Heatlink Plumbing, Heating User Manual

®

Heat Link

Plumbing, Heating, & Panels

Product Catalog / Price List

E ective July 1, 2014

2014

Canada

®

Heat Link

About Us

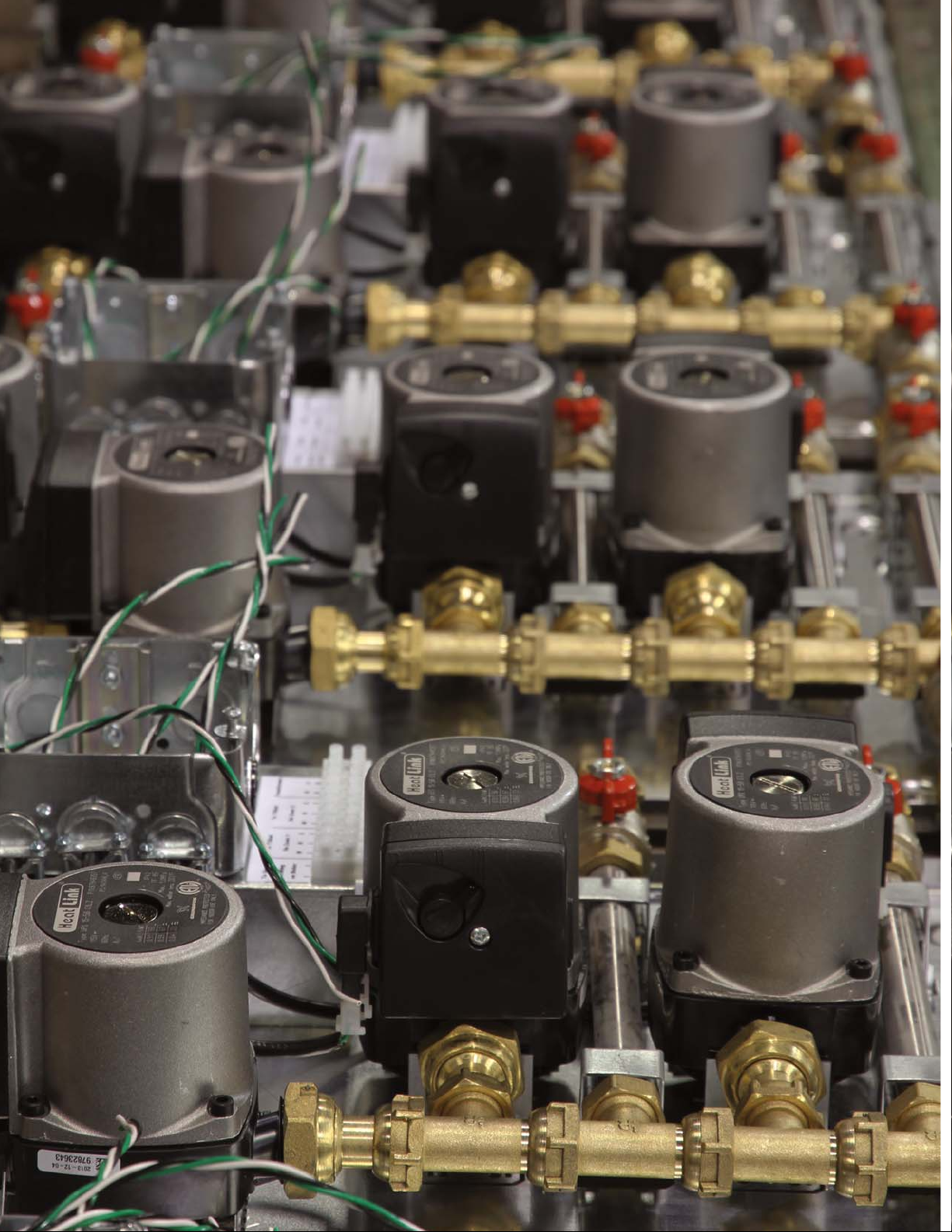

HeatLink is a multi-system supplier of potable water and radiant

hydronic heating/cooling and snow melt systems. For over 20 years

we have created comfortable and e cient heating, cooling and

plumbing systems for residential and commercial construction.

HeatLink’s radiant heating systems create a comfortable and energy

e cient environment for living. Our snow melt systems create safer

public and private spaces that reduce liability for property owners,

reduce maintenance, and ensure accessibility. Our well engineered

plumbing systems provide peace of mind for property owners

through extensive warranty protection, and enable quick and

e cient installations for builders and contractors.

History

HeatLink began as a family owned business developed to service

a number of industries including HVAC. The company grew to

meet the needs of builders, contractors, and architects and began

designing and installing radiant heating systems in 1985. Since

1985 HeatLink has grown into an industry leading designer and

manufacturer of radiant heating, cooling, and potable water systems.

HeatLink has developed and manufactured a long list of industry

rsts such as the “TwistSeal” tool-less manifold in 1996. The company

began manufacturing PEX-a tubing in 1998 and now supplies the

highest quality PEX-a systems to customers throughout North

America and parts of Europe and Asia.

HeatLink works with a network of experienced and successful partner

agencies to meet the design, system installation and training needs

of the construction industry, designers, and architects.

Solutions

HeatLink in an industry leader in providing a broad range of potable

water and radiant heating/cooling and snow melt systems for

customers throughout the world. Our focus from our inception

remains on creating well engineered and energy e cient solutions

that are easy to install and last a lifetime.

Company Description

Our innovative plumbing and heating systems help provide a

comfortable and worry free environment for people in residential

and commercial work and living spaces. We continue to design quiet

and energy e cient heating and potable water systems that are easy

to install and last a lifetime. HeatLink was built on a strong family

work ethic and a value system that remain the foundation for our

continuing growth and industry leadership role.

Heat Link

www.heatlink.com

®

Table of Contents

Canada - July 1, 2014

Discounts Structure & Shipping Allowances ........................................ 3

Terms and Conditions of Sale, Delivery and Payment....................... 4

Heating

PEX Heating Tubing with O2 Barrier ......................................................... 5

PEX Heating Tubing Non Barrier ...............................................................7

TwistSeal® (55 mm) Manifold Assembly Kits......................................... 9

TwistSeal® (55 mm) Manifold Modules .................................................10

TwistSeal® Mini (40 mm) Manifold Assembly Kit...............................12

TwistSeal® Mini (40 mm) Manifold Modules .......................................13

TwistSeal® Manifold Accessories .............................................................14

1-1⁄4” Stainless Steel Manifolds ..................................................................16

1-1⁄4” Stainless Steel Manifold Accessories ............................................17

2” Stainless Steel Manifolds .......................................................................19

2” Stainless Steel Manifold Accessories ................................................20

Manifold Housings ....................................................................................... 22

PEX Compression Adapters ......................................................................23

2-way Injection Mixing ...............................................................................25

3-way Compact Mixing System ...............................................................26

3-way Mixing System ..................................................................................27

4-way Mixing System ..................................................................................28

Mixing Valves .................................................................................................29

Valves ................................................................................................................32

Mixing Valve Motors ....................................................................................35

Thermostatic Heads .....................................................................................36

Actuators .........................................................................................................37

Thermostats ....................................................................................................40

24V AC Relay ................................................................................................... 42

StatLink® Modules ........................................................................................43

Controls ............................................................................................................44

Sensors .............................................................................................................45

“Wet” System ..................................................................................................48

DryAbove™ System ...................................................................................... 51

DryBelow™ System .......................................................................................52

Floor Heating Accessories .........................................................................53

Chemicals ........................................................................................................56

Water Testing ..................................................................................................57

Sidestream Filter ........................................................................................... 58

Mechanical Room in a Box (Panels)

Introduction ...................................................................................................60

System Panel Selection ..............................................................................61

ECO - ECO Boiler Panels .............................................................................. 62

V100 - V100 Boiler Panels ...........................................................................64

CAD - CAD Boiler Panels .............................................................................66

ELBP - Electric Boiler Panels ......................................................................68

TMP – 3-Way Mixing Panels ...................................................................... 72

TWH – Tankless Water Heater Panels ..................................................... 80

HEP – Isolation Heat Exchanger Panels ................................................86

WHP - Water Heater Panels .......................................................................90

CDP – 2-Temperature Combi DHW Panels ..........................................92

SOL - Solar Heat Exchanger Panel ..........................................................98

SSM - Stainless Steel Manifold Panels ................................................ 100

SSP - Stainless Steel Manifold Pump Panels ..................................... 102

SSTS - Stainless Steel Manifold Small Mixing Panels ....................104

SSTL - Stainless Steel Manifold Large Mixing Panels .................... 106

SMP – Snow Melt Panels ......................................................................... 108

Snow Melt Panel Options & Accessories ........................................... 116

Plumbing

PureLink® Potable Water PEX-a Tubing .............................................. 117

PureLink® Pipe-in-Pipe ............................................................................. 121

EasyFit™ Manifold ...................................................................................... 122

HPP Multiport Tees .................................................................................... 125

SS Press Sleeves .......................................................................................... 126

PEX Insert Couplings ................................................................................ 128

PEX Insert Elbows ......................................................................................129

PEX Insert Threaded Elbows .................................................................. 130

PEX Insert FNPT Adapters ....................................................................... 131

PEX Insert Fixture Adapters ................................................................... 132

PEX Insert MNPT Adapters .....................................................................133

PEX Insert Sweat Adapters ..................................................................... 134

PEX Insert Tees ............................................................................................ 134

PEX Insert Plugs ......................................................................................... 137

Ball Valves ..................................................................................................... 138

Stubout Elbows .......................................................................................... 140

Accessories, Tools, and Parts

Accessories ................................................................................................... 141

Tools ............................................................................................................... 142

Parts ................................................................................................................ 150

Listing by Stk#

Listing by Stk# ............................................................................................. 160

2

®

Heat Link

www.heatlink.com

Please note: this price list supersedes all previous price lists.

For your discount please contact your local sales representative.

Shipping Allowances

• Prices and speci cations are subject to change without notice.

• Products shipped in multiples of quantity listed only.

Standard shipping times: 3 days from con rmed order (or less).

D/C pickups: 3 days from con rmed order (or less), scheduled with local HeatLink shipping department.

Minimum order value: $100.00 net

Rush orders: Same day shipment if order con rmed by 11AM.

Next day if order con rmed after 11AM.

Next day freight charges applicable.

Rush charges may apply.

Backorders: Shipped with subsequent order to stocking distributor (if no subsequent order is in place, product will be

shipped freight prepaid ground n/c).

Prepaid freight: $ 5,000 net minimum order. Subject to change without notice.

Fuel surcharge: May apply on prepaid orders. Rates are subject to change without notice.

Discounts Structure & Shipping Allowances

Canada - July 1, 2014

3

Heat Link

www.heatlink.com

®

Terms and Conditions of Sale, Delivery and Payment

Canada - July 1, 2014

General Provisions

1. (a) This agreement, performances of contract and quotations are made exclusively

(b) The Purchaser hereby accepts the terms and conditions herein contained

(c) In the event that any one or more of the provisions herein contained shall

Plans and Specifi cations

2. Drawings, specifi cations and technical data appended to or forming part of the

Prices and Quotations

3. (a) HeatLink Group Inc. hereby specifi cally reserves the right to change, alter,

(c) All contract prices are guaranteed for thirty (30) days from date of contract.

(d) Contracts for delivery of goods or performance of services without specifi c

Terms of Payment

4. (a) Save and except as otherwise specifi cally agreed upon in writing, all invoices

(b) Holdbacks or deductions of any kind whatsoever without prior written authori-

(c) Discounts, if any, shall be calculated on the cost of goods as per invoice,

(d) Payment will be in a form agreed to and acceptable by HeatLink Group Inc.

(e) Payments received shall be applied fi rstly to designated accounts, dishonour

(f) In the event the Purchaser defaults in payment or causes a cheque, bank

(g) Overdue accounts shall bear interest at the rate stated on the face of the

Reservation of Title and Property

5. (a) It is hereby expressly agreed that all goods shall remain the exclusive property

(b) Goods delivered shall not, in any event, become part of real estate and the

upon the terms and conditions set out below. Alterations or deviations from

the provisions herein contained shall not be binding upon HeatLink Group

Inc. unless confi rmed in writing.

in their entirety. Stipulations of terms and conditions contrary to the provision hereof according to the Purchaser’s business or purchasing practices,

invoicing, manner of payment or custom of the trade are hereby specifi cally

agreed to be inapplicable to this agreement.

become or be deemed to be invalid, illegal or unenforceable by operation of

law, the validity, legality and enforceability of the remaining provisions or any

part thereof shall not in any manner be affected or impaired thereby. In place

and stead of any such invalid, illegal or unenforceable provisions of any part

thereof, the parties hereto shall be deemed to have agreed upon terms and

conditions, which, as far as permitted by law, express the intent and purpose

of the within terms and conditions.

agreement shall at all times remain the property of HeatLink Group Inc., with

all rights reserved and shall not be provided, submitted or disclosed to third

parties without the express written consent of HeatLink Group Inc. Changes,

alterations, deletions or additions thereto shall not be binding upon HeatLink

Group Inc. unless confi rmed in writing.

amend or revoke quotations but the same shall become binding and irrevocable only upon written acceptance by both HeatLink Group Inc. and the

Purchaser or upon delivery to and acceptance of goods by the Purchaser.

(b) Prices are, save and except as otherwise agreed upon, as at HeatLink Group

Inc.’s location in Calgary, Alberta, Canada, exclusive of cost of packaging,

crating, freight or shipping, federal, provincial or local rates, tariffs and taxes

in effect on date of delivery.

Cost increases 30 days after contract date, including but not limited to cost

increases of materials, wages, fuel, transportation or energy charges and

increases in applicable federal, provincial and local rates, tariffs or taxes shall

be added to the contract price and form part thereof as if originally agreed

upon.

agreement as to price shall be subject to the price or prices in effect on the

date of delivery of goods.

or accounts, as the case may be, shall become due and payable in full without

deduction whatsoever thirty (30) days after invoice or account date.

zation from HeatLink Group Inc. are expressly prohibited.

exclusive of cost of packaging, crating, freight or shipping, federal, provincial

or local rates, tariffs or taxes, where applicable, or other costs or surcharges

beyond control of HeatLink Group Inc.

All costs for dishonour, presentment for payment or collection shall be at

the expense of the Purchaser and Payor. All payments by cheque, whether

certifi ed or uncertifi ed, shall be deemed as having been received on the date

of acceptance for payment of the said cheque or cheques by the Purchaser’s

or Payor’s bank, trust company or fi nancial institution upon whose account

the cheque has been issued.

or collection; secondly, to outstanding interest charges on the oldest accounts;

and, thirdly, the balance, if any, of any payment shall be applied to the most

recent accounts, outstanding balance or balances. If an account is past due

at the time of payment, then application of received funds will be in the order

best interest to HeatLink Group Inc.

draft or money order to be dishonoured or stops payment thereon, or HeatLink

Group Inc. shall deem the Purchaser insecure, all accounts shall forthwith

become due and payable notwithstanding any agreement as to credit or

periodic payment.

invoice or (if no rate is displayed on the invoice), 2% calculated and compounded monthly.

of HeatLink Group Inc. and title shall not pass until payment in full of all invoices

or accounts rendered, including cost of goods, packaging, carting, shipping or

freight charges, federal, provincial or local taxes, rates and tariffs, insurance,

extras to contract, interest charges, exchange or collection expenses and

other sums or charges applicable has been received pursuant to the terms

and conditions herein contained.

Purchaser shall at all times take or initiate all steps necessary to preserve

HeatLink Group Inc.’s right, title and property to such goods.

(c) The Purchaser shall not permit any goods sold or delivered by HeatLink

(d) In the event of breach of contract by the Purchaser of the terms or condi-

(e) Seizure of goods by HeatLink Group Inc. shall not be deemed to constitute

Delivery of Goods

6. (a) HeatLink Group Inc. shall at all times use its best efforts to maintain the

(b) Delivery dates or periods shall be extended by reason of delays causes by

(c) In the event of delay in delivery of goods caused by the Purchaser for any

Risk of Property

7. (a) Commencing on the date of delivery of goods for shipment or transport to

(b) Any goods or part thereof delivered for shipment or transport to the Purchaser

(c) Defi ciencies or defects in goods or part thereof shipped or the shipment of

Return of Goods

8. (a) All or any goods returned without prior authorization by HeatLink Group Inc.

(b) If returns are authorized by HeatLink Group Inc., goods will be accepted as

(i) New and unused goods upon authorization by HeatLink Group Inc.,

(ii) Outdated goods, with freight prepaid plus 25% restocking charge plus

Insurance

9. During the period commencing with the delivery of goods for shipment or

Applicable Law

10. All disputes, claims or demands arising from or relating to warranties, guar-

Group Inc. to be pledged or encumbered without express written consent from

HeatLink Group Inc. In the event of seizure by third parties, the Purchaser

shall forthwith disclose HeatLink Group Inc.’s reservation of title, right and

property to such goods and shall forthwith notify HeatLink Group Inc. of such

seizure and shall assist HeatLink Group Inc. at the Purchaser’s cost in the

preservation and enforcement of HeatLink Group Inc.’s right, title and property

to the said goods.

tions herein contained and, in particular, default of payment of invoices as

hereinbefore provided, HeatLink Group Inc. shall be entitled, without prior

notice, to demand delivery up of goods sold and delivered and to seize the

same wherever the same may be located at any time of day or night or to

cause its agents, workmen or bailiffs to seize the same, wherever the same

may be located at any time of day or night notwithstanding the goods may

be in possession of a subsequent purchaser or user.

termination of contract or contractual rights and obligations as between

HeatLink Group Inc. and the Purchaser.

delivery dates agreed upon. The delivery date or period shall be deemed

to have been maintained or complied with in all events, cases or situations

where the goods to be delivered leave HeatLink Group Inc.’s premises on or

before such date, before the expiry of such period or the Purchaser is notifi ed

before the applicable date that the goods are ready for shipment.

labour shortages, strikes or lockouts or other circumstances beyond the reasonable control of HeatLink Group Inc. Any delay or postponement of delivery

to HeatLink Group Inc. of goods and supplies by its suppliers, subcontractors

or co-contractors caused by strike, lockout, labour shortage or unrest or other

causes beyond the reasonable control of HeatLink Group Inc., its suppliers,

subcontractors or co-contractors shall in like manner extend delivery dates

and periods as if the same applied to HeatLink Group Inc.

reason whatsoever, HeatLink Group Inc. shall be entitled to charge the cost

of storage calculated at the rate of one half (1/2%) percent per month upon

the cost of goods, such calculation commencing one month after delivery of

Notice of Readiness for shipment and continuing for each and every month

or part thereof thereafter until the goods can be delivered to the Purchaser.

the Purchaser, the said goods or any part thereof shall be at the risk of the

Purchaser.

from the factory Calgary, Alberta, or elsewhere, including goods with unessential or minor defects, shall be deemed to have been accepted by the

Purchaser without recourse.

the wrong goods, or part or part thereof, shall be endorsed upon the bill of

lading and shall be communicated to HeatLink Group Inc. in writing within

three (3) business days of arrival at destination. Failing such notifi cation, the

Purchaser shall be deemed to have accepted the goods without recourse.

shall not be accepted.

follows:

with freight to be prepaid plus 25% restocking charge.

(c) In all cases, unless express written authorization is given, goods must be

refurbishing costs.

returned in condition for immediate resale. If goods and packaging are not

in condition for immediate resale, HeatLink Group Inc. reserves the right

to refuse to accept the returned goods, charge additionally for refurbishing

goods or packaging, or any other agreed to return remedy negotiated with

the customer. In all cases, HeatLink Group Inc. will have the fi nal approval

as to whether returned goods are accepted or unaccepted under any of the

above remedies.

transport to the Purchaser and ending upon receipt of payment in full for

the said goods pursuant to the terms and conditions hereof, the Purchaser

shall insure the said goods in the joint names of HeatLink Group Inc. and the

Purchaser against all risk of loss or damage howsoever caused.

antees, representations authorized and published by HeatLink Group Inc.,

and from the terms and conditions herein contained and all claims, demands,

rights or liabilities arising from such warranties, guarantees, representations

or terms and conditions shall be determined in accordance with the laws of

the Province of Alberta, Canada.

4

Heat Link

3

1

1

1

1

5

5

5

3

3

3

3

1

1

1

1

www.heatlink.com

®

PEX Heating Tubing with O

Barrier

2

Canada - July 1, 2014

Special

Order*

PEX Tubing Coils with O2 Barrier

94000 Series

High molecular cross-linked poly eth yl ene (PEX) with minimum bend ing radii of

6× the diameter at 68°F (20°C). Maximum op er at ing tem per a ture: 180°F @ 100 PSI

(82°C @ 690 kPa). Covered by a twen ty- ve year manufacturer’s limited warranty.

Comes with oxygen di u sion barrier which pre vents ox y gen from entering the

heat ing system through the tubing wall.

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

Stk# Description Pkg Qty Skid Qty Unit List Price / Unit

94312

94205

94305

94505

94105

94319

94519

94119

94922

94322

94522

94122

94128 1" 100ft O

94528 1" 500ft O

94135

94335

94141

94341

⁄8" 300ft O2 Barrier HeatLink® UV Stabilized PEX-a

Tubing

⁄2" 250ft O2 Barrier HeatLink® UV Stabilized PEX-a

Tubing

⁄2" 300ft O2 Barrier HeatLink® UV Stabilized PEX-a

Tubing

⁄2" 500ft O2 Barrier HeatLink® UV Stabilized PEX-a

Tubing

⁄2" 1000ft O2 Barrier HeatLink® UV Stabilized PEX-a

Tubing

⁄8" 300ft O2 Barrier HeatLink® UV Stabilized PEX-a

Tubing

⁄8" 500ft O2 Barrier HeatLink® UV Stabilized PEX-a

Tubing

⁄8" 1000ft O2 Barrier HeatLink® UV Stabilized PEX-a

Tubing

⁄4" 100ft O2 Barrier HeatLink® UV Stabilized PEX-a

Tubing

⁄4" 300ft O2 Barrier HeatLink® UV Stabilized PEX-a

Tubing

⁄4" 500ft O2 Barrier HeatLink® UV Stabilized PEX-a

Tubing

⁄4" 1000ft O2 Barrier HeatLink® UV Stabilized PEX-a

Tubing

Barrier HeatLink® UV Stabilized PEX-a Tubing 1 19 coil

2

Barrier HeatLink® UV Stabilized PEX-a Tubing 1 5 coil

2

⁄4" 100ft O2 Barrier HeatLink® UV Stabilized PEX-a

1-

Tubing

1-

⁄4" 300ft O2 Barrier HeatLink® UV Stabilized PEX-a

Tubing

1-

⁄2" 100ft O2 Barrier HeatLink® UV Stabilized PEX-a

Tubing

1-

⁄2" 300ft O2 Barrier HeatLink® UV Stabilized PEX-a

Tubing

1 40 coil

1 40 coil

1 40 coil

1 20 coil

1 16 coil

1 20 coil

1 16 coil

1 12 coil

3 48 coil

1 16 coil

1 12 coil

1 5 coil

1 14 coil

1 5 coil

1 5 coil

1 5 coil

Radiant Heating & Cooling

* Check with your local representative for availability.

5

Heat Link

1

1

15

16

3

1

1

1

3

www.heatlink.com

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

Stk# Description Pkg Qty Master Bag Unit List Price / Unit

Radiant Heating & Cooling

94222

94228

94235

94241

⁄4" 10×20ft O2 Barrier HeatLink® UV Stabilized PEX-a

1" 5×20ft O

1-

⁄4" 5×20ft O2 Barrier HeatLink® UV Stabilized PEX-a

1-

⁄2" 5×20ft O2 Barrier HeatLink® UV Stabilized PEX-a

®

PEX Tubing Straight Lengths with O2 Barrier

94000 Series

High molecular cross-linked poly eth yl ene (PEX) with minimum bend ing radii of

6× the diameter at 68°F (20°C). Maximum op er at ing tem per a ture: 180°F @ 100 PSI

(82°C @ 690 kPa). Covered by a twen ty- ve year manufacturer’s limited warranty.

Comes with oxygen di u sion barrier which pre vents ox y gen from entering the

heat ing system through the tubing wall.

Tubing

Barrier HeatLink® UV Stabilized PEX-a

2

Tubing

Tubing

Tubing

PEX Heating Tubing with O

Canada - July 1, 2014

1 20 bundle

1 20 bundle

1 20 bundle

1 20 bundle

Barrier

2

HeatLink® O2 Barrier Pipe-in-Pipe

94000 Sheathed Series

PEX-a carrier tubing speci ed on previous pages. The exible, impact resistant red PE sheath designed as a raceway for electrical

installations provides mechanical and UV protection to the PEX-a carrier tubing. The sheath allows for easy replacement of the PEX-a carrier

tubing if needed.

Minimum bending radius @ 68˚F (20˚C) for:

PE sheath is rated to UL94HB “Tests for Flammability of Plastic Materials.”

Corrugated sheath outside diameter for:

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

Stk# Description Pkg Qty Skid Qty Unit List Price / Unit

New!

Special

Order*

94305rs

94322rs

⁄2" 300' O2 Barrier HeatLink® Pipe-in-Pipe Red Sheath 1 14 coil

⁄4" 300' O2 Barrier HeatLink® Pipe-in-Pipe Red Sheath 1 9 coil

⁄2" = 3" (77 mm)

15

⁄2" =

⁄

16" (23 mm)

6

* Lead time may vary. Call to con rm time line.

Heat Link

3

1

1

1

3

3

3

www.heatlink.com

®

PEX Heating Tubing Non Barrier

Canada - July 1, 2014

WSL

Non Barrier PEX Tubing Coils

20000 & 99000 Series

High molecular cross-linked poly eth yl ene (PEX) with minimum bend ing radii of

6× the diameter at 68°F (20°C). Maximum operating tem per a ture: 180°F @ 100 PSI

(82°C @ 690 kPa). Covered by a twen ty- ve year manufacturer’s limited warranty.

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

Stk# Description Pkg Qty Skid Qty Unit List Price / Unit

99212

20305

20505

20905

20322

20522

20922

20128 1" 100ft Blue PureLink® Plus UV Stabilized PEX-a Tubing 1 19 coil

20328 1" 300ft Blue PureLink® Plus UV Stabilized PEX-a Tubing 1 9 coil

⁄8" 200ft Non-Barrier HeatLink® UV Stabilized PEX-a

⁄2" 300ft Blue PureLink® Plus UV Stabilized PEX-a Tubing 1 32 coil

⁄2" 500ft Blue PureLink® Plus UV Stabilized PEX-a Tubing 1 20 coil

⁄2" 1000ft Blue PureLink® Plus UV Stabilized PEX-a

⁄4" 300ft Blue PureLink® Plus UV Stabilized PEX-a Tubing 1 14 coil

⁄4" 500ft Blue PureLink® Plus UV Stabilized PEX-a Tubing 1 9 coil

⁄4" 1000ft Blue PureLink® Plus UV Stabilized PEX-a

Tubing

Tubing

Tubing

1 coil

1 14 coil

1 5 coil

Radiant Heating & Cooling

7

®

3

1

5

3

3

1

Heat Link

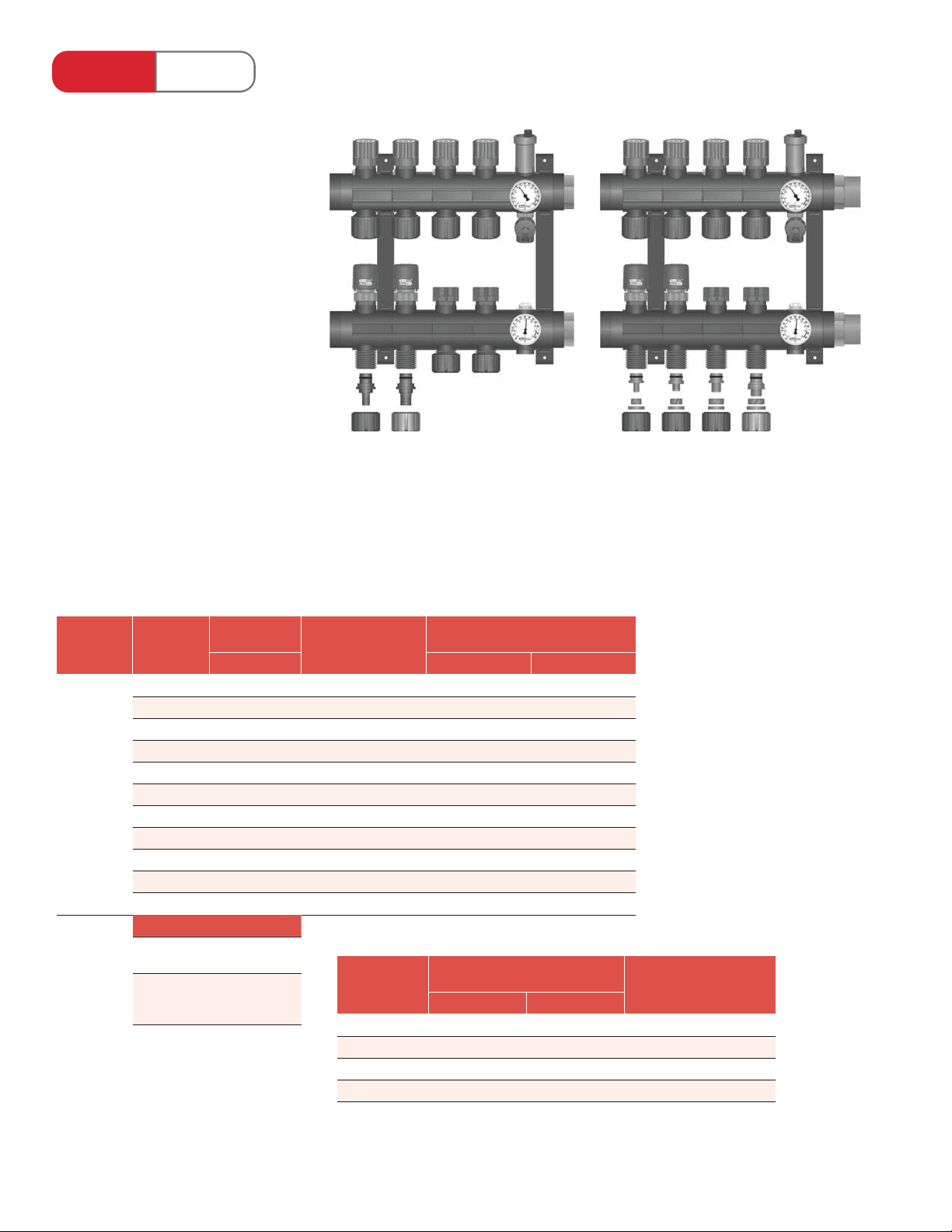

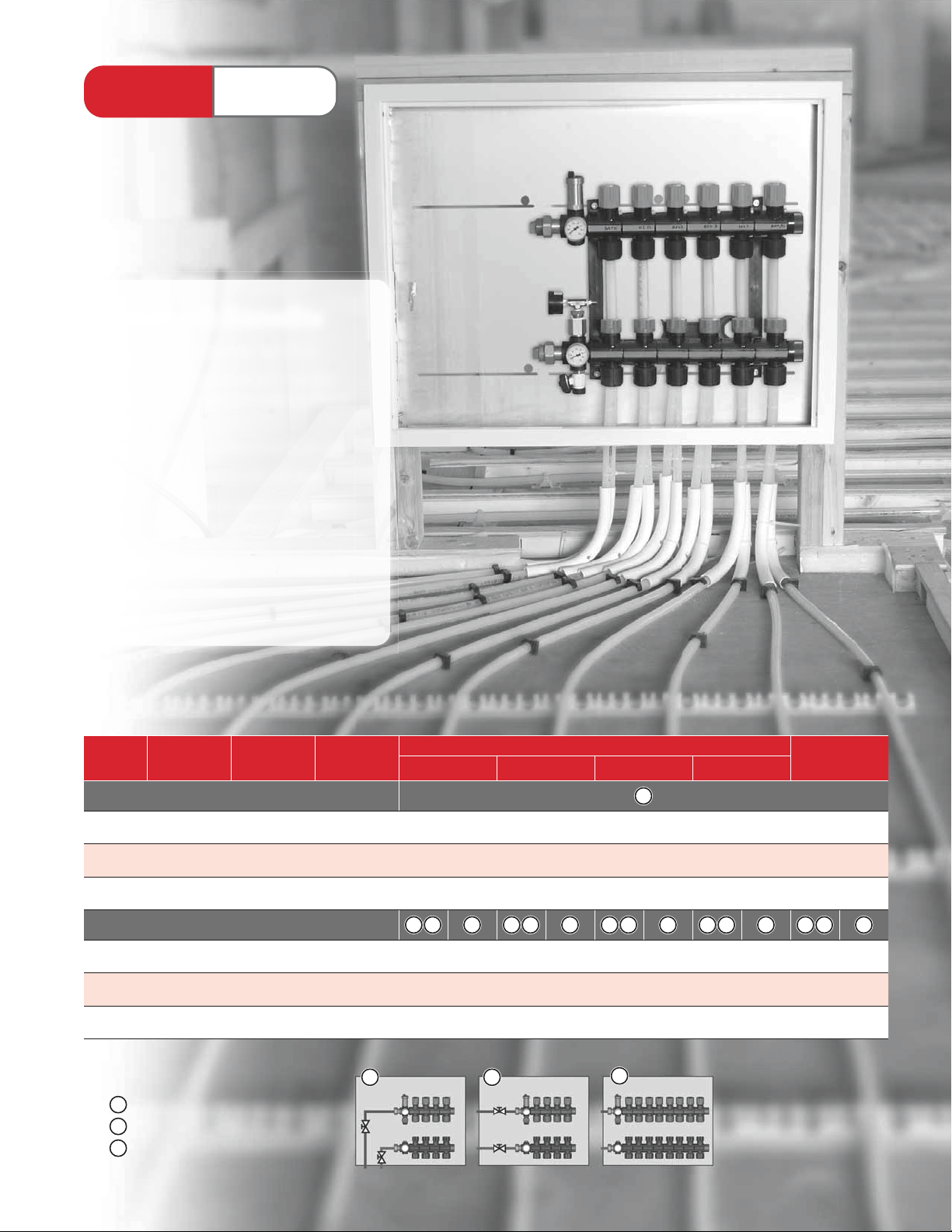

TwistSeal® (55 mm) Manifolds

Features & Bene ts :

• Modular “tool-less” assembly.

• Multiple con gurations from basic

to deluxe (all interchangeable; can

be recon gured on-site).

• Unlike a xed loop manifold,

loops can be added or removed as

required.

• Stock is exible, as there is no need

to stock xed-length manifolds.

Minimal SKUs on the shelf.

• Balancing return.

• Zone valve supply with manual

shut-o ; accepts optional actuators.

• Max. trunk ow rate:

79400 kit - 18 US gpm (4.1 m3/h)

79402 kit - 22 US gpm (5 m3/h)

• Max. circuit ow rate:

2.5 US gpm (0.57 m3/h)

• 3⁄8", 1⁄2", 5⁄8", and 3⁄4" tubing to manifold

connecters available.

• Test rated to over 230 PSI @ 180°F

water temperature.

• 5 year limited warranty.

L to R

⁄2" & 3⁄4" PEX insert

tubing to manifold

connecters

(79400 assembly kit shown with 4× 78400

module pairs and 2 actuators)

Typical Applications:

• Commercial.

• Snow melting.

L to R

⁄8", 1⁄2", 5⁄8", & 3⁄4"

tubing to manifold

connecters

(79402 assembly kit shown with 4× 78400

module pairs and 2 actuators)

Assembly

Kit

79400

or

79401

or

79402

Choose

# of Loops

2 2× 78400 - 71724 71424

3 3× 78400 - 71724 71424

4 4× 78400 - 71730 71430

5 5× 78400 - 71730 71430

6 6× 78400 1× 79991 71743 71430

7 7× 78400 1× 79991 71743 71442

8 8× 78400 1× 79991 71743 71442

9 9× 78400 2× 79991 71743 71442

10 10× 78400 2× 79991 71743 71442

11 11× 78400 2× 79991 n/a n/a

12 12× 78400 3× 79991 n/a n/a

Actuator Selection

Actuator

with LED

Actuator

with End

Switch

Module Type

Balancing Recessed** Surface Mount

56200

56230

Additional Brackets

Tubing Size

⁄8" 77012 n/a 2× 86005

⁄2" 77005 2× 23015 2× 86005

⁄8" 77019 n/a 2× 86020

⁄4" 77022 2× 23032 2× 86022

Recommended Housing*

Tubing to Manifold Connecters

/ Loop

Compression PEX Insert

Conduit Elbows / Loop

for “Wet” Installation

* Recommended housing based on 79402 kit and 90° mains piping.

** Thermometers must be removed.

Heat Link

www.heatlink.com

®

TwistSeal® (55 mm) Manifold Assembly Kits

Canada - July 1, 2014

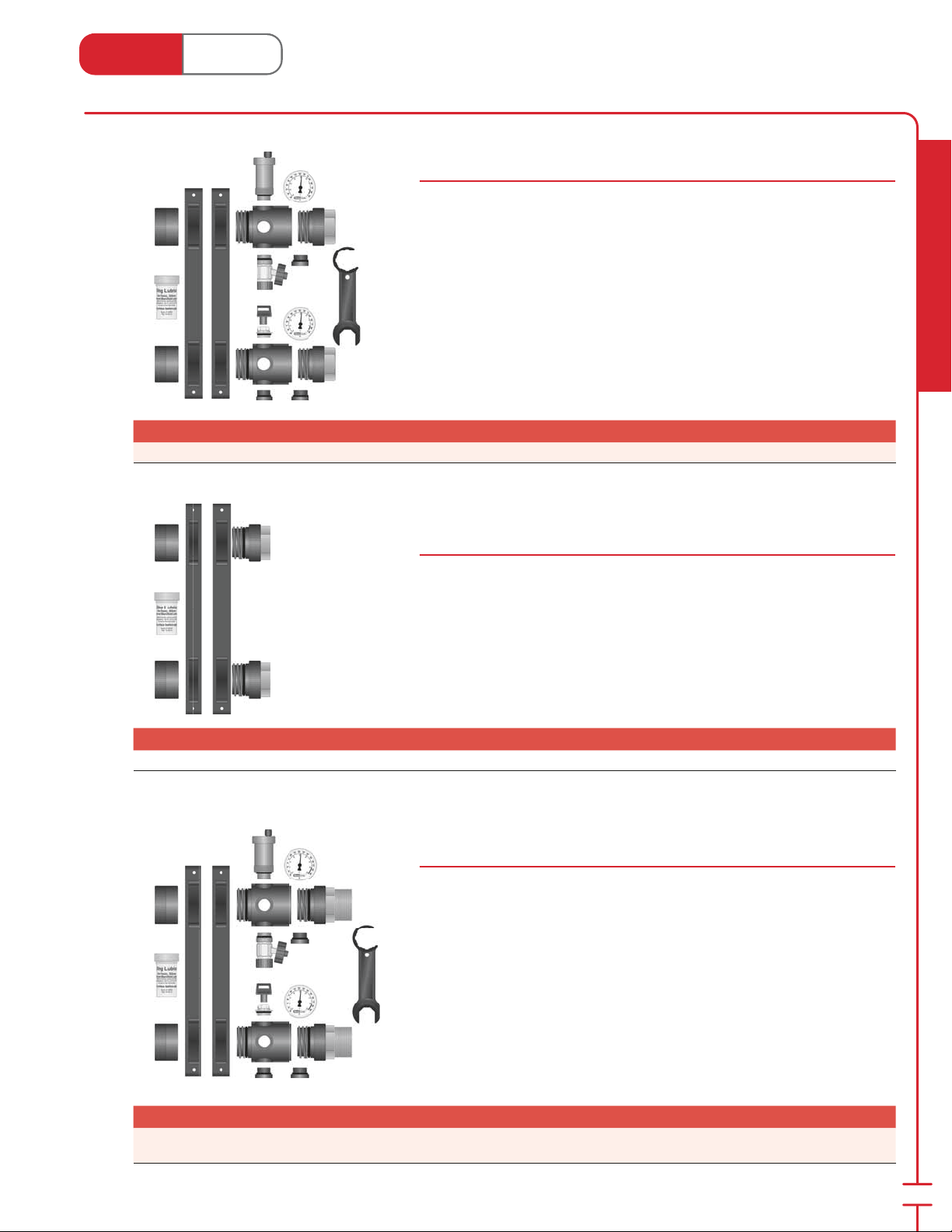

TwistSeal® (55 mm) Deluxe Manifold Assembly Kit

Stk# 79400

This package contains the items need ed to assemble a Deluxe TwistSeal®

Manifold. Contents include:

• 2 mounting brackets

• 2 - 1" FNPT supply end connections

• 2 closed end caps

• 1 lube bottle

• 2 cross tees c/w 3 - 1⁄2" cross tee plugs

• 1 thermometer pair c/w wells

• 1 manual air vent with 1 key

• 1 au to mat ic air vent

• 1 hose bib

• 1 wrench for plastic nut

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

79400 1" TwistSeal® (55mm) Deluxe Manifold Assembly Kit 1 20 ea.

TwistSeal® (55 mm) Basic Manifold Assembly Kit

Stk# 79401

This package contains the items need ed to assemble a TwistSeal® Man i fold.

Contents include:

• 2 mounting brackets

• 2 - 1" FNPT supply end connections

• 2 closed end caps

• 1 lube bottle

Wrench (#79922) sold separately.

Radiant Heating & Cooling

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

79401 1" TwistSeal® (55mm) Basic Manifold Assembly Kit 1 20 ea.

TwistSeal® (55 mm) Commercial Manifold Assembly Kit

Stk# 79402

This package contains the items need ed to assemble a Com mer cial TwistSeal®

Manifold. Contents include:

• 2 mounting brackets

• 2 - 1-1⁄2" MNPT supply end connections

• 2 closed end caps

• 1 lube bottle

• 2 cross tees c/w 3 - 1⁄2" cross tee plugs

• 1 thermometer pair c/w wells

• 1 manual air vent with 1 key

• 1 au to mat ic air vent

• 1 hose bib

• 1 wrench for plastic nut

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

79402

1-1⁄2" TwistSeal® (55mm) Commercial Manifold Assembly

Kit

1 20 ea.

9

Heat Link

www.heatlink.com

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

79991 TwistSeal® (55mm) Mounting Bracket 1 ea.

Radiant Heating & Cooling

®

TwistSeal® (55 mm) Manifold Modules

Canada - July 1, 2014

Mounting Bracket (55 mm)

Stk# 79991

Plastic mounting bracket which al lows easy ‘snap-on’ mount ing of manifolds.

TwistSeal® Deluxe (55 mm) Supply / Return Modules c/w Heavy

Duty Zone Valve Supply & Balancing Return

Stk# 78400

The supply module provides on/o manual control to allow iso la tion of individual

loops, and may be tted for electric actuator and ther mo stat op er a tion. The

return mod ule permits the bal anc ing of the ow rate. Comes with o-rings.

Modules can be locked in place with a couple of turns. No threaded rod, solder, or

tools required. Just twist and seal.

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

78400

TwistSeal® Deluxe (55mm) Z.V. Supply & Balancing

Return Module Pair

1 10 pair

10

®

3

1

3

1

5

3

Heat Link

TwistSeal® Mini (40mm) Manifolds

Features & Bene ts :

• Modular “tool-less” assembly.

• Multiple con gurations from basic

to deluxe (all interchangeable; can

be recon gured on-site).

• Unlike a xed loop manifold,

loops can be added or removed as

required.

• Stock is exible, as there is no need

to stock xed-length manifolds.

Minimal SKUs on the shelf.

• Maximum trunk ow rate:

11 US gpm (2.5 m3/h)

• Maximum circuit ow rate:

78300 and 78320 series - 1 US gpm

(0.23 m3/h)

78200 - 1.25 US gpm (0.28 m3/h)

• 3⁄8", 1⁄2", 5⁄8", and 3⁄4" tubing to manifold

connecters available.

• Test rated to over 230 PSI @ 180°F

water temperature.

• 5 year limited warranty.

Typical Applications:

• Residential.

• Small commercial.

L to R

⁄2" & 3⁄4" PEX insert

tubing to manifold

connecters

(79200 assembly kit shown with 78322 and

78323 module pairs and 2 actuators)

7832x Module Speci c Features:

• Lockable balancing return.

• Zone valve supply with manual shut-o ;

accepts optional actuators.

L to R

⁄8", 1⁄2", 5⁄8", & 3⁄4"

tubing to manifold

connecters

(79200 assembly kit shown with 78302 and

78303 module pairs and 2 actuators)

7830x Module Speci c Features:

• Lockable balancing return with

0.4 - 1 US gpm (1.5 - 3.8 L/min) ow meter.

• Zone valve supply with manual shut-o ;

accepts optional actuators.

Assembly

Kit

79200

*recommended housing based on 79200 kit and 90° mains piping

# of Loops

2 2× 78200 1× 78322 1× 78302 - 71724 71424

3 3× 78200 1× 78323 1× 78303 - 71724 71424

4 4× 78200 2× 78322 2× 78302 - 71724 71424

5 5× 78200 1× 78322

6 6× 78200 2× 78323 2× 78303 1× 79892 71730 71430

7 7× 78200 2× 78322

8 8× 78200 1× 78322

9 9× 78200 3× 78323 3× 78303 2× 79892 71743 71442

10 10× 78200 2× 78322

11 11× 78200 1× 78322

12 12× 78200 4× 78323 4× 78303 3× 79892 71743 n/a

Actuator Selection

Actuator

with LED

Actuator

with End

Switch

Balancing

56200 56202 56202

56230 56232 56232

Choose Module Type

Multiport

Balancing

1× 78323

1× 78323

2× 78323

2× 78323

3× 78323

Multiport

Flow Meter

1× 78302

1× 78303

2× 78302

1× 78303

1× 78302

2× 78303

2× 78302

2× 78303

1× 78302

3× 78303

Recommended Housing*

Additional Brackets

- 71730 71430

1× 79892 71730 71442

1× 79892 71743 71442

2× 79892 71743 71442

2× 79892 71743 71442

Tubing

Size

Compression PEX Insert

⁄8" 77012 n/a 2× 86005

⁄2" 77005 2× 23015 2× 86005

⁄8" 77019 n/a 2× 86020

⁄4" 77022 2× 23032 2× 86022

Recessed Surface Mount

Tubing to Manifold

Connecters / Loop

Conduit Elbows

/ Loop for “Wet”

Installation

Heat Link

www.heatlink.com

Radiant Heating & Cooling

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

79200

1" TwistSeal® Mini (40mm) Deluxe Manifold Assembly

®

TwistSeal® Mini (40 mm) Manifold Assembly Kits

Canada - July 1, 2014

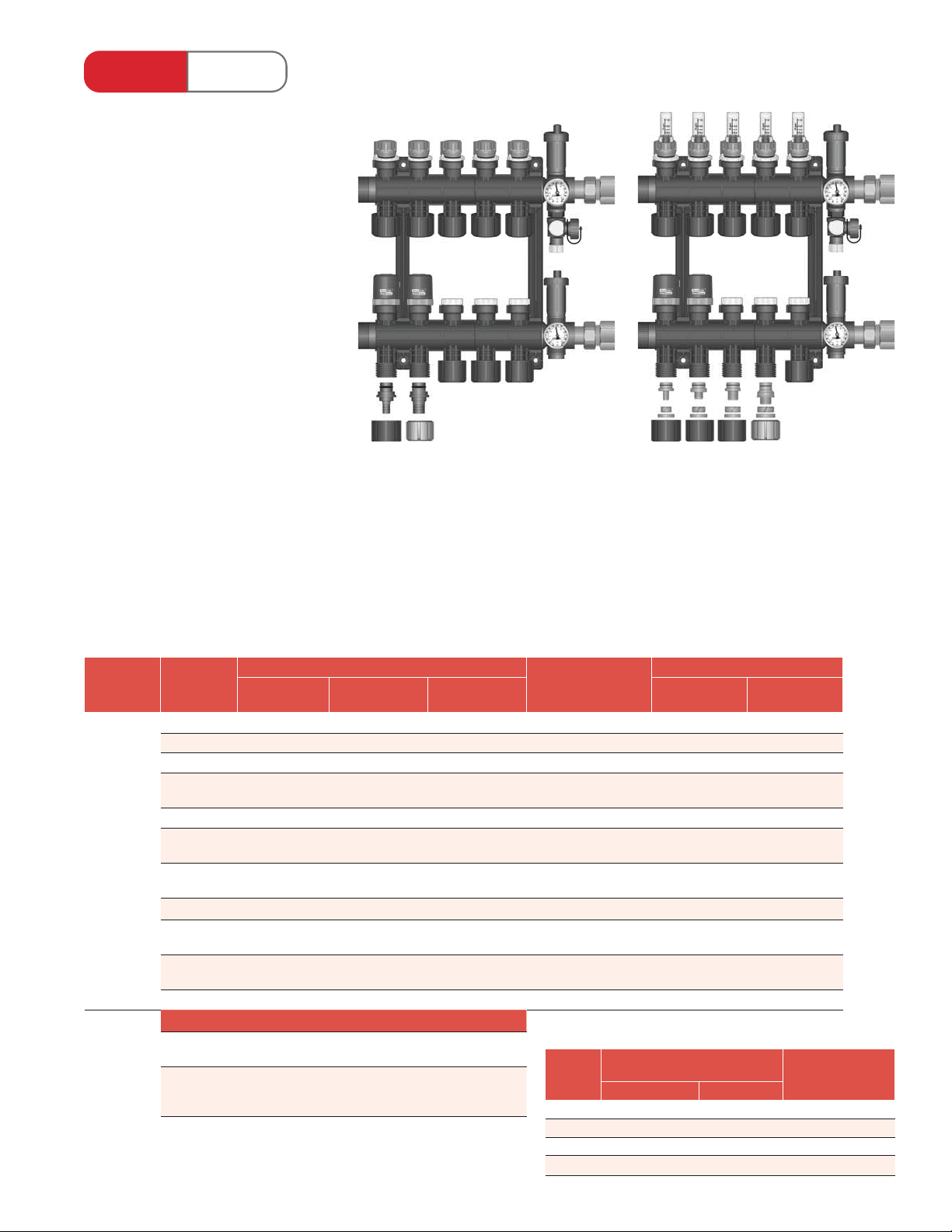

TwistSeal® Mini (40 mm) Deluxe Manifold Assembly Kit

Stk# 79200

This package contains the items needed to assemble a mini deluxe heating

manifold. Contents include:

• 2 mounting brackets

• 2 - 1" union cross tee end connection c/w green bre gasket

• 2 - 1" MBSP × 1" FNPT adapter

• 2 red rubber gaskets for air testing

• 2 closed end caps

• 1 - 1⁄2" cross tee plug

• 1 thermometer pair

• 2 automatic air vents

• 1 hose bib

• 1 lubricant package

Kit

1 20 ea.

Mini Mounting Bracket (40 mm)

Stk# 79892

Plastic mounting bracket which allow easy ‘snap-on’ mounting of manifolds.

O set provides tubing passage behind 2nd manifold.

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

79892 TwistSeal® Multiport (40mm) Double Mounting Bracket 1 ea.

12

Heat Link

www.heatlink.com

®

TwistSeal® Mini (40 mm) Manifold Modules

Canada - July 1, 2014

TwistSeal® Mini Deluxe (40 mm) Supply / Return Modules c/w Heavy

Duty Zone Valve Supply & Balancing Return

Stk# 78200

The supply module provides on/o manual control to allow isolation of individual

loops. The return module permits balancing of the ow rate with ow setting dial.

Comes with o-rings.

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

78200

TwistSeal® Mini Deluxe (40mm) Z.V. Supply & Balancing

Return Module Pair

1 10 pair

TwistSeal® Mini (40 mm) Multiport Zone Valve Supply & Flow

Meter Balancing Return Module Pair

78300 Series

The supply module provides on/o manual control to allow isolation of individual

loops. The return module permits visual balancing of the ow rate with the ow

meter. Comes with o-rings.

Radiant Heating & Cooling

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

78302

78303

TwistSeal® Mini (40mm) 2-port Z.V.Supply & Flow Meter

Return Module Pair

TwistSeal® Mini (40mm) 3-port Z.V.Supply & Flow Meter

Return Module Pair

1 6 pair

1 4 pair

TwistSeal® Mini (40 mm) Multiport Zone Valve Supply &

Balancing Return Module Pair

78320 Series

The supply module provides on/o manual control to allow isolation of individual

loops. The return module permits balancing of the ow rate. Comes with o-rings.

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

78322

78323

TwistSeal® Mini (40mm) 2-port Z.V.Supply & Flow Bal.

Return Module Pair

TwistSeal® Mini (40mm) 3-port Z.V.Supply & Flow Bal.

Return Module Pair

1 6 pair

1 4 pair

13

Heat Link

3

1

5

3

1

3

www.heatlink.com

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

77012

77005

77019

Radiant Heating & Cooling

77022

⁄4" PEX to TwistSeal® Manifold Connecter c/w Nut 1 10 pair

®

TwistSeal® Manifold Accessories

Canada - July 1, 2014

PEX Connecters for TwistSeal® Manifolds

77000 Series

Solid brass tting attaches to the end of the PEX tubing and allows for easy

installation onto the bottom of the manifold module. Comes with o-ring.

⁄8" PEX to TwistSeal® Manifold Connecter 1 10 pair

⁄2" PEX to TwistSeal® Manifold Connecter 1 10 pair

⁄8" PEX to TwistSeal® Manifold Connecter 1 10 pair

PEX Insert Connecters for TwistSeal® Manifold

23000 Series

Plastic tting is installed into the bottom of the manifold module and is held in

place by the nut. The tubing is then pressed on to this tting. Comes with o-ring.

SS press sleeves sold separately.

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

23015

23032

⁄2" PEX Insert Manifold Connecter 5 ea.

⁄4" PEX Insert Manifold Connecter c/w Nut 5 ea.

14

®

76

200 Series

100 Series

1

5

3

1

Heat Link

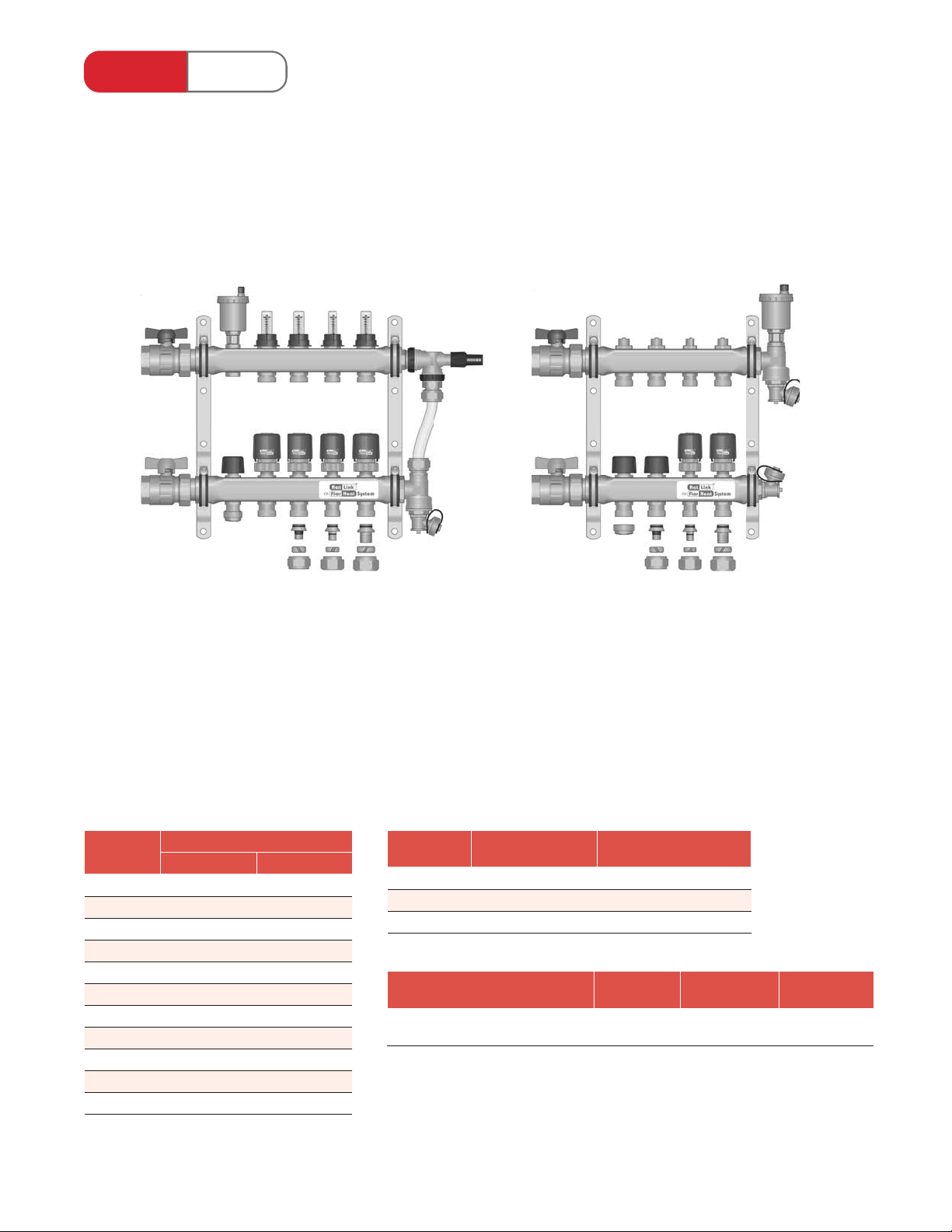

1-1⁄4" Stainless Steel Manifolds

Common Features:

• Preassembled con gurations from 2 to 12 loops.

• Integrated 1" FNPT isolation valves and hosebibs.

• Zone valve return balancing with manual shut-o ; accepts optional actuators.

• Maximum trunk ow rate: 18 US gpm (4.1 m3/h)

• 1⁄2", 5⁄8", and 3⁄4" PEX connecters available.

76100 Series 76200 Series

(76105 - 5 loop model shown with 4 actuators,

automatic air vent, 1⁄2" plug, port cap, and pressure

bypass valve)

Model Speci c Features:

• Maximum circuit ow rate: 1.5 US gpm (0.34 m3/h)

• Balancing supply with 0-1.5 US gpm (0-5 L/min)

ow meter.

Typical Applications:

• Residential.

• Small commercial.

# of Loops Recommended Housing*

Recessed Surface Mount

2 71724 71424

3 71724 71424

4 71730 71424

5 71730 71430

6 71730 71430

7 71743 71430

8 71743 71442

9 71743 71442

10 71743 71442

11 71743 71442

12 71743 71442

L to R

⁄2", 5⁄8", & 3⁄4" PEX

connecters

(76204 - 4 loop model shown with 2 actuators and

side mount automatic air vent)

Model Speci c Features:

• Maximum circuit ow rate: 2.5 US gpm (0.57m3/h)

• Balancing supply.

Typical Applications:

• Commercial.

• Snow melting.

Tubing Size PEX Connecters /

⁄2" 77105 2× 86005

⁄8" 77119 2× 86020

⁄4" 77122 2× 86022

Manifold Series Actuator

1-1⁄4" Stainless Steel

(76100 or 76200 series)

Loop

Conduit Elbows / Loop

for “Wet” Installation

with LED

56201 56231 56121

Actuator with

End Switch

L to R

port cap, 1⁄2", 5⁄8", & 3⁄4"

PEX connecters

DDC Actuator

*recommended housing based on 90° mains piping

Heat Link

www.heatlink.com

®

1-1⁄4" Stainless Steel Manifolds

Canada - July 1, 2014

1-1⁄4" Stainless Steel Manifolds with Flow Meters

76100 Series

Manifold includes:

• 1 assembled ow balancing supply manifold with 1" FNPT isolation valve and

hose bib/air vent.

• 1 assembled balancing shut-o return manifold with 1" FNPT isolation valve

and hose bib/air vent.

• 2 mounting brackets.

PEX connecters & port caps sold separately.

Radiant Heating & Cooling

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

76102 2 Loop SS Manifold with Flow Meters 1 ea.

76103 3 Loop SS Manifold with Flow Meters 1 ea.

76104 4 Loop SS Manifold with Flow Meters 1 ea.

76105 5 Loop SS Manifold with Flow Meters 1 ea.

76106 6 Loop SS Manifold with Flow Meters 1 ea.

76107 7 Loop SS Manifold with Flow Meters 1 ea.

76108 8 Loop SS Manifold with Flow Meters 1 ea.

76109 9 Loop SS Manifold with Flow Meters 1 ea.

76110 10 Loop SS Manifold with Flow Meters 1 ea.

76111 11 Loop SS Manifold with Flow Meters 1 ea.

76112 12 Loop SS Manifold with Flow Meters 1 ea.

1-1⁄4" High Flow Stainless Steel Manifolds

76200 Series

Manifold includes:

• 1 assembled balancing supply manifold with 1" FNPT isolation valve and hose

bib/air vent.

• 1 assembled balancing shut-o return manifold with 1" FNPT isolation valve

and hose bib/air vent.

• 2 mounting brackets.

PEX connecters & port caps sold separately.

16

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

76202 2 Loop High Flow SS Manifold 1 ea.

76203 3 Loop High Flow SS Manifold 1 ea.

76204 4 Loop High Flow SS Manifold 1 ea.

76205 5 Loop High Flow SS Manifold 1 ea.

76206 6 Loop High Flow SS Manifold 1 ea.

76207 7 Loop High Flow SS Manifold 1 ea.

76208 8 Loop High Flow SS Manifold 1 ea.

76209 9 Loop High Flow SS Manifold 1 ea.

76210 10 Loop High Flow SS Manifold 1 ea.

76211 11 Loop High Flow SS Manifold 1 ea.

76212 12 Loop High Flow SS Manifold 1 ea.

Heat Link

1

1

5

3

1

www.heatlink.com

®

1-1⁄4" Stainless Steel Manifold Accessories

Canada - July 1, 2014

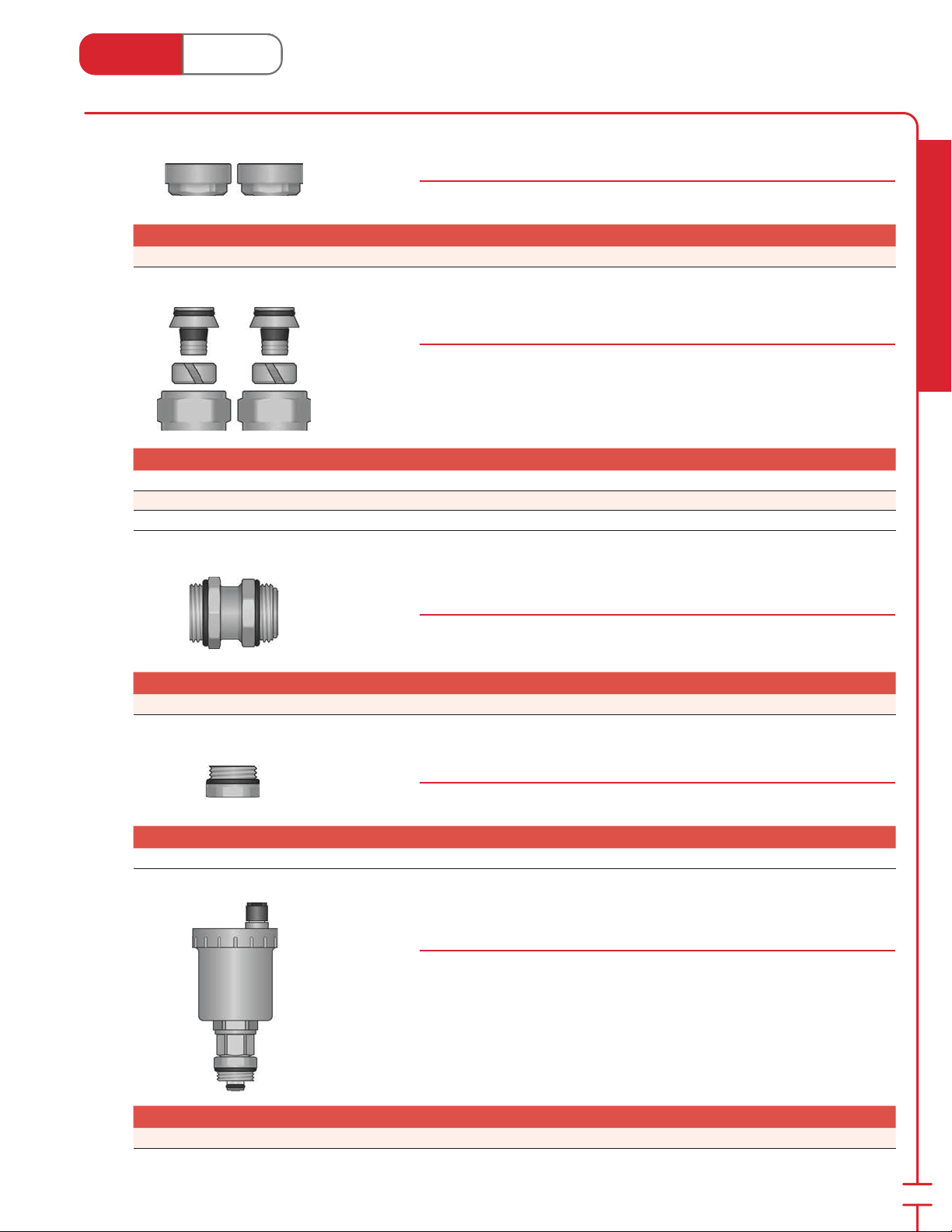

Port Caps for 1-1⁄4" Stainless Steel Manifolds

Stk# 77100

Caps o unused ports on the 1-1⁄4" Stainless Steel Manifold.

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

77100 Port Cap for 1-1⁄4" SS Manifold 1 10 pair

PEX Connecters for 1-1⁄4" Stainless Steel Manifolds

77100 Series

Solid brass tting attaches to the end of the PEX tubing and allows for easy

installation onto the bottom of the 1-1⁄4" SS manifold. Comes with o-ring.

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

77105

77119

77122

⁄2" PEX to 1-1⁄4" SS Manifold Connecter 1 10 pair

⁄8" PEX to 1-1⁄4" SS Manifold Connecter 1 10 pair

⁄4" PEX to 1-1⁄4" SS Manifold Connecter 1 10 pair

Coupling for 1-1⁄4" Stainless Steel Manifold

Stk# 76100

Radiant Heating & Cooling

Used to connect 1-1⁄4" SS manifolds together. Comes with o-rings.

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

76100 Coupling for SS Manifold 1 ea.

⁄2" Plug for 1-1⁄4" Stainless Steel Manifold

Stk# 76905

Plug to seal 1-1⁄4" SS manifold outlet. Comes with o-ring.

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

76905

⁄2" Plug for 1-1⁄4" SS Manifold 1 ea.

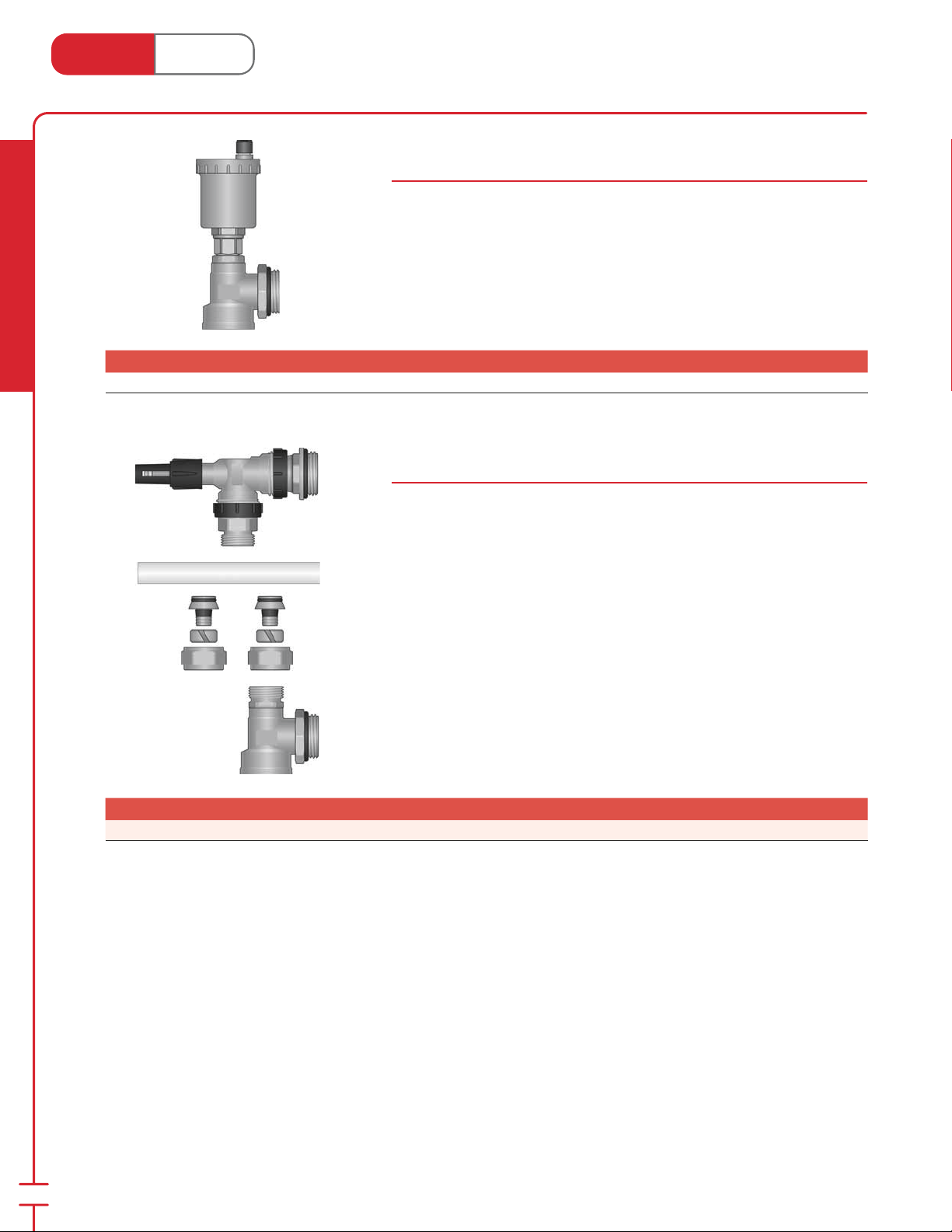

Automatic Air Vent for 1-1⁄4" Stainless Steel Manifold

Stk# 76932

Add an automatic air vent to the 1-1⁄4" SS manifold by replacing a valve. Comes

with o-ring.

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

76932 Automatic Air Vent for 1-1⁄4" SS Manifold 1 ea.

17

Heat Link

www.heatlink.com

®

1-1⁄4" Stainless Steel Manifold Accessories

Canada - July 1, 2014

Side Mount Automatic Air Vent Set for 1-1⁄4" Stainless Steel Manifold

Stk# 76935

Add an automatic air vent to the 1-1⁄4" SS manifold without occupying a loop.

Comes with o-ring.

Side Mount Automatic Air Vent is not compatible with the Pressure Bypass Kit

(#76937).

Radiant Heating & Cooling

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

76935 Side Mount Automatic Air Vent Set for 1-1⁄4" SS Manifold 1 ea.

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

76937 Pressure Bypass Kit for 1-1⁄4" SS Manifold 1 ea.

Pressure Bypass Kit for 1-1⁄4" Stainless Steel Manifold

Stk# 76937

This valve prevents a steep rise of the pump head and maintains ow at a stable

rate. Also ensures only required amount of cir cu lat ing water is used for hydronic

systems. The valve can be ad just ed to any point between 0.05 and 0.5 bar (1.67

and 16.7 ft H2O). Comes with o-rings.

Pressure Bypass Kit is not compatible with the Side Mount Automatic Air Vent Set

(#76935).

18

Heat Link

www.heatlink.com

®

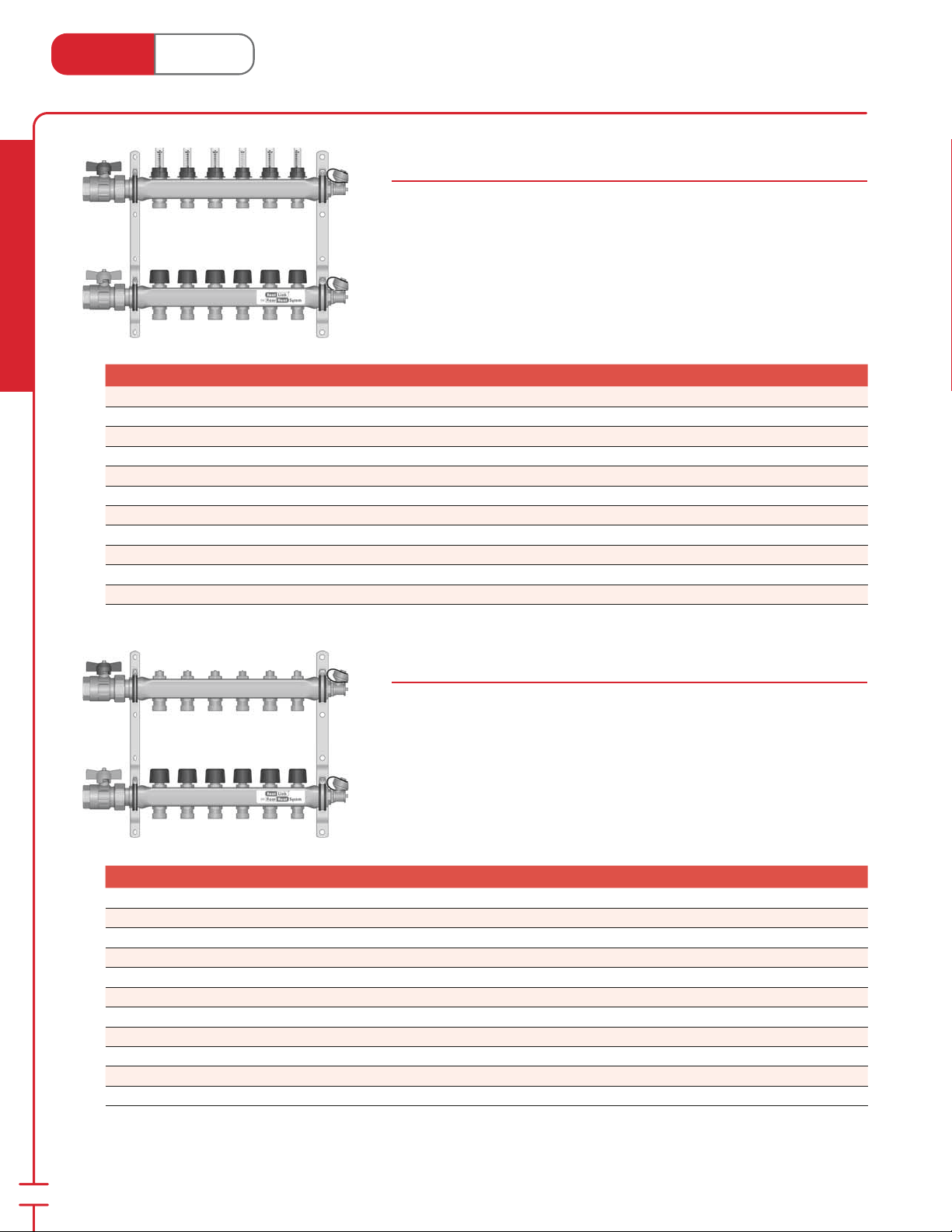

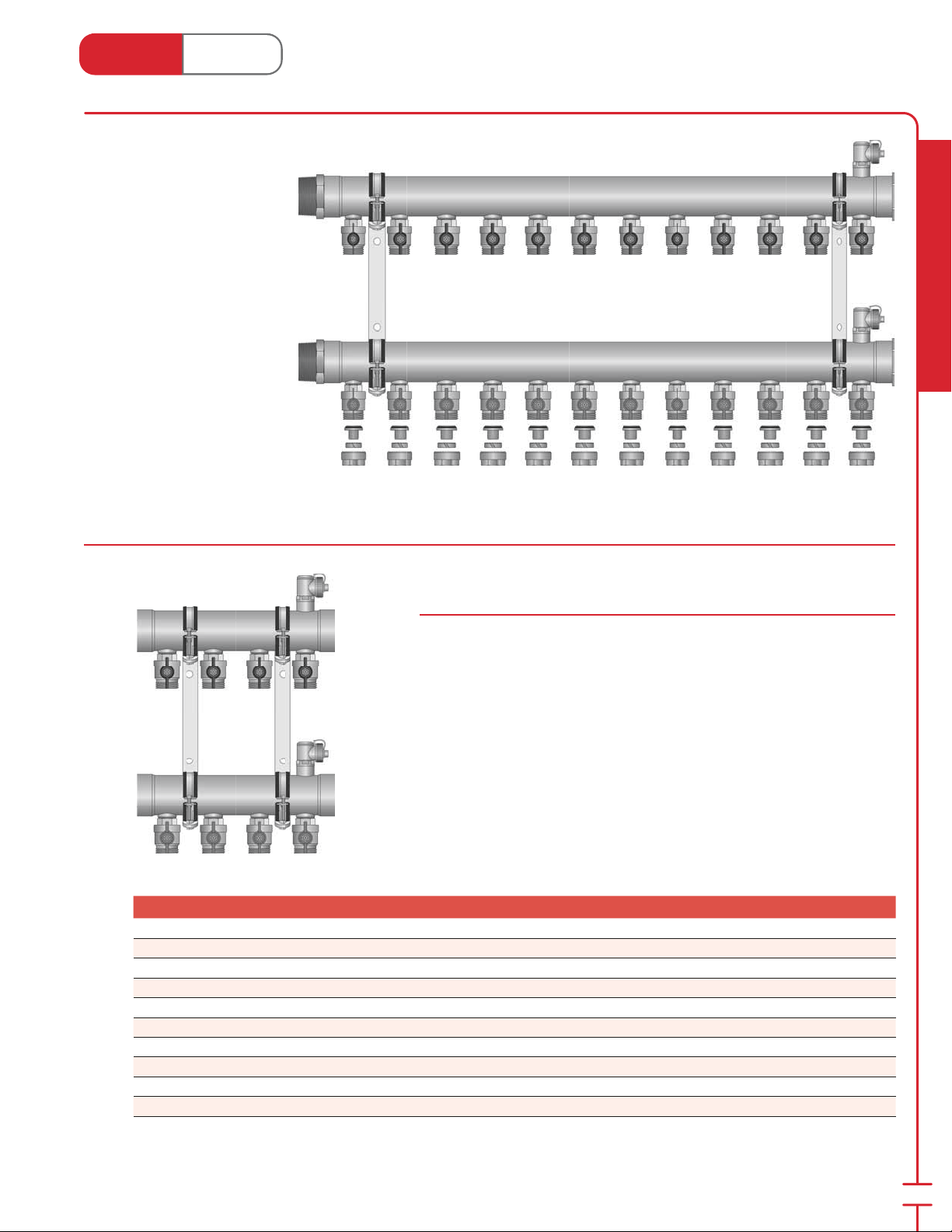

2" Stainless Steel Manifold

Canada - July 1, 2014

Features:

• Preassembled

con gurations from 4 to 14

loops.

• Ball valve isolation for each

loop.

• 1-1⁄2" and 2" MNPT open end

adapters.

• Maximum trunk ow rate:

50 US gpm (11.4 m3/h).

• Branch pair Cv = 6.

• 5⁄8", 3⁄4", and 1" PEX

connecters.

Typical Applications:

• Large commercial.

• Snow melting.

• Distribution header.

Radiant Heating & Cooling

(76612 - 12 loop model shown with 2" MNPT Assembly Kit, and 3⁄4" PEX connecters)

2" Stainless Steel Manifolds

76600 Series

Manifold includes:

• 1 assembled supply manifold with ball valves and hose bib/air vent.

• 1 assembled return manifold with ball valves and hose bib/air vent.

• 2 mounting brackets.

Assembly Kit and PEX connecters sold separately.

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

76604 4 Loop 2" SS Manifold 1 ea.

76605 5 Loop 2" SS Manifold 1 ea.

76606 6 Loop 2" SS Manifold 1 ea.

76607 7 Loop 2" SS Manifold 1 ea.

76608 8 Loop 2" SS Manifold 1 ea.

76609 9 Loop 2" SS Manifold 1 ea.

76610 10 Loop 2" SS Manifold 1 ea.

76611 11 Loop 2" SS Manifold 1 ea.

76612 12 Loop 2" SS Manifold 1 ea.

76614 14 Loop 2" SS Manifold 1 ea.

19

Heat Link

5

3

www.heatlink.com

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

76600 Coupling for 2" SS Manifold 1 pair

®

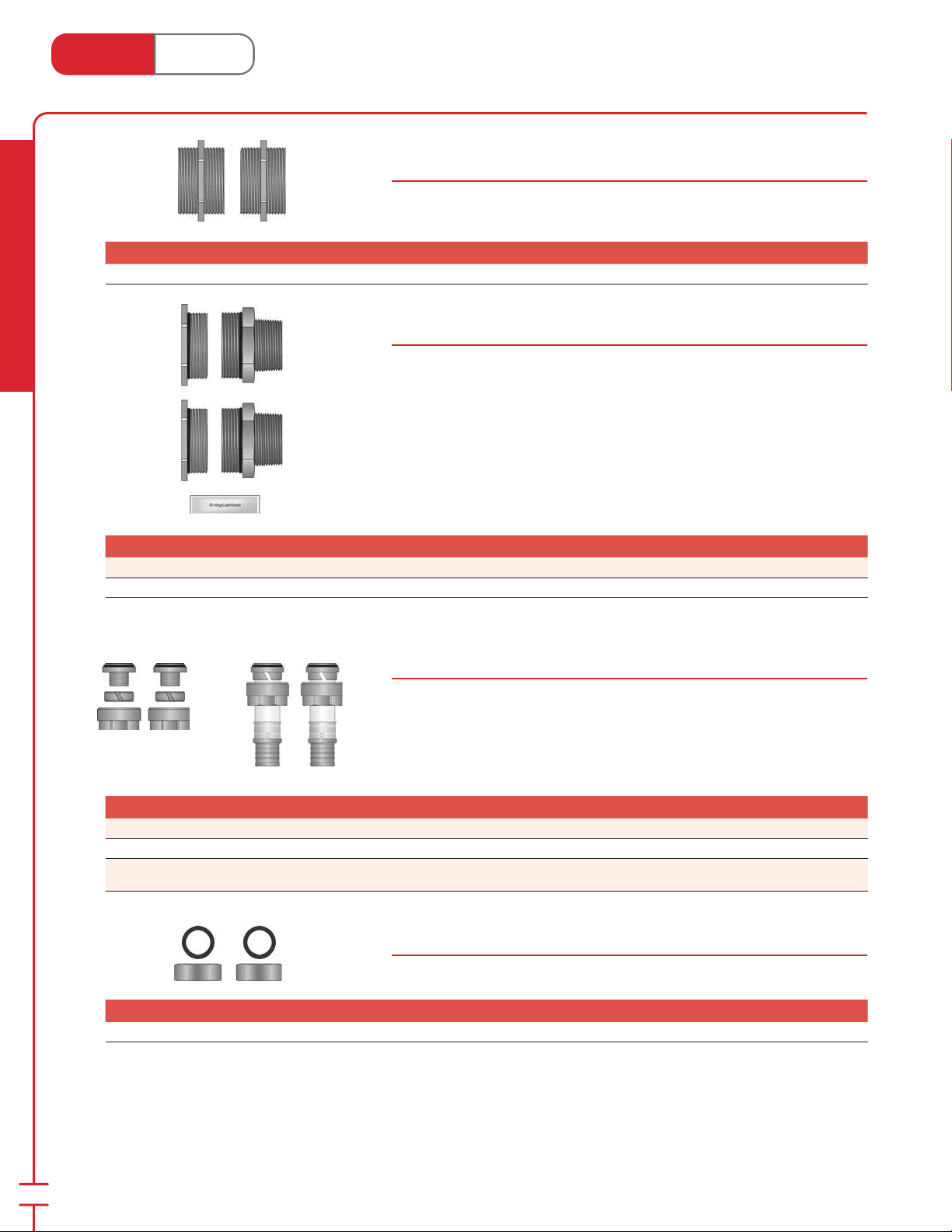

2" Stainless Steel Manifold Accessories

Canada - July 1, 2014

Coupling for 2" SS Manifold

Stk# 76600

Couple 2" SS Manifolds together. Loctite 55 pipe sealing cord is recommended for

thread sealing (not included).

Assembly Kits for 2" Stainless Steel Manifold

Stk# 76800 Series

Radiant Heating & Cooling

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

New!

New!

New!

New!

Special

Order*

76840 1-1⁄2" MNPT Assembly Kit for 2" SS Manifold 1 ea.

76850 2" MNPT Assembly Kit for 2" SS Manifold 1 ea.

77622 77628

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

77619

77622

77628 1" PEX to 2" SS Manifold Connecter 1 pair

Assembly Kit includes:

• 2 Closed Ends for 2" SS Manifold with o-ring.

• 2 Open End Adapters (1-1⁄2" or 2" MNPT) for 2" SS Manifold with o-ring.

• 1 packet of lubricant.

PEX Connecters for 2" Stainless Steel Manifold

Stk# 77600 Series

Solid brass tting attaches to the end of the PEX tubing and allows for easy

installation onto the shut-o valves of the 2" SS manifold. Comes with o-ring.

1" connecters require 1" SS Press Sleeves (#24228; page 126) and use of a 1"

Press Tool (e.g. 11328).

⁄8" PEX to 2" SS Manifold Connecter 1 pair

⁄4" PEX to 2" SS Manifold Connecter 1 pair

20

New!

1" Cap and Washer for 2" Stainless Steel Manifold

Stk# 76675

Cap to seal 2" SS manifold outlet.

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

76675 1" Cap and Washer for 2" SS Manifold 1 pair

* Check with your local representative for availability.

Manifold

Housings

7

Heat Link

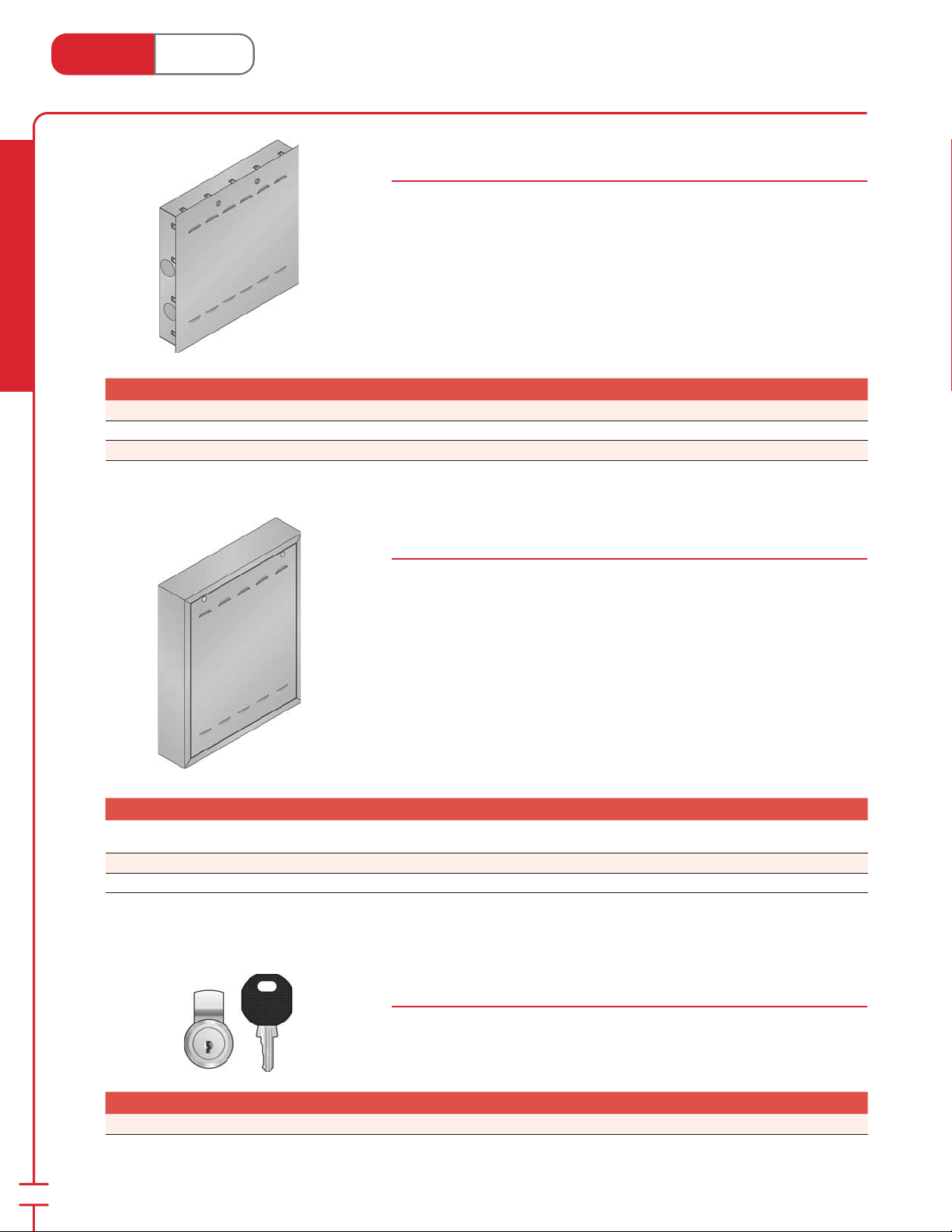

Features & Bene ts

;

;

;

;

;

;

Manifold

Housings

Features & Bene ts

allows easy access to manifold

;

visible parts made of satin coated

;

steel and are ready to paint without

priming

cover enables a structural ush seal

;

locking, removable (lift o ) door

;

stylish ventilation apertures to

;

prevent build up of heat and

formation of condensation

®

openings for mains piping on left &

;

right sides (recessed only)

Stk. # Width Height Depth

71400 Series: Surface Mounted Manifold Housing

71424

71430

71442

71700 Series: Recessed Manifold Housing

71724

71730

71743

24"

(610 mm)

30"

(762 mm)

42"

(1067 mm)

24"

(610 mm)

30-1⁄4"

(768 mm)

43-1⁄2"

(1105 mm)

30"

(762 mm)

30"

(762 mm)

30"

(762 mm)

23"

(584 mm)

23"

(584 mm)

23"

(584 mm)

5-1⁄2"

(140 mm)

5-1⁄2"

(140 mm)

5-1⁄2"

(140 mm)

⁄8"

3-

(98 mm)

3-7⁄8"

(98 mm)

3-7⁄8"

(98 mm)

Maximum # of Loops with Manifold Assembly Kit #: Max # of

79400* 79401* 79402* 79200

1

45344

77667

11 12 10 11 12

1 2 3 1 2 3 1 2 3 1 2 3 1 2 3

4 7 5 8 3 6 4 8 3 7

6 9 7 10 5 8 7 10 6 7

11 12 12 12 10 12 12 12 12 12

SS Manifold

Loops

Installation Methods:

1

Allowance for 90˚ mains piping.

2

Allowance for straight isolation valves.

3

Manifolds only, no piping allowances.

* Thermometers must be removed in recessed housing.

21

3

Heat Link

7

1

1

1

www.heatlink.com

Radiant Heating & Cooling

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

71724 Recessed Manifold Housing 24"×23"×3-7⁄8" 1 ea.

71730 Recessed Manifold Housing 30"×23"×3-

71743 Recessed Manifold Housing 43-

®

Manifold Housings

Canada - July 1, 2014

Manifold Housing: Recessed

71700 Series

Allows easy access to the manifold through its locking, removable door.

Features: visible parts made of satin coated steel, surfaces ready to paint without

priming, and stylish ventilation apertures to prevent build up of heat and

formation of condensation.

For use with TwistSeal® and Stainless Steel Manifolds (76100 and 76200 series).

Not compatible with 2" Stainless Steel Manifolds (76600 series).

⁄8" 1 ea.

⁄2"×23"×3-7⁄8" 1 ea.

Special

Pricing

Manifold Housing: Surface Mount

71400 Series

Allows easy access to the manifold through its locking, removable door.

Features: made of satin coated steel, surfaces ready to paint without priming,

and stylish ventilation apertures to prevent build up of heat and formation of

condensation. Skirting by others.

For use with TwistSeal® and Stainless Steel Manifolds (76100 and 76200 series).

Not compatible with 2" Stainless Steel Manifolds (76600 series).

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

71424 Surface Mounted Manifold Housing 24"×30"×5-1⁄2" 1 ea.

71430 Surface Mounted Manifold Housing 30"×30"×5-

71442 Surface Mounted Manifold Housing 42"×30"×5-

⁄2" 1 ea.

⁄2" 1 ea.

Key Lock for Manifold Housing Door

Stk# 71902

22

Key lock that can eld replace the standard coin/screwdriver lock of manifold

housings (71700 and 71400 Series).

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

71902 Key Lock for Housing Door 1 ea.

Heat Link

3

1

5

3

3

1

5

3

www.heatlink.com

®

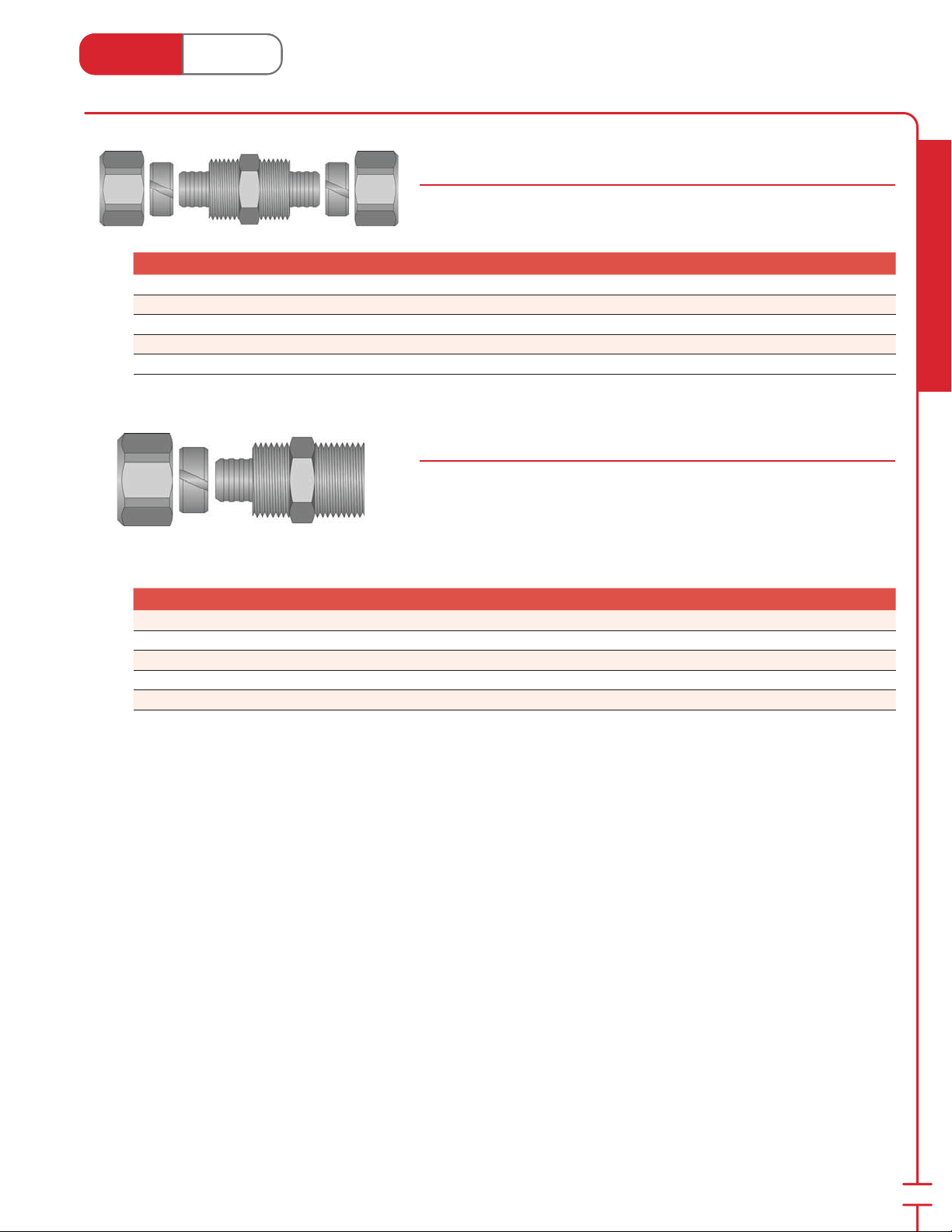

PEX Compression Couplings & Adapters

Canada - July 1, 2014

PEX Tubing Compression Couplings

69000 Series

Solid brass ttings couples PEX tubing to PEX tubing.

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

69012

69005

69019

69022

69028 1" × 1" PEX Comp. Coupling 1 25 ea.

⁄8" × 3⁄8" PEX Comp. Coupling 1 25 ea.

⁄2" × 1⁄2" PEX Comp. Coupling 1 25 ea.

⁄8" × 5⁄8" PEX Comp. Coupling 1 25 ea.

⁄4" × 3⁄4" PEX Comp. Coupling 1 25 ea.

PEX Compression to MNPT Adapters

68000 Series

Solid brass ttings converts PEX tubing to male NPT thread.

Note: When used with PEX tubing there is a risk of thermal expansion /

contraction due to temperature uctuation. It is recommended that a

swing joint or expansion loop is installed at the high temp (supply) end of

the tubing.

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

68012

68005

68019

68022

68028 1" PEX Comp. × 1" MNPT Adapter 1 25 ea.

⁄8" PEX Comp. × 1⁄2" MNPT Adapter 1 25 ea.

⁄2" PEX Comp. × 1⁄2" MNPT Adapter 1 25 ea.

⁄8" PEX Comp. x 3⁄4" MNPT Adapter 1 25 ea.

⁄4" PEX Comp. × 3⁄4" MNPT Adapter 1 25 ea.

Radiant Heating & Cooling

23

Heat Link

1

1

5

1

1

5

1

5

3

www.heatlink.com

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

67305

Radiant Heating & Cooling

67705

67319

®

PEX Compression Adapters

Canada - July 1, 2014

PEX Compression to 90˚ Female Sweat Elbows

67300 & 67700 Series

Solid brass ttings converts PEX tubing to female copper pipe.

Ideal for baseboard connections.

⁄2" PEX Comp. × 1⁄2" F/Sweat 90° Elbow 1 25 ea.

⁄2" PEX Comp. × 3⁄4" F/Sweat 90° Elbow 1 25 ea.

⁄8" PEX Comp. × 3⁄4" F/Sweat 90° Elbow 1 25 ea.

PEX Compression to Female Sweat Adapters

67100 & 67500 Series

Solid brass ttings converts PEX tubing to female copper pipe.

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

67105

67505

67119

⁄2" PEX Comp. × 1⁄2" F/Sweat Adapter 1 25 ea.

⁄2" PEX Comp. × 3⁄4" Straight F/Sweat Adapter 1 25 ea.

⁄8" PEX Comp. × 3⁄4" F/Sweat Adapter 1 25 ea.

PEX Compression to Male Sweat Adapters

67000 Series

Solid brass ttings converts PEX tubing to male copper pipe.

Stk# Description Pkg Qty Carton Qty Unit List Price / Unit

67005

67019

67022

⁄2" PEX Comp. × 1⁄2" M/Sweat Adapter 1 25 ea.

⁄8" PEX Comp. × 3⁄4" M/Sweat Adapter 1 25 ea.

⁄4" PEX Comp. × 3⁄4" M/Sweat Adapter 1 25 ea.

Note: For 1⁄2", 3⁄4", 1", 1-1⁄4", and 1-1⁄2" PEX tubing the SS press sleeve tting system can be used, see the ”Potable Water System” section.

24

Heat Link

www.heatlink.com

®

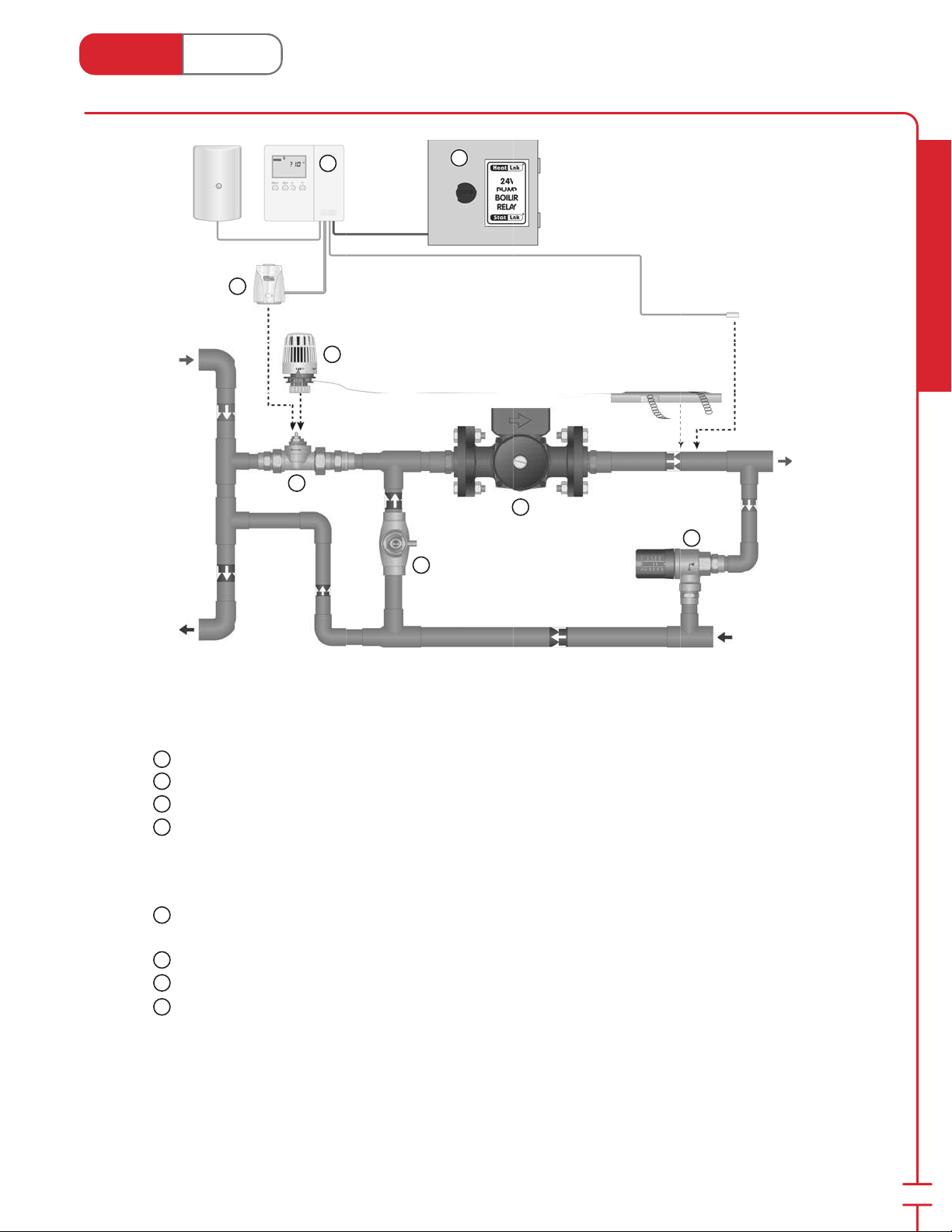

2-way Injection Mixing

Canada - July 1, 2014

Primary

Supply

6

8

5

1

7

Secondary

Supply

3

4

2

Radiant Heating & Cooling

Primary

Return

Components

1

HeatLink® Injection Valve (62000 series; page 33)

2

HeatLink® Balancing Valve (#62325; page 32)

3

Secondary Pump

HeatLink® Pressure Activated Bypass Valve (60000 series; page 34)

4

Control Options

Setpoint

5

HeatLink® Thermostatic Head with Capillary (#57094; page 36)

Setpoint or Outdoor Reset

6

HeatLink® Compact Mixing Reset Control (#31355; page 44)

7

HeatLink® 24Vac DPDT Pump Relay (#45112; page 42)

HeatLink® DDC Actuator (#56121; page 37)

8

Secondary

Return

Note: Not all required components are shown. Local codes, regulation, and authorities have nal jurisdiction.

25

Heat Link

www.heatlink.com

®

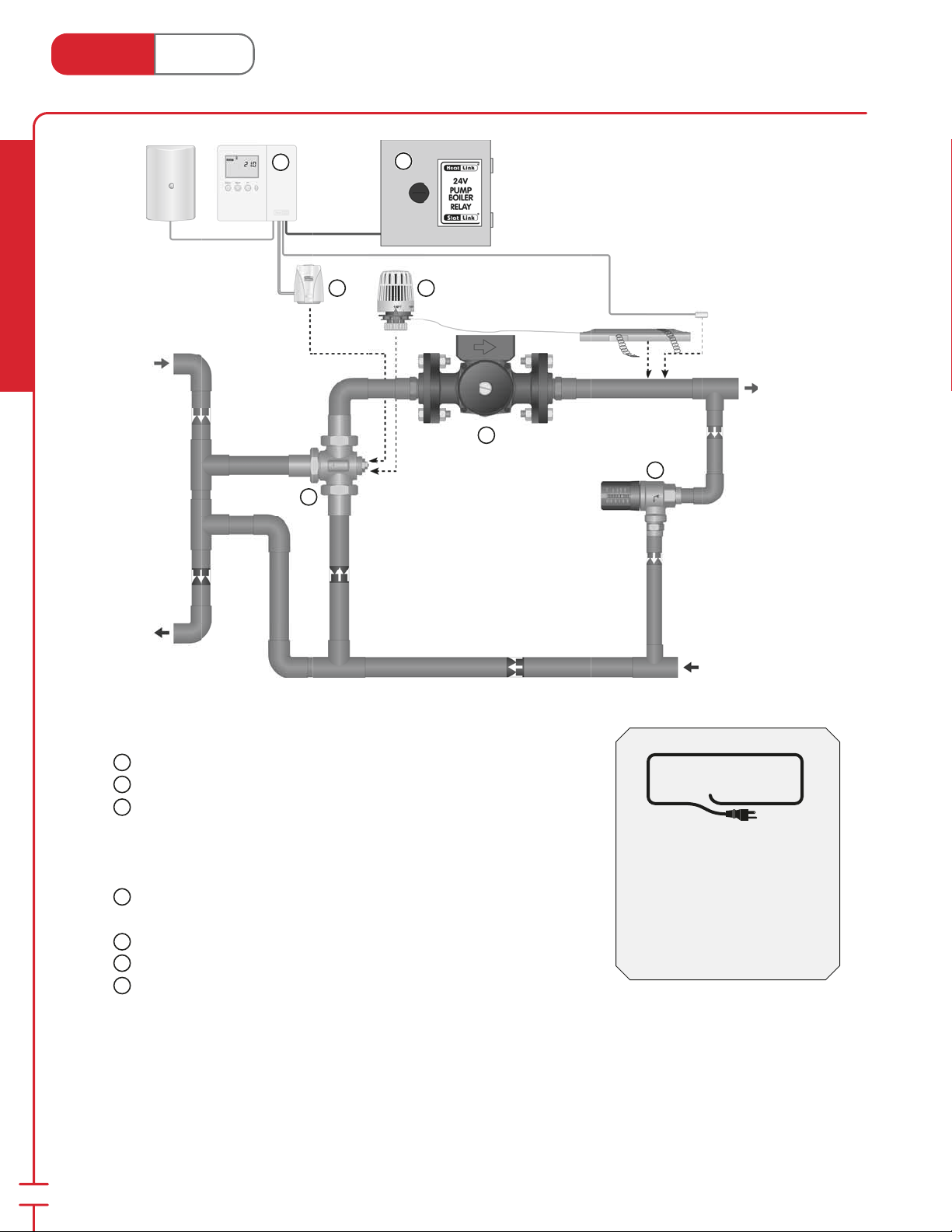

3-way Compact Mixing System

Canada - July 1, 2014

Radiant Heating & Cooling

Primary

Supply

5

7

1

6

4

Secondary

Supply

2

3

Primary

Return

Components

1

HeatLink® Compact 3-way Mixing Valve (63700 series; page 31)

2

Secondary Pump

3

HeatLink® Pressure Activated Bypass Valve (60000 series; page 34)

Control Options

Setpoint

4

HeatLink® Thermostatic Head with Capillary (#57094; page 36)

Setpoint or Outdoor Reset

HeatLink® Compact Mixing Reset Control (#31355; page 44)

5

6

HeatLink® 24Vac DPDT Pump Relay (#45112; page 42)

7

HeatLink® DDC Actuator (#56121; page 37)

Note: Not all required components are shown. Local codes, regulation, and authorities have nal jurisdiction.

Secondary

Return

™

MECHANICAL

ROOM IN A BOX

Panel Alternatives

TMP series - pages 72-79

TWH series - pages 80-85

CDP series - pages 92-95

SSTS series - pages 104-105

26

Heat Link

www.heatlink.com

®

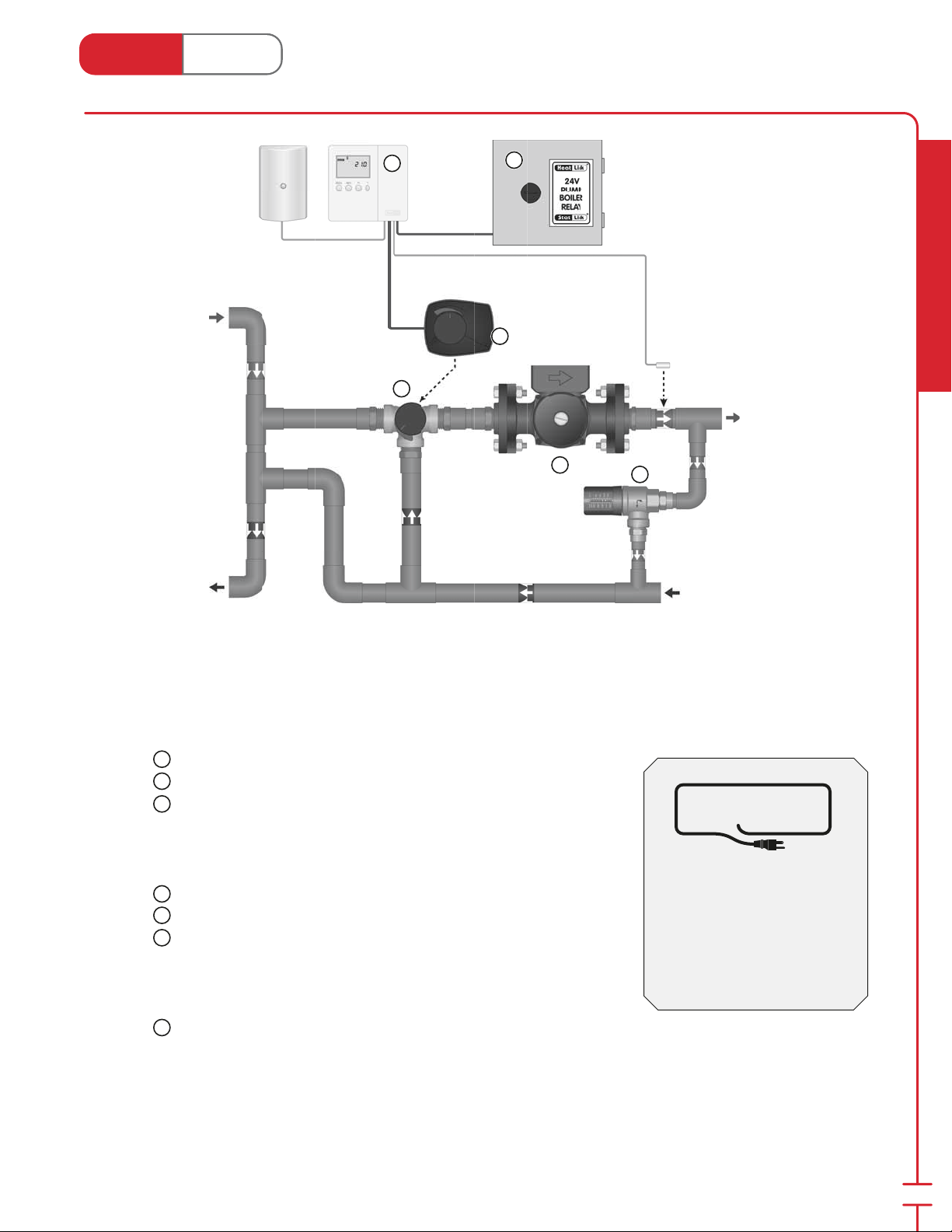

3-way Mixing System

Canada - July 1, 2014

Primary

Supply

Primary

Return

4

1

5

6

Secondary

Supply

2

3

Secondary

Return

Radiant Heating & Cooling

Components

1

HeatLink® 3-way Mixing Valve (63500 series; page 30)

2

Secondary Pump

3

HeatLink® Pressure Activated Bypass Valve (60000 series; page 34)

MECHANICAL

ROOM IN A BOX

Control Options

Setpoint or Outdoor Reset

HeatLink® Compact Mixing Reset Control (#31355; page 44)

4

5

HeatLink® 24Vac DPDT Pump Relay (#45112; page 42)

6

HeatLink® Mixing Valve Motor (58100 series; page 35)

Snow melt (not shown)

HeatLink® Snow/Ice Detector & Melting Control (#31667; page 45)

HeatLink® Snow/Ice Detector (#30090, 30091; page 45)

6

HeatLink® Mixing Valve Motor (58100 series; page 35)

Note: Not all required components are shown. Local codes, regulation, and authorities have nal jurisdiction.

Panel Alternatives

CDP310R - pages 96-97

SSTL series - pages 106-107

SMP series - pages 108-116

™

27

Heat Link

www.heatlink.com

®

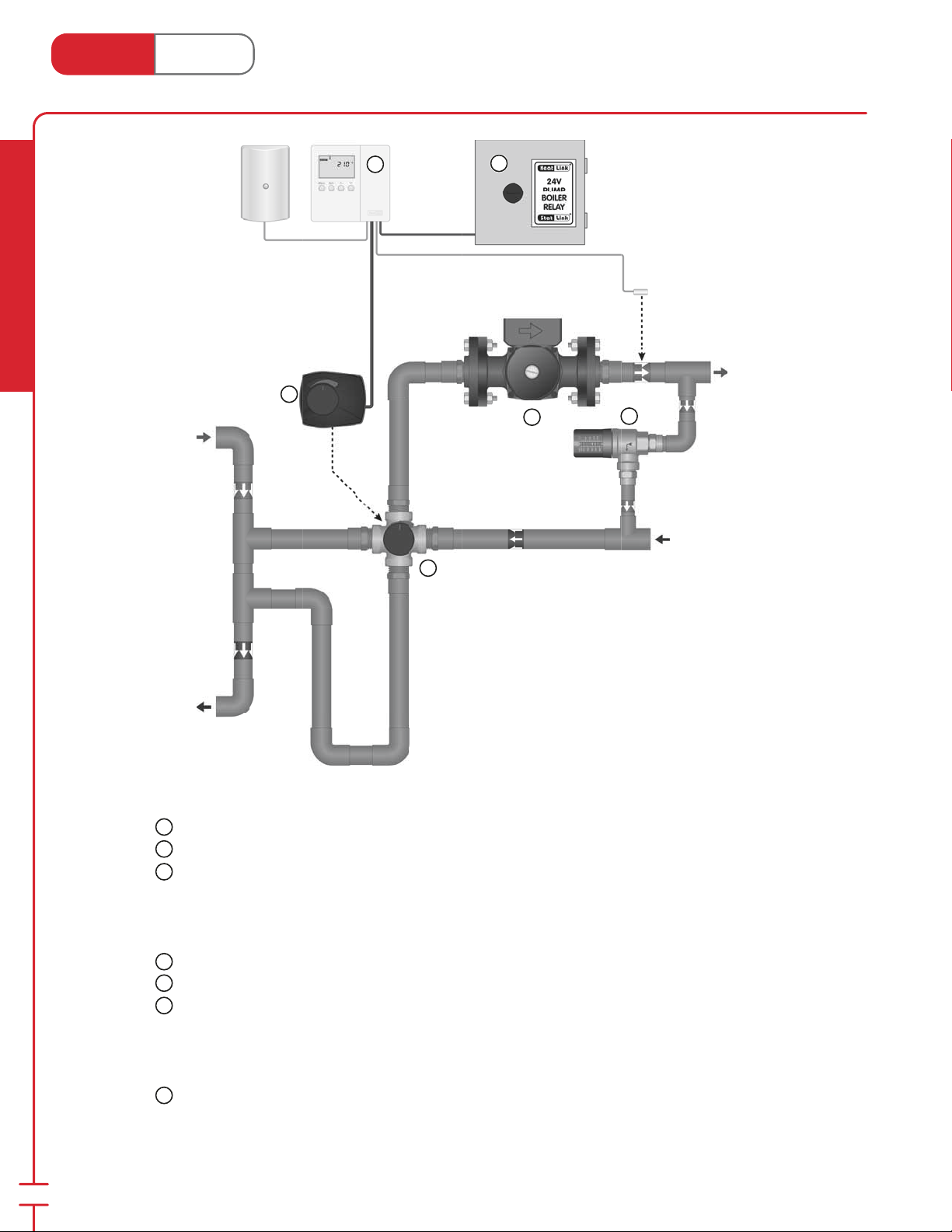

4-way Mixing System

Canada - July 1, 2014

Radiant Heating & Cooling

Primary

Supply

4

6

1

5

Secondary

Supply

2

3

Secondary

Return

Primary

Return

Components

1

HeatLink® 4-way Mixing Valve (64000 series; page 30)

2

Secondary Pump

3

HeatLink® Pressure Activated Bypass Valve (60000 series; page 34)

Control Options

Setpoint or Outdoor Reset

HeatLink® Compact Mixing Reset Control (#31355; page 44)

4

5

HeatLink® 24Vac DPDT Pump Relay (#45112; page 42)

6

HeatLink® Mixing Valve Motor (58100 series; page 35)

Snow melt (not shown)

HeatLink® Snow/Ice Detector & Melting Control (#31667; page 45)

HeatLink® Snow/Ice Detector (#30090, 30091; page 45)

6

HeatLink® Mixing Valve Motor (58100 series; page 35)

Note: Not all required components are shown. Local codes, regulation, and authorities have nal jurisdiction.

28

Loading...

Loading...