Installation and Operation Manual

Steam Outdoor Reset Boiler /Motorized

MPC

Valve Cycling Heating Control

R

C O R P O R A T I O N

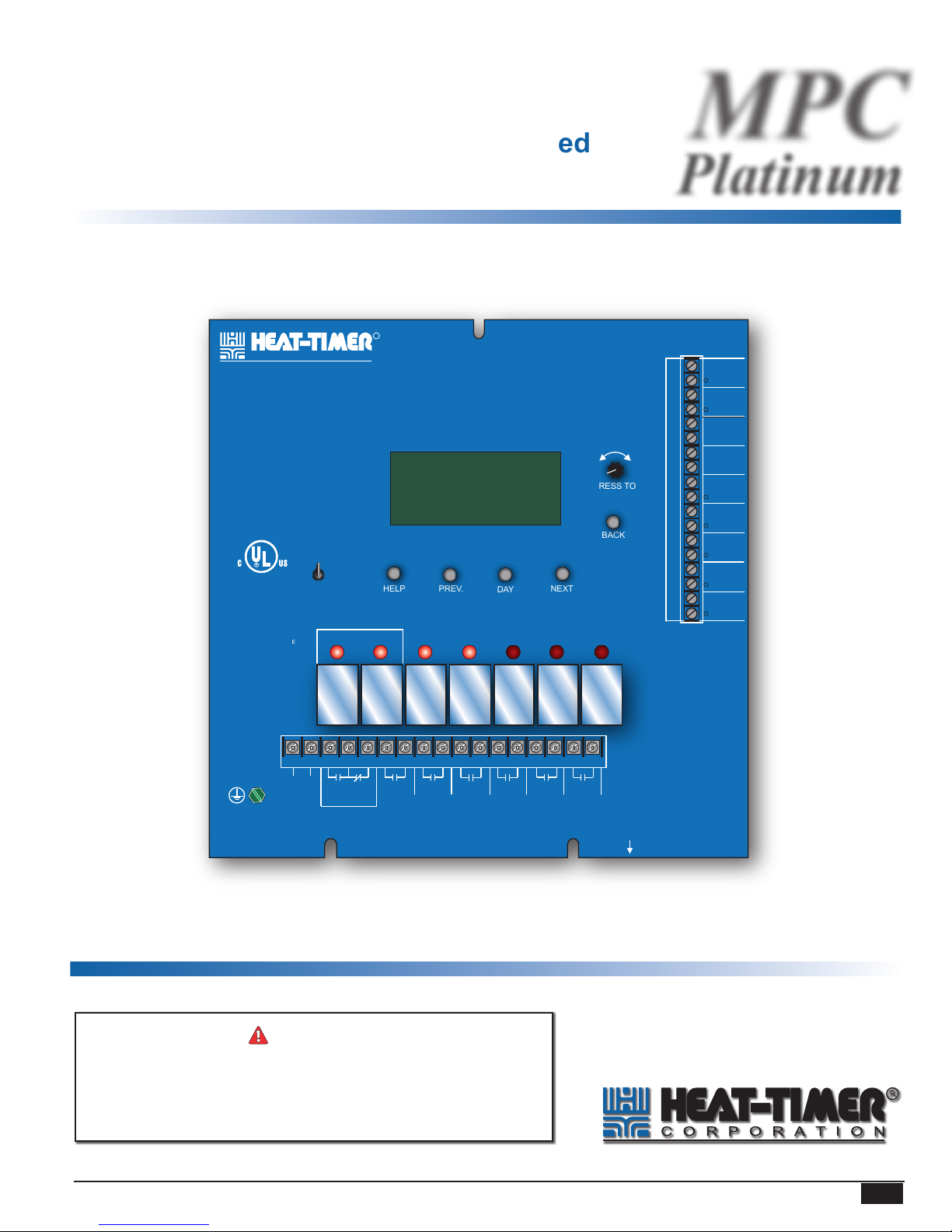

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

DAY selects next day

PREV./NEXT steps through output status

AUTO

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

BYPASS

OUTPUT SYS

2 3 4 5

MON 12/01/2010 10:01Am

Cycle On 13/15

Cutoff = 55

OD = 31

HELP NEXT

6 7 8 9 10 11 12 13 14 15 16 17

MPC

Platinum

o

F SYS = 138oF

PREV.

(DEL)

CLOCK

o

AUX

F Day

DAY

OPTION

1

OPTION

2

INPUTS

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

ALL SENSORS MUST BE

GOLD SERIES SENSORS

ADJUST

PRESS TO

SELECT

BACK

OPTION

3

18

Platinum

T

A1

SYSTEM

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

TEMP

SHUTDOWN

PROVE

NETWORK

MSI CONNECTION

ON BACK

AUX

INPUT 0

T

OUT

TEMP

T

AUX

TEMP 0

T

AUX

TEMP 1

T

AUX

TEMP 2

LINE

SAFETY

GROUND

MUST BE

CONNECTED

MADE IN U.S.A.

NEUTRAL

WARNING

This Heat-Timer control is strictly an operating control; it should

never be used as a primary limit or safety control. All equipment

must have its own certified limit and safety controls required by local

codes. The installer must verify proper operation and correct any

safety problems prior to the installation of this Heat-Timer control.

MPC Platinum Installation and Operation Manual

B R W

MOTORIZED

VALVE

BURNER

SYSTEM AUX

CLOCK

OPTION1OPTION2OPTION

3

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

HT# 059085-00 F

1

MPC Platinum Function Chart . . . . . . . . . . .3

Understanding the Cycle Concept. . . . . . . . .4

Sequence of operation . . . . . . . . . . . . . . . . 5

Cycle Timeline . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . 6

Initial Program. . . . . . . . . . . . . . . . . . . . .6

Selecting the System Features . . . . . . . . . . . . 6

Making Sure You Have the Right Control . . . . . .7

Installation . . . . . . . . . . . . . . . . . . . . . . . 8

Mounting the enclosure . . . . . . . . . . . . . . . .8

Rear of Control. . . . . . . . . . . . . . . . . . . . . 8

Sensor Installation. . . . . . . . . . . . . . . . . . . 9

Outdoor Sensor Installation . . . . . . . . . . . . . . 9

Heating System Sensor (HSS) Installation . . . . . .9

Wiring the power. . . . . . . . . . . . . . . . . . . 10

Output Wiring . . . . . . . . . . . . . . . . . . . . 10

Wiring To a motorized valve . . . . . . . . . . . . . 10

Wiring To a Boiler . . . . . . . . . . . . . . . . . . 10

Wiring To System Output. . . . . . . . . . . . . . . 11

Wiring to Auxiliary Clock . . . . . . . . . . . . . . . 11

Wiring to Option Outputs. . . . . . . . . . . . . . . 11

Input Wiring . . . . . . . . . . . . . . . . . . . . . 12

Wiring System Sensor . . . . . . . . . . . . . . . . 12

Wiring the Outdoor Sensor. . . . . . . . . . . . . . 12

Wiring the Shutdown . . . . . . . . . . . . . . . . . 12

Wiring The Prove. . . . . . . . . . . . . . . . . . . 12

Network and Aux Temp . . . . . . . . . . . . . . . 12

Testing the Sensors . . . . . . . . . . . . . . . . . 13

Aux Input . . . . . . . . . . . . . . . . . . . . . . . 13

Wiring Network Sensors . . . . . . . . . . . . . . . 13

Connecting Wireless Sensor System . . . . . . . . 13

Remote Communication Wiring . . . . . . . . . . 14

BACnet Wiring . . . . . . . . . . . . . . . . . . . . 14

BACnet IP Wiring . . . . . . . . . . . . . . . . . . 14

BACnet MS/TP Wiring . . . . . . . . . . . . . . . . 14

MODBUS RTU Wiring . . . . . . . . . . . . . . . . 15

Internet Wiring . . . . . . . . . . . . . . . . . . . . 15

Ethernet Connection to Modem . . . . . . . . . . . 15

Ethernet Connection to Platinum Control . . . . . . 15

DHW Energy Saver Wiring . . . . . . . . . . . . . 15

AUTO/BYPASS Switch. . . . . . . . . . . . . . . . 16

Setting the Control . . . . . . . . . . . . . . . . . 16

Display and Changing Settings. . . . . . . . . . . 16

menu Types . . . . . . . . . . . . . . . . . . . . . 16

Display Messages . . . . . . . . . . . . . . . . . . 17

Menu Settings . . . . . . . . . . . . . . . . . . . . 18

Startup Settings . . . . . . . . . . . . . . . . . . . 20

Sensor Type . . . . . . . . . . . . . . . . . . . . . 20

Operation Mode . . . . . . . . . . . . . . . . . . . 20

Cycle Length . . . . . . . . . . . . . . . . . . . . . 20

Sensor Fault . . . . . . . . . . . . . . . . . . . . . 20

Day light saving mode . . . . . . . . . . . . . . . . 21

Option Outputs Modes . . . . . . . . . . . . . . . 21

Option relay 1 mode . . . . . . . . . . . . . . . . . 21

Option 2 Relay Mode . . . . . . . . . . . . . . . . 21

Option 3 relay mode . . . . . . . . . . . . . . . . . 21

DHW Supply and return Defaults . . . . . . . . . . 22

Setting the Date and Time . . . . . . . . . . . . . . 22

HT# 059085-00 F

2

Content

Operation. . . . . . . . . . . . . . . . . . . . . . . 23

System Settings . . . . . . . . . . . . . . . . . . . 23

Season . . . . . . . . . . . . . . . . . . . . . . . . 23

Day and Night Heat Adjustment . . . . . . . . . . . 23

Cycle Length Table. . . . . . . . . . . . . . . . . . 24

Boost Mode . . . . . . . . . . . . . . . . . . . . . 26

Vari Boost Curves . . . . . . . . . . . . . . . . . . 26

Early Shutdown Curves . . . . . . . . . . . . . . . 27

Warm-up Enable and Learn . . . . . . . . . . . . . 27

System Run-On . . . . . . . . . . . . . . . . . . . 28

Thermal Lockout . . . . . . . . . . . . . . . . . . . 28

Space Lockout . . . . . . . . . . . . . . . . . . . . 28

Day and Night Space Targets . . . . . . . . . . . . 28

Schedules . . . . . . . . . . . . . . . . . . . . . . 29

Setting the DAY/NIGHT Schedule . . . . . . . . . . 29

Copy Schedule. . . . . . . . . . . . . . . . . . . . 30

Vacation Schedule Setting . . . . . . . . . . . . . . 30

Aux Relay Schedule . . . . . . . . . . . . . . . . . 30

Maintenance . . . . . . . . . . . . . . . . . . . . . 31

System and Outdoor Sensor Trim . . . . . . . . . 31

Fast Cycle . . . . . . . . . . . . . . . . . . . . . . 31

Password and Local Security. . . . . . . . . . . . 31

DHW Settings . . . . . . . . . . . . . . . . . . . . 32

Using the Supply/Return Sensor. . . . . . . . . . . 32

Supply/Return Set Point . . . . . . . . . . . . . . . 32

Supply/Return Peak/Light Differential . . . . . . . . 32

DHW Demand Schedule . . . . . . . . . . . . . . . 33

DHW Copy Schedule . . . . . . . . . . . . . . . . 33

Shift . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Communication Options. . . . . . . . . . . . . . 34

Internet Communication Features . . . . . . . . . 34

Internet Communication. . . . . . . . . . . . . . . 35

Internet ID . . . . . . . . . . . . . . . . . . . . . . 35

Internet Port forwarding Table . . . . . . . . . . . . 35

BACnet Communication Features . . . . . . . . . 37

BACnet Communication

Selecting BACnet IP or BACnet MSTP . . . . . . . 37

. . . . . . . . . . . . . . 37

BACnet Device ID . . . . . . . . . . . . . . . . . . 37

IP and Mask Addresses . . . . . . . . . . . . . . . 37

. . . . . . . . . . . . 37

BACnet Device ID . . . . . . . . . . . . . . . . . . 37

MS/TP Address/ MAC Address . . . . . . . . . . . 38

MSTP Baud rate . . . . . . . . . . . . . . . . . . . 38

MPC Platinum BACnet Variable List . . . . . . . . . 38

BACnet PICS Statement . . . . . . . . . . . . . . . 40

MODBUS Communication Features . . . . . . . . 41

. . . 41

MODBUS Communication Options . . . . . . . . . 41

MAC

Address . . . . . . . . . . . . . . . . . . . . 41

MODBUS Baud . . . . . . . . . . . . . . . . . . . 41

MPC Platinum MODBUS Variable List. . . . . . 41

Troubleshooting. . . . . . . . . . . . . . . . . . . 43

Diagrams . . . . . . . . . . . . . . . . . . . . . . . 45

Warranty . . . . . . . . . . . . . . . . . . . . . . . 54

. . . . . . . . . . . . . . . . . . . 56

MPC Platinum Installation and Operation Manual

. . . . . . . . . . . . . . . 37

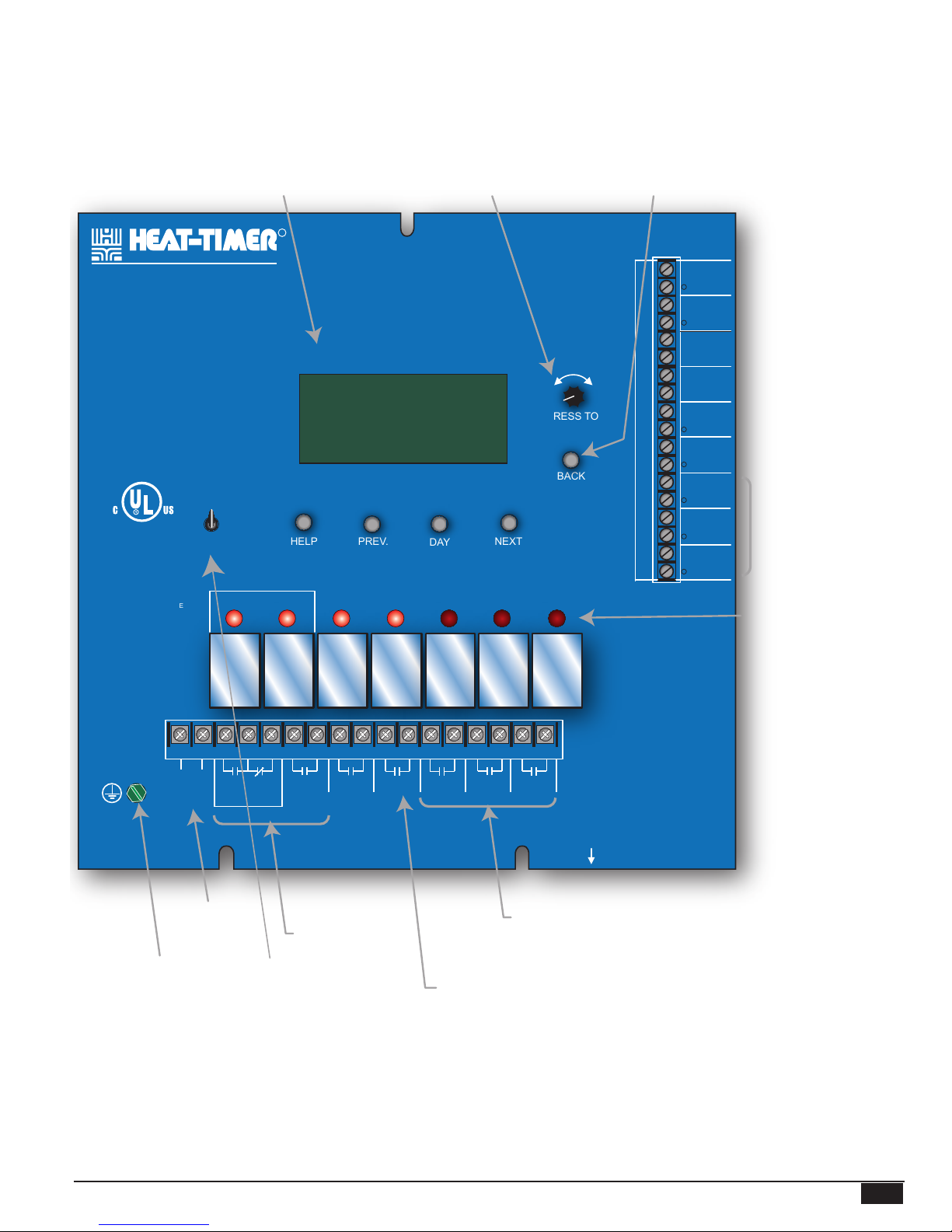

MPC PLATINUM FUNCTION CHART

Digital display shows the cycle status,

outdoor cutoff, outdoor, and system temperatures.

To view and adjust settings, press the

Adjust/Select button.

R

C O R P O R A T I O N

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

DAY selects next day

PREV./NEXT steps through output status

AUTO

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

BYPASS

OUTPUT SYS

2 3 4 5

MON 12/01/2010 10:01Am

Cycle On 13/15

Cutoff = 55

OD = 31

HELP NEXT

6 7 8 9 10 11 12 13 14 15 16 17

Depress the knob to move

forward through the menus and to

accept changes. To change a

setting's value, rotate the knob.

MPC

Platinum

o

F Day

o

F SYS = 138oF

PREV.

(DEL)

CLOCK

AUX

DAY

OPTION

Depress the button to go back

through the menus

T

INPUTS

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

ALL SENSORS MUST BE

GOLD SERIES SENSORS

ADJUST

PRESS TO

SELECT

BACK

OPTION

1

OPTION

2

3

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

SYSTEM

TEMP

SHUTDOWN

PROVE

NETWORK

MSI CONNECTION

ON BACK

AUX

INPUT 0

T

OUT

TEMP

T

AUX

TEMP 0

T

AUX

TEMP 1

T

AUX

TEMP 2

From heating system sensor

When closed, outputs

are turned off*

Checks status of system

components*

From Heat-Timer network

sensors**

From DHW Control*

From outdoor sensor

mounted in the shade

Remote Communication

Option**

Red lights indicate when the

associated stage relay

is activated

18

SAFETY

GROUND

MUST BE

CONNECTED

MADE IN U.S.A.

LINE

NEUTRAL

120VAC

Power

B R W

MOTORIZED

VALVE

BURNER

Valve and Burner

Outputs are active

when MPC requires

steam

Green Earth

Ground screw

BYPASS position runs

the output.

* DRY CONTACT ONLY

** Only available with the Remote Communications package

MPC Platinum Installation and Operation Manual

SYSTEM AUX

CLOCK

OPTION1OPTION2OPTION

3

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

OPTION outputs can be programmed

to operate additional equipment or

Internet Modem.

Operates additional equipment based

on a separate Aux Schedule

HT# 059085-00 F

3

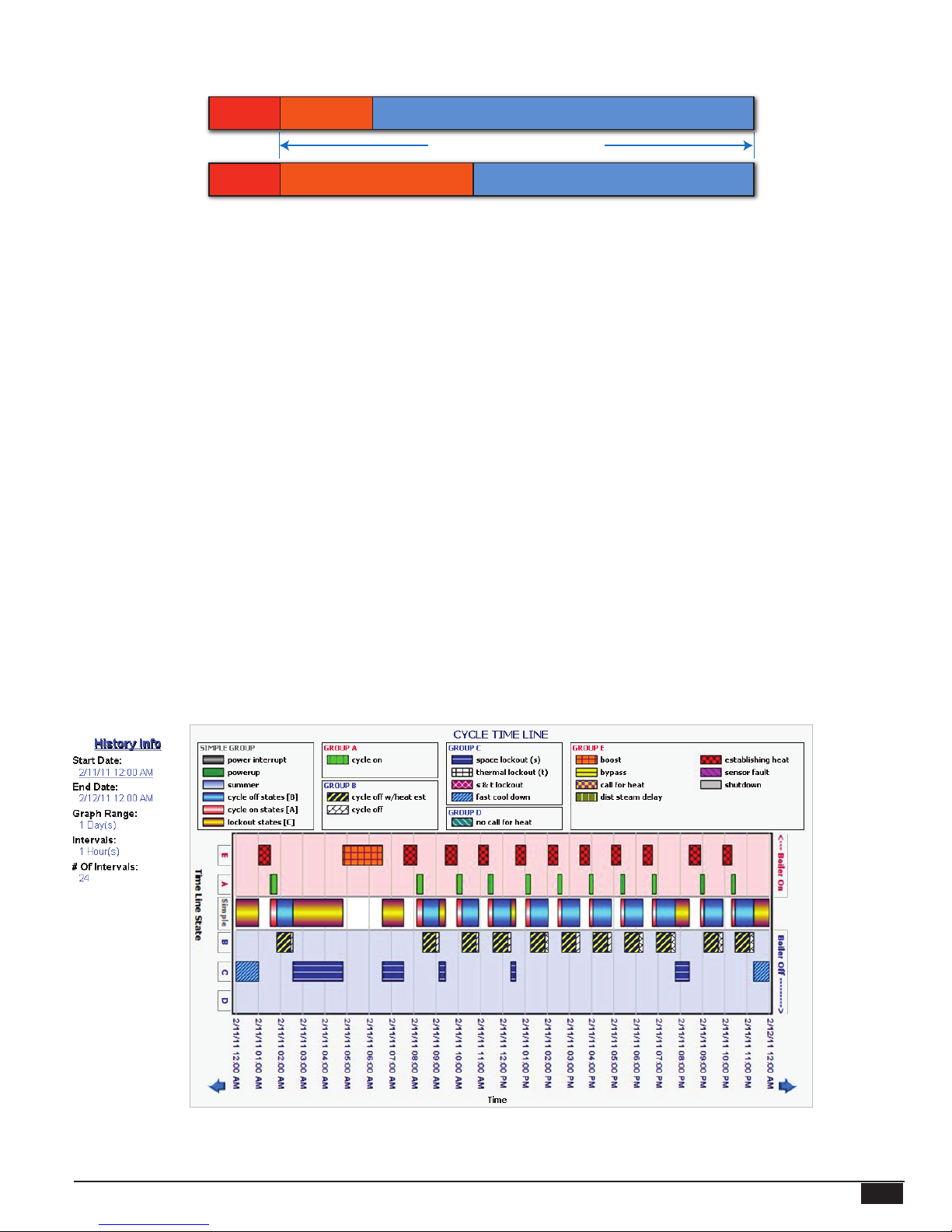

UNDERSTANDING THE CYCLE CONCEPT

The Heat-Timer MPC Platinum is a microprocessor-based control designed to manage a low-pressure steam heating system. It

operates a steam boiler or a two-way steam valve to provide the desired amount of heat to the building.

The MPC Platinum operates based on the CYCLE principle. Heat-Timer created this principal specically for steam heating

systems to overcome the inabilities of standard thermostatic controls to cope with the unique challenges of low-pressure steam

heating. Unlike water and air systems, steam systems take time to build up a "head of steam". Moreover, once the system starts

heating up, it has momentum that takes time to dissipate. This makes it difcult to control its temperature.

60 Minute Cycle

(Cycle-On=21 + Cycle-O=39)

Establish

Heat

Cycle-On

21 Minutes

Cycle-Off

39 Minutes

Cycle delayed until

System Temperature drops

below System Set Point-Diff

Establish

Heat

Cycle-On

21 Minutes

Cycle length based on outdoor temperature

By monitoring the outside temperature, the MPC Platinum is able to anticipate the building heating needs. Each CYCLE period

(usually 60 minutes long, but adjustable depending on the type of radiation units) consist of a Cycle-ON segment and a Cycle-OFF

segment. The length of the Cycle-ON segment will vary with the outside temperature. The colder it is outside, the longer the

Cycle-ON part.

MPC Platinum

R

Zone C

Zone A

Zone B

C O R P O R A T I O N

MENU FUNCTIONS

SELECTenters menus or accepts changes

ADJUSTselects menu items or changes settings

BACK returns to previous menu

DAY selects next day

PREV./NEXT steps through output status

AUTO

BYPASS

MON 12/28/04 10:43Am

Cut= 55

OD= 31

HELP NEXT

OUTPUT

2 3 4 5 6 7 8 9 11 12 13 14 15 16 17

R W

B

LINE

MOTORIZED

VALVE

NEUTRAL

Platinum

PREV.

Cycle On

o

F SYS= 148oF

(DEL)

BURNER

MPC

o

F Day

DAY

AUX

CLOCK

SYS

10 18

SYSTEM OPTION1OPTION2OPTION3AUX

CLOCK

T

A1

INPUTS

SYSTEM

TEMP

A2

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

A3

SHUTDOWN

A4

ALL SENSORS MUST BE

GOLD SERIES SENSORS

A5

PROVE

A6

ADJUST

A7

NETWORK

MSI CONNECTION

A8

ON BACK

A9

AUX

PRESS TO

INPUT 0

A10

SELECT

T

A11

OUT

TEMP

A12

BACK

A13

T

AUX

TEMP 0

A14

T

A15

AUX

TEMP 1

A16

T

A17

AUX

TEMP 2

A18

OPTION1OPTION

OPTION

2

3

Outdoor

Sensor

Optional Location:

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

System Sensor

At Furthest Radiator

System Sensor

Installed on Dry

Boiler Water Line

Return Above

Water Line

Boiler

Burner

Condensate

Receiver

The MPC Platinum constantly checks the outside temperature by means of a solid-state sensor located on the exterior of the

building. At the same time, it monitors the heating system of the building by means of a heating system sensor. This heating system

sensor is located where it will show that heat has reached the furthest location in the building (or the hardest to heat area). Based on

this combined data, the MPC Platinum sends instructions to the heating plant to control the heat level in the building.

In addition to adjusting the length of the Cycle-ON segment, the outdoor temperature acts as a system cutoff. When the outdoor

temperature rises above one of the adjustable cutoff temperatures (Two outdoor cutoffs are available. One is for the day and the

other is for the night), the MPC Platinum will not call for any heat. When the outdoor temperature drops below the cutoff, the

MPC Platinum will automatically begin controlling the heating cycle. Once the heating system is active, the heating system sensor

will register when heat has reached throughout the building. The combined effect of these two sensors is to provide an even,

comfortable level of heat throughout the building.

HT# 059085-00 F

4

MPC Platinum Installation and Operation Manual

Sample Mild Weather Cycle

Establish

Heat

Establish

Heat

Cycle-On

Heat On Heat Off

8 Minutes

Cycle-On

21 Minutes

Cycle-Off

52 Minutes

Cycle Length 60 minutes

Cycle-Off

39 Minutes

Sample Cold Weather Cycle

The MPC Platinum is able to maintain two different heat levels. The Day heat level is the higher level of heat. It provides

comfortable temperatures when the building tenants are active. The Night heat level provides lower heat and conserves energy when

the building is empty or when tenants are asleep. Both heat levels rely on the identical cycle concept, but the lower Night settings

provide less heat given the same outdoor temperature.

SEQUENCE OF OPERATION

• The MPC Platinum activates the steam source when the outside temperature falls below the outdoor sensor cutoff (factory set at

55°F for Day and 40°F for Night, but fully adjustable).

• The MPC Platinum will continue to call for heat, keeping the steam source active, until the heating system sensor reaches its

adjustable Set Point. This indicates that steam has gotten entirely through the system, or that "heat is established".

• Once "heat is established", the Cycle-ON segment of the cycle will begin.

• During the Cycle-ON period, the MPC Platinum will keep the steam source activated. The length of the ON part of the cycle

is dependent on the outdoor temperature, the Day/Night setting, and several user selectable adjustments that can be tuned to the

specic heat loss characteristics of the building.

• Once the Cycle-ON part has ended, the Cycle-OFF part of the cycle will begin. The MPC Platinum will turn off the boiler or

close the steam valve for the remainder of this cycle.

• When the Cycle-OFF part is over, the MPC Platinum will once again activate the steam source unless either the outside

temperature has risen above the cuttoff, or the thermal lockout is active.

• With the thermal lockout, the heating system sensor temperature must fall below the Set Point through an adjustable differential

before the heating source can be reactivated. This allows residual heat in the pipes to continue to heat the building. Once the

pipes have cooled sufciently, a new cycle can begin.

• However, if the MPC Platinum is an Internet capable control and space sensors are installed, the control checks for Space Lockout

before staring another cycle.

CYCLE TIMELINE

Internet Control Cycle Timeline view

MPC Platinum Installation and Operation Manual

HT# 059085-00 F

5

• During a heating cycle, the control switches between the different cycle states. The states are divided into groups.

• During any of the operational states, the control has the output relays energized. And during the energy saving states, the control

has the output relays de-energized.

• An Internet control Cycle Timeline is viewable on the History tab of the ICMS site. They are part of the Stock History.

• State Groups are divided into either Boiler-On or Boiler-Off. The Boiler-On groups are represented by the reddish background.

They are graphed on the upper portion of the Cycle-Timeline Internet history graph. The Boiler-Off groups are graphed on the

bottom portion of the graph and has a bluish background.

• These Internet graphs help troubleshoot and ne tune the control operation.

TYPICAL STEAM HEAT CONFIGURATION

The MPC Platinum works with virtually any non-vacuum steam heated system. The MPC Platinum can control a boiler directly to

create steam. For systems where a central plant provides steam, the MPC Platinum opens or closes a motorized valve to allow or

prevent steam from entering the heating system. The MPC Platinum also works with one or two-pipe steam systems.

However, based upon the specic layout of the steam heating system there are several differences in locating the heating system

sensor and in the output wiring to the boiler or motorized valve that the user need to observe. It is important to carefully check the

piping diagrams at the end of this manual to determine which of the following four layouts matches your heating system:

• One Pipe Steam - Motorized Valve

• Two Pipe Steam - Motorized Valve

• One Pipe Steam - Direct Burner Operation

• Two Pipe Steam - Direct Burner Operation

For subatmospheric vacuum type steam systems, see Heat-Timer SRC Platinum Control on the Heat-Timer web site

(http://www.heat-timer.com).

INITIAL PROGRAM

Setting an Initial Program ease's the conguration of the MPC Platinum while giving the opportunity to utilize many of the energy

saving and comfort features. The program should consist of the following:

• Select the features your system can utilize,

• Make sure you have the right control and accessories,

• Install the Control,

• Set the System Startup,

• Set the System Settings,

• Set the Schedules

• Adjust the Day and Night Heat Adjustments and the Set Point

SELECTING THE SYSTEM FEATURES

Heat-Timer designed the MPC Platinum with low-pressure steam building heating as the primary purpose. With this in mind, the

user can use many of the control features to ease, enhance, and improve the system performance. Below is a list of its major features.

Steam Outdoor Reset

• The MPC Platinum regulates the amount of steam sent to the building based on the outdoor temperature. It uses the Cycle concept

based on the Day and Night Heat Adjustment and outdoor cutoffs to regulate the heat. The colder it gets, the longer the Cycle-On

runs. See "AUTO/BYPASS Switch" on page 16.

Night Setback

• Whenever the outdoor temperature falls below the Outdoor Cutoff, the MPC Platinum adjusts the Cycle-ON and Cycle-OFF ratio

to hold a constant Day or Night heat level. The Night heat level is for when the building is unoccupied or tenants are sleeping.

Day and Night Schedules

• The MPC Platinum has 4 Day and 4 Night settings for each day of the week. By setting a Schedule, Day and Night Heat

Adjustments, and Outdoor Cutoffs, you can save energy while providing comfortable heat to the building. The settings allow

the MPC Platinum to reduce the length of the steam Cycle-ON portion during the night or when building is unoccupied. See

"Schedules" on page 29.

HT# 059085-00 F

6

MPC Platinum Installation and Operation Manual

Vacation Schedule (Available with Internet Control Only)

• This feature gives the user the ability to provide a lower-than-night space target between two specied date-time combinations.

This provides additional savings for schools and ofce buildings to use in long holiday periods. See "Vacation Schedule Setting"

on page 30.

Space Sensor Feedback (Available with Internet Control Only)

• For better control and much more energy saving capabilities you can add wireless or wired space sensors to the MPC Platinum to

ne tune its operation and increase the system's overall efciency. When you add space sensors to the space average, the MPC

Platinum checks the space average before the beginning of each cycle to determine if the building is sufciently heated. See

"Space Lockout" on page 28.

System Output

• The system output relay connects to and operates a combustion air-damper or other boiler room equipment and it will energize

whenever there is a call for the boiler. In addition, if you connect the combustion air-damper's end-switch to the Prove input

terminals, it will stop the boiler from ring if the damper is not fully open. See "Installation" on page 8.

Boost and Early Shutdown

• The boost returns the building to its Day (Normal) heat level after Night (Setback) heat level. It does it by running the burner

or valve output for a period of time that depends on the outside temperature. It offers an adjustable curve parameter to tune its

operation to the specic building. See "Boost Mode" on page 26.

• The Early Shutdown feature shifts the Day schedule to Night Setback before the last Night Time setting for that day. The Early

Shutdown varies based on Outdoor temperature (OD). The warmer the Outdoor temperature the earlier the MPC Platinum shifts to

Night Setback. See "Early Shutdown Curves" on page 27.

Remote Communication

• The MPC Platinum is upgradable to Internet, BACnet IP, BACnet MSTP, or MODBUS communication to allow monitoring and

controlling of all of its functions from a remote location. Only the Internet communication package allows the MPC Platinum to

accept a variety of additional sensor inputs to monitor their status and provide web, E-Mail, or text message alarms under specied

adjustable conditions.

MAKING SURE YOU HAVE THE RIGHT CONTROL

If you need the MPC Platinum to do additional tasks that either are not listed or you do not know how to congure them,

contact Heat-Timer Corp. Sales Department either by Phone (973)575-4004, Fax (973) 575-4052, or over the web (visit

http://www.heat-timer.com).

MPC Platinum Installation and Operation Manual

HT# 059085-00 F

7

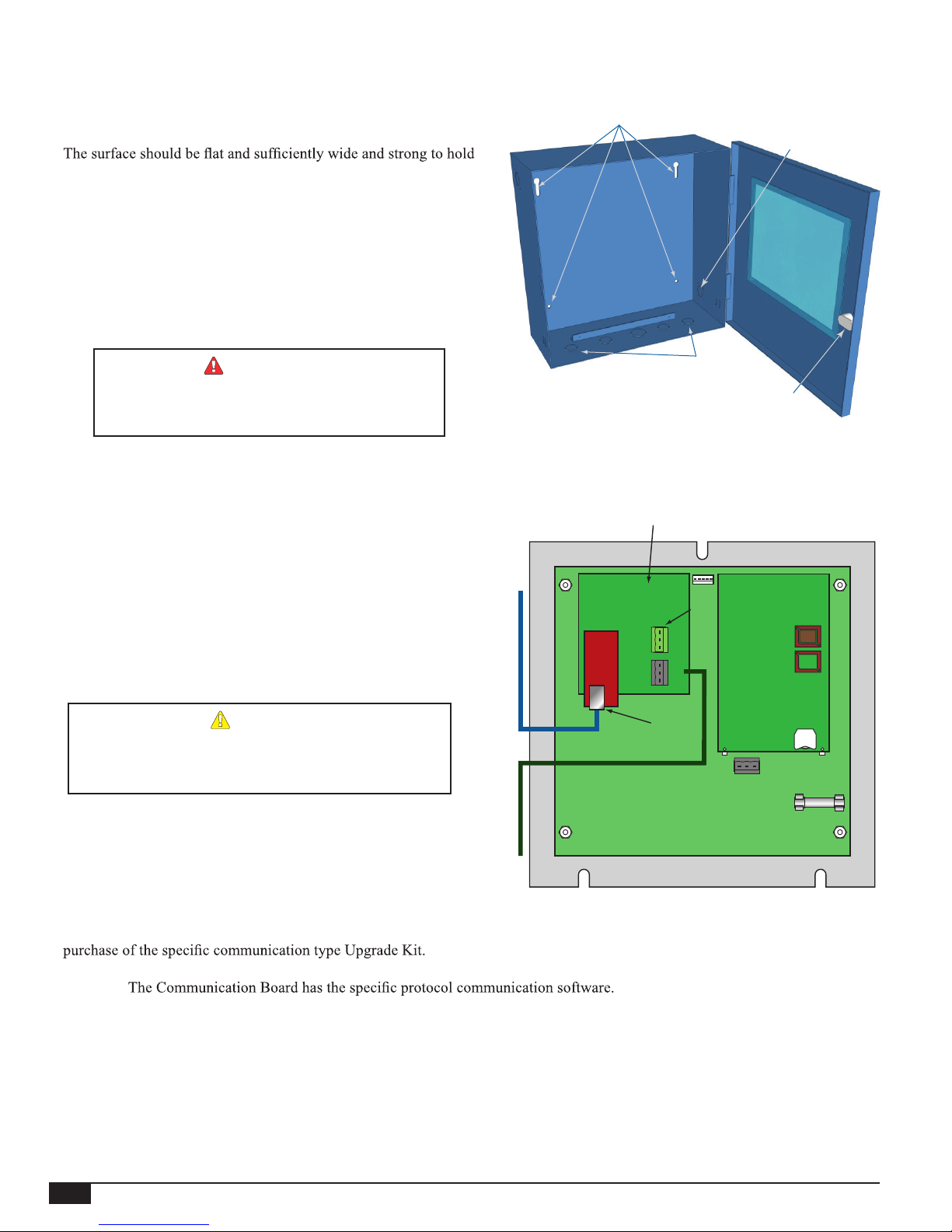

INSTALLATION

MOUNTING THE ENCLOSURE

• Select a location near the equipment to be controlled.

•

the MPC Platinum.

• Keep the MPC Platinum control away from extreme heat, cold, or

humidity. Ambient operating temperature is from 20 to 120°F.

• Remove the control from the metal enclosure by removing the top

center screw and loosening the two bottom screws. Then, lift the

control out of the enclosure.

• Screw the enclosure to the surface through its back mounting holes.

• Return the control to the enclosure, replace the top screw, and

tighten the bottom two screws.

WARNING

Use only the provided Enclosure Knockouts. DO

NOT DRILL HOLES THROUGH THE ENCLOSURE

AS IT WILL VOID CONTROL WARRANTY.

REAR OF CONTROL

Activate the Battery

• Turn the MPC Platinum control over to reveal the piggyback

circuit board (CPU board).

• Remove the plastic strap that covers the battery. The contacts

should be touching the battery.

• The control has a coin Lithium battery (CR2032)

(HT# 020002-00) that is used to maintain the control's date and

time during power outages. This battery can maintain the clock

for up to a total of 100 days.

Mounting Holes

Internet Communication Board (-RINet),

BACnet Communication Board (-BAC),

or MODBUS Communication Board (-BUS)

or the Internet

Communication

Board

Connect to BACnet IP Network

A(+)

G

B(-)

A(+)

G

B(-)

Wiring

Knockouts

MSI

Use Only

Communication

Knockout

Enclosure

Lock

CPU Board

ALERT

Do not install the battery unless you plan to keep the

control continuously powered. If the control has no power,

the battery will lose its charge in 100 days.

CAT5 Cable

RS485 Cable

Connect to BACnet MSTP Network

or MODBUS RTU Network

RJ45

Socket

Motherboard

RS485 (B)

Battery

Control Communication Upgrade

• All non-communication MPC Platinum controls are upgradable to any of the available communication options. This, requires the

• The Upgrade Kit consist of two boards, a CPU Board and a Communication Board. The CPU Board has the control operating

software.

• All communication boards have an Ethernet socket that is used for the BACnet IP or Internet communication and a RS485 socket

that is used for BACnet MS/TP or MODBUS communication.

• Both boards are mounted on the back of the Platinum control's motherboard. Thus, to install both boards you need to remove the

control from the enclosure by removing 3 facing screws. Then, turn the control over to reveal its back.

• Each of the boards is mounted on a group of standoffs that must be replaced during the upgrade. See "Remote Communication

Wiring" on page 14.

• Connect the communication cable from the side Knockout.

• Reinstall the Panel in the enclosure using 3 screws.

HT# 059085-00 F

8

MPC Platinum Installation and Operation Manual

SENSOR INSTALLATION

Outdoor Sensor

Shield

Immersion Well

3/8" ID 1/2" NPT

Immersion Heating System Sensor

Common Supply Pipe

Heating System

Sensor

Sensor Probe

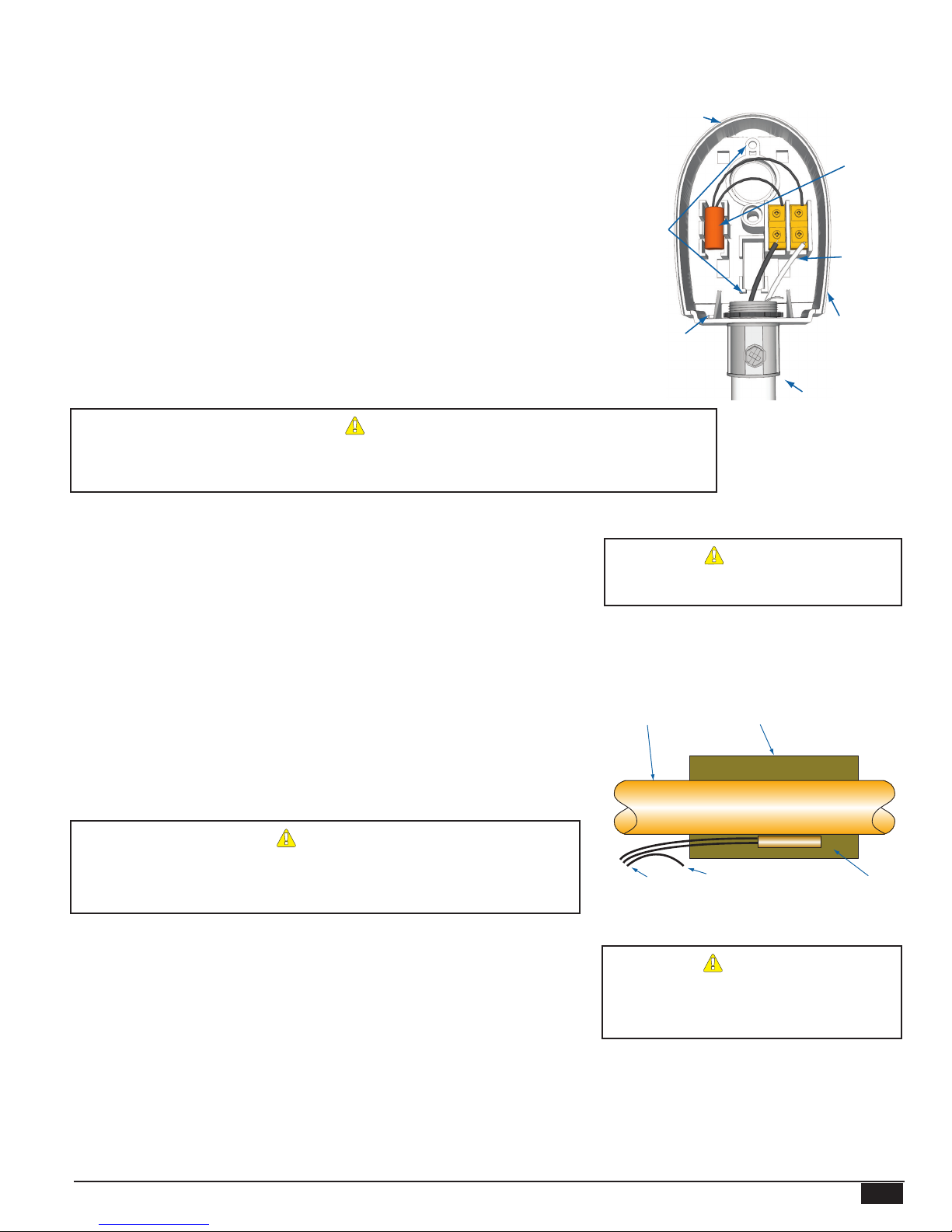

OUTDOOR SENSOR INSTALLATION

Only use the Heat-Timer sensor included with the unit (HT# 904220-00).

• Locate the sensor in the shade on the north side of the building. The sensor

should never be in direct sunlight.

• Be sure the location is away from doors, windows, exhaust fans, vents, or other

possible heat or cool sources.

• The sensor should be mounted approximately 10’ feet above ground level.

• Adhere the Outdoor Label provided to the back of the sensor base.

• Use the Enclosure Base bottom knockout for the conduit. Use the locknut to hold

the conduit and enclosure base together. Screw the cover to the base.

• Make sure to seal around the sensor enclosure and wall except from the bottom.

• The sensor wires can be extended up to 500’ using shielded 2-conductor cable

(HT# 703001-01) (#18/2). Do not connect the shield at the sensor. However,

connect it at the control using the terminal marked with an “O”.

• Do not run sensor wires in conduit with line voltage wiring.

Determining the proper location for the Outdoor Sensor is very important. The MPC Platinum will

base the heat on the outdoor temperature information it receives from this location. If the sensor is in

the sun, or covered with ice, its reading will be different from the actual Outdoor temperature (OD).

HEATING SYSTEM SENSOR (HSS) INSTALLATION

• Install the sensor at one of the following locations:

The ideal location for the HSS is on the furthest radiator in the system. This

radiator is usually the hardest to heat.

The sensor may be located on the furthest return riser. However, the sensor

MUST be above the boiler water line (on a dry return).

• Only use the sensor provided with the control. If you are replacing an earlier

Gold model Heat-Timer, it is NOT necessary to upgrade the sensor.

• Strap the HSS to the pipe using the tie-wraps provided with the outdoor sensor.

Then wrap insulation around the sensor and pipe to achieve the highest accuracy.

• The sensor wires can be extended up to 500' using a shielded 2-conductor cable

(HT# 703001-01) (#18/2).

• Do not connect the shield at the sensor. However, connect it at the control using

the terminal marked with an “O”.

• Do not run sensor wires in conduit or trough with line voltage wiring.

ALERT

Seal around

sensor and wall

Mounting

screws

location

Outdoor

drip-hole

on back of Sensor

Conduit

ALERT

NEVER Install the HSS between the

condensate receiver and the boiler.

Strap-On Heating System Sensor

Common Supply Pipe

Pipe Insulation

Outdoor Sensor

snap-in location

Shield

not connected

Outdoor Label

ALERT

If the HSS cannot sense the system is full of steam, the MPC Platinum

will not provide comfortable heat levels. Be sure the HSS is located on

a properly vented pipe that cannot easily be isolated from the system.

Using a Pressutrol instead of the HSS

• Heat-Timer MPC Platinum control requires the use of a HSS. However, if a

good location for the HSS is not possible, it is acceptable to install a Pressuretrol

Adaptor Kit (HT# 900043-00) that connects to the boiler operating pressuretrol.

In this case, the system may not be as efcient as when using the HSS and the

Thermal Lockout feature will not be available..

MPC Platinum Installation and Operation Manual

Connect

To control

Shield

Sensor Probe

ALERT

The use of the Pressuretrol Adaptor Kit

(HT# 900043-00) may reduce the system

operating efciency.

9

HT# 059085-00 F

WIRING THE POWER

MPC

Platinum

PREV.

(DEL)

OUT

TEMP

AUX

INPUT 0

AUX

TEMP 0

AUX

TEMP 1

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

DAY selects next day

PREV./NEXT steps through output status

DAY

HELP NEXT

PRESS TO

SELECT

BACK

MON 12/01/2010 10:01Am

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

AUX

TEMP 2

DO NOTAPPLY ANY VOLTAGE

TO SENSOR TERMINALS

A13

A14

A15

A16

A17

A18

NETWORK

PROVE

SHUTDOWN

SYSTEM

TEMP

BYPASS

ALL SENSORS MUST BE

GOLD SERIES SENSORS

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

T

T

T

Cycle On 13/15

Cutoff = 55

o

F Day

OD = 31

o

F SYS = 138oF

AUTO

T

T

C O R P O R A T I O N

R

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

AUX

CLOCK

OPTION1OPTION2OPTION

3

12 13 14 15 16 17

18

OPTION

3

OPTION

2

OPTION

1

AUX

CLOCK

MPC

Platinum

PREV.

(DEL)

OUT

TEMP

AUX

INPUT 0

AUX

TEMP 0

AUX

TEMP 1

MENU FUNCTIONS

BACK returns to previous menu

DAY selects next day

DAY

HELP NEXT

PRESS TO

SELECT

BACK

MON 12/01/2010 10:01Am

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

AUX

TEMP 2

DO NOTAPPLY ANY VOLTAGE

TO SENSOR TERMINALS

A13

A14

A15

A16

A17

A18

NETWORK

PROVE

SHUTDOWN

SYSTEM

TEMP

BYPASS

ALL SENSORS MUST BE

GOLD SERIES SENSORS

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

T

T

T

Cycle On 13/15

Cutoff = 55

o

F Day

OD = 31

o

F SYS = 138oF

AUTO

T

T

C O R P O R A T I O N

R

ENCLOSED

ENERGY

EQUIPMENT

LISTED

OPTION2OPTION

3

16 17

18

OPTION

3

OPTION

2

MPC

Platinum

PREV.

(DEL)

OUT

TEMP

AUX

INPUT 0

AUX

TEMP 0

AUX

TEMP 1

MENU FUNCTIONS

BACK returns to previous menu

DAY selects next day

DAY

HELP NEXT

PRESS TO

SELECT

BACK

MON 12/01/2010 10:01Am

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

AUX

TEMP 2

DO NOTAPPLY ANY VOLTAGE

TO SENSOR TERMINALS

A13

A14

A15

A16

A17

A18

NETWORK

PROVE

SHUTDOWN

SYSTEM

TEMP

BYPASS

ALL SENSORS MUST BE

GOLD SERIES SENSORS

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

T

T

T

Cycle On 13/15

Cutoff = 55

o

F Day

OD = 31

o

F SYS = 138oF

AUTO

T

T

C O R P O R A T I O N

R

ENCLOSED

ENERGY

LISTED

OPTION2OPTION

3

16 17

18

OPTION

3

OPTION

2

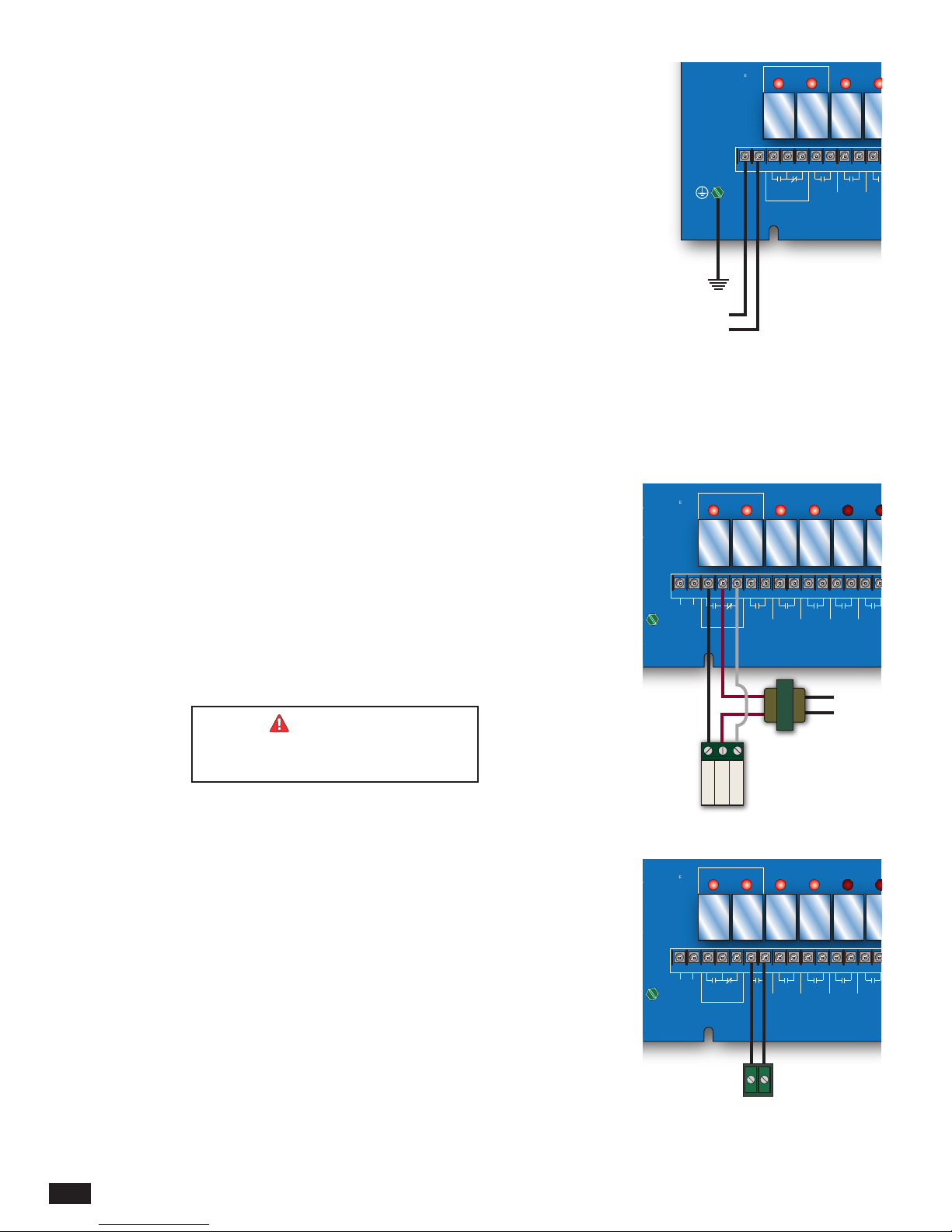

• If possible, provide a dedicated circuit breaker for the MPC Platinum. DO NOT connect

the MPC Platinum to a circuit breaker connected to high inductance devices such as

relays, pumps, fans, or motors.

• Bring the 120VAC 60Hz power wires through a bottom knockout (KO) of the enclosure.

• Class 1 voltages must enter the enclosure through a different knockout from any Class 2

voltage wiring.

• Connect the hot line to terminal marked LINE.

• Connect the neutral line to the terminal marked NEUT. DO NOT share neutrals. The

neutral line MUST come directly from the circuit breaker.

• Connect the green ground screw to earth ground. DO NOT use the neutral line as a

ground.

• Heat-Timer recommends the installation of a Surge Suppressor and a Power Switch

before the Power Line connection for safety and ease of service.

OUTPUT WIRING

• All of the MPC Platinum's outputs DO NOT SOURCE any power. If power is needed at

a specic output, a separate power source must be wired in series with the output.

• Each of the output relays can switch a 6A resistive at 120VAC load or a 1A inductive

load.

SAFETY

GROUND

MUST BE

CONNECTED

MADE IN U.S.A.

Earth

Ground

120 VAC

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

L

N

2 3 4 5

B R W

LINE

MOTORIZED

NEUTRAL

OUTPUT SYS

6 7 8 9 10 11

BURNER

VALVE

SYSTEM

WIRING TO A MOTORIZED VALVE

• The MPC Platinum is capable of operating a boiler, a oating motorized valve, or both.

• The MPC Platinum output terminal R (5) is the Common. Wire it to the 24 VAC power

source (transformer).

• Connect the transformer's second wire to the actuator Common terminal.

• The MPC Platinum output terminal B (4) is the Normally Open (N.O.). Wire it to the

actuator Open terminal.

• The MPC Platinum output terminal W (6) is the Normally Closed (N.O.). Wire it to the

actuator Close terminal.

• The N.O. and N.C. contacts are dry contacts only. They do not source any power. The

transformer is the actuator power source.

WIRING TO A BOILER

• The MPC Platinum s designed to operate a boiler, a oating motorized valve, or both.

• The BURNER output terminals are 7 and 8. They do not source any power. Wire the

burner output in series with the boiler limit circuit.

outages activates the Output and System.

WARNING

Switching to BYPASS during power

99RA

99RA

OUTPUT SYS

2 3 4 5

B R W

LINE

MOTORIZED

VALVE

NEUTRAL

Common

Open

Floating

Valve Actuator

OUTPUT SYS

2 3 4 5

B R W

LINE

MOTORIZED

VALVE

NEUTRAL

OPTION

AUX

1

CLOCK

6 7 8 9 10 11 12 13 14 15

BURNER

SYSTEM AUX

CLOCK

OPTION

1

120 VAC

24 VAC

Transformer

Close

OPTION

AUX

1

CLOCK

6 7 8 9 10 11 12 13 14 15

BURNER

SYSTEM AUX

CLOCK

OPTION

1

HT# 059085-00 F

10

Boiler

MPC Platinum Installation and Operation Manual

WIRING TO SYSTEM OUTPUT

MPC

Platinum

PREV.

(DEL)

OUT

TEMP

AUX

INPUT 0

AUX

TEMP 0

AUX

TEMP 1

DAY

HELP NEXT

PRESS TO

SELECT

BACK

MON 12/01/2010 10:01Am

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

AUX

TEMP 2

DO NOTAPPLY ANY VOLTAGE

TO SENSOR TERMINALS

A13

A14

A15

A16

A17

A18

NETWORK

PROVE

SHUTDOWN

SYSTEM

TEMP

BYPASS

ALL SENSORS MUST BE

GOLD SERIES SENSORS

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

T

T

T

Cycle On 13/15

Cutoff = 55

o

F Day

OD = 31

o

F SYS = 138oF

AUTO

T

T

R

OPTION

OPTION

OPTION

AUX

MPC

Platinum

PREV.

(DEL)

OUT

TEMP

AUX

INPUT 0

AUX

TEMP 0

AUX

TEMP 1

DAY

HELP NEXT

PRESS TO

SELECT

BACK

MON 12/01/2010 10:01Am

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

AUX

TEMP 2

DO NOTAPPLY ANY VOLTAGE

TO SENSOR TERMINALS

A13

A14

A15

A16

A17

A18

NETWORK

PROVE

SHUTDOWN

SYSTEM

TEMP

ALL SENSORS MUST BE

GOLD SERIES SENSORS

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

T

T

T

Cycle On 13/15

Cutoff = 55

o

F Day

OD = 31

o

F SYS = 138oF

T

T

R

MPC

Platinum

PREV.

(DEL)

OUT

TEMP

AUX

INPUT 0

AUX

TEMP 0

AUX

TEMP 1

DAY

PRESS TO

SELECT

BACK

MON 12/01/2010 10:01Am

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

AUX

TEMP 2

DO NOTAPPLY ANY VOLTAGE

TO SENSOR TERMINALS

A13

A14

A15

A16

A17

A18

NETWORK

PROVE

SHUTDOWN

SYSTEM

TEMP

ALL SENSORS MUST BE

GOLD SERIES SENSORS

INPUTS

T

T

T

Cycle On 13/15

Cutoff = 55

o

F Day

OD = 31

o

F SYS = 138oF

T

T

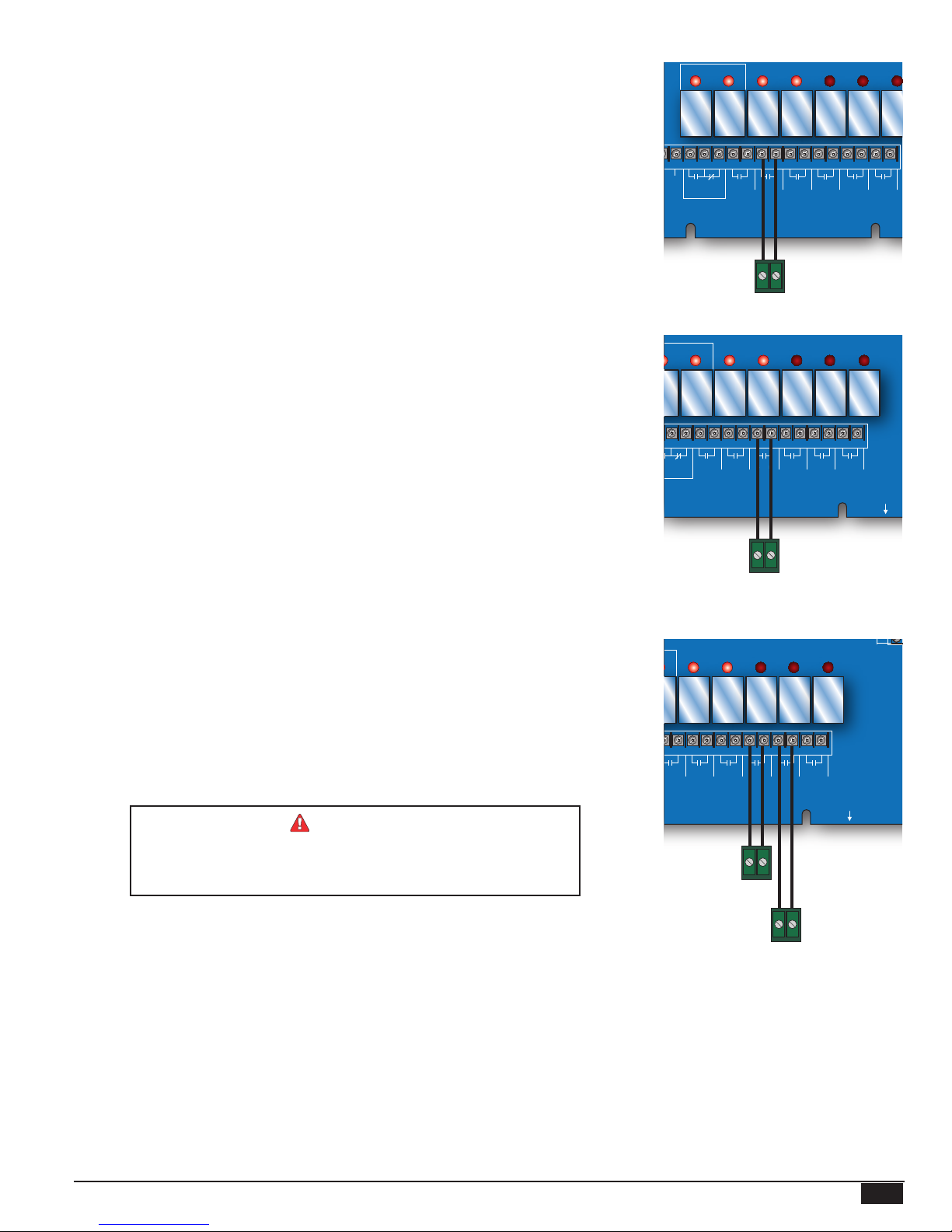

• The MPC Platinum is equipped with a System output to operate additional equipment.

The most common use for this output is operating a combustion air-damper.

• The SYSTEM output terminals are 9 and 10. These terminals do not source any power.

Wire these terminals directly to the combustion air-damper activation terminals.

• The contacts can switch a 6A resistive at 120VAC load.

• A good practice is to use the MPC Platinum's Prove input terminals to connect to the

combustion air-damper End Switch. This prevents the MPC Platinum from activating

the boiler before fully opening the damper. See "Wiring The Prove" on page 12.

• The System relay energizes whenever the Output relay energizes. When the Output relay

de-energizes, the System relay remains energized for the System Run-On period before

de-energizing.

WIRING TO AUXILIARY CLOCK

• The MPC Platinum is equipped with an AUX CLOCK output (terminals 11 and 12). Use

the output to operate additional equipment based on the Aux Schedule. A common use is

to turn on and off a set of lights based on a schedule. See "Aux Relay Schedule" on page

30.

• The AUX CLOCK output terminals do not source any power. Wire the AUX CLOCK

terminals directly to the equipment activation terminals if the equipment does not require

any power.

• If the equipment controlled require powering, make sure that its power consumption does

not exceed the output relay rating. Otherwise, use an isolation relay.

OUTPUT SYS

6 7 8 9 10 11 12 13 14 15 16 17

3 4 5

B R W

BURNER

MOTORIZED

VALVE

NEUTRAL

CLOCK

SYSTEM AUX

CLOCK

Combustion

Air Damper

OPTION

OUTPUT SYS

6 7 8 9 10 11 12 13 14 15 16 17

5

R W

BURNER

CLOCK

SYSTEM AUX

AUX

OPTION1OPTION2OPTION

CLOCK

1

OPTION1OPTION2OPTION

OPTION

2

1

OPTION

18

3

3

2

18

3

3

WIRING TO OPTION OUTPUTS

• The MPC Platinum is equipped with three optional relay outputs (OPTION1 terminals 13

and 14, OPTION2 terminals 15 and 16, and OPTION3 terminals 17 and 18). Use these

outputs to operate additional equipment based on the control logic. Each of the Option

output relays has different logic operating choices. Select the desired choice from the

Startup Menu. See "Option Outputs Modes" on page 21.

• If the control is an Internet capable control, the OPTION3 output relay will function as a

relay to manage a cable or DSL modem's power.

• The OPTION output terminals do not source any power. Wire the OPTION terminals

directly to the equipment activation terminals if the equipment does not require any

power.

• If the equipment controlled require powering, make sure that its power consumption does

not exceed the output relay rating. Otherwise, use an isolation relay. In this case, use the

OPTION terminal to break the hot power wire. going to the equipment. Then, connect

the neutral wire directly the equipment second terminal.

On Internet capable controls, you MUST use Option 3 output to

manage the power to Cable and DSL modems. However, DO NOT

use Option 3 Output to manage the power to Cellular Modems.

WARNING

Auxilary

Schedule

Activated

Device

SYS

CLOCK

8 9 10 11 12 13 14 15 16 17

SYSTEM AUX

CLOCK

2

1

OPTION1OPTION2OPTION

OPTION

OPTION

AUX

Option1

Option2

OPTION

3

18

3

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

MPC Platinum Installation and Operation Manual

HT# 059085-00 F

11

INPUT WIRING

AUX

A1

A2

A3

A4

A5

A6

A7

A8

A9

NETWORK

PROVE

SHUTDOWN

SYSTEM

TEMP

T

A1

SYSTEM

TEMP

T

Shutdown

A1

A2

A3

SHUTDOWN

SYSTEM

TEMP

T

OUT

TEMP

AUX

INPUT 0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

NETWORK

PROVE

SHUTDOWN

SYSTEM

TEMP

T

T

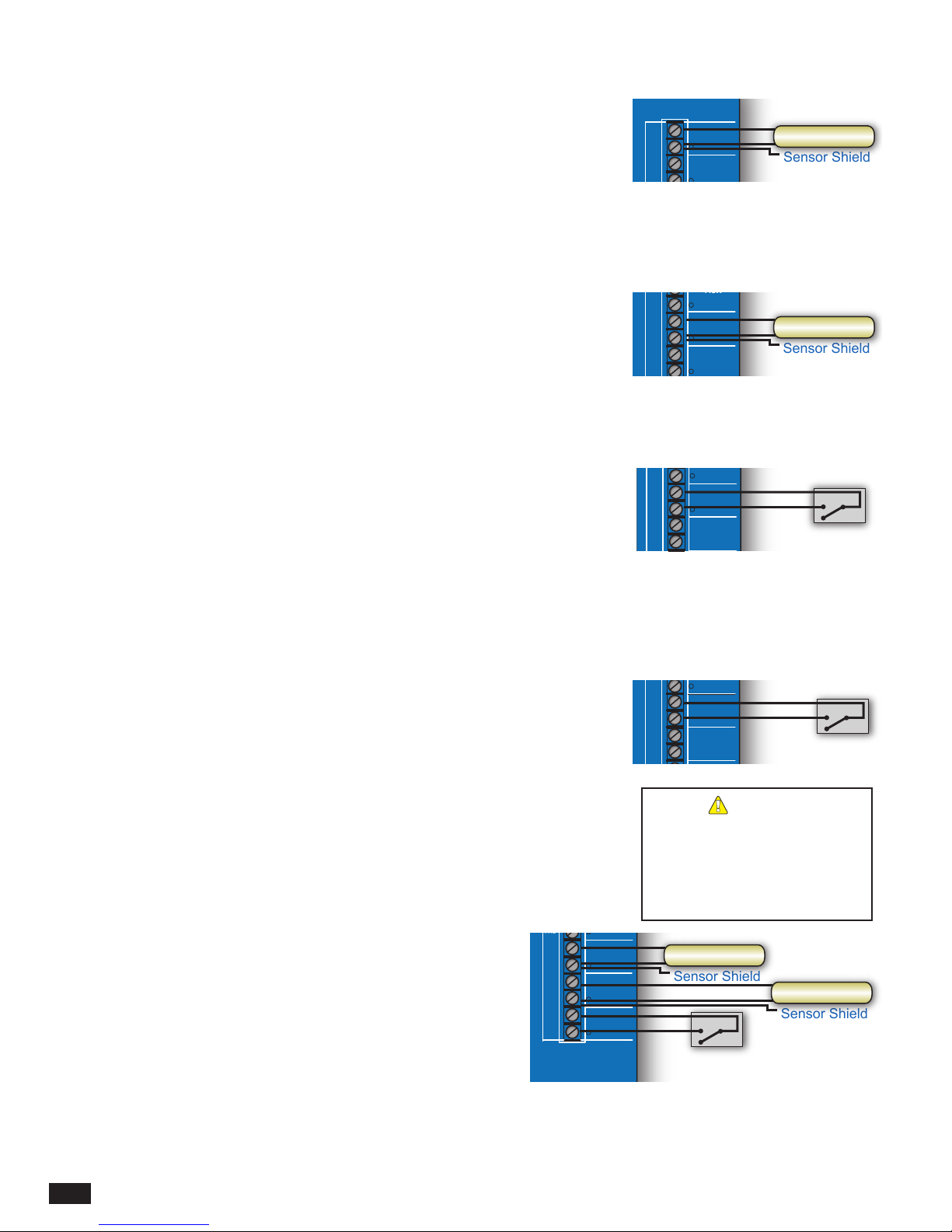

WIRING SYSTEM SENSOR

• Only use the Heat-Timer Outdoor sensor included with the MPC Platinum (#904250-00).

• You can extend the sensor wires up to 500’ by splicing it with 18 gauge shielded wire

(Belden #8760 or equivalent).

• DO NOT run sensor wire in conduit or trough with line voltage.

• Heat-Timer temperature sensors have no polarity. Connect the sensor wires to the MPC

Platinum terminals marked SYSTEM TEMP (terminals A1 and A2).

• Connect the shield to the circled terminal SYSTEM TEMP-A2 with one of the sensor

wires and cut shield off at sensor end.

T

A1

A2

A3

SYSTEM

TEMP

SHUTDOWN

System Sensor

Sensor Shield

WIRING THE OUTDOOR SENSOR

• You can extend the sensor wires up to 500’ by splicing it with 18 gauge shielded wire

(Belden #8760 or equivalent).

• DO NOT run sensor wire in conduit or trough with line voltage.

• Heat-Timer temperature sensors have no polarity. Connect the sensor wires to the MPC

Platinum terminals marked OUT TEMP (terminals A11 and A12).

• Connect the shield to the circled terminal OUT TEMP-A12 with one of the sensor wires

and cut shield off at sensor end.

WIRING THE SHUTDOWN

• You can use this feature whenever it is desirable to deactivate the MPC Platinum from a

remote location or another controller like a Building Management System (BMS).

• The Shutdown feature de-energizes the BURNER and MOTORIZED VALVE output

relays, turning off the boiler or closing the motorized valve. However, the SYSTEM relay

will remain energized for the period of the System Run-On. See "System Run-On" on

page 28.

• The Shutdown signal must be a dry contact only. DO NOT place voltage across the

SHUTDOWN terminals.

• Bring the two wires from the dry contact to the terminals marked SHUTDOWN- A3, A4.

WIRING THE PROVE

• The MPC Platinum uses the Prove input to check system operation before activating the

outputs. A good practice is to use the MPC Platinum's Prove input terminals to connect

to the combustion air-damper End Switch. This prevents the MPC Platinum from

activating the boiler before fully opening the damper. See "Installation" on page 8.

• If the PROVE input terminals are open, the MPC Platinum will enable only the System

relay. The Burner and Motorized valve (OUTPUT) relays will be de-energized when the

PROVE input is open.

• The Prove signal must be a dry contact only. No voltage can be placed across the

PROVE terminals.

• Bring the two wires from the dry contact to the terminals marked A5 and A6.

NETWORK AND AUX TEMP

• The only way to congure all Network sensors and

switches is through the Internet using the ICMS web site

(http://www.htcontrols.com).

• Heat-Timer offers a large variety of network sensors. Visit

our web site (http://www.heat-timer.com) for a list of available

Network Sensors.

• The Aux Temp inputs are capable of accepting a temperature or

a switch sensor. The user can access their values by pressing

the BACK button while in the default screen.

HT# 059085-00 F

12

MPC Platinum Installation and Operation Manual

A10

A11

A12

A13

A14

A2

A3

A4

A5

A6

A4

A5

A6

A7

A8

INPUT 0

T

OUT

TEMP

T

AUX

TEMP 0

SHUTDOWN

PROVE

PROVE

NETWORK

Outdoor Sensor

Sensor Shield

Shutdown

Prove

ALERT

The PROVE input terminals must

be shorted for MPC Platinum to

provide heat. DO NOT remove the

factory installed PROVE jumper

unless replacing it with a Prove

signal.

A13

T

AUX

T

T

TEMP 0

AUX

TEMP 1

AUX

TEMP 2

A14

A15

A16

A17

A18

Temp. Sensor

Sensor Shield

Space Sensor

Sensor Shield

Switch Input

TESTING THE SENSORS

A1

A2

A3

A4

A5

A6

A7

A8

NETWORK

PROVE

SHUTDOWN

SYSTEM

TEMP

T

External Boiler Call

• On a power up, the Platinum control goes through a countdown followed by the default screen.

• The default screen displays

Sensor temperature.

• If either of the two temperatures reads

• You can only view Network sensor readings on the Internet.

(SYS) to show the Heating System Sensor (HSS) temperature and (OD) to show the Outdoor

OPEN, SHORT, or an incorrect temperature. See "Troubleshooting" on page 44.

AUX INPUT

• If the boiler is activated by another control, i.e. domestic hot water aquastat, the Aux

Input will allow a Heat-Timer communication package to chart a time line for boiler

status.

WIRING NETWORK SENSORS

(Requires Internet Communication Package Upgrade)

•

the ICMS website (http://www.htcontrols.com).

• The MPC Platinum Network terminals can connect up to 64 or 128 network sensors,

depending on the control hardware.

• Use the Mini-MIG to handle up to 16 temperature, switch, or count sensors. Multiple

Mini-MIG’s can connect to an MPC Platinum.

• A variety of network sensors is available for the MPC Platinum:

◦ Stack Sensor (measures the stack temperature),

◦ Water Meter Count/Pulse sensor (measures water consumption),

◦ Oil Tank Monitor (measure the amount of oil in a tank),

◦ Pressure, vacuum, and humidity transducers,

◦ Multiple Input Gateway (Mini-MIG) that gives the capability of connecting the

control to multiple temperature or switch sensors and a single count sensors.

◦ Conductivity sensors (to measure boiler chemical requirement).

CONNECTING WIRELESS SENSOR SYSTEM

(Requires Internet Communication Package Upgrade)

•

Internet (http://www.htcontrols.com).

• The MPC Platinum can connect to up to 64 or 128 network

sensors, depending on the control hardware. These numbers

include wireless sensors, wireless Transceivers, and the

wireless Network Manager.

• Use Wireless Transceivers to extend the range of the wireless

network and reduce building sensor wiring.

• The wireless Network Manager connects directly to the

communication board's RS485.

• The balance of the wireless system communicates its

information to the wireless Network Manager.

Send Packet

Button

NM RS485

Cable (Provided)

RS485

Connect to

Wireless NM

Wireless Network Manager

1 2 3 4

ON

A9

A10

A11

A12

T

AUX

INPUT 0

OUT

TEMP

Network

Sensors

Platinum

PWR

Network

L N

N1

1 2

3 4

Platinum Control

A(+)

G

B(-)

A(+)

G

B(-)

External Boiler Call

RS485

T

OUT

TEMP

SHUTDOWN

S+S

PRESS

4-20 mA

Network

NETWORK

PROVE

A10

T

AUX

TEMP 0

A12

A13

T

AUX

TEMP 1

A14

A15

T

AUX

TEMP 2

A16

A17

A18

MIG

Mini-MIG

Multiple Input Gateway

Power

Comm

T1 T2 T3 T4

125 72 73 75

VIEW

RESET

6

Input 719Input 821Input

20 22

Input 923Input 1025Input 1127Input 12

29

24 26 28 30 32 34 36 38

Pulse

Input 13

14

Input 15

Input

Input 16

31 33

35

37

Input 5

Input 29Input 311Input 4

Input 1

7

13

15 17

10 12 14 16 18

8

CPU Board

Wireless

Wireless

Network

Manager

0056789

Water

Meter

Stack

Sensor

Sensor

Oil Level

MPC Platinum Installation and Operation Manual

Motherboard

HT# 059085-00 F

13

REMOTE COMMUNICATION WIRING

PLATINUM PANEL CONNECTED

TO BACnet IP Network

Ethernet socket

PLATINUM PANEL CONNECTED

TO BACnet MS/TP Network

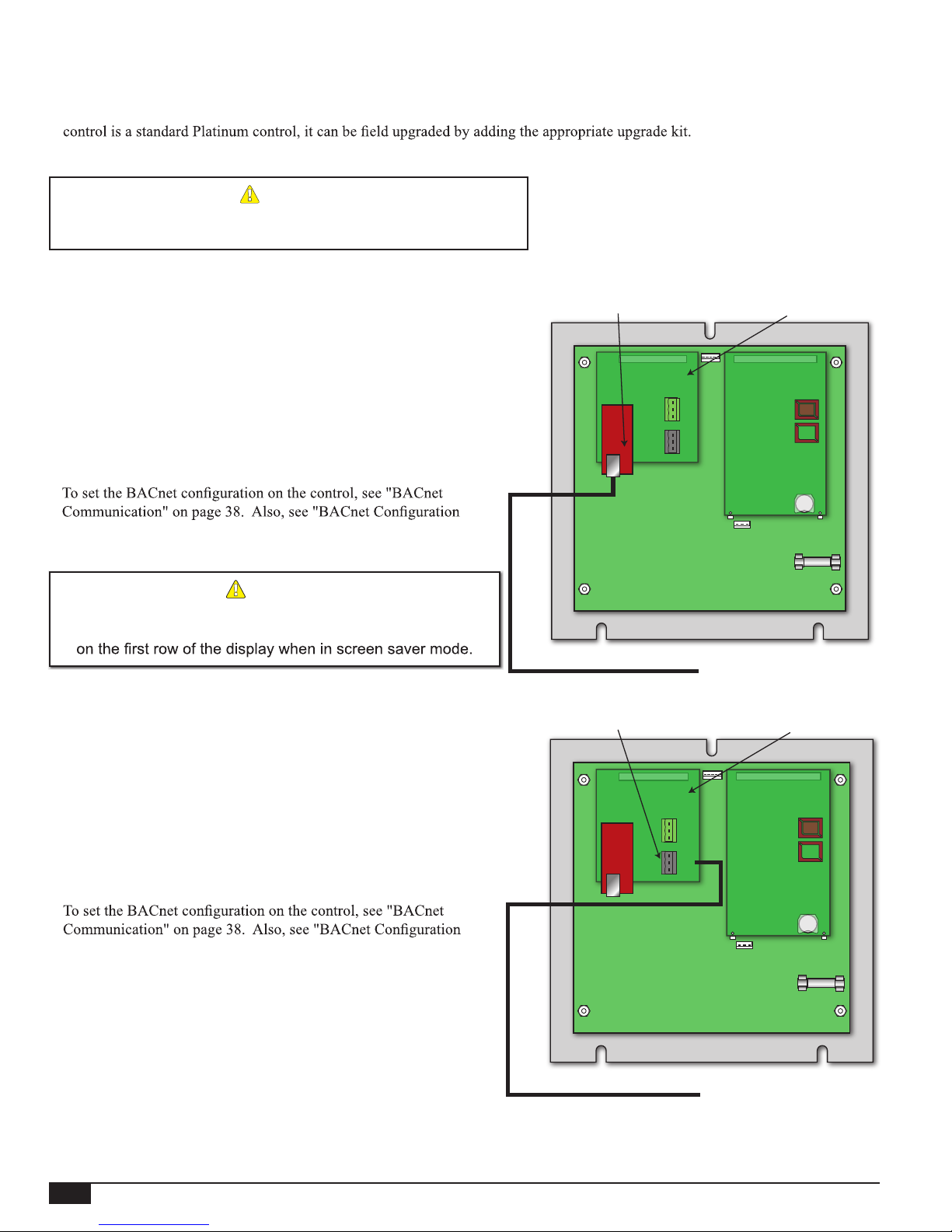

• All standard Platinum controls come with a Motherboard and a CPU board.

• If the Platinum control part number ends with RINET, BAC, or BUS; then it also comes with a communication board. If a

A new CPU board and the

respective communication board will be included in any of the Upgrade Kits.

ALERT

Always bring your communication cable through one of the side

knockouts. DO NOT use the bottom knockouts for communication cabling.

BACNET WIRING

BACNET IP WIRING

• The Ethernet cable should use the Platinum control's enclosure closest

side knockout.

•

Connect the CAT-5E BACnet IP cable to the

socket on the back of the control's Communication Board.

• For reliable communication, do not run CAT-5E cables more than

150 Ft. CAT-6 cables can have a maximum run of 300 Ft.

•

Manual".

ALERT

A BACnet capable Platinum control displays

-- NETWORK PANEL --

BACNET MS/TP WIRING

• The RS485 cable should use the Platinum control's enclosure closest

side knockout.

• Connect the BACnet MS/TP cable to the RS485 connector

communication socket on the back of the control's Communication

Board. The Communication Board terminals are labeled 'A (+)', G

(Ground), and 'B (-)'.

• Use 18# AWG Twisted Pair cable. The cable length must not exceed

3500 feet.

• The ground RS485 terminal (G) MUST be connected to the BMS

RS485 Ground.

•

RS45 communication

connect to Cat-5 cable

Motherboard

CAT5/Ethernet Cable

Black RS485 socket

connect to BACnet MS/TP

Communication Board

A(+)

G

B(-)

A(+)

G

A(+)

G

B(-)

A(+)

G

B(-)

B(-)

CPU Board

Connect to Ethernet

Connection on BACnet Network

Communication Board

CPU Board

Manual".

HT# 059085-00 F

14

Motherboard

RS485 Cable

Connect to BACnet MS/TP Network

MPC Platinum Installation and Operation Manual

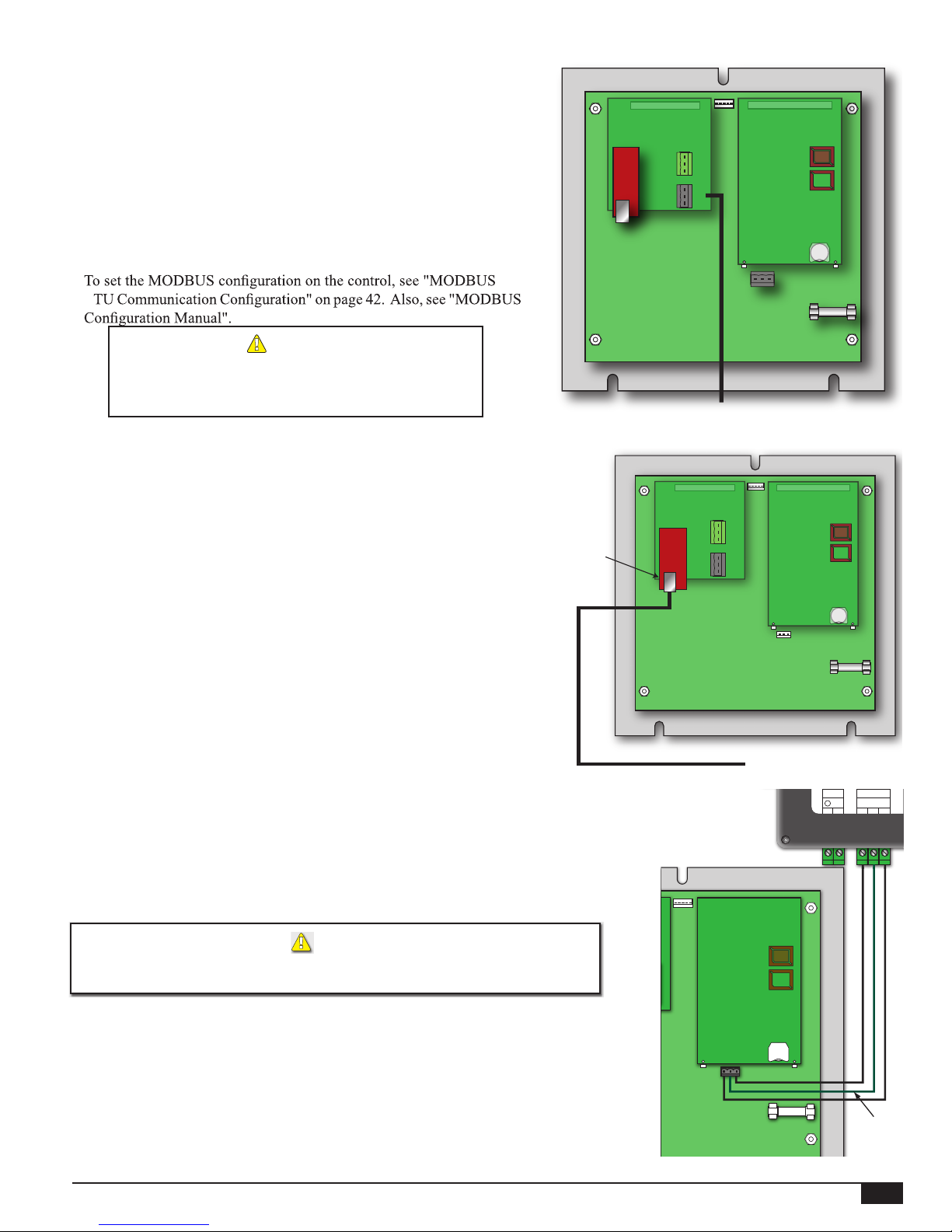

MODBUS RTU WIRING

TO MODBUS NETWORK

PLATINUM PANEL CONNECTED

TO THE INTERNET

DHW Energy Saver

DHW Energy Saver

COM

3 4 5

A GND B

16VAC

1 2

~ ~

• A MODBUS communication board and a CPU board with the

MODBUS software is required for proper MODBUS communication.

• Heat-Timer Platinum control MODBUS communication uses a

RS485 connection.

• Connect the MODBUS RS485 cable to the Communication Board's

RS485 socket. The Communication Board's RS485 socket has ‘A

(+)’, G (Ground), and ‘B (-)’ terminals. Polarity is observed,

• The cable length must not exceed 3500 feet.

• Must Connect the ground RS485 terminal (G) to the BMS RS485

Ground.

•

R

ALERT

DO NOT USE the RS485 Connector on the Motherboard

for MODBUS communication. Use the RS485 Connector

on the MODBUS Communication Board instead.

INTERNET WIRING

MODBUS

Communication

Board

Motherboard

Connect Black RS485

to MODBUS Network

A(+)

G

B(-)

A(+)

G

B(-)

CPU Board

ETHERNET CONNECTION TO MODEM

• Connect the Ethernet cable (provided) to the modem socket marked

Ethernet/LAN. Class 2 voltage wires must use a different knockout

from Class 1 voltage wires.

Ethernet socket

connect to

Cat-5 cable

• Connect the other Ethernet cable end to the Communication board,

through the side knockout.

ETHERNET CONNECTION TO PLATINUM

CONTROL

• Bring the Ethernet line through one of the Platinum Enclosure side

knockouts. Class 2 voltage wires must use a different knockout from

Class 1 voltage wires.

• Connect the Ethernet cable to the Communication Board on the back

of the Platinum control. See "Platinum Internet Setup Manual".

DHW ENERGY SAVER WIRING

• The DHW Energy Saver communicates all of its information to the Platinum control

using RS485 (3-wire connection).

• The DHW Energy Saver RS485 terminals are wired to the Platinum main board’s

RS485 (under the PCB board).

• Follow the wiring as per the graph on the right.

ALERT

DO NOT connect the DHW Energy Saver to the RS485 on the Platinum RI board.

Instead, connect the DHW Energy Saver RS485 to the Platinum main board.

• Maximum wiring length should not exceed 100 Feet. Use 18 gauge 2-conductor

shielded wire (#18). Connect the shield to the middle terminals on both of the RS485

connections. To eliminate communication errors, DO NOT splice the communication

cable wires.

• When connecting the DHW Energy Saver and a Platinum Extension to the same

connector, make sure to splice the cables externally before bringing them to the RS485

Plug Connector on the main Platinum Board. See "DHW Energy Saver Manual".

Communication

Motherboard

CAT5/Ethernet Cable

Platinum main board

Board

A(+)

G

B(-)

A(+)

G

B(-)

PCB board

Use RS485

Communication

on the back of the

CPU Board

Connect to Internet

16VAC

~ ~

1 2

COM

A GND B

3 4 5

Shield

MPC Platinum Installation and Operation Manual

HT# 059085-00 F

15

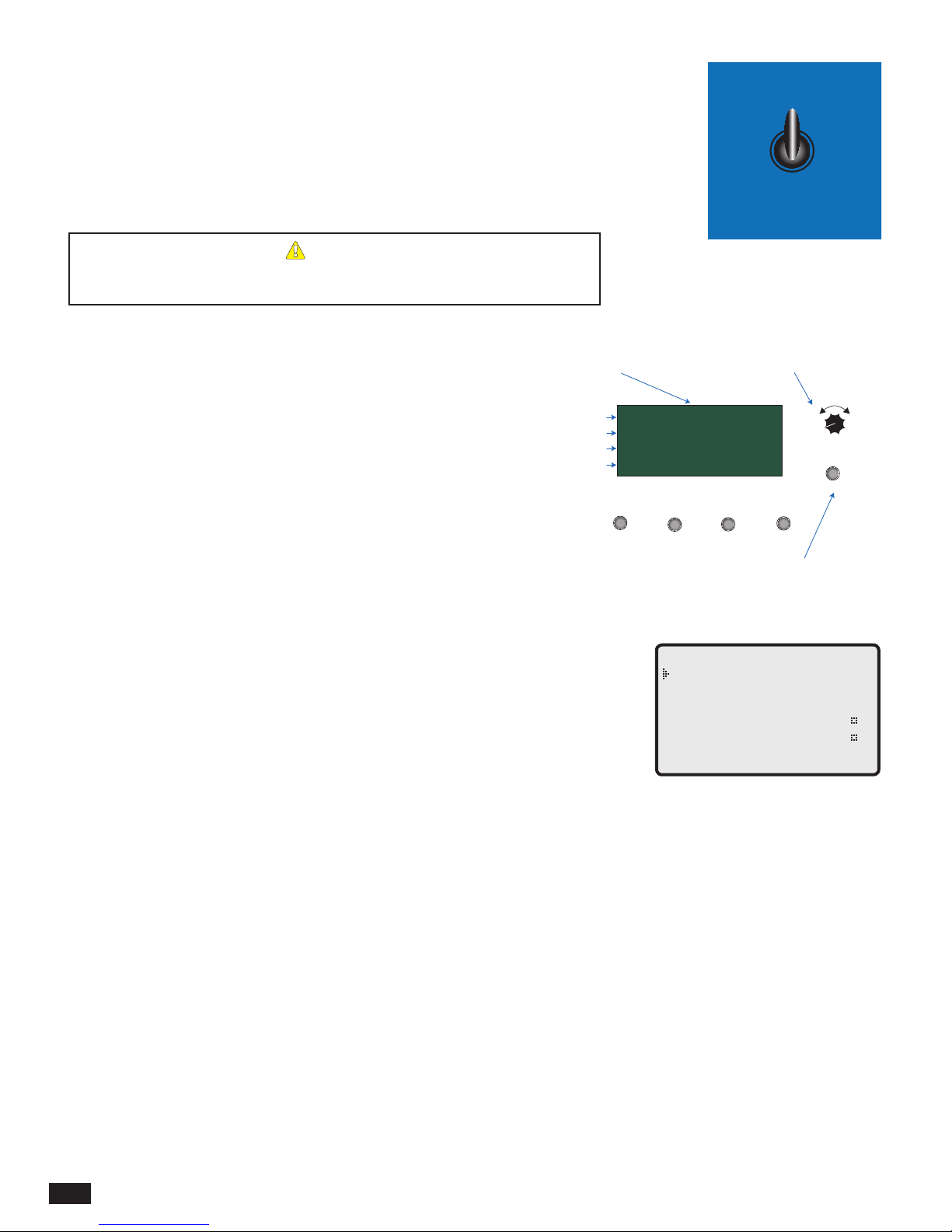

AUTO/BYPASS SWITCH

MPC

Platinum

PREV.

DAY

HELP NEXT

MON 12/01/2010 10:01Am

Cycle On 13/15

Cutoff = 55

o

F Day

OD = 31

o

F SYS = 138oF

R

• The switch must be in the AUTO position for the MPC Platinum to control the heating

system.

• The BYPASS position overrides all automatic control of the MPC Platinum.

• If the MPC Platinum has power and is operational, switching to BYPASS automatically

activates the Motorized Valve, the Burner, and the System output.

• Switching the control to BYPASS manually during a power outage, activates the

Motorized Valve, Burner , and System outputs.

ALERT

Switching the MPC Platinum into Bypass overrides all automatic operation. In

Bypass, the boiler will run constantly on its own limits or the valve will be fully open.

AUTO

BYPASS

SETTING THE CONTROL

Digital display shows the date, heating

status, and cutoff, outdoor, and system

values. To view and adjust settings,

press the Adjust/Select button.

DISPLAY AND CHANGING SETTINGS

The MPC Platinum comes with an 80 character (20 character per row x 4

rows) digital display with simple English menus.

ADJUST/SELECT This knob turns to ADJUST and when pressed

it SELECTs. Turn the knob to scroll through

settings. Press a menu option to accept a setting,

BACK Use to go back to the previous menu,

NEXT In Schedules, goes to next schedule period,

DAY In Schedules, advances through weekdays,

PREV.(DEL) Clears a specic schedule setting.

HELP Provides help instructions regarding the current

menu function.

Date and Time

Messages

Cutoff and Schedule

Sensor Status

MENU TYPES

When powering up the MPC Platinum for the rst time, it will take you through an 70

second count down followed by the System Startup Settings then another 10 second boot

setup and nally end with the default screen. Once the control is mounted and wired, set

up an initial pilot program.

• Set and adjust System Startup Settings: The contractor sets these values after installing

the control for the rst time. End users should avoid changing these settings as they

will change the control operating logic. If the Startup Settings are not correct, the MPC

Platinum may operate the system incorrectly.

• Set and adjust System Settings: These settings adjust the system to the specic building

characteristics. These are general settings that control the amount of heat provided. The

default settings will generally work in most applications, but adjustments should ne-

tune the performance of your system.

• Set and adjust Maintenance: Provide calibration tools for the sensors and allow a

password to be set.

• Set and adjust Schedules: Sets the Day/Night heat schedule and the Aux clock schedule.

Four pairs of Day/Night times can be set for each day of the week. In addition, the Aux

relay is capable of following the Aux Schedule. It is programmable to turn on or off up

to eight times per day.

• Shift: Allows you to temporarily shift from Day (higher heat level) to Night (lower

heat level) settings, or vice versa, without reprogramming the times of the Day/Night

Schedule.

Depress the knob to move

forward through the menus and to

accept changes. To change a

setting's value, rotate the knob.

MON 12/01/2010 10:01Am

Cycle On 13/15

Cutoff = 55

OD = 31

o

F Day

o

F SYS = 138oF

PREV.

(DEL)

- SYSTEM SETTINGS Season Winter

Day Heat Adjust E

Night Heat Adjust B

Day Cutoff 55

Night Cutoff 40

<More Settings>

DAYHELP NEXT

Depress the button to go back

through the menus, or to view a

setting value without changing it

ADJUST

PRESS TO

SELECT

BACK

F

F

HT# 059085-00 F

16

MPC Platinum Installation and Operation Manual

DISPLAY MESSAGES

The MPC Platinum normal display layout utilizes the second line for message indications. The following is a list of the most

common Message Display Line information:

• BYPASS: 0D 0H 15M The control is switched to Bypass for the amount of time indicated. See "AUTO/BYPASS Switch"

on page 16.

• Cycle On: 1/5 min The MPC Platinum is in the Cycle-ON period for a minute out of a total Cycle-ON of 5 minutes.

See "Troubleshooting" on page 44.

• Cycle Off: 6/60 min The MPC Platinum is in the Cycle-OFF period. Only 6 Cycle-ON minutes out of the Cycle 60

minutes has elapsed. See "Understanding the Cycle Concept" on page 4.

• Est Heat at: 125°F The MPC Platinum is energizing Output relay to establish heat before starting a heating cycle. See

"Understanding the Cycle Concept" on page 4.

• Fast C/D: 68°F The Boost option selected is Vari+ESD. The MPC Platinum turns the output off before the last

Night Schedule setting for the Fast Cool Down until the space average temperature drops below

68°F (Night Space Target). See "Early Shutdown Curves" on page 27.

• Manual Boost 25/30 min The MPC Platinum has started a Manual Boost in a Cycle Operation Mode. 25 minutes have

elapsed of the 30 Manual Boost minutes. See "Boost Mode" on page 26.

• Prove Failure The Prove input terminals are now open. The boiler relays are de-energized. However, the System

relay will remain energized. See "Wiring The Prove" on page 12.

• Sensor Fault Either the Outdoor or the System sensor is reading Short or Open. The Output relay will be

energized or de-energized based on the Sensor Fault setting. See "Sensor Fault" on page 20.

• Shutdown Active The SHUTDOWN input is Shorted. Outputs are not active. See "Wiring the Shutdown" on page 12.

• Space L/O: 71°F In Cycle Operation Mode the MPC Platinum is in Space Lockout (utilizing space sensors) until the

space average drops below 71°F. See "Space Lockout" on page 28.

• Steam Time 12/15 min District Steam is the Operating Mode choice. The control activated the output relay for 12 out of 15

minutes before starting the cycle. See "Operation Mode" on page 20.

• Summer The control is set to Summer. No heat is active. See "Season" on page 23.

• Thermal Lockout: 125°F In Cycle Operation Mode the MPC Platinum is in Thermal Lockout until the System Sensor

Temperature drops below the System Set Point less the Differential. See "Thermal Lockout" on

page 28.

• Vari Boost Active The MPC Platinum has started a Vari Boost in a Cycle Operation Mode. See "Boost Mode" on

page 26.

• Waiting for Prove There is a call for heat and the Prove terminals are open before the boilers start ring. The boiler

relay is de-energize while the System relay is energized. See "Wiring The Prove" on page 12.

The third line is reserved for the Cutoff and any day or night setting messages. The following is a list of the most common third

line Messages:

• Day Ext The control is shifted to the Extended Day schedule for specied amount of time. See "Shift" on

page 33.

• Day Shf The control is shifted to the Day schedule from the Night Schedule. See "Shift" on page 33.

• Night ESD The Night Early-Shutdown is active. See "Early Shutdown Curves" on page 27.

• Night Shf The control has been shifted to the Night schedule from the Day Schedule. See "Shift" on page 33.

• No Call for Heat The outdoor temperature is above the Outdoor Cutoff. See "Day and Night Outdoor Cutoff" on

page 24.

• Sys RunOn: 2/5 min The Output relay has turned off and the System relay has been running for 2 minute and will need

to run for a total of 5 minutes. See "System Run-On" on page 28.

MPC Platinum Installation and Operation Manual

HT# 059085-00 F

17

MENU SETTINGS

------ SETTINGS ----- Season Summer

Shift

<System Settings>

<Schedules>

<Maintenance>

<System Startup>

SYSTEM STARTUP pg 20

- SYSTEM STARTUPSELECT

To continue

- ARE YOU SURE? -

NO

YES

--- SENSOR TYPE -- F

C

-- OPERATION MODE --

Burner or Valve

District Steam

--- SHUTDOWN/TSTAT ---

Shutdown/Disable

Tstat/Enable

--- CYCLE LENGTH ---

60 Min

[

--- SENSOR FAULT -- Output On

Output Off

- DAY LIGHT SAVING

Enable

Disable

SHIFT pg 33

SHIFT FROM NIGHT TO

Day

SHIFT FROM DAY TO

Night

Extend Day

Schedule

Night

Extend Day Sched

Day

Schedule

- EXTEND DAY TIME-

90 Min

[

]

SCHEDULES pg 29

----- SCHEDULES ---- Day/Night Schedule

Copy Schedule

Set Date/Time

Aux Schedule

------ SCHEDULES -----Copy Mon Schedules

To All Other Days

(Select to Execute)

MAINTENANCE pg 31

- MAINTENANCE MENU System Trim +0 F

Outdoor Trim +0

Fast Cycle Off

Password

<DHW Settings>

F

------ SCHEDULES -----MON # 1

Day Time 6:00Am

Night Time 10:00Pm

Press DAY

------ SCHEDULES -----TUE # 1

Day Time 6:00Am

Night Time 10:00Pm

Press NEXT

------ SCHEDULES -----TUE # 2

Day Time **:**

Night Time **:**

---- SYSTEM TRIM ----

F

+0

[

]

DHW pg 32

]

--- DHW SETTINGS -- <Supply Settings>

<Return Settings>

Demand Schedule

Copy Schedule

DHW SUPPLY SETTINGS

Use Sensor? No

Setpoint 140

Peak Diff 10

Light Diff 20

F

F

F

- FAST CYCLE TEST Off

On

PASSWORDS ENABLED?

No

Yes

--------- LOGIN ---------

Enter Password:

****

OPTION RELAY 1 MODE

Off

Inverse of Aux

Day

Below Outdoor Cut

OPTION RELAY 2 MODE

Off

Inverse of Output

Heat Established

Summer

HT# 059085-00 F

18

DHW RETURN SETTINGS

Use Sensor? No

Setpoint 120

Peak Diff 10

Light Diff 20

DHW SUPPLY DEFAULT

Off

On

MPC Platinum Installation and Operation Manual

CHANGE PASSWORD?

No

F

F

F

Yes

--- SET YEAR --2000

[

DHW RETURN DEFAULT

Off

On

]

------ SETTINGS ----- Season Summer

Shift

<System Settings>

<Schedules>

<Maintenance>

<System Startup>

SEASON pg 23

-- DAY ADJUSTMENT -Higher = More heat

E

[

-------- SEASON ------ Winter

Summer

-- SYSTEM SETPOINT --

F

]

[

140

]

SETTINGS pg 23

- SYSTEM SETTINGS Season Winter

Day Heat Adjust E

Night Heat Adjust B

Day Cutoff 55

Night Cutoff 40

<More Settings>

--- SYSTEM RUN-ON --2 min

[

- THERMAL LOCKOUT On

Off

- BACNET SETTINGS BACnet ID 5

IP___,___,___,___

Msk___,___,___,___

Gwy___,___,___,___

Switch to MS/TP

----- DAY CUTOFF ----F

55

[

F

F

SYSTEM SETTINGS 2

Sys Setpoint 140 F

Sys Diff 25

Dis Stm Dly 15min

]

BACnet

Boost Mode Vari

Sys Run-On 2 Min

Thermal Lockout On

<Remote Interface>

]

F

REMOTE INTERFACE

pg 34

SYSTEM SENSOR DIFF

F

25

[

DISTRICT STEAM DELAY

15min

[

]

]

BOOST pg 26

--- BOOST MODE-- Disabled

Manual

Vari

Vari+ESD

- BOOST ADJUSTMENT Higher = More Boost

3.0

[

- BOOST ADJUSTMENT Higher = More Boost

0min

[

]

]

- BACNET SETTINGS BACnet ID 5

MS/TP Address 1

Baud 9600

Switch to IP

INTERNET SETTINGS

IP___,___,___,___

Msk___,___,___,___

Gwy___,___,___,___

DNS___,___,___,___

MODBUS SETTINGS

MAC Address

Baud 9600

MPC Platinum Installation and Operation Manual

Internet

MODBUS

REMOTE INTERFACE

<Network Settings>

SpaceLockout Disable

Day Target 75

Night Target 65

- SPACE LOCKOUT -

Disable

F

F

Enable

- DAY SPACE TARGET F

75

[

NIGHT SPACE TARGET

F

65

[

]

]

HT# 059085-00 F

19

STARTUP SETTINGS

Enter menu by pressing SELECT: Settings/System Startup

If entering this menu option after the control has been set, several warnings will display before

continuing. After accepting all the warnings, the following Startup option menus must be set:

• Sensor Type (°F for Fahrenheit or °C for Celsius.)

• Operation Mode (Burner/Valve or District Steam)

• Cycle Length

• Sensor Fault (Output On or Output Off)

• Daylight Savings (Enable or Disable)

• Option relays' modes

ALERT

All Startup settings cannot

be changed on the Internet

except for Sensor Fault

SENSOR TYPE

°F Fahrenheit or °C for Celsius Default: °F Fahrenheit

SELECT Settings/System Startup/.../Sensor Type

• This option allows you to change the sensors' display and all temperature settings between

Fahrenheit and celsius.

OPERATION MODE

Burner/Valve or District Steam Default: Burner/Valve

SELECT Settings/System Startup/.../ Sensor Type / Operation Mode

• In most buildings, the time required for the heating system to ll with steam depends on

several factors. For example, using direct burner operation, the time it takes to generate

steam depends on the boiler off time length. With a valve, the amount of time also depends

on the status of the heating plant and may additionally vary depending on the balance of the

heating zones' valve position.

• However, in cases where steam is distributed from a local power authority (district steam) or

other sources where the steam is always available at a constant pressure, the time required

to ll the heating system with steam will be relatively constant.

• If your steam source is of the later type, you may decide to select the District Steam option.

• With the District Steam option, the HSS is not used. The MPC Platinum uses a timer to

start the Cycle-ON. See "District Steam Delay" on page 25.

• Selecting the District Steam option may result in overheating and unnecessary energy

expenses as the Thermal Lockout feature will not be available.

CYCLE LENGTH

Adjustable from 10 to 240 minutes Default: 60 minutes

SELECT Settings/System Startup/.../ Sensor Type / Operation Mode / Cycle Length

• The Cycle Length is directly related to the type of radiation used. The following is Heat_

Timer recommended Cycle Length:

○ For most cast iron radiation, choose a 60-minute cycle. If the radiators are very large or

the system is oversized, choose a 90-minute cycle.

○ For convector or baseboard radiation, choose a 30-minute cycle.

○ For air handlers or blower units, choose a 20-minute cycle.

--- SENSOR TYPE -- F

C

-- OPERATION MODE - Burner or Valve

District Steam

--- CYCLE LENGTH ---

60 Min

[

]

SENSOR FAULT

Output On or Output Off Default: Output On

SELECT Settings/System Startup/.../Sensor Fault

• In cases where the Outdoor sensor reads SHORT or OPEN, you can select whether you

want to default to providing continuous heat, or no heat at all.

• To help prevent a freeze-up in such a circumstance, the user can select Output On which

turns on the output relay energizing the boiler or maintain the valve open, thereby providing

continuous heat until the sensor problem can be corrected.

• The Output Off option does not provide any heat if the sensor reads a fault value.

HT# 059085-00 F

20

MPC Platinum Installation and Operation Manual

--- SENSOR FAULT -- Output On

Output Off

DAY LIGHT SAVING MODE

Enable or Disable Default: Enable

SELECT Settings/System Startup/.../Sensor Fault/Day Light Saving