Page 1

ASSEMBLING

AND

USING

YOUR

-II

e_a±/z.k

ii:

-·'·

Signal

Generator

Model SG-6

THE

HEATH

COMPANY

BENTON

HARBOR,

MICH.

PRICE

$1.00

.

Page 2

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,..

,,,,,,,,,,,,,,,,,,, ,,,,,,,,,,,

Resistors

general

The

ance

colors

the

On

dot

the

are

types

other,

code

are

third

indicates

uninsulated

the

number

next

band

identified

o~

resistors.

the

insulated

uses

three

arranged

resistors,

of

is

the

''"''

.....

so

the

digits.

second

''

,,,,,,

by a color

type,

bands

that

number

the

On

U S E F U L

One,

the

has

or

colors,

the

first

of

digits

body

insulated

figure

and

INFORMATION

code

used

uninsulated

the

wire

while a fourth,

two

indicate

(zeros

is

the

first

resistors,

the

third

in

several

type,

connected

the

or

multiplier)

figure,

the

band

has

internally

usually

first

the

end

band

the

bands

the

connecting

silver

two

figures

which

color

nearest

number

FOR

around

and

coming

or

of

follow

the

the

of

digits.

the

wires

gold,

the

the

second

end

is

KIT

resistors.

bound

out

the

indicates

resistance,

first

two

figure,

the

first figure,

BU

I L

There

around

ends.

the

tolerance. The

while

figures

and

the

DE

are

the

The

''''''''''''''''''''"''"'"'''''''''''''''''''

two

ends.

resist-

=l!ID=~w.

''"'''''''''''''''''''''''''''"''''''''''''''

Rs

=m~~~

--1~~~

F

'Aw

~1W.

WATTAGE.

The

chart

tage

size

resistors

amperes

200

volts,

A

higher

Uninsulated

Insulated

(·01or

Black

Brown

He

ct

Orang

e

Ye

llow

Green

Blue

Viol

et

Gr e y

Whit

e

llF:!"J!"TANCF:

~o.ooo

2

20,000

l Meg o

Condensers

If

the

In

there

If

two

RMA,

tolerance,

the A WS

name.

In

rating,

tolerance, and

Resistors

shows

necessary

in

(.01

250

1fi00

approximate

volts.

Amperes)

giving a drop

wattage

Body

First

1~~1rJ111t

0

l

2

3

4

5

fi

7

8

9

I~

OllM~

50

hm

use

is

one

row

rows

of

the

top

row

and

decimal

code, the

decimal

are

multiply

Example

has a voltage

of

resistor

Color

Ring

Ftg11re

the

same

of

dots, they

dots

appear

of

dots

multiplier

rated

as

to

sizes

- A

volts.

can

End

Second

~econd

which

through

plate

always

Color

.t""lgure

0

l

2

3

4

5

6

7

8

9

current

100

Some

DOD\'

The fo

urth

t o lf'r n n <'e ) 0 1·

code

as

are

, it

can

are

.

row

the

of

multiplier.

top

wattage

vary

resistor

loading

on

one

Therefore

be

Ring

Popular

OR

J<'JR!"T

G reen

Ht'<l

B ro

wn

6range

TI0d

Bro

wn

ring or

it

m

ay

resistors

read

in

either

first

three

dots

art

(power

with

resistor

side

100

substituted

Dot

Third

N_

u1nbt"r

oth<'r

h e o

dissipation)

manufacturers. To

in

amperes

for a tube

of

300

volts

Color

Ring

of

Dlglt11

No

,

000

0,

000

00,000

000.000

0,

000.000

00.000.000

000.000.0

HAND

(•nd

may

n1ittt·d

Condenser

and

are

read

direction

pc

of

figures

the

two

first

of

different

(carried

three

Examples

R.MA

by

voltage

volts

and

X .OlA. = 1

for

smaller

UNINSULRTED

ne

0

00

BROWN

00

1

Sizes

J<}ND

b e silver

e

ntir

e l y \Vhich

Code

in

micromicrofarads.

arrow

or

codes:

to

three

figures

according

determine

drop

drawing

on

the

other

Watt.

size.

TYPE'

RED

Resistors

of

~t:l'ONU H .

OR

Black

(;n·,·n

G

Bla~k

Hect

Black

(1

0%

t

olerance

indicatr·s

if

manufacturer's

The

figures), the

while the

to

10

2

n·~·

RMA

size.

wat-

across

milli-

side

ORANGE

n

) o r gold

20"1

bottom

=1111

WATTAGE

Examples

000

\ND

to

name

or

the

bottom

h ·ran

row

BROWN

(5%

cl·.

appears

AWS

(American War Standard).

row

are

are, left

AVVS

INSULAT£D

Forth

!Or

Tolerance

RED

1

DOT

in

left

z.

OR

the

same direction as

to

right

to

right, characteris

f=1w.

SIZES

TYPE

Band

""

ORAllluE

000

TlllRD

Dlac

Hro

H<>d

Orang-"

Y

ello

Green

HAND

k

w n

w

the voltage

•

tic,

RED

GREEN

BROW~

z 5 0

2SO

MMF

MMF.

10

5::>

100

250

500

1000

3000

10

,000

The

tolerance

The

voltage

Blue

- 600

volt

:::.

rating

rating

rating.

.000

ZS MF

Some

MF

.00001

.00005

.0001

.00025

.0005

.001

.003

.01

corresponds

corresponds

Commonly

.

BROWN

RED

GREEN

1 2 5 0

12SO

MMF

=.0012

Used

to

to

the

the

color

code

FIRST

multiplied

DOT

Brown

Green

Brown

Red

Green

Brown

Orange

Brown

code, i.e .,

13ROWl<J

SMF

Condensers

Sizes

of

SECOND

red-2o/r, green

by

100.

Example:

7~

DOT

ALWAYS

BLACK

Black

Black

Black

Green

Black

Black

Black

Black

- S

GREEN

5'

500MMF::::

DOT

o/r

, etc.

Orange

dot

BLACK

0

THIRD

- 300

BROWN

0

.0005

Black

Black

Brown

Brown

Brown

~ed

Red

Orange

volt

DOT

rating

;

Page 3

Assembly and Operation

of the

Generator

Heathkit

Signal

Model

SG-6

•

SPECIFICATIONS

FREQUENCY

RANGE

Band A ..........

:

...................

160 Kc

to

510

Kc.

Band B ..............................

500 Kc

to

1,650

Kc.

Band C ..............................

1.65 Mc

to

5. 7 Mc

Band D ..............................

5.4 Mc

to

19 Mc

Band E ..............................

17

Mc

to

50 Mc .

Calibrated

Harmonics

....................

51

Mc

to

150 Mc

RADIO

FREQUENCY

OUTPUT

...............

In

excess

of 100,000

microvolts.

MODULATION

FREQUENCY

.................

Approximately

400 cy<;:les.

AUDIO

OUTPUT

.........................

1~

to 2 Volts. , .....

.

AUDIO

FREQUENCY

INPUT

.................

Approximately

5V

across 1 Megohm

•

TUBES

6C4

RF

Oscillator

.......................

6C4 Audio

Oscillator

or

Audio

Amplifier

.

POWER

REQUIREMENTS

...................

105-125V.

50/60

cycles

....

.

Page

1

Page 4

The

Heathkit

Model SG-6 Signal

Generator

has

been

designed

so

that

with

simple

easy

assembly

the

kit

builder

can

construct a signal

generator

which

will

give

him

excellent

performance

and

is

both

pleasant

and

easy

to

use.

This

generator

has

been

engineered

so

that

it

will

be

valuable

to

the

radio

repairman,

ham,

or

experimenter

over

a wide

range

of

uses

in

addition

to

being

a

rugged

and highly

dependable

piece

of

test

equipment'made

of

the

highest

quality

parts

through-

out.

PRELIMINARY

INSTRUCTIONS

AND

NOTES

Before

starting

construction

be

certain

to

read

the

manual

through

completely

and

note

all

dia-

grams

and

pictorials.

In

the

step

by

step

procedure,

when

actually

assembling

and

wiring,

read

the

whole

article

through

(articles

are

numbered

1, 2, 3, etc.)

so

that

no

suggestions

in

the

article

will

be

missed.

To

facilitate

describing

the

location

of

parts,

solder

lug

positions

have

been

numbered,

and

tube

socket

positions

have

been

lettered

as

in

Figure

1.

Refer

to

this

figure

when

instruc'tions

say,

"mount

solder

lugs

4 and 5,

etc."

Also

note

that

both

the

schematic

diagram

and

Figures

5 and

11

show

all

switch

contact

lugs

numbered.

The

code

is

as

follows:

for

example,

M3

indicates, M for

modulation

switch

and

3

for

contact

solder

lug

3. BR6

means, B for

bandswitch, R for

rear

deck,

and 6

for

contact

lug

6.

Therefore

when mounting

switches,

be

sure

to mount

them

with

the

same

relative

position

as

shown

in

the

pictorials.

Likewise,

be

sure

and

mount

tube

sockets

as

pictured.

When

wiring,

and

instructions

say,

"connect

to

right

hand lug of

the

two

lug

terminal

strip,

etc."

consult

Figure 1 for

clarity.

It

is

recommended

that

tube

sockets

A and B on

figure

1 be

actually

labeled

A and B on

the

chas-

sis

with a pencil.

Also

writing

the

names

of

the

controls

on

the

inside

of

the

chassis

where

wir-

ing

is

done

will

reduce

the

possibility

of

wiring

to

improper

controls

by

mistake.

An

A,

B,

C,

D,

or E written

by

the

coils

on

the

sub-chassis

might

prove

helpful.

Read

the

note on

soldering

on

the

inside

of

the

back

cover.

Make a good

mechanical

joint

of

each

connection

with

clean

metal

to

clean

metal.

Use

only good

quality

rosin

core

radio

type

solder.

Pastes

or

acids

are

difficult

to

remove

and

minute

amounts

left

combine

with

moisture

from

the

air

forming a corrosive

product.

Weeks

or

months

later

corrosion

may

result

in

untimely

fail-

ure.

•

NOTE: ALL GUARANTEES ARE VOIDED

AND

WE

WILL NOT

REPAIR

OR SERVICE IN-

STRUMENTS IN WHICH ACID CORE SOLDER OR PASTES ARE USED.

Small

changes

in

parts

may

be ,

made

by

the

Heath

Company.

Any

part

supplied

will

work

just

as

well

as

the

part

for

which

it

was

substituted.

All

substitutions

will

be

of

equal

or

better

qual-

ity

than

the

original,

and

will

be

made

in

order

that a minimum

delay

will

occur

in

filling

your

order.

Resistors

aqd

controls

have a

tolerance

rating

of

plus

or

minus

20%

unless

otherwise

stated.

Therefore

a

lOOK

ohms

resistor

may

test

between

80K and 120K

ohms.

The

letter K stands

for

1,000

and M

for

1,000,000.

Thus.a

resistor

marked

90K=90,000

Ohms,

etc.

Frequently

conden-

sers

show

an

even

greater

variation

such

as

minus

50% to

plus

100%.

This

Heathkit

is

designed

to

accomodate

such

variation

.

The

tube

socket

pins

are

numbered

from 1 to 7 starting

at

the

spacing

and

reading

clockwise

when viewed

from

the

bottom.

See

Figure

2.

A

circuit

description

is

included

in a later

section

of

this

manual

so

that

those

with

some

knowl-

edge of

radio

will

be

able

to

obtain a clearer

picture

as

to

the

actual

workings

of

this

equipment

.

It

is

not

expected

that

those

with

little

radio

experience

will

understand

the

description

com-

pletely,

but

it

should

be

of

help

in

the

event

that

they

desire

to

become

more

familiar

with

cir-

cuit

operation

and

thus

learn

more

from

building

the

kit

than

just

the

placing

of

parts

and

wiring.

In

any

case,

this

section

points

out

the

use

of

the

various

controls

and

switches.

Page

2

Page 5

STEP

BY

STEP

ASSEMBLY

Use

of

bare

wire

where

indicated

will

facilitate

wiring,

but

insulated

wire

may

be

used.

Place

spaghetti

(insulated

sleeving)

over

bare

wires

on

condensers

or

resistors

where

riecessary

to

prevent

the

leads

from

accidentally

touching

other

bare

wires

or

metal

parts.

(S}

means

solder

·

(NS)

means

do

not

solder

yet

Begin

by

checking

the

parts

against

the

parts

list.

Identify

each

part,

using

the

charts

on

the

inside

of

the

cover

of

this

manual

where

necessary.

Thus,

you

will

avoid

throwing

away any

small

parts

with

the

packing.

MOUNTING

OF

PARTS

ON

CHASSIS

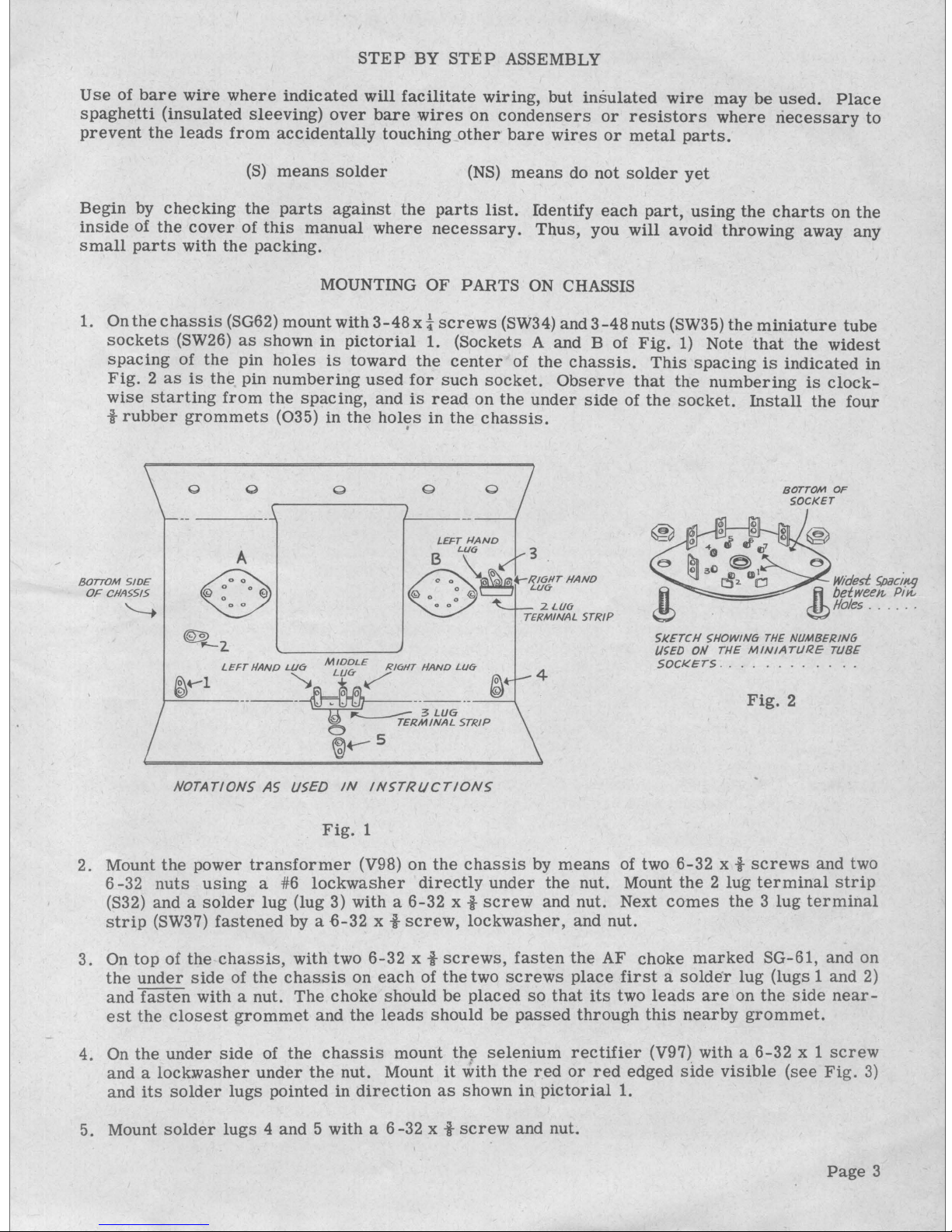

1. On

the

chassis

(SG62)

mount

with3-48x t screws

(SW34) and

3-48nuts

(SW35}

the

miniature

tube

sockets

(SW26}

as

shown

in

pictorial

1.

(Sockets

A and B of

Fig.

l}

Note

that

the

widest

spacing

of

the

pin

holes

is

toward

the

center

of

the

chassis.

This

spacing

is

indicated

in

Fig. 2 as

is

the

pin

numbering

used

for

such

socket.

Observe

that

the

numbering

is

clock-

wise

starting

from

the

spacing,

and

is

read

on

the

under

side

of

the

socket.

Install

the

four

t

rubber

grommets

(035) in

the

holes

in

the

chassis

.

BOTTOM SIDE

OF

CllA551S

'---.

.

Q

A

~

,._2.

LEFT

llAND

Ll.16

MJ_~~LE

RIGHT

HAND

LU<i"

,__©_..-_i ____

__

'¥::.~z,~~r

;,,.

fJj

@...-s

NOTATIONS

A5

USED

IN

IN>TRl/CTION~

Fig.

1

4

BOTTONI

OF

SOCKET

Wtde>f

5/JaCif:tl}

Jj

between

Pin,

®Holes

....

_.

5J<ETCH 5HOWIN6

THE

NUMBERING

/JSED

Oii

THE

MINIATURE

TUBE

SOCKETS .... _ ...

Fig.

2

2. Mount

the

power

transformer

(V98) on

the

chassis

by

means

of two

6-32

x t

screws

and two

6-32

nuts

using

a #6

lockwasher

directly

under

the

nut. Mount

the 2 lug

terminal

strip

(S32) and a

solder

lug

(lug 3) with a

6-32

x t

screw

and nut. Next

comes

the 3 lug

terminal

strip

(SW37)

fastened

by a -6-32 x t

screw,

lockwasher,

and nut.

3.

On

top

of

the

chassis,

with two

6-32

x t

screws,

fasten

the

AF

choke

marked

SG-61,

and

on

the

under

side

of

the

chassis

on

each

of

the

two

screws

place

first a solder

lug

(lugs 1 and

2)

and

fasten

with a nut.

The

choke

should

be

placed

so

that

its

two

leads

are

on

the

side

near-

est

the

closest

grommet

and

the

leads

should

be

passed

through

this

nearby

grommet.

4. On

the

under

side

of

the

chassis

mount

th~

selenium

rectifier

(V97) with a

6-32

x 1

screw

and a lock:washer

under

the

nut. Mount

it

with

the

r.ed

or

red

edged

side

visible

(see

Fig.

3)

and

its

solder

lugs

pointed

in

direction

as

shown

in

pictorial

1.

5. Mount

solder

lugs 4 and

5 with a

6-32

x t

screw

and nut.

Page

3

Page 6

MOUNTING

OF

PARTS

ON

FRONT

PANEL

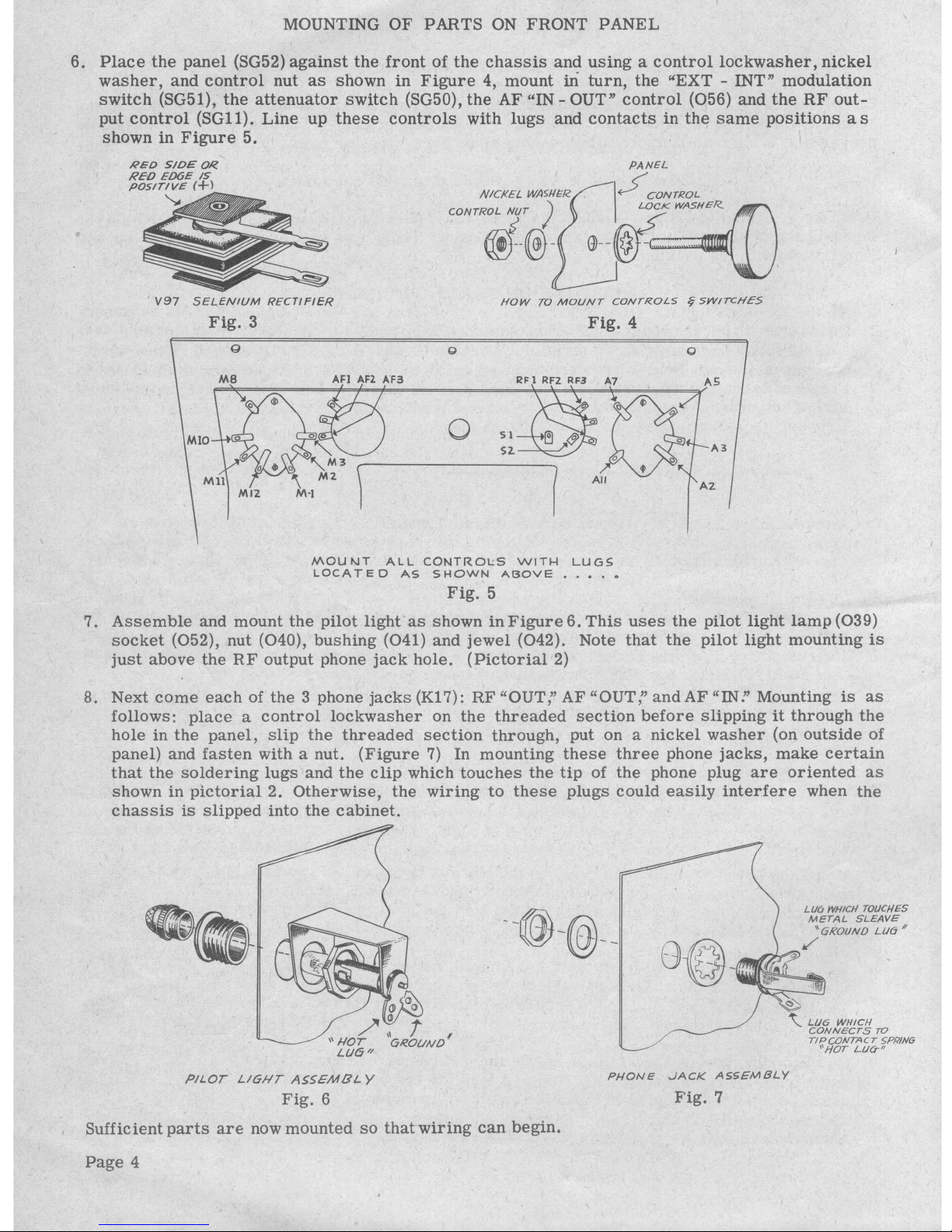

6.

Place

the

panel

(SG52)

against

the

front

of

the

chassis

and

using a control

lockwasher,

nickel

washer,

and

control

nut

as

shown

in

Figure

4, mount iri

turn,

the

"EXT

- INT"

modulation

switch

(SG51),

the

attenuator

switch

(SG50),

the

AF "IN - OUT"

control

{056) and

the

RF

out-

put

control

(SGll).

Line

up

these

controls

with

lugs

and

contacts

in

the

same

positions

as

shown

in

Figure

5.

•

RED

S!DEOR

RED

ED6E

IS

POSITIVE

(+l

""

V97

SEL.ENtUM

RECTIFIER

Fig.

3

NICKEL

WA91£R

CONTROL

1T

)

@--®-

PANEL

\

~CONTROL

LOCK

WASHER..

~--~--Mmfffl

HOW

TO

MOUNT

CONTROLS

~SWITCHES

Fig.

4

0

SI

n

S2.

,--~~~~~~~~--..

All

0

A3

A2

MOUNT

ALL

CONTROLS

WITH

LUGS

LOCATED

AS

SHOWN

AC30VE

•••••

Fig.

5

7.

Assemble

and

mount

the

pilot

light

as

shown

in

Figure

6.

This

uses

the

pilot

light

lamp

{039)

socket

(052), nut (040),

bushing

(041)

and

jewel

{042). Note

that

the

pilot

light

mounting

is

just

above

the

RF

output phone

jack

hole.

(Pictorial

2)

8. Next

come

each

of

the

3 phone

jacks

{Kl 7):

RF

"OUT;'

AF

"OUT:'

and

AF

"IN!'

Mounting

is

as

follows:

place a control

lockwasher

on

the

threaded

section

before

slipping

it

through

the

hole in

the

panel,

slip

the

threaded

section

through,

put on a

nickel

washer

(on

outside

of

panel) and

fasten

with a nut.

(Figure

7) In

mounting

these

three

phone

jacks,

make

certain

that

the

soldering

lugs

and

the

clip

which

touches

the

tip

of

the

phone plug

are

oriented

as

shown

in

pictorial

2.

Otherwise,

the

wiring

to

these

plugs

could

easily

interfere

when

the

chassis

is

slipped

into

the

cabinet.

--@-@--

L/16

WHICH

TOI/CHES

METAL

SLEAVE

"GROUND

LU6

II

8@-W.1111https://manualmachine.com/

...

~

\__

LUG

WHICH

CONNECTS

TO

TIPU)NTACT

5PR!N6

''HOT

Lll<T//

PILOT

LIGHT

ASSEMBLY

Fig.

6

PHONE

JACK

A55£MBLY

Fig.

7

Sufficient

parts

are

now mounted

so

that

wiring

can

begin.

Page

4

Page 7

WIRING

PROCEDURE

9.

Wire

in

the

power

transformer

(V9S)

as

shown

in

pictorial 1 and

as

follows:

twist

the

two

black

leads

together,

cut

them

to

proper

length,

and

fasten

them

to

the

two

outside

lugs

of

the

three

lug

terminal

strip

(NS).

Fasten

one

yellow

lead

to

solder

lug

1 (NS)

and

the

other

yel-

low

lead

to

pin 4 of

tube

socket

A (NS). One

red

lead

goes

to

solder

lug

1 (NS)

and

the

other

red

lead

connects

to

the

bottom

lug

{lug

furthest

from

the

red

edged

insulator

piece)

of

the

selenium

rectifier

{S).

Wire

from

pin

4 of

socket A (S)

to

pin

4 of

socket

B (NS).

Note

that

this

wire

follows

along,

and

is

close

to,

the

bend

of

the

chassis.

Wire

from

pin 4 of

socket

B

{S)

to

the

pilot

light

"HOT"

solder

lug

(S)

(see

Fig.

6)

passing

the

wire

through

the

nearby

rubber

grommet.

Ground

the

pilot

light's

"GROUND"

solder

lug

to

the

pilot

light

frame

(S).

Wire

from

pin

3 of

socket

B (NS)

to

solder

lug

3 (NS).

Wire

from

pin

3 of

socket

A (NS)

to

solder

lug

2 (NS).

10.

To

the

left

hand

lug

of

the 3 lug

terminal

strip,

fasten

one

lead

of

a .001

MFD

condenser

(SG46) (NS)

and

this

condenser's

other

lead

connects

to

solder

lug

5 {NS).

Note

that

lead

near

"outside

foil"

or

black

ring

marking

on

body

of

condenser

is

the

lead

which

goes

to

the

solder

lug

(ground).

Hereafter,

whenever

condensers

are

grounded,

have

the

outside

foil

lead

as

the

grounded

lead.

Connect

the

other

.001

MFD

condenser

to

the

middle

lug

of

the 3 lug

terminal

strip

(NS)

and

its

outside

foil

lead

to

solder

lug

5 (S).

11. Note

that

the

"RF

output -AC

off"

control

has

two

solder

lugs

protruding

from

the

back

of

it.

Twist

two

pieces

of

wire

together,

and

wire

from

control's

back

lugs,

(lugs

Sl

and

S2,

Fig.

5)

(S)

to

the

middle

{NS)

and

right

hand

solder

lugs

(S)

of

the 3 lug

terminal

strip.

Refer

to

pic-

torial

1.

12.

Wire

from

the

upper

lug

(the

lug

nearest

the

red

edge

insulator

piece)

of

the

selenium

rec-

tifier

(S)

to

the

right

hand

lug

on

the

two

lug

terminal

strip

(NS).

To

this

right

hand

lug

also

connect

one

lead

(on

the

side

marked

positive

or

with

a+++

marking)

of

the

dual

20

MFD

con-

denser

(K13) (NS).

The

single

lead

at

the

other

end

of

the

condenser

goes

to

solder

lug4

(S).

The

other

positive

lead

goes

to

the

left

hand

lug

of

the

two

lug

terminal

strip

(NS).

Wire

the

2700

resistor

(KlO)

between

the

right

hand

lug

of

the 2 lug

terminal

strip

(S)

and

the

left

hand

lug

(NS).

To

this

left

hand

lug

also

connect

one

lead

of

the

5600

resistor

(Gl2)

(S)

and

the

resistor's

other

lead

to

pin 5 of

socket

B (NS).

Wire

from

pin

5 of

socket

B (S)

to

pin

1 of

socket

A (S).

This

wire

follows

along

the

bend

of

the

chassis.

13.

SOCKET

B:

Wire

to

socket B as

follows:

to

pin 1 connect

one

lead

of

a .01

condenser

(T13)

{S)

and

fasten

the

outside

foil

lead

to

solder

lug

3 (S).

Fasten

to

pin

6 a

lead

of

the

27K

re-

sistor

(FM36) (NS)

and

connect'

the

other

lead

of

this

resistor

to

pin

3 (S).

14.

SOCKET

A:

Socket A wiring

is

as

follows:

to

pin 3 connect

one

leadofa330resistor

(AR25)

(NS)

and

the

resistor's

other

lead

to

pin

7 (S).

To

pin 3 connect

one

lOOK

resistor

lead

(012)

(S)

and

the

other

lead

goes

to

pin

6 (NS).

Wire

from

pin 5 (S)

to

the

"EXT -INT"

modulation

switch

contact

M12(S).

Connect

one

lead

of a .05

condenser

(AR2S}

to

pin

6 (S)

and

the

out-

side

foil

lead

of

this

condenser

fastens

to

"EXT

- INT."

modulation

switch

contact

M2

{S).

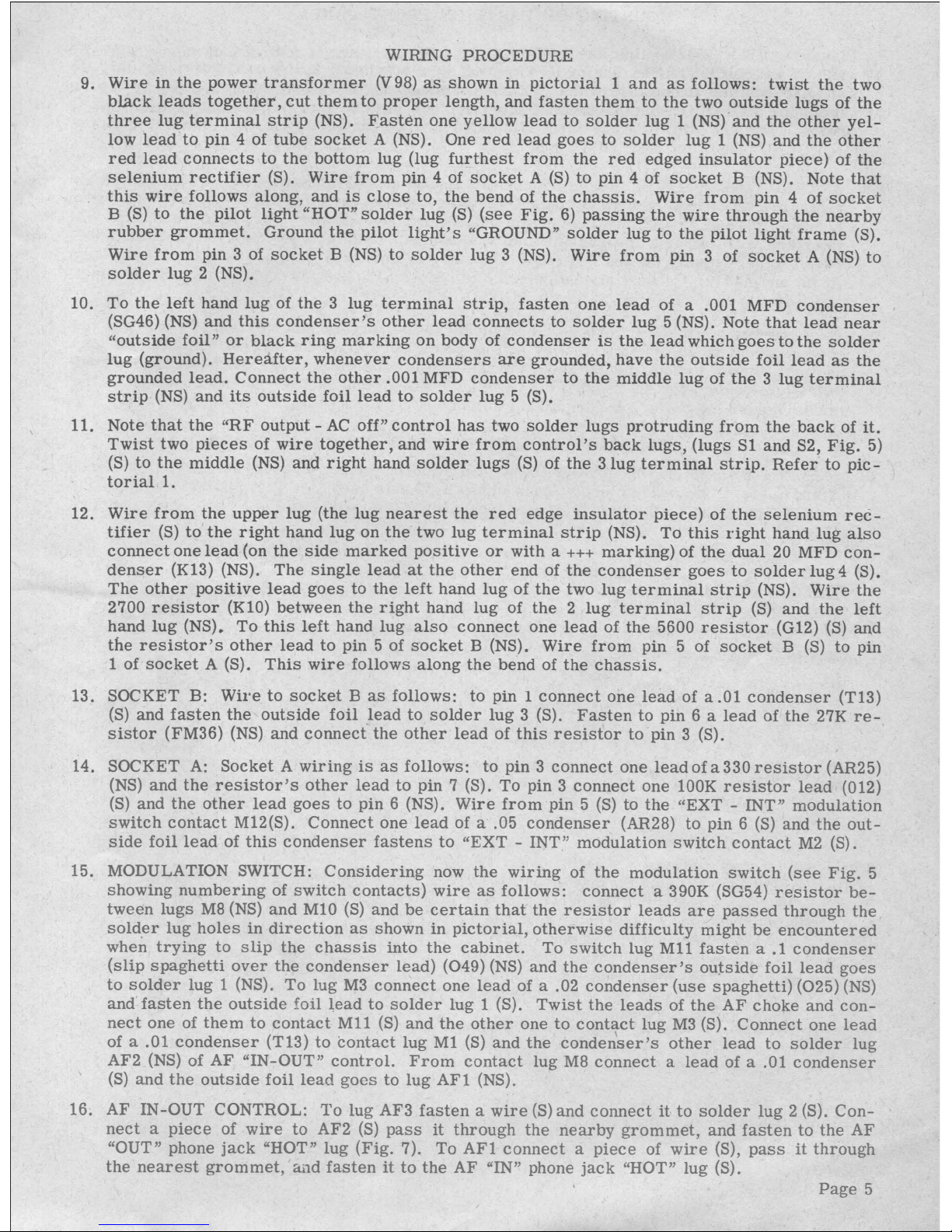

15. MODULATION SWITCH:

Considering

now

the

wiring

of

the

modulation

switch

(see

Fig.

5

showing

numbering

of

switch

contacts)

wire

as

follows:

connect

a 390K (SG54)

resistor

be-

tween

lugs

MS

(NS)

and

MlO

(S)

and

be

certain

that

the

resistor

leads

are

passed

through

the

sold.er

lug

holes

in

direction

as

shown

in

pictorial,

otherwise

difficulty

might

be

encountered

when

trying

to

slip

the

chassis

into

the

cabinet.

To

switch

lug

Mll

fasten

a .1

condenser

{slip

spaghetti

over

the

condenser

lead)

(049)

(NS)

and

the

condenser's

outside

foil

lead

goes

to

solder

lug 1 (NS).

To

lug

M3

connect

one

lead

of a .02

condenser

(use

spaghetti)

(025)

(NS)

and

fasten

the

outside

foil

iead

to

solder

lug

1 (S).

Twist

the

leads

of

the

AF

choke

and

con-

nect

one

of

them

to

contact

Mll

(S)

and

the

other

one

to

contact

lug

M3

(S).

Connect

one

lead

of a .01

condenser

(T13)

to

contact

lug

Ml

(S)

and

the

conden'ser's

other

lead

to

solder

lug

AF2

(NS)

of

AF

"IN-OUT"

control.

From

contact

lug

MS

connect a lead

of

a .01

condenser

(S)

and

the

outside

foil

lead

goes

to

lug

AFl

(NS).

16.

AF

IN-OUT

CONTROL:

To

lug

AF3

fasten a wire

(S)

and

connect

it

to

solder

lug

2 (S).

Con-

nect a piece

of

wire

to

AF2

(S)

pass

it

through

the

nearby

grommet,

and

fasten

to

the

AF

"OUT"

phone

jack

"HOT"

lug

(Fig.

7).

To

AFl

connect a piece

of

wire

(S),

pass

it

through

the

nearest

grommet,

and

fasten

it

to

the

AF

"IN" phone

jack

"HOT"

lug

(S).

Page

5

Page 8

17.

RF

OUTPUT CONTROL:

To

lug

RFl

connect

(use

spaghetti) a lOK

resistor

lead

(Oll)

(S)

and

the

resistor's

other

lead

goes

to pin 7 of

socket

B (NS).

Connect a short

piece

of

wire

from

lug

RF2

(S)

to

lug

A7

(NS).

Fasten a piece

of

stiff

bare

wire

to

lug

RF3

(S),

slip

it

through

lug

All

(NS),

pass

the

wire

through

the

nearby

grommet,

and

then

connect

it

to

the

"GROUND"

lug

of

the

RF

"OUT"

jack

(S).

18. ATTENUATOR SWITCH:

To

lug

A.7

connect a lead

of a

620-680

resistor

(SG53)

(S)

and

the

resistor's

other

lead

fastens

to

contact

A5

(NS).

Connect

the

other

620-680

resistor

between

lugs

A5

(NS)

and

A3

(NS)

making

certain

that

the

resistor

does

not

protrude

so

that

it

will

interfere

with

slipping

the

chassis

into

the

cabinet.

Connect

a 47

ohm

resistor

(TS29)

be-

tween

solder

lugs

A5

(S)

and

All

(NS).

The

other

47

ohm

resistor

goes

between

contact

lugs

A3

(S)

and

All

(S).

Connect a length

of

wire

to

lug

A2

(S)

pass

it

through

the

nearby

grommet,

and

fasten

it

to

the

RF

"OUT"

jack's

"HOT"

lug

(S).

19.

Pass

the

line

cord

(078)

through

the

grommet

in

the

very

back

of

the

chassis,

and knot

the

cord

at a convenient

length

so

that

by

pulling

on

the

cord, a strain

will

not

be

placed

on

con-

nections

of

cord

to

equipment.

These

connections

are

as

follows: one

lead

of

the

cord

goes

to

the

left

hand

solder

lug

of

the 3 lug

terminal

strip

(S)

and

the

other

lead

connects

to

the

middle

solder

lug

of

the 3 lug

terminal

strip

(S).

THE

TURRET

COIL ASSEMBLY

AND

SUB

CHASSIS WIRING

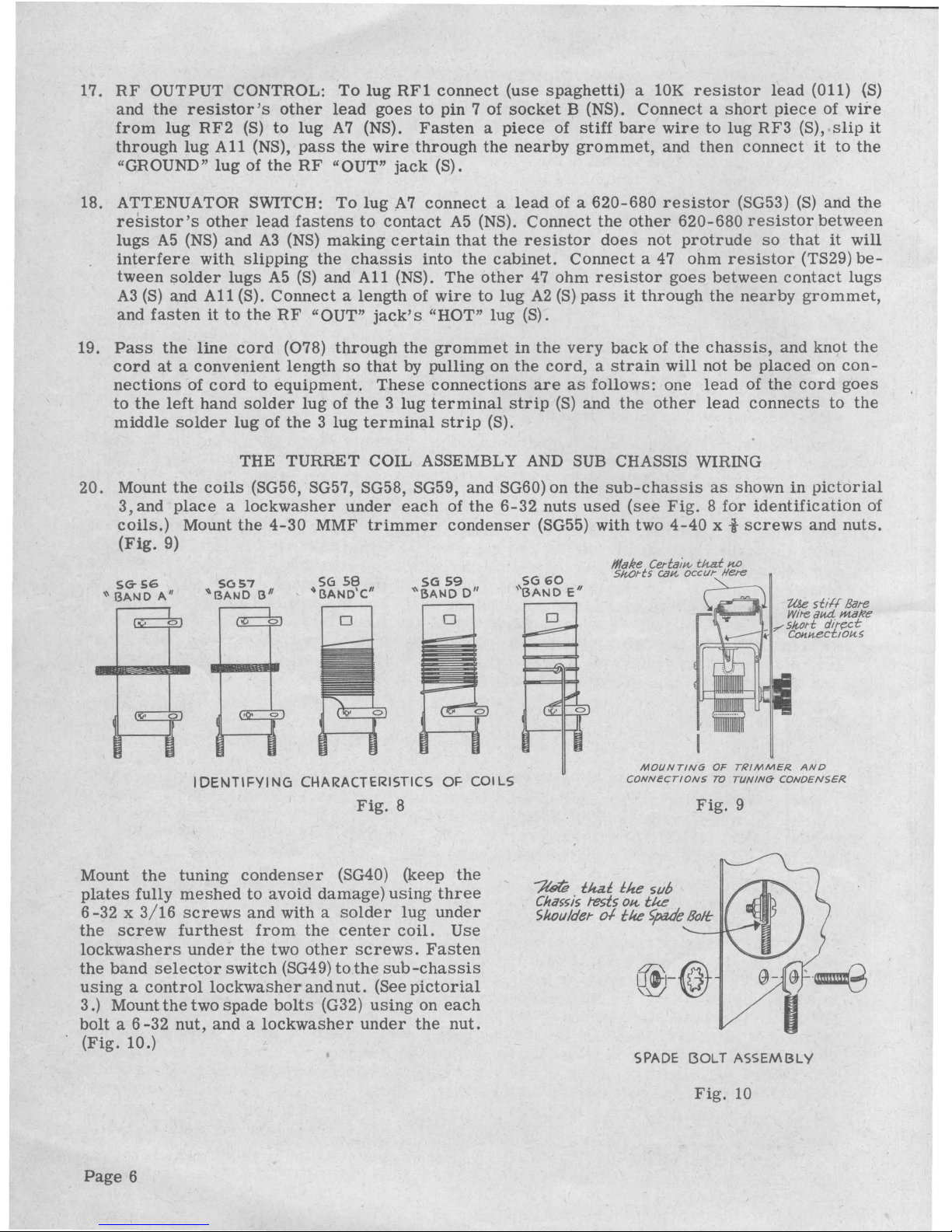

20. Mount

the

coils

(SG56, SG57, SG58, SG59,

and

SG60) on

the

sub-chassis

as

shown

in

pictorial

3, and

place a lockwasher

under

each

of

the

6-32

nuts

used

(see

Fig. 8 for

identification

of

coils.)

Mount

the

4-30

MMF

trimmer

condenser

(SG55)

with

two

4-40

x t

screws

and

nuts.

(Fig.

9)

SG-56

SCJS7

"BAND

A''

"BAND

13

11

SG

58

"BAND'C"

SG

59

''BAND

D"

IDENTIFYING

Cl-\ARACTERISTICS

OF

COILS

Fig.

8

Mount

the

tuning

condenser

(SG40) (keep

the

plates

fully

meshed

to

avoid

damage)

using

three

6-32 x 3/16

screws

and

with a

solder

lug

under

the

screw

furthest

from

the

center

coil.

Use

lockwashers

under

the

two

other

screws.

Fasten

the

band

selector

switch

(SG49)

to

the

sub-chassis

using a control

lockwasher

and

nut.

(See

pictorial

3

.)

Mount

the

two

spade

bolts

(G32)

using

on

each

bolt a 6-32

nut,

and a lockwasher

under

the

nut.

(Fig.

10.)

Page

6

SG60

''BAND

E"

D

MOUNTING

OF

TRIMMER

AND

CONNECTIONS

TO

TUNIN6

CONOEN5£R

Fig.

9

~

tkat

lite svb

Chassis

tests

OH..

tt<.e

Shoulder

o.f

tlte

~e

Bolt

(@-@

SPADE

!30LT

ASSEMBLY

Fig.

10

Page 9

NOTE:

IN

ARTICLES

21 AND 22, IN

ALL

CASES USE

STIFF

BARE

WffiE

A good way

to

prepare

the

supplied

length

of

bare

wire

for

wiring

purposes

is

to

uncoil

the

wire

and

place

one

end

in a vise,

for

instance,

and

with a pair

of

pliers,

stretch

the

wire

about

t".

The

stretching

cold-works

the

wire

so

that

it

becomes

stiffer

(therefore

better

for

wiring),

and

it

also

removes

kinks.

21.

Note

carefully

pictorial 3 showing

the

wiring

of

the

coils

to

the

selector

switch

and

the

wiring

of

the

selector

.switch.

Observe

Fig.

11

carefully

for

contact

numbering.

FRONT

Bf:IZ~DECK)

o D o

BFI

BF6

BF

BFS

15F3

BF4

REAR'

'

OECI(

-.....J

·:.~~

...

B~RS

BR3

BR4

NUMBERIN<Jr

OF

CONTACT

WGS

ON

SELECTO/l.

SWITCH

Fig.

11

----

.,,,-

Plastic

/Mi,-cal:or

it'~

Leave

clet11'ilkCe

betw~

/Hdicat~

a.Ht.I

PaH.el

METHOD

IN

WHICH

INDICATOR.

ASSEMBLY

ANO

l<NOB

MOUNT

ON

VARIABLE

TUNING

CONDENSER

SHAFT

•••••••••

°

Fig.

12.

Make

connection

from

the

selector

switch

rear

deck

contact

lug

BR12 (S)

to

the

front

deck

contact

lug

BF12

(S)

and

continue

the

wire

to

the

nearby

solder

lug

on

the

sub-chassis

(S).

SWITCH

AND

COIL

CONNECTIONS:

Bottom

lug

(if

present)

of

coil

E

leave

blank.

(The

bottom

lug

is

the

lug

nearest

the

spade

bolts.)

The

wire

tapped

about

midway

of

coil E con-

nect

to

BF5

(S).

Bottom

lug

of

coil D (S)

to

BF4

(S).

Bottom

lug

coil

C (S)

to

BF3

(S).

Bottom

lug

coil B (S)

to

BF2

(S).

Bottom

lug

coil

A (S)

to

BFl

(S).

Top

lug

coil

E (S)

to

BR5

(S).

Top

lug

coil

D (S)

to

BR4

(S).

Top

lug

~oil

C

(S)

to

BR

3 (S).

Top

lug

coil

B (S)

to

BR2 (S).

Top

lug

coil

A (S)

to

BRl

(S).

Make

certain

that

none

of

the

wires

of

above

connections

touch

or

could

touch

each

other

with

slight

jarring.

From

BR6

(NS)

connect a wire

to

the

nearest

stator

solder

connection

of

the

tuning

condenser

(S)

(see

pictorial

3).

(Stator

plates

are

those

plates

of

the

condenser

which

do

not

rotate,

that

is,

they

are

the

stationary

plates.)

See

Fig.

9

and

make

the

short

direct

connection

from

the

trimmer

condenser

(S)

to

the

nearest

stator

plate

solder

lug

(S).

Connect

from

the

trimmer

(S)

to

the

tuning

condenser

frame

(S).

Use

bare

wire

for

these

two

connections.

22.

The

sub-chassis

should

nowbe

mounted

on

the

main

chassis

by

means

of

the

spade

bolts

and

two

6-32

nuts, a lockwasher

being

placed

under

each

nut.

Connect

the

150 MMF

condenser

(AR26)

between

BR6 (S)

and

pin 6 of

tube

socket

B (S).

Make

a

short

direct

connection

from

BF6

(S)

to

pin

7 of

socket

B (S).

The

wiring

of

the

signal

generator

is

now

completed.

23.

Place

the

five

pointer

knobs

(051)

on

the

control

shafts

and

fasten

each

with

the

small

set

screw

that

is

in

the

knob.

Fully

mesh

the

variable

tuning

condenser,

and

with a set

screw

(TS55)

fasten

(do

not

tighten

down

the

screw

very

hard)

the

indicator

assembly

(SG45)

on

the

control

shaft

so

that

the

hair

line

coincides

with

the

left

end

of

the

dial

scale.

Be

sure

that

the

plastic

indicator

does

not

rub

against

the

panel

but

rather

has a little

clearance.

Fasten

knob SG44

on

the

tuning

condenser

shaft

and

leave a slight

clearance

between

the

knob

and

the

plastic

indicator.

Note FigurP. 12.

Page

7

Page 10

24.

Observe.that

the

phone plug (V41)

cap

unscrews

from

the

plug

tip

assembly.

Assemble

the

test

lead

as

shown

in

Fig.

13

checking

closely

to

see

that

the

connection

of

the

inner

conductor

goes

to

the

proper

solder

lug

of

the

phone plug.

Screw

the

cap

over

the

plug

before

attaching

the

alligator

clips

(V44).

Plug

the

6C4

tubes

into

their

sockets

and

the

generator

is

ready

for

test.

Fig.

13

CALIBRATION

DROP

OF

SOLDER

METALLIC

COATING

MAY.IM

UM

MIN

IM

UM

CAPACITANCE

CAPACITANCE

!D£NT/t=Y/N6

TRIMMER

FOR

MAX/MUNI

AND

MINIMUM

CAPACITANCE

5ETTIN65

Fig

. 14

On a

receiver,

tune

in a

strong

station

of known

frequency

between

1,200

and

1,600

Kc.

Place

the

test

lead

from

the

generator

close

to

the

antenna

of

the

receiver

and

tune

the

generator

to

approximately

the

same

frequency.

This

will

cause a whistle

in

th~

1

receiver.

The

lowest

pitch

whistle

(zero

beat)

indicates

that

the

signal

generator

and

station

are

on

the

same

fre-

quency. Now

set

the

generator's

plastic

indicator

to

read

the

same

frequency

as

the

station,

and

adjust

the

trimmer

to

again

give

zero

beat.

The

trimmer

should

be

nearly

in

the

minimum

ca-

pacity

position.

(Fig.

14).

The

calibration

will

now hold

quite

accurately

on

all

bands.

The

calibration

on

the

higher

frequency

bands

may

be

upset

by

excessively

long

leads

on .

the

tuning

assembly.

Such

variations

in

inductance

cannot

be

compensated

for

by

trimmer

adjust-

ment.

If

the

trimmer

is

in

the

minimum

capacity

position

before

zero

beat

can

be

obtained,

there

is

an

excessive

amount

of

distributed

capacity

due to

wiring

in

the

tuning

circuits.

Make

sure

all

the

"hot"

leads

(from

the

top

lug

on

the

coils

to

the

switch,

and

from

the

switch

to

the

tuning

conden-

ser

and

trimmer)

are

at

least a quarter

inch

away

from

the

metal

chassis

and

all

other

wiring.

After

calibration

is

completed,

place

the

rubber

feet

on

the

cabinet

( T32 )

(Fig.

15)

and

fasten

on

the

carrying

handle

(079)

using

two

10-24

x t

handle

screws

(030).

Slio

the

chas-

sis

into

the

cabinet

and

using

#6

xt

sheet

metal

screws

{0102)

fasten

the

panel

to

the

cabinet.

In

the

back

of

the

cabinet,

fasten

the

chassis

to

the

cabinet

using

sheet

metal

screws.

ACCURACY

Fig.

15

Any

signal

generator

is

designed

as a convenient

and

controllable

source

of

modulated

or

un-

modulated

signals.

No

signal

generator

is

designed

as a frequency

standard

·.

Expensive

stand-

ard

signal

generators

have

fairly

accurate

(3-20%)

attenuators

which

control

the

output

voltage,

and

the

calibration

accuracy

is

rarely

closer

than

1%.

The

Heathkit

generator

may

be

expected

to

fall

within

2-3% of

the

frequency

calibration,

which

is

quite

satisfactory

for

service

work

and

alignment.

In

receiver

alignment,

the

frequency

at

which

the

particular

adjustment

is

made

is

rarely

critical,

but

the

adjustment

itself

for

maximum

signal

output

from

the

receiver

is .fre

-

quently

quite

critical.

Page

8

Page 11

For

accurate

calibration

of

home

built

receivers

or

equipment

proceed

as

follows:

make a rough

calibration

with

the

signal

generator.

Then,

with a

receiver,

tune

in

WWV

(Bureau

of

Standards)

at

2. 5,

5,

or

10 Mc. Set

the

signal

generator

to a

suitable

sub

harmonic

such

as

for

instance

500

Kc, and

adjust

the

generator

for

zero

beat.

Now

the

harmonics

of

the

signal

generator

occur

very

accurately

every

500

Kc

and

these

harmonics

may

be

used

to give

accurate

calibration

points

at

500

Kc

intervals

such

as

2,500'Kc,

3,000 Kc, 3,500 Kc, 4,000 Kc,

etc.

These

known

frequency

points

can

be

marked

on

the

dial

of

the

equipment

being

calibrated.

The

object

of

the

rough

calib:t'ation

is

merely

to

furnish a means

of

identifying

for

example

the

3,000 Kc point

from

the

2,500 Kc

or

3,500 Kc

points.

For

calibration

of

higher

frequency

equipment, a choice

of a

higher

sub

harmonic

will

reduce

confusion

between

the

multitude

of

harmonics

and

will

also

insure

adequate

signal

strength.

When

checking

the

calibration

accuracy

of

the

Heathkit

Generator,

the

most

convenient

standards

of

comparison,

of

sufficient

accuracy,

are

broadcast

stations

of

knownfrequency.

Crystal

oscil-

lators

of

standard

frequencies,

when

zero

beat

against

WWV,

are

also

convenient

to

use,

if

avail-

able.

The

use

of

receiver

dial

calibrations

is

frequently

not of

sufficient

accuracy

to

warrant

consideration.

USE OF

R.F.

SIGNAL GENERATOR

This

Signal

Generator

can

be

used

to

align

radio

receivers.

It

furnishes a source

of

radio

fre-

quency

or

modulated

radio

frequency

by

means

of

signal

generator

fundamental

frequencies

be-

tween

160

Kilocycles

and

52

Megacycles

(1

Megacycle=l

,000

Kilocycles)

and

useful

calibrated

har-

monics

of

the

signal

generator

furnish

output

to

over

150

Megacycles.

Wherever

possible,

the

recommendations

of

the

manufacturer

of

the

radio

being

aligned

should

be

used.

When

this

is

not

available,

the

following

procedure

can

be followed.

Output

Indication.

With

the

new

types

of

receivers,

especially

those

using

AVC

(automatic

vol-

ume

control), a visual

means

of

indicating

resonance

is

desirable.

If

convenient,

in

all

receiver

alignments,

the A VC

should

be

disabled

during

the

process

of

alignment.

Otherwise a signal

weak

enough to

not

operate

the A VC

should

be

used

.

IF

Alignment.

Connect

the

signal

generator

shield

to

chassis

and

clip

the

shielded

wire

to

the

signal

grid

terminal

on

the

converter

tube

socket.

Set

the

signal

generator

to

the

IF

frequency

required.

RMA

standard

is

455 Kc, but

other

frequencies

like

262 and 175 Kc

are

sometimes

used.

Adjust

generator

output

for

minimum

readable

output

indication.

Adjust

IF

transformers

starting

with

the

one

nearest

the

second

detector

and

working

forward.

The

adjustment

mecha-

nism

consists

generally

of two

screws

which

operate

trimmer

condensers,

or

iron

cores

inside

the

coils.

They

may

be

located

on top,

on

the

side,

or

on

the

top

and

bottom

of

the

IF

transfor-

mer.

Turn

the

adjusting

screw

for

maximum

output,

reducing

the

signal

generator

output

if

nec-

essary

to

keep

the

output

indicator

from

going off

scale.

Oscillator

Alignment.

With

the

generator

connected

as

above,

set

the

generator

dial

to

the

high-

est

frequency

marked

on

the

receiver

dial

(1,600

or

1,720 Kc).

Set

the

receiver

dial

to

this

same

frequency.

Adjust

the

receiver

oscillator

trimmer

to

bring

in

the

signal.

An

additional

adjustment

is

often

provided

in

the

form

of a

padding

condenser

or

an

iron

core.

This

is

gen-

erally

adjusted

at

600 Kc

and

its

final

adjustment

is

made

later.

RF

Alignment.

Using

a 200 MMF

condenser

between

generator

and

antenna

post,

set

receiver

and

generator

to 1,400 Kc.

Adjust

antenna

(and

RF,

if

used)

trimmer

(frequently

located

on

the

tuning

condenser)

for

maximum

output.

Set

generator

to 600 Kc

and

"rock"

tuning

condenser

through

the

signal

while

adjusting

the

oscillator

padder

for

maximum

output

at

resonance.

For

receivers

with a

loop

antenna,

couple

the

signal

through a single

turn

loop

connected

to

the

generator

output.

Tuned

radio

frequency

receivers

are

aligned

as

shown

under

RF

Alignment.

Page

9

Page 12

The

AF "Output"

source

can

be

used

to

test

audio

amplifiers.

To

make

such

tests,

plug

the

test

lead

into

the

AF "OUT"

jack

and

throw

the

modulation

switch

to

internal

position.

Connect

the

alligator

clip

on

the

braided

lead

to

the

chassis

of

the

amplifier

under

test.

The

alligator

clip

on

the

center

conductor,

when

touched

to

the

grid

(through

a .05 MFD

condenser)

of

the

audio

stage

should

produce

an

audible

output

of

approximately

a 400

cycle

note

if

the

stage

is

ope

rat

-

ing

correctly

and

is

connected

to

a good

speaker.

OUTPUT

VOLTAGE

The

RF

signal

strength

going

into

the

output

control

depends

upon

the

strength

of

oscillation

of

the

6C4

oscillator.

In

all

variable

frequency

oscillators,

the

amplitude

will

vary

with

the

tuning

condenser

setting.

With

careful

design,

the

variation

may

be

minimized.

In

the

Heathkit

signal

generator,

the

variation

is

kept

down

to a ratio

of

about

2~

to 1 on

each

band,

except

on

band

E

where

the

L/C

(inductance

to

capacitance)

ratio

becomes

sufficiently

unfavorable

that

oscil-

lation

may

stop

with

the

tuning

condenser

nearly

fully

closed.

However,

sufficient

overlap

is

provided

to

insure

complete

frequency

coverage.

The

maximum

output

on

all

bands

is

usually

greater

than

100,000

microvolts.

CIRCUIT DESCRIPTION

Incorporated

in

the

design

are

the

following

features:

the

RF

oscillator

coils

are

prec1s10n .

wound

and

adjusted

to

calibration

before

shipment,

thereby

assuring

maximum

accuracy.

The

coils,

bandswitch,andthe

tuningcondenser

all

mount

as a turret

assembly

so

as

to

offer

the

ad-

vantage

of

short

wiring

leads

and

easy

mounting

of

parts.

To

prevent

tuning

past a desired

RF

output

signal

when

operating

the

generator,

the

tuning

con-

denser

has a vernier

drive

(3

revolutions

of

the

outside

knob

produce

~revolution

of

condenser

rotors).

This

condenser

varies

the

capacitance

in

the

Hartley

osciilator

thus

giving

the

band

cove-rage.

The

individual

bands

are

selected

by

means

of

the

bandswitch

which

connects

any

one

of

the 5 coils

acting

as

inductance

in

the

Hartley

oscillator.

The

audio

oscillator

is a Colpitts

oscillator

which

produces

approximately

a 400

cycle

note

of

good wave

form.

This

oscillator

has

the

advantage

of

being a source

of audio

output

by

merely

throwing

the

modulation

switch

to

"INT"

position

and

plugging into

the

AF

output

jack.

This

handy

source

of

AF

can

be

used

for

testing

of

audio

amplifier

stages,

etc.

When

the

modulation

switch

is

in

the

"INT"

position,

the

AF

oscillator

modulates

the

RF

output.

External

modulation

can

be

obtained

by plugging

the

external

source

into

the

AF "IN" phone

jack

on

the

panel

and

throwing

the

modulation

switch

to

"EXT"

position.

Design

is

such

that

external

modulation

of

small

signal

strength

from

a high

impedance

source

can

be

used,

and

thus

the

ver-

satility

of

the

instrument

is

increased.

The

6C4

tube

which

is

in

the

audio

oscillator

circuit

on

"INT"

modulation

position,

on

"EXT"

position

acts

as

an

audio

amplifier

to

the

external

modula-

tion.

The

RF

output

circuit

is

of low

impedance.

This

is

accomplished

by

the

use

of

cathode

coupling

to

the

output

jack.

The

level

of

RF

output

is

varied

by

means

of

the

RF

steps

switch

located

on

the

panel.

On

this

switch,

"HI"

indicates

high

RF

output

(therefore

low

attenuation).

The

middle

position

of

the

switch

produces a lower

RF

output

and,

the

maximum

C'ounterclockwise

position

gives

the

lowest

RF

output.

(Maximum

attenuation).

With low

attenuation,

the

smallest

amount

of

resistance

is

in

the

cathode

coupling

circuit

to

the

RF

output

jack.

In

the

middle

position

of

the

steps

switch, a single

pi

section

is

added and

for

highest

attenuation, a second

pi

network

is

thrown

into

the

circuit.

AC

line

input

is

connected

to a high

quality

varnish

impregnated

power

transformer.

A

ruby

red

pilot

light

on

the

front

panel

acts

as a convenient

indicator

as

_to

whether

power

is

on

or

off.

The

1

lOV

power

line

has

both

sides

bypassed

to

minimize

the

signal

feeding

back

through

the

power

lines.

The

power

supply

circuit

consists

of a

selenium

rectifier

connected

to

one winding of

the

power

transformer

and

thus

half

wave

rectification

is

produced,

the

filtering

being

accomplished

by

an

RC

filter

circuit.

A unique

design

feature

is

the

convenient

AF

"IN-OUT"

control

which

adjusts

audio input

if

ex-

ternal

modulation

is

employed

and

likewise

adjusts

the

AF output

level

when

using

the

generator

as a source

of audio

output.

'

Page

10

Page 13

IN CASE

OF

DIFFICULTY

1.

Recheck

entire

wiring.

Follow

each

lead

and

color

it

on

the

pictorial

with

colored

pencil.

Most

cases

of

difficulty

result

from

wrong

or

reversed

connections.

(Often

having a friend

check

the

wiring

will

divulge

an

error

being

consistently

overlooked.)

2.

Be

sure

that

the

output

is

connected

to

the

tip

connection

of

the

jack

and

that

the

output

cable

is

not

shorted

inside

the

phone plug.

3.

Check

the

voltages.

The

table

below

lists

voltages

from

pins

of

the

6C4's

to

chassis.

All

readings

are

DC

except

where

indieated.

These

voltages

were

measured

with

an

11

megohm

input

vacuum

tube

voltmeter.

A

normal

variation

of

±

15%

is

to

be

expected.

SOCKET

A

SOCKET B

Pin

1

60 - 80V

Pin

1

60 - 80V

Pin

2

Pin

2

•

Pin

3

0

Pin

3

0

Pin

4

4 -

6V

AC

Pin

4

4 -

6V AC

Pin

5

60 - 80V

Pin

5

60 - 80V

Pin

6

Very

slightly

negative

Pin

6

Anywhere

between

2 - 15V

negative

on

all

bands

except

E

Pin

7

1 -

1.5V

which

is

0 - lOV

negative.

Pin

7

0

Line

Voltage

105 - 125V

AC

With

regular

voltmeters,

readings

may

be

very

much

lower.

4.

If

you

are

unable

to

obtain

results,

write

the

Heath

Company,

giving

all

possible

information,

such

as

voltages

obtained,

indications

if

any,

and

all

other

helpful

information.

5.

If

desired,

your

instrument

may

be

returned

to

the

factory.

The

Heath

Company

will

inspect

it

and

put

it

into

operating

condition

for a charge

of

$3.00

plus

the

cost

of

any

new

parts

or

extra

labor

required

due

to

damaged

parts

or

improper

construction.

NOTE:

Before

returning

your

instrument

to

factory,

be

sure

to

install

all

panel

and

chassis

mounting

screws,

including

tliose

in

rear

of

cabinet.

Tighten

power

transformer

securely

to

chassis.

Attach a tag,

giving

name,

address

and

trouble

experienced,

to

your

instrument.

Pack

instrument

in a

rugged

container,

preferably

wood

using

at

least

three

inches

of

shredded

newspaper

or

excelsior

on

all

sides.

Do

not

use

folded

newspaper.

Do

not

ship

in

original

car-

ton

only.

Ship by

prepaid

express

if

possible.

Return

shipment

will

be

made

by

express

collect.

NOTE

that a carrier

cannot

be

held

liable

for

damage

in

transit

if

packing,

in

HIS

opinion

is

insufficient.

Prices

subject

to

change

without

notice.

The

Heath

Company

reserves

the

right

to

change

the

design

of

its

instruments

without

incurring

liability

for

equipment

previously

supplied.

WARRANTY

The

Heath

Company

limits

its

warranty

on

any

part

supplied

with

any

Heathkit

(except

tubes,

meters, anq

rectifiers,

where

the

original

manufacturer's

guarantee

only

applies)

to

the

re-

placement

within

three

(3)

months

of

said

part

which,

when

returned

with

prior

permission,

post-

pa

id,

was, in

the

judgment

of

the

Heath

Company,

defective

at

the

time

of

sale.

The assembler

is

urged

to

follow

the

instructions

exactly

as

provided.

The

Heath

Company

a

ssumes

no

responsibility

for

the

operation

of

the

completed

instrument, nor

liability

for

any

damages or

injuries

sustained

in

the

assembly

or

operation

of

the

device.

HEATH COMPANY

Benton

Harbor

, Mi

chigan

Page

11

Page 14

PARTS