Heatilator G136, G136L, G136LE, G136E Owner's Manual And Installation Instructions

OWNERS MANUAL AND

INSTALLATION INSTRUCTIONS

G136 SERIES GAS APPLIANCE

MODELS: G136, G136L, G136E, G136LE

FOR RESIDENTIAL USE

CAUTION:

Do not expose the appliance to the elements

(such as rain, etc.).

WARNING: If the information in this manual

is not followed exactly, a fire or explosion may

result causing property damage, personal injury or loss of life.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

What to do if you smell gas

Do not try to light any appliance.

Do not touch any electrical switch; do not use

any phone in your building.

Immediately call your gas supplier from a

neighbors phone. Follow the gas suppliers

instructions.

If you cannot reach your gas supplier, call the

fire department.

Installation and service must be performed by a

qualified installer, service agency or the gas

supplier.

Improper installation, adjustment, alteration, service or maintenance can cause injury or property damage. Refer to this

manual. For assistance or additional information, consult a qualified installer, service agency or the gas supplier.

08-03 20356 Rev R 1

WARNING!

G136 SERIES INSTALLATION INSTRUCTIONS

Please retain this manual for future reference.

Table of Contents

Design and Installation Considerations for B-Vents ..................................................................................... 3

A. Appliance Specifications ............................................................................................................................. 4

B. Description of the Gas Appliance ................................................................................................................ 5

C. System Components................................................................................................................................... 7

D. Pre-Installation Preparation ......................................................................................................................... 8

E. Step-by-Step Installation ............................................................................................................................ 11

F. Operating Instructions ............................................................................................................................... 21

G. Maintenance Instructions .......................................................................................................................... 26

H. Troubleshooting ........................................................................................................................................ 28

I. Replacement Parts.................................................................................................................................... 30

J. Accessories .............................................................................................................................................. 32

Index ......................................................................................................................................................... 35

Warranty ................................................................................................................................................... 36

WARNING!

DO NOT use this appliance if any part has been under water. Immediately call a qualified service technician to

inspect the appliance, to replace any part of the control system and any gas control which has been under

water.

Safety Precautions

1. Please read these installation instructions completely before beginning installation procedures. Failure to follow them

could cause a malfunction resulting in serious injury and/or property damage.

2. Always check your local building codes prior to installation. The installation must comply with all local, regional, state

and national codes and regulations.

3. Installation and repair should be done by a qualified service person. This appliance should also be inspected annually

by a qualified service person. More frequent inspections/cleaning may be required due to excessive lint from carpeting,

bedding material, etc. It is imperative that the control compartment, burners and circulating air passageways of the

appliance be kept clean.

4. This is a vented gas appliance. Do not burn wood or other material in this appliance.

5. NEVER leave children unattended when there is a fire burning in the appliance.

6. This appliance must be vented with a minimum 5 B-Vent system and must terminate above the roof line. Venting

must not be connected to a chimney flue servicing a solid fuel burning appliance. Never downsize pipe.

7. Use only the fuel gas specified on the rating label of this gas appliance. Keep any flammable liquids a safe distance

from the appliance.

8. While servicing this appliance, always shut off all electricity and gas to the appliance. This will prevent possible

electrical shock or burns. Also, make sure the appliance is completely cooled before servicing.

9. The appliance and its manual shutoff valve must be disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of 1/2 psi (3.5 kPa). The appliance must be isolated from

the gas supply piping system by closing its manual shutoff valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 psi (kPa).

10. Do not use this appliance if any part has been under water. Immediately call a qualified service technician to inspect

the appliance and to replace any part of the control system and any gas control which has been under water.

11. Be sure to provide adequate clearances around the air openings into the combustion chamber and adequate

accessibility clearances for servicing and proper operation.

12. Provisions shall be made to provide adequate combustion and ventilation air.

13. The appliance area shall be kept clear and free from combustible materials, gasoline and other flammable vapors and

liquids.

14. The flow of combustion and ventilation air should not be obstructed.

2 20356 Rev R 08-03

G136 SERIES INSTALLATION INSTRUCTIONS

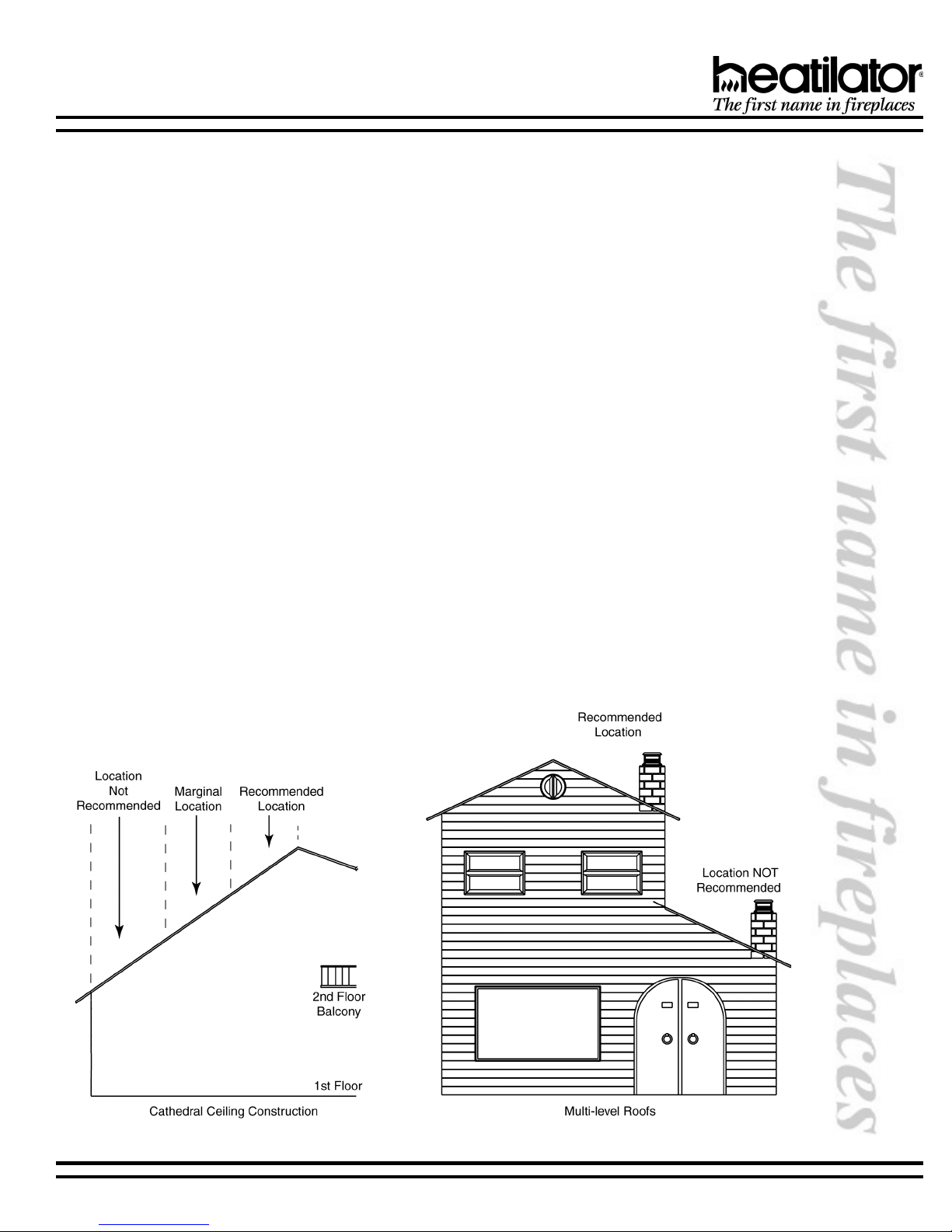

DESIGN AND INSTALLATION CONSIDERATIONS FOR B-VENTS

When selecting a location for your B-Vent appliance, it is important to evaluate a number of considerations. Modern

construction techniques can create conditions that may not allow your vent to draft properly. This may result in spillage

from your B-Vent appliance, as well as cause other combustion appliances to operate incorrectly.

Tightly sealed construction is important for energy efficiency. Unfortunately, a great deal of effort has been directed to

tightening up sidewall construction, while considerably less attention has been paid to tightening upper portions of the

warm air envelope (insulated ceilings). This has increased the Stack Effect, a condition that increases the negative

pressure generated by the structure. This negative pressure will directly affect the drafting performance of a B-Vent

appliance vent. To minimize the negative pressure generated by stack effect, make certain that all duct work installed in

the attic spaces is sealed airtight. Minimize the number of recessed light fixtures installed in the insulated ceiling and use

sealed recessed light fixtures. Finally, make certain the whole house fans and attic access panels are tightly sealed.

These are important design considerations that must be observed during the design and construction stage of the home.

If you desire to put an appliance in your basement, we recommend that you consider a direct vent gas appliance. Basements

always have a significant negative air pressure that causes the B-Vent system to be more susceptible to spillage and cold

flue back drafting. Since direct vent gas appliances are sealed, they are not affected by the negative pressure that exists

in basements.

Finally, a B-Vent appliance performs best when the vent (roof termination) is located on the upper half of the roof, especially

when cathedral ceilings are present. Vents that are located on the lower half of the roof realize what is known as lazy flue

and will not draft as well as a vent that is located in the upper portion of the roof. The reason for this is that the stack effect

generated by the overall height of the living spaces inside the house will exceed the draft generated by the vent system.

If you desire to place an appliance in a location where the termination cap would be located on the lower half of a roof;

such as on an outside wall at the base of a cathedral ceiling, we recommend that you consider using a direct vent gas

appliance. This will ensure an appliance that operates correctly.

These properties do not affect just your B-Vent appliance. They can cause any woodburning fireplace as well as any

conventionally vented (B-Vent) gas appliance to operate improperly. Careful planning at this stage of your project will

ensure satisfaction with the operation of your appliance once it is completed.

08-03 20356 Rev R 3

G136 SERIES INSTALLATION INSTRUCTIONS

A. APPLIANCE SPECIFICATIONS

1. Certification

The G136 Series Vented Gas Appliance has been

tested in accordance with the standard ANSI Z21.50-

1998-CGA 2.22-M98 and has been certified by

Warnock Hersey for installation and operation as

described in these Installation and Operating

Instructions. All components are AGA or UL safety

certified.

2. Local Codes

Check with your local building code agency prior to

installing this appliance to ensure compliance with

local codes, including the need for permits and follow-

up inspections. This appliance must conform with

local codes, or in the absence of local codes, comply

with the National Fuel Gas Code, ANSI Z223.1-latest

edition in the U.S.; in Canada, the CANI-B149-latest

edition.

3. Optional Components

This gas appliance has been tested and listed for use

with the optional components listed below. Many

optional components may be purchased separately

and installed at a later date. However, installation of

a remote control or fan kit will require electrical power.

To avoid costly reconstruction, a separate course of

electrical power should be supplied to the appliance

at the time of initial installation of the system for

possible addition of these accessories at a later date.

4. Fuel

Any additions, changes or conversions required in

order for the appliance to satisfactorily meet the

application needs, must be made by a qualified

service technician using factory specified and

approved parts.

This product is manufactured to use natural gas or

propane gas, depending on model purchased. A

natural gas appliance can be converted to use

propane gas later, but only if done by a qualified

service technician and only if the CKP Natural Gas to

Propane Gas Conversion Kit is used. In the event your

appliance must be converted back to natural gas from

propane, you must use a CKN Propane Gas to Natural

Gas Conversion Kit.

If you require assistance during installation, please

contact your local dealer or contact Heatilator Technical

Services Department, Hearth & Home Technologies,

1915 W. Saunders Street, Mt. Pleasant, Iowa 52641.

HEATILATOR® is a registered trademark of Hearth &

Home Technologies, a division of HON INDUSTRIES.

WARNING!

This appliance is tested and listed for use only with the optional accessories listed in

these instructions. Use of optional accessories not specifically tested for this appliance

could void the warranty and/or result in a safety hazard.

4 20356 Rev R 08-03

G136 SERIES INSTALLATION INSTRUCTIONS

B. DESCRIPTION OF THE GAS APPLIANCE

The G136 Series is a vented gas appliance. While a significant amount of heat is created by the G136, it is not intended

to be and should not be used as a heater.

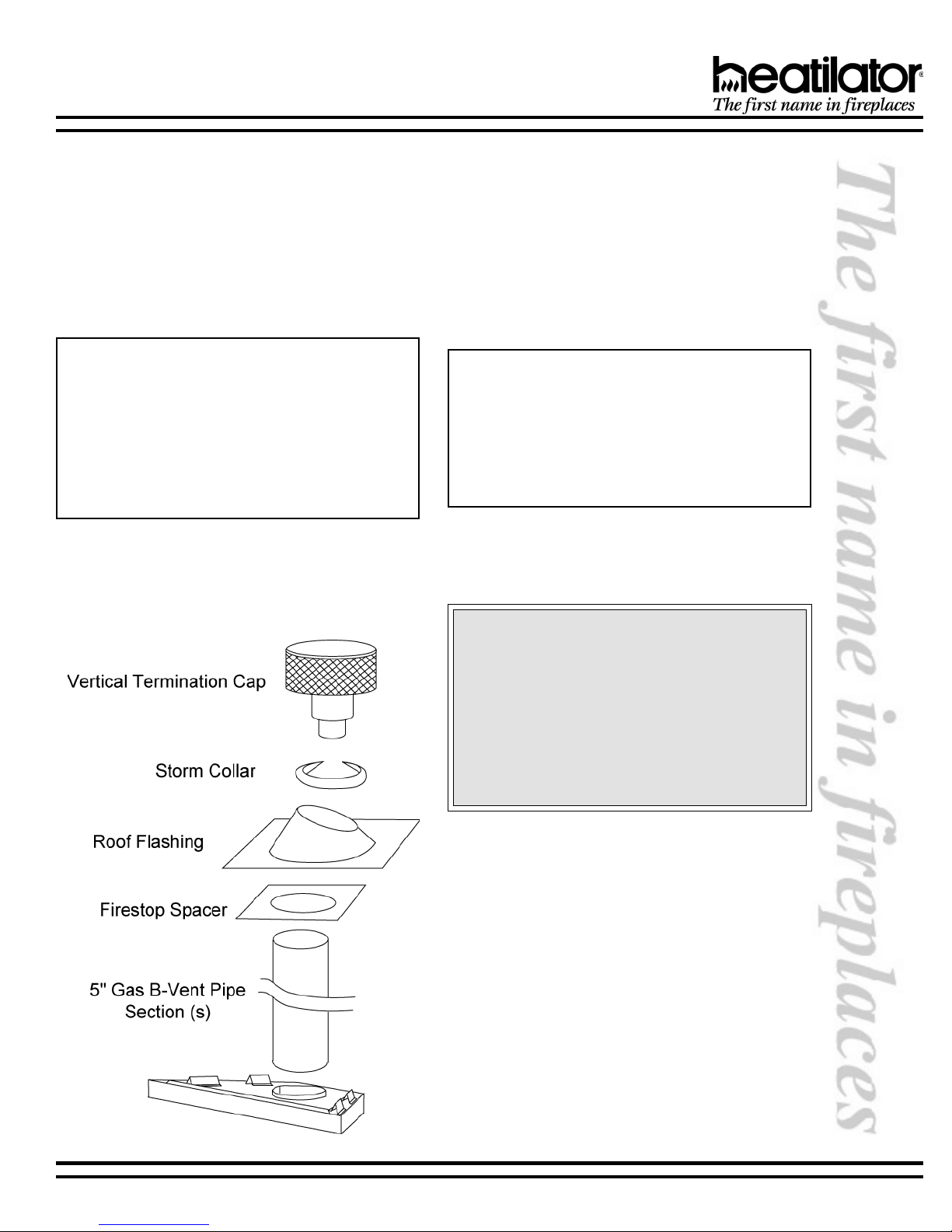

The HEATILATOR system must consist of the following:

1. Gas Appliance

2. B-Vent System

3. Termination

Tools and building supplies normally required for

installation:

Saw Wall-finishing materials

Pliers Framing material

Hammer Surround

Phillips screwdriver Caulking material

Tape measure Square

Plumb line Electric drill/bits

Level

Typical Vertical Installations

Optional components include:

1. Fan Kit

2. Remote Control

3. Outside Air Kit

4. Glass Doors

5. Rheostat Control

Note: Illustrations throughout these instructions reflect typi-

cal installations and are for design purposes only. Actual

installation may vary slightly due to individual design preferences. However, minimum and maximum clearances must

be maintained at all times.

The illustrations and diagrams used throughout these installation instructions are not drawn to scale.

We strongly recommend that you DO NOT install BVent Gas Appliances in strong negative air locations,

such as a basement or a public facility. Living rooms

with cathedral ceilings could be susceptible to a

negative air situation, but such installations can be

overcome through raising the termination,

depending on specific installations. This appliance

uses room air for normal operation and could have

problems establishing a positive draft in a negative

air location. In lieu, we recommend a Direct Vent Gas

Appliance.

08-03 20356 Rev R 5

G136 SERIES INSTALLATION INSTRUCTIONS

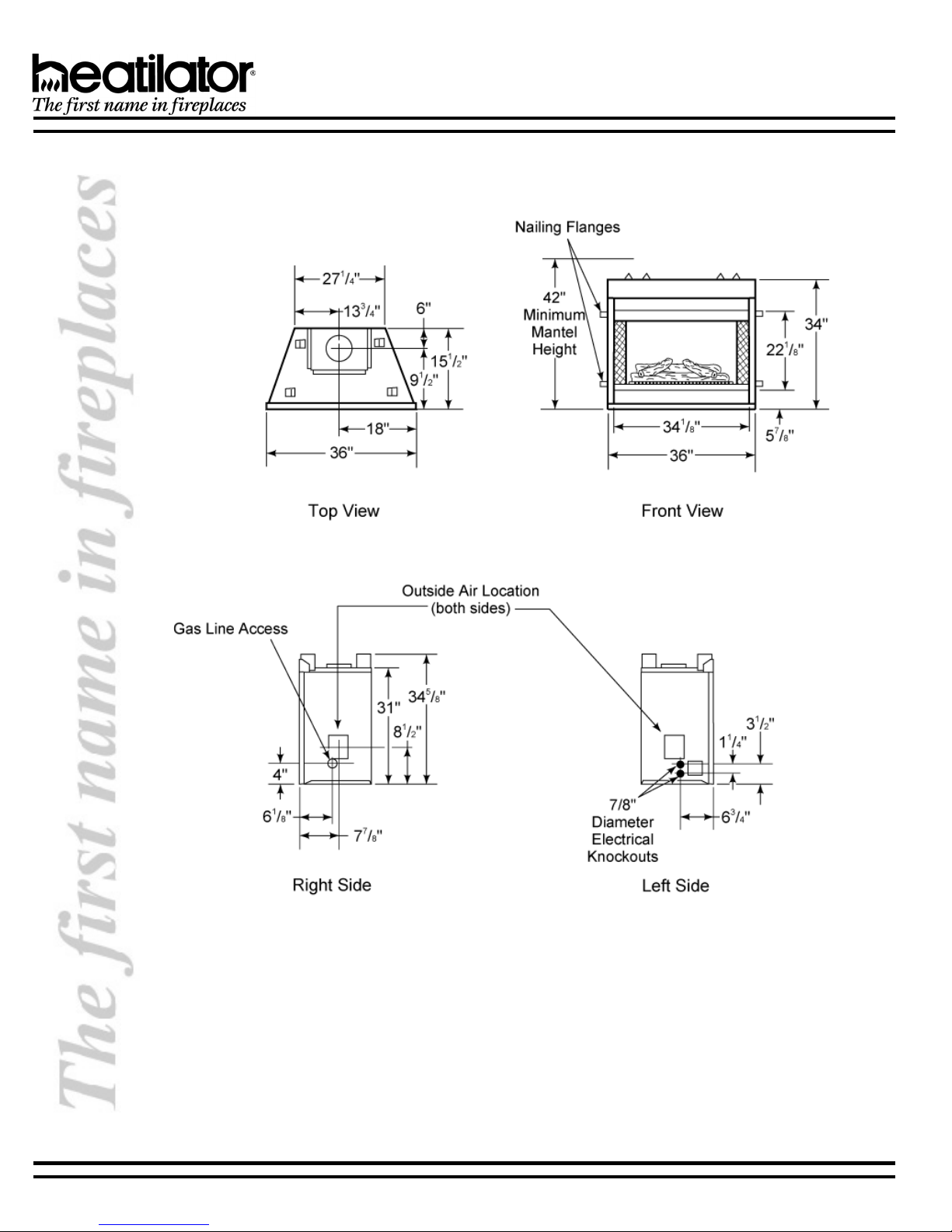

Dimensions

Framing dimensions can be found on page 9.

6 20356 Rev R 08-03

G136 SERIES INSTALLATION INSTRUCTIONS

C. SYSTEM COMPONENTS

The Table below is a list of only those components which may be safely used with this decorative gas appliance. Only trim

kits supplied by the manufacturer shall be used in the installation of this appliance.

#golataCnoitpircseD

631G .ecnailppagnitalucrictaeh,tolipgnidnats,saglarutan"63

L631G .ecnailppagnitalucrictaeh,tolipgnidnats,sagenaporp"63

E631G .ecnailppagnitalucrictaeh,noitingicinortcele,saglarutan"63

EL631G ecnailppagnitalucrictaeh,noitingicinortcele,sagenaporp"63

PKCehtgnisusagenaporpotdetrevnocebyamsledomsaglarutan(

.)tiKnoisrevnoC

41KAtiKriAedistuO

01CB.detnuomllaw,lortnoctatsoehrrotomnaF

11CB.lortnocnafdetavitca-erutarepmeT

*LTH-TRAMS-CRlortnocetomeR

*LTH-TLM-TCR

*LTH-TATS-TRAMS .remit,.pmettatsomreht,.pmetmoor,FFO/NO:etomerlanoitcnufitluM

*LTH-TTAB-TRAMS .remit,.pmettatsomreht,FFO/NO:etomerlanoitcnufitluM

PKC.tiknoisrevnocsagenaporpotsaglarutaN

NKC.tiknoisrevnocsaglarutanotsagenaporP

91KF)dedulcnilenapsseccalortnocellirgkcalb(tiKnaF

6361MD.sroodssalgmirtkcalbdlof-ibelytslanigirO

B6361MD.sroodssalgmirtssarbdehsilopdlof-ibelytslanigirO

B631FD.sroodssalgssarbdehsilopdlof-ibdexiF

)ylnotolipgnidnats(deeps

naf,.pmetmoor,lortnocemalfwol/hgih,FFO/NO:etomeRlanoitcnufitluM

.sdeenruoyotelbacilppasietomerhcihwenimretedoterutaretilotrefeR*

08-03 20356 Rev R 7

G136 SERIES INSTALLATION INSTRUCTIONS

D. PRE-INSTALLATION PREPARATION

Installation and repair should be done by a qualified service person. The appliance should be inspected before use

and at least annually by a qualified service person. More frequent cleaning may be required due to excessive lint from

carpeting, bedding material, etc. It is imperative that control compartments, burners and circulating air passageways of

the appliance be kept clean.

Due to high temperatures, the appliance should be located out of traffic and away from furniture and draperies.

WARNING!

This appliance may use the B-Vent chimney system only and must not be connected to a chimney flue servicing

a separate solid fuel burning appliance.

1. Gas Pressure

For natural gas, the minimum inlet gas supply

pressure is 4.5 inches water column, and the

maximum inlet gas pressure is 7.0 inches water

column, for the purpose of input adjustment. Input rate

is 25,000 BTU/hr. For propane gas, the inlet gas supply

pressure must be at least 11.0 inches water column and

a maximum 14.0 inches water column.

Pressure taps are provided on the gas control valve,

near the outlet to the main burner immediately

upstream of the gas supply connection to the

appliance, accessible for a test gage connection.

Optimum manifold pressure is 3.5 inches water column

for natural gas, and 10.0 inches water column for

propane gas.

2. High Altitude Installation

a. U.S. Installation

Appliances are tested and approved for elevations

from 0-2000 feet.

When installing this appliance at an elevation above

2000 feet, United States codes require a decrease

of the input rating by changing the existing burner

orifice.

Input should be reduced 4% for each 1000 feet

above sea level. Check with the local gas utility for

proper orifice size identification. This appliance

uses a .096 in./2.44 mm. orifice size on natural gas

versions and a .059 in./1.49 mm. orifice size on

propane gas versions.

Consult your local gas company for assistance in

determining the proper orifice for your location or

refer to ANSI Z223.1-latest edition, Appendix F.

b. Canadian Installation

Appliances are certified for elevations from 0-4500

feet. When installing this appliance at an elevation

between 0-4500 feet in Canada, the input rating does

not need to be reduced.

When installing this appliance at an elevation above

4500 feet in Canada, check with local authorities.

Consult your local gas company for assistance in

determining the proper orifice for you location or refer

to ANSI Z23.1-latest edition, Appendix F.

3. Location and Space Requirements

This appliance may be installed along a wall, across a

corner or in an exterior chase. This appliance must be

installed so that the draft hood is in the same

atmospheric pressure zone as the combustion air inlet

and the appliance shall be located so that the relief

opening is accessible for checking vent operation. The

G136 Series may be installed at a height level with the

floor, or it can be raised up from the floor to enhance

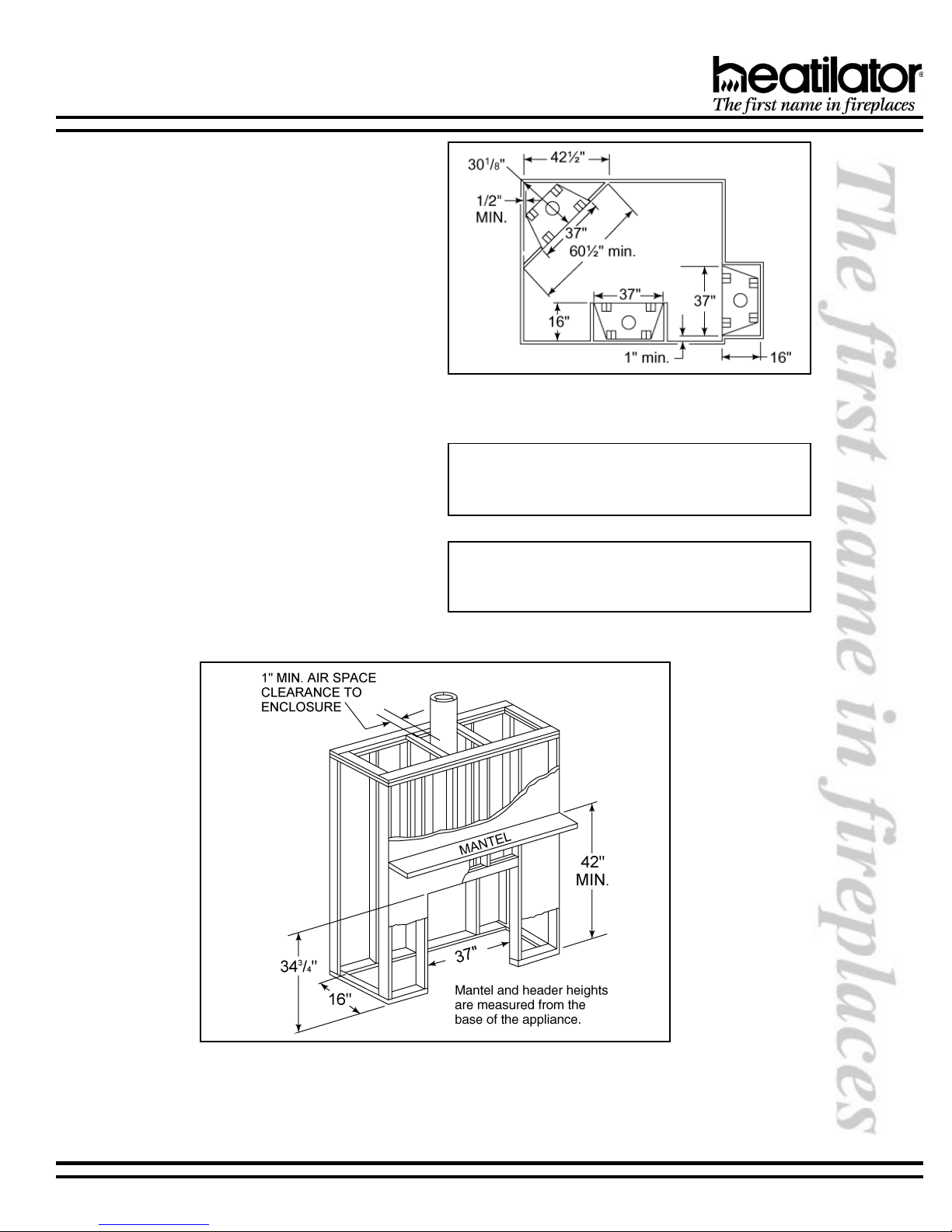

its visual impact. Figure 1 illustrates a variety of ways

the appliance may be located in a room. These

appliances are also certified for installation in a

bedroom or bed/sitting room in the U.S. and Canada

(bedroom installations in Canada require the addition

of non-operable doors), provided that the bedroom or

bed/sitting room has a volume of at least 1,250 cubic

feet.

WARNING!

To prevent contact with sagging or loose insulation, the appliance must not be installed

against vapor barriers or exposed insulation.

8 20356 Rev R 08-03

G136 SERIES INSTALLATION INSTRUCTIONS

4. Clearances

The following clearances to combustibles must be

maintained: Minimum clearances to the top standoffs

of the appliance - 0, floor - 0, back - ½, sides - ½,

face of the appliance to ceiling - 30. Minimum

clearances to venting are as follows: Horizontal run

sections require a 3 minimum air space on the top

and a 1 minimum air space on the sides and bottom

of the vent section. Venting that is vertical requires a

1 minimum air space completely around the vent

section. See Figure 1.

5. Framing the Gas Appliance

The G136 Series Gas Appliance will fit a framed

opening of 37 w x 16 d x 34-3/4 h.

Figure 2 shows a typical framing of this appliance

assuming combustible materials are used. All

required clearances to combustibles around the

appliance must be adhered to. A 1/2 air space

clearance must be maintained at the back and sides

of the appliance. Any framing on top of the appliance

must be above the top standoffs. Vent sections for a

horizontal run require a 3 minimum air space

clearance on top and a 1 minimum air space

clearance on the sides and bottom. Vertical vent

sections require a 1 minimum air space clearance

completely around the vent section.

Figure 1

Appliance Locations and Clearances

Note: If an optional fan kit or hand held remote control

are to be used, wiring must be done prior to finishing to

avoid reconstruction.

Note: The remote wall switch must be wired prior to ap-

plying the finishing material to the wall in order to avoid

reconstruction.

08-03 20356 Rev R 9

Figure 2 - Framing Requirements

6. Finishing Materials

Only noncombustible materials may be used to cover

the black surface of the appliance front.

a. Combustible Materials

Material made of or surfaced with wood,

compressed paper, plant fibers, plastics, or any

material capable of igniting and burning, whether

flame proofed or not, plastered or unplastered.

b. Noncombustible Material

Material which will not ignite and burn. Such

materials are those consisting entirely of steel,

iron, brick, tile, concrete, slate, glass or plasters,

or a combination of the materials.

c. High Temperature Sealant Material

Sealants that will withstand high temperatures;

General Electric RTV103 Black) or equivalent,

Rutland, Inc. Fireplace Mortar #63 or equivalent.

After completing the framing and applying the

facing material (dry wall) over the framing, a

noncombustible sealant, one-half inch wide

maximum, must be used to close off any gaps at

the top and sides between the appliance and

facing to prevent cold air leaks. See Figure 3.

G136 SERIES INSTALLATION INSTRUCTIONS

WARNING!

Hood and control access panel on this appliance

cannot, in any way, be covered as it may create

a fire hazard. Draft relief openings must not be

covered or blocked.

Figure 3 - Finishing Materials

10 20356 Rev R 08-03

G136 SERIES INSTALLATION INSTRUCTIONS

E. STEP-BY-STEP INSTALLATION

WARNING!

Before starting, do the following:

1. Wear gloves and safety glasses for protection.

2. Keep hand tools in good condition. Sharpen cutting edges and make sure tool handles are secure.

3. Always maintain the minimum air space required to the enclosure to prevent fire.

1. Positioning the Gas Appliance

This appliance may be placed on either a combustible

or noncombustible continuous, flat surface. If the appliance is installed on combustible flooring other than wood,

a metal panel needs to be installed underneath the appliance extending its full width and depth. Slide the appliance into position and level from side-to-side and frontto-back. Shim with noncombustible material, such as

sheet metal, as necessary.

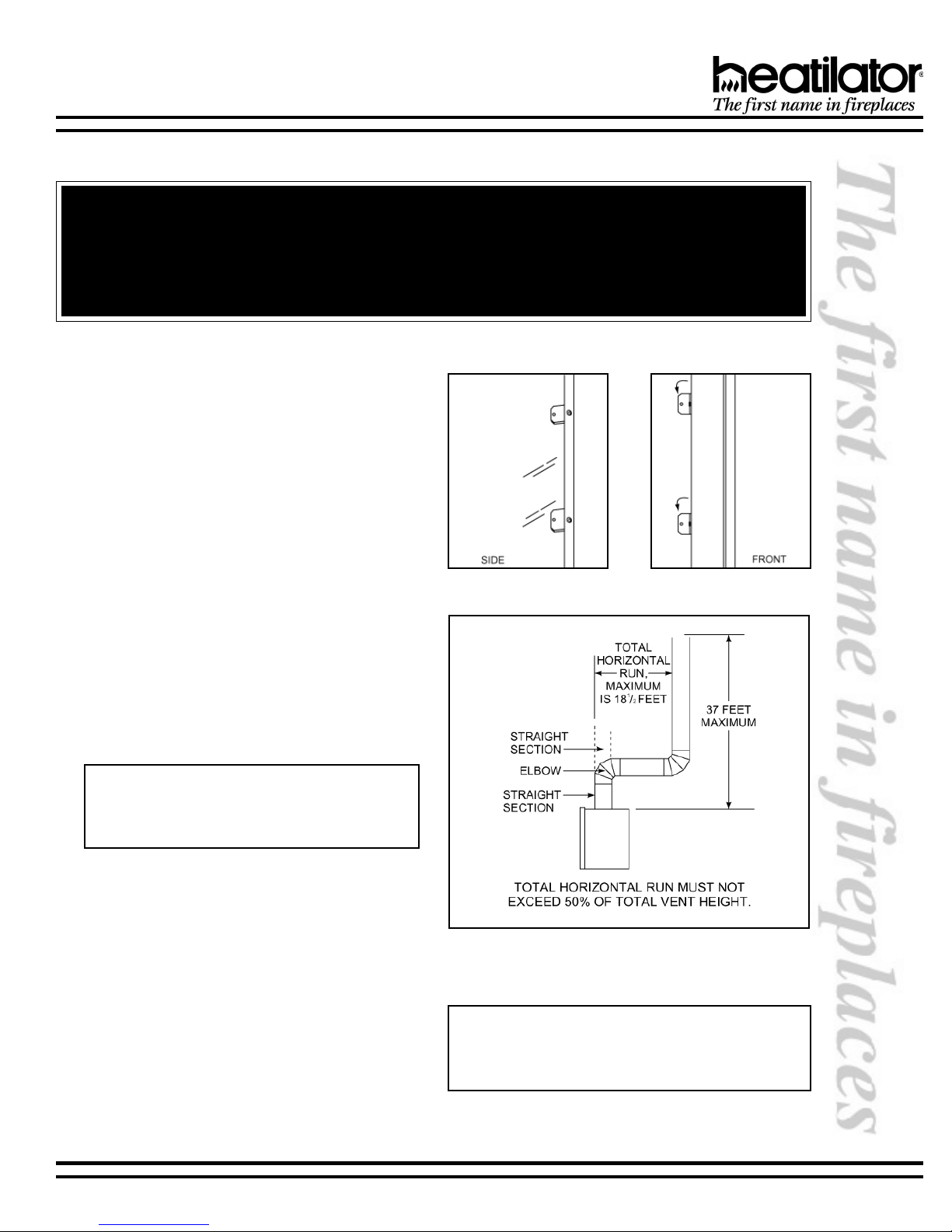

Secure the appliance by bending out the nailing

flanges located on each side of the appliance and

nailing the appliance to the framing. See Figure 4.

2. Termination

Common venting of this gas appliance with other gas

appliances is not allowed in multifamily dwellings.

Possible problems which may occur from common

venting are usually more costly and does not prevent

possible spillage of flue gas products into other

occupied spaces sharing the common vent. Noise is

easily transmitted from one area to another if common

venting is used.

Figure 4 - Nailing Flanges

Note: This appliance requires the use of a 5 B-

vent for operation and must be terminated above

the roof line. Never downsize pipe. Follow all Bvent requirements and installation instructions.

The minimum height of vent installation must be 9 from

the top or 12 from the base of the appliance. Horizontal

run must never exceed 50% of the height of the vent

system as shown in Figure 5.

The following figures are the maximum distances

from the base of the appliance, as well as the

minimum air space clearances that must be

maintained during termination of this appliance.

Maximum straight unsupported rise - 25 feet;

maximum horizontal unsupported run - 3 feet; air

space clearances around vertical rise - 1 on all sides;

air space clearances around the horizontal run - 3

on top and 1 on sides and bottom; maximum

height-40 from the base of the appliance. Every 1

of horizontal run requires at least 2 of vertical rise.

08-03 20356 Rev R 11

Figure 5

Venting Off The Top of Appliance

Note: The horizontal run of vent must have a 1/4 rise for

every 1 ft. of run towards the termination. Never allow the

vent to run downward. This could cause high temperatures and may present the possibility of a fire.

Loading...

Loading...