Heatilator G141, G141L, G141E, G141LE Owner's Manual

Heatilator

WARNING!

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

Improper installation, adjustment, alteration, service or maintenance can cause injury or property damage. Refer to this manual. For assistance or additional information, consult a qualified installer, service agency or the gas supplier.

1915 W. Saunders Street

Mt. Pleasant, IA 52641

A Division of Hearth Technologies Inc.

G141 SERIES B-VENT GAS APPLIANCE

OWNERS MANUAL

AND INSTALLATION INSTRUCTIONS

MODELS G141, G141L, G141E, G141LE

WARNING: If the information in this manual

is not followed exactly, a fire or explosion may

result causing property damage, personal injury or loss of life.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

What to do if you smell gas

Do not try to light any appliance.

Do not touch any electrical switch; do not

use any phone in your building.

Immediately call your gas supplier from a

neighbors phone. Follow the gas suppliers

instructions.

If you cannot reach your gas supplier, call

the fire department.

Installation and service must be performed by

a qualified installer, service agency or the gas

supplier.

CAUTION:

Do not expose the fireplace to

the elements (such as rain, etc.)

10-00 1 32921 Rev A

This manual must be used for installation of the

G141 Series Gas Appliance and retained by the

homeowner for operation and maintenance

instructions.

G141 SERIES B-VENT GAS APPLIANCE

Table of Contents

A. Preparation ..................................................................................................................... 3

B. Locations & Clearances .................................................................................................. 5

C. Framing ........................................................................................................................... 6

D. Setting the Fireplace ........................................................................................................ 6

E. Venting ............................................................................................................................ 7

F. Utilities .......................................................................................................................... 10

G. Finishing Materials. ........................................................................................................ 15

H. Firebox Preparation ....................................................................................................... 16

J. Lighting Instructions ....................................................................................................... 18

K. Seasonal Checklist ........................................................................................................ 20

L. Maintenance Instructions ................................................................................................ 21

M. Trouble Shooting ............................................................................................................ 24

N. Optional Components .................................................................................................... 26

O. Replacement Parts ........................................................................................................ 27

Safety Precautions

1. Please read these installation instructions

completely before beginning installation

procedures. Failure to follow them could cause a

malfunction resulting in serious injury and/or

property damage.

2. Always check your local building codes prior to

installation. The installation must comply with all

local, regional, state and national codes and

regulations.

3. Installation and repair should be done by a

qualified service person. This appliance should

also be inspected annually by a qualified service

person. More frequent inspections/cleaning may

be required due to excessive lint from carpeting,

bedding material, etc. It is imperative that the

control compartment and burners of the

appliance be kept clean.

4. The G141 is a vented gas fireplace. Do not burn

wood or other material in this appliance.

5. NEVER leave children unattended when there is

a fire burning in the fireplace.

6. This appliance must be vented with a minimum

5 B-Vent system and must terminate above the

roof line. Venting must not be connected to a

chimney flue servicing a solid fuel burning

appliance.

7. Use only the fuel gas specified on the rating label

of this gas appliance.

8. The appliance area shall be kept clear and free

from combustible materials, gasoline and other

flammable vapors and liquids.

9. While servicing this appliance, always shut off all

electricity and gas to the fireplace. This will prevent

possible electrical shock or burns. Also, make

sure the fireplace is completely cooled before

servicing.

10. The appliance and its individual shut-off valve

must be disconnected from the gas supply piping

system during any pressure testing of that system

at test pressures in excess of 1/2 psi (3.5 kPa).

11. Do not use this appliance if any part has been

under water. Immediately call a qualified service

technician to inspect the appliance and to replace

any part of the control system and any gas control

which has been under water.

12. Be sure to provide adequate clearances around

the air openings into the combustion chamber

and adequate accessibility clearances for

servicing and proper operation.

13. Provisions shall be made to provide adequate

combustion and ventilation air. The flow of

combustion and ventilation air should not be

obstructed.

32921 Rev A 2 10-00

G141 SERIES B-VENT GAS APPLIANCE

A. PREPARATION

1. CERTIFICATION.

The G141 Series Gas Fireplace has been tested in

accordance with the standard ANSI Z21.50-1998CGA 2.22-M98. The G141 has been certified by

Underwriters Laboratories Inc. for installation and

operation as described in these Installation

Instructions. All components are AGA or UL safety

certified.

2. LOCAL CODES.

Check with your local building code agency prior

to installing this appliance to ensure compliance

with local codes, including the need for permits

and follow-up inspections. This appliance must

conform with local codes, or in the absence of local

codes, comply with the National Fuel Gas Code,

ANSI Z223.1-latest edition in the U.S.; in Canada,

the CANI-B149-latest edition.

3. OPTIONAL COMPONENTS.

This gas appliance has been tested and listed for

use with the optional components listed below.

Many optional components may be purchased

separately and installed at a later date. However,

installation of a remote control will require electrical

power. To avoid costly reconstruction, a separate

course of electrical power should be supplied to

the fireplace at the time of initial installation of the

system for possible addition of these accessories

at a later date.

4. FUEL.

Any additions, changes or conversions required

in order for the appliance to satisfactorily meet

the application needs, must be made by a

qualified service technician using factory

specified and approved parts.

This product is manufactured to use natural gas or

propane gas, depending on model purchased. A

natural gas fireplace can be converted to use

propane gas later, but only if done by a qualified

service technician and only if the CKP Natural Gas

to Propane Gas Conversion Kit is used. In the event

your appliance must be converted to natural gas

from propane, you must use a CKN Propane Gas

to Natural Gas Conversion Kit.

If any assistance is required during installation, please

contact your local dealer or contact Heatilator, Technical

Services Department, 1915 W. Saunders Street, Mt.

Pleasant, Iowa 52641.

HEATILATOR® is a registered trademark of Heatilator,

a Division of Hearth Technologies Inc.

The G141 Series is a vented gas fireplace. While a significant amount of heat is created by the G141, it is not

intended to be and, therefore, should not be used as a heater.

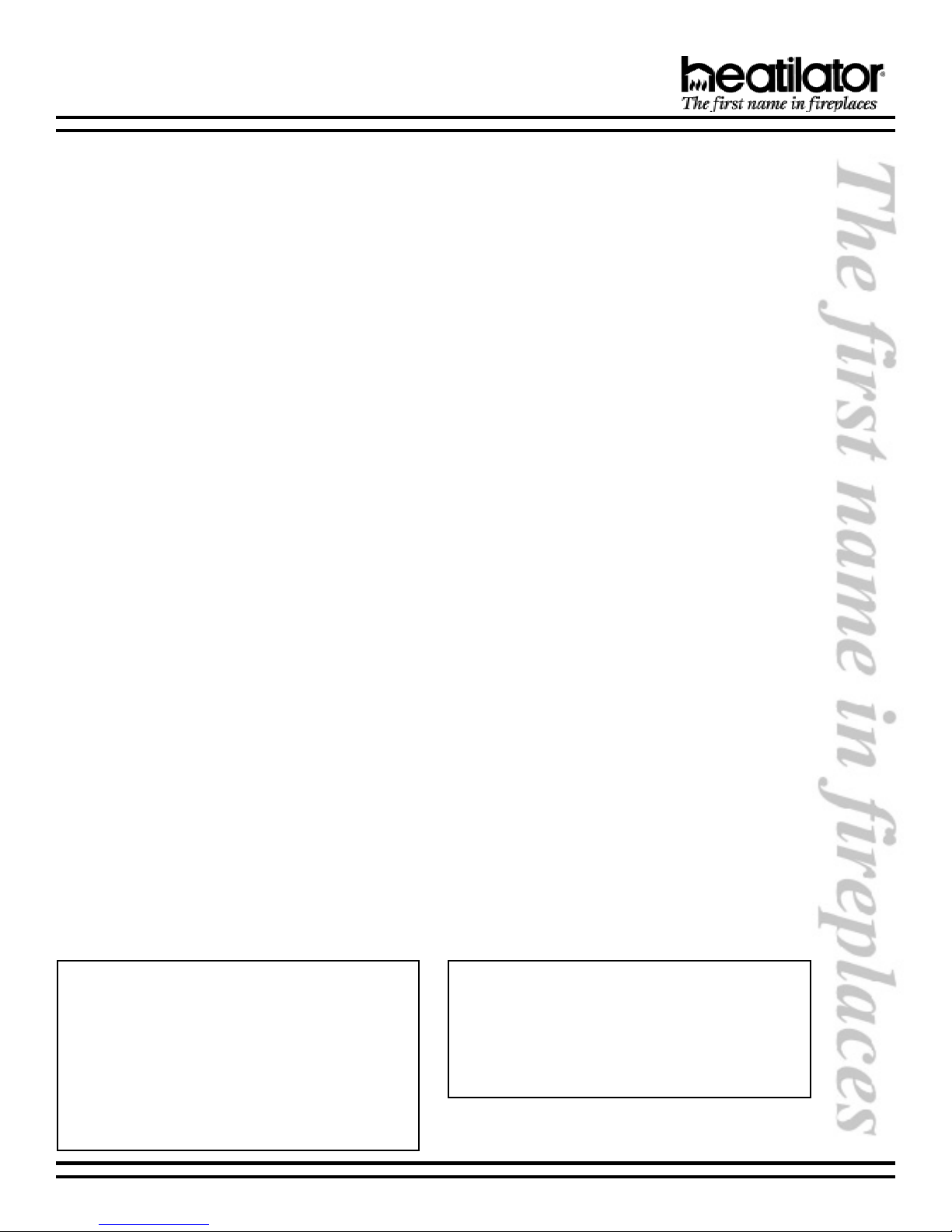

The G141 B-Vent Gas Appliance

must consist of the following:

1. Fireplace

2. B-Vent System

3. Termination

Tools and building supplies normally required

for installation:

Saw Wall-finishing materials

Pliers Framing material

Hammer Fireplace surround

Phillips screwdriver Caulking material

Tape measure Plumb line

Level Electric drill/bits

Square

Note: Illustrations throughout these instructions

reflect typical installations and are for design

purposes only. Actual installation may vary slightly

due to individual design preferences. However,

minimum and maximum clearances must be

maintained at all times.

Optional components include:

1. Remote Control

2. Outside Air Kit

3. Glass Doors

4. Refractory Upgrade

5. Quick Tile Trim

6. ID4

7. UD4

10-00 3 32921 Rev A

Vertical Termination Cap

Storm Collar

Roof Flashing

Firestop Spacer

5 Gas B-Vent

Pipe Section(s)

G141 SERIES B-VENT GAS APPLIANCE

The table below is a list of only those components which may be safely used with this decorative gas appliance.

Only trim kits supplied by the manufacturer shall be used in the installation of this appliance.

#golataCnoitpircseD

141Gecnailppatnaidar,tolipgnidnats,saglarutan"63

L141Gecnailppatnaidar,tolipgnidnats,sagenaporp"63

E141Gecnailppatnaidar,noitingicinortcele,saglarutan"63

EL141Gecnailppatnaidar,noitingicinortcele,sagenaporp"63

RyrotcarfeR

63GRtiKyrotcarfeR

PKCtiknoisrevnocsagenaporpotsaglarutaN

NKCtiknoisrevnocsaglarutanotsagenaporP

4CR)tolipgnidnats(lortnocetomeR

5CR)noitingicinortcele(lortnocetomeR

6CRlortnocetomeR

41KAtiKriA

6301MD)kcalB(sroodssalgdlof-iB

A6301MD)ssarBeuqitnA(sroodssalgdlof-iB

B6301MD)ssarBdehsiloP(sroodssalgdlof-iB

B2EKQdnuorruSeliT

A163FD)ssarBeuqitnA(rooDdexiF

B163FD)ssarBdehsiloP(rooDdexiF

32921 Rev A 4 10-00

G141 SERIES B-VENT GAS APPLIANCE

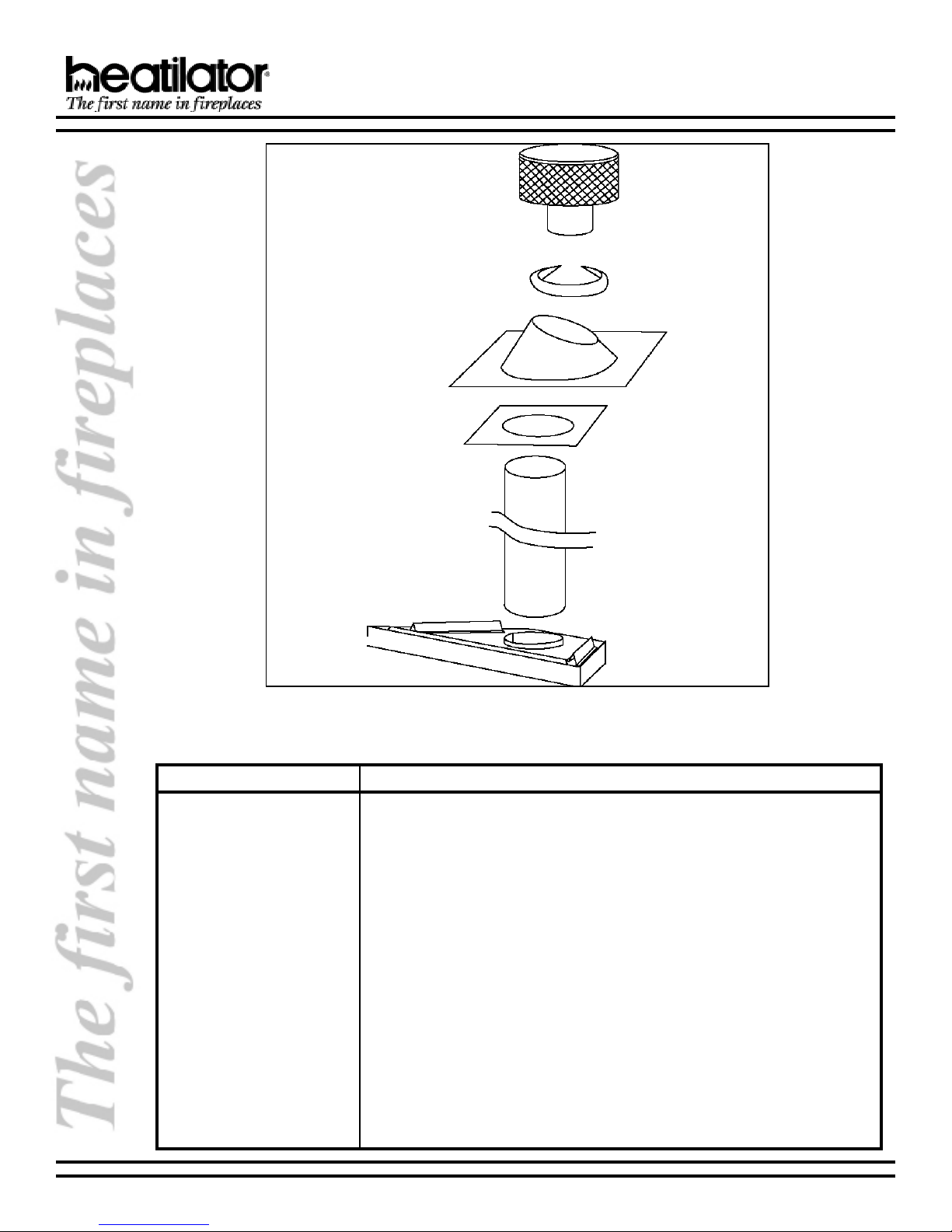

B. LOCATIONS & CLEARANCES

31

1

/

2

3

/

15

4

5

/

36

8

21

3

36

38

FRONT LEFT SIDE TOPRIGHT SIDE

Junction Box

FIREBOX DIMENSIONS

3

/

2

4

3

/

36

4

Air Kit

Gas Line

19

38

1. LOCATION AND SPACE REQUIREMENTS.

This appliance may be installed along a wall, across a corner or in an exterior chase. DO NOT install B-Vent

Gas Appliances in strong negative air locations, such as a basement or a public facility. This fireplace

uses room air for normal operation and could have problems establishing a positive draft in negative

air locations. In lieu, we recommend a direct vent appliance.The G141 Series may be installed at a

height level with the floor, or it can be raised up from the floor to enhance its visual impact. Figure 1 illustrates

a variety of ways the fireplace may be located in a room. These fireplaces are also certified for installation in

a bedroom or bed/sitting room in the U.S. and Canada. (Bedroom installations in Canada require the addition

of non-operable doors.)

2. CLEARANCES.

The following clearances to combustibles must be maintained: Minimum clearances to the top standoffs of the

fireplace - 0, floor - 0, back - 1, sides - 1, face of the fireplace to ceiling - 30. Minimum clearances to venting

are as follows: Horizontal run sections require a 3 minimum air space on the top and a 1 minimum air space

on the sides and bottom of the vent section. Venting that is vertical requires a 1 minimum air space completely

around the vent section.

32

1

/

2

46

16

10

1

Min.

Figure 1 - Fireplace Locations and Clearances

Before moving to the following pages, do the following:

1. Wear gloves and safety glasses for protection.

2. Keep hand tools in good condition. Sharpen cutting edges and make sure tool handles are secure.

3. Always maintain the minimum air space required to the enclosure to prevent fire.

10-00 5 32921 Rev A

65

40

17

171

WARNING!

G141 SERIES B-VENT GAS APPLIANCE

C. FRAMING

1. FRAMING THE FIREPLACE.

The G141 Series Gas Appliance will fit a framed opening of 17 deep x 40-1/4 wide x 36-3/4 tall.

Figure 2 shows a typical framing of this appliance assuming combustible materials are used. All required

clearances to combustibles around the fireplace must be adhered to. A 1 air space clearance must be

maintained at the back and sides of the firebox assembly. Any framing on top of the fireplace must be above

the top standoffs. Vent sections for a horizontal run require a 3 minimum air space clearance on top and a 1

minimum air space clearance on the sides and bottom. Vertical vent sections require a 1 minimum air space

clearance completely around the vent section.

Note: If a hand held Remote Control (RC4 or RC5)

is to be used, wiring must be done prior to finishing to avoid reconstruction.

Minimum vent

clearances are

per vent

manufacturers

specifications

3

36

1

/

40

17

Figure 2 - Framing Requirements

4

Note: The Wall Switch must be wired prior to applying the finishing material to the wall in order to avoid

reconstruction.

9 to 12 Mantel Projection: 41 height

0 to 9 Mantel Projection: 38 height

/

4

Figure 3 - Mantle Heights

Minimum allowable mantel heights are shown in

Figure 3. All required clearances must be adhered

to.

This fireplace may be placed on either a combustible

or noncombustible continuous, flat surface. If the

fireplace is installed on combustible flooring other than

wood, a metal or wood panel needs to be installed

underneath the appliance extending its full width and

depth. Slide the fireplace into position and level the

fireplace from side-to-side and front-to-back. Shim with

noncombustible material, such as sheet metal, as

necessary.

Secure the fireplace by bending out the nailing flanges

located on each side of the fireplace and nailing the

fireplace to the framing. See Figure 4.

32921 Rev A 6 10-00

D. SETTING THE FIREPLACE

Figure 4 - Nailing Flanges

G141 SERIES B-VENT GAS APPLIANCE

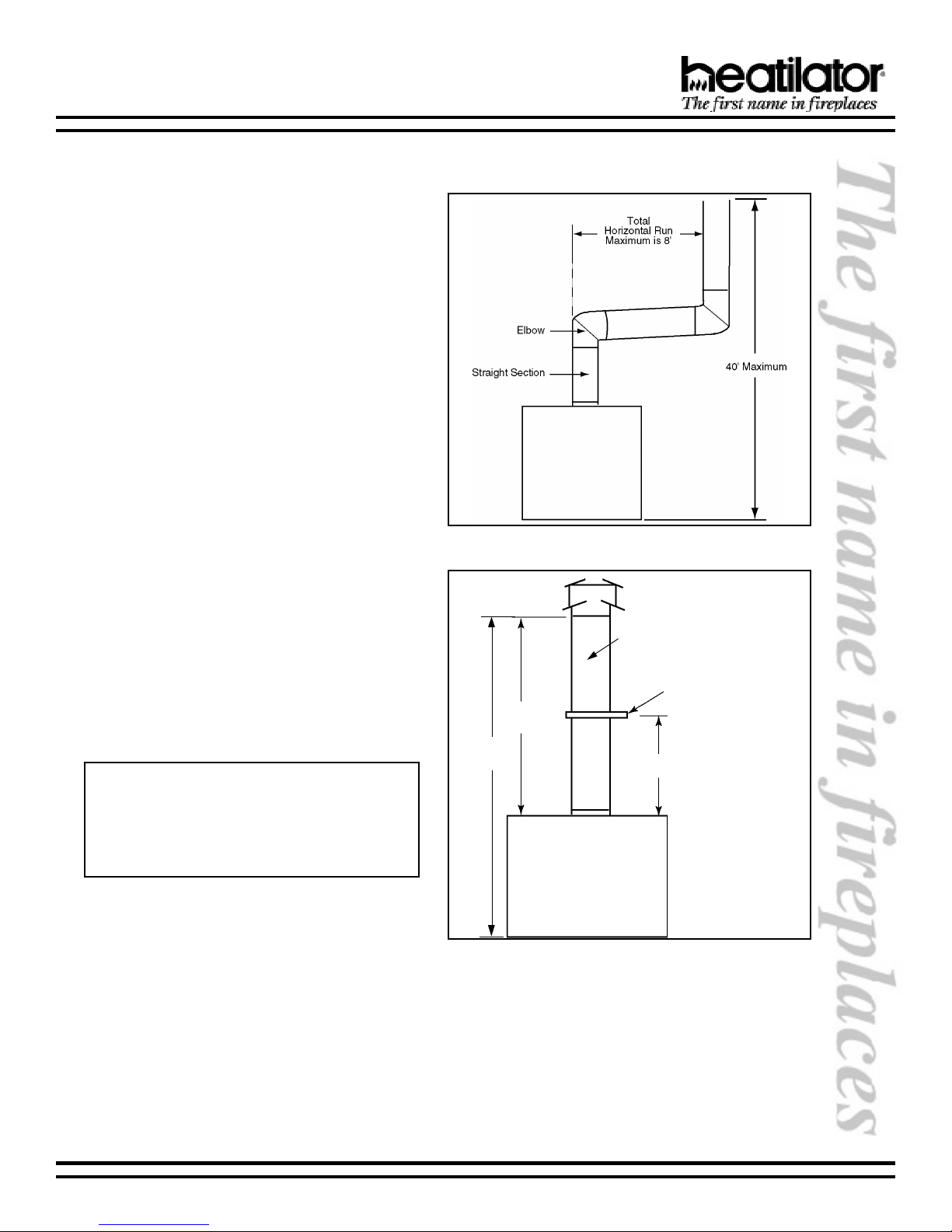

E. VENTING

1. TERMINATION.

Common venting of this gas appliance with other

gas appliances is not allowed.

This fireplace requires the use of a 5 B-vent pipe

for operation and must be terminated above the

roof line. Never downsize pipe. Follow all B-vent

requirements and installation instructions.

The minimum height of vent installation must be 9

from the top or 12 from the base of the appliance.

Horizontal run must never exceed 20% of the height

of the vent system as shown in Figure 5.

The Figures 5 and 6 show the maximum distances

from the base of the fireplace, as well as the

minimum air space clearances that must be

maintained during termination of this appliance.

Maximum straight unsupported rise - 25 feet;

maximum horizontal unsupported run - 3 feet; air

space clearances around vertical rise - 1 on all

sides; air space clearances around the horizontal

run - 3 on top and 1 on sides and bottom; maximum

height - 40 from the base of the fireplace.

Figure 5 - Venting Off The Top of Appliance

Note: The horizontal run of vent must have a

1/4 rise for every 1 ft. of run towards the termination. Never allow the vent to run downward.

This could cause high temperatures and may

present the possibility of a fire.

Minimum clearances are per vent

manufacturers specifications

9 Min.

40

Max.

Figure 6 - Framing Requirements

Metal plumbers strap

secured to framing

Vent supports are per

vent manufacturers

specifications

10-00 7 32921 Rev A

G141 SERIES B-VENT GAS APPLIANCE

2. ASSEMBLY.

a. Assembling Vent Sections. Attach a straight

vent section to the top of the fireplace. Elbows

directly off the top of the fireplace are not

allowed. This may cause the fireplace to

operate ineffectively. Secure the attached vent

section to the appliance with the three screws

supplied. Use only B-vent sections.

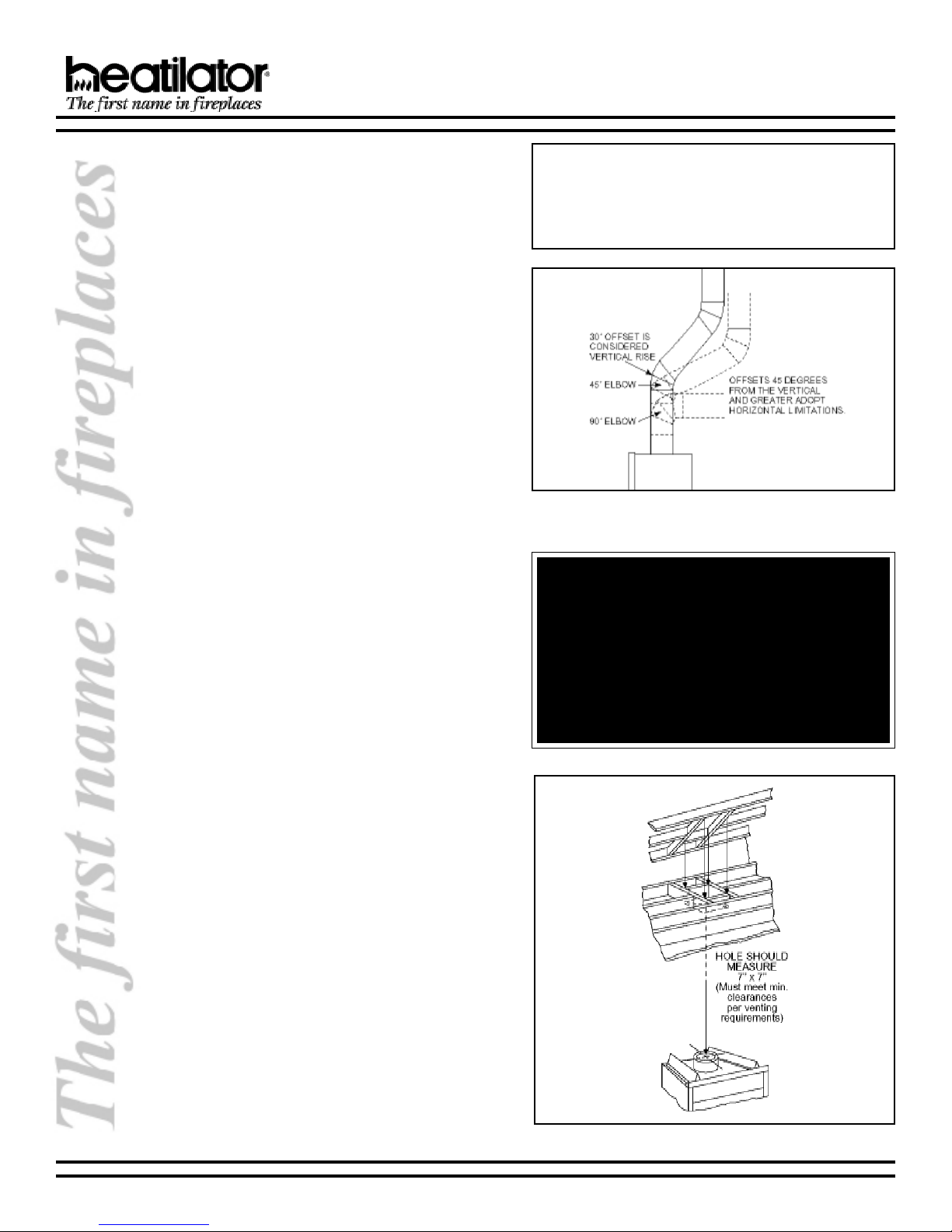

b. Using Elbows. Elbows 45 degrees and greater

from the vertical shall be considered horizontal

and therefore adopt horizontal run limitations.

See Figure 7.

c. Penetrating the Ceiling. Mark and cut out

an opening in the ceiling for the firestop spacer.

Frame the opening with the same size lumber

used in the ceiling joists.

d. Installing the Firestop Spacers. Firestop

spacers must be used whenever the venting

penetrates a ceiling/floor area.

In all situations, firestop spacers are to be

nailed to the ceiling joists from the bottom or

appliance side, EXCEPT when the space above

is an insulated ceiling or attic space. In this

situation, the firestop spacer must be nailed

from the top side to prevent loose insulation

from falling into the required one inch air space

around the vent system.

Install the firestop spacer by positioning and

nailing the four sides of the firestop spacer to

the joists using a minimum of three nails per

side.

Note: Be sure to provide intermediate support

for the vent during construction and check to

be sure inadvertent loading has not dislodged

the vent from the appliance or any vent joint.

Figure 7 - Using Elbows

WARNING!

When vent sections exceeding 3 feet

in length are installed between an offset and return, structural support must

be provided to reduce off-center loading and prevent vent sections from

separating at the vent joints. Follow all

B-vent manufacturer guidelines.

e. Securing Vent System. Continue assembling

the vent sections up through the firestop

spacers as needed. Vent sections must be

locked into position. Elbows and chimney

stabilizers have straps for securing these parts

to joists or rafters.

f. Marking the Exit Point in the Roof. Locate

the point where the venting will exit the roof by

plumbing down to the center of the vent system.

Drive a nail up through the roof to mark the

center. See Figure 8.

g. Cutting Out the Hole in the Roof. Measure

to either side of the nail and mark that 7 x 7

opening required (must meet minimum

clearances per venting requirements). This is

measured on the horizontal; actual length may

32921 Rev A 8 10-00

Figure 8 - Exiting Through the Roof

G141 SERIES B-VENT GAS APPLIANCE

be larger depending on the pitch of the roof.

Cut out and frame the opening. See the Uniform

Building Code for Roof Framing details. A one

inch minimum air space clearance must be

maintained between the vent section and the

roof.

h. Install Roof Flashing or Site-Produced

Chase Top. Position a roof flashing or a site-

produced chase to and secure into place.

i. Assembling Vent Sections. Continue to add

vent sections through the roof opening,

maintaining a minimum of one inch air space

clearance.

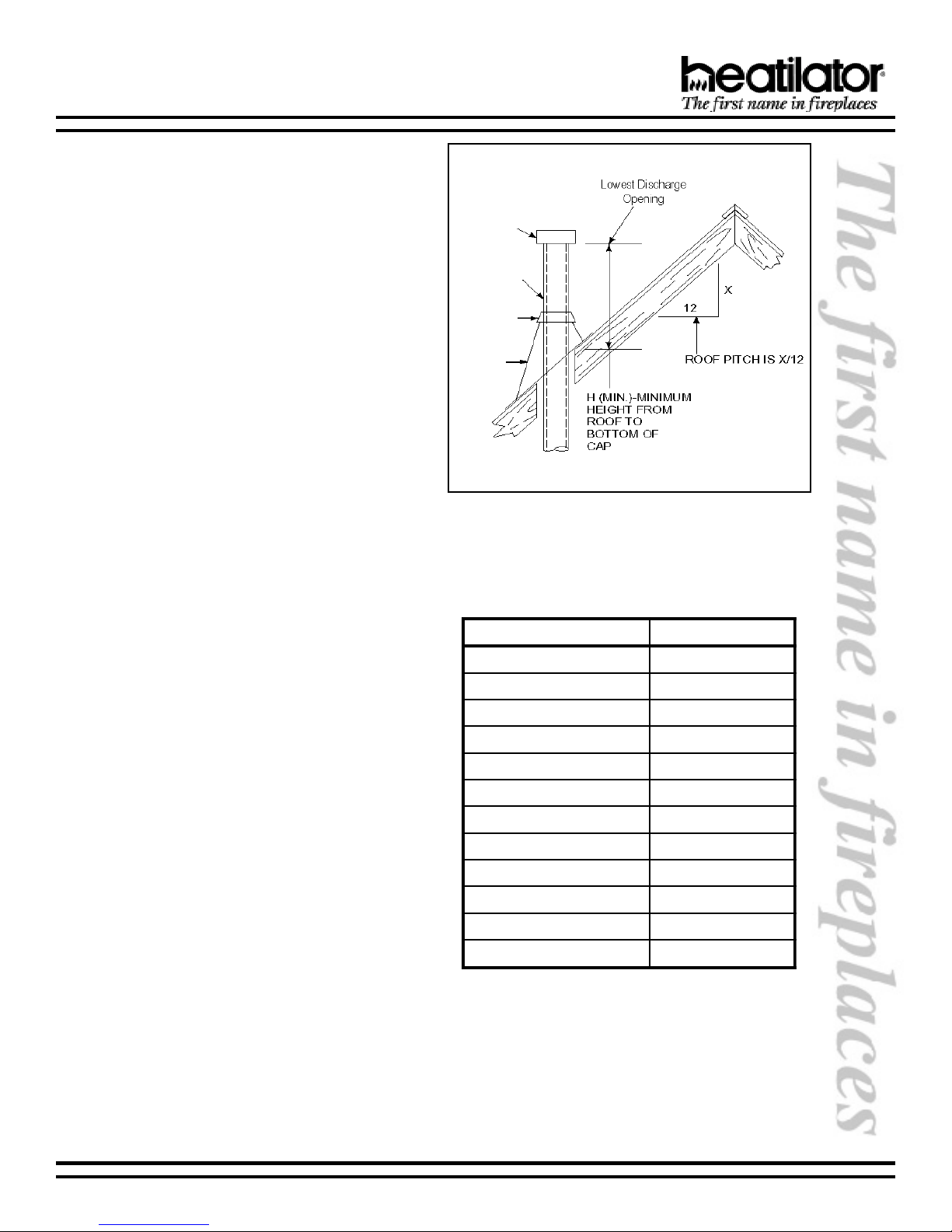

j. Termination Cap. Major building codes

specify a minimum termination height above

the roof top depending on the roof pitch. See

Figures 9 and 10.

These termination heights are necessary in the

interest of safety and do not guarantee proper

operation. Trees, buildings, adjoining roof lines,

adverse wind conditions, etc. may create a

need for a taller roof termination should down

drafting occur.

To install the termination cap, slide the cap

vent sections into the vent pipe. Secure the

cap using the screws provided.

k. Checking the Vent System. Periodically the

venting system should be tested to assure

proper operation. This can be done with a

match while the fireplace is operating.

Hold a lighted match at the top edge of the

firebox opening. If the flames and smoke remain

upright, ventilation is acceptable. If the flames

and smoke are drawn into the firebox, this

means ventilation is good. If the flames and

smoke are forced away from the firebox, this

may indicate a ventilation blockage or down

draft resulting in gas spillage into your home. If

this occurs, turn off the fireplace and do not

burn it until it has been inspected by a qualified

service person.

If you have installed optional doors, close the

doors and conduct the test following the same

instructions above. See Figure 11.

Listed

Cap

Listed

Gas

Vent

Storm

Collar

Roof

Flashing

Secured

with

Nails

Figure 9

Vent Height for Vertical Termination

hctiPfooRteef).niM(H

21/6ottalF0.1

21/7ot21/652.1

21/8ot21/7revO5.1

21/9ot21/8revO0.2

21/01ot21/9revO5.2

21/11ot21/01revO52.3

21/21ot21/11revO0.4

21/41ot21/21revO0.5

21/61ot21/41revO0.6

21/81ot21/61revO0.7

21/02ot21/81revO5.7

21/12ot21/02revO0.8

Figure 10

Minimum Termination Height

10-00 9 32921 Rev A

Loading...

Loading...