Page 1

OPERATING INSTRUCTIONS

AND OWNER’S MANUAL

READ INSTRUCTIONS CAREFULLY: Read and follow all instructions. Place instructions in a safe place

for future reference. Do not allow anyone who has not read these instructions to assemble, light, adjust

or operate the heater.

HS250AG

HS400AG

Model #

HS250AG

HS400AG

HS408AG

HS408AG

WARNING:

— Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance.

— An LP cylinder not connected for use shall not be stored in the vicinity of this or any other

appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light appliance.

• Extinguish any open flame.

• Shut off gas to appliance.

— Service must be performed by a qualified service agency.

This is an un-vented gas-fired portable heater. It uses air (oxygen) from the area in which it is used.

Adequate combustion and ventilation must be provided. Refer to pages

If the information in this manual is not followed exactly, a fire or explosion

may result, causing property damage, personal injury or loss of life.

LANGUAGES INCLUDED

•ENGLISH

•FRENCH

2017 CB HEAT STAR, Inc., 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 866-447-2194

Page 2

WARNING:

YOUR SAFETY IS IMPORTANT TO YOU AND TO OTHERS,

SO PLEASE READ THESE INSTRUCTIONS BEFORE YOU

OPERATE THIS HEATER.

WARNING:

NOT FOR HOME OR RECREATIONAL VEHICLE USE

WARNING:

GENERAL HAZARD WARNING:

FAILURE TO COMPLY WITH THE PRECAUTIONS AND

INSTRUCTIONS PROVIDED WITH THIS HEATER, CAN

RESULT IN DEATH, SERIOUS BODILY INJURY AND

PROPERTY LOSS OR DAMAGE FROM HAZARDS OF

FIRE, EXPLOSION, BURN, ASPHYXIATION, CARBON

MONOXIDE POISONING, AND/OR ELECTRICAL SHOCK.

ONLY PERSONS WHO CAN UNDERSTAND AND FOLLOW

THE INSTRUCTIONS SHOULD USE OR SERVICE THIS

HEATER.

IF YOU NEED ASSISTANCE OR HEATER INFORMATION

SUCH AS AN INSTRUCTIONS MANUAL, LABELS, ETC.

CONTACT THE MANUFACTURER.

THE STATE OF CALIFORNIA REQUIRES THE FOLLOWING WARNINGS:

FIRE, BURN, INHALATION, AND EXPLOSION HAZARD.

KEEP SOLID COMBUSTIBLES, SUCH AS BUILDING

MATERIALS, PAPER OR CARDBOARD, A SAFE DISTANCE

AWAY FROM THE HEATER AS RECOMMENDED BY THE

INSTRUCTIONS. NEVER USE THE HEATER IN SPACES

WHICH DO OR MAY CONTAIN VOLATILE OR AIRBORNE

COMBUSTIBLES, OR PRODUCTS SUCH AS GASOLINE,

SOLVENTS, PAINT THINNER, DUST PARTICLES OR

UNKNOWN CHEMICALS.

WARNING: Combustion by-products produced when using this product contain carbon monoxide, a chemical

known to the State of California to cause cancer and birth defects (or other reproductive harm).

WARNING: This product contains chemicals known to the State of California to cause cancer and birth defects or

other reproductive harm.

CONTENTS

WARNINGS ..........................................................................2

SPECIFICATIONS ...................................................................3

OPERATING PRECAUTIONS ..................................................4

SAFETY PRECAUTIONS .........................................................4

INSTALLATION .....................................................................5

ELECTRICAL CONNECTIONS .................................................5

GAS LINE OPERATION ..........................................................6

CONTROL PANEL ..................................................................7

FUEL CONVERSION .............................................................9

OPERATING INSTRUCTIONS .................................................8

MAINTENANCE ....................................................................9

TROUBLESHOOTING ......................................................10-11

WIRING DIAGRAM .........................................................12-13

PARTS LISTS AND EXPLODED VIEWS .............................. 14-15

WARRANTY INFORMATION ...............................................16

Forced-Air Agricultural Construction Heater Operating Instructions and Owner’s Manual

2

Page 3

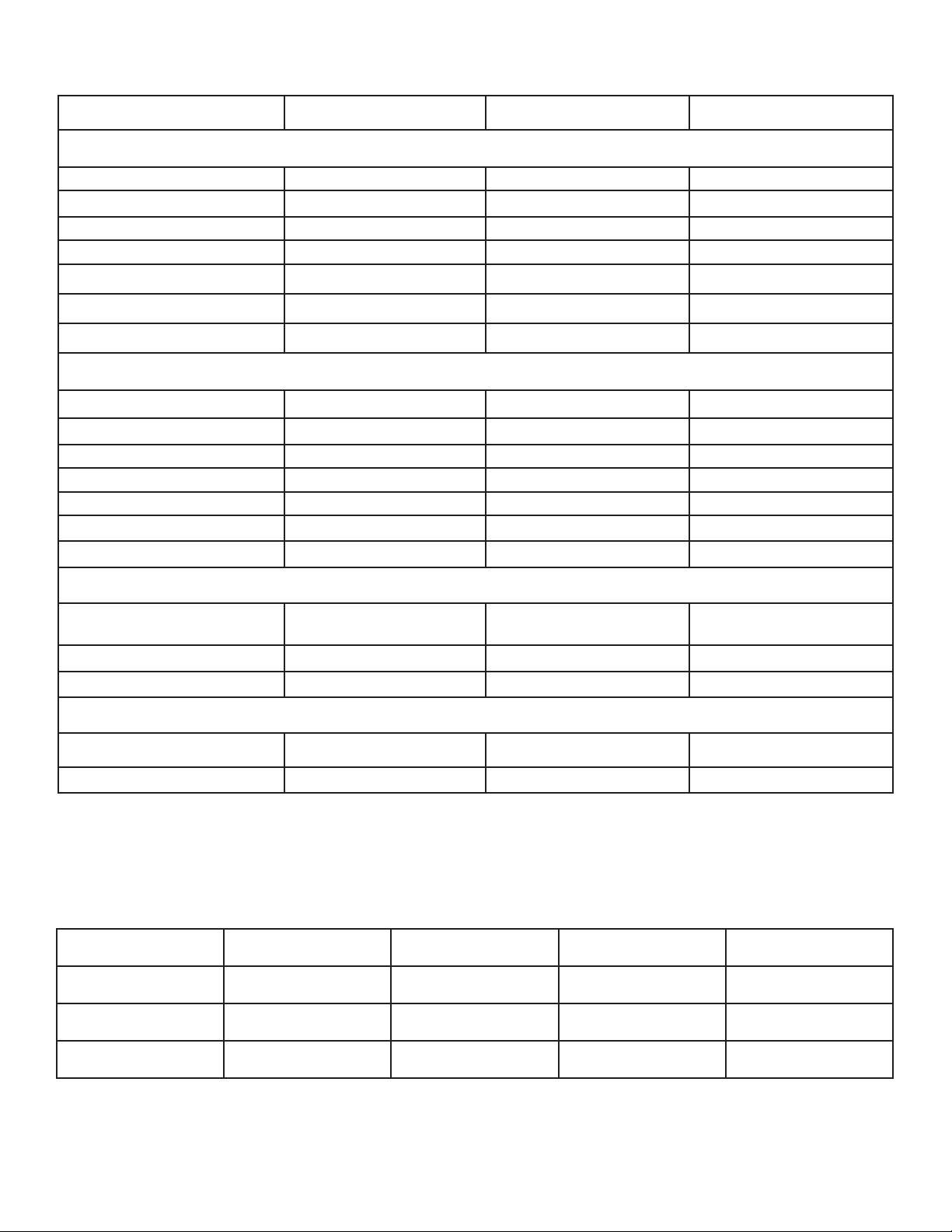

SPECIFICATIONS

MODEL# (Stock#)

SUPPLY PRESSURE

RING NOZZLE (INCHES)

HEAT INPUT (BTU/HR)

MANIFOLD PRESSURE

FUEL CONSUMPTION (CFH)

GAS INLET

NOISE LEVEL AT 1m

SUPPLY PRESSURE

RING NOZZLE (INCHES)

HEAT INPUT (BTU/HR)

MANIFOLD PRESSURE

FUEL CONSUMPTION (CFH)

GAS INLET

NOISE LEVEL AT 1m

HS250AG (F130105) HS400AG (F130110) HS408AG (F130115)

Natural Gas

Min 8" W.C - Max 10" W.C Min 8" W.C - Max 10" W.C Min 8" W.C - Max 10" W.C

N. 16 Holes x 0.102" N. 16 Holes x 0.138" N. 16 Holes x 0.138"

250,000 400,000 400,000

2,61 2,38 2,38

233.51 355.52 355.52

3/4" NPT 3/4" NPT 3/4" NPT

77 (dBA) 74 (dBA) 74 (dBA)

L.P.

Min 8" W.C - Max 13" W.C Min 8" W.C - Max 13" W.C Min 8" W.C - Max 13" W.C

N. 12 Holes x 0.079" N. 12 Holes x 0.098" N. 12 Holes x 0.098"

250,000 400,000 400,000

3.64 4.01 4.01

85.94 141. 95 141. 9 5

3/4" 3/4" 3/4"

77 (dBA) 74 (dBA) 74 (dBA)

ELEC. SUPPLY

(VOLTS/Hz/PHASE)

CONTINUOUS AMPS

120V-60HZ- 1Ø 120V-60HZ-1Ø 208V-60HZ-1Ø

5.0 AMPS 9.5 AMPS 5.0 AMPS

WAT TS

LENGTH X WIDTH X HEIGHT (in)

45.1" X 23.2" X 17.4" 46.7" x 26.9" x 21.1" 46.7" x 26.9" x 21.1"

WEIGHT (LBS)

CLEARANCE TO COMBUSTIBLES

MODEL

HS250AG

HS400AG

TOP SIDES BACK OUTLET

3'ft- 1M 3'ft- 1M 3'ft- 1M 10'ft- 3m

3'ft- 1M 3'ft- 1M 3'ft- 1M 10'ft- 3m

ELECTRICAL

530 W 1000 W 105 0 W

DIMENSIONS

101 123 12 3

HS408AG

3'ft- 1M 3'ft- 1M 3'ft- 1M 10'ft- 3m

** Heater shall not be directed toward any propane-gas container within 6 m (20 feet) and minimum

clearances from gas cylinder must be 3 m (10 feet)**

Forced-Air Agricultural Construction Heater

Operating Instructions and Owner’s Manual

3

Page 4

OPERATING PRECAUTIONS

This is a propane or natural gas, direct-fired, forced air

heater. It's intended use is primarily temporary heating of

buildings under construction, alteration or repair.

The hot air generator is designed for heating medium and

large ventilated premises, for which a fixed heating system is

required.

Heater is to be run on heating with natural gas or LPG

according to gas supply pressures that must be in conformity

with the national laws.

Heater is supplied after a complete functional test and it’s

therefore prearranged for one of the working gas indicated

in SPECIFICATION: an adhesive label applied on the gas

selector valve (a) indicates the selected gas.

To change the type of gas, follow the detailed instructions

indicated in section “CHANGING TYPE OF GAS”.

The heater is of the direct combustion type. The air is heated

by the energy developed during combustion and then

conveyed to the environment to be heated together with the

combustion products, thus making available 100% of the

thermal power produced. The environment must be suitably

ventilated in order to ensure adequate air circulation.

In the event of serious malfunction various safety devices

(electronic flame control unit, overheating thermostat, air

pressure switch) trigger turning off the heater .

The electronic flame control unit monitors if the flame is

irregular or goes out, the safety thermostat triggers when

the temperature in the combustion chamber exceeds the

safety limit value, the air pressure switch will cut in if the

airflow is insufficient.

In each of the said cases the unit stops according to the

procedure described in “OPERATING INSTRUCTIONS”.

In each of the said cases the lamp (8) will light up and the

heater will stop working. The heater can be restarted only

by pressing the reset button (8). Nonetheless, the cause

that triggered the safety device should always be carefully

analyzed and resolved before restarting the generator (cfr.

“FAULTS, CAUSES AND REMEDIES”).

SAFETY PRECAUTIONS

1. Check the heater thoroughly for damage. DO NOT

operate a damaged heater.

2. DO NOT modify the heater or operate a heater which has

been modified from its original condition.

3. Use only fuel types for which the heater has been

certified.

4. Minimum clearances from combustible material must be:

1 m (3 feet) from side, ceiling, floor and rear (air inlet) of

heater 3 m (10 feet) on air outlet of heater.

5. Heater shall not be directed toward any propane-gas

container within 6 m (20 feet) and minimum clearances

from gas cylinder must be 3 m (10 feet)

6. Don’t install the heater in places where there may be a

risk of fire or explosion

7. All fire prevention regulations must be adhered to.

8. The heater is not duct able and shall not be connected to

any duct work for air distribution.

9. The room or building which is being heated must be

sufficiently ventilated so that the heater has enough air to

function properly;

10. The air suction and/or supply pipes are not blocked in any

way, there are not sheets or covers resting on the machine

or walls and bulky objects near the heater;

11. The generator is placed near a power switchboard having

specifications in conformity with those declared;

12. The unit is placed in a fixed position;

13. The generator is regularly monitored during operation and

checked before being started up;

14. Don’t let animals or children near the heater.

15. Make sure heater is inspected before each use, and at

least annually by a qualified service person.

16. After use make sure the disconnecting switch is off.

17. When using any type of heater it is obligatory: not to

exceed the maximum level of heat output of the furnace

(“SPECIFICATION TABLE”);

18. Make sure that there is adequate air circulation and air

supply to the heater and that nothing is obstructing the

aspiration and expulsion of air; movement of air may

be obstructed in various ways including placing covers

or other objects on the heater or positioning the heater

too near a wall or other large object. If the airflow is not

adequate, the combustion chamber will overheat and the

overheat thermostat will turn the burner off

19. Use only the electrical power specified. The electrical

connection and grounding must comply with National

Electrical Code - ANSI/NFPA 70 (USA) and CSA C22.1

Canadian Electrical Code, Part 1 (Canada).

20. Use only in accordance with local codes or, in the absence

of local codes, with the Standard for the Storage and

Handling of Liquefied Petroleum Gases ANSI/NFPA 54 and

CSA B149.1, Natural Gas and Propane Installation Code.

Forced-Air Agricultural Construction Heater Operating Instructions and Owner’s Manual

4

Page 5

NO

INSTALLATION

All the operations described in this paragraph must be

performed by professional and skilled personnel only.

An approved manual gas valve shall be provided by the

installer.

The space heater can be installed suspended from the

ceiling or a top a support base.

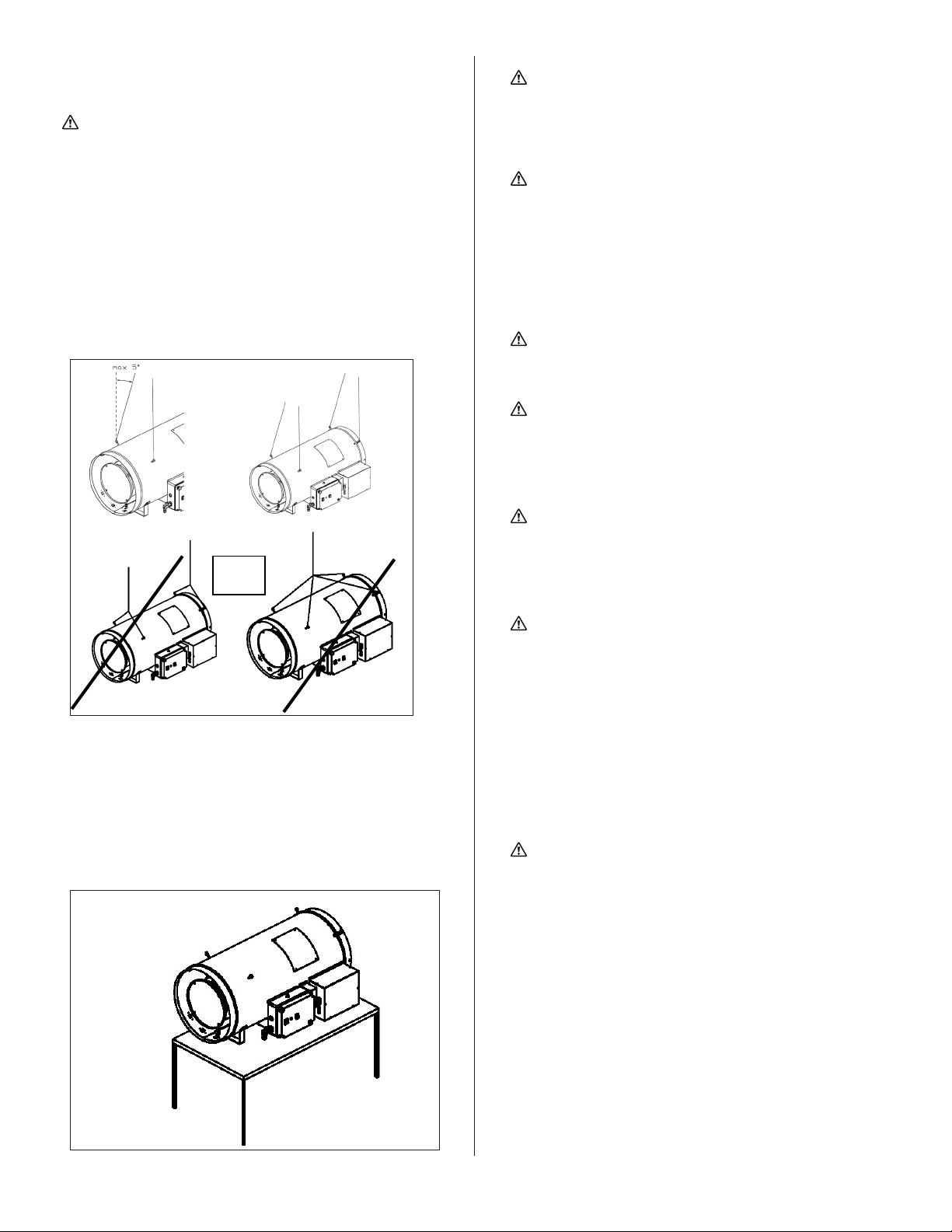

Ceiling Mount(Fig 1)- These heaters include eye bolt

support hooks. It may be hung from the ceiling with

metal chain or rope of appropriate load capacity and

length. Use the packaged factory eyebolts attach to the

four suspension points.

Fig. 1

Warning:

Make sure that the ropes and/or chains form an

angle not more than 5° with vertical to the ceiling,

that the ropes do not cross, and that a different rope

is used for each hook.

Warning:

In case of installation in greenhouses, mechanical

ventilation shall be interlocked to the heater

operation or permanent openings shall be fixed for

ventilation air.

ELECTRICAL CONNECTIONS

Warning:

The equipment is fitted with a temporary power

cable, used for the final control test at factory.

Warning:

The temporary power cord must be removed and

replaced with a proper power cord whose type

and dimension shall be in accordance with national

rules.

Warning:

The power line of the generator must feature an

earth lead and a residual current circuit breaker.

The supply cable must be connected to a

switchboard with sectioning switch.

Warning:

When installed, the appliance must be electrically

grounded in accordance with local codes, or in the

absence of local codes, with the National Electrical

Code, ANSI/NFPA 70, and/or the CSA C22.1,

Canadian Electrical Code, if an external electrical

The space heater can be installed on a support base

(Fig. 2), which must be:

• Stable, horizontal, broader in bas than heater length

and width.

• Made of non-combustible material

• Able to hold 150 lbs.

Fig. 2

source is utilized.

Only for 120 V models, the electrical power cable must be

connected in conformity to the polarity specified on the

main terminal board of the electrical panel: phase (L) and

neutral (N).

Warning:

Only for 120 V models, if polarities L and N are

incorrect, the space heater may stop a few seconds

after it is switched on for the first time.

If any room thermostat or other accessories are

connected to the system (such as the timer for example)

this must be done by connecting the electrical cable to

the thermostat plug (10):

• Take the plug (c) out of the power switchboard, open it

and remove the electrical jumper between terminals 2

and 3 of the plug.

• Connect the thermostat electrical cable to terminals 2

and 3 of the thermostat plug (c);

• Close the plug again and plug it back into the power

switchboard.

Forced-Air Agricultural Construction Heater

Operating Instructions and Owner’s Manual

5

Page 6

Having completed all these operations check carefully

that all electrical connections correspond to the wiring

diagram. When the heater is first turned on you must

check that the fan does not use more current than the

maximum permitted limit.

GAS LINE CONNECTIONS

The connection to the gas feed pipe, whose sizes must

correspond to the kind of system to be made, must be

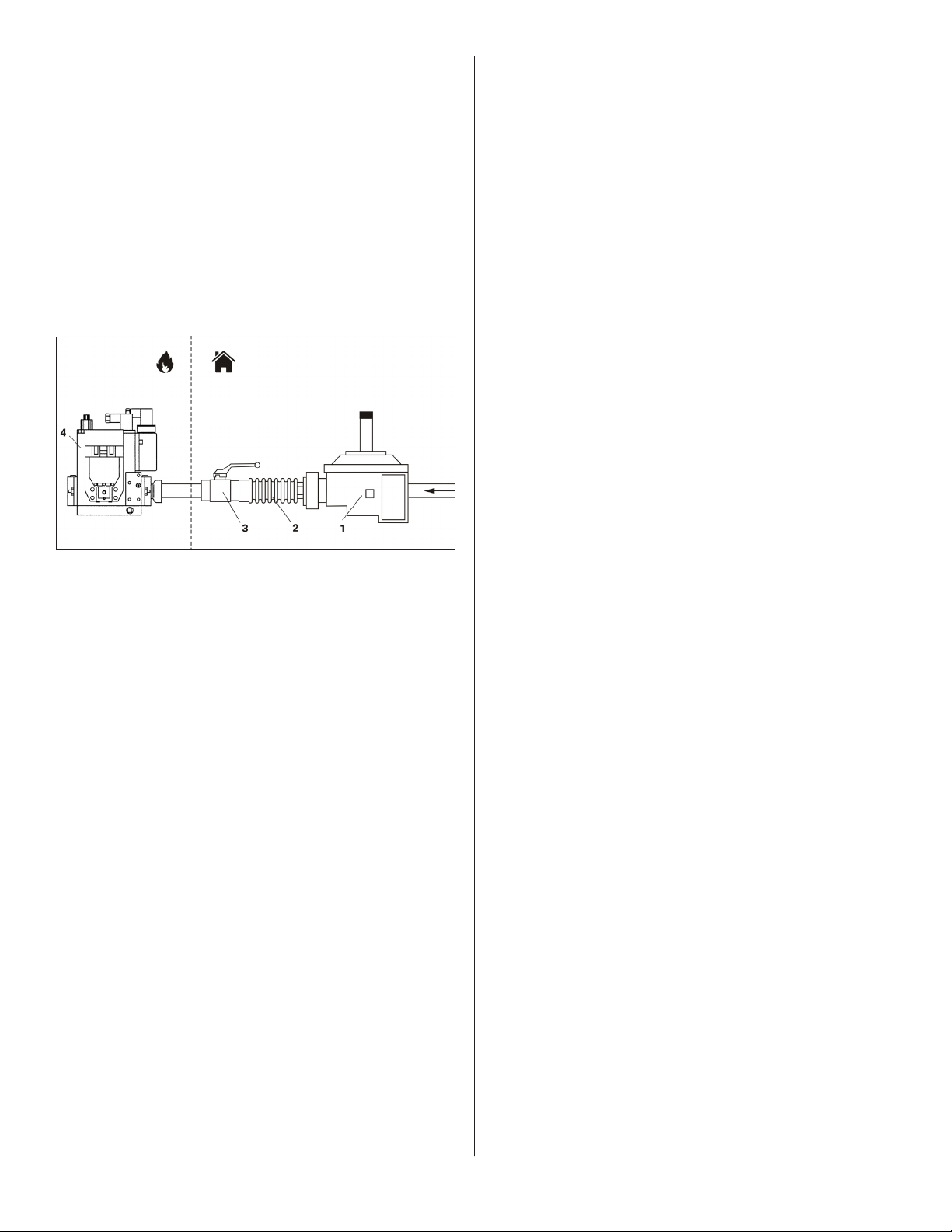

carried out by placing the“gas valve”as indicated in Fig. 3:

the gas pipe, the interception tap and the anti-vibration

joint are not supplied with the heater and they must be

arranged by the person in charge of installation.

Fig. 3

1: Filter-pressure regulator or filter

2: Anti vibration joint

3: Manual shut-off valve

4: Gas valve

In case of connection of heater to natural gas, the

installation shall conform with local codes or, in the

absence of local codes, with the National Fuel Gas Code

ANSI Z223.1/NFPA 54 and the Natural Gas and Propane

Installation Code, CSAB149.1.

In case of connection to a propane supply cylinder:

(a) the installation must conform with local codes or, in

the absence of local codes, with the Standard for the

Storage and Handling of Liquified Petroleum Gases,

ANSI/NFPA 58 and the Natural Gas and Propane

Installation Code, CSA B149.1.

(b) to determine size and capacity of the cylinder(s) and

for any specific requirements consult your LP gas supplier. In any case propane tank should not be lower

than 100 lb (90 liters)

(c) the cylinder supply system shall be arranged to provide

for vapour withdrawal from the operating cylinder;

(d) the gas shall be turned off at the propane supply

cylinder when the heater is not in use;

(e) when the heater is to be stored indoors, the

connection between the propane supply cylinder and

the heater must be disconnected and the cylinders

removed from the heater and stored in accordance

with Standard for the Storage and Handling of

Liquefied Petroleum Gases, ANSI/NFPA 58 and CSA

B149.1, Natural Gas and Propane Installation Code.

The appliance and its individual shut-off valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 psi (3.5 kPa).

The appliance must be isolated from the gas supply piping

system by closing its individual manual shut-off valve during

any pressure testing of the gas supply piping system at test

pressures equal or less than 1/2 psi (3.5 kPa).

A minimum 1/8” NPT plugged tapping, accessible for

test gauge connection, must be installed immediately

upstream of the gas supply connection to the appliance.

The heater is supplied after a complete functional test and

it’s therefore prearranged for one of the gas (natural or

LPG) indicated in Specification: an adhesive label applied

on the gas valve (Fig. 3) indicates the working gas (usually

it’s natural gas). Should it be necessary to change the kind

of gas (from natural gas to LPG or vice versa) follow the

detailed instructions indicated in section “Fuel Conversion"

Only when the heater has been prearranged according to

the proper working gas will it be possible to carry out the

following operations:

• Leak away some gas from the feed pipe;

• Check that the pipe is gas proof;

• Open the gas stop on/off valve and start the hot air

generator;

For installation in the U.S.A. at elevation above 2,000 feet

(610 m), the appliance shall be derated 4 per cent for each

1,000 feet (305 m) of elevation above sea level.

For installation in Canada at elevation above 2,000 feet to

4,500 feet above sea level, the heater is derated reducing

the output for the appropriate fuel in accordance with the

rating plate manifold pressure.

Forced-Air Agricultural Construction Heater Operating Instructions and Owner’s Manual

6

Page 7

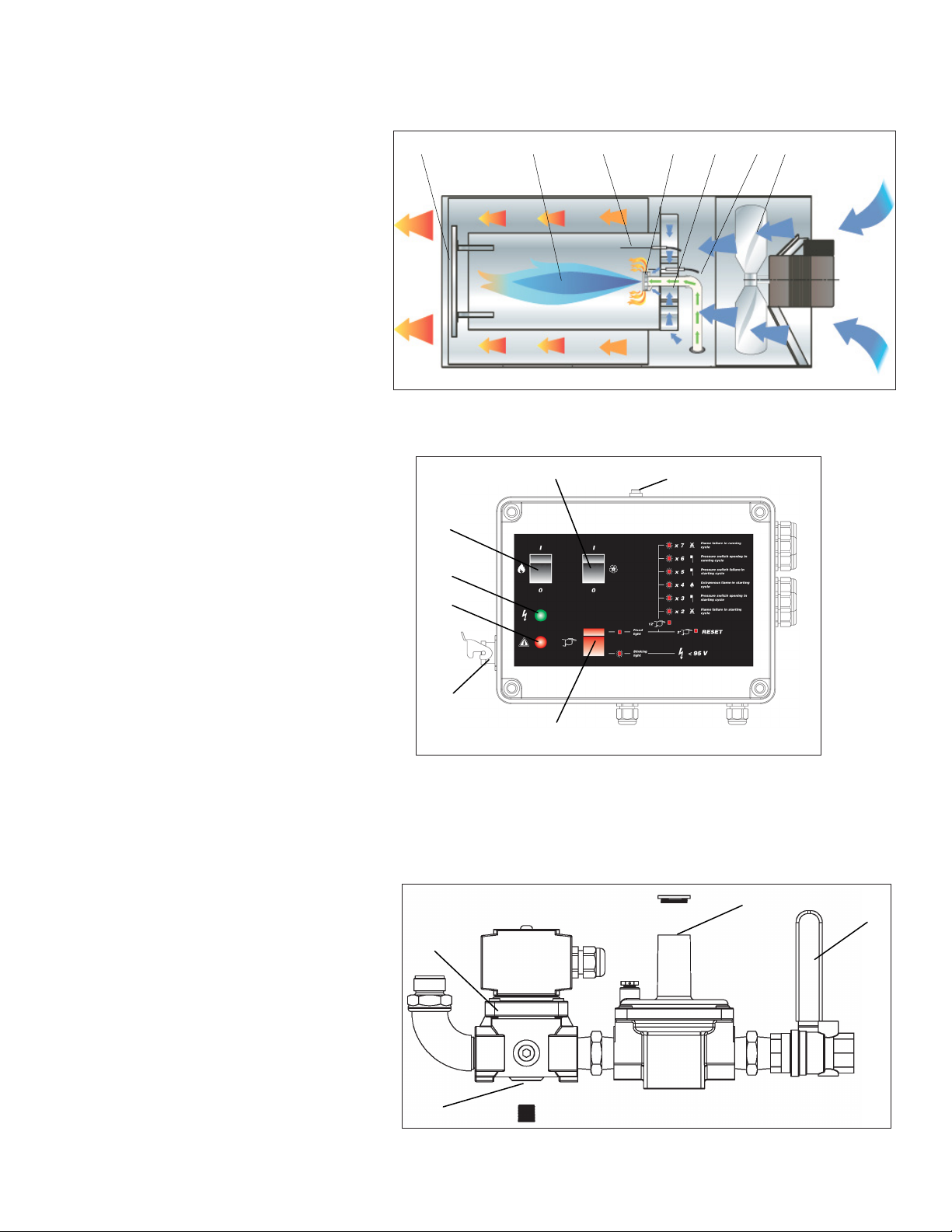

CONTROL PANEL

a

b c d

8 9 10

13

11

12

14

15

1 COMBUSTION CHAMBER

2 BURNER

3 DIFFUSION RING

4 FLAME GUARD SHIELD

5 COOLING FAN

6 IONIZATION ELECTRODE

7 IGNITION ELECTRODE

8 CONTROL FLAME RESET BUTTON

9 HEATING SWITCH

10 ROOM THERMOSTAT PLUG

FIG. 4

4

1 6

3

2

5

7

FIG. 5

11 POWER CONTROL LAMP

12 SAFETY THERMOSTAT LAMP

13 VENTILATION MODE SWITCH

14 SAFETY THERMOSTAT RESET BUTTON

15 CABLE FASTENER FOR POWER CORD

¬¬¬

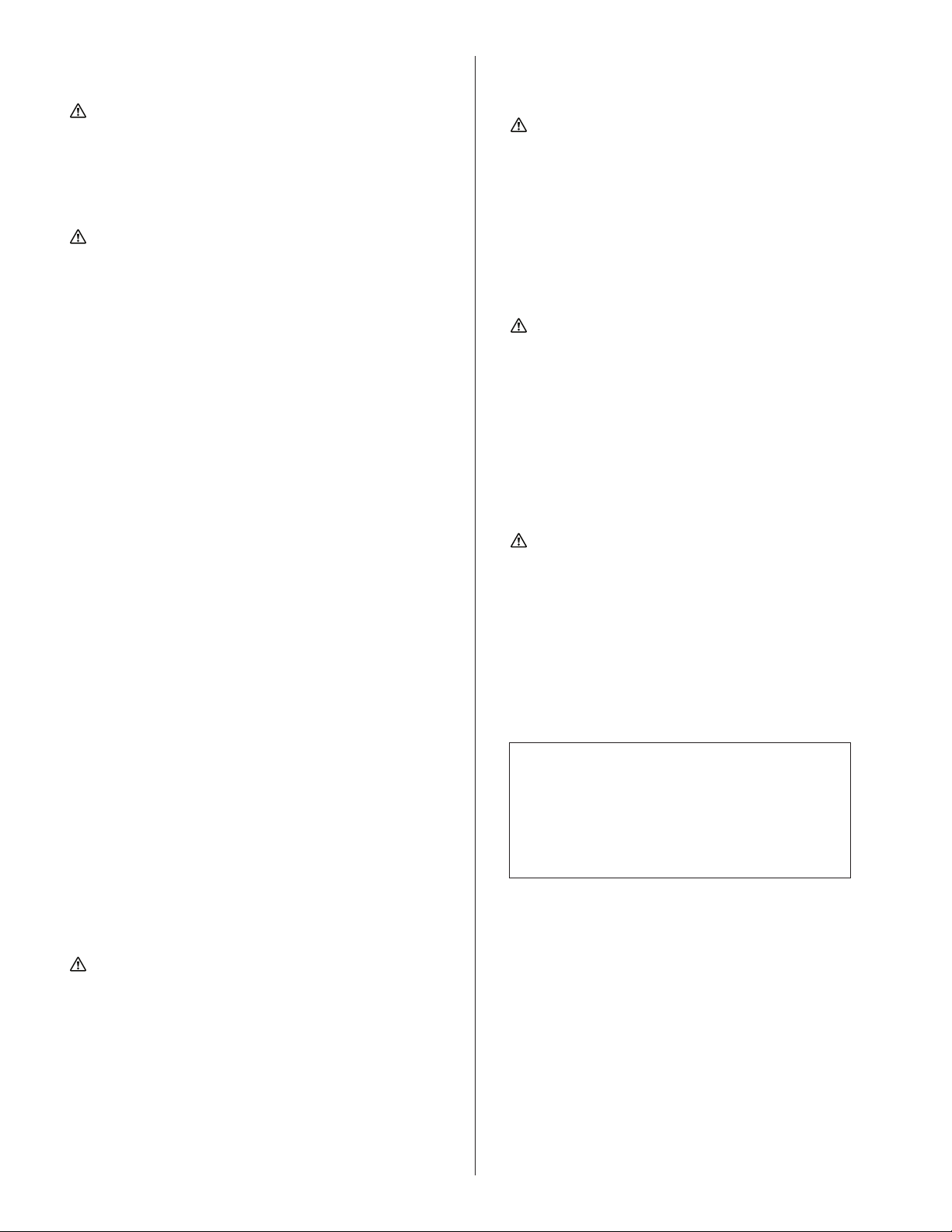

MANIFOLD ASSEMBLY

a SHUT OFF / FIRING VALVE

b MANIFOLD PRESSURE PORT (MANIFOLD)

c MANIFOLD PRESSURE REGULATOR

d MAIN GAS VALVE

FIG. 6

Operating Instructions and Owner’s Manual

7

Forced-Air Agricultural Construction Heater

Page 8

OPERATING INSTRUCTIONS

Warning

Any time the power cord of the heaters is connected

to a receptacle check the polarity of power supply:

• Check switch (9) and (13) are on “0” (REFER to FIG. 5)

• Connect plug to receptacle

• If lamp (#14 FIG. 5) lights up, then reverse polarity

Warning

If the correspondence of phase / neutral polarity is

not correct, the unit may stop in the reset mode.

HEATING MODE

Turning ON:

• Make sure switch (#9 FIG. 5) is on “0”;

• Power the heater by means of the sectioning switch on

the switchboard;

• If the unit is operated manually (without any thermostat

or any other control device) turn the switch (9) to posi-

tion “1”. The burner starts up, the combustion chamber

heats up and then the fan starts;

• If the unit operates automatically (being connected to

any thermostat or any other control device) turn the

switch (9) to position “1” and set the room thermostat

at the desired level: the heater will now start and stop

automatically.

• If after these operations, the generator does not work,

refer to the “FAULTS, CAUSES AND REMEDIES” para-

graph and find the cause.

SETTING POST VENTILATION MODE:

By the switch (#13 FIG. 5) on control panel, select the

post-ventilation mode, that is the time the fan goes on

blowing air when unit is switched off:

• When switch (#13 FIG. 5) is on pos. “0” then post ventilation lasts for 30 sec.

• When switch (#13 FIG. 5) is on pos. “1” then post ventilation is continuous.

Turning OFF:

In manual operation turn switch (#9 FIG. 5) to “0” or turn

thermostat control knob off.

After switching off the machine, a post ventilation function works according to the previous setting.

Warning

Finally, close the gas supply on/off valve, close the

shut-off valve (f) and turn off the sectioning switch

(Fig. 5).

VENTILATION MODE

To obtain the ventilation function only, make sure switch (#9

FIG. 5) is on position “0” and then simply turn the switch

(#13 FIG. 5) to position “1”. To stop it, turn the switch to

position “O”.

Warning

Whichever the reason, the unit only tries to restart

once. If the cause of malfunction remain, the unit

definitively stop and lamp (8# FIG. 5) will light up.

The heater can be restarted only by pressing the reset

button (#8 FIG. 5). Nonetheless, the cause that triggered

the safety device should always be carefully analyzed and

resolved before restarting the generator (cfr.“FAULTS,

CAUSES AND REMEDIES”).

TRANSPORT AND HANDLING:

Warning

Before moving the unit:

• Stop the machine as indicated in the “STOP”

paragraph;

• Disengage the power supply by removing the plug

from the power socket;

• Fully unscrew the fitting connecting the gas hose

pipe to the heater;

• Wait for the heater to cool down.

Fuel Conversion

Warning:

The conversion shall be carried out by a

manufacturer’s authorized representative,

in accordance with the requirements of the

manufacturer, provincial or territorial authorities

having jurisdiction and in accordance with the

requirements of the can/cga-b149.1 Or can/cgab149.2

Installation codes.

A conversion label shall be applied adjacent to the Rating

Label:

THIS APPLIANCE HAS BEEN CONVERTED FOR USE

AT AN ALTITUDE OF ___________ FEET (ABOVE 2000 FEET)

Orifice size: ______________________________________

Manifold pressure: ______________________________________

Input rate: ______________________________________

Date of conversion: ______________________________________

Type of fuel: ______________________________________

Converted by: ______________________________________

This operation may be carried out several times during the

working life of the heater and not only at initial start-up.

First of all refer to SPECIFICATIONS to identify the

reference category for natural gas or propane gas type.

For each gas category the supply pressure, the working

pressure and the arrangement of the diffusion ring (#3

FIG. 4) are stated.

To convert from one type of gas to another proceed as

follows:

•If stated in Tab.I, change the diffusion ring (#3 Fig. 4):

•Remove the upper body of the heater;

•Unscrew and remove the ionization electrode (#6 FIG. 4)

Forced-Air Agricultural Construction Heater Operating Instructions and Owner’s Manual

8

Page 9

• Undo the screws that secure the combustion head (3) to the

combustion chamber (#1 FIG. 4)

• Remove the three screws on the burner head plate and

change the diffusion ring securing it in such a way that the

ignition electrode is equidistant between the two subsequent

holes;

• Calibrate the gas pressure switch on the gas valve group (#4

Fig.3):

• Regulate the gas pressure switch to a value equal to 80% the

supply pressure;

• Regulate the pressure regulator for the gas valve group

(Fig.3); to the burner pressure stated in SPECIFICATIONS.

• Connect a gauge to the pressure intake (1) upstream and a

second gauge to the pressure intake downstream (2) of the

valve group;

• Start the heater and take the reading off the 1st supply

pressure gauge and if necessary adjust the pressure regulator

(#3 FIG. 6) for the gas supply system until the correct supply

pressure shown in SPECIFICATIONS is reached.

• Take a reading off the 2nd working pressure gauge and if

necessary use a screwdriver to adjust the pressure of the

gas valve group (#4 FIG. 3) to restore the working pressure

shown in SPECIFICATIONS.

• Apply the adhesive label with the words “SET UP FOR …”

corresponding to the type of fuel and the chosen category

on the gas valve group

clean carefully inside the combustion chamber and the whole

burner head and electrodes.

This heater can be washed, provided that:

A. The heater is disconnected from the electrical supply.

B. All access panels are securely closed.

C. Water spray nozzle shall not discharge within 6 feet of the

heater.

D. The heater is not reconnected to electrical supply until

thoroughly dried.

Improper cleaning of the heater can cause severe personal

injury or property damage due to water and/or cleaning

solutions:

A. In electrical components, connections and wires causing

electrical shocks or component failure.

B. On gas control components causing corrosion which can

result in gas leaks and fire or explosion from the leak. The

hose assembly must be protected from the traffic, building

materials and contact with hot surfaces both during use and

while in storage.

Warning

After cleaning, the flame guard shield must be screwed

securely back in place before operating heater.

Operating the heater without the flame guard shield can result

in combustion producing CO (carbon monoxide) which can

pose danger to those exposed to this to this environment.

MAINTENANCE

To regulate operation of the unit, the fans, combustion

chamber and the burner must be at least annually inspected

and periodically cleaned by a qualified service person.

Warning

Before performing any maintenance operation:

• Stop the machine as indicated in the “STOP”

paragraph;

• Disengage the power supply by removing the plug

from the power socket;

• Close the gas supply stop on/off valve and shut-off

valve (f);

• Wait for the heater to cool down.

During cleaning any foreign bodies must be removed from the

fan suction grille.

To access the burner, remove the flame guard panel (4)

by removing the four screws and clean carefully inside the

combustion chamber and the whole burner head: any debris

shall be taken away.

Warning

Do not direct jets of compressed air towards the air

pressure points near the main fan: the air pressure

switch could be permanently damaged.

Cleaning of the burner shall be regularly performed by

qualified service person. To access the burner, remove the

flame guard panel of combustion chamber (front side) and

Forced-Air Agricultural Construction Heater

Operating Instructions and Owner’s Manual

9

Page 10

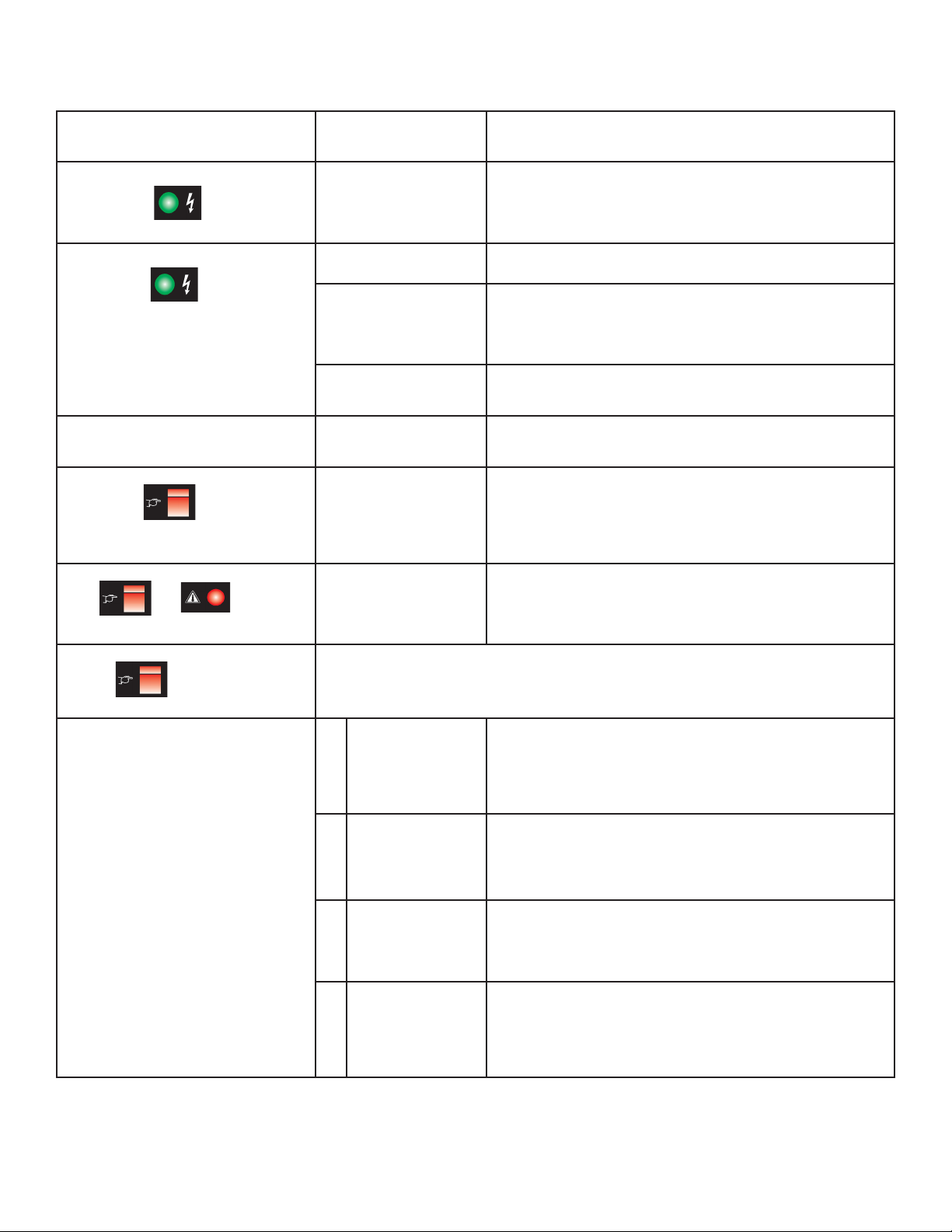

TROUBLESHOOTING

SYMPTOMS CAUSE SOLUTIONS

The heater does not start:

Lamp is off

The heater does not start:

Lamp is on

The heater works erratically and the burner

goes on and off alternately: Gas flow insufficient

The heater does not work:

Lamp flashes

The heater does not work:

Lamps and are on.

No power supply

Switch (#9 FIG. 5) in wrong

position

Defective room thermostat

Gas pressure switch tripped

due to no gas or insufficient

pressure

Voltage control has tripped

due to insufficient electrical

supply (V < 95V)

Manual reset safety thermostat has tripped due to excessive overheating of combustion chamber

• Check functioning and position of switch

• Check the mains

• Check power connections

• Check the fuse

Select correct position

• Check that thermostat connection plug is inserted

• Check the electrical connections of the thermostat

• Check thermostat setting and correct it

• Check functioning of thermostat

• Check that gas feed pipe has been bled

• Check gas feed pressure

• Check and clean gas filter.

• Clean and recalibrate the burner.

• The heater restarts automatically when sufficient voltage is restored

(V>95V)

• Check the power line if the heater starts and stops several times

• Check the power line if the heater does not start and remains in safety

stop

• Check that the fan motor starts correctly and is not obstructed

• Check that the fan motor is not burned out or that the motor condenser is

not broken

• Check burner calibration

The heater does not work:

Lamp is steady on

Number of flashes of lamp (8)

No flame during ignition

cycle

2

Micro switch with blade

has tripped (electrical

contact remained open)

3

at start of ignition cycle

Parasite flame detected

in pre-wash phase dur-

4

ing ignition cycle

Micro switch with blade

has tripped (electrical

contact has opened)

5

during ignition cycle

LAUNCH THE SELF-DIAGNOSIS PROCEDURE

PUSH BUTTON (8) FOR 12 SECONDS AND RELEASE:

THE BUTTON LAMP FLASHES WITH 2 TO 7 FLASHES

• Check gas pressure at burner

• Check and clean gas filter

• Check that ionization probe is not discharging to ground

• Check ionization probe connection cables (they must not discharge to

ground)

• Check wire connection of pressure switch

• Check pressure switch and replace if necessary

• Check that there is no remaining gas in the combustion chamber

• Check that ionization probe is not discharging to ground

• Check ionization probe connection cables (they must not discharge to

ground)

• Check wire connection of pressure switch

• Check that burner motor and fan are not blocked or broken; replace if

necessary

• Check that smoke exhaust chimney is not partially or totally obstructed

• Check pressure switch and replace if necessary

Forced-Air Agricultural Construction Heater Operating Instructions and Owner’s Manual

10

Page 11

TROUBLESHOOTING

SYMPTOMS CAUSE SOLUTIONS

Micro switch with blade

has tripped (electrical

contact has opened)

6

during work cycle

Number of flashes of lamp (8)

Fan is noisy or vibrates

Insufficient heating

No flame during work

cycle

7

Dirt on fan blades • Remove dirt

Poor air circulation • Eliminate all obstacles to air flow

Insufficient burner capacity • Contact Customer Service

In case of serious malfunction, the electronic equipment

causes the heater to go into safety stop, and lamp (#8 FIG. 5)

lights with a steady red light (stop light).

Warning

In case of a safety stop, you have to push the reset

button (#8 FIG. 5) for 3 seconds to restart the heater.

Warning

NEVER do more than two restarts in a row: unburned

fuel can accumulate in the combustion chamber and

suddenly flare up at the next restart.

• Check connection of pressure switch pipes

• Check that burner motor and fan are not blocked or broken; replace if

necessary

• Check that smoke exhaust chimney is not partially or totally obstructed

• Check pressure switch and replace if necessary

• Check gas pressure at burner

• Check and clean gas filter

• Check that ionization probe is not discharging to ground

• Check ionization probe connection cables (they must not discharge to

ground)

In case of safety stop, press the reset button (#8 FIG. 5) for at

least 12 seconds to launch a self-diagnosis programme, after

which the button will flash at different rates (Self-diagnosis

lamp) according to the type of safety intervention: the synoptic

on the electrical panel shows the possible types.

If the combustion chamber overheats, the safety thermostat

(14) trips to shut off the burner and lamp (#8 FIG 5.) lights: to

reset the burner, you have to shut off the heater completely,

cut electrical power and push button (#14 FIG. 5).

Warning

You must always find the cause of the safety intervention

and remove it before pushing reset button (#8 FIG 5) or

button (#14 FIG 5) and restarting the heater.

If the heater is still not working properly, please contact your

nearest dealer or authorized Service Centre.

Forced-Air Agricultural Construction Heater

Operating Instructions and Owner’s Manual

11

Page 12

WIRING DIAGRAM

AP CONTROL BOX

TA ROOM THERMOSTAT PLUG

ST ELECTRIC PILOT LAMP

FU FUSE

EV GAS TRAIN

CO CONDENSER

MV FAN MOTOR

FUA FUSE

Forced-Air Agricultural Construction Heater Operating Instructions and Owner’s Manual

RV HEATING SWITCH

IT TRANSFORMER H.V.

PA AIR PRESSURE SWITCH

EL IONISATION ELECTRODE

RV1 VENTILATION SWITCH

TS OVERHEAT THERMOSTAT

RL REMOTE BLOCK INDICATOR LIGHT

12

Page 13

WIRING DIAGRAM

ACCESSORIES

Forced-Air Agricultural Construction Heater

Operating Instructions and Owner’s Manual

13

Page 14

PARTS LIST AND DIAGRAM

Model 250AG

# P/N PART DESCRIPTION QTY

1 5 0330 Control board 2

2 5 0735 Electrode

3 5 0736 Electrode Cable 1

4 5 0738 Gas regulator 1

5 5 074 0 Gas Train 1

6 5 0741 Ioniz. Cable 1

7 5 0742 Ioniz. Probe 1

# P/N PART DESCRIPTION QTY

8 5 0743 Motor 1

9 5 074 6 Pressure switch

1

10 50747 Propeller

11 5 0749 Protection press. Switch

12 50349 Thermostat

13 50329 Transformer

4

D

D

Forced-Air Agricultural Construction Heater Operating Instructions and Owner’s Manual

14

Page 15

PARTS LIST AND DIAGRAM

Model 400AG & 408AG

# P/N PART DESCRIPTION QTY

1 50330 Control board 2

2 50735 Electrode

3 5073 6 Electrode Cable 1

4 50737 Gas regulator 1

5 5073 9 Gas Train 1

6 50741 Ioniz. Cable 1

7 50742 Ioniz. Probe 1

8 50744 Motor

# P/N PART DESCRIPTION QTY

8 50745 Motor

9 50746 Pressure switch

1

10 5 074 8 Propeller

11 50 749 Protection press. Switch

12 50349 Thermostat

13 50329 Transformer

* 13 50750 Transf. 220/110 **(only for model 408AG)**

4

D

D

Forced-Air Agricultural Construction Heater

Operating Instructions and Owner’s Manual

15

Page 16

Model #

OPERATING INSTRUCTIONS

AND OWNER’S MANUAL

HS250AG

HS400AG

HS408AG

READ INSTRUCTIONS CAREFULLY: Read and follow all instructions. Place instructions in a safe

place for future reference. Do not allow anyone who has not read these instructions to assemble,

light, adjust or operate the heater.

WARNING:

USE ONLY MANUFACTURER’S REPLACEMENT PARTS. USE OF ANY OTHER PARTS

COULD CAUSE INJURY OR DEATH. REPLACEMENT PARTS ARE ONLY AVAILABLE DIRECT

FROM THE FACTORY AND MUST BE INSTALLED BY A QUALIFIED SERVICE AGENCY.

PARTS ORDERING INFORMATION:

PURCHASING: Accessories may be purchased at any HEAT STAR local dealer or direct

from the factory

FOR INFORMATION REGARDING SERVICE

Please call Toll-Free 866-447-2194 • HEATSTARBYENERCO.COM

Our office hours are 8:00 AM – 5:00 PM, EST, Monday through Friday.

Please include the model number, date of purchase, and description of problem in all

communication.

LIMITED WARRANTY

The company warrants this product to be free from imperfections in material or

workmanship, under normal and proper use in accordance with instructions of

The Company, for a period of one year from the date of delivery to the buyer. The

Company, at its option, will repair or replace products returned by the buyer to the

factory, transportation prepaid within said one year period and found by the Company

to have imperfections in material or workmanship.

If a part is damaged or missing, call our Technical Support Department at 866-447-2194.

Address any Warranty Claims to the Service Department, HEAT STAR Group, Inc.,

4560 W. 160th St., Cleveland, Ohio 44135. Include your name, address and telephone

number and include details concerning the claim. Also, supply us with the purchase

date and the name and address of the dealer from whom you purchased our product.

The foregoing is the full extent of the responsibility of the Company. There are no

other warranties, express or implied. Specifically there is no warranty of fitness for a

particular purpose and there is no warranty of merchantability. In no event shall the

Company be liable for delay caused by imperfections, for consequential damages, or

for any charges of the expense of any nature incurred without its written consent. The

cost of repair or replacement shall be the exclusive remedy for any breach of warranty.

There is no warranty against infringement of the like and no implied warranty arising

from course of dealing or usage of trade. This warranty will not apply to any product

which has been repaired or altered outside of the factory in any respect which in our

judgment affects its condition or operation.

Some states do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you. This Warranty gives

you specific legal rights, and you may have other rights which vary from state to state.

HEAT STAR Group, Inc. reserves the right to make changes at any time, without notice or

obligation, in colors, specifications, accessories, materials and models.

PRODUCT REGISTRATION: Thank you for your purchase.

Please log in to HEATSTARBYENERCO.COM to register your product.

HEAT STAR, INC., 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 866-447-2194

Page 17

INSTRUCTIONS D'UTILISATION

ET MANUEL DU PROPRIÉTAIRE

VEUILLEZ LIRE ATTENTIVEMENT LES INSTRUCTIONS : Lire et observer toutes les instructions.

Conserver ces instructions dans un endroit sécuritaire pour vous y référer ultérieurement. Interdisez

à quiconque n’ayant pas lu les présentes instructions d'assembler, d'allumer, de régler ou de faire

fonctionner cette fournaise.

HS250AG

HS400AG

No de modèle

HS250AG

HS400AG

HS408AG

HS408AG

AVERTISSEMENT :

— N’entreposez et n’utilisez pas d’essence ou d’autres liquides ou vapeurs inflammables à proximité

de ce type d’appareil ou de tout autre appareil.

— Un cylindre de gaz propane (liquéfié) non branché pour utilisation ne devrait pas être entreposé

près de cet appareil ou de tout autre appareil.

— QUOI FAIRE SI VOUS SENTEZ DU GAZ

• N’essayez pas d’allumer l’appareil.

• Éteignez toute flamme nue.

• Fermez l'entrée de gaz allant vers l'appareil.

— L'entretien doit être effectué par une entreprise d'entretien accréditée.

Il s'agit d'une fournaise portable alimentée au gaz et non aérée. L'appareil utiliser de l'air (oxygène) de

l'endroit où il est utilisé. Une combustion et une ventilation adéquates doivent être fournies.

Si l'information dans ce manuel n'est pas suivie exactement, un incendie

ou une explosion pourrait se produire causant des dommages aux biens,

des blessures personnelles ou un décès.

LANGUES INCLUS

•ANGLAIS

•FRANÇAIS

2017 CB HEAT STAR, Inc., 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 866-447-2194

Page 18

AVERTISSEMENT :

VOTRE SÉCURITÉ EST IMPORTANTE POUR VOUS ET POUR LES

AUTRES, PAR CONSÉQUENT VEUILLEZ LIRE CES DIRECTIVES AVANT

DE FAIRE FONCTIONNER CET APPAREIL DE CHAUFFAGE.

AVERTISSEMENT :

NON CONÇU POUR UNE UTILISATION À L'INTÉRIEUR DE LA

MAISON OU DANS UN VÉHICULE RÉCRÉATIF.

AVERTISSEMENT :

AVERTISSEMENT GÉNÉRAL DE:

LE NON-RESPECT DES MESURES DE PRÉVENTION ET DES

INSTRUCTIONS FOURNIES AVEC CET APPAREIL DE CHAUFFAGE

RISQUE DE CAUSER LA MORT, DES BLESSURES GRAVES ET

DES DOMMAGES OU DES PERTES MATÉRIELLES RÉSULTANT

D'INCENDIE, D'EXPLOSION, DE BRÛLURE, D'ASPHYXIE,

D'INTOXICATION AU MONOXYDE DE CARBONE ET/

OU D'ÉLECTROCUTION. SEULES LES PERSONNES APTES À

COMPRENDRE ET À RESPECTER LES INSTRUCTIONS DEVRAIENT

UTILISER OU EFFECTUER LE SERVICE DE CET APPAREIL DE

CHAUFFAGE. SI VOUS AVEZ BESOIN D'AIDE OU D'INFORMATION

CONCERNANT LA FOURNAISE TELS QUE MANUEL

D'INSTRUCTIONS, ÉTIQUETTES, ETC., VEUILLEZ COMMUNIQUER

AVEC LE FABRICANT.

L'ÉTAT DE CALIFORNIE EXIGE QUE L'AVERTISSEMENT SUIVANT SOIT FOURNI :

DANGER D'INCENDIE, D'INHALATION ET D'EXPLOSION.

GARDEZ LES COMBUSTIBLES SOLIDES TELS QUE LES

MATÉRIAUX DE CONSTRUCTION LE PAPIER ET LE

CARTON À UNE DISTANCE SÉCURITAIRE DE L'APPAREIL

DE CHAUFFAGE TEL QUE RECOMMANDÉ DANS LES

INSTRUCTIONS. N'UTILISEZ JAMAIS LA FOURNAISE

DANS UN ENDROIT QUI CONTIENT OU RISQUE DE

CONTENIR DES COMBUSTIBLES VOLATILES OU EN

SUSPENSION DANS L'AIR, OU DES PRODUITS TELS

QUE DE L'ESSENCE, DES SOLVANTS, DU DILUANT À

PEINTURE, DES PARTICULES DE POUSSIÈRE OU DES

PRODUITS CHIMIQUES INCONNUS.

AVERTISSEMENT :

de carbone, un produit chimique reconnu par l'état de Californie comme pouvant causer le cancer et des malformations

congénitales (ou autres dommages au système reproducteur).

Les sous-produits de combustion émis lors de l'utilisation de cet appareil contiennent du monoxyde

AVERTISSEMENT : Cet appareil contient des produits chimiques reconnus par l'état de Californie comme pouvant

causer le cancer et des malformations congénitales ou autres dommages au système reproducteur.

CONTENU

AVERTISSEMENTS ................................................................2

SPÉCIFICATIONS ..................................................................3

PRÉCAUTIONS LIÉES AU FONCTIONNEMENT ..............................4

PRÉCAUTIONS DE SÉCURITE .....................................................4

INSTALLATION .....................................................................5

RACCORDEMENT ÉLECTRIQUE .............................................5

GAS LINE OPERATION ..........................................................6

GAZ LIGNE ..........................................................................7

CONVERSION DE COMBUSTIBLE ..........................................8

MODE D'EMPLOI ..................................................................8

ENTRETIEN ...........................................................................9

DÉPANNAGE ..................................................................10-11

SCHÉMA ........................................................................ 12-13

LISTES DE PIÈCES ET VUES ÉCLATÉES ............................. 14-15

INFORMATIONS DE GARANTIE .......................................... 16

À air forcé agricole Chauffe-Construction Instructions d'utilisation et le manuel du propriétaire

2

Page 19

SPÉCIFICATIONS

No DE MODÈLE

PRESSION D'ALIMENTATION

RING BUSE (POUCES)

APPORT DE CHALEUR (BTU /H)

PRESSION D'ADMISSION

CONSOMMATION DE CARBURANT (CFH)

ENTRÉE DE GAZ

NIVEAU DE BRUIT À 1M

PRESSION D'ALIMENTATION

RING BUSE (POUCES)

APPORT DE CHALEUR (BTU / H)

PRESSION D'ADMISSION

CONSOMMATION DE CARBURANT (CFH)

ENTRÉE DE GAZ

NIVEAU DE BRUIT À 1M

HS250AG (F130105) HS400AG (F130110) HS408AG (F130115)

Gaz naturel

Min 8" W.C - Max 10" W.C Min 8" W.C - Max 10" W.C Min 8" W.C - Max 10" W.C

N. 16 Holes x 0.102" N. 16 Holes x 0.138" N. 16 Holes x 0.138"

250,000 400,000 400,000

2,61 2,38 2,38

233.51 355.52 355.52

3/4" NPT 3/4" NPT 3/4" NPT

77 (dBA) 74 (dBA) 74 (dBA)

DU PROPANE

Min 8" W.C - Max 13" W.C Min 8" W.C - Max 13" W.C Min 8" W.C - Max 13" W.C

N. 12 Holes x 0.079" N. 12 Holes x 0.098" N. 12 Holes x 0.098"

250,000 400,000 400,000

3.64 4.01 4.01

85.94 141. 95 141. 9 5

3/4" 3/4" 3/4"

77 (dBA) 74 (dBA) 74 (dBA)

SPÉCIFICATIONS ÉLECTRIQUES

ÉLEC. ALIMENTATION

(VOLTS/Hz/PHASE)

AMPÈRES EN CONTINU

WAT TS

120V-60HZ- 1Ø 120V-60HZ-1Ø 208V-60HZ-1Ø

5.0 AMPS 9.5 AMPS 5.0 AMPS

530 W 1000 W 105 0 W

DIMENSIONS/POIDS DE LA FOURNAISE

LONGUEUR X LARGEUR X

45.1" X 23.2" X 17.4" 46.7" x 26.9" x 21.1" 46.7" x 26.9" x 21.1"

HAUTEUR (EN)

POIDS DE LA BOÎTE (LB/KG)

101LB (45.8 kg) 123 (55.7 kg) 123 (55.7 kg)

Longueur x largeur x hauteur (en)

No DE MODÈLE SUPÉRIEUR CÔTÉS ENDOS SORTIE

HS250AG

HS400AG

HS408AG

3'ft- 1M 3'ft- 1M 3'ft- 1M 10'ft- 3m

3'ft- 1M 3'ft- 1M 3'ft- 1M 10'ft- 3m

3'ft- 1M 3'ft- 1M 3'ft- 1M 10'ft- 3m

** Chauffe-eau doit pas être dirigé vers un conteneur de propane au gaz dans les 6 m (20 pieds) et les

distances minimales par bouteille de gaz doit être de 3 m (10 pieds) **

À air forcé agricole Chauffe-Construction

Instructions d'utilisation et le manuel du propriétaire

3

Page 20

PRÉCAUTIONS D'UTILISATION

Ceci est un propane ou au gaz naturel, de chauffage à air

pulsé à feu direct. Il est destiné utilisation est principalement le

chauffage temporaire de bâtiments en cours de construction,

de modification ou de réparation.

Le générateur d'air chaud est conçu pour les moyennes et

grandes de chauffage des locaux ventilés, pour lesquels un

système de chauffage fixe est nécessaire.

Chauffe-est pour être exécuté sur le chauffage au gaz naturel

ou au GPL selon pressions d'alimentation en gaz qui doivent

être en conformité avec les lois nationales.

Chauffage est fourni après un test fonctionnel complet et il est

donc prédisposé pour l'un des gaz de travail indiqué dans la

spécification: une étiquette adhésive appliquée sur la vanne de

sélection de gaz (a) indique le gaz choisi.

Pour changer le type de gaz, suivre les instructions détaillées

indiquées dans la section "Modification TYPE DE GAZ".

Le chauffage est du type de combustion directe. L'air est

chauffé par l'énergie développée lors de la combustion et

ensuite transporté à l'environnement à chauffer en même

temps que les produits de combustion, ce qui rend disponible

100% de la puissance thermique produite. L'environnement

doit être suffisamment ventilé afin d'assurer une circulation d'air

adéquate.

Dans le cas de divers dispositifs de sécurité de

dysfonctionnement grave (unité de contrôle électronique de la

flamme, thermostat de surchauffe, l'interrupteur de pression

d'air) déclenchement d'éteindre le chauffage.

Les moniteurs de l'unité de contrôle électronique de la flamme

si la flamme est irrégulière ou sort, le thermostat de sécurité

se déclenche lorsque la température dans la chambre de

combustion dépasse la valeur limite de sécurité, l'interrupteur de

pression d'air sera coupé si le débit d'air est insuffisant.

Dans chacun de ces cas, l'unité arrête selon la procédure décrite

dans "MODE D'EMPLOI".

Dans chacun de ces cas, la lampe (8) brille et le chauffe-eau

cesser de travailler. Le chauffe-eau peut être redémarré en

appuyant simplement sur le bouton de réinitialisation (8).

Néanmoins, la cause qui a déclenché le dispositif de sécurité

doit toujours être soigneusement analysé et résolu avant de

redémarrer le générateur (cfr. "DEFAUTS, causes et remèdes").

PRÉCAUTIONS DE SÉCURITÉ

1. Vérifiez l'appareil de chauffage à fond pour les dommages. NE

PAS faire fonctionner un appareil de chauffage endommagé.

2. NE PAS modifier le chauffage ou fonctionner un chauffe qui a

été modifié depuis son état original.

3. Utilisez les types de carburant seulement pour lequel le

chauffage a été certifiés.

4. Dégagements minimum aux matériaux combustibles doivent

être: 1 m (3 pieds) d'un côté, plafond, plancher et à l'arrière

(entrée d'air) du chauffe-eau de 3 m (10 pieds) sur la sortie de

l'air de chauffage.

5. Chauffe ne doit pas être dirigé vers un conteneur de propane

au gaz dans les 6 m (20 pieds) et les distances minimales par

bouteille de gaz doit être de 3 m (10 pieds)

6. Ne pas installer l'appareil dans des endroits où il peut y avoir un

risque d'incendie ou d'explosion

7. Tous les règlements de prévention des incendies doivent être

respectées.

8. Le chauffage est conduit pas capables et ne doit pas être raccordé à

tous les travaux de canalisation de distribution d'air.

9. La pièce ou un bâtiment qui est chauffé doit être suffisamment

ventilé afin que le chauffage a assez d'air pour fonctionner

correctement;

10. L'aspiration de l'air et / ou d'approvisionnement tuyaux ne

sont pas bloquées en aucune façon, il n'y a pas de feuilles ou

couvertures reposant sur la machine ou sur les murs et les objets

encombrants proximité de l'appareil;

11. Le générateur est placé près d'un tableau de distribution de

puissance ayant des spécifications conformes à ceux déclarés;

12. L'appareil est placé dans une position fixe;

13. Le générateur est régulièrement surveillée pendant le

fonctionnement et vérifié avant d'être mis en marche;

14. Ne laissez pas les animaux ou les enfants à proximité de l'appareil

de chauffage.

15. Assurez-vous de chauffage est inspecté avant chaque utilisation,

et au moins annuellement par une personne qualifiée.

16. Après utilisation, vérifiez le sectionneur est éteint.

17. Lors de l'utilisation de tout type de chauffe, il est obligatoire: ne

pas dépasser le niveau maximal de production de chaleur du four

(le «tableau des spécifications");

18. Assurez-vous qu'il ya une circulation d'air adéquate et

alimentation en air de l'appareil de chauffage et que rien ne

fait obstacle à l'aspiration et l'expulsion de l'air; mouvement

de l'air peut être obstrué de diverses manières, y compris la

mise couvertures ou d'autres objets sur le chauffage ou le

positionnement de l'appareil de chauffage trop près d'un mur ou

tout autre objet volumineux. Si la circulation d'air est suffisante,

la chambre de combustion va surchauffer et le thermostat de

surchauffe éteindre le brûleur

19. Utilisez uniquement l'alimentation électrique spécifiée. Le

raccordement électrique et de mise à la terre doivent être

conformes au Code national de l'électricité - ANSI / NFPA 70

(Etats-Unis) et CSA C22.1 Code canadien de l'électricité, Partie 1

(Canada).

20. Utiliser uniquement conformément aux codes locaux ou, en

l'absence de codes locaux, à la norme pour le stockage et la

manipulation des gaz de pétrole liquéfiés ANSI / NFPA 54 et CSA

B149.1, gaz naturel et propane Code d'installation.

À air forcé agricole Chauffe-Construction Instructions d'utilisation et le manuel du propriétaire

4

Page 21

NO

INSTALLATION

Toutes les opérations décrites dans ce paragraphe doivent

êtreeffectué uniquement par du personnel professionnels

et qualifiés.

Un robinet de gaz manuel approuvé doit être fourni par

l'installateur.

Le radiateur peut être installé suspendu au plafond ou au

sommet d'une base de soutien.

Ceiling Mount (figure 1) - Ces appareils incluent un

support de boulon yeux crochets. Il peut être suspendu

au plafond avec une chaîne ou une corde de la capacité

de charge et de la longueur métallique. Utilisez les

anneaux de l'usine em

Fig. 1

Attention:

S’assurer que les élingues et/ou les chaînes forment

un angle maximum de 5° avec la verticale au plafond,

que les élingues ne s’entrecroisent pas et qu’une

élingue différente est utilisée pour chaque crochet.

Attention:

En cas d'installation dans des serres, une ventilation

mécanique doit être enclenché à l'opération de

chauffage ou des ouvertures permanentes doit être

fixé pour l'air de ventilation.

RACCORDEMENT ÉLECTRIQUE

Attention:

L'appareil est équipé d'un câble d'alimentation

temporaire, utilisé pour le test de contrôle final en

usine.

Attention:

Le cordon d'alimentation temporaire doit être

enlevé et remplacé par un cordon d'alimentation

approprié dont le type et la dimension doit être en

conformité avec les règles nationales.

Attention:

La ligne d'alimentation du générateur doit figurer un

conducteur de terre et d'un disjoncteur de courant

résiduel.Le câble d'alimentation doit être connecté à

un standard avec sectionnement commutateur.

Attention:

Lors de l'installation, l'appareil doit être relié à la

terre dans le respect des réglementations locales ou,

à défaut, de la réglementation électrique nationale

ANSI / NFPA 70 et/ou de la CSA C22.1, Canadian

ballés attachent aux quatre points de suspension.

L'appareil de chauffage peut être installé sur une base de

support

(Fig. 2), qui doit être:

• Stable, horizontal, plus large en bas que la longueur et

la largeur de chauffage.

• Fait de matériau incombustible

• Capable de tenir 150 lbs.

Fig. 2

Electrical Code, en cas d'utilisation d'une source

électrique extérieure.

Seulement pour les modèles 120 V, le câble d'alimentation

électrique doit être raccordé conformément à la polarité

indiquée sur le bornier principal du panneau électrique:

phase (L) et neutre (N).

Attention:

Seulement pour les modèles 120 V, si les polarités

L et N sont incorrects, le radiateur peut arrêter

quelques secondes après il est allumé pour la

première fois.

Si un thermostat d'ambiance ou autres accessoires sont

reliés au système (tel que la minuterie par exemple) cela

doit être fait en connectant le câble électrique à la prise

du thermostat (10):

• Prenez le bouchon (c) sur le tableau de distribution de

puissance, l'ouvrir et retirez le cavalier électrique entre

les bornes 2 et 3 de la fiche.

• Branchez le câble électrique du thermostat aux bornes 2

et 3 de la fiche du thermostat (c);

• Fermez le bouchon encore et rebranchez-le dans le

tableau de puissance.

À air forcé agricole Chauffe-Construction

Instructions d'utilisation et le manuel du propriétaire

5

Page 22

Having completed all these operations check carefully

that all electrical connections correspond to the wiring

diagram. When the heater is first turned on you must

check that the fan does not use more current than the

maximum permitted limit.

RACCORDEMENT AU GAZ LINE

Le branchement au conduit d'alimentation du gaz doit

avoir desdimensions adéquates et correspondantes au

type d'installation à effectuer et il doit être exécuté en

réalisant la "rampe de gaz" comme illustré sur la Fig. 3

: tuyau de gaz, robinet d'arrêt et manchon de couplage

antivibrations ne sont pas fournis avec le générateur et

doivent être posés par l'installateur.

Fig. 3

1: Filtre-régulateur de pression ou filtre

2: Joint anti-vibrations

3: Vanne d’arrêt

4: rampe de gaz

En cas de raccordement du générateur au gaz naturel,

l'installation doit être conforme aux réglementations

locales ou, àdéfaut, au National Fuel Gas Code ANSI

Z223.1/NFPA 54 et au Natural Gas and Propane installation Code CSAB149.1

In case of connection to a propane supply cylinder:

(a) L'installation doit être conforme aux réglementations

localesou, à défaut, au Standard for the Storage and

Handling of Liquified Petroleum Gases, ANSI/NFPA 58

et au Natural Gasand Propane Installation Code, CSA

B149.1

(b) Pour déterminer la taille et la capacité de la/des

bouteille (s) et pour toutes les exigences spécifiques,

consulter le fournisseur de GPL. Dans tous les cas, la

contenance de la bouteille de propane ne doit pas être

inférieure à 90 litres (100 lb).

(c) Le système d'approvisionnement par bouteille doit être

conçu pour assurer le retrait de vapeur de la bouteille

utilisée

(d) La vanne d'arrêt de gaz de la cuve doit être fermée

lorsque le générateur d'air chaud n'est pas utilisé ;

(e) Si le générateur d'air chaud est stocké à l'intérieur

d'un local, il doit être débranché de la cuve de gaz

; le récipient contenant le gaz doit être conforme

aux prescriptions des "Standard for the Storage and

Handling of Liquified Petroleum Gases" ANSI/NFPA 58

et au "Natural Gas and Propane Installation Code" CSA

B 149.1.

À air forcé agricole Chauffe-Construction Instructions d'utilisation et le manuel du propriétaire

L'appareil et son robinet d'arrêt doivent être débranchés

dusystème d'alimentation de gaz en cas de test de pression

dusystème à des pressions supérieures à ½ psi (3,5 kPa.)

L'appareil doit être isolé du système d'alimentation en gaz

en fermant son robinet d'arrêt manuel pendant tout le

test de pression du système d'alimentation en gaz à des

pression égales ou inférieures à ½ psi (3,5 kPa.)

Un bouchon taraudé de 1/8 NPT minimum, destiné à

la connexion du manomètre de test, doit être installé

immédiatement en amont de la connexion d'alimentation

en gaz de l'appareil.

Le générateur PHOEN N est fourni après un test de

fonctionnement complet et il est donc prédisposé pour

l'un des gaz(naturel ou GPL) indiqué dans le Specification:

L'étiquette adhésive collée sur la soupape principale du

gaz indique la catégorie de gaz (Fig. 3) (généralement

gaz naturel). Si l'alimentation se fait avec un autretype

de gaz (de gaz naturel à GPL et inversement) suivre

scrupuleusement les instructions du paragraphe

“Conversion de Combustible"

Ce n'est qu'après avoir réglé le générateur conformément

aux indications de la catégorie de service effective qu'il sera

possible de continuer et d'exécuter les opérations suivantes :

• Purger le tuyau d'alimentation de gaz ;

• Contrôler l'étanchéité du tuyau de gaz ;

• Ouvrir la vanne d'arrêt du gaz et démarrer le générateur

d'air chaud.

Pour l'installation aux Etats-Unis, à une altitude supérieure

à 610m (2.000 pieds) la puissance de l'appareil devra être

réduite de 4%pour chaque palier supplémentaire de 305

m (1.000 pieds).

Pour l'installation au Canada, à une altitude supérieure à

610 m(2.000 pieds) et jusqu'à 1.372 m (4.500 pieds), la

puissance du générateur doit être diminuée en réduisant

l'arrivée de carburant enconformité à la pression du

collecteur indiquée sur la plaquette.

MODE D'EMPLOI

Attention

Chaque fois que le cordon d'alimentation de

la chauffe est connecté à une prise vérifier la

polarité de l'alimentation:

• Vérifiez l'interrupteur (9) et (13) sont sur "0"

(voir Fig. 5)

• Branchez la prise de réceptacle

• Si la lampe (n ° 14. La figure 5) allume, puis

l'inversion de polarité

Attention

Si la correspondance de phase / neutre polarité

est pas correcte, l'unité peut arrêter dans le

mode de réinitialisation.

MODE DE CHAUFFAGE

Allumer:

• Vérifier que l'interrupteur (#9 FIG. 5) est bien sur la

position "0”

6

Page 23

TABLEAU DE COMMANDE

a

b c d

8 9 10

13

11

12

14

15

4

1 CHAMBRE DE COMBUSTION

2 BRÛLEUR

3 BAGUE DIFFUSEUR

4 PARE-FLAMME

5 VENTILATEUR REFROIDISSEMENT

6 IONISATION ELECTRODE

7 IGNITION ELECTRODE

8 BOUTON RÉARMEMENT DU CONTRÔLE FLAMME

9 INTERRUPTEUR DE CHAUFFAGE

10 PRISE THERMOSTAT D'AMBIANCE

1 6

FIG. 4

3

2

5

7

FIG. 5

11 VOYANT DE MISE SOUS TENSION

12 TEMOIN SECURITE DE SURCHAUFFE

13 INTERRUPTEUR MODE VENTILATION

14 BOUTON RÉARMEMENT DU THERMOSTAT

DE SÉCURITÉ

15 CABLE FASTENER FOR POWER CORD

¬¬¬

ENSEMBLE COLLECTEUR

FIG. 6

a VALVE CO UPURE CO MBUSTION

b PORT PRESSION COLLECTEUR (COLLECTEUR

c RÉGULATE PRUR ESSI CON OLLECTEUR

d SOUPAPE PRINCIPALE GAZ

À air forcé agricole Chauffe-Construction

Instructions d'utilisation et le manuel du propriétaire

7

Page 24

• Alimenter l'appareil en agissant sur l'interrupteur général

du coffret électrique d'alimentation;

• Si l'appareil est actionné manuellement (sans thermostat

ni autre dispositif de contrôle) placer l'interrupteur (9)

sur la position "1". Le brûleur démarre, la chambre de

combustion chauffe et le ventilateur se met en marche.

• Si l'appareil fonctionne en mode automatique (connexion à un thermostat ou tout autre dispositif de

contrôle), placer l'interrupteur (9) sur la position "1"

et régler le thermostat d'ambiance sur la température

désirée : le chauffage s'allumera et s'éteindra automa-

tiquement.

• Si après ces opérations, le générateur ne fonctionne

pas, reportez-vous à la "DEFAUTS, causes et remèdes"

paragraphe et trouver la cause.

Réglage du mode post-ventilation:

Avec le commutateur (#13 FIG. 5) sur le tableau de contrôle, sélectionner le mode post-ventilation ; c'est le temps

pendant lequel le ventilateur continue de fonctionner

après l'arrêt du générateur.

• lorsque l'interrupteur (#13 FIG. 5) est sur la position "0",

la postventilation dure 30 secondes.

• lorsque l'interrupteur (#13 FIG. 5) est sur la position "1",

la postventilation est continue.

Arrêt:

En fonctionnement manuel, placer l'interrupteur (9) sur

"0" ou tourner le bouton de commande du thermostat sur

"off".

Après avoir éteint le générateur d'air chaud, la postventilation se poursuit pendant le temps programmé

Attention:

Fermer le robinet d'alimentation du gaz, le robinet

d'arrêt (f) et éteindre l'interrupteur de sectionnement

(Fig. 5).

VENTILATION

Pour obtenir la fonction ventilation uniquement, contrôler

que l'interrupteur (9) est sur "0" et placer l'interrupteur (13)

sur la position "1". Pour l'arrêter, placer l'interrupteur (13) sur

la position "0".

Attention

Quel que soit la raison, l'unité essaiera de redémarrer

une fois. Si la cause du dysfonctionnement continue,

le générateur s'arrêtera définitivement et la voyant

(8) s'allumera.

Le générateur ne pourra être redémarré qu'en appuyant

sur le bouton de réinitialisation (8.) Néanmoins, la cause

du déclenchement du dispositif de sécurité doit toujours

être soigneusement analysée et résolue avant de redémarrer le générateur (cf. ANOMALIES –CAUSES – SOLU-

TIONS.)

TRANSPORT ET MANUTENTION:

Attention

Avant tout déplacement :

• Arrêter le générateur en suivant les consignes

fournies au paragraphe "ARRÊT”;

• Débrancher l'alimentation électrique en retirant la

fiche de la prise ;

• Dévisser complètement le raccord qui relie le tuyau

du gaz au générateur ;Attendre que le générateur

soit froid.

MAINTENANCE

Pour réguler le fonctionnement de l'unité, les fans, la

chambre de combustion et le brûleur doit être au moins

annuellement inspecté et nettoyé périodiquement par une

personne qualifiée.

Attention

Avant d'effectuer toute opération de maintenance:

• Arrêter la machine comme indiqué dans le

paragraphe "STOP";

• Dégagez l'alimentation électrique en retirant la

fiche de la prise de courant;

• Fermez l'arrêt de l'approvisionnement en gaz

marche / arrêt et la vanne d'arrêt (f);

• Attendez que le chauffe-eau refroidir.

Pendant le nettoyage des corps étrangers doivent être

retirés de la grille ventilateur d'aspiration. Pour accéder

au brûleur, retirer le panneau de protection de flamme

(4) en enlevant les quatre vis et nettoyez soigneusement

l'intérieur de la chambre de combustion et l'ensemble de

la tête du brûleur: tous les débris sera ôté.

Attention

Ne pas diriger des jets d'air comprimé vers les points

de pression de l'air près du ventilateur principal:

l'interrupteur de pression d'air pourrait être

endommagé de façon permanente.

Nettoyage du brûleur doit être effectué régulièrement

par personne qualifiée. Pour accéder au brûleur, retirer

le panneau de protection de la flamme de la chambre

de combustion (face avant) et nettoyez soigneusement

l'intérieur de la chambre de combustion et de la tête et

des électrodes du brûleur ensemble.

Ce chauffe-eau peut être lavé, à condition que:

A. Le chauffage est déconnectée de l'alimentation

électrique.

B. Tous les panneaux d'accès sont bien fermés.

Buse de pulvérisation C eau ne doit pas décharger dans les

6 pieds de l'appareil de chauffage.

D. Le chauffage est pas reconnecté à l'alimentation

électrique jusqu'à ce que complètement séché.

Un mauvais nettoyage de l'appareil de chauffage

peut causer des blessures graves ou des dommages

à la propriété grâce à des solutions d'eau et / ou de

nettoyage:

A. dans les composants électriques, les connexions

et filscausing chocs électriques ou défaillance d'un

composant.

B. Sur les composants de commande de gaz provoquant

de la corrosion qui peut entraîner des fuites de gaz et

incendie ou une explosion de la fuite. Le flexible doit

être protégé de la circulation, les matériaux et le contact

À air forcé agricole Chauffe-Construction Instructions d'utilisation et le manuel du propriétaire

8

Page 25

avec des surfaces chaudes pendant l'utilisation Et tandis

que dans le bâtiment d'entreposage.

Attention

Après le nettoyage, la garde bouclier de flamme

doit être vissée en place avant de faire fonctionner

chauffe.

Emploi du réservoir sans la garde bouclier de flamme peut

résulter en une combustion produisant CO (monoxyde

de carbone) qui peuvent présenter un danger pour les

personnes exposées à ce à cet environnement.

Conversion de Carburant

ATTENTION:

LA CONVERSION DOIT ÊTRE EXÉCUTÉE PAR UN

REPRÉSENTANT AGRÉÉ DU FABRICANT,

CONFORMÉMENT AUX EXIGENCES DU FABRICANT,

DES AUTORITÉS PROVINCIALES OU TERRITORIALES

COMPÉTENTES ET AUX EXIGENCES DE LA

RÉGLEMENTATION D'INSTALLATION CAN/CGAB149.1 OU

CAN/CGAB149.2

Une plaquette de conversion doit être apposée près de

l'étiquette des caractéristiques:

spécifications.

• Raccorder un manomètre à la prise de pression (1) en amont

et une seconde jauge à la prise de pression en aval (2) du

groupe de soupapes;

• Lancer le chauffage et prendre la lecture au large de la

1ère jauge de pression d'alimentation et si nécessaire,

ajuster le régulateur de pression (. N ° 3 figure 6) pour le

système d'alimentation de gaz jusqu'à ce que la pression

d'alimentation correcte indiquée dans les spécifications est

atteint.

• Prenez une lecture large de la 2e manomètre de travail et si

nécessaire utiliser un tournevis pour ajuster la pression du

groupe de la vanne de gaz (n ° 4. La figure 3) pour rétablir la

pression de service indiquée dans les spécifications.

• Appliquer l'étiquette adhésive avec les mots "mis en place

pour ..." correspondant au type de carburant et la catégorie

choisie sur le groupe de la vanne gaz

Cet appareil a été converti pour être utilisé

A une altitude de ___________ PIEDS (CI-DESSUS 2000 pieds)

Orifice size: ______________________________________

Manifold pressure: ______________________________________

Input rate: ______________________________________

Date of conversion: ______________________________________

Type of fuel: ______________________________________

Converted by: ______________________________________

Cette commutation peut être effectuée plusieurs fois au cours

de la vie de la machine et pas uniquement à la première mise

en marche. Commencer par contrôler le SPECIFICATIONS

repérer la catégorie de référence pour gaz naturel ou gaz

liquide en fonction du pays d'utilisation de l'appareil. Pour

chaque catégorie sont indiquées la

pression d'alimentation, la pression de service, et le réglage de

labague diffuseur (#3 FIG. 4) are stated.

Pour convertir d'un type de gaz à un autre, procédez comme

suit:

• Si cela est indiqué dans les spécifications, changer l'anneau

de diffusion (n ° 3 figure 4.):

• Retirez la partie supérieure du corps de l'élément chauffant;

• Dévissez et retirez l'électrode d'ionisation (n 6. La figure 4)

• Desserrer les vis qui fixent la tête de combustion (3) à la

chambre de combustion (n ° 1 figure. 4)

• Retirez les trois vis sur la plaque de la tête du brûleur et

changer l'anneau de diffusion de fixation d'une manière

telle que l'électrode d'allumage est à égale distance entre les

deux trous suivants;

• Calibrer l'interrupteur de pression de gaz sur le groupe de la

vanne gaz (# 4 Fig.3):

• Régler le commutateur de pression du gaz à une valeur

égale à 80% de la pression d'alimentation;

• Régler le régulateur de pression pour le groupe de la vanne

de gaz (figure 3); à la pression du brûleur indiquée dans les

À air forcé agricole Chauffe-Construction

Instructions d'utilisation et le manuel du propriétaire

9

Page 26

TROUBLESHOOTING

ANOMALIE DE FONCTIONNEMENT CAUSE SOLUTIONS

L'appareil ne démarre pas:

Lamp is off

L'appareil ne démarre pas:

le témoin est allumé

L’appareil fonctionne de manière irrégulière et

le brûleur s’allume/s’éteint alternativement: Débit de gaz insuffisante

L'appareil ne fonctionne pas :

le témoin sont allumé

Le chauffe-eau ne fonctionne pas:

le témoin et sont allumé

L'appareil ne fonctionne pas:

le témoin est allumé fixe

Manque d'alimentation

électrique

Mauvaise position de

l'interrupteur (9)

Fonctionnement irrégulier du

thermostat

d'ambiance

Gas pressure switch tripped

due to no gas or insufficient

pressure

Intervention du contrôle de

tension pour cause

d’alimentation électrique insuffisante (V < 95V)

Manual reset safety thermostat has tripped due to excessive overheating of combustion chamber

APPUYER SUR LE BOUTON (8) PENDANT 12 SECONDES, PUIS LE RELACHER :

LE TEMOIN DU BOUTON CLIGNOTE (2 A 7 CLIGNOTEMENTS)

• Vérifier le fonctionnement et la position de l'interrupteur

• Vérifier les caractéristiques du réseau électrique

• Vérifier les branchements électriques

• Vérifier que le fusible est intact

Placer l'interrupteur sur la position correcte

• Vérifier que la fiche de connexion du thermostat estbien branchée

• Vérifier le raccordement électrique du thermostat

• Vérifier la programmation du thermostat et la modifier

• Vérifier le fonctionnement du thermostat

• Check that gas feed pipe has been bled

• Check gas feed pressure

• Vérifier et nettoyer le filtre à gaz

• Procéder au nettoyage et à un nouvel étalonnage du brûleur

• Dès que la valeur de tension correcte est rétablie (V> 95V), le générateur

redémarre automatiquement

• Si le générateur démarre et s'arrête à plusieurs reprises, contrôler la ligne

d'alimentation électrique

• Si le générateur ne démarre pas et demeure à l’état de blocage, contrôler

la ligne d'alimentation électrique

• Vérifier que le moteur du ventilateur démarre régulièrement et n’est pas

bloqué

• Vérifier que le moteur du ventilateur n’est pas grillé et que son condensateur n’est pas défectueux

• Vérifier l’étalonnage du brûleur

LANCER LA PROCEDURE D’AUTODIAGNOSTIC

Nombre de clignotements du témoin (8)

Pas de flamme pendant

le cycle de démarrage

2

Intervention du pres-

sostat d’air (pas de

fermeture

3

du contact électrique) au

début du cycle de

démarrage

Détection de flamme

parasite lors de la phase

4

de prélavage pendant le

cycle de démarrage

Intervention du presso-

stat d’air (ouverture du

5

contact électrique)

pendant le cycle de

démarrage

• Vérifier la pression du gaz vers le brûleur

• Vérifier et nettoyer le filtre à gaz

• Vérifier que la sonde de ionisation ne décharge pas vers la terre

• Vérifier les câbles de raccordement de la sonde de ionisation (ils ne doivent

pas décharger à la terre)

• Vérifier le raccordement des tuyaux du pressostat

• Contrôler le pressostat et le remplacer si nécessaire

• Vérifier l’absence de poches de gaz dans la chambre de combustion

• Vérifier que la sonde de ionisation ne décharge pas vers la terre

• Vérifier les câbles de raccordement de la sonde de ionisation (ils ne doivent

pas décharger à la terre)

• Vérifier le raccordement des tuyaux du pressostat

• Vérifier que le moteur et le ventilateur du brûleur ne sont pas bloqués ou

défectueux ; si nécessaire, les remplacer

• Contrôler le pressostat et le remplacer si nécessaire

À air forcé agricole Chauffe-Construction Instructions d'utilisation et le manuel du propriétaire

10

Page 27

TROUBLESHOOTING

ANOMALIE DE FONCTIONNEMENT CAUSE SOLUTIONS

Intervention du presso-

stat d’air (ouverture du

6

contact électrique)

pendant le cycle de

Nombre de clignotements du témoin (8)

Le ventilateur est bruyant ou produit des

vibrations

Chauffage insuffisant

fonctionnement

Pas de flamme pendant

le cycle de

7

fonctionnement

Des corps étrangers se

trouvent sur les pales du

ventilateur

La circulation d'air est

insuffisante

Capacité insuffisante du

brûleur

En cas de grave anomalie, l’équipement électronique

entraînera leblocage de sécurité du générateur d’air chaud

et le témoin (8)s’allumera en rouge fixe (signalisation de

blocage).

Attention

Après un blocage de sécurité, il est nécessaire

d'appuyer sur le bouton réarmement (8) pendant 3

secondes pour faire redémarrer le générateur

Attention

Ne jamais effectuer plus de deux redémarrages

consécutifs : le fuel imbrûlé peut s'accumuler dans la

chambre de combustion et s'enflammer soudainement

lors de la deuxième mise en marche.

En cas de blocage de sécurité, appuyer sur le bouton de

réarmement (8) pendant au moins 12 secondes pour lancer un

programme d'autodiagnostic au terme duquel le témoin du

bouton

clignotera avec une fréquence plus ou moins élevée

(signalisation

d’autodiagnostic) en fonction du type d'intervention de

sécurité : le schéma synoptique reproduit sur l’armoire

électrique résume les cas possibles .

En cas de surchauffe excessive de la chambre de combustion,

lethermostat de sécurité (14) intervient en mettant le

brûleur horstension; dans ce cas, le témoin (8) s’allume :

pour réarmer, éteindre complètement le générateur, couper

l’alimentation électrique, et

appuyer sur le bouton (14).

Attention

Toujours localiser et éliminer la cause de l’intervention

du blocage de sécurité avant d’appuyer sur le bouton

de réarmement (8) ou sur le bouton (14) et de remettre

le générateur en marche.

Si malgré les contrôles et les remèdes décrits la cause du

dysfonctionnement n'a pas été trouvée, contacter le centre