Page 1

Installer: Leave this manual with the appliance. Consumer: Retain this manual for future reference.

MODEL#

OPERATING INSTRUCTIONS

AND OWNER’S MANUAL

READ INSTRUCTIONS CAREFULLY: YOUR SAFETY IS IMPORTANT TO YOU AND TO OTHERS.

Read and follow all instructions. Place instructions in a safe place for future reference. Do not allow

anyone who has not read these instructions to assemble, light, adjust or operate the heater.

HSU200NG

HSU250NG

HSU300NG

HSU400NG

LARGE UNIT HEATER

FOR RESIDENTIAL/COMMERCIAL USE

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause

injury or property damage. Refer to this manual. For assistance or additional information

consult a qualified installer, service agency or the gas supplier.

-WHAT TO DO IF YOU SMELL GAS

Ǟ DO NOT try to light appliance.

Ǟ DO NOT touch any electrical switch, do not use any phone in your building

Ǟ Leave the building immediately

Ǟ Immediately call your gas supplier from a phone remote from the building. Follow the gas suppliers

instructions

Ǟ If you cannot reach your gas supplier, call the Fire Department.

- Installation and service must be performed by a qualified installer, service agency or the gas supplier.

FOR YOUR SAFETY:

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

WARNING: If the information in these instructions are not followed exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

WWW.HEATSTARBYENERCO.COM 1-(866)-447-2197

60266

Page 2

SAFETY

WARNING:

YOUR SAFETY IS IMPORTANT TO YOU AND TO OTHERS,

SO PLEASE READ THESE INSTRUCTIONS BEFORE YOU

OPERATE THIS HEATER.

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result

in serious injury, death or property damage. Be sure to

read and understand the installation, operation, and

service in this manual. Improper installation, adjustment,

alteration, service or maintenance can cause serious

injury, death or property damage.

WARNING: Fuels used in liquefied propane

gas appliances, and the products of combustion of such

fuel, can expose you to chemicals including benzene, which

is known to the state of California to cause cancer and

cause birth defects or other reproductive harm, for more

information go to www.P65Warnings.ca.gov

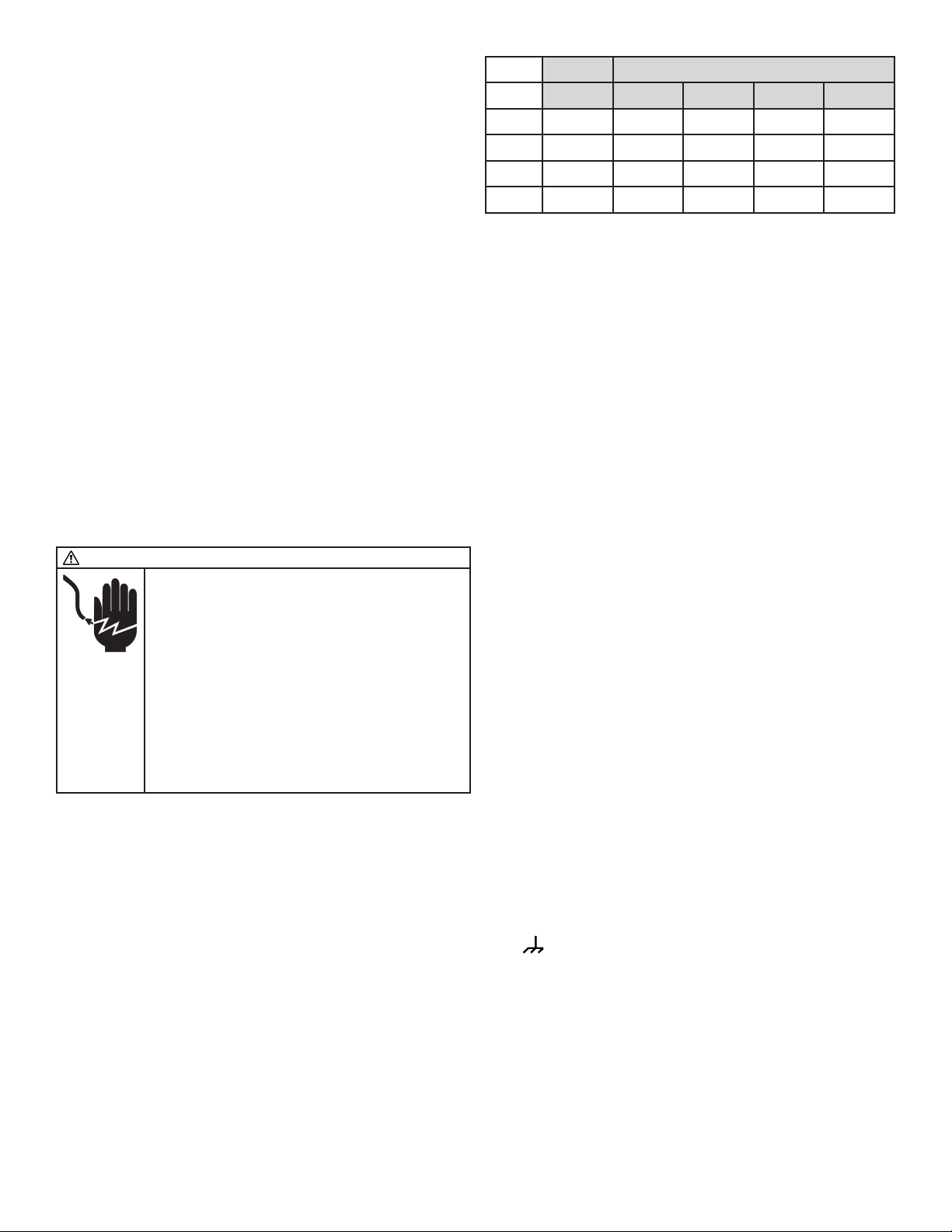

HSU200 HSU250 HSU300 HSU400

WARNING:

FIRE, BURN, INHALATION, AND EXPLOSION HAZARD.

KEEP SOLID COMBUSTIBLES, SUCH AS BUILDING

MATERIALS, PAPER, OR CARDBOARD, A SAFE DISTANCE

AWAY FROM THE HEATER. AS RECOMMENDED BY

THE INSTRUCTIONS NEVER USE THE HEATER IN SPACES

WHICH DO OR MAY CONTAIN VOLATILE OR AIRBORNE

COMBUSTIBLES, OR PRODUCTS SUCH AS GASOLINE,

SOLVENTS, PAINT THINNER, DUST PARTICLES OR

UNKNOWN CHEMICALS.

WARNING:THIS PRODUCT CAN EXPOSE

YOU TO CHEMICALS INCLUDING LEAD AND LEAD

COMPOUNDS, WHICH ARE KNOWN TO THE STATE

OF CALIFORNIA TO CAUSE CANCER AND BIRTH

DEFECTS OR OTHER REPRODUCTIVE HARM. FOR MORE

INFORMATION VISIT WWW.P65WARNINGS.CA.GOV

V/A/H/Phase

BTU Input

BTU Output

Efficiency %

120v / 6.3A / 60hZ / 1Ø 120v / 6.3A / 60hZ / 1Ø 120v / 10A / 60hZ / 1Ø 120v / 10A / 60hZ / 1Ø

200,000 BTU 250,000 BTU 300,000 BTU 400,000 BTU

160,000 BTU 200,000 BTU 240,000 BTU 320,000 BTU

80% 80% 80% 80%

CONTENTS

SAFETY.............................................................................2

INTRODUCTION...............................................................5

INSTALLATION.............................................................. ...6

START-UP........................................................................16

MAINTENANCE..............................................................20

FUEL CONVERSION INSTRUCTIONS................................22

TROUBLESHOOTING GUIDE............................................24

PARTS LIST ................................................................... 26

WARRANTY ................................................................ 28

LANGUAGES

ENGLISH .......................................................... 1 - 28

SPANISH ....................................................... 29 - 56

FRENCH ........................................................ 57 - 84

GENERAL INFORMATION

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

FOR QUESTIONS, PROBLEMS, MISSING PARTS BEFORE

RETURNING TO RETAILER PLEASE CALL WITH MODEL

NUMBER AND SERIAL NUMBER OF HEATER:

1-866-447-2194

MONDAY-FRIDAY 8-5 EASTERN TIME

OR E-MAIL USING THE HEATSTAR WEBSITE:

WWW.HEATSTARBYENERCO.COM

In order to provide the best service possible HEATSTAR is

now giving you more ways to get in touch with us. Find

informational videos at:

YouTube: youtube.com/heatstarTV

Large Unit Heater

HEATSTAR’S full line of products are now at:

WWW.HEATSTARBYENERCO.COM

Operating Instructions and Owner’s Manual

2

Page 3

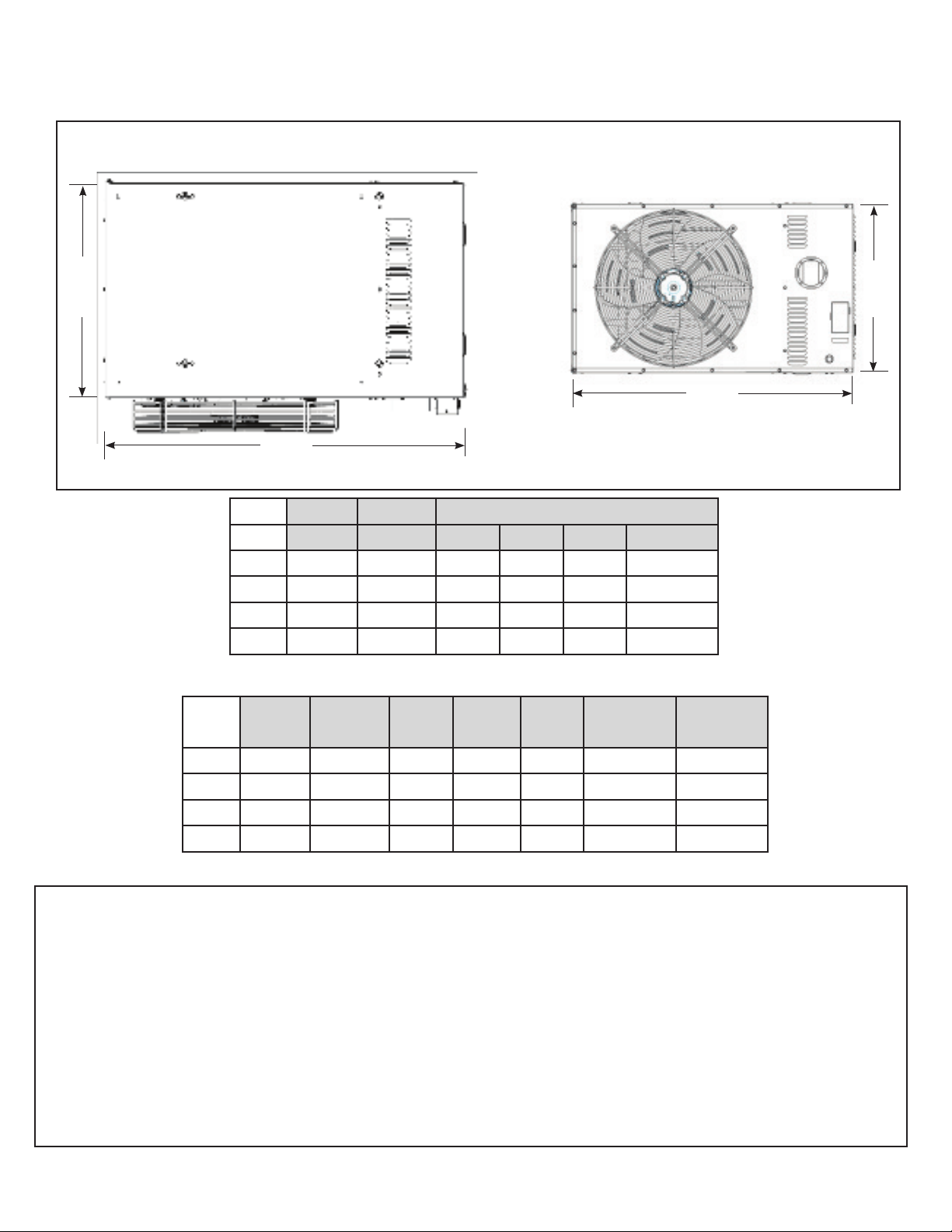

PRODUCT SPECIFICATIONS

This unit heater is a single input warm air heater with an average thermal efficiency of 80%. All units are to be supplied with single-phase 60 Hz

120VAC power. For specific information on each model, see Table 1.

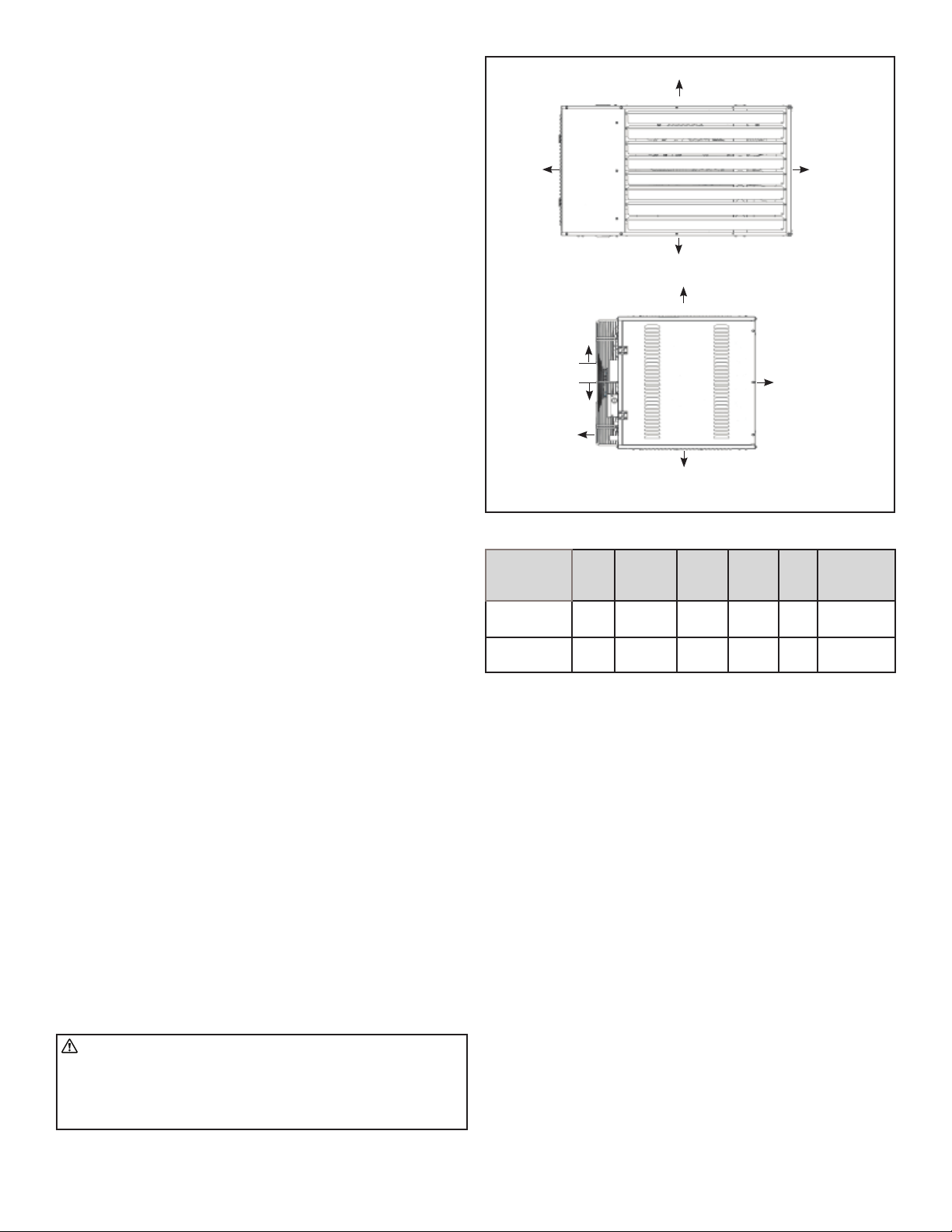

Dimensional Data

Top View

Rear View

Length

HSU200

HSU250

HSU300

HSU400

Width

FIGURE 1

BTU input BTU output Size

[BTU/HR] [BTU/HR] WIDTH LENGTH HEIGHT WEIGHT[Lbs.]

HSU200

HSU250

HSU300

HSU400

200,000 160,000 41.3” 28.7” 24.8” 175

250,000 200,000 41.3” 28.7” 24.8” 180

300,000 240,000 41.3” 28.7” 30.3” 227

400,000 320,000 41.3” 28.7” 38.6” 280

TABLE 1: Specifications

BTU input

[BTU/HR]

200,000 3,377 960 45.0 650 1,500 21. 7

250,000 3,435 976 55.3 650 1,500 21. 7

300,000 4,507 1,040 50.6 1,000 1,560 24.8

400,000 5,763 1,040 52.7 1,000 1,560 24.8

Entering

Airflow

[CFM]

Outlet

Velocity

[FPM]

AIr Temp.

Rise [ºF]

Motor

[Watt]

Motor

[RPM]

Fan Diameter

Height

Width

[Inch.]

TABLE 2: General Performance Data

START-UP AND PERFORMANCE CHECK LIST

Job Name: ___________________________ Job No.: _____________________________ Date: _______________________________

Job Location: _________________________ City: ________________________________ State/Province: _______________________

Installer: _____________________________ City: ________________________________ State/Province: _______________________

Unit Model No.: _______________________ Serial No.: ____________________________ Service Technician: ____________________

Electrical Connections Tight? _____________________________ Flue Connections Tight? _____________________________________

Supply Voltage ________________________________________ Fan Timer Operation Checked? _______________________________

Gas Piping Connections Tight & Leak-Tested? _______________ THERMOSTAT Calibrated? ___________________________________

Motor Amps __________________________________________ Heat Anticipator Properly Set? ________________________________

Furnace BTU input _____________________________________ Level? ___________________________________________________

Line Pressure _________________________________________

Manifold Pressure W.C. _________________________________

Large Unit Heater

Operating Instructions and Owner’s Manual

3

Page 4

SHIPPING

The heater is completely assembled. Installation instructions, two

mounting brackets (shipped loose), and a flue transition are included.

Check the unit for shipping damage. The receiving party should

contact the last carrier immediately if any shipping damage is found.

APPLICATIONS

This is not an explosion proof heater. This heater may not be used

in a Class 1 or Class 2 Explosive Environment. Consult your local fire

marshal, insurance carrier, and other authorities for approval if the

proposed installation is in question.

COMMERCIAL/INDUSTRIAL

The heater is designed and certified for use in industrial and

commercial buildings, such as warehouses, manufacturing plants,

aircraft hangars, and vehicle maintenance shops. For maximum safety,

the building must be evaluated for potential problems before installing

the heater system. This unit is certified for use as furnished by the

manufacturer. Do not alter the fan or operate motors at a reduced

speed.

CAUTION: Installation of restrictive devices to the inlet or

outlet of the fan motor may result in premature failure of the

exchanger pipe, overheating of the appliance, or damage to

the components. Do not attach ductwork, air filters, or polytubes to any HEATSTAR unit heater.

STANDARDS, CERTIFICATIONS, AND

GOVERNMENT REGULATIONS

Installation of this gas-fired heater must conform with all applicable

local, state, and national specifications, regulations, and building

codes. Contact the local building inspector and/or fire marshal for

guidance.

In the absence of local codes, the installation must conform to the

latest edition of:

CSA IN USA

Installation of gas unit heaters must conform with local building codes

or, in the absence of local codes, with the current National Fuel Gas

Code ANSI Z223.1.

Installation in aircraft hangars must be in accordance with the current

Standard for Aircraft Hangars ANSI/NFPA No. 409.

Installation in parking structures must be in accordance with the

current Standard for Parking Structures ANSI/NFPA No. 88A.

For installation in a residential garage these units must be installed so

that the bottom of the heater is located no less than 8 feet (2.438m)

above floor. Heater must be located or protected to avoid physical

damage by vehicles. Refer to the National Fuel Gas Code, ANSI Z223.1,

current edition.

Authorities having jurisdiction should be consulted before NFPA

installation. Air for combustion and ventilation must conform to the

methods outlined in ANSI Z223.1, section 5.3, Air for Combustion

and Ventilation, or applicable provisions of local building codes. ANSI

Z83.8 / CSA 2.6 is the standard for Gas Unit Heater Construction. The

National Fuel Gas Code is available from:

American National Standard Institute Inc.

11 West 42nd Street

New York, NY 10036

These units are CSA International design certified. These unit heaters

are certified for installation to combustible material as listed in Table

3 and on unit rating plate. Accessibility and service clearances must be

observed in addition to fire protection clearances.

All electrical wiring and ground for unit must be in accordance with

the regulations of the current National Electric Code ANSI/No. 70.

The National Electric Code is available from:

National Fire Protection Association

1 Batterymarch Park

PO Box 9101

Quincy, MA 02269-9101

CSA IN CANADA

The instructions are intended only as a general guide and do not

supersede local codes in any way. Authorities having jurisdiction

should be consulted before installation. The installation must conform

with local building codes or in the absence of local codes, with the

current CSA B149.1, Natural Gas and Propane Installation Code. All

electrical wiring and grounding for the unit must also comply with the

Canadian Electrical Code CSA C22.1, current edition.

These heaters are CSA International certified for the clearances to

combustible material listed on the rating plate and Table 3. Provide

adequate clearance around air openings into the combustion

chamber, clearances from combustible material, and provisions for

accessibility and for combustion and ventilation air supply. Provision

shall be made for service accessibility to the heater. Note that fire

protection clearances may be exceeded to provide additional space for

service and accessibility. CAN/CGA B149.1-10 is the code for Natural

Gas and Propane Installation.

Copies of these Standards can be viewed or purchased at www.nfpa.

org or www.scc.ca.

GARAGE INSTALLATIONS

Installation in parking structures must be in accordance with the

current Standard for Parking Structures ANSI/NFPA No. 88A.

Installation in repair garages must be in accordance with the current

Standard for Repair Garages ANSI/NFPA No. 88B.

1. In a storage area, clearance from heaters to combustible materials

must be such that the material shall not attain a temperature above

160 �°F by continuous operation of the unit.

2. Eight foot minimum clearance from the floor to the bottom of the

heater must be maintained. Refer to the CSA B149.1, Natural Gas

and Propane Installation Code.

Canada: Refer to CAN/CGA B149.1: Installation Codes for Gas Burning

Appliances and applicable Standards for Public Garages.

Guidelines:

• Heaters must not be installed less than 8 ft. (2.4 m) above the

floor. Minimum clearances to combustibles must be maintained from

vehicles parked below the heater.

• When installed over hoists, minimum clearances to combustibles

must be maintained from the upper most point of objects on the

hoist.

AIRCRAFT HANGAR INSTALLATIONS

Installation of gas unit heaters must conform with local building codes

or, in the absence of local codes, with the current National Fuel Gas

Code ANSI Z223.1.

Large Unit Heater

Operating Instructions and Owner’s Manual

4

Page 5

IN UNITED STATES: Refer to Standard for Aircraft Hangars, ANSI/

NFPA 409 (latest edition).

1. In aircraft storage and servicing areas, heaters shall be installed at

least 10 ft. (3 m) from above the upper surface of wings or of the

engine enclosures of the highest aircraft that may be housed in the

hangar. The measurement shall be made from the wing or engine

enclosure, whichever is higher from the floor, to the bottom of the

heater.

2. In areas adjoining the aircraft storage area (e.g., shops, offices) the

bottom of heaters shall be installed no less than 8 ft. (2.4 m) above

the floor.

3. Heaters should be located so as to be protected from damage

from aircraft or other appliances needed for servicing of aircraft.

Refer to requirements of the enforcing authorities. Provisions shall

be made to assure accessibility to suspended heaters for recurrent

maintenance purposes.

For installation in hangars, these units must be installed so that

burners and ignition source are located no less than 18” (457mm)

above floor. Heater must be located or protected to avoid physical

damage by vehicles. Refer to CSA B149.1, Natural Gas and Propane

Installation Code current edition.

IN CANADA: In a confined area, the heater must be installed in

accordance with the CSA B149.1, Natural Gas and Propane Installation

Code. Be sure to check with local codes and ordinances for additional

requirements.

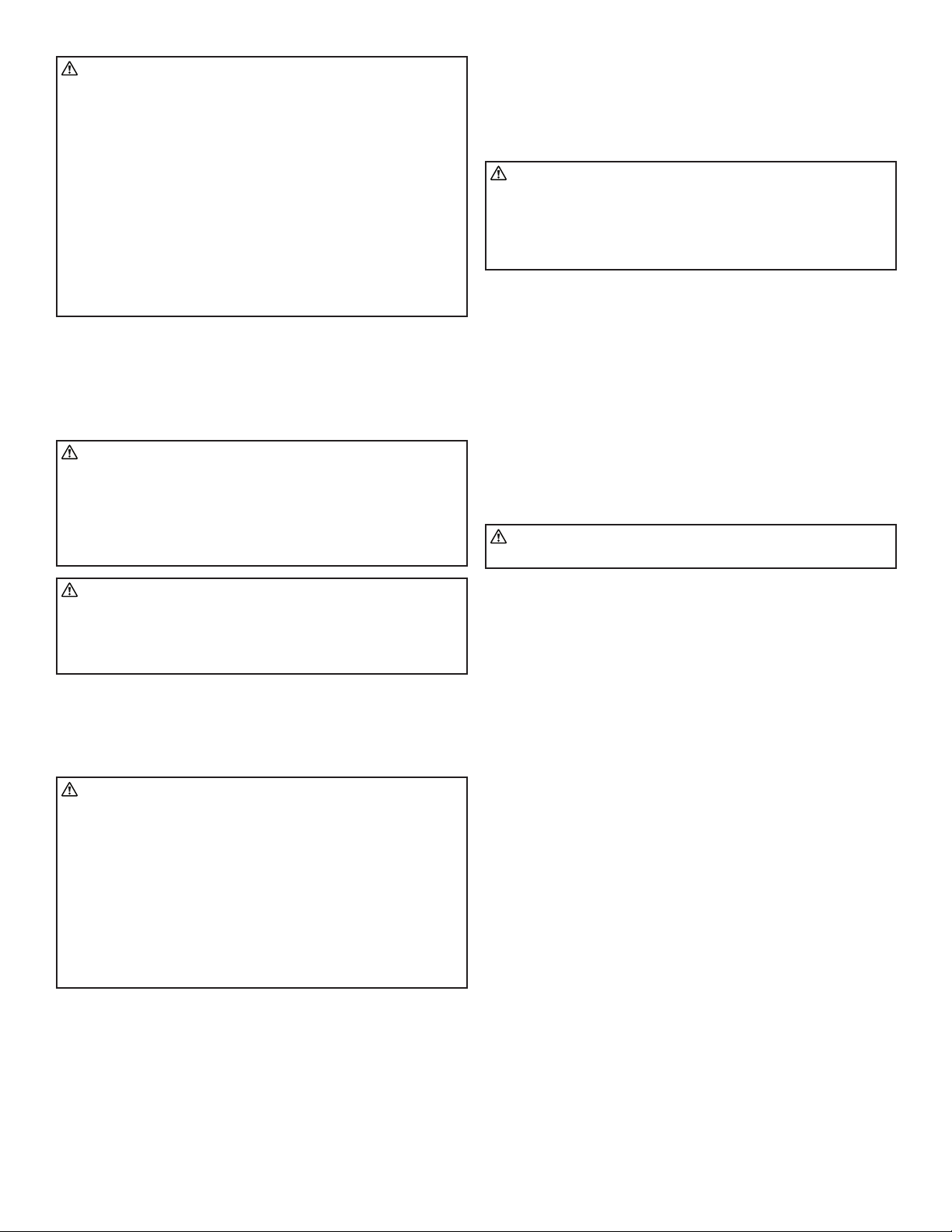

Clearances To Combustibles

Front View

Access

Side

Side View

Vent

Connection

Rear

Top

Bottom

Top

Bottom

FIGURE 2

Non-Access

Side

Front

NON-STANDARD BTU GAS

Unless otherwise noted on the rating plate, this heater is designed and

orificed to operate on standard BTU gas. Contact the factory if utilizing

non-standard BTU gas.

INTRODUCTION

This heater is a gas-fired unit heater. This manual provides specific

information related to the Heatstar models. All persons involved with

the installation, operation, and maintenance of the heater must read

and understand the information in this manual.

The intent of this manual is to provide information regarding safety,

design guidelines, installation, operation, and maintenance of the this

gas-fired unit heater. You must read and understand the instructions

and all safety warnings before installing the gas-fired unit heater. This

manual is property of the owner and must stay with the owner or unit

after installation is complete.

CLEARANCES TO COMBUSTIBLES

Clearance to combustibles is defined as the minimum distance

that must exist between the specified feature of the heater and

any combustible items. It also pertains to the distance that must

be maintained from moving objects around the unit heater. A

recommended service clearance is defined as the minimum distance

that is needed to properly service the heater. When installing the

unit heater, clearances to combustible for the model heater must be

maintained. Refer to Table 3 to determine the required distances for

your model.

Unit Side Front Top and

Clearance to

Combustibles

Clearance to

Allow Service

Bottom

60” 6” 6” 6” 18” 6”

60” 18” 29” 18” 18 ” 18”

Access

Side

Non-

Access

Side

Rear Vent

Connection

TABLE 3: Clearances To Combustibles

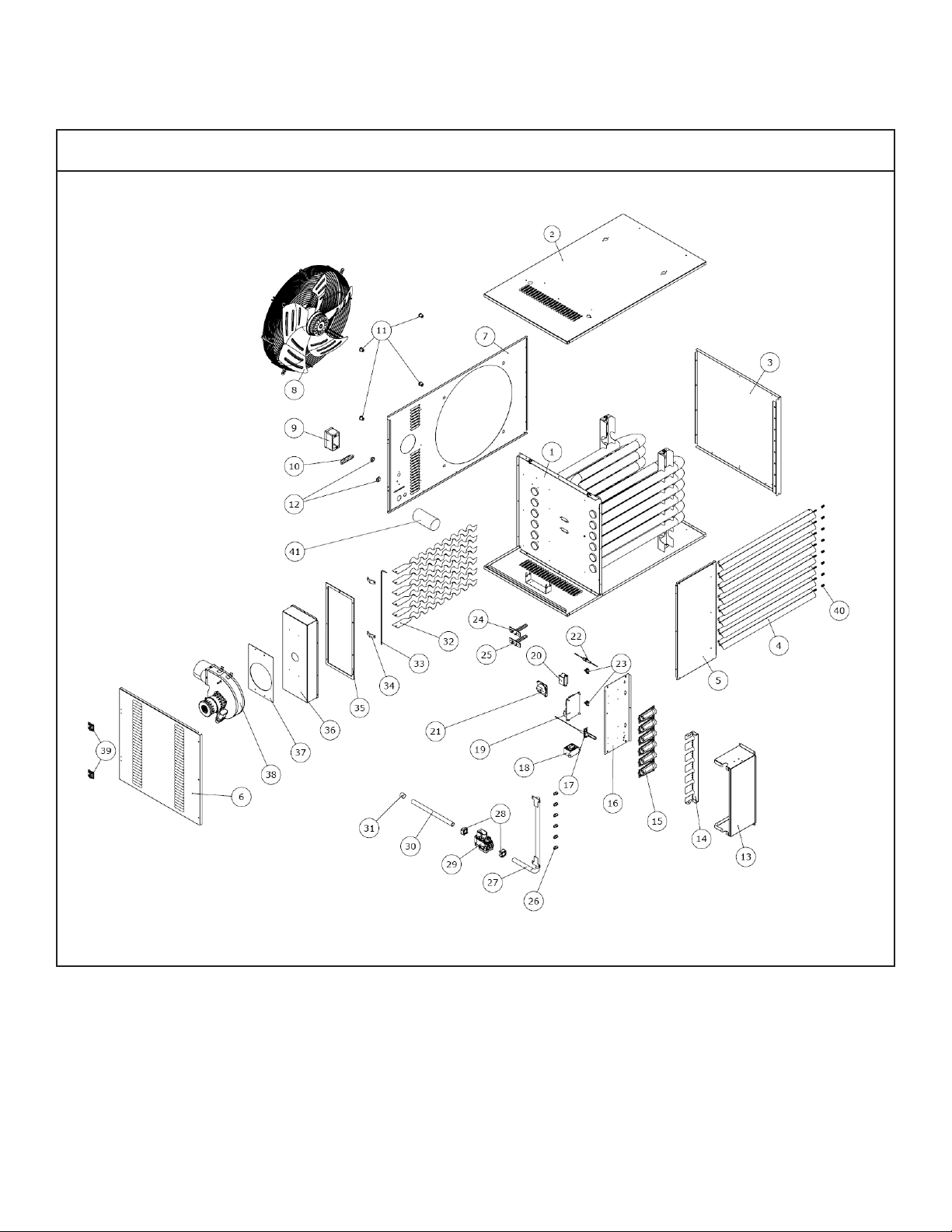

HEATER COMPONENTS

Prior to installation, verify that the heater’s gas type and voltage (as

listed on the rating plate) match that of your application. The heater

is standard produced for operation with natural gas. In case of use

with LP / propane gas, see Fuel Conversion instructions. Also verify

that you have received the entire heater contents included with your

unit. Materials not included with the unit (e.g. screws, vent material,

threaded rod, etc.) are the responsibility of the installer. Notify your

product representative or the factory of any discrepancy of missing

items prior to installing the unit.

WARNING: Placement of explosive objects, flammable

objects, liquids, and vapors close to the heater may result in

explosion, fire, property damage, serious injury, or death.

Do not store or use explosive objects, liquids, or vapor in the

vicinity the heater.

Large Unit Heater

Operating Instructions and Owner’s Manual

5

Page 6

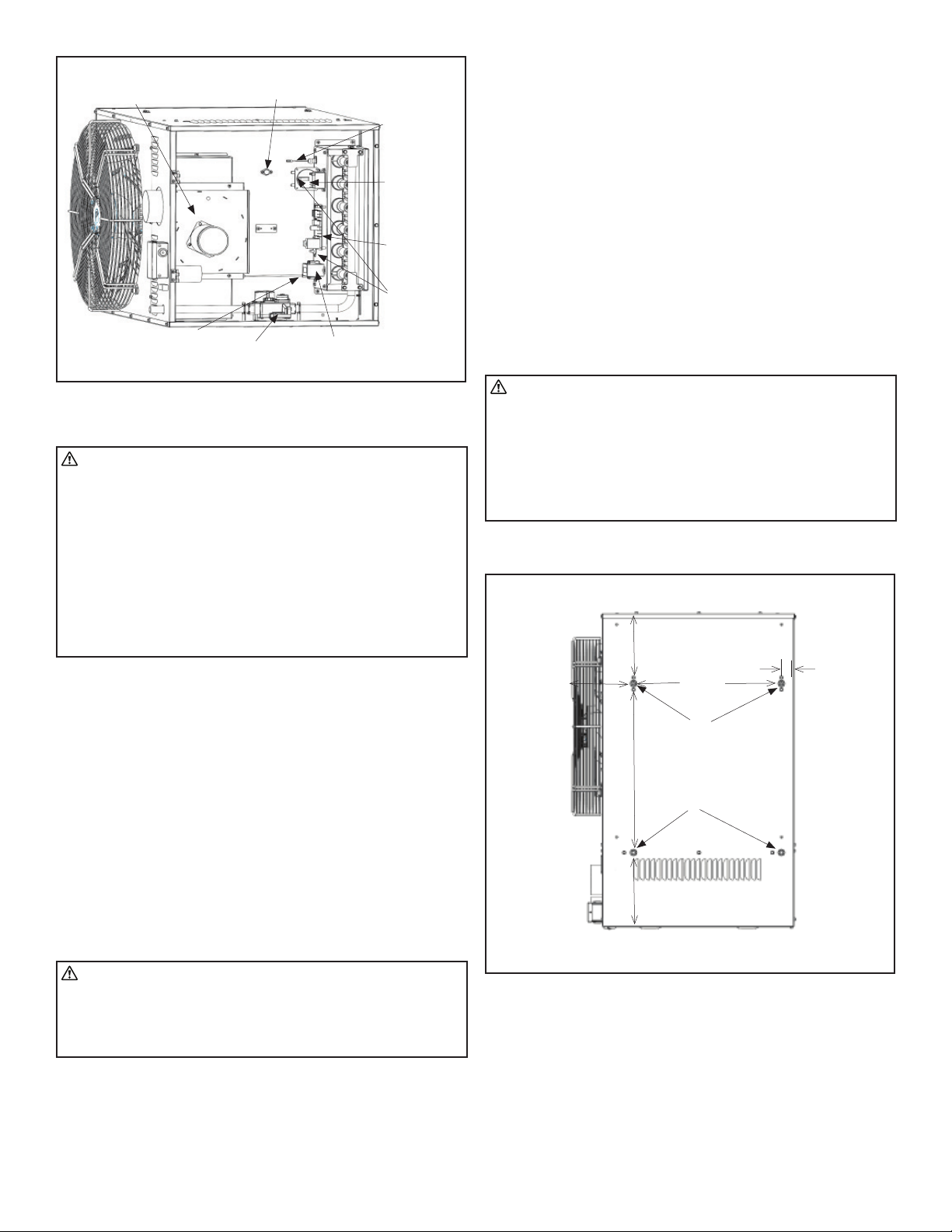

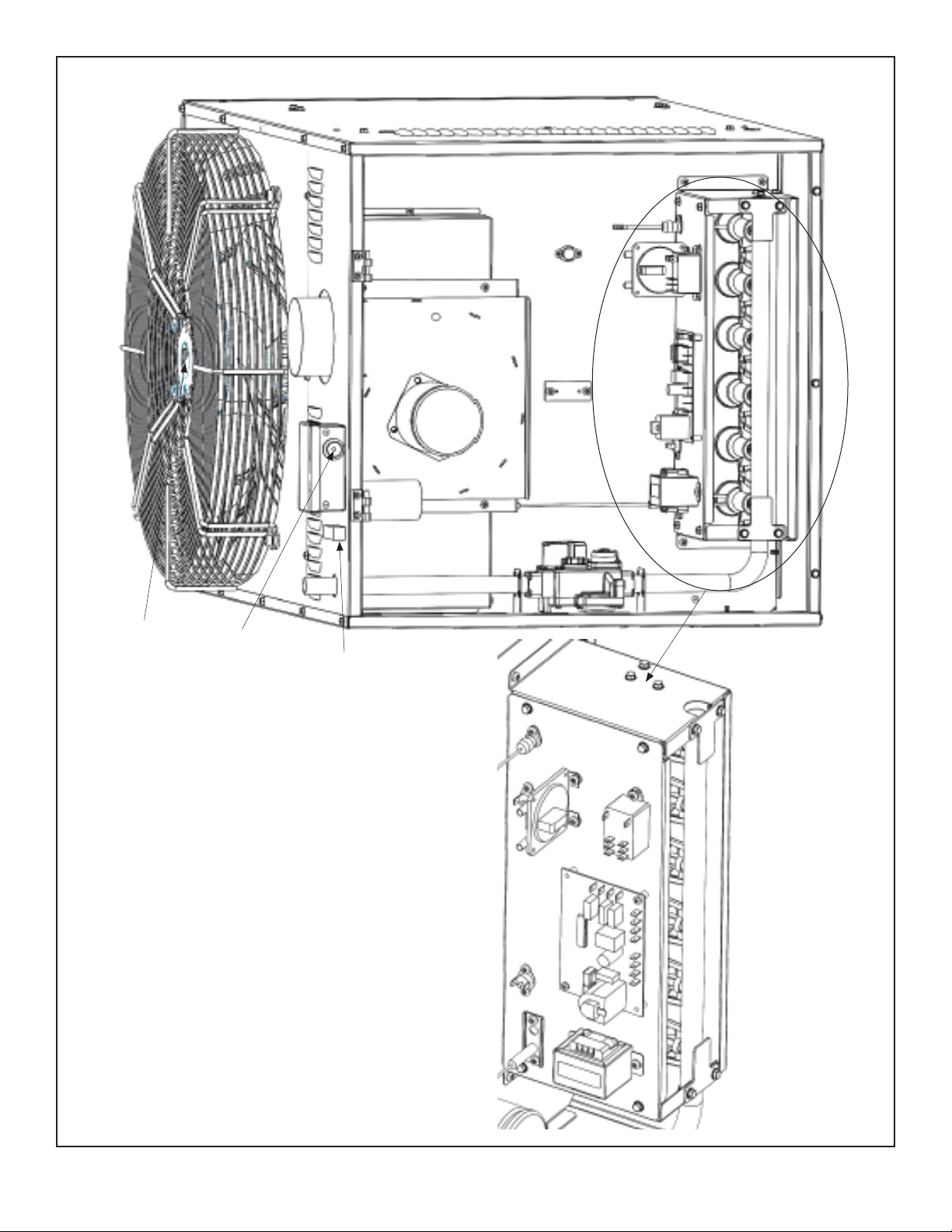

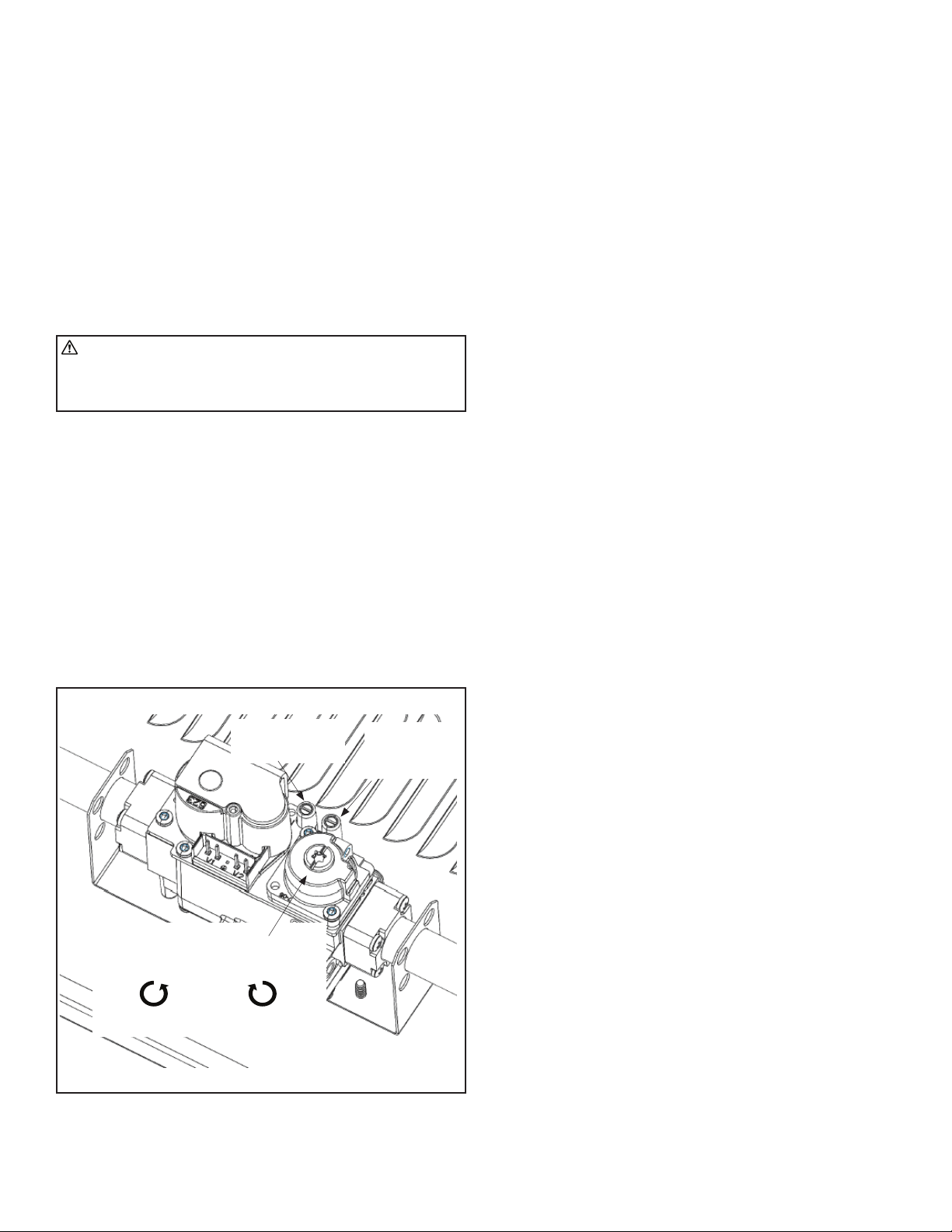

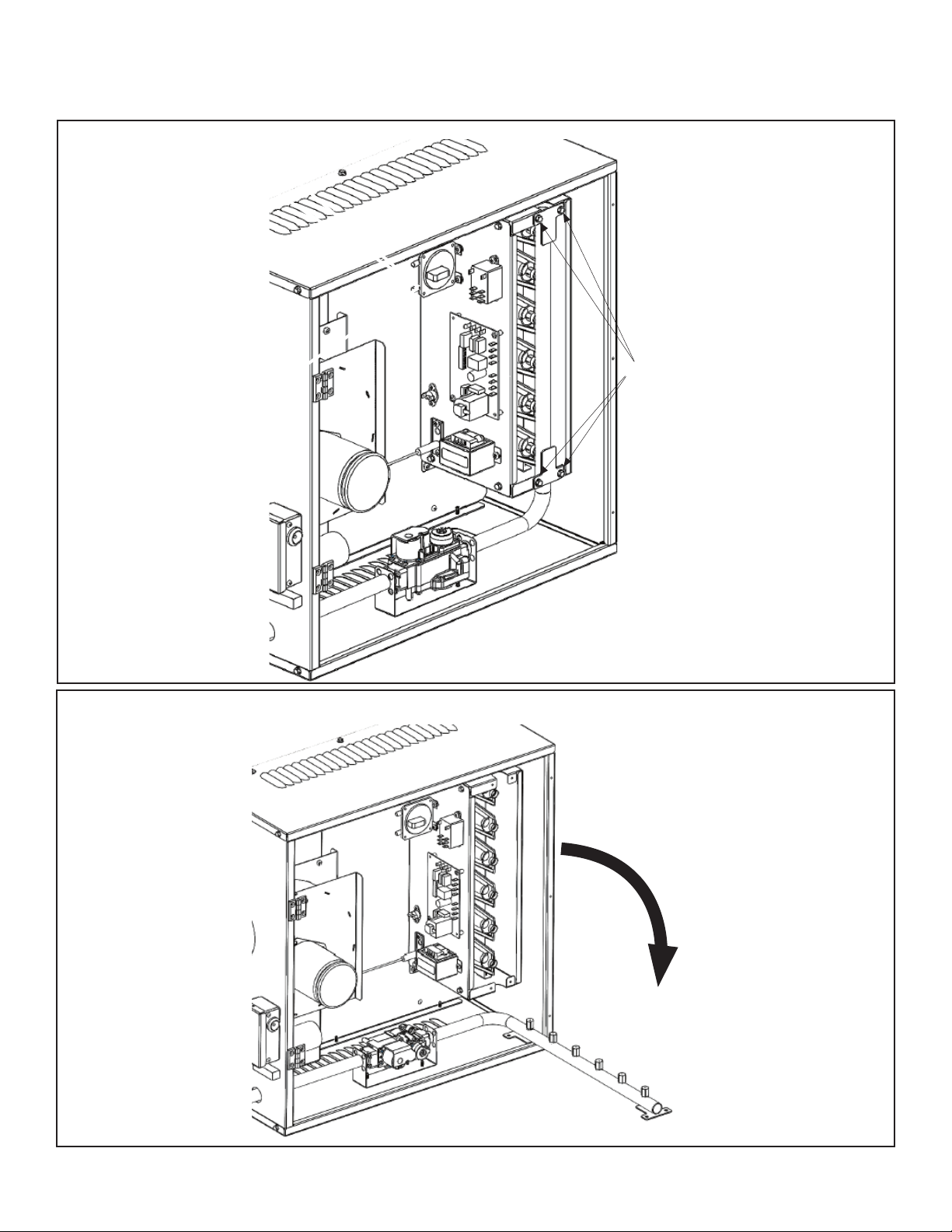

Draft Inducer

Heater Subcomponents

High Limit Switch

Flame Sensor

Pressure

Switch

Control

Board

All installation and service of these units must be performed by a

qualified installation and service agency only as defined in ANSI Z223.1

(NFPA 54) - latest edition or in Canada by a licensed gas fitter.

This unit is certified with the controls furnished. For replacements

parts, please order according to the replacement parts list on rating

plate. Always know your model and serial numbers, we reserves the

right to substitute other authorized controls as replacements.

Unit is balanced for correct performance. Do not alter fan or operate

motors at speeds below what is shown in this manual.

Information on controls is supplied separately. The same burner is used

for natural and propane gas.

Manual Reset

Safety Gas

Spark Electrode

Gas Valve

Control Transformer

Switchers

FIGURE 3

INITIAL INSTALLATION CONSIDERATIONS AND

PRE-CHECKS

WARNING: Improper installation, adjustment, alteration,

service, or maintenance can cause property damage, serious

injury, or death. Read and understand the installation,

operating, and maintenance instructions thoroughly before

installing or servicing this equipment.

This manual should be kept for future use for servicing or

service diagnostics. Leave manual with the owner. Do not

discard any literature shipped with this unit. Only a trained,

qualified installation or service personnel may install or

service this equipment.

Do not attach ductwork, air filters, or polytubes to any

propeller unit heater.

Placement of the heater is influenced by many factors. Aside from

safety factors, considerations for the general space and heating

requirements, availability of gas and electrical supply, and proximity of

possible vent locations are a few examples of factors that should all be

considered.

Inspect and evaluate the location of the heater to ensure that the

structural support is adequate to support the unit’s weight. The unit

must be installed in a horizontally level position to ensure proper

operation. To reduce noise attenuation along the structure caused by

vibration of the unit, the heater should be installed within 15 feet of

a primary building support. In the cases where this installation is not

practical or feasible, the use of spring vibration isolators may be used,

so long as they are rated for use of the unit’s weight.

Adequate space around the heater must also be considered in order

to maintain the published minimum clearance to combustibles and

recommended service clearances (see Table 3).

WARNING: Do not locate any gas-fired units in area where

chlorinated, halogenated, or acid vapors are present in the

atmosphere. These substances can cause premature heat

exchanger failure due to corrosion which can cause property

damage, serious injury, or death.

In the U.S., the installation of these units must comply with the

National Fuel Gas Code, ANSI Z223.1 (NFPA 54) - latest edition and

other applicable local building codes. In Canada, the installation of

these units must comply with local plumbing or waste water codes

and other applicable codes and with the current code CSA-B149.1.

Large Unit Heater

INSTALLATION

NOTICE: High humidity or saltwater atmospheres will accelerate heater

corrosion and reduce useful life. Do not install the heater in locations

where water (in the form of rain, drips, or spray) could fall onto the

gas ignition components.

WARNING: Improper suspension of the unit heater may

result in collapse and being crushed.

Always suspend from a permanent part of the building

structure that can evenly support the total force and weight

of the heater.

Failure to maintain minimum clearance to combustibles may

result in fire and/ or explosion, property damage, serious

injury, or death. Always maintain minimum clearances.

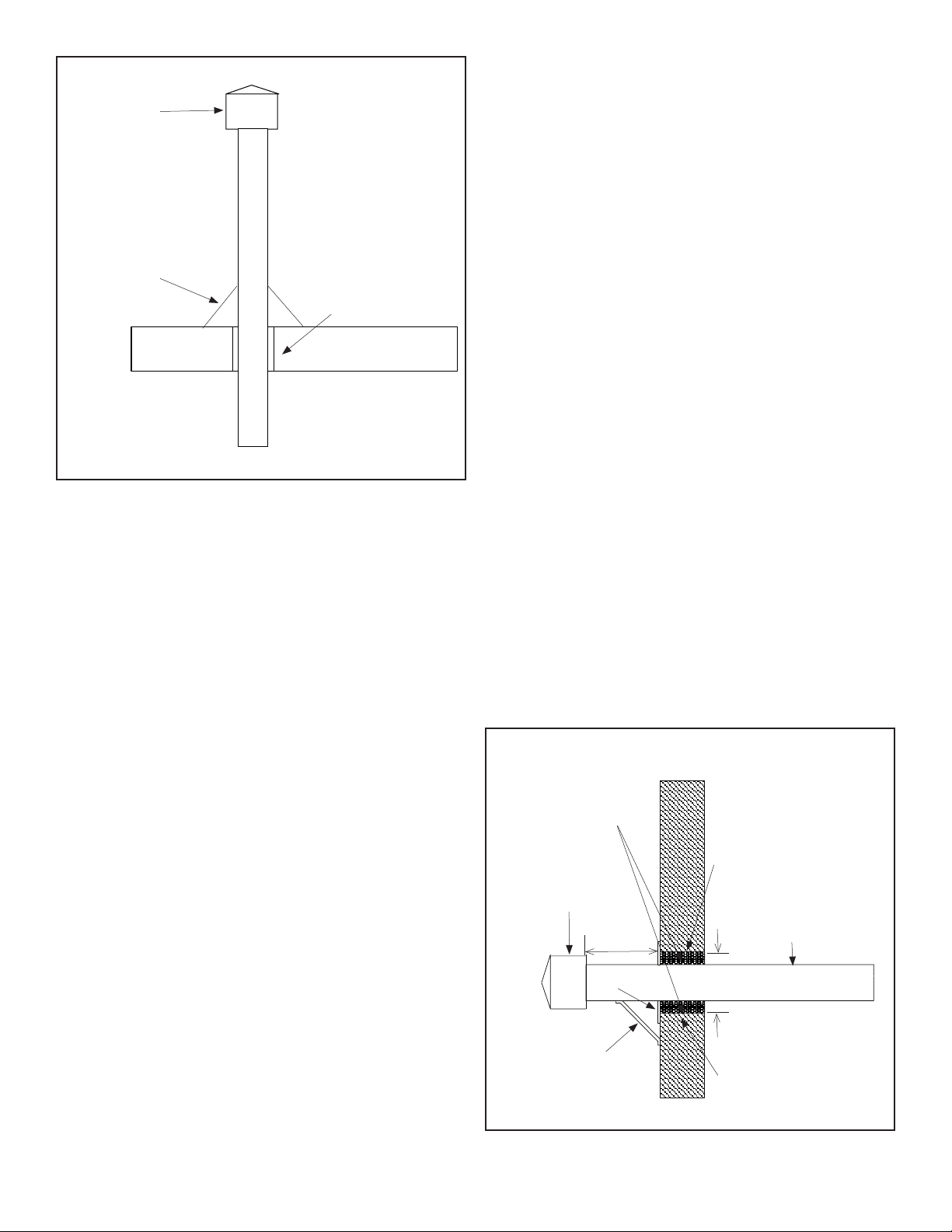

The units are designed to be hung with threaded bolts via the four (4)

threaded inserts on the top panel of the heater:

Hanging Points

7.89 inch

(200.5mm)

9.16 inch

(233mm)

(562mm)

22.13 inch

9.73 inch

(247mm)

18.86 inch

(479mm)

HANGING

POINTS:

For the anchorage

of the unit heater

use 3/8”-16 bolts

or eyebolts

FIGURE 4

The suspension of the heater must conform to all applicable codes

referenced in the STANDARDS section.

To ensure proper operation, the heater must be installed in a level

horizontal position depending on desired location as governed by

clearances, vent connection, air direction, gas supply, electrical supply

and service accessibility.

Be sure the means of suspension is adequate to support the

weight of the unit (see Table 1 for unit weights).

Operating Instructions and Owner’s Manual

6

1.63 inch

(41.5mm)

Page 7

CAUTION: Do not install units below 7’ measured from the

bottom of the unit to the floor in commercial applications

(unless unit is properly guarded to provide user protection

from moving parts).

Be sure no obstructions block air intake and discharge of unit

heaters.

The minimum distance from combustible material is based

on the combustible material surface not exceeding 160�°F.

Clearance from the top of the unit may be required to be

greater than the minimum specified if heat damage, other

than fire, may occur to materials above the unit heater at the

temperature described.

Allow 18” clearance at rear (or 12” beyond end of motor at

rear of unit, whichever is greater) and access side to provide

ample air for proper operation of fan.

VENTING

Heatstar unit heaters must be vented as described here to properly

direct the flue gases from the unit to the outside atmosphere. The

venting can terminate vertically through the roof (up) or horizontally

through a sidewall (sideways).

WARNING: Gas-fired heaters must be vented. Do not operate

unvented. A built in power exhauster is provided. Additional

external power exhausters are not required or permitted.

Insufficient ventilation and/or improperly sealed vents may

release gas into the building which could result in health

problems, carbon monoxide poisoning, or death. Improper

venting may result in fire, explosion, injury, or death.

Determine that there is not blockage, restriction, leakage, corrosion,

or other deficiencies that can cause hazards. The vent pipe should

be corrosion-resistant galvanized steel of a thickness that meets the

National Fuel Gas Code. Minimum thickness for connectors varies

depending on the pipe diameter. Never vent this unit heater with PVC

or plastic pipe.

WARNING: If replacing an existing heater, vents may require

re-sizing. Improperly sized venting systems can result in vent

gas leakage or condensation. Refer to the National Fuel Gas

Code ANSI Z223.1 (NFPA 54) or CSA B149.1 - latest edition.

Failure to follow these instructions can result in serious injury

or death.

GENERAL VENTING REQUIREMENTS

NOTICE: The vent is a passageway, vertical or nearly so, used to

convey flue gases from an appliance, or its vent connector, to the

outside atmosphere. The vent connector is the pipe or duct that

connects a fuel-gas burning appliance to a vent or chimney.

Do not intermix different vent system parts from different

manufacturers in the same venting system.

Vent connectors serving Category I and Category II Appliances shall

not be connected into any portion of mechanical draft systems

operating under positive pressure.

All joints shall be secured with at least two corrosion resistant screws.

All joints must be checked for gas tightness after installation.

CAUTION: The heater and the venting system shall be

inspected once a year by a qualified service agency.

CAUTION: Installation must conform with local building

codes or in the absence of local codes, with Part 7, Venting

of Equipment, of the National Fuel Gas Code, ANSI Z223.1

(NFPA 54) – latest edition. In Canada installation must be in

accordance with CSA B149.1.

Heatstar heaters come with a factory-installed vent for attaching vent

pipe to the heater. Attach the venting material to the adapter with

three (3) non-corrosive sheet metal screws. If necessary, drill pilot holes

prior to attaching the vent pipe. The venting material must not be

smaller than the factory installed adapter.

WARNING: Do not vent this appliance into another heater’s

vents or through a masonry chimney.

Do not use dampers in the heater vent pipe.

The venting system must be exclusive to a single appliance

and no other appliance is allowed to be vented into it.

Precautions must be taken to prevent degradation of

building materials by flue products.

Single Wall vent pipe must not pass through any unoccupied

attic, inside wall, concealed space, or floor.

Un-insulated single wall vent pipe must not be used

outdoors for venting appliances in regions where winter

design temperature is below freezing.

REPLACING EXISTING EQUIPMENT

If the unit heater is replacing existing equipment and using an existing

vent system, inspect the venting for proper size and horizontal pitch as

directed in these instructions and the latest edition of the National Fuel

Gas Code, ANSI Z223.1 (NFPA 54) or CSA B149.1 Installation Code.

Configuration of the vent termination determines the category type.

All model heaters must be installed in accordance to the requirements

of this section, as well as the requirements of its category

determination, as described in this manual.

All Heatstar Model Requirements:

• Use vent pipe material that is corrosion-resistant galvanized steel

of a thickness that meets the National Fuel Gas Code.

• Do not exceed a maximum vent length as indicated in Table 4.

• Maintain a minimum vent length of 3 feet (914mm).

• Have all vent pipe seams or connectors fastened together with at

least three corrosion resistant sheet metal screws (supplied by the

installer).

• Maintain a 6 inch clearance around all single wall vent pipe from

any combustible materials. For double wall vent pipe (type B)

follow the vent manufacturer’s clearance to combustibles.

• The equivalent length for a 4 inch 90�°elbow is 5 feet.

• The equivalent length for a 6 inch 90�°elbow is 7 feet.

• Avoid using more than two 90�°directional changes in the venting

system.

• Suspend and secure all horizontal runs at points no greater than 3

feet (914mm) apart.

• Vent termination must maintain a minimum distance of 6 feet

from any mechanical air supply inlet.

• Vent must terminate a minimum of 4 feet below, 4 feet

horizontally from, or 1 foot above any window or door that may

be opened or gravity air inlet into the building.

Large Unit Heater

Operating Instructions and Owner’s Manual

7

Page 8

• Vent must terminate a minimum of 4 feet above grade level

and must extend beyond any combustible overhang. When

condensation may be a problem, the vent system shall not

terminate over public walkways or over an area where condensate

or vapor could create a nuisance or hazard or could be

detrimental to the operation of regulators, relief openings, or

other equipment.

• The vent terminal must be installed to prevent any blockage by

snow and protect building material from degradation by flue

gases.

• The vent cap must be a minimum of 6 inches from the sidewall of

the building.

• Vent must be a minimum of 36 inches below or extend beyond

any combustible overhang.

• Consult NFPA ANSI Z223.1 Gas Vent Termination criteria for vents

that terminate on a roof pitch that exceeds 9:12.

• Canada: vents must terminate a minimum of 3 feet (914mm) from

a window or door that may be opened, and a non-mechanical air

supply inlet or combustion air inlet into the building.

Model Vent Pipe

HSU200

HSU250

HSU300

HSU400

Diameter

4” 3’ 70’

6” 3’ 70’

Equivalent Vent Length

Minimum Maximum

TABLE 4

Vent Pipe Diameters and Equivalent Vent Pipe

Lengths for Horizontal Venting Systems

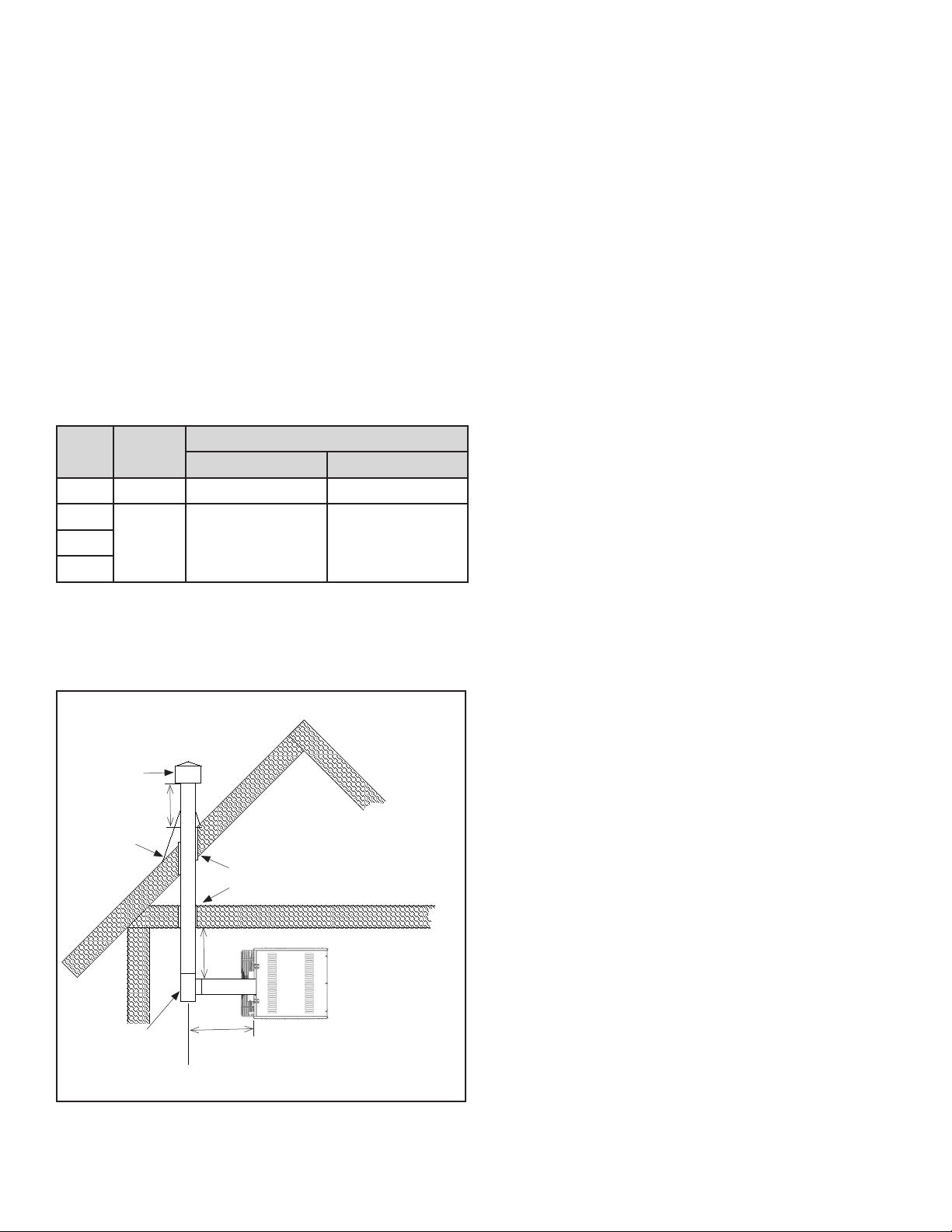

General Venting Requirements

Listed Terminal

When possible, avoid venting through an unconditioned space. Venting

through an unconditioned space promotes condensation. When

venting through an unconditioned space is unavoidable, or if the unit

is installed in an area that is prone to condensation, insulate venting

runs greater than 5 feet to minimize the production of condensation.

Inspect for leakage prior to insulating the venting and only use

insulation that is non-combustible with a temperature rating of not less

than 500�°F. It is recommended that the venting system is installed

with a tee, drip leg, and clean-out cap as shown in Figure 5.

When venting pipe passes through a combustible interior wall or

floor, a metal thimble with a diameter 4 inches greater than the vent

pipe diameter must be used. If there is 6 feet or more of vent pipe

prior to passing through the combustible wall or floor, then the metal

thimble need only be 2 inches greater than the vent pipe diameter.

If a metal thimble is not used, all clearance to combustibles from the

vent pipe must be 6 inches. Where permitted, type B vent may be

used for the last section of vent pipe to reduce the required clearance

to combustibles when passing through a combustible wall or floor.

When using type B venting, follow the manufacturer’s recommended

clearance to combustibles. Any material used to close or insulate the

opening must be non-combustible.

How to attach a single wall vent terminal to double wall (Type B) vent

pipe:

1. Look for the “flow” arrow on the vent pipe.

2. Slide the vent terminal inside the exhaust end of the double wall

vent pipe.

3. Drill 3 holes through the pipe and the vent terminal. Using 3/4”

long sheet metal screws, attach the cap to the pipe. Do not

overtighten.

How to connect a single wall vent system to a double wall (Type B)

vent pipe:

1. Slide the single wall pipe inside the inner wall of the double wall

pipe.

2. Drill 3 holes through both walls of the single and double wall vent

pipes. Using 3/4” sheet metal screws, attach the 2 pieces of pipe.

Do not overtighten.

3. The gap between the single and double wall pipe must be sealed

but it is not necessary to fill the full volume of the annular area. To

seal, run a large bead of 500�°F silastic around the gap.

“H” Min.

Roof Flashing

Tee with drip leg and

cleanout cap (slope

1/4” per foot

downward toward

drip leg)

Use listed

thimble

through roof

and ceiling

4” Min.

Exhaust

12” Min.

Recommended

FIGURE 5

Large Unit Heater

VERTICAL VENTING

An appliance that operates with a positive vent static pressure

and with a vent gas temperature that avoids excessive condensate

production in the vent is said to be ‘Category III’. This unit heater is

considered a Category III appliance if the venting system meets all of

the following criteria:

• The vent system terminates vertically (up).

• The length of the horizontal portion of the vent run is less than 75%

of the vertical rise length. (e.g.- If the vertical vent height is 10 feet,

the horizontal run is less than 7-1/2 feet).

• Horizontal sections of the vent pipe must be installed with an

upward slope from the appliance at a pitch of 1/4 inch per foot and

suspended securely from overhead structures at points not greater

than 3’ apart.

• The vent terminates a minimum of 5 feet above the vent connection

on the unit.

Operating Instructions and Owner’s Manual

8

Page 9

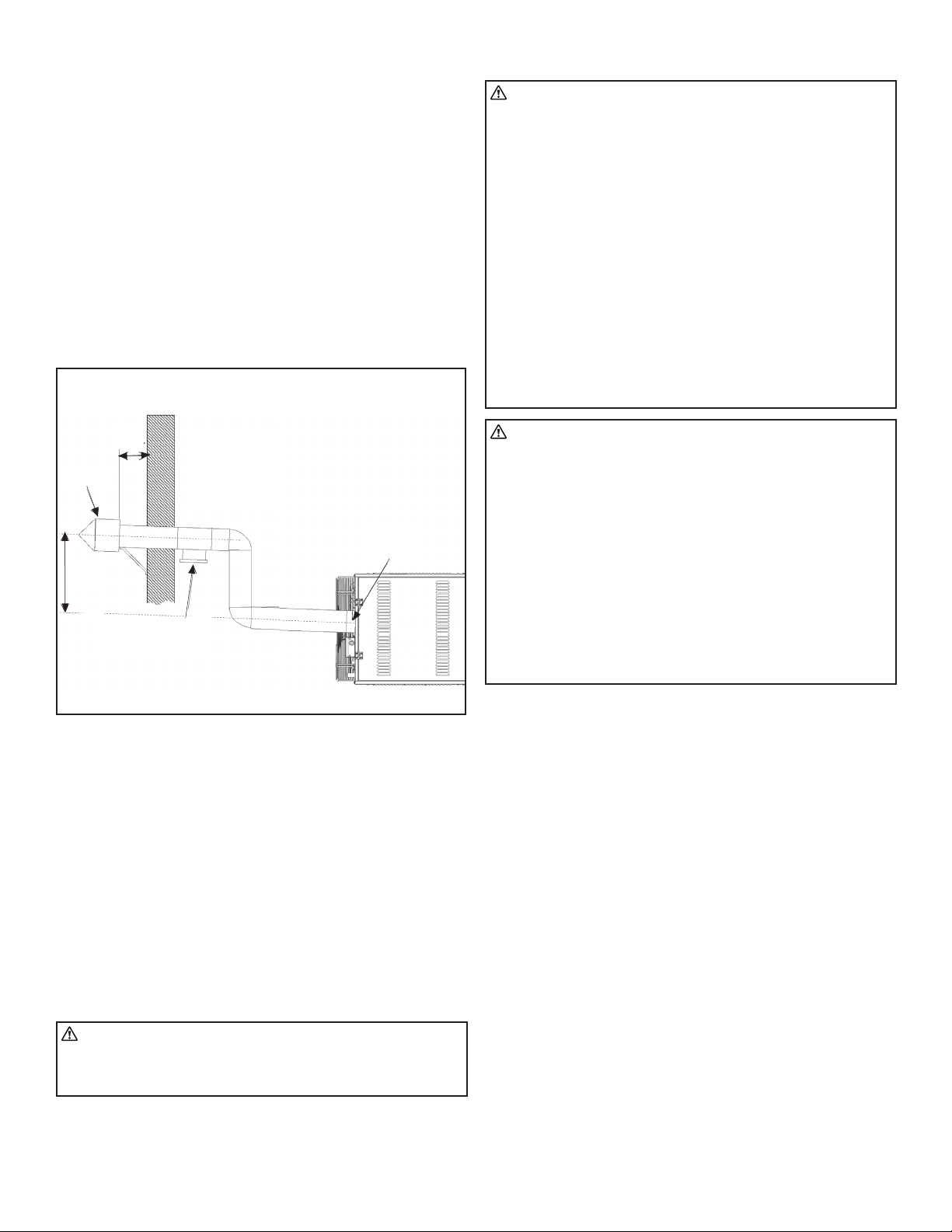

Venting Through Combustible Roof or Wall

Specied

Terminal

Roof Flashing

Listed Thimble

FIGURE 6

For vertical vent termination, the venting must comply with all the

General Venting Requirements and with the following vent locations

and clearances:

• Separate air intake duct from vent pipe by a minimum of 4 feet by

placing vent pipes higher than adjacent air intake ducts.

• Utilize a listed type B vent termination cap.

• The vent terminal must extend a minimum of 2 feet above the roof.

• Vent caps should be located a minimum of 2 feet away from

adjoining structures.

• All vertically vented heaters that are Category I must be connected

to a chimney or vent complying with a recognized Standard, or

lined masonry (or concrete) chimney with a material acceptable to

the authority having jurisdiction. Venting into an unlined masonry

chimney is not permitted. Refer to the National Fuel Gas Code.

• Use a listed vent terminal to reduce down drafts and moisture in the

vent.

• Ensure the vent connector runs as short as possible with a minimum

number of elbows. Refer to the (American) National Fuel Gas Code

ANSI Z223.1 or (Canada) CSA B149.1 Natural Gas and Propane

Installation Code for maximum vent and vent connector lengths.

Horizontal run of the vent connector from the induced draft blower

to the chimney/vent cannot exceed the values in Table 4.

• When the length of a single wall vent including elbows, exceeds 5

feet (1.5m), the vent shall be insulated along its entire length with a

minimum of 1/2” thick foil faced fiberglass 1-1/2# density insulation.

If a single wall vent is used in an unheated area it shall be insulated.

Failure to do so will result in condensation of flue gases.

• All vertical type B-1 vents, single wall vents, or listed chimney lining

system must be terminated with a listed vent cap or listed roof

assembly.

• The vent must extend at least 3’ (1m) above the highest point

where it passes through a roof of a building and at least 2’ (0.6m)

higher than any part of a building within a horizontal distance of

10’ (3.05m) unless otherwise specified by the (American) National

Fuel Gas Code, ANSI Z223.1 or (Canada) CAN/CGA-B149 Installation

Code. The vent must extend at least 5’ (1.6m) above the highest

connected equipment flue collar.

HORIZONTAL VENTING

An appliance that operates with a positive vent static pressure

and with a vent gas temperature that avoids excessive condensate

production in the vent is said to be ‘Category III’. This unit heater is

considered a Category III appliance if the venting system meets all of

the following criteria:

• The vent system terminates horizontally (sideways).

• The vent terminates vertically, but the length of the horizontal

portion of the vent run exceeds 75% of the vertical rise length.

(e.g.- If the vertical vent height is 10 feet, the horizontal run is

greater than 7-1/2 feet).

• Horizontal venting sections of the vent pipe must be installed with

a downward slope from the appliance at a pitch of 1/4 inch per

foot.

• The vent terminates below 5 feet of the vent connection on the

unit.

Due to changes to Z83-8 2009 CSA2.6-2009, the use of single wall

B-Vent is no longer permitted as an acceptable material when venting

horizontally, this change covers both residential and commercial

installations. All horizontally vented units manufactured after July of

2011 must be vented as a Category III Unit/Utility Heater in compliance

with UL 1738 & ULS636.

Seal vent pipes with high temperature sealant and three (3) #8 sheet

metal screws. Vent enclosed spaces and buildings according to the

guidelines in this manual and applicable national, state, provincial and

local codes.

You must use venting approved for Category III applications, and

manufactured by a listed vent system manufacturer. For single wall

vent systems, one continuous section of double wall vent pipe may be

used with the vent system to pass through a wall or barrier.

All horizontal Category III vents must be terminated with a listed vent

cap.

Exhaust Vent Construction Through

Combustible Walls

Fiber Glass

Insulation

Min. 2”

Metal

Sleeve

Terminal

Vent Pipe

Diameter

12” Min.

Metal Face

Plate

Vent Termination

Support Bracket

(where required)

2” Min.

2” Min.

Metal

Sleeve

FIGURE 7

Large Unit Heater

Operating Instructions and Owner’s Manual

9

Page 10

Additional requirements for horizontal venting:

• Category III venting systems may NOT be common vented, and no

other gas units are allowed to be vented into it.

• Vent must terminate a minimum of 3 feet (914mm) above any

forced air inlet that is located within 10 feet.

• The bottom of the vent terminate must be located a minimum

of 12 inches above grade level and must extend beyond any

combustible overhang.

• Never join two sections of double wall vent pipe within one

horizontal vent system, as it is impossible to verify that inner pipes

are completely sealed.

• For a vent termination located under an eave, the distance of the

overhang must not exceed 20”. The clearance to combustibles

above the exterior vent must be maintained at a minimum of 12”.

Consult the National Fuel Gas Code for additional requirements

for eaves that have ventilation openings.

Horizontal Venting

GAS CONNECTIONS

WARNING: Danger of explosion and fire. Improperly

connected gas lines may result in serious injury and death,

explosion, poisonous fumes, toxic gases, or asphyxiation.

Connect gas lines in accordance to national, state, provincial,

and local codes.

This heater burns natural gas or liquefied petroleum (LP) gas

and is equipped with a regulator. The regulator is built into

the gas valve. The maximum inlet pressure to this regulator

is 20 in. W.C.. If gas line pressure exceeds 20 in. W.C., then

an additional regulator must be installed before the heater/

regulator to step down the pressure to a maximum of 20 in.

W.C..

All field gas piping must be pressure/leak tested prior to

operation. Never use an open flame. Use a soap solution or

equivalent for testing.

You must follow these instructions exactly. If over-heating

occurs or if gas supply fails to shut off, shut off the manual

gas valve to the appliance before shutting off electrical

supply.

12”

Min.

Terminal

5 ft.

Min.

Tee with Drip Leg and

Cleanout Cap at Low

Point of Vent System

The Horizontal Run

of Vent Pipe Shall

be Pitched Upward

1/ 4 IN. to the FT.

(21 MM to the M).

Power

Exhauster

Outlet

FIGURE 8

COMBUSTION AIR REQUIREMENTS

Adequate facilities for supplying air for combustion and ventilation

must be provided in accordance with the latest edition of section 5.3,

Air for Combustion and Ventilation, of the National Fuel Gas Code,

ANSI Z223.1, in the U.S.A., CSA B149.1 Natural Gas and Propane Installation Code, the National Standards of Canada or applicable provisions

of local building codes.

All gas fired appliances require air to be used for the combustion

process. In many buildings today, there is a negative indoor air pressure

caused by exhaust fans, etc. If sufficient quantities of combustion air

are not available, the heater or another appliance will operate in an inefficient manner, resulting in incomplete combustion which can result

in the production of excessive carbon monoxide.

Follow these guidelines and all applicable codes for all models prior to

installing the combustion air duct work.

WARNING: Suf ficient combustion air must be supplied

to the appliance at all times. Lack of combustion air may

result in property damage, headaches, nausea, dizziness,

asphyxiation, serious injury, or death.

CAUTION: Gas lines should be purged of air as described

in ANSI Z223.1 (NFPA 54) or CSA-B149.1– latest version.

Installation of the piping must also conform with the local

building codes, or in the absence of local codes, with the

latest edition of the National Fuel Gas Code (NFPA 54). In

Canada, installation must be in accordance with CSA-B149.1.

When leak testing the gas supply piping system, the

appliance and its combination gas control must be isolated

during any pressure testing in excess of 14” W.C. (1/2 psi).

The unit should be isolated from the gas supply piping

system by closing its field installed manual shut-off valve.

This manual shut-off valve should be located within 6’ of the

heater.

Turn off all gas before installing appliance

NOTICE: The total input to the appliance must fall within +/- 5% of

the rated input as indicated on the rating plate. Otherwise the heat

exchanger may prematurely fail.

All piping installed must comply with local codes and ordinances or

with National Fuel Gas Code, ANSI Z223.1 (NFPA 54), whichever takes

precedence. When installing piping, the following requirements must

be taken into consideration: Canadian installations must comply with

the B149.1.2 Gas Code.

• Use new properly reamed black pipe free from chips.

• Apply a good quality pipe compound to all male threads prior

to assembly. If LP gas is the fuel, ensure that pipe compound is

resistant to LP gas. Do not use Teflon™ tape.

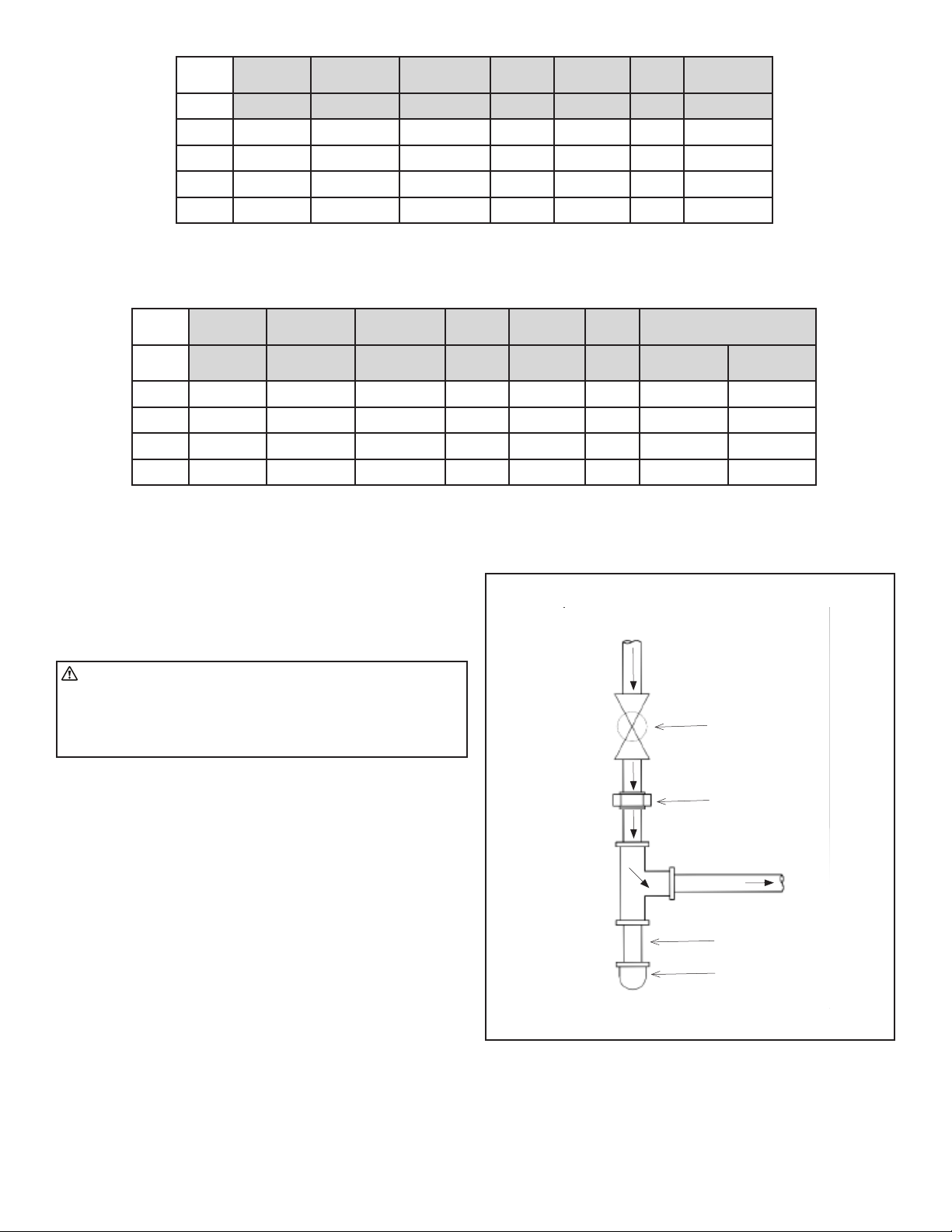

• A sediment trap meeting the typical requirements of Figure 9 shall

be installed in the line to the gas valve.

• A dedicated shutoff valve for the heater must be installed in the

gas supply line.

Refer to Table 5 for natural gas and Table 6 for propane to determine

the cubic feet per hour (CFH) required for the type of gas and size of

unit to be installed. To determine the proper pipe diameter, use the

CFH value and the length of pipe necessary. In the case where several

units are serviced by the same main gas line, the total capacity (CFH)

and length of main must be adequate to service all appliances downstream of this main.

Large Unit Heater

Operating Instructions and Owner’s Manual

10

Page 11

HSU200

HSU250

HSU300

HSU400

Gas supply

Connection

[“] [“ W.C.] [“ W.C.] [“ W.C.] [“] [CFH]

1/2 8 20 4.5 0.110 6 190.5

1/2 8 20 4.9 0.110 7 238.1

1/2 8 20 1.73 0.138 9 285.7

3/4 8 20 2.13 0.138 11 380.9

Gas supply

Pressure min.

Gas supply

Pressure max.

Manifold

Pressure

Orifice Drill

Size

# of

Orifices

Consumption

TABLE 5: Natural Gas Consumption

*Assumes an average heating value of 1050 BTU/SCF and a Specific Gravity of 0.60.

HSU200

HSU250

HSU300

HSU400

Gas supply

Connection

[“] [“ W.C.] [“ W.C.] [“ W.C.] [“] [CFH] [Gal/Hr.

1/2 11 20 7. 2 3 0.075 6 80.0 2.19

1/2 11 20 7. 2 3 0.075 7 100.0 2.74

1/2 11 20 3.81 0.083 9 120.0 3.29

3/4 11 20 4.74 0.083 11 160.0 4.38

Gas supply

Pressure min.

Gas supply

Pressure max.

Manifold

TABLE 6: Propane Gas Consumption

*Assumes an average heating value of 2500 BTU/SCF and a Specific Gravity of 1.53.

• All piping must be installed in accordance with the requirements

outlined in the National Fuel Gas Code ANSI/Z223.1 (latest

edition) or CSA-B149.1 and B149.2. Support all gas supply piping

with pipe hangers, metal strapping, or other suitable material. Do

not rely on the heater to support the gas pipe.

WARNING: Always use two (2) opposing wrenches to tighten

mating pipe connections to prevent excessive torque on the

gas valve and manifold pipe. Excessive torque can damage

the valve and/or misalign the orifice, resulting in fire,

explosion, serious injury, or death.

Pressure

Orifice Drill

Size

# of

Orifices

Consumption

Propane]

Gas Supply Connection

Manual

Main Shut-o Valve

(Furnished by Installer)

• When connecting gas supply lines, the length of the piping run

from the gas meter to the heater must be considered in determining the pipe size to avoid excessive pressure drop.

• A drip leg should be installed in the vertical pipe run to the unit.

In some localities, codes may require that a manual main shutoff

valve and union (furnished by installer) be installed external to the

unit. Union must be of the ground joint type. A drip leg should be

readily accessible to permit cleaning and emptying. See Figure 9.

NOTICE: Leave a min of 4’’ clearance to the electrical connections box

on the back of the heater to allow for access.

A 1/8” NPT plugged tap shall be installed immediately upstream of the

gas supply connection to the heater. The purpose of this is to be able

to check for proper gas pressure entering the heater.

Large Unit Heater

Operating Instructions and Owner’s Manual

11

Grounded Joint Union

Gas Flow

Drip Leg

Sediment Trap

FIGURE 9

Page 12

LEAK TESTING

WARNING: Use a soap solution or equivalent for leak testing.

Never test for leak with an open flame such as with matches

or candles. Failure to comply could result in personal injury,

property damage, or death.

• Always leak test final gas assembly for gas leaks according to

the procedures outlined in NFPA 54 and all local codes and/or

Standards.

• After gas piping is completed, carefully check all piping connections, (field and factory), for gas leaks.

• Due to the natural heating cycles and vibration of this unit it is

recommended, as part of its annual maintenance, to check these

connections for proper tightness and leak-check with a soap solution or other preferred means prior to putting into service.

For leak testing on pressures below 20 inches W.C.:

Before leak testing, close the field installed manual shut off valve

shown on Figure 9 on the supply line to isolate the gas valve from the

pressure.

NOTICE: All factory installed gas connections have passed an approved

leak test.

For leak testing on pressures above 20 inches W.C.:

When leak testing with pressures above 20 inches W.C., the unit must

be isolated from the supply pipe. Close the field installed manual shut

off valve, disconnect the supply line to the unit, and temporarily cap

the supply line for testing purposes.

WARNING: Gas pressures to the appliance controls must

never exceed 20 inches W.C.. Supply pressures greater than

20” W.C. can damage the controls, resulting in personal

injury, property damage, or death.

NOTICE: In case emergency shutdown is required, shut down main

gas valve and disconnect main power to unit. These devices should be

properly labeled by the installer.

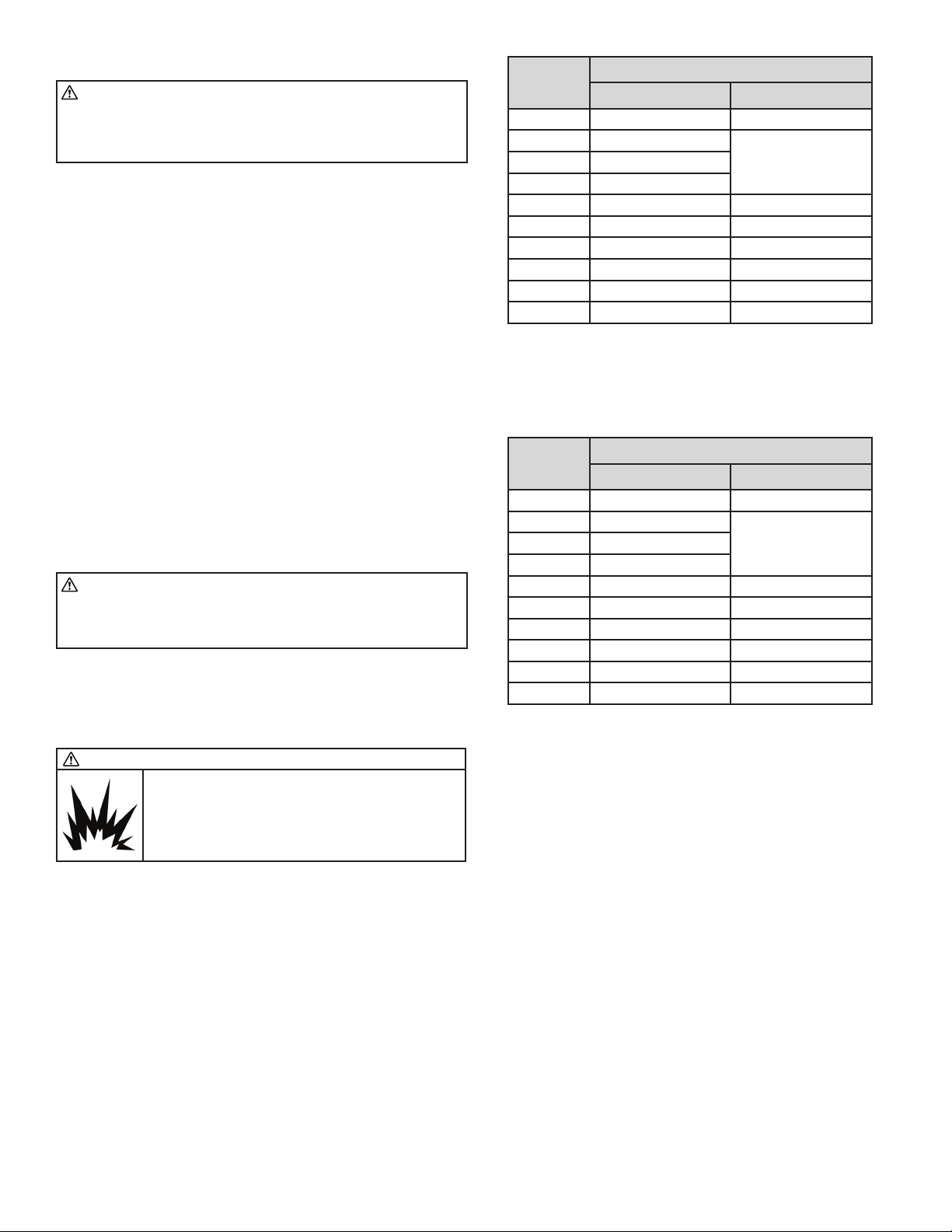

Altitude (ft)

0-2,000 1,050 1,050

2,001-3,000 929

3,001-4,000 892

4,001-4,500 874

4,501-5000 856 856

5,001-6,000 822 822

6,001-7,000 789 789

7,001-8,000 757 757

8,001-9,000 727 727

9,001-10,000 698 698

Gas Heating Values at Altitude (BT/ f t3)

USA Canada

945

TABLE 7

Natural Gas Heating Values at Altitude

Altitude (ft)

0-2,000 1,050 1,050

2,001-3,000 929

3,001-4,000 892

4,001-4,500 874

4,501-5000 856 856

5,001-6,000 822 822

6,001-7,000 789 789

7,001-8,000 757 757

8,001-9,000 727 727

9,001-10,000 698 698

Gas Heating Values at Altitude (BTU/f t3)

USA Canada

945

HIGH ALTITUDE OPERATION

WARNING

Explosion hazard. This heater must be converted

by a trained gas installation and service personnel only. Failure to comply could result in

personal injury, asphyxiation, death, and fire or

property damage.

This Unit heater is factory configured for altitudes from 0 – 2,000 ft

above sea level. If the heater is being installed at an elevation above

2,000 ft, the input rate will have to be de-rated to ensure proper

operation. The deration is achieved by an adjustment of manifold

pressure. Adjust pressure regulator to pressure shown in Table 6 for

natural gas and Table 7 for LP/propane gas.

Large Unit Heater

TABLE 8

Propane Gas Heating Values at Altitude

• Gas heating values are derated 4% per 1,000’ of elevation in the

U.S.A. and 10% between 2,000’ and 4,500’ elevation in Canada

in accordance with ANSI Z223.1 and CSA-B149, respectively.

• Refer to the unit rating plate or carton label to obtain the

necessary information about the unit. After obtaining this

information, refer to the gas pressure and selection charts shown

in Table 5 and Table 6. The pressure charts are differentiated by

elevation, fuel type, and country the product is being installed in.

The selection charts are differentiated by product type, altitude

and fuel type.

• Some utility companies may derate the BTU content (heating

value) of the gas provided at altitude to a value other than 1,050

BTU/ft3 for natural gas or 2,500 BTU/ft3 for propane gas to allow

certain heating appliances to be used with no manifold pressure

adjustments. For this reason it is necessary that the supplying

utility be contacted for detailed information about the gas type

and BTU content (heating value) before operating any heater.

Operating Instructions and Owner’s Manual

12

Page 13

Table 7 and Table 8 show the standard derated heating values

(4% per 1,000’ of elevation in the USA and 10% between 2,001’

and 4,500’ elevation in Canada) of natural and propane gases at

various altitudes. If the utility is supplying gas with heating values

as shown in Table 5 and Table 6, the manifold pressure should

be set accordingly.

NOTICE: Only the high fire gas pressure need be adjusted, low fire gas

pressure should remain the same.

If the heating value of the gas being supplied is different than the

values shown in Table 5 and Table 6 use the following equation to

determine the appropriate manifold pressure for the altitude and gas

heating value being supplied:

MPACT=(BTUTBL/BTUACT)squared X MPSL

where:

MPACT = Manifold Pressure (in. W.C.) at Altitude –

Manifold pressure setting for the heater being installed

BTUTBL = BTU/ft3 Content of Gas –

Obtained from Tab. 7 or Tab. 8 (whichever is applicable)

BTUACT = BTU/ft3 Content of Gas –

Obtained from the local utility company

MPSL = Manifold Pressure (in. W.C.), at Sea Level (see Table 5 or

Table 6)

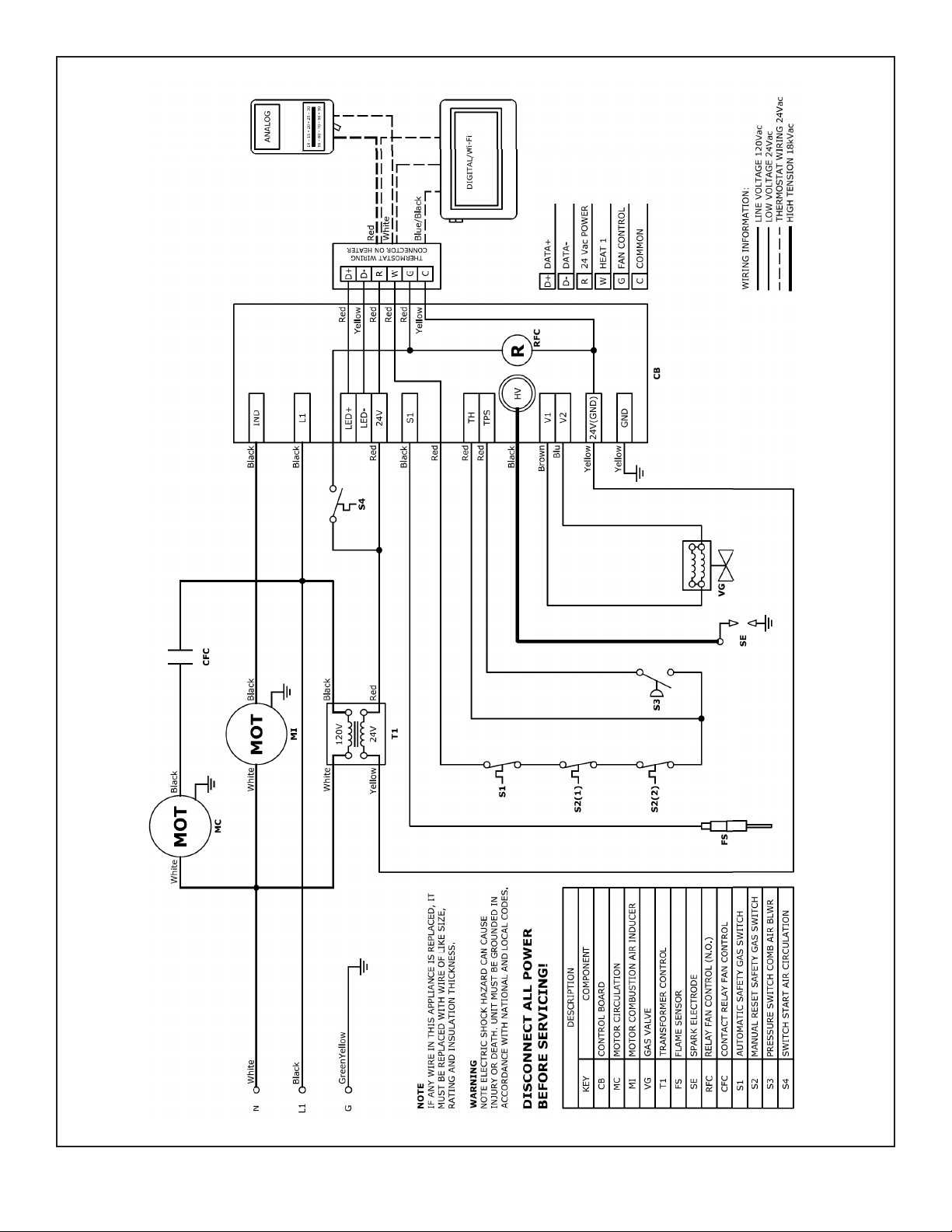

ELECTRICAL REQUIREMENTS

WARNING

Shock hazard. Disconnect power supply before

making wiring connections to prevent electrical

shock and equipment damage. All appliances

must be wired strictly in accordance with wiring

diagram furnished with the appliance. Any wiring

different from the wiring diagram could result in a

hazard to persons and property.

Ensure that the supply voltage to the appliance,

as indicated on the rating plate, is not 5% greater/

less than rated voltage.

Any original factory wiring that requires replacement must be replaced with wiring material having a temperature rating of at least 221ºF (105ºC).

• Installation of wiring must conform with local building codes,

or in the absence of local codes, with the National Electric Code

ANSI/NFPA 70 - Latest Edition. Unit must be electrically grounded

in conformance to this code. In Canada, wiring must comply with

CSA C22.1, Part 1, Electrical Code.

• Two copies of the unit wiring diagram are provided with each

unit. One is located in the side access control compartment and

the other is supplied in the literature packet. Refer to this diagram

for all wiring connections.

• Make sure all multi-voltage components (motors, transformers,

etc.) are wired in accordance with the power supply voltage.

• The power supply to the unit must be protected with a fused

or circuit breaker switch, so that power can be turned off for

servicing.

Power Supply

[V] [A] [Hz] [Ph] [W]

HSU200

HSU250

HSU300

HSU400

120 6.3 60 1 756

120 6.3 60 1 756

120 10 60 1 1,200

120 10 60 1 1,200

TABLE 9: Electrical Specifications

External electrical service connections that must be installed include:

a. Supply power connection (115, 208, 230, 460, or 575 volts).

b. Connection of thermostats, or any other accessory control devices

that may be supplied (24 volts).

All supply power electrical connections are made in the side access

control compartment of the unit. The low voltage (thermostat and

accessory control devices) can be wired to the terminals in the side

access control compartment. Refer to the wiring diagram for the

terminal location of all low voltage wiring.

NOTICE: These unit heaters use a direct spark ignition system. There

is no pilot necessary as the spark lights the main burner as the gas

valve is turned on. The direct spark ignition control board emits radio

noise during burner ignition. The level of energy may be enough to

disturb a logic circuit in a microprocessor controlled thermostat. It is

recommended that an isolation relay be used when connecting the

unit heater to a microprocessor controlled thermostat. Select circuit

protection and wire size according to the unit rating plate. Remove

electrical junction box cover and connect wiring through knockout

on the junction box located on the side of the heater. Refer to heater

wiring diagram for connection information. Use a wire for line power

connections with proper section size according to the electrical power

data indicated in Table 9 and its length. Make sure to connect line

power to wires located in the external electrical junction box behind

junction box cover. DO NOT CONNECT LINE POWER TO THERMOSTAT

TERMINAL STRIP ON OUTSIDE OF HEATER.

Electrically ground the unit in accordance with local codes or in the

absence of local codes, in accordance with the current National

Electrical Code (ANSI/NFPA No. 70) in the USA, and in Canada with

the current Canadian Electrical Code, Part 1 CSA C22.1.

Un-insulated ground wire must be wrapped in electrical tape to avoid

damage to the electrical system.

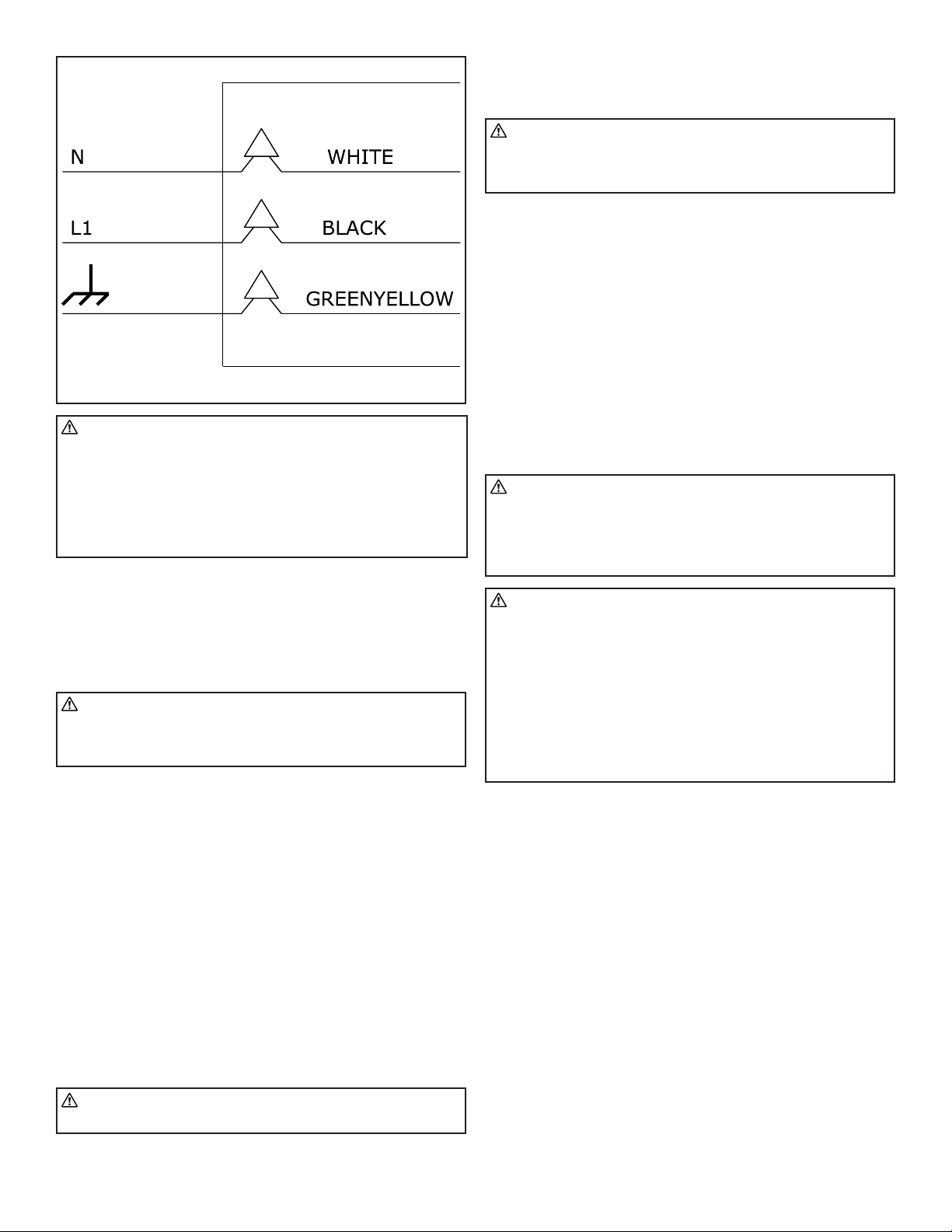

• Make line voltage connections as shown in Figure 10. Connect

field wiring as shown on wiring diagram on unit. Also, refer to

typical diagram in this manual.

• To use the blower for air circulation only, your thermostat must

have a “fan only” or fan selection setting. In case your thermostat

has this option, an additional wire should be run to the

“ ”terminal on the thermostat connection block. See wiring

schematic in Figure 11 .

Large Unit Heater

Operating Instructions and Owner’s Manual

13

Page 14

Main Components

FIGURE 10

M1

S1

S4

VG

MC

Line Voltage

Thermostat

Wiring Connector

on Heater

S2

SE

FS

S2

S3

RFC

CFC

CB

T1

Large Unit Heater

Operating Instructions and Owner’s Manual

14

Page 15

Internal Wiring Diagram

FIGURE 11

Large Unit Heater

Operating Instructions and Owner’s Manual

15

Page 16

Line Voltage Field Wiring

FIGURE 12

• Connect wires together with UL approved wire connectors.

NOTICE: A UL Listed switch may be installed in the 2x4 junction box

for use as a service disconnect.

CAUTION: Route the field supplied power wires so that

they do not come in contact with the flue wrapper or

venter housing. These hot surfaces may damage the wire’s

insulation, resulting in damage to the unit.

THERMOSTAT LOCATION

The location of the thermostat should be determined by the desired

heating requirements and be mounted on an inside wall five (5) feet

above the finished floor. Locate the thermostat in a conspicuous

location, away from where it could be influenced by heat from the unit

or other sources, as this may cause the unit to short cycle. Care should

be given to locate the thermostat away from drafts or frequently

opened doors. To prevent drafts inside the wall from affecting the

thermostat’s performance, plug hole for the wire with insulation

or suitable caulk. For further information, see the accompanying

instructions with the thermostat.

WARNING: Electric shock hazard. Can cause injury or death.

Do not use this heater if any part has been under water.

Immediately call a qualified service technician to inspect the

furnace and to replace any part of the control system and

any gas control which has been under water.

Before attempting to perform any service or maintenance,

turn the electrical power to unit OFF at disconnect

switch(es). Unit may have multiple power supplies.

FIELD WIRING SUPPLY VOLTAGE

Before proceeding with electrical connections, ensure that the supply

voltage, frequency, phase, and current capacity meet the requirements

specified on the rating plate. A dedicated line voltage supply with

properly sized wire should run directly from the main electrical panel to

the heater.

CAUTION: The power supply to the heater must be within

+/- 5% of the voltage rating as indicated on the rating

plate of the appliance. If input power does not meet these

specifications, contact your utility company.

• An electrical service disconnect must be provided at the furnace

location. A 2 x 4 junction box can be mounted directly to the unit

panel utilizing the provided 1/2” knock-out. If conditions do not

allow for this, locate the service disconnect not more than 5 feet

away from the service access panel.

• The main electrical supply enters at the rear of the heater utilizing

1/2” electrical knock-out. When routing the electrical supply

conduit to the unit, ensure that it does not interfere or obstruct

the heater’s service access panel.

• Unit comes with three wire leads to connect the main power

supply. Connect the hot, neutral, and ground wires as shown

in the field wiring diagram. When routing wires through the

knockout, use a UL Listed bushing or chase nipple to prevent

damage to the wire insulation. When operating this unit as a

sealed combustion appliance, the cabinet opening to the junction

box must be sealed air tight using either a UL approved bushing

or a non-reactive UL approved sealant to bushing.

WARNING: Edges of sheet metal holes may be sharp. Use

gloves as a precaution when routing wires.

Large Unit Heater

START-UP OPERATION

UNIT START–UP

WARNING: Improper installation, adjustment, alteration,

service, or maintenance can cause property damage, serious

injury, or death. This heater must be installed and serviced

by a trained gas installation and service personnel only.

During heater startup ensure that building is well ventilated.

CAUTION: Shock Hazard. Before attempting to perform any

service or maintenance, turn electrical power to unit OFF at

disconnect switch.

During the first unit startup, an odor and, perhaps,

some vapor will come from the heater. This is the gasket

binding material emitting this odor and/ or vapor. After

approximately 20 minutes, this odor will disappear and not

occur again.

During these 20 minutes it is recommended to ventilate the

room as much as possible (open doors, windows, turn on

any fans).

Pre-Start Up Checks

Verify that the installation conforms to all of the specifications of the

manual, as well as with local, state, national, and provincial codes. In

absence of local codes, the unit heater must be installed according to

the current National Fuel Gas Code ANSI Z223.1 (NFPA 54). In Canada,

the installation must conform to the current National Standard of

Canada CSA-B149 Sections 1 & 2.

Prior to starting up the unit, verify that:

• The gas type listed on the rating label matches that of your

application.

• The gas connections have been purged of air and properly leak

tested.

• The voltage type and frequency listed on the rating label matches

that of your application.

• The unit is properly grounded as per the National Electrical Code,

ANSI/NFPA 70 or Canadian Electrical code CSA C22.1 Part 1.

• The unit is properly mounted to a permanent structure able to

bear the weight of the unit.

Operating Instructions and Owner’s Manual

16

Page 17

• The proper mounting height is observed for the application.

• All clearance to combustible distances or service clearances are

maintained.

• The unit is properly isolated or installed to prevent excessive

vibration.

• The unit is level horizontally.

• Venting is properly installed in accordance with this manual and

any applicable codes.

• Combustion air supply is sufficient to support proper operation at

all times.

See Annex 1 for a start up and performance check list to fill for each

unit.

Verify Proper Inlet Pressure

WARNING: Before starting up the unit, smell all around

the unit heater for gas. Be sure to smell next to the floor

because some gas is heavier than air and will settle on the

floor.

When turning the gas shut off valve, only use your hand. Never use

tools to turn the knobs, as it may damage the valve resulting in a fire

or explosion. If the knob is stuck, do not try to repair it.

Contact a qualified service technician or your local gas company.

To verify the proper inlet pressures, follow the following steps:

1. Turn off the gas supply at the manual gas shut off valve.

2. Unscrew the screw inside the inlet pressure hose connector. See

Figure 13.

3. Turn on the gas supply at the manual gas shut off valve.

4. Turn on the electrical power to the unit heater.

5. To light the main burners, set the room thermostat to a point

above room temperature.

Gas Valve

Inlet Pressure:

Unscrew this screw to

read the pressure.

Manifold Pressure Regulation:

• Remove the cap with a at blade screw

driver:

• Act on the plastic regulator:

Decrease pressure

Counter-clockwise

FIGURE 13

Increase pressure

Clockwise

Manifold Pressure:

Unscrew this

screw to read the

pressure.

FIGURE 13

NOTICE: This unit heater is equipped with an ignition device, which

automatically lights the burner. This unit heater cannot be lit manually.

Do not try to light the burner by hand.

Large Unit Heater

The minimum and maximum inlet gas supply pressure are

indicated in Table 5 and in Table 6.

Verify minimum inlet gas supply pressure:

6. Turn on all other gas appliances that are on the same supply

line. If the other gas appliances have multiple inputs, set it to the

maximum rating.

7. Observe the pressure rating on the pressure gauge.

Verify maximum inlet gas supply pressure:

8. Turn off all other gas appliances on the same supply line.

9. Observe the pressure reading on the pressure gauge.

IMPORTANT: If the inlet gas supply pressure is not within the

minimum and maximum range as shown on the rating plate, contact

your gas supplier.

Removing pressure gauge from inlet port on gas valve:

10. Set thermostat or other control device to the lowest set point.

11. After heater has completed the post-purge cycle, turn off the

electrical power to the unit heater.

12. Turn off the gas supply at the manual gas shut off valve.

13. Remove the pressure gauge tube.

14. Close the screw inside the inlet pressure hose connector.

15. Leak check using a soap solution or equivalent method as

described in ANSI Z223.1 (NFPA 54).

Verify Manifold Pressure

Before starting up the unit, smell all around the unit heater for gas.

Be sure to smell next to the floor because some gas is heavier than air

and will settle on the floor.

When turning the gas shut off valve, only use your hand. Never use

tools to turn the knobs, as it may damage the valve resulting in a fire

or explosion. If the knob is stuck, do not try to repair it, contact a

qualified service technician or your local gas company.

To verify the proper manifold pressure, follow the following

steps:

1. Turn off the electrical power to the unit heater.

2. Unscrew the screw inside the manifold pressure hose connector

(see Figure 13).

3. Connect the pressure gauge tube and manometer.

4. Turn on the electrical power to the unit heater.

5. To light the main burners, set the room thermostat to a point

above room temperature.

NOTICE: This unit heater is equipped with an ignition device, which

automatically lights the burner. This unit heater cannot be lit manually.

Do not try to light the burner by hand.

6. After the unit has successfully ignited, wait five minutes prior to

taking any readings. The unit heater must be in a steady state of

operation prior to taking a manifold pressure reading.

7. While waiting for the unit to stabilize, observe the characteristics

of the flame. The flame should be stable and should not lift form

any burner. The burner color should be light blue, and not create

excessive noise.

8. After five minutes, observe the pressure rating on the pressure

gauge.

Operating Instructions and Owner’s Manual

17

Page 18

The target manifold gas supply pressure is indicated in Table 5

and Table 6 :

NOTICE: Manifold pressure of the heater is pre-set at the factory. No

adjustment should be necessary.

During the verification process, a tolerance of +/- 5% of the full scale is

acceptable due to varying atmospheric conditions.

If manifold pressure is outside of this tolerance, then an adjustment

may be necessary.

9. Set the adjustment screw until reach the pressure indicated in the

rating plate.

Removing pressure gauge from manifold port on gas valve:

10. Set thermostat or other control device to the lowest set point.

11. After heater has completed the post-purge cycle, turn off the

electrical power to the unit heater.

12. Turn off the shut-off gas valve.

13. Remove the pressure gauge tube and the manometer.

14. Close the screw inside the manifold pressure hose connector (see

Figure 13).

15. Turn on the shut-off gas valve.

16. Set thermostat or other control device to the highest set point.

17. Wait until the unit starts.

18. Leak check the manifold pressure hose connector using a soap

solution or equivalent method as described in ANSI Z223.1 (NFPA

54).

Prior to Leaving Job Site

Prior to leaving the job site, verify that:

• Service access door is properly secured to the unit.

• The heater is clear of any objects that would interfere with

the proper air circulation or that violate the listed clearance to

combustibles.

• Air directional louvers are adjusted for desired air flow and are

not shut or adjusted beyond 60º°from perpendicular to the face of

the unit.

• Manual gas shut off is ON.

• Electrical power is ON.

• Thermostat is set to desired temperature.

• Properly dispose of all packaging materials.

• Check to be sure you have all of your tools.

• Leave the Installation, Operation, Maintenance and Parts Manual

to the owner or end user.

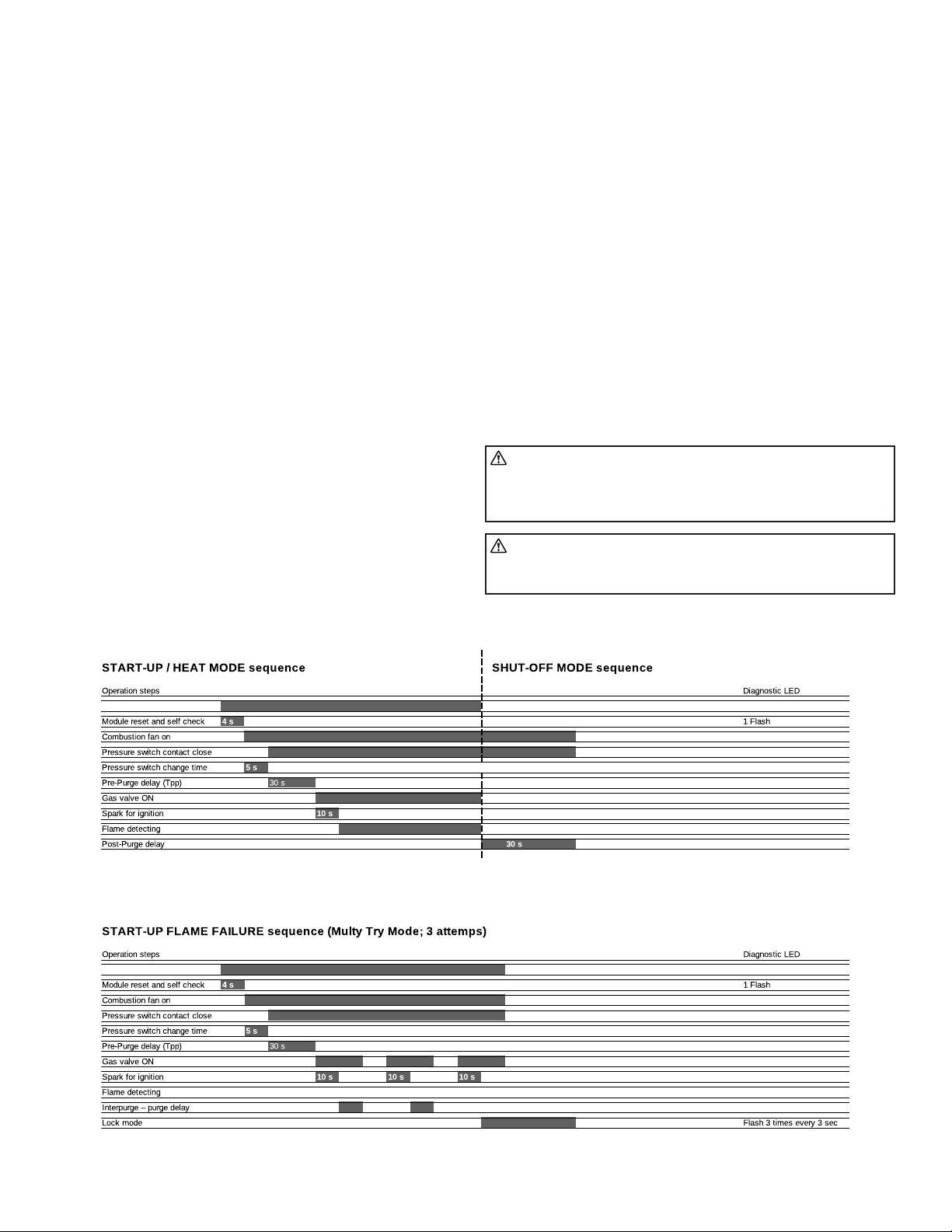

UNIT WORKING SEQUENCE

WARNING: FOR YOUR SAFETY READ BEFORE LIGHTING

BEFORE LIGHTING smell all around the appliance area for

gas. Be sure to smell next to the floor because some gas is

heavier than air and will settle on the floor.

WARNING: This appliance does not have a pilot ignition. It is

equipped with an ignition device which automatically lights

the burner. Do not attempt to light the system by hand.

Call for heat

Call for heat

Start-Up Sequence

Start-Up Flame Failure Sequence

Large Unit Heater

Operating Instructions and Owner’s Manual

18

Page 19

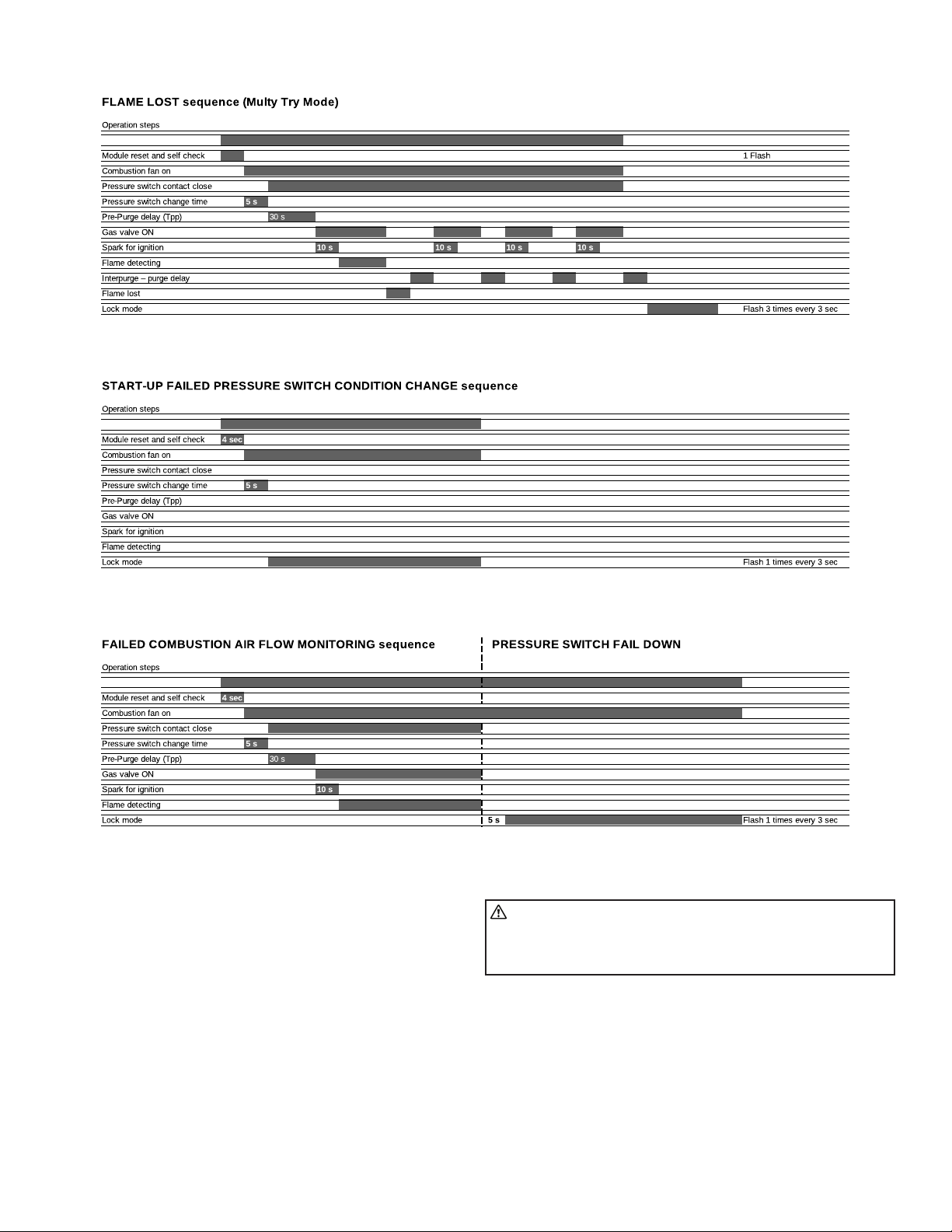

Call for heat

Call for heat

Flame Lost Sequence

Start-Up Failed Pressure Switch Condition Change Sequence

Failed Combustion Air Flow Monitoring Sequence

Call for heat

SEQUENCE OF OPERATION

1. STOP! Make sure you have read and understand all of the safety

information regarding the operation of this gas appliance. Any and

all service should be performed by a licensed installer

2. Set the thermostat to lowest setting.

3. Turn off all electrical power to appliance.

4. This appliance is equipped with an ignition device which

automatically lights burner. DO NOT attempt to light the burners

manually.

5. There is a main shut-off valve upstream of the unit. Open it. (See

Figure 9 on Page 11)

6. Wait five minutes to clear out any gas. If you then smell gas, STOP!

Immediately call your gas supplier from a neighbor’s phone. Follow

the gas supplier’s instructions. If you do not smell gas go to next

step.

Large Unit Heater

7. Turn on electrical power to unit.

8. Set the thermostat to desired setting.

WARNING: Should overheating occur, or the gas supply

control system fail to shut off the flow of gas, shut off the

manual gas valve to the utility heater before shutting off the

electrical supply

SHUTDOWN PROCEDURES

1. Set thermostat to lowest level.

2. Turn off all electrical power to unit if service is to be performed.

3. Turn manual shut off knob upstream the unit. Do not force.

Operating Instructions and Owner’s Manual

19

Page 20

MAINTENANCE

CAUTION: Turn off gas and electrical power to unit before

performing any maintenance or service operations on this

unit. Remember to follow lighting instructions when putting

unit back into operation after service or maintenance.

If any of the original wire as supplied with the appliance

must be replaced, it must be replaced with wiring material

having a temperature rating of at least 105°C.

Do not use this appliance if any part has been under water.

Immediately call a qualified service technician to inspect the

appliance and replace any gas control which has been under

water.

• Check gas tightness of the safety shut off valves on at least an

annual basis.

• To check gas tightness of the safety shut off valves, turn off the

manual valve upstream of the appliance combination control.

Remove the hex head plug on the inlet side of the combination

control and connect a manometer to that tapping.

• Turn the manual valve ON to apply pressure to the combination

control. Note the pressure reading on the manometer, then turn

the valve off. Any loss of pressure indicates a leak. If a leak is

detected, use a soap solution to check all threaded connections.

If no leak is found, combination control is faulty and must be

replaced before putting appliance back in service.

Should maintenance be required, perform the following inspection and

service routine:

BURNERS

• Periodically examine burner flames for proper appearance during the

heating season.

• Before each heating season examine the burners for any deposits or

blockage that may have occurred.

Clean burners as follows:

1. Turn off both electrical and gas supplies to unit.

2. Disconnect gas supply piping, high tension and sensor leads.

Remove gas manifold. Remove burner tray.

3. Clean burners as necessary. Make sure that burner heads line up

properly to ensure flame crossover. Check spark gap on electrode

and adjust if required. The gap should be between 0.110 inch and

0.140 inch (2.79mm to 3.56mm). The gap may be checked with

appropriately sized twist drills or feeler gauges.

4. Reinstall burner tray, gas manifold, high tension and sensor leads.

Reconnect gas supply piping.

5. Restore electrical power and gas supply. Follow lighting instructions

to light unit. Check burner flame.

FLUE PASSAGEWAY AND FLUE BOX

The flue passages and flue box should be inspected and cleaned

prior to each heating season. The sequence of operation should be as

follows:

1. Turn off both electrical and gas supply to unit.

2. Disconnect combustion air blower wiring.

3. Remove screws securing flue box to unit. Remove flue box. If

necessary, remove blower assembly from flue box. Clean flue box

with wire brush.

4. Remove turbulator retention bracket and turbulators. Clean

turbulators with wire brush.

5. Remove burners as described in section “BURNERS” section.

6. Clean tubes with a wire brush.

7. Reassemble unit. The combustion air and flue box gaskets should

also be replaced during reassembly.