Page 1

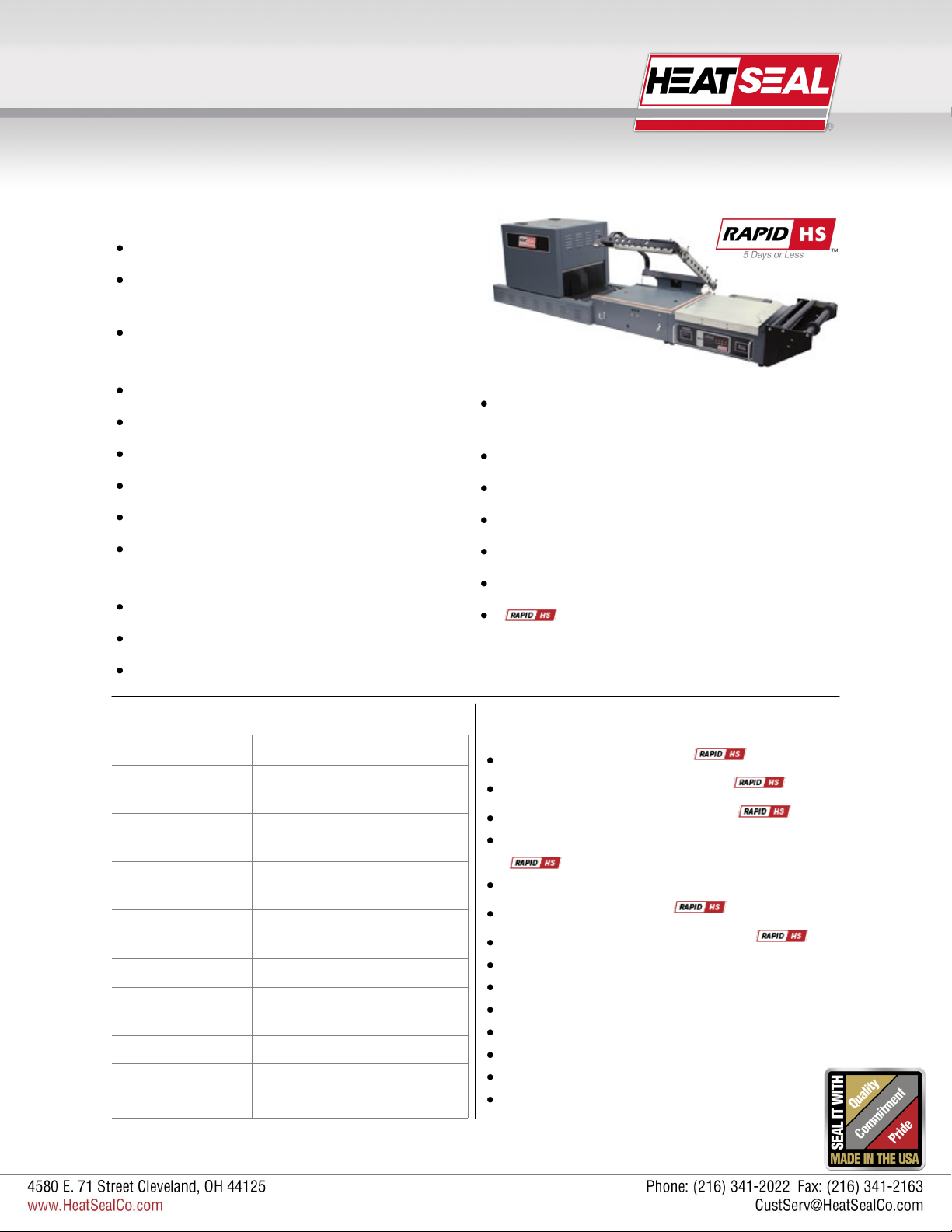

TABLE TOP COMBO SHRINK SYSTEM

MODEL: HS115

FEATURES

CONTROL PANEL

U.L. Listed Control Panel

RS-3 Digital Controller For Easy System Setup and Operation with Built In Diagnostics and Alarms

Single Plug 115V power supply with GFCI

SEALING AREA

Impulse Wire Seal System

Large 15” W by 20” L Seal Area

Heavy Duty Seal Head Design With Film Clamps

Adjustable Height Wrapping Platform

Mechanical Cold Hole Punch

Pre-Wired Power Take Away Ready

SHRINK TUNNEL

6" H by 15" W Tunnel Opening

Digital Tunnel Temperature Control

Specification Sheet

Model HS115

Adjustable Heat Tunnel Conveyor Belt for Bottom Shrink

Control

Automatic Cool Down Extends Heating Element Life

Other Features

Two Year Warranty

Heavy Gauge Steel Construction

Stainless Steel Model Available

or Less

Standard Machine Options will Ship in 5 Days

High Velocity Turbo Tunnel Design

MODEL SPECS

FILM CAPACITY

L BAR SEALING

INSIDE TUNNEL

DIMENSIONS

TUNNEL CONVEYOR

SPEED

OVERALL

DIMENSIONS

WORKING HEIGHT

POWER

REQUIREMENTS

WATTAGE

WEIGHT

17” Wide (44 cm)

15” W, 20” L

AREA

22” L,14 1/2” W, 6” H (53 L, 37 W,

15 H cm)

0-20 Feet per Minute

(0-6 meters per minute)

84” L, 23” W, 49” H (213 L, 58 W,

125 H cm)

35” (89 cm)

115 Volts, 20 Amp

Single Circuit with Ground

Tunnel: 2,000, Belt: 500

350 lbs. (159 kg) (without leg kit);

450 lbs (204.5 kg) (with leg kit)

AVAILABLE OPTIONS

Console Leg Kit With 3” Casters

Single Magnetic Hold Down With Dwell

Double Magnetic Hold Down With Dwell

Three Individually Adjustable Perforating Wheels

Hot Hole Punch (Replaces cold hole punch)

Posi-Trac Power Take Away

Power Take Away Conveyor (Silicone Belt)

5" Casters

Spare Parts Kit

Export Wiring: 220 Volt

Left Hand Reverse Flow

GTC180/16- 180 Degree Gravity Turn Around Conveyor

GTC90/16- 90 Degree Gravity Turn Around Conveyor

AT36- 36" Powered Accumulator Table

Revised 2013

Loading...

Loading...