Page 1

INSTALLER: Leave this manual with the appliance. CONSUMER: Save these Instructions for future reference.

OPERATING INSTRUCTIONS

AND OWNER’S MANUAL

READ INSTRUCTIONS CAREFULLY: Please read this entire manual before installation and use of this

pellet fuel-burning room heater. Failure to follow these instructions could result in property damage, bodily

injury or even death. Do not allow anyone who has not read these instructions to assemble, light, adjust or

operate the stove. Place instructions in a safe place for future reference.

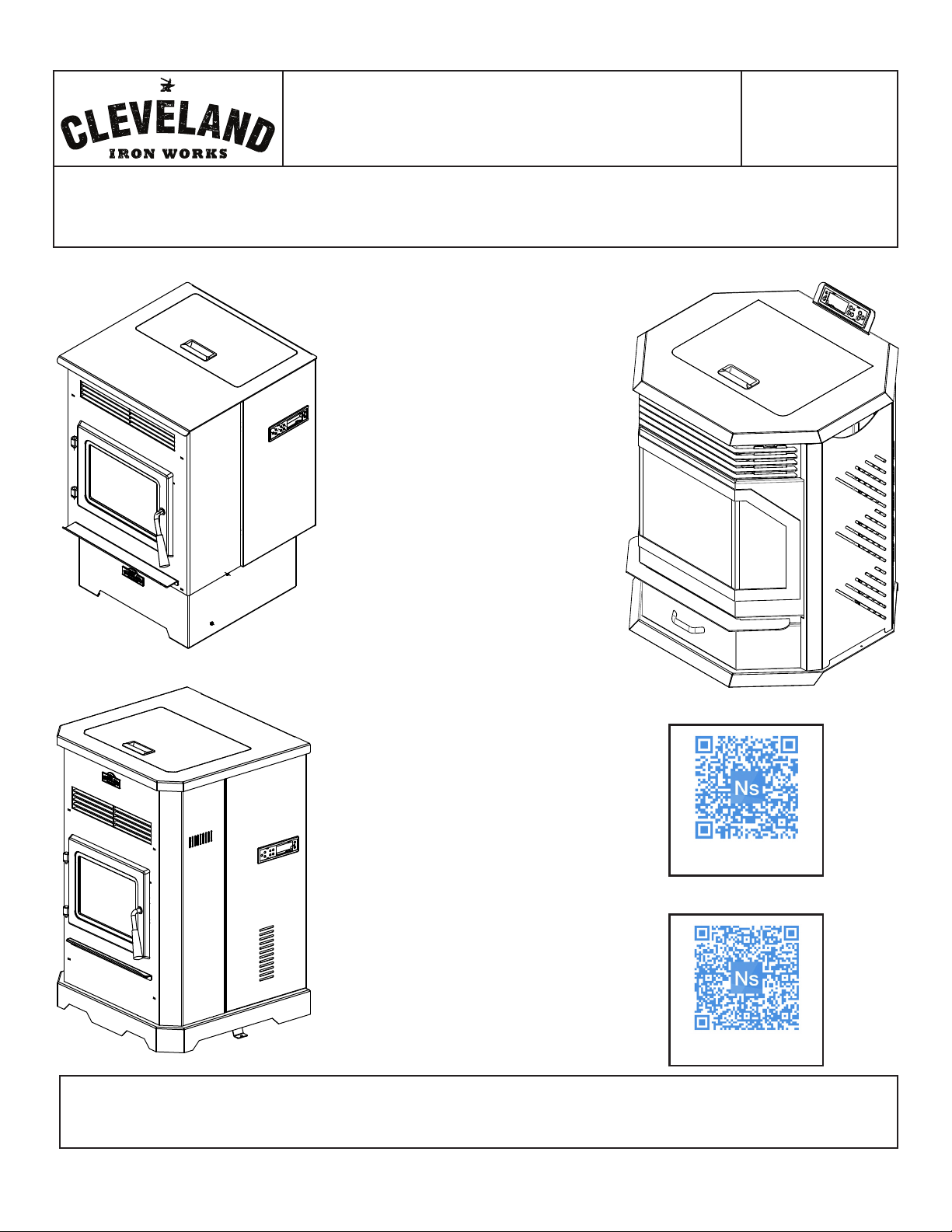

Model #

PS60W

PS130W

PSBF66W

WOOD PELLET FIRE STOVE

PS60W (F500200)

PSBF66W (F500210)

Apple Store

PS130W (F500205)

THE AUTHORITY HAVING JURISDICTION (SUCH AS MUNICIPAL BUILDING DEPARTMENT, FIRE

DEPARTMENT, FIRE PREVENTION BUREAU, ETC.) SHOULD BE CONSULTED BEFORE INSTALLATION

TO DETERMINE ANY NEED TO OBTAIN A PERMIT. OBSERVE ALL LOCAL BUILDING CODES.

Cleveland Ironworks a subsidiary of Enerco Group Inc.

4560 West 160th st Cleveland, Ohio 44135 1-800-251-0001

Google Play Store

Page 2

GENERAL HAZARD WARNING:

FAILURE TO COMPLY WITH THE PRECAUTIONS

AND INSTRUCTIONS PROVIDED WITH THIS

STOVE CAN RESULT IN DEATH, SERIOUS

BODILY INJURY AND PROPERTY LOSS OR

DAMAGE FROM HAZARDS OF FIRE, EXPLOSION,

BURN, ASPHYXIATION, CARBON MONOXIDE

POISONING, AND/OR ELECTRICAL SHOCK.

ONLY PERSONS WHO CAN UNDERSTAND AND

FOLLOW THE INSTRUCTIONS SHOULD USE OR

SERVICE THIS STOVE.

IF YOU NEED ASSISTANCE OR STOVE

INFORMATION SUCH AS AN INSTRUCTIONS

MANUAL, LABELS, ETC. CONTACT THE

MANUFACTURER.

WARNING:

FIRE, BURN, INHALATION, AND EXPLOSION

HAZARD. KEEP SOLID COMBUSTIBLES, SUCH AS

BUILDING MATERIALS, PAPER OR CARDBOARD,

A SAFE DISTANCE AWAY FROM THE STOVE

AS RECOMMENDED BY THE INSTRUCTIONS

NEVER USE THE STOVE IN SPACES WHICH DO

OR MAY CONTAIN VOLATILE OR AIRBORNE

COMBUSTIBLES, OR PRODUCTS SUCH AS

GASOLINE, SOLVENTS, PAINT THINNER, DUST

PARTICLES OR UNKNOWN CHEMICALS.

WARNING: This product can expose you to

chemicals including lead and lead compounds, which

are known to the State of California to cause cancer

and birth defects or other reproductive harm. For

more information visit www.P65Warnings.ca.gov

Contents

SPECIFICATIONS ................................................................................. 3

SAFETY PRECAUTIONS ....................................................................... 4

CLEARANCE TO COMBUSTIBLES ........................................................ 5

UNPACKING & ASSEMBLY .................................................................. 6

INSTALLATION ................................................................................... 6

ADDITIONAL MOBILE HOME REQUIREMENTS ................................. 10

OPERATION ......................................................................................12

SMART STOVE WIFI CONNECTION ................................................... 14

WIFI CONTROLS ................................................................................15

PS60W, PS130W, AND PSBF66W MULTI FUNCTION CONTROLS ....... 16

MAINTENANCE .................................................................................17

WIRING DIAGRAM ........................................................................... 25

SERVICE PARTS ................................................................................ 26

2

Operating Instructions and Owner’s ManualCleveland Iron Works Wood Pellet Fire Stove

Page 3

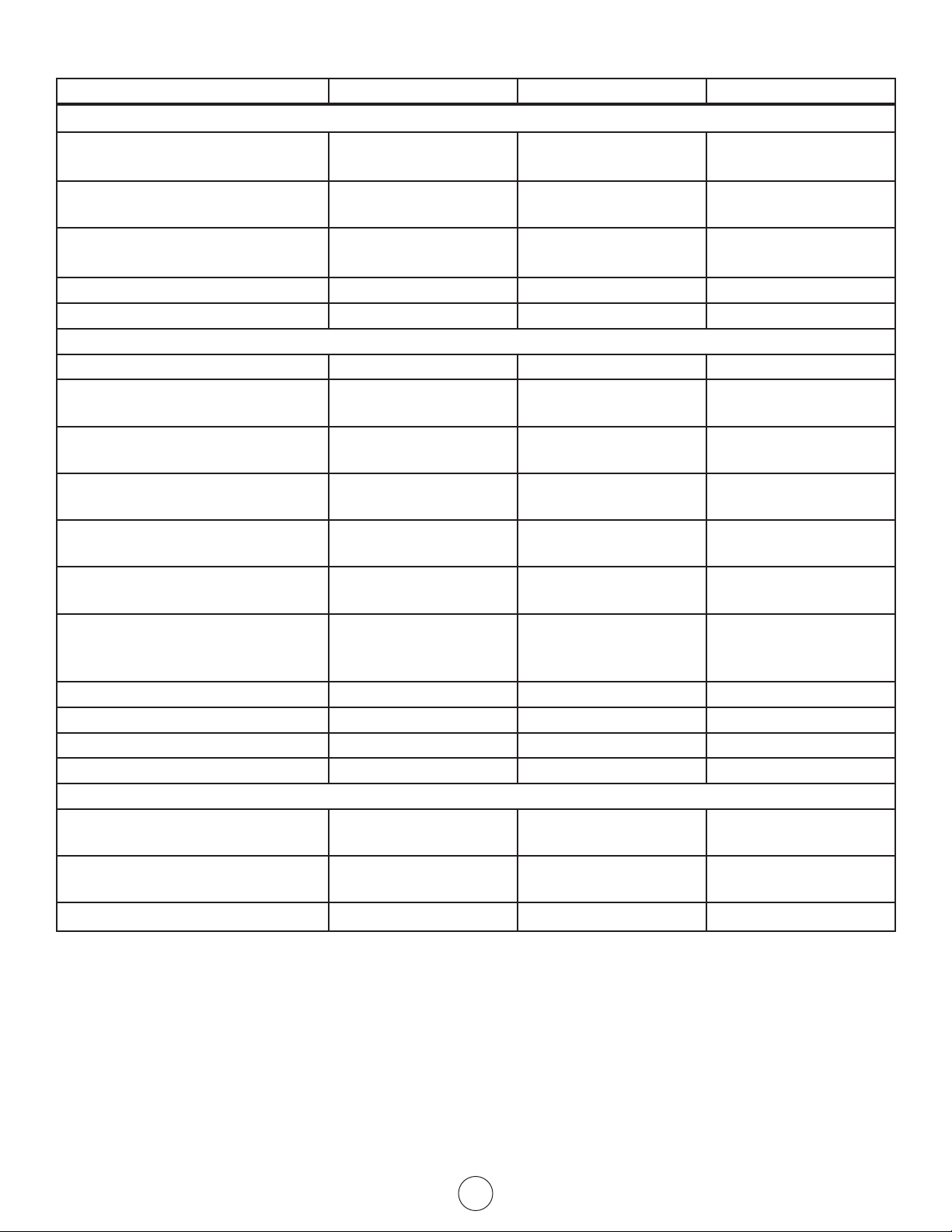

SPECIFICATIONS

Model #

PS60W PS130W PSBF66W

DIMENSIONS

Stove Weight

[LBS (kg)]

Stove Dimensions LxWxH [in (cm)]

Air Inlet Pipe Diameter [in (mm)]

Air Outlet Pipe Diameter [in (mm)] 3” (80) 3” (80) 3” (80)

Pellet Hopper Capacity [LBS (kg)]

Fuel Wood Pellet Wood Pellet Wood Pellet

Heats approximately **

[ft2 (m2)]

Carbon Monoxide Produced

(g/min)

Pellet Consumption Rate Low [LBS/

HR (kg/HR)]

Pellet Consumption Rate Medium

[LBS/HR (kg/HR)]

Pellet Consumption Rate High

[LBS/HR (kg/HR)]

Automatic Mode Duration

[minimum hours (maximum

hours)]

Stove Efficiency 82.3% 75.8% 82.2%

Output Rate Low [BTU/HR (kW)]

Output Rate Medium [BTU/HR (kW)]

Output Rate High [BTU/HR (kW)]

Electrical Supply Requirements

[Voltage / Frequency / Phase]

Electric Current During Lighting

Phase [Amperes]

Auger Motor R.P.M.

23.5” x 21.75 “ x 33.25”

120V / 60 Hz / Single 120V / 60 Hz / Single 120V / 60 Hz / Single

198 (90) 221 (100) 265 (120)

24.0” x 24.5 “ x 36.5”

(59.7 x 55.2 x 84.5)

2” (50) 2” (50) 2” (50)

60 (27.2) 130 (59.0) 66 (29.9)

OPERATION SPECIFICATIONS

1500 (139.4) 2500 (232.3) 1800 (167.2)

0.100 on High

0.033 on Low

1.41 (.64) 2.20 (1.00) 2.20 (1.00)

1.85 (0.84) 2.69 (1.22) 3.04 (1.38)

4.01 (1.82) 5.71 (2.59) 6.12 (2.77)

42.5 (15.0) 62.2 (23.9) 62.3 (11.3)

9,265 (2.72) 13,535 (3.97) 7,420 (2.17)

12,297 (3.60) 16,714 (3.60) 13,421 (3.93)

26,865 (7.87) 34,129 (10.00) 40,259 (11.80)

ELECTRICAL SPECIFICATIONS

3.3 3.3 3.3

2.4 2.4 2.4

(61.0 x 62.2 x 92.7)

0.160 on High

0.053 on Low

26.18” x 24.53 “ x 30.39”

(66.5 x 62.3 x 77.2)

0.118 on High

0.020 on Low

This manual describes the installation and operation of the brand “Cleveland Ironworks” wood pellet fire stove.

This stove meets the applicable U.S. Environmental Protection Agency’s emission limits for pellet fired heaters sold

after 2020.

*BTU input/output will vary, depending on the brand of fuel you use in your Stove

** Depending on climate zone. Variations in climate and location affect attributes such as stove efficiency

and CO produced.

3

Operating Instructions and Owner’s ManualCleveland Iron Works Wood Pellet Fire Stove

Page 4

SAFETY PRECAUTIONS

HAVE AN ESTABLISHED PLAN FOR WHAT

TO DO IN THE EVENT OF A FIRE. CONTACT

YOUR LOCAL FIRE AUTHORITY TO ACQUIRE

INFORMATION AND A PLAN FOR WHAT TO DO

IN THE EVENT OF A CHIMNEY FIRE.

WARNING: DO NOT INSTALL IN SLEEPING

ROOM.

CAUTION: HANDLE STOVE WITH CARE.

AVOID STRIKING, SCRATCHING OR

SLAMMING GLASS ASSEMBLIES. DO NOT

OPERATE WITH CRACKED, BROKEN OR

SCRATCHED GLASS.

WARNING: HOT WHILE IN OPERATION. KEEP

CHILDREN, CLOTHING AND FURNITURE

AWAY. CONTACT MAY CAUSE SKIN BURNS.

WARNING: NEVER LEAVE CHILDREN NEAR

THE STOVE UNATTENDED WHILE THE STOVE

IS OPERATING.

CARBON MONOXIDE

WARNING:

WHEN USED WITHOUT ADEQUATE

COMBUSTION AND VENTILATION AIR, THIS

STOVE MAY GIVE OFF EXCESSIVE CARBON

MONOXIDE, AN ODORLESS, POISONOUS GAS.

WARNING:

EARLY SIGNS OF CARBON MONOXIDE

POISONING RESEMBLE THE FLU, WITH

HEADACHE, DIZZINESS AND/OR NAUSEA. IF

YOU HAVE THESE SIGNS, STOVE MAY NOT

BE WORKING PROPERLY. GET FRESH AIR AT

ONCE! HAVE STOVE SERVICED.

SOME PEOPLE - PREGNANT WOMEN,

PERSONS WITH HEART OR LUNG DISEASE,

ANEMIA, THOSE UNDER THE INFLUENCE OF

ALCOHOL, THOSE AT HIGH ALTITUDES - ARE

MORE AFFECTED BY CARBON MONOXIDE

THAN OTHERS.

WARNING: DO NOT OVERFIRE. OVERFIRING

THE APPLIANCE MAY CAUSE A FIRE. IF THE

UNIT OR CHIMNEY CONNECTOR GLOWS,

YOU ARE OVERFIRING.

WARNING: THIS WOOD HEATER HAS A

MANUFACTURER-SET MINIMUM LOW

BURN RATE THAT MUST NOT BE ALTERED.

IT IS AGAINST FEDERAL REGULATIONS

TO ALTER THIS SETTING OR OTHERWISE

OPERATE THIS WOOD HEATER IN A

MANNER INCONSISTENT WITH OPERATING

INSTRUCTIONS IN THIS MANUAL.

Regardless of how safe this stove is, every fuel burning

appliance creates Carbon Monoxide. It is always a good

plan to reduce risk to you and your loved ones as much

as possible by installing a Carbon Monoxide detector.

It is recommended to install monitors in areas that are

expected to generate carbon monoxide such as heater

fueling areas, pellet fuel bulk storage areas, or sheds

containing hydronic heaters. Follow the installation,

operation, & maintenance instructions provided by the

manufacturer of your detector.

SMOKE DETECTORS

Have at least 1 smoke detector on each floor of

your building. Follow the installation, operation, &

maintenance instructions provided by the manufacturer

of your detector. Avoid false alarms by placing the

detector outside the immediate vicinity of the stove.

Typically a good installation location for smoke

detectors is near bedrooms.

FOR MORE SAFETY INFORMATION

For auxiliary information regarding pellet stove safety

and operation information contact the National Fire

Protection Association (NFPA) by mail at:

NFPA, Batterymarch Park, Quincy, MA 02269

or visit the NFPA website:

https://www.nfpa.org/

4

Operating Instructions and Owner’s ManualCleveland Iron Works Wood Pellet Fire Stove

Page 5

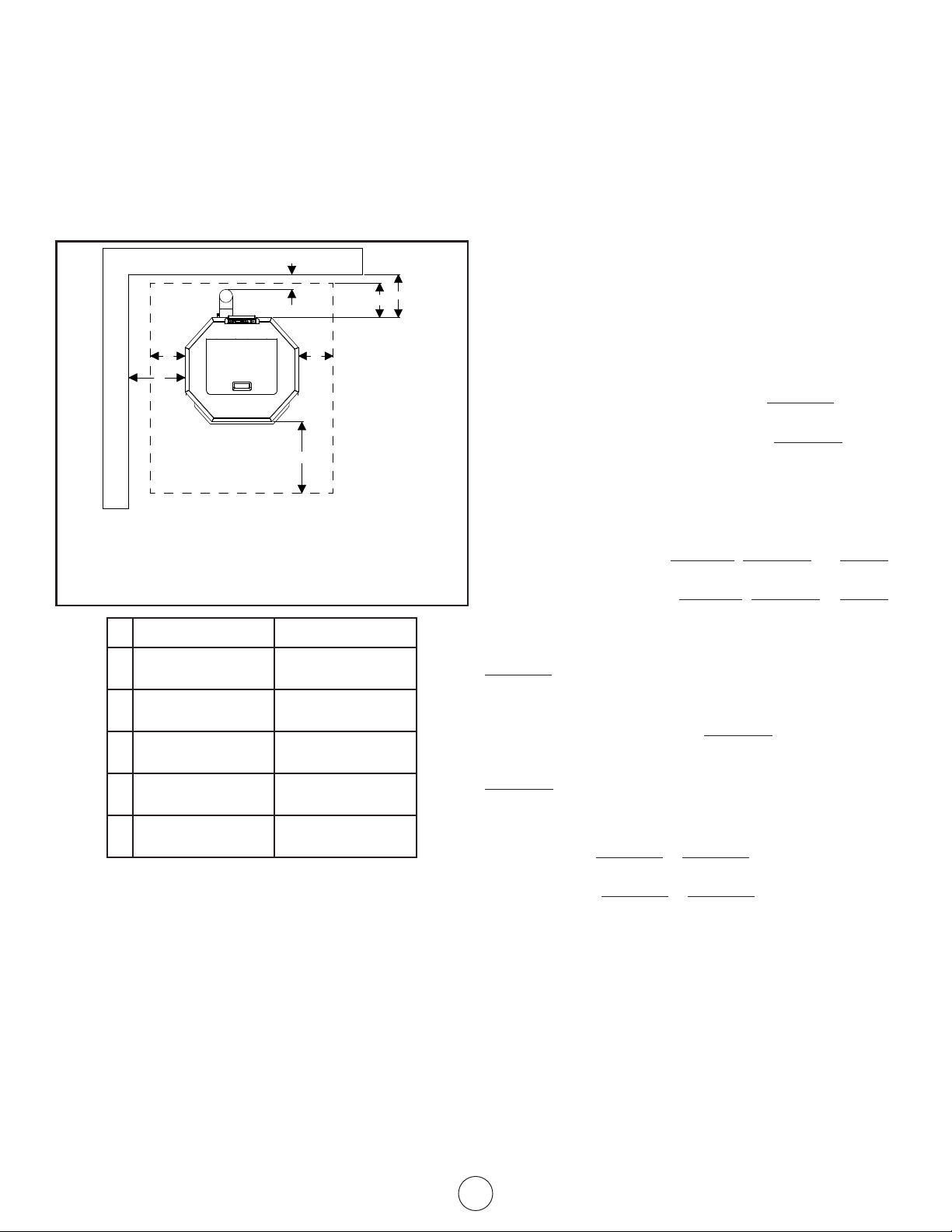

CLEARANCE TO COMBUSTIBLES

NON-COMBUSTIBLE

FLOOR PROTECTION

The following stated clearances represent the minimum

distances between the stove and any other object. No

objects should encroach into this space. This includes

but is not limited to carpet, furniture, children, pets,

clothing, fuel, or any other object. These clearances

may only be reduced by means approved by the

regulatory authority having jurisdiction.

REAR WALL

B

E

DD

A

SIDE WALL

C

FRONT OF HEATER

Figure 1 Clearance to Combustibles

USA CANADA

A 13” (330 mm) 13” (330 mm)

D

• It has at least 2” (51 mm) of clearance from the

rear to the nearest body.

• Vertical runs of vent pipe must be at least 3” (76

mm) from any wall.

Finally, the area which the wood pellet fire stove is

installed shall have a floor-to-ceiling distance of at least

84” (2134 mm).

FLOORING MATERIAL

Floor protection must be all of the following:

• Listed to UL 1618.

• At least 0.5” (13 mm) thick

• Constructed of non-combustible material.

• Have either:

(ft2)(hr)(0F)

Thermal resistance value R of 1.19

Thermal conductivity value k of 0.84

Btu

(Btu) (inch)

(ft2)(hr)(0F)

For assistance evaluating the suitability of substitute

materials, the following equivalences of specifications

and example below have been provided.

(Imperial or SI units)

(Btu) (inch)

(

(ft2)(hr)(0F)

(Btu)

(

(ft2)(hr)(0F)

or

or

W

(m)(0K)

W

(m2)(0K)

Thermal conductivity k =

Thermal conductance C =

thickness

R

1

R

Example: Required to protect floor with R value of 1.19

(ft2)(hr)(0F)

Btu

.

)

)

B 2” (51 mm) 2” (51 mm)

C 18” (457 mm) 18” (457 mm)

D 8” (203 mm) 8” (203 mm)

E 3” (76 mm) 3” (76 mm)

FLOORING SPACE & CLEARANCES

When installed on a combustible floor, noncombustible floor protection is required to:

• Cover the area beneath the stove and extend at

least 18 inches (457 mm) to the front

• Cover the area at least 8 inches (203 mm) beyond

each side of the room heater.

• Cover the area under the exhaust venting and 2

inches (50.8 mm) beyond each side.

Additionally, the wood pellet fire stove shall be

positioned such that:

• It has at least 13” (330 mm) of clearance from the

each side to the nearest body.

Evaluating merit of 2¼ inch (57 mm) thick brick with

(Btu) (inch)

thermal conductivity k = 4.16

(ft2)(hr)(0F)

on top of ¼ inch

(6.3 mm) thick mineral board that has C value of 2.3

(Btu)

(ft2)(hr)(0F)

.

Step 1. Calculate the R value of each floor material

R

R

BRICK

BOARD

=

=

thickness

k

1

C

=

=

2.25

4.16

2.3

= 0.54

1

= 0.434

Step 2. Add the equivalent R values for each floor

material

R

BRICK

+ R

= 0.54 + 0.434 = 0.974

BOARD

Step 3. This combined R value is insufficient and so

more protection must be provided. For example,

by using 2 layers of bricks:

R

BRICK

+ R

BRICK

+ R

= 0.54 +0.54 + 0.434 = 1.514

BOARD

Step 4. Because this combined R value is larger than

the specification, this is a sufficient method for

protecting the floor area underneath the stove.

5

Operating Instructions and Owner’s ManualCleveland Iron Works Wood Pellet Fire Stove

Page 6

UNPACKING & ASSEMBLY

Termination Cap

1. Remove heater from carton.

2. Remove all protective packaging applied to heater

for shipment.

3. Check heater for any shipping damage. If any

damage is found immediately contact the

manufacturer at 800-251-0001.

CAUTION: DAMAGED PARTS MAY

COMPROMISE SAFE OPERATION.

• DO NOT INSTALL INCOMPLETE COMPONENTS.

• DO NOT INSTALL SUBSTITUTE COMPONENTS.

• DO NOT INSTALL DAMAGED COMPONENTS.

4. Some components are packaged unattached from

the stove in order to ensure their safety during

shipping. Please find the protective packaging, likely

inside the stove door, to proceed with assembly.

Main Power Cord

The main power cord attaches to the stove at the

exposed socket in the rear of the stove. Once any

necessary assembly of the display panel screen is

complete (PSBF66W only) you may briefly plug your

stove in make sure that it functions properly before

proceeding with installation. Unplug the stove once

you confirm that the display panel works.

as may be required per recommendations in “FRESH

AIR AND VENTILATION REQUIREMENTS 1” on page

7. Follow all ventilation requirements and guidelines

specified in “INSTALLATION” on page 6.

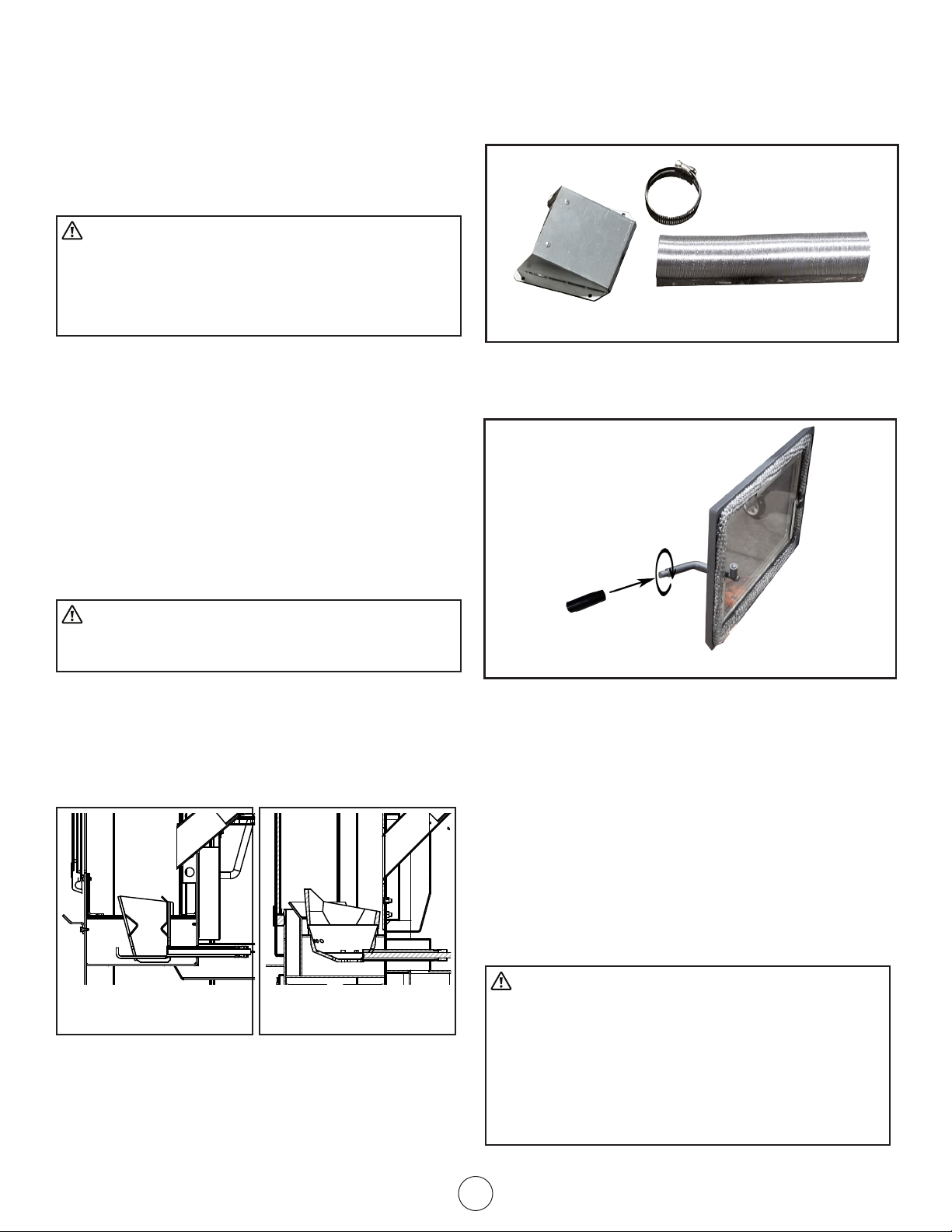

Hose Clamp

2” Flex Hose

Figure 4 Intake Kit

Additional Assembly PS60W, PS130W

• The door handle: open the door, and screw the

plastic grip onto the thread of the handle.

Firepot

With the stove unplugged from any power supply, the

firepot should be inserted into the stove so that it is

securely positioned and also the hot surface igniter

should be able to make physical contact with pellets

that would be held in the firepot. See figure 2 or 3.

Figure 2 PS60W and

PS130W firepot

A cleaning kit is also packaged which facilitates safely

cleaning the firepot perforations of debris.

Air Intake Kit

Locate the air intake kit packaged with the stove. See

Figure 4. Take measurements of your space and plan

for the installation of horizontal venting to the outside

CAUTION: DO NOT LEAVE THE STOVE

PLUGGED INTO ANY ELECTRICAL SUPPLY

DURING ASSEMBLY OR INSTALLATION.

Figure 3 PSBF66W

firepot

Figure 5 Door Handle

Additional Assembly PSBF66W

• The display panel: insert the display panel into the

top and rear of the stove. Be sure that the display

panel screen is facing towards the front of the stove.

Secure the screen using two of the provided screws.

• The power cord for the display panel: this cord

should be wrapped up near the top of the stove.

Insert free end into the back of the display panel

(see figure 16 on page 14). This wire should

already be connected to the stoves power board. This

connection can be checked behind the access plate at

the bottom and rear of stove .

INSTALLATION

WARNING: WHEN THIS STOVE IS NOT

PROPERLY INSTALLED, A HOUSE FIRE MAY

RESULT. TO REDUCE THE RISK OF FIRE,

FOLLOW THE INSTALLATION INSTRUCTIONS.

CONTACT LOCAL BUILDING OR FIRE

OFFICIALS ABOUT RESTRICTIONS AND

INSTALLATION INSPECTION REQUIREMENTS

IN YOUR AREA.

6

Operating Instructions and Owner’s ManualCleveland Iron Works Wood Pellet Fire Stove

Page 7

CAUTION: ANY DEVIATION OR ALTERATION

FROM THESE INSTALLATION INSTRUCTIONS

MAY RESULT IN DAMAGE TO YOU, THE

STOVE, YOUR CHIMNEY, AND YOUR HOME.

YOUR WARRANTY MAY BECOME VOID. READ

AND FOLLOW ALL INSTRUCTIONS. Contact

Cleveland Iron Works with any comments,

concerns, or questions.

CAUTION: CONTACT LOCAL BUILDING OR

FIRE OFFICIALS ABOUT RESTRICTIONS AND

INSTALLATION INSPECTION REQUIREMENTS

IN YOUR AREA.

CONTACT INFORMATION

If you have any questions regarding ventilation options

of your stove, contact either:

The manufacturer Cleveland Ironworks Company at

1-800-251-0001 • CLEVELAND-IRONWORKS.COM Our

office hours are 8:00 AM – 5:00 PM, EST, Monday

through Friday.

The National Fire Protection Association (NFPA) and

request a copy of the latest editions of NFPA Standard

211. The mailing address of the NFPA is Batterymarch

Park, Quincy, MA 02269

PLANNING

Make sure that you have selected the correct stove

for your heating requirements by checking the

specifications table on page 3.

Take measurements of your space and plan for

your chimney system as detailed in the following

instructions.

This stove may be installed for use in a mobile home.

In addition to the following instructions, review and

adhere to the mandatory requirements on page 10.

ELECTRICAL CONSIDERATIONS

The rear of the stove will need to be within power cord

distance, which is roughly 80 inches (203 cm), of an

electrical outlet. Lay the power cord out such that it will

not come into contact with the stove’s surface.

TOOLS REQUIRED (NOT SUPPLIED)

• Safety Glasses

• Gloves

• Tape Measure

• Phillips Screwdriver or

comparable electric

screw driver & drill bit.

• Stud Finder

• Plumb bob

PARTS & MATERIALS REQUIRED (NOT SUPPLIED)

• Floor Protection (see “FLOORING SPACE” and

“FLOORING MATERIAL” on page 5)

• Reciprocating saw

• High Temperature

Silicone

• A friend (the stove is

heavy, do not attempt

to move the stove

without assistance)

• Manufactured venting of 3” (80 mm) diameter, of

type “L” or “PL” which is listed to UL 641, ULC S609

(Standard for 650°C Factory-Built Chimneys), or

ULC/ORD C441. Install per chimney manufacturer’s

instructions.

FRESH AIR AND VENTILATION REQUIREMENTS

When deciding the location of the stove ensure

that the space will always have a source of fresh air

available. Failure to do so may result in air starvation

of other fuel burning appliances and the possible

development of hazardous conditions.

Provision for outside combustion air may be necessary

to ensure that fuel-burning appliances do not discharge

products of combustion into the house. Guidelines to

determine the need for additional combustion air may

not be adequate for every situation. If in doubt, it is

advisable to provide additional air. Outside combustion

air may be required if these or other indications

suggest that infiltration air is inadequate:

• The wood pellet fired stove does not draw steadily,

experiences smoke roll-out, burns poorly, or backdrafts, whether or not there is combustion present.

• Existing fuel-fired equipment in the house, such as

fireplaces or other heating appliances, smell, do

not operate properly, suffer smoke roll-out when

opened, or back-draft, whether or not there is

combustion present.

• Any of the above symptoms are alleviated by

opening a window slightly on a calm (windless) day.

• The house is equipped with a well-sealed vapor

barrier and tight fitting windows and/or has any

powered devices which exhaust house air.

• There is excessive condensation on windows in the

winter.

• A ventilation system is installed in the house.

Additional combustion air may be directly provided

from the outdoors to the wood pellet fired stove by

using the included air intake kit to connect to the

inlet at the bottom and rear of the stove. Any such

installation must satisfy Clause 4 of CSA Standard

B365.

CAUTION: NEVER DRAW OUTSIDE

COMBUSTION AIR FROM:

• A WALL, FLOOR OR CEILING CAVITY.

• AN ENCLOSED SPACE SUCH AS AN ATTIC,

GARAGE OR CRAWL SPACE.

CAUTION: IF USING AN AIR INTAKE CONNECTION

THEN THE STOVE MUST BE INSTALLED SUCH THAT

IT IS ATTACHED TO THE STRUCTURE.

7

Operating Instructions and Owner’s ManualCleveland Iron Works Wood Pellet Fire Stove

Page 8

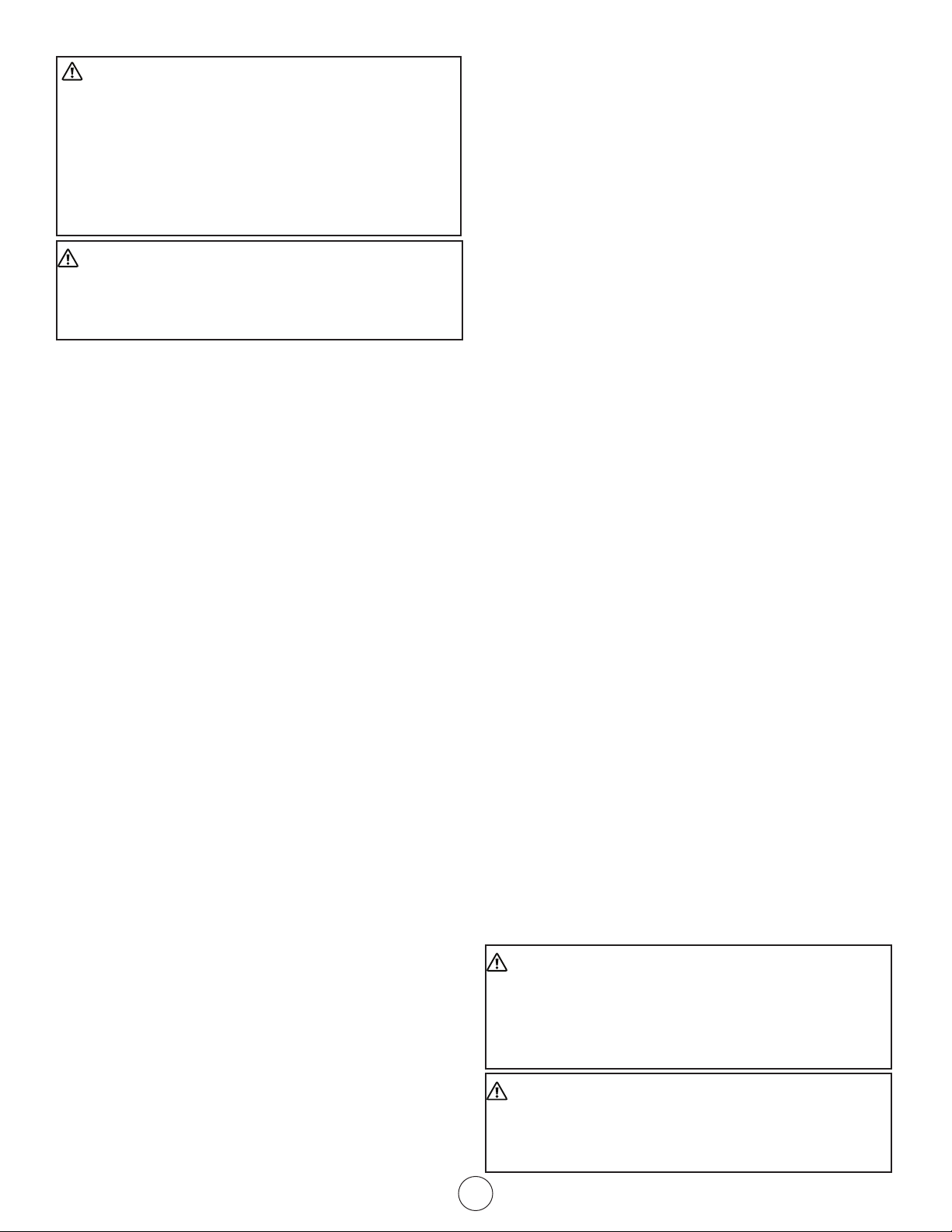

CONNECTOR REQUIREMENTS AND ASSEMBLY

Hole with a minimum

clearance of 18” (450

mm) between

connector and wall

Non-combustible cover, one

used, each must be mounted

CAUTION: A CHIMNEY CONNECTOR SHALL

NOT PASS THROUGH AN ATTIC OR ROOF

SPACE, CLOSET OR SIMILAR CONCEALED

SPACE, OR A FLOOR, OR CEILING. WHERE

PASSAGE THROUGH A WALL, OR PARTITION

OF COMBUSTIBLE CONSTRUCTION IS

DESIRED, THE INSTALLATION SHALL

CONFORM TO CAN/CSA-B365, INSTALLATION

CODE FOR SOLID-FUEL-BURNING

APPLIANCES AND EQUIPMENT

Any connector pipes or elbows should be installed with

the crimped end on the stove end of the path (not the

chimney cap end) and should be secured with three

evenly spaced sheet metal screws.

Connectors, elbows, and chimneys should be type

‘L’ or ‘PL’ and have a 80mm, or 3 inch diameter as

the flue system is based on negative pressure in the

combustion chamber and a slight overpressure on the

flue gas outlet. It is therefore important that the flue

gas connection is fitted correctly and is airtight.

It is recommended that connectors, elbows, and

chimneys be at least 24 gauge, double walled, type B

ventilation.

Note that bends in the exhaust path restricts air flow,

reducing performance and provides a collection point

for ash deposits requiring more frequent cleaning.

CAUTION: THE JOINTS OF ANY AND ALL

CONNECTIONS FOR ANY VENTILATION

SYSTEMS (COMBUSTION EXHAUST AND

OPTIONAL INLET AIR DUCT) MUST BE

SEALED WITH HIGH TEMPERATURE

SILICONE.

GENERAL VENTING REQUIREMENTS

CAUTION: DO NOT CONNECT TO ANY AIR

DISTRIBUTION DUCT OR SYSTEM.

(ICBO) standards for solid fuel Stoves codeapproved masonry chimney.

VENT TERMINATION

• Install exhaust vent at clearances specified by the

vent manufacturer.

• Install exhaust vent terminations at clearances

specified by the vent manufacturer.

• If using the air intake kit, ensure that there is at

least 12 inches clearance between the exhaust vent

termination and the intake air inlet.

• It is recommended to keep at least 12” (30.5 cm)

of clearance between any vent termination and

windows, doors, or outside corners.

• Use silicone to create an effective vapor barrier at

the location where the chimney or other component

penetrates to the exterior of the structure.

• For additional requirements check local codes.

Any vertically terminated chimney systems must meet

the following minimum requirements:

• Must be at least 15 feet (4.6 m) tall, measured from

the top of the stove to the tip of the chimney cap.

• Must be at least 3 feet above the roof, measured

from the highest point of contact with the roof and

the tip of the chimney cap.

• Must be at least 2 feet (61 cm) above the highest

point of the slope of the roof within 10 feet (305

cm) horizontally.

Any horizontally terminated chimney systems must

meet the following minimum requirements:

• Must have at least 12” (30.5 cm) clearance above

grade, veranda porch, deck or balcony (Including

vegetation and mulch).

PASSING THROUGH A WALL

Where passage through a wall or partition of

combustible construction is desired, the installation

shall conform to chimney manufacturer’s instructions.

NOTE: In Canada, installation must conform to

CAN/CSA-B365 when passing through combustible

construction, illustrated in figure 6 .

CAUTION: DO NOT CONNECT THIS UNIT

TO A CHIMNEY FLUE SERVING ANOTHER

APPLIANCE.

CAUTION: DO NOT INSTALL A FLUE DAMPER

IN THE EXHAUST VENTING SYSTEM OF THIS

WOOD PELLET FIRED STOVE.

This wood pellet fire stove must be connected to either

of the following:

• Class A listed chimney complying with the

requirements for Type HT chimneys in the Standard

for Chimneys, Factory-Built, Residential Type and

Building Heating Appliance, UL 103.

• A International Conference of Building Officials

side only. If two covers are

on non-combustible spacers

at least 7/8” (21mm) away

from the wall.

Stove connector pipe

1” (25mm) clearance

Figure 6

ONLY APPROVED CANADIAN WALL PASS

THROUGH

8

Operating Instructions and Owner’s ManualCleveland Iron Works Wood Pellet Fire Stove

Page 9

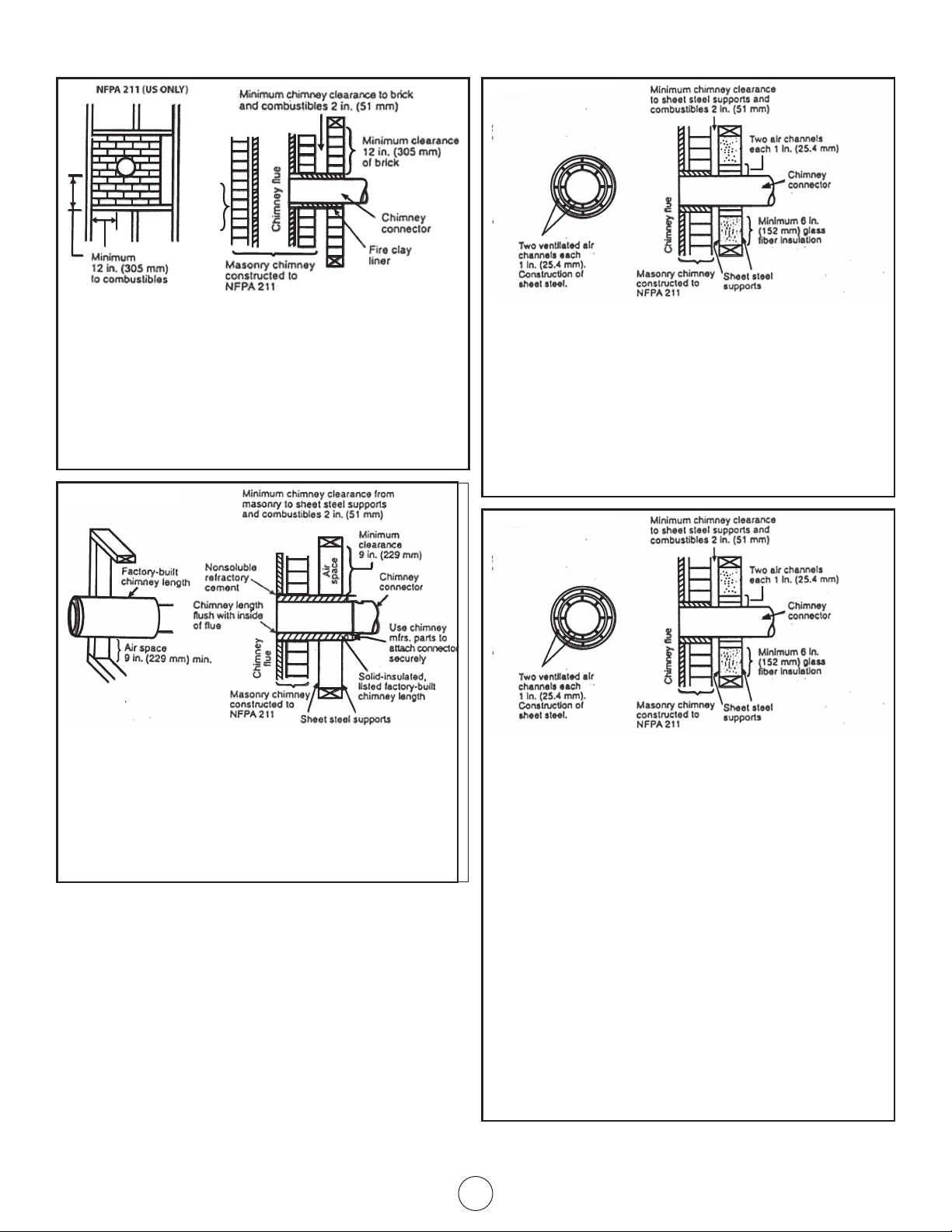

NFPA 211 (US ONLY) APPROVED WALL PASS THROUGH TECHNIQUES

Figure 7 (US ONLY)

Brick Masonry: Minimum 3.5 inch (89 mm)thick brick

masonry all framed into combustible wall with a

minimum of 12 inch (305 mm) brick separation from

clay liner to combustibles. The fireclay liner shall run

from outer surface of brick wall to, but not beyond,

the inner surface of chimney flue liner and shall be

firmly cemented in place.

Figure 8 (US ONLY)

Insulated Sleeve: Solid-insulated, listed factory-built

chimney length of the same inside diameter as the

chimney connector and having 1 inch (25.4 cm) or

more of insulation with a minimum 9 inch (229 mm)

air space between the outer wall of the chimney

length and combustibles.

Figure 9 (US ONLY)

Ventilated Thimble: Sheet steel chimney connector,

minimum 24 gauge in thickness, with a ventilated

thimble, minimum 24 gauge in thickness, having

two 1 inch (25.4 mm) air channels, separated from

combustibles by a minimum of 6 inches (152 mm)

of glass fiber insulation. Opening shall be covered,

and thimble supported with a sheet steel support,

minimum 24 gauge in thickness.

Figure 10 (US ONLY)

Chimney Section Pass-through: Solid insulated, listed

factory-built chimney length with an inside diameter

2 inches (51 mm) larger than the chimney connector

and having 1 inch (25.4 mm) or more of insulation,

serving as a pass-through for a single wall sheet

steel chimney connector of minimum 24 gauge

thickness, with a minimum 2 inches (51 mm) of air

space between the outer wall of chimney section and

combustibles. Minimum length of chimney section

shall be 12 inches (305 mm) chimney section spaced

1 inch (25.4 mm) away from connector using sheet

steel support plates on both ends of chimney section.

Opening shall be covered, and chimney section

supported on both sides with sheet steel support

securely fastened to wall surfaces of minimum 24

gauge thickness. Fasteners used to secure chimney

section shall not penetrate chimney flue liner.

9

Operating Instructions and Owner’s ManualCleveland Iron Works Wood Pellet Fire Stove

Page 10

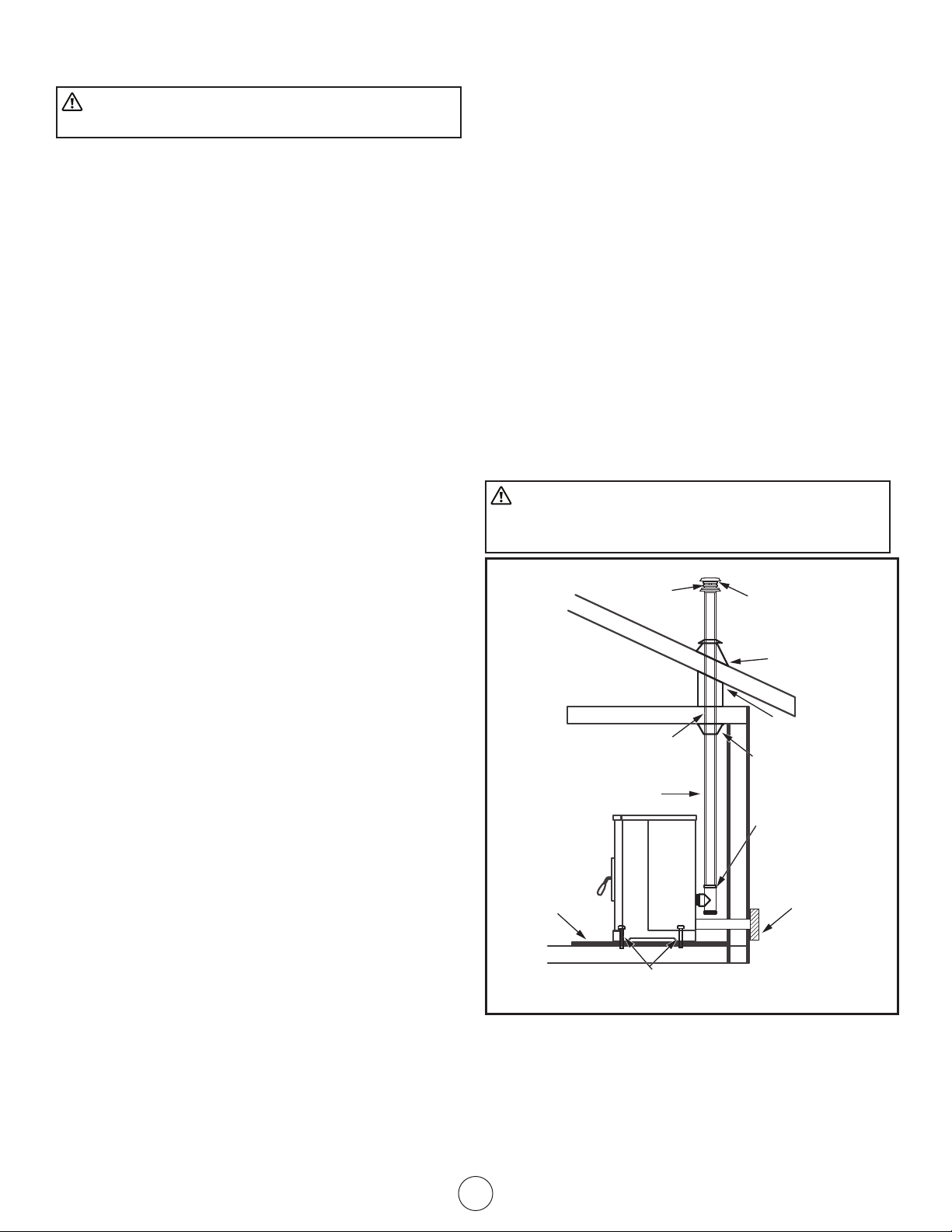

ADDITIONAL MOBILE HOME REQUIREMENTS

Mandatory Chimney Cap &

WARNING: DO NOT INSTALL IN SLEEPING

ROOM.

PARTS & MATERIALS REQUIRED (NOT SUPPLIED)

• A 80mm diameter chimney which complies to

UL 103, Standard for Factory-Built Chimneys for

Residential Type and Building Heating Appliances.

• Ceiling thimble suitable for use in mobile home.

• Roof thimble suitable for use in mobile home.

• Spark arrestor suitable for use in mobile home.

• Roof flashing suitable for use in mobile home.

ADDITIONAL INSTALLATION REQUIREMENTS

• The chimney shall attach directly to the room heater

and shall extend at least 3 feet (0.9 m) above the

part of the roof through which it passes.

• The top of the chimney is to be at least 2 feet (0.6

m) above the highest required elevation of any part

of the mobile home within 10 feet (3 m) of the

chimney.

• All roof-chimney terminations shall be able to be

readily removed at or below an elevation of 13½ feet

(4.1 m) above ground level and reinstalled without

the use of special tools or instructions.

• The chimney assembly shall be provided with

a mechanical securement means to secure the

chimney to the ceiling support box.

• Chimney Guard Requirements:

— When the chimney exits the mobile home at

a location other than through the roof, and

exits at a point 7 feet (2.1 m) or less above

the ground level on which the mobile home is

positioned, a guard or method of enclosing the

chimney shall be provided at the point of exit for

a height up to 7 feet.

— The chimney guard shall not have any openings

large enough that a 3/4 inch diameter rod can

enter.

— The chimney guard shall not have any openings

large enough that a 1/2 inch diameter rod can

enter beyond 4 inches

• The stove must be on installed on a level surface

which can support the weight of the stove.

• The stove must be bolted to the level surface so

that it permanently secured and can not be moved,

tipped, or have ventilation seals compromised.

• The stove must be provided a permanently ducted

source of outside air to support combustion which

meets the following requirements:

— The duct must be made of metal exclusively, not

other materials such as plastic.

— The end of this duct must be equipped with a

screen which prevents rodents from infiltrating.

— The end of this duct must be kept free of leaves,

snow, ice, or other debris that could restrict air

supply when the appliance is in operation.

• The joints of any and all connections for both of

ventilation systems (the inlet air and the combustion

exhaust) must be sealed with high temperature

silicone.

• The chimney must comply with all applicable

codes and requirements of the authority having

jurisdiction.

• The chimney must be removed for any mobile

home transportation, and reinstalled abiding all

requirements after transportation.

The flue system is based on negative pressure in

the combustion chamber and a slight overpressure

on the flue gas outlet. It is therefore important

that the flue gas connection is fitted correctly and

is airtight.

CAUTION: THE STRUCTURAL INTEGRITY OF

THE MOBILE HOME FLOOR, WALL, CEILING,

AND ROOF MUST BE MAINTAINED.

UL 103 Chimney

Joist Shield

/ Firestop

UL 103 Pass-through system

according to Manufacturer’s Parts

& Instructions

Double-wall UL 103 High

Temperature Chimney Pipe

Floor

Protector

Bolted to floor

Storm Collar & Roof

Mobile Home Building

Spark Arrestor

Flashing per Local

Codes

Mobile Home

Thimble

Chimney Support

Clean Out T

Permanent,

All-metal

Combustion air

Source with

Exterior Seal &

Screen

Figure 11 Mobile Home Vertical Chimney

10

Operating Instructions and Owner’s ManualCleveland Iron Works Wood Pellet Fire Stove

Page 11

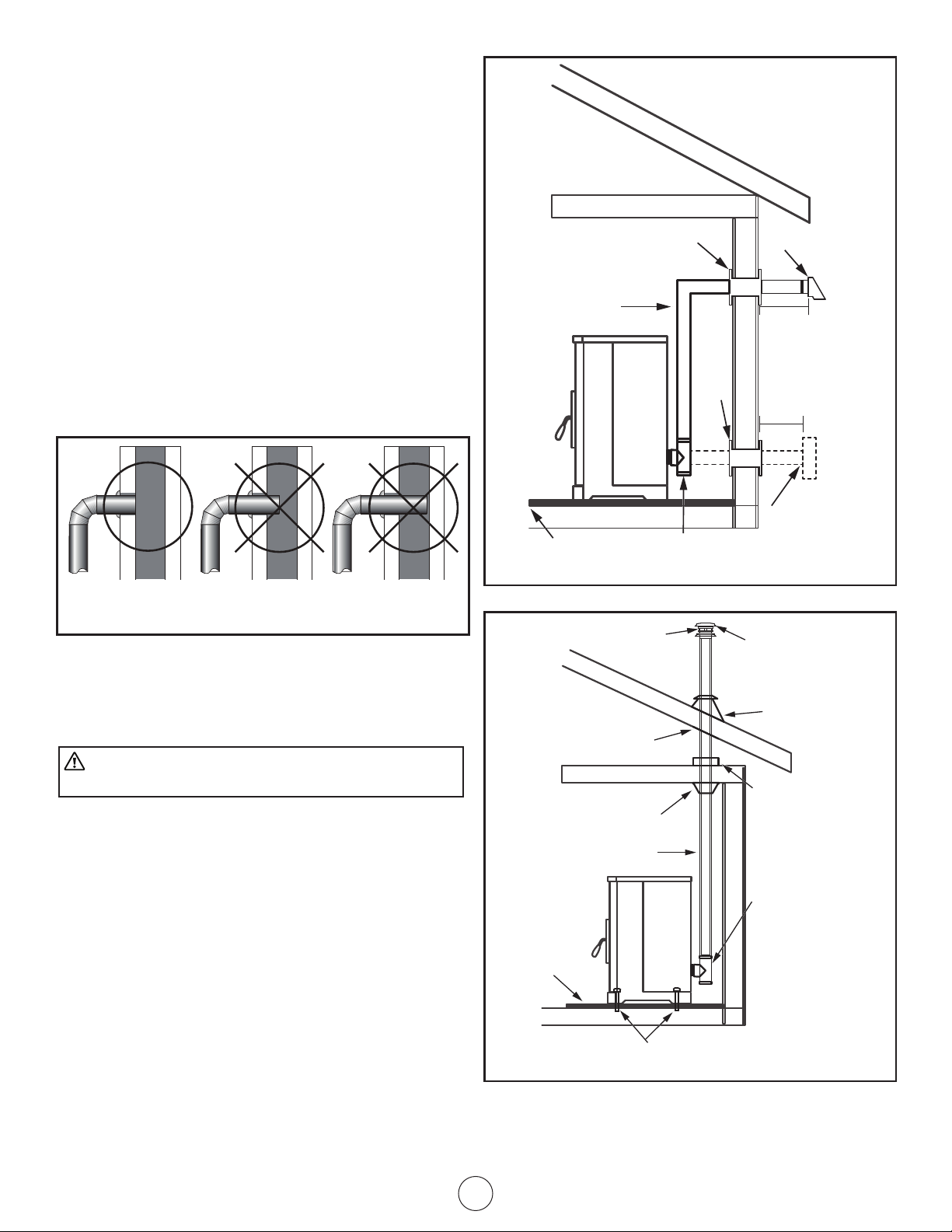

LINED MASONRY CHIMNEY INSTRUCTIONS &

Mandatory Chimney Cap &

UL 103 Chimney

DIAGRAM

This stove is designed to be vented through a masonry

chimney which conforms to local building codes, fire

codes, and latest edition of NFPA 211 US or CAN/

CSA-B365.

1. If the connection piping from the stove to a

masonry chimney is made through a combustible

wall, consult a qualified mason or chimney dealer

for consultation. To ensure safety, the installation

should only be done by a qualified installer. The

installation must conform to the regulations

established by local fire codes and building codes

Wall

Thimble

Double-wall UL 103

High Temperature

Chimney Pipe

Termination

Cap

6 in

(152mm)

Minimum

2. The chimney connection must not be obstructed by

the chimney connector pipes, such as the figure 12

below illustrates.

Correct Wrong Wrong

Figure 12 Connection Pipe & Chimney Connection

3. If there is an opening at the base of the chimney it

must be closed tightly.

MANUFACTURED CHIMNEY INSTRUCTIONS &

DIAGRAM

WARNING: DO NOT USE SINGLE-WALL

CONNECTION PIPE AS A CHIMNEY.

This stove is designed to be used with either a UL

103HT (US)/ULC-S629 (CAN) listed manufactured

chimney or an approved lined masonry chimney. Not all

manufactured chimney are UL103 HT/ULC-S629 listed.

Home centers, hardware stores, HVAC supply stores,

and the Online websites of chimney manufacturers

will be able to provide stove pipe that is rated to these

standards.

6 in

Thimble

Floor Protector

Wall

Clean Out T

(152mm)

Minimum

Horizontal

Termination

Cap

Figure 13 Manufactured Chimney through Wall

Spark Arrestor

Storm Collar & Roof

Flashing per Local

Mobile Home Building

Codes

Joist Shield

/ Firestop

Attic Insulation

Shield

Chimney Support

Double-wall UL 103 High

Temperature Chimney Pipe

Clean Out T

Floor

Protector

This listing indicates that the Chimney is rated for high

temperatures up to 2100 °F (1149 °C)

Only use components that all come from the same

manufacturer. Do not mix brands of components for

the same ventilation system.

The following figures illustrate various methods and

requirements of using a manufactured chimney and

connection pipes to vent the stove.

Bolted to floor

Figure 14 Manufactured Chimney through Attic

11

Operating Instructions and Owner’s ManualCleveland Iron Works Wood Pellet Fire Stove

Page 12

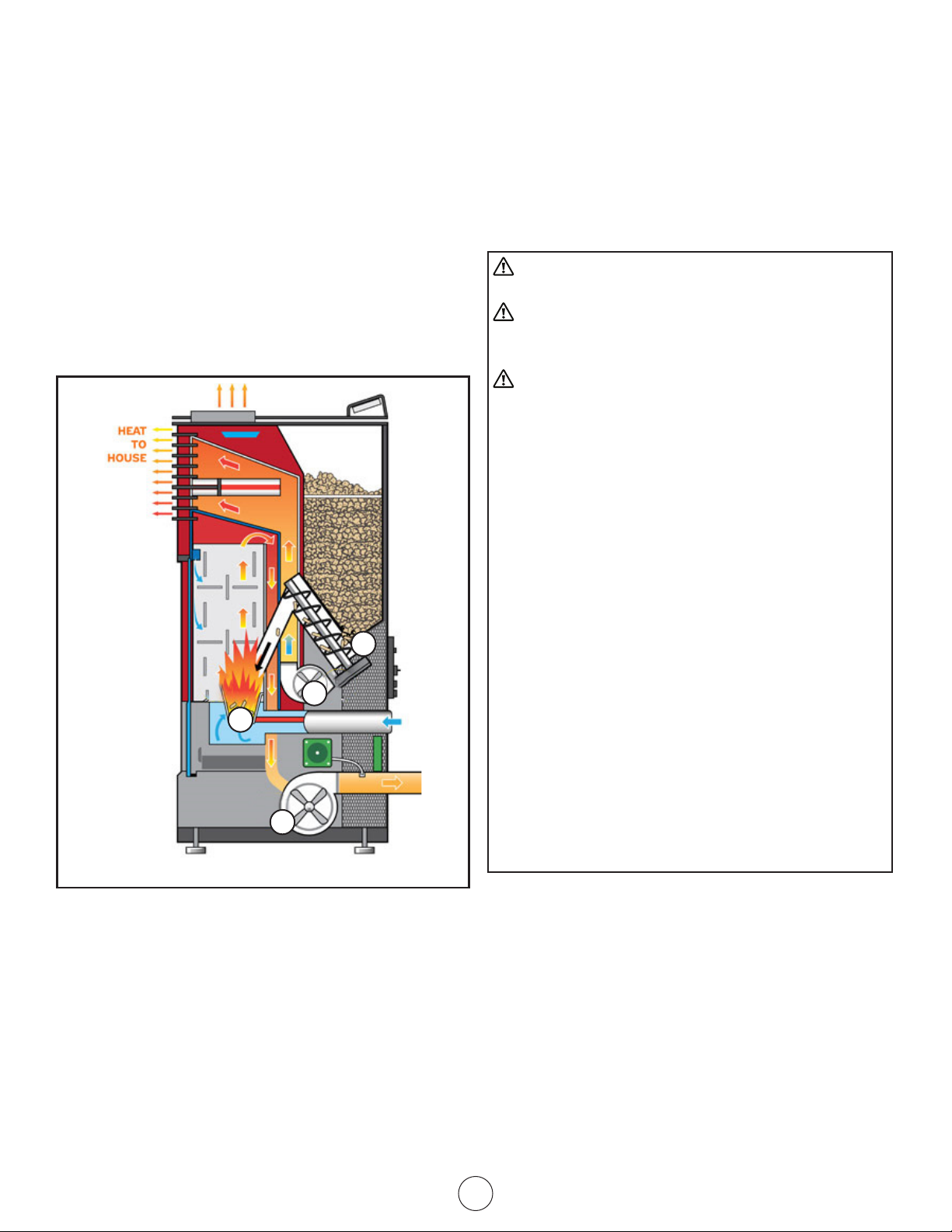

OPERATION

THEORY OF OPERATION

1. Combustion occurs in the fire pot, supported by

air introduced to and under the fire pot. Note that

some air blows in from the top of the combustion

chamber; this helps keep ash and debris from

accumulating on the door.

2. The exhaust blower draws combustion products

from the stove and directs it out user-installed

venting.

3. The auger transfers pellets from the hopper to the

fire pot to sustain the fire.

4. A convection blower propagates air along the

outside of the fire box, circulating warm and clean

air into the room.

3

4

1

2

bottom of the pellet container.

• Store pellets in sacks, made of environmentally

neutral or biologically degradable plastic or from

paper (2-3 layers / similar to cement packaging).

Use of wood pellets that do not meet these

specifications may result in ignition difficulty,

accelerated creosote or flyash build up, incomplete

combustion, low heat yield, and blackening of the glass

in the door.

CAUTION: DO NOT USE CHEMICALS OR

FLUIDS TO START THE FIRE.

CAUTION: DO NOT BURN GARBAGE OR

FLAMMABLE FLUIDS SUCH AS GASOLINE,

NAPHTHA OR ENGINE OIL.

CAUTION: NEVER ATTEMPT TO USE ANY OF

THE FOLLOWING MATERIALS AS FUEL:

• Paper products, cardboard, or particleboard;

• Garbage;

• Animal remains or manure;

• Lawn clippings or yard waste;

• Waste petroleum products;

• Coal;

• Construction or demolition debris;

• Railroad ties or pressure-treated wood;

• Materials containing

—asbestos

—plastic

—rubber (including tires)

• Petroleum products such as

—paints

—paint thinners

—asphalt products

BURNING THESE MATERIALS MAY RESULT IN

RELEASE OF TOXIC FUMES OR RENDER THE

HEATER INEFFECTIVE AND CAUSE SMOKE

Figure 15 Stove Operation Process

APPROVED FUEL:

Do not use less than PFI premium-grade pellets. Use

100% natural wood pellets, untreated and without

bonding agents added (max bark proportion of 5%)

are the only fuel approved for use with this pellet stove.

For best results see the specifications below:

• Calorific Value of 5.3 kWh/kg

• Density of 700 kg/m

3

• The pellets should be low ash (less than 1 % ash)

• The pellets should be less then 30mm long, with a

diameter between 5 and 6.5 mm.

• Do not use the pellet sediment & debris at the

Do not store wood pellet fuel or other fire starting

materials on floor protector, underneath stovepipe,

or anywhere within minimum clearances from

combustible surfaces specified on page 5.

Wood pellet fuel should be stored in a dry, well

ventilated area.

12

Operating Instructions and Owner’s ManualCleveland Iron Works Wood Pellet Fire Stove

Page 13

OPERATING PRECAUTIONS

WARNING: HOT WHILE IN OPERATION. DO

NOT TOUCH THE STOVE. KEEP CHILDREN,

CLOTHING AND FURNITURE AWAY. CONTACT

MAY CAUSE SKIN BURNS.

CAUTION: ENSURE THAT THE FIREPOT AND

THE PAN UNDERNEATH ARE CLEAN AND IN

THE PROPER OPERATING POSITION BEFORE

USING THE STOVE.

WARNING: NEVER USE GASOLINE,

GASOLINE-TYPE LANTERN FUEL, KEROSENE,

CHARCOAL LIGHTER FLUID, OR SIMILAR

LIQUIDS TO START OR ‘FRESHEN UP’ A FIRE

IN THIS HEATER. KEEP ALL SUCH LIQUIDS

WELL AWAY FROM THE HEATER WHILE IT IS

IN USE.

PAINT CURING

To allow the paint to bond durably to the stove, start

by running the stove on P1 Maximum Power for at

least 30 minutes. Provide cross ventilation to eliminate

odors or smoke cause by this curing process.

OPERATING PROCEDURE: TURN ON STOVE

NOTE: If the display screen indicates that the

stove is “Switching Off” the stove can not

be interrupted. The Display Message will

highlight to indicate that the state will not be

changed. Only once the “Switching Off” cycle

has finished and the exchanger has cooled

can the stove be turned back on again.

1. Make sure that seals on the ash drawer and door

are in good condition. If the stove has never been

run before, add a handful of pellets directly to the

firepot. Close the ash drawer and doors securely,

and check that all side panels are all properly

installed.

• Cleaning Cycle: The firepot draws dust, ash, &

remnants out.

• Feeding Cycle: Pellets will be transported from the

Pellet Hopper into the fire pot by the auger. This

can take 5 to 15 minutes depending on the model

of stove.

• Lighting Cycle: The electrically powered hot surface

igniter will power on for 8 minutes and begin

combustion of the pellets in the firepot. The heater

will remain in the Lighting Cycle until the exhaust

smoke reaches a designated temperature.

• Stabilization Cycle: The heater adjusts to fine tune

the stove output to the desired temperature. This

can take a few minutes

4. The stove has been successfully turned on.

OPERATING PROCEDURE: TURN OFF STOVE

NOTE: THE STOVE MAY BE TURNED OFF,

REGARDLESS OF WHAT CYCLE THE DISPLAY

SCREEN INDICATES THAT THE STOVE IS IN,

BY DEPRESSING AND HOLDING THE POWER

BUTTON FOR TWO SECONDS. ONCE THE

DISPLAY SCREEN INDICATES THAT THE STOVE

IS IN THE STABILIZATION CYCLE PRESS THE

POWER BUTTON AGAIN. THE STOVE WILL

ENTER THE COOLING CYCLE, STATED ON THE

DISPLAY SCREEN.

CAUTION: AFTER THE COOLING CYCLE THE

STOVE AUTOMATICALLY BEGINS

THE PROCESS OF CYCLING ON.

1. Depress the power button for 3 seconds. The stove

will begin to automatically progress through the

following stages:

• Switching Off: Any remaining fuel in the firepot

will continue to burn and produce heat and

flame. After 5 to 8 minutes the firepot ought to

be devoid of fuel. The heat exchanger may then

begin to cool off.

NOTE: DO NOT USE GRATES, IRONS, OR ANY

OTHER METHODS OF SUPPORTING WOOD

PELLET FUEL. ONLY THE FIREPOT SPECIFIC TO

YOUR MODEL OF STOVE MAY BE USED.

2. Open the hopper. Ensure that there are a

sufficient number of pellets to satisfy your heating

requirements. Close the hopper.

3. Depress the power button for 3 seconds. The

stove will begin to automatically progress through

the following stages:

• Goodbye: The final message from the display

screen to designate that the stove has cooled.

2. The stove has been successfully turned off.

OPERATION WITH AN ELECTRICAL GENERATOR

This stove is designed to have the option of being

powered by an electrical generator, though not

all electrical generator’s may be compatible with

this stove. Consult the information regarding your

generator’s electrical regulator and make sure that

it meets the electrical requirements of this stove, as

stated on page 3.

13

Operating Instructions and Owner’s ManualCleveland Iron Works Wood Pellet Fire Stove

Page 14

MINIMIZING CREOSOTE FORMATION

POWER

See “MAINTENANCE” on page 17 for an explanation

of Creosote formation and removal. To slow the build

up of creosote within your chimney burn only the

recommended fuel, see page 12.

DISPOSAL OF ASHES

CAUTION: EMBERS MAY BE OBSCURED BY ASH.

HANDLE ASH WITH TOOLS SUFFICIENT FOR

FIRE TENDING, NEVER DIRECTLY WITH YOUR

HANDS. WEAR FIRE RETARDANT CLOTHING AND

PROTECTIVE EYEWARE.

Ashes should be placed in a metal container with a

tight fitting lid.

1. Other waste shall not be placed in ash containers.

2. The closed container of ashes should be placed

on a noncombustible floor or on the ground, well

away from all combustible materials, pending final

disposal.

3. Wood mineral residue (approximately 1-2%) remains

in the ash and is an excellent natural fertilizer

product for all garden plants. Before disposing ashes

of by burial in soil or otherwise locally dispersed,

they should be retained in the closed container until

all any and all cinders have thoroughly cooled and

should also be “quenched” with water.

Remote Button Functionality:

The buttons on the remote controller affect the stoves

operation in the same way that the mounted button

do, explained in v:

Remote Controller

Button

Mounted Button

Counterpart

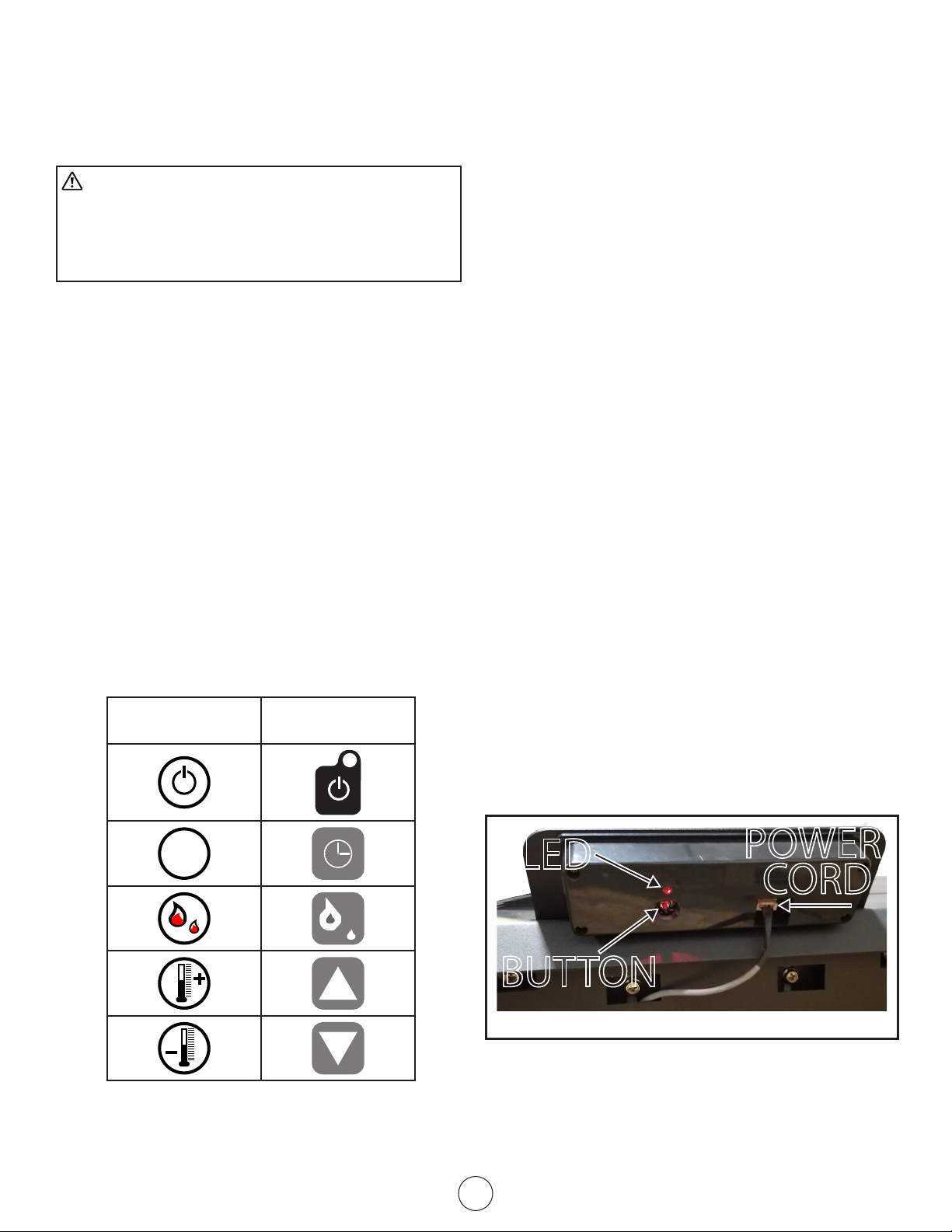

SMART STOVE WIFI CONNECTION

This stove can be monitored, controlled, and

programmed by using the smart stove app by NHHATC

which is available for iOS or android device through the

app store.

Step 1. Download the Smart Stove app by NHHATC.

Step 2. Open the Smart Stove app. The app opens, by

default, to the “Register” screen. Click on the

“Register” button.

Step 3. Enter your email address in the “Email” field

and click the “Get Verification Code” button.

Step 4. Enter the verification code that was emailed to

you in the “Enter Verification Code” field.

Step 5. Now you can set a unique password for your

device in the “Set Password” field and hit the

“Done” button.

Step 6. If you have no other wifi enabled devices

already added to this app there will be a large

“Add Device” button in the center of the screen

which you can select. Otherwise, select the +

symbol in the top right of the screen.

Step 7. Make sure that your device is connected to the

wifi network which you want the stove to be

connected to.

Step 8. Make sure that the wood pellet fire stove is

plugged into an electrical outlet and can be

powered on.

Step 9. Follow the directions on the screen by pressing

and holding the connection button for 3

seconds on the rear of the display panel

as illustrated in the figure below. Once you

observe the desired blinking pattern on the

indicator light, press the confirmation button at

the bottom of the screen.

Auto

Note: There are no lights or display screen on the

remote controller that can indicate to you that the

button presses are being received by the stove. In

order to remotely control the stove but also monitor its

settings, try installing the Smart Stove app.

LED

CORD

BUTTON

Figure 16 Display Panel Back

Step 10. Enter the password for the wifi network

so that the stove can connect to the wifi

network.

Step 11. The stove will begin pairing with the device

running the application through the wifi

14

Operating Instructions and Owner’s ManualCleveland Iron Works Wood Pellet Fire Stove

Page 15

network. This process may take a few

minutes.

Step 12. After the device and stove are paired, you

will be able to see the pellet stove as a

connection option on the “Devices” tab at the

bottom of the app screen.

Step 13. On your device, go to your device’s wifi

settings which will now include the stove

as an option. Select the stove as your wifi

connection.

Step 14. Open the Smart Stove phone app again.

Step 15. You may now select this stove from this

added devices list in order to monitor, control,

and program the stoves operation.

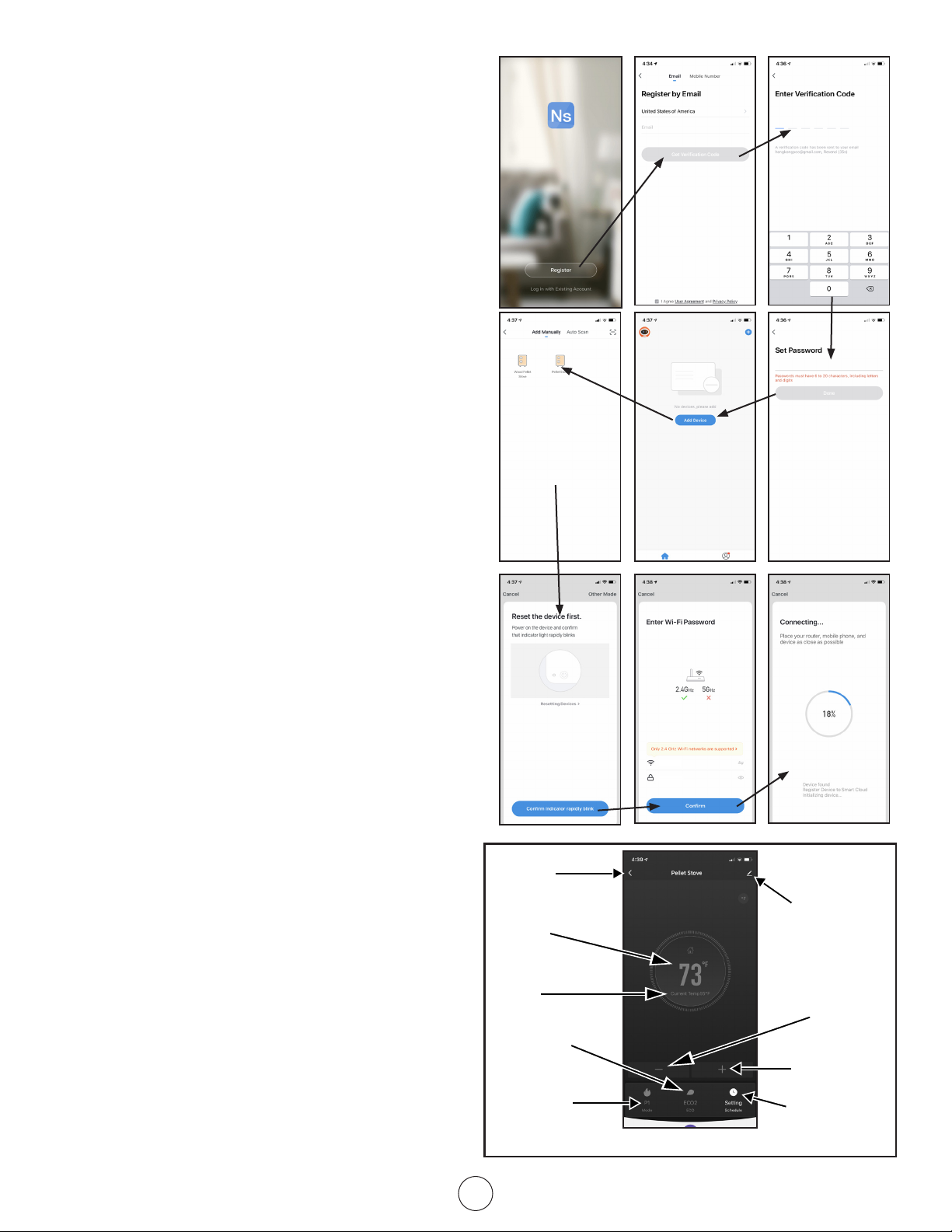

WIFI CONTROLS

Once connected to the stove (See step 13 of Wifi

Connection) you an remotely monitor and adjust the

operation of the stove. See below for explanation:

• Device Name: it is possible to rename the stove, so

that if you have multiple stoves set up for operation

you can more easily differentiate between while

using the smart stove application.

• Device Sharing: it is possible to share connection to

the stove with other devices via SMS or email.

• Eco Mode: There are two ECO settings which can

be selected which will conserve wood pellets while

maintaining the desired temperature. Pressing the

ECO button will allow you to toggle whether a

specific eco setting is enabled, or to turn off the

feature entirely.

• ECO 1: The stove shuts off when the desired

temperature has been reached. The stove will

turn back once the room cools to a factory set

temperature.

• ECO 2: The stove turns to minimum power

preset P4 when the desired temperature has

been reached. The stove will turn on to higher

power settings once the room cools to a factory

set temperature.

• Preset configurations: There are four selectable

configurations which adjust the speeds of the

combustion fan and the room air circulation fan.

Pressing the preset configuration button will allow

you to toggle whether a specific preset configuration

is enabled, or to turn off the feature entirely.

• P1 [Maximum Power] Settings

• P2 [Medium Power] Settings

• P3 [Low Power] Settings

• P4 [Minimum Power] Settings

Device

Select

Screen

Stove

setting

Current

room

temperature

Eco Setting

Preset

configurations

Figure 17 Wifi Controls

Device Name and

Device Sharing

settings

Decrease stove

output

Increase stove

output

Program and

set stove

scheduled

operation

15

Operating Instructions and Owner’s ManualCleveland Iron Works Wood Pellet Fire Stove

Page 16

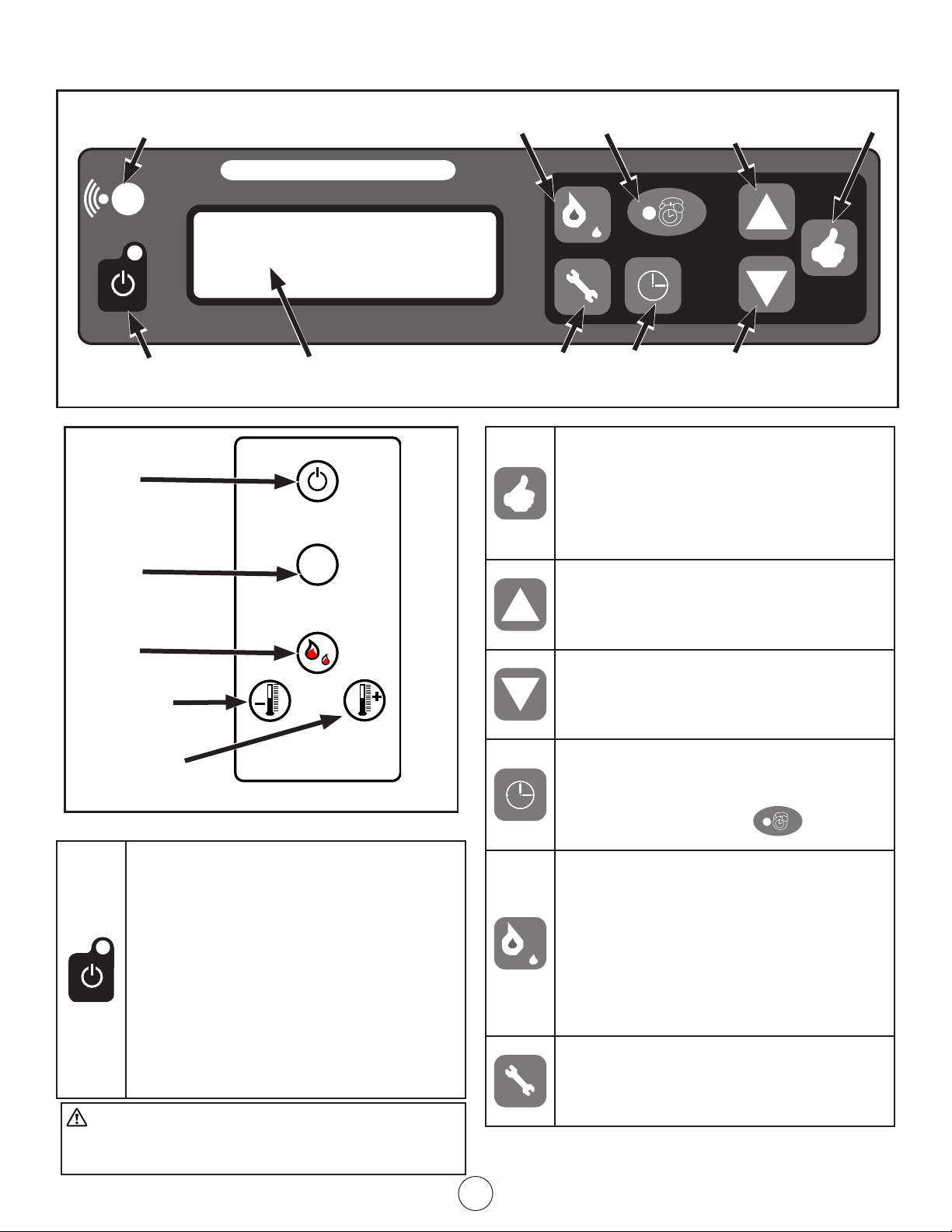

PS60W, PS130W, AND PSBF66W MULTI FUNCTION CONTROLS

Wireless Connection

Notification Light

MULTI FUNCTION DISPLAY

Rate Select

Power

Figure 18a Mounted Multi Function Controls Panel

Power

Manual /

Automatic

Toggle

Auto

Rate Select

Temperature

Decrease

Temperature

Increase

Figure 18b Remote Controller

Mounted Button Functionality: Normal Operation

• The light illuminates when the stove is

plugged into an electrical supply.

• Press the power button to turn the display

on for the purpose of adjusting settings.

The screen will become dim after 10

seconds on inactivity.

• Press and hold the power button for 3

seconds to begin stove heating if the stove

was off.

• Press and hold the power button for 3

seconds to begin stove shut off if the stove

was on.

CAUTION: The manufacturer has programmed

preset rates to ensure proper operation. It is not

advised to reprogram rate settings.

Manual / Automatic

Notification Light

SettingsDisplay Screen

Time

Press to cycle between temperature reports

(in Fahrenheit) display in the top right of the

multi function display screen:

• ##(R): Room temperature

• ##(S): Exhaust temperature

• ##(P): Protection Temperature Sensor

Press to increase the temperature which

the stove is intended to heat the room to.

This value is displayed in the top right of the

multi function display screen as ##0F.

Press to decrease the temperature which

the stove is intended to heat the room to.

This value is displayed in the top right of the

multi function display screen as ##0F.

Press to toggle the stove between manual

control and programmed control. If the

stove is in the program controlled setting

then the notification light will be

illuminated.

Pressing the rate select will toggle between

four configurable heating presets. The

currently set preset is available in the top

middle of the multi function display screen

as P#.

• P1: Maximum Power

• P2: Medium Power

• P3: Low Power

• P4: Minimum Power

• Press and hold the settings button for 2

seconds to enter the set up menu.

• Press the settings button at any time to

exit the set up menu.

Up Selector

Down Selector

Confirm

16

Operating Instructions and Owner’s ManualCleveland Iron Works Wood Pellet Fire Stove

Page 17

MAINTENANCE

This wood heater needs periodic inspection and repair

for proper operation. It is against federal regulations

to operate this wood heater in a manner inconsistent

with operating instructions in this manual.

CAUTION: TURN OFF AND UNPLUG THE

STOVE FROM ANY SOURCE OF ELECTRICAL

POWER TO UNIT BEFORE PERFORMING ANY

MAINTENANCE OR SERVICE OPERATIONS.

CAUTION: ALLOW STOVE TO COOL DOWN

BEFORE PERFORMING ANY MAINTENANCE

OR SERVICE OPERATIONS.

CAUTION: DURING ANY ASSEMBLY OR

DISASSEMBLY, BE WARY TO NOT DROP ANY

ITEMS (SCREWS, ETC.) INTO THE PELLET

HOPPER. DEBRIS CAN JAM THE AUGER AND

DAMAGE THE STOVE.

The frequency which your stove’s requires cleaning and

maintenance depends on the fuel that you use. High

moisture, ash, dust, and chips can more than double

the necessary maintenance. Use only the tested and

recommended wooden pellets fuel.

Clean the fire pot and fire pan every day, before using

the stove and while the stove is cooled down, the stove

is unplugged, and there are no embers. Use a vacuum

cleaner to remove ash and debris from the fire pot,

and then lift the fire pot to also clean the fire pan. It

is important that ash or debris does not block any air

openings.

A general cleaning schedule is as follows:

• Fire Pot: After 10 bags of wood pellets, or every

day. Whichever is more frequent.

• Ash Drawer: After 50 bags of wood pellets

• Passageways: After 100 bags of wood pellets

• Blower: After 100 bags of wood pellets

CLEANING: GLASS

WARNING: DO NOT CLEAN GLASS WHEN

HOT.

Though the circulation of air across the glass reduces

acidic ash build up, cleaning the glass in the stove door

is still required periodically. Cleaning is necessary to

prevent glass from being weakened which may increase

likelihood of cracks. It is not acceptable to operate the

stove with cracked or broken glass.

The best way to clean the door glass is using a damp

cloth that has a smear of cool ash on it. For extra

stubborn dirt, consult your local hardware store or

stove specialist for a suitable cleaner.

WARNING: DO NOT CLEAN GLASS WITH

ABRASIVE CLEANERS OR BY ANY OTHER

PROCESS WHICH MAY SCRATCH OR DAMAGE

THE GLASS.

CLEANING: INLET AND OUTLET PASSAGEWAYS

The inlet and outlet passageways should be cleaned at

least once a year. Burning high ash pellets may require

that the passageways are cleaned more frequently.

Figure 19 Inlet Duct

CLEANING: FIRE POT & PAN

CAUTION: IF STOVE IS INTENDED TO

OPERATE CONTINUOUSLY, IT MUST BE

TURNED OFF TWICE WITHIN EACH 24 HOUR

PERIOD IN ORDER TO CLEAN THE FIRE POT

AND FIRE PAN. ALWAYS ALLOW THE STOVE

TO COOL DOWN AND ANY EMBERS TO

EXTINGUISH BEFORE CLEANING THE FIRE

POT AND FIRE PAN.

Make sure that you put the fire pot back onto the fire

pan in the correct orientation, so that pellets can be

added to the pot and successfully ignited for the next

operation of the stove.

Figure 20 Outlet Duct

17

Operating Instructions and Owner’s ManualCleveland Iron Works Wood Pellet Fire Stove

Page 18

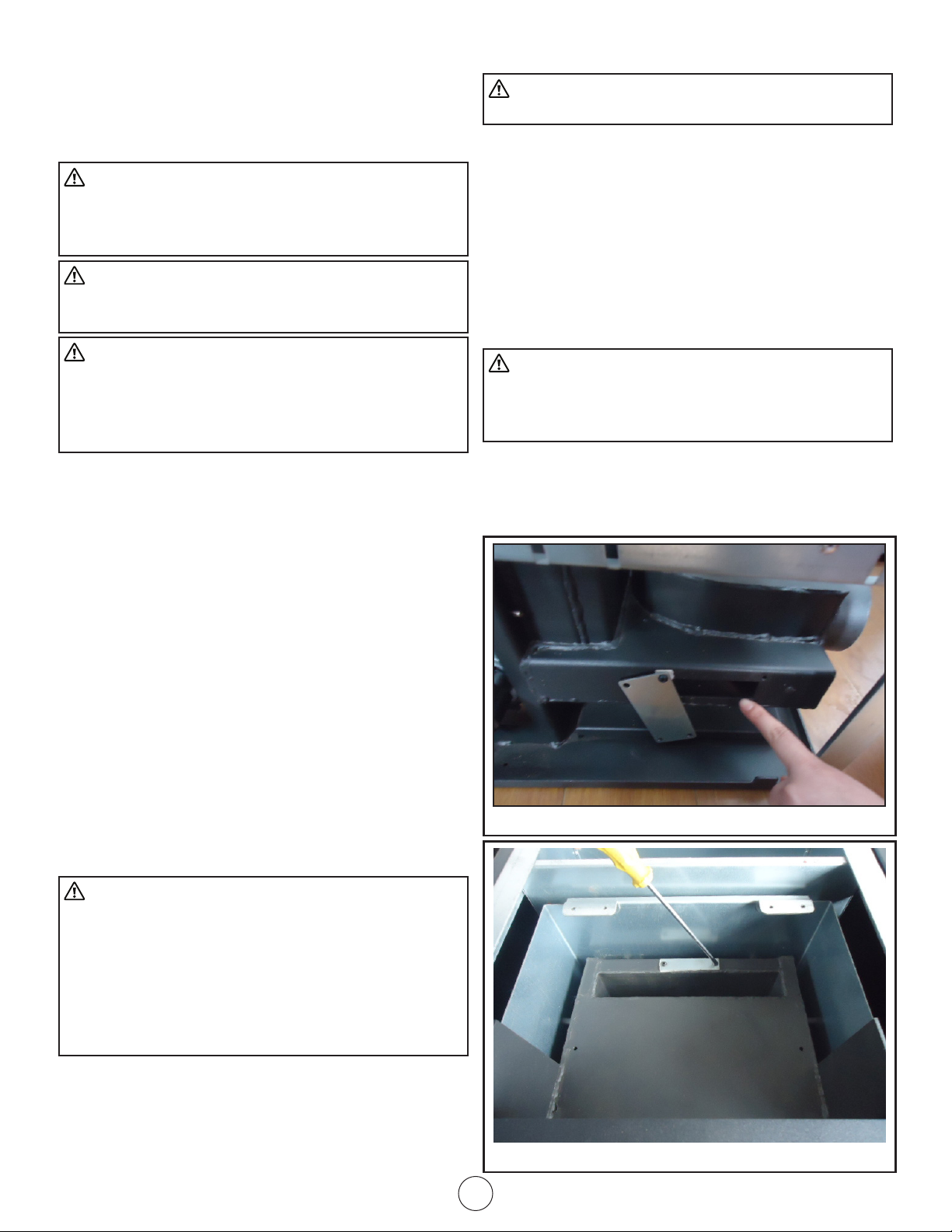

On each side of the stove there are two access covers

that can be removed by removing the fastening screws.

See Figures 22, 25 and 26. Turn off the stove, allow

the stove to cool down, and unplug the stove before

disassembly and cleaning. Insert a cleaning brush into

the openings to loosen any ash build up and then use

a vacuum cleaner to remove the loosened ash. Replace

the covers and secure with the allen head screws.

There are two more openings to the inlet and outlet

passageways which can be accessed by removing the

ash drawer. Loosen the two 5/32” allen head screws

shown in Figure 20. Rotate the covers to expose the

opening. Use a cleaning brush to loosen any ash build

up. Insert a cleaning brush into the openings to loosen

any ash build up and then use a vacuum cleaner to

remove the loosened ash. Rotate the covers back over

the openings and secure with the allen screws.

CLEANING: CONVECTION BLOWER

creosote. To clean the exhaust venting system insert

an appropriate sized cleaning brush into the pipe to

loosen and remove any ash or debris build up. Build up

of debris and ash can restrict the flow of gases which

will affect stove performance, and failure to remove

creosote may result in a dangerous chimney fire.

FLYASH - FORMATION AND NEED FOR REMOVAL

The products of combustion will contain small

particles of flyash. The flyash will collect in the exhaust

venting system and restrict the flow of the flue gases.

Incomplete combustion, such as occurs during startup,

shutdown, or incorrect operation of the room heater

will lead to some soot formation which will collect

in the exhaust venting system. The exhaust venting

system should be inspected at least once every year to

determine if cleaning is necessary. Use the appropriate

sized chimney brush to remove ash and buildup from

the venting.

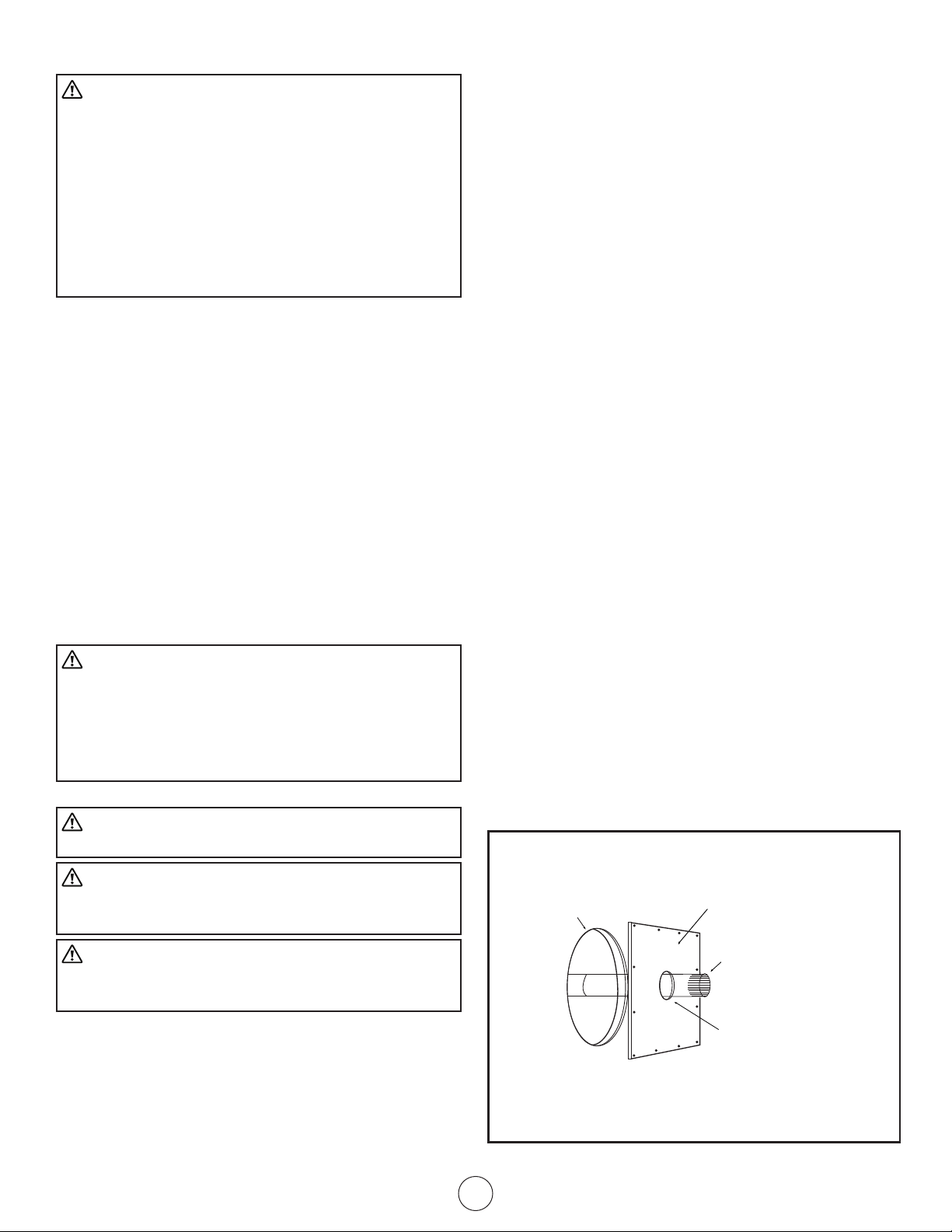

When facing the heater, the blower motor responsible

for introducing air for heating and circulation to the

room is located on the right hand side. Remove or open

the side panel to obtain access. Clean the convection

blower as required, before using the stove and while

the stove is cooled down, the stove is unplugged,

and there are no embers. Take care to not damage

the blower’s blades during cleaning. Use a vacuum to

remove any dust accumulation of the blower’s blades

or inside the blower duct.

PS130W PS60W, PSBF66W

Figure 22 Convection Blower Disassembly

CLEANING: EXHAUST VENT PIPE

Inspect the exhaust venting system at least once a

year to determine if cleaning is necessary. During start

up, shut down, and erroneous operation of the stove

incomplete combustion can produce ash, soot, and

CREOSOTE - FORMATION AND NEED FOR

REMOVAL

Failure to remove creosote may result in a dangerous

chimney fire.

When wood pellets burn at a low temperature they

produce tar and other organic vapors, which combine

with expelled moisture to form creosote. The creosote

vapors condense in the relatively cool chimney flue of

allow-temperature fire. As a result, creosote residue

accumulates on the flue lining. When ignited this

creosote makes an extremely hot fire. The chimney

connector and chimney should be inspected at least

once every few months during the heating season

to determine if a creosote buildup has occurred. If a

significant layer of creosote has accumulated (eighth

of an inch, 3 mm, or more) it should be removed to

reduce the risk of a chimney fire. Use the appropriate

sized chimney brush to remove ash and buildup from

the venting.

Be aware that the hotter the fire the less creosote is

deposited, and weekly cleaning may be necessary

in mild weather even though monthly cleaning may

be enough in the coldest months. Contact your local

municipal or provincial fire authority for information

on how to handle a chimney fire. Have a clearly

understood plan to handle a chimney fire.

REPLACING: GLASS

Replacing the door glass is only permitted by replacing

the entire door assembly provided by the manufacturer.

See pages 27 through 30.

18

Operating Instructions and Owner’s ManualCleveland Iron Works Wood Pellet Fire Stove

Page 19

WARNING: SUBSTITUTING ALTERNATE

MATERIAL MAY SHATTER GLASS AND CAUSE

INJURY.

REPLACING: SEALING GASKETS

Over time the sealing gaskets along the glass, door,

or ash drawer may lose their rigidity. These seals are

essential for providing a seal which allows the stove

to operate safely. Inspect the gaskets periodically, and

if they become worn contact the manufacturer for

information on original or equivalent gasket.

To replace the gasket:

1. Ensure that all pellets are extinguished and that the

stove is cool to the touch.

2. Remove old gasket and clean the gasket gutter.

3. Apply a thin coat of high temperature gasket

cement along the inside of the gasket gutter.

4. Press the beginning of the replacement gasket into

the most up and most left position of the prepared

gasket gutter.

5. Continue pressing the replacement gasket clockwise

along the gasket gutter until it has wrapped back

to where the gasket was pressed in initially.

6. Trim any excess replacement gasket away ,and press

the remaining end into the gutter to complete the

seal.

Close the door, drawer, or ash drawer and allow 3 to 4

hours for the cement to set before operating the stove.

REPLACING: HOT SURFACE IGNITER

Ensure that the stove is off and allow it time to become

cool to the touch. After gaining access to the back,

undo the screw located on the back inside of the

main body. Pull the hot surface igniter free, and install

replacement service part. See Figure 23 and 25.

Figure 24 Auger

Disassembly

Ensure that the stove is off and allow it time to become

cool to the touch. After gaining access to the back, the

auger can be disassembled part by part in the order

indicated in Figure 24.

Figure 23 Igniter Disassembly

REPLACING: AUGER SYSTEM

19

Operating Instructions and Owner’s ManualCleveland Iron Works Wood Pellet Fire Stove

Page 20

REMOVING BACK AND SIDE PANEL

Figure 25 PS130W Back & side disassembly

• To remove the PS130W side panels, remove the

screws securing it on the rear of the heater. Then

slide the panel along the side of the heater away

from the front.

• To remove the PS130W rear plate, remove the 8

screws securing it at the bottom and rear of the

stove.

• To remove the PS60W side panels, remove the

screws securing it on the rear of the heater. Then

pull the panel directly away from the heater.

• To open the side of the PSBF66W model, simply

swing the side panel free of the magnetic lock.

REPLACING: HEAT EXCHANGE BLOWER

Unplug the heater. Disconnect any wiring leading to

the Heat Exchange Blower. Remove the screws holding

the mounting plate to the heater. Slowly remove

blower and replace with new one. Replace screws and

wiring.

REPLACING: EXHAUST BLOWER

Unplug the heater. Disconnect any wiring leading to

the Exhaust Blower. Remove the wing nuts holding the

Exhaust Blower plate to the blower housing. Slowly

remove blower and replace with new one. Replace

wing nuts and wiring.

Figure 27 PSBF66W Exhaust Blower

SAFETY COMPONENTS

1. Vacuum Pressure Switch: A safety vacuum switch is

located behind the left door, fastened to the base.

If a low pressure is created in the firebox by a leak,

opening the door to the firebox, a blocked flue, or

an unsealed ash drawer then the switch will shut

the stove off as a precaution. Error code E5 will

appear on the display panel.

2. High Limit Thermostat: A high temperature limiter

is installed on the bottom of the hopper. If this

sensor is exposed to temperatures higher than 158

degrees then the stove is shut off.

3. Vent Pipe High Temperature Thermostat: A high

temperature limiter is installed on the vent pipe.

If this sensor is exposed to temperatures higher

than 104 degrees then the circulation fan blower is

switched on.

4. Vent Pipe Low Temperature Thermostat: If the stove

cools below a minimum temperature the stove will

switch off. This may occur when the operating

procedure fails to quickly and sufficiently heat the

stove.

5. Fuse: A fuse on the rear of the device protects the

stove from power surges. See Figure 28.

Figure 26 PSBF66W Heat Exchange Blower

20

Figure 28 Fuse

Operating Instructions and Owner’s ManualCleveland Iron Works Wood Pellet Fire Stove

Page 21

ERROR CODES

NOTE: IN THE EVENT OF A POWER FAILURE (ERROR CODE E7), A SMALL AMOUNT OF SMOKE MAY BE

EMITTED. THIS LASTS 3 TO 5 MINUTES AND DOES NOT REPRESENT A SAFETY RISK.

CAUTION: IF OVERHEATING HAS OCCURRED (ERROR CODES E5 AND E6), THEN AN INSPECTION,

MAINTENANCE, AND/OR CLEANING MUST OCCUR BEFORE THE STOVE CAN SAFELY BE OPERATED

AGAIN.

After following the suggested solution steps, press the confirm button to clear the error code from the error

code from the multi function display screen. Then go through the operation procedure specified on page 13 to

restart the heater.

ERROR

CODE

E1

E2

E5

E6

E7

CAUSE SOLUTION

Exhaust temperature is below 40 - 45 oF

Operation has been interrupted and the

fire has been discontinued.

Failure to ignite the fuel in fire pot.

Low pressure detected at the vacuum

switch (located behind the left door,

fastened to the base).

Failure at the high temperature sensor

(located below the pellet hopper).

Power failure.

1. Check that the pellet hopper has fuel.

2. Check that the auger motor is not damaged and is

able to fill the firepot with fuel.

1. Check that there are no “clinkers” (glass like lumps

of various sizes formed by debris exposed to high

heat, more common when using low quality fuel)

in fire pot.

2. Check that the firepot is sitting in the holder

correctly and that the igniter is not obstructed.

3. Check that the exhaust gas temperature sensor

switch, beside the combustion fan, is not broken.

4. Check that the igniter is not broken.

1. Check that the door, and ash drawer if present, has

been closed properly.

2. Check that there is nothing obstructing the exhaust

duct nor that the duct is leaking.

3. Check that the combustion fan is not broken.

1. Check that the switch is not broken.

2. The temperature of the sensor is too high. The

stove is not running properly. Call customer service.

Press the Confirm button to clear the error code.

Then restart the stove. You may chose to skip

directly into the stabilization cycle by depressing and

holding the rate selector button for 3 seconds.

ESC1

ESO1

ESC2

Short circuit at temperature sensor #1.

Open circuit at temperature sensor #1.

Short circuit at temperature sensor #2.

1. Check wires and connection points.

2. Replace Motherboard.

1. Check wires and connection points.

2. Replace Motherboard.

1. Check wires and connection points.

2. Replace Motherboard.

21

Operating Instructions and Owner’s ManualCleveland Iron Works Wood Pellet Fire Stove

Page 22

ERROR CODES CONTINUED

ESO2

ESC3

ESO3

TROUBLESHOOTING

Open circuit at temperature sensor #2

Short circuit at temperature sensor #3

Open circuit at temperature sensor #3

SYMPTOM CAUSE SOLUTION

Heater does not turn on.

1. Check wires and connection points.

2. Replace Motherboard.

1. Check wires and connection points.

2. Replace Motherboard.

1. Check wires and connection points.

2. Replace Motherboard.

Power Switch

turned off.

Power Cord

disconnected.

Turn on power switch.

1. Press power cord tightly into the heater

2. Ensure that the wall socket is delivering 120 Volts.

Fuse is blown. Replace the fuse.

The blower does not turn

on during Cleaning Cycle,

Feeding Cycle, or Lighting

Cycle.

The blower does not turn on

during Stabilization Cycle.

During the Lighting phase

the auger is not filling the

firepot with pellets.

During operation, besides the

Lighting phase, the auger is

not filling the firepot with

pellets.

This is normal.

No power in stove

or in control panel.

Mother board

disconnected.

Low Temperature

sensor is broken.

This is normal.

No fuel in Pellet

Hopper.

Auger is blocked,

jammed, or

disconnected.

There is no problem, the blower does not turn on

until the stabilization cycle.

Check the power and wires.

Make sure all terminals to mother board are

connected.

Replace the low temperature sensor.

There is no problem, the auger does not operate

during the Lighting phase.

Add Fuel to Pellet Hopper.

1. Unplug the unit so that it will not start suddenly

and then unblock the auger.

2. Check that the auger is not blocked. If it is blocked,

remove the cause of the jamming.

3. Check that the auger screw fastening the auger to

the motor is secure.

22

Operating Instructions and Owner’s ManualCleveland Iron Works Wood Pellet Fire Stove

Page 23

TROUBLESHOOTING CONTINUED

SYMPTOM CAUSE SOLUTION

Too much fuel in the

firepot. The fuel can not be

completely and thoroughly

burned.

Not enough fuel in the

firepot.

After the fire has started, the

stove turns off 15 minutes

later.

Orange flame, pellets piling

up in firepot,carbon residue

forming on glass.

The feeding speed

is faster than what

combustion can

support.

The feeding speed

is too low to

support the rate of

combustion.

The pellet hopper is

low on fuel.

The auger is not

operating.

The 30 o C

temperature switch

has triggered.

The pressure switch

inside the stove is

broken.

Insufficient air

for sufficient

combustion.

1. Increase the fan’s speed to increase the rate of

combustion.

2. Reduce the feeding speed.

1. Decrease the fan’s speed to decrease the rate of

combustion.

2. Increase the feeding speed.

Check that the pellet hopper has a sufficient

amount of fuel.

1. Unplug the unit so that it will not start suddenly

and then unblock the auger.

2. Check that the auger is not blocked. If it is blocked,

remove the cause of the jamming.

3. Check that the auger screw fastening the auger to

the motor is secure.

1. Check that wires to the switch are sufficiently

connected.

2. Replace the 30 o C temperature switch.

Replace the pressure switch.

1. Check that the air inlet vent in the front is open.

2. Check that the door and window gaskets are

intact.

3. Check if the air inlet ducting and the combustion

exhaust ducting are blocked.

4. Increase the cross sectional area of the ducting.

5. Increase the fan’s speed to increase the rate of

combustion.

6. Contact the manufacturer for assistance.

23

Operating Instructions and Owner’s ManualCleveland Iron Works Wood Pellet Fire Stove

Page 24

TROUBLESHOOTING CONTINUED

SYMPTOM CAUSE SOLUTION

The fire extinguishes and the

power shuts off.

The fire extinguishes and the

power shuts off (continued).

The circulation blower

continues to operate after

the stove is cool and the fuel

consumption has ceased.

No fuel in Pellet

Hopper.

Auger is blocked

or jammed or

disconnected.

The feeding speed

is too low to

support the rate of

combustion.

The 30 o C

temperature switch

has triggered.

Requested

temperature has

been reached.

The 30 o C

temperature switch

has triggered.

Add Fuel to Pellet Hopper.

1. Unplug the unit so that it will not start suddenly

and then unblock the auger.

2. Check that the auger is not blocked. If it is blocked,

remove the cause of the jamming.

3. Check that the auger screw fastening the auger to

the motor is secure.

1. Decrease the fan’s speed to decrease the rate of

combustion.

2. Increase the feeding speed.

1. Check that wires to the switch are sufficiently

connected.

2. Replace the 30 o C temperature switch.

This is normal “ECO” mode behavior. The stove will

automatically switch on once the ambient room

temperature drops below the temperature that the

stove is set to maintain.

1. Check that wires to the switch are sufficiently

connected.

2. Replace the 30 o C temperature switch.

The stove is not circulating

a sufficient volume of

sufficiently hot air.

The fuel is

inadequate.

The circulating

blower is set

too slow or is

compromised.

Heat exchange

tubes or flue pass is

dirty.

Use pellet fuel specified by this manual.

1. If the blower is broken, change out the blower

2. If the mother board which connects to the blower

is broken, change out the mother board.

Clean the heat exchanger tubes or flue pass.

24

Operating Instructions and Owner’s ManualCleveland Iron Works Wood Pellet Fire Stove

Page 25

WIRING DIAGRAM

NOTE: IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THE APPLIANCE MUST BE REPLACED, IT

MUST BE REPLACED WITH WIRING MATERIAL HAVING A TEMPERATURE RATING OF AT LEAST 105 °C

AND RATED FOR 600V

Room sensor

Protection sensor

Exhaust sensor

Blower

Combustion Fan

Vaccum switch

Auger motor

FUSE

L

Display panel

N

NO

NC

Igniter

Power

C

k

25

Operating Instructions and Owner’s ManualCleveland Iron Works Wood Pellet Fire Stove

Page 26

40 66619 Display Panel

38 n/a Clamp (see # 45)

39 66618 Motherboard

41 n/a Inner Pedestal Plate

37 n/a Aluminum Expansion Tube (see # 45)

34 66617 Switch

36 n/a Fresh Air Intake Vent (see # 45)

33 66622 Silicone Rubber Sealing Ring

35 n/a Cleaning Tool (see # 45)

30 66631 Rear Cover

32 66616 Room Sensor

31 66615 Power Socket

29 n/a Motherboard Fixed Plate

28 66613 Safety Sensor

27 n/a Chamber Insulation Cover

22 66609 Temperature Sensor

23 n/a Grouding Screw

25 66629 Vacuum Switch Silicone Tube

26 66630 Circulation Blower

24 66628 Vacuum Switch

20 n/a Pedestal Plate

21 66608 Igniter

18 n/a Insulation Support Plate

16 66627 Right Side panel

19 66607 Combustion Blower

17 n/a Thermal Insulation Plate

14 n/a Pedestal Fixed Plate

15 66626 Left Side panel

13 n/a Flue Fixed Plate-Short

12 n/a Flue Fixed Plate-Long

10 n/a Flue Board-Right

11 n/a Upper Flue Plate

8 n/a Flue Board-Left

9 n/a Flue Board-Middle

7 66625 Fire Pot

3 n/a Hopper

4 n/a Main Body

5 66603 Door Handle

NO. P/N DESCRIPTION

1 66623 Top Cover

2 66624 Door Assembly

MODEL PS60WSERVICE PARTS

44 66658 Remote (not shown)

46 66660 Auger Assembly

2

5

7

10

8

9

11

12

42

41

20

12

13

14

16

40

26

46

27

15

4

18

18

22

19

21

29

23

34

39

17

1

SPECIFICALLY APPROVED

WITH THIS STOVE MAY

RESULT IN PROPERTY

DAMAGE OR PERSONAL

INJURY.

45 66659 Accessory Kit

POSITION THE PARTS IN

ACCORDANCE WITH THESE

DIAGRAMS OR FAILURE

TO USE ONLY PARTS

NO. P/N DESCRIPTION

42 n/a Nameplate

43 66621 Auger Motor

QUESTIONS CONTACT MANUFACTURER.

WARNING: FAILURE TO

NOTE: NOT ALL PARTS AVAILABLE. FOR

45

35

38

37

36

24

43

28

33

25

30

3

31

32

26

Operating Instructions and Owner’s ManualCleveland Iron Works Wood Pellet Fire Stove

Page 27

31

32

36

38

23

39

MODEL PS130W

33

29

43

30

28

27

24

48

18

44

20

20

19

21

22

18

15

34

3

25

1

17

26

41

4

42

12

37

11

13

40

35

16

45

12

47

11

41 66620 Blower Fixed Plate

42 n/a Nameplate

39 66618 Motherboard

40 66619 Display Panel

NO. P/N DESCRIPTION

10

9

7

43 66621 Auger Motor

44 66622 Silicone Rubber Sealing Ring

47 66659 Accessory Kit

45 n/a Upper Flue Plate

46 66658 Remote (not shown)

48 66660 Auger Assembly

SERVICE PARTS

WARNING: FAILURE TO

NOTE: NOT ALL PARTS AVAILABLE. FOR

QUESTIONS CONTACT MANUFACTURER.

POSITION THE PARTS IN

ACCORDANCE WITH THESE

DIAGRAMS OR FAILURE

TO USE ONLY PARTS

SPECIFICALLY APPROVED

WITH THIS STOVE MAY

RESULT IN PROPERTY

DAMAGE OR PERSONAL

INJURY.

NO. P/N DESCRIPTION

1 66601 Top Cover

2 66602 Door Assembly

3 n/a Hopper

2

4 n/a Main Body

5 66603 Door Handle

7 66604 Fire Pot

8 n/a Flue Plate-Left

8

9 n/a Flue Plate-Middle

10 n/a Flue Plate-Right

31 66615 Power Socket

32 66616 Room Sensor

21 66608 Igniter

22 66609 Temperature Sensor

33 n/a Rating Label

34 66617 Switch

24 66610 Vacuum Switch

23 n/a Ground Screw

29 n/a Motherboard Fixed Plate