Page 1

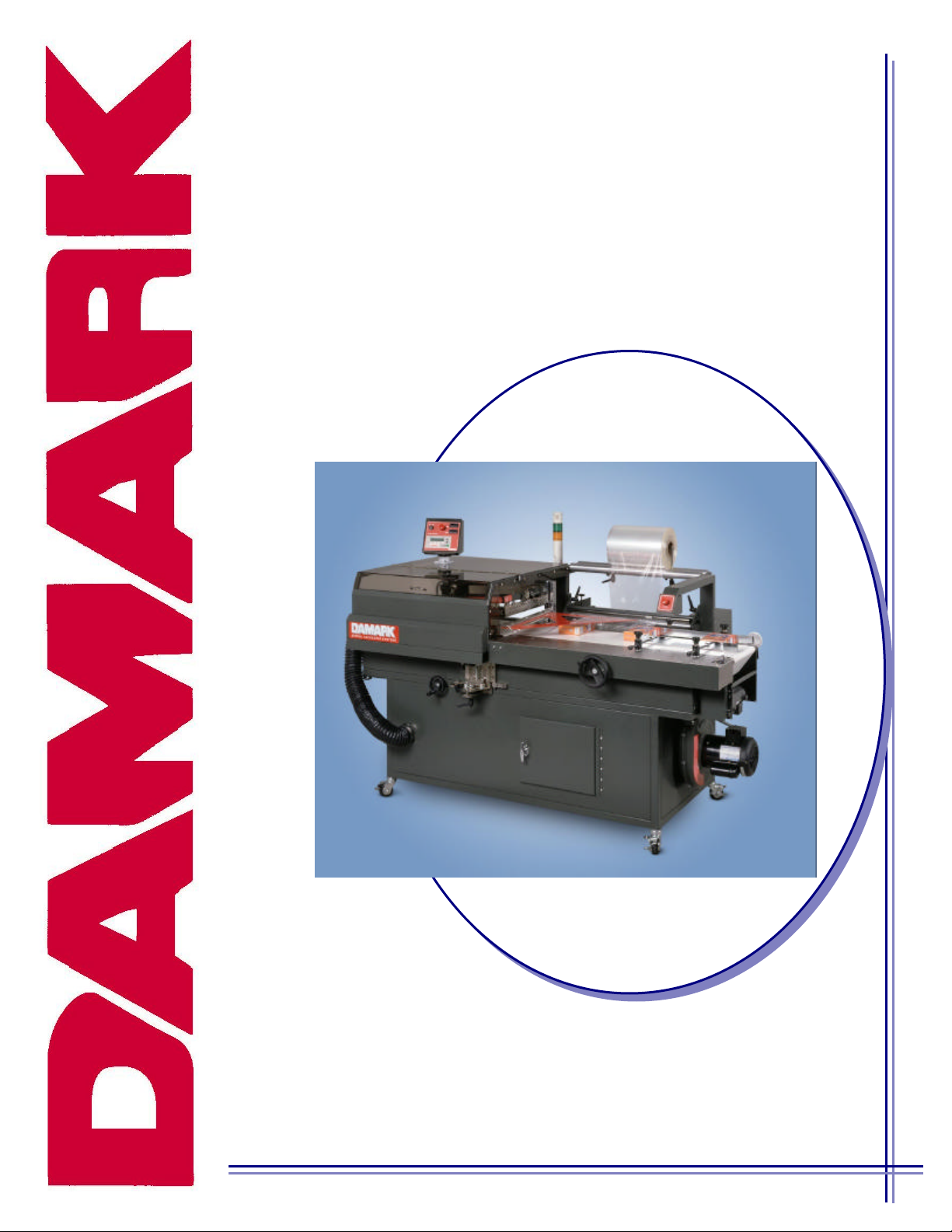

Automatic Shrink

APS SERIES

APS SERIES

Automatic Shrink

Packaging Systems

Packaging Systems

The APS series of Automatic "L" Sealers are the third generation of automatic

shrink packaging systems engineered by DAMARKDAMARK. With three different models

and sizes to choose from, there is an APS machine for your packaging needs.

Page 2

STANDARD FEATURES:STANDARD FEATURES:

TECHNICAL SPECIFICATIONS:TECHNICAL SPECIFICATIONS:

West Coast Plastics Equip.

800-392-8569

www.sealer.net

•17" x 25" Seal Area

•Micro-Processor controlled low voltage sealing system

•Siemens PLC controlled electrical system

•Photocell product sensors

•Adjustable package transfer area

•Variable speed infeed and discharge conveyors

•Variable speed film unwind w/adj. inverting head

•Easy film loading and changeover

•Adjustable roller perforator air venting device

•Power film puller, adj. for height and pull direction

•Full safety features on seal head

•Internal vacuum scrap removal system w/manifold

•Heavy duty welded structur al tube steel construction

•Heavy duty locking casters and adjustable legs

•Up to 30 packages per minute

•Operates with all shrink films

OPTIONS:OPTIONS:

•Adjustable seal height

•Dual belted infeed separation conveyor

•Transition indexing/closing conveyor

•Hot Knife sealing head

•Plexiglass safety shield

•USDA approved epoxy paint

•Steel It stainless steel paint

•Spare parts kit

•Export wiring

•Audio visual operations indicator tower

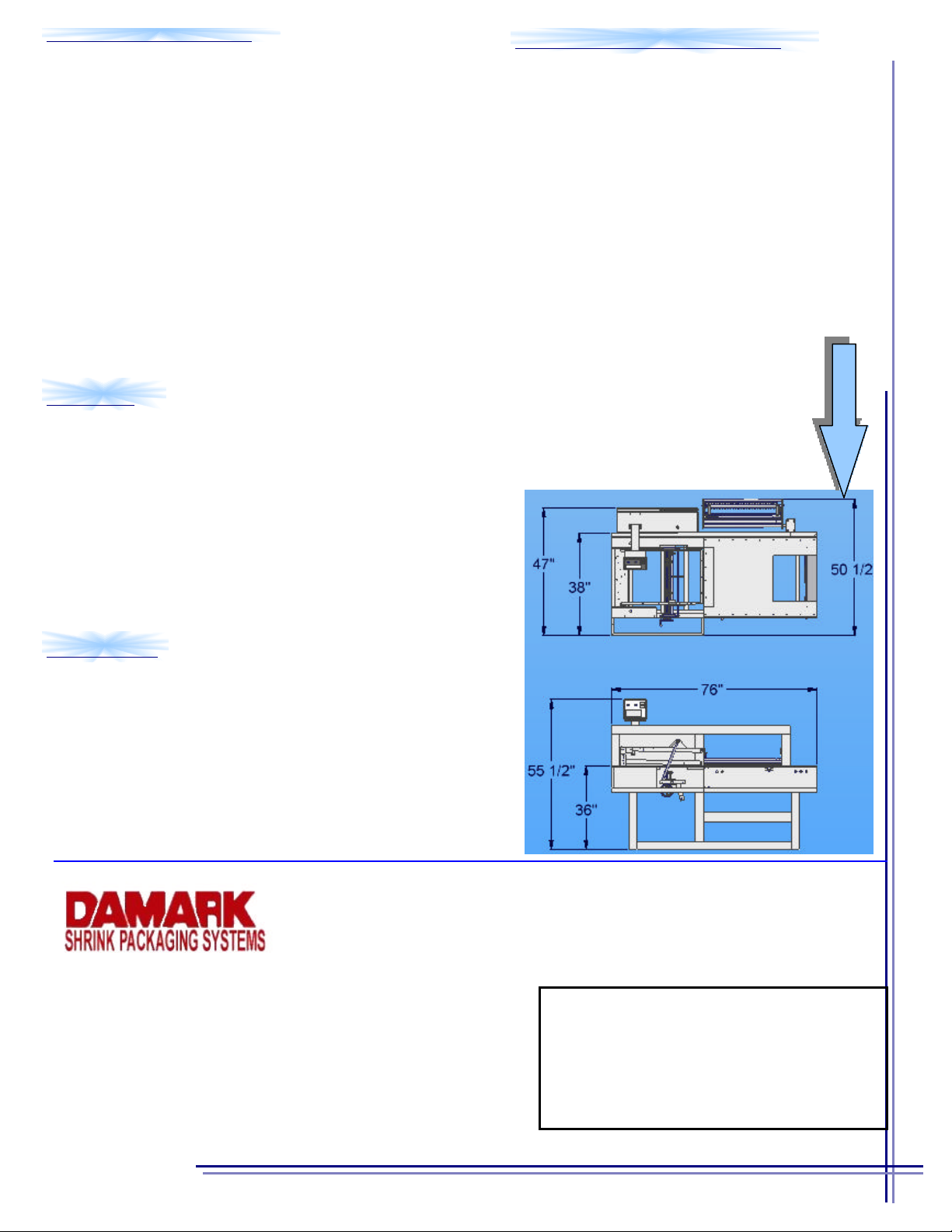

•Electrical - 220V/1PH/15A

•Compressed air - 75psi @ 4-5 cfm

•Effective seal area - 16" x 24"

•Maximum jaw opening - 6"

•Maximum film width - 24"

•Maximum package size - Determined by height

•Packaging speed - Up to 30 ppm**

•Conveyor speed - 0-50 fpm

•Conveyor hei ght - 36" from floor

•Unit dimension - 60"H x 40"W x 90"L

•Shipping dims. - 68"H x 50"W x 110"L

•Shipping weight - 910 lbs

•F.O.B. factory

•Warranty - 1 year on parts

**Package speed varies with package size

OPERATION:OPERATION:

Products may be hand or automatically loaded onto

the wrapper's infeed conveyor. A photocell senses

the product which activates a film advance system

that carries it into the film and then sealing area.

When the product is in place, in the seal area, the

seal jaw activates sealing a bag around the product.

After the seal cycle is complete the product is

conveyed to the shrink tu nnel conveyor.

DAMARK PACKAGING INC DAMARK PACKAGING SYSTEMS INC. DISTRIBUTED BY:DAMARK PACKAGING INC DAMARK PACKAGING SYSTEMS INC. DISTRIBUTED BY:

1200 Tapscott Road P.O. Box 560901

Scarborough, Ontario Lewisville, TX

Canada M1X 1M5 USA 75056-0901

Tel: (416) 609-8011 Tel: (972) 625-8311

Fax: (416) 609 -8008 Fax: (972) 370-9113

www.damarkpackaging.com

We reserve the right to modify designs, discontinue models, change specifications or prices without notice and/or obligation.

Loading...

Loading...