PROGRAM LOCK

THERMAL LOCKOUT

DIFFERENTIAL

E

PRESS TO DISPLAY

MADE IN U.S.A.

CONNECTED

MUST

CLOCKNEUTRAL

LINE

1 32

OPTION

READ INSTRUCTIONS BEFORE PROGRAMMING

PROGRAM

BE

R

B

OUTPUT

W

1 2

3 4

5 6

AUX. OPTION

789

10 1211 13

OUTPUT

RELAY

UNLOCK

BY-PASS

AUTO

CLOCK

AUX.1OPTION

SUMMER

WINTER

RUN

N

C

R

ADJUSTMENT

BOOST

VARI

OPTIONOPTION

1714 15 16

MANUAL

X

WITH

VARI

SHUT DOWN

Z

ON

I

3

OPTION

2

ADVANCE

REVIEW

PAIR SHOWN

ERASE

Y

HEATING

SYSTEM

SENSOR

A

S

E

OFF

FAST

CYCLE FOR

TESTING

MORNING BOOST

120

SHUT DOWN CURVE

Series

(DAY)

SYSTEM IN

NORMAL

AM

TUE

N

HEAT ADJUSTMENT

SYSTEM IN

SAVE

(NIGHT)

OUTDOOR SENSOR SET POINTS

SHIFT

HOURS

MON

CURRENT STATUS INDICATORS

E

A

L

C

B

P

O

NORMAL

H

G

F

E

S

S

D

J

K

M

L

-DAY

I

THU

CLOCK PROGRAM CONTROLS

MINUTESPMDAY

WED SATFRI

SUN

TEMP

2

COPYDAY

OFF

MANUAL MINUTES

VARI-BOOST /

1

20

OUTSIDE

40

3

60

4

80

BOOST

K

-NIGHT

R

E

A

L

E

C

B

SAVE

F

S

S

O

M

D

E

G J

H

I

R

P

E

N

O

M

O

L

M

Gold

SERIAL NO.

5

6

100

USE COPPER WIRE ONLY

OUTPUTS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL FOR ALL CIRCUITS

HEAT-TIMER PANEL

HWR, HWRQ, MPC, MPCQ, SRC, Multi-MOD

HEAT SOURCE

ACTIVATED

HEAT CIRCULATION

ESTABLISHED

SYSTEM

IN CYCLE

J1

X1X2 X3

120

VAC

Power

Sensor Link

Receiver

Sensor Link

Transmitter

INSTALLATION/OPERATING INSTRUCTIONS

SENSOR LINK

The Sensor Link system consists of a

Receiver and one or more Temperature

or Pressure Transmitters. The Receiver

is designed to intercept and decode

the wireless information being emitted

by the Transmitters and forward the

data to the Heat-Timer panel (HWR,

HWR-Q, MPC, MPC-Q, SRC, or MultiMOD) via a wired connection.

Instruction to User

This equipment has been tested and found to

comply with the limits for a class B digital

device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide

reasonable protection against harmful

interference in a residential installation. This

equipment generates, uses and can radiate

radio frequency energy and if not installed

and used in accordance with the instructions,

may cause harmful interference to radio

communications. However, there is no

guarantee that interference will not occur in

a particular installation. If this equipment

does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on,

the user is encouraged to try to correct the

interference by one or more of the following

measures:

* Reorient or relocate the receiving

antenna.

* Increase separation between the

equipment and receiver.

* Connect the equipment into an outlet on

a circuit different from that to which the

receiver is connected.

* Consult the dealer or an experienced

radio/TV technician for help.

This equipment has been certified to comply

with the limits for a class B computing

device, pursuant to FCC Rules. In order to

maintain compliance with FCC regulation,

shielded cables must be used with this

equipment. Operation with non-approved

equipment or unshielded cables is likely to

result in interference to radio and TV

reception. The user is cautioned that changes

or modifications made to the equipment

without the approval of the manufacturer

could void the users authority to operate this

equipment.

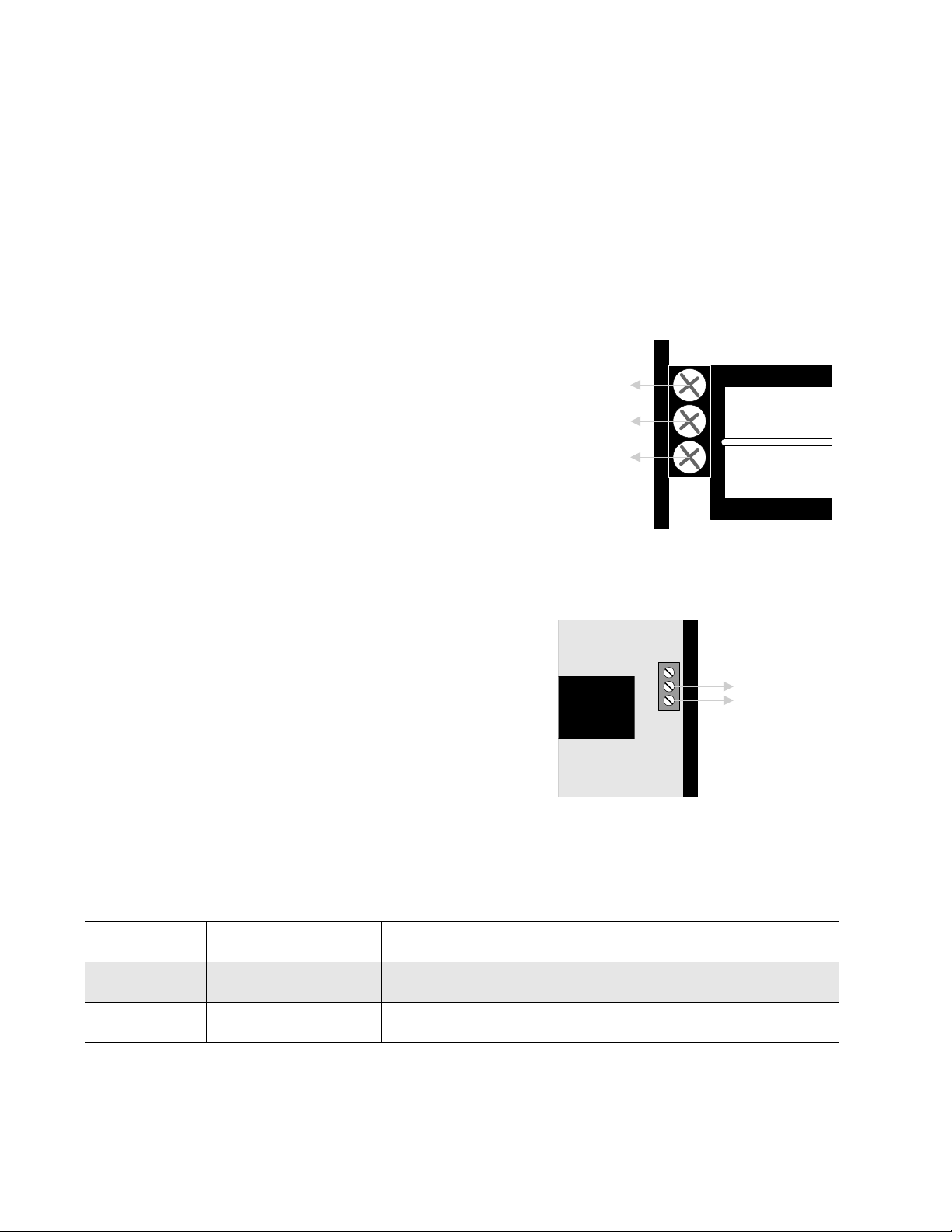

SENSOR LINK RECEIVER INSTALLATION

GND

Neutral

Line

Wire Type

Belden 8471

Belden 85102

Unshielded

Twisted Pair

16AWG

Gauge Maximum Length (ft) Maximum Temp (°F)

Unshielded

Twisted Pair

16AWG

1200

1200

140

185

J1

X1 X2 X3

To

Network

Terminals

A &B

Mount the enclosure

In a location central to the various Transmitters.

To prevent unauthorized tampering, the Receiver should be located

in an inconspicuous area, or in an area with limited access.

The Receiver must be located where the ambient temperature will not

exceed 130°F and away from any steam or moisture.

Attach the Receiver to a flat surface by screwing through the

mounting holes located on the top and bottom flange.

If desired, the Receiver may also be installed inside a metal enclo-

sure.

Power Wiring

Bring the 120VAC 60Hz power wires through the round opening in

the enclosure.

Class 1 voltages must enter the enclosure through a different

opening from any Class 2 voltage wiring.

Connect power to the terminals as shown at right.

The GND terminals MUST be connected to earth ground.

Network Wiring

Use 2-wire unshielded twisted pair (see specification below).

There is no polarity to observe. Either network wire from the

Receiver can be attached to Heat-Timer panel (HWR, HWRQ, MPC,

MPCQ, SRC, or Multi-MOD) Network terminals A or B.

Bring the network wiring through the rectangular opening in the

enclosure.

Network wiring must enter the enclosure through a different opening

from any Class 1 voltage wiring.

Wire the network connections to the terminal block marked J1,

terminals X1 and X2.

The wires can be run in virtually any configuration back to the Heat-

Timer panel. They can be wired sensor to sensor (daisy chained).

They can be wired in a star configuration, with each sensor pair

brought back to the panel. Finally, there can be any combination of

the two.

The Receiver has a specific ID number. The ID number is on the back

of the Receiver, and is on the Network Identification card which is

provided. Fill out the location of the Receiver on the Network

Identification card and return it to the Heat-Timer network adminis-

trator.

D3 D2 D1

D3 D2 D1

Push

Button

Mounting and Connecting the Antenna

Antenna

Wire

Adhesive

Pad

Only

Transmitters in

Test Mode

All

Transmitters

Description

Sn S.n Serial number of the Transmitter

tE t.E Temperature of the Transmitter

Display Code

coUn c.oUn

The total number of packets correctly received since startup

(used for diagnostic purposes)

rSSI r.SSI

2 Left hand digits - Data signal strength

2 Right hand digits - Noise strength

The Antenna should be mounted in a convenient location within six

feet of the Receiver.

Do not cut or splice the antenna wire provided.

Make sure the surface where the Antenna will be mounted is flat,

clean, dry, and will not be subject to moisture or temperatures which

exceed 130°F.

Remove the backing to expose the adhesive pad on the back of the

antenna and press it to the mounting surface.

To connect the Antenna to the Receiver, screw the nut on the end of

the Antenna wire to the threaded metal connector extending from the

Receiver enclosure.

SENSOR LINK RECEIVER OPERATION

Power Up Display

When the receiver is first powered, 8 will be displayed in each of the

digits in turn, moving from right to left.

Next the display will briefly show the version number, and then go

blank.

During this period, the green LED (D1), yellow LED (D2), and red

LED (D3) will flash or light.

When the display goes blank, only the red LED (D3) will remain on

to indicate the Receiver is powered.

Display Modes

Pressing the push button will set the display mode for the Receiver.

Once a display mode is selected, the Receiver will remain in the

selected display mode until the push button is pressed and a new

mode is selected.

If the display code with a dot is selected, then the selected display

information will be shown whenever the Receiver gets data from any

Transmitter on its channel. Each Transmitter normally emits data

every 4 to 5 minutes.

When setting up Transmitters, they can be put in a Test mode so

they emit data much more frequently. To only display information

from a Transmitter in Test, select the display code without a dot.

The chart below describes the various display modes:

SENSOR LINK TRANSMITTER

Test

Mode

Button

Batteries

Installation

Find an approximate location for the Transmitter, located away from

direct sunlight or other heat sources. Do not locate a Transmitter in

either a kitchen or a bathroom.

The range of temperatures at the Transmitter location should be

between 32 and 150°F. If the temperature experienced by the Transmitter is outside of this range, battery life will be shortened.

Open the Transmitter by inserting your two thumbs in the large

rectangular opening at the back of the enclosure and prying it open.

Make sure the Receiver is programmed to read Sn (see above).

Remove the plastic tab to connect the batteries and activate the

Transmitter.

Push the button on the Transmitter to put it in the Test mode. It will

remain in the Test mode for five minutes. In the Test mode, the

Transmitter will emit data more often than during normal operation.

Go to the Receiver and watch the display until the serial number of

the new Transmitter being installed is displayed. Only the last 4

digits of the serial number will be shown.

If the Receiver does not register the new Transmitter, move it to

another location.

When a location with a good signal is found, mount the Transmitter

to a flat surface using the two oval mounting slots molded in the

base of the enclosure.

The Transmitter can be mounted either vertically or horizontally.

Replace the Transmitter cover.

Operation

The Transmitter should operate for years without any maintenance.

The batteries will need to be replaced every 3 to 8 years.

The Transmitter requires three AAA, 1.5 Volt batteries. Be sure to

observe that the positive side of the battery faces the center of the

Transmitter board as shown in the diagram at right and which is also

clearly marked on the board itself.

059265-00 REV A

Loading...

Loading...