Heat-N-Glo ATS-AUST Installation And Operation Instruction Manual

INSTALLATION AND OPERATION

INSTRUCTIONS

MODEL: ATS-AUST

AUSTRALIAN GAS ASSOCIATION APPROVED

AGA Approval Number 5543

THIS MANUAL MUST BE USED FOR INSTALLATION AND RETAINED

BY HOMEOWNER FOR OPERATION AND MAINTENANCE.

HEAT-N-GLO, a division of Hearth Technologies Inc.

6665 W. Hwy 13 Savage, MN 55378, USA (612)890-8367

This product is covered by one or more of the following patents: (United States) 4,112,913; 4,408,594; 4,422,426; 4,424,792; 4,520,791; 4,793,322;

4,852,548; 4,875,464; 5,000,162; 5,016,609; 5,076,254 5,191,877; 5,218,953; 5,328,356; 5,429,495; 5,452,708; 5,542,407; 5,613,487; (Australia) 543790;

586383; (Canada) 1,123,296; 1,297,746; 2,195,264; (Mexico) 97-0457; (New Zealand) 200265; or other U.S. and foreign patents pending.

491-900-C 1/99

INSTALLATION AND OPERATION INSTRUCTIONS

PLEASE READ THIS MANUAL BEFORE INSTALLING AND USING THIS

APPLIANCE.

MODEL ATS-AUST IS AUSTRALIAN GAS ASSOCIATION APPROVED FOR

NATURAL GAS OR PROPANE AS A BALANCED FLUE HEATER.

Refer to the appliance data plates for gas consumptions and pressures.

Installation of this appliance should only be carried out by an authorized person

in accordance with the manufacturers instructions. All relevant codes and regulations laid down by the gas piping authorities, municipal building regulations,

electrical wiring regulations and the requirements of the AGA Gas Installation

Code must be observed.

This appliance and it's components are tested and safe when installed in accordance with this Installation Manual. Report to your dealer any parts damaged in

shipment, specifically check glass condition. The gas logs and flue system components are in separate packages. Read all instructions before starting installation and follow these instructions carefully during installation to ensure maximum benefit and safety . Failure to follow them will void your warranty and may

present a fire hazard.

The Heat-N-Glo Fireplace Products, Inc. warranty will be voided by , and Heat-NGlo Fireplace Products, Inc. disclaims any responsibility for the following actions:

• Installation of any damaged heater or flue system component

• Modification of the heater or balanced flue system Installation other than as

instructed by Heat-N-Glo Fireplace Products, Inc.

• Improper positioning of the gas logs or the glass door

• Installation and/or use of any component part not manufactured or approved by Heat-N-Glo Fireplace Products, Inc., not withstanding any independent testing laboratory or other party approval of such component part

or accessory.

IMPORTANT: Read all instructions carefully before starting installation. Failure to follow these instal-

lation instructions may result in a possible fire hazard and will void the warranty .

Save this Manual for future reference.

Copyright 1999, Heat-N-Glo Fireplace Products, Inc., 6665 W. Hwy 13, Savage, MN 55378 Printed in U.S.A.

1

TABLE OF CONTENTS

1.0 Installation Instructions.................................................................................... 7

1.1 Introduction............................................................................................... 7

1.2 Flue System ............................................................................................. 7

1.2.1 Flue System Approvals................................................................... 7

1.2.2 Connecting the Flue Pipe ............................................................... 8

1.3 Connecting the Gas Supply...................................................................... 8

1.4 Fan ........................................................................................................... 9

1.5 Surround Installation................................................................................. 9

1.6 Finishing ................................................................................................. 11

1.7 Log Installation ....................................................................................... 11

1.8 Installer Testing....................................................................................... 11

2.0 Operating Instructions ................................................................................... 12

2.1 Safety and Lighting Information .............................................................. 13

2.2 Safety Information................................................................................... 13

2.3 Lighting Instructions................................................................................ 14

2.4 Fan Operation......................................................................................... 15

3.0 Servicing and Maintenance........................................................................... 15

3.1 Removal of Covers for Servicing ............................................................ 16

3.2 Removal of Components for Service ...................................................... 16

3.3 Parts Replacement ................................................................................. 16

3.4 Adjustments and Replacement Parts ..................................................... 16

3.5 Troubleshooting...................................................................................... 17

4.0 Replacement Parts........................................................................................ 21

Limited Warranty............................................................................................ 24

2

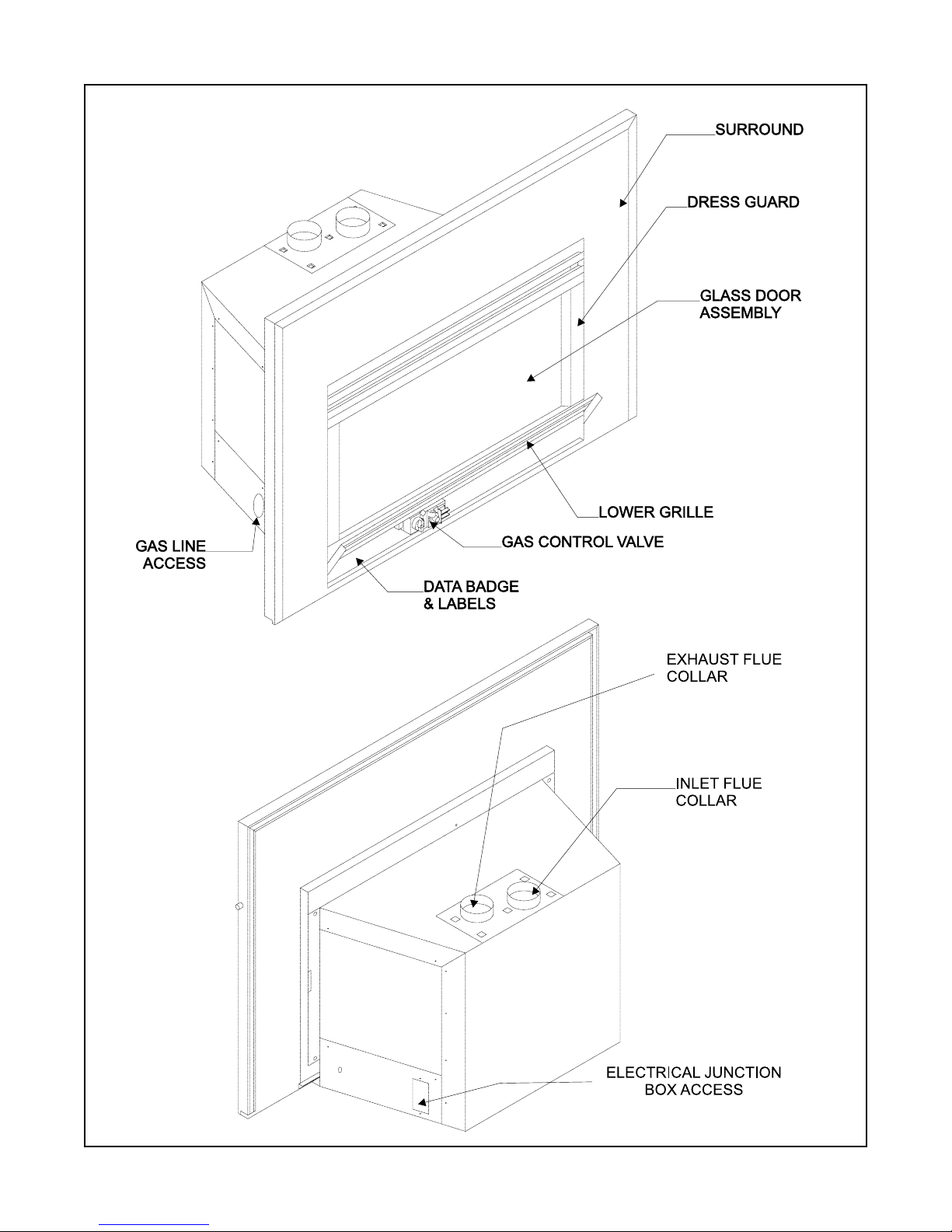

FIGURE 1

3

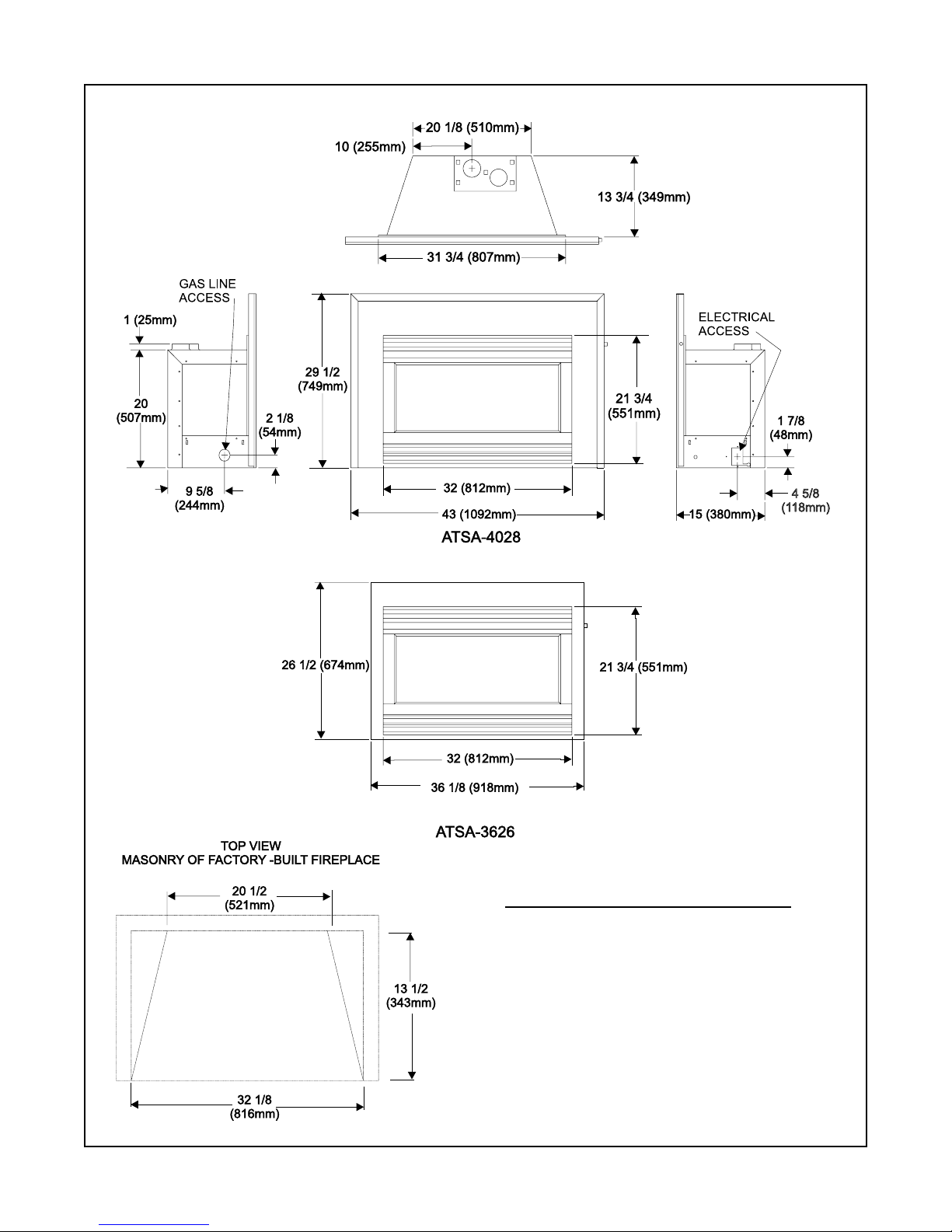

MINIMUM FIREPLACE OPENING

WIDTH: 32 1/8" (816mm)

DEPTH: 13 1/2" (343mm)

HEIGHT : 20 1/2" (521mm)

NOTE: If exhaust collar on insert and fireplace

damper do not line up, add 4 inches (102mm) to

minimum fireplace opening height to accommodate

bends in vent pipe.

FIGURE 2

4

MODEL FLUE TERMINATION APPROVAL

ATS-AUST SLK-991DA VERTICAL TERMINATION CAP

TABLE 1

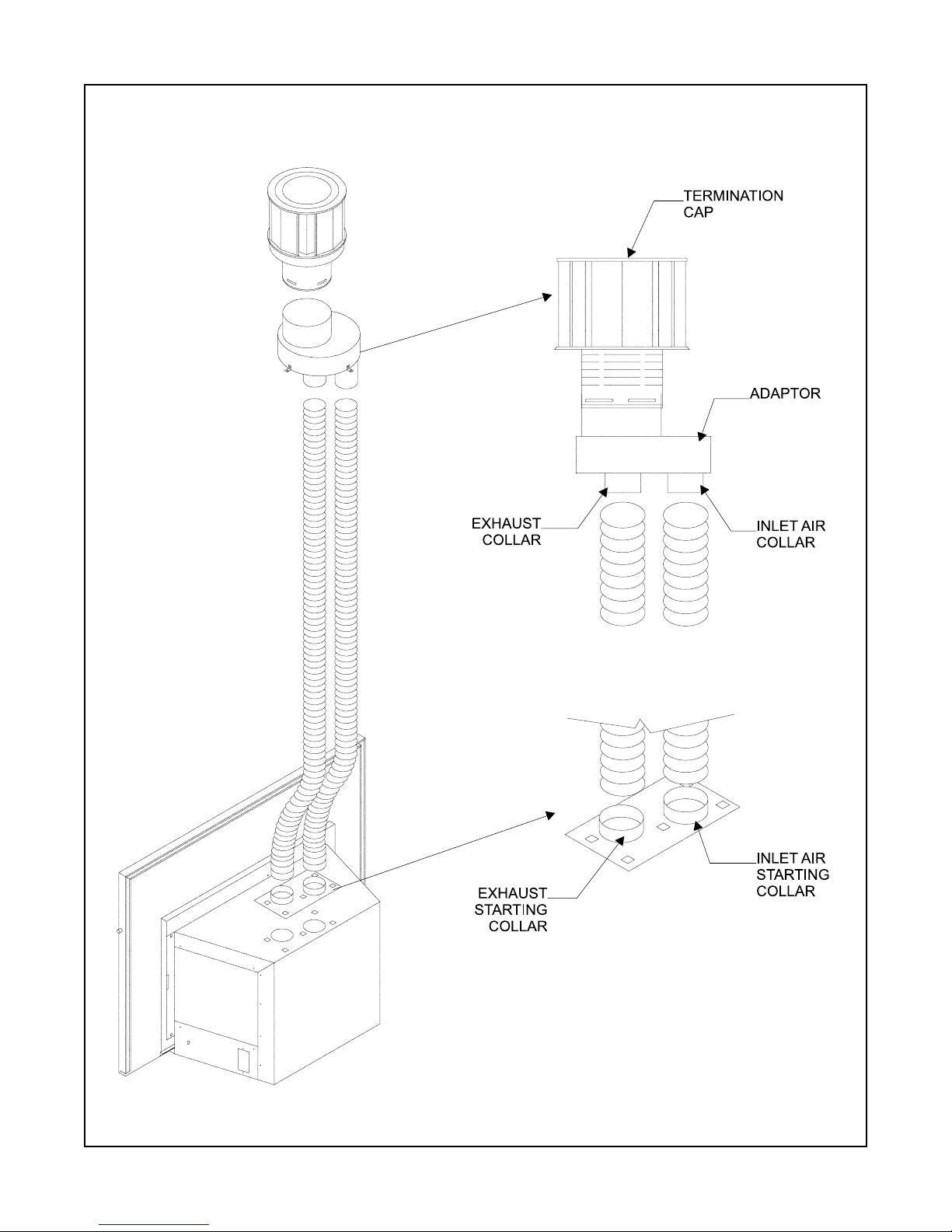

WARNING: THE EXHAUST PIPE

MUST ONL Y BE CONNECTED TO THE

EXHAUST STARTING COLLAR OF

THE UNIT AND THE CENTER COLLAR

OF THE TERMINA TION CAP .

THE INLET AIR PIPE MUST ONL Y BE

CONNECTED TO THE INLET AIR

COLLAR OF THE UNIT AND A TT ACHED

TO THE INLET AIR COLLAR OF THE

TERMINA TION CAP .

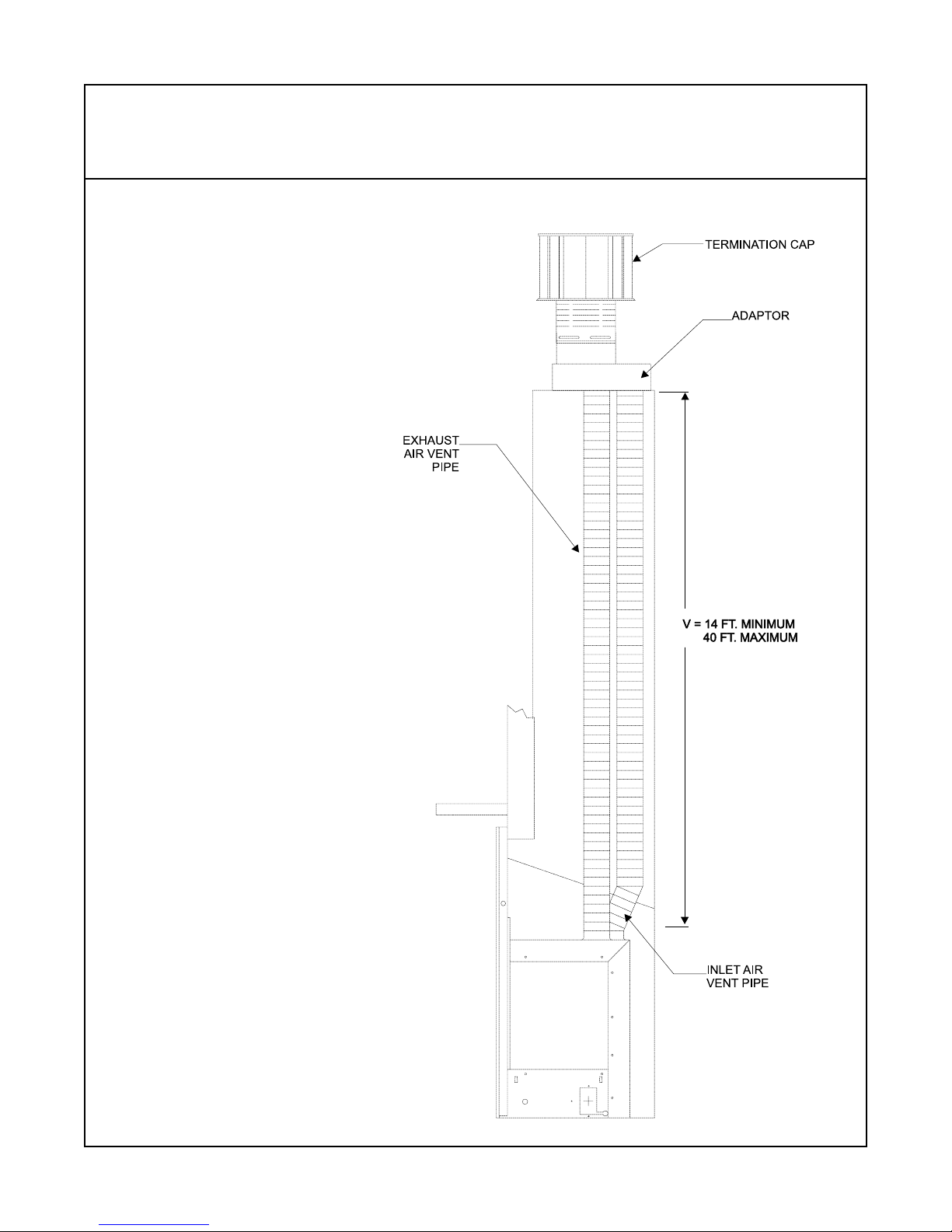

FIGURE 3

5

FIGURE 4

FIGURE 5

6

1.1 INTRODUCTION

This model is designed to operate with all combustion

air being siphoned from the outside of the building and

all exhaust gases expelled to the outside of the building. This model is designed to be installed in a masonry fireplace or factory built fireplace. These units

CANNOT be recessed inside combustible construction.

Minimum dimensions of the masonry or factory-built

fireplace into which these models can be installed, are

32 1/8-inches (816mm) width x 13 1/2 -inches (343mm)

depth x 20 1/2 inches (521mm) height.

WARNING: THIS UNIT IS NOT FOR USE WITH SOLID

FUEL.

WARNING: THIS GAS FIREPLACE AND FLUE

ASSEMBLY MUST BE FLUED DIRECTLY TO THE

OUTSIDE AND MUST NEVER BE ATTACHED TO A

CHIMNEY SERVING A SEPARATE SOLID FUEL

BURNING APPLIANCE. EACH GAS APPLIANCE

MUST USE A SEPARATE FLUE SYSTEM.

CAUTION: Prior to connecting the flue system to

the unit, read sections:

1.3 Connecting the Gas Supply

1.4 Accessory Fan

1.2 FLUE SYSTEM

These units MUST use the flue termination described

in the flueing section of the manual.

The control system for these model are a millivolt type.

It consists of a gas control valve/variable regulator, a

standing pilot/thermopile/thermocouple, a piezo ignitor,

and an ON/OFF switch. The controls are located behind the lower grille. Access to the controls is gained

by rotating the grille up. ON/OFF switch is located on

the front surround. See Figure 1.

Minimum inlet gas supply pressure for purpose of input

adjustment is 4.5 inches w.c. (1.13kPa) for natural gas

and 11 inches w.c. (2.75kPa) for propane. Manifold

(outlet) pressures should be set at 3.2 inches w.c.

(.80kPa) for natural gas models and 9.6 inches w.c.

(2.40kPa) for propane models.

In planning the installation for the insert it is necessary

to determine where the unit is to be installed, and

whether optional accessories (wall switch, thermostat,

or remote control) are desired. Gas supply piping

should also be planned. Model ATS-AUST has a factory installed fan.

This model is designed to be installed in a masonry or

factory-built fireplace. The separate 3-inch (76mm) combustion air and exhaust pipes must be run up through

the chimney and terminated vertically. Horizontal flue

terminations MUST NOT be done.

Before starting installation of flue kits, the installer should

read the Gas Fireplace Instructions and the Flue Kit

Instructions to ensure that a proper flue installation is

completed.

Consult your local Building Codes before beginning the

installation.

1.2.1 FLUE SYSTEM APPROVALS

T able 1 and Figures 3-5 show the flue termination caps

and systems approved for use with these models. Approved flue system terminations are labeled for identification. 3-inch (76mm) diameter listed flexible aluminum or stainless steel gas flue is used for both the

incoming combustion air and exhaust flue pipes. NO

OTHER FLUEING SYSTEMS OR COMPONENTS MA Y

BE USED. Detailed installation instructions are included

with each flue termination kit and should be used in

conjunction with this manual.

HORIZONTAL FLUEING

The flue system on this model CANNOT be terminated

horizontally .

VERTICAL FLUEING

The flue pipes MUST be connected to the proper collars on the unit AND the exhaust flue pipe MUST be

connected to the termination cap or the unit will not

operate. The combustion air flue pipe MUST be connected to the termination cap.

NOTE: The minimum vertical rise (exhaust flue) is

14 feet (3.5M) and the maximum vertical rise is 40 feet

(10M). These dimensions are measured from the starting collars of the unit to the end of the last section of

flue pipe (See dimension V in Figure 3).

A vertical flue termination system installed on this

model will include one (1) length of 3-inch (76mm)

flexible flue pipe for the combustion air, one (1) length

of 3-inch (76mm) flexible flue pipe for the exhaust, one

(1) pipe-to-cap adaptor , and one (1) SLK-991DA V ertical T ermination Kit.

7

Loading...

Loading...