Page 1

OPERATING INSTRUCTIONS AND OWNER’S MANUAL

READ INSTRUCTIONS CAREFULLY: Read and follow all instructions. Place

instructions in a safe place for future reference. Do not allow anyone who has

not read these instructions to assemble, light, adjust or operate the heater.

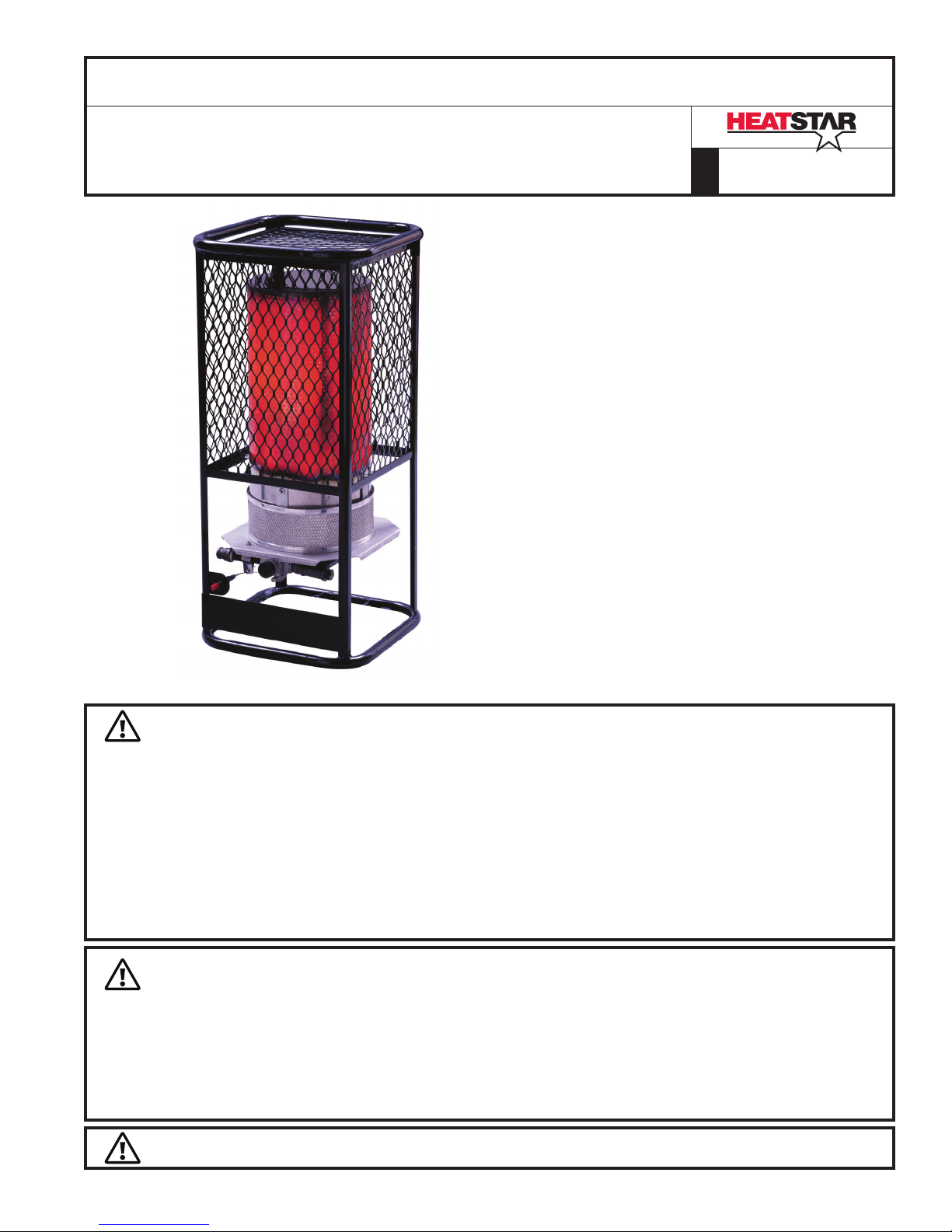

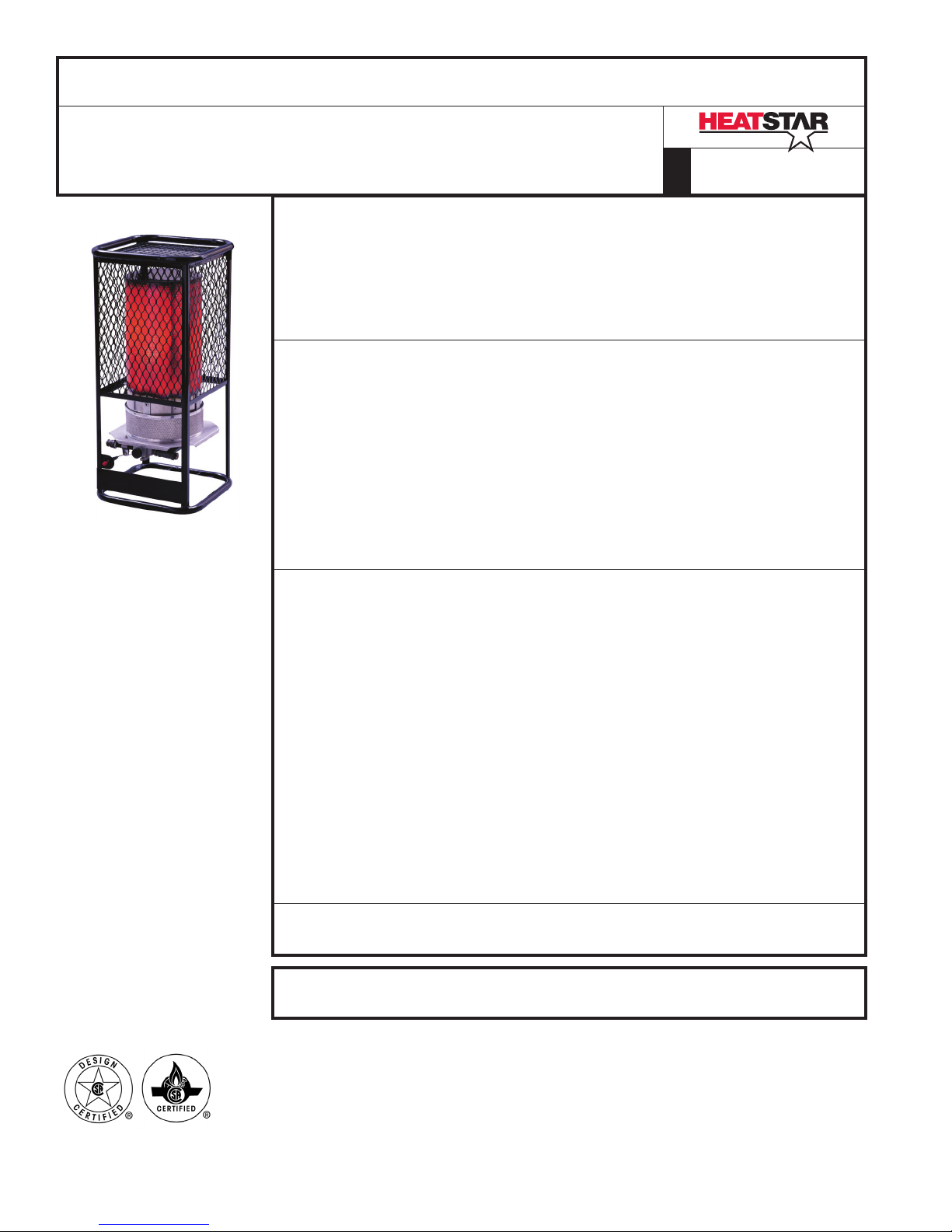

MODEL

HS125NG, HS125LP

GAS-FIRED INFRA-RED

PORTABLE CONSTRUCTION HEATER

DO NOT LEAVE HEATER UNATTENDED OR IN OPERATION WHILE SLEEPING

GENERAL HAZARD WARNING:

FAILURE TO COMPLY WITH THE PRECAUTIONS AND INSTRUCTIONS PROVIDED WITH THIS HEATER

CAN RESULT IN DEATH, SERIOUS BODILY INJURY AND PROPERTY LOSS OR DAMAGE FROM

HAZARDS OF FIRE, EXPLOSION, BURN, ASPHYXIATION, CARBON MONOXIDE POISONING, AND/OR

ELECTRICAL SHOCK.

ONLY PERSONS WHO CAN UNDERSTAND AND FOLLOW THE INSTRUCTIONS SHOULD USE OR

SERVICE THIS HEATER.

IF YOU NEED ASSISTANCE OR HEATER INFORMATION SUCH AS INSTRUCTION MANUALS, LABELS,

ETC., CONTACT THE MANUFACTURER.

WARNING:

FIRE, BURN, INHALATION AND EXPLOSION HAZARD. KEEP SOLID COMBUSTIBLES SUCH AS

BUILDING MATERIALS, PAPER OR CARDBOARD A SAFE DISTANCE AWAY FROM THE HEATER AS

RECOMMENDED BY THE INSTRUCTIONS. NEVER USE THE HEATER IN SPACES WHICH DO OR MAY

CONTAIN VOLATILE OR AIRBORNE COMBUSTIBLES OR PRODUCTS SUCH AS GASOLINE, SOLVENTS,

PAINT THINNER, DUST PARTICLES OR UNKNOWN CHEMICALS.

WARNING: NOT FOR HOME OR RECREATIONAL VEHICLE USE

01/15 18666 2015 JMHEATSTAR by ENERCO, 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 866-447-2194

Page 2

SPECIFICATIONS

MODEL NO. .................................. HS125LP .......... HS125NG

GAS TYPE ........................................ LP-Gas ........ Natual Gas

MAX. INLET PRESSURE. ........... 14 IN. W.C. ....... 14 IN. W.C.

MIN. INLET PRESSURE .............. 14 IN. W.C. ....... 14 IN. W.C.

MANIFOLD PRESSURE .............. 12 IN. W.C. .......6.5 IN.W.C.

WARNING

DO NOT EXCEED ½ psi (14” w.c.) GAS

PRESSURE TO THE GAS CONTROL VALVE.

VENTILATION

WARNING

THIS APPLIANCE IS UNVENTED AND MUST BE

USED ONLY IN A WELL VENTILATED AREA.

The flow of combustion and ventilation air must not be

obstructed. DO NOT use in a tightly enclosed area.

Any combustion process requires and consumes oxygen, and may

produce carbon monoxide. This heater must be operated with

adequate ventilation. Two openings directly to the outdoors must

be provided, one low and one high, preferably on opposite sides

of the area to be heated. Each of these openings must provide

at least three square inches of combustion air-intake area and

exhaust outlet area for every 1000 BTUs per hour of heater input

rate in order to complete the combustion/ventilation process.

Provide additional ventilation for any additional fuel-burning

appliances and/or additional occupants.

CLEARANCE (Minimum clearances to combustible materials)

Do not exceed the gas supply pressures shown on rating plates. The maximum inlet gas supply pressures and minimum inlet supply pressures

(for purposes of input adjustment) for LP-Gas and Natural gas are shown as follows:

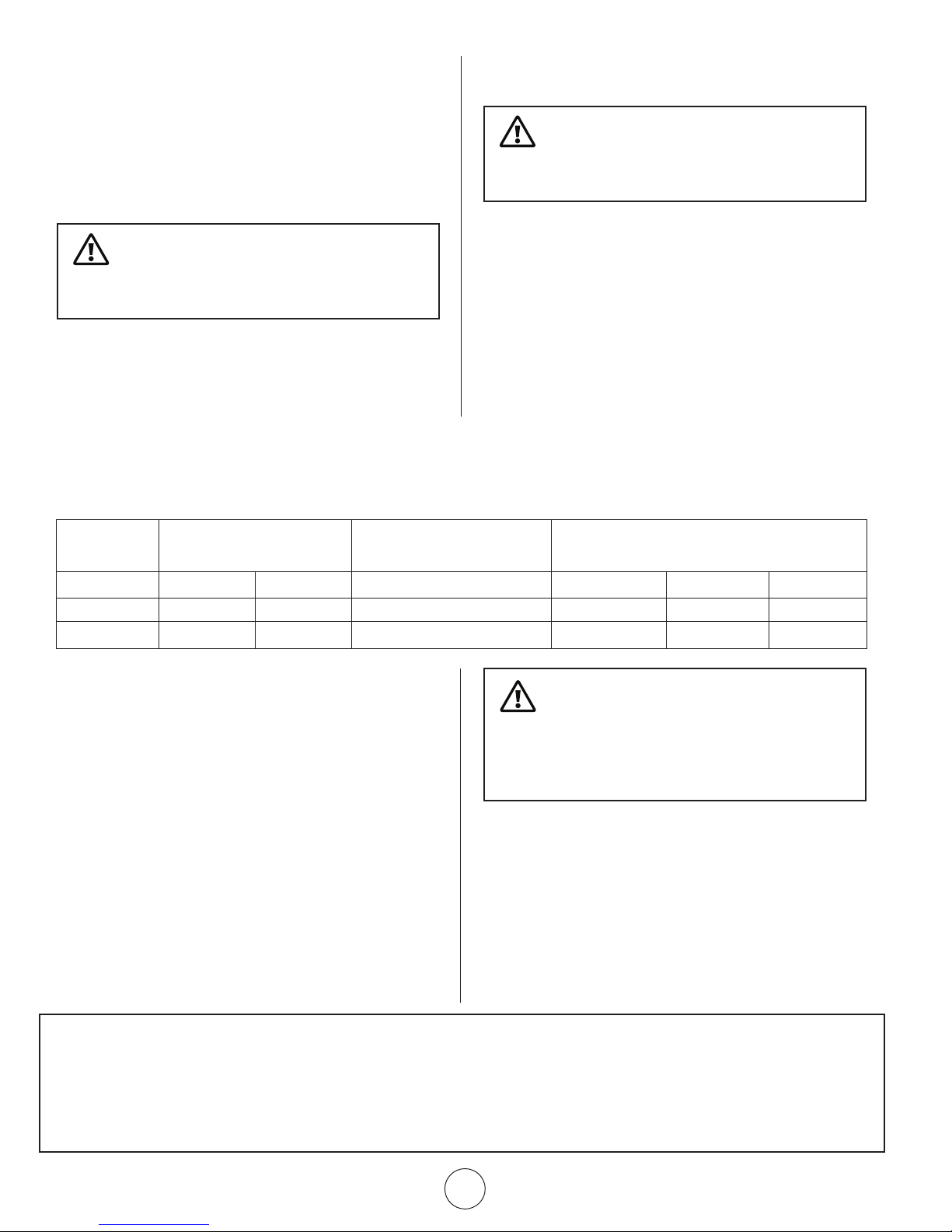

MODEL NO. BTU/HR RATING NORMAL OPERATING CLEARANCES TO

TYPE GAS POSTION COMBUSTIBLES

NATURAL LP-GAS TOP SIDES BACK

HS125LP 95 - 125,000* VERTICAL 48” 60” 60”

HS125NG 72 -2125,000 VERTICAL 48” 60” 60”

*Tank size and tank temperature can directly affect BTU output

CONTENTS

Installation Instructions ..................................................... 3

Location ............................................................................ 3

Piping ............................................................................... 3

Operating Instructions ...................................................... 4

Lighting and Shut Down ...................................................4

Maintenance Instructions ..................................................5

Replacement Parts List ...................................................... 6

Service and Parts Ordering Information .............................8

THE STATE OF CALIFORNIA REQUIRES THE FOLLOWING WARNINGS:

FOR YOUR SAFETY

Do not use this heater in a space where

gasoline or other liquids having flammable

vapors are stored or used.

The heater is designed and approved for use as a construction

heater under ANSI Z83.7 / CGA 2.14

We cannot anticipate every use which may be made of our

heaters. CHECK WITH YOUR LOCAL FIRE SAFETY AUTHORITY IF

YOU HAVE QUESTIONS ABOUT APPLICATIONS.

Other standards govern the use of fuel gases and heat producing

products in specific applications. Your local authority can advise

you about these.

This appliance is intended to be used for temporary heating of

buildings under construction, alteration or repair.

WARNING: Combustion by-products produced when using this product contain carbon monoxide, a chemical

known to the State of California to cause cancer and birth defects (or other reproductive harm).

WARNING: This product contains chemicals known to the State of California to cause cancer and birth defects or

other reproductive harm.

Operating Instructions and Owner’s ManualGas-Fired Infra-Red Portable Construction Heater

2

Page 3

INSTALLATION INSTRUCTIONS

GENERAL:

READ THESE INSTRUCTIONS CAREFULLY. Read and adhere

to these instructions. DO NOT allow anyone who has not

read these instructions to assemble, light, adjust or operate

this heater.

DO NOT attempt to operate the heater with any gas other

than that indicated on the heater nameplate.

For the U.S. and/or Canada, the installation of this appliance must

comply with local and/or Provincial codes or, in the absence of

these codes,

• With the (U.S.) National Fuel Gas Code, ANSI Z223.1 –

Latest Edition (for Natural and LP-Gas operation, Models

HS125NG and HS125LP), and with the (U.S) Standard

for the Storage and Handling of Liquefied Petroleum

Gases, ANSI/NFPA 58 (for LP Gas operation, Model

MH125LP, HS125LP), or

• with the current (Canadian) CAN/CGA B149.1 AND

B149.2 INSTALLATION CODES.

This heater (including hose and regulator assembly if applicable)

must be inspected before each use and at least annually by a

qualified service person. If the hose for Model HS125LP shows

evidence of excessive abrasion or wear, or if the hose is cut, it

must be replaced prior to the heater being put into operation.

The replacement hose assembly shall be that specified by the

manufacturer. See the parts list.

LOCATION

The heater (and LP-Gas supply cylinder if applicable) must be

located on a hard, flat, level surface to minimize the risk of

accidental tipping. If an LP Gas supply cylinder is used (i.e. with

Model HS125LP), the cylinder should be adequately restrained to

prevent accidental tipping. DO NOT operate this heater with

the supply cylinder in any other than the upright position.

This appliance must be installed only in locations where the

potential for physical damage to the appliance (i.e., due to

physical contact) is reduced to a minimum.

The installer must inform the owner/operator of this appliance

that precautions must be taken to protect the appliance from

physical damage.

This appliance produces radiant heat. Therefore, it must be located

at least six feet away from any LP-Gas container and must not be

directed toward any LP-Gas container within 20 feet.

The heater must be installed in a location such that it will not be

exposed directly to water spray, rain, and/or dripping water.

Use of this heater in a draft/windy area decreases its efficiency. If

possible, operate the unit in a draft free area.

PIPING

For Model HS125LP

(for use with LP-Gas)

This model may be connected to a self-contained LP-Gas

supply system using the hose and regulator assembly

supplied with the appliance, OR, it may be connected to a

permanently installed LP-Gas supply system.

If connected to a self-contained LP-Gas supply system, the

hose assembly must be inspected prior to each use of the

heater. If it is evident that there is excessive abrasion or wear,

or if the hose is cut, it must be replaced prior to the heater

being put into operation.

If connected to a self-contained LP-Gas supply system, the

cylinder must have no less than a minimum capacity of

40 pounds and no more than a maximum capacity of 100

pounds of LP-Gas. DO NOT connect this appliance to a

cylinder having less than a nominal 40 pounds capacity of

LP-Gas.

WARNING

NEVER USE A FORK LIFT TRUCK TYPE

CYLINDER.

The connection of Model HS125LP to an LP-Gas cylinder must

be made in a well ventilated area using the regulator and hose

assembly supplied with the appliance. DO NOT attempt to

adjust this regulator. It has been preset at the factory to provide

safe and proper operation of the appliance. Use a 7/8” open end

wrench to connect the POL fitting (supplied with the LP regulator)

to the LP-Gas cylinder. Turn the POL nut in a counter-clockwise

direction (left hand thread) until tight. DO NOT use pipe

compound on POL threads.

The heater must be located at least six feet away from any

LP-Gas cylinder and must not be directed toward any LP-Gas

cylinder within 20 feet. If more than one heater is used, they

and the supply cylinders must be separated by at least 20

feet. Check local codes.

The gas supply must be turned off at the LP-Gas supply

cylinder when the heater is not in use.

When the heater is to be stored indoors, the connection

between the LP-Gas supply cylinder and the heater must be

disconnected and the cylinder removed from the heater and

stored in accordance with Chapter 5 of the Standard for the

Storage and Handling of Liquefied Petroleum Gases. ANSI/

NFPA 58 (U.S.) OR CAN/CGA B149.2 (Canada).

If connected to a permanently installed LP-Gas supply system,

the system requires the use of a two-stage gas regulator

assembly which is normally provided by your LP Gas dealer

as part of the LP-Gas supply system. Consult with your local

LP Gas dealer for details concerning proper equipment and

installation.

For Model HS125NG (for use with natural gas)

Operating Instructions and Owner’s ManualGas-Fired Infra-Red Portable Construction Heater

3

Page 4

For Model HS125NG (for use with natural gas)

Piping must be clean and free from scale or burrs.

Install regulator supplied with heater. Connect with 1/2” NPT

nipple (not included) to Control Valve.

Connect the appliance to an appropriately designed and

installed fuel supply system. This system must include an

approved manual shut-off valve which is readily accessible and

is located within six (6) feet of the appliance. Additionally, a

sediment trap or drip leg must be located upstream of this

manual shut-off valve. Refer to the appropriate (natural gas)

installation code noted above. If a flexible connector is used,

it must be of an approved type.

Before attempting to ignite the appliance, all gas fittings and

connections must be thoroughly checked for gas leaks. Apply a

small amount of a mild soap and water solution to all fittings and

connections and observe for escaping bubbles. If any leaks are

detected, shut off the gas supply to the appliance immediately.

Wait a minimum of five minutes, repair the leak(s) and retest for

leakage. Dry all fittings and connections after leak testing.

WARNING

NEVER USE A FLAME FOR GAS LEAK TESTING.

OPERATING INSTRUC TIONS

ODOR FADE WARNING

WARNING

• Do not use in unventilated areas.

• The flow of combustion and ventilation air must

• Proper ventilation air must be provided to

• Refer to the specification section of the heater’s

• Lack of proper ventilation air will lead to

• Improper combustion can lead to carbon

DO NOT operate this heater if any part has been under

water. Call a qualified service technician to inspect the appliance

and to replace any part of the control system or gas control valve

which has been under water.

This appliance must be installed and operated only in locations

where the potential for physical damage to the appliance is

reduced to a minimum. The owner/operator of this appliance

must ensure that precautions are taken to protect the appliance

from physical damage.

WARNING

Asphyxiation Hazard

IF YOU DO NOT FOLLOW THESE INSTRUCTIONS

EXACTLY, A FIRE OR EXPLOSION MAY RESULT

not be obstructed.

CAUSING PROPERTY DAMAGE, PERSONAL

INJURY, OR LOSS OF LIFE.

support the combustion air requirements of the

heater being used.

CAUTION

manual, heater dataplate, or contact the factory

to determine combustion air ventilation

THIS APPLIANCE IS HOT DURING NORMAL

requirements of the heater.

OPERATION, AVOID PHYSICAL CONTACT.

improper combustion.

monoxide poisoning leading to serious injury or

CAUTION

death. Symptom of carbon monoxide poisoning

DO NOT PLACE CLOTHING OR OTHER

can include headaches, dizziness and difficulty

COMBUSTIBLE MATERIALS ON THIS APPLIANCE.

in breathing.

FUEL GAS ODOR

LP gas and natural gas have man-made odorants

added specifically for detection of fuel gas leaks.

If a gas leak occurs you should be able to smell the

fuel gas. Since Propane (LP) is heavier than air you

should smell for the gas odor low to the floor. ANY

GAS ODOR IS YOUR SIGNAL TO GO INTO IMMEDIATE

ACTION!

• Do not take any action that could ignite the fuel gas.

Do not operate any electrical switches. Do not pull

any power supply or extension cords. Do not light

matches or any other source of flame. Do not use your

telephone.

• Get everyone out of the building and away from the

area immediately.

• Close all propane (LP) gas tank or cylinder fuel supply

valves, or the main fuel supply valve located at the

meter if you use natural gas.

• Propane (LP) gas is heavier than air and may settle in

low areas. When you have reason to suspect a propane

leak, keep out of all low areas.

• Use your neighbor’s phone and call your fuel gas

supplier and your fire department. Do not re-enter the

building or area.

• Stay out of the building and away from the area until

declared safe by the firefighters and your fuel gas

supplier.

• FINALLY, let the fuel gas service person and the

firefighters check for escaped gas. Have them air out

the building and area before you return. Properly trained

service people must repair any leaks, check for further

leakages, and then relight the appliance for you.

ODOR FADING - NO ODOR DETECTED

• Some people cannot smell well. Some people cannot

smell the odor of the man-made chemical added to

propane (LP) or natural gas. You must determine if you

can smell the odorant in these fuel gases.

• Learn to recognize the odor of propane (LP) gas and

natural gas. Local propane (LP) gas dealers will be more

than happy to give you a scratch and sniff pamphlet.

Use it to become familiar with the fuel gas odor.

• Smoking can decrease your ability to smell. Being

around an odor for a period of time can affect your

sensitivity to that particular odor. Odors present in

animal confinement buildings can mask fuel gas odor.

• The odorant in propane (LP) gas and natural gas

is colorless and the intensity of its odor can fade

under some circumstances.

• If there is an underground leak, the movement of gas

through the soil can filter the odorant.

• Propane (LP) gas odor may differ in intensity at different

levels. Since Propane (LP) gas is heavier than air, there

may be more odor at lower levels.

• Always be sensitive to the slightest gas odor. If you

continue to detect any gas odor, no matter how small,

treat it as a serious leak. Immediately go into action as

discussed previously.

Operating Instructions and Owner’s ManualGas-Fired Infra-Red Portable Construction Heater

4

Page 5

Piping must be clean and free from scale or burrs.

ATTENTION - CRITICAL POINTS TO

Install regulator supplied with heater. Connect with 1/2” NPT

REMEMBER!

nipple (not included) to Control Valve.

• Propane (LP) gas has a distinctive odor. Learn to

Connect the appliance to an appropriately designed and

recognize these odors. (Reference Fuel Gas Odor and

installed fuel supply system. This system must include an

Odor Fading sections above.

approved manual shut-off valve which is readily accessible and

• Even If you are not property trained in the service and

is located within six (6) feet of the appliance. Additionally, a

repair of the heater, ALWAYS be consciously aware of

sediment trap or drip leg must be located upstream of this

the odors of propane (LP) gas and natural gas.

manual shut-off valve. Refer to the appropriate (natural gas)

• If you have not been properly trained in repair and

installation code noted above. If a flexible connector is used,

service of propane (LP) gas then do not attempt to

it must be of an approved type.

light heater, perform service or repairs, or make any

Before attempting to ignite the appliance, all gas fittings and

adjustments to the heater on the propane (LP) gas fuel

connections must be thoroughly checked for gas leaks. Apply a

system.

small amount of a mild soap and water solution to all fittings and

connections and observe for escaping bubbles. If any leaks are

detected, shut off the gas supply to the appliance immediately.

Wait a minimum of five minutes, repair the leak(s) and retest for

OPERATING INSTRUC TIONS

leakage. Dry all fittings and connections after leak testing.

WARNING

WARNING

IF YOU DO NOT FOLLOW THESE INSTRUCTIONS

NEVER USE A FLAME FOR GAS LEAK TESTING.

EXACTLY, A FIRE OR EXPLOSION MAY RESULT

CAUSING PROPERTY DAMAGE, PERSONAL

OPERATING INSTRUC TIONS

INJURY, OR LOSS OF LIFE.

WARNING

CAUTION

IF YOU DO NOT FOLLOW THESE INSTRUCTIONS

THIS APPLIANCE IS HOT DURING NORMAL

EXACTLY, A FIRE OR EXPLOSION MAY RESULT

OPERATION, AVOID PHYSICAL CONTACT.

CAUSING PROPERTY DAMAGE, PERSONAL

INJURY, OR LOSS OF LIFE.

CAUTION

DO NOT PLACE CLOTHING OR OTHER

CAUTION

COMBUSTIBLE MATERIALS ON THIS APPLIANCE.

THIS APPLIANCE IS HOT DURING NORMAL

OPERATION, AVOID PHYSICAL CONTACT.

DO NOT operate this heater if any part has been under

water. Call a qualified service technician to inspect the appliance

and to replace any part of the control system or gas control valve

which has been under water.

This appliance must be installed and operated only in locations

where the potential for physical damage to the appliance is

reduced to a minimum. The owner/operator of this appliance

must ensure that precautions are taken to protect the appliance

from physical damage.

DO NOT operate this heater if any part has been under

water. Call a qualified service technician to inspect the appliance

and to replace any part of the control system or gas control valve

which has been under water.

This appliance must be installed and operated only in locations

where the potential for physical damage to the appliance is

reduced to a minimum. The owner/operator of this appliance

must ensure that precautions are taken to protect the appliance

from physical damage.

CAUTION

DO NOT PLACE CLOTHING OR OTHER

COMBUSTIBLE MATERIALS ON THIS APPLIANCE.

LIGHTING AND SHUT DOWN

Lighting the Heater

1 Before attempting to light the heater, smell all around

the heater area for gas. Be sure to smell next to the floor

because LP Gas is heavier than air and will settle on the

floor. Turn on the gas supply to the appliance and check

all fittings and connections for gas leaks using a mild

soap and water solution. NEVER use a match to check

for gas leaks. Should a gas leak occur, shut off the gas

supply to the appliance immediately. Wait a minimum of

five minutes before repairing the leak.

2 Use only the fuel intended for this appliance. Check the

appliance rating plate for the correct fuel information.

3 Depress knob then turn the gas valve knob clockwise to

the “OFF” position. See Fig. 1 and Fig. 2 for location of

appliance parts.

4 Wait a sufficient length of time (at least five minutes)

to allow gas which may have accumulated in burner

compartment to escape.

5 Turn on the main gas supply.

6a Depress and turn Control Knob counterclockwise to

“Pilot” position and hold for 1-2 minutes. This may take

longer to purge air from the supply hose depending on

the length of the hose being used.

Depress red spark ignition button to light pilot flame

(repeat until pilot lights) and continue to hold Control

Knob at “Pilot” positionfor 30-60 seconds to enable Pilot

Light Safety System.

Fully turn Control Knob to “ON” position to light burner.

or...

6b To light the pilot, move the lighting hole cover aside

(see Fig. 1) and place a lighted match into the hole.

Depress the gas valve knob and hold while lighting

and observing the pilot burner. Ensure that the pilot

burner ignites from the match. Allow the pilot to burn

approximately 30 seconds before releasing the gas valve

knob. If pilot does not remain lighted, repeat the lighting

operation allowing a longer period of time before

releasing the gas valve knob.

NOTE: In cases where long runs of gas supply lines have been

installed ahead of the appliance, it may be necessary to bleed

trapped air out of the supply lines before lighting the pilot.

New installations generally require bleed of supply lines. Wait

a minimum of five minutes after bleeding the supply lines

before attempting to light the heater.

Adjust pilot if necessary as noted under “Pilot Burner

Adjustment.”

7. Turn the gas valve knob counter-clockwise to the “ON”

position (see Fig. 1). The burner will light. Turn knob

clockwise until stop for low fire position.

8. IMPORTANT: DO NOT attempt to adjust the main

burner input beyond stop, for this may cause the pilot

and thermocouple to shut down the burner (Fig. 2).

Operating Instructions and Owner’s ManualGas-Fired Infra-Red Portable Construction Heater

5

Page 6

OPERATING INSTRUCTIONS AND OWNER’S MANUAL

READ INSTRUCTIONS CAREFULLY: Read and follow all instructions. Place

instructions in a safe place for future reference. Do not allow anyone who has

not read these instructions to assemble, light, adjust or operate the heater.

WARNING:

USE ONLY MANUFACTURER’S REPLACEMENT PARTS. USE OF ANY OTHER PARTS

COULD CAUSE INJURY OR DEATH. REPLACEMENT PARTS ARE ONLY AVAILABLE

DIRECT FROM THE FACTORY AND MUST BE INSTALLED BY A QUALIFIED SERVICE

AGENCY.

PARTS ORDERING INFORMATION:

PURCHASING: Accessories may be purchased at any Mr. Heater or HeatStar local

dealer or direct from the factory

FOR INFORMATION REGARDING SERVICE

Please call Toll-Free 866-477-2194

www.enerco.com • www.heatstarbyenerco.com

Our office hours are 8:00 AM – 5:00 PM, EST, Monday through Friday.

Please include the model number, date of purchase, and description of problem in

all communication.

MODEL

HS125NG, HS125LP

WARRANTY

Gas Fired Infra Red Portable Construction Heater HS125NG & HS125LP

HEATSTAR by ENERCO warrants that Infra Red Heaters manufactured and sold will be free

from defects in material and workmanship.

Parts assemblies controls, etc. furnished by HEATSTAR by ENERCO will carry a one (1) year

warranty on the applicable warranties of the suppliers.

The sole responsibility of HEATSTAR by ENERCO under this warranty shall be to replace or

repair any part for which a written claim is made to HEATSTAR by ENERCO within the time

limit of this warranty which is returned upon request to HEATSTAR by ENERCO – F.O.B.

Cleveland Ohio – or F.O.B. an HEATSTAR by ENERCO authorized service facility and which is

proved to be defective upon inspection by HEATSTAR by ENERCO Technical Products.

This warranty shall not apply to any part or product which has been subjected to misuse or

neglect, damaged by accident, or rendered defective by reason of improper installation. THIS

WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, and

of any other responsibility of HEATSTAR by ENERCO for parts or products sold by HEATSTAR

by ENERCO, including consequential or special damages.

HEATSTAR by ENERCO reserves the right to make changes at any time, without notice

or obligation, in colors, specifications, accessories, materials and models.

PRODUCT REGISTRATION: Thank you for your purchase.

Please log in to http://www.egiregistration.com to register your product.

HEATSTAR by ENERCO, 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 866-447-2194

Enerco and Mr. Heater are registered trademarks of Enerco Group, Inc.

© 2015, Enerco/Mr. Heater. All rights reserved

ANSI Z83.7b/CSA 2.14b - 2009

Page 7

GUIDE D’UTILISATION ET MANUEL DU PROPRIÉTAIRE

REMARQUE : lisez et suivez les instructions d’utilisation. Rangez le manuel de

l’utilisateur dans un endroit sûr aux fins de référence ultérieure. NE LAISSEZ

PERSONNE qui n’a pas lu le manuel de l’utilisateur tenter de monter, de

mettre en marche, de régler ou de faire fonctionner l’appareil de chauffage.

MODÈLES

HS125NG, HS125LP

APPAREIL DE CHAUFFAGE À AIR PULSÉ AU GAZ

PROPANE POUR CHANTIER DE CONSTRUCTION

NE LAISSEZ PAS L’APPAREIL DE CHAUFFAGE FONCTIONNER SANS SURVEILLANCE

MISE EN GARDE GÉNÉRALE CONTRE LES RISQUES :

LE NON-RESPECT DES PRÉCAUTIONS ET DES INSTRUCTIONS FOURNIES AVEC LE PRÉSENT APPAREIL DE

CHAUFFAGE RISQUE D’ENTRAÎNER DES BLESSURES CORPORELLES GRAVES, DES PERTES OU DOMMAGES

DE BIENS CAUSÉS PAR LE FEU, DES EXPLOSIONS, DES BRÛLURES, DES ÉLECTROCUTIONS, L’ASPHYXIE,

L’EMPOISONNEMENT AU MONOXYDE DE CARBONE OU LA MORT.

SEULES LES PERSONNES COMPRENNANT ET POUVANT SUIVRE LES INSTRUCTIONS DEVRAIENT

UTILISER LE PRÉSENT APPAREIL DE CHAUFFAGE.

SI VOUS DÉSIREZ OBTENIR DE L’AIDE OU DES INFORMATIONS SUR LE PRÉSENT APPAREIL, COMME

DES MODES D’EMPLOI, DES ÉTIQUETTES, ETC., VEUILLEZ COMMUNIQUER AVEC LE FABRICANT.

MISE EN GARDE :

RISQUE D’INCENDIE, DE BRÛLURE, D’INHALATION DE SUBSTANCES TOXIQUES ET D’EXPLOSION. TEL

QUE MENTIONNÉ DANS LE MANUEL DE L’UTILISATEUR, VEUILLEZ GARDER LES COMBUSTIBLES

SOLIDES TELS QUE LES MATÉRIAUX DE CONSTRUCTION, LE PAPIER OU LE CARTON À DISTANCE DE

L’APPAREIL DE CHAUFFAGE. N’UTILISEZ JAMAIS L’APPAREIL DE CHAUFFAGE DANS DES ENDROITS

OÙ IL Y A OU IL PEUT Y AVOIR DES COMBUSTIBLES VOLATILES OU DES PRODUITS TELS QUE DE

L’ESSENCE, DES SOLVENTS, DES DILUENTS, DES PARTICULES DE POUSSIÈRE OU DES PRODUITS

CHIMIQUES INCONNUS.

MISE EN GARDE : LE PRESENT APPAREIL N’EST PAS DESTINE A ETRE UTILISE DANS UN

DOMICILE OU UN VEHICULE RECREATIF.

01/15 18666 2015 JMHEATSTAR by ENERCO, 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 866-447-2194

Page 8

SPÉCIFICATIONS

NO DE MODÈLE. ............................ HS125LP .......... HS125NG

TYPE DE GAZ ............. Gaz propane liquéfié ....... Gaz naturel

PRESSION D’ADM. MAX... .... 14 PO D’EAU. .....14 PO D’EAU

PRESSION D’ADM. MIN. ........ 14 PO D’EAU .....14 PO D’EAU

PRESSION D’ADMISSION ....... 12 PO D’EAU ....6.5 PO D’EAU

MISE EN GARDE

N’EXCÉDEZ PAS ½ PSI (14 POUCES D’EAU) DE

PRESSION À LA VALVE D’ADMISSION DU GAZ.

VENTILATION

MISE EN GARDE

LE PRÉSENT APPAREIL N’EST PAS VENTILÉ ET

DOIT ÊTRE UTILISÉ SEULEMENT DANS UN

ENDROIT BIEN AÉRÉ.

La circulation d’air et le flux de combustion ne doivent pas être

ralentis. N’UTILISEZ PAS l’appareil dans un endroit fermé.

Tout processus de combustion requiert de l’oxygène et peut

produire du monoxyde de carbone. L’appareil de chauffage doit

être utilisé en présence d’une aération adéquate. L’endroit où

l’appareil est mis en marche doit comporter deux ouvertures

qui donnent directement vers l’extérieur, soit une basse et une

haute, de préférence sur des côtés opposés de la pièce. Chacune

de ces ouvertures doit permettre au moins 3 pouces carrés de

prise et de sortie d’air pour chaque 1 000 BTU/heure consommé

par l’appareil de chauffage afin de compléter le processus de

combustion/ventilation. Veuillez assurer une meilleure ventilation si

des appareils à combustible ou des personnes supplémentaires

se trouvent dans la même pièce que l’appareil de chauffage.

DÉGAGEMENT (Distances de dégagement autour de matériaux combustibles)

N’excédez pas les pressions d’admission de gaz indiquées sur les plaques signalétiques. Les pressions d’admission maximale et minimale

(pour le réglage de l’admission) pour le gaz propane liquéfié et le gaz naturel sont les suivantes :

NO DE TAUX BTU/HEURE POSITION NORMALE DISTANCES DE DÉGAGEMENT

MODÈLE TYPE DE GAZ DE FONCTIONNEMENT AUTOUR DES COMBUSTIBLES

NATUREL GAZ PROPANE HAUT CÔTÉS ARRIÈRE

HS125LP 95 - 125 000* VERTICALE 48 po 60 po 60 po

HS125NG 72 - 125 000 VERTICALE 48 po 60 po 60 po

*La capacité et la température du réservoir peuvent influer directement sur la production de BTU

CONTENU

Instructions d’installation ..................................................3

MESURES DE SÉCURITÉ

N’utilisez pas l’appareil de chauffage dans

un endroit où de l’essence ou autres liquides

Emplacement .................................................................... 3

Tuyauterie ......................................................................... 3

Instructions d’utilisation .................................................... 4

Allumage et arrêt ..............................................................4

Entretien ........................................................................... 5

Liste des pièces de remplacement ..................................... 6

Service à la clientèle et commande de pièces .................... 8

L’ÉTAT DE CALIFORNIE EXIGE QUE L’AVERTISSEMENT SUIVANT SOIT FOURNI :

qui dégagent des vapeurs inflammables sont

entreposés ou utilisés.

Cet appareil de chauffage est destiné à être utilisé sur les chantiers de

construction, conformément à la norme ANSI Z83.7 / CGA 2.14

Nous ne pouvons pas prévoir toutes les possibilités d’utilisation

de nos appareils de chauffage. SI VOUS AVEZ DES QUESTIONS

QUANT AUX DIFFÉRENTES UTILISATIONS POSSIBLES, VEUILLEZ

COMMUNIQUER AVEC VOTRE SERVICE DES INCENDIES LOCAL.

Pour certaines applications, d’autres normes régissent l’utilisation

de gaz combustibles et d’appareils de chauffage. Demandez à votre

commission locale pour obtenir de plus amples informations à ce sujet.

Le présent appareil de chauffage est principalement destiné à

chauffer les structures en construction ou en réparation.

MISE EN GARDE : Les sous-produits de combustion émis lors de l’utilisation de cet appareil contiennent du

monoxyde de carbone, un produit chimique reconnu par l’état de Californie comme pouvant causer le cancer et des malformations congénitales (ou autres dommages au système reproducteur).

MISE EN GARDE : Cet appareil contient des produits chimiques reconnus par l’état de Californie comme

pouvant causer le cancer et des malformations congénitales ou autres dommages au système reproducteur.

Operating Instructions and Owner’s ManualGas-Fired Infra-Red Portable Construction Heater

2

Page 9

INSTRUCTIONS D’INSTALLATION

GÉNÉRAL :

VEUILLEZ LIRE ATTENTIVEMENT LES INSTRUCTIONS

SUIVANTES ET LES APPLIQUER NE LAISSEZ PERSONNE

qui n’a pas lu le manuel de l’utilisateur tenter de monter,

de mettre en marche, de régler ou de faire fonctionner

l’appareil de chauffage.

N’ESSAYEZ JAMAIS de faire fonctionner l’appareil de chauffage

avec un type de gaz autre que celui indiqué sur la plaque

signalétique.

Pour les É.-U. et le Canada, l’installation du présent appareil

doit être conforme aux codes locaux et/ou provinciaux ou,

dans l’absence de tels codes,

• au code national (É.-U.) de gaz inflammables (National

Fuel Gas Code), ANSI Z223.1 - dernière édition (pour la

manipulation du gaz naturel et du gaz propane liquéfiés,

modèles HS125NG et HS125LP), et à la norme sur

l’entreposage et la manipulation de gaz liquéfiés

(Standard for the Storage and Handling of Liquefied

Petroleum Gases), ANSI/NFPA 58 (pour la manipulation

du gaz propane liquéfié, modèle HS125LP), ou

• aux CODES D’INSTALLATION (Canada) CAN/CGA B149.1 ET

B149.2

L’appareil de chauffage (y compris le tuyau et l’ensemble de

régulation, le cas échéant) doit être inspecté avant chaque utilisation

et au moins une fois par année par une personne qualifiée. Si le

tuyau du modèle HS125LP montre des signes d’usure excessive, ou

s’il est coupé, remplacez-le avant de mettre l’appareil de chauffage

en marche. La tuyauterie de remplacement doit avoir été approuvée

par le fabricant. Voir la liste des pièces de remplacement.

EMPLACEMENT

L’appareil de chauffage (et la bonbonne de gaz propane, le cas

échéant) doit être placé sur une surface dure, plane et au niveau

afin de réduire les risques de basculement. Si une bonbonne de

gaz propane est utilisée (avec le modèle HS125LP), celle-ci doit être

installée de façon sécuritaire afin d’empêcher qu’elle ne tombe.

N’UTILISEZ PAS l’appareil de chauf fage avec la bonbonne

de gaz en une position autre que verticale.

Le présent appareil de chauffage doit être installé seulement dans

des endroits où le potentiel de dommages physiques à l’appareil

(p. ex. causés par un contact physique) est réduit au minimum.

L’installateur doit informer le propriétaire/l’utilisateur de l’appareil

des précautions à prendre pour protéger l’appareil contre

d’éventuels dommages physiques.

Le présent appareil de chauffage produit de la chaleur rayonnante.

Il doit donc être placé à au moins 2 mètres d’une bonbonne de

gaz et ne doit pas faire face à une bonbonne de gaz à moins de

6 mètres.

L’appareil ne doit pas être exposé directement à l’eau pulvérisée

ou à la pluie.

L’efficacité de l’appareil sera réduite si vous l’utilisez dans un

endroit venteux. Dans la mesure du possible, installez l’appareil

dans un endroit sans courant d’air.

TUYAUTERIE

Modèle HS125LP

(pour utilisation avec du gaz propane

liquéfié)

Ce modèle peut être branché à un système d’alimentation

autonome de gaz propane liquéfié à l’aide du tuyau et de

l’ensemble de régulation fournis avec l’appareil OU peut être

branché à un système d’alimentation de gaz propane liquéfié

installé de façon permanente.

Si branchée à un système d’alimentation autonome de gaz

propane liquéfié, la tuyauterie doit être examinée avant

chaque utilisation. Si le tuyau montre des signes d’usure

excessive, ou s’il est coupé, remplacez-le avant de mettre

l’appareil de chauffage en marche.

Si branchée à un système d’alimentation autonome de

gaz propane liquéfié, la bonbonne doit avoir une capacité

de gaz propane liquéfié minimale et maximale de 18 et

45 kg respectivement. NE BRANCHEZ PAS l’appareil à une

bonbonne ayant une capacité de gaz propane liquéfié

nominale de 18 kg. NE BRANCHEZ PAS l’appareil à plus d’une

bonbonne ayant une capacité de 45 kg.

MISE EN GARDE

N’UTILISEZ JAMAIS UNE BONBONNE DE

TYPE CHARIOT ÉLÉVATEUR À FOURCHE.

Le branchement du modèle HS125LP à une bonbonne de gaz

propane liquéfié doit être effectué dans un endroit bien aéré à

l’aide de la tuyauterie et de l’ensemble de régulation fournis avec

l’appareil. N’ESSAYEZ PAS de régler ce régulateur. Celui-ci a

été réglé en usine afin d’assurer un fonctionnement adéquat et

sécuritaire de l’appareil. Utilisez une clé à fourche 7/8 po pour

brancher la pièce de fixation de gauche (fournie avec le régulateur

à gaz) à la bonbonne de gaz. Vissez l’écrou de gauche en sens

anti-horaire (filetage à gauche). N’UTILISEZ PAS de mastic

pour joints de tuyaux sur le filetage de gauche.

L’appareil de chauffage doit être placé à au moins six pieds

d’une bonbonne de gaz et ne doit pas faire face à une

bonbonne de gaz à moins de 6 mètres. Si plusieurs appareils

de chauffage sont utilisés, ces derniers ainsi que les bonbonnes

doivent être séparés par une distance d’au moins 6 mètres.

Lorsque l’appareil de chauffage n’est pas utilisé, l’alimentation

en gaz doit être coupée à la source, c’est-à-dire à la bonbonne

de gaz.

Si l’appareil de chauffage est entreposé à l’intérieur, le tuyau

entre la bonbonne de gaz et l’appareil doit être débranché,

et la bonbonne enlevée de l’appareil de chauffage et

entreposée de la façon indiquée au chapitre 5 de la norme

d’entreposage et de manipulation des gaz liquéfiés (Standard

for the Storage and Handling of Liquefied Petroleum Gases)

ANSI/NFPA 58 (É.-U.) OU CAN/CGA B149.2 (Canada).

Si branché à un système d’alimentation de gaz installé de

façon permanente, le système requiert l’utilisation d’un

ensemble de régulation à deux phases habituellement fourni

par votre fournisseur de gaz avec le système d’alimentation

de gaz. Pour obtenir de plus amples informations sur les

instructions d’installation et l’équipement appropriés, veuillez

vous renseigner auprès de votre fournisseur de gaz local.

Operating Instructions and Owner’s ManualGas-Fired Infra-Red Portable Construction Heater

3

Page 10

Modèle HS125NG (au gaz naturel)

La tuyauterie doit être rester propre et ne doit pas être salie

de bavure de mortier ou présenter des dépôts calcaires.

Installez le régulateur fourni avec l’appareil de chauffage.

Branchez-le à la valve de contrôle à l’aide d’un raccord fileté

NPT de 1/2 po (non fourni).

Branchez l’appareil à un système d’alimentation en gaz

conçu et installé de façon adéquate. Ce système doit inclure

une valve d’arrêt manuelle approuvée, laquelle doit être

accessible et située à un maximum de 6 pieds de l’appareil.

De plus, un réservoir de décantation ou un collecteur de

condensats doit être installé en amont de la valve d’arrêt

manuelle. Veuillez vous référer au code d’installation

approprié (gaz naturel) susmentionné. Veuillez n’utiliser

qu’un connecteur flexible approuvé.

Avant d’allumer l’appareil, veuillez vous assurer que les pièces

de fixation et les joints sont bien installés afin de prévenir des

fuites éventuelles. Pour détecter des fuites, appliquez une

petite quantité d’eau savonneuse sur tous les joints; des bulles

se formeront en présence de fuite. Dans un tel cas, couper

immédiatement l’alimentation en gaz. Attendez au moins 5

minutes, réparez la fuite et faites une autre vérification. Faites

sécher les joints après la vérification.

MISE EN GARDE

N’UTILISEZ JAMAIS UNE FLAMME NUE POUR

PROCÉDER À LA VÉRIFICATION D’UNE FUITE

COLMATÉE.

MISE EN GARDE LIÉE AUX

SUBSTANCES ODORANTES

ODEUR DU GAZ DE COMBUSTION

Le GPL et le gaz naturel contiennent des substances

odorantes artificielles ajoutées spécifiquement pour la

détection de fuites de gaz de combustion. Si une fuite

de gaz survient, vous devriez pouvoir sentir le gaz de

combustion. Du fait que le propane (liquéfié) est plus lourd

que l’air, vous devriez sentir l’odeur de gaz près du sol.

N’IMPORTE QUELLE ODEUR DE GAZ EST LE SIGNAL POUR

PRENDRE DES MESURES IMMEDIATES !

• Ne pas entreprendre une action qui pourrait enflammer

le gaz de combustion. Ne pas basculer des interrupteurs

électriques. Ne pas tirer une alimentation ou des rallonges

électriques. Ne pas allumer des allumettes ni aucune autre

source de flamme. Ne pas utiliser votre téléphone.

• Faire sortir tout le monde du bâtiment et s’éloigner de la

zone tout de suite.

• Fermer tous les réservoirs de gaz propane (liquéfié) ou les

vannes d’alimentation des cylindres de carburant ou la vanne

d’alimentation principale de carburant située au compteur si

vous utilisez du gaz naturel.

• Le gaz propane (liquéfié) est plus lourd que l’air et peut

séjourner dans les zones basses. Quand vous avez toutes les

raisons pour soupçonner une fuite de propane, empêchez

l’accès à toutes les zones basses.

• Utiliser le téléphone de votre voisin et appeler votre

fournisseur de gaz de combustion et les pompiers de votre

secteur. Ne pas rentrer à nouveau dans le bâtiment ou dans

la zone.

• Vous tenir hors du bâtiment et loin de la zone jusqu’à

ce qu’elle soit déclarée sûre par les pompiers et par le

fournisseur de votre gaz de combustion.

• ENFIN, laisser le personnel d’entretien du gaz de combustion

et les pompiers vérifier si du gaz s’est échappé. Leur

faire aérer le bâtiment et la zone avant d’y retourner. Les

personnels d’entretien correctement formés doivent réparer

toutes les fuites, vérifier qu’il n’y ait pas d’autres fuites

possibles et ensuite rallumer l’appareil pour vous.

MISE EN GARDE

Risque d’asphyxie

• N’utilisez pas l’appareil dans des endroits sans

ventilation.

• Le débit de combustion et l’air de ventilation ne doivent

pas être obstrués.

• Un air de ventilation adéquat doit être fourni pour

supporter les exigences de l’air de combustion de

l’appareil de chauffage utilisé.

• Référez-vous à la section des spécifications du manuel

de l’appareil de chauffage, à la plaque de données

de l’appareil ou communiquez avec le fabricant pour

obtenir les renseignements relatifs aux exigences en

apport d’air de ventilation de l’appareil.

• Un air de ventilation inapproprié occasionnera une

combustion inadéquate.

• Une combustion inadéquate peut provoquer une

asphyxie par le monoxyde de carbone causant de

sérieuses blessures ou la mort. Les symptômes

d’empoisonnement par le monoxyde de carbone

peuvent inclure des maux de tête, des étourdissements

et des difficultés respiratoires.

DISSIPATION D’ODEUR -

PAS D’ODEUR DETECTÉE

• Certaines personnes ne peuvent pas bien sentir les odeurs.

Certaines personnes ne peuvent pas sentir l’odeur artificielle

du produit chimique ajouté au propane (liquéfié) ou au

gaz naturel. Vous devez déterminer si vous pouvez sentir la

substance odorante dans ces gaz de combustion.

• Apprenez à reconnaître l’odeur du gaz propane (liquéfié)

et du gaz naturel. Les revendeurs locaux de gaz propane

(liquéfié) seront plus qu’heureux de vous donner une

brochure que vous grattez et sentez. Utilisez-la pour vous

familiariser avec l’odeur du gaz de combustion.

• Fumer peut diminuer votre capacité à sentir les odeurs. Se

trouver alentour d’une odeur pour une certaine période de

temps peut affecter votre sensibilité à cette odeur particulière.

Les odeurs présentes dans les bâtiments où sont enfermés des

animaux peuvent masquer l’odeur de gaz de carburant.

• La substance odorante dans le gaz propane (liquéfié) et

dans le gaz naturel n’a pas de couleur et l’intensité de

son odeur peut se dissiper dans certaines circonstances.

• S’il y a une fuite souterraine, le passage du gaz à travers le

sol peut filtrer la substance odorante.

• L’odeur de gaz propane (liquéfié) peut différer dans son

intensité à différents niveaux. Du fait que le gaz propane

(liquéfié) est plus lourd que l’air, il peut y avoir plus d’odeurs

à des niveaux inférieurs.

• Soyez toujours en alerte pour l’odeur de gaz la plus

insignifiante. Si vous continuez à détecter n’importe quelle

odeur de gaz, aussi faible soit-elle, traitez-la comme une fuite

sérieuse. Mettez-vous tout de suite en action comme il a été

discuté précédemment.

Operating Instructions and Owner’s ManualGas-Fired Infra-Red Portable Construction Heater

4

Page 11

ATTENTION - POINTS CRITIQUES

À MÉMORISER !

• Le gaz propane (liquéfié) a une odeur reconnaissable. Apprenez

à reconnaître ces odeurs. (Se référer aux sections Odeur de gaz

de combustion et Dissipation d’odeur ci-dessus.

• Même si vous n’êtes pas correctement formé dans l’entretien

et la réparation de l’appareil de chauffage, il faut TOUJOURS

être consciemment averti des odeurs du gaz propane (liquéfié)

et du gaz naturel.

• Si vous n’avez pas été correctement formé dans la réparation

et l’entretien du gaz propane (liquéfié), alors ne tenter pas

d’allumer l’appareil de chauffage, de faire l’entretien ou les

réparations ou de faire des réglages du système de combustion

de gaz propane (liquéfié) de l’appareil de chauffage.

INSTRUCTIONS D’UTILISATION

MISE EN GARDE

SI VOUS NE RESPECTEZ PAS LES

INSTRUCTIONS À LA LETTRE, UN INCENDIE

OU UNE EXPLOSION PEUT S’ENSUIVRE ET

CAUSER DES DOMMAGES DE BIENS, DES

BLESSURES CORPORELLES OU LA MORT.

AVERTISSEMENT

LE PRÉSENT APPAREIL DEVIENT TRÈS CHAUD

EN COURS D’UTILISATION. ÉVITEZ TOUT

CONTACT PHYSIQUE.

AVERTISSEMENT

NE DÉPOSEZ PAS DE VÊTEMENT OU AUTRE

MATÉRIAU COMBUSTIBLE SUR L’APPAREIL

DE CHAUFFAGE.

N’UTILISEZ PAS l’appareil si l’un de ses composants a été en

contact avec de l’eau. Faites appel à un technicien qualifié pour

procéder à une vérification de l’appareil et remplacer toute pièce

du système de contrôle ou de la valve ayant été en contact avec

de l’eau.

Le présent appareil de chauffage doit être installé seulement dans

des endroits où le potentiel de dommages physiques à l’appareil

est réduit au minimum. Le propriétaire/utilisateur doit s’assurer

que les précautions nécessaires sont prises afin de protéger

l’appareil contre d’éventuels dommages physiques.

ALLUMAGE ET ARRÊT

Allumage de l’appareil

1 Avant d’allumer l’appareil, assurez-vous qu’il n’y a pas

d’odeur de gaz. Étant donné que le gaz propane liquéfié

est plus lourd que l’air, il est important de sentir au

niveau du sol. Alimentez l’appareil en gaz et inspectez

les joints pour détecter toute fuite de gaz à l’aide

d’eau savonneuse. N’UTILISEZ JAMAIS une flamme

nue pour détecter une fuite. En cas de fuite, couper

immédiatement l’alimentation en gaz à l’appareil.

Attendez au moins 5 minutes avant de colmater la fuite.

2 Utilisez seulement le type de combustible prévu pour

le présent appareil de chauffage. Consultez la plaque

signalétique pour obtenir des informations sur le type de

combustible à utiliser.

3 Appuyer sur le bouton. Faites tourner le bouton de la

valve de gaz en sens horaire jusqu’à la position « OFF ».

Voir les figures 1

et 2 pour connaître l’emplacement des pièces de l’appareil.

4 Attendez au moins 5 minutes pour laisser s’échapper

le gaz qui s’est peut-être accumulé dans la chambre du

brûleur.

5 Ouvrez l’alimentation de gaz principale.

6a Appuyez sur le bouton de contrôle et faites-le tourner

en sens anti-horaire jusqu’à la position « Pilot ».

Maintenez-le enfoncé pendant 1 ou 2 minutes. Le

processus d’évacuation d’air peut prendre plus de temps

si vous utilisez un long boyau d’alimentation.

Appuyez sur le bouton d’allumage rouge pour allumer

la flamme de la veilleuse (répétez jusqu’à ce que la

veilleuse s’allume) et continuez de maintenir le bouton

de contrôle enfoncé en position« Pilot » pendant encore

30-60 secondes afin d’activer le système de sécurité de

la veilleuse.

Faites tourner le bouton de contrôle jusqu’à la position

« ON » pour allumer le brûleur. ou...

6b Pour allumer la veilleuse, déplacez le couvercle du trou

d’allumage (voir figure 1) et placez une allumette allumée

dans le trou. Appuyez sur le bouton de la valve de gaz

et maintenez-le enfoncé pendant l’allumage tout en

observant le bouton de la veilleuse. Assurez-vous que

l’allumette allume le brûleur. Laissez la veilleuse brûler

pendant environ 30 secondes avant de relâcher le bouton

de la valve de gaz. Si la veilleuse ne reste pas allumée,

répétez la démarche d’allumage et attendez un peu plus

longtemps avant de relâcher le bouton de la valve de gaz.

REMARQUE : si de longues conduites d’alimentation en gaz

ont été installées en avant de l’appareil de chauffage, vous

devrez peut-être enlever l’air de ces conduites avant d’allumer la

veilleuse. C’est souvent le cas pour les conduites d’alimentation

des nouvelles installations. Après voir enlevé l’air des conduites

d’alimentation, attendez au moins 5 minutes avant d’essayer

d’allumer le brûleur.

Réglez la veilleuse au besoin, tel que décrit sous « Réglage de

la veilleuse ».

7. Faites tourner le bouton de la valve de gaz en sens

anti-horaire jusqu’à la position « ON » (voir figure 1).

Le brûleur s’allumera. Le boton de tour dans le sens des

aiguilles d’une montre jusqu’a l’arret pour la position de

Operating Instructions and Owner’s ManualGas-Fired Infra-Red Portable Construction Heater

5

Page 12

GUIDE D’UTILISATION ET MANUEL DU PROPRIÉTAIRE

REMARQUE : lisez et suivez les instructions d’utilisation. Rangez le manuel de

l’utilisateur dans un endroit sûr aux fins de référence ultérieure. NE LAISSEZ

PERSONNE qui n’a pas lu le manuel de l’utilisateur tenter de monter, de

mettre en marche, de régler ou de faire fonctionner l’appareil de chauffage.

MISE EN GARDE :

UTILISEZ SEULEMENT LES PIÈCES DE REMPLACEMENT DU FABRICANT. L’UTILISATION

D’AUTRES PIÈCES PEUT CAUSER DES BLESSURES OU LA MORT. LES PIÈCES DE

REMPLACEMENT SONT UNIQUEMENT DISPONIBLES AUPRÈS DE L’USINE ET DOIVENT

ÊTRE INSTALLÉES PAR UN TECHNICIEN QUALIFIÉ.

COMMANDE DE PIÈCES :

ACHAT : des accessoires peuvent être achetés auprès de votre détaillant local Mr. Heater

ou HeatStar, ou directement de l’usine.

INFORMATION SUR LE SERVICE

Veuillez appeler sans frais le 866-477-2194

www.enerco.com • www.heatstarbyenerco.com

Nos heures de bureau sont de 8:00 h à 17:00 h, fuseau horaire de l’est, du lundi au

vendredi Veuillez inclure le numéro du modèle, la date d’achat et la description du

problème dans toute communication.

MODÈLES

HS125NG, HS125LP

GARANTIE

Appareil de chauffage portatif à infrarouge et au gaz HS125NG et HS125LP

HEATSTAR by ENERCO garantit que les appareils de chauffage infrarouges fabriqués et vendus sont

exempts de défaut de matériel et de fabrication.

Les pièces détachées des ensembles, les contrôles, etc. fournis par HEATSTAR by ENERCO

comporteront la garantie d’un (1) an sur les garanties applicables des fournisseurs.

La seule responsabilité de HEATSTAR par ENERCO sous cette garantie sera de remplacer ou de

réparer n’importe quelle pièce pour laquelle une réclamation écrite est faite à HEATSTAR by

ENERCO dans la limite de validité de cette garantie, qui est retournée sur demande à HEATSTAR by

ENERCO – FOB Cleveland, Ohio - ou FOB à un centre de service autorisé HEATSTAR by ENERCO et

qui s’est révélée défectueuse lors de l’inspection par HEATSTAR par HEATSTAR by ENERCO Technical

Products.

Cette garantie ne s’appliquera pas à toute pièce ou produit qui a été soumis à une mauvaise

utilisation ou à de la négligence, endommagé par accident ou rendu défectueux en raison en raison

d’une mauvaise installation. CETTE GARANTIE VAUT EN LIEU ET PLACE DE N’IMPORTE QUELLE ET

DE TOUTES AUTRES GARANTIES, EXPRIMEES OU IMPLICITES, et d’aucune autre responsabilité de

HEATSTAR par ENERCO pour les parties ou les produits vendus par HEATSTAR by ENERCO, y compris

les dommages conséquents ou spéciaux.

HEATSTAR by ENERCO se réserve le droit de modifier en tout temps, sans préavis ni obligation,

les couleurs, spécifications, accessoires, matériaux et modèles.

ENREGISTREMENT DU PRODUIT : Nous vous remercions de votre achat.

Veuillez vous connectez-à http://www.egiregistration.com pour enregistrer votre produit.

HEATSTAR by ENERCO, 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 866-447-2194

Enerco et Mr. Heater sont des marques déposées d’Enerco Group, Inc.

© 2015, Enerco Group, Inc. Tous droits réservés

ANSI Z83.7b/CSA 2.14b - 2009

Page 13

INSTRUCCIONES DE USO Y MANUAL DEL USUARIO

LEA CUIDADOSAMENTE LAS INSTRUCCIONES: Rlea y siga todas las

instrucciones. Consérvelas en un lugar seguro para futura referencia.

No permita que nadie que no haya leído estas instrucciones arme, encienda,

ajuste o use el calentador.

CALEFACTOR PORTÁTIL PARA

MODELO

HS125NG, HS125LP

CONSTRUCCIÓN INFRARROJO A GAS

NO DEJE EL CALENTADOR DESATENDIDO Y NO LO DEJE FUNCIONANDO

MIENTRAS DUERME.

ADVERTENCIA GENERAL DE PELIGRO:

EL NO CUMPLIR CON LAS PRECAUCIONES E INSTRUCCIONES QUE VIENEN CON ESTE CALENTADOR

PUEDE CAUSAR LA MUERTE, LESIONES GRAVES Y PÉRDIDAS Y DAÑOS MATERIALES DERIVADOS

DEL PELIGRO DE INCENDIO, EXPLOSIÓN, QUEMADURAS, ASFIXIA, ENVENENAMIENTO CON

MONÓXIDO DE CARBONO Y/O DESCARGAS ELÉCTRICAS.

SOLO LAS PERSONAS QUE ENTIENDAN Y PUEDAN SEGUIR LAS INSTRUCCIONES DEBEN USAR

O MANTENER ESTE CALENTADOR.

SI NECESITA AYUDA O INFORMACIÓN ACERCA DEL CALENTADOR, COMO MANUALES DE

INSTRUCCIONES, ETIQUETAS, ETC., PÓNGASE EN CONTACTO CON EL FABRICANTE.

ADVERTENCIA:

PELIGRO DE INCENDIO, QUEMADURAS, INHALACIÓN Y EXPLOSIÓN. MANTENGA LOS

COMBUSTIBLES SÓLIDOS COMO MATERIALES DE CONSTRUCCIÓN, PAPEL O CARTÓN A UNA

DISTANCIA SEGURA DEL CALENTADOR TAL COMO LO RECOMIENDAN LAS INSTRUCCIONES. NUNCA

USE EL CALENTADOR EN ESPACIOS QUE CONTIENEN O PODRÍAN CONTENER COMBUSTIBLES

VOLÁTILES O PRODUCTOS COMO GASOLINA, SOLVENTES, DILUYENTE DE PINTURA, PARTÍCULAS DE

POLVO O PRODUCTOS QUÍMICOS DESCONOCIDOS.

ADVERTENCIA: NO APTO PARA USAR EN EL HOGAR NI EN CASAS RODANTES

01/15 18666 2015HEATSTAR by ENERCO, 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 866-447-2194

Page 14

ESPECIFICACIONES

N.° DE MODELO. .......................HS125LP .................. HS125NG

TIPO DE GAS ............................... Gas LP ............... Gas natural

PRESIÓN DE ENTRADA

MÁXIMA...................... 14 PULGADAS W.C. .... 14 PULGADAS W.C.

PRESIÓN DE ENTRADA

MÍNIMA .....................14 PULGADAS W.C. ... 14 PULGADAS W.C.

PRESIÓN DEL

COLECTOR ................. 12 PULGADAS W.C. . 6.5 PULGADAS W.C.

ADVERTENCIA

NO EXCEDA EL ½ psi (14” w.c.) DE PRESIÓN DE

GAS EN LA VÁLVULA DE CONTROL DE GAS.

VENTILACIÓN

ADVERTENCIA

ESTE ARTEFACTO NO TIENE VENTILACIÓN

Y DEBE USARSE ÚNICAMENTE EN UN ÁREA

BIEN VENTILADA.

No obstruya el flujo de aire necesario para la combustión y la

ventilación. NO lo use en un lugar muy cerrado.

Todo proceso de combustión requiere y consume oxígeno, y puede

producir monóxido de carbono. Este calentador debe usarse con

la ventilación adecuada. Debe haber dos aberturas directamente

hacia el exterior, una baja y otra alta, preferentemente en los lados

opuestos del área que se desea calefaccionar. Cada una de estas

aberturas debe tener por lo menos tres pulgadas cuadradas de

área de entrada de aire de combustión y área de salida de escape

por cada 1000 BTU por hora de la tasa de entrada del calentador

para completar el proceso de combustión/ventilación. Proporcione

ventilación adicional por cada artefacto a combustible y ocupantes

adicionales.

SEPARACIÓN (distancias mínimas a materiales combustibles)

No exceda las presiones del suministro de gas indicadas en las placas de especificación. La presión máxima y la presión mínima de entrada

del suministro de gas (para ajustar la entrada) para gas LP y gas natural son las siguientes:

MODELO N.°: BTU/HR ESPECIFICACIONES POSICIÓN NORMAL DISTANCIA A

DEL TIPO DE GAS DE FUNCIONAMIENTO COMBUSTIBLES

GAS NATURAL GAS LP SUPERIOR COSTADOS INFERIOR

HS125LP 95 -125,000* VERTICAL 48” 60” 60”

HS125NG 72 - 125,000 VERTICAL 48” 60” 60”

*El tamaño y la temperatura del tanque pueden afectar directamente la salida de BTU.

CONTENIDOS

Instrucciones de instalación............................................ S-3

POR SU SEGURIDAD

No use este calentador en un lugar donde

se almacene o se use gasolina u otros

Ubicación ....................................................................... S-3

Tuberías ......................................................................... S-3

Instrucciones de uso ...................................................... S-4

Encendido y apagado .................................................... S-4

Instrucciones de mantenimiento .................................... S-5

Lista de repuestos .......................................................... S-6

Información del servicio técnico y para ordenar piezas ....... S-8

EL ESTADO DE CALIFORNIA EXIGE LAS SIGUIENTES ADVERTENCIAS:

líquidos con vapores inflamables.

El calentador está diseñado y aprobado para usarse como calentador

para construcción bajo las normas ANSI Z83.7 / CGA 2.14.

No podemos anticipar todos los usos que se le pueden dar a

nuestros calentadores. CONSULTE CON LA AUTORIDAD DE

SEGURIDAD ANTIINCENDIOS SI TIENE ALGUNA PREGUNTA SOBRE

SUS APLICACIONES.

Hay otros estándares que rigen el uso de gases combustibles y

productos que producen calor en aplicaciones específicas.

Su autoridad local podrá asesorarlo al respecto.

Este aplicacion es querida para la calefaccion temporal de edificios

bajo construccion, modificascion o reparacion..

ADVERTENCIA: Uno de los elementos generados por la combustión al usar este equipo es monóxido de

carbono, un producto químico que de acuerdo con el estado de California produce cáncer y defectos de nacimiento

(u otros daños reproductivos).

ADVERTENCIA: Este producto contiene sustancias químicas que de acuerdo con el estado de California

producen cáncer y defectos de nacimiento u otros daños reproductivos.

Operating Instructions and Owner’s ManualGas-Fired Infra-Red Portable Construction Heater

2

Page 15

INSTRUCCIONES DE INSTALACIÓN

GENERAL:

LEA CUIDADOSAMENTE ESTAS INSTRUCCIONES. Lea y siga

las siguientes instrucciones. NO permita que nadie que no

las haya leído arme, encienda, ajuste o use este calentador.

NO intente usar el calentador con cualquier otro gas que no

sea el que se indica en la placa del calentador.

Para los EE. UU. y/o Canadá, la instalación de este artefacto debe

cumplir con las normas locales o provinciales o, en ausencia de

dichas normas,

• con el Reglamento nacional de combustible gaseoso

(EE. UU.) ANSI Z223.1 - última edición (para el

funcionamiento con gas natural y gas LP, modelos

HS125NG y HS125LP), y con las Normas para el

almacenamiento y manejo de gases licuados del petróleo

(EE. UU.) ANSI/NFPA 58 (para el funcionamiento con

gas LP, modelos MH125LP, HS125LP), o bien

• con las NORMAS actuales DE INSTALACIÓN CAN/CGA

B149.1 Y B149.2 (Canadá).

Hay que inspeccionar este calentador (incluso la manguera y el

regulador, si corresponde) antes de cada uso y hacerlo revisar

por una persona calificada una vez por año por lo menos. Si la

manguera del modelo HS125LP muestra signos de abrasión o

desgaste excesivo, o si tiene cortes, debe ser reemplazada antes

de hacer funcionar el calentador. La manguera de reemplazo debe

ser la indicada por el fabricante. Consulte la lista de piezas.

UBICACIÓN

El calentador (y el cilindro de suministro de gas LP, si corresponde)

deben colocarse sobre una superficie dura, plana y nivelada para

reducir al mínimo el riesgo de una caída accidental. Si se utiliza

un cilindro de suministro de gas LP (por ejemplo, en el modelo

HS125LP), el cilindro debe sujetarse bien para evitar que se

caiga accidentalmente. NO use este calentador con el cilindro

de suministro en ninguna posición que no sea la vertical.

Este artefacto debe instalarse únicamente en lugares donde el

riesgo de daños físicos al artefacto (originados por contacto físico,

por ejemplo) se reduzcan al mínimo.

El instalador debe informarle al dueño o usuario de este artefacto

que se deben tomar las precauciones necesarias para proteger al

artefacto contra daños físicos.

Este artefacto produce calor radiante. Por lo tanto, debe ubicarse

por lo menos a 2 metros de distancia de cualquier contenedor de

gas LP y no debe apuntar hacia ningún contenedor de gas LP a

menos de 6 metros.

El calentador debe instalarse en un lugar en el que no quede expuesto

directamente a las salpicaduras de agua, lluvia o goteo de agua.

El usar este calentador en un área ventosa/con corrientes de aire

disminuye su eficiencia. De ser posible, use la unidad en un área

sin corrientes de aire.

TUBERÍAS

Para el modelo HS125LP

(para usar con gas LP)

Este modelo puede conectarse a un sistema de suministro

autónomo de gas LP con la manguera y el conjunto del regulador

suministrado con el artefacto, O BIEN, puede conectarse a un

sistema de suministro de gas LP permanentemente.

Si se conecta a un sistema de suministro de gas LP autónomo,

el conjunto de la manguera debe inspeccionarse antes de cada

uso del calentador. Si es evidente que hay abrasión o desgaste

excesivos, o si la manguera está cortada, debe reemplazarse

antes de poner en funcionamiento el calentador.

Si se conecta a un sistema de suministro de gas LP

autónomo, el cilindro debe tener una capacidad de gas LP

mínima de 18 kilogramos y máxima de 45 kilogramos. NO

conecte este artefacto a un cilindro que tenga una capacidad

nominal de gas LP menor a los 18 kilogramos.

ADVERTENCIA

NUNCA USE UN CILINDRO DEL TIPO USADO

EN MONTACARGAS.

La conexión del modelo HS125LP a un cilindro de gas LP debe

hacerse en un área bien ventilada, usando el regulador y la

manguera que vienen con el artefacto. NO intente ajustar

este regulador. Ha sido ajustado en la fábrica para brindar

un funcionamiento seguro y adecuado del artefacto. Use una

llave de extremo abierto de 7/8” para conectar el acople del

POL (suministrado con el regulador de LP) al cilindro de gas LP.

Enrosque la tuerca POL hacia la izquierda (es una rosca izquierda)

hasta que quede fija. NO utilice compuestos para tuberías en

las roscas POL.

El calentador debe ubicarse por lo menos a 2 metros de

cualquier cilindro de gas LP y no debe apuntar hacia ningún

cilindro de gas LP a menos de 6 metros. Si se usa más de un

calentador, deberán separarse de los cilindros de suministro

por más de 6 metros. Verifique las normas locales.

El suministro de gas debe cerrarse en el cilindro de suministro

de gas LP cuando el calentador no se use.

Cuando deba guardar el calentador en un lugar cerrado,

deberá desconectar la conexión entre el cilindro de suministro

de gas LP y el calentador, y deberá retirar el cilindro del

calentador y guardarlo como se especifica en el Capítulo 5

de las Normas para el almacenamiento y manejo de gases

licuados del petróleo. (EE. UU.) ANSI/ NFPA 58, O CAN/CGA

B149.2 (Canadá).

Si se conecta a un sistema de suministro de gas LP

permanentemente, el sistema requiere el uso de un regulador

de gas de dos etapas, generalmente suministrado por el

distribuidor de gas LP como parte del sistema de suministro

de gas LP. Comuníquese con el distribuidor de gas LP local

para obtener información detallada sobre el equipo y la

instalación adecuados.

Operating Instructions and Owner’s ManualGas-Fired Infra-Red Portable Construction Heater

3

Page 16

Para el modelo HS125NG

(para usar con gas natural)

La tubería debe estar limpia y sin sarro o rebabas.

Instale el regulador incluido con el calentador. Conéctelo con

la unión de 1/2” NPT (no incluida) a la válvula de control.

Conecte el artefacto a un sistema de suministro de combustible

diseñado e instalado adecuadamente. Este sistema debe incluir

una válvula de cierre manual aprobada que esté a mano y que

se encuentre a 1,82 m del artefacto. Además, se debe colocar

un separador de sedimentos o una pierna colectora arriba

de esta válvula de cierre manual. Consulte el reglamento de

instalación adecuado (gas natural) mencionado anteriormente.

Si utiliza un conector flexible, debe ser de un tipo aprobado.

Antes de intentar encender el artefacto, deberá verificar bien que

no haya ninguna fuga de gas por los acoples o las conexiones.

Coloque una pequeña cantidad de solución de agua y jabón en

todos los acoples y conexiones y observe si aparecen burbujas.

Si detecta alguna fuga, cierre la entrada de gas al artefacto

inmediatamente. Espere cinco minutos como mínimo, repare

las fugas y vuelva a verificar que no haya fugas. Seque todos los

acoples y conexiones después de la prueba de fugas.

ADVERTENCIA

NUNCA USE UNA LLAMA PARA VERIFICAR

LAS FUGAS.

ADVERTENCIA DE DISIPACIÓN DEL OLOR

OLOR A GAS COMBUSTIBLE

Los gases LP y el gas natural contienen sustancias

aromáticas artificiales añadidas específicamente para

facilitar la detección de fugas de gas. Si se produjera una

fuga de gas, usted debe poder oler el gas combustible. Dado

que el propano (LP) es más pesado que el aire, debe tratar

de detectar el olor lo más cerca del piso posible. CUALQUIER

OLOR A GAS SERÁ LA SEÑAL PARA TOMAR MEDIDAS

INMEDIATAMENTE.

• No haga nada que pudiera inflamar el gas combustible. No

active ningún interruptor eléctrico. No desconecte ninguna

toma de corriente ni cables de extensión. No encienda fósforos

ni ninguna otra fuente de llamas. No utilice el teléfono.

• Saque a todas las personas del edificio y aléjelas del área

inmediatamente.

• Cierre todas las válvulas de suministro de combustible de

los cilindros o del tanque de gas propano (LP), o la válvula

principal de suministro de combustible que se encuentra en el

medidor si emplea gas natural.

• El gas propano (LP) es más pesado que el aire y puede

asentarse en áreas bajas. Cuando sospeche que puede haber

una fuga de propano, manténgase alejado de las áreas bajas.

• Utilice el teléfono de su vecino y llame al proveedor de gas y

al departamento de bomberos. No vuelva a entrar al edificio

ni se acerque al área.

• Manténgase alejado del edificio y del área hasta que los

bomberos y el proveedor de gas hayan declarado que no

hay peligro.

• POR ÚLTIMO, permita que la persona del servicio de gas y los

bomberos revisen si hay fugas de gas. Haga que ventilen el

edificio y el área antes de su regreso. Un agente de servicios

calificado debe reparar cualquier fuga, revisar si hay otras

fugas y volver a encender el artefacto por usted.

ADVERTENCIA

Peligro de asfixia

• No utilice el artefacto en áreas sin ventilación.

• No obstruya el flujo de aire necesario para la combustión

y la ventilación.

• Deberá suministrar la ventilación adecuada para

garantizar que el calentador disponga del aire que

necesita para la combustión.

• Consulte la sección de especificaciones del manual del

calentador, la placa del calentador o póngase en contacto

con el fabricante para conocer los requerimientos de

ventilación del calentador.

• Si la ventilación no es la adecuada, la combustión no se

llevará a cabo correctamente.

• Una combustión inadecuada puede producir

envenenamiento con monóxido de carbono con graves

daños para la salud, o causar la muerte. Los síntomas

de envenenamiento con monóxido de carbono incluyen

dolores de cabeza, mareos y dificultad para respirar.

DISIPACIÓN DEL OLOR:

NO SE DETECTA NINGÚN OLOR

• Algunas personas tienen problemas de olfato. Algunos no

pueden detectar el olor del químico artificial añadido al propano

(LP) o al gas natural. Debe determinar si es capaz de oler la

sustancia aromática que contienen estos gases combustibles.

• Aprenda a reconocer el olor del gas propano (LP) y del gas

natural. Los distribuidores locales de propano (LP) le darán

con gusto un panfleto con muestras de olores. Utilícelo para

familiarizarse con el olor del gas combustible.

• El hábito de fumar puede disminuir el sentido del olfato.

Exponerse a un olor durante un período puede afectar su

sensibilidad a ese olor específico. Los olores presentes en

instalaciones donde se crían animales pueden enmascarar el

olor del gas combustible.

• La sustancia aromática presente en el gas propano (LP)

y en el gas natural es incolora y la intensidad de su olor

puede desvanecerse en algunas circunstancias.

• Si hay una fuga subterránea, el recorrido del gas a través del

suelo puede filtrar esta sustancia aromática.

• El aroma del gas propano (LP) puede variar en intensidad

a diferentes niveles. Dado que el gas propano (LP) es más

pesado que el aire, el olor puede ser más intenso en los

niveles más bajos.

• Manténgase siempre alerta al más mínimo olor a gas.

Si continúa percibiendo el olor a gas, no importa cuán poco

sea, proceda como si fuera una fuga grave. Tome medidas

de inmediato como se explicó anteriormente.

Operating Instructions and Owner’s ManualGas-Fired Infra-Red Portable Construction Heater

4

Page 17

ATENCIÓN: PUNTOS IMPORTANTES

PARA RECORDAR

• El gas propano (LP) tiene un olor característico. Aprenda a

reconocer estos olores. (Consulte las secciones anteriores

“Olor a gas combustible” y “Disipación del olor”).

• Aunque usted no esté capacitado para dar mantenimiento

y reparar el calentador, SIEMPRE esté atento a los olores del

gas propano (LP) y del gas natural.

• Si no ha recibido capacitación para reparar y dar

mantenimiento a equipos que emplean gas propano (LP),

no intente encender el calentador, darle mantenimiento o

repararlo, ni hacer ningún ajuste al calentador en el sistema

de combustible de gas propano (LP).

INSTRUCCIONES DE USO

ADVERTENCIA

SI NO SE SIGUEN AL PIE DE LA LETRA ESTAS

INSTRUCCIONES, PODRÍA PRODUCIRSE

UN INCENDIO O UNA EXPLOSIÓN QUE

PROVOCARÍA DAÑOS MATERIALES, LESIONES

PERSONALES O MUERTES.

CUIDADO

ESTE ARTEFACTO SE CALIENTA DURANTE SU

FUNCIONAMIENTO NORMAL. EVITE TODO

CONTACTO FÍSICO.

CUIDADO

NO COLOQUE ROPA U OTRO MATERIAL

COMBUSTIBLE SOBRE ESTE ARTEFACTO.

NO use este calentador si alguna de las piezas ha estado

bajo el agua. Contáctese de inmediato con un técnico de

mantenimiento calificado para que inspeccione el calentador y

reemplace cualquier pieza del sistema de control o válvula de

control de gas que haya estado bajo el agua.

Este artefacto debe instalarse y usarse únicamente en lugares

donde el riesgo de daños físicos al artefacto se reduzcan al

mínimo. El dueño/usuario de este artefacto debe asegurar que

se tomen las precauciones necesarias para proteger el artefacto

contra daños físicos.

ENCENDIDO Y APAGADO

Encendido del calentador

1 Antes de encender el calentador, huela alrededor del área del

calentador para verificar que no haya olor a gas. Asegúrese

de oler cerca del piso ya que el gas LP es más pesado que

el aire y se acumula en el piso. Abra el suministro de gas

del artefacto y verifique todos los acoples y conexiones

para corroborar que no haya fugas de gas con una solución

de agua jabonosa. NUNCA use un fósforo para buscar

fugas. En caso de que se produzca una fuga de gas, cierre

el suministro de gas del artefacto de inmediato. Aguarde un

mínimo de cinco minutos antes de reparar la fuga.

2 Use únicamente el combustible especificado para este

artefacto. Consulte la placa de especificaciones del artefacto

para obtener información actual acerca del combustible.

3 Pulsar la perilla. Gire la perilla de la válvula de gas hacia

la derecha a la posición “OFF” (APAGADO). Consulte la

fig. 1 y la fig. 2 para ver la ubicación de las piezas del

artefacto.

4 Aguarde el tiempo suficiente (al menos cinco minutos)

para permitir que salga el gas que se pudo haber

acumulado en el compartimiento del quemador.

5 Abra el suministro principal de gas.

6a Presione y gire la perilla de control hacia la izquierda

hasta la posición “Pilot” (Piloto) y manténgala presionada

entre 1 y 2 minutos. Purgar aire desde la manguera de

suministro puede llevar más tiempo, según la longitud

de la manguera que se use.

Oprima el botón de encendido de color rojo para encender

la llama del piloto (repita este paso hasta que se encienda

el piloto) y continúe presionando la perilla de control en

la posición “Pilot” (Piloto) entre 30 y 60 segundos para

habilitar el sistema de seguridad de encendido del piloto.

Gire por completo la perilla de control a la posición “ON”

(ENCENDIDO) para encender el quemador. o bien...

6b Para encender el piloto, retire la tapa del orificio de

encendido (consulte la fig. 1) y coloque un fósforo

encendido en el orificio. Oprima la perilla de la válvula

de gas y manténgala presionada al encenderla y observe

el quemador del piloto. Asegúrese de que el quemador

del piloto se encienda con el fósforo. Permita que el

piloto permanezca encendido durante aproximadamente

30 segundos antes de soltar la perilla de la válvula

de gas. Si el piloto no permanece encendido, repita

la operación de encendido y mantenga presionada la

perilla de la válvula de gas por más tiempo.

NOTA: En caso de que se instalen circuitos largos de líneas de

suministro de gas antes que el artefacto, podría ser necesario

purgar el aire atrapado en ellas antes de encender el piloto.

Generalmente, las instalaciones nuevas requieren del purgado

de las líneas de suministro. Aguarde durante un mínimo

de cinco minutos luego de haber purgado las líneas de

suministro antes de intentar encender el calentador.

Ajuste el piloto si es necesario, según se indica en la sección

“Ajuste del quemador del piloto”.

7. Gire la perilla de la válvula de gas hacia la izquierda a

la posición “ON” (ENCENDIDO) (consulte la fig. 1). El

quemador se encenderá. Perilla de vuelta dextrosum

para parase para posicion de fuego baja.

8. IMPORTANTE: NO intente ajustar la entrada del

quemador principal usando la válvula general del

suministro de gas, ya que esto podría provocar que el

piloto y la termocupla apaguen el quemador (fig. 2).

Operating Instructions and Owner’s ManualGas-Fired Infra-Red Portable Construction Heater

5

Page 18

INSTRUCCIONES DE USO Y MANUAL DEL USUARIO

LEA CUIDADOSAMENTE LAS INSTRUCCIONES: lea y siga todas las

instrucciones. Consérvelas en un lugar seguro para futura referencia. No

permita que nadie que no haya leído estas instrucciones arme, encienda,

ajuste o use el calentador.

ADVERTENCIA:

USE SOLAMENTE REPUESTOS DEL FABRICANTE. EL USO DE CUALQUIER OTRA PIEZA