Heckler&Koch USP TACTICAL User Manual

USP SERIES

OPERATOR’S MANUAL

Covering USP, USP Compact, and

USP Specialized Models

SAFETY PRECAUTIONS

CAUTION: Read these safety rules before handling the pistol!

Read this operators manual before handling your firearm. The following safety rules are placed in this

manual by HK as an important reminder that firearms safety is your responsibility. If handled improperly

firearms can be dangerous and can potentially cause damage to property, serious injury, or death.

1. Never point a firearm at anyone, or in any direction other than a SAFE direction, i.e. downrange.

2. Treat all firearms as if they are always loaded.

3. Keep your finger off the trigger and outside of the trigger guard until your sights are aligned on the

target.

4. Keep your finger off the trigger and outside of the trigger guard while loading or unloading the

firearm.

5. Keep your finger off the trigger and outside of the trigger guard while pulling the firearm out of the

holster or while returning it to the holster.

6. Be sure of your target and the back stop beyond.

7. Never give a firearm to or take a firearm from anyone unless the action is open and the magazine

and/or chamber are free of any ammunition or brass.

8. Be sure that the ammunition you are using is factory loaded, is of the correct caliber for the firearm

in which it is to be used, and that it is not damaged in any way.

9. Before firing, remove the magazine from the firearm, lock the slide open, make sure the chamber

is clear of any ammunition or brass, and check the barrel of the unloaded firearm for any possible

obstructions.

10. Before firing any firearm that is unfamiliar to you, make sure that you understand exactly how it

functions. A lack of familiarity with the firearm can result in serious accidents. Attend a certified

training course on any firearm which you intend to use or with which you are not sufficiently familiar.

11. Always wear hearing and eye protection when using your firearm.

12. Keep all body parts, particularly the hands and fingers, away from the muzzle to avoid injury or burns.

13. Be sure that parts of the hand do not touch or interfere with the slide. The slide moves backwards by

recoil force during firing and may cause serious injury.

14. Firearms should be stored separately from ammunition and beyond the reach of children, and/or any

untrained individuals.

15. Avoid the use of any alcoholic beverages or drugs before and during the use of any firearm.

16. Discharging firearms in poorly ventilated areas, cleaning firearms, or handling ammunition may result

in exposure to lead, a substance known to be associated with birth defects, reproductive harm, and

other serious injury. Have adequate ventilation at all times. Wash hands thoroughly after exposure.

17. To make the pistol safe, one must insure the chambered round is removed during the clearing

procedure. Removal of the pistol’s magazine does not remove the chambered round. This can only

be done with the rearward movement of the slide after the magazine is removed.

STOP! KNOW HOW TO CLEAR THIS PISTOL BEFORE ATTEMPTING TO OPERATE.

CLEARING THE PISTOL

The pistol is not considered “clear” or safe unless:

1. The control lever (if applicable) is on “safe” and;

2. The magazine is removed from the pistol and;

3. The slide is locked to the rear and;

4. The chamber is free of brass or ammunition

To Clear the pistol:

1. Make sure fingers are outside of the trigger guard and the pistol is pointed in a safe direction at all

times!

2. Engage control lever (if applicable) - press the control lever upwards until the “S” (safe) aligns with

the reference line located on the frame.

3. Remove magazine - depress the magazine release lever and remove the magazine from the pistol.

4. Open and lock slide - while keeping the pistol pointed in a safe direction, lock the slide open by

pulling the slide rearward as you press the slide release upward. Watch for a cartridge or empty case

to be ejected from the pistol.

5. Inspect chamber - inspect chamber for the presence of a cartridge or empty case by:

• Visually viewing chamber through the open ejection port and;

• Physically inserting a finger into the chamber through the ejection port to check for the presence of

a cartridge or empty case.

• Remove any cartridges or empty cases from the chamber or from within the pistol.

The Pistol is now considered “Clear.”

USP SERIES

OPERATOR’S MANUAL

Covering USP, USP Compact,

and USP Specialized models

WARNING: A firearm has the capability of taking your life or the life of someone else!

Be extremely careful with your firearm. An accident can occur at anytime and is almost

always the result of not following basic safety rules.

© Heckler & Koch, 11/99, 1/07, 6/09, 8/10, revised May 2013

All rights reserved

Heckler & Koch

5675 Transport Boulevard

Columbus, Georgia 31907

Tel: (706) 568-1906 • Fax: (706) 568-9151

Global Website: www.heckler-koch.com • American Website: www.hk-usa.com

Specifications and models subject to change without notice.

4

5

TABLE OF CONTENTS

Safety Precautions & Clearing .................................. Inside Cover

Section 1 Introduction ..................................................................................6

Section 2 Nomenclature ..............................................................................8

Section 3 Function and Op er a tion ..............................................................9

Clearing the Pistol ........................................................................9

Operating Con trols and Com po nents ......................................10

Sights and Sight Adjustment .....................................................12

Section 4 Ammunition ................................................................................13

Section 5 Instructions for Use ....................................................................15

Filling and Emp ty ing the Magazine ..........................................15

Loading the Pistol .......................................................................15

Firing the Pistol ..........................................................................16

Unloading the Pistol ..................................................................18

Selection and Use of a Holster ..................................................19

Storage and Trans port ..............................................................19

Section 6 Disassembly and Assembly ........................................................20

Disassembling (Fieldstripping) the Pistol ...................................20

Pistol Assembly ..........................................................................21

Magazine Disassembly ...............................................................23

Magazine Assembly ....................................................................25

Clearing the Pistol ......................................................................26

Function Check (Variant 1 & 2) .................................................26

Function Check (Variant 3 & 4) .................................................27

Function Check (Variant 5 & 6) .................................................27

Function Check (Variant 7) ........................................................28

Function Check (LEM) ...............................................................28

Section 7 Cleaning and Main te nance ........................................................29

Inspection ..................................................................................30

Lubrication .................................................................................30

Troubleshooting Prob lems and Re pair ......................................31

Hammer and Catch Notification ...............................................32

Section 8 HK Lock-Out Device ..................................................................32

Section 9 Exploded Views and Parts Lists .................................................33

USP (.40 S&W and 9 mm) Exploded View ................................34

USP (.40 S&W and 9 mm) Parts List ...........................................35

USP (.45 ACP) Exploded View ...................................................36

USP (.45 ACP) Parts List ............................................................37

USP Compact (.40 S&W and 9 mm) Exploded View .................38

USP Compact (.40 S&W and 9 mm) Parts List ...........................39

USP Compact (.45 ACP) Exploded View ...................................40

USP Compact (.45 ACP) Parts List .............................................41

USP Compact (LEM) Exploded View .........................................42

USP Compact (LEM) Parts List ...................................................43

Section 10 USP Specialized Pistols...............................................................44

Section 11 Specifications ..............................................................................48

Firearms Service Record .............................................................50

6

7

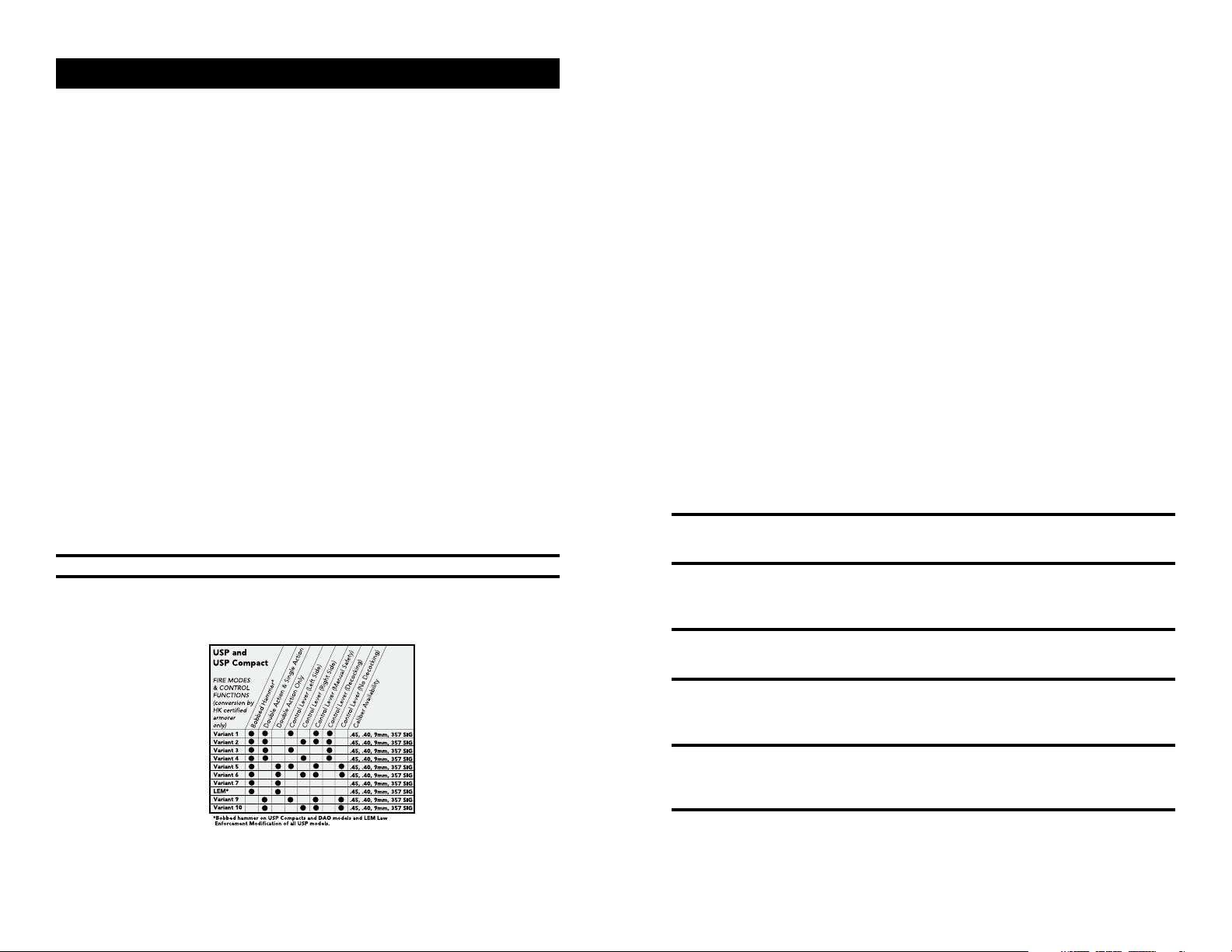

SECTION 1 INTRODUCTION

The HK USP (Universal Self-loading Pistol) is the first HK pistol designed especially for

American shooters. Features favored by the U.S. military, law enforcement agencies, and

civilian users provided the design criteria for the USP. Its controls are uniquely American,

influenced by such famous designs as the Government Model 1911 pistol.

In addition to a wide selection of trigger/firing modes, all USP Pistols have an

ambidextrous magazine release lever which is shielded from in ad vert ent actuation by the

flared trigger guard. The mag a zine release lever can be pressed with the thumb or index

fin ger of the firing hand, in most cases without adjusting the firing grip.

Low profile 3-dot sights, adjustable for windage and elevation, are standard on USP Series

Pistols. Optional tritium sights are also available.

The USP control lever, featured on many variants of the USP, USP Compact, and USP

Specialized models, is a combination safety and/or decocking lever. The control lever

is frame mounted and quickly accessible, unlike the slide mounted safeties common on

many semi-automatic pistols. The USP control lever has a pos i tive stop and returns to the

“fire” position after decocking. A key advantage of the USP control lever is that it allows

many USP models to be safely carried “cocked and locked”.

Using a modified Browning-type action, both full-size and compact models of the USP use

patented recoil reduction systems, enabling all USP series pistols to take the punishment

of powerful +P and +P+ loads. The USP and USP Compact recoil reduction systems

lessen recoil effects on pistol components and also lower the recoil forces felt by the

shooter. These recoil reduction systems are insensitive to ammunition types and require

no special adjustment or maintenance. It functions effectively in all USP models.

By using a modular approach to the internal components, the control lever function of

the USP Series pistols can be switched from the left to the right side of the pistol for lefthanded shooters. The USP and USP Compact can also be converted from one type of

trigger firing mode to another. This includes combination double-action and single-action

(DA/SA) modes, single-action only (SA-Only), and double action only (DA-Only) modes,

including the HK proprietary LEM (Law Enforcement Modification) enhanced trigger

system. Optional “dual” ambidextrous control levers are also available and are standard

on some USP specialized models.

The USP is available in both full-size frame and compact models, as well as specialized

models, with ten trigger/firing mode configurations and four calibers—.45 ACP, .40 S&W,

9 mm, and .357 SIG (special order on some models).

NOTE: Trigger/firing mode con ver sion can only be made by an HK certified armorer.

Due to the USP’s innovative design approach, it is possible to convert a USP Series Pistol

into one of many variants. Changing the trigger/firing mode of the pistol is ac complished

by installing a different set of components.

The polymer frame of the USP Series was designed using tech ni cal ex pe ri ence gained by

HK en gi neers in the de vel op ment of the world’s first com pos ite material pistols, the HK

VP70Z and P9S. These same high-strength/cor ro sion free materials are used in the MK 23

handgun made by HK for the U.S. Special Op er a tions Command.

Major metal components like the one-piece, machined steel slide are also cor ro sion resistant,

treated with a special “HE” (Hostile Environment) protective finish. The HE finish is an

extremely hard, nitro-gas car bur ized black oxide coating, and resists even the worst types

of corrosion and wear, including exposure to salt water.

The full size USP 9 mm and USP .40 S&W models utilize high-strength, light-weight,

polymer magazines while the USP Compact (all calibers) as well as the full-size USP .45

use metal magazines that allow increased ammunition capacity without having to increase

the dimensions of the grip. All HK magazines have a se ries of view ing holes on the back

side for count ing the car tridg es re main ing inside. Interchangeable floorplates are avail able

for the magazines of the many USP Series Pistols. A stan dard flat floorplate and an ex tended mag a zine floorplate with a fin ger ex ten sion provide a choice of grip options with each

pistol. Mag a zine floorplates can be eas i ly removed and changed without tools dur ing disassembly.

The extended slide release is positioned to allow easy actuation without adjustment of

the grip of the shoot ing hand. Another useful feature is the absence of a mag a zine lockout device.

CAUTION: USP models, except special models with a magazine disconnect feature

installed, will fire if the magazine is re moved, a cartridge is in the chamber, and the

trigger is pressed (with the control lever in the FIRE position if applicable).

To reduce barrel wear, most USP Pistols have polygonal cold hammer-forged barrels. This

feature not only ensures longer barrel life and easier bore cleaning, but produces a better

gas seal behind the bullet for increased muzzle velocity.

NOTE: Beginning in 1999, all USP pistols, with the exception of some special order

production runs are fitted with HK’s patented internal Lock-Out Device. The use of

this internal safety lock is described in Section 8 of this manual.

This unique design al lows the USP Series Pistol to be con fig ured for a va ri ety of purposes

depending on the re quire ments of the user, with out having to purchase a new pistol.

Please contact HK for more information on variant changes.

A set of mount ing grooves for installing accessories is molded in the poly mer frame of

all USP models. These grooves al low a variety of accessories and tar get ing devices to be

mount ed on the USP Pistols with out mod i fi ca tion to the pistol.

NOTE: Improperly designed or installed accessories may result in damage to the

mounting grooves and/or the pistol. Such damage is not cov ered un der the lim it ed

lifetime warranty. Be cer tain to use only HK Au tho rized Ac ces so ries and follow in stalla tion and pre cau tions carefully.

USP Series Pistols are ex treme ly safe fire arms, with no less than four safety fea tures, some

pas sive and some ac tive in nature. Simple to field strip and main tain, a USP series pistol is

a re li able and trou ble-free handgun, providing a

wide range of flex i bil i ty for all users.

8

9

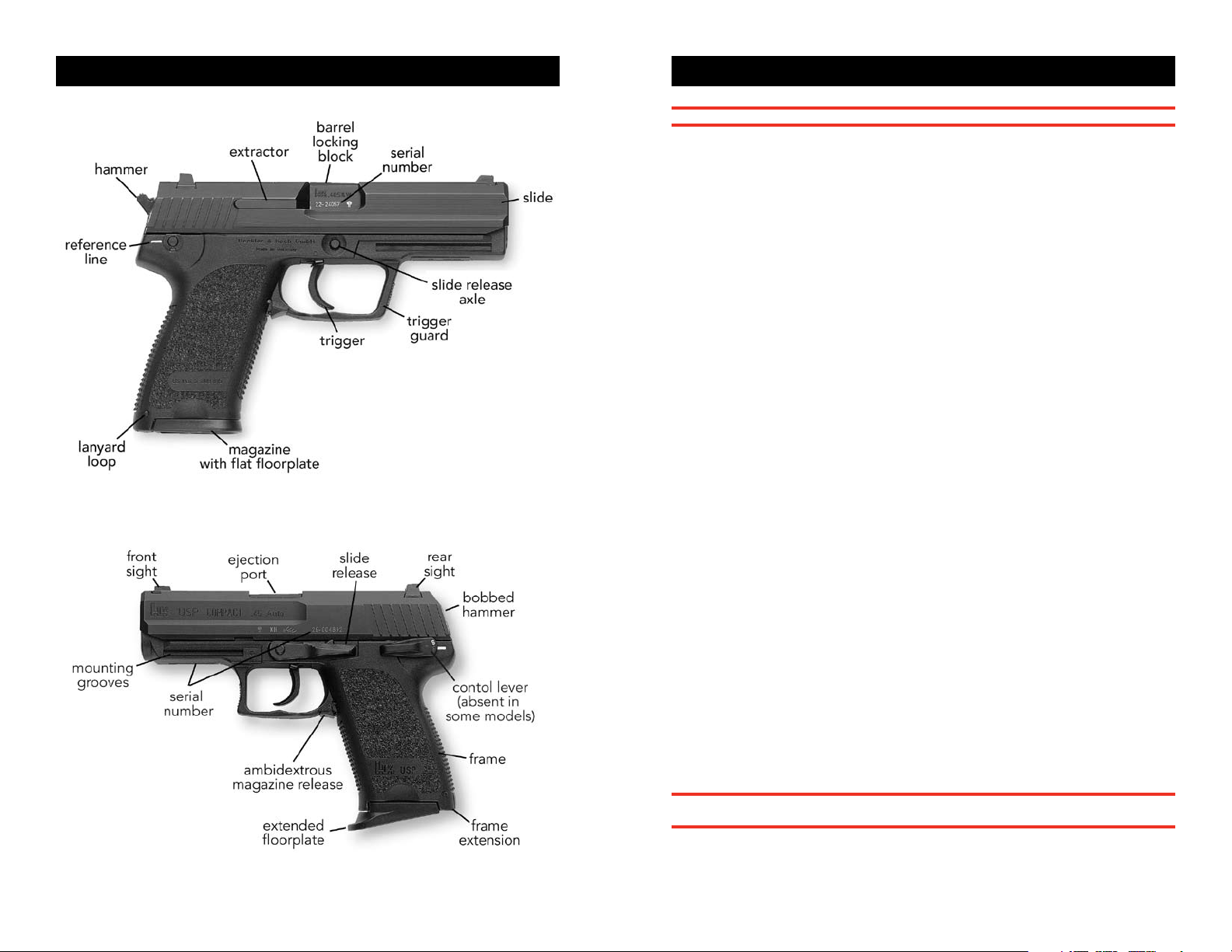

SECTION 2 NO MEN CLA TURE

Fig. 1

USP right side view

SECTION 3 FUNCTION AND OP ER A TION

WARNING: Always clear the pistol before han dling it.

CLEARING THE PISTOL

The pistol is not considered “clear” or safe unless:

1. The control lever (if applicable) is on “safe” and;

2. The magazine is removed from the pistol and;

3. The slide is locked to the rear and;

4. The chamber is free of brass or ammunition

To Clear the pistol:

1. Make sure fingers are outside of the trigger guard and the pistol is pointed in a safe

direction at all times!

2. Engage control lever (if applicable) - press the control lever upwards until the “S” (safe)

aligns with the reference line located on the frame.

3. Remove magazine - depress the magazine release lever and remove the magazine from

the pistol.

4. Open and lock slide - while keeping the pistol pointed in a safe direction, lock the slide

open by pulling the slide rearward as you press the slide release upward. Watch for a

cartridge or empty case to be ejected from the pistol.

5. Inspect chamber - inspect chamber for the presence of a cartridge or empty case by:

• Visually viewing chamber through the open ejection port and;

• Physically inserting a finger into the chamber through the ejection port to check

for the presence of a cartridge or empty case.

• Remove any cartridges or empty cases from the chamber or from within the pistol.

The Pistol is now considered “Clear.”

General

The USP Series Pistols are short recoil operated. They use a modified Browning style

system, without a link, to lock and unlock the barrel.

Fig. 2

USP Compact

left side view

Upon firing, the pressure de vel oped by the propellant gases forc es the slide and barrel

as sem bly to the rear. After moving approximately 3 mm, the locking block will stop the

rearward move ment of the barrel. The bar rel is pulled downward due to the engagement

of the angled lock ing surfaces of the locking block with those located on the end of

the recoil spring guide rod. The locking block disengages from the slide and the slide

continues rear ward in de pen dent ly from the barrel. The extractor, located on the right side

of the slide extracts the spent case. The ejector, positioned in the left side of the frame,

rearward of the magazine well then ejects the fired cartridge case. The rearward moving

slide then cocks the hammer, and com press es the recoil spring.

Once fully to the rear, the compressed recoil spring push es the slide forward, stripping

the next cartridge from the mag a zine into the chamber. If the magazine is empty, the

mag a zine follower lifts the slide release into position where it can stop the forward

progress of the slide and holds the slide open.

WARNING: Do not rely on the slide position to de ter mine if the magazine is empty.

Always check visually and phys i cal ly ensure the pistol is not loaded.

During the last few millimeter of forward movement, the slide forces the angled surfaces

of the barrel locking block against opposing angled surfaces on the recoil spring guide

rod. This action pivots the locking block on the barrel up into engagement with the

ejection port on the slide. The breech is now locked closed and the next shot can be fired.

10

11

CAUTION: A pair of Universal Mounting Grooves located on the front of the USP’s

frame allows for a variety of ac ces so ries to be used with the pistol. Improperly

de signed or in stalled ac ces so ries may re sult in dam age to the mounting grooves and/

or the pistol. Such dam age is not cov ered under warranty. Be certain to use only HK

authorized accessories and follow in stal la tion and pre cau tions care ful ly.

OPERATING CONTROLS & COMPONENTS

WARNING: USP series pistols incorporates single-action and/or double-action

modes of operation. Anytime the trigger is pulled with the control lever in the fire

(horizontal) position and a cartridge in the chamber, the pistol will fire from either the

hammer down or cocked positions.

Trigger (in Double/Single-Action modes)

In the double-action mode, pulling the trigger will cock the hammer and immediately

release it firing the first chambered cartridge. All subsequent cartridges will be fired in the

single-action mode because the slide automatically recocks the hammer after each shot is

fired. To fire the first chambered cartridge in the single-action mode, the hammer must be

manually cocked before pulling the trigger. All shots after the first shot will be fired singleaction because the slide automatically recocks the hammer after each shot is fired.

In the double-action only mode, the hammer always returns to the uncocked (forward)

position after each shot. All shots are fired in the double-action mode. The HK LEM (Law

Enforcement Modification) mode functions similar to double-action only mode.

In the double-action only mode, the hammer always re turns to the uncocked (forward)

position after each shot. All shots are fired in the double-action mode.

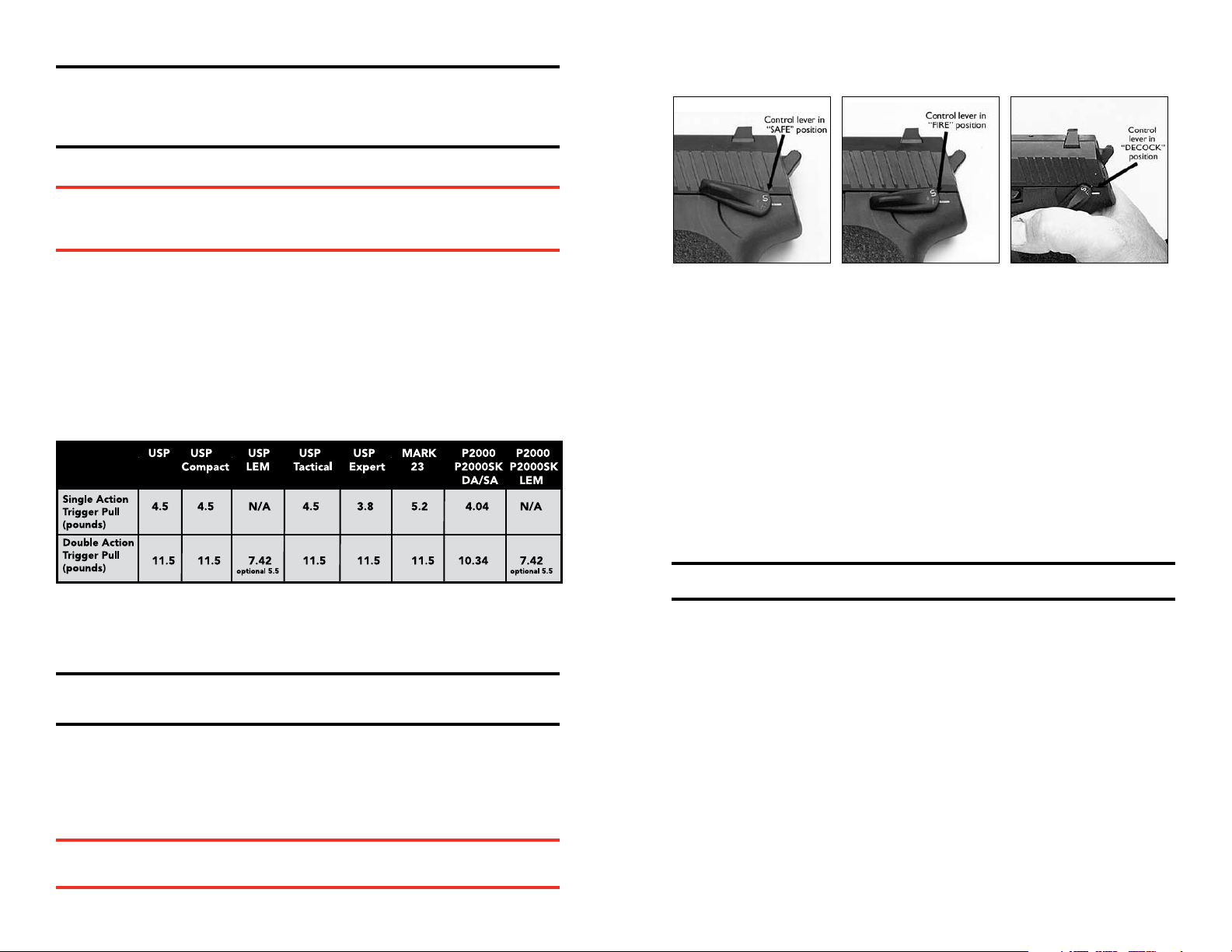

Fig. 3 Fig. 4 Fig. 5

Control Lever “SAFE” Control Lever “FIRE” Control Lever “DECOCK”

Magazine

Depending on the model, USP series magazines are constructed of high-strength, lightweight polymer or metal. Polymer magazines have a metal insert located in the upper

third of the housing for increased strength and durability. Cartridges are positioned

within the magazine in a staggered arrangement but are fed into the pistol from a

single row under the feed lips. The cartridges are visible through the numbered viewing

holes located in the back of the magazine. For main te nance and clean ing, USP Series

mag a zines can be easily dis as sem bled. Interchangeable floorplates are avail able for the

magazines of the many USP Series Pistols. A stan dard flat floorplate and an ex tend ed maga zine floorplate with a fin ger ex ten sion provide a choice of grip options with each pistol.

Mag a zine floorplates can be eas i ly removed and changed without tools dur ing dis assembly.

Extractor

The extractor on the some USP models acts as a loaded chamber in di ca tor. When a

cartridge is in the chamber, the red colored forward edge of the extractor protrudes approx i mate ly 1 mm from the slide and is visible to the operator.

Control Lever

This manually operated lever is located on the side of the frame below the rear sight.

This lever is operated with the firing thumb and can perform both functions of a safety

lever and a decocking lever, depending on the parts installed.

NOTE: Some variants do not have a control lever. On some USPs, including some of

the specialized USP models (USP Elite USP Expert), a control lever is present on both

sides of the frame.

Control lever as a safety lever

On HK USPs with the “SAFE” position (Variants 1, 2, 5, 6, 9, & 10), the front of this lever

is fully raised above horizontal so that the “S” on the lever itself aligns with the reference

line on the frame (see Figure 3 ). With this control lever engaged, the release of the

hammer is blocked in the single-action mode of fire. In the double-action mode, the

hammer will partially cock but will not release to fire the pistol.

WARNING: The USP Series Pistol fitted with LEM parts incorporates dou ble-ac tion

only mode of operation. Any time the trig ger is pulled with a car tridge in the cham ber,

the pistol will fire from the ham mer down position.

CAUTION: Do not depend on the presence of a loaded chamber indicator to determine

if a pistol is loaded. Treat all weapons as if they are always loaded!

Slide Release

This lever is located on the left side of the frame directly above the trigger. This lever is

used to lock the slide open, to release the slide, and to disassemble the pistol.

As a slide stop, it is lifted upward by the magazine follower or the operators finger as the

slide travels rear ward during recoil or manual manipulation. The slide re lease engages

in the recess located on the left side of the slide at its midpoint. The slide release is

spring ac tu at ed and is held down out of engagement with the slide until required. The

slide release will au to mat i cal ly hold the slide open when the last shot is fired. As a

disassembly lever, the slide release is removed from the left side of the frame when the

slide is held partially rearward.

Magazine Release Lever

This ambidextrous, spring actuated le ver holds the magazine in place within the grip by

engaging in the notch found on the front of the mag a zine housing. Depressing this lever

downward with the firing index finger or thumb will allow the magazine, re gard less of

the number of car tridg es inside, to drop free of the frame. The mag a zine release lever is

shielded from accidental ac tu a tion by the design of the polymer frame and flared trigger

guard sur round ing it.

12

13

Frame

All sides of the poly mer frame are tex tured to ensure a firm grip, even with wet hands

or under con di tions of rapid fire. The trig ger guard is slightly recurved and grooved to

provide a firm grip when using two hands or gloves to fire the pis tol. The frame is a onepiece molded component with metal in serts (lock ing insert and guid ing part) cast into

the frame during production.

The slide rides on these metal inserts during op er a tion. The frame contains mounting

grooves for accessory attachment and finger recesses located to the left and right of the

magazine well for manual extraction of the mag a zine, if nec es sary. The serial num ber of

the pistol is en graved in the metal insert in cor po rat ed into the front of the frame in front

of the trigger guard, on the left side of the slide, and on the barrel locking block.

SIGHTS AND SIGHT ADJUSTMENT

The USP Series Pistol uses the prov en 3-dot sighting ar range ment. By align ing all three

dots hor i zon tal ly on the tar get, with the front sight dot cen tered be tween the rear sight

dots, the op er a tor can quick ly and easily en gage the target with a high de gree of

ac cu racy. With the op tion al tritium sights with white outline in stalled, pre cise and rapid

target en gage ments are pos si ble under low light con di tions as well.

Fig. 6 Fig. 7 Fig. 8

Sights aligned Rear sight adjustment Front sight installation

Sights are set at the factory and generally do not require adjustment. The rear sight

can be adjusted for wind age by drifting the sight to the left or right, de pend ing on the

de sired shot placement. Bullet im pact on tar get will move in the same di rec tion that the

rear sight is moved. Be careful not to dam age the slide finish when ad just ing the sights.

Adjustments for elevation are ac com plished by ex chang ing the front sight with a higher

or lower sight. The height of the front sight is in di cat ed on the underside. The front

sight must be re moved by using a drift punch or a USP sight push er. The accessory sight

pusher can be used to install, remove, and adjust the front and rear sights on all USP

Series Pistols.

SECTION 4 AMMUNITION

WARNING: HK specifically disclaims any re spon si bil i ties for any damage or injury that

should occur because of, or as a result of, the use of faulty, remanufactured, or reloaded

(hand load ed) ammunition, or of cartridges oth er than those for which the pistol was orig inal ly cham bered.

The USP Series Pistol is designed to fire quality, factory loaded am mu ni tion load ed to

SAAMI spec i fi ca tions for use spe cif i cal ly in handguns. For use with am mu ni tion with hard

primers (i.e. some NATO spec. cartridges), a spe cial hammer spring is avail able.

The following guidelines should be considered when se lect ing the cor rect am mu ni tion for

your pis tol.

1. Be sure the am mu ni tion you have chosen is com pat i ble with your pistol – proper

caliber, cartridge, bul let weight, etc. Caliber markings on the USP Pistol appear on

the left side of the slide and on the bar rel locking block, visible through the ejection

port on the right side of the slide.

2. Prior to loading the mag a zine and cham ber, carefully in spect all car tridg es for the

following ab nor mal i ties:

• Cracked, split, dirty or cor rod ed cases

• Improperly seat ed pro jec tiles and/or primers

• Damaged pro jec tiles

3. Do not attempt to fire a cartridge in which the pro jec tile has been forced back into

the case. Upon firing, this con di tion may result in increased chamber pres sure above

safe lim its.

4. Do not fire am mu ni tion through the pis tol that:

• Is for eign and/or out dat ed mil i tary sur plus

• Is as sem bled with cor ro sive prim er and/or propellant

• Is ex posed to oil, grease, wa ter, or direct sun light. Re move contaminants if pos si ble

be fore use and cool down am mu ni tion ex posed to di rect sun light or heat. (Ex po-

sure to sourc es of heat could raise the cham ber pres sure of the car tridge above safe

limits.)

• Is loaded spe cif i cal ly for use in submachine guns.

CAUTION: HK firearms are designed to function with quality manufactured brass

cased ammunition. Use of steel or aluminum cased cartridges is not recommended

and could adversely affect safe and reliable functioning. For further information on

ammunition selection, contact HK Customer Service at 706-568-1906.

To raise the bullet impact on tar get, a shorter front sight is installed. To lower the bullet

impact on target, a taller front sight is installed. Installing the next high er or lower front

sight will change the point-of-impact 2 inches at 25 meters, depending on the am mu nition used. USP Series Pistols are function fired and ze roed at the fac to ry at 25 meters,

point-of-aim, point-of-impact. Your actual zero may vary depending on the ammunition

used and/or your style of shooting.

NOTE: In compliance with NIJ Standard—0112.00, cur rent ly there are no known

am mu ni tion types that meet the general guide lines set forth in this sec tion that

are not compatible with the USP series pistols. All USPs are approved for use with

+P and +P+ ammunition as it applies to the specific caliber. The use of +P and +P+

ammunition accelerates wear and reduces the service life on the com po nent parts of

any pistol, including the USP series pistols.

NOTE: There is currently no existing SAAMI spec i fi ca tion +P or +P+ ammunition in

caliber .40 S&W.

14

15

WARNING: The use of in cor rect am mu ni tion in the pis tol could re sult in dam age to the

pis tol and/or in ju ry to the op er a tor or bystanders. Be careful not to inadvertently mix

9mm and .40 caliber am mu ni tion. 9mm ammunition will slide past the cham ber and into

the barrel in a .40 caliber pistol causing a barrel obstruction resulting in damage to the

pistol and/or personal injury.

SECTION 5 INSTRUCTIONS FOR USE

FILLING AND EMPTYING THE MAGAZINE

NOTE: Do not attempt to load more than the prescribed number of cartridges into the

magazine. Do not alter the shape of the magazine housing, fol low er, or spring. To do

so may cause stoppages or the mag a zine may not seat properly in the pistol.

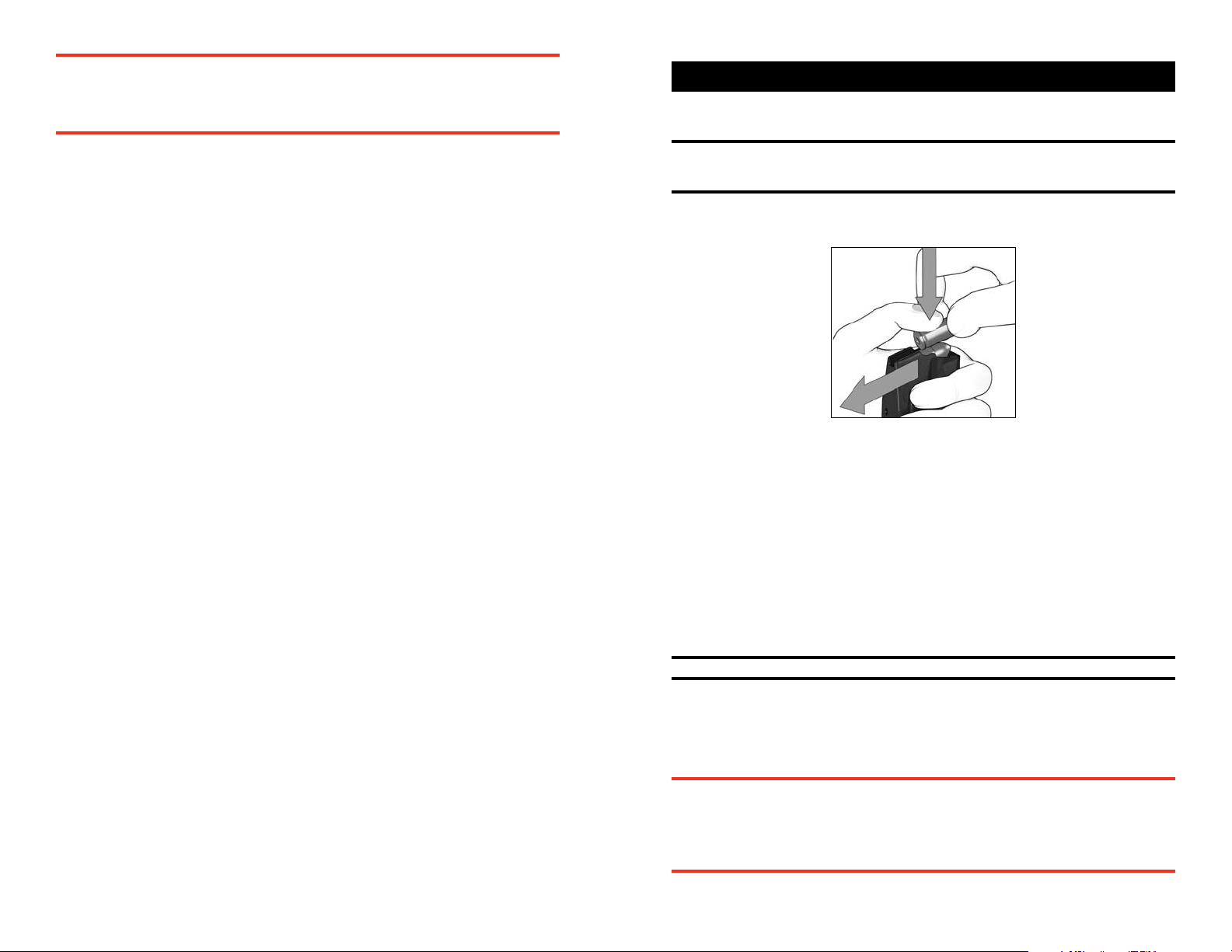

Filling the Magazine - (See Figure 9 below)

Fig. 9 Loading magazine

1. Hold the magazine in the non-firing hand with the back side of the mag a zine

resting against the palm.

2. Using the firing hand, hold a car tridge between the index finger and thumb with

the projectile facing the palm.

3. Press the rim of the cartridge down against the forward edge of the mag a zine

follower or on the top car tridge al ready in the magazine.

4. Slide the cartridge back into the mag a zine under the feed lips.

5. Repeat steps 1-4 until the magazine is full. The viewing holes in the back of the

mag a zine allow the operator to confirm the number of car tridg es present with in

the mag a zine.

NOTE: An optional magazine loading tool is available from HK.

Emptying the Magazine

Exert pressure with a finger on the base of the cartridge and push each cartridge forward

out of the mag a zine one at a time until the magazine is empty.

LOADING THE PISTOL

WARNING: Forcefully inserting a loaded mag a zine into the USP Pistol may cause

the pistols slide to close, cham ber ing a car tridge and mak ing the USP ready to fire.

When inserting a magazine, always be cer tain the control lever (if applicable), is in the

“SAFE” position and that the pistol is point ed in a safe di rec tion with your fingers off

the trigger and outside the trig ger guard. Failure to do so could cause you to un inten tion al ly fire the pistol, re sult ing in se ri ous injury or death.

16

17

Administrative Loading - used to initially load the pistol before it is to be fired.

Slide rearward or forward, chamber empty

1. Make sure fingers are out side of the trig ger guard and the pis tol is point ed in a safe

direction at all times!

2. Insert magazine - insert the mag a zine firmly into the frame. Tug on the magazine to

ensure that it is fully seated and engaged.

3. Chamber a cartridge - chamber a cartridge by de press ing the slide re lease or by

pulling the slide fully to the rear and releasing it. Do not ride the slide for ward!

WARNING: Any attempt to lower the hammer manually (with a round in the chamber),

will allow the hammer to be lowered past the half-cock notch and by passes the passive

safeties which are built into the USP and could result in an ac ci den tal dis charge and

subsequent property damage, injury or loss of life.

On DA/SA models without the decocking func tion in the control lever, it is unsafe to lower

the hammer while there is a round in the chamber.

On Variant 9 and 10 pistols, to lower the hammer on an empty chamber, the following

steps must be followed with extreme care. Remember: low er ing the hammer manually

on the USP pistol re quires pulling the trigger. The action of pulling the trigger bypasses

the passive safeties which are built into the USP. If there is a round in the chamber when

the hammer is being lowered manually, and if the hammer slips, the gun could discharge

causing possible subsequent prop er ty damage, injury or loss of life.

1. Point the pistol in a safe direction and put the manual safety in the “on” or “safe”

position by moving the control lever fully upward.

2. Remove the magazine.

3. While keeping your finger off of the trigger and outside of the trigger guard draw the

slide to the rear and push the slide stop up to lock the slide in the open position. Inspect

the chamber vi su al ly and manually to ensure that there is no round in the chamber.

4. Release the slide by pressing down on the slide stop.

5. Disengage the manual safety by moving the control lever downward to the “fire”

position.

6. Hold the pistol firmly in one hand as if you were going to discharge the firearm. Using

the thumb of the hand which is not holding the pistol, draw the hammer slightly to the

rear. Using the index finger of the hand which is holding the pistol, pull the trigger to the

rear.

Lower the hammer SLOW LY, while at the same time releasing the trigger, removing your

finger from the trigger and placing it outside of the trigger guard. Con tin ue to lower the

hammer SLOWLY until it has come to a complete rest against the back of the slide.

Draw the hammer back slightly until it comes to rest at the half cock notch position.

FIRING THE PISTOL

WARNING

1. Be sure of your target and what’s behind it! A bullet from a pistol travels as far

as a mile. It can easily pen e trate wood or plasterboard walls or even a car door.

2. Be sure that your hands and all parts of your body are kept away from the muzzle

of your pis tol at all times!

3. Always wear eye and ear protection when fir ing the pistol.

Double-action only mode - (Hammer uncocked)

1. Aim - aim at the target.

2. Fire - fire the pistol by press ing the trigger straight to the rear with grad u al ly

increasing pres sure.

NOTE: Variant 7 and LEMs, the double-action only models of the HK USP Series do

not have control levers. The ham mer of these variants will au to mat i cal ly return to the

uncocked po si tion each time the slide returns to its forward po si tion.

The Law Enforcement Modification

The Law Enforcement Modification (LEM) is a series of unique trigger mechanism parts

created specifically to improve the quality and reduce the weight of the Double-Action

Only trigger pull in the USP Pistol. With these parts installed the USP pistol can be fired

like the standard DAO USP pistol where every round is fired by simply pulling the trigger

fully rearward with the hammer starting at the forward rest position. There are no external

decocking or safety levers present or required.

Due to the design of the proprietary HK LEM system the weight of the DAO trigger

pull has been reduced to 7.5-8.5 pounds when new and is easier to use due to the

smoothness of the trigger pull.

NOTE: Optional 4.5-5.5 pound LEM trigger pull is also available for the USP series

pistol.

Parts Unique to the Law Enforcement Modification

The unique LEM parts of the USP pistol are listed below. Additional information can be

found in the exploded diagram and parts list of this manual.

Hammer Spring, trigger rebound Sear, complete

Cocking piece Spring, cocking piece Spring, hammer

Law Enforcement Modification Operation

USP Pistols fitted with Law Enforcement Modification parts operate like standard variants

of the USP Pistol. However, the way in which the hammer is cocked is unique. The

hammer in the LEM is a two-piece hammer comprised of a cocking piece (not visible with

the pistol assembled) and an external (visible) hammer.

In the LEM system the quality of the trigger pull is improved while at the same time a

stronger hammer spring can be employed to improve reliability by increasing the firing

pin indent on the primer. The stronger hammer spring also helps to reduce the slide

velocity when firing “hot” ammunition. The HK LEM uses the rearward movement of the

slide during loading or firing to fully compress the hammer spring.

The cocking piece and hammer are rotated rearward on the hammer axle when the slide

moves fully rearward. When fully to the rear the cocking piece is held in the cocked

position by the sear and the hammer spring has been fully compressed by the hammer

strut. As the slide travels forward the hammer is rotated back to and held in the forward

position by the hammer rebound spring.

When the trigger is pulled rearward against the combined force (7.5 – 8.5 pounds) of the

trigger, hammer rebound, firing pin block, and sear springs the internal passive safeties

are disengaged and the sear releases the cocking piece. The cocking piece is then free to

rotate the hammer forward on its axle under pressure of the compressed hammer spring

imparted through the hammer strut to strike the firing pin and fire the chambered round.

The weight of the trigger pull is adjusted by an armorer replacing or exchanging the firing

pin block spring, firing pin spring, and trigger springs.

Loading...

Loading...