V 1.5.1 Stand: 31.07.2007

Table Folder

TF M series

MINI plus

MULTI plus

OPERATING MANUAL

V 1.5.1 Stand: 31.07.2007

INDEX

1. INTRODUCTION

1.1. General information.........................................................................2

1.2. User information..............................................................................2

1.3. Safety instructions...........................................................................3

2. PREPARATION FOR USING THE FOLDER

2.1. Names of the control elements .......................................................4

2.2. Installation and start-up...................................................................5

2.3. Set-up of the receiving tray.............................................................7

2.4. Paper feeding..................................................................................7

2.4.1 - for the TF MINI plus (1 single feeding station) ....................................7

2.4.2 - for the TF MULTI plus (3 feeding stations)..........................................7

2.5. Daily Mail ........................................................................................8

3. WORKING WITH THE MACHINE

3.1. Switch on the machine.................................................................. 9

3.2. Select the operating mode and the feeding station.......................9

3.2.1 - without pre-counter..............................................................................9

3.2.2 - with pre-counter...................................................................................9

3.2.3 - Folding of single sheets (daily mail) ....................................................9

3.2.4 - Cascade function (only with the TF MULTI plus) ................................9

3.3. Select the fold type........................................................................10

3.4. Set-up instructions ........................................................................10

3.4.1. – Set-up 1 – DIN A4 sheet - wrap fold (c fold).....................................10

3.4.2. – Set-up 2 – DIN A4 sheet - z fold.......................................................10

3.4.3. – Set-up 3 – DIN A4 sheet - single fold ...............................................10

3.4.4. – Set-up 4 – DIN A4 sheet - double-parallel fold.................................10

3.4.5. – Set-up 5 – DIN A4 sheet - door fold..................................................10

3.5 How to correct the fold position...................................................11

3.6 How to correct the feeding station (diagonally) .......................... 13

3.7 How to change the paper pressure............................................. 13

3.8 Additional Set-ups and indications..............................................14

4. REFERENCE PART

4.1. Error handling..................................................................................15

4.2. Changing paper cassette, paper feed roller and pad......................16

4.3. Technical data.................................................................................17

4.4. Maintenance and cleaning..............................................................18

4.5. Repair and customer service ..........................................................18

4.6. CE certificate...................................................................................19

1. INTRODUCTION

2

1.1. General information

The folder TF M series is a folding machine which has been constructed for the office

environment. It can process documents with different widths as well as various fold types.

The different fold types can be adjusted at the fold plates.

1.2. User information

The folder TF M series is a folding machine which is only destined for the folding of paper.

Any other use is not according to its specifications. The manufacturer/supplier is not liable

for any damage resulting of such un-allowed handling.

Use according to its specifications also includes the consideration of the operating manual

and the compliance with the maintenance instructions.

Any service, repair and maintenance must only be performed by skilled persons of the

manufacturer or by authorized persons.

The folder TF M series is a table top machine and can, therefore, be placed onto an

existing table or a cabinet with a plane, scratch resistant and antislip surface. There do not

exist any special requirements with regard to the warranty of the stability duri ng operation.

The mains voltage must correspond to the indication on the type plate and the power.

Just printed documents must be dried completely before they can be processed. Otherwise

the rollers will get dirty.

Very bent or wavy sheets must be smoothed before the folding process starts.

1. INTRODUCTION

3

1.3. Safety instructions

a. The machine must be used only in a technical good condition as well as in

accordance with the regulations, also considering the safety and risk according to

the operating instructions.

b. The operating instructions must be stored close to the machine and ready to

hand.

c. The manufacturer cannot be h eld li able for any personal injury or material

damage occurred due to inadequate handling of the machine.

d. Do only use the power cord supplied or released by HEFTER Systemform. Take

care that the connexion cable is not damaged.

e. In case of re-locating the TF M series from a cold environment: You must wait at

least 2 hours before starting the machine. The TF M series adapts to the room

temperature automatically. Possible humidity escapes.

f. In case of unauthorized reconstruction or changes of the machine the

manufacturer does not undertake any liability.

For your own safety

a. Before starting the machine you need to read the operating instruction and store it

ready to hand.

b. Do not grip into the machine during the operation => Risk of injury!

c. Long hair, clothes such as ties and jewellery can be grasped by the rotary wheels.

Use of the machine under these circumstances is inadequate.

d. Connect the folder only to a plug with grounded contact.

e. Before any grip into the machine it must first be switched of and the power cord

must be disconnected.

f. Do not put any small/thin objects into the machine ⇒ Risk of electrocute!

g. In case of any problems with the TF M series switch the machine of, disconnect

the power cord and have the machine checked by a HEFTER Systemform

Service Technician.

h. Before you clean the TF M series or remove it do not forget to disconnect the

power cord.

i. Disconnect the power cord in case of a thunderstorm or if the machine is not used

for a longer period of time.

j. Have the maintenance a nd repair works only done by a HEFTER Systemform

Service Technician or by skilled personnel, authorized by HEFTER Systemform.

In case of non compliance the warranty claim will stop.

k. The machine must be protec ted against splash water.

l. Take care that no liquids get into the machine.

2. PREPARATION FOR USING THE FOLDER

4

2.1 Names of the control elements

1. Main switch (= rear)

+ Socket for the power connection

+ fixing for the safety device

2. Paper pressure spring

+ Adjusting wheel for the paper feeding angle

3. Feeding station (incl. lever)

4. Adjustment of paper width ( incl. clamping lever)

5. Guiding plate for the daily mail

6. Flap including opening lever

for the paper jam removal

7. Drawer for the paper stacking

8. Display and control unit

Adjusting wheels for the fold plates

9. Position marker A for the

first

fold plate (= Quickadjustment incl. closing pusher)

Vernier adjustment A

10. Position marker B (=Quickadjust.) for

second

fold plate (incl. closing pusher)

Vernier adjustment B

11. Display

a. Display for sheet counter

b. Countdown information

c. Display for machine status

d. Display for the speed

12. Start / Stop button

13. Speed buttons

a. > = Reduce

b. >> = Increase

14. Adjustment for pre-counter

a. 1000 preset

b. 100 preset

c. 10 preset

d. 1 preset

15. Reset button

Display and control unit for TF MINI plus

2. PREPARATION FOR USING THE FOLDER

5

16. Display

a. Display for sheet counter

b. Countdown display

c. Display for machine status

d. Display for the speed

17. Start / Stop button

18. Speed buttons

a. > = Reduce

b. >> = Increase

19. Adjustment for pre-counter

a. 1000 preset

b. 100 preset

c. 10 preset

d. 1 preset

20. Reset button

21. Select button for the paper tray 1, 2 or 3

(You can chose each paper tray independent from each other!)

22. LED display: Green: Paper tray active

Red flashing: Paper tray active / no paper available

or Paper Jam

LED off: Paper tray not selected

2.2. Installation and start-up

The folder TF M-series is delivered completely assembled and can be installed

easily.

Delivery

a. Folder TF M-series incl. paper tray(s)

b. Power cord

c. Operating manual

Installation

a. Unpack the folder TF M-series

(Packing can be used for re-transport, e.g. in case of repair).

b. Place the folder to its location (plane, antislip and scratch resistant surface).

Display and control unit for TF MULTIplus

2. PREPARATION FOR USING THE FOLDER

6

c. Remove the transportation lock

d. Fit in the paper tray(s) (two notches for fitting, one left and one on the right side)

and turn it backwards to the required position (photos 01, 02 and 03).

Caution

: Do not get your fingers caught when turning the paper tray!

e. Plug the power cord to its destined socket at the rear of the machine (see

point 2.1.)

f. Plug the power cord to the wall socket (230V).

Photo 1

TF MINI plus

(replacement)

Photo 02

TF MINI plus

Position 1

daily mail

photo 04

TF MULTI plus

(replacement)

photo 05

TF MULTI plus

Photo 03

TF MINI plus

Position 2

operating mode

2. PREPARATION FOR USING THE FOLDER

7

2.3. Set-up of the receiving tray

Pull out the drawer for the paper tray at the front of the machine (-> photo 03

and 05). Adjust the position needed (stacking width) by moving the drawer

accordingly. No jam may occur (The scores at the drawer help you to find the

correct stacking width)!

2.4. Paper feeding

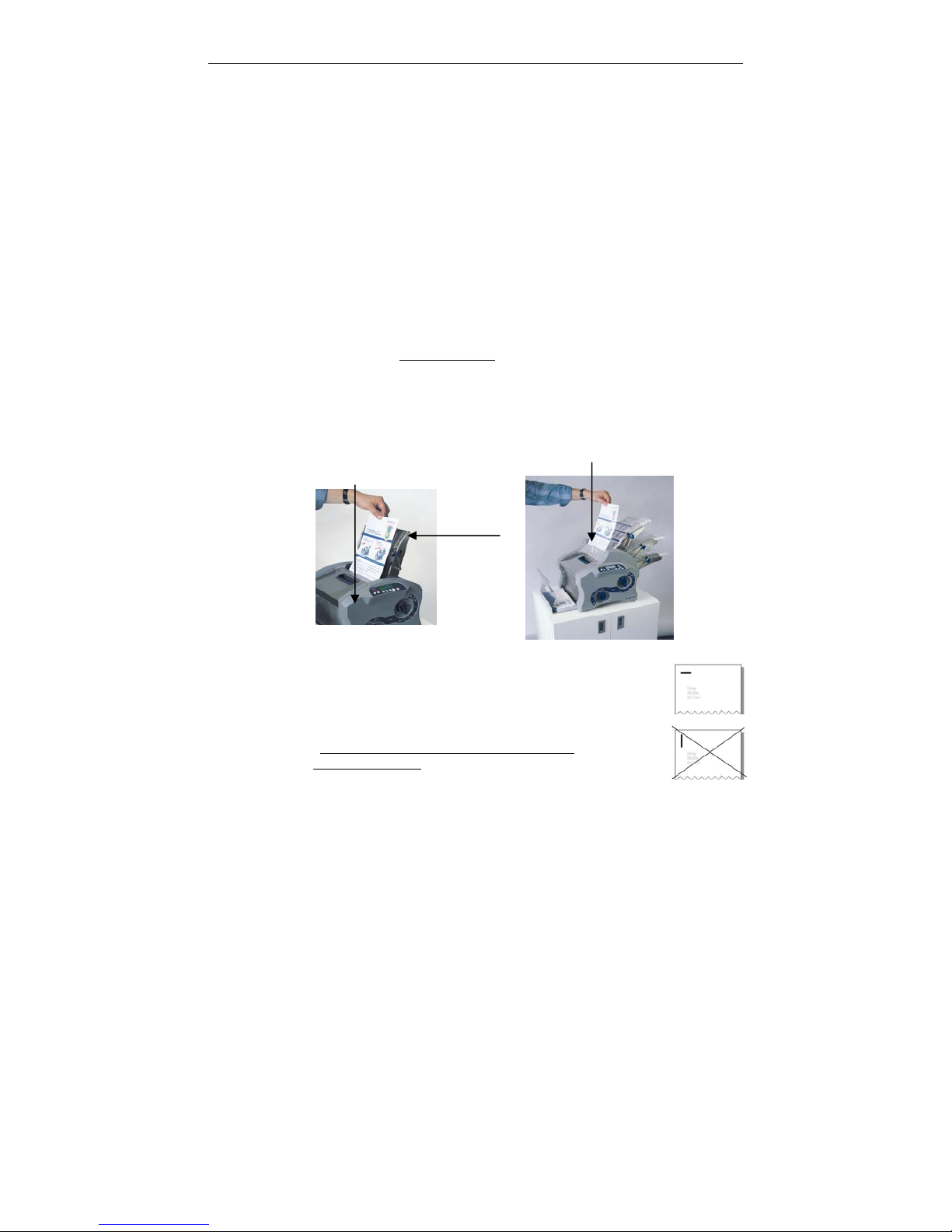

2.4.1 Paper feeding at the TF MINI plus (= one single feeding station, see photo 06)

Adjust both paper guidances centered and

symmetric and with a minimal slack

to the paper width needed.

To adjust the paper guidances please grab

them with the clambing lever.

NOTE: No jam may occur at the paper

guidance,

the paper needs a slack of ~0,5 mm!

Move the lever of the paper tray (right side)

downwards and position the paper so that it

touches the bottom neatly. Then loose the lever.

Example: For the set-up of the wrap fold for A4 sheets (see point 3.4.1) feed the

paper face up and foot first.

Tip: - Fan the paper before you insert it!

- Always make a test fold to check the fold!

2.4.2 Paper feeding at the TF MULTI plus (= 3 feeding stations, see photo 07)

Adjust both paper guidances of each feeding

station centric and symmetric and with a

minimal slack to the paper width needed.

Please use the scale for that purpose.

To adjust the paper guidances please grab

them with the clambing lever.

NOTE: No jam may occur at the paper guidance,

the paper needs a slack of ~0,5 mm!

Move the lever of the paper tray (right side)

downwards and position the paper so that it

touches the bottom neatly. Then loose the lever.

Abb. 07 – TF MULTI plus

Abb. 06

TF MINI plus

2. PREPARATION FOR USING THE FOLDER

8

Example: For the set-up of the wrap fold for A4 (see point 3.4.1) feed the paper face up

and foot first.

Tip: - Fan the paper before you insert it!

- Always make a test fold to check the fold!

-

Note: When foldings out of 2 or 3 feeding stations are necessary there may be no

paper fed before the folding process starts. Otherwise a paper jam may occur.

Please first insert the documents in the paper tray, then start the folding process.

2.5 Daily mail

Folding of single sheets (Daily mail = semi-automatic processing)

a. Empty the feeding station(s)

b. Turn the feeding station (only at the TF MULTI plus)

forward to the first grid position (see point 2.2.)

c. The two paper guidances will help you to feed the sheets (max.

5 sheets together) centered into the daily mail feeding tray (= paper

feeding) as far as possible. Press slightly so that all sheets will be fed

at the same time.

d. The folder starts automatically.

e. It stops automatically after the folding process

NOTE: The sheets may also be stitched! But this stitching should

always be positioned parallel to the folding wheel

__ = correct,

| = wrong!

Example: For stitched documents = Z-fold for DIN A4

(see under 3.4.1)

Insert the paper face down and with the address field first.

3. WORKING WITH THE MACHINE

9

3.1. Switch on the machine

Before starting the machine take care: long hair, clothes such as ties and jewellery can be

grasped by the rotary wheels.

Turn the main switch to the position I (= On) (see under 2.1)

3.2. Select the operating mode and the paper feeding

In general you can choose from four operating modes:

3.2.1. Folding with counter

a. Insert the paper to be folded (see point 2.4)

b. Control the fold type (see fold t ype set-up un der point 3.3 and 3.4)

c. Activate the appropriate paper tray(s) (only for the TF MULTI plus)

d. Start the folding process by pushing the Start-Stop button (see

under 2.1)

e. The machine stops if

i. There is no more paper or

ii. You push the start-stop button again.

3.2.2. Folding with pre-counter (count down function)

a. Insert the paper to be folded (see point 2.4)

b. Control the fold type (see fold t ype set-up un der point 3.3 and 3.4)

c. Enter the required quantity by means of the preset button. The quantity

is shown on the display (see under 2.1)

(Button 1 = 1000, button 2 = 100, button 3 = 10, button 4 = 1)

(from left to right)

d. Activate the paper tray(s) (only at the TF MULT I plus)

e. Start the folding process by pushing the Start-Stop button. (see

under 2.1)

f. The machine stops if

i. Preset quantity of paper is folded or

ii. There is no paper. In this case please refill the paper tray and push

the start button again or

iii. push the start-stop button again.

3.2.3. Folding of single sheets (see point 2.5 daily mail)

3.2.4 Cascade function (only with the TF MULTI plus)

a. Cascade function stands for an automatic folding of the feeding stations

1, 2 and 3. The sheets are fed from 1 feeding station (e.g. station 1)

until this station is empty. The process will continue from the next station

(e.g. station 2 and 3).

b. The cascade function can be set per key stroke! For this you press the

“keys of the feeding stations 1 and 2” simultaneously for 2-3

seconds.

c. To go back to the standard working mode press the two “keys of the

feeding stations 1 and 2” again for 2-3 seconds.

3. WORKING WITH THE MACHINE

10

3.3. Select the fold type

The TF M series has two

fold pockets!

¾ Position marker A for

the first fold pocket

(incl. closing pusher)

Vernier adjustment A

¾ Position marker B for

the second fold pocket

(incl. closing pusher)

Vernier adjustment B

To change the fold pocket position; first push the position marker A or B down

(Quickadjustment, see point 2.1.).

Now you can adjust the position, depending on the required fold type (acc. to the

scale) (also see under point 3.4)

For just one folding (e.g. single fold) the position marker A is turned completely to the

right side (up to the symbol <).

To fix the fold pocket position release the closing pusher (= locked). The position

marker have to snap in complete (flash with the front cover).

NOTE:

During the changing process of the fold pocket position marker no paper may

be in the folding wheel!

3.4. Set-up instructions

Pos. Feeding

instruction

Paper

size

Fold

type

Address

position

Position

lever, fold

pocket 1

Position

lever, fold

pocket 2

3.4.1.

A4 Wrap

fold

3.4.2.

A4 Z fold

3.4.3.

A4 Single

fold

3.4.4.

A4 Double-

parallel

fold

3.4.5.

A4 Door fold

B

A

3. WORKING WITH THE MACHINE

11

3.5 How to correct the fold position

If you need to change the fold position this can be done very easily (scale +/-)

Move the position marker by using the vernier adjustment A or B.

1. Paper feeding

2. Select fold type

Wrap fold (DIN A4 document)

For the correct result of the wrap fold you need to adjust two fold positions.

The position marker A controls the length A.

The position marker B controls the length B.

To reduce length A = move the position marker A to To increase length A = move the position marker A to +

To reduce length B = move the position marker B to To increase length B = move the position marker B to +

Z-fold (DIN A4 documents)

For the correct result of the Z-fold you need to adjust two fold positions.

The position index A controls the length A.

The position index B controls the length B.

To reduce length A = move the position marker A to To increase length A = move the position marker A to +

To reduce length B = move the position marker B to To increase length B = move the position marker B to +

3. WORKING WITH THE MACHINE

12

Single fold (half fold) (DIN A4 documents)

For the correct result of the single fold you need to close the first fold pocket, meaning the

position index A must be turned clockwise as far as possible.

The position index B controls the length B.

To reduce length B = move the position marker B to To increase length B = move the position marker B to +

Double parallel fold (16” documents)

For the correct result of the double parallel fold you need to adjust two fold positions.

The position index A controls the length A.

The position index B controls the length B.

To reduce length A = move the position marker A to To increase length A = move the position marker A to +

To reduce length B = move the position marker B to To increase length B = move the position marker B to +

Door fold (DIN A4 documents)

For the correct result of the door fold you need to adjust two fold positions.

The position index A controls the length A.

The position index B controls the length B.

To reduce length A = move the position marker A to To increase length A = move the position marker A to +

To reduce length B = move the position marker B to To increase length B = move the position marker B to +

3. WORKING WITH THE MACHINE

13

3.6. How to correct the paper tray

To correct the paper tray diagonally you need to adjust the edgewise pape r guidance

by means of the adjusting wheel for the feeding angle (under the paper tray, right).

Adjusting wheel for the paper feeding angle

3.7. How to change the paper pressure

The paper pressure can be adjusted, depending on the paper qualit y.

The paper pressure spring

is under the paper tray (see 2.1).

You can turn the paper pressure button (open) and move to the appropriate position.

To fix the paper pressure button you turn it again (close).

- for low pressure and

+ for high pressure

3. WORKING WITH THE MACHINE

14

3.8. Additional set-ups and indications

3.8.1 Set-up of the feeding time at the TF Mini plus & TF Multi plus for the daily mail

The machine starts automatically with the daily mail mode according to an

adjustable Time (

factory settings: TF MINI +: 1.0 sec., TF MULT +: 2.0 sec.)

i.e. e.g. 1,0 seconds (MINI +) after inserting the sheets into the daily mail channel!

a. T he feeding time can be set per key stroke! Press the key “reset” for about 4

seconds.

b. Then, the time set will be displayed. You can reduce this time by pressing “ >” or

extend it by pressing “>>”.

c. By pressing the key “reset” again you will reach the standa rd opearting mode. The

time lastly displayed was set and stored.

3.8.2 Set-up of the feeding time of the individual TF Multi plus feeding stations

The feeding times of the individual feeding stations are different since the distances

from each station to the folding wheels vary. – This means that the sheets are fed

with different time lags due to the different distances so that they will reach the

folding wheels at the same time.

Distance feeding station 1 = time lag 1 (factory settings: 0.50 sec.)

Distance feeding station 2 = time lag 2 (factory settings: 0.30 sec.)

Distance feeding station 3 = time lag 3 (factory settings: 0.40 sec.)

a. T he feeding time can be set per key stroke!

Press the respective “feeding station key” about 5 seconds.

b. Then the time set will be displayed which you can reduce by press ing

“>” or extend by pressing “>>”.

NOTE:

Change the feeding time only stepwise and only from one station at a time

so that you can find out if the folding result has been improved.

c. By pressing again the selected “feeding station key” you will be back in the

standard operating mode; the lastly displayed time was set and stored.

3.8.3 Display “Total Number of folds”

a. The total number of any folds made with this folder can be displayed per key

stroke! Just press the keys “10”, “1” and Reset simultaneously.

b. Then the total number of folds will be displayed in steps of thousands,

e.g. 0001. = 1000 folds and . 0012 for total 1012 folds.

c. The display will disappear after a few seconds and you will be back in the

standard operating mode.

4. REFERENCE PART

15

4.1. Error handling

Error description Possible reason Corrective action

No current Check the power supply, the socket

and the cable

Machine does not start

Display does not light up

Fuse blown out Check the fuse (see page 14, fuse

type 1,5 A slow)

Fold pockets are

blocked

Remove any possible paper in the fold

pockets (see drawing page 14)

Paper jam in the

machine

Feeding is blocked Remove any possible paper at the

feeding unit (see point 2.4)

Paper jam in the stacker Stacker is not drawn

out far enough

Move the stacker to the correct

position according to the fold type (see

under 2.3)

Fold A is too short Fold pocket 1 is

displaced

Move the position index A for the fold

A downwards (see under 3.5)

Fold A is too long Fold pocket 1 is

displaced

Move the position index A for the fold

A upwards (see under 3.5)

Fold B is too short Fold pocket 2 is

displaced

Move the position index B for the fold

B upwards (see under 3.5)

Fold B is too long Fold pocket 2 is

displaced

Move the position index B for the fold

B downwards (see under 3.5)

Paper is not fed good

enough

Pressure spring

displaced

Move the pressure spring at the rear

of the paper tray (see under 2.1)

Stronger pressure – Spring to +

Reduced pressure – Spring to -

The fold is to slope Paper try displaced Correct the paper try (see under 3.6)

Paper is not fed together

(only for the TF MULTI+)

Feeding time is

wrong

Correct the feeding time for the

feeding stations (see under 3.8.2)

Error description on the display:

Error 1 Lever for the paper

jam removal is open

Close the lever (see under 2.1)

Error 2 Overpowered

The folder was

overpowered

Switch off the folder, remove a possible

paper jam and switch on the machine.

Error 3 Paper jam in the

machine

Remove any possible paper in the

Machine and the fold pockets (see

drawing page 14)

Error 4 No paper tray

selected (only for

the TF MULTI plus)

Select the paper tray(s) needed (see

under 2.1)

4. REFERENCE PART

16

Before changing the fuse or opening the cover for the paper j am clearance please note:

Machine must be switched off and the power supply must be disconnected!

Now open the cover by means of the lever (in the hollow).

The wheels are now easy to reach and the paper can be removed.

Please do not use force!

4.2. Changing paper cassette, paper feed roller and pad (e.g.abrasion)

First remove the paper cassette. Turn move it out of the two notches for fitting.

it frontwards to the shown position and

To remove the paper feed roller

Press in the direction of the arrow to remove After this, you can remove the pad.

the joint of the shaft. Tip it out.

Remove of a paper jam:

In case of a jam open the cover and remove

the paper.

Opening lever

Change the fuse:

The fuse is located between the

main switch and the socket.

Pull out the fixing unit; then you can

exchange the fuse!

4. REFERENCE PART

17

4.3. Technical data

Paper width: 100 mm – 218 mm (3,94 inch – 8,58 inch)

Paper length: TF MINI plus 80mm - 448mm (3,15“–17,64“)

TF MULTI plus 150mm - 448mm (5,90“–17,64“)

Paper weight: 50 – 150 g/m

2

The total weight for the TF MINI (daily mail) and

TF Multi plus should not exceed 300 g/m

2

!

e.g. 80 g in station 1

e.g. 80 g in station 2

e.g. 80 g in station 3

= 240 g total weight

Display: LCD 4 x 7-Segment display

Loading capacity: TF MINI plus max. 200 sheets

TF MULTI plus max. 600 sheets

(= 3 x 200 sheets)

The loading capacity may vary depending on

the paper quality and its weight.

Performance: TF MINI plus: max. 7.200 sheets/h

Performance: TF MULTI plus max. 6.000 sheets/h

Daily Mail = nest fold: max. 5 sheets, also with horizontal

wire stitches

Electricity: Power supply ~230 V → 24 V = / 2.5 A

230V 50 Hz 5,0 A

110V 60 Hz 10,5 A

Fuse: 1,5 A Slow

Dimensions: TF MINI plus 320 x 377 x 398 mm (L/W/H)

TF MULTI plus 320 x 377 x 483 mm (L/W/H)

Weight: TF MINI plus about 13 kg

TF MULTI plus about 17.5 kg

Environmental conditions: Room temperature 15-40°C

Relative humidity 40-70%

Noise level: max. 73 dBA

Technical data is subject to changes!

4. REFERENCE PART

18

4.4. Maintenance and cleaning

Regular and correct cleaning will contribute to a long life cycle of the machine with

high quality.

Therefore, it is important to clean the machine regularly – especially to remove

any possible paper dust and to clean the folding wheels.

⇒ Before cleaning the machine it must be switched off and the power cord must

be unplugged

⇒ The transport rollers, the running surface and the feed stop must be cleaned

regularly.

⇒ Clean the machine only with a damp, non fuzzy cloth; the best would be using

the special cleaner for rollers (2800020) offered by HEFTER.

IMPORTANT:

Please do not use any aggressive cleaning material! The manufactur er does not

take any responsibility for any other cleaning material.

CAUTION:

Take care that no liquids get into the machine!

4.5. Repair and customer service

Hefter Systemform is always available to you in case of any questions to this

folder TF M series or if service support is needed (www.hefter.de).

Please contact HEFTER Systemform directly or one of our distributors close to

your place. You can find the addresses and phone numbers on page 19 of this

manual or on the label at your machine.

4. REFERENCE PART

19

4.6. CE certificate

Product: Table-top folder

Type: TF MINI plus

TF MULTI plus

The design of this 98/37/EWG

machine conforms with 73/23/EWG

the following regulations: 89/336/EWG

Applied harmonised EN 292-1

standards: EN 292-2

EN 294

EN 349

EN 954-1

EN 1010

EN 1010-1

EN 1050

EN 60204-1

Dipl.-Ing. (FH) Ch. Hefter

Development / Construction

Prien, 28 June 2004

HEFTER Systemform

Sales Departement Central-Repair-Shop

Bernauer Straße 71 Am Mühlbach 6

D – 83209 Prien D – 83209 Prien

+49(0) 8051 / 686 201 +49(0) 8051 / 686 2041

Fax +49(0) 8051 / 686 211 Fax +49(0) 8051 / 686 211

systemform@hefter.de

systemform@hefter.de

www.hefter.de

www.hefter.de

Loading...

Loading...