1

Instruction Manual

..................................... x

Manuel d’instructions

................................. x

Manual de Instrucciones ........................... x

Bedienungsanleitung ................................. x

All rights reserved. Printed in China.

Tous droits réservés. Imprimé en Chine.

Todos los derechos reservados. Impreso en Chine.

Alle Rechte vorbehalten. Gedruckt in China.

Instruction Manual

#26-015-10050/51-483

©Heathrow Scientific® LLC

High-Speed

Mini-Centrifuge

www. .com

information@itm.com1.800.561.8187

32

Your mini-centrifuge is designed for laboratories in the bioscience,

medical, and chemistry fields. It may be involved with biohazardous

and/or hazardous materials. This instruction manual cannot address all

safety hazards. It is the responsibility of the user to consult and observe

all health and safety precautions and to assess the instrument’s

suitability to the task.

1. Never use this product in any manner inconsistent with these

instructions.

2. This product is intended to be used indoors only.

3. This product is intended for separating aqueous solutions in

approved test tubes compatible to the RCF of this unit.

4. The product is not intended to centrifuge very dense materials. Do

not use materials with a density greater than 1.2g/cm.

5. Observe general laboratory safety precautions and regulations when

using this product.

6. Do not attempt to operate with the cover removed or open.

7. The rotor and lid must always be securely fastened when in

operation.

8. Always seat the rotor completely onto the shaft, then tighten the rotor

nut.

9. Do not use damaged rotors.

10. Do not put hands onto the rotor unless the rotor is completely

stopped.

11. Do not move unit while the rotor is spinning.

12. Do not immerse the product in water. Injury due to shock or fire may

result.

13. The rotor must be loaded symmetrically. Operating this unit with an

unbalanced rotor will cause severe vibration and damage, which is

not covered by warranty.

14. Do not fill tubes while inserted in rotor. Spilled liquid may harm unit.

15. Close tube lids before starting centrifuge. Open lids can be torn off

during centrifugation and damage the unit. Open lids can cause fluid

to be dispersed inside the centrifuge.

16. Do not insert non-standard tubes or other foreign articles into the

rotor.

Safety Precautions

Caution!

Before starting the mini-centrifuge for the first time, please read

this instruction manual carefully. This manual contains

important information, safeguards, and operating instructions.

17. Follow all precautions from the Material Safety Data Sheet (MSDS) for

any reagent you use with this instrument.

18. Do not use solvent or flammable liquids near this or other electrical

equipment.

19. Do not centrifuge flammable, explosive, or corrosive materials.

20. Do not operate in a hazardous or flammable environment.

21. Do not use any solvent on the unit that may attack plastic or cause

cracks in the rotor.

22. Ensure the rotor is protected from corrosion and mechanical damage.

The rotor must be cleaned with a pH-neutral cleaning liquid.

23. Always work in a manner which endangers neither the user nor any

other person.

24. Should the instrument fail to work to specification, immediately stop

centrifuging. Clean and troubleshoot the instrument according to the

instructions under “Trouble Shooting” before any further use of the

instrument. Contact an authorized dealer or the manufacturer if trouble persists.

25. Do not attempt to stop rotor while unit is running. Doing so may

cause the unit to fail and will void the warranty.

26. Only use original manufacturer’s rotors, AC adapters, tube adapters

and any other spare parts.

27. Repairs are to be performed by trained and authorized service personnel only. Contact Heathrow Scientific

®

LLC.

28. Opening the instrument housing or improper use of the instrument

voids the warranty. If there is a failure during the warranty period,

contact Heathrow Scientific® LLC for warranty service.

29. Do not attempt to use units that have not been correctly installed or

repaired.

30. Do not attempt to disassemble or modify this product.

31. Store at room temperature in a dry area. Do not expose to sunlight,

moisture, or extreme temperatures for prolonged periods of time.

Warning!

If the unit is not used as recommended by the manufacturer, the

overall safety will be impared.

Warning!

Check MSDS, wear required Personal Protective Equipment, and

observe all applicable local and national regulations before

dispensing and disposing of hasardous sample.

www. .com

information@itm.com1.800.561.8187

54

Disposal Responsibilities:

The equipment you purchased may contain hazardous substances that

could impact the environment. Per regulations on electronic devices in

the European Community, you must use the appropriate disposal

systems to avoid exposure of these substances to the environment.

The disposal systems will reuse or recycle hazardous materials from

your equipment responsibly.

The crossed-out wheeled bin symbol invites you

to use those systems.

If you need more information on the collection, reuse and recycling

systems, please contact your local or regional waste administration.

You can also contact us for more information on the environmental

performance of our products.

Changes or modifications to the product not expressly approved by the manufacturer could void the user’s authority to operate the equipment.

This product has been tested and found to comply with the limits of

a Class A digital device pursuant to Part 15 of the FCC rules. These limits

are designed to provide reasonable protection against harmful interference

when the product is operating in a commercial

environment. The product generates, uses, and can radiate radio frequency

energy and if not installed and used in accordance with the user’s manual

may cause harmful interference to radio communications. Operation of the

product in a residential area is likely to caused interference in which case

the user will be required to correct the interference.

Supplied Equipment:

• 1 ea. Centrifuge

• 1 ea. Universal AC power adapter with 4 mains cables

• 1 ea. Standard Tube rotor (1.5mL & 2.0mL tubes) (12,500 rpm)

• 1 ea. Strip tube rotor (8 place 0.2ml Strip Tubes or 32 individual 0.2ml

tubes) (12,500 rpm)

• 12 ea. 0.2mL tube adapters (for use in the standard rotor only)

• 12 ea. 0.5mL tube adapters (for use in the standard rotor only)

Operating Conditions:

Maximum speed: 500rpm - 12,500 rpm

Maximum RCF: 9,800 RCF

Electrical: 100 – 240VAC, 50/60Hz

Ambient temperature: 2°C to 40°C

Relative humidity: ≤80% noncondensing

Power Requirements:

12VDC 8.33A

Storage Conditions:

Storage temperature: 20°C - 55°C

Relative humidity: ≤90% noncondensing

Technical Data

EC Declaration of Conformity

Manufacturer: Heathrow Scientic

®

Address: 620 Lakeview Parkway • Vernon Hills, IL 60061 USA

European Contact: Emergo Europe

Molenstraat 15, 2513 BH, The Hague, The Netherlands

This unit has been constructed and conforms to the following:

Safety Standards:

EN61010-1:2010

EN61010-2-020:2006

IEC61010-1

IEC61010-2-020

UL Std. 61010A-1, 61010A-02-20

CAN/CSA C22.2 No. 61010-1-04 (R2009)

CAN/CSA C22.2 No. 61010-2-020-09

2006/95/EC (Low Voltage Directive)

EMC Standards:

EN61326-1:2006

2002/96/EC (WEEE)

2002/95/EC (RoHS)

Signed:

Jamie Devin, Managing Director

Note:

—

Note:

—

Positive Polarity

This mark is the confirmation that the unit conforms to

the EU guidelines and has been tested according to the

following EU Declaration of Conformity.

Conforms to UL Std. 61010-1.

Certified to CAN/CSA C22.2 No. 1010.2.020-94.

www. .com

information@itm.com1.800.561.8187

76

Operation

General Operation:

1. Turn power switch in the back of the unit ON. The unit will initialize.

2. To open lid, press the OPEN button. The lid should pop up slightly.

Lift the front of the lid gently up and backward until approximately

90 degrees vertical.

3. On benchtop, prepare samples tubes in a rack so that tubes are

filled to equal levels. Close tube lids.

4. Install tubes in the rotor in a balanced manner (see section Balancing the Rotor).

5. Set the appropriate time by pressing the time up/down button.

6. Set the appropriate RPM by pressing the speed up/down button.

7. Place the standard rotor cover on the rotor to limit noise and

aspiration of liquids that may escape from tubes.

8. Close Lid and press down until locked (Display status should read

“READY”).

9. Press Start/Stop (rotor should spin up to the user set speed).

10. At a determined time the rotor will spin down and stop at the preset

time.

11. The unit will then emit a beep when the cycle is complete.

12. To open lid, press the OPEN button.

• Remove the contents from the package examining them carefully for

breakage, defects or missing parts.

• Place the product on a sturdy, level surface away from the edge of

the counter and other moving equipment. Make sure the AC power

adapter and cords are clear of hot surfaces and other hazards.

• Make sure the product has ventilation and is not encased in any

material that will limit airflow. An overheating situation could occur.

• Verify that the power switch in the back of the unit is in the OFF

position. Plug the DC cord into the rear of the unit and the AC cord

an approved outlet.

Display

Display Status

LID OPEN

- Lid is open

READY

- Unit ready to centrifuge

SPIN UP

- Cycle is starting and is increasing speed

SPINNING

- Running in Standard mode

SPIN DOWN

- Cycle is slowing down

STOPPED

- Cycle has stopped

COMPLETED

- Centrifuge cycle is nished

QUICK SPIN (ashes)

- Running in Quick Spin mode

ERROR

- An error has occurred (See error section)

STATUS READY

12300 RPM 12:12 MIN

Speed

RPM/RCF

Time Min:Sec

Status

of Unit

Stop

Start

Front Panel

Rear Panel

Quick

Spin

Open

Speed

Up/Down

Time

Up/Down

On/Off

Switch

DC Jack

Prior to using:

- Turn power switch in the rear ON. The unit will initialize.

- Press the OPEN button. The lid should pop up slightly. Lift the front

of the lid gently up and backward until approximately 90 degrees

vertical.

- Remove any remaining packaging materials.

- Verify that the rotor is installed correctly. (see section Rotor

Installation and Removal) Do not run without the rotor installed.

- Close the lid.

- Press the Start/Stop button (rotor should spin up to the preset

speed). If there is a smooth whirring sound and the unit accelerates

with little or no vibration, the mini-centrifuge is ready to use. If there

are loud or unusual sounds, or excessive vibration, DO NOT

OPERATE. Contact Heathrow Scientific® LLC Technical Support.

- At the set time, the rotor will spin down, stop and the unit will

emit a beep when the cycle is complete.

www. .com

information@itm.com1.800.561.8187

98

Trouble Shooting

Trouble Resolution

No power

present

— Verify that the AC adapter is fully plugged into

the wall and rear of unit

— Verify that the power switch is turned on

Unit or display

is not operating

normally

— Turn off the unit, wait 2 minutes, and turn power

on

Excessive

vibration

Excessive noise

— Inspect the tubes for equal ll or improper

placement

— Inspect the rotor for improper installation

— Remove the tubes and determine if the noise

persists with an empty rotor

Lid will not

close

— Verify that nothing is blocking the lid from fully

closing

— Verify that nothing has fallen into the lock

mechanism opening

Lid will not

open

— If for any reason you need to manually open the

lid to access tubes due to an error or power loss,

please perform the below

— Turn off the unit, remove power cord

— Make sure the rotor has stopped completely

— Use a thin rod and insert it into the opening

on the bottom

— Press gently but rmly. You will feel a

— mechanical movement within the unit and

the lid will release.

— Remove the rod, set the unit on the feet

— Remove your tubes and reclose the lid

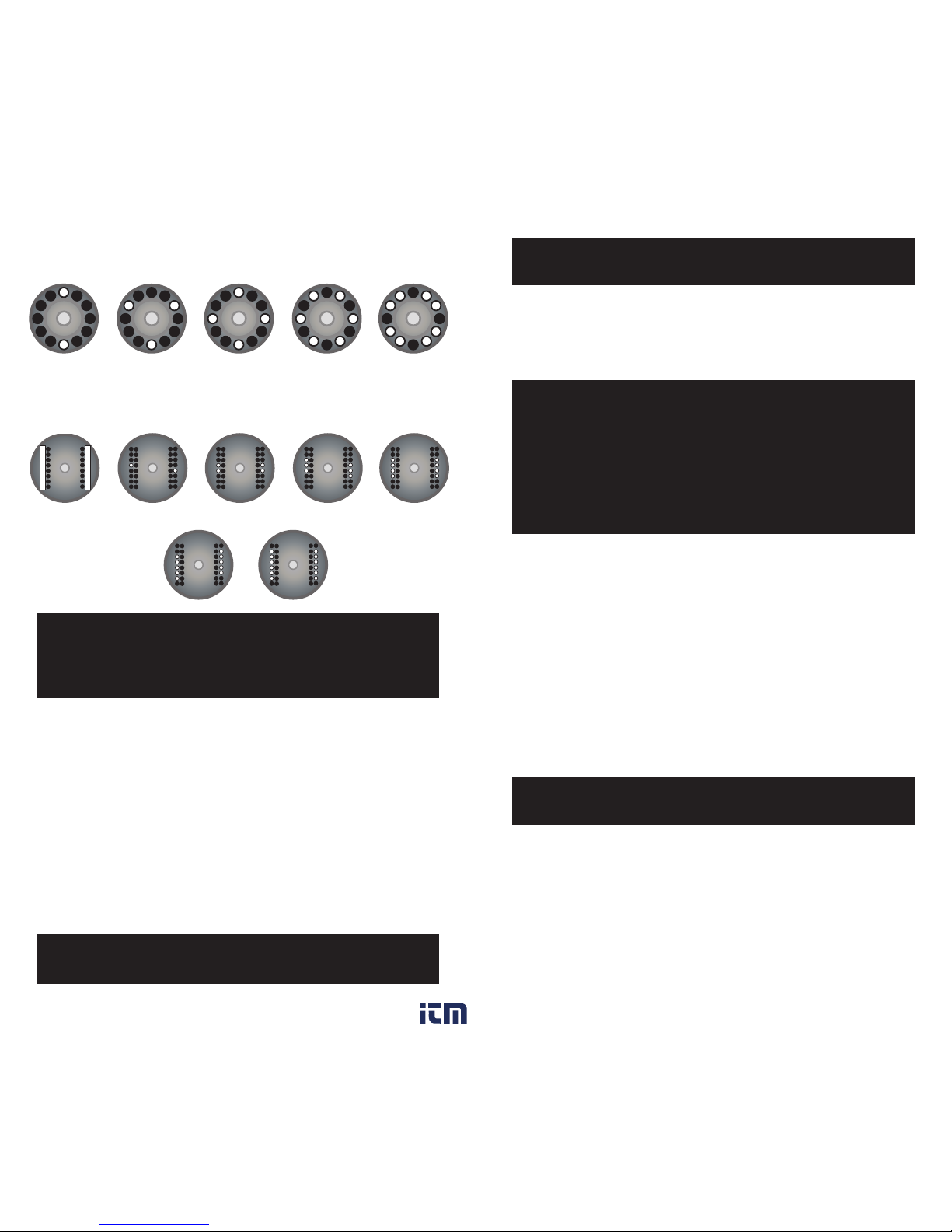

Balancing the Rotor

Tubes of equal weight and size should be placed opposite each other.

Use additional sample or water in other tubes to provide a balanced

rotor. Examples of proper sample balancing are illustrated next.

Warning!

Spin balanced loads only!

Do not place the tubes asymmetrically nor load unequal volume

tubes. Improper placement of tubes will lead to insufficient

centrifugation and may cause serious injury or an accident.

Quick Spin Operation:

1. Prepare the unit for centrifugation as in the General Operation

(section above Steps 1-8).

2. Press Quick Spin button (rotor should spin up to the set speed).

3. The timer will begin counting.

4. Once enough time has elapsed for your needs, release the Quick

Spin button. The rotor will spin down, stop and the unit will emit a

beep when the cycle is complete.

5. To open lid, press the OPEN button.

Other:

Change Between RPM and RCF

- Prior to a spin cycle, press both the Speed Up & Down buttons

simultaneously.

- The speed setting will then convert to the other.

Quick Stop

- If for any reason you need to stop the cycle quickly, press and hold

the Start/Stop button. The cycle will stop more rapidly than normal.

Caution: The tube contents may be disturbed during the quick

stop process.

• If an error happens, the unit will beep and the display will indicate

the error.

• Press Start/Stop to clear the error from the display.

Error:

Error Status Resolution

Motor

Overload

— Something is interfering with the rotor. Clear the rotor and

reset.

User Stop

— The operator has held down the Start/Stop and

implemented a quick stop.

Balance

— Inspect the tubes for equal tube ll or improper placement.

Once corrected, rerun.

— If the balance error continues to happen, remove the tubes

and determine if the balance error still persists with an

empty rotor.

— Inspect the rotor for improper installation.

Temperature

— The unit has exceeded the normal operating temperature.

— Turn off the unit and allow to cool.

Excessive Tilt

— The unit has experienced a non-normal tilt event.

— Make sure the unit is placed on a level surface.

Once corrected, rerun

Lid Fail

— The lid has opened during the cycle. Check for proper

operation of the lid lock mechanism. The lid should stay

locked during the entire cycle.

Rotor Lock

— The unit has experienced a problem with the rotor.

— Correct the rotor interference. Once corrected, rerun.

STATUS ERROR

Rotor Lock

Status of Unit

Error Type

www. .com

information@itm.com1.800.561.8187

1110

Notes

—Ensure all parts are throughly dry prior to operation.

Maintenance

Warning!

Do not use any solvent on the unit that may attack plastic

or cause cracks in the rotor. Ensure the rotor is protected

from corrosion and mechanical damage. The rotor must be

cleaned with a neutral cleaning liquid.

If hasardous sample is spilled on the unit and or leaked

into the unit, do not run the centrifuge unless it is safe to

do so.

Your mini-centrifuge is normally maintenance-free. Clean unit

only when it is not plugged into an electrical outlet. When

necessary, the housing and rotor can be wiped using a damp

cloth and a mild, non-corrosive detergent.

1. Remove rotor from unit

2. Remove screws from the bottom of the rotor

3. Clean as needed

4. Reasssemble rotor, making sure that the alignment tab is

engaged into the slot.

5. Test run reassembled EMPTY rotor to ensure it is still

balanced

1.5mL / 2.0 mL Circular Rotor

0.2mL Tube Rotor

10 Tubes 12 Tubes

Warning!

Do not attempt to open lid until rotor has completely stopped!

Avoid severe personal injury or property damage from moving parts.

Only use rotor compatible with the centrifuge.

Warning!

Do not use damaged or cracked rotors!

Rotor installation and removal

To remove rotor:

— With one hand, grasp the rotor. With the other hand, unscrew

center knob counter clockwise until it disengages from the motor

shaft.

—

Pull up on the center knob firmly. The rotor should easily lift off of

the motor drive.

To install the rotor:

— Check to make sure the bands on the rotor are in the slots.

— Set rotor onto the motor drive and push down until seated.

— With one hand, grasp the rotor. With the other hand, screw the

center knob clockwise until it engages the motor shaft.

Keep turning the knob until it tightens.

—

Do not over tighten the knob.

Mini-centrifuge with AC adapter, 2 rotors,

rotor cover, and tube adapters ........................................HS10050

Standard Rotor................................................................HS100503

Strip Tube Rotor..............................................................HS100504

Rotor Knob......................................................................HS100505

Standard Rotor Cover.....................................................HS100506

Ordering Information

Tubes

2 Strip

Dissassembly of Rotors for Cleaning

www. .com

information@itm.com1.800.561.8187

1312

Limited Warranty

Heathrow Scientific® LLC warrants that your mini-centrifuge will

be free from defects in workmanship and material for two years

from the date of purchase.

If you believe that there is a defect in the product, you must,

during the warranty period, notify Heathrow Scientific

®

LLC,

provide proof of purchase, and return the product to Heathrow

Scientific

®

LLC with a Return Authorization form. To obtain a

Return Authorization form, please call 1-847-816-5070.

If Heathrow Scientific® LLC is properly notified and, after

inspection, confirms that there is a defect and the warranty

period has not expired, Heathrow Scientific

®

LLC will repair,

modify, or replace the product, at its sole option, at no charge.

OTHER THAN THIS LIMITED WARRANTY, HEATHROW

SCIENTIFIC

®

LLC MAKES NO WARRANTIES, EXPRESS OR

IMPLIED, WITH RESPECT TO THE QUALITY OR

PERFORMANCE OF THE PRODUCT, INCLUDING BUT NOT

LIMITED TO THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR PARTICULAR

PURPOSE WHICH ARE HEREBY DISCLAIMED AND

EXCLUDED. HEATHROW SCIENTIFIC

®

LLC WILL IN NO

Warranty

IN NO EVENT WILL HEATHROW SCIENTIFIC® LLC’S

OBLIGATION UNDER THIS WARRANTY EXCEED THE PRICE

OF THE PRODUCT.

Heathrow Scientific® LLC will not accept any product return that is

not appropriately cleaned and decontaminated. In the unlikely

event of repair, or when damage to the unit necessitates return,

contact Heathrow Scientific

®

LLC and obtain return authorization

before sending your product for service.

Return for Repair

Important:

Transporting hazardous materials without a permit is a

violation of federal law.

EVENT BE LIABLE FOR ANY LOSS OF USE, LOSS OF

PROFITS, CONSEQUENTIAL, SPECIAL, EXEMPLARY OR

PUNITIVE DAMAGES.

THIS WARRANTY DOES NOT COVER:

• ANY DEFECT OR DAMAGE CAUSED BY IMPROPER OR

UNREASONABLE USE OF THE PRODUCT. (THE MINICENTRIFUGE IS DESIGNED FOR USE ONLY BY TRAINED

LABORATORY TECHNICIANS. USE BY ANYONE ELSE WILL

VOID THIS WARRANTY.)

• ANY PRODUCT THAT HAS BEEN, IN HEATHROW

SCIENTIFIC® LLC’S SOLE JUDGEMENT, TAMPERED WITH,

ALTERED, OR REPAIRED BY ANYONE OTHER THAN

HEATHROW SCIENTIFIC

®

LLC.

• ANY PRODUCT THAT IS INOPERATIVE BECAUSE OF: (a)

WEAR OCCASIONED BY USE, (b) NEGLIGENCE, (c)

ACCIDENT, (d) INCORRECT MAINTENANCE, OR (e) USE

UNDER ABNORMAL CONDITIONS OF TEMPERATURE, DIRT

OR CORROSION, OR USE WITH ABRASIVE OR CORROSIVE

MATERIALS.

• ACCESSORY PARTS, SUCH AS RUBBER AND PLASTIC

PARTS THAT ARE DAMAGED BY LIQUIDS OR MISUSE.

www. .com

information@itm.com1.800.561.8187

Loading...

Loading...