Heatilator WS18-AU, WS22-AU Installation Instructions Manual

Eco-Choice WS Series Wood Burner Installation Instructions

Eco-Choice WS Series Wood Burner Installation Instructions

Model:

WS18-AU

INSTALLATIONS TO COMPLY WITH AS/NZS2918:2001

AND WILL REQUIRE A BUILDING CONSENT

Model:

WS22-AU

IMPORTANT: Read all instructions carefully before starting installation. Failure to follow these

instructions may result in a fi re hazard and will void the warranty.

• Fig. 3,4,5,6, 7 and Table 1,2,3,4 relate to installations with tested fl ue systems; as per AS/NZS

2918:2001 - Appendix F, with a ceiling angle between 0° - 30° inclusive.

• For installations with a ceiling angle greater than 30°, refer to Fig. 7 & 8 and AS/NZS 2918:2001

4.6.3(b)

• Ceiling Plate may vary in size depending on ceiling angle. Please specify ceiling pitch prior to

ordering the ceiling plate.

• Heatilator Eco Choice series wood burner’s are tested and approved to the N.Z. National Environ-

mental Standards;

WS18-AU Eco-Choice Hardwood Certifi ed

Particulate Emissions = 1.3 g/kg Space Heating Effi ciency = 85%

WS18-AU Eco-Choice Softwood Certifi ed

Particulate Emissions = 1.1 g/kg Space Heating Effi ciency = 73%

WS22-AU Eco-Choice Hardwood Certifi ed

Particulate Emissions = 1.2 g/kg Space Heating Effi ciency = 82%

WS22-AU Eco-Choice Softwood Certifi ed

Particulate Emissions = 1.3 g/kg Space Heating Effi ciency = 66%

Page 1

7056-153C

September 14, 2015

WS Series Wood Burner

Hearth & Home Technologies welcomes you to our tradition of excellence! In choosing a Heatilator appliance, you

have our assurance of commitment to quality, durability, and

performance.

This commitment begins with our research of the market,

including ‘Voice of the Customer’ contacts, ensuring we

make products that will satisfy your needs. Our Research

and Development facility then employs the world’s most

advanced technology to achieve the optimum operation of

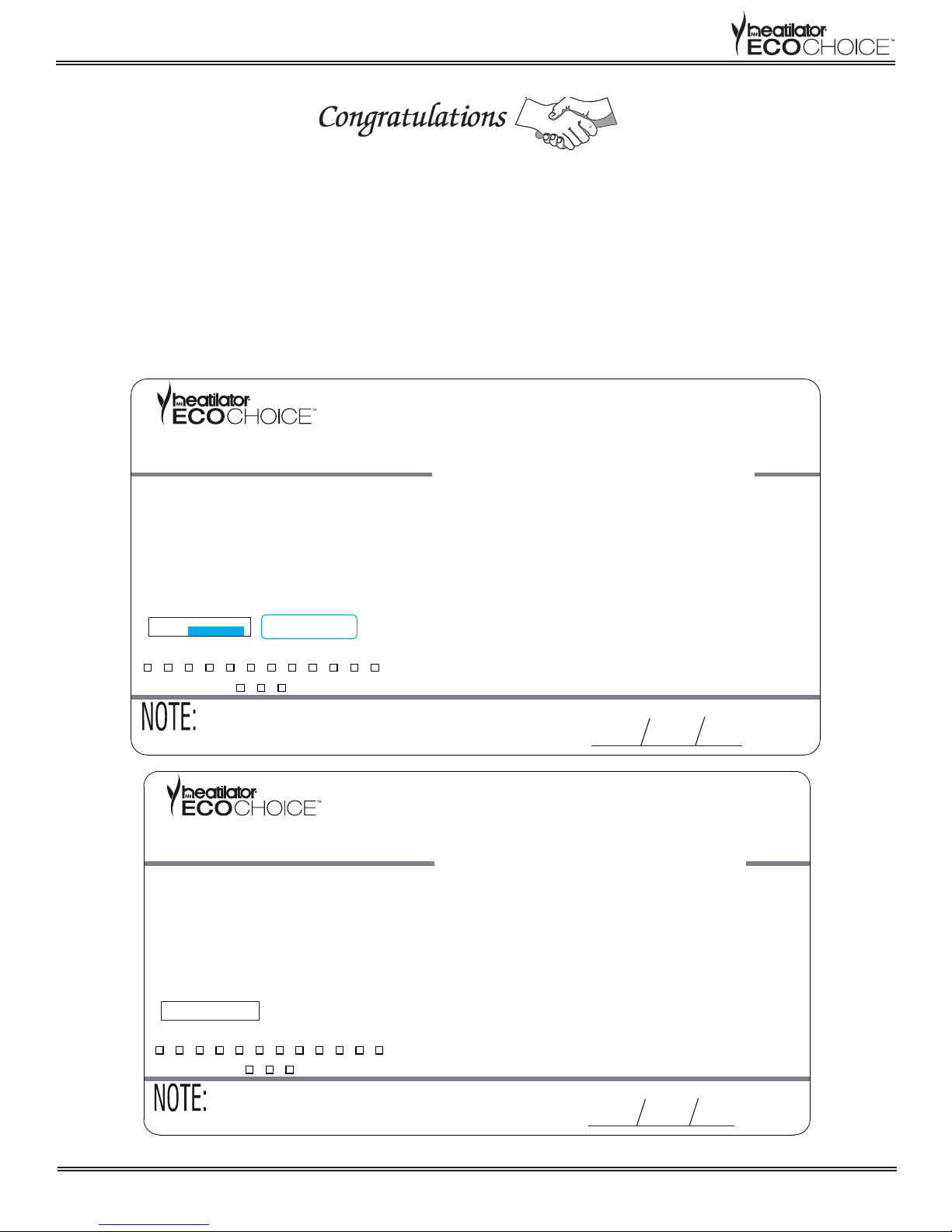

ECO CHOICE WOODFIRE COMPLIANCE LABEL

This appliance has been TESTED TO AS/NZS4013 for Softwood by HRL Technology Report # HCMG/14/027 Date tested: May 2014

This appliance has been TESTED TO AS/NZS4013 for Hardwood by HRL Technology Report # HCMG/14/004 Date tested: February 2014

OVERALL AVERAGE EFFICIENCY

AVERAGE PARTICULATE EMISSION FACTOR

MAXIMUM AVERAGE HEAT OUTPUT

SERIAL NO.

room for .14 x .875” S/N

007065

JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC

2014

2015 2016

1.5” x .375 Barcode Label

WETBACK - ALL MODELS

MODEL ECO CHOICE WS18 WOOD STOVE

TESTED TO AS/NZS 4012

TESTED TO AS/NZS 4013

APPROVED FUEL

MANUFACTURED BY

our stoves, inserts and fi replaces. And yet we are old-fash-

ioned when it comes to craftsmanship. Each unit is meticulously fabricated and surfaces are hand-fi nished for lasting

beauty and enjoyment. Our pledge to quality is completed

as each model undergoes a quality control inspection.

We wish you and your family many years of enjoyment in

the warmth and comfort of your hearth appliance. Thank

you for choosing Heatilator.

SOFTWOOD

73%

1.1 g/kg

7.5 kW

HARDWOOD

85%

1.3 g/kg

7.2 kW

BURN ONLY WOOD WITH A MOISTURE CONTENT LESS THEN 25% (dry

basis).

Wetbacks are NOT an approved option and must not be tted.

Hearth & Home Technologies, 1445 North Highway, Colville, WA

99114, United States of America.

PERFORMANCE MAY VARY FROM TEST VALUES DEPENDING ON ACTUAL

OPERATING CONDITIONS.

U.S. ENVIRONMENTAL PROTECTION AGENCY

Export stove. May not be operated within the United States.

INSTALLATION

DATE

7056-152

ECO CHOICE WOODFIRE COMPLIANCE LABEL

This appliance has been TESTED TO AS/NZS4013 for Softwood by HRL Technology Report # HCMG/14/029 Date tested: May 2014

This appliance has been TESTED TO AS/NZS4013 for Hardwood by HRL Technology Report # HCMG/14/006 Date tested: February 2014

OVERALL AVERAGE EFFICIENCY

AVERAGE PARTICULATE EMISSION FACTOR

MAXIMUM AVERAGE HEAT OUTPUT

SERIAL NO.

007066

JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC

2014

2015 2016

PERFORMANCE MAY VARY FROM TEST VALUES DEPENDING ON ACTUAL

OPERATING CONDITIONS.

U.S. ENVIRONMENTAL PROTECTION AGENCY

Export stove. May not be operated within the United States.

WETBACK - ALL MODELS

MODEL ECO CHOICE WS22 WOOD STOVE

SOFTWOOD

TESTED TO AS/NZS 4012

TESTED TO AS/NZS 4013

APPROVED FUEL

MANUFACTURED BY

BURN ONLY WOOD WITH A MOISTURE CONTENT LESS THEN 25% (dry

basis).

Wetbacks are NOT an approved option and must not be tted.

Hearth & Home Technologies, 1445 North Highway, Colville, WA

99114, United States of America.

66%

1.3 g/kg

8.1 kW

INSTALLATION

DATE

HARDWOOD

82%

1.2g/kg

9.4 kW

7057-139

Page 2

7056-153C

September 14, 2015

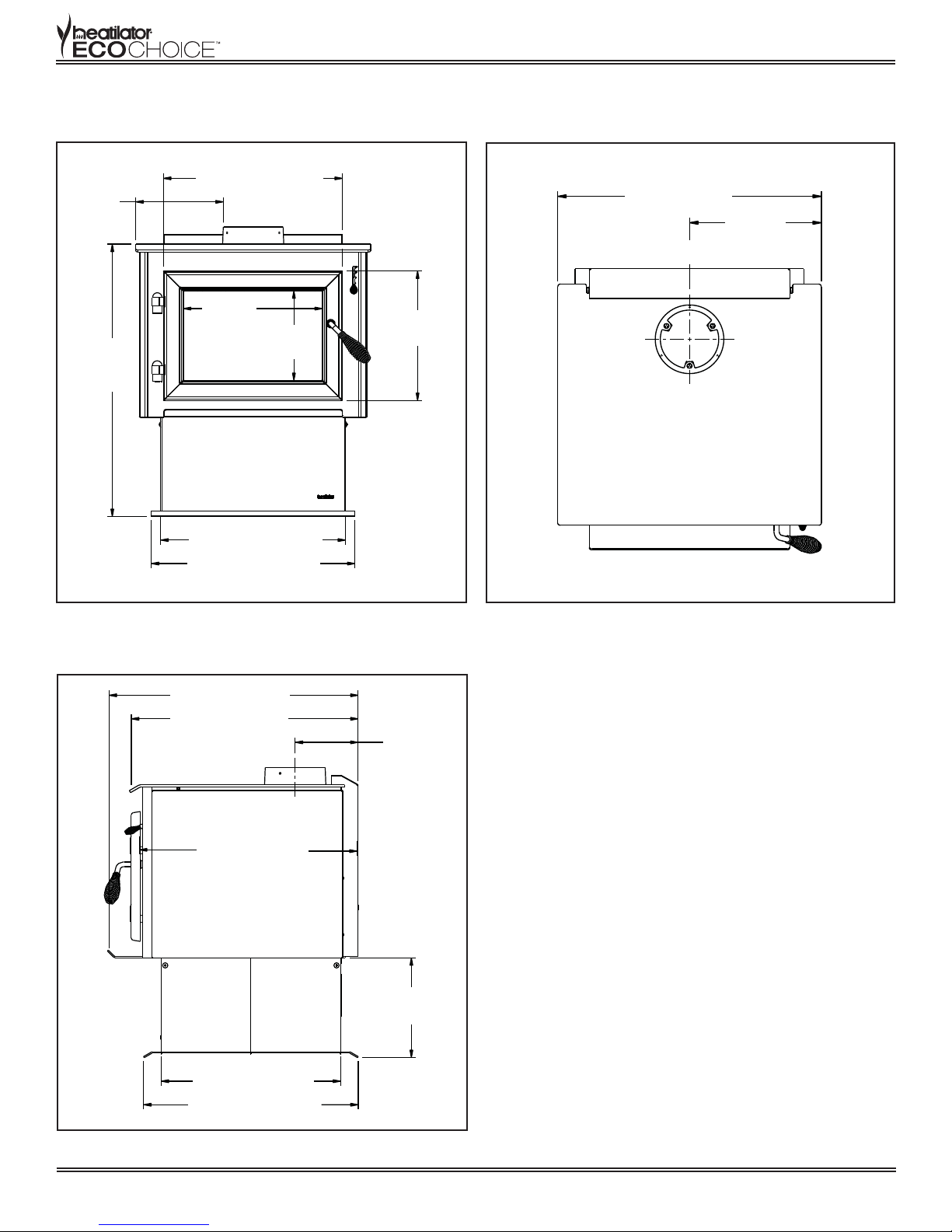

Heatilator WS18 Wood Burner Dimensions

19-1/16 in. (484 mm)

9-5/16 in.

(236 mm)

14-13/16 in.

29 in.

(736 mm)

(376 mm)

9-9/16 in.

(242 mm)

13-13/16 in.

(350 mm)

WS Series Wood Burner

25 in. (635mm)

C

L

12-1/2 in.

(317mm)

19-11/16 in. (500 mm)

21-11/16 in. (550 mm)

Figure 3.1 - Front View

26-1/2 in. (673mm)

24-1/8 in. (612mm)

23-1/4 in. (591mm)

Figure 3.2 -Top View

6-11/16 in.

(169mm)

C

L

19-1/16 in. (484mm)

22-13/16 in. (579mm)

Figure 3.3 - Side View

September 14, 2015

10-5/8 in.

(269mm)

7056-153C

Page 3

WS Series Wood Burner

FLOOR PROTECTOR

Heatilator WS18 does not require a insulating Floor Protector, as they are tested and comply with the

minimum Floor Protector requirements of AS/NZS 2918:2001.

Note:

▪ The minimum Floor Protector sizes are specifi ed in the clearance chart, see Table 1 & 2.

▪ A Floor Protector can include ceramic tiles with grouted joints fi xed directly onto a wooden fl oor or

a sheet of toughened glass, panel steel or any other non combustible material laid directly onto a

wooden fl oor.

▪ If installed directly onto a concrete slab, the concrete slab can be considered as the fl oor

protector,but must maintain the minimum measurement listed.

PARALLEL POSITIONING

Fig. 4

REAR WALL

G

SIDE WALL

Table 1

E

F

FLOOR PROTECTOR

D

C

DESCRIPTION Default Flue Kit

A Min. Clearance from back of unit to rear wall 175

B Min. clearance from center of spigot to rear wall 345

C Min. distance from front of base to fl oor protector front 300

D Min. fl oor protector front width 800

E Min. distance from rear wall to front of fl oor protector 1055

F Min. distance from unit side to side wall 300

G Min. clearance from center of spigot to side wall 618

B

A

REAR WALL

NOTE: HEAT SHIELD REQUIREMENTS FOR HEAT SENSITIVE WALLS

Clearances may be reduced by provision of an appropriately located heat shield refer to

AS/NZS 2198:2001 3.2.3 TABLE 3.1

Page 4

7056-153C

September 14, 2015

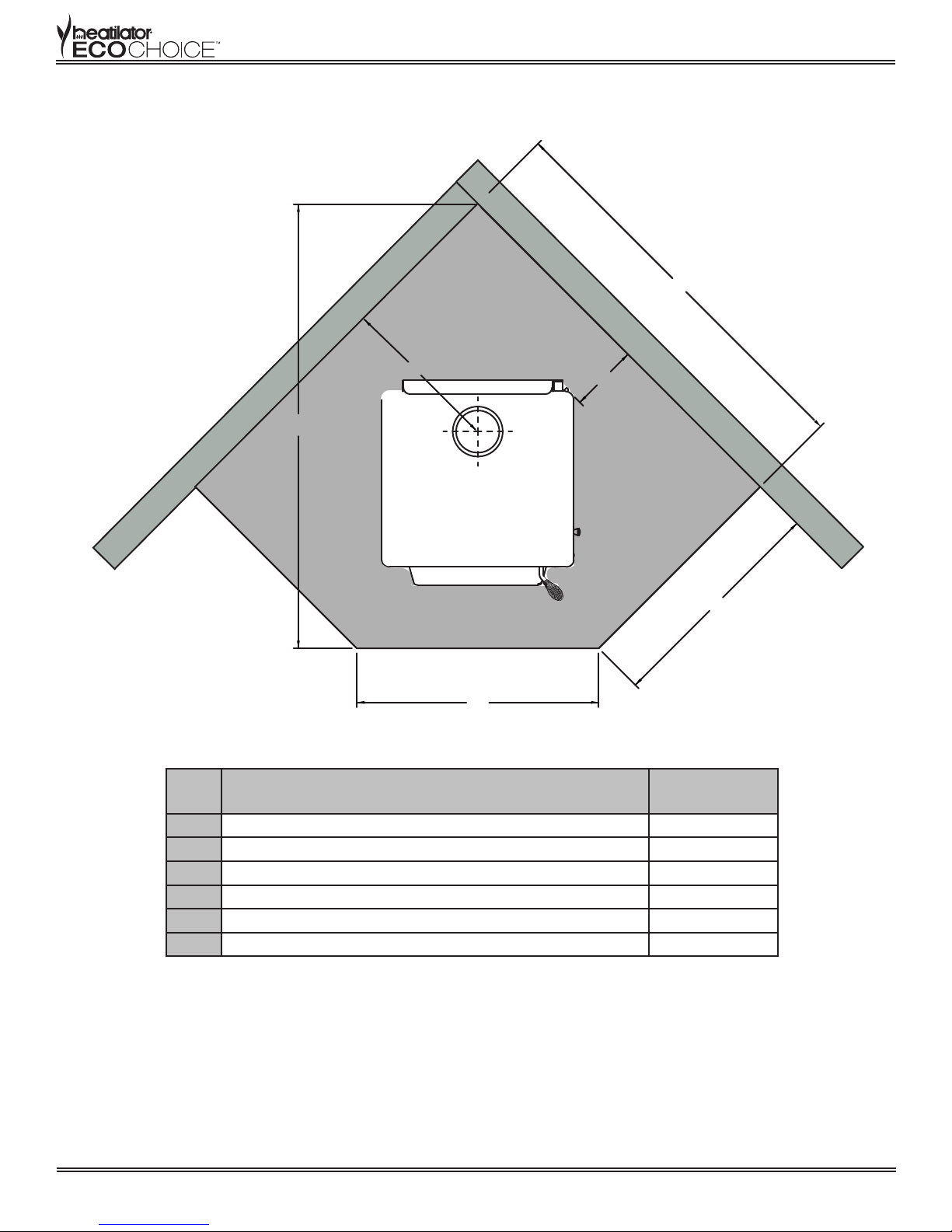

CORNER POSITIONING (45°)

Fig. 5

WS Series Wood Burner

F

CORNER WALL

B

FLOOR PROTECTOR

E

CORNER WALL

A

C

D

Table 2

DESCRIPTION Default Flue Kit

A Min. clearance from fi rebox corner to corner walls 155

B Min. distance from center of spigot to corner walls 470

C Min. distance from corner wall to fl oor protector front 1219

D Min. fl oor protector projection from corner wall 730

E Min. fl oor protector front width 692

F Min. overall fl oor protector depth 1379

FIREBOX INSTALLATION

1. If a separate fl oor protector is being used position now. Place the fi rebox on the fl oor protector to

suit the minimum installation clearances. (See Fig 3 or 4).

2. Seismically restrain the fi rebox and the fl oor protector to the fl oor.

3. Fit 2 x 6mm fi xings suitable for the fl oor material. DO NOT over tighten.

4. Fit timber trim pedestal edging to front and back of base (optional).

September 14, 2015

7056-153C

Page 5

Loading...

Loading...