Heatmor 200X, 350X, X Operation And Maintenance Manual

When these safety symbols appear on the following pages, they will alert

you to the possibility of serious injury if you do not comply with the corresponding instructions. The hazard may originate from something mechanical or electrical shock. Please read the instructions carefully.

When you see this safety symbol on the following pages, it will alert you

to the possibility of damage to your HEATMOR™ Stainless Steel Outdoor

Furnace if you do not comply with the corresponding instructions. Please

read the instructions carefully.

The HEATMOR™ Stainless Steel Outdoor Furnace is certied to offer safe

service provided it is installed, operated and maintained in accordance with

the instructions contained in this manual.

Proper personal protective equipment (PPE) MUST BE WORN AT ALL

TIMES when servicing and maintaining any of the HEATMOR™ Stainless

Steel Outdoor Furnace product line.

This manual describes the installation and operation of the HEATMOR™

200X and the HEATMOR™ 350X cataytic equipped wood heater. These

heaters meet the 2015 U.S. Environmental Protection Agency’s crib wood

emission limits for wood heaters sold after May 15, 2015. Under specic

test conditions the 200X can output 54,019 Bru/hr. Under specic test con-

ditions the 350X catalytic equipped wood heater can output 89,753 Bru/hr.

This wood heater has a manufacturer-set burn rate that must not be altered.

It is against federal regulations to alter this setting or otherwise operate

this wood heater in a manner inconsistent with operating instructions in

this manual.

The 350X contains a catalytic combustor, which needs periodic inspection

and replacement for proper operation. It is against federal regulations to

operate this wood heater in a manner inconsistent with operating instructions in this manual, or if the catalytic element is deactivated or removed.

ii

TABLE OF CONTENTS Page #

I NOTICE TO THE READER 1

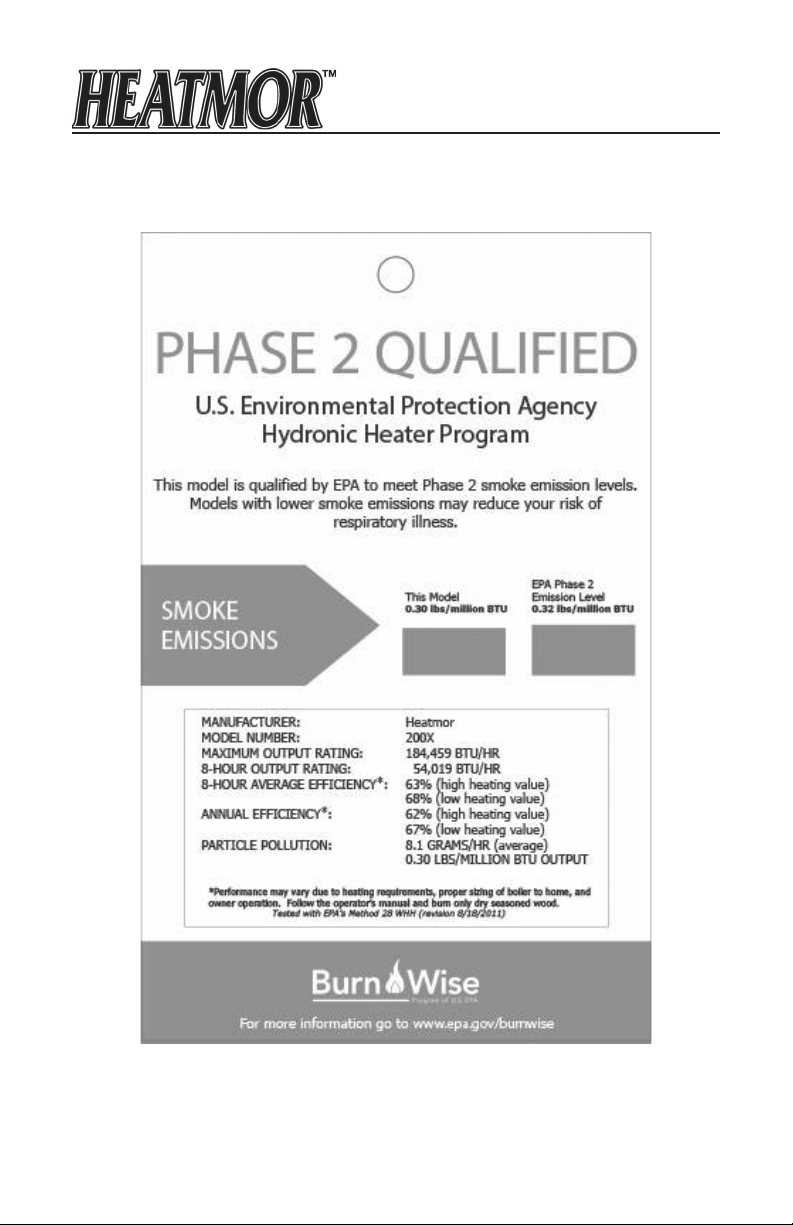

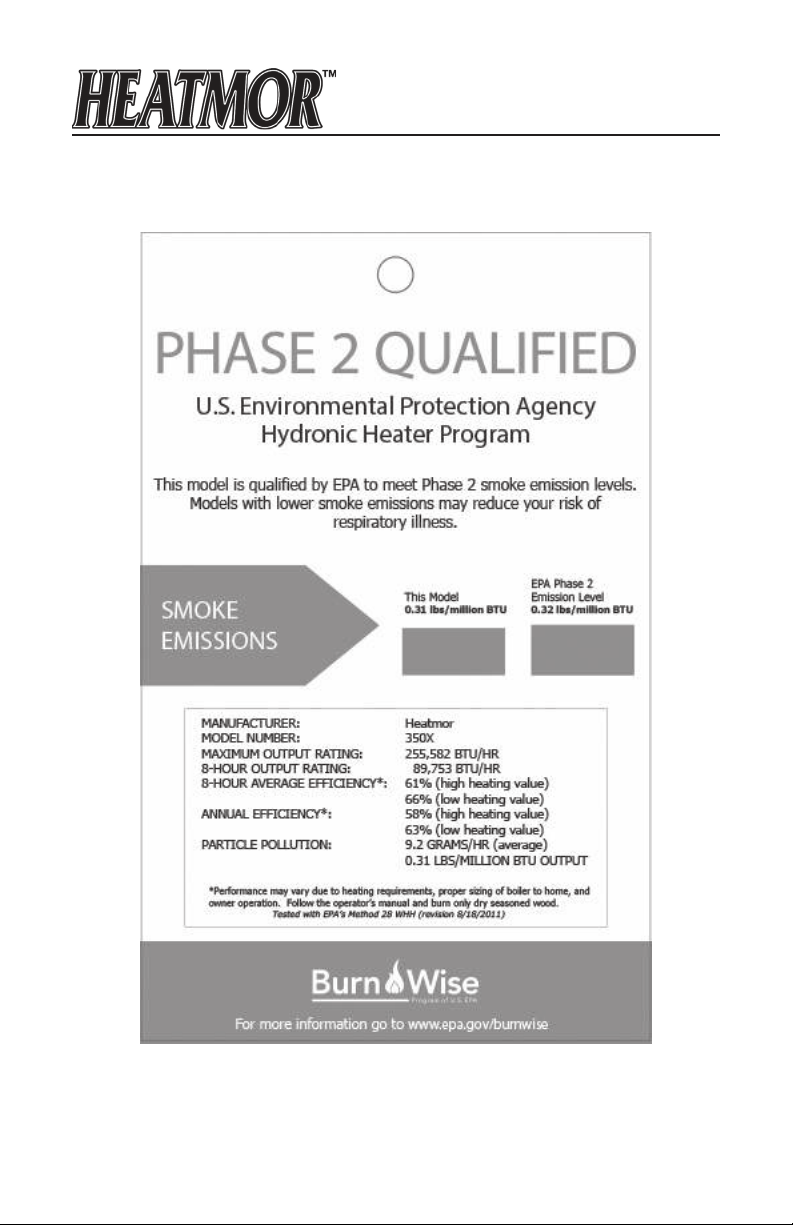

II EPA PHASE HANGTAG X-SERIES 2-3

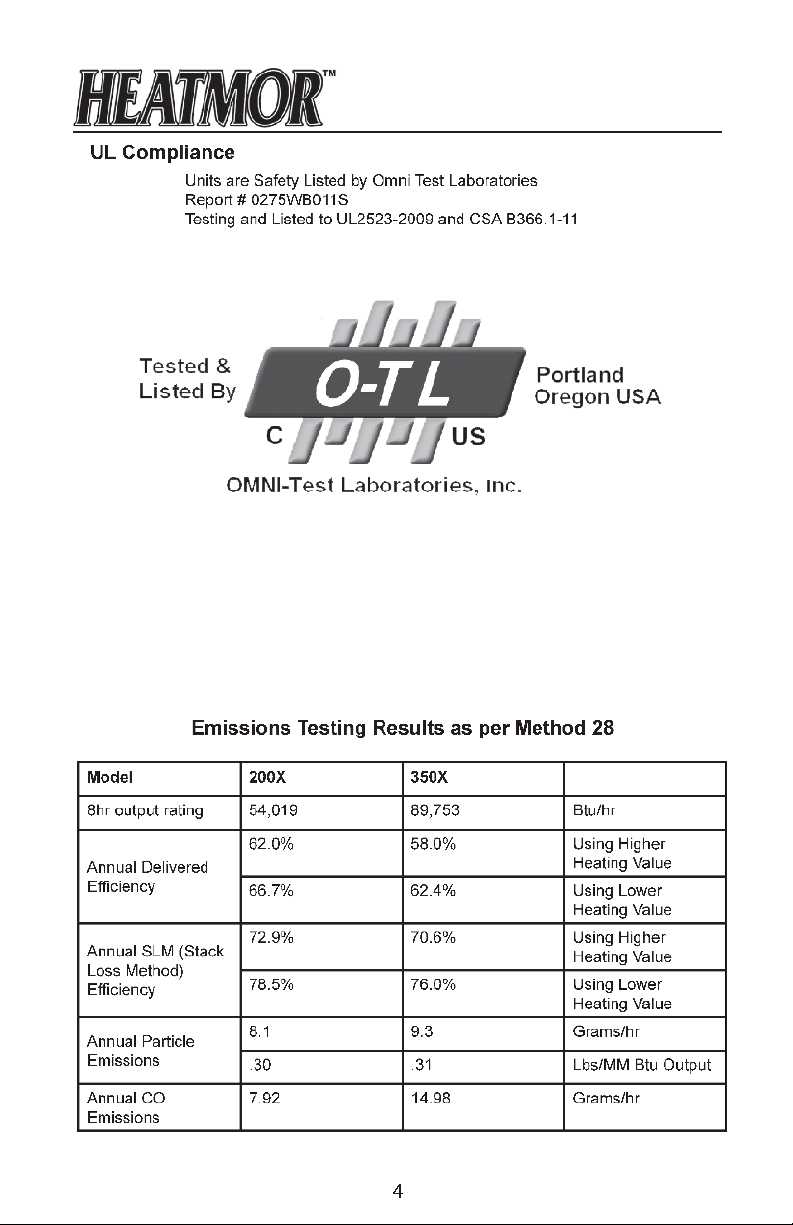

III UL COMPLIANCE & EMISSIONS TESTING RESULTS 4

1 HEATMOR™ X-SERIES OUTDOOR FURNACE MODEL 5

FURNACE SPECIFICATIONS 6

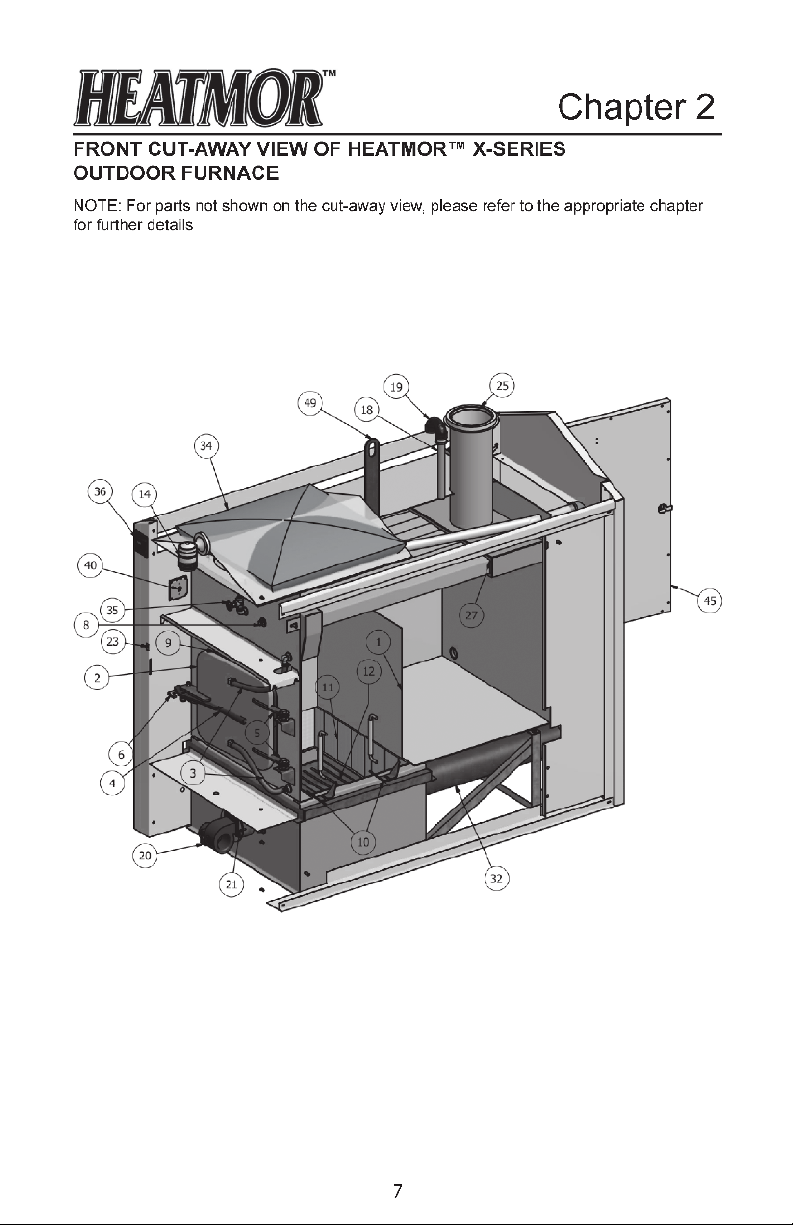

2 FRONT CUT AWAY VIEW OF HEATMOR™ X-SERIES FURNACE 7

FURNACE PARTS LIST 8

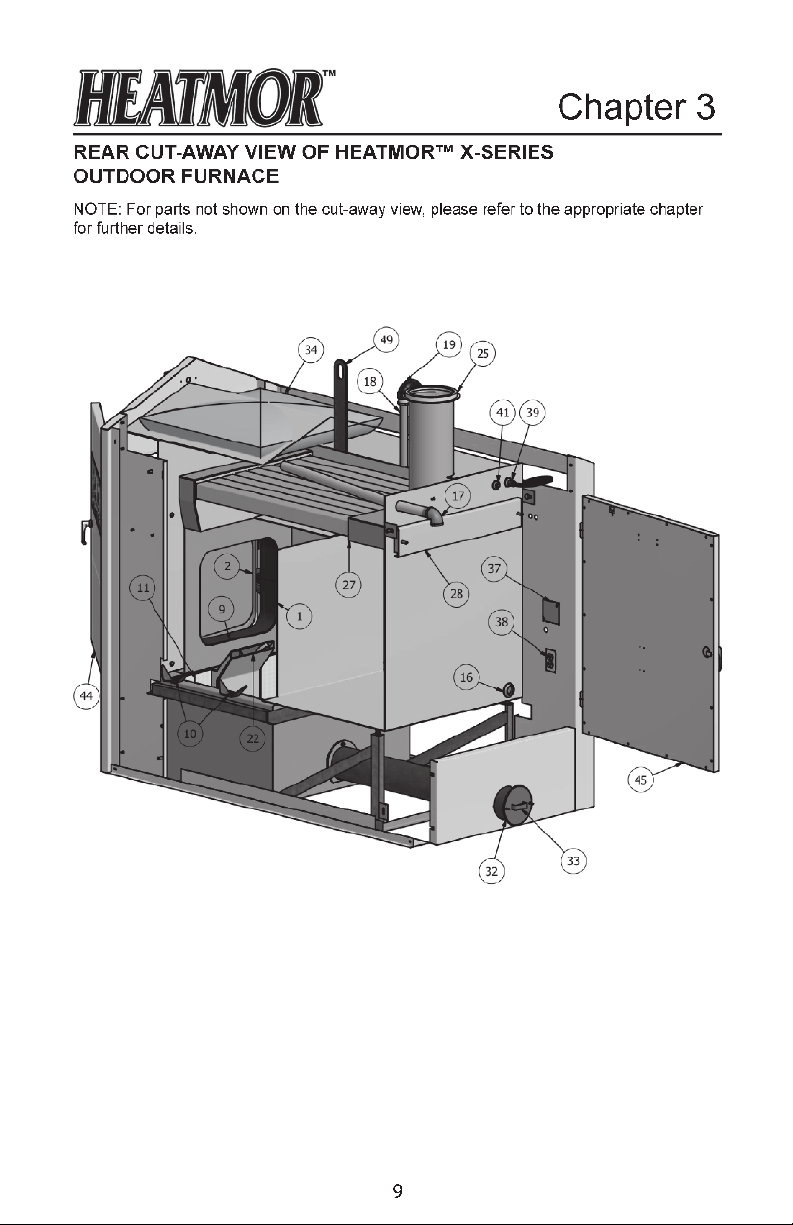

3 REAR CUT AWAY VIEW OF HEATMOR™ X-SERIES FURNACE 9

FURNACE PARTS LIST 10

4 MINIMUM CLEARANCE SEPARATION SPECIFICATIONS 11

5 WARNINGS AND PRECAUTIONS 12

A Installation 12

B Electrical 13

C Other 13

6 CONCRETE PAD SPECIFICATIONS 14

7 INSTALLATION OF THE HEATMOR™ FURNACE 15

A Equipment Required 15

B Placing the HEATMOR™ on the Concrete Pad 15

C Caulking Around the Firebox Base 15

D Caulking Around the Outside Perimeter of HEATMOR™ 15

E Filling the HEATMOR™ Outdoor Furnace Initially with Water 16

F Maintaining Water in the Bladder and in the HEATMOR™ 17

G Initial Installation of Sand 18

i. Types of sand to use

ii. Installation 19

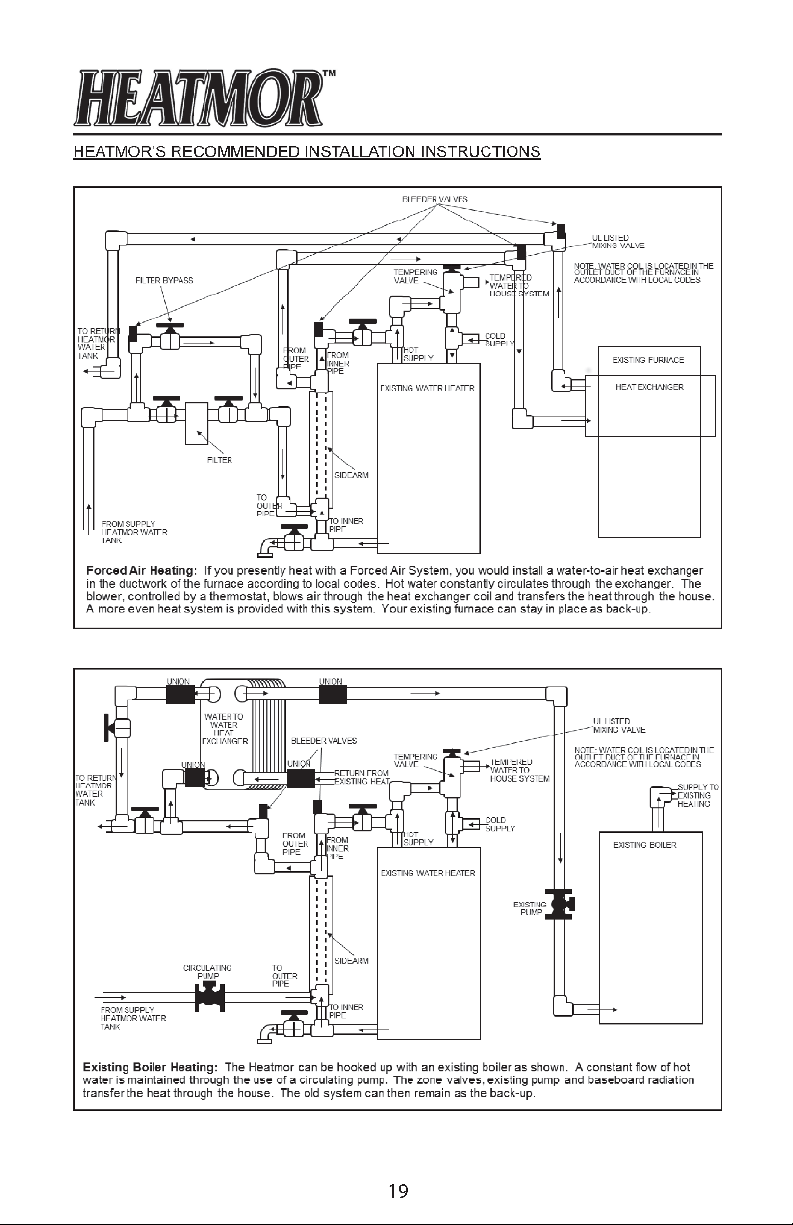

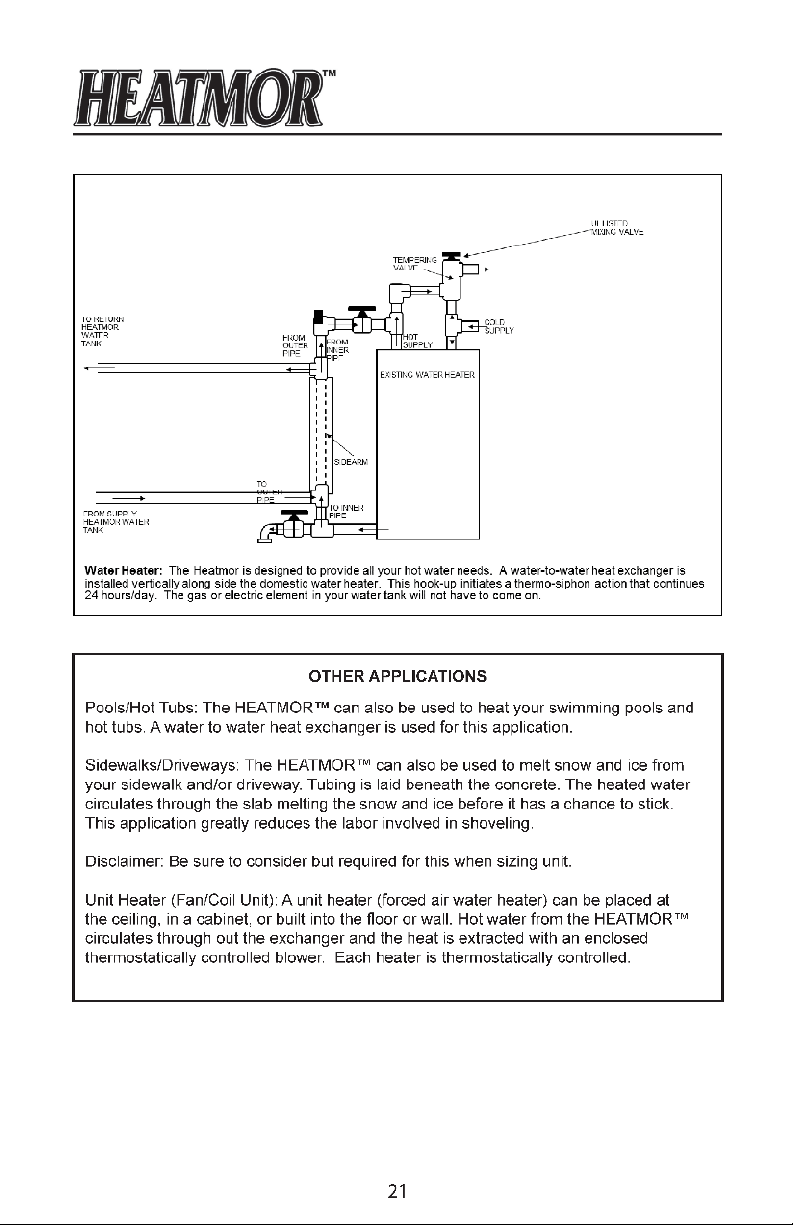

H HEATMOR™'s recommended Installation Instructions diagrams 19-21

8 SAFE OPERATING GUIDELINES 22

A Operation 22-23

B Lighting Your HEATMOR™ for the First Time 24

C Dew Point 25

D Loading Wood into the HEATMOR™ 26

E What should I burn? 27

F How does a fire burn out? 28

G Types of Wood 28

H Wood as a Fuel 28

I Stages of Combustion 29

J Efficiency Measurements 30

K Loading of the Furnace 30

L Handling and Storage of Wood 31

iii

9 WATER 32

A Qualities of Water to Use 32

B Water Level Maintenance 32

C Removal/Replacement of System Water 32

D Water Additives 33

E Water Treatment Additives and Safety Specifications 34

F Freeze Protection 35

G Adding Freeze Protection Products 36

10 BLADDER ASSEMBLY 37

A Bladder 37

B Removal and Replacement of the Bladder 38

C Bladder Gate Valve and Bladder Hose 38

D Water Level Switch 39

11 WATER JACKET 40

A Water Jacket 40

B Supply Line and Return Line Connectors 40

C Relief Vent Pipe and Pop-off Ball 40

12 FIREBOX AND OTHER COMPONENTS 41

A Firebox 41

B Firebox Door 42

C Firebox Door Hoses and Elbows 44

D Firebox Door Handle 45

E Firebox Door Hinge 45

F Firebox Door Latch 46

G Firebox Door Holder 46

H Firebox Door Gasket 46

I Firebox Door Frame 47

J Firebox / Base Connector Clamps 48

K Fire-brick 48

L Standard Grates 48

M Sand 49

i. Types of sand to use 49

ii. Installation 49

13 AIR SUPPLY 50

A Combustion Air Blower and Flipper Assembly 50

i. Operation of the Combustion Air Blower and Flipper Assembly 50

ii. Steps to Maintain your Blower / Flipper Assembly 51

B Air Box(s) 52

C Automatic Fan Switch (A.F.S.) 53

14 CHIMNEY AND TOP FLUE 54

A Chimney 54

B Chimney Extension(s) 54

iv

C Flue 55

D Flue Cover 55

E Flue Scraper 55

15 ASHES 56

A Ash Management and Ash Removal 56

B Ash Pan 57

C Ash Auger 57

D Ash Auger Tube 58

E Ash Auger Tube Cover Plate 58

F Creosote 58

16 ELECTRICAL 59

A Electrical Supply 59

B Electrical Supply Junction Box 59

C Double Electrical Outlets at rear 59

D Electronic Aquastat Controller 60

E Temperature Probe 61

F High Water Temperature Safety Shutoff Control 62

G Front Light and Fan Power Switch 63

17 EXTERIOR CLADDING AND INSULATION 64

A Outer Door of HEATMOR™ 64

B Roof of the HEATMOR™ 64

C Sides of the HEATMOR™ 65

D Insulation 65

18 AIR LEAKS 66

A Checking For Air Leaks 66

B Why do we not want any air leaks? 66

19 DOMESTIC COIL (OPTIONAL) 67

20 CATALYTIC CONVERTER (350X) 68

A Operation/Maintenance 68

B Removal 69

C Cleaning 70

21 SEASON START UP & MAINTENANCE 71

22 END OF SEASON & SHUT-DOWN MAINTENANCE 72

23 FREQUENTLY ASKED QUESTIONS 74

24 TROUBLESHOOTING AND SOLUTIONS 76-82

HEATMOR™ STAINLESS STEEL LIMITED WARRANTY 83

HEATMOR™ FOR LIFE 84

NOTES 86

v

Notice to the Reader

HEATMOR™ Inc. warrants and guarantees ALL HEATMOR™ Stainless Steel Outdoor

Furnace Models. HEATMOR™ Inc. does not warrant or guarantee any of the supporting

products described within this Operations and Maintenance Manual.

The contents, descriptions, directions, diagrams, and recommendations within this material

are for the sole purpose of suggested operation and maintenance methods.

Furthermore, HEATMOR™ Inc. shall not be liable for any special, consequential, or exemplary damages, resulting, in whole or part, from the readers’ neglectful use, based upon the

material within this Operations and Maintenance Manual. Adhere to and follow all maintenance procedures set forth in this manual.

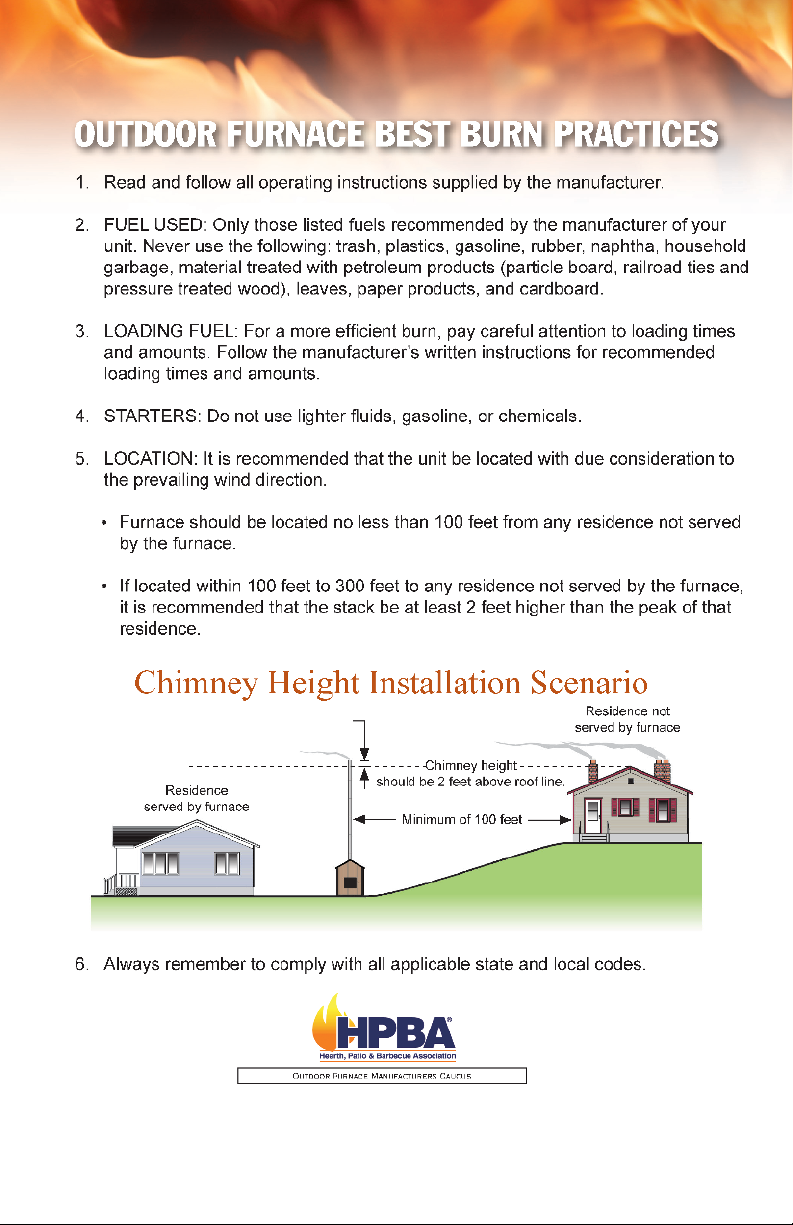

Person(s) operating an OWHH is/are responsible for operation in a manner that does

not create a public or private nuisance condition. Meeting the distance and stack height

recommendations from the manufacturer and requirements in applicable state and local

regulations may not always be adequate to prevent nuisance conditions in some areas due

to terrain or other factors.

The methods of operation described within this Operations and Maintenance Manual have

proven to be effective for HEATMOR™ Inc. for the sole purpose of the operation of a

HEATMOR™ Stainless Steel Outdoor Furnace.

All formulas and gures listed within this Operations and Maintenance Manual are approximated and should be read as such.

For additional copies or information contact

Phone: (218) 386-2769 | Fax: (218) 386-2947

Copyright © 2014 - HEATMOR™ INC

All rights reserved. No part of this Operations and Maintenance Manual may be reproduced

or used in any form or by any means - graphic, electronic or mechanical, including photocopying, recording, taping, or information storage and retrieval systems - without the written

permission of HEATMOR™ Inc.

HEATMOR™ Inc.

105 Industrial Park Court NE

P.O. Box 787

Warroad, MN 56763

E-mail: woodheat@heatmor.com

www.heatmor.com

1

EPA PHASE 2 HANGTAG X-SERIES

2

EPA PHASE 2 HANGTAG X-SERIES

3

Chapter 1

HEATMOR™ X-SERIES OUTDOOR FURNACE MODEL

Model 200X, 350X

5

RESIDENTIAL FURNACE SPECIFICATIONS

Specications Model 200X Model 350X

Overall Width

Base Width (Footprint)

50" 50"

46.5" 46.5"

Overall Height

Overall Length

Base Length (Footprint)

Total Weight (lbs, without water)

Water Capacity (U.S. gallons)

Forced Draft (C.F.M.)

Chimney Size

Maximum Wood Length

Insulated Heating Area*

1 Loading/day

2 Loading/day

Firebox Width

Firebox Length

Firebox Height

Volume of Firebox (Cu. Ft.)

Firebox Door Size (W x H)

Flue Transfer Area

BTU’s (maximum)**

Water Jacket Steel

Gauge

Firebox Steel

Gauge

Base Steel

Gauge

Base of Unit to Bottom of Loading Door

Warranty - Workmanship

Warranty - Corrosion

Approvals Test Standards UL 2523-2009

Hook-ups

Type of Fuel

Electrical Supply 115 V, 60HZ, 1

*This is an estimate only. Actual loadings per day may vary depending on structures heated, type of wood used, and climate.

**This value should only be used as an indication of the furnace’s heat recovery ability. Sustained outputs at this rate will

increase the loadings per day. Some types of wood may prevent the furnace from reaching this maximum output.

82.5" 82.5"

95" 95"

83.75" 83.75"

1,835 1980

310 270

150 2 x 150

8" 8"

19" 30"

2,500 sqft

5,000 sqft

23.75" 23.75"

24" 36"

27.5" 27.5"

14 21

20"x18" 20"x18"

39.75 sqft 39.75 sqft

200,000 280,000

409 Stainless 409 Stainless

10 10

409 Stainless 409 Stainless

10 10

409 Stainless 409 Stainless

14 14

24" 24"

Limited Lifetime Limited Lifetime

Limited Lifetime Limited Lifetime

CSA-B366.1-11

Back Back

Wood Wood

Phase

4,000 sqft

8,000 sqft

UL2523-2009

CSA-B366.1-11

115 V, 60HZ, 1

Phase

6

FURNACE PARTS LIST - FRONT CUT-AWAY OF X-SERIES

Firebox

1. Firebox

2. Firebox door

3. Firebox door hoses and elbows

4. Firebox door handle

5. Firebox door hinge

6. Firebox door latch

7. Firebox door handle holder

(not shown)

8. Firebox door gasket (not shown)

9. Firebox door frame

10. Firebox / base connector clamps

11. Firebrick

12. Standard grates

13. Sand (around ash pan)

50. Firebox heat shield (not shown)

Water Jacket

15. Water jacket (surrounds rebox)

16. Supply line threaded connector

(not shown)

17. Return line threaded connector

(not shown)

18. Relief vent pipe

19. Relief elbow

Ashes

30. Ash pan (under grates #12)

31. Ash auger (not shown)

32. Ash auger tube

33. Ash auger tube cover plate

(not shown)

Bladder assembly

34. Bladder

35. Bladder gate valve and hose

Electrical

14. Front Light

36. Electronic Controller

37. Electrical supply junction box

(not shown)

38. Electrical plug outlets (not shown)

39. Water temperature high-limit

controller (aquastat) (not shown)

40. Front light and combustion air

blower control switch

41. Temperature Probe (not shown)

42. Low Water Switch

(under Bladder)

Air Supply

20. Combustion air blower

21. Flipper assembly

22. Air box (not shown)

23. Automatic Fab Switch (A.F.S.)

Chimney and Top Flue

25. Chimney

26. Chimney extension(s)

(not shown)

27. Tube ue

28. Flue cover plate (not shown)

29. Flue scraper (not shown)

Housing - (not shown)

44. Outer front door

45. Outer rear door

46. Roof

47. Sides

48. Insulation

Lift Hook

49. Lift ring

8

FURNACE PARTS LIST - REAR CUT-AWAY OF X-SERIES

Firebox

1. Firebox

2. Firebox door

3. Firebox door hoses and elbows

4. Firebox door handle (not shown)

5. Firebox door hinge (not shown)

6. Firebox door latch (not shown)

7. Firebox door handle holder (not

shown)

8. Firebox door gasket (not shown)

9. Firebox door frame

10. Firebox / base connector clamps

11. Firebrick

12. Standard grates (not shown)

13. Sand (around ash pan)

50. Firebox heat shield (not shown)

Water Jacket

15. Water jacket (surrounds rebox)

16. Supply line threaded connector

17. Return line threaded connector

18. Relief vent pipe

19. Relief elbow

Ashes

30. Ash pan (under grates #12)

31. Ash auger (not shown)

32. Ash auger tube

33. Ash auger tube cover plate

Bladder assembly

34. Bladder

35. Bladder gate valve and hose (not

shown)

Electrical

14. Front Light (not shown)

36. Electronic Controller (not shown)

37. Electrical supply junction box

38. Electrical plug outlets

39. Water temperature high-limit

controller (aquastat)

40. Front light and combustion air

blower control switch (not shown)

41. Temperature Probe

42. Low Water Switch (not shown)

Air Supply

20. Combustion air blower (not

shown)

21. Flipper assembly (not shown)

22. Air box

23. Automatic Fab Switch (A.F.S.)

(not shown)

Chimney and Top Flue

25. Chimney

26. Chimney extension(s) (not

shown)

27. Tube ue

28. Flue cover plate

29. Flue Ash Catcher (not shown)

Housing - (not shown)

44. Outer front door

45. Outer rear door

46. Roof

47. Sides

48. Insulation

Lift Hook

49. Lift ring

10

Chapter 4

MINIMUM CLEARANCE SEPARATION SPECIFICATIONS

The HEATMOR™ furnace, is certied to be installed outside, away from other buildings.

Please observe the following “Clearance to Combustibles” guidelines. If you have any further questions, which are not addressed in this Operators Manual, please contact your local

dealer for further information.

• To HEATMOR™ Stainless Steel Outdoor Furnace BACK. 96"

• To HEATMOR™ Stainless Steel Outdoor Furnace TOP 18"

• To HEATMOR™ Stainless Steel Outdoor Furnace FRONT 48"

• To HEATMOR™ Stainless Steel Outdoor Furnace Chimney 18"

• To HEATMOR™ Stainless Steel Outdoor Furnace Sides 6"

• DO NOT store combustible liquids or materials near the furnace

• It is not recommended to install the furnace in any form of building

Before installing your HEATMOR™ Stainless Steel Outdoor Furnace, if in the United

States, always check any and all applicable state and local regulations and inform your

insurance agent.

Before installing your HEATMOR™ Stainless Steel Outdoor Furnace, if in Canada, always

check any and all applicable Provincial and Municipal regulations and inform your insurance agent.

HEATMOR™ Inc. strongly recommends not installing a HEATMOR™ Stainless Steel Out-

door Furnace within 50 feet of any ammable structure.

A HEATMOR™ Stainless Steel Outdoor Furnace should be located with consideration to

your neighbor’s property and in accordance with local ordinances. Refer to the “Best Burn

Practices” for further operating considerations.

HEATMOR™ Outdoor Furnace, is not designed or certied to be located in densely populated areas.

11

Chapter 5

WARNINGS AND PRECAUTIONS

Please read the following list of cautions, warnings, and dangers before installing

and operating your HEATMOR™ STAINLESS STEEL OUTDOOR FURNACE. If you

have any questions or concerns regarding any of the following cautions, warnings,

dangers, or instructions in the Operations and Maintenance manual, please contact

your local dealer.

Familiarize yourself with the “Best Burn Practices” located on the inside front cover.

For more information go to http://www.epa.gov/burnwise/

Installation

Installation should be performed by a qualied installer and will comply with all the requirements of the authority having jurisdiction over the installation.

1. The HEATMOR™ furnace is designed for outside installations, away from other buildings.

2. Please observe the following “Clearance to Combustibles” guidelines.

To unit back = 96"

To unit front = 48"

To unit top = 18"

3. Before installing the furnace, always check any and all applicable state, provincial, and

local regulations.

4. HEATMOR™ Inc. strongly recommends not installing a HEATMOR™ Stainless Steel

Outdoor Furnace within 50’ of any ammable structure.

5. A HEATMOR™ Stainless Steel Outdoor Furnace should be located with consideration

to your neighbor’s property and in accordance with local ordinances. The

Outdoor Furnace is not designed to be located in densely populated areas.

6. HEATMOR™ suggests the use of brass ttings when installing the unit.

7. Before installing the HEATMOR™ furnace, contact and inform your insurance agent.

To unit sides = 6"

To chimney = 18"

HEATMOR™

8. The HEATMOR™ Outdoor Furnace is to be installed on a concrete base only. Any

attempt to place the furnace on any other surface may void the warranty.

9. Do not connect the HEATMOR™ furnace to the chimney of an existing heating system.

10. This unit was not designed, nor is it recommended, for use as a stand-alone heating

system. A back up source of heat must be in place to prevent the outdoor furnace from

freezing and to provide supplementary heat for the heated buildings.

11. Do not pressurize the HEATMOR™ Outdoor Furnace. This unit is designed to operate

under atmospheric pressure only.

12. Place the in-line ll/drain assembly in a location where the drained contents of the

HEATMOR™ will not cause damage to the surrounding areas or its content.

12

Electrical

1. Do not connect the electrical components of the HEATMOR™ Outdoor Furnace to any

other electrical appliance.

2. This HEATMOR™ Outdoor Furnace operates on 115-volt power only. Do not connect

the furnace to a 220-volt electrical supply.

3. HEATMOR™ Inc. recommends a licensed professional electrician make all the

necessary electrical connections involved with the installation of the furnace.

4. Always disconnect the HEATMOR™ Outdoor Furnace from the main electrical supply

before servicing any of the electrical components of the HEATMOR™ Outdoor Furnace.

5. Always disconnect any existing electrical connections to any in-house heating system,

before installing the outdoor furnace to any existing indoor heating system or appliances.

6. The red wire from the high-limit aquastat on the back of the HEATMOR™ should

be wired to a 120v indoor temperature control to override the thermostat. This will

dissipate excess heat in the event of a possible malfunction with the HEATMOR™.

The red wire is capped off in the electrical junction box when the HEATMOR™ is

new.

Other

1. The unit may be connected to an existing indoor boiler system by installing a water-to-water heat exchanger.

2. HEATMOR™ INC. recommends that you contact a licensed professional plumber to

make all necessary plumbing installations between the HEATMOR™ furnace and the

existing heating system of your building(s).

3. Do not operate the HEATMOR™ furnace until all electrical and water line connections

have been properly installed and tested.

4. Do not allow any re in the rebox until the HEATMOR™ has the correct amount of

water and sand installed.

5. DO NOT OVER-FIRE THIS HEATER. Attempts to achieve heat output rates that ex-

ceed heater design specications can result in permanent damage to the heater and

to the catalytic combustor if so equipped.

13

X-Series Pad Specications

Chapter 6

The actual pad size is 50" x 88". This

gives approximately 2" extra on all sides of

furnace.

CAUTION: Do not exceed this length

measurement. Overall width may exceed

measurements if desired.

The bottom of the loading door is 24" above

ground or base of furnace. If you desire to

have the leading door higher, you can do so

by making the pad depth thicker.

Example: 12" instead of 4" or any gure in

between.

Patio stones or separate cement pad in

front of the loading door should NOT be

attached to main base of furnace.

It is recommended to use steel mesh or

rebar in pad for strength.

Benets to raising the pad:

1. Gives space below the ash auger

to place a pail for convenient ash

removal.

2. Allows better visibility of the rebox.

3. Less bending when adding wood.

4. Keeps exhaust above the operator.

5. Protects the base of the HEATMOR™

14

Chapter 7

INSTALLATION OF THE HEATMOR™ FURNACE

Installation should be performed by a qualied installer and will comply with all the requirements of the authority having jurisdiction over the installation.

Principles

1. Need to have an airtight seal between the concrete base and the perimeter of the

rebox base.

2. Need to seal the perimeter of the entire HEATMOR™ so rodents are not able to nd a

home inside the HEATMOR™.

3. Need to lift the HEATMOR™ without damaging it.

Equipment Required

1. It is NOT possible to lift a HEATMOR™ with the forks

of a forklift under the HEATMOR™. It MUST BE

LIFTED FROM THE TOP, by the lift hook. A crane or

heavy backhoe works best, although a heavy duty

farm tractor is acceptable.

a. With a farm tractor, extreme care must be taken

to prevent the HEAMTOR™ from swinging and

causing damage to the HEATMOR™.

Placing the HEATMOR™ on the Concrete Base

2. Before setting the HEATMOR™ onto the concrete

base, it is a good idea to place a solid sheet of the

proper “reective air foil” (also called bubble foil)

between the concrete and the HEATMOR™. This will

absorb ridges in the concrete and make it easier to

apply caulking around the inside perimeter of the base

of the HEATMOR™. This reective foil will also reect escaping heat up into the sand,

and help prevent air leaks into the rebox if cement cracks.

3. Make sure the total area of the base (where the sand is going) is on solid concrete. Do

not let the base extend past the hole in the concrete where the lines come in.

4. After the HEATMOR™ is in place perform the following:

Caulking around the Firebox Base

a. One person should get into the HEATMOR™.

b. Apply a substantial bead of caulking around the entire inside perimeter

of the base. This will give an airtight seal so no air will seep through the

sand. This should require about three tubes of High Temperature

Silicone.

Caulking around the Outside Perimeter of HEATMOR™

c. With a sharp knife, trim any excess bubble foil that extends past the

base of the HEATMOR™.

d. Apply a bead of caulking around the entire outside perimeter of the

HEATMOR™ to seal out rodents.

15

FILLING THE HEATMOR™ OUTDOOR FURNACE INITIALLY

WITH WATER

Before your HEATMOR™ furnace with water, all plumbing connections at the back of the

HEATMOR™ furnace, all electrical hookups, and all heating appliances should be installed

and tested for possible leaks.

HEATMOR™ suggests the use of brass ttings when installing the unit.

NOTE: If you have any questions regarding installation of the furnace or any aspect of

installation, contact your local dealer.

NOTE: Never start a re inside the rebox until the water jacket is full of water and sand

has been added to the base to the correct level.

1. Close the bladder gate valve located at the front of the HEATMOR™ furnace.

2. This valve will ensure no water can enter the bladder.

3. Close the bottom supply line valve at this back of the

HEATMOR™.

4. Open the top return line valve at the back of the

HEATMOR™.

5. Ensure the vent pipe is unobstructed. If equipped with a pop-

off ball on the roof of the furnace, remove it from the relief

vent pipe.

6. Connect the water source to the return line leading to the

HEATMOR™. Use a garden hose to add the water to the

return line.

7. Turn on the source of water.

8. The pressured water will now ow through and remove the

air out of the return line as the wter ows into the

HEATMOR™.

9. Continue adding water until water ows out the relief vent

pipe onto the roof of the HEATMOR™.

10. Turn off the source of water.

The HEATMOR™ is now full of water and the return line is also full of water and air free,

BUT the supply line leading from the HEATMOR™ to the building to be heated is still full

of air.

11. Close the top return line valve at the back of the HEATMOR™.

12. Remove the garden hose that was used to deliver the source of water from the top

return line, BUT leave the garden hose valve open.

13. Open the bottom supply line at the back of the HEATMOR™ (bottom). The pressure

of the water in the HEATMOR™ will now force water from the HEATMOR™ through

the supply line back into the building to be heated. This water will soon discharge

from where the garden hose was connected. When there is a steady stream of water

owing, the air will be removed from that supply line. Usually it requires the removal of

approximately ve gallons of water to ensure the line is air-free.

Bladder Gate Valve

16

FILLING THE HEATMOR™ OUTDOOR FURNACE INITIALLY

WITH WATER

NOTE: The circulator pumps cannot “push” much air through a system. They are designed

to move water not air.

14. Start the circulating pump. Remember to properly bleed air from the pump.

ABSOLUTELY NO FIRE IN THE FIREBOX WHEN PERFORMING THIS PROCEDURE.

DO NOT PERFORM THIS PROCEDURE WHEN UNIT WATER TEMPERATURE IS

UNSAFE. ALWAYS WEAR PERSONAL PROTECTIVE EQUIPMENT WHEN WORKING

Maintaining the Correct Amount of Water in the Bladder and in the HEATMOR™

1. Close the bladder gate valve located at the front of the HEATMOR™ furnace. Closing

this valve will ensure no water can enter the bladder.

2. Remove the pop-off ball (if equipped) from the relief vent pipe.

3. Connect the water source to the return line leading to the HEATMOR™. Use a garden

hose to add the water to the return line.

4. Turn on the source of water, but only about half a full ow.

5. The pressured water will now ow through the return line as the water ows into the

HEATMOR™.

6. Continue adding water until water ows out the relief vent pipe, onto the roof of the

HEATMOR™, leave the water running. Some may continue to spill out onto the roof.

7. Place the pop-off ball (if equipped) back onto the relief vent pipe.

8. Turn on the green bladder gate valve and let the bladder ll half full. You can check

this by felling the bladder with your hand inserted through the bladder inspection cover

plate.

9. Turn off the water when the bladder is half full.

Low Water Condition

If the water level is below the bladder port when the water heats up, air will enter the

bladder instead of water. To remove the air from the bladder, follow steps 1 through 7 above

and make sure there is a good seal on the pop-off ball (if equipped). Next:

1. Open the bladder gate valve.

2. CAREFULLY remove the bladder hose, allowing the bladder to empty its contents.

3. After bladder is empty of air/water, re-attach the bladder hose to the bladder gate

valve and tighten the hose clamp.

WITH WATER AND CHEMICALS.

Next, follow steps 7-9 above.

NOTE: Never light a re inside the rebox until the water jacket is full of water and sand

has been added to the base to the correct level.

Installation should be performed by a qualied installer and will comply with all the requirements of the authority having jurisdiction over the installation.

READ THROUGH THE ENTIRE OPERATIONS AND MAINTENANCE MANUAL BEFORE

OPERATING YOUR HEATMOR™ STAINLESS STEEL OUTDOOR FURNACE.

17

Initial Installation of Sand

Types of Sand to Use

1. Sand that does not contain clay, rocks or organic matter is appropriate. Use a sand

that when packed will not allow air to pass through. Mortar sand or sand that is used in

the redi-mix concrete business is good. Never use gravel.

2. 200X requires approximately 0.18 cubic yards.

3. 350X requires approximately 0.28 cubic yards.

Installation

1. Cover the grates with a piece of cardboard.

2. One person enters the rebox.

3. Another person shovels the sand into the

rebox while the person inside packs the sand

completely, using a piece of wood like a 2" x 4"

x10" long.

4. Fill the base with sand, level to the top of the

grates.

Open Bottom without Sand

NOTE: Never light a re inside the rebox until the water jacket is full of water and sand

has been added to the correct level in the base.

18

Chapter 8

SAFE FURNACE OPERATION GUIDELINES

OPERATION

DO NOT USE CHEMICALS OR FLUIDS TO START THE

FIRE DO NOT BURN GARBAGE, GASOLINE, NAPHTHA,

ENGINE OIL, OR OTHER INAPPROPRIATE MATERIALS.

HEATMOR™ OUTDOOR FURNACES X-SERIES ARE CERTIFIED TO BURN WOOD

ONLY.

Burning of other materials may result in serious burns, health consequences, or damage to

this furnace and other components of the heating system and may void warranty.

***IMPORTANT NOTICE***

PLEASE REFER TO “FILLING YOUR HEATMOR™ FURNACE WITH WOOD”,

FOR ADDITIONAL SAFE LOADING PROCEDURES.

1. Never open the rebox door if the combustion air blower is operating or if you suspect

a roaring hot re inside the rebox.

2. Never open rebox door immediately after the combustion air blowers have shut off.

If the water temperature is very close to the high setting, you should assume the air

combustion fans have just shut off.

3. If there is more than a ‘whiff’ of exhaust coming from the chimney and the draft fan is

off, do not open the rebox door for at least two minutes. The burn cycle would heave

just ended and the rebox will be full of unburned gases (exhaust) that may ignite

when fresh air is introduced.

4. Load the unit with wood carefully, but quickly. After loading wood make sure all debris

is cleaned from the rebox door frame and gasket. Then close rebox door securely.

5. Keep the rebox door, ash auger tube cover cap, top ue cover plate, and the outer

door of the HEATMOR™ furnace closed at all times except for servicing and refueling.

6. Keep the locking handle on the outer door locked at all times when not servicing or

refueling to reduce the risk of tampering and possible injury.

7. Never add water to the HEATMOR™ furnace if the internal water temperature is over

212˚ Fahrenheit. Failure to adhere to this warning may cause a steam ash and result

in an explosion.

8. Do not store combustible liquids or materials near the outdoor furnace. Adhere to the

“Clearance to Combustibles” guildelines.

9. Never use gasoline, kerosene, charcoal, lighter uid or similar liquids to start, restart

or freshen up a re. Using such liquids may result in severe burns and injures.

10. When adding water, water treatment or maintaining the HEATMOR™ furnace,

protective clothing must be worn at all times.

11. Never leave the HEATMOR™ furnace unattended while the rebox door is open or

unlatched.

12. Stay clear of any exhaust emitting from the rebox.

13. Do not burn garbage, plastics, rubber naphtha, trash, tires, solvents, engine oil,

gasoline, leaves, paper products, cardboard, material treated with petroleum products

(particleboard, railroad ties and pressure treated wood) or other inappropriate

materials.

22

Loading...

Loading...