Hedler DF15 User Manual

HEDLER

Systemlicht

®

h

c

t

i

l

l

e

r

u

e

c

Thank you for choosing a Hedler light unit and your

con dence in the Hedler light system. Please, read

the following technical informations carefully

before using the light unit.

Codes are given in <Brackets>.

u

a

D

d

n

u

-

z

t

i

l

B

r

e

l

d

e

H

!

t

ä

Handmade in Germany

t

i

h

t

e

n

:

h

o

h

e

L

e

i

s

t

u

n

g

,

e

r

s

t

k

l

a

l

s

a

s

u

i

g

Q

e

TECHNICAL DESCRIPTION

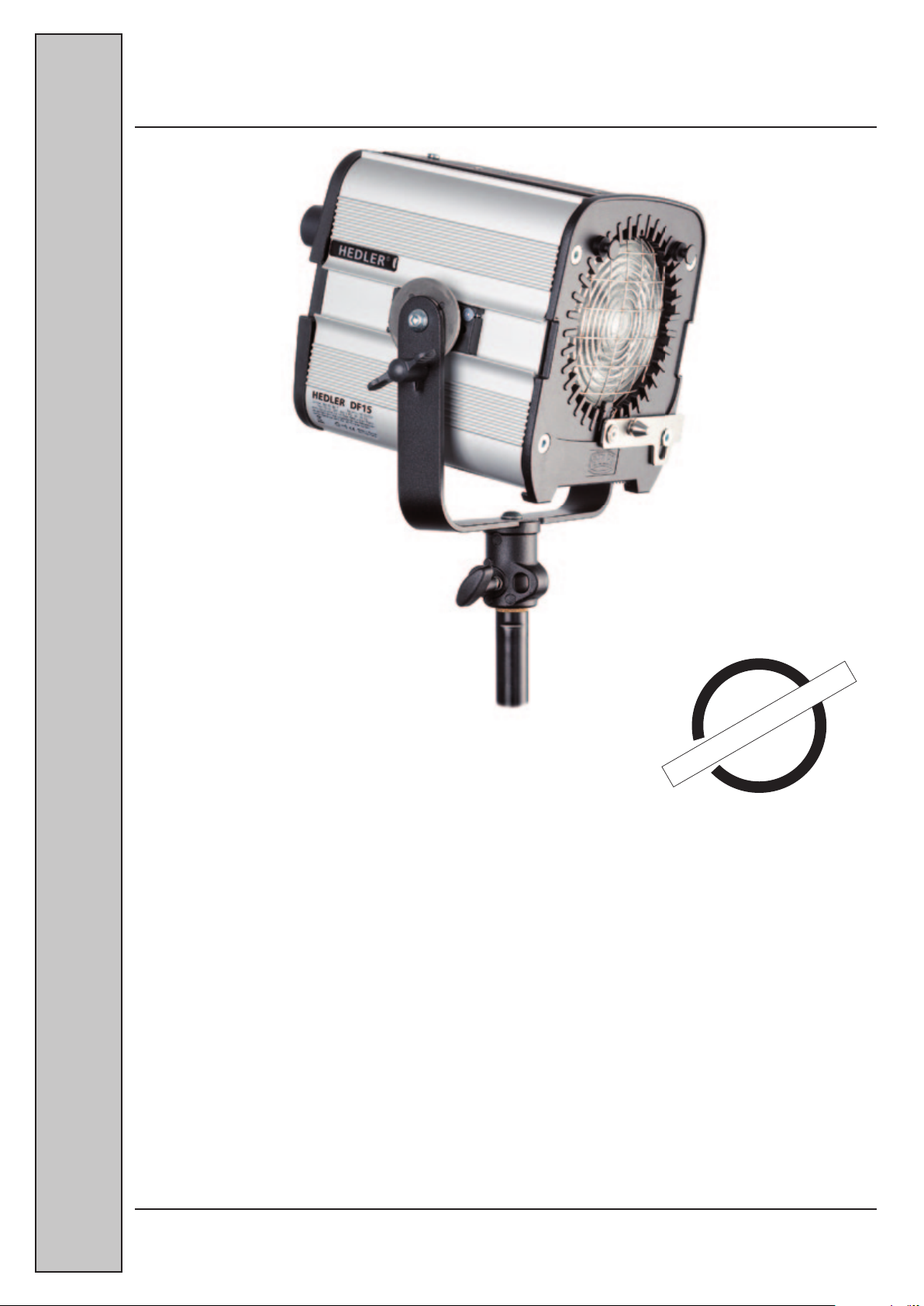

Light units of the HEDLER DF range are designed for professional use, they are assembled by applying precision methods and tested individually

for function and quality. The focusable daylight HEDLER DF15 is provided with an integrated U-bracket and a friction brake and a 5/8” QuickLock light stand attachment. After loosening the hex key screws by approx. 2 turns, the U-bracket can be moved back and forth in its keyway

for gravity adjustment and it is turnable for right and left hand use.

The focusable daylight HEDLER DF15 uses AC of 230 - 250 V and the modern metal halide 150 W SE T bulbs, which can be re-ignited after 2 - 3

minutes while the cooling down has started by switching-off the light unit. As a special feature, the HEDLER DF15 does not have a fan, which

means it suits ideal for original sound recording.

On its front side, the aluminium housing holds the Fresnel lens with its protective grid. AdditionalIy there are the Uni-Adapt studs and the

QuickFit adapter for attaching re ectors. Interchangeable re ectors with bayonet ring can be attached in the following way: place the rim of the

ring into the guide grooves of the upper studs and the round opening over the cone-shaped bolt, and lock it by a turn to the left. To attach the

rotatable 4-Leaf barndoors or a MaxiSoft folding re ector, place the rim of the ring into the guide grooves of the upper studs, and then push

the complete re ector towards the QuickFit´s cone-shaped bolt until the ring locks in the bolt´s groove. Detach the re ector by lifting the

QuickFit´s handle, moving the lower side of the re ector away from the light unit´s housing, and then lifting the re ector´s ring out of the guide

grooves of the upper studs.

On the opposite side of the housing, one will nd the ergonomically incorporated handgrip, the cable and the main switch. Additionally you will

nd on the backside of the housing the focusing turning knob, which allows to adjust precisely and intuitively the size of the light beam from

spot- to oodlight setting.

In addition to the parabolic re ector, bulb socket and ignitor, the housing accomodates the electronic ballast, which supplies stabilized voltage to

the bulb, ensures icker-free light of constant intensity and a colour temperature of app. 6000 K. Besides that, it will extend the average bulb life

by app. 20 percent and reduce the power consumption by about 12 percent. Ignition is effected by 1 x 5 KV symmetrically, faulty bulbs will be

detected and switched off automatically. RF interference reduction meets all applicable EN 61000-3-2 standards.

HEDLER Systemlicht GmbH Heerstrasse 112 D-65594 Runkel / Lahn www.hedler.com

Daylight DF15

Telefon + 49 - (0) 6482 918 100 Telefax + 49 - (0) 6482 918 111 eMail info@hedler.com

HEDLER

The HEDLER DF15 light unit does not have the UL (Underwriters Laboratories) Standards for Safety sign for the USA and Canada.

Systemlicht

BULBS

To replace the bulb: please, make sure that the housing and the bulb of the DF15 has off before interchanging the bulb, otherwise there is a risk

of burning! Always disconnect the DF15 from the power supply before interchanging the bulb. Unscrew the socket screw of the cover plate

guard. The cover plate guard is located on the housings upper side, its socket screw is located at the ange which faces towards the housings

backside. To unscrew the socket screw, use the socket wrench which was delivered with the DF15. After loosening the socket screw completely

remove the cover plate guard.

Turn the focusing knob until the DF15 has its maximum spot light position. Pull the defective bulb out of the socket, after doing so push the new

bulb carefully into the socket, oberving instructions by the bulb manufacturer.

After pushing the bulb into its socket, replace the cover plate guard. Make sure that its lug is located correctly into the housings notch. Afterwards

install the socket screw into the hosuings thread and tighten it hand-tight. Please, before taking the HEDLER DF15 in operation, make sure that

the cover plate guard is mounted correctly!

FRESNEL LENS

To replace the Fresnel lens: please, make sure that the housing of the DF15 has cooled off before interchanging the Fresnel lens, otherwise there

is a risk of burning! Always disconnect the DF15 from the power supply before interchanging the Fresnel lens. Unscrew the four socket screws

of the housings front plate and remove the front plate with the Fresnel lens. Unscrew the securing screws of the Fresnel lens and replace the

defective one with an original Hedler Fresnel lens only. After replacing the Fresnel lens tighten its securing screws hand-tight. Attach the front

plate at the housing and tighten the front plates four securing screws. Please, before taking the HEDLER DF15 in operation, make sure that the

front plate is mounted correctly!

FOCUSING the HEDLER DF15

To focus the HEDLER DF15s light beam turn the focusing knob anti clock-wise (increased oodlight characteristic) or clock-wise (increased

spotlight characteristic) to adjust the light beams size.

®

ACCESSORIES

It is recommended to use light units of the Hedler range only in combination with an original HEDLER 4-Leaf barndoor or one of the HEDLER

accessory re ectors. This permits adjusting the light beam to the requirements of any situation. In addition to the re ectors MaxiNorm, MaxiSun,

MaxiBrite, MaxiBeauty and MaxiBackground or the MaxiSoft folding re ectors (=softboxes) 30 x 30cm, 50 x 50cm, 70 x 70cm, 90 x 90cm,

L110 x 45cm and Octagon 100cm, a 4-Leaf barndoor, re ex umbrellas and grids for several softboxes/re ectors are available. Additionally, the

MaxiSpot 65 and MaxiSpot 130 are available for effect lighting.

For detailed information and the possibilities of forming the light beam to special characteristics, consult the current Hedler catalogue, it will be

sent to you upon request free of charge, or visit our website with the latest information.

HEDLER WARRANTY

All Hedler equipment is fully guaranteed against any material or manufacturing defects for three years after date of purchase. Parts made out of

glass, glass covers, fuses, Tungsten halogen bulbs and ash bulbs are not covered by this warranty.

MAINTENANCE and REPAIR

Used under normal professional conditions, Hedler daylight light units require no maintenance. If repair is required, please, contact your dealer,

the authorized distributor in your country or the Hedler factory directly. Please note, that a pre-dismantled light unit could cause increased

repair costs.

APPROVAL and UL STANDARDS for SAFETY

The HEDLER DF15 light unit is SEV Standard tested, sign Schweiz HD 504.

The HEDLER DF15 light unit does not have the UL (Underwriters Laboratories) Standards for Safety sign for the USA and Canada.

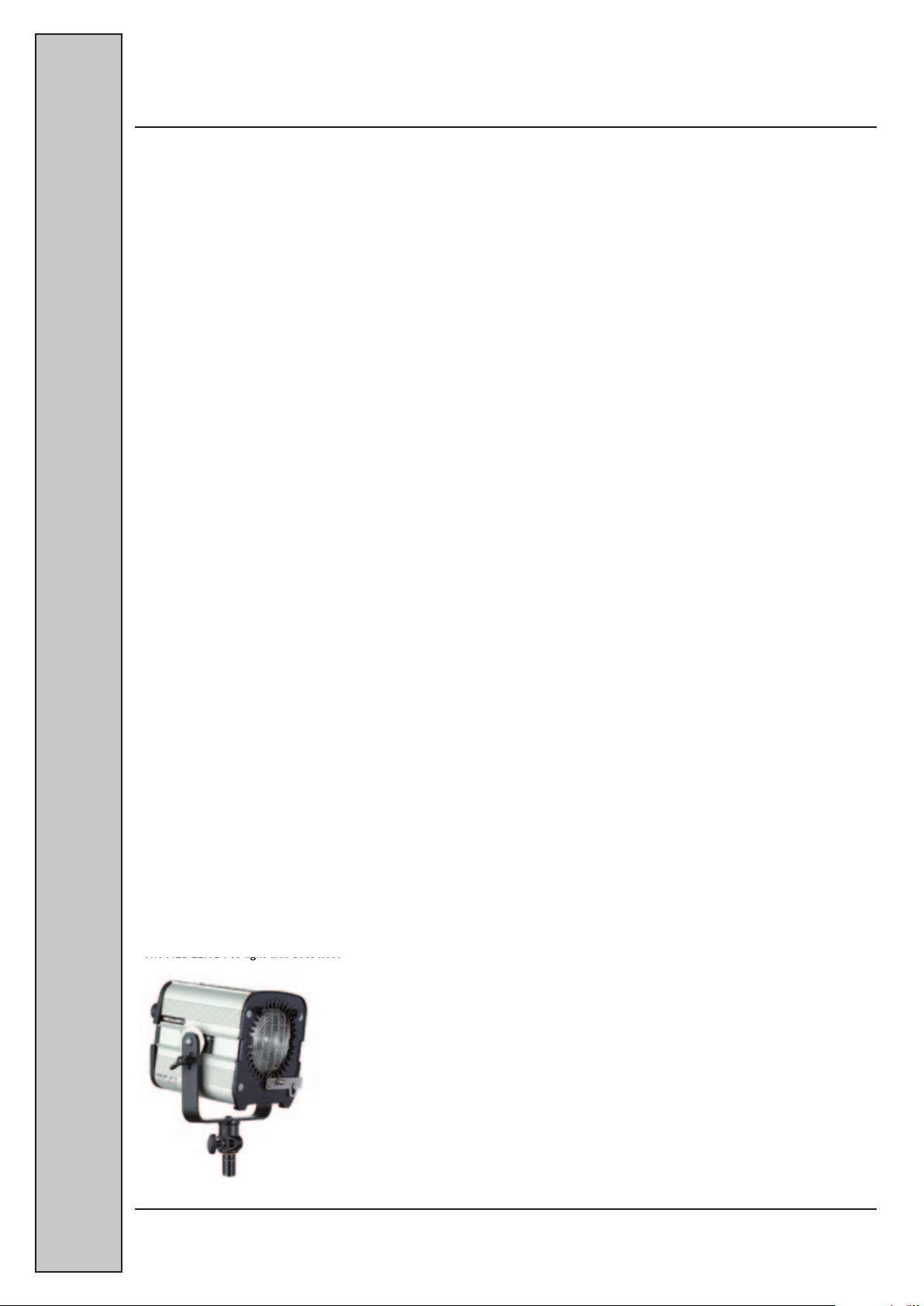

PLEASE NOTE - SPECIAL SET-UP ADVICE

The HEDLER DF15 has an up side and an underside, setting-up the light unit it is important to take care of the

correct position of these sides. The light unit is set-up correctly, if the QuickFit Adapter (located at the front

side of the housing) is located beneath the bulb respectively the safety glass (as shown on the photograph).

To ensure a continuous operation, the HEDLER DF15 has to be set-up / operated in the position described

respectively as shown on the photograph.

If you take the light unit in operation in an upside-down set-up, the internal automatic temperature safety

switch will (according to the ambient conditions) switch off the light unit after some operation time until it has

cooled down. This is not a failure or a maloperation of the HEDLER DF15, it is a protection shutoff for the

internal electronic ballast to prevent overheating.

HEDLER Systemlicht GmbH Heerstrasse 112 D-65594 Runkel / Lahn www.hedler.com

Daylight DF15

Telefon + 49 - (0) 6482 918 100 Telefax + 49 - (0) 6482 918 111 eMail info@hedler.com

Loading...

Loading...