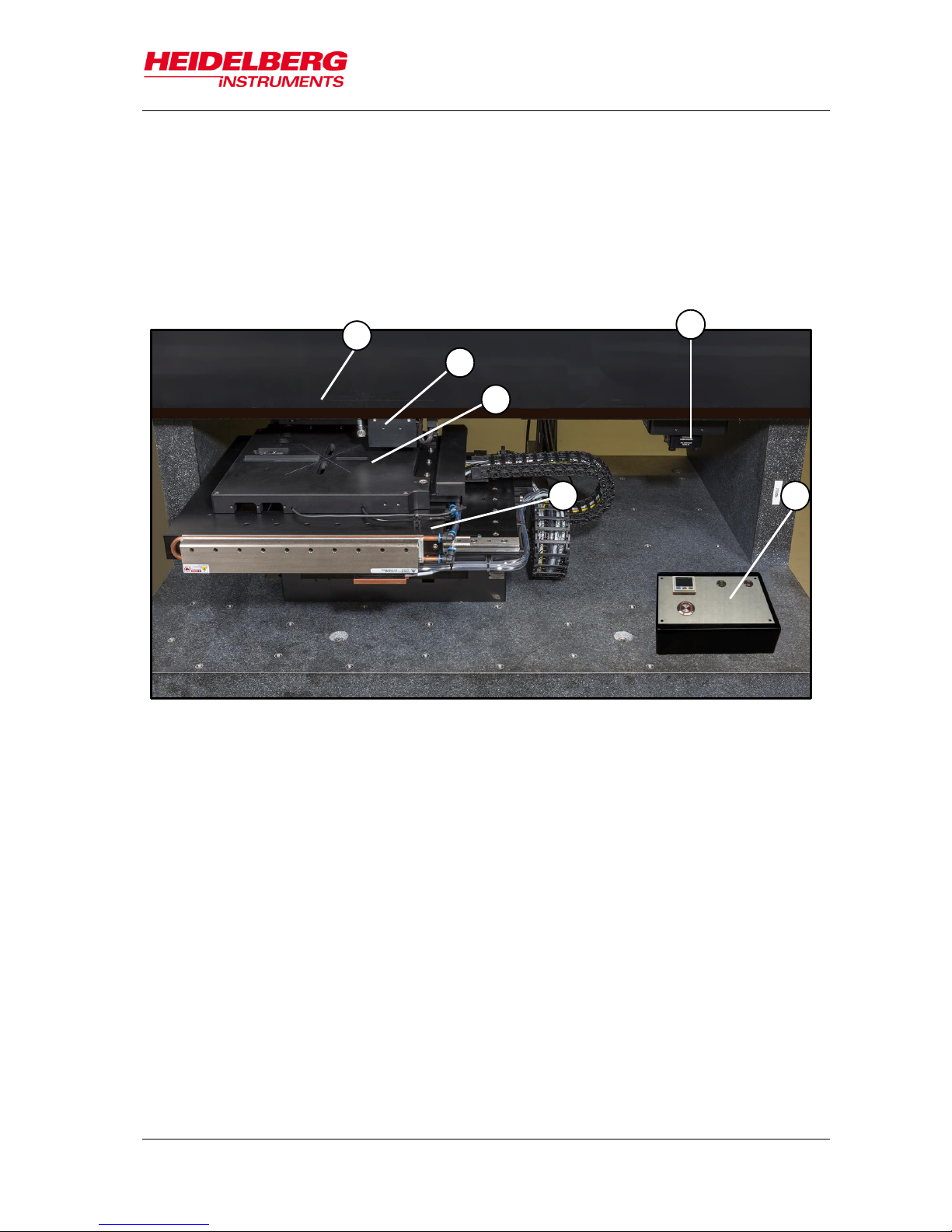

Figure 1: System components .............................................................................. 13

Figure 2: Elements of the laminar flow box ........................................................... 15

Figure 3: Temperature control readout ................................................................. 15

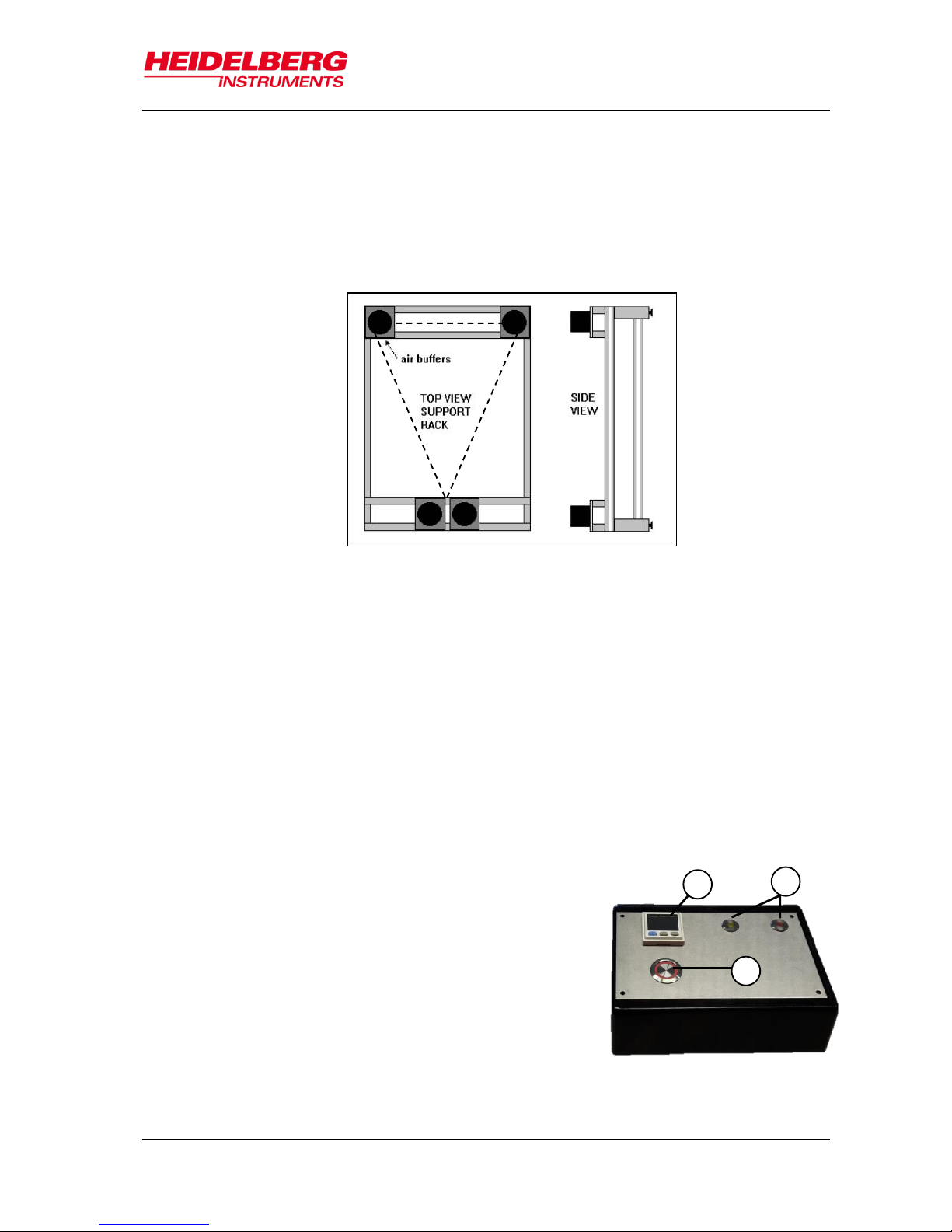

Figure 4: System support ................................ ...................................................... 17

Figure 5: Operator Panel ...................................................................................... 17

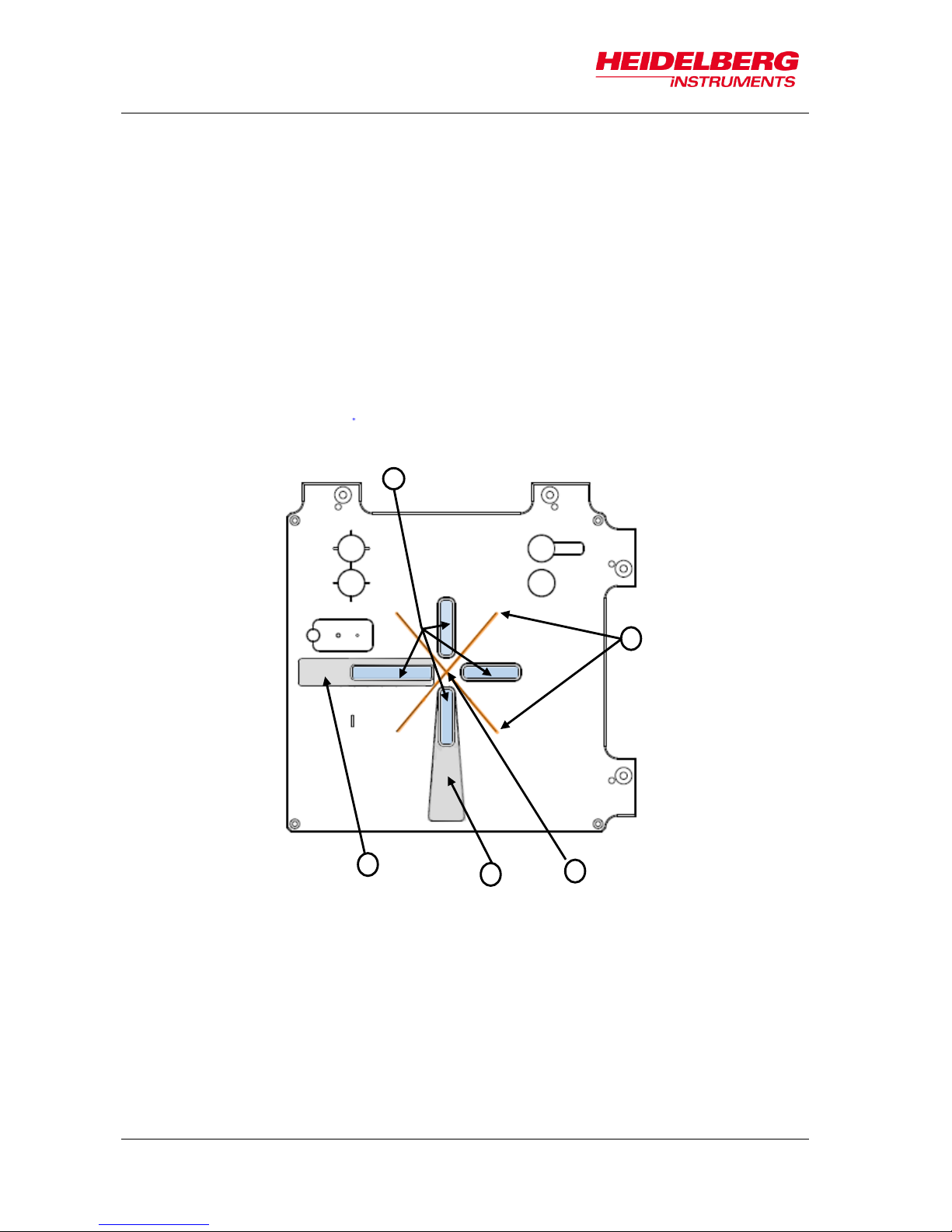

Figure 6: Stage system with optics plane .............................................................. 19

Figure 7: Interferometer function ........................................................................... 21

Figure 8: E-rack components ................................................................................ 22

Figure 9: Orientation of stage and design ............................................................. 23

Figure 10: Machine-related design rotation ........................................................... 23

Figure 11: Rotation of coordinate system on chuck .............................................. 24

Figure 12: Location of coordinate pairs ................................................................. 24

Figure 13: Wizard window overview ..................................................................... 25

Figure 14: Unloading options in Standard Mode and Series Mode ....................... 60

Figure 15: Camera window ................................................................................... 65

Figure 16: BSA marker zones overview ................................................................ 69

Figure 17: Orientation on wafer for BSA ............................................................... 70

List of Tables

Table 1: Field of view (top side, back side) ........................................................... 20

Page 7

MLA150

1 Introduction

User Guide 1

The MLA150 is a high speed direct write lithography tool extended by capabilities

formerly only available on Mask Aligners. It can expose the patterns directly without

prior fabrication of a mask resulting in a significantly shorter prototyping cycle. It offers

topside alignment and backside alignment with high accuracy, and a light source which

generates sufficient dose to expose even thick and less sensitive resists. The MLA150

allows using substrates of any size and shape and provides flexible change of pattern,

distortion compensation and other software corrections. The system can produce

structures down to 1 µm. The alignment accuracy can be as good as 250 nm under

optimized conditions.

1.1 About this User Guide

This user guide gives information and instructions on how to handle the MLA150 system

properly. It is important that every person who intends to work with the system reads

this guide in order to avoid possible mishandling leading to damage to the system or to

persons. Therefore, by all means, read the safety instructions carefully before starting

work with the system. The guide assists the user in performing the exposure procedure

beginning at system startup and ending with the exposure procedure itself. The

subchapters in 6 Job Setup build a sequence of tasks that have to be executed in order

to prepare the exposure job.

Additionally, you find a description of the system and of the Exposure Wizard. Also

information about system utilities and troubleshooting are given in the final chapters.

Technical data can be found in the related document Technical Data Sheet

To facilitate following the instructions and information, a list of conventions indicating the

type of information is given here.

Note:

Indicates that additional information or advice follow to get best results.

1.

Signalizes that this is the first step of a step-by-step instruction followed by

further steps

Indicates a result which the user can see or hear. It can also just be an

intermediate result and can therefore be followed by further steps of the same

instruction.

Indicates that the following information or instruction is an alternative step e. g.,

to abort a process or to be referred to another instruction or chapter.

This symbol is used to mark a location in a figure that is related to the

instruction. The numbers in the symbol correspond to the number of the step in

the instructions.

i

1

Page 8

MLA150

1 Introduction

2 User Guide

1.2 Contact

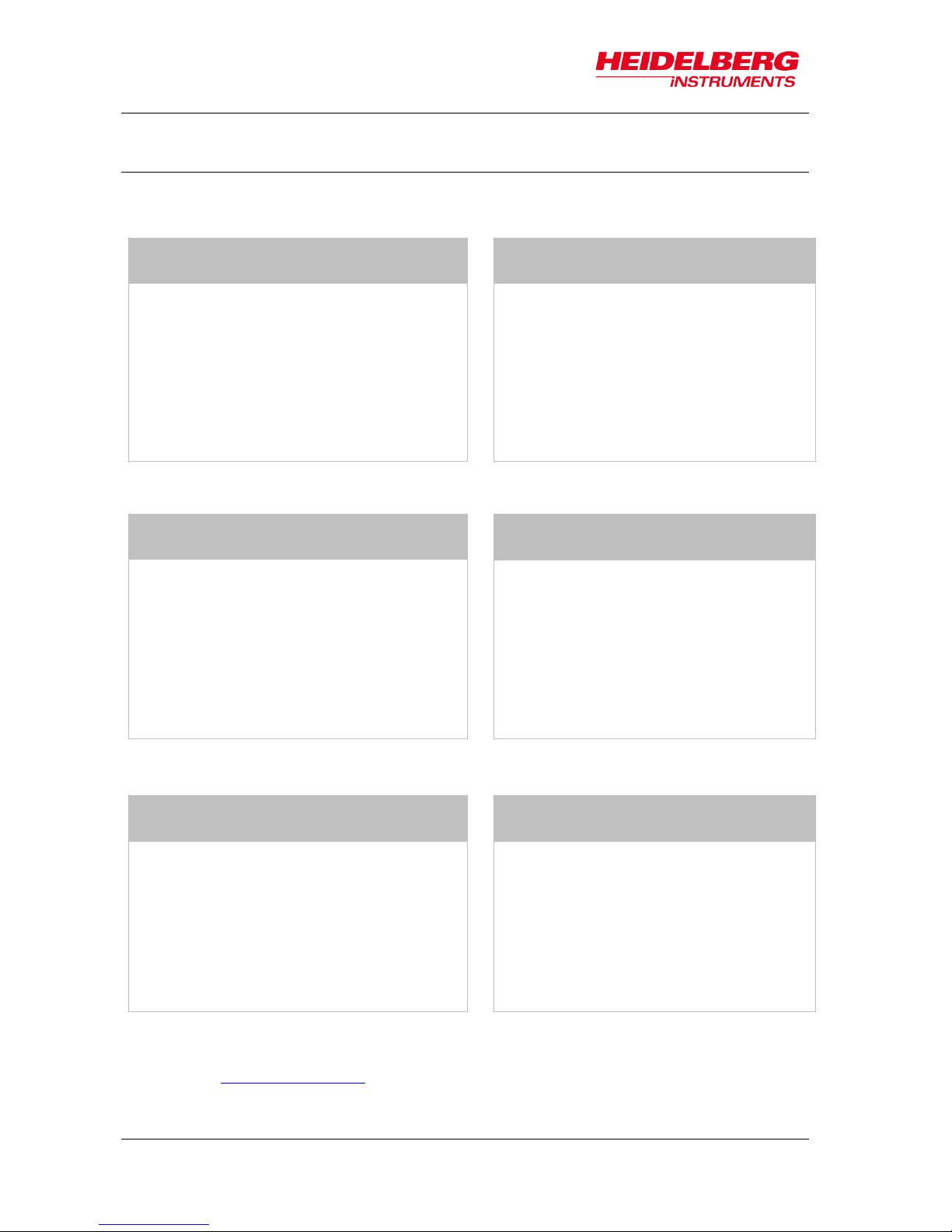

Should you need assistance, please contact your local service office:

You can also reach Heidelberg Instruments via email: himt@himt.de, or visit our site on

the internet: http://www.himt.de

China:

Europe:

Heidelberg Instruments Service China

Rm.101, Block 1, Animation Park,

Yuehai Street, Nanhai Road,

Nanshan Distr., Shenzhen 518045

China

Phone:+86-755-8301599-1 / -2 / -7

Fax: +86-755-8301599-4

Email: service_china@himt.de

Heidelberg Instruments GmbH

Service Department

Tullastraße 2

69126 Heidelberg

Germany

Phone: +49-6221-3430-0

Fax: +49-6221-3430-30

Email: service_europa@himt.de

Japan:

Korea:

Heidelberg Instruments Service Japan

Germany Center for Industry & Trade

1-18-2, Hakusan

Midori-ku, Yokohama, 226-0006

Japan

Phone:+81-45-938-5250

Fax: +81-45-938-5251

Email: service_japan@himt.de

Heidelberg Instruments Service Korea

#316 Expo Officetel, 381

Mannyeon-dong, Seo-gu

Deajeon, 35203

South Korea

Phone:+82-42-482-1668

Fax: +82-42-482-1669

Email: service_korea@himt.de

Taiwan:

USA:

Heidelberg Instruments Service Taiwan

6F-5, No. 192 DongGuang Road

Hsinchu City, 30069

Taiwan

Phone +886-3-5715188

Fax +886-3-5715388

E-Mail: service_taiwan@himt.de

Heidelberg Instruments Inc. USA

2807 Oregon Court, Unit E2

Torrance, CA, 90503

USA

Phone:+1-310-212-5071

Fax: +1-310-212-5254

Email: service_usa@himt.de

Page 9

MLA150

1 Introduction

User Guide 3

1.3 Related Documentation

Heidelberg Instruments offers several further manuals related to the machine and its

operation. If you did not get one of these or need an update, please contact Heidelberg

Instruments, Germany (1.2 Contact). See the list of related documents below:

Pre-Installation Guide

Environmental and electrical

requirements, sizes and weights of

components etc.

PI- Site Inspection checklist

Checklist containing questions regarding

the conditions of the costumer’s

installation site for the system.

Safety guide

Describes necessary safety measures

during move-in, installation as well as

servicing and maintenance times.

Conversion Software Manual

Manual for the HIMT conversion software

used for data preparation and fractioning.

Design Guide

Instructions on design rules and design

creation.

Maintenance Guide

Guide for Maintenance and

Troubleshooting, as well as an overview of

typical service tasks.

Technical Data Sheet

Overview of the systems technical data.

Quick Guide

Short instructions to execute an exposure.

Page 10

MLA150

1 Introduction

4 User Guide

Page 11

MLA150

2 Safety

User Guide 5

The MLA150 protects operators from exposure to laser radiation, dangerous voltages or

moving parts while operating the equipment. All moving parts, lasers and their

associated optics are enclosed within a flow box. During operation, opening the flow box

window will immediately stop any exposure or measurement process.

Still, it is vital that the operators and all other persons who are allowed access to the

system have been informed about any remaining risks.

2.1 Intended Use and Limitations

The intended use of the MLA150 lithography system is to expose structures on

photosensitive, non-flammable layers which are located on non-flammable substrates.

These substrates must not exceed the specified maximum dimensions and must be free

of damage such as scratches or cracks.

The MLA150 is intended only for professional use. The related user documentation is

part of the product, and the user is under the obligation to read the documentation

before using the product.

Every other purpose of use than that stated in this section is prohibited. In case of

damage by using the product outside this stated purpose, no liability is assumed by the

Heidelberg Instruments Mikrotechnik GmbH.

In addition to the intended use stated above, the following purposes of use are

prohibited and defined as misuse:

Operation outside the operating data stated in the data sheet or in the sales

confirmation.

Operation with materials other than the approved materials.

Change of the factory settings by unauthorized persons.

Use of attachment parts other than Heidelberg Instruments components.

Operation of the system in a potentially explosive environment or aggressive

atmosphere.

No untrained person, or person not familiar with the contents of the following sections

is allowed to operate the system or work in its close environment. If instructions are not

followed carefully, danger to personal health and damage to the equipment is at risk.

At all times, follow all warnings and instructions given in this manual, the system

software, safety labels on the system, or by our engineers.

Page 12

MLA150

2 Safety

6 User Guide

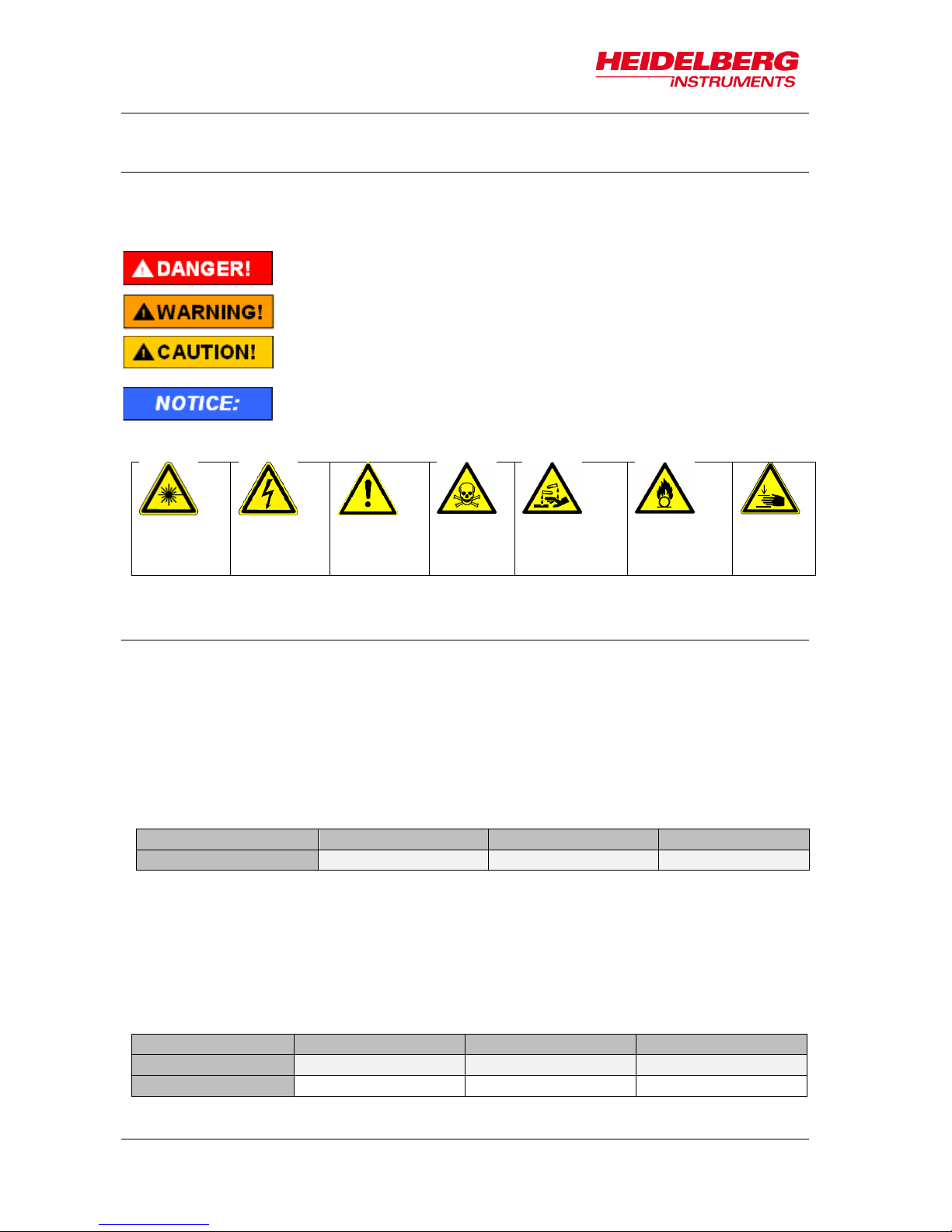

2.2 Conventions

Throughout this manual there are safety warnings. To classify the degree of danger in

each of these situations, this guide uses the conventions defined in ANSI Z535.6-2011:

Laser

beam

hazard

Electrical

shock

hazard

General

warning

Toxic

hazard

Corrosive

material

hazard

Flammable

material

hazard

Pinch

point

hazard

2.3 Laser Safety

The MLA150 employs two types of continuous wave lasers, one for position

measurement of the stage (interferometer laser), one for design exposure (exposure

laser). When the window is closed, all laser light is blocked or absorbed, and the system

is effectively of laser class 1.

When the window is opened for loading or unloading, the interferometer laser beam is

accessible. Under this condition, the system has the same laser class as the

interferometer laser in use, which is laser class 2.

Laser Type

Wavelength (nm)

Power (mW)

Laser Class

HeNe

632

< 6

2

The exposure laser beam is a powerful beam that is usually covered completely by

optics covers. Power and wavelength of the exposure laser depend on the specific

configuration, but the exposure laser beam is always dangerous for the eye, sometimes

also for the skin. Even reflected light may be dangerous.

If the optics covers are opened, the accessible energy is of the class 4 category

(DIN EN-60825-1).

Danger indicates a hazardous situation, which, if not avoided, will

result in death or serious injury.

Warning indicates a hazardous situation, which, if not avoided,

could result in death or serious injury.

Caution indicates a hazardous situation, which, if not avoided,

may result in minor or moderate injury.

Denotes warnings against possible misuse that can lead to

machine damage.

Laser Type

Wavelength (nm)

Power (mW)

Laser Class

Diode, blue

405

≤ 10000

4

Diode, UV

375

≤ 3000

4

Page 13

MLA150

2 Safety

User Guide 7

If conditions require the opening of the optics covers, such as for servicing or

troubleshooting by trained service personnel, then personnel must observe all

precautions required for a laser of above mentioned class in the whole area surrounding

the MLA150.

Eye injuries and/or skin burns!

Severe damage to the eye and possibly to the skin can be

caused by laser radiation of class 3B or 4

Avoid possible direct or indirect exposure of eyes or skin to

laser radiation at all times.

Do not operate the system with open optics cover if not acting

under explicit instruction of an HIMT service engineer.

Do not enter any area cordoned off by HIMT service

engineers during adjustment work.

Do not put anything reflective or flammable into the beam

path.

If the system has to be operated with open optics cover e.g., for

trouble shooting:

Cordon off the area and place warning signs.

Wear appropriate safety goggles. Note that these cannot

protect long against a direct beam, but are only meant as

protection against stray light! Also keep in mind that you

cannot see the laser beam with goggles on, so the risk of skin

burns increases.

Use the lowest possible laser power or reduce the power as

far as possible with filters.

Never leave the laser on when unattended. Make sure only

qualified personnel may switch on the laser in such a

machine state.

Do not place reflective objects in, or near the laser beam path.

Laser light scattered by reflective objects can be as damaging

as the original beam. Objects such as rings, watchbands,

and metal pens or pencils can be hazardous.

Page 14

MLA150

2 Safety

8 User Guide

2.4 Electrical Safety

A CEE type 220-240 V, 16 A single-phase cable connector supplies operating power in

the MLA. It is also possible to attach a local-type cable to a local-type wall connector.

Please refer to the Pre-Installation Guide for details.

Electrical Shock!

Fatal electrical shock and/or severe burns can be caused by the

supply voltage of up to 240VAC 16A for the system, and up to

420VAC 32A for certain laser types.

Never use the equipment if cables or plugs have been

damaged.

Plug the MLA and its components only into approved outlets

with correct ground. Power requirements are described in the

Pre-Installation Guide.

Ensure that both the voltage and frequency of a power source

match the voltage and frequency stated on the equipment’s

electrical label.

Not all power cords have the same current ratings.

Household extension cords do not have overload protection

and are not meant for use with sensitive electronic

equipment. Never use household extension cords for any

component of the MLA.

Always follow the five safety steps if equipment containing

electrical circuits with voltages >50VAC has to be opened:

disconnect, apply restart lockout, check if equipment is deenergized, ground / short circuit equipment, cover

neighboring elements that are still energized

If access to the interior of any electronics component is

necessary while system is in operation, exercise extreme

caution. Only qualified service personnel may have access to

the interior.

Page 15

MLA150

2 Safety

User Guide 9

2.5 Other Risks during Operation

Injuries by moving parts or heat!

If covers are removed, the operator may be exposed to

dangerous collisions with moving parts, or heated components.

Do not remove any covers that are fixed with screws

Heed the warnings if removing any other covers

Pinch risk by closing window!

Mild pinch injuries are possible if fingers are brought between

the upper window frame and the window while the window

closes. The loading window is driven pneumatically with low

pressure. It does not have enough force to injure a body or

limb, but skin may be pinched.

Don not close the window while resting a hand at the upper

frame or upper window edge.

Do not put a hand through the already closing window.

2.6 Interlock

To protect the operator from hazards by laser light or moving stage, interlock circuits

prevent stage movement and access to laser light as soon as the window opens. A

safety switch stops the stage, holding it in position, and closes the laser shutter. If an

exposure has been running at that moment, the result is irreversibly lost.

The stage interlock can be overridden by service engineers by a key switch for

servicing, together with a confirmation from the menu. While this service mode is

activated, the main bar and background of the Exposure Wizard turns red.

Injuries by moving parts or laser light!

While the system is in service mode, dangerous levels of laser

light are accessible, and the stage can move with window open.

Only HIMT service engineers are allowed to put the machine into

service mode.

During servicing or maintenance by service engineers, heed

the warnings given in the Safety Guide.

If service mode was left active accidentally, switch back to safe

mode and remove the key. Return it to the service local office.

Page 16

MLA150

2 Safety

10 User Guide

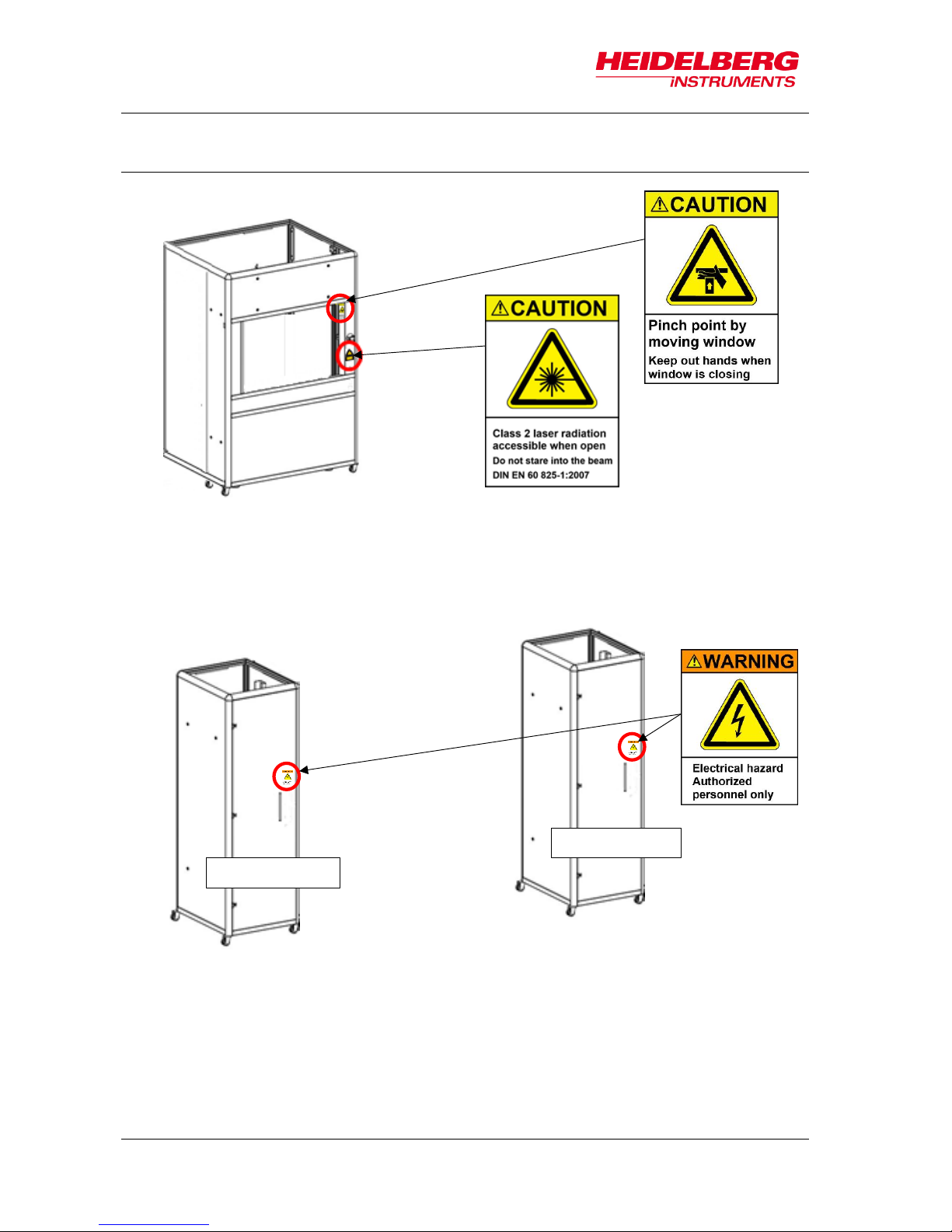

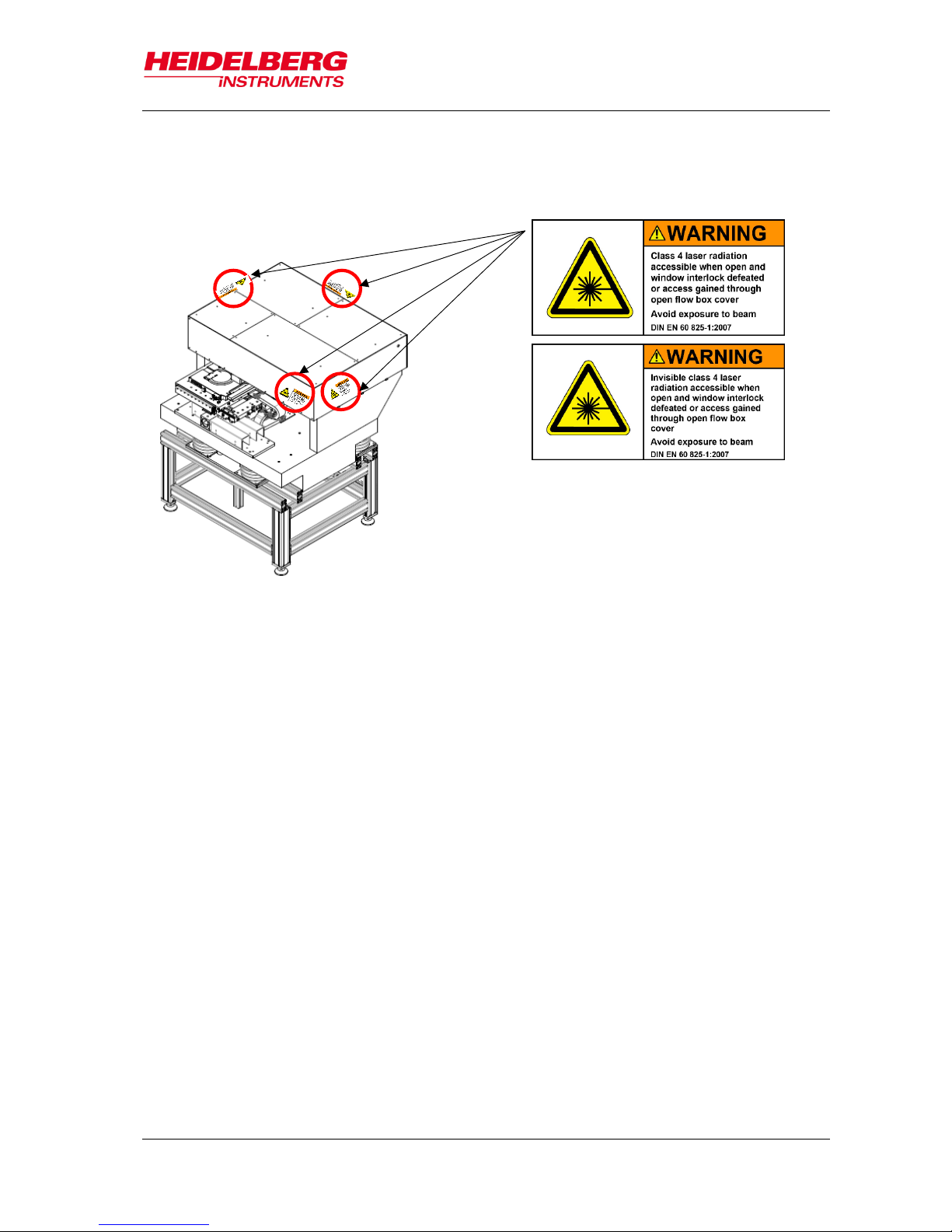

2.7 Labels

Flowbox front

E-Rack

REAR DOOR

FRONT DOOR

Page 17

MLA150

2 Safety

User Guide 11

Optics cover:

front cover, side covers, rear cover

Page 18

MLA150

2 Safety

12 User Guide

Page 19

MLA150

3 System Description

User Guide 13

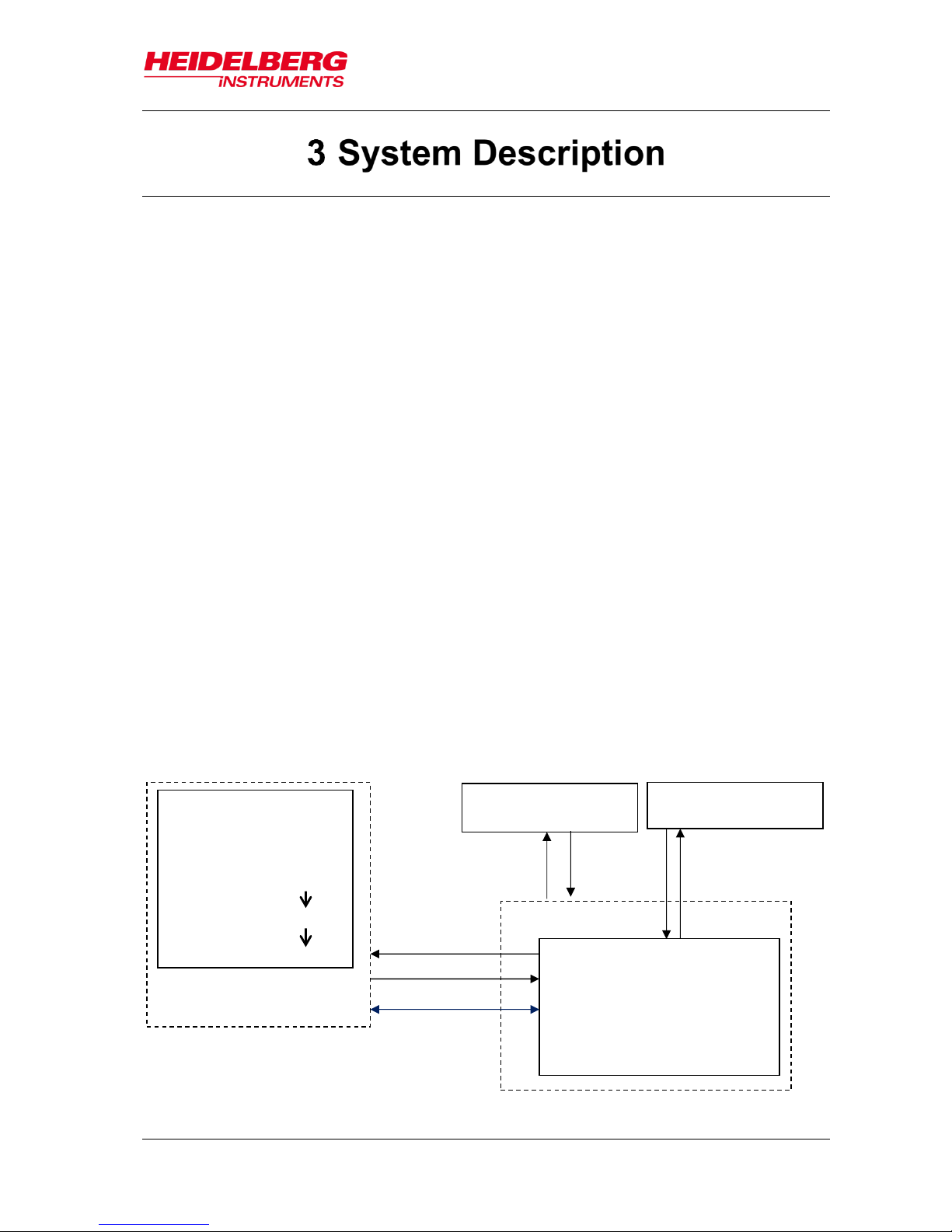

This chapter gives a short description of the MLA150 lithography system. The MLA150

system consists of the following individual components:

Lithography Unit

Electronics Rack

Cooling water supply (not explicitly described in this document)

Operator workstation

The main principle of the functional interaction between the system components is as

follows:

A workstation comprising two computer monitors, a keyboard, a mouse and the User

PC, that is located inside the electronics rack, represents the interface between user

and system. The user controls the system via our graphical user interface on the User

PC. This data is processed by the components located inside the electronics rack such

as the stage controller which communicates with the stage and controls its movement

based on the feedback given by interferometers that are placed in the main unit.

The system has two cooling water supply units, called chillers. One of them makes sure

that the system runs in a stable environment in terms of temperature. The other one

serves as cooling unit for the laser and the motors.

USER PC

design positioning

alignment sequences

system parameters

conversion: CAD design

conversion

exposure data

MLA

Main Unit

Flow Box

sensors

control

cooling water supply

for Flow Box

cooling water supply

for Main Unit

ELECTRONICS RACK

data

Figure 1: System components

Page 20

MLA150

3 System Description

14 User Guide

3.1 Lithography Main Unit

The Main Unit comprises the following elements:

Flow box

Granite Construction

Optics System

3.1.1 FLOWBOX

The flow box is the housing of the lithography system and protects the MLA150 from

damage. It also provides a stable environment in terms of temperature, laminar flow and

clean air. This is of importance because only such a stable environment guarantees

constant exposure conditions which guarantees the smallest possible variation of

exposure parameters. The covers of the flow box are removable, but only for service

purposes.

Injuries by moving parts or laser light!

Severe damage to the eye and possibly to the skin can be

caused by laser radiation of class 3B or 4

Do not open the covers of the flow box.

Flow box covers may be opened only by, or under direct

instruction from, experienced service personnel!

Page 21

MLA150

3 System Description

User Guide 15

ELEMENTS OF THE LAMINAR FLOW BOX:

TEMPERATURE CONTROL UNIT

The flow box is temperature controlled by means of regulated heating of the

incoming air. The air is cooled down by the water-cooling unit and then reheated to

1

TEMPERATURE CONTROL UNIT

2

DISPLAY

3

SWITCH PANEL

4

CASTOR WHEEL

5

WINDOW

6

LIGHT

1

ACTUAL TEMPERATURE

2

TARGET TEMPERATURE

3

RESET BUTTON

4

HEAT OUTPUT REGULATOR

Figure 2: Elements of the laminar flow box

1

2 3 4

5

6

Figure 3: Temperature control readout

1

2

3

4

Page 22

MLA150

3 System Description

16 User Guide

the required process temperature. The temperature control unit is located within the

top compartment and has a display readout accessible from the outside through a

hole in the flow box cover. In case the temperature exceeds +65°C inside the flow

box, which can be caused by a malfunction of the fan, the control unit shuts down

the heating system. The push button switch turns red. The heating system can be

reset by pushing the button once but this should only be done if the reason for the

failure is known. The display readout has a small icon in the left, blinking in regular

intervals. This icon shows the activity of the heat output regulator. If the icon blinks

periodically then the heat regulation works properly. If the icon is illuminated or not

illuminated without any periodical change, then the temperature control unit is not

working trouble-free anymore. It is recommended to shut down the system and call

one of Heidelberg Instruments service offices (see 1.2 Contact).

CASTOR WHEELS

The flow box stands on eight castor wheels that have locking brakes in order to

provide a stable position. These castor wheels are not height-adjustable. The

machine is leveled by adjusting the four feet.

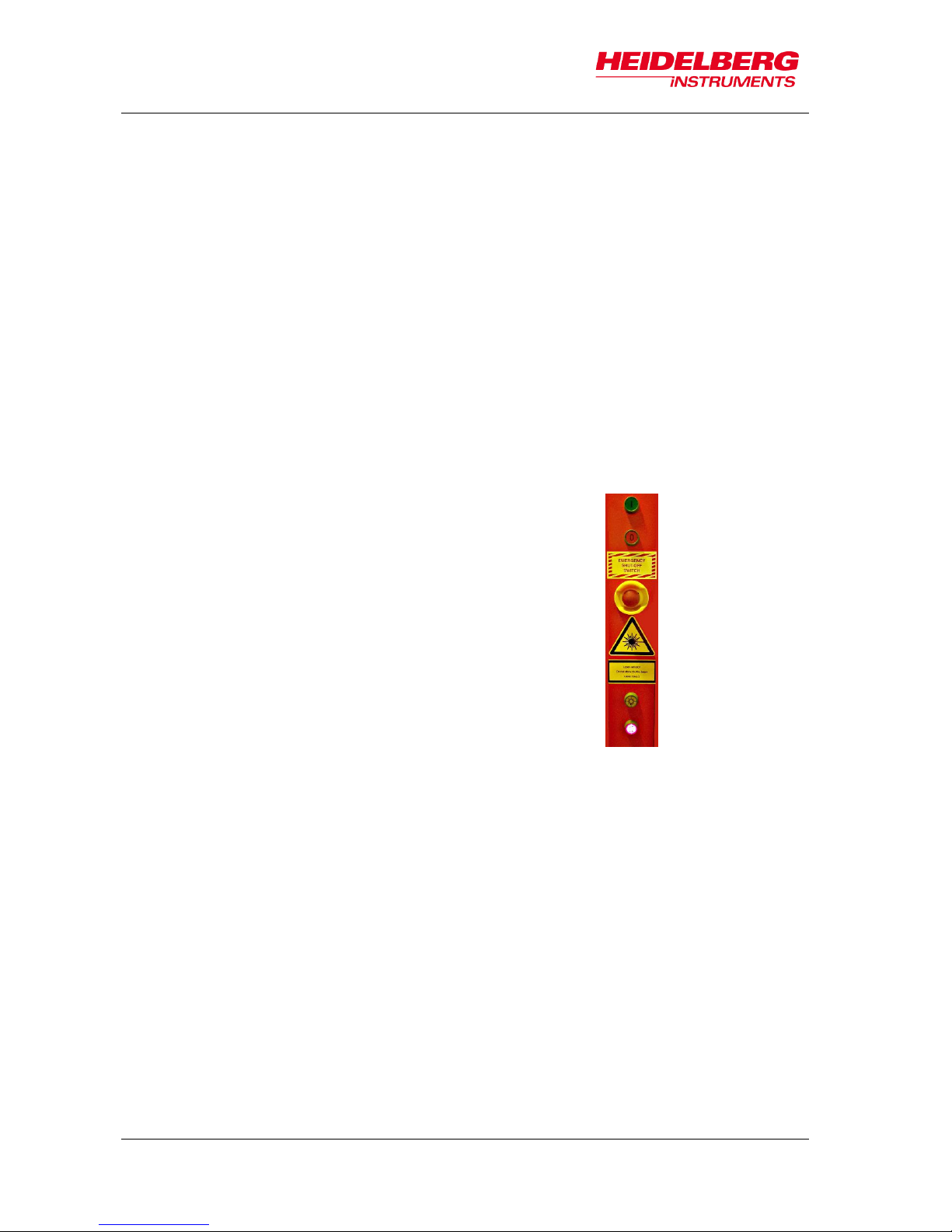

SWITCH PANEL

At the front side of the flow box several buttons are

located. The green button is used for powering up the

system, the red one is for powering it down. The

button in the middle is the emergency off button. For

opening and closing the window, the push button is

used. The flow box provides a light source for inside,

which is, depending on the application, yellow or red

light. The light switch is located between the

emergency off button and the window push button.

WINDOW

The window is opened only for loading and unloading purposes. During operation,

the window cannot be opened for safety reasons. The push button at the front of the

flow box opens and closes the window by means of compressed air. This button is

disabled while an exposure is running.

On (I)

Off (0)

Emergency Off

Window push button

Light push button

Page 23

MLA150

3 System Description

User Guide 17

3.1.2 SYSTEM COMPONENTS

SYSTEM SUPPORT

A heavy-duty aluminum construction and four buffers that are filled with air to ensure

vibration isolation support the granite base plate. To avoid any unnecessary bending

forces in the base plate, these buffers are arranged in a triangular geometry (the two

buffers at the front side are close together and act as one point).

HEIGHT-ADJUSTABLE FEET

The granite construction stands on four height-adjustable feet. By varying the height

of the feet the system is leveled in correspondence with the ground condition in the

location the system is installed. The castor wheels of the flow box are not heightadjustable.

BASE PLATE (MAIN BLOCK)

The main unit has a granite base that gives stability to the system. It has been

selected for its low thermal expansion coefficient. The granite base plate is

supported by air buffers that ensure effective vibration isolation and has threaded

holes to accept other system components. Medium and high-power lasers are

mounted at the bottom of the base plate to minimize heat generation in the areas

that are sensitive to heat.

OPERATOR PANEL

The operator panel has a push button (1) that opens

the vacuum inlet to fix the substrate on the chuck. For

observing the vacuum status, a display (2) shows the

current vacuum status. However, it is not necessary to

observe the status because the wizard informs about

vacuum supply problems. The panel also contains two

LED lights (3) indicating the status of the laser. The

lights are on throughout the whole exposure

procedure. When the window is open, the lights are

off indicating that the laser(s) is (are) off (see 4.2.3

Info Section).

Figure 4: System support

Figure 5: Operator Panel

1

2

3

Page 24

MLA150

3 System Description

18 User Guide

STAGE SYSTEM

The stage is equipped with linear motors in both axes. They provide smooth and

constant movement with low positioning errors. One air bearing and one roller

bearing support the movement in y-direction whereas the x-axis is equipped with two

roller bearings.

The stage carries the frame in which the chuck is located. There is one chuck for all

substrate sizes. The substrate is hold down and kept it in place by vacuum suction.

The chuck features a vacuum suction hole in the center and four small vacuum slits

through which the vacuum reaches the substrate. Due to the viewing slots, backside

alignment is possible without installing a different chuck. One of the slots is

surrounded by a recess in which the adjustment aid is inserted to provide proper

substrate placing on the chuck. Another one is also surrounded by a recess giving

space for a tweezer to facilitate substrate loading.

1

VIEWING SLOTS

2

VACUUM SUCTION SLITS

3

VACUUM SUCTION HOLE

4

RECESS FOR TWEEZER

5

RECESS FOR ADJUSTMENT AID

2

3

4

5

Page 25

MLA150

3 System Description

User Guide 19

OPTICS PLANE

The optics system is located on a smaller granite top plate supported by the base

plate and its granite side elements. The optics plane contains the optical elements

and all camera components. The write head stands at the end of the optical path

and is mounted to this plate with downward beam direction facing the substrate.

1

INTERFEROMETER HEAD

2

OPERATOR PANEL

3

STAGE

4

CHUCK

5

WRITE HEAD

6

OPTICS PLANE

Figure 6: Stage system with optics plane

1

4

6

5

2

3

Page 26

MLA150

3 System Description

20 User Guide

3.1.3 OPTICS SYSTEM

DIGITAL MICROMIRROR DEVICE (DMD)

The DMD is an electrical input and optical output micro-electric-mechanical system

for spatial light modulation. It is composed of an array of micro light switches

containing individually controlled micro mirrors which correspond to the pixels in the

image to be displayed. Laser light is modulated by this device to project and transfer

a pattern into positive or negative resist.

LASER UNIT AND OPTICAL ELEMENTS FOR BEAM GUIDANCE

The laser beam is emitted by several laser diodes, coupled in an optical fiber and

projected on the DMD. The optical elements guide the modulated light through the

system. The light beam passes the write head and is finally projected on the

substrate.

CAMERA UNIT

The camera unit comprises one camera with low resolution, one with high resolution

and one overview camera. The cameras also feature a light source and make it

possible to inspect and measure the exposed substrates. Additionally, the cameras

are used for accurate alignment of a design with existing structures. Here, the High

Res camera is the appropriate choice due to its high resolution. In cases where the

alignment marks are larger than the field of view of the High Res camera, switching

to the macro camera is recommended. The overview camera is not appropriate for

alignment. Additionally, it does not show the complete surface of the substrate due

to mechanical limits. The camera image is transferred to the User PC via camera

software that opens in its own window. Systems with backside alignment have a

second camera unit for back side viewing mounted inside the stage and looking

pointed to the substrate.

PNEUMATIC AUTOFOCUS

The pneumatic autofocus serves to keep the focal point of the write beam stable on

the surface of the substrate. For probing the distance, compressed air passes

through the write head and leaves it through a nozzle. Once the write head is close

enough to the substrate, a pressure builds up between the nozzle and the substrate,

which is monitored by a pressure sensor. The pressure sensor transmits the

information to a controller which regulates the write head movement. The defoc

value shows the focus position of the write head with respect to the offered

Camera type

Field Of View

(size of the substrate area that can be seen)

Top Surface

Back Surface

High Res

190 μm x 140 μm

min.172 x 130 µm

Low Res

640 μm x 480 μm

min 364 x 274 µm -

Overview

20 mm x 20 mm

top side only

*Overview cannot access the entire surface of the substrate due to mechanical

limits.

Table 1: Field of view (top side, back side)

Page 27

MLA150

3 System Description

User Guide 21

defocusing range [-10 to 10]. This range is necessary to adapt the focus distance to

an appropriate value which mainly depends on resist thickness and thus varies.

INTERFEROMETER

The laser interferometer is an optical device for measuring the stage position. The

machine achieves its required positioning precision with this important element.

WRITE HEAD

The write head is mounted to the optics plane. The focal length of the write lens

determines the resolution of the system.

Interferometer

Laser Unit

(HeNe)

X Mirror

X interferometer unit

Y interferometer unit

Stage

Y Mirror

Figure 7: Interferometer function

Page 28

MLA150

3 System Description

22 User Guide

3.2 Electronics Rack

The electronics rack consists of several units. These units drive and control the system

and provide communication with the operator of the system. The following electronic

units are located inside the electronics rack:

1 USER PC WITH CONVERSION

The User PC is a communication interface

between user and system by means of the

graphical user interface (GUI). The User PC

runs Linux on a virtual machine which runs the

conversion software. This software is

necessary for design conversion. Design files

in Gerber, DXF, CIF or GDSII have to be

converted into a machine file format, the LIC

format. LIC stands for Laser Internal Code.

Only this special file format can be read by the

MLA system.

2 STC-RACK

The STC-Rack is a system control unit

consisting of several elements such as the

stepper motor driver, the autofocus electronics

or the laser shutter control.

3 STAGE CONTROLLER

The Stage Controller drives the stage, reads

the interferometer data, triggers the laser and

tells the DMD (digital micromirror device) when

to switch to the next frame. It is the system that

coordinates the exposure procedure.

4 POWER SUPPLY AND EMERGENCY STOP

MODULE

This unit responsible for power distribution.

5 INTEGRATED NETWORK HUB

The Integrated Network Hub connects the

multiple devices and make them work together

on a single network.

1 2 3

4

5

Figure 8: E-rack components

Page 29

MLA150

3 System Description

User Guide 23

3.3 Orientation of Stage and Design

It is important to load the substrate with the correct orientation on the center of the

chuck. The coordinate system of the design to be exposed must match the direction and

orientation of structures already exposed on the substrate.

The coordinate system of the stage is oriented such that the y-axis corresponds to a

left-right movement and the x-axis to a backward-forward movement (see Figure 9)

when standing in front of the machine.

The design is exposed rotated by 90 degrees in clockwise direction (Figure 10).

X

loading side

F

90°

clockwise

Figure 10: Machine-related design rotation

F

Figure 9: Orientation of stage and design

Page 30

MLA150

3 System Description

24 User Guide

Thus, the coordinate system of the design is also arranged rotated by 90 degrees

clockwise (Figure 11).

For easier orientation on the chuck regarding the design coordinates, the following

figure gives an example of alignment crosses and their location on the substrate.

-x

-y

+x

+y

+x

- y

- x

+y

90°

clockwise

-x

-y

+x

+y

+x

- y

- x

+y

Figure 11: Rotation of coordinate system on chuck

loading side

Figure 12: Location of coordinate pairs

1

4

2

3

loading side

Page 31

MLA150

4 Wizard Description

User Guide 25

The MLA150 offers quick setup of exposure and alignment aided by the Exposure

Wizard. This intuitive user interface guides the operator through the steps of an

exposure set up. To start the wizard, double-click on the link icon.

4.1 Overview: Exposure Wizard

The Exposure Wizard has its own window. This window stays open throughout the

entire configuration and exposure procedure (Figure 13). It contains the following main

elements:

MENU BAR

TAB SECTION

INFO SECTION

FRAMES

INFO FIELD

NAVIGATION

BUTTONS

PANEL

Figure 13: Wizard window overview

Page 32

MLA150

4 Wizard Description

26 User Guide

MENU BAR

The menu bar is located at the top of the window, offering a number of menu utilities.

INFO SECTION

The info block gives information about the hardware condition and the progress or

status of the current exposure setup.

PANEL

The panel is located below the info section. This panel changes according to the

tasks that the system has to perform. In figure 13 the panel’s name is Setup Job

panel. Inside the panel are buttons and frames.

FRAME

The panel contains frames e.g., the Layer frame, where the design file and other

options are selected. The frame has mandatory fields that have to be filled with

values, and fields that can be filled optionally. The mandatory fields are highlighted

in orange and turn green once a value has been entered. The optional fields are

highlighted in green before and after the entry of values.

Throughout this manual you find instructions like "double-click Design". In this case,

you are instructed to double-click the value field with the title Design not the word

Design.

BUTTONS

A click on these buttons usually opens another window where you can select items

or set options

NAVIGATION BUTTONS

At the bottom of the wizard window, you find navigation buttons e.g., Load

Substrate or Continue. The functions and names of the buttons depend on the

selected exposure mode. These buttons can stay disabled until certain tasks are

finished.

INFO BOX

Every panel contains a yellow text box, giving information and instructions on the

current task.

TAB SECTION

A block with two tabs is located below the menu bar. In one tap (Exposure Setup) a

tree view shows the procedure steps the system has to execute. The other tab (Info)

shows a list of startup messages (refer 4.2 Static Wizard Elements for more details).

In the following subchapter, you find detailed information about the Exposure Wizard

elements.

TITLE

VALUE

MANDATORY

OPTIONAL

Page 33

MLA150

4 Wizard Description

User Guide 27

4.2 Static Wizard Elements

4.2.1 MENU BAR

FileExit:

To leave the wizard and close the window

ToolsControl Panel:

Activates the Control Panel (see 7.1 Control Panel)

ToolsInitialize Stage:

To initialize the stage in case the hardware info shows that

it is not initialized

UserSelect User:

Login of a certain user

UserManage Users:

To manage the administration rights of the different users

4.2.2 TAB SECTION

The Exposure Setup Tab shows a tree view of the steps to

be completed with the wizard from job setup to exposure and

unloading. It is a graphical representation of the sequence of

panels making up one exposure job. As a kind of panel map

it can be taken for orientation.

The green rectangle shows the options available in the

selected Exposure Mod. The green check indicates that the

task is done.

The Info Tab shows a list of startup messages informing the

user about the condition of the system after startup.

The control system checks the communication between the

electronics and the hardware components. A list of exposure

files and exposure reports is shown featuring a search bar for

easy retrieval of exposure information.

Note:

If the Hardware Info Section shows a red cross,

open the Info Tab and check the startup messages

to find out where the problem is.

Page 34

MLA150

4 Wizard Description

28 User Guide

4.2.3 INFO SECTION

The Info Section consists of four subsections:

Exposure Info

Alignment Info

Progress Info

Hardware Info

Exposure Info

Job Name is a combination of the word job and the job number. It is editable in the

Job frame by double-clicking into the Job Name value field.

No. shows the auto-incrementing number of the job, it is not editable.

Substrate Size[mm] shows the size of the substrate that is currently loaded.

Design Name shows the name of the design that is currently loaded.

Design Size [mm] shows the size of the design.

Dose [mJ/cm²] shows the exposure energy for the current job.

Height shows the height of the substrate on the cuck.

Layer shows the layer that is currently being prepared for exposure.

Mode shows the exposure quality level chosen at conversion. Quality means high

level, Fast means lower quality level but faster completion.

Defoc shows the defocus value selected for the current exposure. The defoc with a

range between -10 to 10 allows fine tuning of the exposure focus (for more

information see 3.1.3 Optics System: Pneumatic Autofocus). This value can be

adjusted before starting the design exposure (6.8 Expose Design)

Page 35

MLA150

4 Wizard Description

User Guide 29

Alignment Info

This info box has two tables:

Expose Cross Positions shows the positions of the alignment crosses set during the

setup of the layer previous to the layer with the design that is to be aligned. For

instance, when setting up the First Exposure job the coordinates of the exposure

crosses for the next layer can be determined and exposed together with the First

Exposure layer.

Align Cross Positions shows the positions of the alignment crosses taken from the

template file. For orientation regarding the location of the coordinate pairs on the

substrate see 3.3 Orientation of Stage and Design.

Progress Info

The Progress Info box gives information about the progress of the exposure.

Exposure Status shows the status of the exposure job.

Design Number shows the number of the design that is being exposed.

Page 36

MLA150

4 Wizard Description

30 User Guide

Stripe Number shows which stripe is being exposed at the moment.

Time [hh:mm]. shows the time that the exposure takes in total.

Remaining Time [hh:mm] shows the time that the exposure is still requiring to be

finished.

Hardware Info

The Hardware Info box shows important information about the system status. The

Refresh button updates the information stated in the tables. The Stage Position fields

show the x-coordinate and the y-coordinate of the current stage position. A click on

Refresh updates the fields to show the current position.

The Status list informs about the status of the system devices. If there is a red cross

instead of the word OK, click Refresh. If the status is still the same, go to the Info Tab

and click Status Messages. Here, you can see why the status does not show OK.

The Numeric Values list shows the condition of the system parts in numeric values.

These values are only interesting for service staff or users with administrator rights. If

any of the values is not in the normal range, the Status list shows the red cross icon

instead of the word OK.

REFRESH

STAGE POSITION

Page 37

MLA150

4 Wizard Description

User Guide 31

4.3 Substrate Representation

In the menu panel you find a simple graphical depiction of the substrate showing the

design position on the substrate. The position of the camera is also displayed in order to

see which part of the substrate is currently visible in the camera image.

Depending on the kind of substrate shape (plate or wafer) the menu offers two different

substrate visualizations. On the substrate, the design position and size is displayed by a

red rectangle. The camera is depicted as a blue rectangle.

1

Camera

2

Design

1

2

Page 38

MLA150

4 Wizard Description

32 User Guide

The horizontal and vertical measure lines indicate the real size of the substrate. The

size of the design representation and the size of the camera are scaled in relation to

these measure lines.

To move the design to a certain position on the substrate, use the Control Panel.

Alternatively, drag the camera (hold mouse button down while moving) to the desired

location. The design follows when the camera position is set to zero by clicking Set zero

in the Control Panel.

Page 39

MLA150

5 System Startup

User Guide 33

This chapter describes how to power up and power down the MLA150. For powering up

and down the system the buttons at the front of the flow box are used.

5.1 Powering Up

Powering up the system:

If not already done, switch on the main switch at the e-rack.

Allow 60 seconds to boot the power supply.

Depending on the system configuration, switch on the User

PC.

To switch on the system power, press the On (I)-button at the

front of the flow box.

You can hear one click and another click 3 seconds later.

In case the system was switched off by using the EMERGENCY OFF button:

Release by turning it in the direction indicated on the button. Otherwise the

system power cannot be switched on.

Press the green On (I)-button.

You can hear one click and another click 3 seconds later.

Note:

If power is not coming up, check whether the main

breaker on the bottom of the electronics rack is turned

off. Turn on the main breaker again!

Switch on the displays and the User PC, if it is not running.

In case the power supply was interrupted (e.g. by a blackout)

Press the green On (I)- button.

You can hear one click and another click 3 seconds later

Reboot the User PC.

Starting the Exposure Wizard:

Click the shortcut at your desktop.

On (I)

Off (0)

Emergency

Off

Page 40

MLA150

5 System Startup

34 User Guide

At each startup, the menu checks for necessary component initializations. A

window shows the status of hardware initialization

5.2 Powering Down

Powering down in emergency case:

In case of emergency, press the EMERGENCY OFF button at the front of the flow box.

Standard power down procedure

Close the Exposure Wizard by selecting FileExit from

the menu bar.

Shut down the User PC.

Press the red Off (0) – button.

The system shuts down.

Complete Shutdown

Execute the standard power down procedure and then turn off the

main breaker that is located on the front of the power distribution

rack at the bottom of the electronics rack (see 3.2 Electronics Rack).

Note:

In general, the system should be powered down completely only if

absolutely necessary. If the exposure laser is off, idle power consumption of

the system is low, and keeping it in standby enhances stability.

We do not recommend to power down the system if the idle time period is

less than at least one week.

Powering down for maintenance

The main circuit breaker in the bottom compartment of the electronics cabinet is

equipped with holes for a padlock. If the system is powered down for maintenance or

servicing, after above steps, secure the main circuit breaker in the Off position with such

a padlock.

On (I)

Off (0)

Emergency Off

Page 41

MLA150

6 Job Setup

User Guide 35

As mentioned before (4 Wizard Description), the MLA150 provides an exposure wizard

that guides the user through the steps needed to perform an exposure. The following

subchapters build a sequence of actions that have to be executed one after the other.

To use the wizard efficiently, follow the instructions given in this chapter. The following

figure is a “panel map” showing the way through the wizard panels.

Load

Substrate

Unload

Substrate

Setup Job

Select Job

Select Substrate

Template

Load Design

(Convert Design)

Exposure

Alignment

Alignment:

Exposure

Series

First

Exposure

Draw Mode

Page 42

MLA150

6 Job Setup

36 User Guide

6.1 Select Job

To start the wizard, double-click on the desktop. The Exposure Wizard opens

and automatically creates a new job. This job has a Name and a Number. The name is

editable and can be changed by clicking into the Name field. The number is fixed and

auto-incrementing.

If you do not intend to start a new job, you can also choose from the following options:

Continue or repeat a job:

Click Load Job.

Repeat an exposed layer of that job:

Click Restart Job and select the job you would like to repeat. The process

data of the selected job is deleted and a new job is set up with the same

settings but with a new job name/number.

Start another new job after you have finished an exposure job:

Click New Job. The new job has a new number and a new, but editable,

name. Continue with the instructions for a new job.

Use the new job that has started automatically with wizard startup:

From the dropdown list, select one of the available exposure modes:

Standard:

To expose a single design for each layer. Overlay exposures

are possible in this mode.

Series:

To expose designs (e.g. dose test) several times at different

positions with varying parameters (dose or/and defoc). It can

Page 43

MLA150

6 Job Setup

User Guide 37

also be used for finding the appropriate dose and defoc

relation for the exposure.

Draw Mode

To create boxes, circles or ellipses of arbitrary size limited

only by the camera field. Used for creating connections

between structures or for repairing imperfections in structures

of an exposed layer.

After you have set up the desired job, choose the appropriate substrate and the

corresponding substrate template at the system (see Substrate Template Selection).

6.2 Select Substrate Template

The system also needs to be provided with the information about the chosen substrate.

It offers a list of templates. In case the required template is not available in the list, it is

possible to load a new substrate template (only for authorized users).

For selecting a substrate template, follow these instructions:

In the Substrate frame:

Double-click into the value field titled Substrate Template.

From the list, select your substrate size or at least the shape e.g.,

automatic_round if you intent to load a wafer.

Above the list, click Load.

The Substrate frame now displays the selected substrate size or shape and the

field is highlighted in green. That means that the task of substrate template

selection is done. If a substrate size was selected the fields Size X, Size Y,

Diameter and Thickness are filled with the corresponding value.

1 1 3

2

Page 44

MLA150

6 Job Setup

38 User Guide

6.3 Load Design

In Draw Mode there is no design loading procedure because this mode is for

exposing boxes, circles and ellipses of arbitrary size limited only by the camera

field. Skip this subchapter and go to 6.5 Load Substrate.

After you have selected one of the exposure modes (see 6.1 Select Job) and

determined the appropriate substrate template (see 6.2 Select Substrate Template), you

load the design. For loading a design that is not in the list, follow the instructions given

in 6.4 Convert Design. The following sections contain instructions on design loading.

Even though the loading procedures differ only slightly from each other in the different

modes, read the section that corresponds to the exposure mode you are about to use.

6.3.1 STANDARD: FIRST EXPOSURE

In the Layer frame:

If available, select a laser from the dropdown list in the Laser field.

Double-click into the value field titled Design. A panel opens containing a list of

available design files.

From the list, select the required design with a left-click.

Click Load. Alternatively, double-click on the design name.

i

Page 45

MLA150

6 Job Setup

User Guide 39

The design is now listed in the Layer frame.

Optional: Double-click the value field titled Resist and select the appropriate

resist type for your application. The recommended dose for exposures on that

type of resist is listed automatically in the Sensitivity field. In the Thickness field

the thickness of the resist is displayed. Select the wavelength for the exposure.

Optional: It is possible to load a template for alignment crosses which are

exposed on the layer. To load this template, double-click into the value field titled

Expose Crosses and select a bitmap template file from the list. If the template

size exceeds 800 x 600 px, the system shows a warning.

6.3.2 STANDARD: ALIGNMENT

For aligned exposures, Layer 2 is the first layer that can be chosen.

If available, select a laser from the dropdown list in the Laser field.

Double-click into the value field titled Design in Layer 2. A panel opens containing

a list of available design files.

From the list, select the desired design file with a left-click.

Click Load. Alternatively, double-click the name.

1

4

Page 46

MLA150

6 Job Setup

40 User Guide

The design is now listed in the Layer frame.

Double-click into the value field titled Align Crosses. A list opens showing

several templates with the crosses required for alignment procedures. A special

template called _Manual.xml is offered for cases in which the cross positions

should be selected in the alignment setup. The exposure is then executed with

the manually selected alignment positions which are saved afterwards as

[jobname]_AlignPos_L[No. of layer] (see below). Additionally, if a

different template was selected, alignment positions can be changed or even

ignored (see 6.7 Setup Overlay Alignment).

From the list, with a left-click select a template and click Load.

The template file is now listed in the Align Crosses field.

Optional: Double-click into the value field titled Resist and select the appropriate

resist type for your application. The recommended dose for exposures on that

type of resist is listed automatically in the Sensitivity field. In the Thickness field

the thickness of the resist is displayed. Select the wavelength for the exposure

Note:

If the first layer does already exist on the substrate, it can be easily skipped.

6.3.3 SERIES

In Series Mode the template and design file is selected automatically when choosing

Series Mode in the Set up panel (see 6.1 Select Job). The Layer frame turns into the

Series frame with different parameters than displayed in the Layer frame (see below).

In case you need a different design file for your series exposure, follow the instructions

given in 6.3.1 Standard: First Exposure.

Page 47

MLA150

6 Job Setup

User Guide 41

6.4 Convert Design

If you have chosen a listed design file, skip to the next section 6.5 Load Substrate. For

converting a new design, follow these instructions:

In the Layer frame:

Double-click into the value field titled Design. A page containing a list of designs

opens. At the bottom you find a button bar.

Click Convert Design. You are led to the conversion software window.

Page 48

MLA150

6 Job Setup

42 User Guide

In the Conversion window:

From the menu bar, select File New Job (alternatively click the sheet icon).

You are asked to enter a name for the job. Enter a name and click Ok.

Click Add, select a design format. A directory opens containing the source files

for the selected design format.

From the directory, select the file to be converted into the LIC format.

If necessary, change settings and / or use the viewer application (see related

document Conversion Job Manager for more details).

Click Complete Task. A message box informs about the completion of the

process.

If the status bar shows 100%, click Finish.

The conversion software closes automatically.

Click into the wizard window to refresh the design list or click Refresh. The new

file is now listed and available for exposure.

Page 49

MLA150

6 Job Setup

User Guide 43

6.5 Load Substrate

After you have chosen the appropriate substrate, selected a substrate template and

loaded a design, you can place the substrate on the chuck. The following instructions

guide you through the loading procedure. You also get on-screen instructions inside the

yellow Info Box.

The chuck is designed to facilitate the manual loading process. It has an indentation

surrounding one of the four viewing slots for backside alignment. This indentation

makes substrate handling on the chuck easier as it offers space for putting a adjustment

aid inside.

ADJUSTMENT AID

The guide bar at the bottom of the adjustment

aid is equipped with rest positions

corresponding to the different wafer sizes that

are possible to be loaded on the chuck.

These rest positions are made visible on a

measuring scale.

In the example the chuck is loaded with a 4”

wafer as it can be seen on the measuring

scale matching the mark at the chuck.

Keep in mind to remove the adjustment aid from

the chuck before starting an exposure.

In order to avoid possible damage caused by

this adjustment aid, the system is equipped with

a monitoring function based on a light barrier

control. The Exposure Wizard disables the

buttons that lead to all subsequent steps. The

exposure function stays blocked until the tool is

removed from the chuck.

Page 50

MLA150

6 Job Setup

44 User Guide

STEP-BY-STEP SUBSTRATE LOADING

In the Setup Job panel:

Click Load Substrate. The stage moves into loading position.

The wizard moves on to the Load Substrate panel. Wait until the movement has

stopped.

At the lithography main unit:

Push the window button and release it again. The window

opens.

Place the adjustment aid so that the guide bar, which is

located at the bottom, fits into the indentation at the

chuck.

Adjust the auxiliary tool’s position to the substrate size.

Use a tweezer to grab the substrate and place the

substrate on the chuck.

Note: Check for correct loading and head position.

At the operator panel press the vacuum button.

Make sure that the substrate is held tight by the vacuum.

Remove the adjustment aid from the chuck.

Check the substrate's orientation (see 3.3 Orientation of

Stage and Design).

Close the window by pushing and releasing the button.

Go back to the User PC.

Resist coated substrates get useless when exposed to

white light!

Non-safe light may only be switched on if all substrates are

stored in boxes impermeable to light. Otherwise, the

substrates become useless.

Page 51

MLA150

6 Job Setup

User Guide 45

In the Load Substrate panel, click Continue.

Check if the substrate is placed under the write head. If not, see below. If the

substrate position is correct, click Continue.

Note:

In case the substrate is not placed under the write head, click Cancel. The

stage moves back to loading position. Start the loading procedure again

and make sure that vacuum is switched on.

Note:

For small substrates the system issues a dialog box if the substrate type

has not been completely defined in the step of substrate template selection.

The system searches for the center of the substrate and gives information about

the progress via a message box. If you wish to abort the Find Plate Center

procedure, click Stop in the message box and start the loading process again.

After the successful loading process, the system leads to the next panel:

In Standard Mode with overlay alignment, the Alignment panel appears (6.7

Setup Overlay Alignment).

In Draw Mode, the system offers the Draw Mode panel for creating boxes,

circles and ellipses (6.6 Draw Structures).

In Standard Mode without overlay alignment, you are led directly to the

Exposure panel (6.8 Expose Design).

In Series Mode, the Series panel shows up offering the exposure procedure

(6.8.3 Series Exposure Procedure).

Page 52

MLA150

6 Job Setup

46 User Guide

6.6 Draw Structures

After having selected the appropriate substrate, you can start drawing the image.

In the Draw Mode panel

In the Procedure frame, select the kind of shape to use for image drawing by activating

the corresponding radio button:

Draw Image: Activate this option to use the shapes offered in the camera

window: rectangle, ellipse, circle or bitmap file.

Draw Line or Polygon: Use this option to draw lines or polygones (lines with

more than two points). Adjust the line width by using the spin control below

the radio button.

Expose crosses: Use this option to expose crosses for alignment orientation

without the design (in Standard Mode a design has to be loaded). In the

Expose Crosses table you can load the bitmap file for cross exposure.

Page 53

MLA150

6 Job Setup

User Guide 47

6.6.1 DRAW IMAGE

Click Draw Image and select the area for the structure on the substrate inside the

camera window (use the Stage Control section for moving on the substrate).

In the camera window select the shapes of the structures that should be drawn

onto the substrate by clicking on the corresponding icon.

You can also load an existing file by clicking Load and selecting the file from

the corresponding folder (usually C:\HIMT\Designs\Bitmaps). To directly

load a bitmap file click BMP located below the structure icons.

To drag the structure to the desired position click into the structure and move the

cursor with the mouse button held down. To rotate the structure click into the

green dot inside the structure and move the cursor without releasing the mouse

button until the desired position has been found.

i

Page 54

MLA150

6 Job Setup

48 User Guide

To confirm the drawn image, click Submit in the menu bar of the camera window.

To clear the image, click Clear and start again.

To save the image, click Save, insert a name for the file and save it. To cancel

the entire drawing procedure, click Cancel.

After submission of the created image, work with the camera window is done.

Return to the wizard window and the Draw Mode panel in which the exposure

process can be started (see 6.8.4 Draw Mode Exposure Procedure).

6.6.2 DRAW LINE OR POLYGON

In the camera window, move to the area near to the

position of the first point of the line or polygon, so

that it is visible in the camera image.

Click Set Point.

In the camera window, a crosshair appears. Move

the crosshair by moving the mouse to the desired

position.

i

Page 55

MLA150

6 Job Setup

User Guide 49

Click the left mouse button at the position in which the first point of the line should

be set.

Move to the next point of the line/polygon by using the arrow buttons of the

Control Panel.

Click Set Point. Repeat the set point procedure.

Check the line position in the camera window and click Accept line.

To draw a polygon, go on with the set point procedure and click Accept Polygon

to submit the polygon drawing.

After accepting the drawn shapes, work with the camera window is done. Return

to the wizard window and the Draw Mode panel in which the exposure process

can be started (see 6.8.4 Draw Mode Exposure Procedure)

6.6.3 EXPOSE CROSSES IN DRAW MODE

If not selected in the Setup panel, a bitmap file has to be selected for every cross

position:

Click Edit and select a template for every cross position. For selecting the same

file in every position, activate the checkbox Use first bitmap for all.

Enter the positions into the table.

Click Edit again, to leave the editing mode.

Note:

Use Edit to change the template selection made in the Setup panel. Go to

back to the original positions from the selected file, click Original.

Page 56

MLA150

6 Job Setup

50 User Guide

6.7 Setup Overlay Alignment

For exposing the first layer, skip this subchapter and continue with 6.8 Expose Design.

The MLA150 is able to execute precise alignment exposures. In order to achieve best

results, the system offers top side as well as back side alignment. Back side alignment

(BSA) is realized by a separate camera unit for back side viewing that is mounted inside

the stage and looks to the substrate. Back side alignment is used in the same way as

the normal top side alignment. For using the available alignment modes, choose

standard exposure mode in the Setup Job panel.

Top side alignment is supported by three different camera types as mentioned before

(see 3.1.3 Optics System). Back side alignment is supported by two cameras, low and

high resolution. The overview camera is still active, but provides only top side view on

the substrate.

The Low Res camera is the default camera. For alignment, it is recommended to use

the High Res camera as its higher resolution is leading to best alignment results.

The alignment function offers two different alignment modes, Cross Alignment and

Manual Alignment.

Cross Alignment is an automatic cross detection mode and is recommended to be

used as standard mode.

Manual Alignment is the manual mode for cross detection and is provided for

exceptional cases in which the automatic detection might not work properly.

In this chapter, you find the information necessary for executing alignment for overlay

exposures. The alignment procedures of top side and back side do not differ from each

other, so the following instructions are for both alignment types.

Page 57

MLA150

6 Job Setup

User Guide 51

Alignment Procedure

In the Alignment panel:

If the template _Manual.xml for manual setup of the alignment cross

coordinates was chosen, select Top Surface for top side alignment or Back

Surface for back side alignment from the dropdown list. The other templates

already contain this information.

Choose a camera from the Stage and Camera Control panel:

Top Surface

Back Surface

Field of view

Field of view

Low Res

640 µm x 480

BS Low Res

min. 364 x 274 µm

High Res

190 µm x 140 µm

BS High Res

min.172 x 130 µm

Overview*

20 mm x 20 mm

*Overview cannot access the entire surface of the substrate due to mechanical

limits.

From the Alignment Mode dropdown list choose between Cross Alignment and

Manual Alignment. This selection can be made for very single cross position.

Note:

Using the High Res/ BS High Res camera for alignment is

recommended whereas the Overview camera is not useful for

alignment procedures.

Page 58

MLA150

6 Job Setup

52 User Guide

Double-check the positions of the alignment crosses taken from the template file.

Editing: The Edit button is used for changing the alignment cross positions.

Click Edit and enter new values. To delete one of the cross coordinates,

delete the value and leave the field blank. If, for instance, you intend to skip

the second cross position in the list, delete the value, copy the value from the

third cross position field into it. Leave the third position field blank. To close

the editing process, click Save. The positions are stored in a temporary file

and turned into a permanent template after exposure start. To restore the

original positions from the file, click Original.

If the template _Manual.xml was selected, set the alignment marks

manually by using the Edit function. For every alignment cross enter the

coordinates, click Save and then Accept Position.

Use the Stage Control frame of the Control Panel to move the cross into the

camera center (see 7.1 Control Panel).

Determine the alignment marks in:

A Cross Alignment Mode:

Click Measure. The system measures the position of the cross and moves it

to the center of the camera window. Examine the positions and click Accept

Position to confirm it. The procedure moves on to the next alignment cross.

In the Pos field, the rectangle turns into a check.

In case of unsatisfying measurements see 7.3.1 Unsatisfying Alignment

Measurements.

B Manual Alignment Mode:

Click Measure. In the camera window, a crosshair appears. Move the

crosshair to the position in which the alignment marks should be set and click.

The crosshair turns from green to orange.

Note:

For fine positioning use the arrow buttons. You can switch between

continuous movement (jogging) and stepwise movement. In step

mode enter the step size [µm] for X and Y direction into the

corresponding fields. In the jogging mode, change the driving speed

[µm/s] either by using the slider or by clicking into the corresponding

field and entering the speed manually. Alternatively, click into the

slider field and use the arrow keys for setting the speed

To center the position of the alignment mark inside the camera window, click

Center Cross.