Page 1

®

Operating Instructions & Parts Manual 2LBL9, 2LBN1

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product

described. Protect yourself and others by observing all safety information. Failure to comply could result in personal injury and/or

property damage! Save these instructions for future reference.

This manual includes operating instructions for a variety of remote controlled products.

All products work on the same principle and use the same code setting information.

Please read all instructional information and note any specic information pertaining to

your particular product.

WARNINGS:

• FOR USE ONLY with 120 volt incandescent or halogen bulbs.

• DO NOT USE with uorescent bulbs, appliances, power supplies, low voltage

Lighting Controls

This man ual appl ies to t he f ollo wing

products:

•

Wireless Transmitters (Indoor / Outdoor)

– 180° Motion Sensor (2)

• Receivers

– Halogen Security Light

– Floodlight

lighting, or any other electrical devices.

• Products are UL/cUL and/or FCC/IC tested and approved.

• Operational range of up to 100 feet.

LumaPro® wireless lighting controls are designed to work together. Simply determine

which transmitter(s) you would like to have control which receiver(s) and set the

code setting to match.

FEATURES

PAGE REFERENCE GUIDE

ENGLISH

HEA 007

Printed in China

12/07

Page 3

2LBN1

Page 5

2LBL9

Page 7

598-1326-01

LPG-6028, LPG-6042

Page 2

DETECT

CODES

12 3 4

DAY

NIGHT

NIGHT

ONLY

ON

1 2 3

4

RAINTIGHT

OUTDOOR USE ONLY.

FOR WALL AND CEILING MOUNT ONLY

SUITABLE FOR WET LOCATION

MADE IN CHINA

THIS END UP

ã

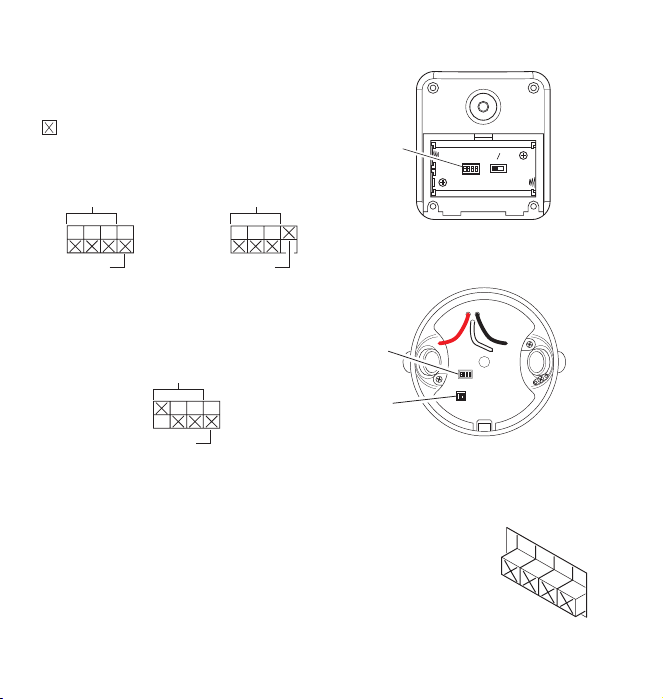

Note: Most single system installations will not require any

change to the code setting. Transmitter(s) and receiver(s)

must have the same code and group setting to work together.

Switches 1 through 3 set the code. Switch 4 sets the Group

(A or B). See page 2 for switch locations.

CODE SETTINGS

( – Indicates Position of Switch)

Example 1 - Code Settings, System 1

(Factory Setting)

Transmitter(s)/

Receiver(s) Code

Transmitter(s)/

Receiver(s) Code

CODE SWITCH LOCATIONS

Code

Switches

180° Motion Sensor

Group “A”

Example 2 - Code Settings, System 2

Note: When operating more than one system independently of each

other, set each system to a different code. There are 8 codes available by changing the settings of switches 1 through 3.

Transmitter(s)/

Receiver(s) Code

Group “B”

Group “A”

Code

Switches

LAMP MODE

switches

Halogen Security Light and Floodlight

Note: The “X” has been

placed on the switches to

help clarify the code settings

on the previous page.

Close-Up of Typical Code Switch

2 598-1326-01

(Factory Default Setting is Off)

Page 3

DETECT

CODES

12 3 4

DAY

NIGHT

NIGHT

ONLY

180° MOTION SENSOR

180° Motion Sensor

Features:

• No wiring required.

• Up to 70 feet sensing range, 180° Coverage.

• Adjustable sensitivity.

• Day/Night or Night only operation.

• Test mode.

• Uses 2 AA batteries.

• Wall or eave mount.

• Controls receivers up to 100 feet (30 m) away.

Select Night or 24 Hour Mode

These motion sensors are able to detect motion day and night or

night only. To set the detection mode, remove battery compartment

cover by sliding the cover down. Remove batteries if necessary.

Slide the DETECT switch to either the DAY/NIGHT or NIGHT

ONLY position. Replace battery compartment cover by reversing

the above instructions.

• Before mounting motion sensor, remove battery compartment

cover by sliding the cover down.

Install 2 AA batteries according to polarity markings inside the

battery compartment. Replace battery compartment cover by

reversing the above instructions.

Installing Batteries

180° Motion Sensor

(Rear View)

Battery Compartment

Detect

Control

1. Install motion sensor mounting bracket where motion detection is

2. Install motion sensor to mounting bracket. Using a Philips-head

IMPORTANT: The motion sensor must be mounted with the bottom

cover facing down in order to maintain water tightness.

Bracket Socket

Installing Motion Sensor

desired. Attach motion sensor mounting bracket to a sturdy object

(i.e. tree, post, house, etc.) using two screws provided. Make

sure unit has an unobstructed view. Note: Attach mounting

bracket vertically if connecting to a curved surface such as a

post.

screwdriver, loosen the clamp screw on the mounting bracket.

Insert swivel ball mount on motion sensor into mounting bracket

socket (Note: You should hear a snap). Aim motion sensor toward

area where detection is desired. Tighten clamp screw.

Mounting

Clamp

Screw

Mounting Bracket

Mounting Screw

Nut

Swivel Ball Mount

Sensor

Installing Motion Sensor

3598-1326-01

ENGLISH

Page 4

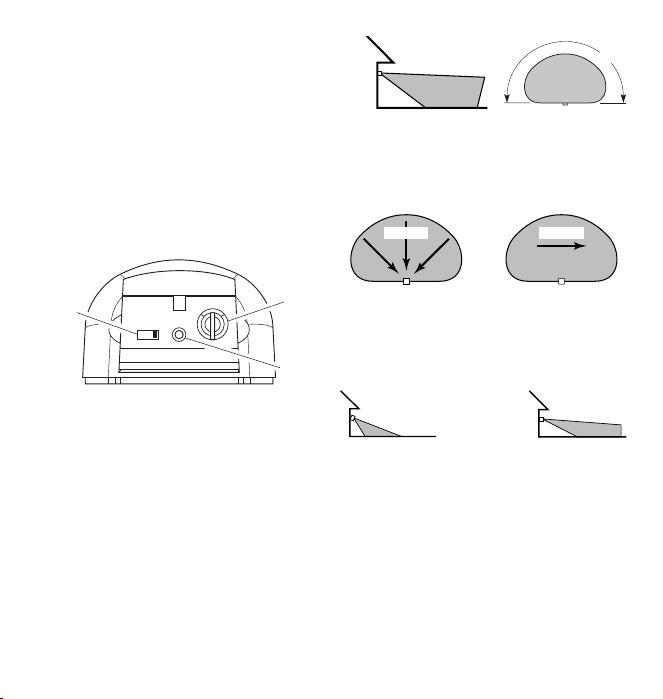

Check Operation and Adjustment

5 1 TEST

ON-TI ME

(MINU TES)

RANGE

MAX

MIN

Note: When rst turned on or when switching modes wait 30

seconds.

Locate the RANGE control and ON-TIME control on the motion

sensor:

• The RANGE control and ON-TIME control are located on the bottom

of the motion sensor. Using your ngernails or a small, at-head

screwdriver, gently pry the cover until it opens.

1. Check Operation. Set the ON-TIME control to TEST mode. Walk in

front of motion sensor. The LED indicator light should ash when

motion is detected (see illustration for location of LED light).

2. Adjust Motion Sensor. Turn the RANGE control to the mid posi-

tion and ON-TIME control to the TEST position. Walk through

coverage area noting where you are when the LED begins to

ash. Loosen the clamp screw and move the motion sensor to

change the coverage area. Tighten clamp screw when nished.

Do not overtighten clamp screw.

8 ft.

(2.4 m)

Maximum Range

180° Motion Sensor Coverage Area

Motion

70 ft.

(21 m)

Maximum

Coverage Angle

Motion

180°

ON-TIME

Control

Range

Control

LED

Indicator

180° Motion Sensor Controls

3. Adjust RANGE Control. To increase sensitivity, turn the RANGE

control toward MAX. To decrease sensitivity, turn the RANGE

control toward MIN. Note: If the RANGE is set too high, false

triggering may result in some environments.

Note: When using test mode to check operation in the day time:

A. Set the DETECT control switch to DAY/NIGHT and

B. Set the ON-TIME control to TEST.

4. Set ON-TIME Control. Determine the amount of time you want

the connected device to stay on after motion is detected (1 or

5 minutes). Slide the ON-TIME control to the corresponding

setting.

Sensor Sensor

Most SensitiveLeast Sensitive

The detector is most sensitive to motion across its eld of view.

Motion Sensor Sensitivity

Aim Sensor Down

for Short Coverage

Aim Sensor Higher

for Long Coverage

Adjusting Motion Sensor Coverage

4 598-1326-01

Page 5

RECEIVER INFORMATION

All receivers have the following features and ratings:

• Rated for 120VAC/60Hz supply voltage.

• Uses existing wiring.

• Fits standard single gang junction box (wall switch only).

• Not for use with Compact Fluorescent bulbs.

• When rst turned on wait 15 seconds.

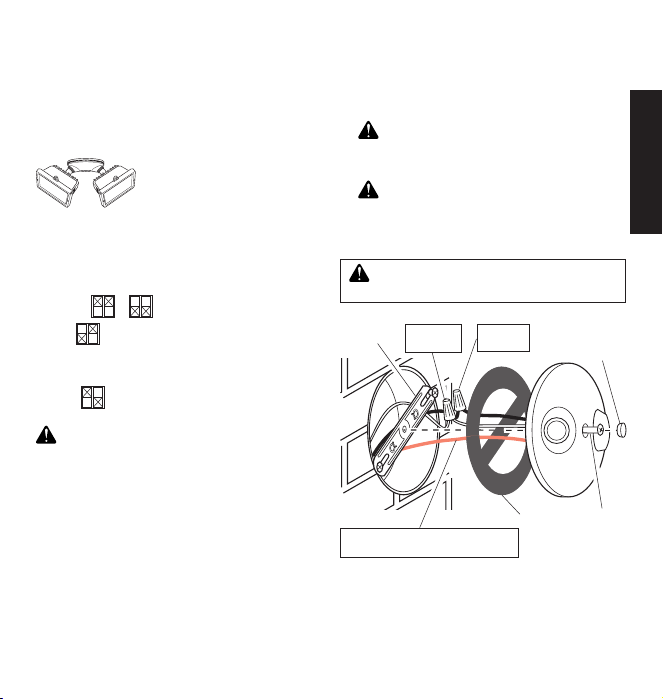

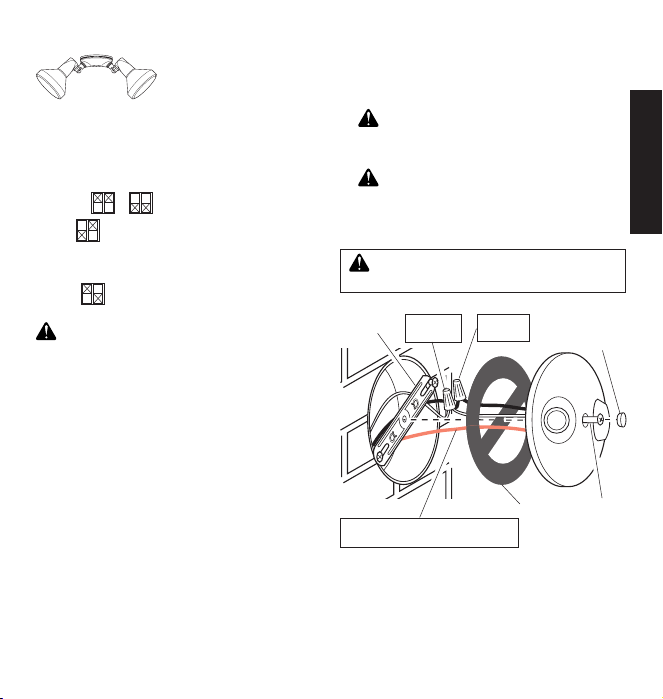

HALOGEN SECURITY LIGHT (2LBN1)

• Minimal wiring required.

• Install xture in accordance with local codes.

There are three lamp modes (light turn-on effects) available when

motion is detected:

• NORMAL

• SOFT

brightness. Light gradually dims to half-bright, pauses, and then

continues dimming to off when motion is no longer detected and

after selected ON-TIME.

• FLASH

full brightness.

WARNING: Turn power off at the fuse or circuit breaker.

1. Remove the existing light xture.

2. Install the mounting strap as shown using two screws that t

your junction box.

Note: The plastic hanger can be used to hold the xture while

wiring. Thread the small end of the plastic hanger through the

hole in the center of the cover plate. Insert the small end into

one of the slots on the mounting strap.

3. Set the LAMP MODE switch to the desired light turn-on effect

(Normal, Soft, Flash).

4. Route the wires from the light receiver through the large gasket

holes.

5. Twist the junction box wires and xture wires together as shown.

Secure with UL approved wire connectors.

6. Align the cover plate and cover plate gasket. Secure with

mounting bolt.

Features and Ratings:

• Up to 200 Watt maximum halogen load

(up to 100 Watt maximum halogen,

per lampholder).

•

Use onl y T3, 100W (m ax.) tu ngsten

halogen 120 VAC lamps.

Lamp Modes

or - Light instantly comes on.

- Light starts dim and gradually increases to full

- Light ashes on then off twice before turning on

7. Push the rubber plug rmly into place.

8. Not intended for waterproof junction boxes. Fixture should be

surface mount only. Caulk the wall plate mounting surface with

silicone weather sealant.

9. Adjust the lamp holders by loosening the lock nuts. Note: Do

not rotate the lamp holders more than 180° from the factory

setting.

CAUTION: To avoid water damage and electrical shock,

keep lamp holders 30° below horizontal.

10. Insert halogen bulb (see Bulb Installation) up to rated wattage

into module.

CAUTION: Do not exceed the maximum load limits listed

above.

11. Check operation. Activate transmitter being used with receiver

(see transmitter instructions). A signal will be sent to the receiver

to turn the receiver ON or OFF.

WARNING: Risk of re. Do not aim the lamps at a

combustible surface within 3 ft. (1 m).

Mounting

Strap

Junction box ground wire to green

White to

White

ground screw on xture.

Wiring Halogen Security Light

Black to

Black

Gasket

Rubber

Plug

Mounting

Bolt

ENGLISH

5598-1326-01

Continued

Page 6

CAUTION: To Avoid Fire Or Burn Hazards:

• Allow xture to cool before touching. The bulb and the xture

operate at high temperatures.

• Keep xture at least 2" (5 cm) from combustible materials.

Do not aim at objects closer than 3 feet. (1 m).

• Use only T3, 100W (max.) tungst en halogen 120 VAC

lamps.

NOTE: Bulbs are included, but you will need to install them.

NOTE: When replacing bulb, turn power off and let the xture

cool.

1. Open glass cover. Remove the old bulb by pushing the bulb

towards the right until the left side of the bulb is clear of the

left socket.

IMPORTANT:

skin can greatly reduce bulb life. Use clean gloves or a cloth

to install new bulb.

2. To insert the new bulb, push the bulb into the right socket so

the bulb ts completely into the left socket.

3. Check that the bulb is seated properly.

4. Close the glass cover.

Bulb Installation

Do not handle new bulb with bare skin. Oil from

6 598-1326-01

Page 7

FLOODLIGHT (2LBL9)

• Use only 75 Watt maximum PAR 38 lamps (not included).

• Minimal wiring required.

• Install xture in accordance with local codes.

There are three lamp modes (light turn-on effects) available when

motion is detected:

• NORMAL

• SOFT

brightness. Light gradually dims to half-bright, pauses, and then

continues dimming to off when motion is no longer detected and

after selected ON-TIME.

• FLASH

full brightness.

1. Remove the existing light xture.

2. Install the mounting strap as shown using two screws that t

your junction box.

Note: The plastic hanger can be used to hold the xture while

wiring. Thread the small end of the plastic hanger through the

hole in the center of the cover plate. Insert the small end into

one of the slots on the mounting strap.

3. Set the LAMP MODE switch to the desired light turn-on effect

(Normal, Soft, Flash).

4. Route the wires from the light receiver through the large gasket

holes.

5. Twist the junction box wires and xture wires together as shown.

Secure with UL approved wire connectors.

6. Align the cover plate and cover plate gasket. Secure with

mounting bolt.

7. Push the rubber plug rmly into place.

or - Light instantly comes on.

- Light starts dim and gradually increases to full

- Light ashes on then off twice before turning on

WARNING: Turn power off at the fuse or circuit breaker.

Features and Ratings:

• Up to 150 Watt max imum

incandesce nt load (up to 75

Watt maximu m incandescent

per lampholder).

Lamp Modes

8. Not intended for waterproof junction boxes. Fixture should be

surface mount only. Caulk the wall plate mounting surface with

silicone weather sealant.

9. Adjust the lamp holders by loosening the lock nuts. Note: Do

not rotate the lamp holders more than 180° from the factory

setting.

CAUTION: To avoid water damage and electrical shock,

keep lamp holders 30° below horizontal.

10. Screw incandescent bulb up to rated wattage into module.

When screwing in the lamps, do not overtighten.

CAUTION: Do not exceed the maximum load limits listed

above.

11. Check operation. Activate transmitter being used with receiver

(see transmitter instructions). A signal will be sent to the receiver

to turn the receiver ON or OFF.

WARNING: Risk of re. Do not aim the lamps at a

combustible surface within 3 ft. (1 m).

Mounting

Strap

Junction box ground wire to green

White to

White

ground screw on xture.

Wiring Floodlight

Black to

Black

Gasket

Rubber

Plug

Mounting

Bolt

ENGLISH

7598-1326-01

Page 8

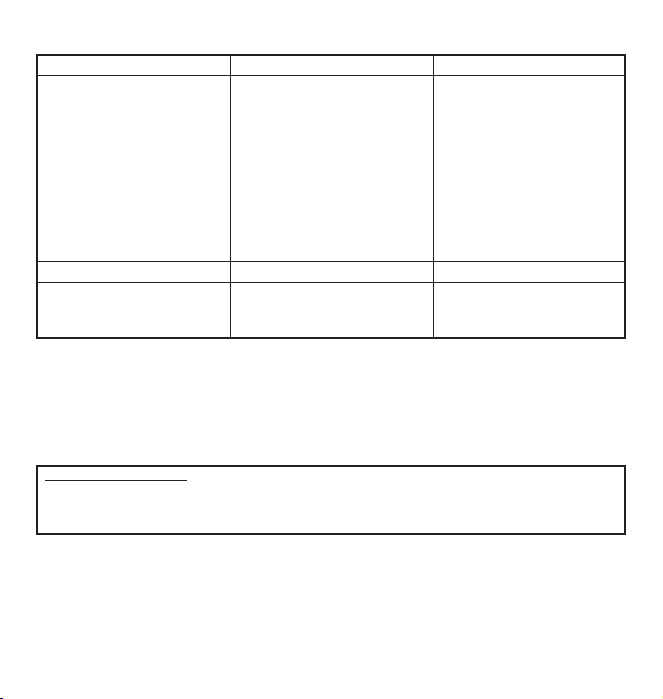

SYMPTOM

Device does not come on.

Device does not turn off.

Device comes on randomly.

TROUBLESHOOTING GUIDE

POSSIBLE CAUSE

1. Circuit breaker or fuse is turned off.

2. Switch on device is turned off.

3. Interrupted by another device.

4. Does not respond immediately after

installation.

5. Signals from tran smitter are being

blocked, or transmitter is out of range.

6. Weak battery in the transmitter.

7. Dip switches on transmitter and receiver

units do not match.

8. Device is defective.

1. Same as 5, 6, and 7 above.

1. Short term power line failure.

2. Anot her tr ansmitt er on the sam e

frequency.

SOLUTION

1. Verify circuit breaker or fuse is turned

on.

2. Verify switched device is turned on.

3. Change codes on transmitter and

receiver units.

4. Wait for 90 second initialization period

(remote motion sensor).

5. Check for metal objects that could

block the signal, or reposition the

transmitter.

6. Check battery charge and replace if

necessary.

7. Verify code settings on transmitter and

receiver units are set the same.

8. Test using different device.

1. Same as 5, 6, and 7 above.

1. Next transmission from transmitter

will reset receiver to correct state.

2. Change codes on transmitter and

receiver units.

This device complies with Part 15 of the FCC Rules and RSS-210 of Industry Canada. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference received, including interference

that may cause undesired operation.

The term “IC:” before the radio certication number only signies that Industry Canada technical specications were met.

The user is cautioned that changes or modications not expressly approved by the party responsible for regulatory compliance could

void the user’s authority to operate the equipment.

1 YEAR LIMITED WARRANTY:

Should this product fail to perform satisfactorily due to a defect or poor workmanship within one year of date of purchase, return it

to the place of purchase and it will be replaced, free of charge. Incidental or consequential damages are excluded from this warranty. Light bulbs are not covered.

Manufactured for Grainger International, Inc.

Lake Forest, IL 60045

REGULATORY INFORMATION

8 598-1326-01

Page 9

®

Manual de Instrucciones y Partes 2LBL9, 2LBN1

Por favor lea y guarde estas instrucciones. Léalas cuidadosamente antes de intentar armar, instalar, operar o dar mantenimiento

al producto descrito. Protéjase Ud. y los otros observando toda la información de seguridad. ¡Si no lo hace podría ocasionar

lesión al personal y/o daño al equipo! Guarde estas instrucciones para referencia futura.

Este manual incluye las instrucciones de operación para una variedad de productos a control

remoto. Todos los productos funcionan basándose en el mismo principio y usan la misma

información para la calibración del código. Por favor lea todas las instrucciones y tome en

cuenta cualquier información especíca relativa a su producto en particular.

ADVERTENCIAS:

. PARA USO SÓLO con bombillas incandescentes o halógenas de 120 voltios.

. NO LO USE con bombillas uorescentes, electrodomésticos, fuentes de energía,

Controles de alumbrado

Este manua l sirve pa ra los siguientes

productos:

• Transmisores Inalámbricos (Interiores /

Exteriores)

– Detector de movimiento de 180° (2)

• Receptores

– Luz halógena de seguridad

– Reector

alumbrado con bajo voltaje ni con ningún otro aparato eléctrico.

• Productos probados y aprobados por laboratorios UL/cUL y/o FCC/IC.

• Distancia de operación: hasta 100 pies.

Los controles inalámbricos LumaPro® para el alumbrado están diseñados para

trabajar juntos. Simplemente determine cual transmisor(es) le gustaría que controlen

tal(es) receptor(es) y je la calibración del código para emparejar.

CARACTERISTICAS

GUÍA DE REFERENCIA DE PÁGINAS

ESPAÑOL

HEA 007

Impreso en la China

12/07

Página 11

9598-1326-01

2LBN1

Página 13

2LBL9

Página 15

598-1326-01 S

LPG-6028, LPG-6042

Page 10

CALIBRACIONES DEL CÓDIGO

DETECT

CODES

12 3 4

DAY

NIGHT

NIGHT

ONLY

ON

1 2 3

4

RAINTIGHT

OUTDOOR USE ONLY.

FOR WALL AND CEILING MOUNT ONLY

SUITABLE FOR WET LOCATION

MADE IN CHINA

THIS END UP

ã

Nota: La mayoría de instalaciones de sólo un sistema no

requerirán ningún cambio en la calibración del código. Para

que funcionen juntos los transmisor(es) y los receptor(es)

deben tener la misma calibración de código y de grupo.

Los interruptores del 1 al 3 jan el código. El interruptor 4

ja el grupo (A o B). Vea en la página 14 la ubicación de los

interruptores.

Ejemplo 1 - Calibraciones del código, sistema 1

Código del transmisor(es)/

receptor(es)

Grupo “A”

(calibración de fábrica)

Código del transmisor(es)/

receptor(es)

Grupo “B”

( – Indica la posición del interruptor)

Ejemplo 2 - Calibraciones del código, sistema 2

Nota: Cuando opere más de un sistema independientemente

el uno del otro, je cada sistema con un código diferente. Hay

8 códigos disponibles al cambiar las calibraciones de los interruptores del 1 al 3.

Código del

receptor(es)

Grupo “A”

UBICACIONES DE LOS INTERRUPTORES

DE CIRCUITO IMPRESO

Interruptores

de circuito

impreso

Detector de movimiento de 180°

Interruptores

de circuito

impreso

interruptores

de FASE DE

LÁMPARA

Luz y faro de seguridad halógenos

Nota: La “X” ha sido colocada

en los interruptores para ayudar

a aclarar las calibraciones del

código de la página anterior.

Vista ampliada de un interruptor típico del código

(la calibración hecha en fábrica es OFF- apagado)

10 598-1326-01

Page 11

DETECT

CODES

12 3 4

DAY

NIGHT

NIGHT

ONLY

DETECTOR DE

MOVIMIENTO

DE 180°

Detector de movimiento

de 180°

Características:

• No se requiere cableado.

• Alcance de detección hasta de 70 pies, cobertura de 180°.

• Sensibilidad ajustable.

• Operación diurna/nocturna o sólo nocturna.

• Modo prueba.

• Usa dos baterías AA.

• Montaje en pared o alero.

• Controla los receptores hasta 30 m de distancia.

Seleccione modo nocturno o modo de 24 horas

Estos detectores de movimiento pueden detectar movimiento durante

el día y la noche o sólo en la noche. Para jar el modo de detección,

retire la tapa del compartimiento de la batería deslizándola hacia

abajo. Si es necesario retire las baterías. Mueva el interruptor DETECT

(DETECTAR) ya sea a la posición DAY/NIGHT ó a la posición NIGHT

ONLY (SÓLO NOCHE). Vuelva a colocar el compartimiento de la

batería siguiendo a la inversa las instrucciones indicadas.

• Antes de montar el detector de movimiento, quite la tapa del

Coloque las dos baterías AA según la polaridad marcada dentro del

compartimento de la batería. Vuelva a colocar el compartimiento de

la batería siguiendo a la inversa las instrucciones indicadas.

Instalación de las baterías

compartimiento de la batería deslizando la tapa hacia abajo.

Control

detector

Instalación del Detector de Movimiento

1. Instale el detector de movimiento montando el soporte donde

se quiera tener la detección de movimiento. Fije el soporte de

montaje del detector de movimiento a un objeto resistente (p.

ej.: árbol, poste, casa, etc.) usando los dos tornillos provistos.

Asegúrese que la unidad no tenga obstrucciones en su línea

de mira. Nota: Sujete la consola de montaje verticalmente si

lo instala a una supercie curva como un poste.

2. Instale el detector de movimiento a la consola de montaje.

Usando un destornillador cabeza Philips, aoje el tornillo de

la abrazadera en la consola de montaje. Inserte el montaje

de bola giratoria del detector de movimiento en el enchufe del

soporte de montaje (Nota: usted debería oír un chasquido).

Apunte el detector de movimiento hacia el área donde se desea

la detección. Apriete el tornillo de la abrazadera.

IMPORTANTE: El detector de movimiento debe ser montado

con la tapa infe rior mirando hac ia abajo para ma ntener su

impermeabilidad.

Zócalo de la consola

de montaje

Tornillo de la

abrazadera

Montura giratoria

de bola

Consola de montaje

Tornillo de montaje

Tuerca

Detector

Instalación del detector de movimiento

ESPAÑOL

Detector de movimiento de

180° (Vista posterior)

Compartimento de la batería

11598-1326-01

Page 12

Revisión de la operación y de la regulación

5 1 TEST

ON-TI ME

(MINU TES)

RANGE

MAX

MIN

Nota: Cuando lo prenda por primera vez o cuando cambie de

modalidad espere 1 1/2 minutos.

Localice en el detector de movimiento los controles de ALCANCE

y DURACIÓN:

•

El control de ALCANCE (RANGE) y de DURACIÓN (ON-TIME) se

encuentran en la parte inferior del detector de movimiento. Usando

las uñas de los dedos o un destornillador pequeño de cabeza plana,

haga suavemente palanca en la tapa hasta que se abra.

1. Revise la operación. Ponga el control de DURACIÓN en el modo

TEST (PRUEBA). Camine frente al detector de movimiento. La

luz indicadora LED debe destellar cuando se detecta movimiento

(vea la ilustración para la ubicación de la luz LED).

2. Ajuste el Detector de Movimiento. Gire el control de ALCANCE

a la posición media y el de DURACIÓN a la posición TEST.

Camine por el área de cobertura y note su posición cuando el

LED empiece a destellar. Aoje el tornillo sujetador y mueva

el detector de movimiento para cambiar el área de cobertura.

Cuando termine apriete el tornillo de la abrazadera. No apriete

excesivamente este tornillo.

Control de

DURACIÓN

Control de

alcance

Indicador

LED

Controles del Detector de Movimiento de 180°

3. Regule el control de alcance. Para incrementar la sensibilidad,

gire el control de ALCANCE hacia MAX. Para disminuir la

sensibilidad, gírelo hacia MIN. Nota: En algunos ambientes

si el ALCANCE se calibra demasiado alto, puede ocurrir una

falsa activación.

Nota: Cuando use el modo de prueba (Test) para comprobar

el funcionamiento durante el día:

A. Ponga el interruptor del control DETECT (DETECTAR) a

DAY/NIGHT (NOCHE/DÍA) y

B. Ponga el control ON-TIME (DURACIÓN) a TEST.

4. Fije el control de DURACIÓN. Determine la cantidad de tiempo

que desea que el dispositivo conectado permanezca encendido

luego que se detecta movimiento (1 ó 5 minutos). Mueva el

control de DURACIÓN a la conguración correspondiente.

2.4 m

180°

21 m

Alcance máximo

Ángulo máximo de

cobertura

Área de Cobertura del Detector de Movimiento de 180°

Movimiento Movimiento

Detector Detector

El detector es más sensible a movimientos transversales a su

campo de mira.

Sensibilidad máximaSensibilidad mínima

Sensibilidad del Detector de Movimiento

Apunte el detector

hacia abajo para una

cobertura menor

Apunte el detector

hacia más arriba para

una cobertura mayor

Ajuste de la Cobertura del Detector de Movimiento

12 598-1326-01

Page 13

INFORMACIÓN DEL RECEPTOR

Todos los receptores tien en las siguientes características y

potencias nominales:

• Clasicado para un voltaje de alimentación de 120 V CA/60Hz.

• Usa el cableado existente.

• Se adapta a una caja de empalme simple estándar (sólo para

interruptor de pared).

• No se los usa con bombillas uorescentes compactas.

• Cuando lo prenda por primera vez, espere 15 segundos.

LUZ HALÓGENA DE SEGURIDAD (2LBN1)

• Se requiere un cableado mínimo.

• Instale el aparato de acuerdo a los códigos locales.

Hay tres fases de lámpara (efectos al prender la luz) disponibles

cuando se detecta movimiento:

• NORMAL

• SUAVE

a su brillo total. La luz gradualmente disminuye a medio-brillo,

hace pausa, y continúa disminuyendo hasta que se apaga cuando

ya no detecta movimiento y después de seleccionar DURACIÓN

(ON-TIME).

• DESTELLO

antes de prenderse con su brillo completo.

ADVERTENCIA: Desconecte la alimentación en el fusible

o en el disyuntor.

1. Retire el aparato de luz existente.

2. Como se muestra, instale la lámina de montaje usando dos

tornillos que encajen en su caja de empalme.

Nota: Puede usarse un colgador plástico para sostener el aparato

mientras se cablea. Enrosque el extremo pequeño del colgador

plástico en el oricio central de la placa cubertora. Inserte el extremo

pequeño en una de las ranuras de la lámina de montaje.

3. Fije el interruptor de FASE DE lámpara al efecto deseado de

encendido de luz (Normal, Suave, Destello).

4. Guíe los cables desde el receptor para lámpara pasando por

el oricio grande del empaque.

Cara cteríst icas y pote ncias n ominales:

•

Hasta una carga halógena máxima de

200 vatios (hasta 100 vatios máximo de

halógena por cada portalámparas).

• Use sólo lámparas hal ógenas de

tungsteno de T3 de 100 vatios máximo

de 120 VCA.

Fases De Lámpara

o – La luz se prende instantáneamente.

– La luz comienza tenue y gradualmente aumenta

– La luz se prende y se apaga por dos veces

5. Tuerza juntos, como se muestra, los cables de la caja de

empalme con los del aparato. Asegúrelos con conectores de

alambre que tengan aprobación UL.

6. Alinee la placa cubertora con su empaque. Asegúrelos con el

perno de montaje.

7. Empuje rmemente el tapón de caucho hasta su sitio.

8. No se lo debe usar con cajas de empalme impermeables. Al

aparato se lo debe instalar sólo sobre una supercie. Calafatee

la supercie de montaje de la placa con un sellador de silicona

contra la intemperie.

9. Regule los portalámparas aojando las contratuercas. Nota: No gire

los portalámparas más de 180° de la calibración de fábrica.

PRECAUCIÓN: Para evitar daño por agua y sacudida

eléctrica mantenga los portalámparas a 30° por debajo de la

horizontal.

10. Inserte en el módulo la bombilla halógena (vea Instalación de

bombilla) hasta el vatiaje indicado.

PRECAUCIÓN: No exceda los límites de carga máximos

indicados arriba.

11. Revise la operación. Active el transmisor que va a usarse con

el receptor (vea las instrucciones del transmisor). Una señal

será enviada al receptor para ENCENDERLO o APAGARLO.

ADVERTENCIA: Rie sgo de incend io. No apunte

las lámparas a supercies combustibles dentro de un

1 metro.

Lámina de

montaje

Conductor de tierra de la caja de empalme al

tornillo verde de tierra en el aparato.

13598-1326-01

Blanco con

blanco

Cableado de la luz halógena de seguridad

Negro con

negro

Empaque

Tapón de

Perno de

montaje

ESPAÑOL

caucho

Continúa

Page 14

CUIDADO: Para evitar los peligros de incendio o

• Deje que el elemento se enfríe antes de tocarlo. La bombilla

y el elemento funcionan a altas temperaturas.

• Mantenga al elemento por lo menos a 5 cm de los materiales

combustibles. No lo apunte hacia objetos que estén más

cerca de 1 m.

• Use sólo lámparas halógenas de tungsteno de T3, de 78mm

y 100 vatios máximo.

quemazón:

NOTA: Incluye lámparas pero, usted deberá instalarlas.

NOTA: Cuando reemplace la bombilla, desconecte la energía

eléctrica y deje que se enfríe el dispositivo.

1. Abra la cubierta de vidrio. Retire la bombilla usada empujando

IMPORTANTE: No toque la nueva bombilla con la piel desnuda. La grasitud de la piel puede reducir mucho la vida útil

de la bombilla. Use guantes limpios o un paño para instalar

la nueva bombilla.

2. Para introducir la nueva bombilla, empuje la bombilla en el

3. Asegúrese de que la bombilla esté asentada correctamente.

4. Cierre la cubierta de vidrio.

Instalación de bombilla

la bombilla hacia la derecha hasta que el lado izquierdo de la

bombilla quede despejado del enchufe izquierdo.

enchufe derecho para que la bombilla se ajuste completamente

en el enchufe izquierdo.

14 598-1326-01

Page 15

REFLECTOR (2LBL9)

Características y potencias nominales:

• Has ta un a car ga in cande scent e

máxima de 150 vatios (hasta 75 vatios

máximo de incandescente por cada

• Use solo lámparas PAR 38 de 75 vatios máximo (no incluidas).

• Se requiere un cableado mínimo.

• Instale el aparato de acuerdo a los códigos locales.

Hay tres fases de lámpara (efectos al prender la luz) disponibles

cuando se detecta movimiento:

• NORMAL

• SUAVE

a su brillo total. La luz gradualmente disminuye a medio-brillo,

hace pausa, y continúa disminuyendo hasta que se apaga cuando

ya no detecta movimiento y después de seleccionar DURACIÓN

(ON-TIME).

• DESTELLO

antes de prenderse con su brillo completo.

ADVERTENCIA: Desconecte la alimentación en el fusible

o en el disyuntor.

1. Retire el aparato de luz existente.

2. Como se muestra, instale la lámina de montaje usando dos

tornillos que encajen en su caja de empalme.

Nota: Puede usarse un colgador plástico para sostener el aparato

mientras se cablea. Enrosque el extremo pequeño del colgador

plástico en el oricio central de la placa cubertora. Inserte el extremo

pequeño en una de las ranuras de la lámina de montaje.

3. Fije el interruptor de FASE DE lámpara al efecto deseado de

encendido de luz (Normal, Suave, Destello).

4. Guíe los cables desde el receptor para lámpara pasando por

el oricio grande del empaque.

5. Tuerza juntos, como se muestra, los cables de la caja de

empalme con los del aparato. Asegúrelos con conectores de

alambre que tengan aprobación UL.

6. Alinee la placa cubertora con su empaque. Asegúrelos con el

perno de montaje.

7. Empuje rmemente el tapón de caucho hasta su sitio.

portalámparas).

Fases De Lámpara

o – La luz se prende instantáneamente.

– La luz comienza tenue y gradualmente aumenta

– La luz se prende y se apaga por dos veces

8. No se lo debe usar con cajas de empalme impermeables. Al

aparato se lo debe instalar sólo sobre una supercie. Calafatee

la supercie de montaje de la placa con un sellador de silicona

contra la intemperie.

9. Regule los portalámparas aojando las contratuercas. Nota: No gire

los portalámparas más de 180° de la calibración de fábrica.

PRECAUCIÓN: Para evitar daño por agua y sacudida

eléctrica mantenga los portalámparas a 30° por debajo de la

horizontal.

10. Enrosque en el módulo una bombilla incandescente cuya

potencia sea hasta la nominal. Cuando la enrosque en la

lámpara no la apriete excesivamente.

PRECAUCIÓN: No exceda los límites de carga máximos

indicados arriba.

11. Revise la operación. Active el transmisor que va a usarse con

el receptor (vea las instrucciones del transmisor). Una señal

será enviada al receptor para ENCENDERLO o APAGARLO.

ADVERTENCIA: Rie sgo de incend io. No apunte

las lámparas a supercies combustibles dentro de un

1 metro.

Lámina de

montaje

Conductor de tierra de la caja de empalme al

tornillo verde de tierra en el aparato.

Blanco con

blanco

Negro con

negro

Empaque

Cableado del reector

Tapón de

caucho

Perno de

montaje

ESPAÑOL

15598-1326-01

Page 16

SÍNTOMA

El dispositivo no se enciende.

El dispositivo no se apaga.

El dispositivo se enciende al azar.

GUÍA DE ANÁLISIS DE AVERÍAS

CAUSA PROBABLE

1. El disyuntor o el fusible está desconec

tado.

2. El in terrupto r del disposi tivo est á

desconectado.

3. Interrumpido por otro dispositivo.

4. No responde inmediatamente luego de

la instalación.

5. Las señales desde el transmisor están

siendo bloqueadas o el transmisor está

fuera de alcance.

6. Batería desgastada en el transmisor.

7. Los interruptores de circuito impreso

en el transmisor y los receptores no

emparejan.

8. El dispositivo está defectuoso.

1. Igual que el 5, 6 y 7 anteriores.

1. Falla de corta duración en la línea de

alimentación.

2. Otro transmisor en la misma frecuencia.

-

SOLUCIÓN

1. Verique que el disyuntor o el fusible

esté conectado.

2. Verique que el dispositivo controlado

con interruptor esté encendido.

3. Cambie los códigos en las unidades

trasmisora y receptora.

4. Espere los 90 segundos del período

de iniciación (detector remoto de

movimiento).

5. Revise objetos metálicos que podrían

bloquear la señal, o vuelva a poner

el transmisor en posición.

6. Revise la carg a de la batería y

reemplace si es necesario.

7. Verifi que que la calibración del

código de las unidades transmisora

y receptora sean iguales.

8. Pruebe usando un dispositivo diferente.

1. Igual que el 5, 6 y 7 anteriores.

1. La siguiente transmisión desde el

transmisor recongurará al receptor

a su estado correcto.

2. Cambie los códigos en las unidades

transmisora y receptora.

Este aparato cumple con la Parte 15 de las Reglas de la FCC (Comisión Federal de Comunicaciones) y con la RSS-210 de las Industrias

del Canadá. El funcionamiento está sujeto a las dos siguientes condiciones: (1) este aparato no puede causar interferencias dañinas,

y (2) este aparato debe aceptar cualquier interferencia recibida, incluyendo una interferencia que pueda causar un funcionamiento

indeseable.

El término “IC:” delante del número de cernticación del radio signica tan solamente que se ha cumplido con las especicaciones

técnicas de Industry Canada.

Se advierte al usuario que cambios o modicaciones no aprobadas expresamente por la parte responsable de cumplir con los reglamentos podría invalidar la autoridad del usuario para el uso de este equipo.

GARANTÍA LIMITADA A UN (1) AÑO:

Si este producto fallara en funcionar satisfactoriamente debido a un defecto o mala fabricación dentro de un año desde la fecha de

compra, devuélvalo al sitio donde lo compró y se lo reemplazará, sin costo para usted. Daños imprevistos o consiguientes están

excluidos de esta garantía. Las bombillas no están garantizadas.

Fabricado para Grainger International, Inc.

Lake Forest, IL 60045

INFORMACIÓN REGULATORIA

16 598-1326-01

Page 17

®

Mode d’emploi et guide des pièces 2LBL9, 2LBN1

Veuillez lire et conserver ces directives. Lisez-les attentivement avant de commencer à assembler, installer, utiliser ou entretenir

le produit qui y est décrit. Assurez en outre votre protection et celle des autres personnes qui vous entourent en respectant

toutes les consignes de sécurité. Le fait de ne pas le faire pourrait entraîner de graves blessures ou des dommages. Conservez

ces directives pour vous y référer, au besoin.

Ce guide comprend des directives d’utilisation pour différents produits télécommandés. Tous

ces produits fonctionnent selon les même principes et utilisent les mêmes types de codes.

Veuillez lire toutes les instructions et noter les informations se rapportant spéciquement

à votre produit.

AVERTISSEMENT :

• UTILISER SEULEMENT avec des ampoules 120 V de type incandescent ou

halogène.

• NE PAS UTILISER avec des ampoules uorescentes, des appareils, des sources

Commandes d’éclairage

Ce ma nuel s’ appl ique au x pr oduits

suivants :

• Transmetteurs

• Transmetteurs sans l (intérieur/extérieur)

- Détecteur de mouvement sur 180 ° (2)

• Récepteurs

– Luminaire de sécurité à halogène

– Projecteur

d’alimentation, des dispositifs d’éclairage basse tension ou tout autre type de

dispositif électrique.

• Les produits sont testés et approuvés par UL/cUL et FCC/IC.

• La portée opérationnelle est de 30 mètres.

Les commandes d’éclairage LumaPro® sont conçues pour fonctionner ensemble.

Il suft de déterminer quel transmetteur doit commander quel récepteur, puis de

régler les codes correspondants.

CARACTÉRISTIQUES

HEA 007

Imprimé en Chine

12/07

PAGE DU GUIDE DE RÉFÉRENCE

Page 19

17598-1326-01

2LBN1

Page 21

2LBL9

Page 23

598-1326-01 F

LPG-6028, LPG-6042

FRANÇAIS

Page 18

Note : La plupart des installations simples n’exige pas la mo-

DETECT

CODES

12 3 4

DAY

NIGHT

NIGHT

ONLY

ON

1 2 3

4

RAINTIGHT

OUTDOOR USE ONLY.

FOR WALL AND CEILING MOUNT ONLY

SUITABLE FOR WET LOCATION

MADE IN CHINA

THIS END UP

ã

dication des codes préréglés. Les codes et les groupes des

transmetteurs et des récepteurs doivent être réglés de façon

identique pour fonctionner ensemble. Les micro-interrupteurs

1 à 3 servent à régler le code. Le micro-interrupteur 4 sert à

sélectionner le groupe (A ou B). Consultez la page 27 pour

connaître l’emplacement des micro-interrupteurs.

Code des transmetteurs/

RÉGLAGE DES CODES

Exemple 1 - Réglage des codes, System 1

récepteurs

Groupe « A »

(réglage en usine)

Code des transmetteurs/

récepteurs

Groupe « B »

( – Indique la position du micro-interrupteur)

EMPLACEMENT DES

MICRO-INTERRUPTEURS

Micro-

interrupteurs

Détecteur de mouvement sur 180 °

Exemple 2 - Réglage des codes, système 2

Note : Lors de l’utilisation indépendante de plus d’un système, établissez un code différent pour chaque système. Vous pouvez avoir

jusqu’à 8 codes distincts en réglant les 3 micro-interrupteurs.

Code des

Récepteurs

Groupe « A »

Micro-

interrupteurs

Interrupteurs

du mode

d’éclairage

Luminaire et projecteur de sécurité à halogène

Note : Le « X » placé sur

les micro-interrupteurs vise

à préciser la position à la

page précédente.

Vue rapprochée d’un micro-interrupteur

(réglage en usine à la position «OFF»)

18 598-1326-01

Page 19

DETECT

CODES

12 3 4

DAY

NIGHT

NIGHT

ONLY

DÉTECTEUR DE

MOUVEMENT

SUR 180 °

Détecteur de mouvement

sur 180 °

Caractéristiques :

• Aucun câblage nécessaire.

• Portée de détection jusqu’à 70 pieds, sur 180 °.

• Sensibilité réglable.

• Fonctionnement Jour/Nuit ou Nuit seulement.

• Mode d’essai.

• Utilise 2 piles AA.

• Montage sur mur ou avant-toit.

• Commande le récepteur sur une distance maximum de 30

mètres.

Sélection du mode de nuit ou du mode 24 heures

Ces détecteurs de mouvement peuvent déceler les mouvements de jour

comme de nuit ou de nuit seulement. Pour régler le mode de détection,

retirez le couvercle du compartiment des piles en le faisant glisser vers

le bas. Enlevez les piles si nécessaire. Glissez l’interrupteur « DETECT

» soit à la position « DAY/NIGHT » (jour/nuit) ou à la position « NIGHT

ONLY » (nuit seulement). Remettez le couvercle du compartiment des

piles en place en le faisant glisser vers le haut.

• Avant d’installer le détecteur de mouvement, retirez le couvercle

du compartiment des piles en le faisant glisser vers le bas.

Installez 2 piles AA en fonction des repères de polarité se trouvant à

l’intérieur du compartiment des piles. Remettez le couvercle du compartiment des piles en place en le faisant glisser vers le haut.

Installation des piles

Commande

de détection

Installation Du Détecteur De Mouvement

1. Installez le support du détecteur de mouvement là où vous

souhaitez détecter les mouvements. Fixez le support à un

objet solide (p. ex. un arbre, un poteau, un mur, etc.) au

moyen des deux vis fournies. Assurez-vous que le détecteur

n’a pas la vue obstruée. Note : Fixez le support de montage à

la verticale lorsqu’il s’agit d’une surface incurvée, par exemple

d’un poteau.

2. Installez le détecteur de mouvement au support de montage.

À l’aide d’un tournevis à pointe cruciforme, desserrez la vis de

serrage sur le support de montage.Insérez le support pivotant à

bille du détecteur de mouvement dans le support (Note : Vous

devriez entendre un « clic ».). Dirigez le détecteur de mouvement

vers la zone à surveiller. Serrez la vis de serrage.

IMPORTANT : Le détecteur de mouvement doit être installé

avec le couvercle inférieur vers le bas pour assurer l’étanchéité

du boîtier.

Douille de support

de montage

Support de montage

Vis de montage

Écrou

Vis de serrage

Monture à rotule

Détecteur

Installation du détecteur de mouvement

FRANÇAIS

Détecteur de mouvement

sur 180 ° (arrière)

Compartiment des piles

19598-1326-01

Page 20

Vérication du fonctionnement et du réglage

5 1 TEST

ON-TI ME

(MINU TES)

RANGE

MAX

MIN

Note : Lorsque l’appareil est mis en circuit ou changé de mode,

attendre 30 secondes.

Localisez les commandes RANGE et ON-TIME sur le détecteur

de mouvements.

• Les boutons RANGE et ON-TIME sont situés sur la partie inférieure du boîtier du détecteur de mouvement. À l’aide de vos

ongles ou d’un petit tournevis à tête plate, soulevez doucement

le couvercle jusqu’à ce qu’il s’ouvre.

1. Vériez le fonctionnement. Mettez la commande « ON-TIME » au

mode « TEST ». Déplacez-vous devant le détecteur de mouvement. Le voyant indicateur à DEL devrait clignoter lorsqu’un

mouvement est décelé (consultez l’illustration pour l’emplacement

des voyants à DEL).

2. Réglage du détecteur de mouvement. Tournez la commande

« RANGE » à la position centrale et la commande « ON-TIME »

à la position « TEST ». Marchez dans la zone de couverture en

notant l’endroit où vous êtes lorsque le voyant DEL commence à

clignoter. Desserrez la vis de la bride, puis déplacez le détecteur

de sorte qu’il modie la zone de couverture. Serrez la vis de

serrage lorsque vous avez terminé. Ne serrez pas trop la vis de

serrage.

Commande

« ON-TIME »

Commande

de portée

Voyant

DEL

Commandes du détecteur de mouvement sur 180 °

3. Réglez la commande de la portée. Pour augmenter la sensibilité,

tournez la commande « RANGE » vers MAX. Pour diminuer la

sensibilité, tourner la commande « RANGE » à MIN. Note : Si la

commande « RANGE » est réglée trop haut, ceci pourrait causer

un faux déclenchement dans certains environnements.

Note : Lors de l’utilisation du mode Test pour vérier le fonc-

tionnement pendant le jour, :

A. Régler le commutateur DETECT à DAY/NIGHT, puis

B. Régler la commande ON-TIME à TEST.

4. Réglez la commande « ON-TIME ». Déterminez pendant

combien de temps vous voulez que le dispositif connecté

reste allumé après que le mouvement ait été détecté (1 ou 5

minutes). Glissez la commande « ON-TIME » vers le réglage

correspondant.

2.4 m

180°

21 m

Portée maximale

Angle de couverture

maximal

Zone de couverture du détecteur de mouvement sur 180 °

Mouvement Mouvement

Détecteur Détecteur

Le plus sensibleLe moins sensible

Le détecteur est plus sensible au mouvement à travers son

champ de vision.

Sensibilité du détecteur de mouvement

Dirigez le détecteur

vers le bas pour une

couverture courte

Dirigez le détecteur

plus haut pour une

couverture longue

Réglage de la couverture du détecteur de mouvement

20 598-1326-01

Page 21

INFORMATIONS SUR LE RÉCEPTEUR

Tous les récepteurs ont les caractéristiques et valeurs nominales

suivantes :

• Valeur nominale pour une tension de 120 VCA/60 Hz.

• Servez-vous des ls en place.

• Convient à une boîte de connexion standard (interrupteur mural

seulement).

• N’utilisez pas cet appareil avec des ampoules uorescentes

compactes.

• Lorsque l’appareil est mis en circuit, attendre 15 secondes.

LUMINAIRE DE SÉCURITÉ

À HALOGÈNE (2LBN1)

Cara ctéris tiques et valeur s nomi nales :

• Ju squ’à 200 w atts maximum de

charge halogène (jusqu’à 100 watts

maximum de charge halogène par

• Utiliser seulement des ampoules halogènes à deux broches T3

au tungstène, de 150 watts maximum, 120 Vca.

• Minimum de câblage nécessaire.

• Installez l’appareil conformément aux codes loc aux en

vigueur.

Trois modes d’éclairage (façon dont l’éclairage se déclenche) sont

proposés lorsqu’un mouvement est détecté :

• NORMAL

• DOUX (SOFT)

et celle-ci s’accroît graduellement jusqu’à l’intensité normale.

L’intensité décroît ensuite graduellement jusqu’à la mi-puissance,

fait une pause, puis continue de diminuer jusqu’à la fermeture

totale lorsque le détecteur cesse de déceler un mouvement ou

lorsque la durée de fonctionnement (ON-TIME) est écoulée.

• CLIGNOTEMENT (FLASH)

fois avant de demeurer allumé à pleine puissance.

AVERTISSEMENT: Coupez le courant au fusible ou au

disjoncteur.

1. Enlevez l’appareil d’éclairage existant.

2. Installez le support de montage tel qu’illustré à l’aide de deux

vis convenant au disjoncteur.

Note : Le support de plastique peut être utilisé pour tenir

l’appareil d’éclairage lors du câblage. Faites passer la petite

extrémité du spport de plastique à travers le trou dans le centre

de la plaque-couvercle. Insérez la petite extrémité dans une

des fentes sur le support de montage.

douille).

Modes D’Éclairage

ou – L’éclairage s’allume instantanément.

– L’éclairage s’allume à faible intensité,

– L’éclairage clignote deux

3. Au moyen du bouton LAM P MODE, sélec tionnez l’e ffet

d’éclairage souhaité (NORMAL, DOUX/SOFT ou CLIGNOTEMENT/FLASH).

4. Acheminez les ls à partir du récepteur optique à travers les

gros trous du joint.

5. Torsadez les ls du disjoncteur et les ls de l’appareil d’éclairage

tel qu’illustré. Fixez-les à l’aide des capuchons de connexion

approuvés UL.

6. Alignez la plaque-couvercle et le joint de plaque-couvercle.

Fixez à l’aide d’un boulon de montage.

7. Poussez le bouchon de caoutchouc fermement en place.

8. Non conçu pour les boîtes de raccordement étanches. L’appareil

doit être monté en surface seulement. Calfeutrez la plaque de

montage au moyen d’un agent d’étanchéité à base de silicone.

9. Ajustez les douilles en desserrant les écrous freinés. Note :

Ne tournez pas les douilles de plus de 180° par rapport au

réglage d’usine.

ATTENTION : An d’éviter les dégâts causés par l’eau et les

chocs électriques, gardez les douilles à 30° sous l’horizontale.

10. Insérez la lampe à halogéene (consultez Installation De

L’ampoule) de la puissance indiquée dans le module.

ATTENTION : Ne dépassez pas les limites maximales

de charge gurant ci-dessus.

11.

Vériez le fonctionnement. Activez le transmetteur utilisé avec le

récepteur (consultez les directives sur le transmetteur). Un signal est

transmis au récepteur pour le mettre SOUS ou HORS tension.

AVERTISSEMENT: Risque d’incendie ! Ne pas pointer

les lampes vers une surface combustible située à moins

de 1 mètre.

Support de

montage

Fil de terre du disjoncteur à la vis de terre

verte sur l’appareil d’éclairage.

21598-1326-01

Blanc à

blanc

Raccordement du luminaire de sécurité à halogène

Noir à noir

Joint

Bouchon de

caoutchouc

Boulon de

montage

FRANÇAIS

Suite

Page 22

ATTENTION : Pour éviter les risques de brûlure ou

• Laisser l’appareil refroidir avant de le toucher. L’ampoule et

l’appareil fonctionnent à haute température.

• Garder l’appareil à au moins 5 cm des matériaux combustibles.

Ne pas pointer vers des objets à moins de 1 m.

• Utiliser seulement des ampoules halogènes à deux broches

T3 au tungstène, de 100 watts maximum, 120 Vca.

d'incendie :

NOTE : Les lampes ont été incluses, mais il vous faudra les

installer.

NOTE : En remplaçant l'ampoule, coupez le courant et laissez

le luminaire refroidir.

1. Ouvrez le couvercle de verre. Retirez la vieille ampoule en

IMPORTANT :

nue. L'huile de la peau peut réduire de beaucoup la durée

utile de l'ampoule. Utilisez des gants ou un chiffon propres

pour installer la nouvelle ampoule.

2. Pour insérer la nouvelle ampoule, poussez l' ampoule dans la

3.

4. Fermez le couvercle de verre.

Installation De L’ampoule

la poussant vers la droite jusqu'à ce que le côté gauche de

l'ampoule soit dégagé de la douille gauche.

Ne touchez pas la nouvelle ampoule à peau

douille droite pour qu'elle entre complètement dans la douille

gauche.

S'assurer que l'ampoule soit solidement assise.

22 598-1326-01

Page 23

PROJECTEUR (2LBL9)

Caractéristiques et valeurs nominales :

• Jusqu’à 150 watts maximum de charge

incandescente (jusqu’à 75 watts maximum de charge incandescente par

• Utiliser seulement des lampes PAR 38 de 75 W maximum (non

comprises).

• Minimum de câblage nécessaire.

• Installez l’appareil conformément aux codes loc aux en

vigueur.

Trois modes d’éclairage (façon dont l’éclairage se déclenche) sont

proposés lorsqu’un mouvement est détecté :

• NORMAL

• DOUX (SOFT)

et celle-ci s’accroît graduellement jusqu’à l’intensité normale.

L’intensité décroît ensuite graduellement jusqu’à la mi-puissance,

fait une pause, puis continue de diminuer jusqu’à la fermeture

totale lorsque le détecteur cesse de déceler un mouvement ou

lorsque la durée de fonctionnement (ON-TIME) est écoulée.

• CLIGNOTEMENT (FLASH)

fois avant de demeurer allumé à pleine puissance.

AVERTISSEMENT: Coupez le courant au fusible ou au

disjoncteur.

1. Enlevez l’appareil d’éclairage existant.

2. Installez le support de montage tel qu’illustré à l’aide de deux

vis convenant au disjoncteur.

Note : Le support de plastique peut être utilisé pour tenir

l’appareil d’éclairage lors du câblage. Faites passer la petite

extrémité du spport de plastique à travers le trou dans le centre

de la plaque-couvercle. Insérez la petite extrémité dans une

des fentes sur le support de montage.

3. Au moyen du bouton LAM P MODE, sélec tionnez l’e ffet

d’éclairage souhaité (NORMAL, DOUX/SOFT ou CLIGNOTEMENT/FLASH).

4. Acheminez les ls à partir du récepteur optique à travers les

gros trous du joint.

5. Torsadez les ls du disjoncteur et les ls de l’appareil d’éclairage

tel qu’illustré. Fixez-les à l’aide des capuchons de connexion

approuvés UL.

6. Alignez la plaque-couvercle et le joint de plaque-couvercle.

Fixez à l’aide d’un boulon de montage.

douille).

Modes D’Éclairage

ou – L’éclairage s’allume instantanément.

– L’éclairage s’allume à faible intensité,

– L’éclairage clignote deux

7. Poussez le bouchon de caoutchouc fermement en place.

8. Non conçu pour les boîtes de raccordement étanches. L’appareil

doit être monté en surface seulement. Calfeutrez la plaque de

montage au moyen d’un agent d’étanchéité à base de silicone.

9. Ajustez les douilles en desserrant les écrous freinés. Note :

Ne tournez pas les douilles de plus de 180° par rapport au

réglage d’usine.

ATTENTION : An d’éviter les dégâts causés par l’eau et les

chocs électriques, gardez les douilles à 30° sous l’horizontale.

10. Vissez l’ampoule incandescente à valeur nominale recommandée dans le module. Ne serrez pas outre mesure.

ATTENTION : Ne dépassez pas les limites maximales

de charge gurant ci-dessus.

11. Vériez le fonctionnement. Activez le transmetteur utilisé avec

le récepteur (consultez les directives sur le transmetteur). Un

signal est transmis au récepteur pour le mettre SOUS ou HORS

tension.

AVERTISSEMENT: Risque d’incendie ! Ne pas pointer

les lampes vers une surface combustible située à moins

de 1 mètre.

Support de

montage

Fil de terre du disjoncteur à la vis de terre

verte sur l’appareil d’éclairage.

Blanc à

blanc

Noir à noir

Câblage du projecteur

Joint

Bouchon de

caoutchouc

Boulon de

montage

FRANÇAIS

23598-1326-01

Page 24

GUIDE DE DÉPANNAGE

SYMPTÔME CAUSE POSSIBLE SOLUTION

Le dispositif ne s'allume pas. 1. Le d isjonct eur ou le f usible sont

Le dispositif ne s'éteint pas. 1. Mêmes cause qu'en 5, 6, et 7 ci-des-

Le dispositif s'allume au hasard. 1. Panne d'électricité de courte de du-

Ce dispositif est conforme aux exigences de la partie 15 des règles FCC et RSS-210 d’Industrie Canada. Son fonctionnement est sujet

aux deux conditions suivantes: 1) Ce dispositif ne doit pas causer de parasites nuisibles, et 2) ce dispositif doit endurer tous les parasites

reçus, y compris ceux susceptibles de provoquer un fonctionnement intempestif.

Le terme « IC : » avant le numéro de certication de radio signie seulement que les spécications techniques d’Industrie Canada

ont été satisfaites.

Avis à l’utilisateur : Les changements ou modications, qui n’ont pas été explicitement approuvés par l’organisme chargé d’assurer la

conformité aux règlements, pourraient invalider le droit de l’utilisateur à faire fonctionner cet appareil.

GARANTIE LIMITÉE D’UN AN :

En cas de défaillance de ce produit attribuable à un défaut de fabrication au cours de l’année suivant la date d’achat, retournez-le

chez le détaillant où vous l’avez acheté où il sera remplacé sans frais. Cette garantie ne vise pas les dommages accessoires ou

consécutifs. Les lampes et ampoules ne sont pas garanties.

éteints.

2. L'int errupteu r sur le disp ositif e st

éteint.

3. Le dispositif est interrompu par un autre

dispositif.

4. Le dispositif ne répond pas immédiatement après l'installation.

5. Les si gnaux du tra nsmett eur so nt

bloqués, ou le transmetteur est hors

de portée.

6. Les piles du transmetteur sont faibles.

7. Les micro-interrupteurs sur le transmetteur et le récepteur ne correspondent

pas les uns aux autres.

8. Le dispositif est défectueux.

sus.

rée.

2. Un autre transmetteur est réglé à la

même fréquence.

RENSEIGNEMENTS DE RÈGLEMENTS

1. Vériez que le disjoncteur ou le fusible

sont allumés.

2. Vérif iez q ue l' inter rupteur su r le

dispositif est allumé.

3. Modiez les codes du transmetteur

et du récepteur.

4. Attendez 90 secondes de période

d'initialisation (détecteur de mouvement à distance).

5. Vériez s'il y a des objets métalliques

pouvant bloquer le signal, ou repositionnez le transmetteur.

6. Vériez si les piles sont chargées et

remplacez-les si nécessaire.

7. Assurez-vous que les commutateurs

du transmetteur et du récepteur sont

réglés aux même positions.

8. Vériez si c'est le cas en utilisant un

dispositif différent.

1. Mêmes solutions qu'en 5, 6, et 7

ci-dessus.

1. Lors de la prochaine émission, le

transmetteur replacera le récepteur

à l’état approprié.

2. Modiez les codes du transmetteur

et du récepteur.

Fabriqué pour Grainger International, Inc.

Lake Forest, IL 60045

24 598-1326-01

Loading...

Loading...