Heatilator MAX60L, MAX60, MAX60LE, MAX60EF, MAX60F Installation & Operating Instructions Manual

...

INSTALLATION & OPERATING

INSTRUCTIONS

MAXUS DIRECT VENT HEATER LISTED GAS APPLIANCE

WARNING: If the information in this manual

is not followed exactly, a fire or explosion may

result causing property damage, personal injury or loss of life.

— Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

— What to do if you smell gas

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

fire department.

— Installation and service must be performed by a

qualified installer, service agency or the gas

supplier.

MAX60 (Shown with the FFMAX1 Face)

For Residential Use - Meets all HUD requirements for

manufactured housing installations.

This appliance may be installed as an OEM installation in a manufactured (mobile) home and must be installed in accordance with the manufacturer’s

instructions and the Manufactured Home Construction and Safety Standard, Title 24 CFR, Part 3280 or Standard for Installation in Mobile

Homes, CAN/CSA Z240 MH. For assistance during installation contact your local dealer or contact the Heatilator Technical Services Department,

Hearth & Home Technologies Inc., 1915 W. Saunders St., Mt. Pleasant, IA 52641. This appliance may be installed in an aftermarket permanently located,

manufactured (mobile) home, where not prohibited by local codes. This appliance is only for use with the type of gas listed on the rating plate. This

appliance is not convertible for use with other gases, unless a certified conversion kit is used.

Improper installation, adjustment, alteration, service or maintenance can cause injury or property damage. Refer to this

manual. For assistance or additional information, consult a qualified installer, service agency or the gas supplier.

09/04 30484 Rev Q 1

CAUTION:

Do not expose the appliance to the elements (such as

rain, etc.).

FOR MANUFACTURED (MOBILE) HOMES:

WARNING!

MAXUS DIRECT VENT HEATER

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE

TABLE OF CONTENTS

A. Listings and Code Approvals........................................................................................................................ 3

B. Appliance Specifications............................................................................................................................. 5

C. Locations and Clearances ........................................................................................................................... 7

D. Framing/Setting the Appliance..................................................................................................................... 9

E. Venting ...................................................................................................................................................... 10

F. Utilities ...................................................................................................................................................... 23

G. Finishing.................................................................................................................................................... 27

H. Appliance Preparation ............................................................................................................................... 28

I. Determining the Ignition Type .................................................................................................................... 30

J. Lighting Instructions .................................................................................................................................. 30

K. Seasonal Checklist ................................................................................................................................... 32

L. Start-up Issues .......................................................................................................................................... 33

M. Maintenance Instructions ........................................................................................................................... 34

N. Replacement Parts .................................................................................................................................... 36

O. Optional Components ................................................................................................................................ 40

Index ......................................................................................................................................................... 43

Warranty .................................................................................................................................................... 44

Note: An arrow () found in the text and in the index signifies change in content.

WARNING!

DO NOT use this appliance if any part has been under water. Immediately call a qualified service technician to inspect

the appliance and to replace any part of the control system and any gas control which has been under water.

Safety Precautions

1. Please read these installation instructions completely before beginning installation procedures. Failure to follow

them could cause an appliance malfunction resulting in serious injury and/or property damage.

2. Always check your local building codes prior to installation. This installation must comply with all local, regional,

state and national codes and regulations.

3. Installation and repair should be done by a qualified service person. This appliance should also be inspected

annually by a qualified service person. More frequent inspections/cleaning may be required due to excessive lint

from carpeting, bedding materials, etc. It is imperative that the control compartment, burners and circulating air

passageways of the appliance be kept clean.

4. This is a vented decorative gas appliance. Do not burn wood or other material in this appliance.

5. NEVER leave children unattended when there is a fire burning in the appliance.

6. This appliance may only use the approved venting systems shown in these installation instructions. Venting must

not be connected to chimney flue servicing a solid fuel burning appliance or a gas fuel burning appliance.

7. NEVER use gasoline, gasoline-type lantern fuel, kerosene, charcoal lighter fluid, or similar liquids in this appliance.

Keep any flammable liquids a safe distance from the appliance.

8. While servicing this appliance, always shut off all electricity and gas to the appliance. This will prevent possible

electrical shock or burns. Also, make sure the appliance is completely cooled before servicing.

9. Do not use this appliance if any part has been under water. Immediately call a qualified service technician to inspect

the appliance and to replace any part of the control system and any gas control which has been under water.

10. Be sure to provide adequate clearances around the air openings into the combustion chamber and adequate

accessibility clearances for servicing and proper operation.

2 30484 Rev Q 09/04

MAXUS DIRECT VENT HEATER

A. LISTINGS AND CODE APPROVALS

1. U.S. and Canadian Certification

The Maxus Series Gas Appliance has been tested in

accordance with the ANSI standard Z21.88-1998, CSA

2.33-M98, and has been listed by UL for installation

and operation as described in these installation and

operating instructions. All components are AGA, CGA,

CSA or UL safety certified.

2. Local Codes

This installation must conform with local codes or, in

the absence of local codes, with the National Fuel

Gas Code, ANSI Z223.1-latest edition in the U.S.A.,

and the CAN/CGA B149-latest edition in Canada.

The Maxus Series gas appliance has been tested

and listed for use in manufactured housing (mobile

homes). These installation instructions conform with

the Manufactured Home Construction and Safety

Standard, Title 24 CFR, Part 3280, or when such a

standard is not applicable, the Standard for

Manufactured Home Installations, ANSI A225.1.

This appliance is approved for installation in

bedrooms and manufactured housing (mobile

homes) in the United States and Canada.

3. Glass Specifications/Certifications

Heatilator gas appliances manufactured with

tempered glass may be installed in hazardous

locations such as bathtub enclosures as defined by

the CPSC. The tempered glass has been tested and

certified to the requirements of ANSI Z97.1-1984 and

CPSC 16 CFR 1202. (Safety Glazing Certification

Council SGCC# 1595 and 1597. Architectural Testing,

Inc. Reports 02-31919.01 and 02-31917.01.)

This statement is in compliance with SPCS 16 CFR

Section 1201.5 “Certification and labeling

requirements” which refers to 15 USC 2063 stating,

“…Such certificate shall accompany the product or

shall otherwise be furnished to any distributor or

retailer to whom the product is delivered.”

Some local building codes require the use of tempered

glass with permanent marking in such locations.

Glass meeting this requirement is available from the

factory. Please contact your dealer or distributor to

order.

4. Efficiency

The efficiency rating of the appliance is a product

thermal efficiency rating determined under continuous

operating conditions and was determined

independently of any installed system.

If any assistance is required during installation please

contact your local dealer or contact the Heatilator

Technical Services Department, Hearth & Home

Technologies Inc., 1915 W. Saunders St., Mt. Pleasant,

IA 52641, 1-800-927-6841.

This appliance is tested and listed for use only with the optional accessories listed in

these instructions. Use of optional accessories not specifically tested for this appliance

could void the warranty and/or result in a safety hazard.

Note: Illustrations throughout these instructions reflect typical installations and are for design purposes only. Actual

installations may vary slightly due to individual design preferences. However, minimum and maximum clearances

must be maintained at all times.

The illustrations and diagrams used throughout these instructions are not drawn to scale.

09/04 30484 Rev Q 3

WARNING!

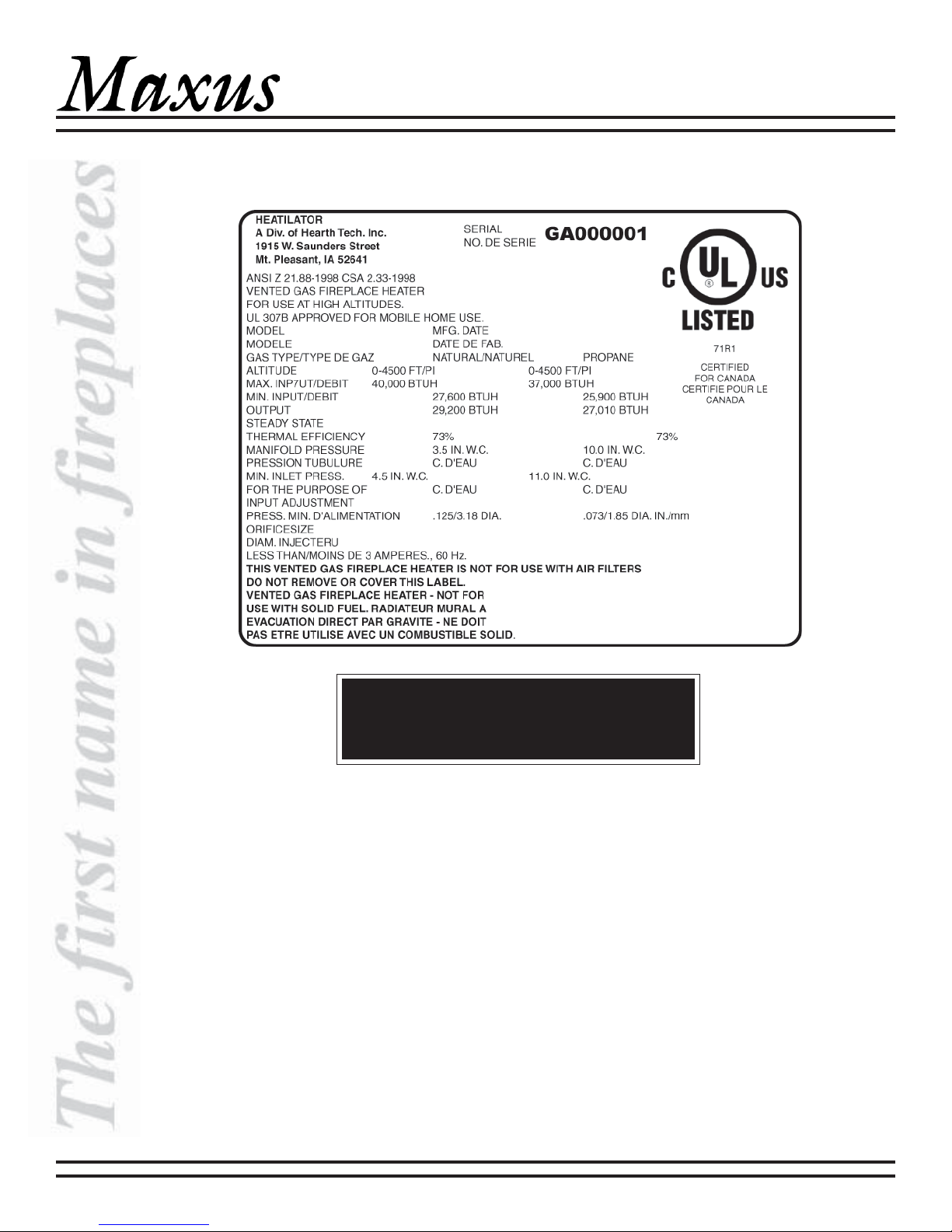

Rating Plate Located in the Heater

MAXUS DIRECT VENT HEATER

(Example only)

WARNING!

This valve has been preset at the factory. Altering

settings may result in fire hazard or bodily injury.

4 30484 Rev Q 09/04

MAXUS DIRECT VENT HEATER

B. APPLIANCE SPECIFICATIONS

Maxus Nomenclature

Catalog # Description

MA X60 38 in. w ide/36 in. glass /natural gas /standing pilot

MAX60L 38 in. w ide/36 in. glass/propane/standing pilot

MA X60F 38 in. w ide/36 in. glass/natural gas /standing pilot/f an kit

MA X60LF 38 in. w ide/36 in. glass/pr opane/standing pilot/fan kit

MA X60E 38 in. w ide/36 in. glass/natural gas /electronic ignition

MA X60LE 38 in. w ide/36 in. glass /propane/electronic ignition

MA X60EF 38 in. w ide/36 in. glass/natural gas/electronic ignition/fan kit

MA X60LEF 38 in. w ide/36 in glass/propane/electronic ignition/f an kit

FFMA X1 Black grille, black hood, bright brass trim around f lat top opening

FFMAX2 Black f illigree fr ont, black hood, bright brass trim around arched top opening

FFMAX2G Gold f illigree front, gold hood, no extra trim and arched top opening

Components Description

DRC-RADIUS Cap Shield

COOL-ADDM Cap Shield - pack of six

DVP-TV Vertical Termination Cap

DVP45 45-deg Elbow

DVP90 90-deg Elbow (for Heatilator appliances only)

DVP90ST 90-deg Starter Elbow (should be the first 90-deg elbow used)

RF6M Roof Flashing (vertical termination for 0/12 to 6/12 pitch) - pack of four

RF12M Steep Pitch Roof Flashing (for 7/12 to 12/12 pitch) - pack of six

DV P4 4 i n. length Ve nt Pi pe

DV P6 6 in. le ngth Vent P ipe

DV P12 12 in. length Vent Pipe

DVP24 24 in. length Vent Pipe

DVP36 36 in. length Vent Pipe

DVP48 48 in. length Vent Pipe

DVP6A 3-6 in. Slip Section Vent Pipe (to be used with another piece of pipe)

DVP12A 3-12 in. Slip Section Vent Pipe (to be used with another piece of pipe)

DV P12MI 12 in. Vent P ipe - non-unitized (can be cut to length)

DVP24MI 24 in. Vent Pipe - non-unitized (can be cut to length)

DVP-HVS Vent Support

DVP-WS Wall Shield to ensure horizontal clearances

DVP-FS Firestop Spacer

DVP-TRAP1 Horizontal Termination Cap with 1-3/4 in. telescoping flue and wall shield with heat shield

DVP-TRAP2 Horizontal Termination Cap with 4 in. telescoping flue and wall shield with heat shield

DV P-TB1 Basement Horizontal Termination Cap

DVP-TRAPK1 Top Vent Horizontal Kit with DVP-TRAP1 Termination Cap, wall shield with heat shield, and starter elbow

DVP-TRAPK2 Top Vent Horizontal Kit with DVP-TRAP2 Termination Cap, wall shield with heat shield, and starter elbow

DVP-HSM Extended Heat Shield

BEK Brick Extensi on K it

DVP-AS Attic Insulation Shield

09/04 30484 Rev Q 5

MAXUS DIRECT VENT HEATER

Note: Minimum and maximum clearances must be

maintained at all times. Illustrations throughout these

instructions reflect typical installations and are for design

purposes only. Actual installation may vary slightly due

to individual design preferences.

The illustrations and diagrams used throughout these

installation instructions are not drawn to scale.

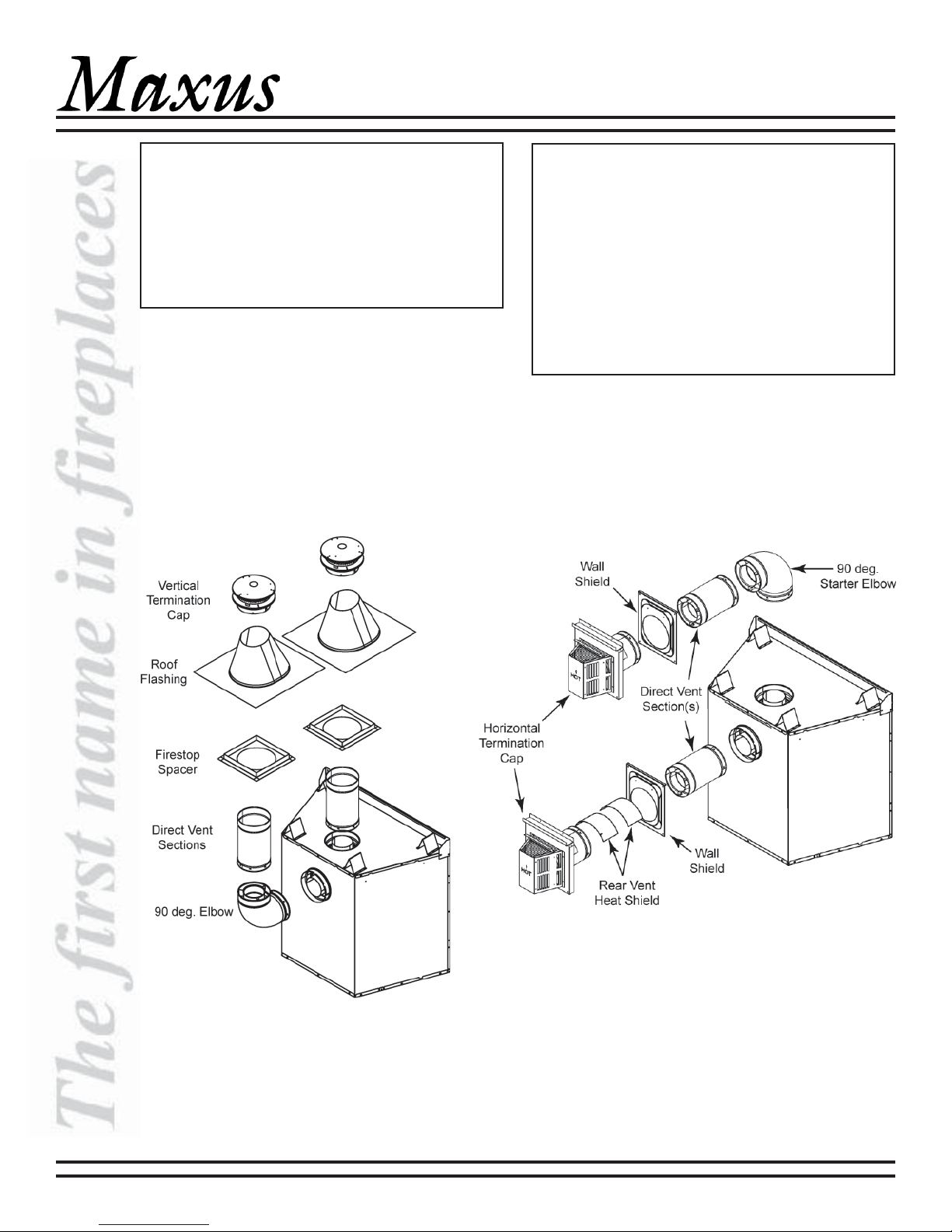

Typical Vertical Installations

(Rear and Top Vent Shown)

Tools and building supplies normally required for

installation:

Saw Wall-finishing

Pliers materials

Hammer Framing material

Phillips screwdriver Surround

Tape measure Caulking material

Plumb line Gloves

Level Framing square

Safety glasses Electric drill and bits

Non-corrosive leak-check solution

Typical Horizontal Installations

(Rear and Top Vent Shown)

6 30484 Rev Q 09/04

MAXUS DIRECT VENT HEATER

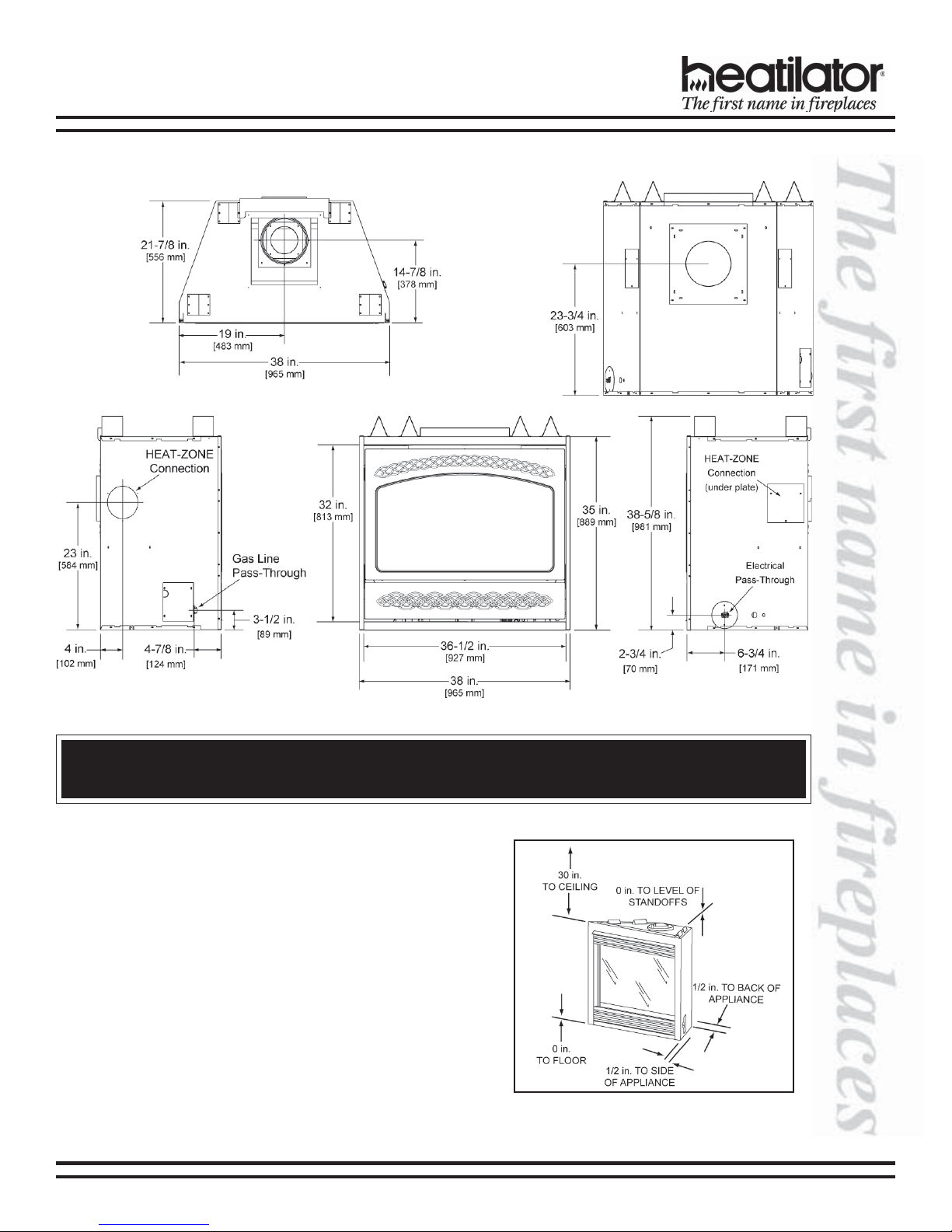

C. LOCATIONS AND CLEARANCES

Appliance Dimensions

WARNING!

Due to high temperatures, the appliance should be located out of traffic and away from furniture and draperies.

1. Clearances to Combustible Materials

Figure 1 illustrates appliance clearances to

combustible materials.

Figure 1

Appliance Clearances to

Combustible Materials

09/04 30484 Rev Q 7

MAXUS DIRECT VENT HEATER

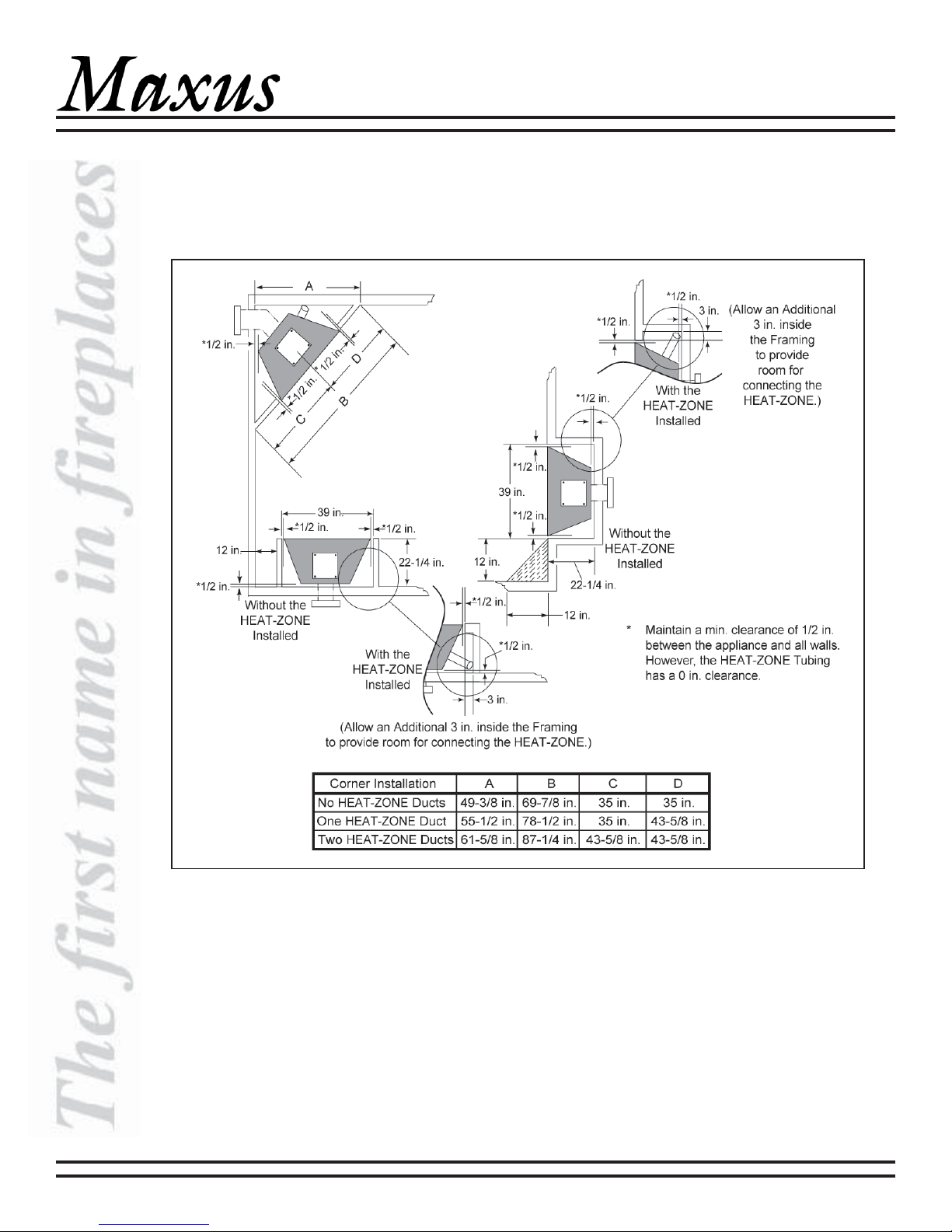

2. Locations and Space Requirements

Figure 2 illustrates different ways the appliance may be located in a room and the space required. This appliance

may be installed directly on the floor or raised on a hearth. Adjacent combustible side walls must be located a

minimum of 12 in. from the appliance. If you are using a decorative surround constructed of combustible material,

it must be located within the shaded area defined in Figure 2. Short stub walls are acceptable if they are contained

within the shaded area.

8 30484 Rev Q 09/04

Figure 2 - Appliance Locations

MAXUS DIRECT VENT HEATER

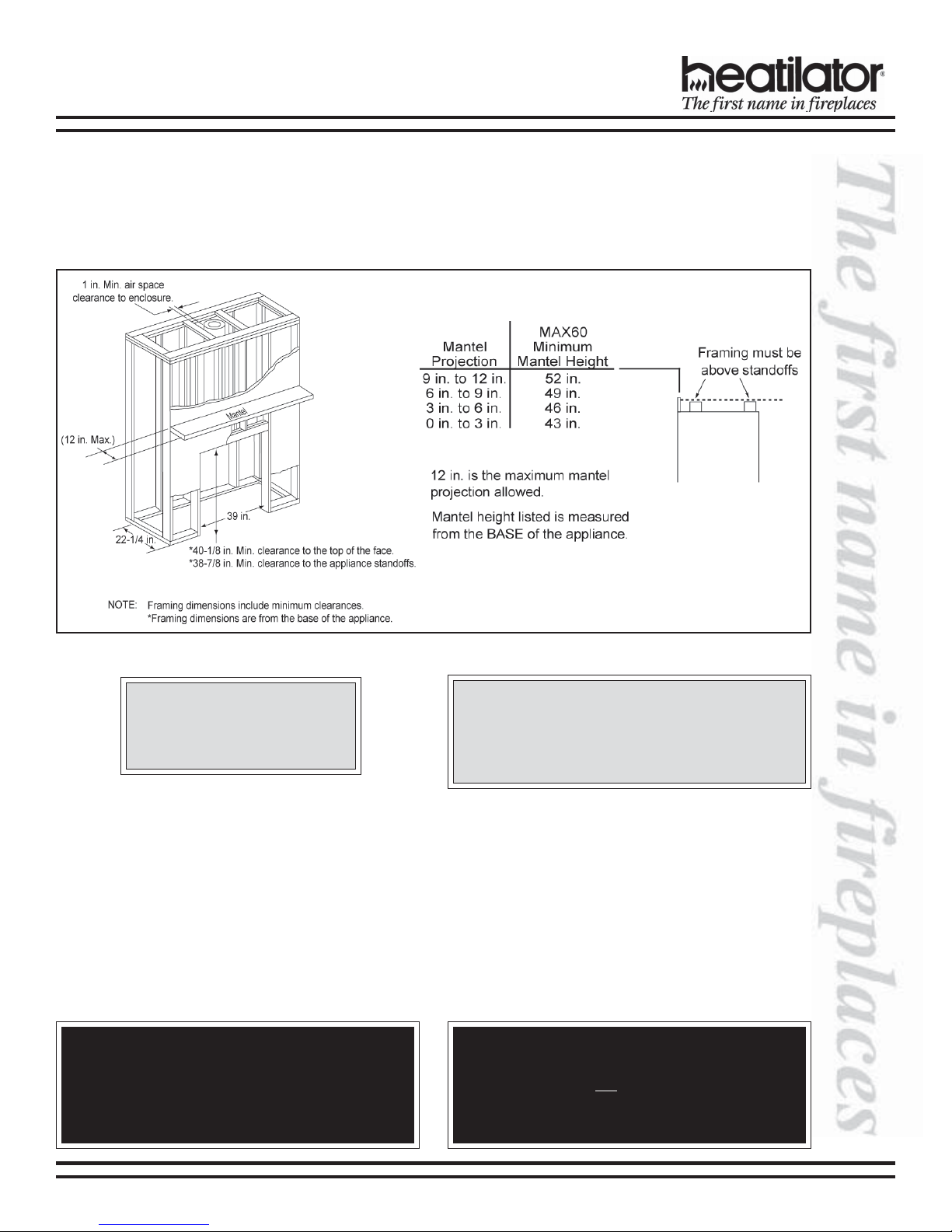

D. FRAMING/SETTING THE APPLIANCE

1. Frame the Appliance

Figure 3 shows typical framing and mantel heights of this appliance using combustible materials. All required

clearances to combustibles must be adhered to.

CAUTION:

Wear gloves and safety glasses

for protection.

2. Setting the Appliance

a. Positioning the Appliance

This appliance may be placed on a smooth combustible or noncombustible continuous, flat surface. When the

appliance is installed directly on carpeting, tile or other combustible material other than wood flooring, the

appliance shall be installed on a metal or wood panel extending the full width and depth of the appliance. Slide

the appliance into position and level the appliance from side-to-side and front-to-back. Shim with noncombustible

material as necessary.

b. Secure the Appliance

Bend out the nailing flanges on each side of the appliance and nail to framing. The nailing flanges have been

positioned 5/8 in. back from the front of the appliance to allow the addition of drywall.

WARNING!

This appliance may only use the approved venting

systems shown in these installation instructions. It

must not be connected to a chimney flue servicing a

separate solid fuel or gas fuel burning appliance.

Figure 3 - Framing

CAUTION:

Provide adequate clearances around the air

openings into the appliance and adequate

accessibility clearances for servicing and proper

operation.

WARNING!

To prevent contact with sagging or loose insulation,

the appliance must not be installed against vapor

barriers or exposed insulation. Localized overheating could occur and a fire could result.

09/04 30484 Rev Q 9

MAXUS DIRECT VENT HEATER

E. VENTING

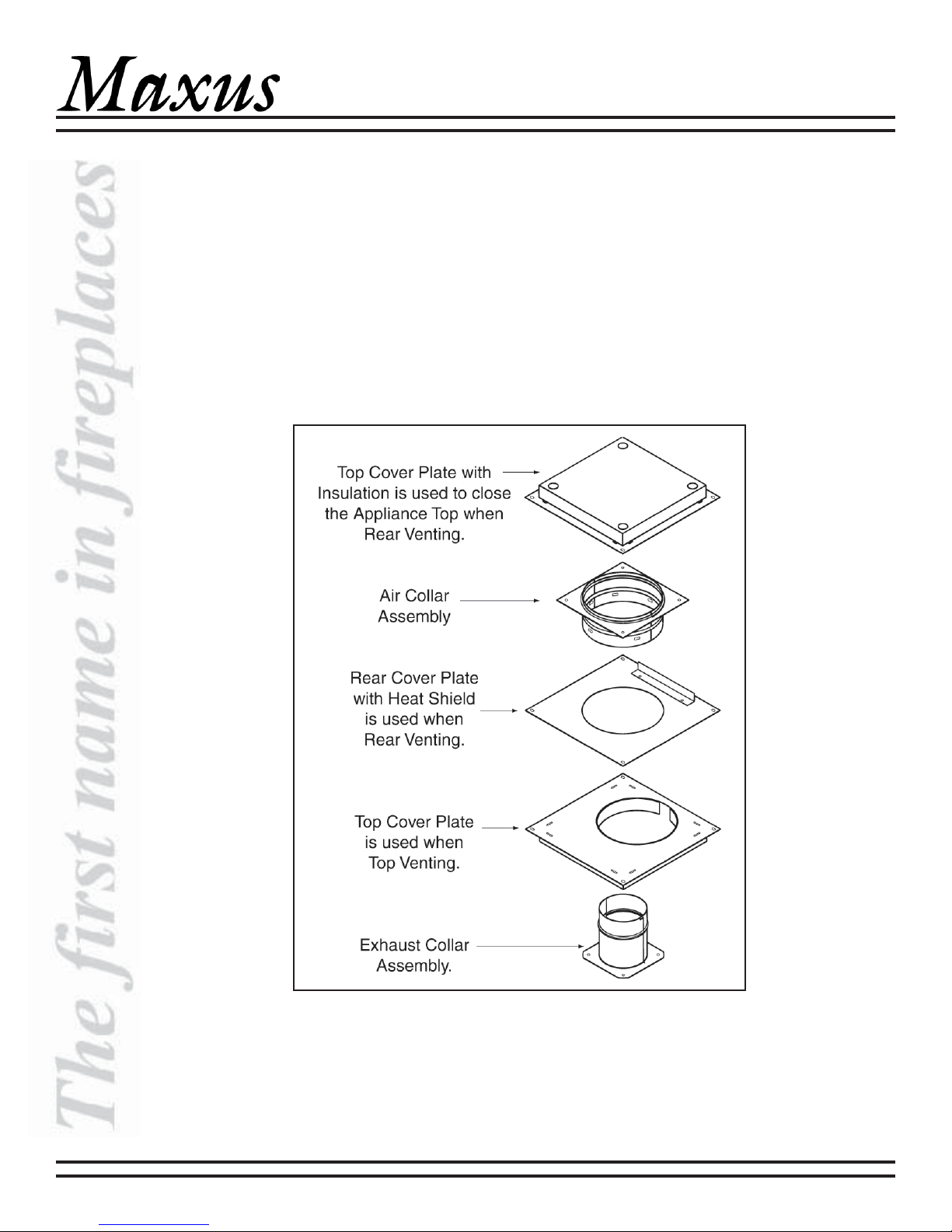

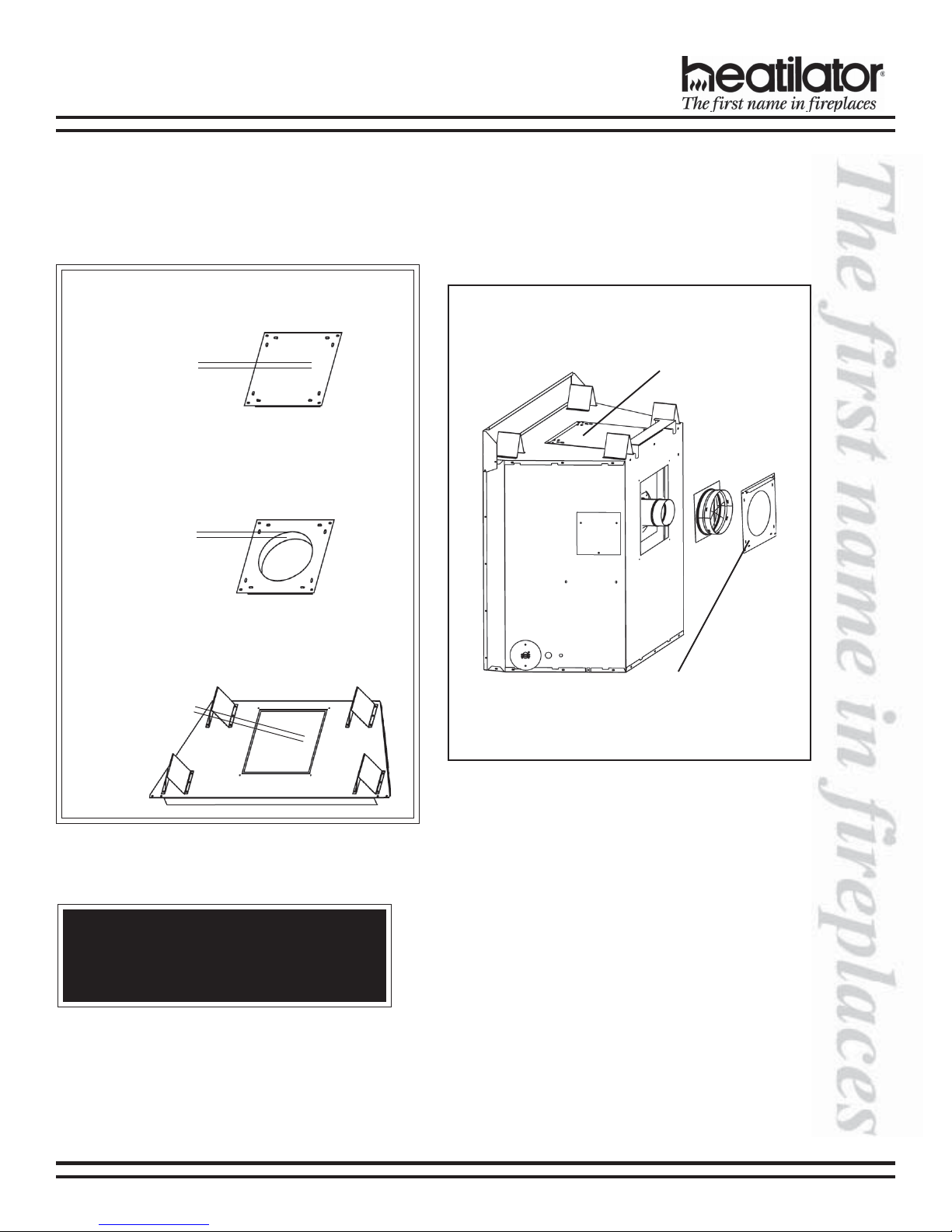

1. Remove the Vent Covers and Place the Collars

This appliance may be vented off the rear or off the top. Depending on your specific installation, a vent cover will

need to be removed from either the top or rear of the appliance and inner and outer collars attached.

Looking at the rear or top of your appliance (depending on which venting style you are going to use), there is a

square plate, and other parts (see Figure 4) held to the firebox with four screws. Remove this plate (insulation is

attached to the top one). Below this piece is another plate attached to the inner shell of the firebox. Remove this plate

as well. A third plate and gasket are attached to the firebox beneath the previous plate with four screws. Remove this

last plate.

2. The Following Venting Components are Shipped Attached to the Top of the Appliance

10 30484 Rev Q 09/04

Figure 4

Venting Components

(in order of disassembly)

MAXUS DIRECT VENT HEATER

3. Rear Venting

a. Attach the collars supplied. See Figure 5.

b. When attaching the 14 in. square plate with an 8 in. hole, there is a heat shield attached. This must be up and

face out (away from the appliance).

WARNING!

When rear venting,

seal the unused top

opening with the

solid cover with the

insulation (install

with the insulation

down).

When top venting,

use the plate with an

8 in. opening and

insulation (install

with the insulation

down).

The opening on the

top of the appliance

must be sealed with

an insulated cover.

The top opening must be

enclosed with the insulated

cover.

When installing this plate, the

heat shield must face upwards

and out (away from the

appliance).

WARNING!

If not sealed, a fire hazard will be created and

the appliance will not operate properly.

09/04 30484 Rev Q 11

Figure 5

MAXUS DIRECT VENT HEATER

4. Top Venting

Use the 5 in. diameter collar assembly (with the

attached gasket) and the four screws removed earlier

to attach the collar assembly where the last plate was

removed. Take care not to strip the screws. Attach the

8 in. diameter collar assembly with four screws, to

where the second plate was removed on the inner

shell. Make sure the gasketing on the plate seals the

firebox inner shell. The third and final piece to install

has insulation attached to it and an 8 in. diameter

hole. This piece should fit around the 8 in. collar

assembly with the insulation going inside the outer

shell of the firebox. Attach with screws. See Figure 6.

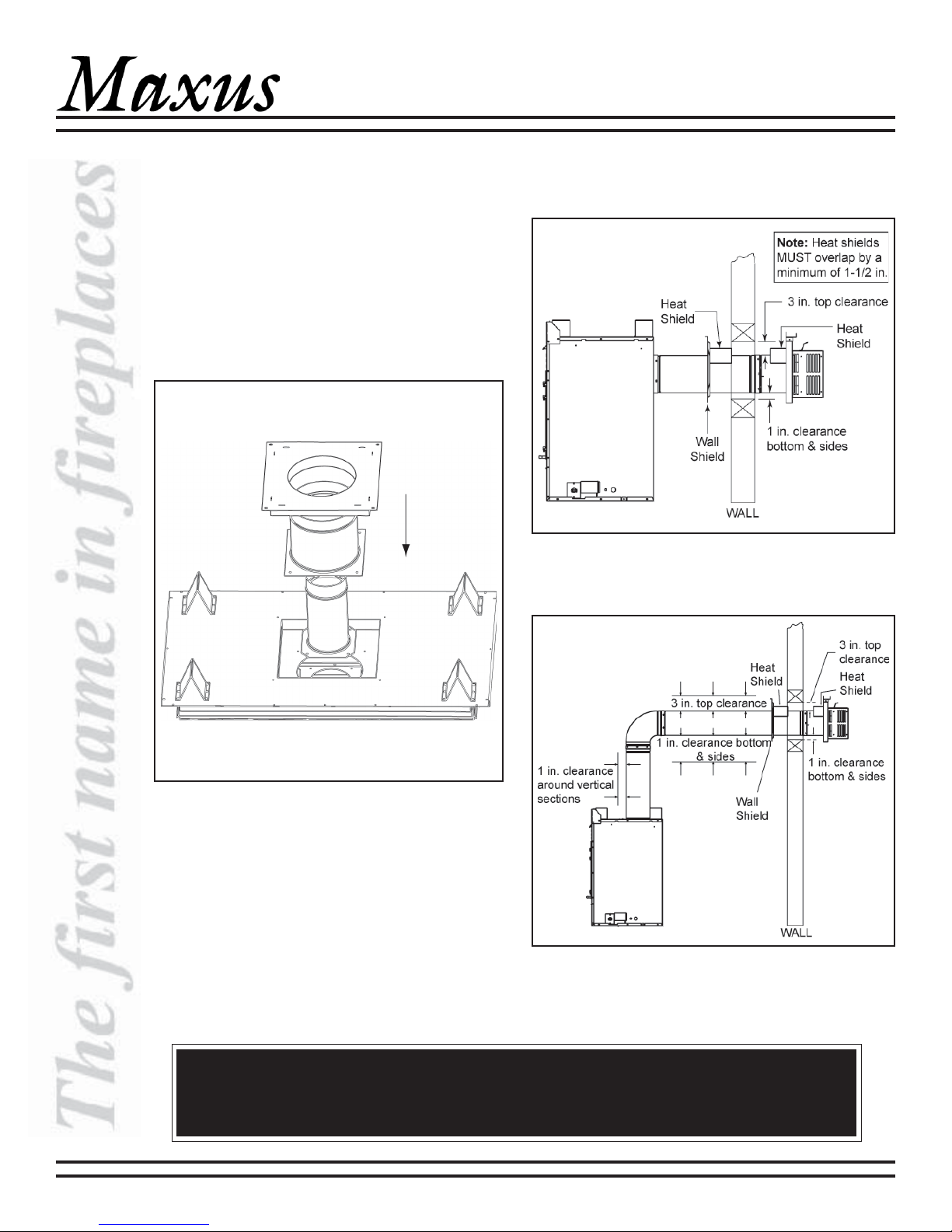

5. Horizontal Termination

a. Clearances

See Figures 7 and 8 for clearance information.

Figure 7

Venting Clearances to

Combustible Materials - Rear Venting

Figure 6

Placement of Inner and Outer collars

Always maintain minimum air space clearances or greater around the vent system. See Figures 7

and 8. Do not pack air spaces with insulation or other material.

12 30484 Rev Q 09/04

Figure 8

Venting Clearances to

Combustible Materials - Top Venting

WARNING!

MAXUS DIRECT VENT HEATER

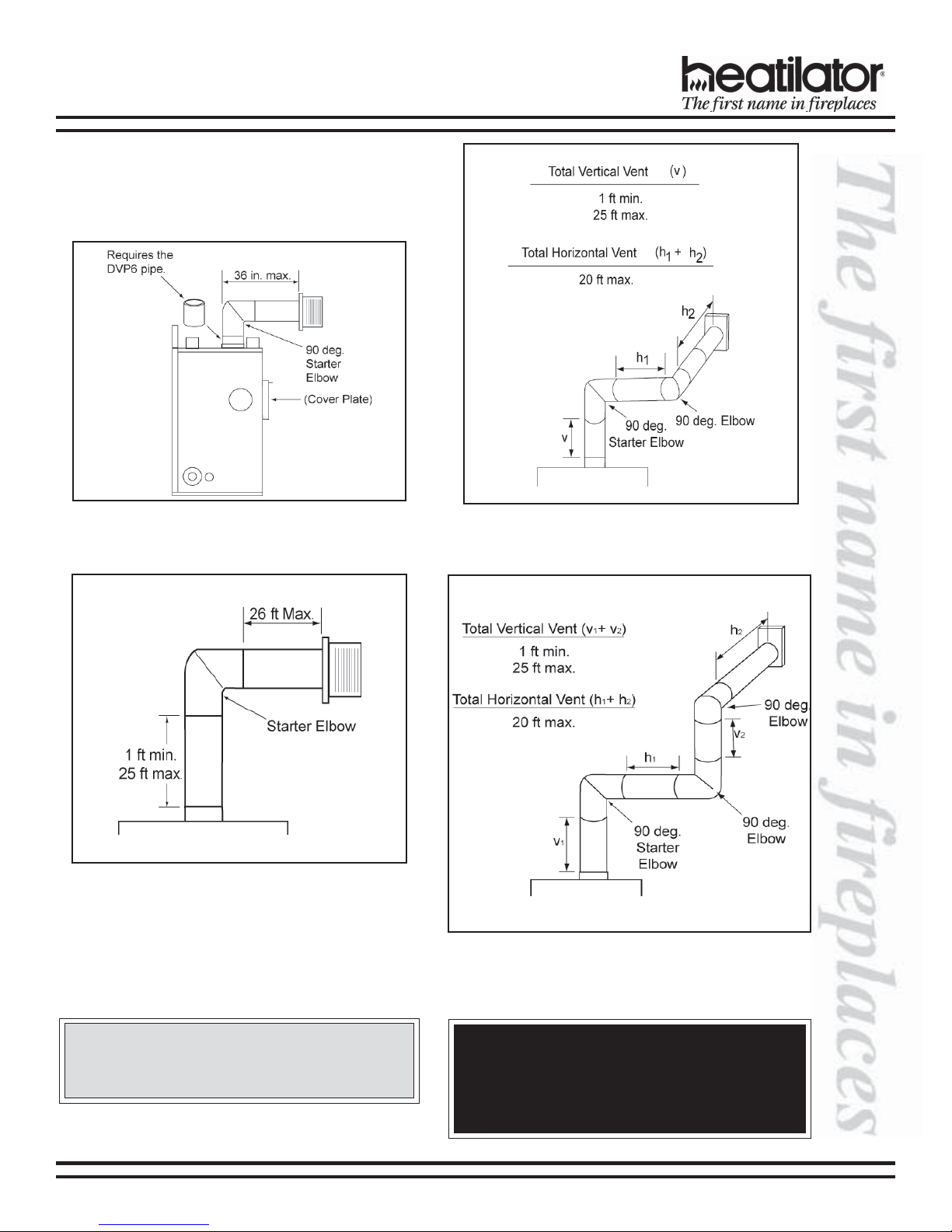

b. Vent Lengths for Top Venting (for rear venting,

see page 14)

Various venting configurations are shown in

Figures 9-12 from which maximum vent lengths

can be determined.

Figure 9

Vent Lengths with One Elbow

(Minimum Vertical)

Figure 10

Vent Lengths with One Elbow

(1 ft vertical or more, 25 ft maximum)

Figure 11

Vent Lengths with Two Elbows

Figure 12

Vent Lengths with Three Elbows

CAUTION:

Provisions shall be made to provide adequate

combustion and ventilation air.

09/04 30484 Rev Q 13

WARNING - RISK OF FIRE!

The horizontal run of vent must have a 1/4 in. rise

for every 1 ft of run towards the termination. Never

allow the vent to run downward. This could cause

high temperatures and may create a fire hazard.

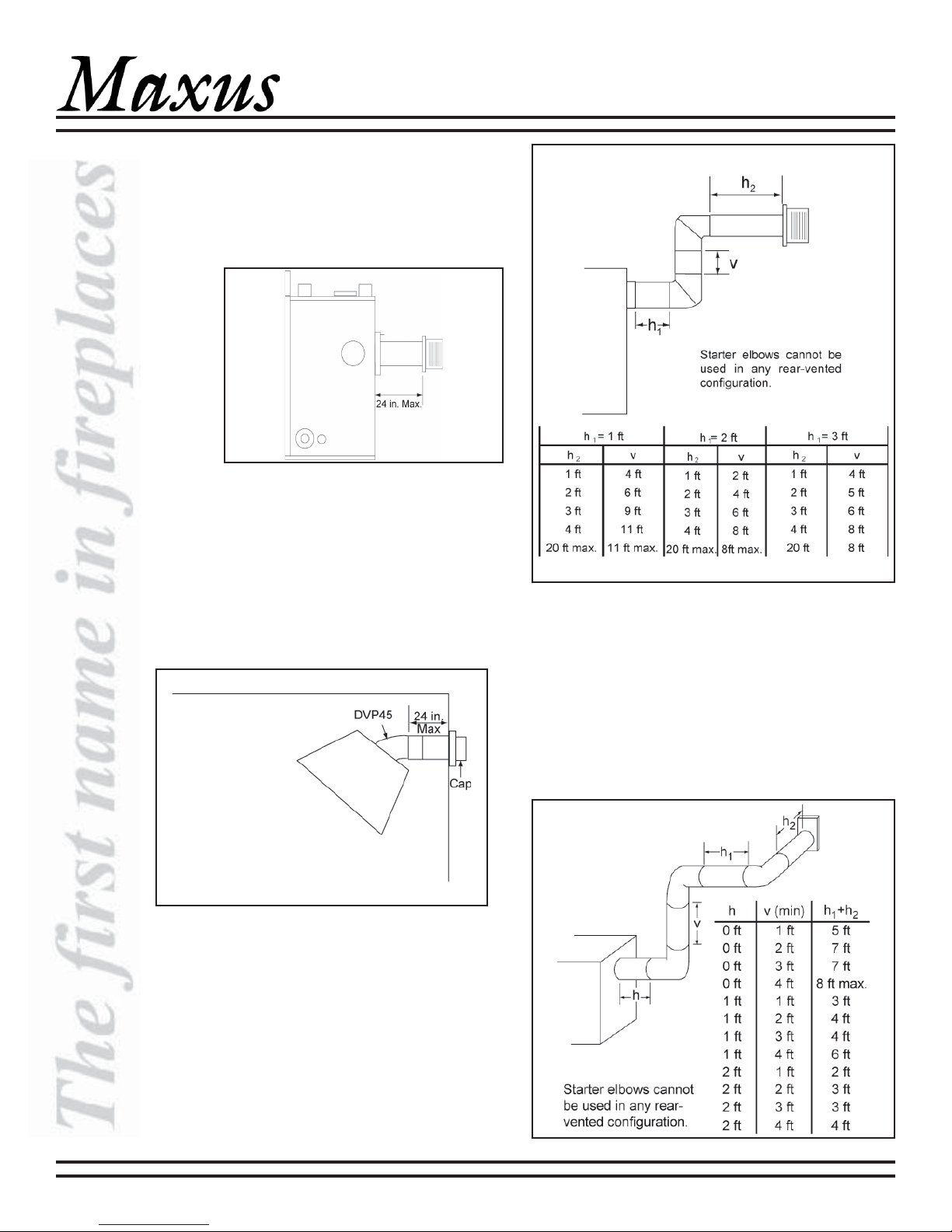

c. Vent Lengths for Rear Vent

1) No Elbows

The maximum horizontal run, with no vertical

sections of vent, is 24 in. from the back of the

appliance to the base of the cap. See

Figure 13.

Figure 13

No Elbows

2) A 45 degree Elbow

For corner installations with horizontal

venting, a maximum of one 45 degree elbow

may be used. The maximum horizontal run

following the elbow is 24 in. to the base of

the cap and will include a 45 degree elbow

and a termination cap. See Figure 14.

MAXUS DIRECT VENT HEATER

Figure 15 - Two Elbows

4) Three Elbows

Elbows used on rear vented configurations

should be either a 90 degree elbow or a

45-deg elbow. A starter elbow cannot be

used in any rear-vented configuration.

Figure 16 shows various venting

configurations using three elbows to

terminate horizontally.

Starter elbows cannot

be used in any rearvented configuration.

Figure 14

One 45 degree Elbow

3) Two Elbows

Elbows used on rear vented venting

configurations should be either a 90 degree

elbow or a 45 degree elbow. A starter elbow

cannot be used in any rear-vented

configuration. Figure 15 shows various

venting configurations using two elbows to

terminate horizontally.

14 30484 Rev Q 09/04

Figure 16 - Three Elbows

Loading...

Loading...