Hedland EZ-View Operating Manual

Installation Instructions For

EZ-View® Flow Meter and

EZ-View

®

Flow-Alert™ Flow Meter

8635 Washington Avenue • Racine • Wisconsin 53406-3738 USA

FORM # HLIT 300

I. INTRODUCTION

The EZ-View series ow meter is a rugged, low-cost

direct reading industrial class ow meter that is simple to

install. It can be mounted (installed) in any position from

vertical to horizontal without costly ow straighteners

or other special plumbing. Constructed of high impact

polysulfone plastic, the EZ-View product line offers

excellent structural integrity and chemical compatibility

with a wide range of industrial chemicals.

EZ-View ow meters provide instantaneous, directreading ow rate measurement of liquids in closed

piping systems. The transparent polysulfone plastic

body allows visual inspection of the uid condition as

well as viewing of the internal ow indicator relative to a

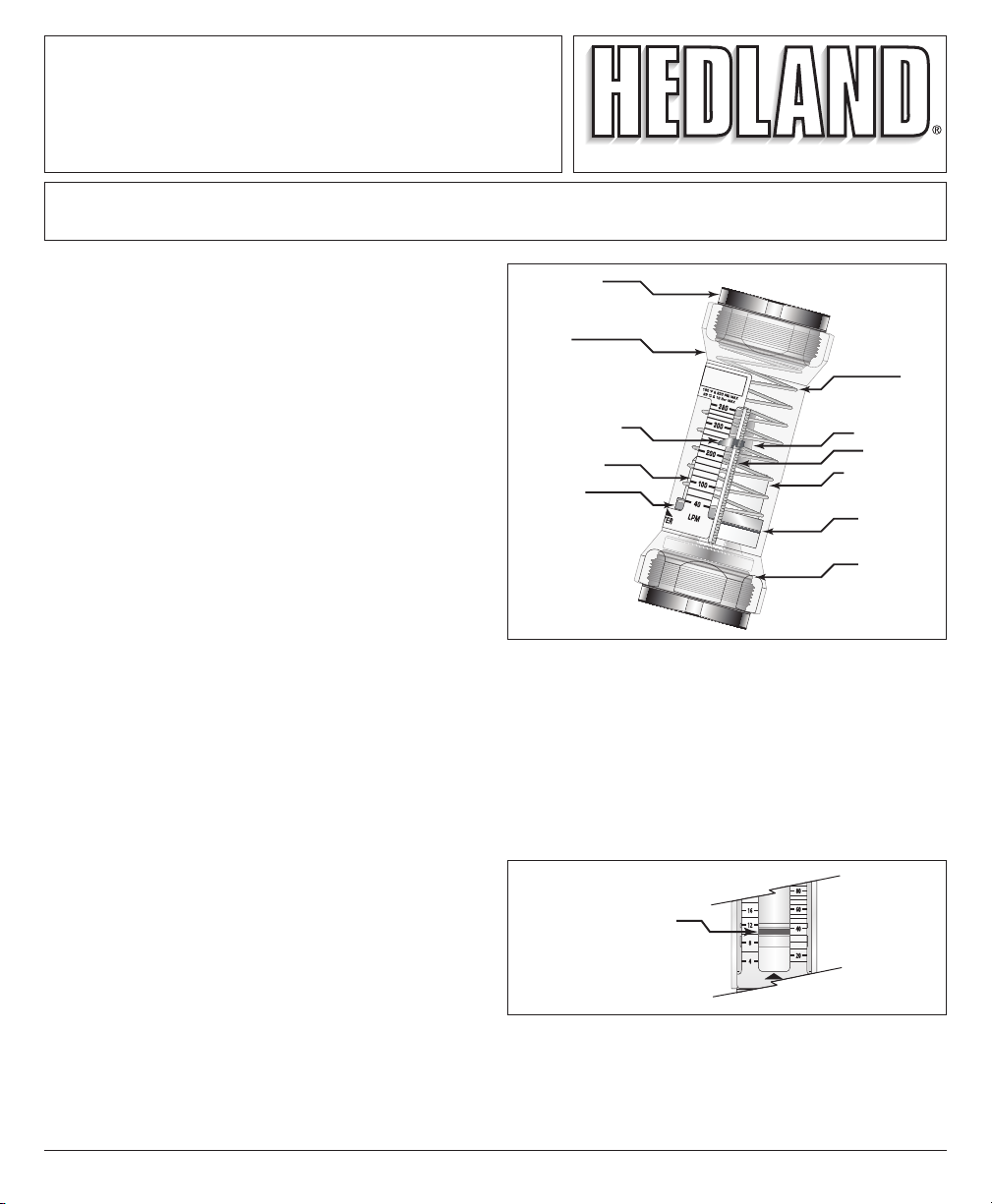

calibrated ow scale. See Figure 1.

EZ-View meters do not require electrical connections

for operation, and provide measurement by creating a

predictable differential pressure across a sharp-edged

orice that is located in the piston assembly.

II. OPERATING PRINCIPLE

The EZ-View series ow meter is a piston-type variable

area ow meter that uses a sharp-edged annular orice,

formed between an open-centered piston and a tapered

metering cone. The piston is held in a “no-ow” position

at the base of the cone by a precision retention spring.

As ow in the pipe increases, the differential pressure

correspondingly increases across the piston orice, and

moves the piston/ow indicator against the spring. The

greater the ow rate, the further the piston moves along

the tapered metering cone. The ow rate is measured

by viewing the red indicator ring, mounted on the

piston, relative to a graduated ow scale located on the

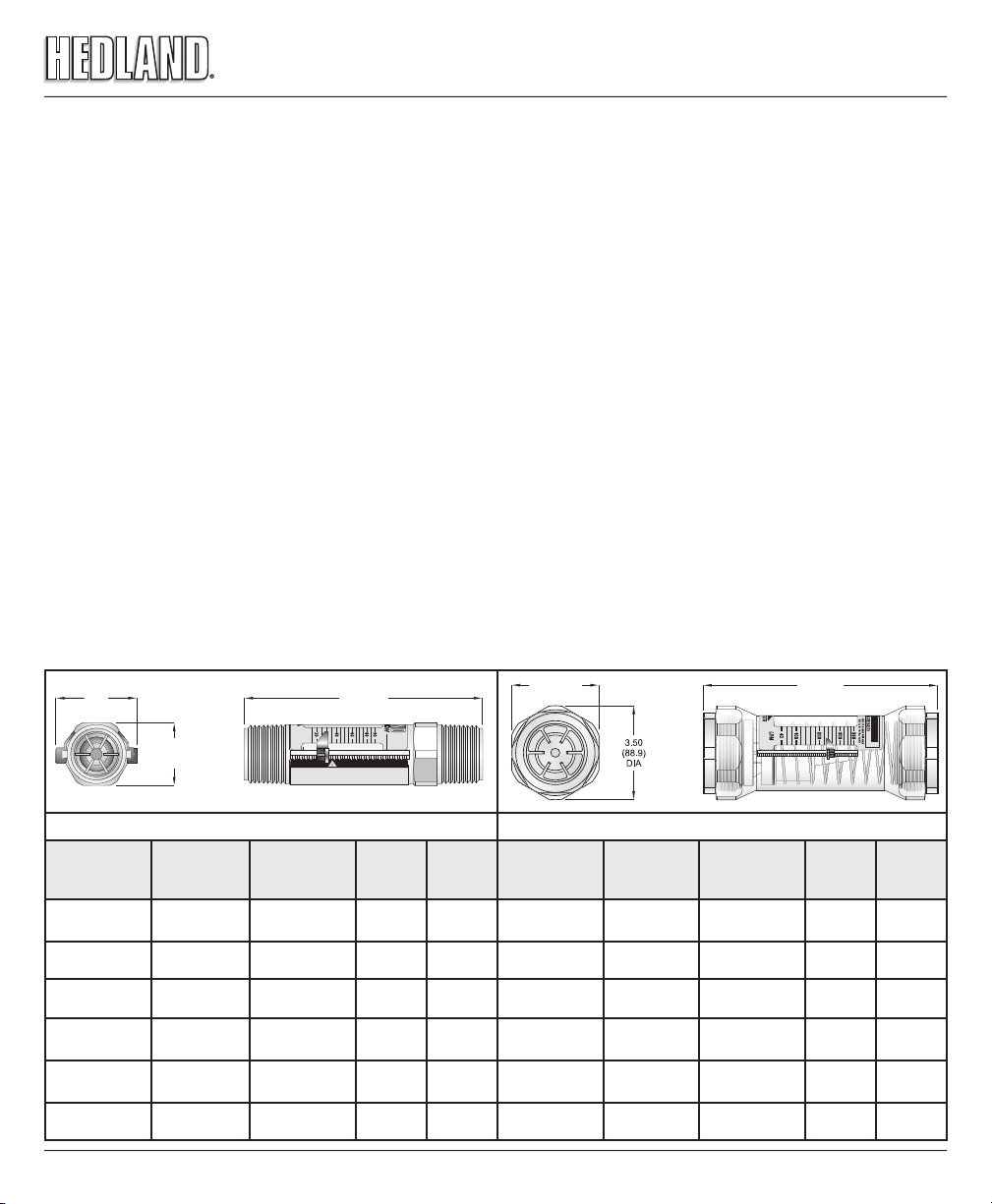

transparent ow meter body. See Figure 2.

DIVISION OF RACINE FEDERATED INC.

TEL 800-HEDLAND • FAX 800-CHK-FLOW

End Fitting

Body

Spring

Limit Indicator

Flow Scale

Magnet

(Switching Models Only)

Metering Cone

Serrated Rail

Piston Assembly

Flow Indicator

Pressure Seal

Figure 1. EZ-View Flow Meter

The unique design allows the EZ-View meter to be

mounted in any orientation–horizontal, vertical, upside

down, etc.–without sacricing measurement performance.

Flow straighteners, located in the inlet and outlet, allow

the ow meter to be less sensitive to turbulent ow

conditions. Liquid measurements are provided in GPM

(Gallons per Minute) and LPM (Liters per Minute).

80

60

GPM

16

12

40

8

20

4

LPM

Flow Rate

Indicator

Figure 2. Flow Rate Indicator

Page 1

EZ-View Flow Meter and EZ-View Flow-Alert Flow Meter

Installation & Maintenance Instructions

III. SPECIFICATIONS

Accuracy

• ±5% of full scale

Repeatability

• ±1%

Pressure Rating

• 325 PSI (22.4 bar) Maximum

• Meters with Type 1 PVC fitting subject to normal PVC

system ratings

Temperature Range

• +32 °F to +250 °F (0 °C to +121 °C)

• +32 °F to +140 °F (0 °C to + 60 °C) for meters with

Type 1 PVC fittings

Pressure Drop

See Pressure Drop Charts on page 14

Fittings/Threads

• NPT ANSI/ASME B1.20.1

• BSPT ISOR7

• BSPP ISO228

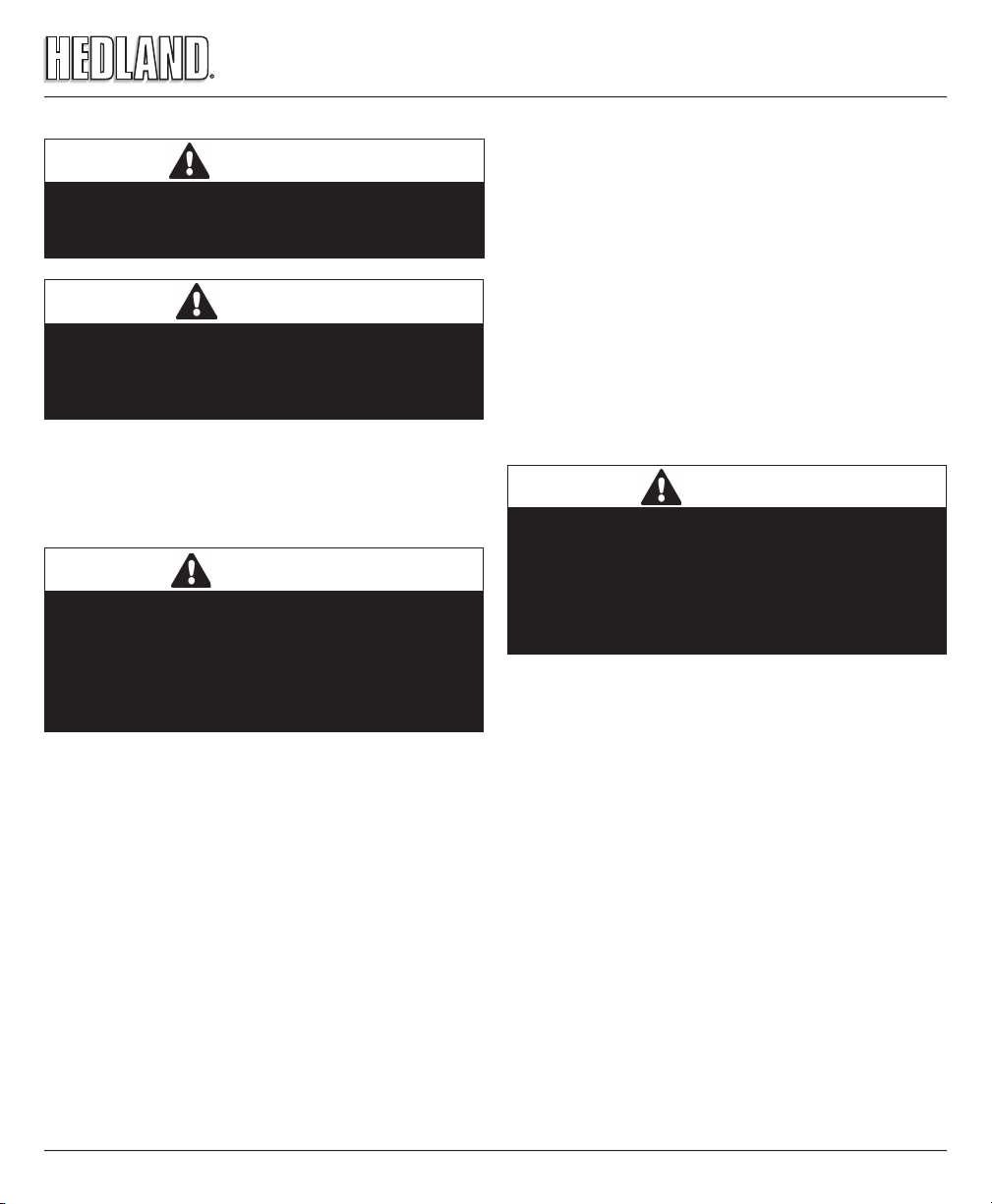

Dimensions

1.78

(45.2)

1.37

(34.8)

BODY FLATS

LENGTH

LPM

2040608090

CAUTION

!

1. Only use Teflon tape to seal threaded fittings.

DO NOT use pipe dope.

2. DO NOT sweat fit adaptor fittings into a system

while mounted to the EZ-VIEW meter.

W

®

Materials (wetted)

• Body

½", ¾" & 1" sizes Polysulfone or Radel

1-½" & 2" sizes Radel

• Piston Polysulfone

• Cone

½", ¾" & 1" sizes Polysulfone or Radel

1-½" & 2" sizes Polysulfone

• Spring T300 Stainless Steel

• Retaining Rings PH15-7MO Stainless Steel

• Seals Buna-N

• Indicator Ring Buna-N

• Magnet Strontium Ferrite

(switching units only)

• Fittings C360 Brass, PVC or T303 Stainless Steel

Materials (non-wetted)

• Limit Indicator Polypropylene

• Scale Polyester

Material Compatibility

• See Fluid Selection Chart on page 13

Calibration Fluid

• Oil 0.876 specific gravity, 32 cSt viscosity

• Water 1.0 specific gravity, 1.0 cSt viscosity

3.25 (82.5)

BODY FLATS

LENGTH

®

®

®

½", ¾" & 1" Sizes 1-½" & 2" Sizes

Size & Type Material Connection Length

in (mm)

½" NPTF &

BSPT

¾" NPTF &

BSPT

¾" &

1" Sweat

1" NPTF Polysulfone Male 5.25

1" Nominal PVC Socket Weld 8.46

1" NPTF PVC Male 8.86

Page 2

Brass & SS Female 7.75

Brass Male 8.25

Brass

Brass

Male

Sweat

(196.8)

(209.5)

7.75

(196.8)

(133.3)

(214.9)

(225.0)

Fitting

Flats

in (mm)

1.50

(38.1)

1.50

(38.1)

1.50

(38.1)

N/A 2" Socket

1.54

(39.1)

1.50

(38.1)

Size & Type Material Connection Length

1-½" NPTF &

BSPP

1-½" Socket

Weld

2" NPTF &

BSPP

Weld

Fitting

in (mm)

Brass Female 8.72

(221.5)

PVC Socket Weld 12.72

(323.1)

Brass Female 8.72

(221.5)

PVC Socket Weld 11.48

(291.6)

-- -- -- -- --

-- -- -- -- --

Flats

in (mm)

3.00

(76.2)

3.00

(76.2)

N/A

N/A

EZ-View Flow Meter and EZ-View Flow-Alert Flow Meter

Installation & Maintenance Instructions

IV. INSTALLATION

CAUTION

This unit should be installed and serviced by technically

qualied personnel trained in maintaining industrial

class ow instrumentation and processing equipment.

CAUTION

Read instructions thoroughly before installing the

unit. If you have any questions regarding product

installation or maintenance, call your local supplier for

more information.

Installation Recommendations

The ow meter is a simple device to install. However,

the following measures are recommended for reliable,

trouble-free operation:

CAUTION

Liquid pipe sealants, PVC/CPVC primers and PVC/

CPVC cements contain solvents that are not compatible

with polysulfone plastic. Allowing liquid pipe sealants

to contact the plastic ow meter will result in weakening

of the ow meter body and potentially cause fracturing

under pressure.

Don’t - Allow liquid pipe sealant, PVC/CPVC primer

or PVC/CPVC cements to come into contact with the

plastic ow meter. These contain solvents that are not

compatible with polysulfone plastic and will result in the

ow meter body weakening and potentially fracturing

under pressure. If a pipe sealant is required, use of

Teon® tape is recommended.

Don’t - Install the ow meter in piping systems that are

not aligned or properly supported.

Don’t - Connect the ow meter male plastic NPT ttings to

female metal NPT couplings. Differences in coefcients

of expansion between metals and plastics can cause

the plastic ow meter body to crack. Utilize a female-tofemale plastic pipe coupling to connect metal pipe to the

plastic ow meter.

Don’t - Use pipe wrenches on the ow meter body.

To avoid scarring or otherwise damaging the external

surface, use an open-end wrench on the integral hex

ats during installation.

Don’t - Subject the ow meter to back pressure or back

ow. The ow meter will operate as a “leaky” check valve

when subjected to reverse ow, but can be damaged if

the reverse hydraulic horsepower is too great.

Don’t - Install the ow meter on systems with large

degrees of particulate contamination. Minimum ltration

of 200 mesh (74 micron) is recommended for troublefree operation.

Don’t - Install O-ring seals that have not been lubricated.

Piping (Plumbing)

CAUTION

To avoid unnecessary pipe exing that could cause

structural stress on the ow meter body, independent

support located as near as possible to the inlet and

outlet of the meter should be used to isolate the meter

from the piping system. Failure to provide this support

could reduce the life of the meter.

Piping should be properly aligned with the meter inlet and

outlet to minimize structural stress on the plastic meter

body. Special attention should be given to this effort if

higher operational pressures and/or temperatures are

anticipated. Piping should be rmly supported by external

mounting brackets, both upstream and downstream from

the meter to avoid any pipe exing that could reduce the

life of the meter.

1. If the ow meter inlet or outlet are to be rigidly

mounted, and the opposing port is to be connected to

a exible hose, the end connected to the exible hose

MUST be rigidly mounted.

2. This unique design does not require special plumbing

or accessories to stabilize turbulent ow. Flow meters

can be installed immediately adjacent to 90° elbows

or other components, providing system design

exibility.

3. A 200 mesh (74 micron) or better ltration is required

to assure reliable performance.

Page 3

EZ-View Flow Meter and EZ-View Flow-Alert Flow Meter

Installation & Maintenance Instructions

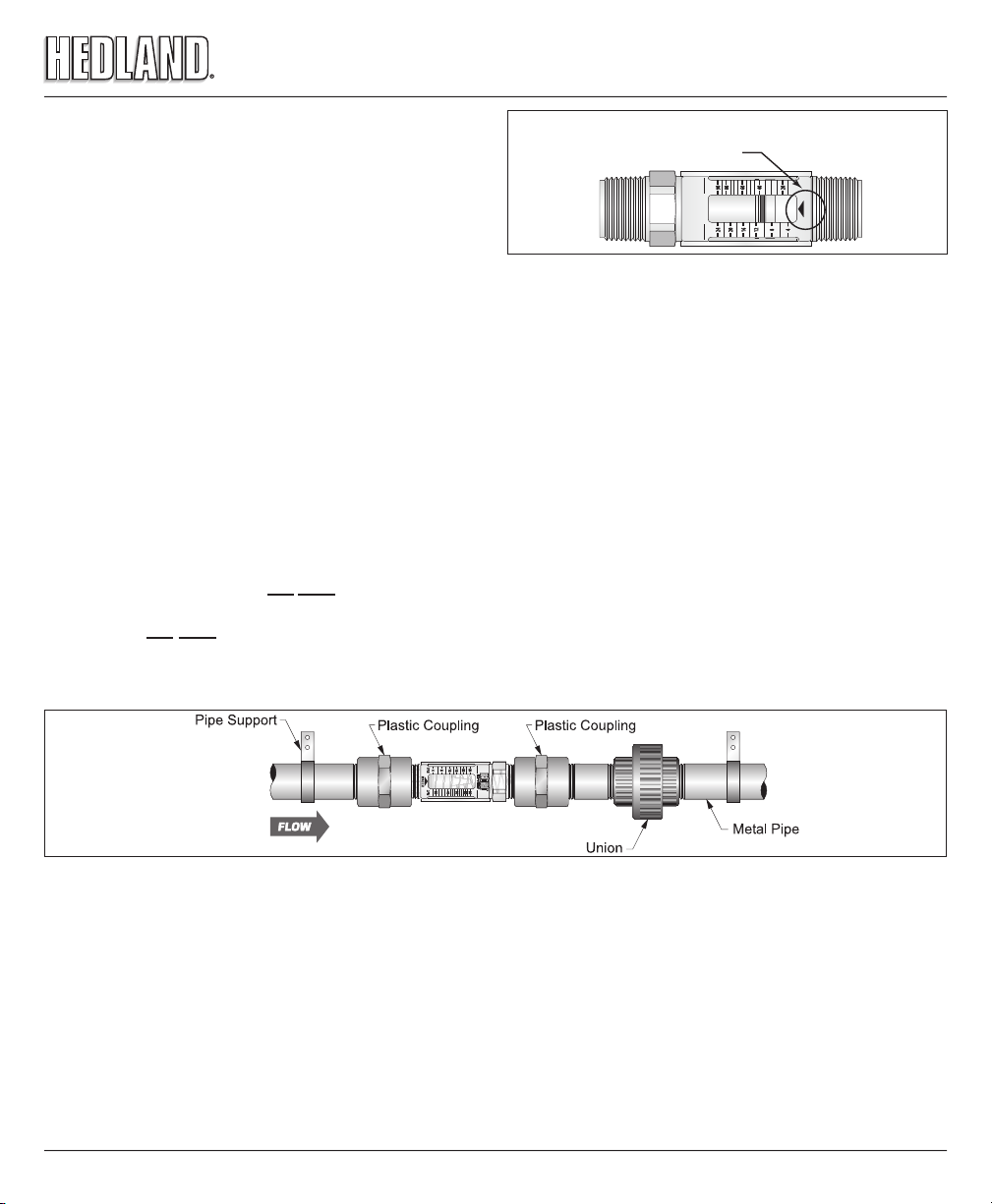

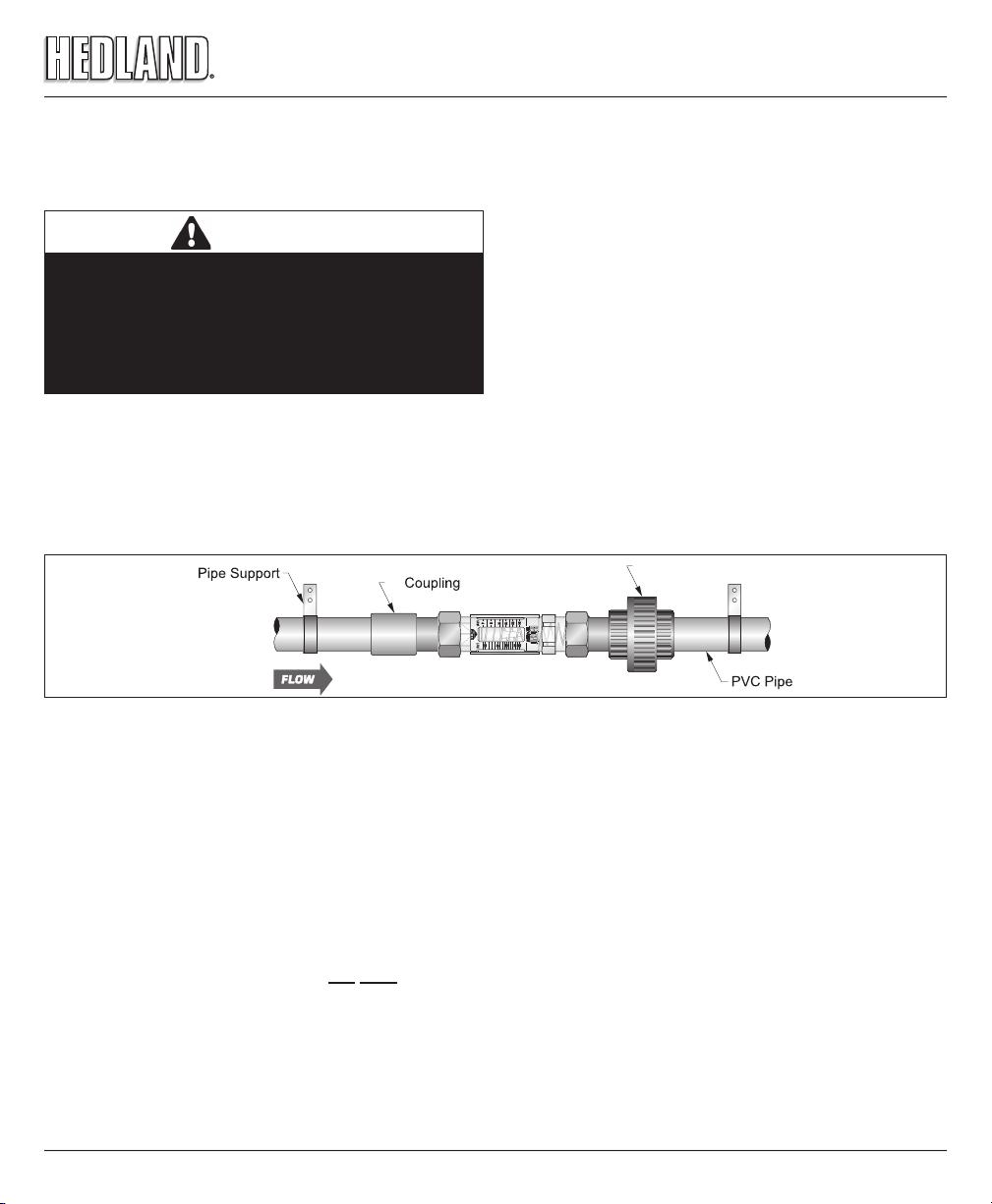

Flow Direction

These meters only accept ow in one direction. Make

sure to align the Flow Arrow, located on the bottom

of the meter’s ow scale, in the same direction as the

anticipated line ow. See Figure 3.

Mounting Orientation

The meter can be installed to operate in any position.

H621-XXX 1" NPT Models (See Figure 4)

1. Apply a single layer of Teon® tape to the male NPT

threads of the ow meter.

2. Thread the ow meter inlet into a 1" NPT plastic,

female pipe coupling.

3. Thread the ow meter and coupling onto the inlet

pipe and hand tighten. Make sure the ow direction

arrow on the ow meter corresponds with the system

ow direction. See Figure 3.

4. Place an open-end wrench on the ow meter body

hex and place a pipe wrench on the metal mating

pipe. Tighten until snug. DO NOT overtighten. Make

sure the ow meter scale is oriented for convenient

viewing. DO NOT back off/unscrew ttings to rotate

scale for better viewing.

Flow Direction

Indicator

9080604020

242016

LPM

WATER

8

4

12

GPM

Figure 3. Flow Direction Indicator

5. Thread a 1" NPT plastic pipe coupling to the outlet

connection of the ow meter. Stack a pipe nipple and

half of a pipe union onto the pipe coupling. Tighten

the assembly as required.

6. Install the other half of the pipe union to the outlet

pipe and connect the union halves together.

7. Piping should be supported and aligned properly to

avoid placing stress on the ow meter body.

8. Slide the limit indicators to point to appropriate positions

on the ow meter scale. To remove the limit indicators,

slide them fully towards the ow meter outlet.

Page 4

Figure 4. Model H621-XXX 1" NPT Models Installation

EZ-View Flow Meter and EZ-View Flow-Alert Flow Meter

1" Union

Installation & Maintenance Instructions

H628-XXX 1", H636-XXX 1-½" and H619-XXX 2" PVC with Socket Weld Models (See Figure 5)

1. Remove the two end ttings from the ow meter.

Lubricate the O-rings and install the ttings onto the

ow meter.

CAUTION

into their mating components and twisting 1/8 turn to

guarantee adhesion. Allow sufcient drying time.

4. Using the method outlined in steps 2 & 3, apply half of

the PVC union to the ow meter outlet tting.

5. Install the other half of the PVC pipe union to the outlet

Liquid pipe sealants, PVC/CPVC primers and PVC/

CPVC cements contain solvents that are not compatible

with polysulfone plastic. Allowing liquid pipe sealants

to contact the plastic ow meter will result in weakening

of the ow meter body and potentially cause fracturing

under pressure.

2. Prepare the ow meter PVC ttings and PVC pipe

couplings with PVC cleaner/solvent.

3. Apply a thin layer of PVC glue to the PVC ow meter

ttings. Orient the meter during curing to ensure that

excessive glue will not run into or onto the ow meter.

Connect all PVC glue joints by inserting the pipes fully

1"

pipe.

6. Make sure the ow direction arrow on the ow meter

corresponds with the system ow direction. See

Figure 3 on page 4. Lubricate the union O-ring and

connect the union together.

7. Piping should be supported and aligned properly to

avoid placing stress on the ow meter body.

8. Slide the limit indicators to point to appropriate

positions on the ow meter scale. To remove the limit

indicators, slide them fully towards the ow meter

outlet.

NOTE: To replace meter body order P.N. H622-XXX.

Figure 5. Model H628-XXX 1", H636-XXX 1-½" & H619-XXX 2" PVC Socket Weld Models Installation

H620-XXX Brass Sweat Fitting Models (See Figure 6 on page 6)

1. Remove both brass ttings from the ow meter inlet

and outlet. Remove O-rings from the ttings.

2. Apply solder ux to the ow meter brass ttings and

mating pipe surfaces.

3. Place the brass hex coupler onto the pipe with the

thread facing the ow meter. Slide the brass sweat

tting onto the prepared pipe.

4. Sweat the ttings onto the pipe. DO NOT apply heat

to the brass ow meter tting with the plastic ow

meter body or seals attached to the tting.

5. Repeat steps 3 & 4 for the other ow meter tting.

Allow ttings to cool.

6. Lubricate the two O-rings removed in step 1. Place

the O-rings onto the brass ttings.

7. Place the ow meter in between the two installed

brass ttings. Make sure the ow direction arrow

on the ow meter corresponds with the system ow

direction. See Figure 3 on page 4. Thread the two

brass hex couplers into the ow meter body.

8. Rotate the ow meter body so the scale can be

conveniently viewed. Tighten the hex couplers.

Typically, only hand tightening is required.

9. Piping should be supported and aligned properly to

avoid placing stress on the ow meter body.

10. Slide the limit indicators to point to appropriate

positions on the ow meter scale. To remove the limit

indicators, slide them fully towards the ow meter

outlet.

NOTE: To replace meter body order P.N. H622-XXX.

Page 5

Loading...

Loading...