Heathkit@ Manual

for the

FET/TRANSISTOR

TESTER

Model IT -3120

595-1989-04

• • -

'':It

TABLE OF CONTENTS

Introduction ...... . . ......................... . ...

..

Parts List . . .

Assembly Notes

Step-by-Step Assembly

Subpanel Assembly and Wiring . .

Front Panel Assembly and Wiring

Subpanel Installation

Final Wiring

Test and Adjustment

Final Assembly .........

HEATH

BENTON

.......

COMPANY

HARBOR,

. . . ... .

..

........

.....

...........

.. . ..

..

.. . ......... . ..

... . ..... . ......

. . .

......

........

... . ..... . ..

. .

..

...

. . .

.....

. .

..

. . . . . . .

.....

MICHIGAN

. .

........

...

. . .

..

. .

..... . .. . ..

......

. . .

..

..

. . .

...... . ..

. . . .

.. . ....

. . .

..

... . ....

....

. .

..

.....

. .

.......

49022

....

2

Operation

2

In

Case

....

.4

...

..

5

Specifications .. . ..........

. .

..

.8 Circuit Description

.

.19

. . 20

Chassis Photograph

13

15 Circuit Board X-Ray Views

17 Schematic

Warranty

Customer Service

......

of

Difficulty . . ......

Troubleshooting

...

(Fold-out from page) .

.........

.. ...

................ ........

.....

. . . . . . . . . . . .........

...

. .

....... . .....

. . . ... . .

.......

...

. . . .

..

. . . . .

......... . .. . ...

....

..

.. . ..

.. ..............

. .

... . ..........

Printed

..

in

. .

.....

20

29

.......

..

..

...

. . . . .

©

30

.

31

32

. .

38

. .

39

41

.

.

1976

..

.. . .......

......

. . . .

...... . .....

. .

......

. .

.....

. .

....

. .

..

..

.........

...

Inside Front Cover

..

Inside Rear Cover

Copyright

Heath Company

All Rights Reserved

the United States of America

Page

2

INTRODUCTION

The Heathkit Model IT -3120 FET /Transistor Tester

instrument for quick, accurate tests of conventional (bipolar)

transistors, diodes, FET's, SCR's, triacs. and unijunction

transistors. Gain (DC Beta), transconductance (Gm), and

leakage values are read directly

meter.

You

can

quickly

out-of-circu it. The Tester provides special

balance

coded

FET sockets

Five current

microampere and collector currents

out

leads

and easily test devices either in-circuit

in-circuit impedances.

for

in-circuit tests

for

out-of-circuit tests.

ranges

permit

on

the large easy-to-read

Use

or

the

built-in

leakage measurements

as

high

is

a quality

circuitry

either the

transistor and

as

low

as

1 ampere.

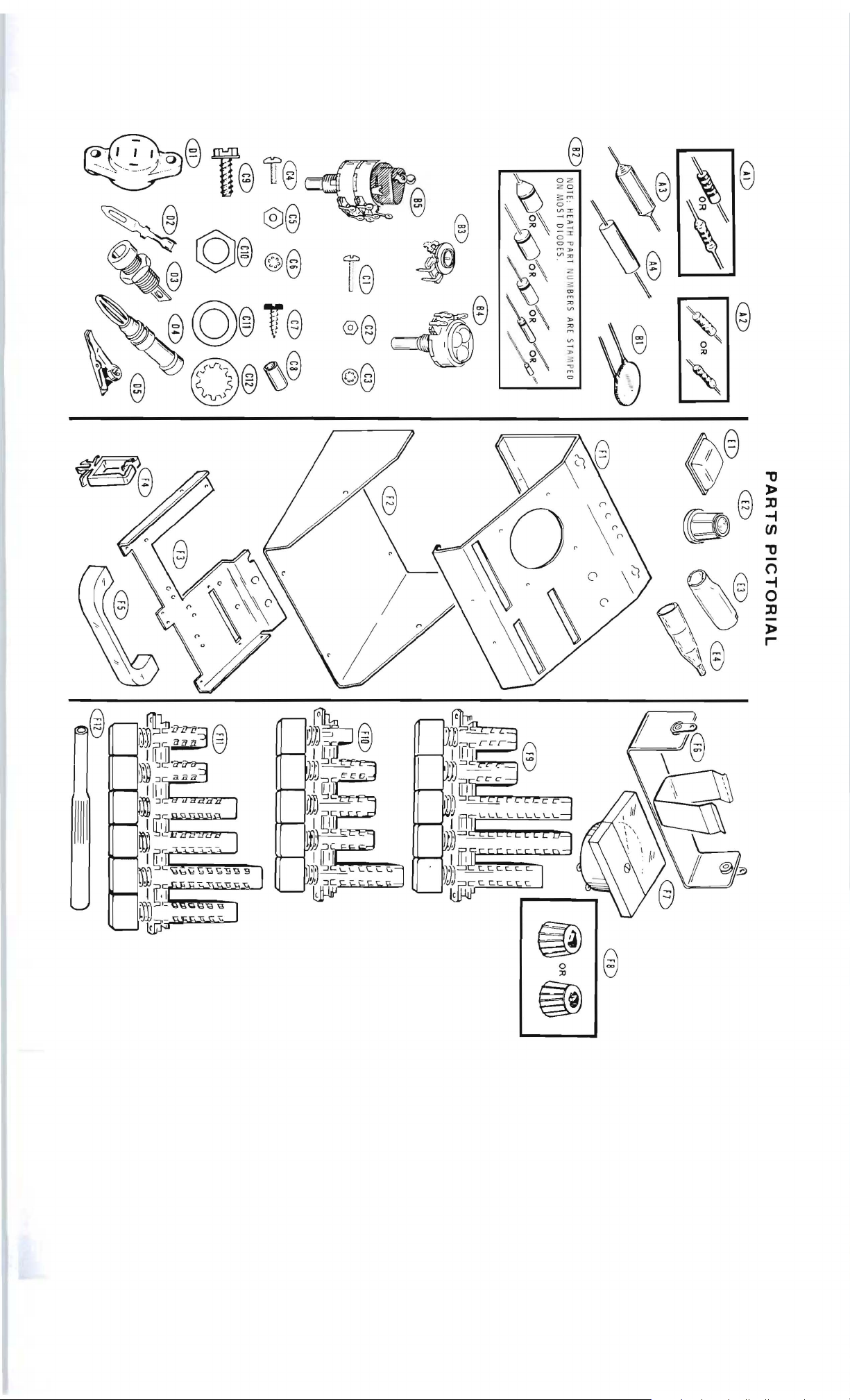

PARTS

Check

each

correspond

from

Page

Any

part

on

it

should

identified

KEY

HEATH

No. Part No.

part against

to

the numbers on the

5) .

that

is

packaged in

be

until

that

PARTS DESCRIPTION

Per

the

following

an

placed back in its envelope after

part

is

called

Kit

list. The key numbers

Parts

Pictorial

envelope

for

with a part

in a step.

(fold-out

or

to

color

as

1

number

it

is

type

Pushbutton

easy,

consistent operation.

A special battery testing

of

the

condition

Another convenience

two-color

conventional (bipolar) transistors and

FET's. Also, separate, brief operating instructions

printed on the rear panel.

Refer

to

the

wiring,

soldering,

range, mode, and

of

front

panel design, black lettering

"Kit

Builders

resistors, and

circuit

the

of

this portable instrument

Guide" for

function

provides a meter indication

self-contained power supply .

capacitors.

switches

red

lettering

information

assure

is

the

on tools,

LIST

To

order a replacement part,

furnished

"Replacement Parts" inside the rear cover

For pricing information, refer to separate "Heath Parts Price

List."

KEY

No. Part No.

with

HEATH

this

kit. If

PARTS

Per

Kit

CAPACITORS-DIODE-CONTROLS

use

the Parts Order Form

one

is

not

DESCRIPTION

available,

of

the Manual.

for

for

are

see

RESISTORS

1/2-Watt

A1

1-129

A1

H05

6-1509

A1

1/4-Watt,

A2 6-1

A2

A2

660-12

6-3600-12

6-1501-

Other

A3 2-11-2

A4 3-13-3

1%

Precision

12

3

4.7

violet-gold)

10

black-orange)

15

green-black-gold)

n,

10% (yellow-

kn,

5%

(brown-

n. 1% (brown

81

82

83

84

85

'

21-57

57-65

10-934

10-926

14-

11

2

.005

J-lF

disc capacitor

1 N4002 silicon diode

750 n control

kn

control

15

250

kn/5000

control

n (5

k)

HARDWARE

#2

166 n

2

(brown-blueblue-black)

360 n (orange-blue

black-black)

1500 n (brown-greenblack-brown)

n,

2-watt, precision

1.5

n.

3-watt,

.15

Hardware

C1

C2

C3

#4

Hardware

C4

C5

C6

250-1'75

252-51

254-7

250-52

252-2

254-9

10

10

10

2-56 x

3/8"

screw

2-

56

nut

#2

lockwasher

1/4"

8

8

8

4-40 x

4-40

#4

lockwasher

screw

nut

I§

~

fUitSf§hi9

Page

3

KEY

No.

-----

#6

Hardware

C7

C8

#10

C9

HEATH

Part No.

250-155

255-49

Hardware

250-83

PARTS DESCR IPTION

Per

Kit

---

6

3

2

#6 x 3/8"

metal screw

#6

# 1 0

self-tapping screw

sheet

spacer

x 1/2" hex head

Control Hardware

C10

C11

C12

252-7

253-10

254-4

2

2

2

Control nut

Control flat washer

Control lockwasher

SOCKETS - JACKS - PLUGS

01

434-342

434-343

02

436-11

03

'03 436-22 Black banana jack

436-24

03

03

436-29

D4 438-47

05

260-53

2

9

1

4

4

Transistor socket

Socket pin

Red banana jack

White banana jack

Green banana jack

Banana plug

Alligator clip

FEET-KNOBS-INSULATORS

E1

261-49

E2

462-362

E3

70-10 Black banana plug

E3

70-11

E3

70-12

E3

70-13

E4

73-34

8

2

4

Rubber

Knob

insulator

Red

insulator

Green banana plug

insulator

White banana plug

insulator

Rubber insulator

foot

banana plug

KEY

HEATH

No. Part No.

~-

-

--

Wire

(cent'd.l

344-70

344-71

344-72

344-73

344-74

344-75

344-77

344-78

PARTS DESCRIPTION

Per

Kit

White-black

White-brown

White-red

White-orange

White-yellow

White-green

White-violet

White-gray

MISCELLANEOUS

85-1167-1

F1

203-1412-2

F2 90-561-3

F3

204-1837

F4

207-82

F5 211-15

F6 214-76

F7

407-173

F8

455-50 2

F9

64-97

F10 64-98

F11

64-99

F12 490-5

597-260

597-308

391-34

The

following

use

in

the

completed

2 O-cell flashlight batteries (alkaline

longer

life).

5

2

1

batteries should

Kit:

Circuit board

Front panel

Cabinet shell

Subpanel

Clamp

Handle

Battery holder

Meter

Knob bushing

Mode switch

Range switch

Function switch

Nut starter

Parts Order Form

Kit Builders Guide

Blue and white label

Manual (See front cover

for part number.)

Solder

be

purchased

type

at

this time

preferred

for

for

WIRE

341-1

341-2

341-5

341·6

344-50

344-51 Brown

344·52

344-54

344-55 Greer.

344-59

Black stranded

Red

stranded

White stranded

Green stranded

Bla.::k

Red

Yellow

White

Page

4

=

= :

1.

Before

have read

the " Kit

2. Resistors

n,

or

kn,

directed otherwise.

starting

Builders

will

to

the

wiring and

Guide."

be

called

and color code.

ASSEMBLY

assemble

out

this

kit. be

soldering

by their respective value in

Use

1/2-watt resistors unless

sure

information

you

in

NOTES

3.

Capacitors

(in

11F)

SAFETY

excess

the

leads.

leads

WARNING:

so

and

We

the

ends

will

be

called

type (disc).

Avoid

suggest

that

will

you wear

not

fly

out

by their capacitance value

eye

injury

when you clip

glasses,

toward

your

or

at least clip

eyes.

off

1"

I I

2"

3"

I

4"

I

5"

I

6"

I

~

~fh*iifHfj]

Page

5

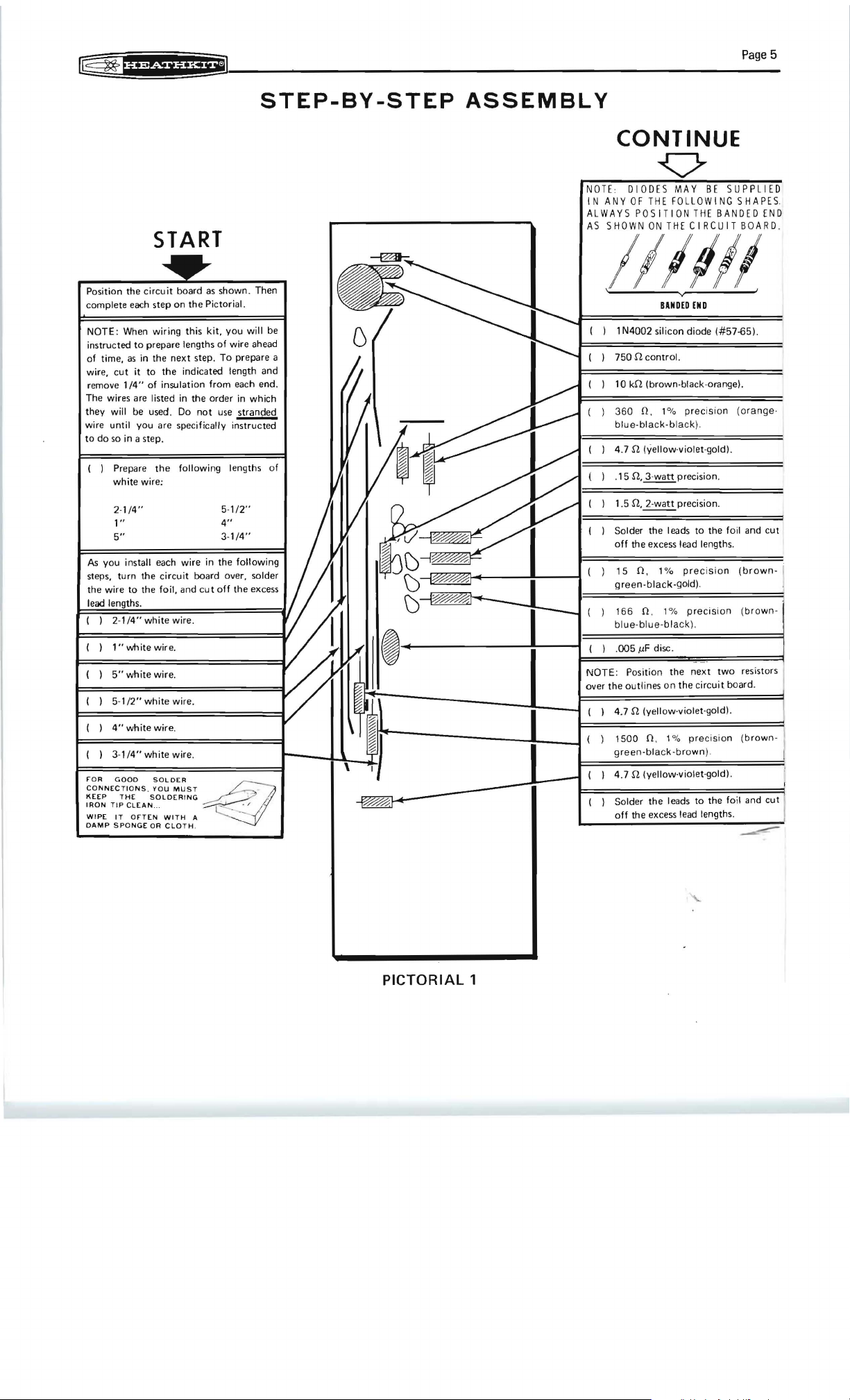

STEP-BY-STEP

START

Position

the

complete each

NOTE: When wiring this kit, you will be

instructed

of time,

wire,

remove

The wires are listed

they will be used .

wire until you are specifically instructed

to

do so

( ) Prepare

As

steps, turn

the

lead

circu it board as shown. Then

step

on

the

to

prepare lengths of wire ahead

as

in

the

cut

1/4"

in

white wire;

1/4"

2·

1"

5"

you install each wire

wire

next

it

to

the

indicated length

of insulation from each end.

in

the

Do

a step.

the

following lengths of

the

circuit board over, solder

to

the

foil, and

Pictorial.

step. To prepare a

order

not

use

in

the following

cut

off

in

~

5·1/2"

4"

3·1/4"

the

and

which

excess

ASSEMBLY

CONTINUE

NOTE

DIODES MAY

I

NAN

Y 0 F

THE

POS

ALWAYS

AS

SHOWN

Il

, v '

750 n control.

10

360

blu

4.7 n (Yellow-violet-gold).

.15

1.5

Solder the leads

off

15

( )

green-black-gold)

166

ITION

ON

lrlll

BANDED

1 N4002 silicon diode

kn

(brown-black-orange).

n.

1%

e-black-black)

n, 3-watt

n,

2-watt precision.

the

excess lead lengths.

n.

1%

n.

F 0 L

THE

CIRCUIT

precision

precision.

precision

LOW

THE

END

.

to

.

BE

the

SUPPLIED

IN

G S HAP E S.

BANDED

BOARD.

(#57-65).

(o

range

foil and

(brown-

(brown-

END

·

cut

I'

1"

white wire.

5"

white wire.

5·1/2"

white

4"

white wire.

3·1/4"

white wire.

rOR

GOOD

CONNECTIONS , YOU

K(EP

~~:

DAMP

SOLDER

THE

SOLDERING

TII~

c~~~:~.

SPONGE

OR

wire.

MUST

WITH

A -. _ _~ I

CLOTH

.

4tl

..

~"

PICTORIAL

1

over

the

outlines

on

4.7 n (yellow·violet·gold).

1500

n. 1%

green-black-brown)

4.7 n (yellow·violet-gold).

the

Solder

off

the excess lead lengths.

the

precision

leads

circuit board.

(brown-

.

to

the

foil and

cut

_pa_g_e_6

______________________________________________________________________

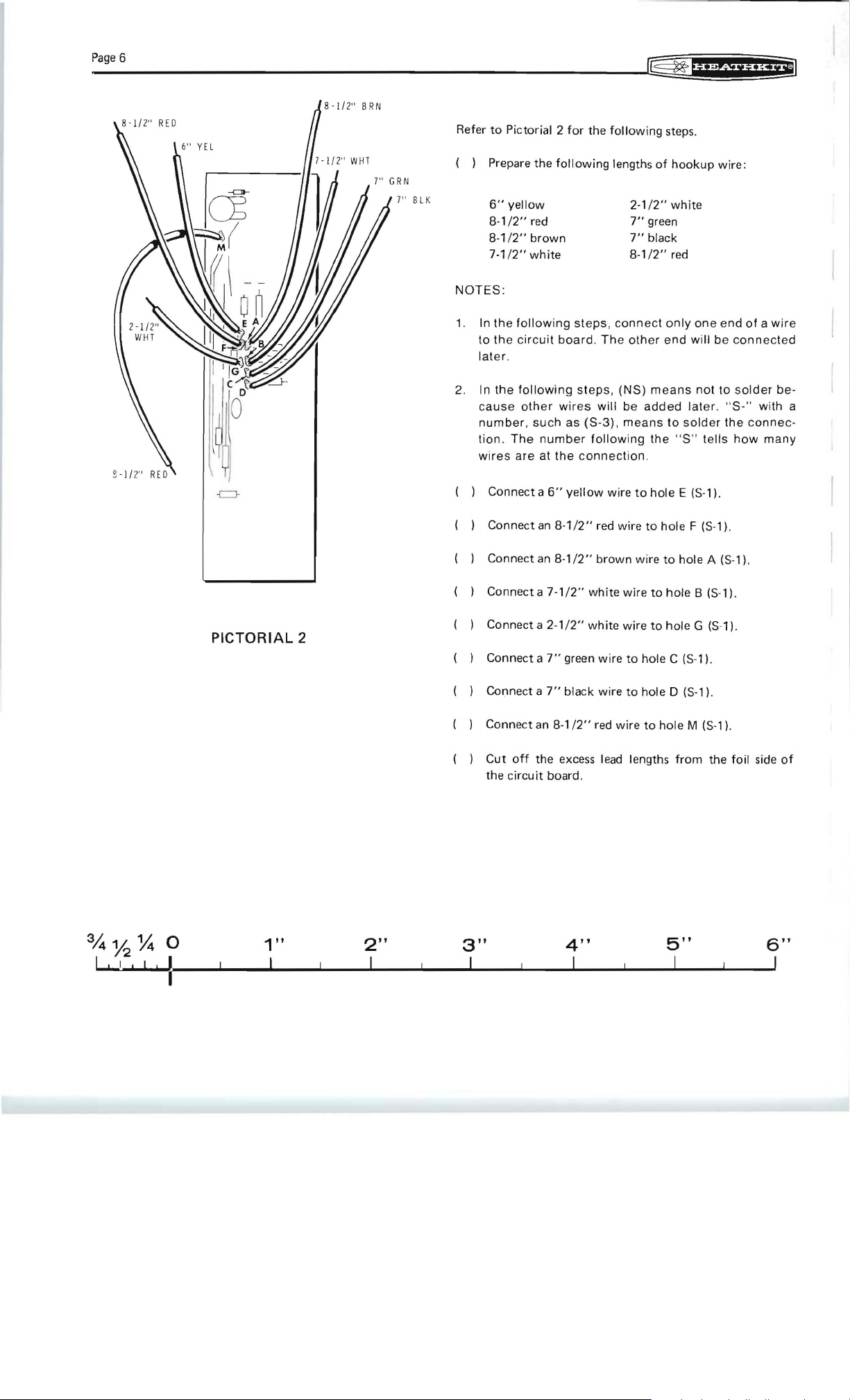

Refer

to

Pictorial 2

yellow

the

the

.

the

The

the

red

brown

white

following

circuit

following

other

such

number

are

at

( ) Prepare

6"

8-1/2"

8-1/2"

7-1/2"

NOTES:

1.

In

to

later

2. In

cause

number,

tion.

wires

for

the

following

following

steps,

board. The

steps,

wires

will

as

(S-3),

following

the

connection.

~~~fifi6Sfff{¥~

steps.

lengths

connect

2-1/2"

7"

7"

8-1/2"

other

(NS)

be

added

means

of

hookup

white

green

black

red

only

end

means

to

the

"S"

one

will

not

later.

solder

tells

wire :

end

be

connected

to

solder

"S-"

the

how

of a wire

be-

with a

connec-

many

PICTORIAL

2

Connect a

Connect

Connect

Connect a 7

Connect a

Connect a

Connect a

Connect

Cut

the

an

an

an

off

the excess lead lengths

circuit

6"

yellow

8-1/2"

8-1/2"

-1/2"

2-1/2"

7"

green

7"

black wire

8-1/2"

board.

wire

red wire

brown

white

white

wire

red

wire

to

hole E (S

to

hole

wire

to

wire

to

hole

wire

to

hole

to

hole C (S-1).

to

hole 0 (S-1).

to

hole

-1).

F (S-1).

hole A (S-1).

B (S-ll.

G (S-1).

M (S-1).

from

the foil side

of

34% % 0

I , I I I 1 I

1"

I

2"

I

3"

I

4"

I

5"

I

6"

,

///1

~

..

fU=.MiifH£§l

_____________________________________

• • • • • • • • • •

• • • • • • • • •

• • • • • • • •

• • • •

• • • • •

..

,'

w...

~

..-..

: ,-,-, .

./

-..

'.~

..

.

_ .

JIll...

~,

f18c.

..

"

,'.

-'

""'

....

..

~

J""\

.

.

..

."

.:

....

'..

~

g

P_a_

e_7

Refer

to

Pictorial 3 for

In

the

NOTE:

switches as follows:

1. Align

2. Press

3.

4.

following steps, install

board.

circuit board holes.

turn

the

each

end

Re-examine

seated against

Make sure

side

of

the

switch.

r..: : ::

YerQ~~:--_?8--

the

following steps.

the

switch over

Then

insert

the

switch against

circuit board over and solder

of

the

switch

the

switch

the

the

jumper wires on

the

circuit board

:

::

the

mode

the

holes

the

switch lugs into

the

circuit board;

to

the

foil.

to

make sure it

circuit board.

do

not

~

and

on

the

touch

cB

oaa

PICTORIAL 3

fu

nction

the

circuit

the

then

one

lug

at

is

still

component

the

lugs

of

~

~

. .

~~

Then

5.

surrounded

the

Install

at

AA. NOTE: To make sure you use

switch,

on

Install

board

Carefully

all

excess lead lengths.

NOTE:. You should have a

it

aside; it will

compare

Pictorial 3.

the

at

AB.

examine

leads

are

be

0

solder

with foil)

mode

switch

it

function switch

the

soldered

used later.

to

166

the

(#64-97)

the

circuit

to

remaining lugs (those

to

the

circuit board foil.

on

the

circuit board

the

correct

one

shown

at

(#64-99)

board foil

the

foil.

on

Then

location

the

to

cut

AA

circuit

make sure

off any

n precision resistor left. Set

Page

8

:::

o

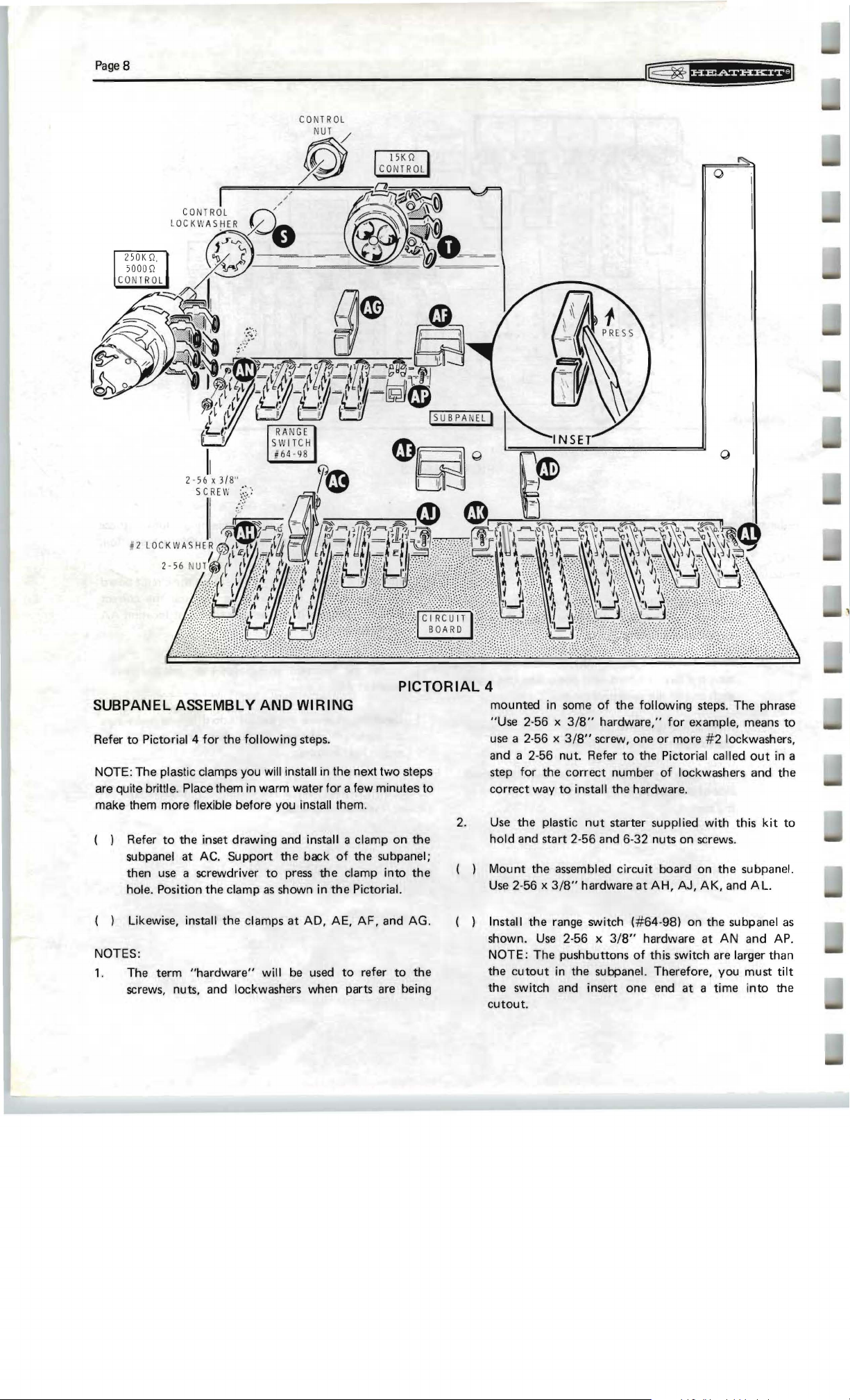

PICTORIAL 4

SUBPANEL ASSEMBLY AND WIRING

Refer

to

Pictorial 4

NOTE: The plastic clamps you will install in the next two steps

are quite brittle. Place them in warm water

make them more flexjble before you install them.

( ) Refer

subpanel at AC. Support the back

then

use

hole. Position the clamp

( ) Likewise, install the clamps

NOTES:

1. The term

screws, nuts, and lockwashers when parts are being

for

the

following

to

the inset drawing and install a clamp

a screwdriver

"hardware"

to

press

as

shown in

at

will

steps.

AD, AE,

be

used

for

a few minutes to

of

the clamp

the

to

on

the

the subpanel;

into

the

Pictorial.

AF,

and AG .

refer

to

the

of

the

mounted in some

"Use 2-56 x

use

a 2-56 x

and a 2-56 nut. Refer

step

for

correct way

2.

Use

the plastic

hold

and start 2-56 and 6-32 nuts on screws.

( )

Mount

Use

2-56 x

( ) Install the range switch

shown.

NOTE:

cutout

the

the switch and insert one end at a time

cutout.

3/8"

3/8"

screw, one

the

correct

to

install the hardware.

nut

the assembled

3/8"

hardware

Use

2-56 x

The push

buttons

in the subpanel. Therefore, you must

following

hardware,"

or

to

the Pictorial called

number

starter suppl ied

circuit

3/8"

of

board on the subpanel.

at

AH,

(#64-98)

hardware at

of

this switch are larger than

steps. The phrase

for

example, means

more

#2

lockwashers,

out

lockwashers and the

with

this

kit

AJ,

AK,

and

AL.

on the subpanel

AN

and AP.

into

to

in a

to

as

tilt

the

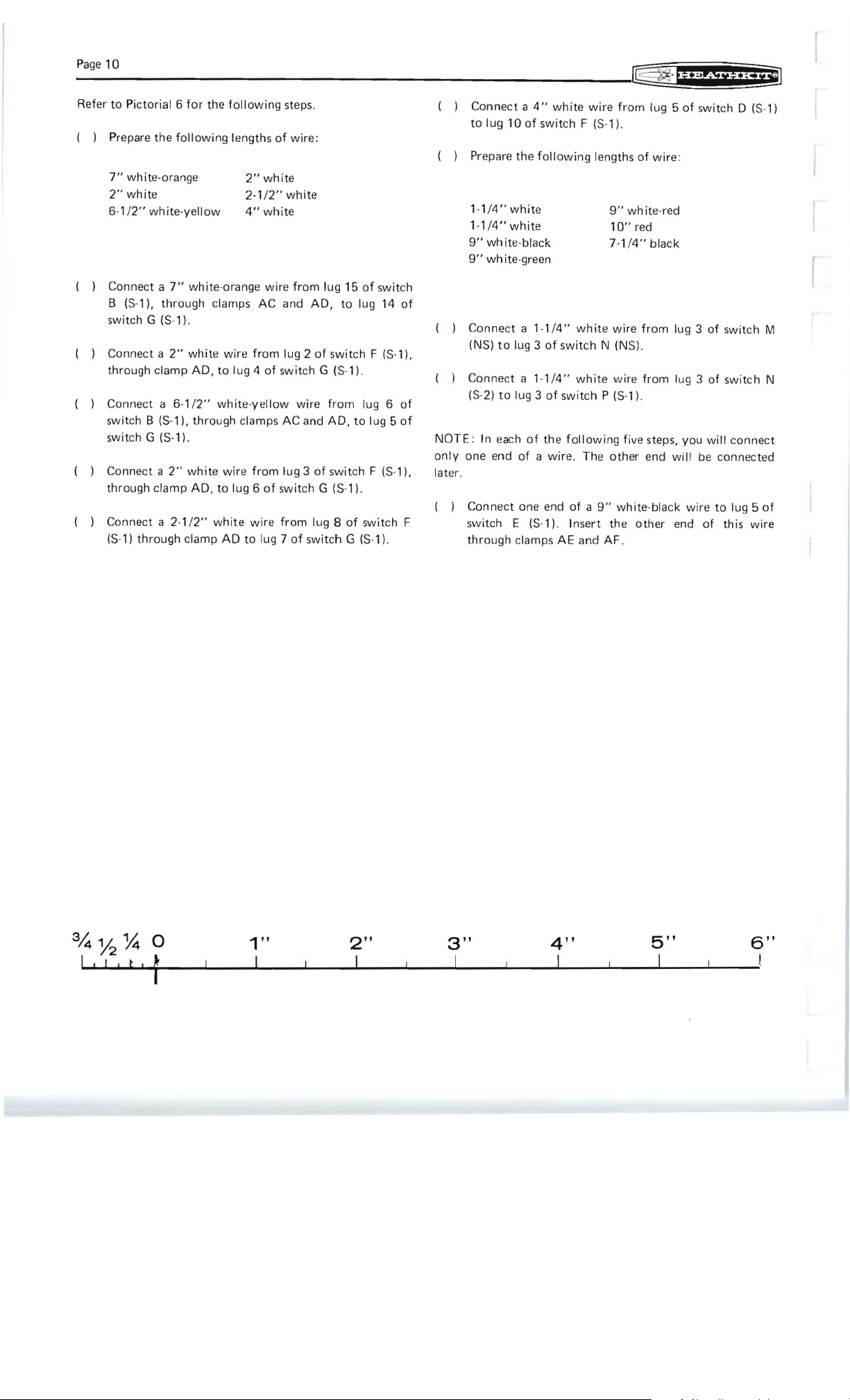

_p_ag_e__1_0

Refer

to

Prepare the

7"

2"

6-1/

_____________________________________________________________________

Pictorial 6

white-orange

white

2"

for

the

following

white-yellow

following

lengths

2"

white

2-1 /2"

4"

white

steps.

of

white

wire:

( )

Connect a 4"

to

lug

( ) Prepare

1-1/4"

1/4"white

1-

9"

white-black

9"

wh

10

of

switch F (S-1).

the

following

white

ite-green

wh

ite

wire

lengths

9"

10"

7-1 /4"

~

from

white

red

fifPhSiifi¥£iU

lug 5

of

switch D (S-

of

wire:

-red

black

1)

Connect a

B

(S

switch G (S-1).

( ) Connect a

through clamp

( ) Connect a 6-1/

switch B (S-1), through clamps

switch G (S-1).

( ) Connect a

through

Connect a 2-1/

(S-1)

-1).

through

clamp

through

7"

white-orange

2"

white

AD.

2"

2"

white wire

AD,

2"

cla

mp

wire

clamps

white

AC

wire

from

to

lug 4

of

white-yellow

from

to

lug 6

of

wire

AD

to

l

ug 7 of

from

lug 15

and AD.

lug 2

switch G (S-1).

wire

AC

lug 3

switch G (S-

from

to

of

switch F (S-1)

from

and

AD,

to

of

switch F (S-1) ,

1)

lug 8

of

switch G (S-1).

of

switch

lug 14

lug 6

lug 5

.

switch F

of

.

of

of

only one end

later .

( )

( )

Connect

(NS)

( )

Connect

(S-2)

NOTE

: In each

Connect

sw itch E (S-1).

through

to

to

lug 3

a 1-

lug 3

of

one end

clamps

a 1-1/

4"

of

switch

1/4"

of

switch P (S

of

the

following

a w ire. The

AE

white

white

of

a 9"

Insert

and

wire

N (NS).

wire

-1).

fiv

other

white

the

AF.

from

lug 3

from

lug 3

e steps,

end

will

-black wire

other

end

of

switch M

of

switch

you

will

connect

be connected

to

lug 5

of

this

N

of

wire

3,4

% % 0

~1~,~I~,~t~,~~----L---~I~--~--~I----~--~1

1"

2"

3"

____

L-

___

4"

!L-

I

5"

__~__~!____~___

6"

,

~ >fif=f§fiif{~

_______________________________________________________________________

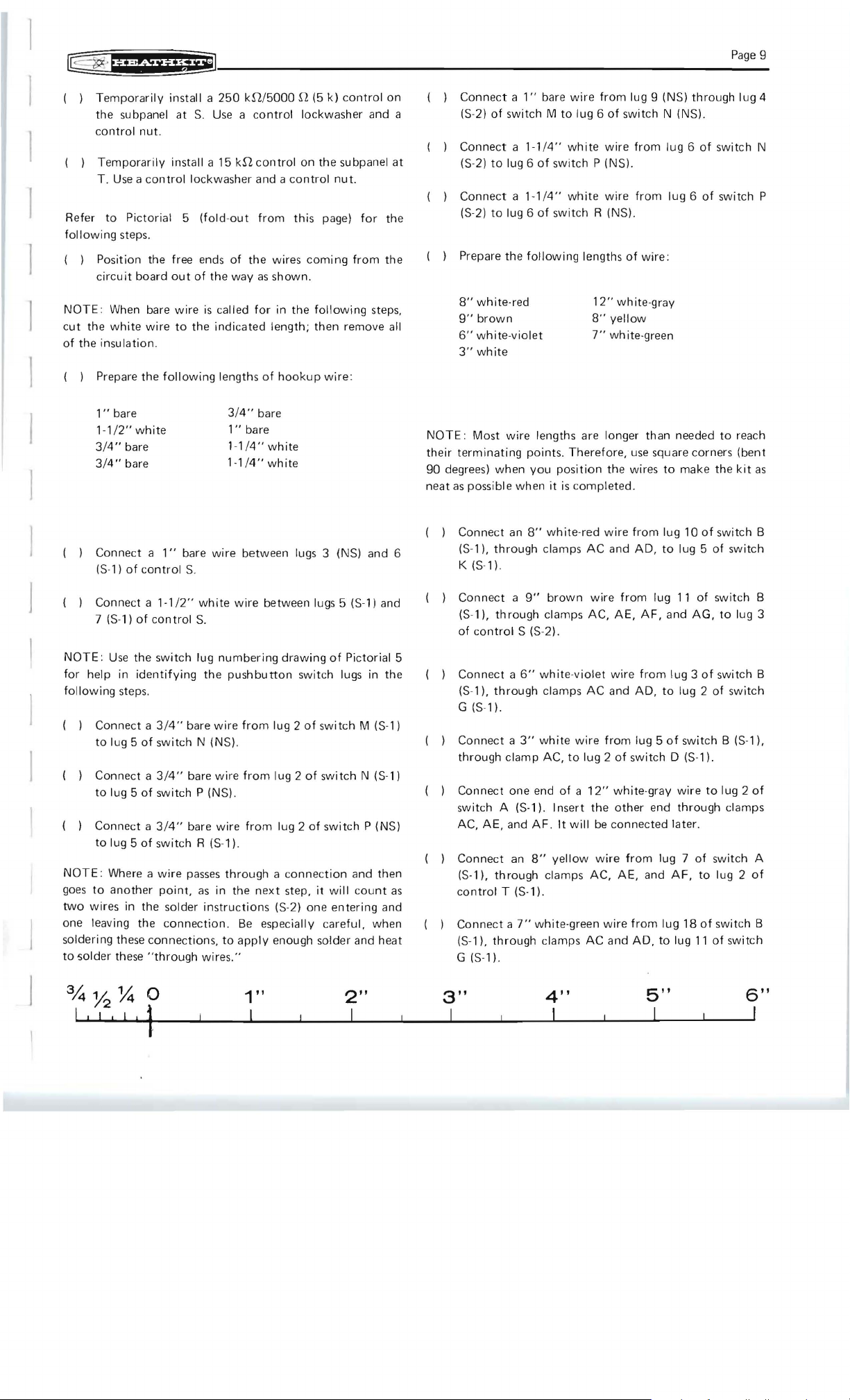

pa

_g_e_9_

( )

Temporarily

su

the

control

( )

Temporarily

T.

Use a control

to

Refer

following

( ) Position the free ends

NOTE:

cut

of

the insulation.

( ) Prepare the

Pictorial 5 (fold-out

steps.

circuit

When bare

the

white

1"

bare 3/

1-1/2"

3/4"

bare

3/4"

bare

install a

bpanel at

nut.

install a 15

board

out

wire

wire

to

following

white

S.

lockwasher and a

of

the way

is

the

250

kD/5000

Use a control

kD

control

from

of

the wires

as

shown.

called

for

in the

indicated

lengths

1"

1-1/4"

1-1/4"white

4"

bare

length;

of

bare

white

hookup

D (5

k)

control

lockwasher and a

on the subpanel

control

nut.

this

page)

coming

following

then remove all

wire

:

for

from

on

the

the

steps,

at

( )

( ) Prepare the

NOTE:

their

90 degrees)

neat

Connect a 1"

(S-2)

of

switch M to

Connect a 1-1/4"

(S-2)

to

lug 6

of

Connect a 1-1/4"

to

lug 6

(S-2)

8"

white-red

9"

brown

6"

white-violet

3"

white

Most

terminating

when

as

possible when

of

following

wire

lengths are longer than needed

points.

you

bare

switch

switch

position

it

is

wire

from

lug 6

of

white

wire

P (NS).

white

wire

R (NS).

lengths

12"

8"

yellow

7"

wh

Therefore,

the wires

completed.

lug 9 (NS)

switch

N (NS).

from

lug 6

from

lug 6 of

of

wire:

white-gray

ite-green

use

square corners (bent

to

make the

through

of

switch

switch

to

lug 4

reach

kit

as

N

P

( )

Connect a 1"

(S·l)

of

( ) Connect a

7

(S-l)

of

NOTE:

for

following

( )

( ) Connect a

( ) Connect a

NOTE

goes

two

one leaving the

soldering these connections,

to

Use

the

help in

to

wires in the solder

solder

identifying

steps.

Connect a 3/4"

to

lug 5

to

lug 5

tolug50fswitch

: Where a

another

these

bare

control

of

of

S.

1-1/2"

white

con

trol

S.

switch

"through

lug

bare

switch

N (NS).

3/4"

bare

switch P (NS).

3/4"

bare

R

wire

passes

point,

as

connection . Be

the

instructions

wires."

wire

between lugs 3 (NS) and 6

wire

between lugs 5

numbering

pushbutton

wire

wire

wire

(S-l).

through a connection

in

the

to

apply

drawing

switch lugs in the ( )

from

lug 2

of

swi tch M

from

lug 2

of

switch N (S-l)

from

lug 2

of

switch

next

step,

it

(S-2) one

especially

enough solder and heat

careful,

(S-l)

of

Pictorial 5

P (NS)

and then

will

count

entering

and

(S-l)

as

and

when

( ) Connect an

(S-l),

K

(S-l).

Connect a 9"

(S-l),

of

control

Connect

(S-l),

G

(S-l).

Connect a 3"

through

( ) Connect one end

switch A

AE,

AC,

Connect

( )

(S-1),

control T (S-l)

Connect

( )

(S-l),

G

(S-l).

8"

through

through

S (S-2).

a

6"

through

clamp

(S-l).

and

an

through

a

7"

through

white-violet

white

AF.

8"

.

white-green

clamps

white-red

clamps

brown

clamps

clamps

wire

AC,

to

lug 2

of a 12"

Insert the

It

will

yellow

clamps

wire

from

AC

and

AD,

wire

from

AC,

AE,

AF,

wire

from

AC

and

AD,

from

lug 5

of

switch D (S-l).

white-gray

other

be

connected later .

wire

from

AC,

AE,

wire

from

AC

and

AD,

lug

end

and

lug

to

lug 5

11

and

lug 3

to

lug 2

of

wire

through

lug 7

AF,

lug 18

to

lug

10

of

switch

of

switch

of

switch

AG,

to

lug 3

of

switch

of

switch

switch B (S-l),

to

lug 2

of

clamps

of

to

of

11

switch

of

lug 2

switch

switch

A

of

B

B

B

B

1"

I I

2"

3"

I

4"

I

5"

I

6"

I

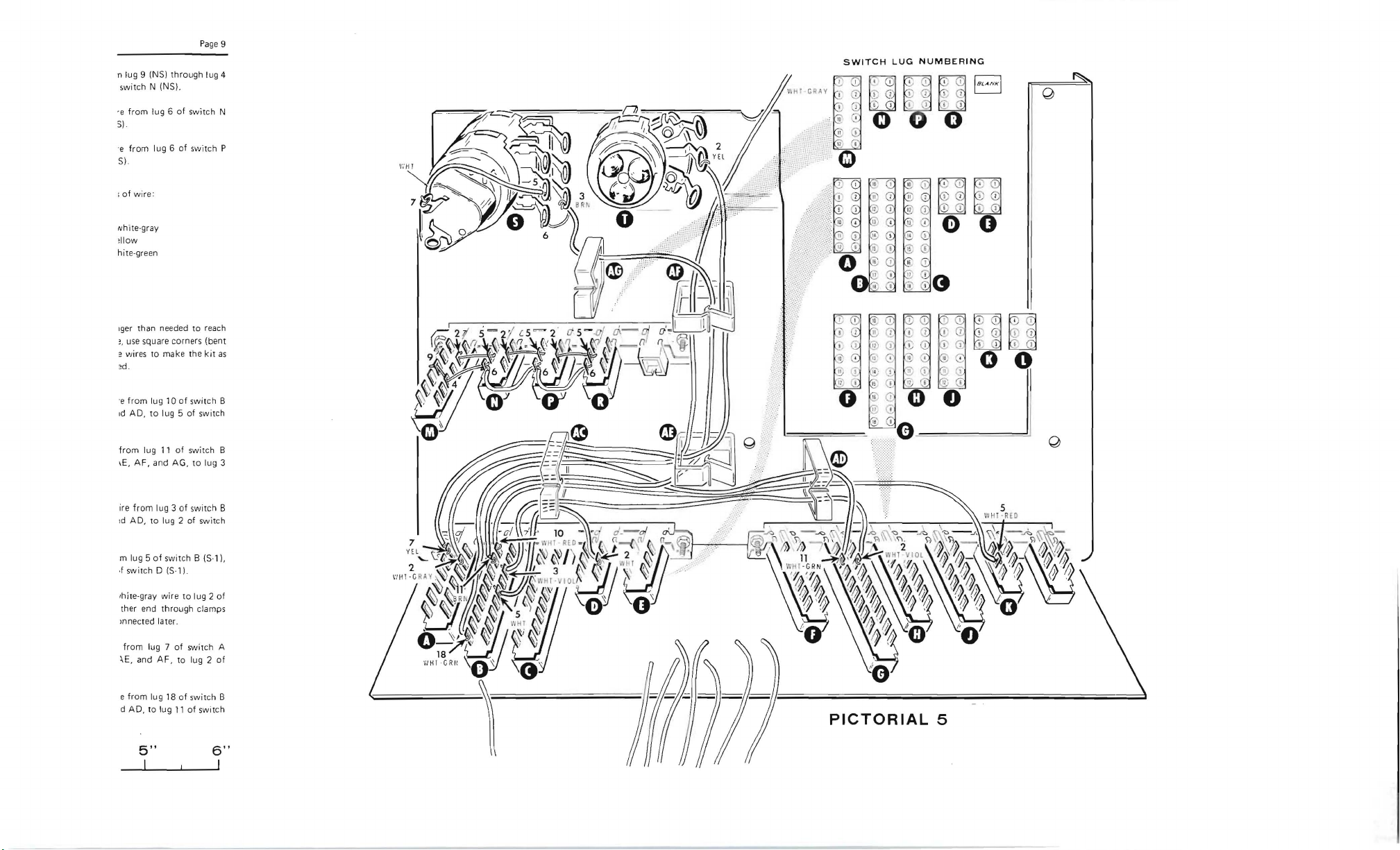

Page

n lug 9 (NS) through lug 4

,witch

N (NS).

from

lug 6

of

lug 6

switch N

of

switch P

'e

5)

-e

from

5)

;

of

wire :

Nhite·gray

,

II

ow

hite-green

9

SWITCH

LUG

NUMBERING

Q

'ger than needed

~

.

us

e square corners (bent

?

INires

to make the kit

,d.

-e

from

lug

,d

AD.

to

from

lug

AF,

IE,

ire

from

AD,

to

,d

m lug 5

sw

itch D

.f

,hi Ie-gray wire

ther end through clamps

mnected late

from

lug 7

>.E,

and

e

from

lug

dAD,

10

to

lOaf switch

lug 5 of switch

11

of

swi tch B

and AG,

to

lug 3

of swit

lug 2 of switch

of

switch B (5·11,

(5·1

J.

to

lug 2

r.

of

switch A

AF,

to

lug 2

18

of switch

lug

11

of

reach

lug 3

ch B

switch

as

B

Q

of

of

B

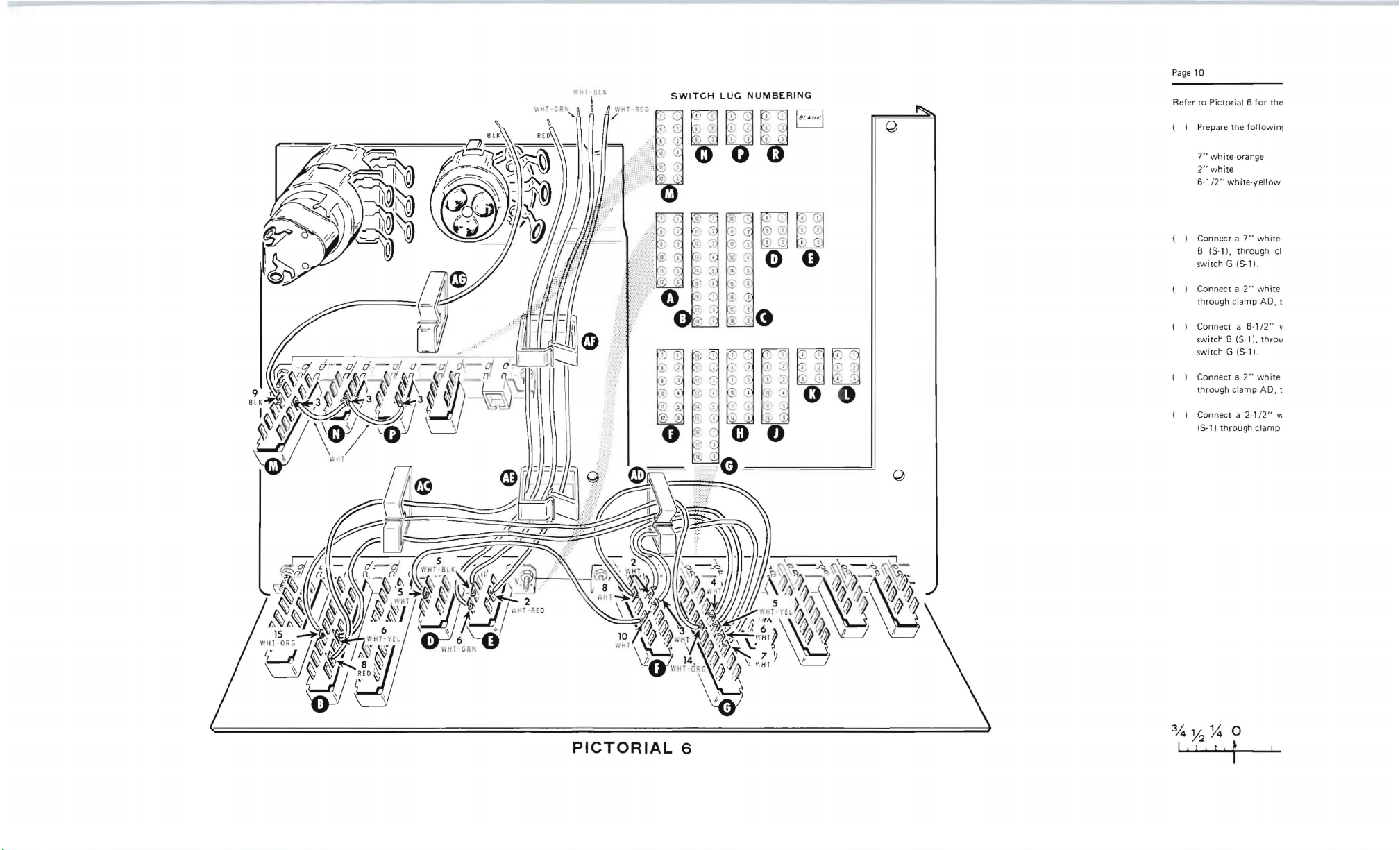

PICTORIAL

5

5"

I I

6"

wH"

-eRN

~

IIhT \

SlK

~

R n\'lhT R[D

'n

n n/ I

Pi

SWITCH

LUG

NUMBERING

Q

Page

10

Refer

to

Pictorial 6

( ) Prepare the

7"

white-orange

2"

white

6-1

/2"

white-yellow

)

(

Connect a

B

(5-1),

switch G (5-11.

)

(

Connect a

through clamp

)

(

Connect a

swil

ch

B (5-1),

switch G

( )

Connect a

through clamp

( )

Connect a

(5-1) through clamp

for

followin'

7"

white-

through

2"

white

AD,

6-1/2"

throu

(S-l).

2" while

AD,

2-1/2"

the

cl

I

v

t

11\

PICTORIAL

6

Q

%%~O

I I ! t! t !

Refer

to

Pictorial 8

Prepare a

10"

for

the

length

following

of

black solid wire.

steps.

. / 5

OPEN

IDE

Page

13

Connect one end

switch A

through clamps

( ) Route the red wire coming

through clamps AC and

( ) Connect the

hole

T

(S-l).

( ) Connect the black wire coming

hole D, through clamps AE,

switch P (S-2).

( ) Connect the green

hole

switch P (S-2).

( ) Connect the

hole B, through clamps

switch N (S·2).

( ) Connect the brown

hole

switch M

( ) Connect the red wire coming

F, through clamps

M (S-1).

( ) Connect the

hole G

( ) Refer

each

arm

This completes the assembly and

it

aside temporarily.

(S-l).

E,

through clamps

C,

through clamps

A,

through clamps

(S-l).

to

lug 3

to

the

clamp.

until

it

locks

of

a

10"

black wire

Insert

the

other end

AC

and

AD.

It

will

from

AD.

It

will

yellow

white

white

To

wire coming

AE

and

AF,

AF,

wire

coming

AE,

AF,

wire coming

AE,

AF,

wire

coming

AE,

AF,

from

AE,

AF,

and

AG,

wire coming

of

switch D

inset drawing on Pictorial 8 and close

do

to

(S-l)

.

this, push inward on

the stationary arm.

wiring

FRONT PANEL ASSEMBLY AND

Refer

to

Pictorial 9

Place a soft

( )

front

panel

( ) Locate the

for

the

following

cloth

on

your

from

becoming scratched.

front

panel and position

work

steps.

surface

to

of

be

connected later.

circuit

board hole M

be

connected later.

from

circuit

to

lug 1

from

circuit

and

AG,

to

from

circuit

and

AG,

to

from

circuit

and

AG,

to

from

circuit

and AG,

from

of

WI

it

circuit

to

lug 6

circuit

the

the

subpanel. Set

RING

to

as

shown.

to

board hole

protect

lug

11

this wire

board

of

control

board

lug 2

board

lug 5

board

lug 5

board

lug 8

of

switch

board

flexible

the

of

't

. 1

/

0'

1,

'

C~K

3

~~

;

15

~~~

70

~

Detail 9A

( )

2.

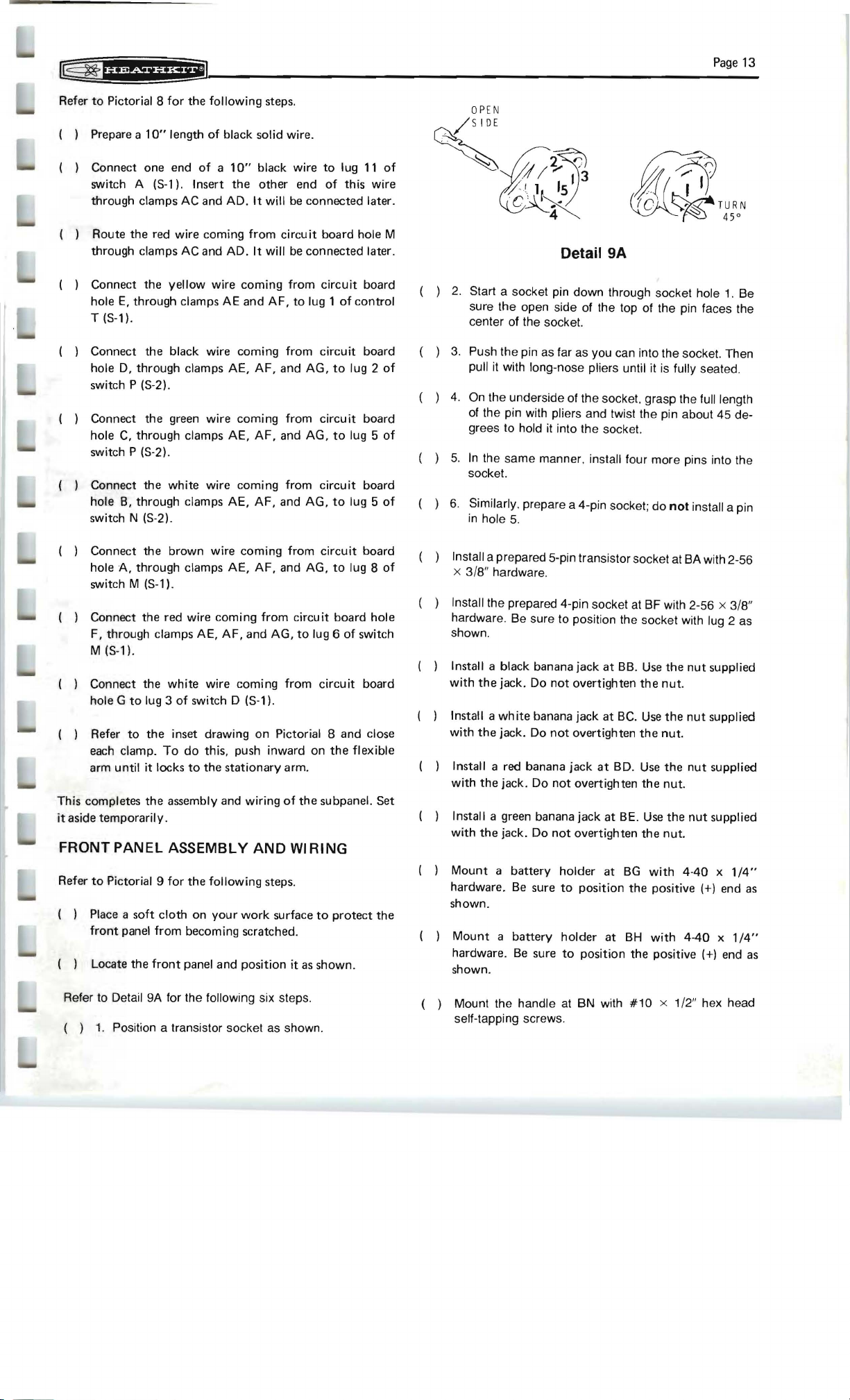

Start a socket pin down through socket hole 1. Be

sure the open side of the top of the pin faces the

center of the socket.

3.

( )

of

( ) 4. On the underside of the socket. grasp the full length

of

( ) 5.

of

( ) 6. Similarly . prepare a 4-pin socket; do

( ) Install a prepared 5-pin transistor socket at BA with 2-56

of

( ) Install the prepared 4-pin socket at BF with 2-56 x 3/8"

( ) Install a black banana jack

( ) Install a

( ) Install a red banana jack

( ) Install a green banana jack at

( )

( )

Push the pin as far as you can into the socket. Then

pull it with long-nose pliers until it is fully seated.

of the pin with pliers and twist the pin about 45 degrees to hold it into the socket.

In

the same manner. install four more pins into the

socket.

in

hole

5.

x 3/8" hardware.

hardware. Be sure to position the socket with lug 2 as

shown.

at

BB.

with

the

jack. Do

white

with

the

jack. Do

with

the jack. Do

with

the jack. Do

Mount a battery

hardware.

shown.

Mount

hardware.

shown.

a battery holder at

not

overtighten

banana jack at BC.

not

overtighten

not

overtighten

not

overtighten the nut.

holder at

Be

sure

to

position the positive (+) end

Be

sure

to

position the positive (+) end

at

BD.

BE. Use

BG

BH

not install a pin

Use

the

the

nut.

Use

the

the

nut.

Use

the

the

nut

the

with

with

'~

TURN

45°

nut

supplied

nut

supplied

nut

supplied

.

nut

supplied

4·40 x 1/4"

as

4-40 x 1/4"

as

'Refer to Detail 9A for the following six steps.

1.

( )

Position a transistor socket as shown.

( ) Mount the handle at BN with

self-tapping screws.

#10

x 1/2" hex head

Page 14

®

~

fH*iifH£il

o

PICTORIAL

o

10

.l

1"

I

2"

I I

3"

4"

I I

5"

6"

I

:;: :;:

Refer

to

Pictorial 10

( ) Prepare the

~

for

the

following

following

lengths

of

steps.

wire:

( ) Cut both

leads

Then connect this capacitor

(NS)

to

the

lug

of

of

jack

a .005

BO

IlF

disc capacitor

from

the lug

(NS).

of

Page

to

jack

15

3/4".

BC

3-1/2"

green

5"

white

5"

white

4"

black

( ) Connect a

(S-1)

tothe

( ) Remove

an

of a 5"

through lugs 2

3-1/2"

white

green

lug

of

jack

additional

1/4"

wire. Connect this end

(S-2)

and 5

socket BA. Connect the other end

BC

(NS) .

( ) Connect a

to

the lug

( ) Connect a

to

the lug

( ) Connect a

to

the lug

Connect a

to

the lug

Connect a

(S-1)

to

5"

of

jack

4"

of

jack

6"

of

jack

4"

of

jack

5-1/2"

the lug

white

wire

BC

(NS).

black wire

BB

(NS).

black wire

BB

(NS).

red wire

BO

(NS).

red wire

of

jack

6"

4"

5-1/2"

wire

BE

from

from

from

from

BO

black

red

from

(NS).

of

insulation

(S-2)

lug 1

lug 3

lug 3

lug 2

from

(NS).

red

lug 4

to

to

of

of

of

of

lug 1

of

socket B F

from

one

end

of

the wire

lug 4

(S-1)

the lug

of

jack

socket BF (S-1)

socket

BA

(S-1

socket

BF

(S-1)

socket

BF

(S-1)

of

socket BA

SUBPANEL

Refer

to

following

( )

Mount

meter

only

included

( ) Place a

INSTALLATION

Pictorial

steps.

the

with

a lockwasher and

11

(fold-out

meter on the

front

the positive (+) terminal

nut

at

with

the meter.

from

Page

panel. Position the

as

BJ.

Use

#6 spacer on meter mounting bolts BK, BL,

and BM.

of

( ) Locate the assembled subpanel and remove the control

nuts

from

controls

Sand

T.

( ) Install the assembled subpanel on the inside

front

panel .

)

( ) Install lockwashers and nuts

the hardware included

pushbutton switches do

panel.

If

necessary, reposition the

( ) Install

controls

()

Remove and discard the shorting wire from between

control

Sand

flat

T.

at

BK,

BL,

with

the meter.

not

bind against the

su

bpanel.

washers and control nuts on

the meter terminals.

17)

for

the

shown. Install

the hardware

of

the

and BM.

Be

Use

sure

front

Page 16

o

o

(

/

o

PICTORIAL

12

o

\

)

[[ ~fffWSi*fl5fj)

Page

17

FINAL

Refer

( ) Connect

Connect

WIRING

to

Pictorial 12 (on

Connect

positive (+)

Connect the black

negative

lug

of

jack

Connect the

lug

of

jack

the

Red

wire

wire

Green

White-red

White

-black

the

(-)

the

wires

to

wire

red

wire

terminal

term

i nal

black

BB (S-3) .

white

BC (S-4).

coming

the

lug

to

the

lug

to

lug 1

wire

to

Page

16)

for

coming

of

the

meter

wire

coming

of

the

meter

wire

coming

wire

coming

from

clamp

of

jack BD (S-4).

of

jack BE (S-2).

of

battery

lug 2

of

battery

the

from

(S-l).

from

from

from

AF

holder

following

clamp

clamp

(S-l).

clamp

clamp

as

follows:

BG

holder

steps.

AD

AD

AG

AG

(S-l).

BG

to

the

to

the

to

the

to

the

(S-l).

IAI

REMO

VE

lEST LE

r-

c~

-

'I

I",

I

THE

AD AII.D TW

3/

4~

;;:»

;:)

sst

I B I I

II:

BA

fl

0

~

:~~l

:

AT

r

_ '

I / PHI LLI

I SC

~/

, PLACE T

t

l

/

'1/8"

I HI E B AN A

-rr

(C

I

IN SERT

INTO

T

HEN INSTALL THE CLI P INSU

~:

''"

''lEO

PS

REWDRIVE

PHI LL IPS SCREWDRI VER ,

TOOl !. PUSH THE

11\5ULATOR SNAPS I N PLACE.

THE OTHER END

THE

ALLIGATOR

INSULA

TIO

I\ I ROM TACH END OF T

I SI T

OGUHER THE FINE WI

0 r 1/4'4

a e

S E R T THE

NANA P

AT AGAI NST THE PLUG BODY.

U

.,"

3/

4" BAR 1 0

LUG

. 8 [ I\D BOl H

IV I RE

WI

G

~

~O]

R -

HE

BANA NA PLUG ON A sr.1

1\

A P

OF

CLI P. SOLD

G

~-~

~

-

-=

- -

OR

I

~SU

IAT

ND \'11 R E

ST LEAD

ER

THE

OR

ON

OR

LU

G A

TH E TE

LAT

/.-d~

CRI M P A

~

I I" T

OT

RE [ N

SIMIL

OV

ER

UN

T IL T

LEA

D.

THE CLI

ND

RES

ALL

AR

HE

OS

.

H E

HE

P.

White·green

White-gray

This

Check

Switches C and L should

to

the switch lugs.

to

Refer

Pictorial 13

Prepare

shown

wire

completes

to

see

the

in Part A

wire

to

lug 1

to

lug 2

the

wiring

that

all

for

the

following

red test lead

of

Pictorial 13 . Then install a banana

of

battery

of

battery

of

your

connections

not

have

steps.

from

holder

holder

BH

Transistor

are soldered.

any

wires connected

red stranded

BH

(S-l).

Tester.

wire

(S-l).

as

~

t

TESTCLIP

INSULATOR

plug

with

clip

and

rubber

lead

as

shown

In a similar manner,

black,

white,

~

__

PICTORIAL

a red

insulator

insulator

in

Parts

and green test leads.

~/

~

13

on one end and an

on

the

Band C of

use

stranded

"

other

end

of

the Pictorial.

wire

and prepare the

alligator

the

test

34

Y2

I , I , I ,

X 0

I

1"

2"

3"

1

4"

1

5"

I

6"

J

Page

18

®

~

fUMeHail

PICTORIAL

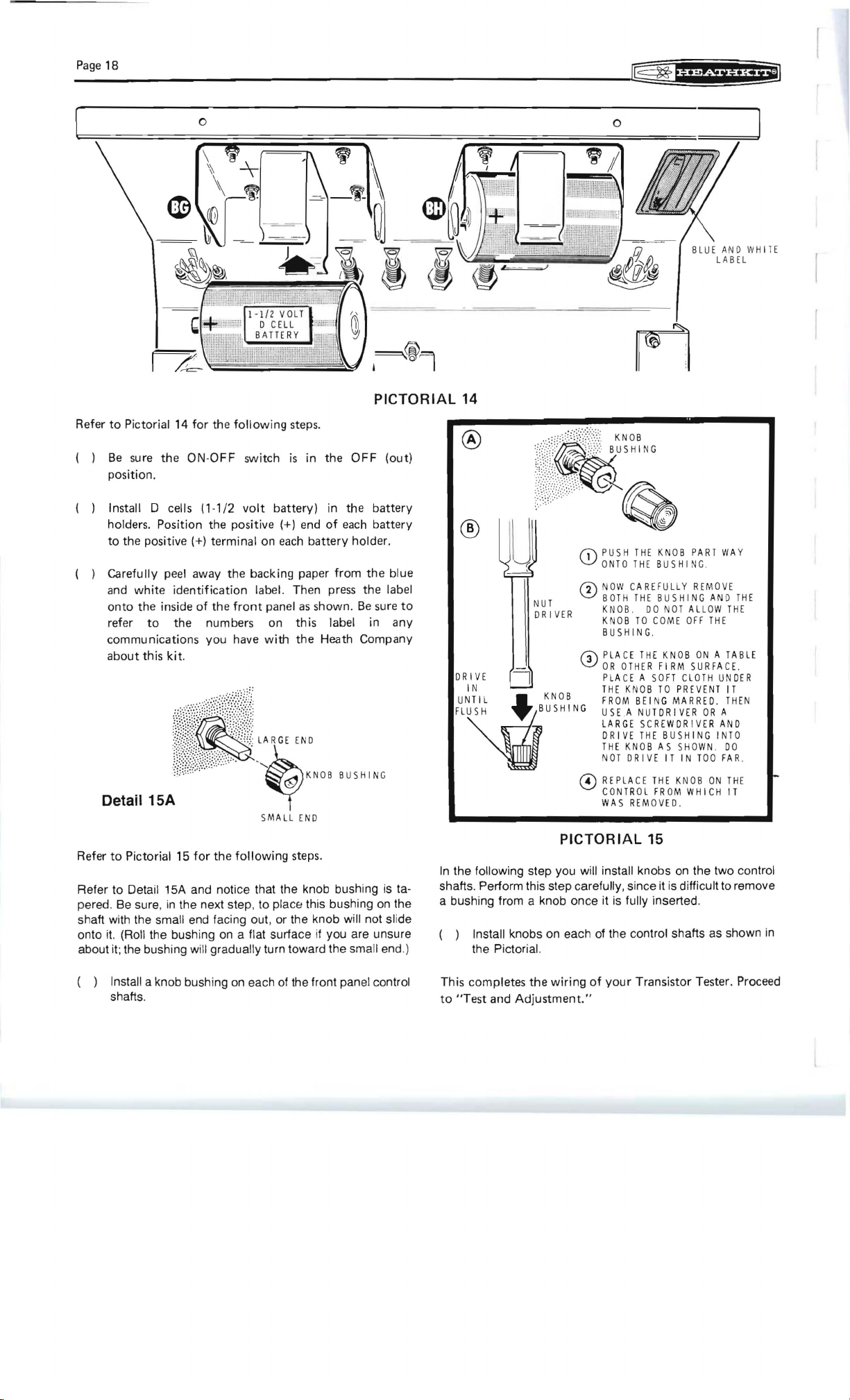

Refer

to

Pictorial

Be

( )

( ) Install D cells

( ) Carefully peel away the backing paper

sure

position.

holders. Position the positive

to

the positive (+) terminal on

and

onto

refer

communications you have

about

14

the

white

identification

the inside

to

the numbers

this

kit.

for

the

following

ON·OFF switch

(1 -1/2

of

the

volt

label. Then

front

panel

with

on

steps.

is

in the OFF (out)

battery) in the battery

(+) end

each

of

each

battery

battery

as

this label in any

the

holder.

from

the

blue

press

the label

shown.

Be

sure

Heath Company

BUSH I

NG

Detail15A

SM ALL

END

Refer

to

Pictorial 15

Refer to Detail

pered . Be sure,

shaft with the small end facing out, or the knob will not slide

it.

onto

about it; the bushing will gradually turn toward the small end.)

(Roll the bushing

for

the

following

15A

and notice that the knob bushing is ta-

in

the next step, to

on

a flat surface if you are unsure

steps.

placE!

this bushing

on

the

14

®

®

f'J\

PUS

H T

HE

KNO B PA

HI

ULLY

TH E BUSHIN

DO

NOT

ALL

ING .

CE

THE

TH

ER

.A NUTDRIVER OR A

SC

THE

KNO

LA

CE T

TR

OL

S REMOVED.

OFF

KNOB

FI

RM

50

FT

CLOTH UNDER

TO

PREVENT

REWDRI V

BUSHING INTO

B AS

SHO

HE KNOB

FR

OM

WHI

15

on

fully inserted .

to

DRI VE

I N

UNTI L

,,~

u

NUT

DR IVER

___

\V

o N

rJ'I

\V

KNOB

m

ING

o REP

ONTO THE BUS

OW CAREF

B

OTH

KNOB .

KNO B TO COME

B

USH

P

LA

OR O

PLACE A

THE KNOB

FR

OM BEI NG MARRED.

USE

RGE

LA

DRIVE

THE

NOT DRIVE I T I N T

CON

WA

PICTORIAL

In

the following step you will install knobs

shafts. Perform this step carefully, since it is difficult to remove

a bushing from a knob once it

( ) Install knobs on each of the control shafts as shown in

the Pictorial.

is

RT WAY

NG

REMOVE

G AND

THE

OW THE

THE

ON A TA BLE

SURFA CE.

I T

THEN

ER

AND

WN . DO

OO

FAR

.

ON THE

CH

IT

the two control

( ) Install a knob bushing

shafts.

on

each of the front panel control

This completes

to

"Test

and

Adjustment."

the

wiring

of

your

Transistor Tester. Proceed

1J

o

-f

o

:IJ

»

r

...

...

--

o

()

---

FINAL

WIRING

Refer

to

Pictorial 12 (on

( ) Connect the red wire

( ) Connect

Connect the

Refer

(+

positive

Connect the black

ve

(-)

negati

the

of

jack BB (5-3).

lug

th

Connect

of

jack BC 15-4).

lug

wi

res coming

Red

wire

wire

Green

White-red

White·black wire to lug 2

White·green wire

White-gray

Thi

s completes

to

Check

Switches C and L should n

to

the switch lugs.

to

Pictorial

Page

) terminal

wir

terminal of the meter (5-1).

black wire coming

e white

wire

to

th e lug

of

to

the lug

wire

to lug 1

to

wire

to

lug 2

the

see

that

13 for

th e fol

16)

for

the

following

steps.

coming

of

from

lug 1

wiring

from clamp

the meter (5-1) .

e coming from clamp

fro

coming

from

clamp

AF

jack BD (5-4) .

of

jack

BE

(5·2).

of

batlery

holder

of

battery

of

battery

of

banery

of your Transist or Tester.

all connections are soldered .

Ot

have any wires connected

lowing

steps.

AD

AD

m clamp AG

clamp AG

as

follows:

BG

holder

holder

holder

BH (5· 1).

(5-1

BG

BH (5·1).

to

to

to

to

).

(5·1).

the

the

the

the

,AI

RfMOv[

Ul£ I " ".

'.H

ATlO""

IISllE~ D

A" O

r-lfL.j 0

1\'/1>

tRO·\' [ACH

,

I

OC.[IHI~

IHE

fiNE ViIRE

ii'

"'==" aI'

,8,

-

' I

I

I",

I

G

hi='

O--

..

I /

I ,

)\\

~

I

/,

.

\

V

ICI

~

T

EllellP

1

~ ,'5

plug

clip

lead

I';;[~IIHI

SA"A.."

flAT

I \ S

UlAIO

SOt

li l\'

,A

flU

I', IUI AI!')

PHIllI

r.E'.',

V", VIP

/ P

P.H lllIP\

11:

~

lOOl

THE

I . ;)UlATOP. S·,AP').

I

NSfRI

lHE

INt O IHE

ALLI G

t

HE

N It

<SIAll

~

/"

_

---

_~,

~

1

UlAlO

R --/~

with

a red insulator on one end and

and rubber insulator on the other end of the test

as

shown

;Id'

."ID

B[\~

PLU

THE

1~,SUU

tutJ

A 'jD

II

TH[

P S

OlotR

NSULAT

-:'A--

13

">I

BOIH ,'

BOI)

G 0 ') A S MAlL

'O R 51

dOR

I,'

.I~{

~

P'

. AC(

I[ST

lEAD

IHE

OR

01,

CR:II\'P AND

S

OL DER

..

the Pictorial.

P,uG

AGA

I'" I IHI PII!G

::?

t.J

L!

R!

o~

PS

~

l;(E

IHI eA ',A:;A

ICRHD.RI'iiR

Pv')H

SA ,,;1

It.

P

OIHER

INO

Of

AT

OR CLI

IH! CLI P I

G

-

~

~

~

PICTORIAL

in

Parts

Band C of

",'~D

Of

--1

1=

RE

1',10 I

IIRE

Y.

Mil

DV{R

U'

.1

LEAD.

IH£

an

Page

IHi

S.

r-

HE

fl·,

D\

A

Il1H(

CliP.

alligator

17

Q_

~

[£

~

.~~

~

t

~

~

)

,\

-=-,-JiIh

-

~-

ii

0 m

_

r7J

,-,--

i

~~

-

·

'"

~-===--i

~

~

Cf-:J

~

PO~illIV[

IER

II

1'

r~

\! ..

I

....... ~ 0 ")f1

1'1(.

®

m

. AL

[ K

~

~

II

..

..

~

:.

.

)!)

.

~

( ) Prepare the red t

shown in Part A

%

Y2 ~ 0

I ! I I ! I II

es

t lead

from

1"

red stranded

2"

of

Pictorial 13. Then install a banana

wire

imilar

manner,

use

as

In a s

black, white, and green test lead

stranded wire and prepare the

s.

- - - - -

~

--

®

o 0

3"

I I I I

4"

5"

~Q:: -~

6"

PICTORIAL

: .

11

;;:J7

Page

19

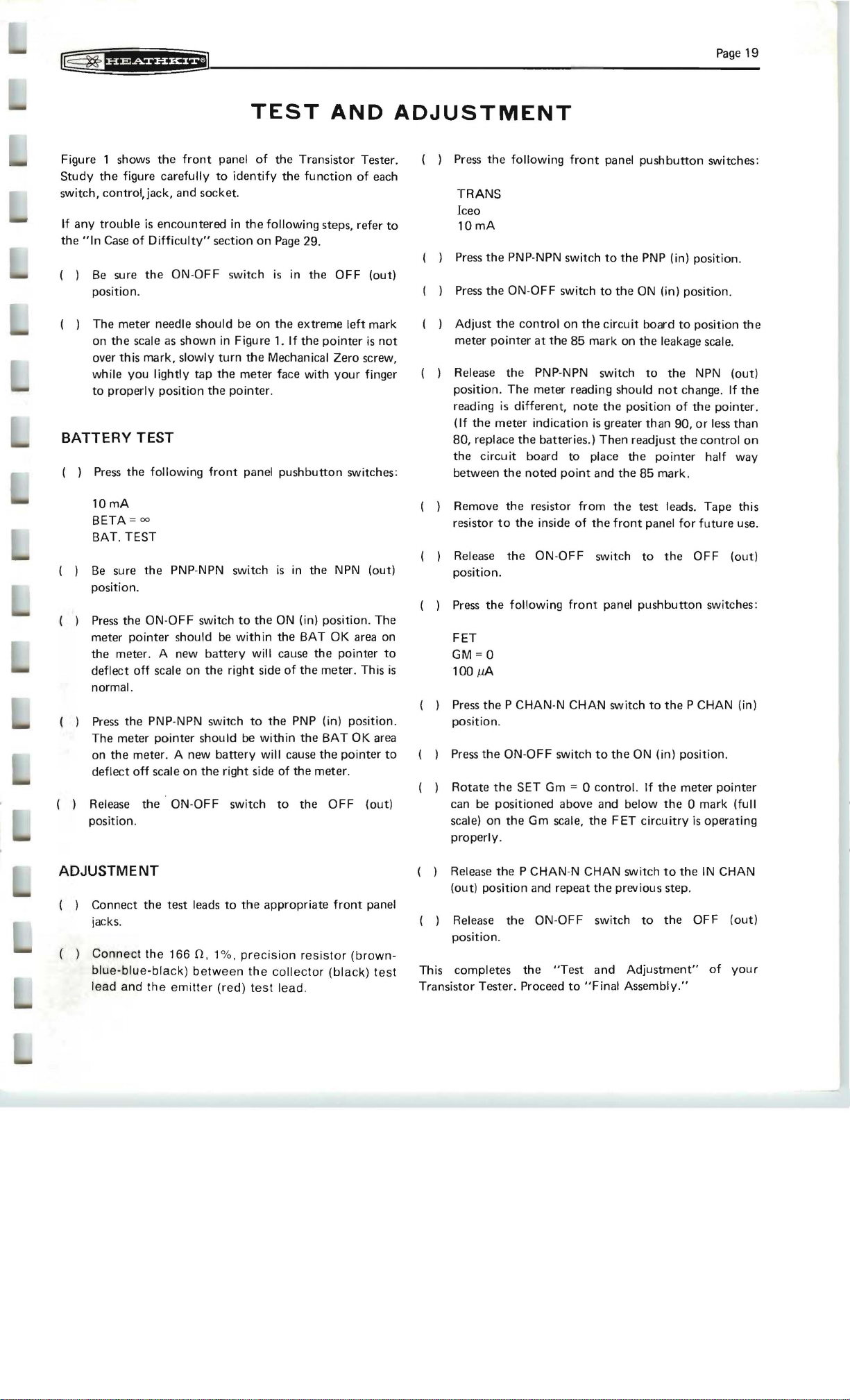

Figure 1 shows

Study

the

switch, control, jack,

If

any

trouble

the

"In

Case

Be

( )

( )

sure

position.

The

on

the

over

while

to

properly

the

figure carefully

is

encountered

of

Difficulty"

the ON-

meter

needle

scale as

this

mark,

you

lightly

position

BATTERY TEST

( ) Press

( )

( ) Press

( ) Press

( ) Release

the

following

10mA

BETA =

BAT. TEST

Be

position.

meter

the

deflect off scale

normal.

The

on

deflect

position.

00

sure

the

the

ON-OFF switch

pointer

meter. A new

the

PNP-NPN switch

meter

pointer

the

meter

off

scale

the

front

panel

to

identify

and

socket.

in

the

section

OFF

switch

should

shown

slowly

tap

PNP-NPN switch

should be

on

. A new

on

ON-OFF switch

in Figure

turn

the

the

front

battery

the

right side

should

battery

the

right side

be

the

meter

pointer.

panel

to

within

be

TEST

of

the

the

following steps, refer

on

Page 29.

is

on

the

1_

If

Mechanical Zero screw,

face with

pushbutton

is

the

ON

the

will cause

of

to

the

within

will cause

of

to

AND

Transistor Tester.

function

in

the

OFF

extreme

the

in

(in) position.

BAT OK area on

the

PNP (in) position.

the

the

the

left mark

pointer

your

switches:

the

NPN

the

pointer

meter. This

BAT

the

pointer

meter.

OFF

of

OK

ADJUSTMENT

( ) Press

each

TRANS

to

(out)

is

not

finger

(out)

The

to

area

to

(out)

is

Iceo

10mA

Press

the

the

Press

( ) Adjust

meter

( ) Release

position.

reading

(If

the

80,

replace

the

circu it board

between

( ) Remove

resistor

Release

position.

( ) Press

( ) Press

the

FET

GM

= 0

100l1A

the

position.

Press

the

Rotate

can be

scale)

on

properly

the

following

PNP-NPN switch

ON-OFF switch

the

control

pointer

the

The

is

different,

meter

the

the

noted

the

to

the

the

following

P CHAN-N CHAN switch

ON-OFF switch

the

SET

positioned

the

.

front

to

on

the

at

the

85

mark on

PNP-NPN switch

meter

reading should

note

indication

batteries

resistor from

inside

ON-OFF switch

Gm = 0

Gm

to

point

front

above

scale,

.)

of

the

is

Then

place

and

the

to

control.

and

panel

pushbutton

to

the

PNP (in) position.

the

ON

circuit

board

the

to

the

position

greater

than

readjust

the

the

85

the

test leads.

front

panel

to

panel

pushbutton

to

the

ON

If

below

F ET

circuitry

switches:

(in) position.

to

position

leakage scale.

the

NPN

not

change.

of

the

pointer.

90,

or

less

the

control

pointer

mark.

the

(in) position.

the

the

for

future

OFF

the

P CHAN (in)

meter

0 mark (full

is

half way

Tape

switches:

pointer

operating

the

(out)

If

the

than

on

this

use.

(out)

ADJUSTMENT

( )

Connect

jacks.

Connect

( )

blue-blue-black)

lead

and

the

the

the

test

leads

166.n,

between

emitter

to

1%,

(red)

the

appropriate

preciSion

the

collector

test

lead.

front

resistor

(black)

panel

(brown-

test

( )

Release

(out) position and

( ) Release

position.

This

Transistor Tester. Proceed

the

completes

P CHAN-N CHAN switch

the ON-

the

repeat

OFF

"Test

to

the

previous step.

switch

and

"Final

to

the

to

the

Adjustment"

Assembly."

IN

OFF

of

CHAN

(out)

your

Page

20

GENERAL

The

Transistor Tester measures

characteristics

characteristics

characteristics

same type. These

characteristics

"good"

control

tested.

Refer

controls, switches,

Transistors may

the

Transistor Tester

the

test leads,

(C),

the

to

the

test

FET's

transistors),

red

test

gate

(G)

connect

INFORMATION

of

transistors

of

that

of a transistor

rating. Also,

·led rectifiers,

to

Figure 1

either

connect

white

test

emitter

lead

of

the

(E)

(field

connect

to

the

the

green

will even vary between transistors

unijunction

and

for

and

or

lead

of

effect

the

source (S),

device.

test

PICTORIAL

and

the

F ET's (field

tests

give you actual

and

transistors, diodes, silicon

triode

AC switches can be easily

the

locations

connections

be plugged

the

test

leads may be used'.

the

black

to

the

base (B),

the

transistor

transistors)

black

test

and

If

the

lead

to

the

second gate (G).

FINAL

16

the

DC

Gm

(transconductance)

effect

not

merely a

and

descriptions

on

the

Tester

into

the

test

test

lead

to

and

the

being

tested.

or

UJT's

lead

to

the

the

white

test

transistor has

ASSEMBLY

Refer

~"ii@

#6 , j 18

S

HEET

i.1

E1

AL

SC

REW

This

Proceed

OPERATION

When devices are tested

difficult

it

beta

(gain)

transistors),

of

operating

"bad"

of

.

sockets

To

the

collector

red

test

When

(unijunction

drain

(0),

lead

to

two

gates,

the

the

use

I'ead

you

the

the

leads are

can usually

component

device.

on

or

this will

components. In

piece

the

wire.

The

black lettering catls

on

transistors are

controls

performing

is

pressed in, refer

pressed in, refer

Proceed

perform

the

Tester has

to

Pictorial 16 for

the

Install

3/8"

sheet

Remove

install them on

front

panel as

completes

to

the

to

connect

either

connect

that

To

determine

the

circuit

let

you

of

wire

to

lead

of

the

front

panel lettering

relating

any

to

the

. Remember, it

batteries

not

the

following steps.

cabinet

metal screws.

the

the

"Operation"

too

is

board, shine a light

trace

cases

the

device;

tested,

of

to

before

been used for

shell on

backing paper

the

cabinet

shown.

assembly

section.

in

·circuit, you may

the

test

leads

short

or

inaccessible.

each

test

connected

where

each foil from

where

printed circuit foil

out

to

the

to

the

the

particular test

you

to

you can

this

then

connect

is

in

two

the

controls

while

the

F ET testing. Remember, when

following tests,

black lettering; if

red Ilettering.

is

a good idea

use

the

some

the

front

panel

from

the

rubber

shell

and

the

of

your

Transistor Tester.

sometimes

to

the

device because its

In

such cases, you

lead

to

the

lead

the

desired terminal on

connect

through

the

is

impractical, solder a

the

colors, black

used primarily

red lettering calls

if

procedure

Tester, especially if

time.

the

the

circuit

device

that

is

connected

test

the

TRANS

the

FET

you wish

to

occasionally

rear

of

to

lead

and

with

feet

another

test

the

to

red.

out

switch

#6

and

of

the

find

the

leads

board;

other

short

to

this

The

when

the

switch

is

to

test

the

x

Some transistors have a

shield. Leave this lead

(bend it

transistor

CAUTION: Never

device, while power

and/or

the

out

test

circuit

of

the

way

socket).

connect

could be damaged.

fourth

disconnected

when

you plug transistors

the

is

applied

lead

connected

in

Transistor Tester,

to

the

the

test

circuit.

to

an internal

procedure

into

the

or

test

The

Tester

a

BATTERY

Test

the

batteries

Release

1.

position

TEST

as follows:

the

NPN-PNP switch

to

check

one

battery.

to

the

NPN (out)

Page

The

possibl e

fo r eac

c

ol

CLASS

2:

fol

umn

NPN

COLLEC TOR

B

ASl

~

EMI

0

SILICON

GERMANIUM

ANO

DE

~~

o

TRANSISTORS

S

AS:

E TTER

CATHO

DIODES

I

DE

A

~

N~D~C~

PNP

COLL

EM I H

0

ZENER

ECTOR

E +

ER

KO

DE

C A

TCE

~+

N

~+

F

M

I

TT

~_

N

CHANNEL

DR

AIN

CATCE

~

S -

S

OUR

CE

G

UJT

CHANNEL

SA

S E 2

E\~ ITT

Et

BAS

E 1

~

o

Figure

(Repeat)

3

FET

DR

A I N

C A T

+

S -

SOURCE SOURCE

0

P

CHANNEL

(u

nco

mm on)

BASE

S +

BASE

cE

~-

2

0

GA

o

P

CHANNEL

C

AT~

~-

DRAIN

SOURC E

D

RA

I N

S +

0

SCR

ANODE

TE

G GERI G

C

~

CATHODE

o

TRIAC

IA

GAT

~

ITRI C-

C

(C

S

+

OT

ODEI

C

OMMO

Ai D

SIGNAL

INTERM

POWER

POWER

N

EI

E[

The

bet

X10, C,

m

ost

01

The cha

urrent

c

cu rre

nt

collec

to

case a

me

ter in

ni

Page

22

~UOJ§i*BM

I

The

following

possible applications, and the

for

each

column when you select the

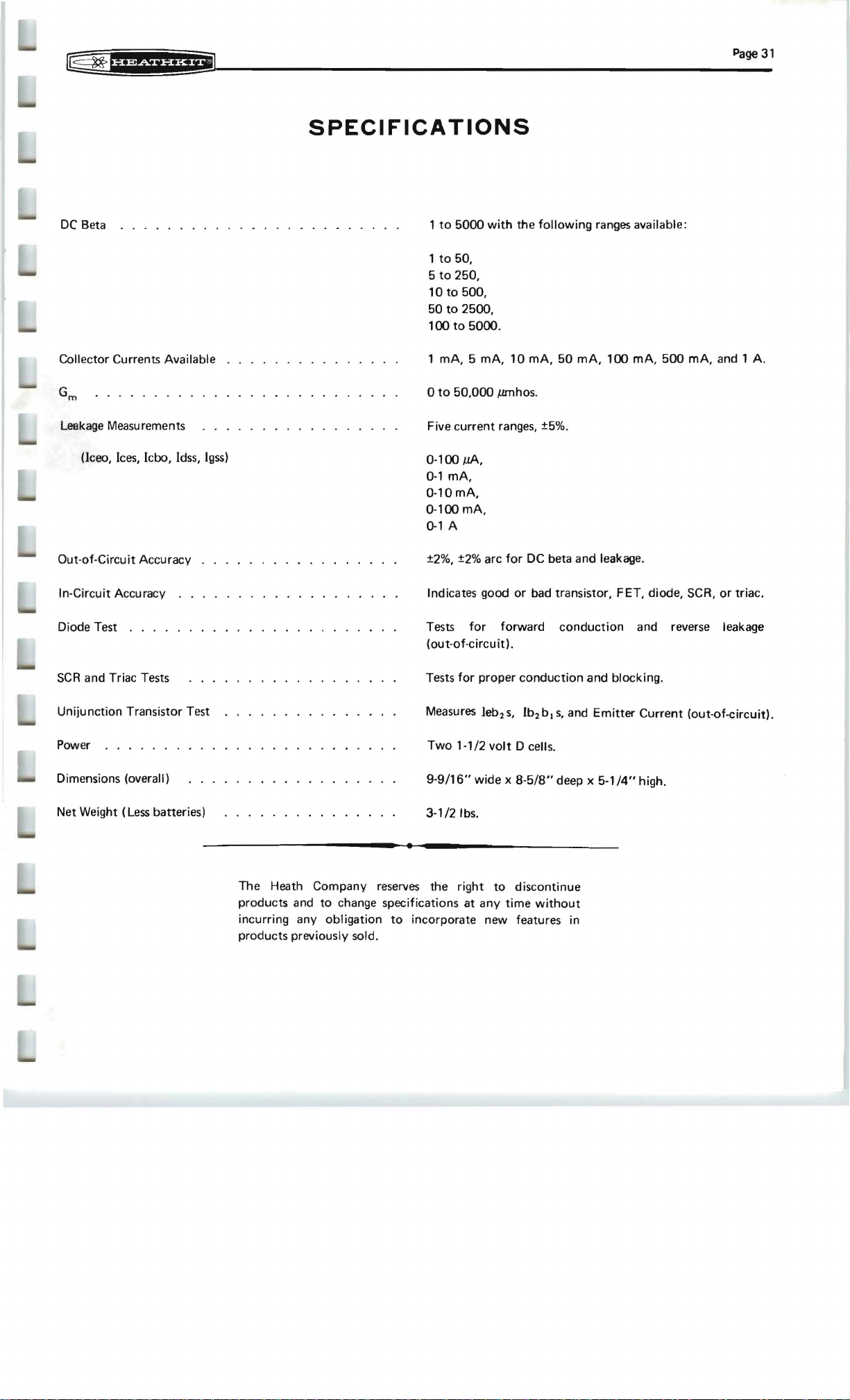

CLASS

SIGNAL

INTERMEDIATE

POWER

POWER

- - - - -

The beta

Xl0,

CAL

most often when transistors are tested

The chart in Figure 4 shows the relationships

current

current

collector

case

and

indication

meter

chart shows the three

class.

Use

the figures in the

APPLICAT ION

AUDIO,

RF, IF

AUDIO,

SWITCHING

AUDIO,

REGULATOR,

OUTPUT

scale

of

the meter

X5, and

ranges and the

range,

current

as

a general rule, the beta

CAL

calibration

for

instance, supplies a

when the

mu I tipl ied

approximate

current

has

three

Xl

. The

CAL

Xl0

by

the

range for a test.

CAL

settings. The 100

cal

classes

of

operating

current

CURRENT

CAPABILITY

1

mA

10 m A - 100 m A I

100

mA

calibration

Xl0

out

maximum

setting

of

ibration

points

setting

of

the

of

is

used

a transistor

setting.

transistors,

current

capability

- 10

mA

- 1 A

----

CAL

is

used

circuit.

the various

mA

of

100

mA

. In this

is

the

For example:

Meter

Calibration Setting =

BETA=3.5x

However,

next

I

I

lower

multiply

new

current

factor

of

I

I

EXAMPLE:

,

I

Meter

Select

10)

New meter

Calibration setting =

BETA=6.5x

Keep in

only

when the meter

for

the 1 A, 100

indication

10 =

if

the meter

current

the new meter

10.

indication

mind

range switch (in this

range provides

next

lower

indication

lOx

that

the

mA,

= 3.5

CAL

Xl0

35

indication

indication

= greater than 50

current

10=650

next

indication

and

CAL

10

is

greater than 50,

by 100. Notice

an

additional

range (additional factor

= 6.5

X10

lower

current

is

greater than 50 and

mA

current

case,

10

multiplication

range can

ranges.

press

mAl

that

be

the

and

this

of

used

only

I

I

I

I

I

I

I

CURRENT

RANGE

100

1

mA

10

100

1 A

-

~lA

mA

mA

CALIBRATION

SETTING

Not

Used

CAL

Xl

CAL

X5

CAL

XlO

CAL

Xl

CAL

X5

CAL

Xl0

CAL

Xl

CAL

X5

CAL

Xl0

CAL

Xl

CAL

X5

CAL

X10

COLLECTOR

CURRENT

.1

mA

.5

mA

. 1

mA

1

mA

5mA

10

mA

10

mA

50

mA

100

mA

.1

A

.5 A

1 A

Figure 4

BETA

MULTIPLICATION

FACTOR

Xl

X5

Xl0

Xl

X5

X10

Xl

X5

X10

Xl

X5

Xl0

- -

BETA

FACTOR

TO

RANGE

NOT

NOT

NOT

Xl0

X50

X100

X10

X50

Xl00

X10

X50

Xl00

~

-

MULTIPLICATION

AFTER

NEXT

LOWER

AVAI

LABLE

AVAILABLE

AVAILABLE

SWITCHING

CURRENT

J

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

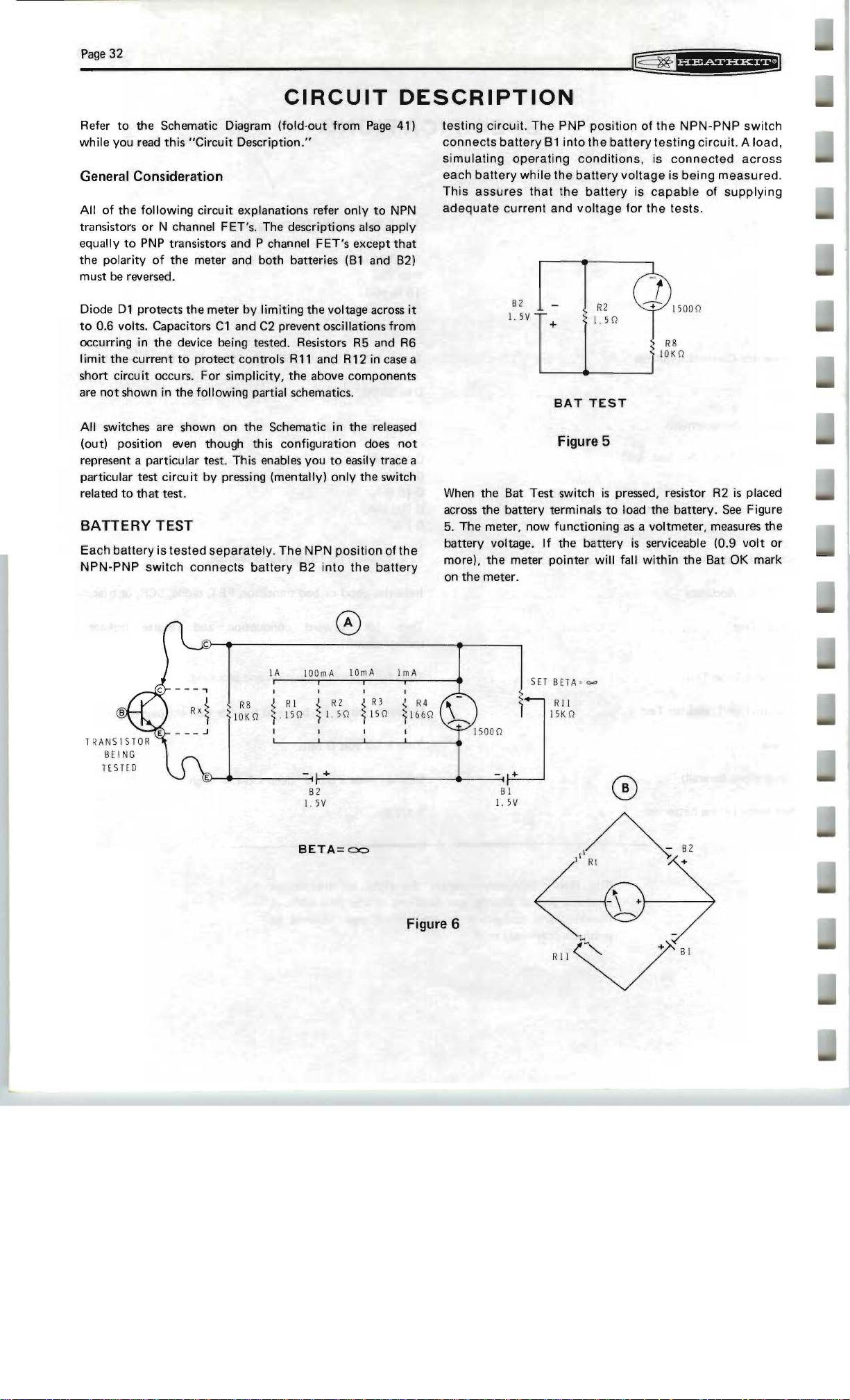

2.

Press

the

the

Press

3.

pointer

Press

4.

check

within

5. Release

position.

NOTE: Do

any

longer

shortened.

TRANSISTOR

General

Out-of-circuit

the

accuracy

resistances

used.

If

you may

must

always be

since

the

reading.

beta

test.

should

the

the

the

the

not

than

beta

of

of

the

the

transistor

consider

resistance

To

make a quick

BAT

TEST

switch.

ON-OFF

NPN-PNP switch

other

BAT OK

leave

TESTING

an in-circuit

made

to

fall

within

battery.

mark.

ON-OFF

the

Tester

necessary

(gain)

tests

circuit

the

in

indicates gain

transistor

with

in

the

good

the

or

are

test

which

the

circuit

ON

(in)

the

BAT OK mark.

to

the

The

meter

switch

in

the

the

battery

always

depends

the

when

to

be

transistor

could

or

bad test,

position.

PNP (in)

pointer

to

the

battery

quite

on

transistor

tested

good.

out

cause

perform

The

position

should

OFF

test

life will

accurate,

the

shunting

in-circuit,

Leakage

of

the

an

erroneous

only

meter

to

fall

(out)

position

be

but

is

being

tests

circuit,

the

Before

you

test a transistor,

to

determine

and

its

The

current

class . Both

be used

through a transistor. A schematic

identifying

metal cases

devices. Medium size metal cases

heat

sinks fall

transistors

large

heat

Figure 2

However, since

know

test

it.

The

schematic

transistor

show

the

Notice

the

base

a PNP

collector-to-emitter

negative

determine

steps

are

its class (signal,

type

(NPN

or

PNP).

capability

the

specific

to

estimate

the

particular

or

plastic cases will usually be classed as signal

in

the

are

usually large

sinks. Figure 2

shows

several lead

there

the

lead

configuration

diagram can also

type

(NPN

or

symbols

that

the

in

the

transistor.

collector·to-emitter

the

provided

for

arrow

NPN

transistor

Also,

voltage

transistor

to

identify

it

is

intermediate

of a transistor

application

the

amount

application.

intermediate

and

shows

examples

configurations

are

other

configurations,

of

your

PNP). Drawings A

both

an

on

the

emitter

and

an

NPN

transistor

while

voltage.

type,

proceed

the

type.

helpful,

and

most

NPN

the

but

power,

is

what

and

the

of

current

diagram

Transistors

transistors

power

generally used

of