Page 1

Installer: Leave this manual with the appliance. Consumer: Retain this manual for future reference.

Model #

Operating instructiOns

HS

25NG

and Owner’s Manual

read instructiOns careFullY: Read and follow all instructions. Place instructions in a safe

place for future reference. Do not allow anyone who has not read these instructions to assemble,

light, adjust or operate the heater.

GAS FIRED INFRA-RED WORKSHOP HEATER

HS22LP

LANGUAGES

ENGLISH

Pages E1 — E16

SPANISH

Pages S1 — S16

FRENCH

Pages F1 — F16

WARNING: If the information in this manual is not followed exactly, a re or explosion may result causing

property damage, personal injury, or loss of life.

- Do not store or use gasoline or other ammable vapors and liquids in the vicinity of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS

Shut off gas supply

•

• Do not try to light any appliance

Do not touch an electrical switch; do not use any phone in your building.

•

Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

•

If you cannot reach your gas supplier, call the re department.

•

- Installation and service must be performed by a qualied installer, service agency, or the gas supplier.

WARNING: This is an unvented gas-red heater. It uses air (oxygen) from the room in which it is installed.

Provisions for adequate combustion and ventilation air must be provided. Refer to Fresh Air for Combustion

and Ventilation section on page 6 of this manual.

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause property damage,

injury or death. Read the installation, operation, and maintenance instructions thoroughly before installing or

servicing this equipment. For assistance or additional information consult a qualied installer, service agency,

or gas supplier.

5 18672

Heatstar, INC., 4560 W. 160TH ST., CLEVELAND, OHIO 4

E1

4135 · 800-2

Installation ins

51-0001

tructions and Owner’s Manual

04/1

Page 2

WARNINGS

WARNING: Improper installation, adjustment,

alteration, service or maintenance can cause

property damage, injury or death. Read the

installation, operation, and maintenance instructions thoroughly before installing or servicing this

equipment. For assistance or additional information consult a qualied installer, service agency,

or gas supplier.

WARNING: When used without fresh air, heater

may give off CARBON MONOXIDE, an odorless

poisonous gas. OPEN WINDOW AN INCH OR

TWO FOR FRESH AIR WHEN USING HEATER.

WARNING: This heater is equipped with a PILOT

LIGHT SAFETY SYSTEM. DO NOT TAMPER

WITH PILOT LIGHT SAFETY SYSTEM.

DANGER: Carbon monoxide poisoning may lead to

death.

Carbon Monoxide Poisoning:

Early signs of carbon monoxide poisoning resemble the

u, with headaches, dizziness, or nausea. If you have

these signs, the heater may not be working properly.

Get fresh air at once! Have heater serviced. Some

people are more affected by carbon monoxide than others. These include pregnant women, persons with heart

or lung disease or anemia, those under the inuence of

alcohol, and those at high altitudes.

CAUTION

• Never connect gas valve or thermostat to line voltage or a transformer.

• If the infra-red color of the grid becomes dull when

the building furnace is operating, consult gas supplier on correct gas supply piping sizes.

• This heater is for indoor installation only!

WARNING: If heater shuts off, do not relight until

you provide fresh air. If heater keeps shutting off,

have it serviced. Keep burner and control clean.

Open door for 5 minutes.

Maintain clearances as shown in Figure 2 or on

heater nameplate.

• DO NOT USE MATCH OR OTHER FLAME

FOR LEAK TESTING.

• DO NOT EXCEED 1/2 PSI INLET PRESSURE TO HEATER.

TABLE OF CONTENTS

Chapter Title Page

I Introduction ............................................. E3

II Heater Installation .................................. E5

III Heater Operating Instructions ................ E10

IV Operator Maintenance Instructions ........ E12

V Replacement Parts List .......................... E15

NOTE

Gasket binder material used in this heater assembly will

temporarily emit an odor and/or vapor. This condition

will clear up in approximately 20 minutes and thereafter

will not reoccur. Refer to Chapter 2 for ventilation.

warning:

The State of California requires the following

warning:

COMBUSTION BY-PRODUCTS PRODUCED WHEN USING THIS PRODUCT CONTAIN CARBON MONOXIDE,

A CHEMICAL KNOWN TO THE STATE OF CALIFORNIA

TO CAUSE CANCER AND BIRTH DEFECTS (OR OTHER

REPRODUCTIVE HARM).

THIS PRODUCT CONTAINS CHEMICALS KNOWN TO

THE STATE OF CALIFORNIA TO CAUSE CANCER AND

BIRTH DEFECTS OR OTHER REPRODUCTIVE HARM.

CANADA ONLY:

Per CAN/CGA-B149.1.2 gas code, this heater can not

be installed in residential garages in Canada

E2

Installation instructions and Owner’s Manual

Page 3

CHAPTER I

INTRODUCTION

1. EQUIPMENT

This heater is the consumer version of our highly successful, thoroughly tested, gas red, infrared, industrial

utility heater.

This heater does not require an external electrical

source for operation.

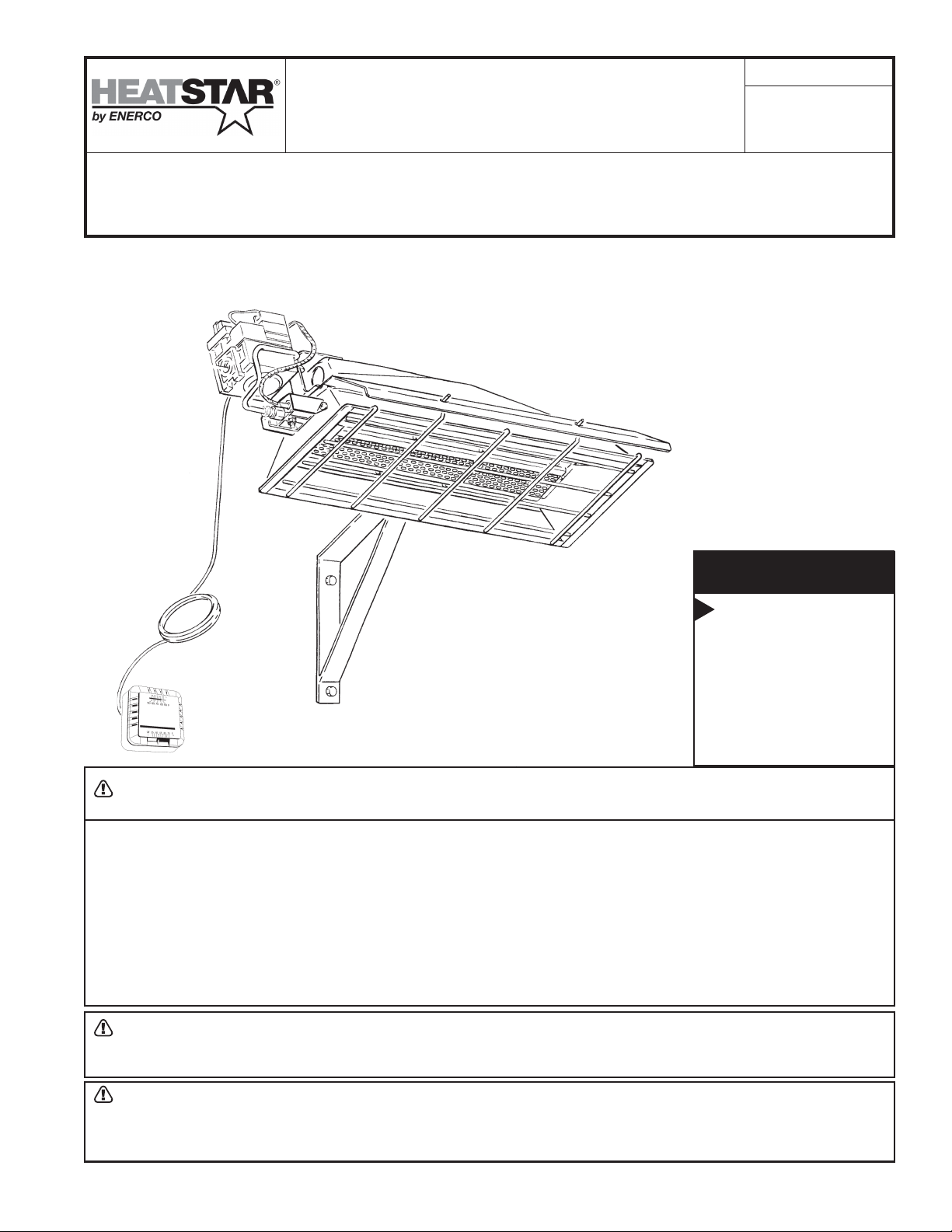

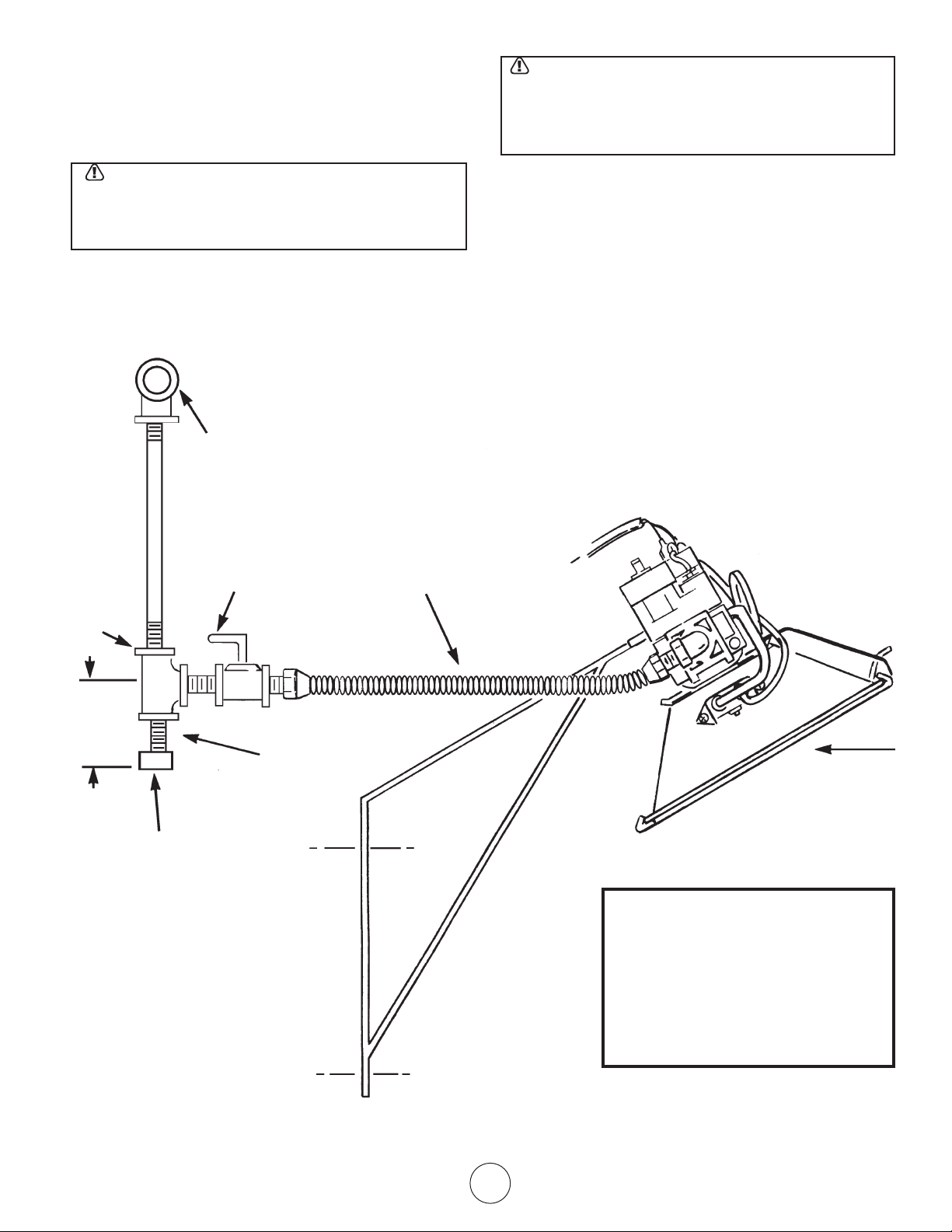

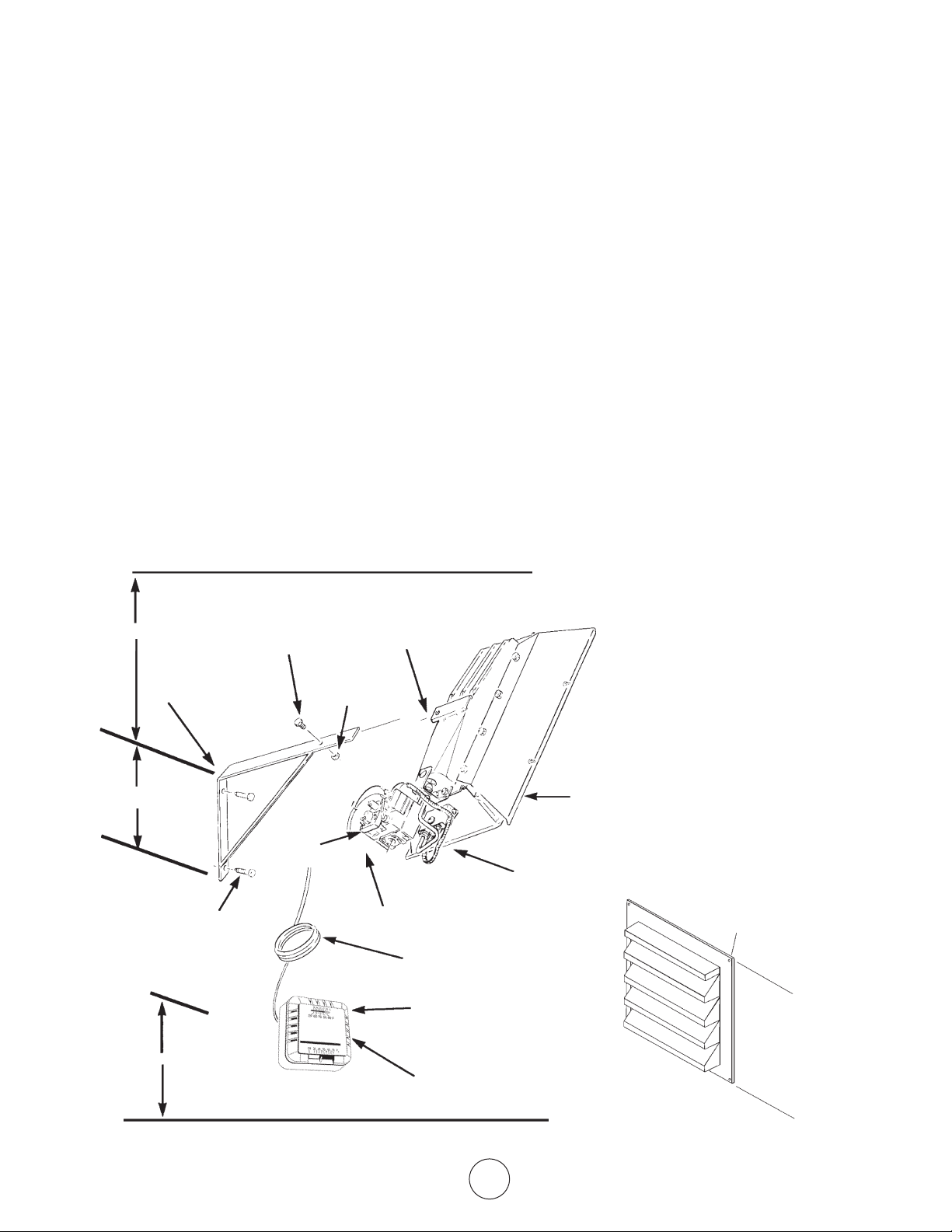

The major components of the heater and a typical

installation are identied in Figure 1. The basic heater

GAS CONTROL

VALVE

POWERPILE

GENERATOR

consists of the complete burner assembly, ue deector, grid, reector assembly and face guard.

2. PURPOSE OF EQUIPMENT

WARNINGS

This heater is for indoor installation only.

This heater is designed to heat indoor areas. Do not

use for inhabited or small, enclosed areas.

EXHAUST

VENT

THERMOSTAT

CABLE

THERMOSTAT

BASIC HEATER

WALL MOUNTING

BRACKET

Figure 1. Heater Major Components

Installation instructions and Owner’s Manual

E3

Page 4

3. GENERAL INFORMATION

• Your heater comes fully assembled and is tested

at the factory with the appropriate type of gas

and at the input pressures stated on the nameplate.

• Upon receipt and prior to attempting installation,

be sure to inspect the heater and its packaging

for damage and/or missing components. If damage is found or missing components are suspected, contact your dealer. See Chapter 5 for a

complete listing of items required for the safe and

efcient installation and use of this heater.

• Never attempt to operate the heater using a

fuel other than that specically identied on the

nameplate.

• The installation of the heater must conform with

all local building codes or, in absence of governing local codes, with the National Fuel Gas

Code, ANSI Z223.1 (NFPA 54). This code can

be obtained from either the: Canadian Standards

Association, 8501 East Pleasant Valley Road,

Cleveland, OH 44131; or, NFPA, Battery March

Park, Quincy, MA 02269.

• Canadian installations must comply with CAN/

CGA-B149.1.2 gas code which can be purchased

from Canadian Gas Association, 55 Scarsdale

Road, Don Mills, Ontario M3B 2R3.

• Contact factory when appliance is to be installed

at high altitudes. Factory can supply high altitude

conversion kit with instructions and data plate.

• A plugged 1/8” N.P.T. Test Gage Connection is

provided on the heater gas control.

• See Tables 1 and 2 for heater specications:

WARNING: Improper installation, adjustment, al-

teration, service or maintenance can cause property

damage, injury or death. Read the installation, operation, and maintenance instructions thoroughly before

installing or servicing this equipment. For assistance

or additional information consult a qualied installer,

service agency, or gas supplier.

• For additional information contact Mr. Heater Toll-

Free 800-251-0001—www.mrheater.com

The following extra NFPA Manuals are helpful when

installing this heater in a location not anticipated in this

manual:

Number Related Subject

NFPA 88 Clearances to Combustible Surfaces

NFPA 409 Clearances to Combustible Surfaces

DO NOT EXCEED 1/2 PSI INLET PRESSURE TO HEATER

Provide adequate clearance to combustibles per Table 3

at control end of heater for servicing and minimum on top

and sides for ventilation and combustion air supply.

A minimum clearance of 8’ above oor for public garages

in accordance with NFPA No. 88 most recent edition, or

Figure 1; whichever is larger.

Canadian installations in public garages must comply with

CGA 149B.1.9 most recent edition.

WARNING: Maintain clearances as shown in Figure 2

or on heater nameplate.

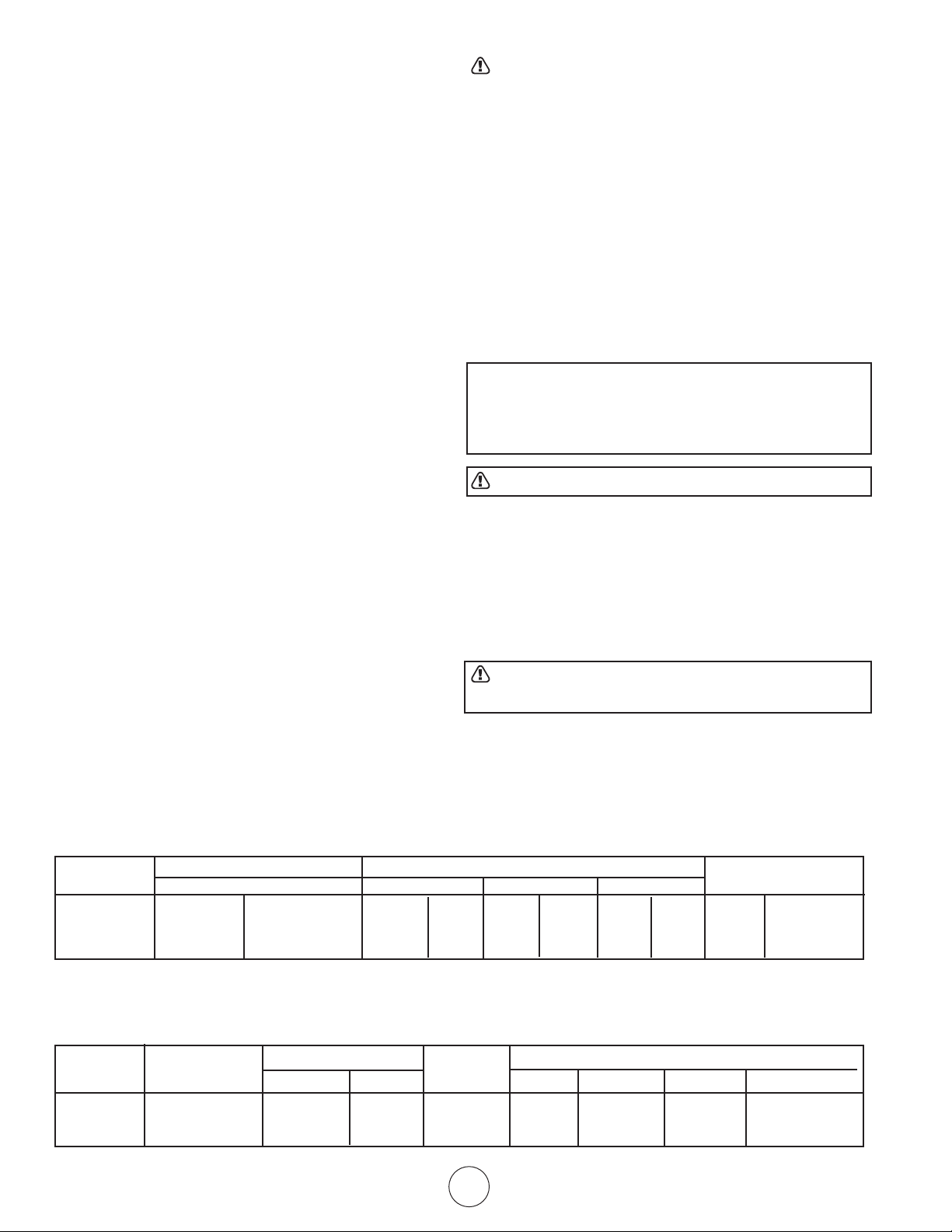

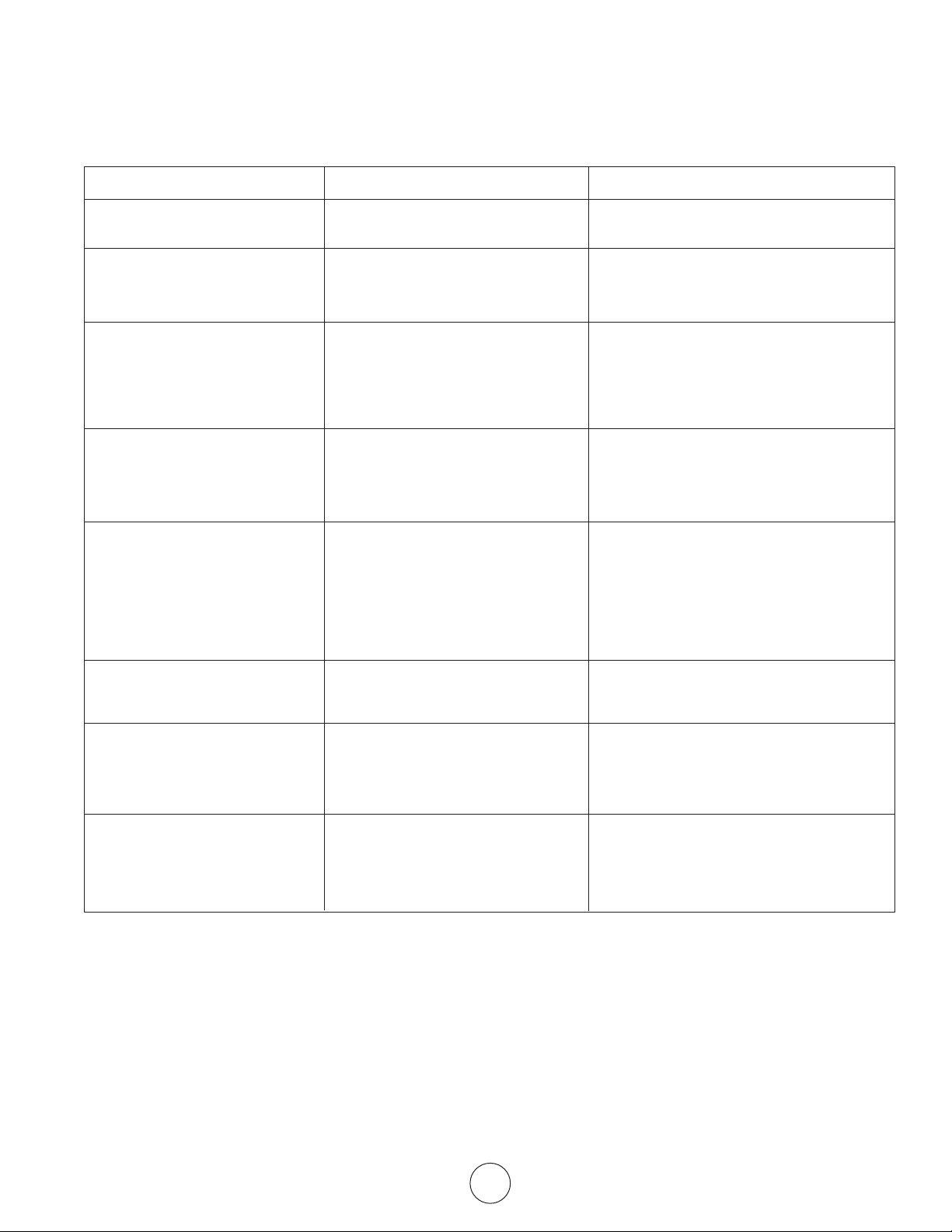

Table 1. BTU Ratings and Supply Pressures

MODEL BTU/HR. RATING GAS SUPPLY PRESSURE (W.C.) ORIFICE

NO. GAS MIN. MAX. MANIFOLD SIZE

NATURAL PROPANE NAT. L.P. NAT. L.P. NAT. L.P. NAT. L.P.

MH25NG 25,000 — 7.0” — 14” — 6” — 45 —

MH25LP — 22,000 — 11” — 14” — 10” — 55

Table 2. Heater Dimensions and Orice Sizes

MODEL OPERATING ORIFICE SIZE INPUT SIZE

NO. PRESSURE BURNER PILOT BTU/H WIDTH LENGTH HEIGHT WEIGHT

MH25NG 6.0”w.c. 45 .018 25.000 12-1/4” 29-3/4” 7” 20 lb.

MH25LP 10”w.c. 55 .011 22,000 12-1/4” 29-3/4” 7” 20 lb.

E4

Installation instructions and Owner’s Manual

Page 5

CHAPTER II

HEATER INSTALLATION

1. GENERAL INSTALLATION INFORMATION

AND REQUIREMENTS

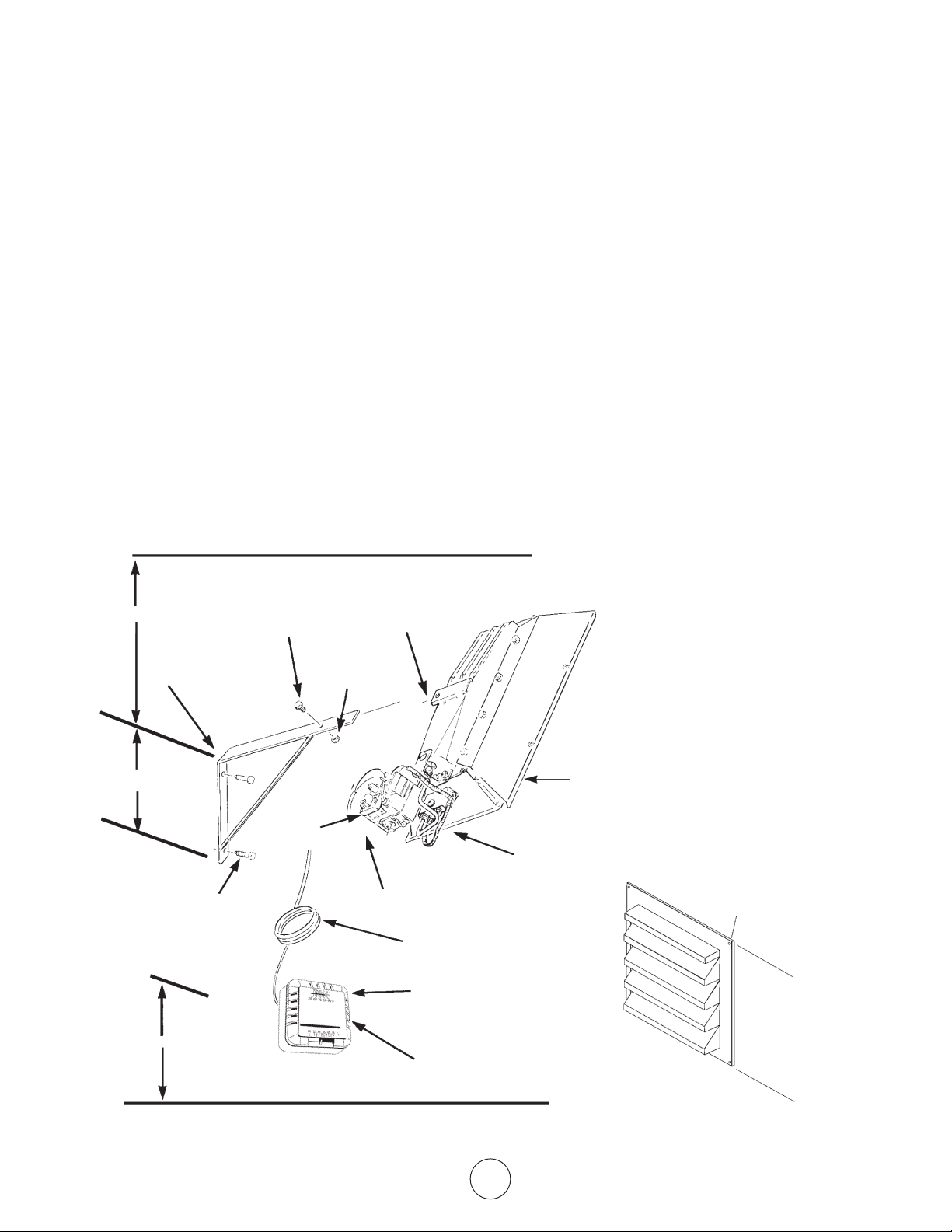

CLEARANCES

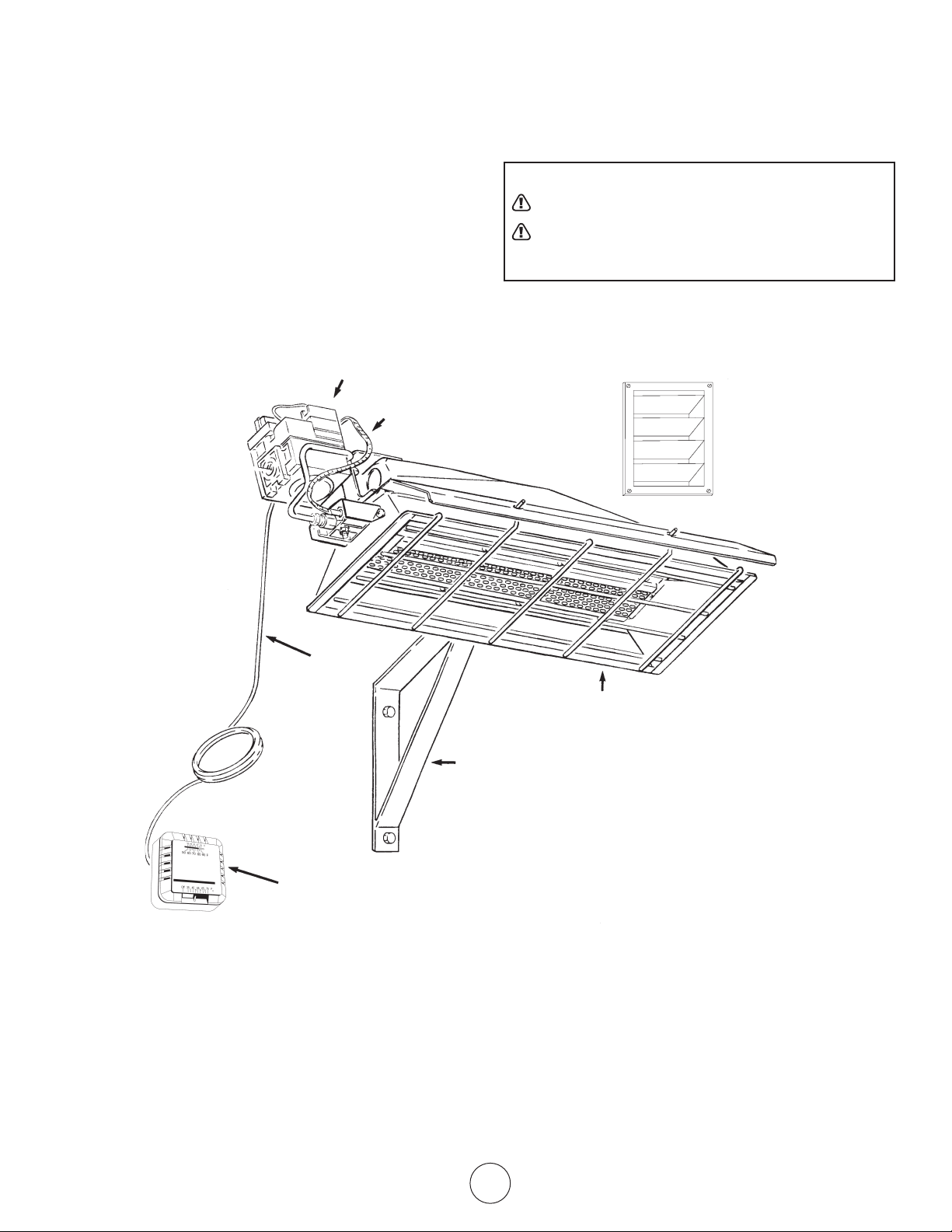

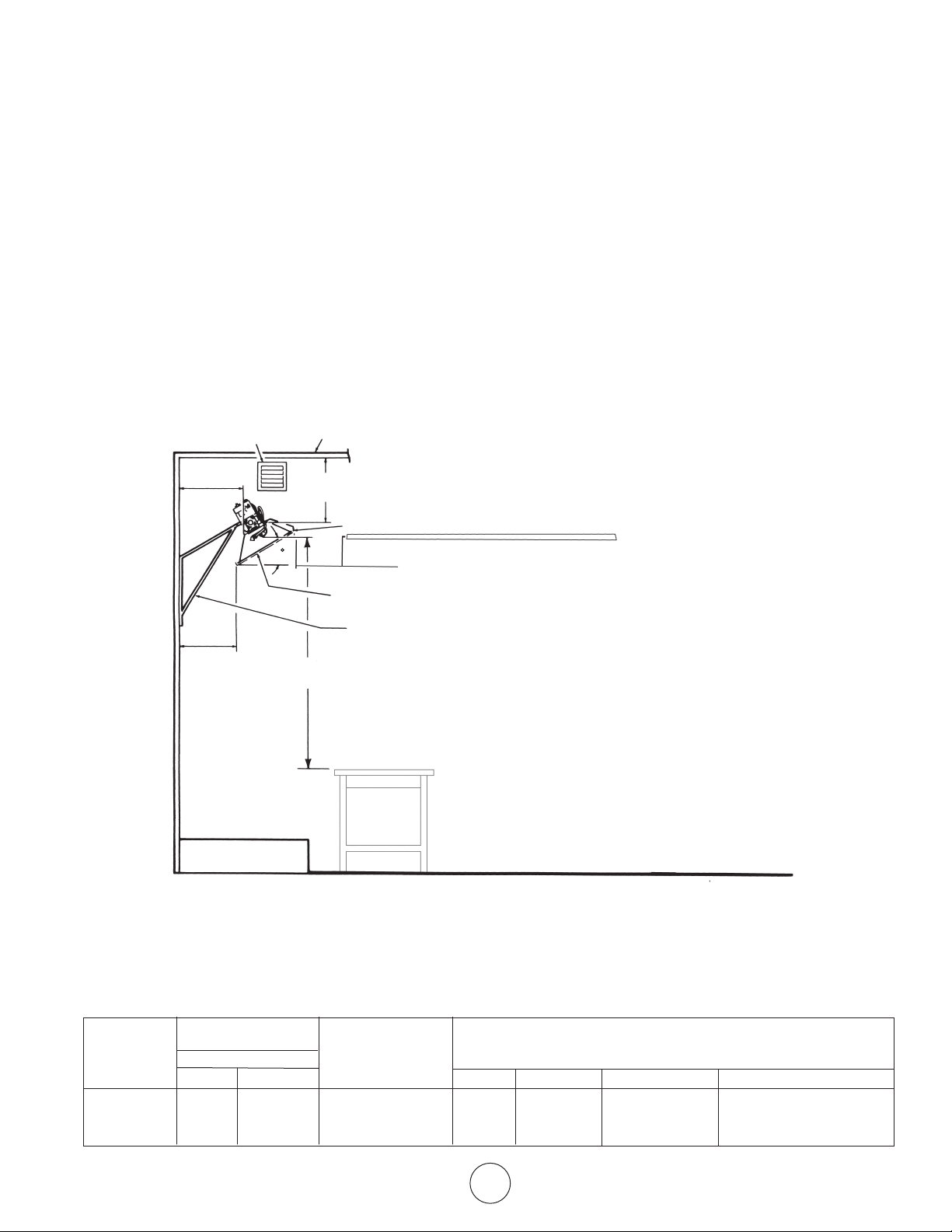

• The required minimum clearances to combustible

surfaces are illustrated in Figure 2 and Table 3.

As shown on Figure 2, the front of the heater is

installed at the minimum required clearance to

combustible surfaces and toward open space,

and then the other sides must have a minimum

clearance of 16 inches to combustible surfaces.

16”

MINIMUM

14-1/2”

EXHAUST

VENT

30

MINIMUM

CEILING

14”

MINIMUM

48”

OPEN

WORKSHOP DOOR

16”

MINIMUM

HEATER

WALL BRACKET

The clearances to combustibles represent a surface

temperature of 90°F (32°C) above room temperature.

Building materials with low heat tolerance may be

subject to degradation at lower temperatures. It is the

installer’s responsibility.

NOTE:

1. ONLY FLUE SIDE OF HEATER CAN

BE ELEVATED (30o).

2. HEATER SIDE REFLECTOR MUST

BE HORIZONTAL.

FLOOR LINE

Figure 2. Installation Clearances to Combustible Surfaces

Table 3. Installation, Ventilation and Mounting Information

BTU/HR. RATING NORMAL

MODEL GAS MOUNTING CLEARANCES TO COMBUSTIBLE SURFACES

NO. NAT. L.P. POSITION TOP SIDES BACK BELOW

MH25NG 25,000 — 30o 14” 16” 16” 48”

MH25LP — 22,000 30o 14” 16” 16” 48”

Installation instructions and Owner’s Manual

E5

Page 6

• This heater may be mounted on any wall;

however, it is recommended that the heater be

mounted in the middle of the wall opposite any

overhead doors.

• When selecting installation locations for this

heater ensure that the opening of any exterior

or interior doors or windows will not violate

minimum clearances or contact any heater

components.

• If an overhead door is installed in the build-

ing, verify that the heater is not installed in

such a way as to interfere with door operation

and verify that the door in its open position

will not reduce clearances below the minimum

requirements. Never mount the heater in such

a way that would position the heater above an

opened overhead door.

HEATER VENTILATION

Unrestricted air ow during heater operation is essential to prevent the area above the installed heater from

overheating. In most cases the infiltration around your

uninsulated entry doors and windows will provide

enough air flow for efficient heater operation. If your

workshop/utility building is tightly insulated (including

windows, doors, openings, etc.) the following

ventilating methods must be followed:

• A single exhaust vent is supplied with your

heater for your convenience. This vent must

be located above the heater (preferably at the

highest point in the building interior) and it must

vent to the exterior of the building. An additional vent is available from the factory for those

having a nished workshop or utility building.

• An intake vent, or equivalent, from the exterior

of the building and having an effective area of

75 square inches must be located below the

heater (preferably within 2 feet of the building’s

oor).

• Openings equivalent to intake vent would be:

partially open doors and partially open windows.

• Openings of this size (5 inch by 13 inch, or 3

inch by 25 inch) will prevent dangerous heat

buildup above the heater.

Ensure that no gas lines or electrical wiring or conduits

will interfere with mounting of the heater to the wall.

Depending on local codes and requirements and the

installer’s skill level, the sizing and installation of gas

lines required to supply the heater may require the

assistance of a professional. If in doubt as to these

requirements, discuss the requirements of this manual

with the dealer from whom the heater was purchased

and your gas supplier, or call our customer service

department at 1-800-251-0001.

The selection of the thermostat mounting location is

critical to efcient and effective heater operation.

• The thermostat should be mounted about 5 feet

above the oor where air can circulate freely

around it.

• The thermostat should not be mounted directly

to a cold exterior wall without an insulated

mounting block.

• The thermostat should not be mounted in direct

drafts.

• The thermostat should not be mounted directly

below the installed the heater.

• The thermostat should not be installed at a

distance that is farther from the heater than the

length of the thermostat cable.

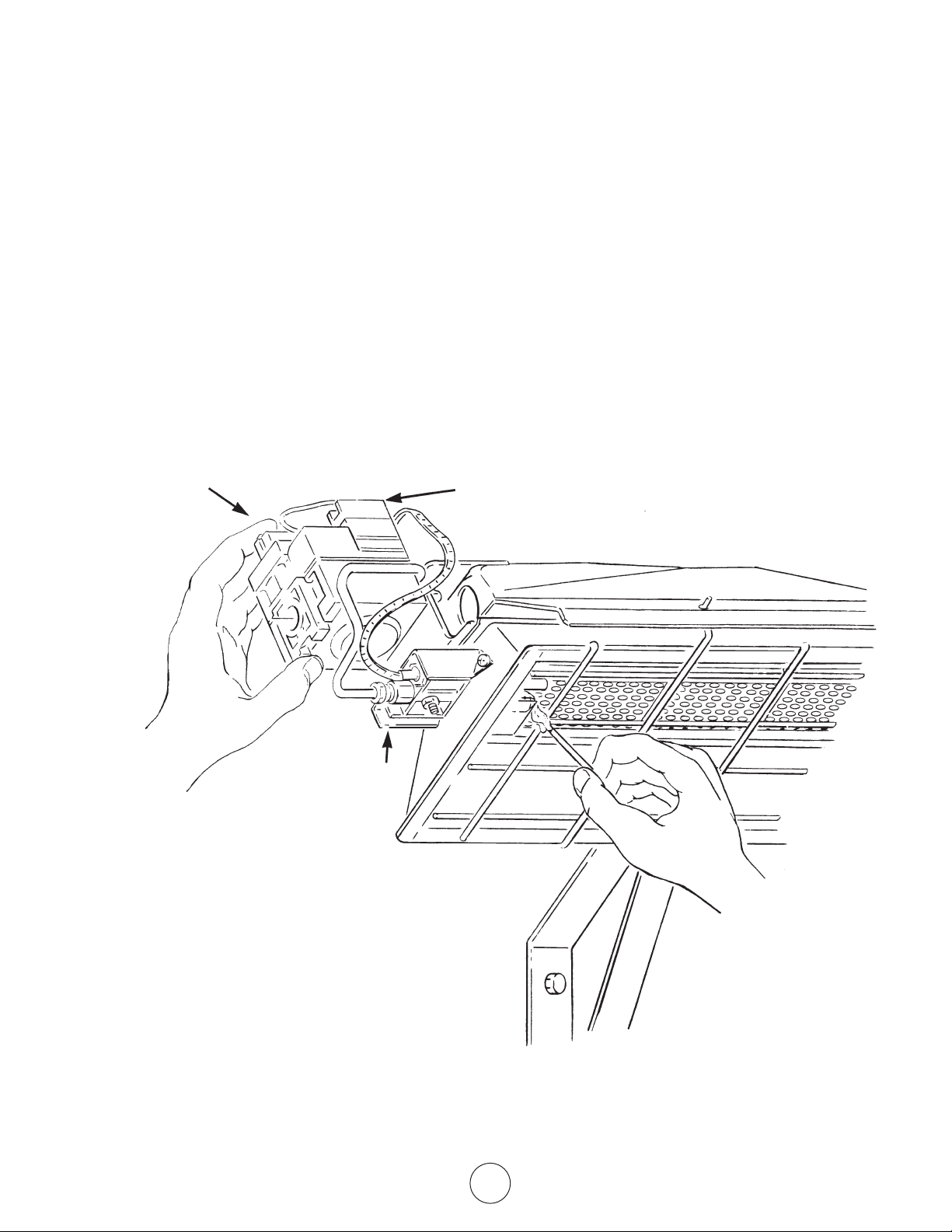

2. HEATER MOUNTING INSTRUCTIONS

After selecting the heater installation location and the

thermostat location and after verifying and ensuring that

all of the above placement requirements are fullled,

mount the heater as follows:

A. Determine how you wish to install the vent based

on the construction of the building and your

personal preference. (i.e., do you wish the anged

(nished) side on the interior or the exterior of the

building or do you want two vents so that both

exterior and interior will be nished?) If needed,

order an additional vent from the factory. Our

address and toll free phone number are on the rear

cover of this manual. Install the vent as follows:

1. See Figure 3 for dimensions and information on

the vent.

2. Select a place as high above the heater as

possible in accordance with the above requirements and ensure that the vent or vents will

not contact or interfere with existing building

systems (i.e., ducts, wiring, plumbing, etc.)

3. Place the unnished side of the vent against

the wall in its elected location and trace its

dimensions on the wall with a pencil or other

suitable marker.

4. Cut or otherwise open a hole in the wall, or

walls for nished buildings, having the dimensions of the unnished side of the vent.

5. Install the vent or vents as desired and retain

E6

Installation instructions and Owner’s Manual

Page 7

with 4 suitable fasteners through the predrilled

holes in vent ange.

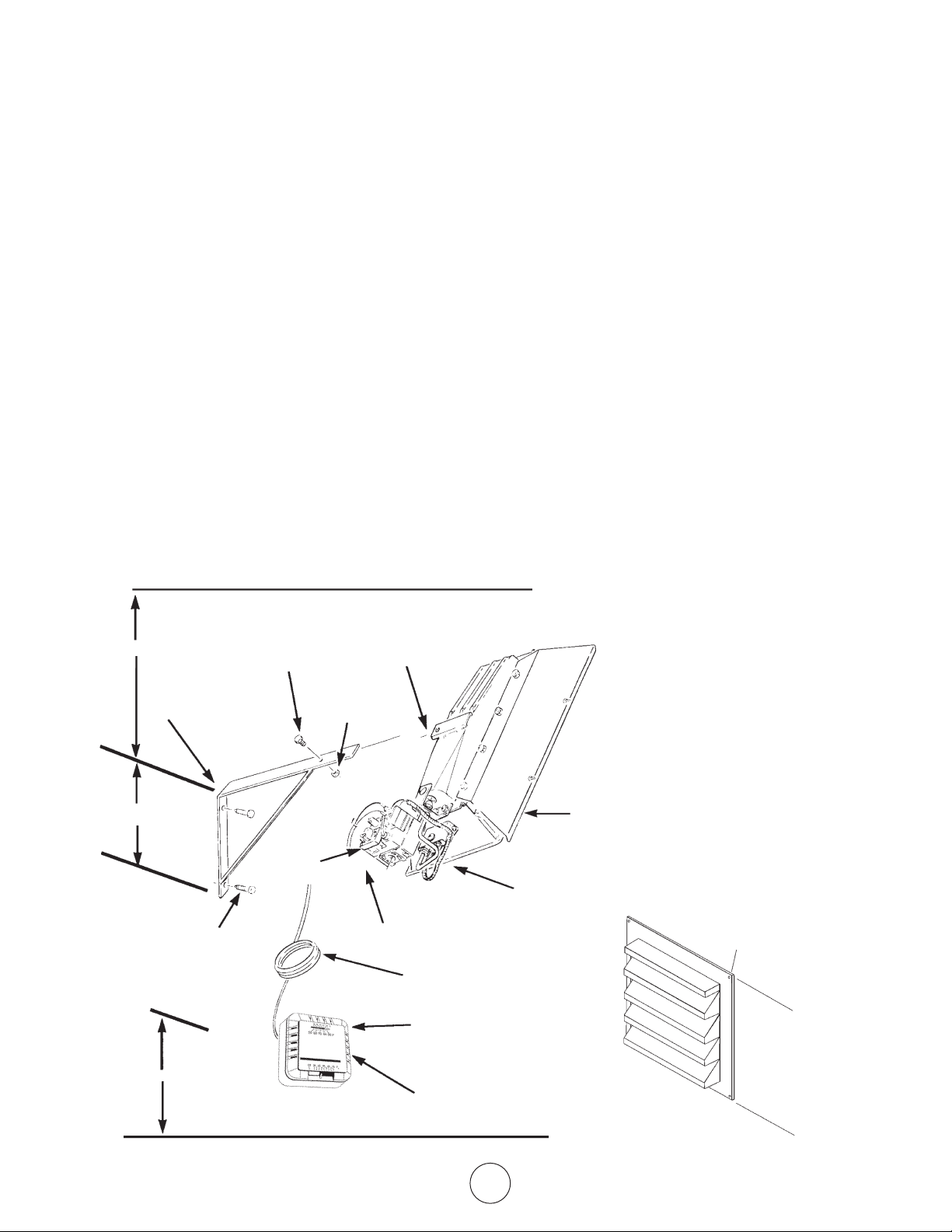

B. Prepare to install the heater wall mounting bracket

as follows:

1. If the wall mounting bracket is to be attached to

a stud and wallboard wall, refer to Figure 3 for

dimensions, locate a stud, and drill two 1/8” pilot holes into the stud centerline. Use template

for simplied installation.

2. If the wall mounting bracket is to be attached

to a brick or masonry wall, refer to Figure 3 for

dimensions. Obtain two 1/4 inch (inside diameter) expansion anchors and determine the

correct drill size to be used with them. Drill the

appropriate size holes in the brick or masonry

to accept the anchors.

C. Place the wall mounting bracket on the wall and

align the two through holes on the bracket with

the pilot holes or anchors. Install 1/4 inch by 2-1/2

inch lag screws through the bracket into the stud or

anchors. Tighten securely.

D. Locate heater mounting clip on back of heater and

select the 1/4” – 20 by 3/4” hex head bolt and 1/4” 20 hex nut.

E. Position the heater as shown in Figure 3 and slide

the heater mounting clip over the bracket and install

the bolt through the clip and bracket.

F. Thread the hex nut onto the bolt and tighten

securely.

G. Ensure that the selected thermostat location

meets all of the above requirements. Refer to

the instructions that come with the thermostat for

additional grounding information and mounting

instruction.

H. If the wall is of stud and wallboard construction,

then use the #6 by 1 inch sheet metal screws,

included with the thermostat, and mount the

thermostat in the selected location.

I. If wall is brick or masonry, the appropriate anchors

must be obtained to accommodate thermostat

mounting screws. Use the back plate of the

thermostat as a template to mark the hole locations,

drill appropriate size anchor holes, install the

anchors, securely attach the thermostat using the

mounting screws.

J. Connect thermostat wires to gas valve as shown in

Figure 4.

24” MIN

HEATER WALL

MOUNTING

BRACKET

9”

1/4” X 2-1/2” LONG

LAG SCREWS

(2 REQUIRED)

Figure 3. Heater Mounting Information

CEILING

HEATER

1/4”-20x3/4” HEX-

HEAD BOLT

GAS

CONTROL

VALVE

MOUNTING

CLIP

1/4”-20

HEX NUT

FLUE DEFLECTOR

HEATER REFLECTOR

1/2” NPT GAS INLET

(DO NOT EXCEED 1/2 PSI)

THERMOSTAT CABLE

(SEE FIGURE 4)

58”

FLOOR

#6 X 1” SHEET METAL SCREWS

(2 REQUIRED - INCLUDED WITH

THERMOSTAT)

UNFINISHED

SIDE

THERMOSTAT (SEE INSTRUCTIONS

INCLUDED WITH THERMOSTAT

Installation instructions and Owner’s Manual

E7

FINISHED

SIDE

FLANGE

PREDRILLED

HOLES

Page 8

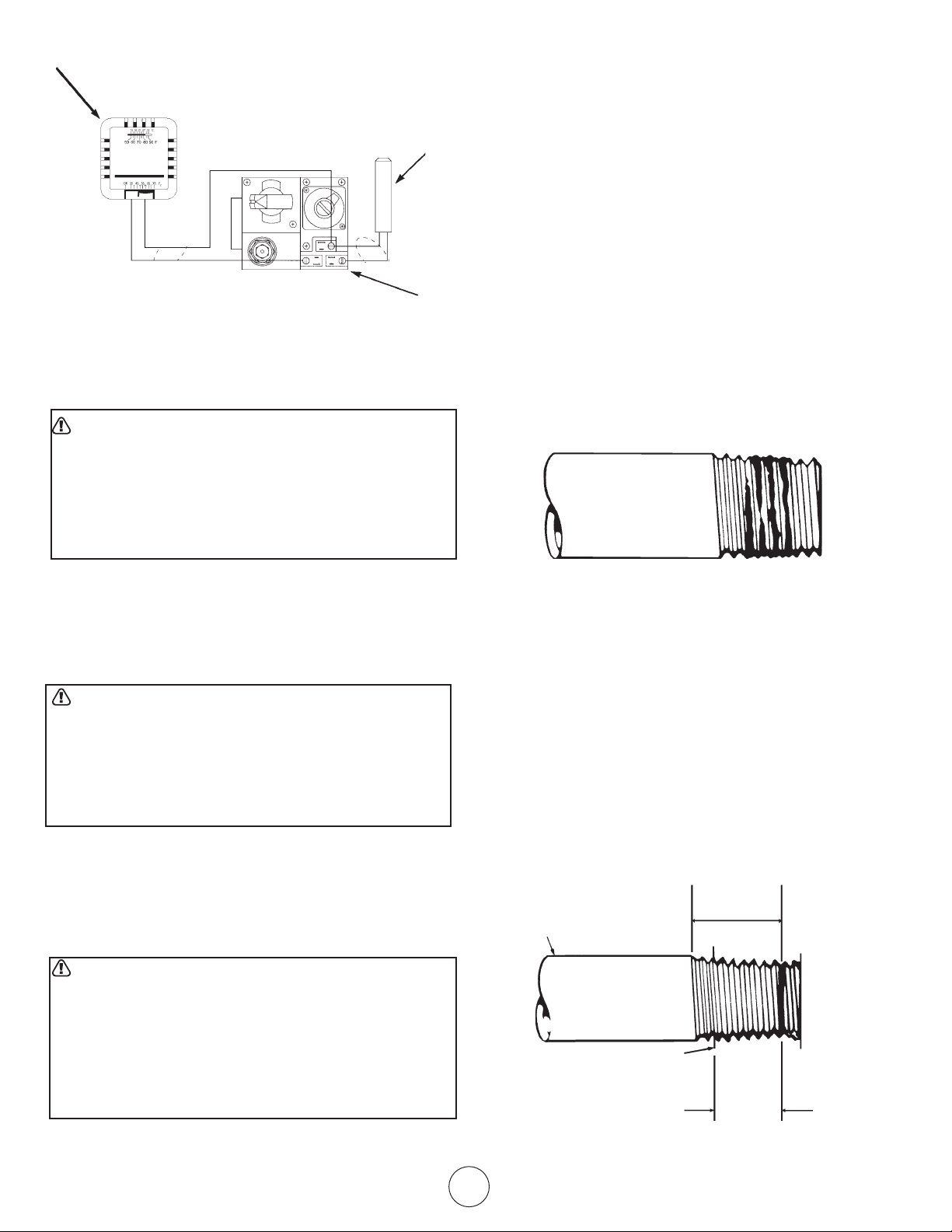

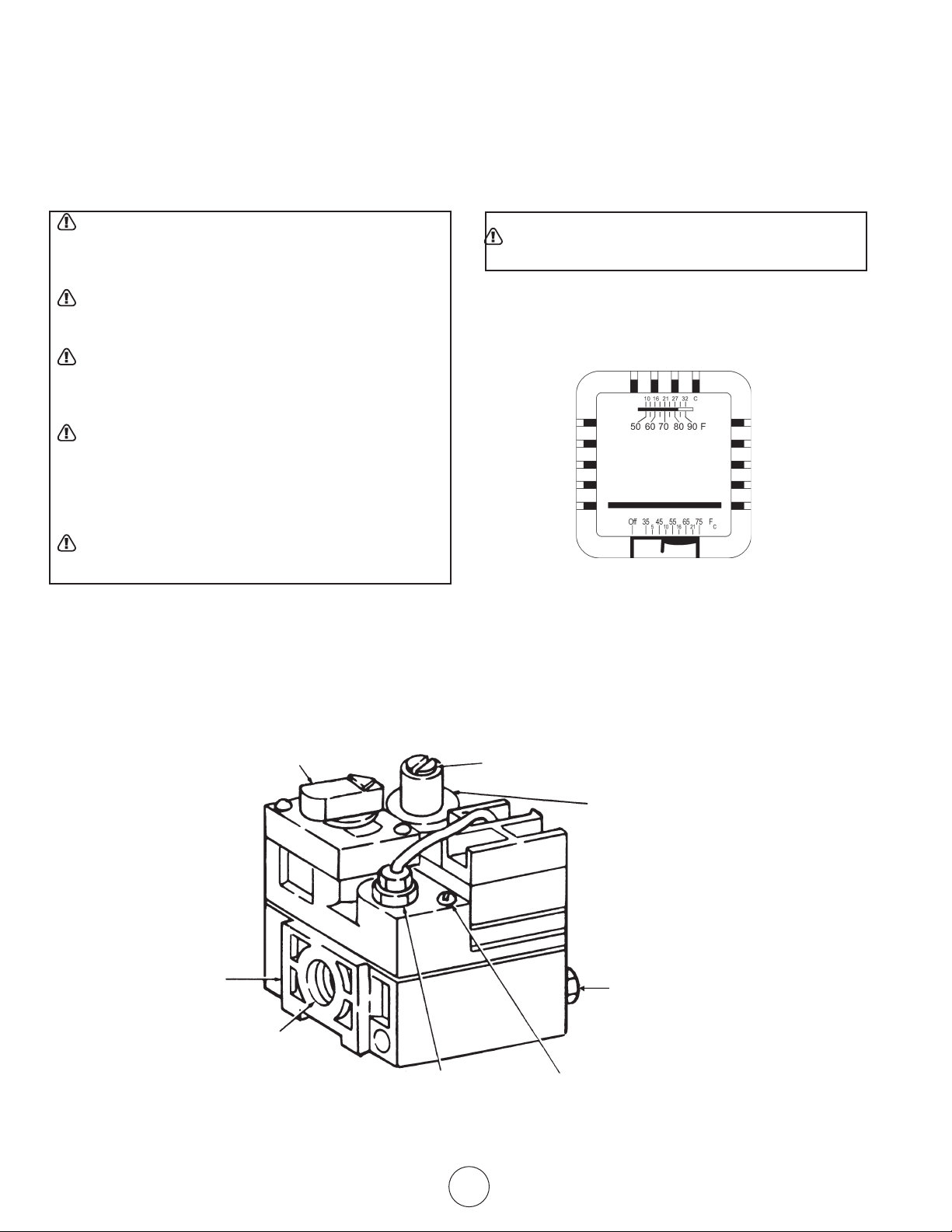

THERMOSTAT

POWERPILE GAS VALVE

POWERPILE GENERATOR

Figure 4. Connection Diagram

Refer to National Electrical Code NFPA70-1993 and

for Canadian installations to current CODE C22.1-

3. CONNECTING HEATER TO GAS SUPPLY

heater, make sure the supply manifold pressure is at least 1/2 psi (14 in W.P.).

3.2 Piping Requirements

All piping installed must comply with local codes and

ordinances or with National Fuel Gas Code,

ANSI Z223.1 (NFPA 54), whichever takes precedence.

When installing piping, the following requirements

must be taken into consideration: Canadian installations must comply with the B149.1.2 Gas Code.

• Use new properly reamed black pipe free from

chips.

• Apply a good quality pipe compound to all

male threads as shown in Figure 5 prior to assembly. If LP gas is the fuel, ensure that pipe

compound is resistant to LP gas. Do not use

Teon™ tape.

WARNING: Depending on local codes and require-

ments and the installer’s skill level, the sizing and

installation of gas lines required to safely and efciently

supply the heater may require the assistance of a professional. If in doubt as to these requirements, discuss

the requirements of this manual with the dealer from

whom the heater was purchased and your gas supplier.

3.1 Gas Supply Requirements

• See Tables 1 and 2 for gas supply minimum, maxi-

mum, operating, and manifold pressures for both

heater models. Pressures are provided in inches of

W.C. (water column). Also, see heater rating plates

located on the heater.

WARNING: Model MH25NG is designed to burn

natural gas and it comes equipped with a regulator.

The regulator is built into the gas valve. The maximum

inlet pressure to this regulator is 1/2 psi (14 in. W.C.) If

gas line pressure exceeds 1/2 psi, then an additional

regulator must be installed before the heater/regulator

to step down the pressure to a maximum of 1/2 psi.

• Most non-commercial natural gas services provide

a line pressure of 4 oz. (6.9 in. W.C.). If in doubt

consult your natural gas supplier.

• To ensure the best performance from your natural

gas heater make sure the supply manifold pressure is at least 6” W.C.

USE MODERATE AMOUNT OF PIPE DOPE

LEAVE 2 THREADS BARE

Figure 5. Pipe Compound Application

• Male threads on pipe to be installed into gas

valve shall meet the requirements of Figure 6.

Threads longer than those shown in the gure

may cause gas valve distortion and malfunction.

• A sediment trap meeting the typical require-

ments of Figure 7 shall be installed in the line

to the gas valve.

• A dedicated shutoff valve for the heater must

be installed in the gas supply line.

3.3 Piping Installation

While ensuring that all of the above gas supply re-

3/4” MAXIMUM

THREAD LENGTH

1/2” BLACK PIPE

WARNING: Model MH25LP is designed to burn

liqueed petroleum (LP) gas and it comes equipped

with a regulator. The regulator is built into the gas

valve. The maximum inlet pressure to this regulator

is 1/2 psi (14 in. W.C.). If gas line pressure exceeds

1/2 psi, then an additional regulator must be installed

before the heater/regulator to step down the pressure

to a maximum of 1/2 psi.

• To ensure the best performance from your LP gas

GAS VALVE BODY

1/2” MAXIMUM

DEPTH OF IN-

SERTS INTO GAS

VALVE

Figure 6. Gas Valve Connection Requirements

E8

Installation instructions and Owner’s Manual

Page 9

quirements and piping requirements are fullled, install

piping as follows:

A. In accordance with the above piping requirements,

assemble piping, sediment trap, shutoff valve, and

necessary ttings. Tighten all components securely.

WARNING: Failure to ensure that male threads on

pipe to be installed into gas valve meet the requirements of Figure 6 may cause gas valve damage,

distortion and malfunction.

B. Install a threaded nipple, prepared in accordance

with paragraph 3.2 into gas valve.

C. Connect gas piping to nipple installed in the gas

valve.

SUPPLY

LINE

WARNING: When testing gas piping use only a

soap and water solution. Do not use a match or

other ame for leak testing. If during leakage check

gas is smelled, turn off the gas supply and ventilate

building.

D. Ensure the building is properly ventilated. Without

lighting the pilot light of the heater, open the gas

supply valve and pressurize the piping up to the

heater’s gas valve.

E. Using a brush, apply a soap and water solution to

all connections and look for bubbles indicating a

leak. If a leak is detected, turn off gas supply and

tighten connections. Retest and tighten connections

1/2”

TEE

3”

CAP

SHUTOFF

VALVE

NIPPLE

RIGID PIPE WITH

UNION OR A FLEXIBLE CONNECTOR TO HEATER

HEATER

NOTE:

1. ONLY USE A PIPE COMPOUND

WHICH IS RESISTANT TO

LIQUIFIED GASES ON LP

INSTALLATIONS.

2. FITTINGS SHOWN ARE NOT

INCLUDED WITH HEATER.

Figure 7. Typical Piping Installation

Installation instructions and Owner’s Manual

E9

Page 10

CHAPTER III

HEATER OPERATING

INSTRUCTIONS

NOTE

Gasket binder material used in this heater assembly will temporarily emit an odor and/or vapor. This

condition will clear up in approximately 20 minutes

and thereafter will not reoccur. Refer to Chapter 2 for

ventilation.

1. OPERATING SAFETY INSTRUCTIONS

WARNING: When used without fresh air, heater

may give off CARBON MONOXIDE, an odorless

poisonous gas. OPEN WINDOW AN INCH OR

TWO FOR FRESH AIR WHEN USING HEATER.

WARNING: This heater is equipped with a PILOT

LIGHT SAFETY SYSTEM. DO NOT TAMPER

WITH PILOT LIGHT SAFETY SYSTEM.

WARNING: If heater shuts off, do not relight until

you provide fresh air. Open door for 5 minutes. If

heater keeps shutting off, have it serviced. Keep

burner and control clean.

WARNING: CARBON MONOXIDE POISONING

MAY LEAD TO DEATH. Early signs of carbon mon-

oxide poisoning resemble the u with headache,

dizziness and/or nausea. If you have these signs,

heater may not be working properly. Get fresh air at

once! Have heater serviced.

WARNING: DO NOT USE MATCH OR OTHER

FLAME FOR LEAK TESTING.

CAUTION: If the infra-red color of the grid becomes

dull when the building furnace is operating, consult

gas supplier on correct gas supply piping sizes.

CAUTION: This heater is for indoor installation

only!

2. HEATER STARTUP

WARNING: During heater startup ensure that build-

ing is well ventilated.

A. Open the gas supply valve or valves.

B. Set the thermostat to the OFF position.

See Figure 8.

FIGURE 8. THERMOSTAT CONTROLS

C. If the manual gas control knob on the gas valve is

not in the OFF position, partially depress the knob

and rotate to the OFF position. See Figure 9.

MANUAL GAS

CONTROL

KNOB

WRENCH

BOSS

GAS IN-

LET

PRESSURE

REGULATOR

ADJUSTMENT

PILOTSTAT

POWER UNIT

PILOT FLOW ADJUSTING SCREW

(BENEATH COVER SCREW)

Figure 9. Gas Valve Components

STANDARD

PRESSURE

REGULATOR

PILOT GAS OUTLET

(PRESSURE TAPPING

DIRECTLY BENEATH)

E10

Installation instructions and Owner’s Manual

Page 11

D. Wait 5 minutes to allow gas that may have

accumulated in the main burner to escape

(especially important after installation).

E. Turn the manual gas control knob to the PILOT

position.

F. Depress the manual gas control knob. Using a

match, light the pilot light. See Figure 10. Hold

the knob down for approximately 30 seconds to

allow any air in gas lines to pass through pilot and,

once pilot is lit, allow the thermocouple to heat

up enough to activate the safety valve in an open

position.

G. Release manual gas control knob and turn to ON.

H. Reset thermostat to desired temperature.

DEPRESS TO

LIGHT

NOTE

During the initial startup of heater, an odor and, perhaps, some vapor will come from the heater. This is

the gasket binding material emitting this odor and/or

vapor. After approximately 20 minutes, this odor will

disappear and not occur again.

3. HEATER SHUTDOWN

A. Turn thermostat to OFF.

B. Turn manual gas control knob on gas valve to PILOT

position.

C. Partially depress knob and rotate to the OFF

position.

D. Close gas supply valves.

GAS VALVE

PILOT BURNER

Figure 10. Lighting of Pilot Burner

E11

LIGHT PILOT WITH MATCH

AS SHOWN

Installation instructions and Owner’s Manual

Page 12

CHAPTER IV

OPERATOR MAINTENANCE

INSTRUCTIONS

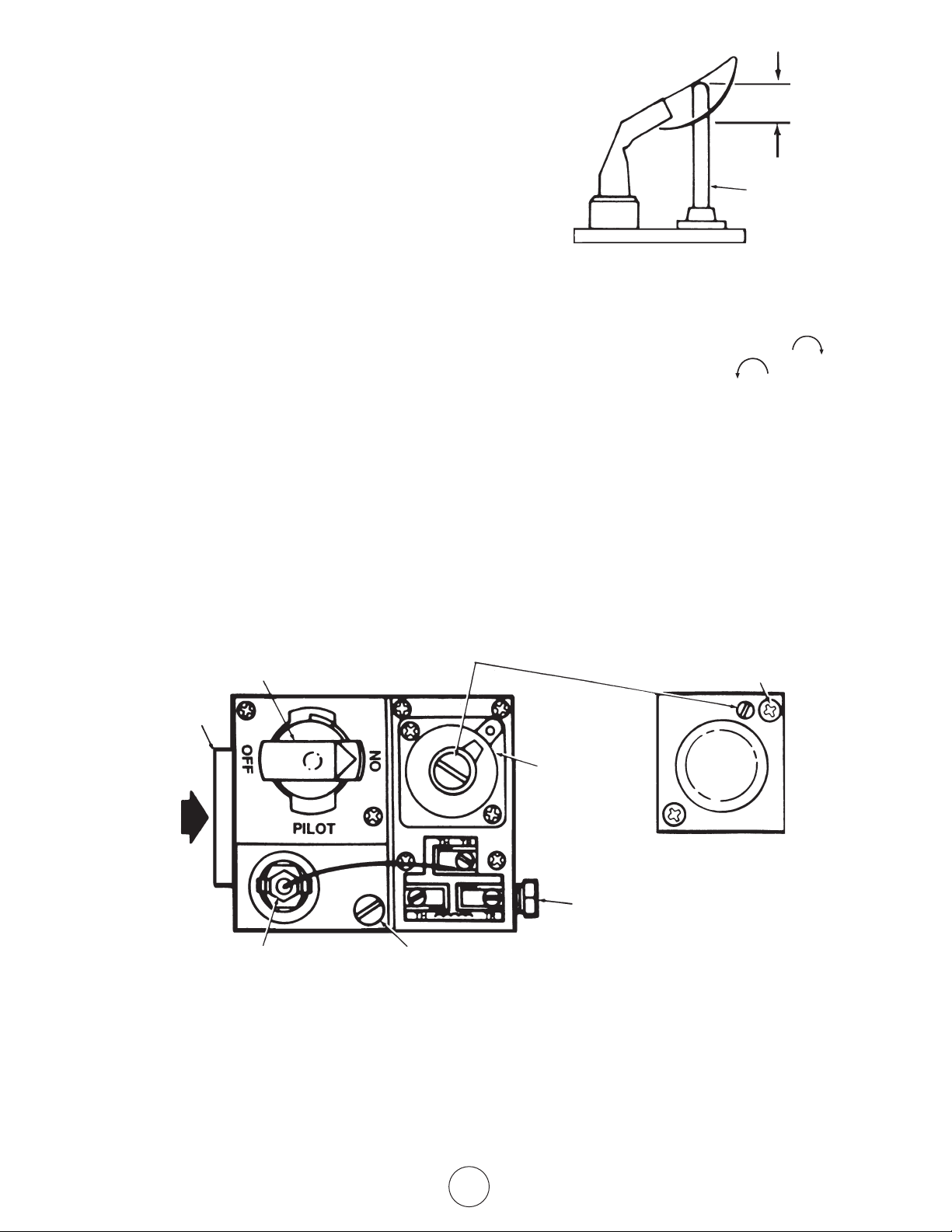

PROPER FLAME

ADJUSTMENT

3/8 TO 1/2 INCH

(10-13 MILLIMETERS)

1. TROUBLESHOOTING

A. Table 4 lists the common malfunctions which you

may nd during the operation or maintenance of your

heater.

B. For additional information, refer to Honeywell Field

Bulletin enclosed in the heater carton.

C. In the event results cannot be obtained after

performing all listed solutions, call the factory.

2. ADJUSTING THE PILOT FLAME

The pilot ame should envelop 3/8 to 1/2 in. (10 to

13 mm) of the tip of the thermocouple or generator.

Refer to Figure 11. To adjust:

PRESSURE REGULATOR ADJUSTMENT

MANUAL GAS

CONTROL KNOB

WRENCH

BOSS

Figure 11. Proper Flame Adjustment

A. Remove pilot adjustment cover screw. Refer to

Figure 12.

B. Turn inner adjustment screw clockwise to

decrease or counterclockwise to increase

pilot ame.

C. Always replace cover screw after adjustment and

tighten rmly to ensure proper operation.

(BENEATH COVER SCREW)

THERMOCOUPLE

INSTALL LONG

SCREW IN

OUTSIDE CORNER

GAS

INLET

PILOTSTAT POW-

ER UNIT

STANDARD

PRESSURE

REGULATOR

(“A” MODEL)

STEP OPENING REGULATOR

(“C” MODEL)

PILOT GAS OUTLET

(PRESSURE TAPPING

DIRECTLY BENEATH)

PILOT FLOW ADJUSTING SCREW

(BENEATH COVER SCREW)

Figure 12. Top View of Standard Capacity Gas Control

E12

Installation instructions and Owner’s Manual

Page 13

Table 4. Trouble Shooting Chart

Below in chart form are various symptoms of a malfunctioning system, possible defects that will cause these symptoms and suggested corrective measures. The chart assumes that the proper gas pressure is available to the heater

and that the lighting procedure is as stated on the plate attached to the heater.

SYMPTOMS CAUSES SOLUTIONS

burner light off very slow partially block pilot orice replace

burner light off very slow infra-red partially blocked burner orice replace

color stays dull

burner ash back low gas pressure call your gas supplier

(roaring noise during operation and ceramic grid surface will be

dark) damaged burner replace

ceramic grid or burner sooting up rst check for damaged burner replace if damaged

(when new or after cleaning) orice

pilot cannot be ignited blocked pilot orice replace

pilot out of adjustment re-adjust pilot

if burner orice is not damaged replace

then check for damaged manifold

gas cock not in position gas cock knob must be

turned to pilot and held

depressed

pilot gas ow adjustment open and adjust

screw may be closed (see Figure 12)

pilot lights but goes out defective thermocouple replace

defective control replace

pilot stays lit but main burner loose wire or improperly wired tighten connections, check

will not light wiring diagram

defective control replace

blocked burner orice clean orice or replace

failure to ignite main gas off open manual valves

3. REPLACING THE GAS VALVE UNIT

A. Remove the two gas valve unit wires at the gas

control valve labeled “PP”.

B. Unscrew gas valve from gas piping.

C. Reconnect gas valve and unit wires to terminals

“PP”. Be sure to leave thermostat wire on one

terminal.

4. FREQUENCY OF OPERATOR CHECKS

air in gas line bleed gas line

loose wire connections tighten wire connections

dirty wire connections clean terminals and secure

terminals

Dusty, wet or corrosive environment. Since these

environments can cause the gas control to deteriorate

more rapidly, the system should be checked more often.

The gas control should be replaced if:

A. It does not perform properly on checkout or trouble

shooting.

B. The gas control knob Is hard to turn or push down,

or it fails to pop back up when released.

Intermittent use. Appliances that are used seasonally

should be checked before shutdown and again before

the next use.

E13

Installation instructions and Owner’s Manual

Page 14

IF SERVICE IS REQUIRED

PLEASE DO NOT RETURN THIS APPLIANCE TO YOUR STORE

For information regarding service, please call our Toll-Free Number:

1-800-251-0001.

Our office hours are 8:00 AM – 5:00 PM, Eastern Time Zone

Monday through Friday

Please include the model number, date of purchase, and description of

problem in all communication.

E14

Installation instructions and Owner’s Manual

Page 15

Model #

Operating instructiOns

and Owner’s Manual

HS25NG

HS22LP

read instructiOns careFullY: Read and follow all instructions. Place instructions in a safe

place for future reference. Do not allow anyone who has not read these instructions to assemble,

light, adjust or operate the heater.

warning:

USE ONLY MANUFACTURER’S REPLACEMENT PARTS. USE OF ANY OTHER PARTS

COULD CAUSE INJURY OR DEATH. REPLACEMENT PARTS ARE ONLY AVAILABLE

DIRECT FROM THE FACTORY AND MUST BE INSTALLED BY A QUALIFIED SERVICE

AGENCY.

FOr inFOrMatiOn regarding serVice Or parts:

Contact your local heating service technician or dealer.

FOr additiOnal inFOrMatiOn:

Please call Toll-Free 800-251-0001—www.mrheater.com

Our office hours are 8:00 AM — 5:00 PM, EST, Monday through Friday.

Please have the model number, serial number and date of purchase ready

.

liMited warrantY

The company warrants this product to be free from imperfections in material or

workmanship, under normal and proper use in accordance with instructions of The Company,

for a period of one year from the date of delivery to the buyer. The Company, at its option,

will repair or replace products returned by the buyer to the factory, transportation prepaid

within said one year period and found by the Company to have imperfections in material or

workmanship.

If a part is damaged or missing, call our Customer Service Department at 800-251-0001.

Address any Warranty Claims to the Customer Service Department, Mr. Heater, 4560 W.

160TH ST., CLEVELAND, OHIO 44135. Include your name, address and telephone number and

include details concerning the claim. Also, supply us with the purchase date and the name

and address of the dealer from whom you purchased our product.

The foregoing is the full extent of the responsibility of the Company. There are no other

warranties, express or implied. Specifically there is no warranty of fitness for a particular

purpose and there is no warranty of merchantability. In no event shall the Company be liable

for delay caused by imperfections, for consequential damages, or for any charges of the

expense of any nature incurred without its written consent. The cost of repair or replacement

shall be the exclusive remedy for any breach of warranty. There is no warranty against

infringement of the like and no implied warranty arising from course of dealing or usage of

trade. This warranty will not apply to any product which has been repaired or altered outside

of the factory in any respect which in our judgment affects its condition or operation.

Some states do not allow the exclusion or limitation of incidental or consequential damages,

so the above limitation or exclusion may not apply to you. This Warranty gives you specific

legal rights, and you may have other rights which vary from state to state.

ANSI Z83.19a-2011/CSA 2.35a-2011

Heatstar, reserves the right to make changes at any time, without notice or

obligation, in colors, specifications, accessories, materials and models.

PRODUCT REGISTRATION: Thank you for your purchase.

Please log in to http://www.egiregistration.com to register your product.

Heatstar

Corporation, 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 800-251-0001

© 2003, Mr. Heater. All rights reserved

E16

Page 16

Instalador: deje este manual junto con el artefacto. Consumidor: conserve este manual para referencia futura.

Modelo N.°

INSTRUCCIONES DE USO

Y MANUAL DEL USUARIO

HS25NG

HS22LP

LEA CUIDADOSAMENTE LAS INSTRUCCIONES: lea y siga todas las instrucciones. Conserve estas

instrucciones en un lugar seguro para futura referencia. No permita que nadie que no haya leído

estas instrucciones arme, encienda, ajuste o use el calentador.

CALENTADOR INFRARROJO A GAS PARA TALLER

IDIOMAS

INGLÉS

Páginas E1 — E16

ESPAÑOL

Páginas S1 — S16

FRANCÉS

Páginas F1 — F16

ADVERTENCIA: Si no se sigue la información de este manual con exactitud, puede producirse un incendio o una explosión,

y provocar daños a la propiedad, lesiones personales o la muerte.

- No almacene ni utilice gasolina ni otros vapores y líquidos inamables en las proximidades de este artefacto ni de ningún otro

artefacto.

- QUÉ HACER SI DETECTA OLOR A GAS

• Corte el suministro de gas.

• No intente encender ningún artefacto.

• No toque ningún interruptor eléctrico; no use ningún teléfono del edicio.

• Llame de inmediato al suministrador de gas desde el teléfono de un vecino. Siga las instrucciones del suministrador de gas.

• Si no puede comunicarse con el suministrador de gas, llame al departamento de bomberos.

- La instalación y el mantenimiento deben ser realizados por un instalador calicado, una agencia de reparación calicada

o el suministrador de gas.

ADVERTENCIA: Éste es un calentador a gas sin ventilación. Utiliza aire (oxígeno) de la habitación en la que se instala.

Se debe proporcionar aire de ventilación y de combustión adecuado. Consulte la sección Aire fresco para la combustión

y ventilación en la página 3 de este manual.

ADVERTENCIA: La instalación, el ajuste, la alteración, la reparación o el mantenimiento indebidos pueden provocar

daños, lesiones o la muerte. Antes de instalar o reparar este equipo, lea detenidamente las instrucciones de instalación,

funcionamiento y mantenimiento. Para obtener ayuda o información adicional, consulte con un instalador calicado, una

agencia de reparación calicada o el suministrador de gas.

Heatstar, INC., 4560 W. 160TH ST., CLEVELAND, OHIO 44135 · 800-251-0001

04/15 18672

Page 17

ADVERTENCIAS

ADVERTENCIA: La instalación, el ajuste, la alteración,

la reparación o el mantenimiento indebidos pueden

provocar daños, lesiones o la muerte. Antes de

instalar o reparar este equipo, lea detenidamente

las instrucciones de instalación, funcionamiento y

mantenimiento. Para obtener ayuda o información

adicional, consulte con un instalador calicado, una

agencia de reparación calicada o el suministrador

de gas.

ADVERTENCIA: Cuando el calentador se utiliza sin

aire fresco, es posible que emane MONÓXIDO DE

CARBONO, que es un gas tóxico e inodoro. CUANDO

USE EL CALENTADOR, ABRA LA VENTANA UNA O

DOS PULGADAS PARA QUE ENTRE AIRE FRESCO.

ADVERTENCIA: Este calentador tiene un SISTEMA

DE SEGURIDAD CON LLAMA PILOTO. NO TOQUE

EL SISTEMA DE SEGURIDAD CON LLAMA PILOTO.

ADVERTENCIA: Si el calentador se apaga, no vuelva

a encenderlo hasta que ingrese aire fresco. Si continúa apagándose, hágalo reparar. Mantenga limpios

el quemador y el control. Abra la puerta durante cinco

minutos.

Mantenga los espacios libres que se indican en la

Figura 2 o en la placa del calentador.

• PARA COMPROBAR SI EXISTEN FUGAS

DE GAS, NO USE FÓSFOROS U OTRO TIPO

DE LLAMA.

• NO SUPERE LA PRESIÓN DE ENTRADA

DE 3,45 KPA (1/2 PSI) AL CALENTADOR.

ÍNDICE

Capítulo Título Página

I Introducción ...................................................... S3

II Instalación del calentador ................................ S5

III Instrucciones de funcionamiento

del calentador ................................................... S10

IV Instrucciones de mantenimiento

para el operador ...............................................S12

V Lista de repuestos ............................................S15

PELIGRO: La intoxicación por monóxido de carbono puede

causar la muerte.

Intoxicación por monóxido de carbono:

Los síntomas tempranos de intoxicación por monóxido

de carbono se asemejan a la gripe, con dolor de cabeza,

mareos o náuseas. Si tiene estos síntomas, es posible que

el calentador no esté funcionando correctamente. Tome aire

fresco de inmediato. Haga reparar el calentador. Algunas

personas se verán más afectadas por el monóxido de carbono

que otras. Por ejemplo, mujeres embarazadas, personas

con afecciones cardíacas o pulmonares, anemia, quienes se

encuentren bajo la inuencia del alcohol o en la altura.

AVISO

• Nunca conecte la válvula de gas o el termostato al voltaje

de línea o a un transformador.

• Si el color infrarrojo de la parrilla se oscurece cuando la

calefacción del edicio está en funcionamiento, consulte

al suministrador de gas cuáles son los tamaños correctos

de los conductos para el suministro de gas.

• ¡Este calentador sólo debe instalarse en interiores!

NOTA

El material jador de las juntas que se utiliza en el ensamble

de este calentador emitirá temporalmente un olor o vapor.

Ese estado pasará en aproximadamente 20 minutos y no

volverá a ocurrir en lo sucesivo. Consulte sobre ventilación

en el Capítulo 2.

ADVERTENCIA:

El Estado de California exige la publicación

de la siguiente advertencia:

LA COMBUSTIÓN GENERADA CUANDO SE UTILIZA ESTE

PRODUCTO CONTIENE MONÓXIDO DE CARBONO, UN

QUÍMICO QUE EL ESTADO DE CALIFORNIA RECONOCE

COMO CAUSANTE DE CÁNCER Y MALFORMACIONES

CONGÉNITAS (U OTROS DAÑOS REPRODUCTIVOS).

ESTE PRODUCTO CONTIENE SUSTANCIAS QUÍMICAS QUE

DE ACUERDO CON EL ESTADO DE CALIFORNIA PRODUCEN

CÁNCER, DEFECTOS DE NACIMIENTO U OTROS DAÑOS

REPRODUCTIVOS.

CANADÁ SOLAMENTE:

Por código gas / CGA-B149.1.2 CAN, este calentador

no se puede instalar en garajes residenciales en

Canadá

S2

Instrucciones de uso y manual del usuario

Page 18

CAPÍTULO I

INTRODUCCIÓN

1. EQUIPO

Este calentador es la versión comercial de un calentador

industrial para empresas de servicio público altamente

exitoso, ampliamente probado, infrarrojo y de funcionamiento

a gas.

No requiere una fuente eléctrica externa para funcionar.

En la Figura 1 se indican los principales componentes del

calentador y su instalación característica. El calentador

básico está compuesto por el ensamble completo del

VÁLVULA DE CONTROL

DE GAS

GENERADOR

POWERPILE

quemador, un deector de gas de combustión, una parrilla, el

ensamble del reector y un protector.

2. FINALIDAD DEL EQUIPO

ADVERTENCIAS

Este calentador sólo debe instalarse en interiores.

Este calentador ha sido diseñado para calentar espacios

de interior. No debe usarse en espacios habitados,

pequeños o cerrados.

VENTILACIÓN

DE ESCAPE

CABLE DEL

TERMOSTATO

TERMOSTATO

CALENTADOR

BÁSICO

SOPORTE PARA

PARED

Figura 1. Principales componentes del calentador

S3

Instrucciones de uso y manual del usuario

Page 19

3. INFORMACIÓN GENERAL

• El calentador viene de fábrica completamente

ensamblado y ha sido probado con el tipo de gas

adecuado y con las presiones de entrada que guran

en la placa.

• Al recibirlo y antes de instalarlo, asegúrese de

inspeccionar el calentador y su embalaje para

determinar si presentan daños o si faltan componentes.

Si se detecta que ha sufrido daños o se sospecha

que pueden faltar componentes, comuníquese con el

vendedor. Consulte en el Capítulo 5 la lista completa

de artículos necesarios para la instalación y el uso de

este calentador con seguridad y eciencia.

• Nunca intente hacer funcionar el calentador con

un combustible que no sea el que se establece

especícamente en la placa.

• La instalación del calentador debe cumplir con todos

los códigos de construcción locales o, si no existieran

códigos locales en vigencia, con el National Fuel

Gas Code (Código Nacional de Gas Combustible),

ANSI Z223.1 (Instituto Nacional Estadounidense

de Estándares), (NFPA 54 [Asociación Nacional de

Protección contra Incendios]). Este código se puede

solicitar a: Canadian Standards Association, 8501 East

Pleasant Valley Road, Cleveland, OH 44131; o a la

NFPA, Battery March Park, Quincy, MA 02269.

• Las instalaciones que se realicen en Canadá deberán

cumplir con el código de gas CAN/CGA-B149.1.2, que

puede comprarse en la Canadian Gas Association

(Asociación Canadiense de Estándares), 55 Scarsdale

Road, Don Mills, Ontario M3B 2R3.

• Cuando el artefacto deba ser instalado a gran altura,

comuníquese con la fábrica. La fábrica entrega un

juego de conversión para gran altura con instrucciones

y placa con fecha.

• Se provee la conexión de medición de prueba en un

control de gas del calentador NPT de 0,31 cm (1/8")

conectado.

• Consulte las especicaciones del calentador en la

Tabla 1 y 2:

ADVERTENCIA: La instalación, el ajuste, la alteración, la

reparación o el mantenimiento indebidos pueden provocar

daños, lesiones o la muerte. Antes de instalar o reparar este

equipo, lea detenidamente las instrucciones de instalación,

funcionamiento y mantenimiento. Para obtener ayuda o

información adicional, consulte con un instalador calicado,

una agencia de reparación calicada o el suministrador

de gas.

• Para obtener más información, comuníquese con:

Mr. Heater Llame al número gratuito 800-251-0001

o visite www.mrheater.com

Los siguientes manuales adicionales de la NFPA son útiles al

momento de instalar este calentador en un lugar no previsto en

este manual:

Número Tema relacionado

NFPA 88 Espacios libres con respecto a supercies

inamables

NFPA 409 Espacios libres con respecto a supercies

inamables

NO SUPERE LA PRESIÓN DE ENTRADA DE 3,45 KPA

(1/2 PSI) AL CALENTADOR

Asegúrese de que haya un espacio libre adecuado con respecto

a los combustibles según lo establecido en la Tabla 3 en el

extremo de control del calentador para realizar reparaciones,

y un espacio mínimo arriba y en los lados para favorecer la

ventilación y el suministro de aire para la combustión.

Un espacio libre mínimo de ocho pulgadas sobre el piso para los

garajes públicos según la edición más actualizada de la norma

n.° 88 de la NFPA, o la Figura 1; el que sea más grande.

Las instalaciones en garajes públicos en Canadá deben cumplir

con la edición más actualizada de la norma 149B.1.9 de la CGA.

ADVERTENCIA: Mantenga los espacios libres que se

indican en la Figura 2 o en la placa del calentador.

Tabla 1. Índices en BTU y presiones de suministro

N.° DE

MODELO

MH25NG 25,000 — 18 cm

MH25LP — 22,000 — 28 cm

ÍNDICE EN BTU/HR. PRESIÓN DEL SUMINISTRO DE GAS (W.C.) TAMAÑO

NATURAL PROPANO NAT. L.P. NAT. L.P. NAT. L.P. NAT. L.P.

(7.0")

— 35,6 cm

(14")

— 35,6 cm

(11")

— 15,2 cm

(6")

— 25,4 cm

(14”)

Tabla 2. Dimensiones del calentador y tamaños de oricio

N.° DE

MODELO

MH25NG 6.0" w.c. 45 .018 25,000 31,11 cm

MH25LP 10" w.c. 55 .011 22,000 31,11 cm

PRESIÓN DE

FUNCIONAMIENTO

TAMAÑO DE ORIFICIO POTENCIA

QUEMADOR PILOTO ANCHO LONGITUD ALTURA PESO

EN BTU/HR.

S4

(12-1/4")

(12-1/4")

Instrucciones de uso y manual del usuario

DEL ORIFICIOGAS MÍN. MÁX. COLECTOR

— 45 —

— 55

(10")

DEL ORIFICIO

75,56 cm

(29-3/4")

75,56 cm

(29-3/4")

17,78 cm

(7")

17,78 cm

(7")

9 kg (20

libras)

9 kg (20

libras)

Page 20

CAPÍTULO II

INSTALACIÓN DEL

CALENTADOR

1. INFORMACIÓN Y REQUISITOS GENERALES DE

INSTALACIÓN

• En la Figura 2 y en la Tabla 3 se ilustran los espacios

libres mínimos que deben dejarse con respecto a las

supercies inamables. Como se observa en la Figura 2,

la parte delantera del calentador se instala dejando

el espacio libre mínimo obligatorio con respecto a las

supercies inamables y de cara al espacio abierto,

mientras que los demás lados deben tener un espacio

libre mínimo de 40,64 cm (16 pulgadas) con respecto

a las supercies inamables.

VENTILACIÓN DE

ESCAPE

40,64 cm (16")

MÍNIMO

36,83 cm

(14-1/2")

35,56 cm (14")

MÍNIMO

30

1,21 m (48")

MÍNIMO

TECHO

CALENTADOR

SOPORTE

PARA PARED

PUERTA

DEL TALLER ABIERTA

40,64 cm (16")

MÍNIMO

NOTA:

1. SÓLO SE PUEDE ELEVAR EL LADO

2. EL LADO DEL REFLECTOR DEL CALENTADOR

Las separaciones a los combustibles representan una

temperatura supercial de 90 ° F (32 ° C) por encima de la

temperatura ambiente. Materiales de construcción con la

tolerancia al calor bajo puede estar sujeto a la degradación a

temperaturas más bajas. Es responsabilidad del instalador.

o

DE COMBUSTIÓN DEL CALENTADOR (30

DEBE ESTAR HORIZONTAL.

).

LÍNEA DEL PISO

Figura 2. Espacios libres que deben dejarse en la instalación

con respecto a las supercies inamables

Tabla 3. Información de instalación, ventilación y montaje

ÍNDICE EN BTU/HR.

N.° DE

MODELO

NAT. L.P. ARRIBA LADOS ATRÁS ABAJO

MH25NG 25,000 — 30º 35,56 cm (14") 40,64 cm (16") 40,64 cm (16") 1,21 m (48")

MH25LP — 22,000 30º 35,56 cm (14") 40,64 cm (16") 40,64 cm (16") 1,21 m (48")

POSICIÓN

NORMAL DE

MONTAJE

ESPACIOS LIBRES CON RESPECTO A SUPERFICIES INFLAMABLESGAS

S5

Instrucciones de uso y manual del usuario

Page 21

• Este calentador puede montarse sobre la pared.

Sin embargo, se recomienda montarlo en la mitad

de la pared opuesta a las puertas basculantes.

• Al elegir lugares de instalación para este

calentador, asegúrese de que al abrir puertas o

ventanas exteriores o interiores no se interera

con los espacios libres mínimos ni se toquen los

componentes del calentador.

• Si existe una puerta basculante en el edicio,

verique que el calentador no esté instalado de

modo tal que interera con el funcionamiento de la

puerta y verique que la puerta en posición abierta

no reduzca los espacios libres a una distancia

inferior a la que establecen los requisitos mínimos.

Nunca coloque el calentador en una posición por

encima de una puerta basculante abierta.

• En la mayoría de los casos, la inltración alrededor

de las puertas y ventanas de entrada no aisladas

permitirá que entre la suciente cantidad de

aire fresco para que el calentador funcione

ecientemente.

La elección del lugar para montar el termostato es fundamental

para que el calentador funcione con eciencia y ecacia.

• El termostato debe instalarse a alrededor de cinco

pies por encima del piso para que pueda circular aire

libremente a su alrededor.

• No se debe montar el termostato directamente sobre

una pared exterior fría sin un bloque de montaje

aislado.

• No se debe montar el termostato en corrientes de

aire directas.

• No se debe montar el termostato directamente

debajo del calentador instalado.

• No se debe instalar el termostato a una distancia

mayor con respecto al calentador que la longitud

del cable del termostato.

2. INSTRUCCIONES DE MONTAJE DEL

CALENTADOR

Es fundamental que exista un ujo de aire ilimitado durante

el funcionamiento del calentador para evitar que el área que

se encuentra por encima del calentador instalado se caliente

en exceso. Si el taller o edicio de servicio público está

rigurosamente aislado (por ejemplo, en las ventanas, puertas,

aberturas, etc.), deben seguirse los siguientes métodos de

ventilación:

• El calentador viene con una sola ventilación de

escape para su practicidad. Dicha ventilación

debe colocarse por encima del calentador

(preferentemente en la parte más alta del interior

del edicio) y debe ventilar hacia afuera del edicio.

Para quienes tienen un taller o edicio de servicio

público terminado, la fábrica provee una ventilación

adicional.

• Debajo del calentador (preferentemente a no más de

61 cm (dos pies) de distancia del piso del edicio),

se debe colocar una ventilación de entrada de aire, o

equivalente, desde el exterior del edicio con un área

efectiva de 483,9 cm

2

(75 pulgadas cuadradas).

• Las aberturas equivalentes a una ventilación

de entrada de aire serían: puertas y ventanas

parcialmente abiertas.

• Con aberturas de este tamaño (13 cm por 33 cm

(5 pulgadas por 13 pulgadas), o 7,62 cm por 63,5 cm

(3 pulgadas por 25 pulgadas)), se evitará la peligrosa

acumulación de calor encima del calentador.

Asegúrese de que no haya líneas de gas o conductos o

cables eléctricos que intereran con el montaje del calentador

en la pared.

Según los códigos y requisitos locales y la capacidad

del instalador, es posible que se requiera la ayuda de un

profesional para determinar el tamaño e instalar las líneas

de gas necesarias para suministrar gas al calentador. Si

tiene dudas sobre estos requisitos, hable sobre los requisitos

de este manual con el vendedor del calentador y con el

suministrador de gas, o llame a nuestro departamento de

atención al cliente al 1-800-251-0001.

Después de elegir el lugar para instalar el calentador y

el lugar del termostato y de vericar y asegurarse de que

se cumpla con todos los requisitos de colocación antes

mencionados, coloque el calentador de la siguiente manera:

A. Determine cómo desea instalar la ventilación de acuerdo

con la construcción del edicio y su preferencia personal.

(Es decir, ¿desea el lado con brida [terminado] del

interior o exterior del edicio, o desea dos ventilaciones

para que tanto el exterior como el interior queden

terminados?) Si es necesario, pida otra ventilación a la

fábrica. Nuestra dirección y nuestro número de teléfono

gratuito guran en la contratapa de este manual. Instale

la ventilación de la siguiente manera:

1. Consulte en la Figura 3 las dimensiones y la

información sobre la ventilación.

2. Elija un lugar lo más alto posible con respecto al

calentador de acuerdo con los requisitos antes

mencionados y asegúrese de que el respiradero o

los respiraderos no estén en contacto ni intereran

con los sistemas existentes en el edicio (es decir,

conductos, cableado, cañerías, etc.).

3. Coloque el lado incompleto del respiradero contra

la pared en el lugar elegido y, con un lápiz u otro

marcador adecuado, trace sus dimensiones sobre la

pared.

4. Corte o haga un agujero en la pared, o las paredes

en el caso de edicios terminados, que tenga las

dimensiones del lado incompleto del respiradero.

5. Instale el respiradero o los respiraderos como desee

y afírmelo con cuatro soportes de ajuste adecuados

que pasen por los oricios ya perforados en la brida

del respiradero.

B Prepárese para instalar el soporte del calentador para

pared de la siguiente manera:

1. Si el soporte se colocará sobre una pared de

tablaroca y entramado, consulte las dimensiones

en la Figura 3, ubique un entramado y perfore dos

S6

Instrucciones de uso y manual del usuario

Page 22

oricios de guía de 0,31 cm (1/8") en la línea central

del entramado. Use una plantilla para facilitar la

instalación.

2. Si el soporte se colocará sobre una pared de

ladrillo o mampostería, consulte las dimensiones

en la Figura 3. Obtenga dos tacos de expansión

de 0,63 cm (1/4 de pulgadas) (diámetro interno)

y determine el tamaño correcto que usará para

perforarlos. Perfore oricios del tamaño correcto en

el ladrillo o la mampostería para colocar los tacos.

C. Coloque el soporte para pared sobre la pared y alinee

los dos oricios pasantes del soporte con los oricios o

tacos de guía. Pase tornillos de compresión de 0,63 cm

(1/4 pulgadas) por 6,35 cm (2-1/2 pulgadas) por el

soporte hasta el entramado o los tacos. Ajústelos.

D. Ubique el sujetador de montaje del calentador en la

parte trasera del calentador y elija el perno de cabeza

hexagonal de

0,63 cm (1/4") – 20 por 1,90 cm (3/4") y la

tuerca hexagonal de 0,63 cm (1/4") - 20.

E. Coloque el calentador como se observa en la Figura 3,

y pase el sujetador de montaje del calentador sobre el

soporte, y pase el perno por el sujetador y el soporte.

F. Coloque la tuerca hexagonal en el perno y ajústela.

G. Asegúrese de que el lugar elegido para colocar el

termostato cumpla con todos los requisitos antes

mencionados. Para obtener información adicional sobre

la conexión a tierra e instrucciones de montaje, consulte

las instrucciones que vienen con el termostato.

H. Si la pared es de entramado y tablaroca, entonces use

tornillos autorroscantes n.° 6 por 2,54 cm (1 pulgada),

que vienen con el termostato, y coloque el termostato en

el lugar elegido.

I. Si la pared es de ladrillo o mampostería, deberá obtener

los tacos adecuados para adaptar los tornillos de montaje

del termostato. Use la placa trasera del termostato como

plantilla para marcar los lugares de los oricios, perfore

oricios de tamaño adecuado para los tacos, instale los

tacos y arme el termostato con los tornillos.

J. Conecte los cables del termostato a la válvula de gas

como se observa en la Figura 4.

61 CM (24") MÍN.

0,63 CM (1/4")-20 x 1,90 CM (3/4")

SOPORTE DEL

CALENTADOR

PARA PARED

22,86 CM (9")

TORNILLOS DE COMPRESIÓN

LARGOS DE 0,63 CM (1/4") X

6,35 CM (2-1/2")

(SE NECESITAN DOS)

Figura 3. Información de montaje del calentador

TECHO

CALENTADOR

PERNO DE CABEZA

HEXAGONAL DE

TUERCA

HEXAGONAL DE

0,63 CM (1/4")-20

VÁLVULA

DE

CONTROL

DE GAS

SUJETADOR

DE MONTAJE

DEFLECTOR

DE GAS DE

COMBUSTIÓN

REFLECTOR DEL

CALENTADOR

ENTRADA DE GAS DE 1/2" NPT

(NO DEBE SUPERAR 3,45 KPA (1/2 PSI))

CABLE DEL TERMOSTATO

(CONSULTE LA FIGURA 4)

1,47 M (58")

PISO

TORNILLOS AUTORROSCANTES

N.° 6 X 2,54 CM (1") (SE NECESITAN

DOS, INCLUIDOS CON EL

TERMOSTATO)

TERMOSTATO (CONSULTE LAS

INSTRUCCIONES DEL TERMOSTATO)

S7

LADO INCOMPLETO

Instrucciones de uso y manual del usuario

LADO COMPLETO

BRIDA

ORIFICIOS YA

PERFORADOS

Page 23

TERMOSTATO

VÁLVULA DE GAS POWERPILE

• Para que el calentador a gas natural funcione

óptimamente, asegúrese de que la presión de

suministro del colector sea de 3,45 kPa (1/2 psi)

como mínimo (14 pulgadas W.P.).

3.2 Requisitos relativos a los conductos

Todos los conductos instalados deben cumplir con los

códigos y las ordenanzas locales o con el Código Nacional

de Gas Combustible,

ANSI Z223.1 (NFPA 54), el que tenga prioridad. Al instalar

los conductos, se deben tener en cuenta los siguientes

requisitos: las instalaciones realizadas en Canadá deben

cumplir con el código de gas B149.1.2.

GENERADOR POWERPILE

Figura 4. Diagrama de conexión

Consulte el Código Eléctrico Nacional NFPA70-1993 y para las

instalaciones eléctricas en Canadá, el CÓDIGO C22.1-

3. CONEXIÓN DEL CALENTADOR AL SUMINISTRO

DE GAS

ADVERTENCIA: Según los códigos y requisitos locales

y la capacidad del instalador, es posible que se requiera

la ayuda de un profesional para determinar el tamaño e

instalar las líneas de gas necesarias para suministrar gas

al calentador de forma segura y eciente. Si tiene dudas

sobre estos requisitos, hable sobre los requisitos de

este manual con el vendedor del calentador y con el

suministrador de gas.

3.1 Requisitos para el suministro de gas

• Consulte en las Tablas 1 y 2 cuál es la presión

mínima, máxima, de funcionamiento y del colector

para ambos modelos de calentador. Las presiones

se establecen en pulgadas de W.C. (water column,

columnas de agua). Además, consulte las placas de

especicaciones del calentador.

ADVERTENCIA: el modelo MH25NG está diseñado para

quemar gas natural y viene equipado con un regulador.

El regulador está incorporado en la válvula de gas. La

presión máxima de entrada al regulador es de 3,45 kPa

(1/2 psi) (14 pulgadas W.C.). Si la presión de las líneas de

gas supera 3,45 kPa (1/2 psi), entonces habrá que instalar

otro regulador antes del calentador/regulador para bajar la

presión a un máximo de 3,45 kPa (1/2 psi).

• La mayoría de los servicios de gas natural para uso

no comercial proporcionan una presión de línea de

114 cm3 (4 onzas) (6,9 pulgadas W.C.). Si tiene alguna

duda, consulte con su proveedor de gas natural.

• Para que el calentador a gas natural funcione óptimamente,

asegúrese de que la presión de suministro del colector sea

de 114 cm

3 (

6 pulgadas W.C.) como mínimo.

• Use un conducto negro nuevo debidamente

escariado que no tenga virutas.

• Antes del ensamble, aplique un compuesto para

conductos de buena calidad en todas las roscas

macho según se observa en la Figura 5. Si se usa

gas licuado como combustible, asegúrese de que

el compuesto para conductos sea resistente al gas

licuado. No use cinta Teon™.

USE UNA CANTIDAD MODERADA DE SELLADOR

PARA CONDUCTOS

DEJE DOS ROSCAS DESCUBIERTAS

Figura 5. Aplicación del compuesto para

conductos

• Las roscas macho del conducto que se instalará en

la válvula de gas deben cumplir con los requisitos

de la Figura 6. Las roscas que superen la longitud

de las que se muestran en la gura pueden

provocar la distorsión y el funcionamiento indebido

de la válvula de gas.

• En la línea que conduce a la válvula de gas, se debe

instalar un separador de sedimentos que cumpla

con los requisitos característicos de la Figura 7.

• En la línea de suministro de gas se debe instalar

una llave de paso especial para el calentador.

LARGO MÁXIMO DE

ROSCA DE 1,90 CM CM (3/4")

CONDUCTO NEGRO DE 1,27 CM (1/2")

ADVERTENCIA: el modelo MH25LP está diseñado para

quemar gas licuado del petróleo (liqueed petroleum,

LP) y viene equipado con un regulador. El regulador está

incorporado a la válvula de gas. La presión máxima de

entrada al regulador es de 3,45 kPa (1/2 psi) (14 pulgadas

W.C.). Si la presión de las líneas de gas supera 3,45 kPa

(1/2 psi), entonces habrá que instalar otro regulador antes

del calentador/regulador para bajar la presión a un máximo

de 3,45 kPa (1/2 psi).

CUERPO DE LA VÁLVULA

DE GAS

PROFUNDIDAD MÁXIMA DE 1,27 CM

(1/2") DE LAS INSERCIONES EN LA

VÁLVULA DE GAS

Figura 6. Requisitos de conexión de la válvula de gas

S8

Instrucciones de uso y manual del usuario

Page 24

3.3 Instalación de conductos

Instale los conductos de la siguiente manera, asegurándose

de que se cumpla con todos los requisitos relativos al

suministro de gas y los conductos:

A. De acuerdo con los requisitos antes mencionados para

conductos, ensamble los conductos, el separador de

sedimentos, la llave de paso y los accesorios necesarios.

Ajuste todos los componentes.

ADVERTENCIA: Si las roscas macho del conducto

que se instalará en la válvula de gas no cumplen con

los requisitos de la Figura 6, pueden producirse daños,

distorsión y un funcionamiento indebido en la válvula

de gas.

B Instale una boquilla roscada en la válvula de gas,

preparada de acuerdo con el párrafo 3.2.

LÍNEA DE

SUMINISTRO

C. Conecte el conducto de gas a la boquilla instalada en la

válvula de gas.

ADVERTENCIA: Al probar el conducto de gas, use sólo

una solución de agua y jabón. Para probar si pierde gas,

no use fósforos u otro tipo de llama. Si al comprobar si

existen fugas se detecta olor a gas, corte el suministro

de gas y ventile el edicio.

D. Asegúrese de que el edicio esté debidamente ventilado.

Sin encender la llama piloto del calentador, abra la

válvula del suministro de gas y presurice los conductos

hasta la válvula de gas del calentador.

E. Con un cepillo, aplique una solución de agua y jabón en

todas las conexiones y verique si se forman burbujas

que indiquen una fuga. Si se detecta una fuga, corte

el suministro de gas y ajuste las conexiones. Repita la

prueba en las conexiones y ajústelas.

1,27 CM

(1/2") T DE

10 CM

(3")

TAPA

LLAVE DE PASO

BOQUILLA

CONDUCTO RÍGIDO CON

UNIÓN O UN CONECTOR

FLEXIBLE AL CALENTADOR

CALENTADOR

NOTA:

1. USE SÓLO UN COMPUESTO

PARA CONDUCTOS QUE

SEA RESISTENTE A LOS

GASES LICUADOS EN LAS

INSTALACIONES DE GAS

LICUADO.

2. LOS ACCESORIOS QUE

SE OBSERVAN NO ESTÁN

INCLUIDOS CON EL

CALENTADOR.

Figura 7. Instalación característica de los conductos

S9

Instrucciones de uso y manual del usuario

Page 25

CAPÍTULO III

INSTRUCCIONES

DE FUNCIONAMIENTO

DEL CALENTADOR

1. INSTRUCCIONES DE FUNCIONAMIENTO

SEGURO

ADVERTENCIA: Cuando el calentador se utiliza sin

aire fresco, es posible que emane MONÓXIDO DE

CARBONO, que es un gas tóxico e inodoro. CUANDO

USE EL CALENTADOR, ABRA LA VENTANA UNA O

DOS PULGADAS PARA QUE ENTRE AIRE FRESCO.

ADVERTENCIA: Este calentador tiene un SISTEMA DE

SEGURIDAD CON LLAMA PILOTO. NO TOQUE EL

SISTEMA DE SEGURIDAD CON LLAMA PILOTO.

ADVERTENCIA: Si el calentador se apaga, no vuelva a

encenderlo hasta que ingrese aire fresco. Abra la puerta

durante cinco minutos. Si continúa apagándose, hágalo

reparar. Mantenga limpios el quemador y el control.

ADVERTENCIA: LA INTOXICACIÓN POR MONÓXIDO

DE CARBONO PUEDE CAUSAR LA MUERTE. Los

síntomas tempranos de intoxicación por monóxido de

carbono se asemejan a la gripe, con dolor de cabeza,

mareos o náuseas. Si tiene estos síntomas, es posible

que el calentador no esté funcionando correctamente.

Tome aire fresco de inmediato. Haga reparar el calentador.

ADVERTENCIA: PARA COMPROBAR SI EXISTEN

FUGAS DE GAS, NO USE FÓSFOROS U OTRO TIPO

DE LLAMA.

AVISO: Si el color infrarrojo de la parrilla se oscurece

cuando la calefacción del edicio está en funcionamiento,

consulte al suministrador de gas cuáles son los tamaños

correctos de los conductos para el suministro de gas.

AVISO: ¡Este calentador sólo debe instalarse en

interiores!

PERILLA DE

CONTROL

MANUAL DE GAS

NOTA

El material jador de las juntas que se utiliza en el ensamble

de este calentador emitirá temporalmente un olor o vapor.

Ese estado pasará en aproximadamente 20 minutos y no

volverá a ocurrir en lo sucesivo. Consulte sobre ventilación

en el Capítulo 2.

2. ENCENDIDO DEL CALENTADOR

ADVERTENCIA: Durante el encendido del calentador,

asegúrese de que el edicio esté bien ventilado.

A. Abra la válvula o las válvulas del suministro de gas.

B. Coloque el termostato en posición de apagado (OFF).

Consulte la Figura 8.

Figura 8. Controles del termostato

C. Si la perilla de control manual de gas que se encuentra

en la válvula de gas no está en posición de apagado,

oprímala parcialmente y rótela hasta la posición OFF.

Consulte la Figura 9.

AJUSTE DEL

REGULADOR

DE PRESIÓN

REGULADOR

DE PRESIÓN

ESTÁNDAR

SALIENTE

ENTRADA

DE GAS

SALIDA DE GAS DEL

PILOTO (TOMA DE

PRESIÓN JUSTO DEBAJO)

TORNILLO DE AJUSTE DEL FLUUNIDAD DE POTENCIA DEL

TERMOSTATO DEL PILOTO

JO DEL PILOTO (DEBAJO DEL

TORNILLO DE LA TAPA)

Figura 9. Componentes de la válvula de gas

S10

Instrucciones de uso y manual del usuario

Page 26

D. Espere cinco minutos para que salga el gas que se haya

acumulado en el quemador principal (especialmente

importante después de la instalación).

E. Gire la perilla de control manual de gas hasta la posición

piloto (PILOT).

F. Oprima la perilla de control manual de gas. Con un

fósforo, encienda la llama piloto. Consulte la Figura 10.

Mantenga oprimida la perilla durante aproximadamente

30 segundos para que el aire que haya en las líneas de

gas pase por el piloto y, cuando éste esté encendido,

deje que la termocupla se caliente lo suciente para

activar la válvula de seguridad en posición abierta.

G. Suelte la perilla de control manual de gas y gírela hasta

la posición de encendido (ON).

H. Congure el termostato a la temperatura deseada.

OPRIMIR PARA

ENCENDER

NOTA

Durante el encendido inicial del calentador, es posible que

salga del calentador un olor y quizás un poco de vapor.

Es el material jador de las juntas que emana ese olor o

vapor. Después de aproximadamente 20 minutos, el olor

desaparece y no se vuelve a producir.

3. APAGADO DEL CALENTADOR

A. Gire el termostato hasta la posición de apagado (OFF).

B. Gire la perilla de control manual de gas que se encuentra

en la válvula de gas hasta la posición piloto (PILOT).

C. Oprima parcialmente la perilla y rótela hasta la posición

de apagado (OFF).

D. Cierre las válvulas de suministro de gas.

VÁLVULA DE GAS

QUEMADOR DEL

PILOTO

Figura 10. Encendido del quemador del piloto

S11

Instrucciones de uso y manual del usuario

ENCIENDA EL PILOTO CON

UN FÓSFORO COMO SE

OBSERVA AQUÍ

Page 27

CAPÍTULO IV

INSTRUCCIONES DE

MANTENIMIENTO PARA

EL OPERADOR

AJUSTE

CORRECTO DE

LA LLAMA

10 A 13 MILÍMETROS

(3/8 A 1/2 PULGADAS)

1. REPARACIÓN DE AVERÍAS

A. En la Tabla 4 se mencionan los problemas habituales que

puede tener durante el funcionamiento o mantenimiento

del calentador.

B Para obtener más información, consulte el boletín

informativo técnico de Honeywell (Honeywell Field

Bulletin) incluido en la caja del calentador.

C. En caso de no obtener resultados después de intentar

todas las soluciones mencionadas, llame a la fábrica.

2. AJUSTE DE LA LLAMA DEL PILOTO

La llama del piloto debe envolver 10 a 13 mm

(3/8 a 1/2 pulgadas) de la punta de la termocupla o del

generador. Consulte la Figura 11. Para ajustarla:

AJUSTE DEL REGULADOR DE PRESIÓN

(DEBAJO DEL TORNILLO DE LA TAPA)

PERILLA DE

CONTROL

MANUAL DE GAS

SALIENTE

TERMOCUPLA

Figura 11. Ajuste correcto de la llama

A. Retire el tornillo de ajuste de la tapa del piloto. Consulte

la Figura 12.

B. Gire el tornillo de ajuste interno hacia la derecha

para bajar o hacia la izquierda para subir la llama

del piloto.

C. Después de ajustar la llama, cambie siempre el tornillo

de la tapa y ajústelo fuertemente para que funcione

correctamente.

INSTALE EL TORNILLO

LARGO EN EL VÉRTICE

EXTERNO

ENTRADA

DE GAS

UNIDAD DE POTENCIA DEL

TERMOSTATO DEL PILOTO

Figura 12. Vista superior del control de gas de capacidad estándar

REGULADOR

DE PRESIÓN

ESTÁNDAR

(MODELO “A”)

REGULADOR DE APERTURA GRADUAL

(MODELO “C”)

SALIDA DE GAS DEL PILOTO

(TOMA DE PRESIÓN JUSTO DEBAJO)

TORNILLO DE AJUSTE DEL FLUJO DEL PILOTO

(DEBAJO DEL TORNILLO DE LA TAPA)

S12

Instrucciones de uso y manual del usuario

Page 28

Tabla 4. Cuadro de reparación de averías

A continuación se presentan en forma de cuadro los síntomas de un sistema que no funciona debidamente, los posibles defectos

que provocan estos síntomas y las medidas correctivas propuestas. La información del cuadro se presenta con la suposición de

que el calentador recibe la presión de gas adecuada y que el procedimiento de encendido se lleva a cabo según se indica en la

placa adjunta al calentador.

SÍNTOMAS CAUSAS SOLUCIONES

el quemador se apaga

muy lentamente

el quemador se apaga muy lentamente

color infrarrojo se mantiene oscuro

retroceso de la llama del quemador

(ruido crepitante durante el

funcionamiento y la supercie de la

parrilla de cerámica se oscurece)

la parrilla de cerámica o el quemador

se llenan de hollín (cuando el

calentador es nuevo o después

de limpiarlo)

no se enciende el piloto el oricio del piloto está bloqueado

la llama piloto se enciende pero

se apaga

bloqueo parcial del oricio del piloto

piloto no ajustado

oricio del quemador parcialmente

bloqueado

presión de gas baja

quemador roto

primero controle si el oricio del

quemador está roto

si el oricio del quemador no está roto

entonces verique si el colector está

roto

la llave de gas no está en posición

es posible que el tornillo de ajuste del

ujo de gas del piloto esté cerrado

termocupla defectuosa

control defectuoso

cambiarla

reajustar piloto

cambiarla

corregir presión de la línea o llamar

al suministrador de gas

cambiarla

cambiarlo si está roto

cambiarla

cambiarla

se debe girar la perilla de la llave

de gas hasta piloto y oprimirla

abrirlo y ajustarlo

(consulte la Figura 12)

cambiarla

cambiarla

el piloto queda encendido pero el

quemador principal no se enciende

no enciende no hay suministro de gas

cable suelto o cableado incorrecto

control defectuoso

oricio del quemador bloqueado

aire en la línea de gas

conexiones de cables sueltas

conexiones de cables sucias

3 CAMBIO DE LA UNIDAD DE LA VÁLVULA

DE GAS

A. Retire los dos cables de la unidad de la válvula de gas que

se encuentran en la válvula de control de gas rotulados “PP”.

B Desatornille la válvula de gas del conducto de gas.

C. Vuelva a conectar los cables de la válvula de gas y la

unidad a los terminales “PP”. Asegúrese de dejar el cable

del termostato en un terminal.

4. FRECUENCIA DE LOS CONTROLES DEL

OPERADOR

Uso intermitente. Los artefactos que se usan por temporada

deben controlarse antes de apagarlos y nuevamente antes de

su próximo uso.

ajustar las conexiones, vericar el

diagrama de cableado

cambiarla

limpiar oricio o cambiarlo

abrir válvulas manuales

purgar la línea de gas

ajustar conexiones de cables

limpiar los terminales y ajustarlos

Ambiente con polvo, humedad o corrosión. Dado que

estos ambientes pueden hacer que el control de gas se

deteriore más rápidamente, es necesario vericar el sistema

con más frecuencia.

Se debe cambiar el control de gas si:

A. No funciona bien al realizar el control o la reparación de

averías.

B. Cuesta girar u oprimir la perilla del control de gas, o si no

se levanta al soltarla.

S13

Instrucciones de uso y manual del usuario

Page 29

SI DEBE REPARARLO,

NO DEVUELVA EL ARTEFACTO A LA TIENDA

Para obtener información sobre reparación, llame a nuestro número

gratuito:1-800-251-0001.

Nuestro horario de atención es de lunes a viernes, de 8:00 a17:00,

hora del este

En todas las comunicaciones recuerde incluir el número de modelo,