Heatstore HS10U, HS15U Installation And User Instructions Manual

MULTIPOINT

1

Installation and User Instructions

HS10U, HS15U.

.

Please read and understand these instructions before starting work.

Please leave this leaflet with the user following installation

PACK CONTENTS

Heater, Factory fitted temperature and pressure relief valve, Fixing

screws and plugs, Installation and User Instructions.

WARNING

This water heater must only be installed by qualified persons.

36005794 Issue 2

2

Please read and understand these instructions prior to installing your Heatstore

unvented water heater. Particular attention should be paid to the section headed

IMPORTANT INSTALLATION POINTS. Following installation and commissioning

the operation of the heater should be explained to the customer and these instructions

left with them for future reference.

TECHNICAL SPECIFICATIONS

Electrical rating .................................................... 2.75kW @ 230V

..................................................... 3kW @ 240V

Capacities ............................................................. 10 or 15 litres

Weight (full) ......................................................... 10 litre - 16.4 kg

............................................................................. 15 litre - 23.1 kg

Rated pressure ..................................................... 6 bar (0.6 MPa)

Minimum recommended supply pressure ............ 0.8 bar (0.08 MPa)

Temperature/Pressure Relief Valve ....................... 90oC/7 bar

1.0 IMPORTANT INSTALLATION POINTS

1.1 This unvented water heater MUST be fitted with a Pressure Relief Valve. The

factory fitted Temperature/Pressure Relief Valve can fulfill this function. FAILURE

TO PROVIDE ADEQUATE PRESSURE RELIEF WILL INVALIDATE ANY

GUARANTEE AND LEAD TO A DANGEROUS INSTALLATION

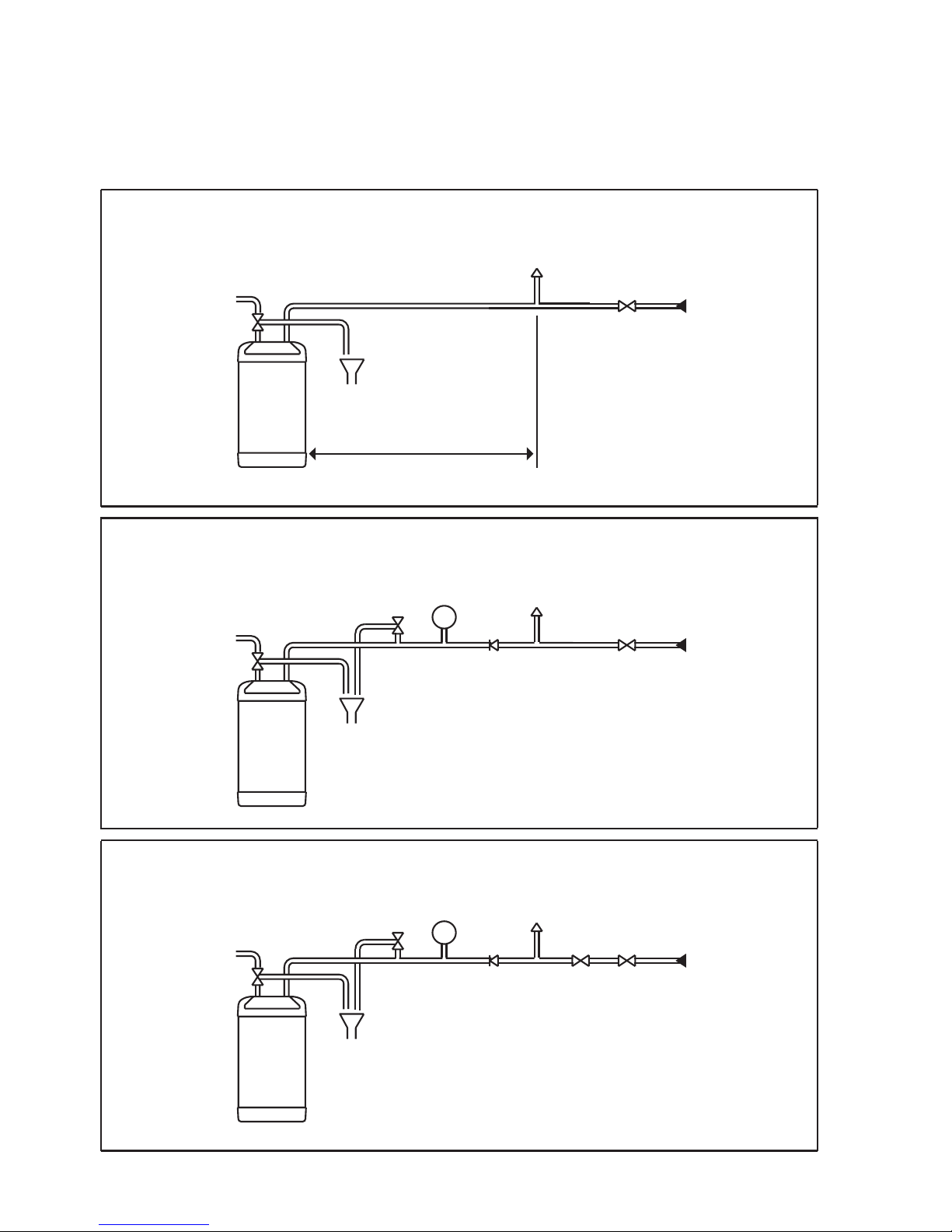

1.2 Expansion can take place within the cold water supply PROVIDED THAT BOTH :

(a) Backflow in the main is not prevented by any stopvalve with loose jumper,

check valve, pressure reducing valve or similar, AND

(b) Hot water expansion does not enter a branch to a cold water outlet (see

Figure 1 for expansion pipe lengths).

N.B. Both the above conditions must be met. Additionally expansion within the cold

water supply will not be possible if the static supply pressure exceeds 4.1 bar

(60p.s.i.).

1.3 If any of the conditions in 1.2 above cannot be met expansion must be

accomodated using an Expansion Vessel. To ensure all expansion takes place in

the vessel Non Return Valve must also be fitted together with a Pressure

(expansion) Relief Valve (see Figure 2). Use Accessory Pack B.

1.4 If the static supply pressure exceeds 4.1 bar (60p.s.i.) a Pressure Reducing Valve

must be fitted to the cold main supply. If a Pressure Reducing Valve is used an

Expansion Vessel must also be used (see Figure 3). Use Accesory Packs A and B.

MULTIPOINT

3

WARNING:

IF WATER FLOWS FROM THE PRESSURE RELIEF VALVE OR

TEMPERATURE / PRESSURE RELIEF VALVE THE ELECTRICITY SUPPLY

MUST BE SWITCHED OFF IMMEDIATELY AND PROFESSIONAL ADVICE

SOUGHT.

3

HS10U

OR

HS15U

HOT

COLD

TUNDISH

TO DRAIN

(WASTE)

NEAREST COLD

DRAW OFF

SERVICE

VALVE

2.8 (10L) OR 4.2 (15L) METERS

IS REQUIRED FOR EXPANSION

IN PIPEWORK.

HS10U

OR

HS15U

HOT

COLD

TUNDISH

TO DRAIN

(WASTE)

EXPANSION

VESSEL

NON RETURN

VALVE

NEAREST COLD

DRAW OFF

SERVICE

VALVE

PRESSURE

(EXPANSION)

RELIEF VALVE

HS10U

OR

HS15U

HOT

COLD

TUNDISH

TO DRAIN

(WASTE)

EXPANSION

VESSEL

NEAREST COLD

DRAW OFF

PRESSURE

REDUCING

VALVE

SERVICE

VALVE

PRESSURE

(EXPANSION)

RELIEF VALVE

COLD

WATER

MAINS

NOTE: IF PRESSURE REDUCING VALVE

IS USED EXPANSION DOWN THE MAINS

IS NOT POSSIBLE

FIGURE 1: FOR INLET WATER PRESSURES UP TO 4.1 BAR (60 P.

S.I.) - NO ADDITIONAL KITS USED.

COLD

WATER

MAINS

FIGURE 2 : FOR INLET WATER PRESSURES UP TO 4.1 BAR (60 P.S.I.)

WHERE EXPANSION IN MAIN SUPPLY IS NOT POSSIBLE - USING PACK B.

COLD

WATER

MAINS

FIGURE 3 : FOR INLET WATER PRESSURES ABOVE 4.1 BAR (60 P.S.I.) - USINK PACKS A AND B.

NON RETURN

VALVE

4

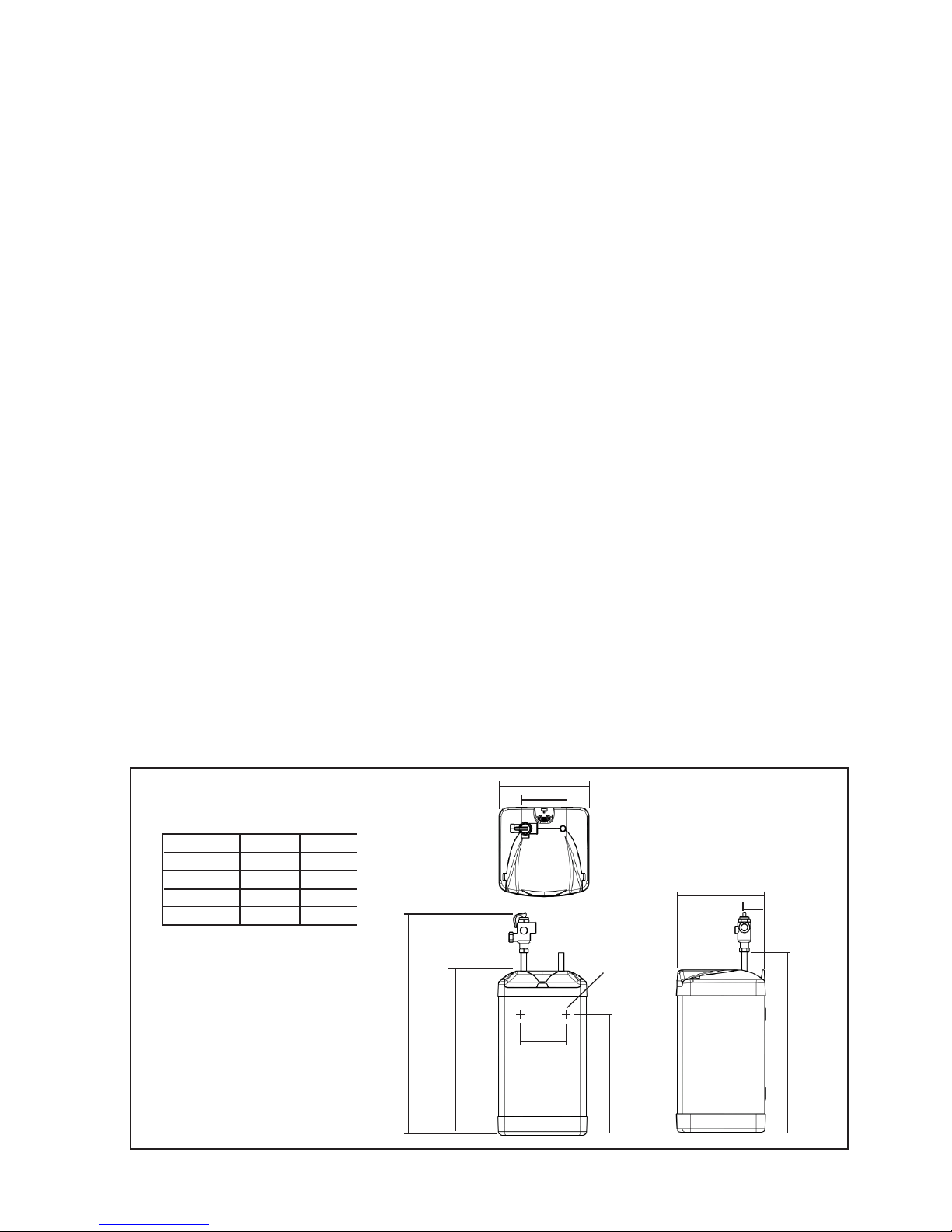

2.0 INSTALLATION - GENERAL REQUIREMENTS:

2.1 National Wiring rules may contain restrictions concerning the installation of these

units in bathrooms.

2.2 The unit should be vertically wall mounted. Fixing screws and rawplugs are

supplied for this purpose. Refer to Figure 4 for position of fixing holes. The water

connections must always be to the top of the unit.

2.3 Enough space should be left at the top above the unit for pipe connections and

access to the Temperature/Pressure Relief Valve. Refer to Figure 4 and the

Dimensions Table to determine a suitable position for the heater.

2.4 NOTE: Ensure that the wall can support the full weight of the unit

(see TECHNICAL SPECIFICATIONS) and that there are no hidden services

(electricity, gas, or water) below the surface of the wall.

2.5 DO NOT install where the unit may freeze.

2.6 Refer to the section IMPORTANT INSTALLATION POINTS to determine which

valves and accessories are required. Plumb in the valves in the sequence shown in

the relevant Diagrams ( Figures 1, 2, and 3).

2.7 The inlet water connection is a 15mm diameter copper tube suitable for

compression fittings.

The outlet water connection is made to the 15mm commpression fitting located on

the factory fitted temperature and pressure relieve valve.

A WRAS listed isolating valve (not supplied) must be fitted on the cold water

supply to the heater. Several hot outlets can be served.

2.8 Do not use solder joints as this will damage the heater and may prevent servicing

under warranty.

2.9 Plumbers Paste must not be used as it can impair the operation of the valves.

240

120

50

240

100

A

D

C

B

2 KEYHOLE

FIXING SLOTS

6mm WIDE

DIMENSION 10 LITRE 15 LITRE

A 442mm 598mm

B 478mm 634mm

C 492mm 648mm

D 322mm 478mm

FIGURE 4: DIMENSIONS

Loading...

Loading...