heat-timer DIGI-SPAN VSP Elite Installation And Operation Instructions Manual

INSTALLATION AND OPERATION INSTRUCTIONS

®

Elite Series

White

Yellow (System Output)

Injection Pump Output

Boiler

SYS

Pump

DHW

Pump

SET

®

C O R P O R A T I O N

R

SYSTEM = 147F

TARGET = 150F

DECREASE SYSTEMINCREASE

2 Line Alphanumeric Display

Displays sensor values and

menu settings

Output Lights indicate

output status

Display Section Locking Screws

Black (120VAC power)

VSP DIGI-El I t E

Variable Speed Pump Control

Injection Pump Control for Hydronic Heating in

Outdoor Reset or Set Point Applications

The DIGI-SPAN VSP Elite establishes ambient

comfort by varying the temperature of the Secondary

Loop’s circulating hot water in response to changes

in the loop temperature. The temperature of the

heating water is controlled by regulating the speed

of a pump which injects water from a hot Boiler

Loop (Primary Loop) into a cooler heating loop

(Secondary Loop). As the speed of the pump

increases, more hot water is sent into the Secondary

Loop resulting into warmer water temperature.

This Heat-Timer control is strictly an operating control; it should never be used as a primary limit or safety control. All

equipment must have its own certified limit and safety controls required by code. The installer must verify proper operation

and correct any safety problems related to the installation of this Heat-Timer control.

This control must be installed by a licensed electrician.

The VSP Elite can be used as an outdoor reset

control. The VSP can also be used as a set point

control. In this mode of operation, the VSP will

control the injection pump speed to hold a constant

temperature (determined by the user) in the

Secondary Loop. In addition, it provides an outdoor

temperature based cutoff and system pump control.

Three new features have been added to this control.

A customized reset ratio curve for specialized

buildings , a manual pump speed control to manually

adjust the pump speed based on a well balanced

system, and a minimum pump speed adjustment to

allow for pump operation at all heating levels.

WARNING

Two sensors are used for outdoor reset, one to monitor the outdoor temperature,

T1 T2 T3+

COM COM

T3-

EXT+ EXT-

P+ P-

COM 24VAC

Display Cover Mounting Screws

Display SectionBase Section

Base Mounting Holes

Input Terminals 24VAC optional power input

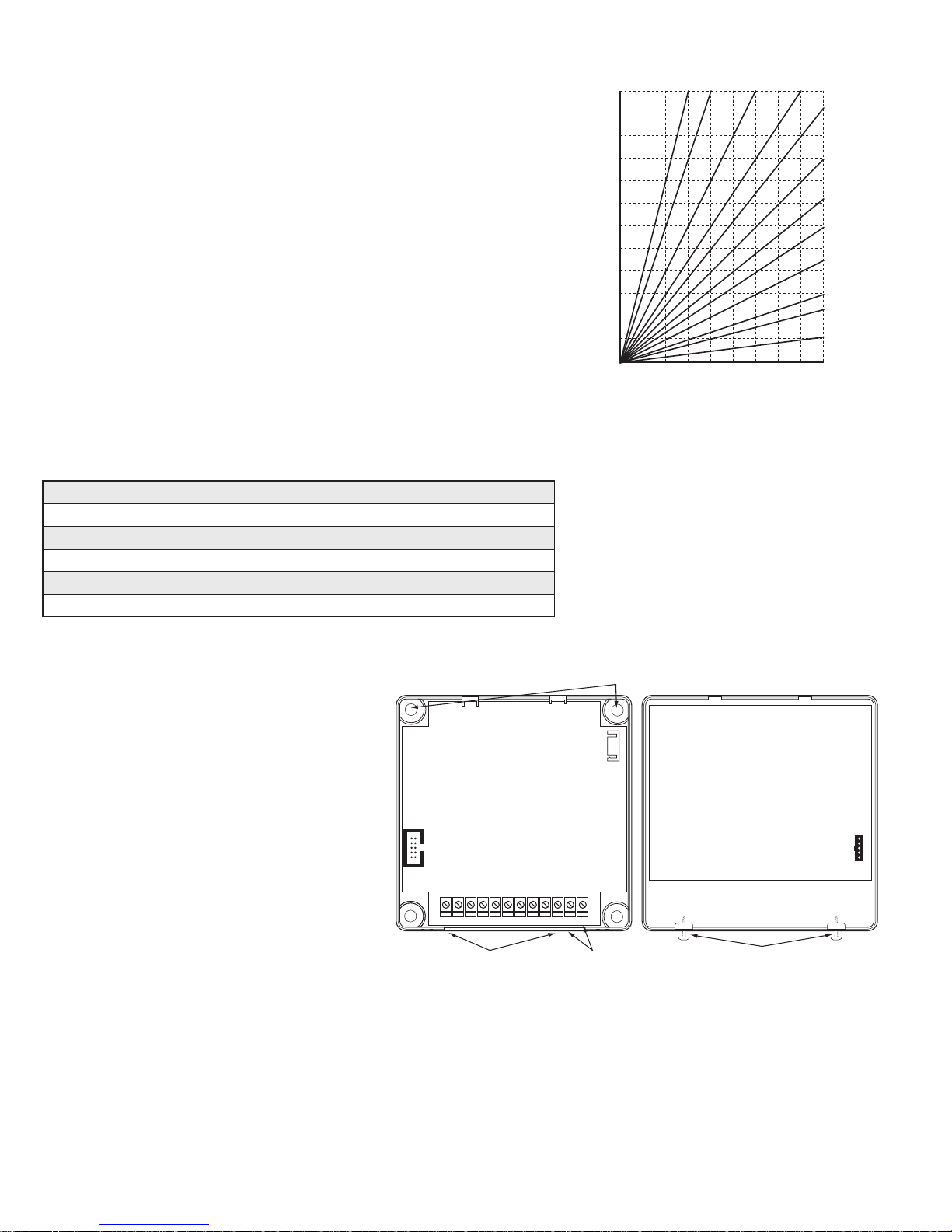

Outdoor Temperature (in °F)

70 60 50 40 2030 0 -1010 -20

120

140

130

150

160

170

180

200

190

210

220

100

110

12 11 10 9

8

7

6

4

3

2

5

1

1:4 1:3 1:2 1:1.5

1:1.25

1:1

1.25:1

1.5:1

2:1

3:1

4:1

8:1

Water Temperature (in °F)

Reset Ratio Curves

Reset Ratios are presented as

Outdoor : Water

and one to monitor the Secondary Loop circulating hot water temperature. When

the outdoor temperature falls below outdoor cutoff setting, the heating system is

activated and the Secondary Loop hot water temperature is increased proportionally

to satisfy the load. Should it get warmer outdoors, the hot water temperature is

automatically lowered by the control. If the outdoor temperature continues to rise to

the outdoor cutoff setting then the heating system is automatically turned off.

Because of the many different physical characteristics of buildings, and the type of

radiation, i.e., baseboard or radiant, the heat loss varies. In one building, a 1-degree

temperature change outdoors may require a change of 1 degree in heating water

temperature; for another it may require a change of 2, 3, or even 4 degrees in order

to gain the desired comfort level. This is known as the Reset Ratio. The middle chart

shows the wide range of Reset Ratios available for the VSP Elite.

The installer ts the VSP Elite to a specic building by adjusting the Reset Ratio

curve. With curve 4 (2:1 reset ratio) a 2-degree change in outdoor temperature will

change the circulating hot water temperature by 1 degree; at curve 11 (1:3 reset ratio)

an outdoor change of 1 degree will change the water temperature by 3 degrees. Most

buildings with baseboard radiation require curve 6, 7, or 8. Radiant heat applications

usually require a lower curve. Another, is a Setback input that will switch the

heating system to a lower set point determined by the Set Back setting.

Type of Radiation in Building Reset Ratio Offset

Radiators (Steel & Cast Iron) 1.00 (O) : 1.00 (S) 0˚F

Baseboard (Finned copper tube& Cast Iron) 1.00 (O) : 1.00 (S) 0˚F

Radiant (High Mass/Concrete) 4.00 (O) : 1.00 (S) -10˚F

Radiant (Low Mass/Joists) 2.00 (O) : 1.00 (S) -10˚F

Fan Coils & Air Handlers 1.00 (O) : 1.00 (S) 20˚F

2

The Boiler Return water sensor and well are provided

to avoid thermal shock to the boiler and, therefore, to

help prolong boiler life. If the sensor registers that the

boiler return water is colder than 120°F, the VSP Elite

immediately lowers the temperature of the circulating

heating water to reduce the load on the boiler,

allowing the return water temperature to rise.

Mounting the Controller

• The VSP Elite is designed to mount on a 1900

(4”x4”) deep electrical box.

• If additional room is needed for wiring use the

extension skirt provided in the box.

• Place the VSP Elite in a convenient location near

the unit to be controlled.

• Mount the VSP Elite indoors and away from

excessive heat or cold.

• Partially unscrew the Display Cover Mounting

screws. This allows for its removal.

• Lifting the Display Section away from the base will unplug it from the Base section.

• Proceed with the power and output wiring instructions.

• Use the screws provided to mount the VSP Elite to the 1900 box or the extension skirt.

• Mount Display Section back to the Base Section. Tighten the Display Cover Mounting Screws.

3

120VAC Power Source

BLACK

BLACK

System

Strap-On

Sensor

Shield

Not connected

Plastic

Tie-Wraps

Around Pipe

Outdoor

Sensor

snap-in

location

Shield

not connected

Conduit

Outdoor Label

on back of Sensor

Outdoor Sensor

Strap-On Sensor

Mounting

screws

location

Seal around

sensor and wall

Outdoor

drip-hole

T1

T2

COM

COM

T3+

T3-

EXT+

EXT-

P+

P-

COM

24VAC

Enable/Disable

Dry Contact

Boiler

SYS

Pump

DHW

Pump

SET

®

C O R P O R A T I O N

R

SYSTEM = 147F

TARGET = 150F

Outdoor

Sensor

System

Sensor

DECREASE SYSTEMINCREASE

Setback

Dry Contact

Boiler Return

Sensor

VSP Digi-Elite Installation & Operation Manual

Wiring

Wiring Power Input

The VSP Elite is designed to accept 120VAC using the two Black wires. Heat-Timer

recommends the installation of a Surge Suppressor and a Power Switch before the Power

Line connection for safety and ease of service.

• Attach line voltage, 120VAC, to the two Black wires extending from the back of the

VSP Elite. Remember to use the power line from a different source than the equipment

being controlled.

Wiring Input Terminals

System (T1, COM) Sensor Installation

• Place the System sensor in the Secondary Loop past the pump where it will register the temperature of

the loop before any takeoffs.

• Insert the Brass Tube sensor provided (HT #904250-00) into a ⅜" ID ½" NPT immersion well (HT

#904011-00).

• The sensor wires can be extended up to 500' using a shielded 2-conductor cable (Belden #8760 or

equivalent (#18/2)). Do not ground the shield at the sensor but at the control using the COM terminal.

• Do not run sensor wires in conduit with line voltage wiring.

Boiler Return Sensor Installation (T3+, T3-)

• The provided Boiler Return Sensor is designed to be installed in the provided ⅜” ID immersion well.

• The sensor should be located where it will register the correct return from all loops to boiler.

• The sensor wires can be extended up to 500’ by splicing it with shielded 2-conductor cable (Belden

#8760 or equivalent (#18/2)).

• The sensor has no polarity. Connect either sensor wire to the front terminal marked T3±. Connect the other sensor wire and the

shield to the front terminal marked T3-. Do not ground the shield at the sensor.

• Do not run sensor wires in conduit with line voltage wiring.

Outdoor Sensor Installation (T2, COM)

• The Outdoor Sensor must be used when Outdoor Reset is selected as the Control Mode from the Startup menu. However, in Set

Point mode, the Outdoor Sensor is optional. When connected in that mode, it will be used as an input for the Outdoor Cutoff only.

• Only use the Heat-Timer outdoor sensor provided (HT# 904220-00).

• Place the sensor in the shade on the north side of the building.

• Be sure the location is away from doors, windows, exhaust fans, vents, or other heat or cool sources.

• The sensor should be mounted approximately 10' feet above ground level.

• Adhere the Outdoor Label provided to the back of the sensor base.

• Use the Enclosure Base bottom knockout for the conduit. Use the conduit locknut

to hold the conduit and enclosure base together. Screw the cover to the base.

• If screws are used to afx the enclosure to the wall, make sure to seal around the

sensor and wall except from the bottom.

• The sensor wires can be extended up to 500' using shielded 2-conductor cable

(Belden #8760 or equivalent (#18/2)).

• Cut the shield and do not connect it at the sensor end. Only connect it at the control

end using the outdoor terminal marked COM.

• Do not run sensor wires in conduit with line voltage wiring.

Determining the proper location for the Outdoor Sensor is very important.

The VSP will base the heat on the outdoor temperature information it

receives from this location. If the sensor is in the sun, or covered with

ice, its reading will be different from the actual Outdoor temperature (O).

ALERT

Wiring the Enable/Disable (EXT+, EXT-)

EXT+ EXT-

P+ P-

COM 24VAC

Setback/Boost

Wiring

Floating

Motorized

Valve

OPEN.

COM

CLOSE

Boiler

SYS

Pump

DHW

Pump

SET

®

C O R P O R A T I O N

R

SYSTEM = 147F

TARGET = 150F

120 VAC

System/Secondary

Loop Pump

Power (Black)

(Yellow)

120 VAC

VSP Output Wiring

DECREASE SYSTEMINCREASE

Injection Pump

(White)

120 VAC

L

N

L

N

L

N

T3-

EXT+ EXT-

P+ P-

COM 24VAC

Enable/Disable

Wiring

T3-

EXT+ EXT-

P+ P-

COM 24VAC

Setback/Boost

Wiring

N.O.

N.O.

Floating

Motorized

Valve

OPEN.

COM

CLOSE

• The EXT± terminals can be used to enable or disable the system by connecting it to a thermostat, external

control, or a switch. It accepts dry contact input only. No voltage can be placed across these terminals.

• If no thermostat or control is connected to the EXT± terminals, leave the jumper supplied as a contact to the

terminals. The VSP Elite will not provide heat unless the EXT± terminals are closed/shorted.

Wiring the Setback/Boost (P+, P-)

• The Setback feature can be used to provide a lower temperature Set Point when less heat is required.

• A typical use for Setback is to provide less system temperature during the night or on the weekends, but heat is

still required.

• The Setback is activated by closing/shorting the P± terminals using an external timer.

• The Setback can accept only dry-contact input. No voltage can be placed across these terminals.

Wiring Outputs

Wire Colors and Output Lights

• The VSP Elite has a one N.O. S.P.S.T. (Single-pole single-throw) relay rated at 1A pilot load (⅛ HP).

• The VSP Elite has three LED lights. The right most LED represents the System relay operation. When the relay energizes, its LED

will turn on.

• The other two LEDs blinks when the Injection pump increase or decrease its speed.

• Both pump outputs are dry contacts only. They do not source any power.

• The two Yellow wires control the System pump relay and the right LED.

• The two White wires control the injection pump.

4

Wiring the System Pump

• The Secondary Loop/System pump is the one circulating the water in the Secondary Loop.

• The VSP Elite will control the Secondary Loop / System Pump up to a maximum output of 1 Amp inductive or 1/8 HP.

• Wire the two Yellow wires to the System Pump circuit.

• The VSP Elite does not source any output power to the pump. The

relay makes when energized to switch the power to the pump.

Wiring the Injection Pump

• The Injection pump is the one installed on the Injection Loop

between the Secondary Loop and the Boiler Loop.

• The VSP Elite will control the Injection Pump up to a maximum

output of 1.2 Amp (1/8 HP) (i.e. B&G NRF-33, Taco 0010,

Grundfos 26-64, or equivalent). The pump must be of the

permanent split capacitor type.

• Wire the two White wires to the Injection Pump circuit. They must

be in series with the pump power. The signal cannot be wired

• The VSP Elite does not source any output power to the pump. A

through any pilot duty relay or pump starter.

separate power source is required for pump operation. What the VSP Elite does is change the electric signal powering the pump to

achieve the desired speed need to achieve or maintain the target set point.

• After installing the Injection Pump, it is important to set the Minimum Speed Adjustment to guarantee injection pump ow at all

levels. See Minimum Speed Adjustment on page 13.

5

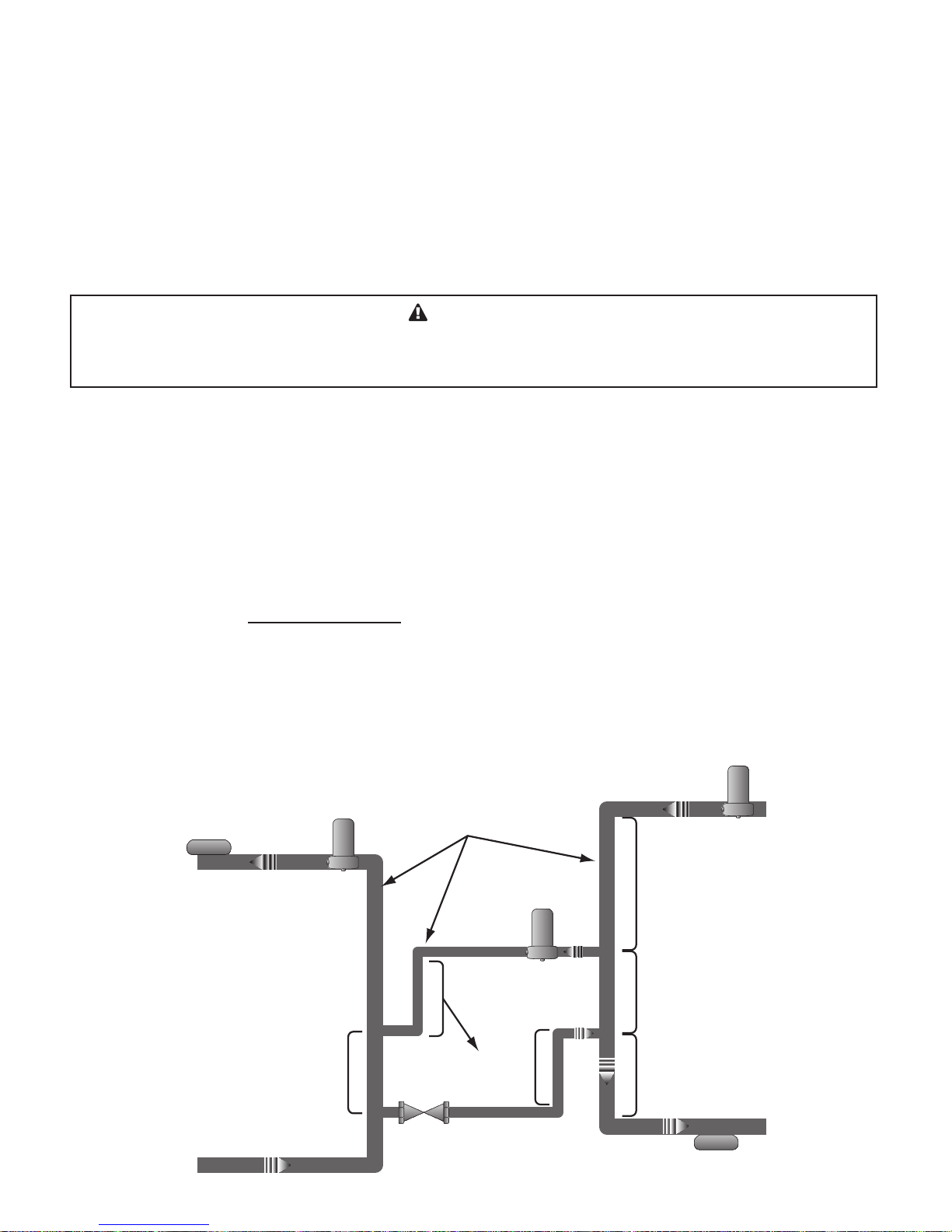

Secondary

Loop

Boiler Loop

Pump

Injection

Pump

Injection

Loop

Return Sensor

System

Sensor

Boiler

Loop

Secondary

Loop

Pump

Balancing

Valve

Maximum 4

Pipe Diameter

Min. of 1’ pipe drop

as thermal trap

Minimum 8 Pipe

Diameters Upstream

Minimum 4 Pipe

Diameters Downstream

Maximum 4

Pipe Diameter

Injection Loop Pipe diameter

is at least one size smaller than

Boiler Loop and Secondary Loop

VSP Digi-Elite Installation & Operation Manual

Piping Design

When designing an injection systems, it is eminent that the Boiler Loop and the Secondary Loop are completely isolated. This can be

achieved by following these simple rules (see Injection Piping Rules on page 5.):

• The Injection piping size must be at least one pipe size smaller than smaller of the Boiler Loop and the Secondary Loop piping.

• The distance between the Injection Loop tees on any of the other loops must not exceed 4 loop pipe diameters.

• After the injection pipe tee, there must be a minimum of 8 pipe diameters upstream the tees and a minimum of 4 pipe diameters

downstream the tees on the Boiler Loop side to prevent any jet ow.

• A vertical drop of a minimum of one foot on each of the supply and return pipes of the Injection Loop will act as a thermal trap to

prevent the Boiler Loop from supplying the Secondary Loop with heat when the injection pump is off.

• A circuit setter or globe or balancing valve can be used on the return leg of the Injection Loop to accurately balance the system.

• The Injection Pump must be of the permanent split capacitor type with a fraction horse power motor.

WARNING

The Injection Pump and pipe size selection MUST be done properly by a qualied engineer or trained

technician to insure proper operation and prevent excessive or under heat zones as well as hazardous

situations. The provided piping and pump sizing are general guidelines to help in general cost estimation.

Injection Pump and Pipe Size

To size the system properly, start by calculating the Injection Heat Load. To select a pump, use the formula to calculate the Injection

Flow Rate. Then, select a pump size, pipe size, and valve size based on the predetermined conguration provided.

• Total Injection Heat Load (Btu/Hr) for the secondary loop

• Boiler Loop Temperature (TB)

• Secondary Loop Temperature (TS)

• The design differential between the Secondary Loop supply and return temperatures (ΔTS)

• Injection Flow Rate (Gal/Min)

Injection Flow Rate =

The Injection pump, pipe size, and valve size combination can then be selected from the table;

Injection Heating Load

500 x (T

- TS + ΔTS)

B

Injection Piping Rules

Loading...

Loading...