Page 1

XL

ER

OPERATING INSTRUCTIONS

ERXL-40 ERXL-60

ERXL-80 ERXL-100

Model #

AND OWNER’S MANUAL

ERXL-125 ERXL-150

ERXL-175

READ INSTRUCTIONS CAREFULLY: YOUR SAFETY IS IMPORTANT TO YOU AND TO OTHERS Read and

follow all instructions. Place instructions in a safe place for future reference. Do not allow anyone who has

not read these instructions to assemble, light, adjust or operate the heater.

Heatstar ERXL

Gas-Fired Low-Intensity Infrared Heaters Approved

For Residential Garage/Commercial Applications

LANGUAGES INCLUDED

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death. Read the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment.

- WHAT TO DO IF YOU SMELL GAS

• Open Windows

• DO NOT try to light any appliance.

• DO NOT use electrical switches.

• DO NOT use any telephone in your house. Immediately call your local gas supplier from a telephone remote from the

area of the leak. Follow the gas supplier’s instructions.

• Do not touch any electrical switch; do not use any phone in your building.

• Installation and service must be performed by a qualified installer, service agency, or the gas supplier.

• If you cannot reach your gas supplier, call the Fire Department.

FOR YOUR SAFETY:

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

•ENGLISH

•FRENCH

•SPANISH

WARNING: If the information in these instructions are not followed exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

ENERCO Group, Inc., 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 866-447-2194

18677XL

Page 2

WARNING:

YOUR SAFETY IS IMPORTANT TO YOU AND TO

OTHERS, SO PLEASE READ THESE INSTRUCTIONS

BEFORE YOU OPERATE THIS HEATER.

GENERAL HAZARD WARNING:

FAILURE TO COMPLY WITH THE PRECAUTIONS AND

INSTRUCTIONS PROVIDED WITH THIS HEATER, CAN

RESULT IN DEATH, SERIOUS BODILY INJURY AND

PROPERTY LOSS OR DAMAGE FROM HAZARDS OF

FIRE, EXPLOSION, BURN, ASPHYXIATION, CARBON

MONOXIDE POISONING, AND/OR ELECTRICAL

SHOCK.

ONLY PERSONS WHO CAN UNDERSTAND AND

FOLLOW THE INSTRUCTIONS SHOULD USE OR

SERVICE THIS HEATER.

IF YOU NEED ASSISTANCE OR HEATER INFORMATION

SUCH AS AN INSTRUCTIONS MANUAL, LABELS, ETC.

CONTACT THE MANUFACTURER.

WARNING:

FIRE, BURN, INHALATION, AND EXPLOSION

HAZARD. KEEP SOLID COMBUSTIBLES, SUCH AS

BUILDING MATERIALS, PAPER OR CARDBOARD,

A SAFE DISTANCE AWAY FROM THE HEATER AS

RECOMMENDED BY THE INSTRUCTIONS NEVER

USE THE HEATER IN SPACES WHICH DO OR MAY

CONTAIN VOLATILE OR AIRBORNE COMBUSTIBLES,

OR PRODUCTS SUCH AS GASOLINE, SOLVENTS,

PAINT THINNER, DUST PARTICLES OR UNKNOWN

CHEMICALS.

WARNING:

THIS PRODUCT CAN EXPOSE YOU TO CHEMICALS

INCLUDING LEAD AND LEAD COMPOUNDS, WHICH

ARE KNOWN TO THE STATE OF CALIFORNIA TO CAUSE

CANCER AND BIRTH DEFECTS OR OTHER REPRODUCTIVE

HARM. FOR MORE INFORMATION VISIT WWW.

P65WARNINGS.CA.GOV

WARNING: Fuels used in liquefied propane

gas appliances, and the products of combustion of such

fuel, can expose you to chemicals including benzene,

which is known to the state of California to cause cancer

and cause birth defects or other reproductive harm, for

more information go to www.P65Warnings.ca.gov

CONTENTS

Section 1 INTRODUCTION ................................................................2

Section 2 PLANNING .......................................................................3

Section 3 INSTALLATION & ASSEMBLY ............................................. 6

Section 4 ENGINEERING SPECIFICATIONS ....................................... 13

Section 5 VENTING/DUCTING ........................................................ 14

Section 6 GAS PIPING .................................................................... 17

Section 7 WIRING .......................................................................... 18

Section 8 OPERATION MAINTENANCE ........................................... 18

Section 9 TROUBLESHOOTING ....................................................... 21

REPLACEMENT PARTS .................................................................... 22

WARRANTY INFORMATION ...........................................................28

SECTION 1:Introduction

Heatstar ERXL models are low-cost, field assembled infrared heaters

that are easy to install and require only minimal maintenance. They

are designed to provide years of economical operation and

trouble-free service.

Checking Shipment

Check the shipment against the Bill of Lading for shortages. Also,

check for external damage to cartons. Note any shortages, and/

or external damage to cartons on the Bill of Lading in the presence

of the delivery trucker. The delivery trucker should acknowledge

any shortages or damage by initializing this “noted” Bill of Lading.

Immediately report any claims for damaged material, or shortages

that were not evident at the time of shipment, to the carrier and your

Enerco Group, Inc Factory Representative.

Installer Responsibility

All heaters and associated gas piping should be installed in

accordance with applicable specifications and this installation made

only by firms (or individuals) well qualified in this type of work.

Consult local building inspectors, Fire Marshals or your local Enerco

Group, Inc Factory Representative for guidance.

Heatstar ERXL heaters are installed on the basis of information

given in a layout drawing, which together with the cited codes and

regulations, comprise the basic information needed to complete the

installation. The installer must furnish all needed material that is not

furnished as standard equipment, and it is his responsibility to see that

such materials, as well as the installation methods he uses result in a

job that is workmanlike and in compliance with all applicable codes.

Enerco Group, Inc Factory Representatives have had training and

experience in the application of this equipment and can be called on

for suggestions about installation which can save material and money.

Enerco | Heatstar ERXL Series Heater Operating Instructions and Owner’s Manual

E-2

Page 3

SECTION 2: Planning

The following codes and instructions should be followed when

planning the installation of the Heatstar ERXL heater. In addition

to these instructions, the warnings in (Section 1) must be carefully

adhered to since improper installation may lead to property damage,

injury, or death.

National Standards and Applicable

Codes

Gas Codes:

The type of gas appearing on the nameplate must be the

type of gas used. Installation must comply with local codes

and recommendations of the local gas company, and the

National Fuel Gas Code, ANSI Z223.1 – latest revision,

(same as NFPA Bulletin 54) or the Natural Gas and Propane

Installation Code, CSA B149.1.

• Clearance between the heater and its vent and adjacent

combustible material (which is part of the building or its

contents) shall be maintained to conform with the Standard

for Installation of Gas Appliances and Gas Piping, NFPA-54 /

ANSI Z223.1 – latest revision, National Fuel Gas Code or the

Natural Gas and Propane Installation Code, CSA B149.1.

Aircraft Hangers:

Installation in aircraft hangers must be in accordance with

the Standard for Aircraft Hangers, ANSI / NFPA-409 – latest

revision.

• Heaters in aircraft storage or service areas shall be installed

at a height of 10 feet above the upper surface of wings

or engine enclosures of the highest aircraft which may be

housed in the hanger. (This should be measured from the

bottom of the heater to the wing or engine enclosure,

whichever is highest from the floor.)

• In other sections of aircraft hangers, such as shops or offices,

heaters must not be installed less than 8 feet above the

floor.

• Heaters installed in aircraft hangers shall be located so as

not to be subject to damage by aircraft, cranes, moveable

scaffolding or other objects.

Public Garages:

Installations in garages must be made in accordance with the

Standard for Parking Structures, NFPA-88A – latest revision

or the Standard for Repair Garages, NFPA-88B – latest

revision.

• Heaters must not be installed less than 8 feet above

the floor. Minimum clearances to combustibles must be

maintained from vehicles parked below the heater.

• When installed over hoists, minimum clearances to

combustibles must be maintained from the uppermost point

on the hoist.

Venting:

The venting must be installed in accordance with NFPA-54 /

ANSI Z223.1 or CSA 149.1– latest revision, National Fuel Gas

Code. Partial information with regard to this code is provided

in (Section 5) of this installation manual with regard to size

and configurations for venting arrangements.

Hazardous Locations:

Where there is the possibility of exposure to combustible

airborne material or vapor, consult the local Fire Marshal, the

fire insurance carrier or other authorities for approval of the

proposed installation.

Critical Considerations

Heatstar ERXL is a suspended heater. Therefore, its stability,

flexibility, and safety are very important. Before starting

installation, be sure the system can meet the following

requirements.

• For either indoor or outdoor installation. Not for use in resi-

dential dwellings.

• Maintain specified clearances to combustibles, and safe distance from the heat-sensitive material, equipment and work

stations.

• The stated clearances to combustibles represent a surface

temperature of 90°F (30°C) above room temperature.

Building materials with low heat tolerance (such as plastic,

vinyl siding, canvas, etc.) may be subject to degradation at

lower temperatures. It is the installers responsibility to assure

that adjacent materials are protected from degradation.

• Provide a suspension with vertical length of chain or swinging

rod which has at least 2 inches of horizontal travel for each

burner in a straight run. Be sure the suspension system is

sufficiently flexible to accommodate thermal expansion which

occurs as the system heats up (see Figure 6 on page 12).

• Provide access to burners for servicing, preferable on both

sides, above and behind the burner for removal.

• Provide a minimum of 18 inches of clearance between burners and building walls. (Always observe minimum clearances

to combustibles.)

• Be sure the heater has a downward pitch of one-half inch per

20 feet away from the burner. (1.25 cm per 6.1 m)

• Provide signs in storage areas to specify maximum stacking

height to maintain required clearances to combustibles.

• Plan location supports (see Figure 2A-G starting on page 8).

Locate a support near all elbows.

• The installation must conform with local building codes or

in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54 or the Natural Gas and Propane Installation Code, CSA B149.1.

• If an external electrical source is utilized, the heater, when

Available Venting Kits

F102848 Category I 4" Vertical Vent Kit

F102849 Category I 6" Vertical Vent Kit

• Any portion of flue pipe passing through a combustible wall

must be dual insulated or have an approved thimble. Refer to

ANSI-Z223.1 or CSA149.1– latest revision.

F102860 Category III 4" Stainless Steel Horizontal Vent Kit

Operating Instructions and Owner’s ManualEnerco | Heatstar ERXL Series Heater

E-3

Page 4

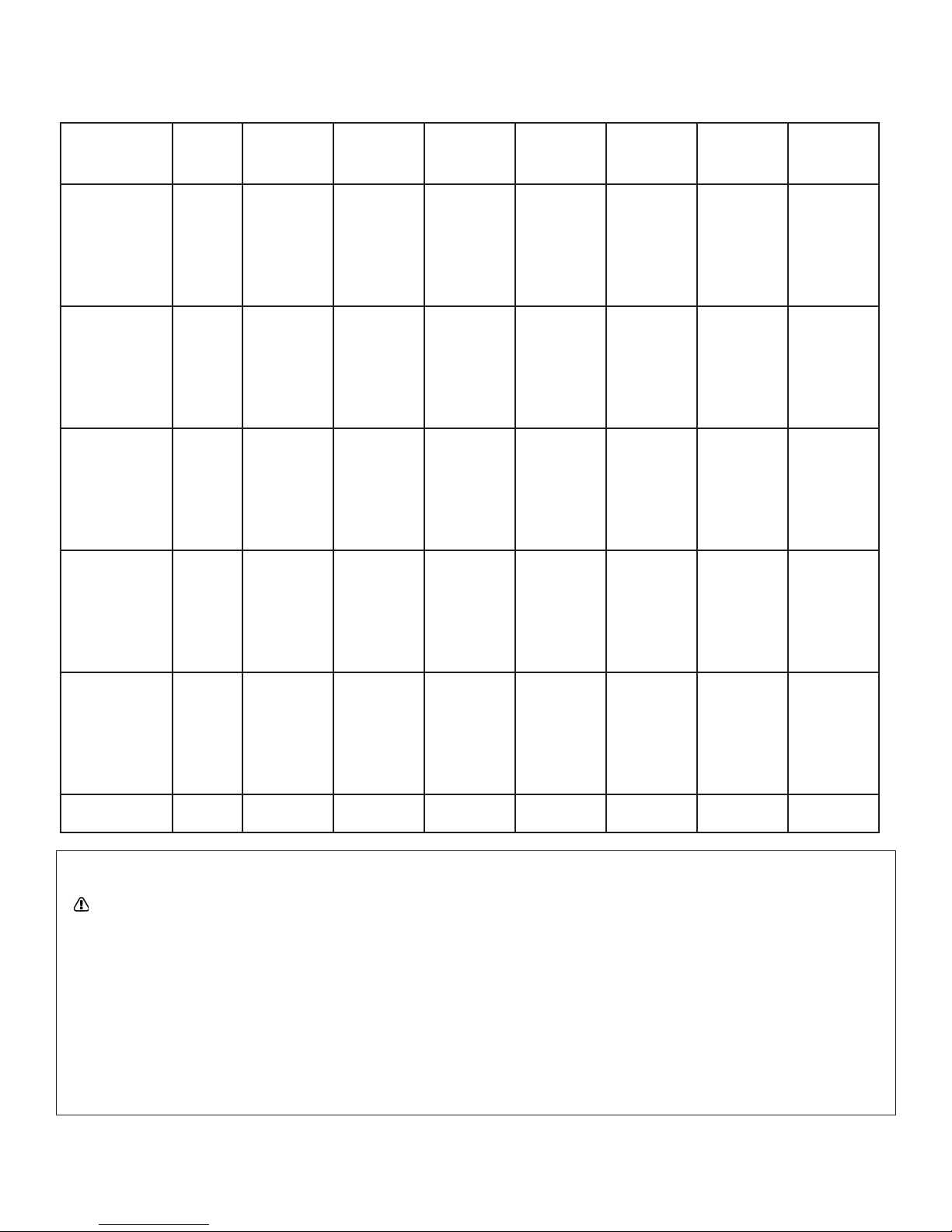

Clearances To Combustibles

TABLE 1: Minimum Clearances to Combustibles (Use Figure 1 on page 5 as a Guide)

Reflector Type Position ERXL-40 ERXL-60 ERXL-80 ERXL-100 ERXL-125 ERXL-150 ERXL-175

Standard

Reflector

(Horizontal)

45° Reflector Tilt

U-Tube Standard

(Horizontal)

U-Tube Opposite

45°

A

B

C

D

A

B

C

E

F

A

B

C

D

A

B

C

F

6" (15.25cm)

30" (76.25 cm)

55" (140 cm)

30" (76.25 cm)

12" (30.5 cm)

30" (76.25 cm)

55" (140 cm)

36" (30.5 cm)

60" (152.5 cm)

6" (15.25cm)

30" (76.25 cm)

55" (140 cm)

30" (76.25 cm)

12" (30.5 cm)

30" (76.25 cm)

55" (140 cm)

60" (152.5 cm)

6" (15.25cm)

30" (76.25 cm)

55" (140 cm)

30" (76.25 cm)

12" (30.5 cm)

30" (76.25 cm)

55" (140 cm)

36" (30.5 cm)

60" (152.5 cm)

6" (15.25cm)

30" (76.25 cm)

55" (140 cm)

30" (76.25 cm)

12" (30.5 cm)

30" (76.25 cm)

55" (140 cm)

60" (152.5 cm)

6" (15.25cm)

36" (30.5 cm)

55" (140 cm)

36" (30.5 cm)

18" (46 cm)

36" (30.5 cm)

55" (140 cm)

36" (30.5 cm)

60" (152.5 cm)

6" (15.25cm)

36" (30.5 cm)

55" (140 cm)

36" (30.5 cm)

18" (46 cm)

36" (30.5 cm)

55" (140 cm)

60" (152.5 cm)

6" (15.25cm)

36" (30.5 cm)

74" (188 cm)

36" (30.5 cm)

18" (46 cm)

36" (30.5 cm)

74" (188 cm)

36" (30.5 cm)

60" (152.5 cm)

6" (15.25cm)

36" (30.5 cm)

74" (188 cm)

36" (30.5 cm)

18" (46 cm)

36" (30.5 cm)

74" (188 cm)

60" (152.5 cm)

6" (15.25cm)

36" (30.5 cm)

87" (221 cm)

36" (30.5 cm)

18" (46 cm)

36" (30.5 cm)

87" (221 cm)

36" (30.5 cm)

60" (152.5 cm)

6" (15.25cm)

36" (30.5 cm)

87" (221 cm)

36" (30.5 cm)

18" (46 cm)

36" (30.5 cm)

87" (221 cm)

60" (152.5 cm)

6" (15.25cm)

36" (30.5 cm)

87" (221 cm)

36" (30.5 cm)

18" (46 cm)

36" (30.5 cm)

87" (221 cm)

36" (30.5 cm)

60" (152.5 cm)

6" (15.25cm)

36" (30.5 cm)

87" (221 cm)

36" (30.5 cm)

18" (46 cm)

36" (30.5 cm)

87" (221 cm)

60" (152.5 cm)

8" (20.5 cm)

36" (30.5 cm)

87" (221 cm)

36" (30.5 cm)

18" (46 cm)

36" (30.5 cm)

87" (221 cm)

36" (30.5 cm)

60" (152.5 cm)

8" (20.5 cm)

36" (30.5 cm)

87" (221 cm)

36" (30.5 cm)

18" (46 cm)

36" (30.5 cm)

87" (221 cm)

60" (152.5 cm)

A

B

U-Tube Full 45°

C

E

F

Unvented Above A

12" (30.5 cm)

30" (76.25 cm)

55" (140 cm)

36" (30.5 cm)

60" (152.5 cm)

36" (30.5 cm) 36" (30.5 cm) 36" (30.5 cm) 36" (30.5 cm) 36" (30.5 cm) 36" (30.5 cm) 36" (30.5 cm)

12" (30.5 cm)

30" (76.25 cm)

55" (140 cm)

36" (30.5 cm)

60" (152.5 cm)

18" (46 cm)

36" (30.5 cm)

55" (140 cm)

36" (30.5 cm)

60" (152.5 cm)

18" (46 cm)

36" (30.5 cm)

74" (188 cm)

36" (30.5 cm)

60" (152.5 cm)

18" (46 cm)

36" (30.5 cm)

87" (221 cm)

36" (30.5 cm)

60" (152.5 cm)

18" (46 cm)

36" (30.5 cm)

87" (221 cm)

36" (30.5 cm)

60" (152.5 cm)

18" (46 cm)

36" (30.5 cm)

87" (221 cm)

36" (30.5 cm)

60" (152.5 cm)

WARNING:

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE, SEVERE INJURY OR DEATH.

In all situations, clearances to combustibles must be maintained. Failure to observe clearances to combustibles may result in property

damage, severe injury, or death.

Minimum clearances must be maintained from vehicles parked below the heater. Signs should be posted in storage areas to specify

maximum stacking height to maintain required clearances to combustibles.

Caution should be used when running the system near combustible materials such as wood, paper, rubber, etc. Consideration should be

given to partitions, storage racks, hoists, building construction, etc.

TABLE 1 gives minimum acceptable clearances to combustibles. Clearances as shown in TABLE 1 are not for use in four-sided enclosures.

Enerco | Heatstar ERXL Series Heater Operating Instructions and Owner’s Manual

E-4

Page 5

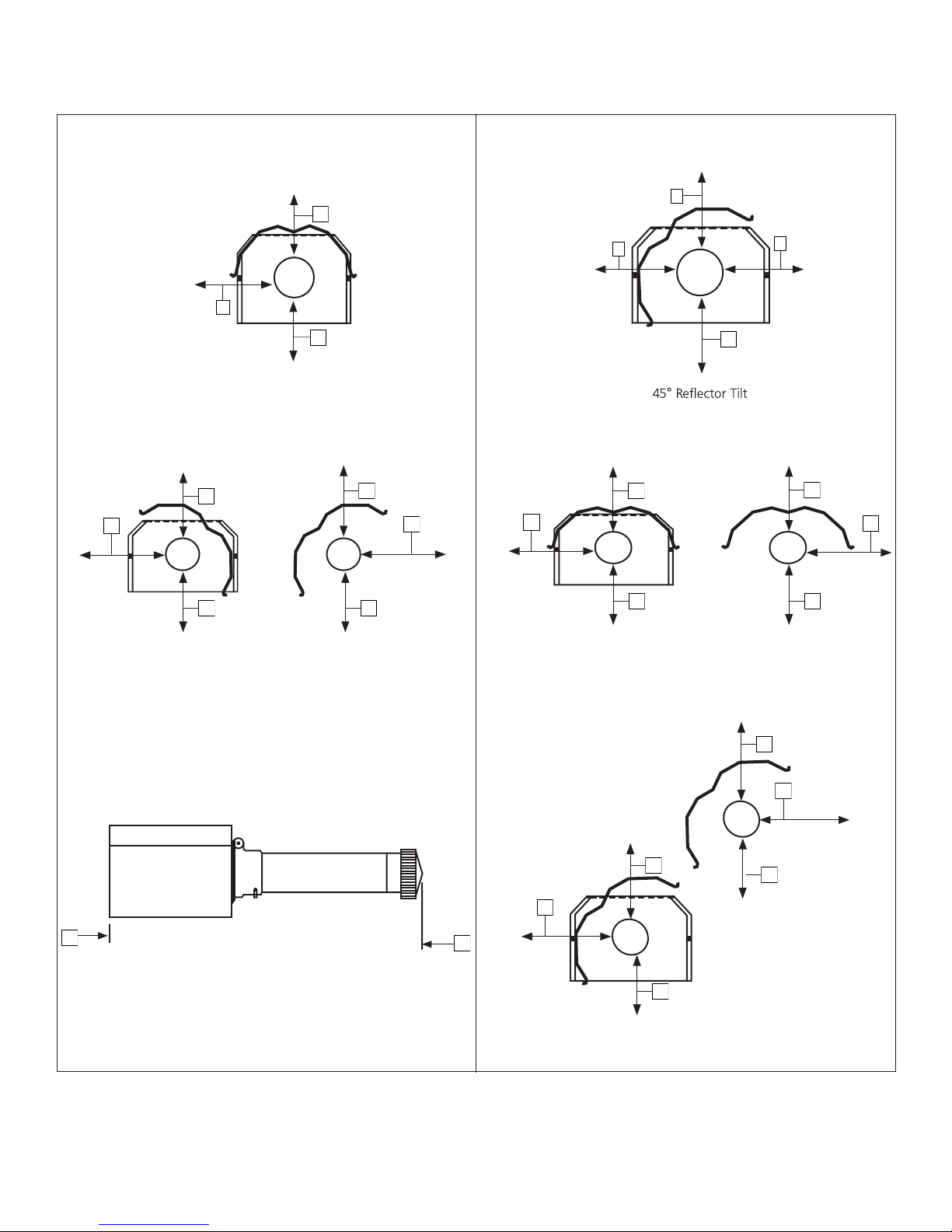

Clearances To Combustibles

Figure 1: Clearances To Combustibles (Refer to TABLE 1 on page 4)

A

C

D

A

A

A

E

F

C

C

D

STANDARD REFLECTOR

STANDARD REFLECTOR

45 DEGREE REFLECTOR TILT

E

A

A

F

C

C C

U-TUBE OPPOSITE 45 DEGREE

“U”-Tube, Opposite 45°

A

F

EF

D

C

A

C

U-TUBE STANDARD

“U”-Tube, Standard

C

E

A

A

D

D

C

A

A

E

E

F

B

B

Front and Back Clearance

FRONT AND BACK CLEARANCE

E

E

B

A

C

C

“U”-Tube, Full 45°

U-TUBE FULL 45

C

Operating Instructions and Owner’s ManualEnerco | Heatstar ERXL Series Heater

E-5

Page 6

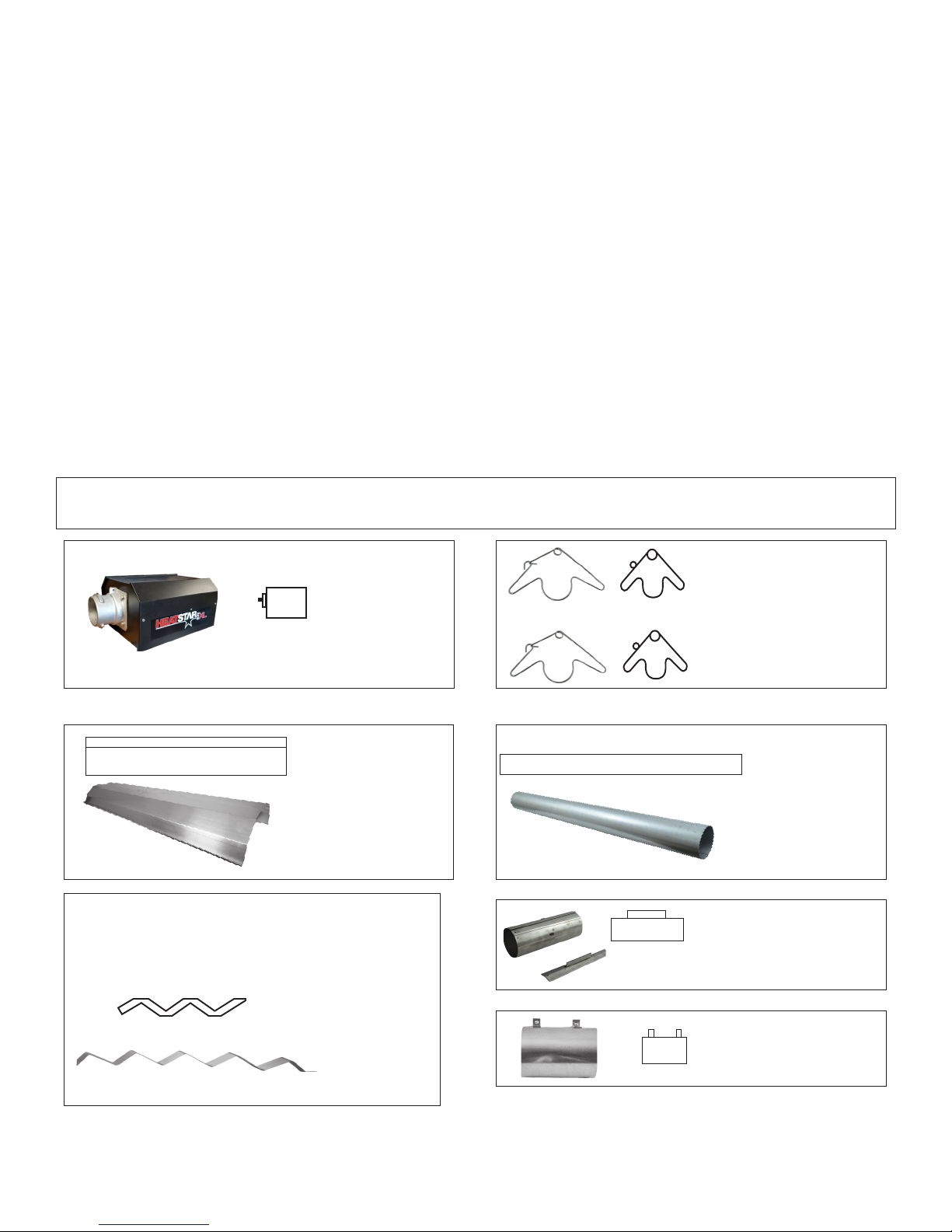

SECTION 3: Installation & Assembly

TUBE COUPLING(14612)

KEY FOR TUBE COUPLING

(14616)

BURNER BOX

TUBE HANGER

(14585P)

VENT ADAPTER

(19021)

REFLECTOR 10'

(00418A)

HEAT EXCHANGER TUBE 10'

(06413)

Enerco | Heatstar ERXL Series Heater Operating Instructions and Owner’s Manual

TURBULATOR BAFFLE 10' (03445)

TURBULATOR BAFFLE 5' (03447)

**NOT INCLUDED WITH ALL MODELS**

**ONLY HEATERS 30' LENGTH AND UNDER**

E-6

Page 7

installed, must be electrically grounded in accordance with the National Electrical Code, ANSI/ NFPA 70 or current Canadian Electrical

Code, CSA C22.1.

Installation Procedure

NOTE: For either indoor or outdoor installation. Not for use in residential dwellings.

Take maximum advantage of the building upper structure, beams, joists, purlins, etc., from which to suspend the heater. There is no

unique sequence for installation of the tubing. On-site observation will usually reveal a logical sequence. Begin the installation at the most

critical dimension. This could save time. Watch for swinging doors, overhead cranes, car lifts etc. Reflectors and tubing can be installed as

you move along. Carefully adjust system pitch at each position to level the heater. Pitch down one-half inch in 20 feet (away from burner).

DON’T Pressure test the gas line using high pressure (greater than ½ PSIG) without closing the high-pressure shutoff cocks. Failure to do so will

result in damage to the burners.

DO Familiarize yourself with local and national

codes.

Develop a planned procedure which will conserve material and labor on the job.

Check to see that all material and equipment is on the job before starting installation.

Allow for thermal expansion of the hot tube.

Install the gas connector only as shown in instructions (see Figure 14 on page 17).

Have slip joints where required between reflectors to keep them from buckling or coming apart.

Provide 1 sq. inch of free air opening to each 1,000 BTU/hr. of heater input (but not less than 100 sq. inches) in enclosed spaces. One

FIGURE 2: Ener-Radiant XL Overview

Assemble the heater components as shown in Figures 2A, 2B, 2C, 2D, 2E, 2F and 2G. Optional reflector configurations are shown in Figure

1. Install appropriated suspension hardware, beam clamps, chain or rod at predetermined locations. Adjustment of chain length will provide

uniform pitch.

Burner Housing

Must always be

installed horizontally.

10' 2-1/2"

Turbulator Assembly

Enerco Group, Inc normally ships Ener-Radiant heaters with

turbulators assembled into appropriate tubes.

Reflectors

Alternate overlap as shown

on overview. Length of

reflector and amount of

overlap is indicated.

Tube and Reflector Hanger

Install immediately after first

coupling.

Tube and Reflector Hanger

Suspend system from these hangers.

Minimum two (2) required per tube.

ALUMINIZED

Heat Exchange Tubes

Supplied in 10 ft. lengths.

Tube Coupling Assembly

Coupling should be oriented with

slide bar on top, and all couplings

should “point” in the same direction.

E-7

Vent Adapter

Used to attach the heat

exchanger tubing to vent pipe.

Operating Instructions and Owner’s ManualEnerco | Heatstar ERXL Series Heater

Page 8

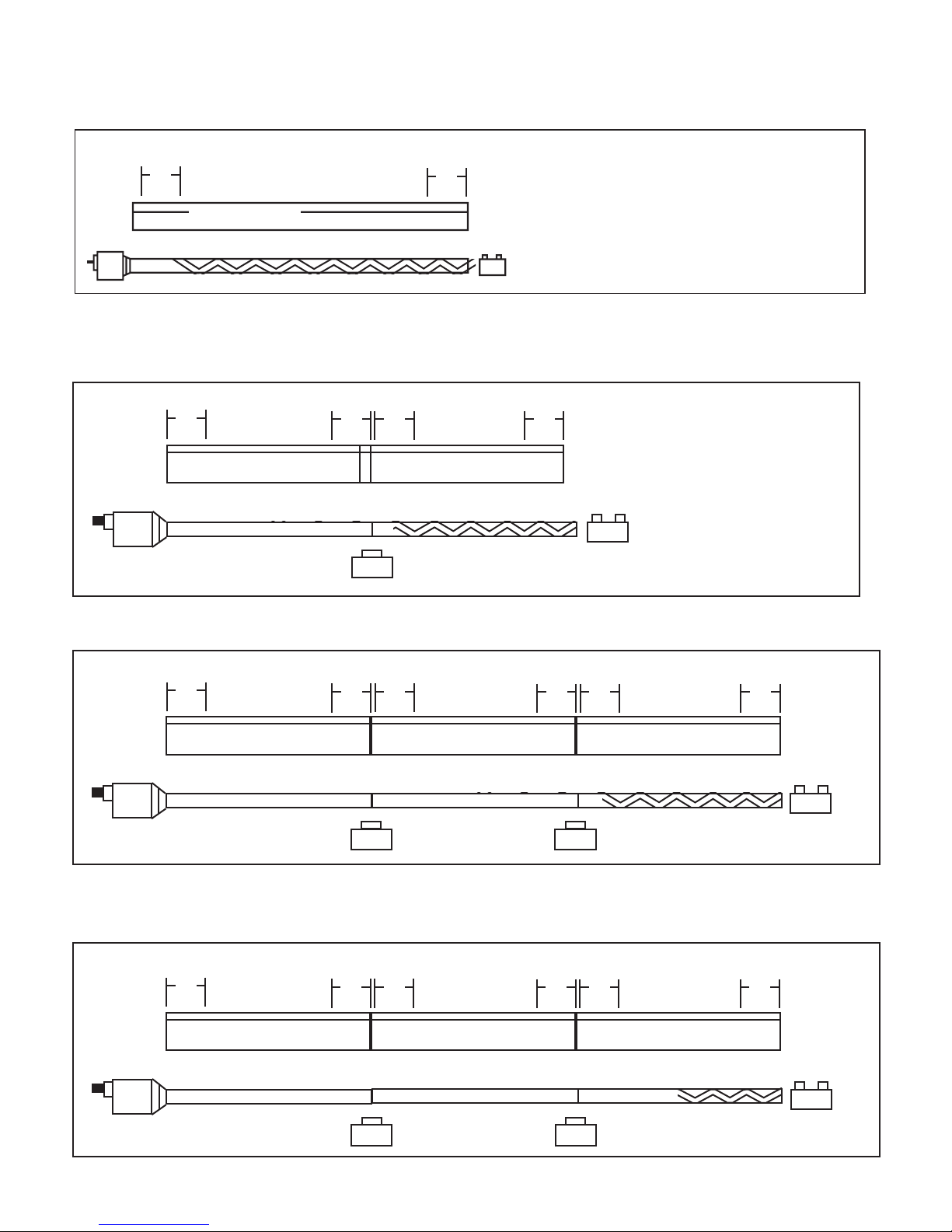

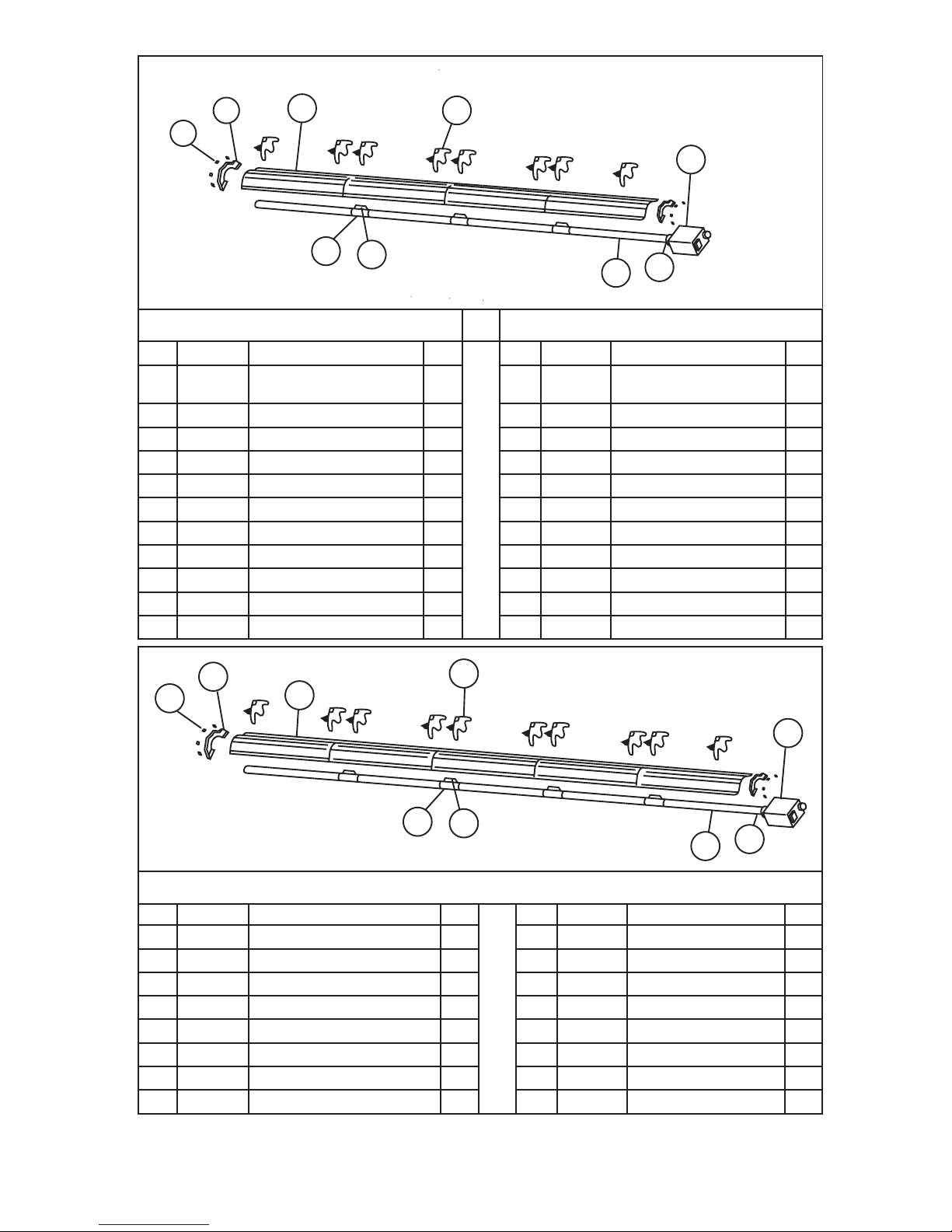

FIGURE 2A: Ener-Radiant XL Model ERXL-40

10 ft. Exchanger length. 11 ft. - 4 in. Total Heater length. 2 Suspension points as indicated.

HANGER

18"

(46cm)

HANGER

18"

(46cm)

10' 2½" (3.11m)

AL

UMINIZED

9' (2.75 m) Long Turbulator Section

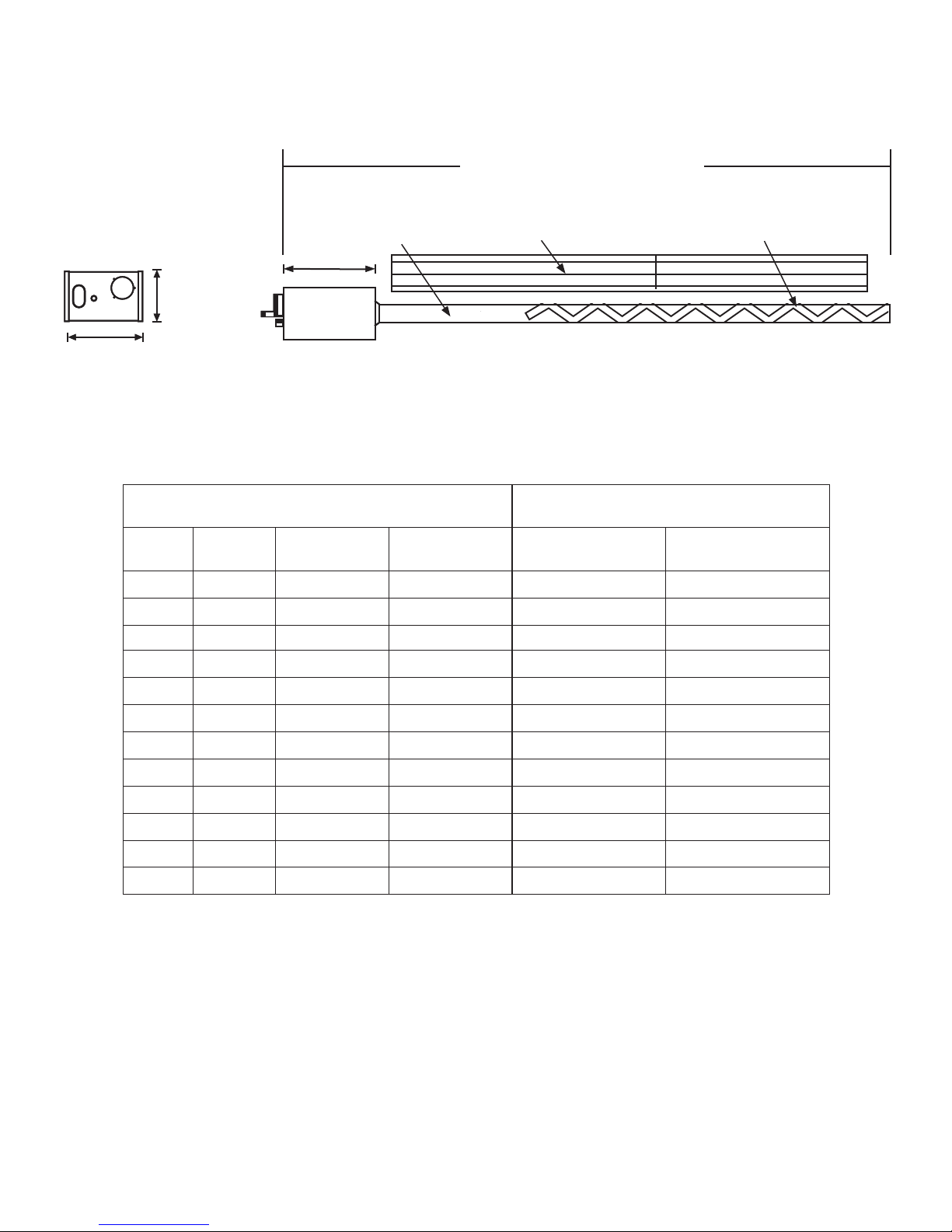

FIGURE 2B: Ener-Radiant XL Model ERXL-60, ERXL-80, Assembly Overview

20 ft. Exchanger length. 21 ft. - 4 in. Total Heater length. 4 Suspension points indicated.

HANGER

18"

(46cm)

10' 2½" (3.11m)

ALUMINIZED

HANGER

(46cm)

18"

HANGER

18"

(46cm)

2½ OVERLAY TYP

10' 2½" (3.11m)

HANGER

18"

(46cm)

10' (3.05 m) Long Turbulator Section

FIGURE 2C: Ener-Radiant XL Model ERXL-80, Assembly Overview

30 ft. Exchanger length. 31 ft. - 4 in. Total Heater length. 6 Suspension points as indicated

HANGER

18"

(46cm)

HANGER

(46cm)

18"

HANGER

18"

(46cm)

HANGER

(46cm)

18"

HANGER

18"

(46cm)

10' 2½" (3.11m) 10' 2½" (3.11m) 10' 2½" (3.11m)

ALUMINIZED

FIGURE 2D: Ener-Radiant XL Model ERXL-100 Assembly Overview

30 ft. Exchanger length. 31 ft. - 4 in. Total Heater length. 6 Suspension points as indicated.

HANGER

18"

(46cm)

HANGER

(46cm)

18"

HANGER

18"

(46cm)

ALUMINIZED

HANGER

18"

(46cm)

HANGER

18"

(46cm)

10' 2½" (3.11m) 10' 2½" (3.11m) 10' 2½" (3.11m)

HANGER

18"

(46cm)

10' (3.05 m) Long Turbulator Section

HANGER

18"

(46cm)

ALUMINIZED

Enerco | Heatstar ERXL Series Heater Operating Instructions and Owner’s Manual

ALUMINIZED

5' (1.5 m) Long Turbulator Section

E-8

Page 9

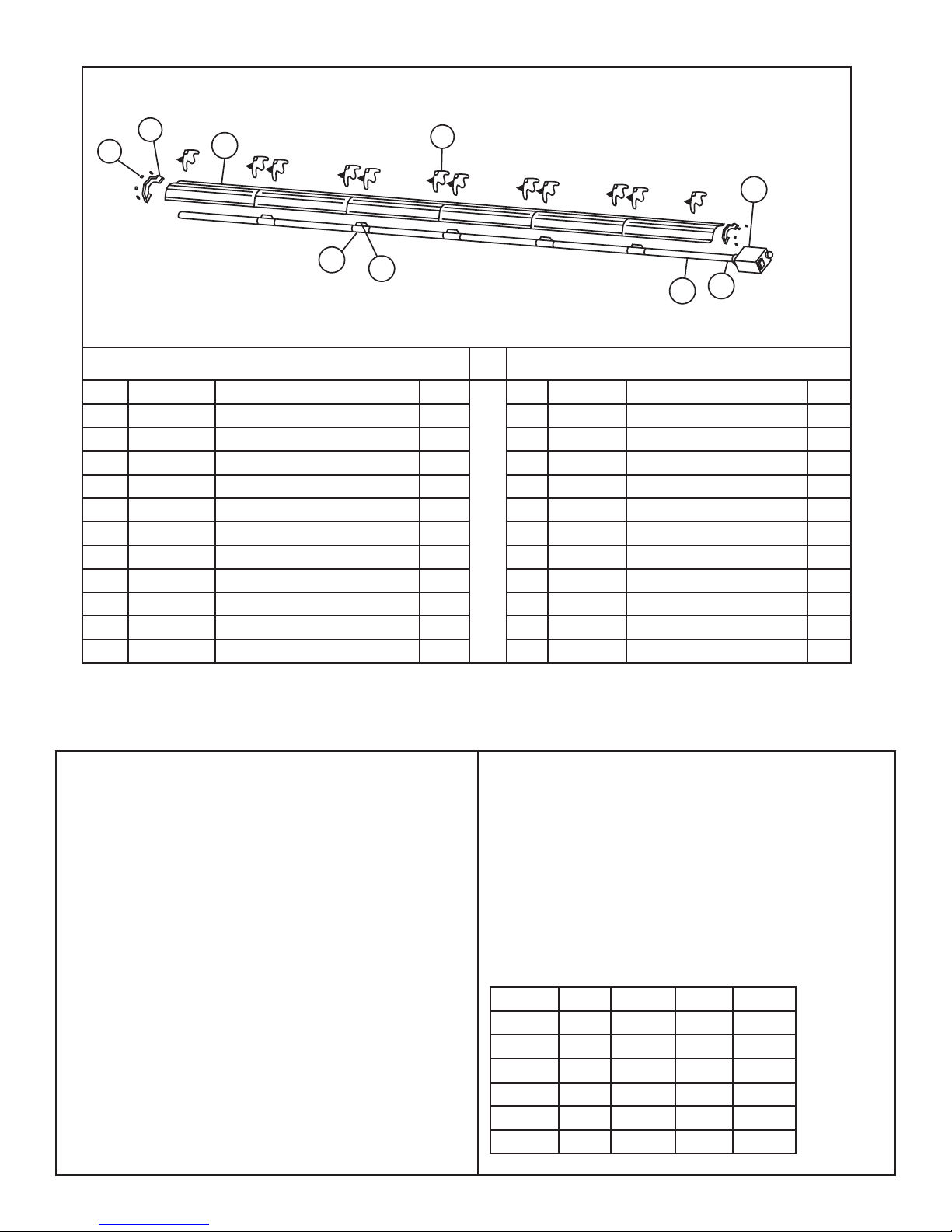

FIGURE 2E: Ener-Radiant XL Model ERXL-100, ERXL-125

40 ft. Exchanger length. 41 ft. - 4 in. Total Heater length. 8 Suspension points as indicated.

HANGER

18"

(46cm)

HANGER

10' 2½" (3.11m)

ALUMINIZED ALUMINIZED

18"

(46cm)

HANGER

18"

(46cm)

10' 2½" (3.11m) 10' 2½" (3.11m)

HANGER

18"

(46cm)

HANGER

18"

(46cm)

HANGER

10' 2½" (3.11m)

ALUMINIZED ALUMINIZED

18"

(46cm)

HANGER

18"

(46cm)

HANGER

(46cm)

FIGURE 2F: Ener-Radiant XL Model ERXL-125, ERXL-150, ERXL-175

50 ft. Exchanger length. 51 ft. - 4 in. Total Heater length. 10 Suspension points as indicated.

HANGER

18"

(46cm)

HANGER

10' 2½" (3.11m)

ALUMINIZED ALUMINIZED

18"

(46cm)

HANGER

18"

(46cm)

10' 2½" (3.11m) 10' 2½" (3.11m)10' 2½" (3.11m)

HANGER

18"

(46cm)

HANGER

18"

(46cm)

HANGER

10' 2½" (3.11m)

ALUMINIZED ALUMINIZED ALUMINIZED

18"

(46cm)

HANGER

18"

(46cm)

HANGER

(46cm)

18"

18"

HANGER

18"

(46cm)

HANGER

18"

(46cm)

FIGURE 2G: Ener-Radiant XL Model ERXL-150, ERXL-175

60 ft. Exchanger length. 61 ft. - 4 in. Total Heater length. 12 Suspension points as indicated.

HANGER

18"

(46cm)

HANGER

10' 2½" (3.11m)

ALUMINIZED ALUMINIZED

18"

(46cm)

HANGER

18"

(46cm)

10' 2½" (3.11m) 10' 2½" (3.11m)10' 2½" (3.11m)10' 2½" (3.11m)

HANGER

18"

(46cm)

HANGER

18"

(46cm)

HANGER

10' 2½" (3.11m)

ALUMINIZED ALUMINIZED ALUMINIZED ALUMINIZED

18"

(46cm)

HANGER

18"

(46cm)

HANGER

18"

(46cm)

HANGER

18"

(46cm)

HANGER

18"

(46cm)

HANGER

18"

(46cm)

HANGER

18"

(46cm)

E-9

Operating Instructions and Owner’s ManualEnerco | Heatstar ERXL Series Heater

Page 10

9.25"(23.49cm)

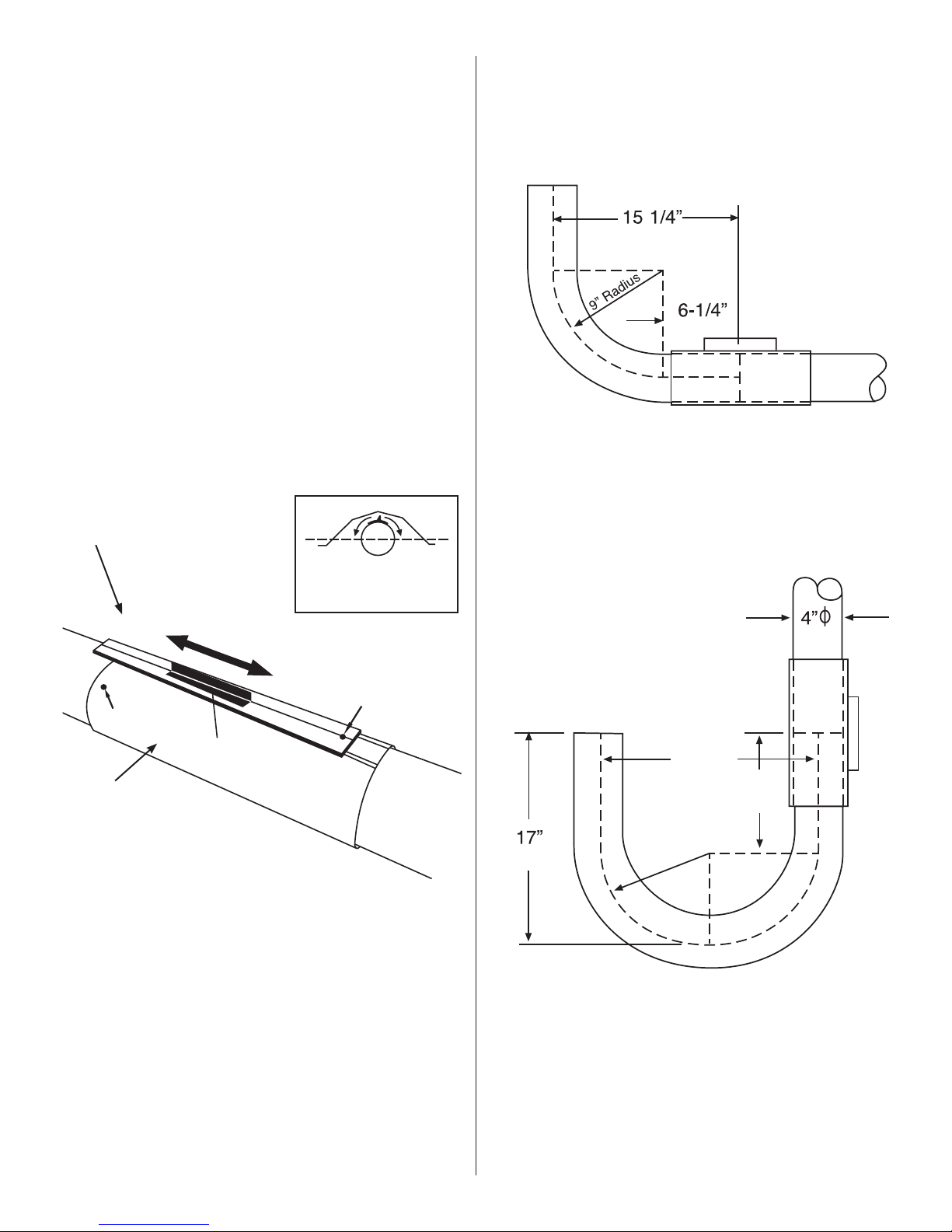

FIGURE 3: Ener-Radiant XL Dimensions & Suggested Mounting Heights

Minimum Total Length (see chart below)

Heat Exchanger Tubing

17.75"(45.08)

Reector

Turbulator

(some Models)

9.25"(23.49cm)

Burner Rear View

Burner Ratings and Heat Exchanger Lengths: (NG and LP) Suggested Mounting Heights

Model #

ERXL-40 40,000 10 ft. (3.05 m) 9 ft. (2.75 m)

ERXL-60 60,000 20 ft. (6.1 m) 10 ft. (3.05 m)

ERXL-80 80,000 20 ft. (6.1 m) 10 ft. (3.05 m) 21 ft. 4" (6.50 m) 12’ (3.66 m) - 15' (4.57 m)

ERXL-80 80,000 30 ft. (9.15 m) 10 ft. (3.05 m)

ERXL-100 100,000 30 ft. (9.15 m) 5 ft. (1.5 m)

ERXL-100 100,000 40 ft. (12.2 m) None

ERXL-125 125,000 40 ft. (12.2 m) None

ERXL-125 125,000 50 ft. (15.25 m) None

ERXL-150 150,000 50 ft. (15.25 m) None

ERXL-150 150,000 60 ft. (18.3 m) None

ERXL-175 175,000 50 ft. (15.25 m) None

ERXL-175 175,000 60 ft. (18.3 m) None

Rate

(BTU/Hr.)

Burner Side View

Heat Exchanger

Length

Turbulator

Minimum

Total Length

Typical Mounting

Height Spot

11 ft. 4" (3.45 m) 10’ (3.05 m) - 14' (4.27 m)

21 ft. 4" (6.50 m) 10’ (3.05 m) - 14’ (4.27 m)

31 ft. 4" (9.55 m) 12’ (3.66 m) - 15' (4.57 m)

31 ft. 4" (9.55 m) 12’ (3.66 m) - 15' (4.57 m)

41 ft. 4" (12.60 m) 12' (3.66 m) - 15' (4.57 m)

41 ft. 4" (12.60 m) 14' (4.27 m) - 19' (5.79 m)

51 ft. 4" (15.65 m) 14' (4.27 m) - 19' (5.79 m)

51 ft. 4" (15.65 m) 15' (4.57 m) - 25' (7.62 m)

61 ft. 4" (18.69 m) 15' (4.57 m) - 25' (7.62 m)

51 ft. 4" (15.65 m) 15' (4.57 m) - 25' (7.62 m)

61 ft. 4" (18.69 m) 15' (4.57 m) - 25' (7.62 m)

Enerco | Heatstar ERXL Series Heater Operating Instructions and Owner’s Manual

E-10

Page 11

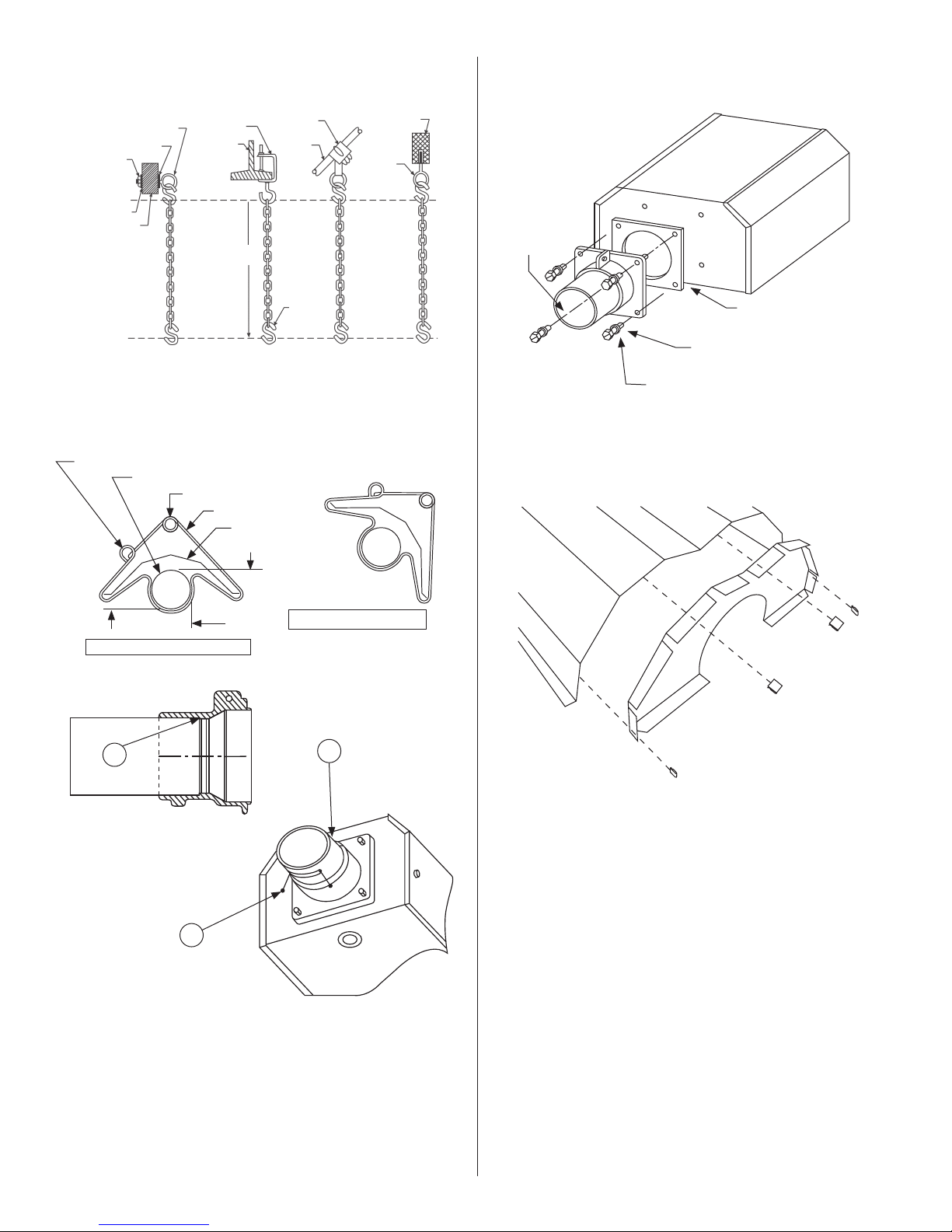

COUPLING ASSEMBLY

Couplings: Tube and tube fittings are connected by wrap-around

couplings which clamp by means of a tapered,

hammer-driven lock member. The starting ends of

the coupling and lock member are identified by 1/4”

holes which are put together when starting assembly.

Be sure the tube ends are in line and tube ends butt

against stop pin(s) inside coupling. The slide bar is to

be hammer-driven to a point of securing the coupling

snugly to the tubes. Over-driving will result in distortion

of the coupling or slide bar lip to a point decreasing

the holding the capability of the coupling.

(See Figure 4)

FIGURE 5: Installation of Elbow & Coupling

Elbow Package: Stk. # F106415 Elbow Package includes:

(1) elbow, (1) coupling. Install elbow

into radiant tube sequence where plans

indicate a 90° bend (see Figure 4).

(38.73 CM)

FIGURE 4:

KEY for COUPLING

Loosen

Hole 2

Impact

Block

TUBE COUPLING

When assembling coupling note

the location of Hole 1 and Hole 2

Orient coupling so that

the impact block is above

tube centerline.

Tighten

Hole 1

Coupling

Assembly

(22 cm)

90°

Elbow Fitting Dimensions

Stk. # i ncludes:F106414 U-Tube Package

(1) U-tube, (1) coupling

Install U-tube elbow into

radiant tube sequence where

plans indicate a 1800 bend

(see Figure 4)

(43cm)

(22cm)

9"

(15.24 CM)

(10cm)

18" (45cm)

10"

(25cm)

Radius

Plain Coupling - 14612

Key for Coupling - 14616

E-11

U-Tube Fitting Dimensions 180° U-Tube

Operating Instructions and Owner’s ManualEnerco | Heatstar ERXL Series Heater

Page 12

FIGURE 6: Typical Suspension Details

FIGURE 8: Burner Box / Transition Tube Detail

Screw Hook

min. 3/8" (10 mm)

Washer

Locknut

Beam

Clamp

I-Beam

Bar Joist

Clip

Truss

Concrete

Beam

Anchor

Washer

Wood Beam

As Req'd

S-Hook

Chain kit - Stk. #17370

One chain kit will suspend one 10 ft. section of tube and one 10 ft.

section of reflector.

FIGURE 7: Tube and Reflector Hanger

angle mounting ring

radiant tube

horizontal mounting ring

hanger

reflector

top

Burner Box

(flame observation

window facing down)

Mounting Flange

Gasket

Stk. #12397

Split Lock Washer

Stk. #98527

Cap Screw

Stk. 98012

Flange Kit #06428XL

Kit Includes: Flange,Screws(4), Lock Washers(4), Gasket(1)

FIGURE 9: Reflector End Cap

below

horizontal reflector position (standard)

A

side

B

45° reflector position (optional)

FIGURE 7: Mounting Flange / Tube Detail

1) Insert tube 06413 into front casting to point (A).

2) Tighter all set screws marked (B) until snug.

3) After both set screws are snug, turn each

additional 1/4 turn to secure tube in place.

B

Parts list

1 00419 Reflector End Cap (Qty 1)

2 09369 Spring Clip (Qty 4)

Enerco | Heatstar ERXL Series Heater Operating Instructions and Owner’s Manual

E-12

Page 13

SECTION 4

Engineering Specifications

The total heating system supplied shall be design certified by CSA

under ANSI Z83.20a latest revision and CGA 2.34a latest revision.

A. Burner & Burner Controls

1. Burners shall be capable of firing with one of the fuel options as

specified on the purchase documents: Natural Gas or LP.

2. Burners shall be supplied to fire at any one of the input rates as

specified.

ERXL-40 40,000 BTU/Hr. (11.72 kW)

ERXL-60 60,000 BTU/Hr. (17.58 kW)

ERXL-80 80,000 BTU/Hr. (23.45 kW)

ERXL-100 100,000 BTU/Hr. (29.31 kW)

ERXL-125 125,000 BTU/Hr. (36.63 kW)

ERXL-150 150,000 BTU/Hr. (43.96 kW)

ERXL-175 175,000 BTU/Hr. (51.29 kW)

3. Burner shall be equipped with a direct sense silicon-carbide hot

surface ignition control system with 100% shut-off ignition device.

Power supplied to each heater shall be 120V, 60Hz, single phase.

Burners shall be rated for 1.0 Amp (run) and 5.0 Amp (start.)

4. Burner shall be equipped with thermal overload motor

protection, balanced air rotor, combustion air proving safety

pressure switch, and viewing window for flame observation.

5. When specified, in contaminated environments, the burner

shall be capable of supplying outside air to each burner for the

support of combustion.

6. All burners shall be pre-wired with a grounded electrical

cord and plug.

7. At customer’s choice, burners may be controlled with either

an optional line voltage thermostat or by optional low voltage

thermostats with an appropriate low voltage transformer relay.

8. Gas supply to the burners shall conform to the following:

Gas pressure at MANIFOLD:

Natural Gas: 3.5” W.C. (0.87 kPa)

LP Gas: 10.5” W.C. (2.61 kPa)

1/2” NPT Gas Connector Size

Gas INLET pressure:

Natural Gas: 4.5” W.C. Min (1.12 kPa MIN)

11.0” W.C. Max (2.74 kPa MAX)

LP Gas: 11.0” W.C. Min (2.74 kPa MIN)

14.0” W.C. Max (3.48 kPa MAX)

1/2” NPT Gas Connector Size

Electrical Rating: (All Models)

120V - 60Hz

1.0 AMP (Run) 5.0 AMP (Start)

Dimensions:

Flue Connection Size…………………4” (10 cm)

Outside Air Connection Size………4” (10 cm)

1/2” NPT gas connector size

Natural Gas: 4.5” W.C. MIN, 11.0” W.C. MAX

(1.12 kPa MIN, 2.74 kPa MAX)

LP Gas: 11” W.C. MIN, 14.0” W.C. MAX

(2.74 kPa MIN, 3.48 kPa MAX)

B. Heat Exchanger

1. Radiant tubing shall be 4” (10 cm) diameter aluminized steel

supplied in 10 ft. sections (3.05 m). Sections shall be joined with

stainless steel wrap-around couplings.

2. Reflector to be of aluminum material and designed to direct all

radiant output below horizontal center line of radiant tube.

3. Heaters shall be vented according to manufacturer’s

recommendations.

E-13

Operating Instructions and Owner’s ManualEnerco | Heatstar ERXL Series Heater

Page 14

SECTION 5

Venting / Ducting

General Requirements

This heater must be vented in accordance with the specifications

contained in this manual and with the following national codes

and any state, provincial or local codes which may apply:

• Refer to National Fuel Gas Code NFPA 54/ANSI Z223.1- latest

revision.

• CANADA: Refer to Natural Gas and Propane Installation Code

CSA B149.1- latest revision.

The heater may be vented to the outdoors either vertically or

horizontally.

Optional outside air supply may be directed to the heater

horizontally or vertically.

Be sure that the method selected for venting heater complies with

all codes as required for each particular location

The use of single-wall vent pipe (26 gauge) is recommended. A

section of double-wall vent pipe is recommended when passing

through the roof or wall.

Exhaust end of heater will accept a 4' (10 cm) vent pipe using

the vent adapter. Install the vent adapter with the seam on top,

secure all vent joints with a minimum of 3 #8 x 3/8" sheet metal

screws and seal all joints using a high temperature silicone sealant.

If condensation in the flue is a problem, the flue length should be

shortened or insulated.

Vent pipe must be sloped downward away from the burner 1/4"

(0.6 cm) for ever 10' (3m).

VENT LENGTHS:

• Maximum total vent length allowed in thirty (30’) (9.15 m) feet.

• Maximum outside air supply duct allowed thirty (30’) (9.15 m) feet.

• Maximum total vent length plus outside air supply length shall not

exceed fifty (50’) (15.25 m) feet.

NOTE:

A total of two (2) elbows are allowed for vent and

outside air supply combination. Subtract 5' feet (1.5 m) per

additional elbow from maximum length allowed if 3 or more elbows

are used.

Install a minimum 18" (30 cm) straight length of duct for air intake

or vent before any Tee or elbow.

Alternative Arrangements / Optional Equipment for Venting

Unvented Operation

a) Sufficient ventilation must be provided in the amount of 4 CFM

per 1,000 BTU/hr. firing rate.

b) Refer to ANSI Z223.1 - latest revision, NFPA-54 and local codes

for additional information.

c) Use of optional outside combustion air is not recommended with

unvented heaters due to pressure considerations. Refer to page

16

Horizontal Venting

This heater, when horizontally vented, must be installed with the

approved venting system. For horizontal venting installations these

tube heater are certified as a category III appliance.

a) Four (4”) inch (10 cm) O.D. flue pipe is required. Thirty (30’)

(9.15 m) feet maximum length is recommended.

b) All flue joints should be sealed using suitable product such as

General Electric RTV106 or Permatex Form-A-Gasket Red High

Temperature Silicone Adhesive Sealant.

c) Do not install any elbow or 45 fitting to bring vent lower than

the horizontal tube system.

d) Vent terminal should be installed at a height sufficient to prevent

blockage by snow.

1) Vent must exit building not less than seven (7’) feet (2.13 m)

above grade when located adjacent to public walkways.

2) Vent must terminate at least three (3’) feet (.91 m) above

any forced air inlet located within ten feet (10’) (3.05 m).

3) Vent must terminate at least four (4’) feet (1.2 m) below,

four (4’) feet (1.2 m) horizontally from, or one (1’) foot

(30.5 cm) above any door, window, or gravity inlet into any

building.

4) Vent terminal shall be located at least twelve (12”) inches

(30.5 cm) from any opening through which vent gases could

enter the building.

5) Vent terminal must be beyond any combustible over hang

Vertical Venting

This heater, when vertically vented, must be installed with the

approved venting system. For vertical vent installations,

ERXL40-150 models are category I appliances. The ERXL175 model

is only Category I when vented vertically with 6" (15.25cm) diameter

vent pipe.

a) Four (4”) inch (10 cm) O.D. flue pipe, maximum thirty (30’) feet

(9.15 m) in length may be used as shown with approved vent

cap. (See General Requirements on this page for additional

information.)

b) An insulated thimble may be required to pass through

combustible structures (check local codes).

c) All flue joints should be sealed using suitable products (see

recommendation for horizontal venting.)

Common Venting

a) Horizontal run to vent must never exceed 75% of the vertical

height of the vent. Refer to ANSI Z223.1 - latest revision, NFA-54

for proper vent sizes and installation.

b) Open area of common vent must equal the sum of the open

area of individual vents connected to it. (See chart below and

diagrams - page 14.)

c) Use double wall vent as required (check codes.)

d) All joints must be sealed using suitable products.

e) Connections to common stack must be positioned to avoid direct

opposition between streams of combustion gases.

COMMON VENTING - (2) Heaters (Horizontal and Vertical)

Model #

ERXL-40

ERXL-60

ERXL-80

ERXL-100

ERXL-125

ERXL-150

ERXL-175

H = 6 ft. (1.82 m) H = 8 ft. (2.44 m) H = 15 ft. (4.57 m)

D = 7" (17.8 cm) D = 6" (15.25cm) D = 6" (15.25cm)

D = 7" (17.8 cm) D = 6" (15.25cm) D = 6" (15.25cm)

D = 8" (20.5 cm) D = 7" (17.8 cm) D = 6" (15.25cm)

D = 8" (20.5 cm) D = 8" (20.5 cm) D = 7" (17.8 cm)

D = 10" (25.4 cm) D = 10" (25.4 cm) D = 8" (20.5 cm)

D = 10" (25.4 cm) D = 10" (25.4 cm) D = 8" (20.5 cm)

D = 10" (25.4 cm) D = 10" (25.4 cm) D = 8" (20.5 cm)

Enerco | Heatstar ERXL Series Heater Operating Instructions and Owner’s Manual

E-14

Page 15

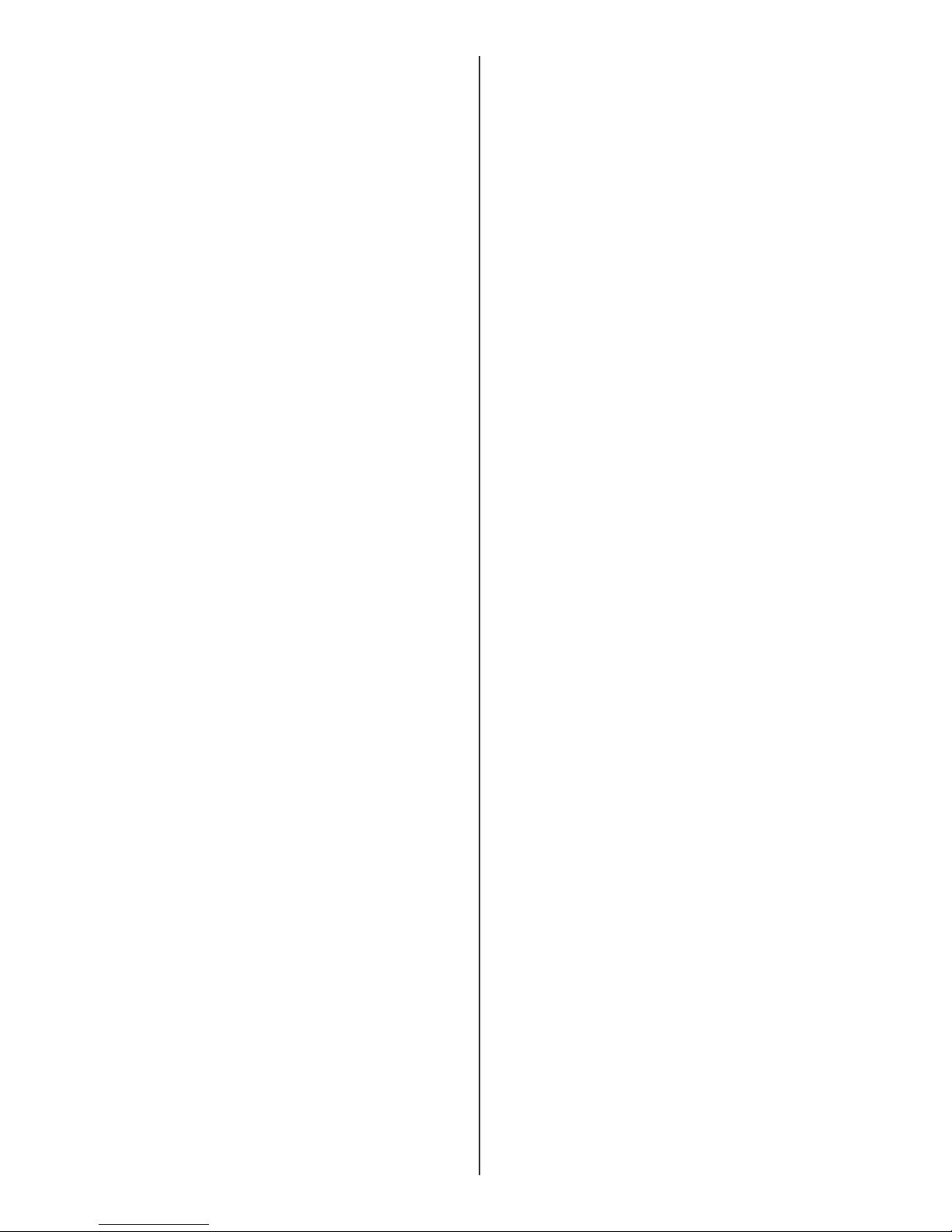

FIGURE 12: Common Roof Venting

VERTICAL COMMON VENTING

Approved Vent Cap

SIDE VIEW

Vent Adapter Stk. #19021

Burner Box Burner Box

HORIZONTAL COMMON VENTING

Flashing

H

Secure all joints with 3 (minimum) #8 x 3/8"

sheet metal screws and seal all joints.

D

D

Type "B" Vent required outdoors.

Roof

H

Vent Adapter Stk. #19021

Burner Box

Wall Thimble

(If Applicable)

Vent Cap

Type "B" Vent required outdoors.

Outside Wall

Secure all joints with 3 (minimum) #8 x 3/8"

sheet metal screws and seal all joints.

D

Burner Box

E-15

Operating Instructions and Owner’s ManualEnerco | Heatstar ERXL Series Heater

Page 16

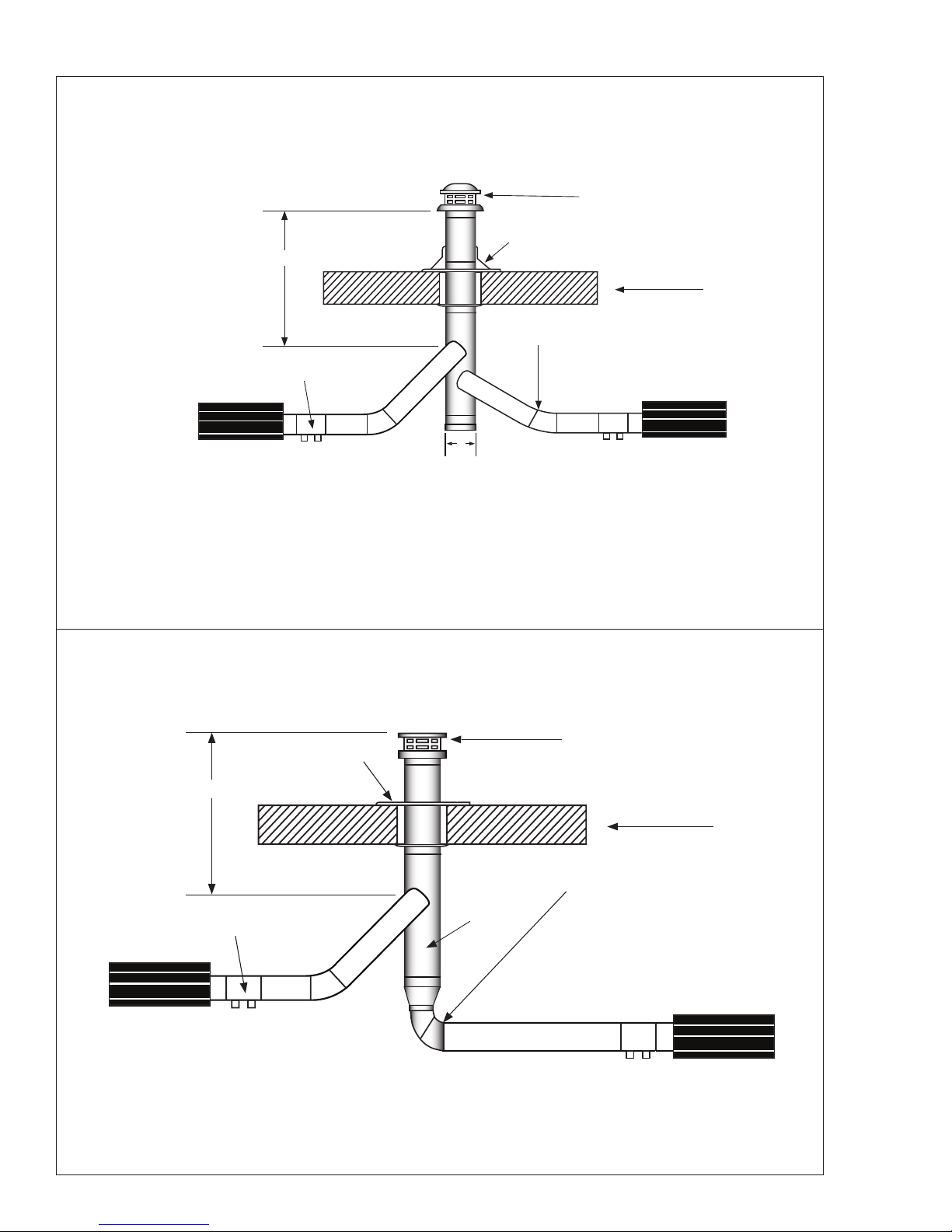

FIGURE 10: Unvented Operation

FIGURE 10b: Double Wall

Double wall vent run

Double wall terminal end

A

36”

(91cm)

36”

(91cm)

1. Ventilation equal to 4 CFM per 1,000 BTU/HR firing rate must

be provided in unvented heater installations

2. For dimensions A "unvented" refer to ( Figure 1- Minimum

Clearances to Combustibles.)

FIGURE 10A: Single Wall

Single wall vent run

Single wall terminal end

8"(20cm) to 10"(25cm) Max.

18" (45cm) Min. 3'-0" (91cm) Min.

6' (182cm) Min.

Pitch flue pipe down

toward outlet 1/4" per

foot (0.6 cm per 0.3m) for

condensate drainage.

FIGURE 11: Vertical Venting

18" (45cm)

2"(5cm) Clearance thimble

required when u pipe

extends through

combustible materials

18" (45cm) Min. 3'-0" (91cm) Min.

6' (182cm) Min.

Pitch flue pipe down

toward outlet 1/4" per

foot (0.6 cm per 0.3m) for

condensate drainage.

2"(5cm) Clearance thimble

Enerco | Heatstar ERXL Series Heater Operating Instructions and Owner’s Manual

E-16

Page 17

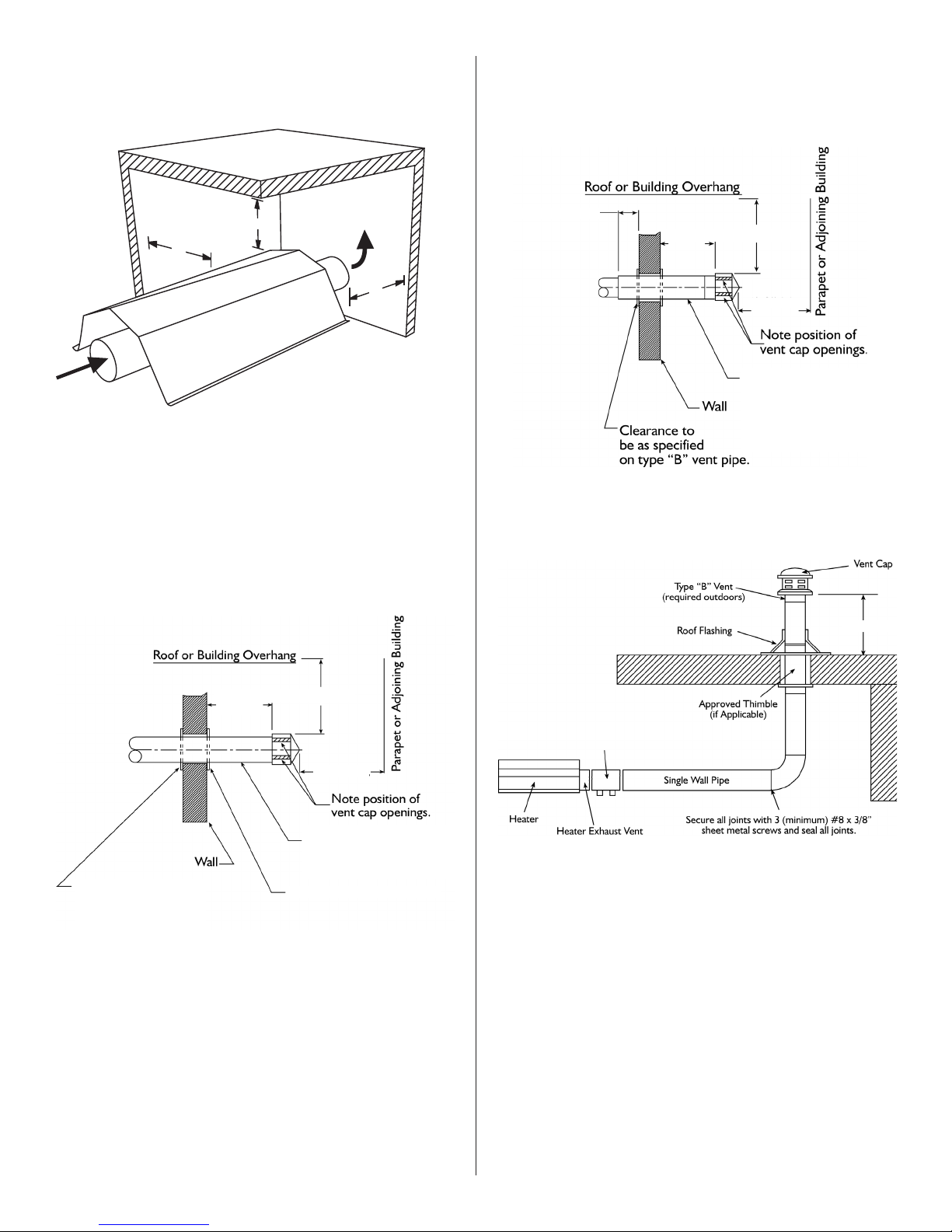

Outside Combustion Air Supply

The Ener-Radiant XL heater is approved for installation with an

outside air supply system. Some compounds such as halogenated

hydrocarbons or other corrosive chemicals in the air can be drawn

into the equipment and cause an accelerated rate of corrosion

of some of the heater components. The use of such chemical

compounds near the enclosure should be avoided.

IMPORTANT: If the building has a slight negative pressure or

contaminants are present in the air, an outside combustion air

supply to the heaters is strongly recommended.

For an outside air supply, a four (4”) inch (10 cm) O.D. single

wall pipe may be attached to the heater. The duct may be up to

thirty (30’) ft (9.15 m). maximum length or two (2’) ft. minimum

(0.61m) length with no more than two (2) elbows. (See General

Requirements on page 14 for additional information.)

The air supply duct may have to be insulated to prevent

condensation on the outer surface. The outside air terminal should

be securely fastened to the outside wall by drilling four (4) 1/4”

(0.635 cm) diameter holes in the outside flange; wood screws or

bolts and expansion sleeves may be used to fasten terminal.

FIGURE 13: Non-Pressurized Outside Air Supply Duct

Outside Air

Outside Air

Terminal

Terminal

4" (10 cm)

Seal All Joints

4" (10 cm)

Seal All Joints

Flex Pipe

6" (15 cm) to

12" (30 cm) Long

Flex Pipe

6" (15 cm) to

12" (30 cm) Long

NOTE:

Flue pipe requires additional

support. Flex pipe will not

support riser and outside

air terminal

Vertical Outside Air

Horizontal Outside Air

SECTION 6

Gas Piping

Read applicable warnings in (Section 1) before proceeding with

Gas Pipe installation. Improper installation may result in property

damage, severe injury, or death.

Meter and service must be large enough to handle all the burners

being installed plus any other connected load. The gas line which

feed the system must be large enough to supply the required gas

with a maximum pressure drop of 1/2” water column (0.12 kPa).

When gas piping is not included in the layout drawing, the local gas

supplier will usually help in planning the gas piping.

A 1/2” tapping at each burner location must be located and

oriented as shown in (Figure 14). To check system pressure, put a

plugged 1/8” NPT tapping in the gas line at the connection to the

burner farthest from the supply. Before connecting the burners to

the supply system, verify that all high pressure testing of the gas

piping has been completed. Do not high pressure test the gas piping

with the burners connected.

Follow these instructions to ensure a professional gas supply

installation:

• Support all gas piping with suitable pipe hanging

materials.

• Use wrought iron or wrought steel pipe and malleable

iron fitting. All pipe fittings should be new and free

from defects. Carefully ream the pipe and tubing ends

to remove obstructions and burrs.

• Use L.P. gas-resistant joint compound on all pipe

threads.

• Check the pipe and tubing ends for leaks before

placing heating equipment into service. When

checking for gas leaks, use soap and water solution:

NEVER USE AN OPEN FLAME.

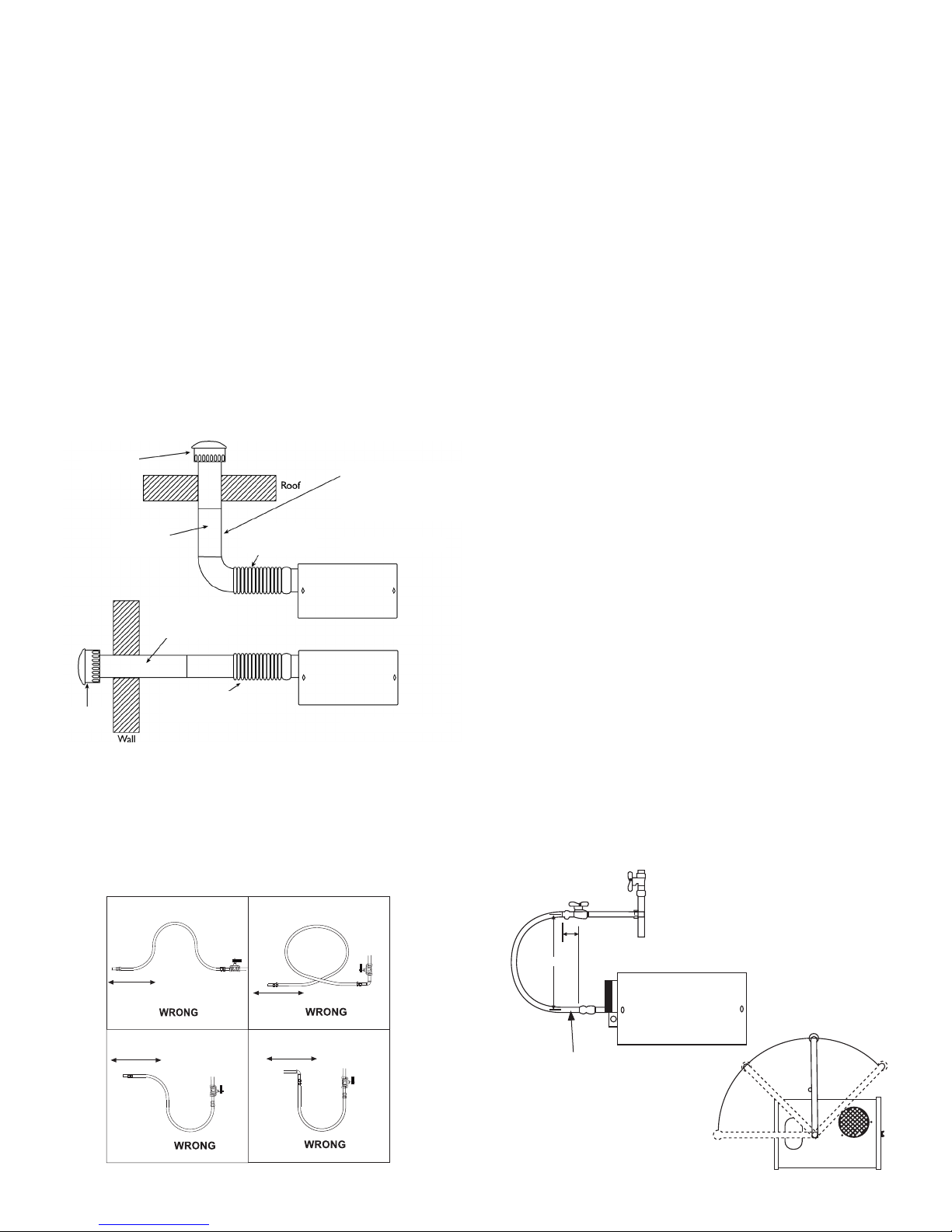

Install the flex gas connector as shown. The flex gas connector

accommodates expansion of the heating system and allows for easy

installation and service of the burner.

PVC Pipe, “Dryer Hose”, or equivalent may be used instead of

standard vent pipe.

FIGURE 14A: Incorrect Gas Line Connection with Stainless

Steel Flex Gas Connector

Heater Movement

Heater Movement

Heater Movement

Heater Movement

FIGURE 14: Gas Line Connection with Stainless Steel Flex Gas

Connector

Shut – off Valve

Shut-Off Valve must be parallel

to burner gas inlet. The 2” (5 cm)

displacement shown is for the cold

condition. This displacement may

reduce when the system is fired.

45°

90°

E-17

2"

12 "

1/2" Stainless Steel Flex Gas Connector

Stk. #16401

Operating Instructions and Owner’s ManualEnerco | Heatstar ERXL Series Heater

0°

45°

Page 18

SECTION 7

T

H

N

120v – 60 Hz

White

Green

Supply Circuit

Burners

(Maximum – 2 per Thermostat)

Black

T

H

N

120v – 60 Hz

White

Green

Supply Circuit

Burners

(Maximum – 2 per Thermostat)

Black

Wiring

Heaters are normally controlled by thermostats. Line voltage

thermostats are wired directly (see Figure 15), 24V thermostats

are wired directly by finding and removing the jumper wire on the

back of the burner box and wiring the thermostat to the terminals

(see Figure 16). Heaters must be grounded in accordance with the

National Electric Code ANSI/NFPA- 70 or current Canadian Electrical

Code, CSA C22.1. Heaters may also be controlled with a manual line

voltage switch or timer switch in place of the thermostat.

FIGURE 15: Line Voltage Thermostat Wiring

FIGURE 18: Ener-Radiant XL Burner Internal Wiring Ladder

Diagram

L2

(NEUTRAL)

White

Orange

120V

24V

Transfomer

Blue

Thermostat

L2 (HOT)

Black

FIGURE 16: Low Voltage Thermostat Wiring

(Maximum – 1 per Thermostat)

H

N

120v – 60 Hz

Supply Circuit

Black

White

Green

FIGURE 17: Ener-Radiant XL Burner Internal Wiring

• If any of the original wire as supplied with the

appliance must be replaced, it must be replaced with

wiring material having a temperature rating of at

least 105°C and 600 volts.

• Each burner must be electrically grounded in

accordance with the National Electric Code ANSI/

NFPA - 70 or current Canadian Electrical Code, CSA

C22.1.

Transformer

120V

White

120

Black

VAC

Green

Green

Black

Motor / Blower

Door Switch

Black

White

24V

Blue

THERMOSTAT

White

Black

Terminal

Bushing

Orange

Purple

Black

Sensor

Enerco | Heatstar ERXL Series Heater Operating Instructions and Owner’s Manual

Burners

Gas Valve

White

Ignitor

Air Switch

Yellow

Purple

White

Ignitor

Sensor

White

Door Switch

Black

Black

Motor / Blower

Gas Valve

White

Black

White

Yellow

White

Gray

SECTION 8

T

Operation & Maintenance

Sequence of Operation

1. Turn the thermostat up. When the thermostat calls for heat,

blower motor will energize.

2. When the motor approaches nominal running RPM, the air

proving switch closes and activates the ignition module.

3. The ignition module then energizes the hot surface igniter for a

timed warm-up period (approximately 45 to 60 seconds.)

4. After the warm-up period, the gas valve is energized.

5. During the last part of the sequence, the igniter is de-energized

and is converted to a flame sensing rod.

6. If a flame is detected, the gas valve remains open. When the

call for heat is satisfied, and the system control mechanism

de-energizes the burner line voltage supply, the gas valves are

Yellow

Yellow

Air Switch

E-18

turned off.

7. If no flame is detected on a single-try module, the gas valve

is closed, and the module will lockout until it is reset. Reset is

accomplished by removing power from the module for at least

five (5) seconds (thermostat cycle required.)

8. If no flame is detected on a three-trial module, the gas valve is

closed, and a purge period begins. After the purge, the module

acts to power the igniter for a second warm-up period, and a

second trial for ignition period. If flame is still not established, a

third and final purge, warm-up, and trial cycle begins. After three

trials, the module will lockout until reset. Reset is accomplished

by removing power from the module for at least five (5) seconds

(thermostat cycle required.)

9. On a three-trial module, if flame is established and lost on the

first or second trial, the gas valve is turned off, a purge, warm-up,

and trial for ignition will occur on a three-trial module, only three

trials for ignition are allowed per thermostat cycle.

Page 19

HIGH ALTITUDE

Heaters may be fired at full input up to 2000 ft. (610m) above sea

level. Above 2000 ft. (610m) a high altitude conversion kit may be

required to ensure proper burner performance, please consult the

manufacturer. Be prepared to answer factory questions regarding:

type of fuel for the proposed appliance conversion, gas pressure

available at site, and specific altitude at site. The conversion shall

be carried out by a manufacturer’s authorized representative, in

accordance with the requirements of the manufacturer, provincial,

or territorial authorities having jurisdiction and in accordance with

the requirements of the CSA B149.1 or CSA149.2 installation codes.

Maintenance

For best performance, the following maintenance procedures should

be performed before each heating season:

1. Be sure gas and electrical supply to heater are off before

performing any service or maintenance.

2. Check condition of blower scroll and motor. Dirt and dust

may be blown out with compressed air, or a vacuum cleaner

may be used. When using compressed air do not exceed 30

psi in order to not damage fragile hot surface igniter.

3. Check condition of burner. Carefully remove any dust or

debris from inside the burner box or burner cup.

4. Inspect the igniter. Replace igniter if there is excessive carbon

residue, erosion, breakage or other defects.

5. Check the inside of the firing tube with a flashlight. If carbon

or scale are present, scrape out the deposits with a wire

brush or rod, or metal plate attached to a wooden pole.

6. Check to see that the burner observation window is clean

and free of cracks or holes. Clean or replace as necessary.

7. Check the flue pipe for soot or dirt. After cleaning as

necessary, re-attach the flue pipe to the heater.

8. Outside surfaces of heater may be cleaned by wiping with a

damp cloth.

9. A qualified service agency should be contacted for service

other than routine maintenance.

10. Check vent terminal and fresh air inlet to see that they have

not been blocked during the non-heating season. If either

pipe is restricted, the air switch won’t close, resulting in a

no-heat situation.

Troubleshooting

CAUTION: Before opening the Ener-Radiant XL

burner door for any type of service, be sure

the gas supply has been shut off at the heater

and the electrical cord from the burner box

has been unplugged.

Blower Motor 1. Is the thermostat calling for heat? Is there

Fails to Run: 115V at the burner receptacle?

2. Check blower side door for seal. Check

door switch. Replace if necessary.

3. Check blower for obstructions. Replace

blower if necessary.

Igniter 1. Check igniter for damage. Replace if

Does Not Glow: necessary.

2. Check voltage and resistance at igniter.

(Voltage should be 115V. Resistance should

be 40-75 ohms.)

3. Check for obstructions to the air inlet and

outlet.

4. Check wiring and hose connections to the

air switch. Replace if necessary.

5. Check voltages at transformer primary and

secondary. Replace transformer or module

if necessary.

Valve Does Not Gas pressure downstream of gas control can

Come On: be measure by using a manometer and

connecting to pressure tap on control/.

1. Check to see if manual valve heater is ON.

2. Check to see if manual valve knob on

heater gas control in ON.

3. Supply gas pressure can be checked at 1/8”

NPT pressure tapping on heater external

manual valve.

4. Check to see if gas control is opening: no

manifold pressure indicates valve is closed.

If the valve is closed, either the gas valve or

the ignition module is faulty.

WARNING: Do not disconnect ground leads

inside heater. Do not interchange grounded

and ungrounded leads on transformer or

ignition module.

Burner Does Not 1. Check to see if gas lines were properly

Light: purged of air.

2. Check inlet and outlet gas pressure during

ignition period.

• Natural inlet pressure should be 4.5” (1.12 kPa)

• Natural outlet pressure at manifold should be 3.5” (0.87 kPa)

• LP inlet pressure should be 11.0” (2.74 kPa)

• LP outlet pressure at manifold should be 10.5” (2.61 kPa)

3. Check for proper orifice and air plate.

E-19

Operating Instructions and Owner’s ManualEnerco | Heatstar ERXL Series Heater

Page 20

Burner Does Not 1. Check ground wire continuity.

Stay Lit: 2. Check burner internal wiring for reversed

leads.

3. Check insulation on the igniter leads.

4. Replace module if necessary.

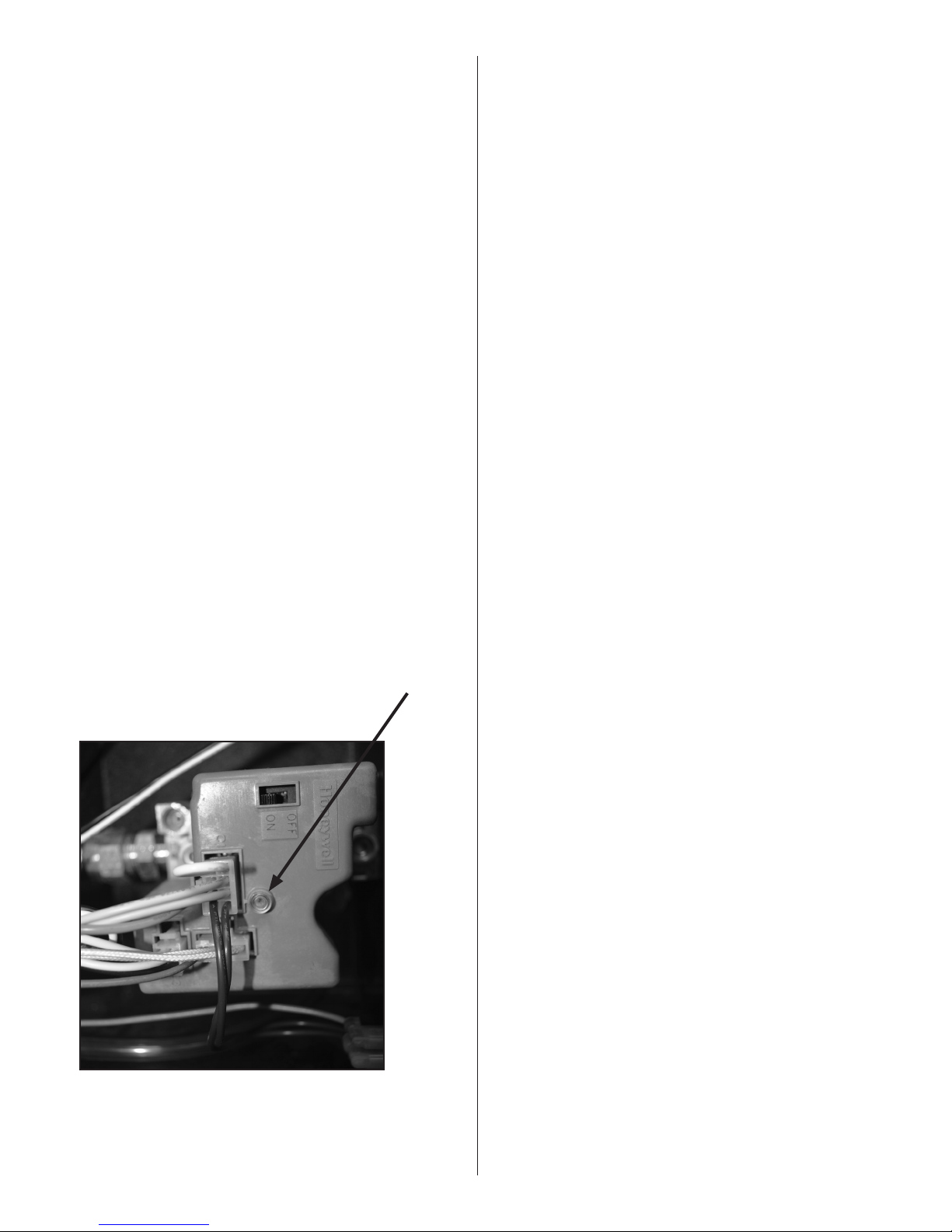

Honeywell Valve LED Status

The Ener-Radiant XL series Tube Heater is equipped with a

honeywell Smart Valve. This valve has a built-in diagnostic program,

which will assist in troubleshooting in the event of a valve-related

problem. The LED or (Light Emitting Diode) is located on the top of

the valve as shown in diagram below. The LED status indications are

listed below to help with the troubleshooting.

FIGURE 19:

OFF INDICATED

Off No power to the control

Bright-Dim Normal operation.

This indication shows whenever the system is

powered, unless some abnormal event has occurred.

2-Flashes Airflow providing switch remains closed longer than

30 seconds after call for heat begins (air providing

switch stuck closed.)

3-Flashes Airflow providing switch remains open longer than 30

seconds after combustion air blower is energized - or

blower does not energize.

4-Flashes White jumper wire is loose.

5-Flashes Flame signal sensed out of proper sequence.

6-Flashes System Lockout.

Honeywell Smart Valve

LED

Enerco | Heatstar ERXL Series Heater Operating Instructions and Owner’s Manual

E-20

Page 21

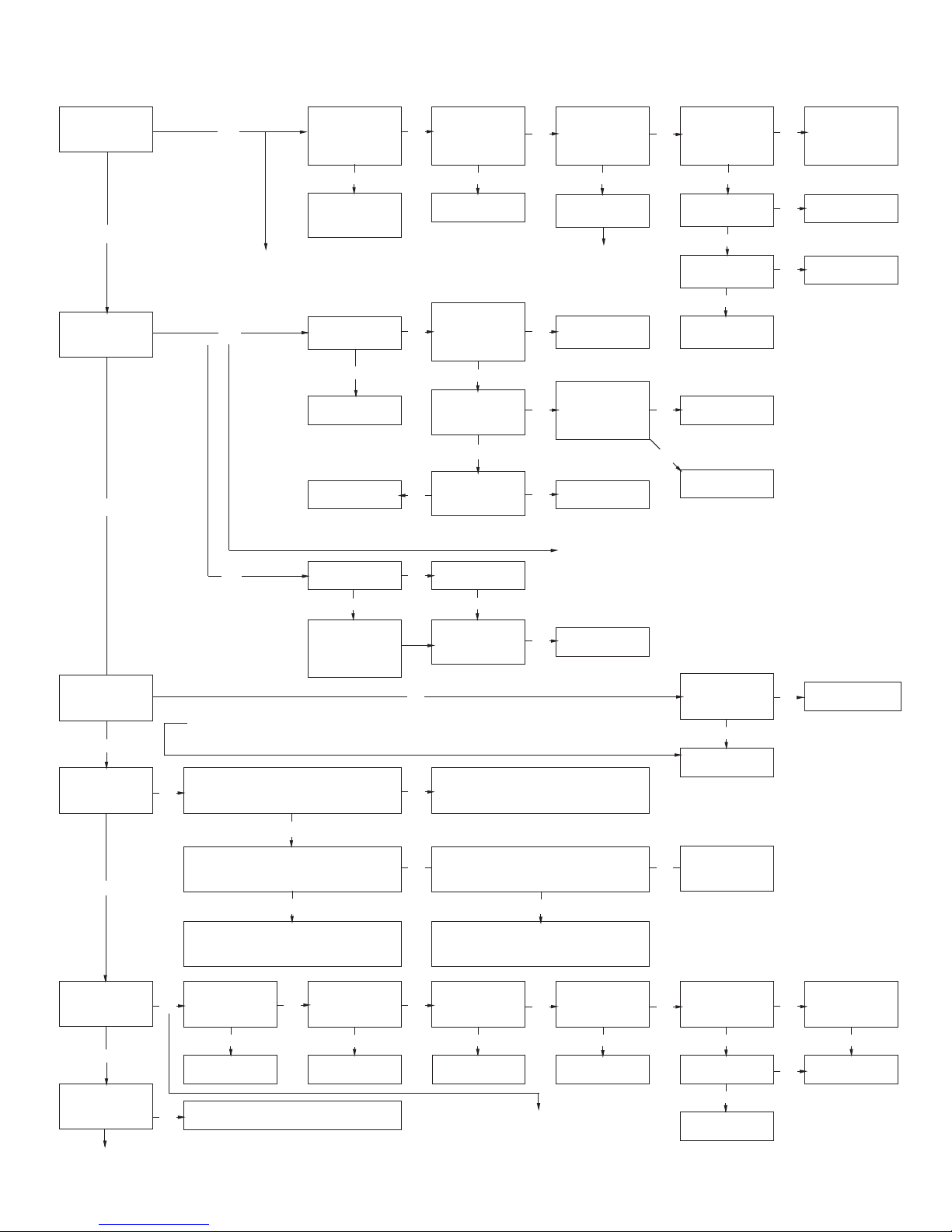

SECTION 9: Troubleshooting Guide. Ener-Radiant XL

START

Turn on thermostat

Does blower turn

on?

Yes

Does the igniter

warm up and glow

red?

Yes

No

Check LED indicator on SmartValve for

indication of fault. Refer to SmartValve testing

on page 20 to determine problem.

No

Check Thermostat

and Wiring. Is the

power supply to unit

115V?

No

Find the source

of the electrical

problem

Is the air intake or

exhaust blocked?

Yes

Remove Obstruction

Check wiring and

connections

Is blower side door

Yes

No

No

in place?

Replace door

Check wiring and

hose connection to

air switch. Are they

Is the voltage at

the transformer

secondary 24V?

Is the voltage at the

transformer primary

Yes

No

Check for 115V transformer input at plug

C3 on SmartValve. Check for 115V output

of C3. If no output voltage is present

replace SmartValve.

Replace wiring and/

No

or hose connection.

OK?

Yes

Yes

No

115 V

Remove door. Is

voltage at door

switch 115V?

No

Check voltage at

gas valve.

Jumper wires at

pressure switch.

Does the ignitor

glow red?

Replace transformerYes

Depress switch.

Yes

Does blower come

Check voltage to

motor. Is it 115V?

Is the blower fan

obstructed?

Replace blower

Replace pressure

Yes

No

Replace SmartValve.

on?

No

Yes

No

motor.

switch.

Check door fit. If

Yes

damaged, replace

Replace switch.

No

Remove obstruction

Yes

door.

After ignitor warm-

up period, does the

valve click?

Yes

Does the burner

light?

Yes

Check LED indicator on SmartValve for

indication of fault. Refer to SmartValve testing

No

The SmartValve checks the status of the blower proving switch contacts must see a change in the

contact with every firing cycle. Placing a jumper at the switch out of sequence will result in a fault with

No

Were the gas lines purged of air?

Check inlet gas pressure. Is pressure correct?

Refer to page 13 for correct pressure for unit.

Check inlet gas shutoff. Adjust regulator.

Contact gas supplier

Is the ignitor

damaged?

No

Check voltage at

ignitor. Is it 115V

during ignition

cycle?

the LED indicator flashing two times.

Yes

Yes

Replace ignitor.

Yes

No

Is the resistance

through igniter 40

to 75 ohms?

No

The switch on the gas valve must be in the on

No

Yes

position and the line purged of air.

Check outlet gas pressure during ignition cycle.

Is the pressure 3.5” w.c. for natural or 10.5”

w.c. for lp?

Adjust to proper pressure.

Yes

No

Check wire

connections.

on page 21 to determine problem.

Are the wires to

the SmartValve OK?

Yes

Replace SmartValve

Check for proper

Yes

burner orifice and

air plate.

Replace/repair wires.

No

Does the burner

stay on?

Yes

Does the burner

run until the call

for heat ends?

If a problem still exists, contact Enerco Group, Inc Technical Products

Is the continuity of

the ground wire

No

No

Customer Service 1-866-447-2194

OK?

No

Repair wiring.

Check the continuity of the ground wire.

Yes

Check the thermostat.

Are L1 and L2

reversed?

Yes

Repair wiring

Is the wiring at the

No

SmartValve OK?

No

Repair wiring

A fault indication of six flashes may indicate

that the flame sensing circuit is not functioning

properly. Perform the following series of checks

to correct the problem.

Operating Instructions and Owner’s ManualEnerco | Heatstar ERXL Series Heater

E-21

Is the insulation on

Yes

the sensor lead OK?

Repair wiring

No

Is the sensor

positioned

Yes

Is the sensor dirty?

Replace Sensor

properly?

Yes

No

No

Yes

Repair/Replace

Yes

Clean sensor.

Page 22

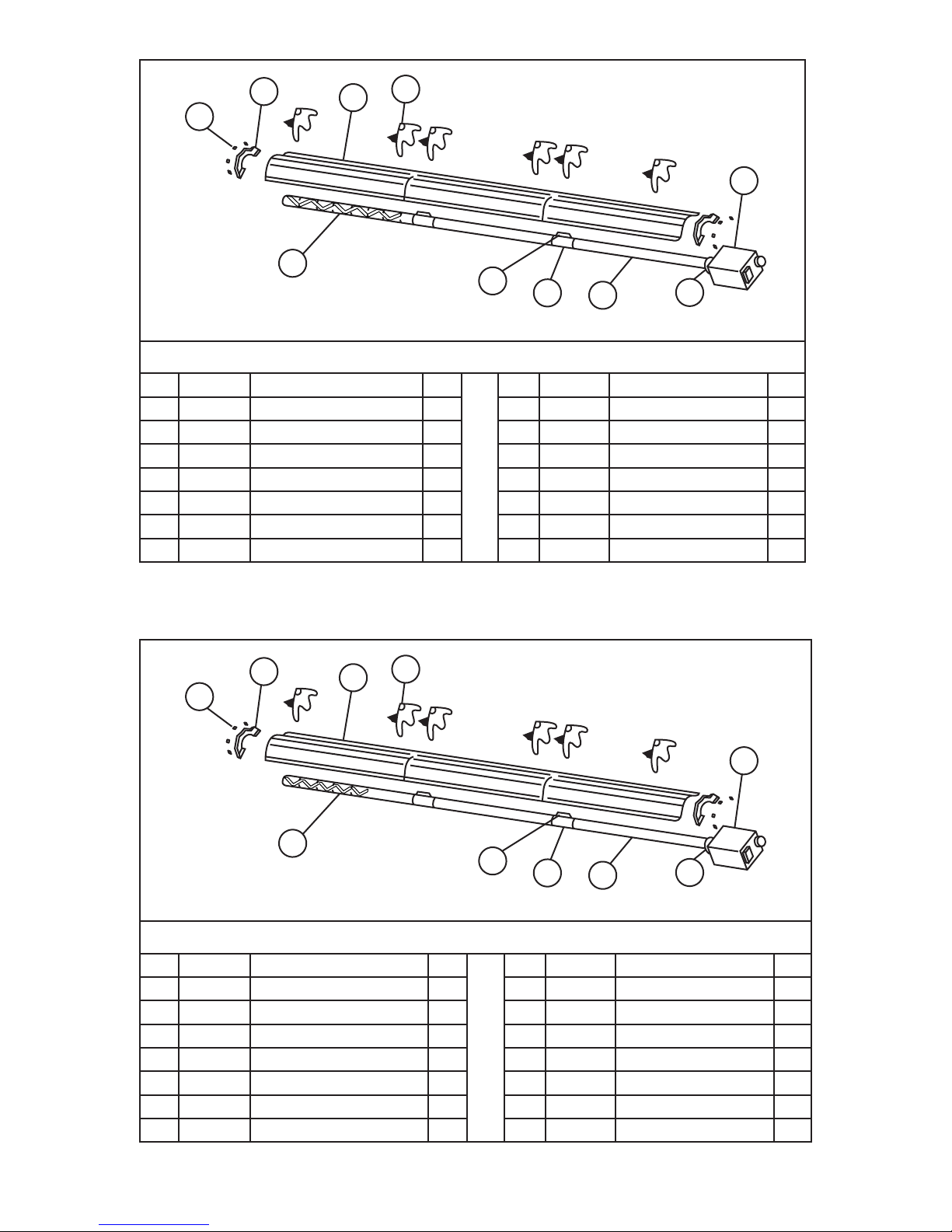

Parts List for Ener-Radiant XL Tube Heaters

7

3

5

8

1

4

2

6

ERXL-40

Item Stock # Description QTY Item Stock# Description QTY

1 F102594XL ERXL-40 NG / BRN & Cont Box 1 6 02753 Front Flange 1

1 F102595XL ERXL-40 LP / BRN & Cont Box 1 7 00 419 Reflector End Cap 2

2 F106408XL Tube Set- 10' 1 8 09369 Spring Clips 8

06413 Tube H.E. 4" O.D. X 10' 2

3 00418A Reflector 2

4 03445 Turbulator Baffle 9' 1

5 14585P Hanger 4

5

3

9

10

1

4

7

8

2

ERXL-60

Item Stock # Description QTY Item Stock# Description QTY

1 F102650XL ERXL-60 NG / BRN & Cont Box 1 1 F102652XL ERXL-80 LP / BRN CONT Box 1

F102651XL ERXL-60 LP / BRN & Cont Box 1 F102653XL ERXL-80 NG / BRN CONT Box 1

2 F106404XL ERXL-60, / Tube Set- 20' 1 2 F106404XL ERXL-80, / Tube Set- 20' 1

06413 Tube H.E. 4" O.D. X 10' 2 06413 Tube H.E. 4" O.D. X 10' 2

3 00418A Reflector 2 3 00418A Reflector 2

4 03445 Turbulator Baffle 10' 1 4 03445 Turbulator Baffle 10' 1

5 14585P Hanger 4 5 14585P Hanger 4

6 02753 Front Flange 6 02753 Front Flange

7 14 612 Tube Coupling 1 7 14 612 Tube Coupling 1

8 14 616 Key for Tube Coupling 1 8 14 616 Key for Tube Coupling 1

9 0 0 419 Reflector End Cap 2 9 0 0419 Reflector End Cap 2

10 09369 Spring Clips 8 10 09369 Spring Clips 8

6

ERXL-80

Enerco | Heatstar ERXL Series Heater Operating Instructions and Owner’s Manual

E-22

Page 23

9

3

5

10

1

4

8

7

2

6

ERXL-80

Item Stock # Description QTY Item Stock# Description QTY

1 F102652XL ERXL-80 NG / BRN & Cont Box 1 6 02753 Front Flange 1

F102653XL ERXL-80 LP / BRN & Cont Box 1 7 14 612 Tube Coupling 2

2 F106405XL ERXL-80, / Tube Set- 30' 1 8 14 616 Key for Tube Coupling 2

06413 Tube H.E. 4" O.D. X 10' 3 9 0 0419 Reflector End Cap 2

3 00418A Reflector 3 10 09369 Spring Clips 8

4 03445 Turbulator Baffle 10' 1

5 14585P Hanger 6

9

3

5

10

1

4

8

7

2

6

ERXL-100

Item Stock # Description QTY Item Stock# Description QTY

1 F102654XL ERXL-100 NG / BRN & Cont Box 1 6 02753 Front Flange 1

F102655XL ERXL-100 LP / BRN & Cont Box 1 7 14 612 Tube Coupling 2

2 F106401XL ERXL-100, / Tube Set- 30' 1 8 14 616 Key for Tube Coupling 2

06413 Tube H.E. 4" O.D. X 10' 3 9 0 0419 Reflector End Cap 2

3 00418A Reflector 3 10 0 9369 Spring Clips 8

4 03447 Turbulator Baffle 5' 1

5 14585P Hanger 4

E-23

Operating Instructions and Owner’s ManualEnerco | Heatstar ERXL Series Heater

Page 24

9

6

7

8

1

4

5

3

2

ERXL-100

Item Stock # Description QTY Item Stock# Description QTY

1 F102654XL ERXL-100 NG / BRN & Cont

F102655XL ERXL-100 LP / BRN & Cont Box 1 F102657XL ERXL-125 LP / BRN & Cont Box 1

2 F106406XL ERXL-100, / Tube Set- 40' 1 2 F106406XL ERXL-125, / Tube Set- 40' 1

06413 Tube H.E. 4" O.D. X 10' 4 06413 Tube H.E. 4" O.D. X 10' 4

6 02753 Front Flange 1 3 02753 Front Flange 1

4 14 612 Tube Coupling 1 4 14 612 Tube Coupling 1

5 14 616 Key for Tube Coupling 1 5 14616 Key for Tube Coupling 1

6 00418A Reflector 4 6 00418A Reflector 4

7 14585P Hanger 8 7 14585P Hanger 8

8 0 0 419 Reflector End Cap 2 8 0 0419 Reflector End Cap 2

9 09369 Spring Clips 8 9 0 9369 Spring Clips 8

Box

9

8

6

1 1 F102656XL ERXL-125 NG / BRN & Cont

7

ERXL-125

1

Box

1

Item Stock # Description QTY Item Stock# Description QTY

1 F102656XL ERXL-125 NG / BRN & Cont Box 1 3 02753 Front Casting 1

1 F102657XL ERXL-125 LP / BRN & Cont Box 1 4 14 612 Tube Flange 2

1 F102658XL ERXL-150 NG / BRN & Cont Box 1 5 14 616 Key for Tube Coupling 2

1 F102659X L ERXL-150 LP / BRN & Cont Box 1 6 00418A Reflector 5

1 F102660XL ERXL-175 NG / BRN & Cont Box 1 7 14585 Hanger 10

1 F102661XL ERXL-175 LP / BRN & Cont Box 1 8 0 0419 Reflector End Cap 2

2 F106407XL Tube Set- 50' 1 9 09369 Spring Clips 8

06413 Tube H.E. 4" O.D. X 10' 3

Enerco | Heatstar ERXL Series Heater Operating Instructions and Owner’s Manual

4

5

ERXL-125 / ERXL-150 / ERXL-175

E-24

3

2

Page 25

8

9

6

7

1

4

5

3

2

ERXL-150 ERXL-175

Item Stock # Description QTY Item Stock# Description QTY

1 F102658XL ERXL-150 NG / BRN & Cont Box 1 1 F102660XL ERXL-175 NG / BRN & Cont Box 1

1 F 102659XL ERXL-150 LP / BRN & Cont Box 1 1 F102661XL ERXL-175 LP / BRN & Cont Box 1

2 F106403XL Tube Set- 60' 1 2 F106403XL Tube Set- 60' 1

06413 Tube H.E. 4" O.D. X 10' 6 06413 Tube H.E. 4" O.D. X 10' 6

3 02753 Front Flange 1 3 02753 Front Flange 1

4 14 612 Tube Coupling 5 4 14 612 Tube Coupling 5

5 14616 Key for Tube Coupling 5 5 14 616 Key for Tube Coupling 5

6 00418A Reflector 6 6 00418A Reflector 6

7 14585 P Hanger 12 7 14585P Hanger 12

8 0 0419 Reflector End Cap 2 8 0 0 419 Reflector End Cap 2

9 0 9369 Spring Clips 8 9 09369 Spring Clips 8

ACCESSORY PARTS LIST

Stock Number Description

10371 ................................... Thermostat 24 volt

10392 ................................... Thermostat 110Volt

17370 ................................... Chain Kit

16401 .................................. 24” Stainless Steel Flexible

16405 .................................. 1/2"x24" 3/4" Stainless Steel

F106414 ............................... 180° U-Tube Accessory Kit

F106415 ............................... 90° Elbow Accessory Kit

19021 ................................... Vent Adaptor

06430 .................................. Vent Cap

00 438 .................................. Side Reflector kit

01376 ................................... Deflector kit (5')

19031 ................................... Turnbuckle 5/16"-18"

INSTALLATION KITS

F111751…………Installation kit for 20’ tube heater

F111752…………Installation kit for 30’ tube heater

F111753…………Installation kit for 40’ tube heater

F111754…………Installation kit for 50’ tube heater

F111755…………Installation kit for 60’ tube heater

Installation kit includes:

24-volt thermostat, vent cap, 24” stainless steel flexible gas

connector, gas shutoff valve, and chain kits required to hang heater.

CONVERSION KITS

ERXL-40

ERXL-60

ERXL-80

ERXL-100

ERXL-125

ERXL-150

ERXL175

117 32 LP TO NG 117 33 NG TO LP

117 34 LP TO NG 117 35 NG TO LP

117 36 LP TO NG 117 37 NG TO LP

117 38 LP TO NG 117 39 NG TO LP

117 4 0 LP TO NG 11741 NG TO LP

117 30 LP TO NG 117 31 NG TO LP

E-25

Operating Instructions and Owner’s ManualEnerco | Heatstar ERXL Series Heater

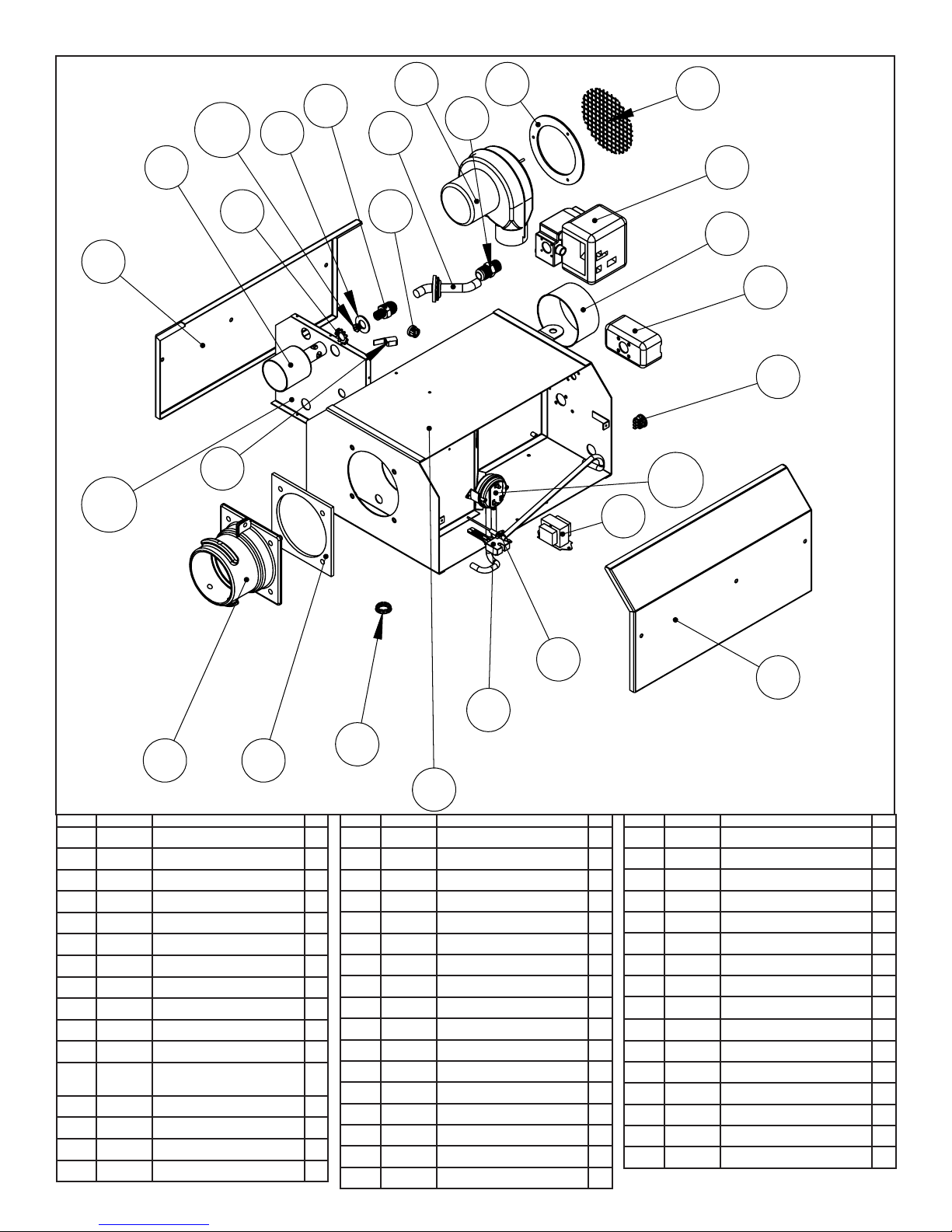

Page 26

2740

26

25

45 46

24

47

23

3

15-

21

42

43

41

22

44

14

13

12

7-9

6

5

ITEM# EGI # DESCRIPTION QTY

1 02716XL ENCLOSURE

2 02725XL CONTROL SIDE COVER

3 02749XL MOTOR SIDE COVER

4 12397 FRONT FLANGE GASKET

5 02753 FRONT TUBE FLANGE

6 08364A TRANSFORMER

7 02836 40K PRESSURE SWITCH

8 10 413A 60-125K PRESSURE SWITCH

9 10 414A 150K-175K PRESSURE SWITCH

10 02730 FLAME SENSOR ROD

11 02765 HOT SURFACE IGNITER

12 02847 THERMOSTAT 3 TERMINAL

13 9 9101 ELECTRICAL JUNCTION BOX

14 02747 BLOWER INTAKE FLANGE

15 05510XL 40K AIR PLATE

16 05505XL 60K AIR PLATE

BUSHING

4

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Enerco | Heatstar ERXL Series Heater Operating Instructions and Owner’s Manual

10

11

48

1

ITEM# EGI # DESCRIPTION QTY

17 05502XL 80K AIR PLATE

18 05501XL 100K AIR PLATE

19 05500XL 125K AIR PLATE 1

20 05503XL 150K AIR PLATE 1

05508XL 175K AIR PLATE 1

21

22A 00016 HONEYWELL SMARTVALVE(NG) 1

22B 00017 HONEYWELL SMARTVALVE(LP) 1

23 0275 8 GAS VALVE OUTLET FITTING 1

24 17379 GAS MANIFOLD 1

25 02720 ORIFICE HOLDER FITTING 1

26 985 41 ORIFICE HOLDER FLAT WASHER 1

27 05794 40K ORIFICE (NG) 1

28 0 5749 40K ORIFICE (LP) 1

29 05726 60K ORIFICE (NG) 1

30 05 74 4 60K ORIFICE (LP) 1

31 0 5718 80K ORIFICE (NG) 1

32 05737 80K ORIFICE (LP) 1

E-26

2

ITEM# EGI # DESCRIPTION QTY

33 0 5712 100K ORIFICE (NG) 1

1

34 05733 100K ORIFICE (LP) 1

1

05703 125K ORIFICE (NG) 1

35

36 05730 125K ORIFICE (LP) 1

37 05796 150K ORIFICE (NG) 1

38 05728 150K ORIFICE (LP) 1

39 05799 175 ORIFICE (NG) 1

40 05725 175K ORIFICE (LP) 1

41 98547 EXTERNAL TOOTH WASHER

42 02371 BURNER CUP 1

43 10391 A DOOR SWITCH 1

44 02721 BLOWER 2-TERMINAL BUSHING 1

45 07376 MOTOR 1

46 12 395 BLOWER GASKET 1

47 02718 BLOWER SCREEN 1

48 02795 SIGHT WINDOW 1

1

Page 27

NOTES :

E-27

Operating Instructions and Owner’s ManualEnerco | Heatstar ERXL Series Heater

Page 28

OPERATING INSTRUCTIONS AND OWNER’S MANUAL

XL

ER

WARNING:

USE ONLY MANUFACTURER’S REPLACEMENT PARTS. USE OF ANY OTHER PARTS

110V MODELS

ERXL-40 ERXL-60

ERXL-80 ERXL-100

ERXL-125 ERXL-150

ERXL-175

COULD CAUSE INJURY OR DEATH. REPLACEMENT PARTS ARE ONLY AVAILABLE DIRECT

FROM THE FACTORY AND MUST BE INSTALLED BY A QUALIFIED SERVICE AGENCY.

PARTS ORDERING INFORMATION:

FOR INFORMATION REGARDING SERVICE OR PARTS

Contact your local heating service technician or dealer.

FOR ADDITIONAL INFORMATION:

Please call Toll-Free 866-447-2194—www.heatstarbyenerco.com

Our office hours are 8:00 AM — 5:00 PM, EST, Monday through Friday.

Please have the model number, serial number and date of purchase ready.

LIMITED WARRANTY

The company warrants this product to be free from imperfections in material or

workmanship, under normal and proper use in accordance with instructions of the

Heatstar Company, for a period of 10 years from the date of delivery to the buyer with

the following exceptions.

• For installation in a car wash and in areas with exposure to corrosive chemicals, such

as ammonia, chlorine, etc., the warranty will be limited to 2 years on tubes and 1

year on all other components.

The Heatstar Company, at its option, will repair or replace products returned by the

buyer to the factory, transportation prepaid within said warranty period and found by

the Heatstar Company to have imperfections in material or workmanship.

If a part is damaged or missing, call our Customer Service Department at 866-447-2194.

Address any Warranty Claims to the Customer Service Department, Enerco Group,

Inc, 4560 W. 160TH ST., CLEVELAND, OHIO 44135. Include your name, address and

telephone number and include details concerning the claim. Also, supply us with the

purchase date and the name and address of the dealer from whom you purchased our

product.

The foregoing is the full extent of the responsibility of the Heatstar Company. There are

no other warranties, express or implied. Specifically there is no warranty of fitness for

a particular purpose and there is no warranty of merchantability. In no event shall the

Company be liable for delay caused by imperfections, for consequential damages, or for

any charges of the expense of any nature incurred without its written consent. The cost

of repair or replacement shall be the exclusive remedy for any breach of warranty. There

is no warranty against infringement of the like and no implied warranty arising from

course of dealing or usage of trade. This warranty will not apply to any product which

has been repaired or altered outside of the factory in any respect which in our judgment

affects its condition or operation.

Some states do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you. This Warranty gives

you specific legal rights, and you may have other rights which vary from state to state.

Enerco Group, Inc reserves the right to make changes at any time, without notice or

obligation, in colors, specifications, accessories, materials and models.

Enerco Group, Inc, 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 866-447-2194

© 2019, Enerco Group, Inc All rights reserved

C

US

Enerco | Heatstar ERXL Series Heater Operating Instructions and Owner’s Manual

E-28

Page 29

XL

ER

INSTRUCTIONS D'UTILISATION

ERXL-40 ERXL-60

ERXL-80 ERXL-100

ET MANUEL DU PROPRIÉTAIRE

ERXL-125 ERXL-150

ERXL-175

No de modèle

VEUILLEZ LIRE ATTENTIVEMENT LES INSTRUCTIONS

POUR LES AUTRES.

pour vous y référer ultérieurement. Interdisez à quiconque n’ayant pas lu les présentes instructions d'assembler,

d'allumer, de régler ou de faire fonctionner cette fournaise.

Lire et observer toutes les instructions. Conserver ces instructions dans un endroit sécuritaire

: VOTRE SÉCURITÉ EST IMPORTANTE POUR VOUS ET

Heatstar ERXL

Fournaises à infrarouge de faible intensité alimentées

au gaz et approuvées pour applications commerciales

LANGUES INCLUSES

• ANGLAIS

• FRANÇAIS

• ESPAGNOL

AVERTISSEMENT: Une installation, un réglage, une modification, une réparation ou un

entretien incorrect peut entraîner des dommages matériels, des blessures ou la mort. Lisez

attentivement les instructions d'installation, de fonctionnement et d'entretien avant de procéder a

l'installation ou a l'entretien de cet équipement.

— QUOI FAIRE SI VOUS SENTEZ DU GAZ

• Ouvrez les fenêtres

• N’ESSAYEZ PAS d’allumer quelque appareil que ce soit.

• NE BASCULEZ PAS les interrupteurs électriques.

• N'UTILISEZ PAS les téléphone dans l'édifice. Appelez immédiatement votre fournisseur de gaz local à partir du

téléphone d'un voisin. Suivez les instructions du fournisseur de gaz.

• Ne touchez à aucun commutateur électrique; n'utilisez aucun téléphone dans votre bâtiment.

•

L'installation et l'entretien doivent être réalisés par un installateur qualifié, une entreprise d'entretien ou un fournisseur de gaz.

• Si vous ne pouvez pas rejoindre votre fournisseur de gaz, appelez le service des incendies.

POUR VOTRE SÉCURITÉ :

N’entreposez et n’utilisez pas d’essence ou d’autres liquides ou vapeurs inflammables à proximité de ce type

d’appareil ou de tout autre appareil.

AVERTISSEMENT : Si l'information dans ces instructions n'est pas suivie exactement, un incendie ou une explosion

pourrait se produire causant des dommages aux biens, des blessures personnelles ou un décès.

ENERCO Group, Inc., 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 866-447-2194

18677XL

Page 30

AVERTISSEMENT

:

VOTRE SÉCURITÉ EST IMPORTANTE POUR VOUS ET

POUR LES AUTRES, PAR CONSÉQUENT VEUILLEZ LIRE

CES DIRECTIVES AVANT DE FAIRE FONCTIONNER CET

APPAREIL DE CHAUFFAGE.

AVERTISSEMENT GÉNÉRAL DE DANGER:

LE NON-RESPECT DES MESURES DE PRÉVENTION ET

DES INSTRUCTIONS FOURNIES AVEC CET APPAREIL

DE CHAUFFAGE RISQUE DE CAUSER LA MORT,

DES BLESSURES GRAVES ET DES DOMMAGES OU

DES PERTES MATÉRIELLES RÉSULTANT D'INCENDIE,

D'EXPLOSION, DE BRÛLURE, D'ASPHYXIE,

D'INTOXICATION AU MONOXYDE DE CARBONE ET/

OU D'ÉLECTROCUTION.

SEULES LES PERSONNES APTES À COMPRENDRE ET À

RESPECTER LES INSTRUCTIONS DEVRAIENT UTILISER

OU EFFECTUER LE SERVICE DE CET APPAREIL DE

CHAUFFAGE.

SI VOUS AVEZ BESOIN D'AIDE OU D'INFORMATION

CONCERNANT la fournaise TELS QUE MANUEL

D'INSTRUCTIONS, ÉTIQUETTES, ETC., VEUILLEZ

COMMUNIQUER AVEC LE FABRICANT.

WARNING:

DANGER D'INCENDIE, D'INHALATION ET D'EXPLOSION.

GARDEZ LES COMBUSTIBLES SOLIDES TELS QUE LES