Heat-N-Glo SL-550TRS-AUC Installation And Operation Instructions Manual

INSTALLATION AND OPERATION

INSTRUCTIONS

MODEL: SL-550TRS-AUC

AUSTRALIAN GAS ASSOCIATION APPROVED

Approval Number 5666

THIS MANUAL MUST BE USED FOR INSTALLATION AND RETAINED

BY HOMEOWNER FOR OPERATION AND MAINTENANCE.

HEAT-N-GLO, a division of Hearth Technologies Inc.

20802 Kensington Boulevard, Lakeville, MN 55044 USA • 1-888-427-3973

This product is covered by one or more of the following patents: (United States) 4,112,913; 4,408,594; 4,422,426; 4,424,792; 4,520,791; 4,793,322;

4,852,548; 4,875,464; 5,000,162; 5,016,609; 5,076,254 5,191,877; 5,218,953; 5,328,356; 5,429,495; 5,452,708; 5,542,407; 5,613,487; (Australia)

543790; 586383; (Canada) 1,123,296; 1,297,746; 2,195,264; (Mexico) 97-0457; (New Zealand) 200265; or other U.S. and foreign patents pending.

347-900C 9/02

1

INSTALLATION AND OPERA TION INSTRUCTIONS

PLEASE READ THIS MANUAL BEFORE INSTALLING

AND USING THIS APPLIANCE.

MODEL SL-550TRS-AUC

IS AUSTRALIAN GAS ASSOCIATION

APPROVED FOR NATURAL GAS OR

PROPANE AS A BALANCED FLUE

HEATER.

Refer to the appliance data plates for gas

consumptions and pressures.

Installation of this appliance should only be

carried out by an authorized person in accordance with the manufacturer's instructions. All relevant codes and regulations laid

down by the gas piping authorities, municipal building regulations, electrical wiring

regulations and the requirements of the AGA

Gas Installation Code must be observed.

This appliance and its components are

tested and safe when installed in accordance with this Installation Manual. Report

to your dealer any parts damaged in shipment, specifically check glass condition. The

gas logs and flue system components are

in separate packages. Read all instructions

before starting installation and follow these

instructions carefully during installation to

ensure maximum benefit and safety. Failure to follow them will void your warranty and

may present a fire hazard.

The Heat-N-Glo, a division of Hearth Technologies Inc. warranty will be voided by, and

Heat-N-Glo, a division of Hearth Technologies Inc. disclaims any responsibility for the

following actions:

• Installation of any damaged heater or

flue system component

• Modification of the heater or balanced

flue system installation other than as

instructed by Heat-N-Glo, a division of

Hearth Technologies Inc.

• Improper positioning of the gas logs or

the glass door

• Installation and/or use of any component

part not manufactured or approved by

Heat-N-Glo, division of Hearth Technologies Inc., not withstanding any independent testing laboratory or other

party approval of such component part

or accessory.

IMPORTANT: Read all instructions carefully before starting installation.

Failure to follow these installation instructions may result in a possible fire

hazard and will void the warranty. Save this Manual for future reference.

Copyright 2002

Heat-N-Glo, a division of Hearth Technologies Inc.

20802 Kensington Boulevard, Lakeville, MN 55044

Printed in U.S.A.

2

TABLE OF CONTENTS

1.0 Installation Instructions........................................................................................ 5

u

1.1 Introduction.................................................................................................. 6

1.2 Flue System Approvals and Installation ........................................................ 8

1.3 Connecting the Gas Supply........................................................................ 21

1.4 Fan ........................................................................................................... 21

1.5 Finishing ................................................................................................... 23

1.6 Installer Testing .......................................................................................... 24

1.7 Log Placement .......................................................................................... 25

2.0 Operating Instructions ...................................................................................... 27

2.1 Safety and Lighting Information .................................................................. 27

2.2 Safety Information...................................................................................... 28

u

2.3 Lighting Instructions ................................................................................... 29

2.4 Fan Operation ........................................................................................... 30

3.0 Servicing and Maintenance.............................................................................. 30

3.1 Removal of Covers for Servicing................................................................ 31

3.2 Removal of Components for Service.......................................................... 31

3.3 Parts Replacement.................................................................................... 31

3.4 Adjustments and Replacement Parts ......................................................... 31

u

3.5 Troubleshooting......................................................................................... 32

u

4.0 Replacement Parts .......................................................................................... 36

Limited Warranty.............................................................................................. 38

u = Contains updated information.

3

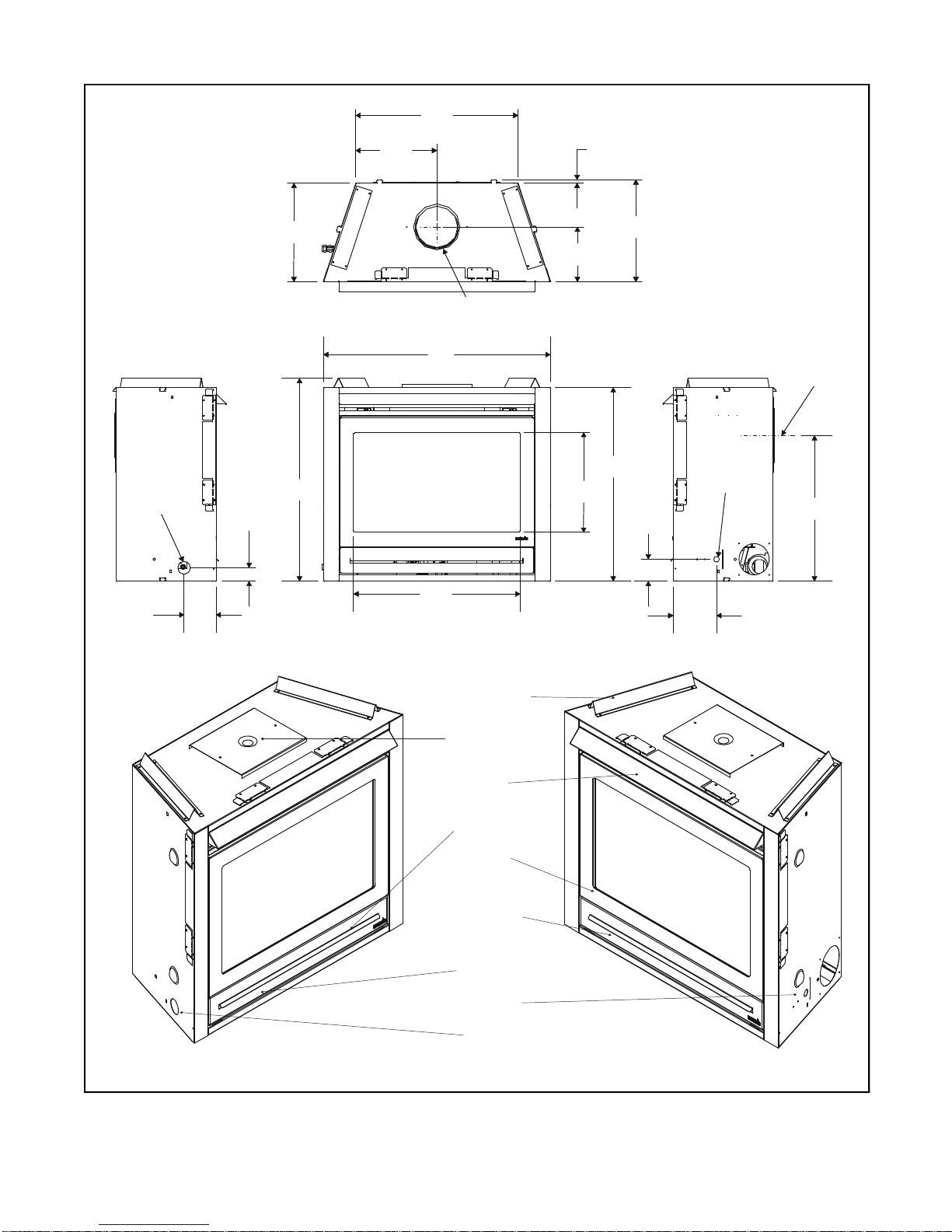

12-7/8

1/2

23-3/8

6-7/8

3-1/2

31

16-1/8

26-3/8

36

(REAR FLUE

CENTER LINE)

327[ ]

25-3/4

653[ ]

14[ ]

GAS

LINE

ACCESS

2-1/8

55[ ]

5

129[ ]

15-7/8

402[ ]

32-1/2

827[ ]

6 5/8 (168)

(TOP FLUE COLLARS)

913[ ]

671[ ]

8-3/4

223[ ]

408[ ]

[ ]

789

16-3/8

415[ ]

90[ ]

ELECTRICAL

ACCESS

174[ ]

COLLARS

8 5/8 (219)

593[ ]

u

FIGURE 1. Diagram of SL-550TRS-AUC

TOP STANDOFFS

FLUE COLLARS

HOOD

DATA BADGE

& LABELS

DRESS

GUARD

BOTTOM GRILLE

COVER

GAS

CONTROLS

ELECTRICAL

ACCESS

GAS LINE

ACCESS

4

1.0 INSTALLATION INSTRUCTIONS

1/2” MIN. (13mm)

C

3” MIN. (76mm)

BDE

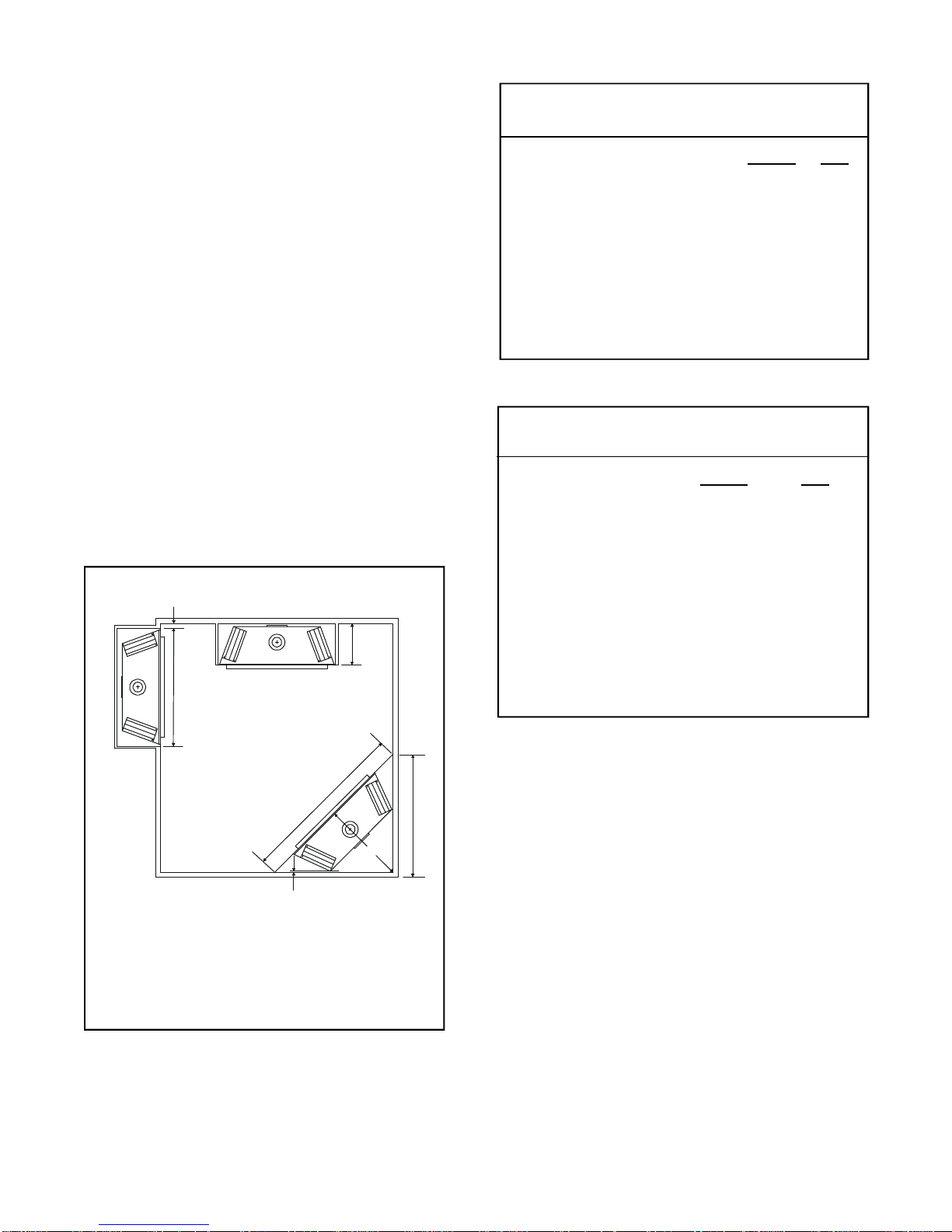

In planning the installation for the heater it is necessary to determine where the unit is to be installed, the

type of flue system to be used (straight out, corner, or

elevated), and whether optional accessories (wall

switch or remote control) are desired. Gas supply piping should also be planned. Refer to the appliance data

plate on the base pan of the heater for all gas pressures and input rate information.

The heater can be mounted on any of the following

surface:

1. A flat surface (minimum 6mm base).

2. Four (4) corner supports.

(Example: Four (4) concrete masonry blocks). These

supports must be positioned so they contact all four

(4) perimeter edges on the bottom of the unit.

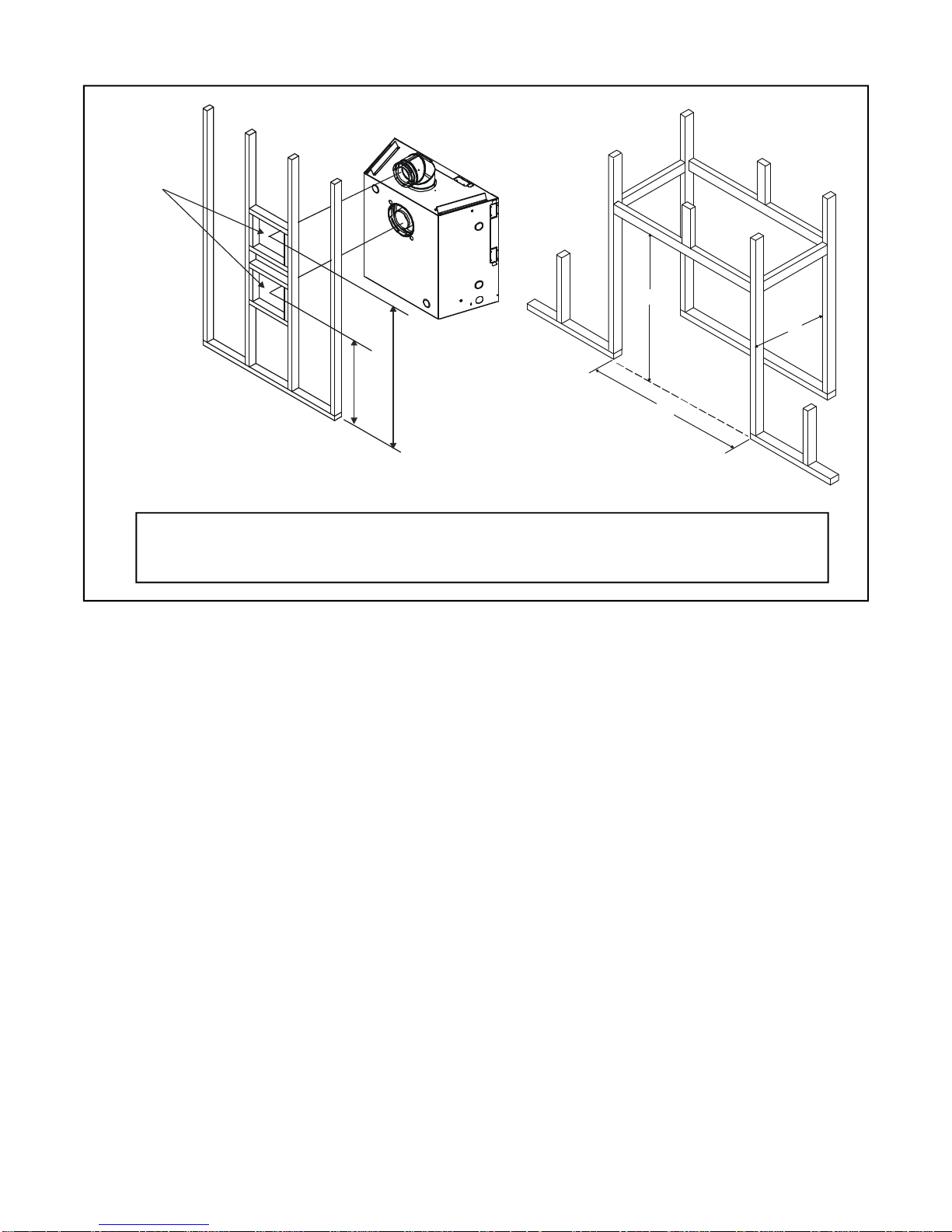

Heater framing can be built before or after the heater is

set in place. Framing should be positioned to accommodate wall covering and heater facing material. The

heater framing should be constructed of 2" X 4" (51 x

102mm) lumber or heavier. The framing headers may

rest on the heater standoffs. Refer to Figure 2 and Figure 3 for heater and framing reference dimensions.

Minimum Clearances

from the Fireplace to Combustible Materials

Inches mm

Glass Front ......................................36 ........ 914

Floor ..................................................0........... 0

Rear ................................................. 1/2 ........ 13

Sides ............................................... 1/2 ........ 13

Top .................................................1 1/2 ....... 38

Ceiling* .............................................31 ........ 787

*The clearance to the ceiling is measured from the top

of the unit, excluding the standoffs (see Figure 27).

Minimum Clearances

from the Vent Pipe to Combustible Materials

Inches mm

Vertical Sections............... 1................. 25

Horizontal Sections

Top ...................................... 3................. 75

Bottom................................ 1................. 25

Sides .................................. 1................. 25

A

A B C D E

37 16 1/4 29 3/8 41 1/2 58 3/4

(940mm) (418mm) (746mm) (1054mm)(1492mm)

NOTE: DIMENSIONS SHOWN WITH THE SIDES, BACK

AND/OR CORNERS OF THE UNIT TOUCHING THE WALL.

Figure 2. Fireplace Dimensions, Locations, and

Space Requirements

At Wall Firestops

Top ................................... 2 1/2.............63.7

Bottom.............................. 1/2 ............... 13

Sides .................................. 1................. 25

For minimum clearances, see the direct vent termination clearance in Figures 19 and 24.

5

ABC

FLUE

FRAMING

HOLE

D

E

*NOTE: The center of

the framing hole is one

inch (254mm) above

the center of the

horizontal flue pipe.

Model A B C D E*

SL-550TRS-AUC 37" 33 1/2" 16 1/4" 36 1/2" 24 3/8"

(940mm) (851mm) (418mm) (927mm) (619mm)

u

FIGURE 3. Framing Dimensions

CAUTION: Measure heater dimensions, and verify

framing methods and wall covering details before framing construction begins.

1.1 INTRODUCTION

This model is designed to operate with all combustion air being siphoned from the outside of the building and all exhaust gases expelled to the outside of

the building.

WARNING: THIS UNIT IS NOT FOR USE WITH

SOLID FUEL.

These units MUST use the flue termination described

The framing headers may rest on

the fireplace stand-offs.

Framing should be constructed

of 2 X 4 lumber or heavier.

in the flueing section of the manual.

The control system for these models are a millivolt type.

It consists of a gas control valve/variable regulator, a

standing pilot/thermopile/thermocouple, a piezo ignitor, and an ON/OFF switch. The controls are located

behind the lower grille. Access to the controls is gained

by rotating the grille down. See Figure 1.

Minimum inlet gas supply pressure for purpose of input adjustment is 4.5 inches w.c. (1.13kPa) for natural

gas and 11 inches w.c. (2.75kPa) for propane. Manifold (outlet) pressures should be set at 3.5 inches w.c.

(.8kPa) for natural gas models and 9.6 inches w.c.

(2.40kPa) for propane models.

6

T = Flue terminal M = Gas meter Shading indicates prohibited

I = Mechanical air inlet P = Electricity meter or fuse box areas for flue terminals

a - Below eaves, balconies or other projections: MIN. CLEARANCE (mm)

Appliances to 50 MJ/h input ................................................................................................ 300

Appliances over 50 MJ/h input............................................................................................500

b - From the ground or above a balcony .....................................................................................300

c - From a return wall or external corner .....................................................................................500

d - From a gas meter (M)...........................................................................................................1000

e - From an electricity meter or fuse box (P) ............................................................................... 500

f - From a drain or soil pipe ........................................................................................................ 150

g - Horizontally from any building structure (unless appliance approved

for closer installation) or obstruction facing a terminal ......................................................... 500

h - From any other flue terminal, cowl, or combustion air intake...............................................500

j - Horizontally from an openable window, door, non-mechanical air

inlet, or any other opening into a building, with the exception of

sub-floor ventilation:

Appliances up to 150 MJ/h input.........................................................................................500

Appliances over 150 MJ/h input........................................................................................ 1500

k - From a mechanical air inlet, including a spa blower .........................................................1500

n - Vertically below an openable window, non-mechanical air

inlet or any other opening into a building, with the exception of ................................. See table

sub-floor ventilation ............................................................................................................ below

CLEARANCES 'n' (mm)

Space heaters All other appliances

Up to 50 MJ/h

input

150 500 1000 1500

NOTES: 1. All distances are measured vertically or horizontally along the wall to a point

in line with the nearest part of the terminal.

2. Prohibited area below electricity meter or fuse box extends to ground level.

3. See clause 5.13.6.6 for restrictions on a flue terminal under a roofed area.

4. See Appendix J, Figure J1(a) and J2(a) for clearances required from a flue

terminal to a LP Gas cylinder. A flue terminal is considered to be a source of ignition.

MINIMUM CLEARANCES REQUIRED FOR BALANCED FLUE TERMINALS

OR THE FLUE TERMINALS OF OUTDOOR APPLIANCES

FIGURE 4

UP to 50 MJ/h

input

Over 50 MJ/h &

up

to 150 MJ/h

7

Over 150 MJ/h

input

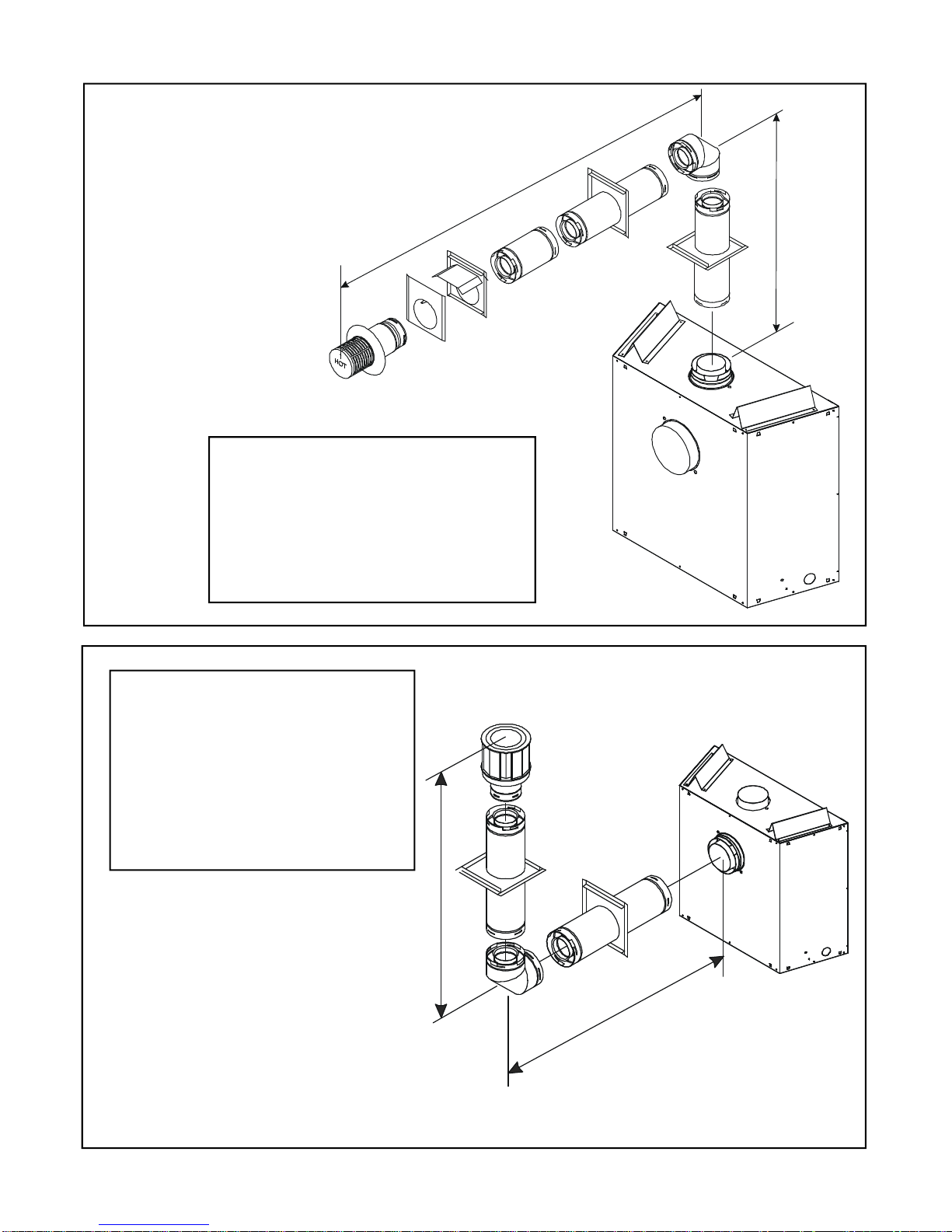

TABLE 1

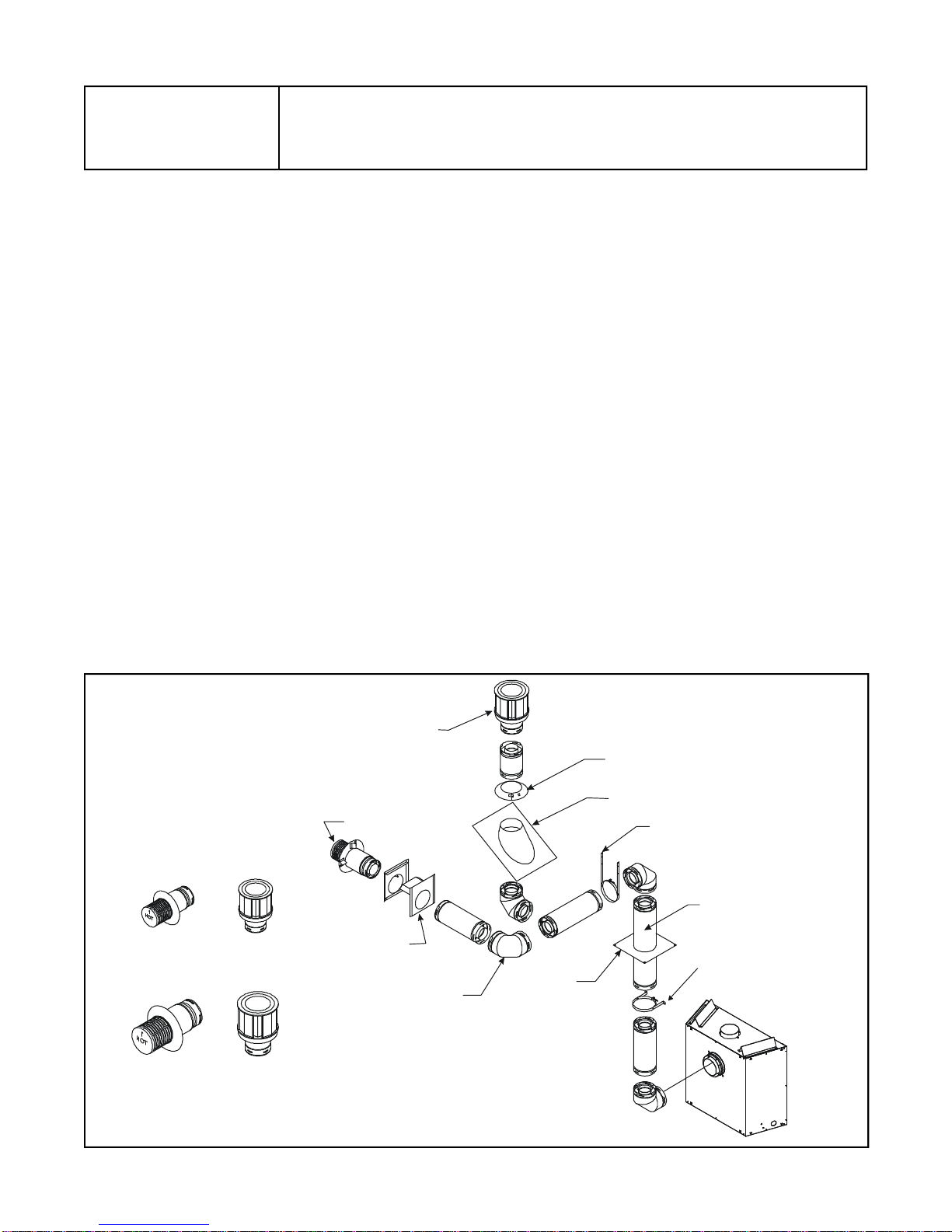

TERMINATION

WALL FIRESTOP

ROOF FLASHING

HORIZONTAL PIPE

MODEL

SL-550TRS-AUC

DVK-01DA & SLK-01DA HORIZONTAL TERMINATION CAP

DVK-TVCD & SLK-991DA VERTICAL TERMINATION CAP

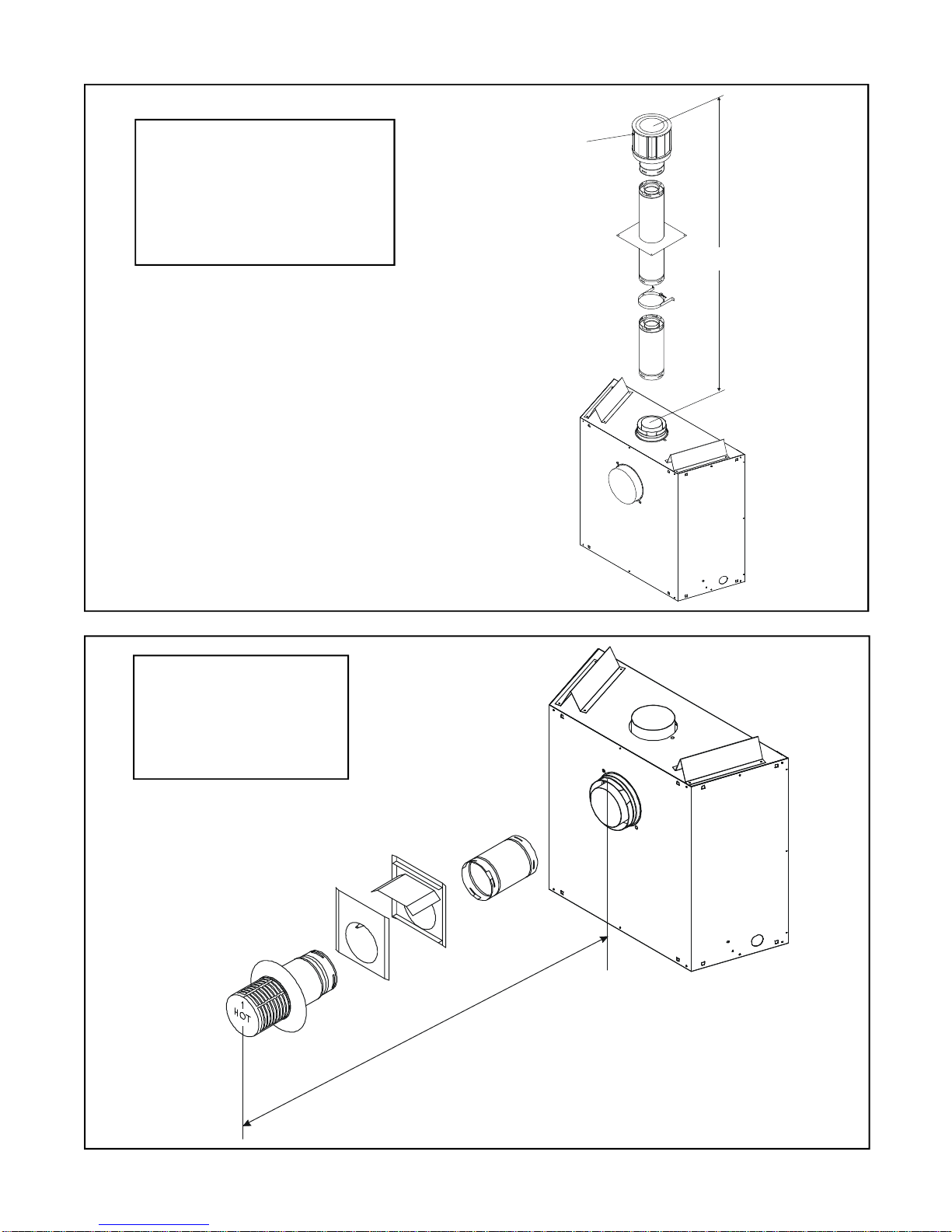

1.2 FLUE SYSTEM APPROVALS

These models have flue starting collars on both the top

and the back of the unit. Depending upon the installation, decide which ONE set of starting collars will be

used to attach the flue system. The starting collar sealing

cap must remain on the starting collar NOT used.

These models use SL-D-series direct flue components

when using the TOP flue collars and D-series direct

flue components when using the REAR flue collars.

WARNING: YOU MUST NOT MIX D-SERIES AND

SL D-SERIES COMPONENTS IN ANY FLUE

SYSTEM CONFIGURA TION.

Approved flue system components are labeled for

identification. NO OTHER FLUEING SYSTEMS OR

COMPONENTS MAY BE USED. Detailed installation

instructions are included with each flue termination kit

and should be used in conjunction with this manual. Figure

5 below shows flue system components and terminations.

Identifying Flue Components

The flue systems installed on this gas fireplace may

include one, two, or three 90° elbow assemblies. The

relationships of vertical rise to horizontal run in flue

configurations using 90° elbows MUST BE strictly

FLUE TERMINATION APPROVALS

adhered to. The rise to run relationships are shown in

the flueing drawings and tables on the next few pages.

If a 90° elbow is first attached to the unit, the maximum

horizontal run is 2 feet (610mm).

WARNING: THIS GAS APPLIANCE AND FLUE AS-

SEMBLY MUST FLUE DIRECTL Y TO THE OUTSIDE

AND MUST NEVER BE ATTACHED TO A CHIMNEY

SERVING A SEP ARATE SOLID FUEL BURNING APPLIANCE. EACH GAS APPLIANCE MUST USE A

SEPARATE FLUE SYSTEM-COMMON FLUE SYSTEMS ARE PROHIBITED.

CAUTION: UNDER NO CONDITION SHOULD

COMBUSTIBLE MATERIAL BE CLOSER THAN 3

INCHES (2 1/2 INCHES (64MM) AT WALL FIRESTOPS) FROM THE TOP OF THE PIPE OR 1-INCH

TO THE SIDES AND THE BOTTOM FOR HORIZONTAL

SECTIONS OF THIS FLUE SYSTEM. VERTICAL

SECTIONS OF THIS SYSTEM REQUIRE A MINIMUM OF 1-INCH (25MM) CLEARANCE TO COMBUSTIBLE MATERIALS ALL AROUND THE PIPE.

For alternative installations, other than depicted, contact your dealer for further information.

Refer to Figure 4 for required clearances to flue terminals.

VERTICAL

TERMINATION

HORIZONTAL

Flue system termination kits

D-SERIES

DVK-01D

SL D-SERIES

SLK-01DA

DVK-TVCD

SLK-991DA

FIGURE 5 Flue Components and Terminations

90 DEGREE

ELBOW

CEILING

FIRESTOP

Flue system components

STORM COLLAR

SUPPORT

PIPE LENGTH

WALL BRACKET

8

¾

”

m

)

5 ¾”

(146mm)

DV-90

D

(18

8 ½

2

16mm)11 5/8(295mm

)

/8 (219mm

)

1

5/16 (303mm

)

7 3

7

m

/

D

8

m

V-4

6 5/3

2

(

156

m

m

)

(

5 7

/

(14

8

9

m

m

)

)

8 5

11

8

D

DV-

3

6

D

DV-12D

4

7

(

1

¾”

.2m

)

(

908

35

m

DV-09D

11 ¾”

(298mm)

8 ¾”

DV-06D

(222mm)

NOTE: PIPES OVERLAP 1 3/8 INCHES (35MM) AT EACH JOINT.

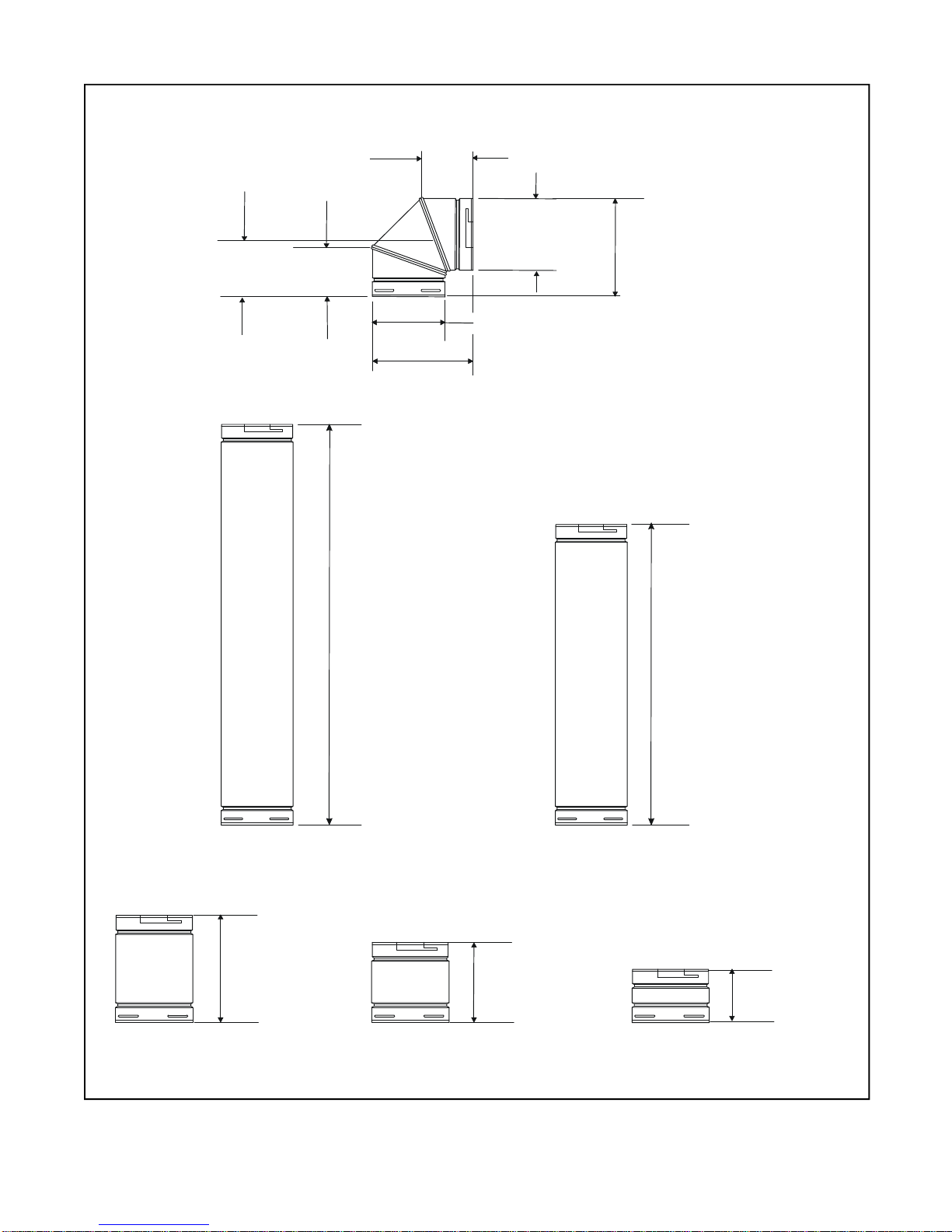

FIGURE 6 D-Series Balanced Flue Component Specifications

(5-inch (127mm) inner pipe / 8 5/8-inch (219mm) outer pipe)

9

6 ½

SL-17/24D

(432-610mm)

SL-12/17D

(165mm)

6 3/8

(162mm)

6 5/8

(168mm)

6 3/8

(162mm)

SL-90D

6 ½

(165mm)

9 5/8

(244mm)

9 5/8

(244mm)

5 ¾

(146mm)

(222mm)

8 ¾

SL-06D

6 5/8

(168mm)

(305-432mm)

12-17

11 ¾

(298mm)

(603mm)

23 ¾

SL-12D

35 ¾

(908mm)

17-24

47 ¾

(1213mm)

SL-09D

NOTE: PIPES OVERLAP 1 3/8 INCHES (35mm) AT EACH JOINT.

FIGURE 7 SL D-Series Balanced Flue Component Specifications

(4-inch (102mm) inner pipe / 6 5/8-inch (168mm) outer pipe)

SL-24D SL-36D SL-48D

10

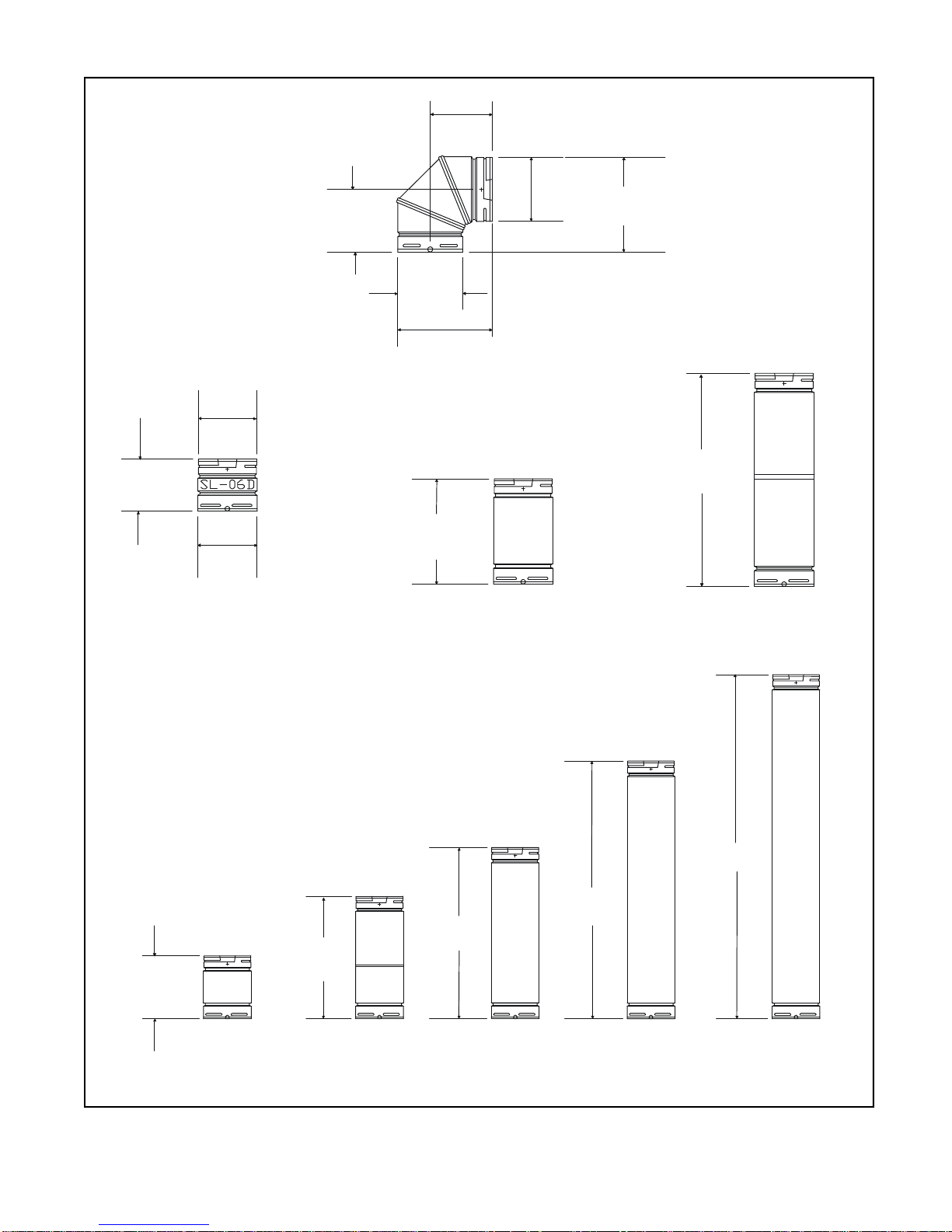

FIGURE 8

V

VERTICAL FLUEING

V

FT. (M)

30' MAXIMUM (9.1M)

USE SL D-SERIES COMPONENTS ONL Y.

CAP

STRAIGHT OUT HORIZONTAL

FLUEING

H

Max. Run

24" (610mm)

H

USE D-SERIES COMPONENTS ONL Y.

FIGURE 9

11

USE SL D-SERIES

H

V

COMPONENTS

ONL Y.

FLUEING WITH ONE (1) 90° ELBOW

V H

FT. (M) FT. (M)

1' MIN.(.3M) 2' MAX.(.6M)

2' MIN.(.6M) 4' MAX.(1.2M)

3' MIN.(.9M) 8' MAX.(2.4M)

4' MIN.(1.2M) 10' MAX.(3M)

V + H = 30' (9.1M)

FIGURE 10

FLUEING WITH ONE (1) 90o ELBOW

V (FT.) H (FT.)

1' MIN. (.3M) 3' MAX. (.9M)

2' MIN. (.6M) 6' MAX. (1.8M)

3' MIN. (.9M) 9' MAX. (2.7M)

4' MIN. (1.2M) 12' MAX. (3.7M)

V+H =30' MAX. (9.1M) H= 12' MAX. (3.7M)

USE D-SERIES

COMPONENTS

ONL Y.

FIGURE 11

V

H

12

Loading...

Loading...