Page 1

HEATHKIT

®

MANUAL

5 Megahertz

Dual Trace

Oscilloscope

Model 10-4205

595-2072

.·':::;_·. 7 ...

·.

'·

.

. ·

..

, ,,_

~:···

...:::

.....

.

;~~:.

·.:

.. · .:

..

·

::·.:.~--~

0

L~~-;·-~

HEATH

COMPANY • BENTON

HARBOR,

MICHIGAN

Page 2

HEATH COMPANY PHONE DIRECTORY

The following telephone numbers are direct lines to the departments listed:

Kit orders and delivery information

Credit

......... .

Replacement Parts .

......

....

.....

. . . . .

.................. .... (616) 982-3411

................

.....

. . .

..................

Technical Assistance Phone Numbers

8:

00A.M.

RtC, Audio, and Electronic Organs ..

Amateur Radio

to

12

.....

P.M.

...

and

...

1:00 P.

M.

....

...............

to

..

4:30P

. .

......

Test Equipment, Weather Instruments and

.......

. . .

.......

. .

...

Home Clocks . .

Television

............... ....

....

...

......

. . . . . .

............

Aircraft, Marine, Security, Scanners, Automotive,

Appliances and General Products

Computers

..

. ....

....

...

. . .... . . . .

..........

......... ....

......

...

. (616) 982-3561

(616) 982-3571

.M., EST, Weekdays Only

...

......

(616) 982-3310

...

. . . . . . (616) 982-3296

. .... .... (616) 982-3315

(616) 982-3307

......

•...

. (616) 982-3496

...... (616) 982-3309

YOUR HEATHKIT 90 DAY LIMITED WARRANTY

If

you are

not

satisfied

with

our

Services, Heath Company, Benton Harbor,

attention.

Our

attorney,

who

happens

phrases in order to

For a period of ninety (90) days after

either in materials or workmanship. You

telephoning

warrant

We

and

used in accordance with

If

a defective part or error in

fault of yours, we will service it free

Electronic Center (units of Schlumberger

You will receive free

drop us a

Our

incorrect assembly, misuse, fire, or by

advertised.

This warranty covers only Heathkit products

our

limitation of incidental or consequential damages , so

gives you specific legal rights,

line

warranty does

products. We

comply

us at (616) 982-3571.

that

during

consultation

or give us a call. Sorry,

not

Our

warranty does

are

service- warranty or

to

be

with

the first

ninety

our

design

cover

and

not

not

responsible

and

quite

a kitbuilder himself, insists that

the

new

purchase

can

And

we'll

(90) days after

printed

has caused

upon

on

any

problem you

we

we

are

not

unauthorized

include

for

you may also have

otherwise-

Michigan

warranty regulations. Fine. Here they

, Heath

obtain parts directly from Heath

pay

shipping

instructions, will meet published specifications.

your

proof of

purchase

Products

cannot

accept

responsible for

reimbursement

and

is not

incidental

HEATH COMPANY ~

BENTON HARBOR, MI. 49022

oROOo&~uoOOOootooooomo~

or

with

our

49022. He will make certain your problems receive

Company

purchase,

Heathkit

Corporation). or

will replace or repair free of charge any parts that are defective

charges to get those parts to

our

product

and

might

encounter

collect calls.

damage

modifications to or uses of

for

customer

extended

or

consequential

the

above limitation or exclusion may not

other

rights

products, write directly to

we

describe

our

warranty using all the necessary legal

are

:

Company

products,

to

malfunction

delivery at your expense to the Heath factory,

any

of

our

in

the

caused by

assembly or set-up time.

to allied

equipment

damages.

which

vary from state to state.

by writing us at

you-

when

correctly assembled, calibrated , adjusted

during

authorized

assembly or

the

use of corrosive solder, defective tools,

our

products for

or

components

Some

states

our

anywhere

the

warranty period

overseas distributors.

use

of your Heathkit product. Just

used in

do

not

apply

Director of Customer

immediate,

the

address

purposes

allow

to you. This warranty

personal

below or by

in

the world.

through

any

Heathkit

other

than

conjunction

the

exclusion or

no

as

~

with

~

~

~

Prices and specifications subject to change without notice.

Page 3

Heathkit® Manual

for

the

5 Megahertz

Dual Trace

Oscilloscope

Model 10-4205

595-2072

HEATH

BENTON

COMPANY

HARBOR,

MICHIGAN

490

2 2

Copyright © 1978

Heath Company

All Rights Reserved

Printed in the United States of America

Page 4

Page 2

TABLE OF CONTENTS

INTRODUCTION o 0 0 0 0 0 0 0 0 0 0 0 0 0 o o o o 0 0 0 0 0 0 0 0 0 0 0 0 3

UNPACKING

ASSEMBLY NOTES

o o o o 0 0 0 0 0 0 0 0 0 0 0 0 0 o o 0 0 0 0 0 0 0 0 0 0 0 0 0 0 4

0 o o o o o 0 0 0 0 0 0 0 0 o o o o 0 0 0 0 0 0 0 0 0 5

VERTICAL CIRCUIT BOARD

Parts List

Step-by-Step Assembly

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 8

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 11

HORIZONTAL CIRCUIT BOARD

Parts List

Step-by-Step Assembly

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 33

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 36

POWER SUPPLY CIRCUIT BOARD

Parts List

Step-by-

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 50

Step

Assembly 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 52

CHASSIS

Parts List

Step-by-Step Assembly

INITIAL TESTS

CALIBRATION

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 59

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 61

0 0 0 0 0 0 0 0 o 0 o o o 0 0 0 0 0 0 0 0 o o o o o o o 0 o 80

0 0 0 0 0 0 0 0 0 0 o o o 0 0 o 0 0 0 0 0 0 o o o o 0 0 0 0 82

FINAL ASSEMBLY

OPERATION

IN

CASE OF DIFFICULTY 0 0 0 0 0 0 0 0 0 0 o o 0 0 0 0 0 0 0 o

o o 0 0 0 0 0 0 0 o o 0 0 o 0 0 0 0 0 o o o 0 0 0 0 88

0 0 0 0 0 0 0 0 0 o 0 0 0 0 0 0 0 0 o 0 0 o o o 0 0 0 0 0 0 o 0 89

97

SPECIFICATIONS 0 0 0 0 0 o o o 0 0 0 0 0 0 0 0 0 0 o o 0 0 0 0 0 0 106

THEORY OF OPERATION

CIRCUIT DESCRIPTION

0 o 0 o o o 0 o 0 o 0 0 0 0 0 o o 0 0 108

o o o 0 0 0 0 0 0 0 0 0 0 o 0 0 0 0 0 0 0 109

SEMICONDUCTOR IDENTIFICATION

CHART

0 0 o o o o o o o 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 o 0 o 0 0 0 0 0 0 116

CIRCUIT BOARD X-RAY

VIEWS

0 0 0 0 0 0 0 0 0 0 0 0 0 Illustration Booklet, Page

36

SCHEMATIC DIAGRAM 0 0 0 0 0 0 0 0 0 0 0 o 0 0 0 0 (Fold-in)

WARRANTY

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

CUSTOMER SERVICE

0 0 0 0 0 0 0 0 0 0

Inside

Inside

front cover

rear cover

Page 5

;

;

:

INTRODUCTION

The

Heathkit

cilloscope is a compact, versatile, easy-to-build, electronic

waveforms

to

measure

to 5 MHz

ity of

the

Oscilloscope for nearly all

tions. The

many

and

other

capabilities

priced

Model

instrument

in

10-4205, 5 MHz, Dual-Trace Os-

that

electronic circuits. You

frequency,

bandwidth

and

vertical amplifiers

triggered

horizontal

outstanding

that

are

oscilloscopes.

you

and

the

types

features

usually

can

AC or

excellent

allow

of waveform

sweep

found

use

DC

voltages.

provide

to

can

input

you

circuit

only

study

also

use

The

sensitiv-

to

use

applica-

and

accuracy

in

higher

the

DC

this

the

it

easier

to

trigger

on

the

vertical frequency of

a TV set.

• A

10

to 1 attenuation

for signals

input

tal

applied

jack.

circuit

to

that

the

external, horizon-

• Accurately calibrated vertical

with

variable controls.

• A calibrated

selections, variable

time

base (seven

within

each selection).

Page 3

can

be

used

attenuators

time

base

Among

fers are:

• A

the

many

special

This

rejecting

other

TV

allows

high

features

position

low

frequencies

frequencies,

this

Oscilloscope of-

on

the

trigger selector.

to

thus

pass

making

while

it

These

make

features, along

this

Oscilloscope a

with

laboratory, service shop, or

the

attractive styling,

welcome

the

ham

shack

asset to

.

will

the

Page 6

Page 4

UNPACKING

Inside

which

box removed from

bags

will refer to these areas as

rected

All other parts

ered

parts from

specifically called for

the

shipping

contained

stamped

to

open

the

"final

their

carton

this

the

PACK 2

each

of

in

the

pack."

bags or

Assembly Manual.

shipping

through

these

shipping

Caution: Do

the

in

was

the

box

carton, you

PACK 4.

"packs."

"packs"

carton

"final

pack"

a Parts List

stamped

The

You

as

it

will

not

until

in

the

With

will

Manual

will

be

is needed.

be

consid-

remove

they

Manual.

PKl

this

find

di-

any

are

Each assembly section of

"Parts List"

At

tions.

be

instructed

be

directed,

parts from

and

the

beginning

to

in

the

"Step-by-Step Assembly" instruc-

open

one

some Parts Lists,

final pack.

the

of

Manual

each

of

the

contains its

"Parts

List," you

packs. You

to

remove

will

certain

own

will

also

Page 7

~~~~;allllll;ll:ll=u~

.................................................................... ..

ASSEMBLY NOTES

TOOLS

You

will

need

these tools to assemble

your

kit

.

Page 5

PLIER S

-------------------------------------------------

OTHER

HELPFU~

TOOLS

/

NUT STAR

1IMAY

I WITH" KI TI

I

I

I * TO

BE

SUP

TER

PLIED

DIA

GON

C

UTT

~

DE SOLDERING

AL

ERS

BUL

B*

ESO

LDER I NG

D

BR

AID

*

REMOVE SOLDER FROM

CIRC

UIT CON

NECTIONS

HEATH

KI T

SOLDERING

RO

N

I

OR

PENCIL

SO

LDERI

TO 40

NG I RON

WATT

S!

125

.

·------------------------------------------------~

ASSEMBLY

1.

2.

Follow

tire

The

rials

eration

generally

directed

following

until

another

the

instructions

step before

you

illustrations

and

Details. Pictorials

for a

group

illustrate a

to refer to a

steps,"

you

are referred

group

of steps.

perform

in

the

Manual

of

single

certain

continue

to

carefully. Read

each

operation

are called Picto-

show

the

assembly

step.

steps

When

Pictorial

using

that

another

Pictorial for

the

en-

.

overall op-

; Details

you

are

"for

the

Pictorial

3.

4.

5.

Most kits

that

etc.)

Keep

sembly

ranged

Position

use

contains

that

are too large for

the

"Illustration Booklet"

Manual.

in

Pictorial

all

Solder a part

are

instructed

a separate

"Illustration

Booklet"

illustrations (Pictorials , Details,

the

Assembly Manual.

with

the

The

parts

or a

to

illustrations

number

as

shown

group

of

do

so.

sequence.

parts

in

in

the

Pictorials.

only

it are ar-

when

As-

you

Page 8

Page 6

6. Each circuit

component

numbers

part

in

These

part

has

In

At

part

number

when

the

various sections of

numbers, which

to

be

the

Parts List,

the

beginning

component

In

some

In

the

Schematic,

In

the

section

7.

When

you

are

particular

vided

at

length,

the

bottom

SAFETY WARNING:

off excess

fly

toward

lead

your

lengths.

eyes.

in

an

electronic kit

(R2, C4, etc .

you

want

are especially

replaced

, appear:

of each step

is

installed,

illustrations,

at

the

instructed

use

Avoid

Hold

of

to

the

the

eye

the

has

its

).

Use

these

to

identify

the

the

same

Manual.

useful

where

rear of

cut

something

the

Manual.

scales (rulers) proManual

injury

leads

when

so

they

pages.

you

cannot

own

if a

to

cut

SOLDERING

Soldering

will perform

der

connection

tween

circuit

vent

properly.

a

It is easy to make a

follow a few

1.

a

2.

two

board

an

otherwise

Use

40-watt

3/16"

Keep

on a wet

the

process is called

tip

When

the

ned.

is one of

while

will form

parts, such

foil. A

simple

the

right

pencil

chisel or

the

soldering

sponge

tip

to give

and

enable

solder

tip,

the

the

most

important

assembling

an

electrical

as a

component

bad

solder

connection

operations

your

kit. A good sol-

connection

lead

could

you

be-

and

pre-

well-assembled kit from operating

good

solder

connection

if you

rules:

type

of

soldering

pyramid

or

the

tinning, and

you

tends

tip

needs

soldering

tip

iron

tip

cloth; then

entire

to

to

tip a wet

make

"ball"

to

be

iron. A

iron

with

works best.

clean.

Wipe

apply

it

will protect

good

connections

or does

cleaned

a

solder

look.

not

and

25

to

1/8"

or

it often

to

This

the

stick to

retin-

a

.

Page 9

Page 7

PARTS

Resistors

in

0 (ohms),

will

kO

be

types of resistors

body,

while

others

The colors of

the

steps, therefore

for

information

Color

Black

Brown 1

Red

Orange

Yellow

Green

Blue

Violet 7

Gray

White

the

Band 1

1st Digit

Digit

called

(kilohms), or

bands

out

will

have

will

be

identified

and

the

following color

by

their

resistance

MO

(megohms). Certain

the

value

by

the

value

will

only.

Band 2

2nd Digit

Color

0

2

3

4

5

6

8 Gray 8

9

Black

Brown

Red

Orange

Yellow

Green

Blue

Violet

White 9

value

printed

code

BANDS

Digit

0

1

2

3

4 Yellow

5

6

7 Violet

on

the

a color

be

code

given

.

in

is given

: 1 2 3 / /Tolerance

Multiplier

Band 3

3rd Digit

Color

Black

Brown

Red

Orange

Green

Blue

Gray

White

1/4-WATT

==

==fllm-===OR~

1/2-WATT

(if used)

Digit

0

1

2

3 Orange

4

5

6

7 Silver

8

9

OR

1-WATT

*Note

Wide

Space

Multiplier

Color

Black 1

Brown

Red 100

Yellow

Green

Blue

Gold

=======~--~=

2-WATT

Resistance

Tolerance

Multiplier

10

1,000

10,000

100,000

1,000,000

0.

01

0.1

Color

Silver

Gold

Brown

Tolerance

:!:

10%

:!:

5%

:!:

1%

Capacitors

value

will

in

JLF

(microfarads) or

be

called

out

by

pF

(picofarads)

ceramic, Mylar* , electrolytic , etc.

may

have

their

value

ner

:

First digit of

capacitor's value : 1

Second digit of

capacitor's value: 5

Multiplier: Multiply the

& second digits by

first

the proper value from the

Multiplier Chart.

To find the tolerance of

the capacitor, look up

this letter

columns.

*

DuPont

in

the Tolerance

Registered

printed

Trademark

in

____

their

Some

the

following

_,

capacitance

and

type:

capacitors

man-

FOR THE

NUMBER:

EXAMPLES:

151K

759 = 75

NOTE:

decimal

MULTIPLIER

0

1

2

3

4

5

8

9

=:=

15 X 10 = 150

X0.1

= 7.5

The

letter "R"

pF

pF

may

be

used

point: as in: 2R2 = 2.2 (pF or

TOLERANCE OF CAPACITOR

1

10 pF OR

LESS

±0.1

pF

±0.

25

pF

±0.5

pF

±1.0

pF

±2.0

pF

LETTER

MULTIPLY

BY:

10

100

1000

10,000

100,000

O.D1

0.1

at

B

c

D

F

G

H

J

K

M

times

JLF).

to

signify a

OVER

10 pF

:±

± 2°/o

±3

±5°/o

±

±

20%

1o/o

o/o

10%

Page 10

Page

8

VERTICAL

CIRCUIT

Remove

each

correspond

part

the

parts from

against

to

the

the

BOARD

the

pack

following list.

numbers

on

the

marked

The

#1.

key

numbers

Vertical Circuit

Board Parts Pictorial (Illustration Booklet, Pages

and

2).

Any

part

that

is

in

an

the

envelope

step. Do

parts are

KEY

HEATH

Part

No.

individual

part

number

after

not

accounted

No

. Comp. No.

on

it

should

you

identify

discard any

for.

QTY.

DESCRIPTION

be

it

until

packing

envelope

placed

it

is called for

materials

back

CIRCUIT

RESISTORS

All resistors

(fourth

NOTE: The

velope

pack

1/2-Watt

AI

A1

A1

A1

are

15q

5%

silver).

resistors

RES).

you

check

band

(stamped

before

(p-

6-279

6-100

6-220 4

(fourth

may

Open

the

\.S

2

3 2.7

20

band

gold)

be

packed

all

the

resistors

3L

\

Y;·

tV\-G

n (Red-Viol-Gold)

10

n (Brn-Bik-Bik)

22

n (Red-Red-Bik)

unless

designated 1 0%

in

more

resistor

against

envelopes

the

M~)

than

one

Parts List.

~

tcf-i

R179,

R182

R124A, R124B,

R131A, R131B,

R142A, R142B,

R145A, R145B,

R157A, R157B,

R158A, R158B,

R159A, R159B,

R164A, R164B,

R166, R168,

R174

R147A, R147B,

R148A, R148B

PARTS LIST

Some

Check

1

with

into

the

in

a

until

all

en-

in

this

~

I R \05~

R181,

, R175

KEY

No.

Resistors (Cont'd.)

A1

parts

aging number.

purposes

List."

To order a

PART NUMBER. Use

with

the

Parts"

separate "

HEATH

Part No. Comp. No.

6-330

A1

6-390 2

A1

6-470 2

A1

6-820 2

A1

6-101

A1

6-201

6-221

A1

6-271

A1

A1

6-331

A1

6-391

A1

6-471

A1

6-511

A1

6-751

are

only

kit

.

inside

Heath

If

marked

These

and

with

numbers

do

not

replacement

the

one

is

not

available, see "Replacement

the

rear cover.

Parts Price List."

QTY.

DESCRIPTION

33

{

n (Org-Org-Bik)

n (Org-Wht-Bik)

39

47

n (Yei-Vioi-Bik) R134A, R134B

82

n (Gry-Red-Bik) R144A, R144B

100

6

2

8

2

2

6

2

2

2

n (Brn-Bik-Brn) R161A,

200

n (Red-Bik-Brn)

220

n (Red-Red-Brn)

270

n (Red-Vioi-Brn)

330

n (Org-Org-Brn)

390

n (Org-Wht-Brn)

470

n (Yei-Vioi-Brn)

510

n (Grn-Brn-Brn)

750

n (Vioi-Grn-Brn)

a "

171-

are

used

appear

in

the "Manual

part, always

Parts

Order

For

prices, refer to

" or

"172-

for packaging

include

Form

furnished

CIRCUIT

R1A, R1B

R2A, R2B

::::ftj:()SA, R4059;

R106A, R106B

R151A, R151B

R162A, R162B,

R171,

R117A, R117B

R111A, R111B,

R113A, R113B,

R114A, R114B,

R183,

R108A, R108B

R116A, R116B

R135A, R135B,

R139A, R139B,

R153A, R153B

R136A, R136B

R115A, R115B

R163A, R163B

" pack-

Parts

the

the

,

,

R16·1B,

R172

R184

Page 11

®

~

f§1%f#fB+@

Page 9

KEY

HEATH QTY. DESCRIPTION

No

. Part No. Comp. No.

CIRCUIT

Resistors (Contd.)

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

6-102

6-122

6-182

6-272

6-332

6-912

6-103

6-153

6-223

6-913

6-104

6-914

20 1000

2

1200

2 1800

4

2700

4 3300

2

9100

10

kfi

4

2 15

kfi

kfi

22

2

91

kfi

2 100

2 910

n (8rn-81k-Red)

n (8rn-Red-Red)

n (8rn-Gry-Red)

n {Red-Viol-Red)

n (Org-Org-Red)

n (Wht-8rn-Red)

(8rn-81k-Org)

(8rn-Grn-Org)

(Red-Red-Org)

(Wht-8rn-Org)

kfi

(8rn-81k-Yel)

kfi

(Wht-8rn-Yel)

R104A, R1048;

R133A, R1338,

R141A, R1418,

R146A, R1468,

R149A, R1498,

R156A, R1568,

R165, R167,

R185, R186,

R187, R188,

R191

R155A, R1558

R137A, R1378

R118A, R1188,

R122A, R1228

R119A, R1198,

R121A, R1218

R103A, R1038

R109A, R1098,

R154A, R1548

R132A, R1328

R169

R102A, R1028

R107A, R0178

R101A, R1018

Other Resistors

'/t..j

A2

6-1801-

~

IZ.

A2

6-4320-11

1-19-1

A3

A4

5-11-2

AS

3-55-5

CAPACITORS

Ceramic

81

21-7 2

81

21-121 4

81

21-75 1

81

21-722

81

21-140 2

81

21-36

4

4

2

2

2

n (1.8

k)

~

watt

,

1800

1%

(8rn-Gry-81k-8rn)

432

n' 1 /8-watt, 1% R125A, R1258,

(Yei-Org-Red-81k)

n, 1-watt, 10%

220

{Red-Red-8rn)

15

kfi

, 2-watt, 10% R176

(8rn-Grn-Org)

2000

n

(2

k), 5-watt R177, R178

33 pF C117A, C1178

56

pF C112A, C1128,

100 pF

330 pF C105A, C1058

.

001

JLF

.002

JLF

R123A, R1238,

R127A, R1278

R126A, R1268

R173

C116A, C1168

C121

C128, C129

C108A, C1088

, R192

KEY HEATH

QTY. DESCRIPTION CIRCUIT

No. Part No. Comp.

Capacitors, Ceramic (Cont'd.)

81

21-141

81

21

81

21-47

81

21-31

81

21-199 2

-27

1

4

3 .

.0033

.005

01

.02

JLF

.1

JLF

JLF

JLF

JLF

C131

C107A, C1078,

C135, C136

C109A, C1098,

C122

C124

C114A, C1148

Electrolytic

82 25-115

83

25-117 4

25-160

B3

8

10

JLF

100

JLF

3

250

JLF

C111A, C1118,

C113A, C1138,

C123, C132,

C133, C134

C118A, C1188,

C119A, C1198

C125, C126,

C127

Trimmer

84

84

84

85

31-56

31-54

31-52

31-77

4 1.

5-

2 4-40

4 8-60

2 80-400

20 pF C101A, C1018,

C103A, C1038

pF

pF

pF

C102A, C1028

C104A, C1048,

C115A, C1158

C106A, C1068

Other Capacitors

86 27-28

2 .1

JLF

Mylar

C1, C2

DIODES

C1

C1

C1

56-56

56-67

56-89

~

\(o

4

1 N4149

VR10A

G0510

g~e~A. o~e+So

9Hl2A., 0192&,-

0103A, 01038,

0104A,

0105A,

0106A,

0108A,

0109A,

0111A,

0112A,

0107

0113, 0114,

0115, 0116

No.

01048

01058

01068

01088

01098

01118

01128

Page 12

Page

10

KEY HEATH

No. Part

No.

QTY.

DESCRIPTION

CIRCUIT

Comp.

TRANSISTORS-INTEGRATED CIRCUITS (IC's)

NOTE: Transistors and integrated circuits are marked for identification

in

one

1.

Part Number.

2.

Type number.

of

the following four ways:

(On

integrated circuits, this refers

only to the numbers and letters listed. Any additional letters or numbers

on

an

IC

are not signifi-

cant.)

and

3. Part number

4.

Part number with a type number other than the one

type number.

listed.

01 417-235

01 417-237

01 417-260

01 417-293

01 417-801

02

417-834

03

417-902

04

443-1

04

443-4

pi

LJll-

~Lf

8 2N4121 transistor

2 SE6020 transistor

4 2N4258A transistor

4 2N5770 transistor

4 MPSA20 transistor

2 MPSU10 transistor

4 5566 transistor

7400 IC

1 7472 IC

1../

"=>e1

eo

tfl.!M!?

I s

'\tJ

0106A, 01068

0107AI 01078

01

08A,

0109AI 01098

01131 0114

0104A, 01048

01

05A,

0111A, 01118

0112A

, 0 1

0103A

, 0 1

0117, 0118

0115,0116

0101A, 01018

0102A, 01028

U101

U102

f

DID\

1::>10\5

)

DIDZ.AJ

OTHER CIRCUIT COMPONENTS

E1

10-357

E2 10-917

E2

10-918

E2

10-936

E3

10-1118

E4

60-73

E5

60-624

E6

63-1316

E7

475-16

2 1 00

3 200

2

2

2

2

1

2

2

n control

n control

500 n control

1 000

ll

( 1 K) control

ll

( 1 K) control

1 000

DP3T 3-position slide switch

DP4T 4-position slide switch

Rotary switch with 5000

(5K) control

Ferrite bead

n

R112A, R112B

R152A, R152B ,

R189

R143A, R143B

R138A, R138B

R4A, R4B

SW1A, SW1B

SW3

SW2A-R3A,

SW2B-R3B

HARDWARE

#4

Hardware

No.

01088

01

05B

128

038

"))l

Z!S

KEY HEATH QTY. DESCRIPTION

No. Part

#6

G1

G2 250-33 4 6-32

G3 250-416 4 6-32

G4 250-56 4 6-32 x 1/4" screw

G5

G6 254-1

No.

Hardware

250-1282 3 6-32 x 1/8" black setscrew

x 1/8" setscrew

x 1/4" flat head screw

252-3 4 6-

32

nut

4

#6

lockwasher

Other Hardware

H1

253-50 2 1/4" plastic spacer

H2 252-7 4 3/8-32 nut

1

H3 255-145 2 3/8" spacer

1

1

MISCELLANEOUS

J1

,

,

,

,

75-769

J2 75-770

J3 266-1008

85-2043-1

J4

204-2315

204-2333

J5

206-1273

J6

J7

215-95

343-15

344-

346-1

347-55

390-1436

J8 432-892

J9 434-230

J10 434-298

J11

453-66

J12 455-44

J13 456-7

J14 462-1049

J15 462-1050

J16 462-1055

L 1 490-5

134-237

L2

260-16

L3 73-34

390-147

390-1255

390-1483

391-34

597-260

51

Slide switch cover (1-7/16")

Slide

switch cover (29/32")

Slide switch cover

Vertical circuit board

Sw

itch bracket

2 Control bracket

1 Circuit board shield

2 Heat sink

4' Shielded cable

3' Brn wire

8-1

/2" Sleeving

1-1

/2' a-conductor flat cable

1 Metal front panel

2 BNC connector

4 8-pin IC socket

2 14-pin IC socket

2 5" extension shaft

2 Split plast ic bushing

2 Shaft coupling

Red knob

2 Small black knob

Large black knob

Plastic nut starter

Cable with connector

1

2 Alligator clip

2 Red alligator clip insulator

Danger label

Fuse label

Power consumption label

Blue and white label

Parts Order Form

(1

-3/16")

CIRCUIT

No.

Comp.

J1

, J2

F1

250-428

F2 250-52

F3 250-186

F4 252-15

F5 254-9

0

Y.

}'2

I 1

(8

I

3~ 8

I"' I II II

Q .

I " ( 8 I 7

1 I I I

!5

1 (CM )

1 4-40 x 1/4" flat head screw

2 4-40 x 1/4" screw

#4

4

3 4-40 nut

3

"/.

~

8

I . I I I I I I

'2

x 3/8" screw

#4

lockwasher

(I

N C

3

HES

) 2

' I I

I'

"

3

,.

1, I I I I

e 7 · e

'I

I I I

' I

Solder

Assembly Manual (See Page 1

for Part Number)

'II

7

I

17

4

I I

I I I ' I

I

I ' I I ' I

11

10

9

5 6

·,I

I

12

I'

13

I l ' I I I

1 4

15

I I

,.,

I

Page 13

In

the

following steps, you will be

given detailed

install

circuit

step carefully.

cedure

circuit

NOTE: Only a

board is

ing Pictorials.

tion

Drawing" at

shows

the

assembled.

( )

Position

shown

the

NOTE:

that

has its

the

value

read

ily

with

their

possible.

Hold

sistor

bend

the

board

instructions

and

solder

board. Read

Then

whenever

board.

portion

shown

in

The

area

ofthe

the

with

foil side) up.

When

you

value

printed

marking

. Diodes

type

or

a 910

k.O

with

long-nose pliers

the

leads

hole

spacing

.

the

and

use

you install parts

some of

small

the

circuit

circuit board as

the

install a

up,

should

part

straight

on

first

top of

printed

so it

(Wht-Brn-Yel) re-

how

part

on

perform each

the

same

proon

of

the

circuit

the

follow-

"Identifica-

the

page

board to be

side

(not

component

on

it,

position

can

be eas-

be

mounted

number

on

down

the

up,

to fit

circuit

the

and

STEP-BY-STEP ASSEMBLY

to

a

The

steps performed

in this area of

if

the

in

this Pictorial are

circuit

board.

IDENTIFICATION

DRAWING

CONTINUE<:/

( )

Turn

the

solder

as follows:

1.

COMPONENT

circuit

the

resistor leads to

Push

the

soldering

against

both

circuit board foil. Heat

for

two

or

three

SOLDERING

iRON

LEAD

w

~~~

2.

Then

apply

other

side

of

IMPORTANT: Let

and

the

lead

melt

SOLDER

FOIL'\_

circuit board foil

the

solder.

SOLDERING

IRON

Page

board over

the

/)

the

the

iron

lead

and

seconds.

BOARD

solder to

connection

the

heated

11

and

foil

tip

the

both

the

.

( ) R101B:

the

holes at

on

the

color

either

Press

cuit

board.

outward

tor

in

Push

the

the

circuit board .

bands

way

the

place

indicated

may

.

resistor

Then

slightly to

.

leads

The

be

positioned

against

bend

hold

through

location

end

with

the

the

leads

the

resis-

cir-

PICTORIAL 1-1

3. As

the

solder begins to melt ,

allow it

connection. Then

solder

connection

FOIL

( ) Cut off

close to

ING: Clip

will

not

( ) Check each connection. Compare

it to

the

After you have checked

connections, proceed

sembly

soldering

connection

to

flow

and

the

iron

cool.

SOLDERING

IRON

the

excess lead lengths

the

connection

the

leads so

fly toward

illustrations

on

Page 13. Use

.

your

on

with

procedure

around

the

remove the

and

let

the

. WARN-

the

ends

eyes.

Page 12.

the

solder

the

as-

the

same

for each

Page 14

Page 12

A GOOD SOLDER CONNECTION

~-------------------,

S

OLDER

AND

GRADUALLY

THE

WITH

THE LEAD

FLOWS

FOIL

.

OUTWARD

BLEND

AND

S

,~;~

',,

,')

//

/

,'

/

, (_;;

OLDER

IRON

POSITIONED

CORRECTLY

IN G

I

I

I

I

I

When

you

heat

the

lead

and

the

circuit

time, the

1

The

Lt~

POOR

~----------------------------~-----,

I

I BEAD SURROUN DS

I

I

I

I

I

1 rect,

1

Lc~~c~r:_

SOLDER CONNECTIONS

SOLDER DOES NOT

ONTO LEA

SUL

T

HE

When

will

D. A

ATE

S THE LEAD

CONNECT ION.

the

not

flow

reheat

small

amount

FL

OW / / I

DARK ROSIN

AND

IN -

FRO

M

FO

IL

lead

is

not

onto

the

the connection

of

additional

_____________

heated

lead as

and

solder will flow

solder

~~~

ROS

will make a

IN

,<;

//,'S

''

'

//•

,,,

, I NC

""

sufficiently,

shown

,

if

necessary,

solder

to obtain a good

evenly

good

electrical

~

!!!i~

___________

,

//

,'

, IN

OLDERING OF THE FOIL

IRON '

POSITIONED

ORRECTL

the

Y

solder

above. To cor-

apply

a reheat

_!~;....

board

onto

the

SOLDER

WA

RD

When

the

blob

on

amount

foil at

the

same

lead

and

the

foil. I

connection

APPEARS

AND S

.

foil is

the

circuit

the

connection

of

additional

ET

not

between

TO

FLOW

ON

TOP

heated

board

-~

//,'

as

and

, if necessary,

solder

______________

I

I

,') ,'SOLDERING

//,.-........_

/ ,

',

sufficiently

shown

to obtain a good connec- I

IRON

PO

SIT IONED

INCORRECTL

the

Y

solder

will

above. To correct,

apply

a small 1

.J

A

solder

in

nection

you

dered

you "drag"

remove

is:

lead before

connection

and

important

NOTE:

tions

Use

and

board

circuit

tween

the

solder

boards

bridge

photograph

should

accidentally

connection,

the

it

from

alwa

ys take a good look

you

, make

does

not

bridge

when

It

is alright for

on

the

same foil.

only

enough

lift

the

soldering

.

If

a

solder

board

foil -

connections.

tip

of

the

soldering

bridge

. NOTE :

has a coating

is a protective

bridges.

between

A.

Photograph B shows

appear. A

touch

soldering

the

solder

sure

the

solder to

side-down

two

adjacent

solder

an

adjacent

if

you

use

too

iron

across

connection

it.

the

to

another

. A good

at

the

Then, when

sold

er

foils are small

solder

to

make

iron

straight

bridge

should

and

The

excess

foil.

iron, and

The

foil

on

it

called "solder

insulation

to

help

foils is

bridge

previously

much

other

foil area

you

remains

This

and

close together.

bridge

a good

up

from

develop ,

heat

the

solder

this

will

side

of

prevent

SOLDER BRIDGES

shown

how

the

con-

may

occur

if

sol-

solder, or if

foils as you

rule

to follow

around

is especially

two connec-

connection

will

most

resist." This

solder

in

this

the

circuit

turn

solder

run

remove

circuit

solder

each

the

area

,

the

be-

onto

the

A

SOLDER

BRIDGE

B

Page 15

Page

::

::

::

The

steps performed in this Pictorial a

in this area of

the

circuit board.

IDENTIFICATION

DRAWING

re

--~,.-fi

PART

NUMRER

13

Be sure you

in

Pictorial 1-1 (Page 11).

R102B:

R105B: 1.5

NOTE: Your circuit board

marked 33 at

R104A: 1000

R105A: 1.5

NOTE: Your circuit board

Solder the leads to

off the excess

NOTE: When you install a diode, always

match

the

band

the

DIODE

IF

See Detail 1-2A.

mark on

WILL

IT

IS

INSTALLED BACKWARDS.

BAN:~

···:·::

:-:.:·

:·:·:"

··BAND

If

your

diode

is clearly defined.

body, do

glass

end

inside

end

outside

the diode for the

. Look for a

of the glass .

installed

91

kfl (Wht-Brn-Org).

0 (Brn-Grn-Gold).

this

0 (Brn-Blk-Red) .

tf

(Brn-Crn-Go1d) .

at

this

33

lead

band

on the

the

NOT WORK PROPERLY

}/

'¥-

GLASS'--..

BODY

has a solid

If

your

not mistake the colored

band

resistor

foil

lengths

diode

may

may

and

.

with

location.

location.

the

circuit board. A

NO

COLORED

END

body, the

painted

diode

band

has a

banded

on

be

be

cut

the

)

07B: 100 kfl (Brn-Blk-

01B:

Selected

(#417-854). See Detai11-2B.

""""

'""',"~the

··1ho1A:

U

(#417-854) . See Detail1-2B.

Solder the leads to the foil and cut

off the excess lead lengths .

IMPORUNT:

BE

MARKED

leads to

excess lead

: 100 kfl (Brn-Blk-

Selected

THE

BANDED

IN A NUMBER

transistor

the

foil

lengths

transistor

END

OF

DIODES

OF

WAYS.

Yel)

and

~

Yel)

.

cut

.

CAN

~

BANDED

END

Detail1-2A

__

_

PICTORIAL 1-2

.._

___

Page 4 of 5

10-4205/595-2072

591-3025

Page 16

Page 14

IDENTIFICATION

DRAWING

The

steps performed in

in

this area of the

178: 200

168: 330

1278: 1800

Gry-Blk-Brn).

1158: 510

1148: 220

Solder the

off the excess

17

A:

200

circuit

.n

.n

.n

.n

.n

leads

lead

.n

this

Pictorial are

board.

(Red-Blk-Brn).

(Org-Org-Brn).

(1.8 k). 1% (Brn-

'

/4

~

(Grn-Brn-Brn) .

(Red-Red-Brn).

to

the

foil

and

lengths

.

(Red-Blk-Brn).

--~---~.....:;

cut

PART

NUMBER

CONTINUEO

NOTE:

When a wire

step,

cut

the

brown

specified length.

insulation

2-1/4" Brn

D104B: 1N4149

D103B: 1N4149

R118B: 2700

R126B: 432

Blk).

R125B: 432

Blk).

R124B:

R127 A: 1800

Gry-Blk-Brn).

R123A: 1800

Gry-Blk-Brn).

Sol

der

the

Then

from

each

wire

!l

.0, 1% (Yel-Org-Red-

.0 , 1% (Yel-Org

10

!l

(Brn-Blk-Blk).

.n

!l

the

leads

excess

lead

is called for

wire

remove

in

to

1/4" of

end.

.

diode

(#56-56).

diode

(#56-56).

(Red-Viol-Red).

-R

(1.8 k). 1% (Brn-

'

/'1

~

(1

.8 k), 1% (Brn-

'/~

~

to the foil

and

lengths.

IDENTIFIC

DRAWl

a

the

ed-

cut

R116A: 330

NOTE:

a step,

the

specified l

1"

R125A: 432

When a bar

remove

bare wire.

!l

all

ength

.0 , 1% (Yel-Org-Red-

Blk).

R126A : 432

.0, 1% (Yel-Org-Red-

Blk).

R115A : 510

R114A: 220

R113A : 220

Sol

der

the

.n

.n

!l

leads to

off the excess lead lengths.

0

I 1 ( 8 I

iifljiill)

0

y.

.e

Yo

3~ 8

1

~(8

I

I

(CM) 2

:y.

I

1;

8 1

I

(Org-Org-Brn).

e wire is

the

insulation

of

brown

called

(Grn-Brn-Brn).

(Red-Red-Brn).

(Red-Red-Brn).

the

foil

1

(I

N C HIES)

I

I

I I

I

I

I

4

3

for

from

wire.

and

in

cut

c=:>

r-----l

I I

: I

I I

I I

I I

I

I

I

I

I

PICTORIAL 1-3

2

I

I

e

I

I

I

I

I

8

3

I

I

I

I

I

I

7

I

I

I

I

I

I

8

"

I I

4

I

I I

I

I

10

I

I

I

I

I

,

12

R122A: 2700

R136A: 470

nP

, n r

n<>

the

off

5

I

I

I I

I

I

I

13 14 18

r

the leads

excess

I

I

I I I

I

I I

!l

(Red-Viol-Red).

.n

(Yel-Viol-Brn).

to

the

foil

lead

lengths.

6

I

I

18

and

I I

cut

7

I

I

I

17

Page 17

The

ste

ps

in

this area of

R136B: 470

performed

the

in

this Pictorial are

circuit

0 (Yel-Viol-Brn).

board.

IDENTIFICATION

DRAWING

: 82 0 (Gry-Red-Blk).

1000

Page

0 (Brn-Blk-Red).

15

R137B: 1800

1000

1800

0 (Brn -Gry-Red).

0 (Brn-Blk-Red).

0 (Brn-Gry-Red).

82

R154A: 10

0 (Gry-Red-Blk).

0 (Brn-Blk-Blk).

Solder

off

the

the

leads

excess lead

to

the

foil

lengths

and

.

cut

PICTORIAL 1-4

22

R147A:

Solder the leads to

off

0 (Red-Red-Blk).

the

excess lead l

the

foil

engths.

and

cut

Page 18

Page

16

The

in

steps

this

performed

area of

in

the

circuit board.

this Pictorial are

PART

NUMBER

R154B: 10

k!l

(Brn-Blk-Org).

1

fi

(Brn-Blk-Brn).

100

: 100

n (Brn-Blk-Brn).

Solder the leads to

off the excess lead lengths.

R146A: 1000

149A: 1000

R155A: 1200

the

foil

fi

(Brn-Blk-Red).

n (Brn-Blk-Red).

fi

[Brn-Red-Red).

and

cut

R187: 1000

D111B: 1N4149

R159B: 10

;Y

Solder

the

off

the

excess lead lengths.

fi

(Brn-Blk-Red).

diode

(#56-56).

n (Brn-Blk-Blk).

leads

to

the

foil

and

cut

./

J

R151A: 39

R154A: 10

the

Solder

off

the

excess

fi

(Org-Wht-Blk).

k!l

(Brn-Blk-Org).

leads

to

the

lead

lengths

foil

and

.

cut

PICTORIAL 1-5

Solder

off

the

the

leads to

excess lead

( Wt"S}

the

foil

lengths

and

.

cut

Page 19

IDENTIFICATION

DRAWING

Page 17

PART

NUMBER

D113: GD510

( ,..YR192: 1000

,)--

R186: 1000 n (Brn-Blk-Red).

(

(

vJ'

R188: 1000 n (Brn-Blk-Red).

R185: 1000

diode

n (Brn-Blk-Red).

n (Brn-Blk-Red).

--------~----~-

~-;-~---

(#56-89).

The

steps performed

in

this area of

in

the

this Pictorial are

circuit

board.

: 2.7 n (Red-Viol-Gold).

n (Red-Viol-Gold).

: 2.7

79

: 2.7 n (Red-Viol-Gold).

O

I

l i

Q ·

1[8

flj

Solder

off

Solder

off

y.y,•;.

I

•;

lll

ij

5

the

166: 10

the

a I

5[B

I I I '

1

(CM)

the

excess

the

excess

leads

to

the

lead

lengths

n (Brn-Blk-Blk).

n (Brn-Blk-Blk

10

leads

to

the

lead

lengths

1

( I

I

I I I I I I

3

NCHES)

I

7ta

2

foil

foil

I

and

.

).

and

.

cut

cut

: VR10A

9:

l

L.__

__

~

(~Solder

off

the

PICTORIAL

2

I

I

I

I

"

3

I

I

I

I

I

I

I

8

1-6

4

I

I

I

I

I

I

I

9

10

I I

I

I

I

,

I I

5

I

I

I

I

I

12

I

I

I

13

14

22

kn

the

excess

I

leads to

I

diode

(#56-67).

(Red-Red-Org) .

the

foil

lengths

I

I

I

1<0

and

.

lead

I

I

15

6

I

cut

7

I

I

I

I

17

Page 20

Page

18

The

steps performed in this Pictorial are

in this area of the circuit board.

START•

) Reposition the circuit board as

shown. Solder

as you install each part.

NOTE: When you install

insert the pins

holes.

The

board

must

socket is installed.

the

pins

to

an

into

index mark on

still be visible after

IC

the circuit b.oard

the

......--~

the

foil !DENT! FICA TION

socket,

circuit

the

Q

~

ORA

WING

nc=:>

~I

PART

NUMBER

CONTI

NOTE: When you install a control, insert

the

holes

NU

pins

and

solder them to

into

Ev

the

circuit

the

board

foil.

~

1 ....

~

....

.•

,.;ip'i''>

100 n control (#10-357).

...

in

in

14-pin

IC

socket at

IC

socket at Q102A.

IC

IC

QlOlA.

socket at U102.

socket at U101.

PICTORIAL

1-7

Page 21

Page

19

When

NOTE:

capacitor,

circuit

board

the

end

each trimmer. All

soldered.

lengths.

'

'

insert

leaves

Then

:4-40

you

its

slots.

to

the

cut

·

' ',

. C

pF

The

steps

thi

s area of

performed

in

install a

end

Solder

foil as

the

off

'\

~~~!~

trimmer

leaves

both

you

leaves

the

excess leaf

SO

LDE

IRCUIT

trimmer

into

the

sid

es of

install

must

be

R

BOARD

(#31-54).

in

the

circuit board

this

L torial are

IDENTIFICATION

DRAWING

PART

NUMBER

:4-40

pFtrimmer(#31-54)

. 5-20

pF

:8

-60

pFtrimmer

:8-60

pF

trimmer

trimmer

(#31-52).

(#31-52).

(#31-

.

---

---

-----1

I

f

1-

-

-

-

~Jo

m

PICTORIAL 1-8

Page 22

Page 20

NOTE:

When

each

of the following

its flat

with

the

leads into

holes. Position

above the board.

to

the

foil

lengths.

and

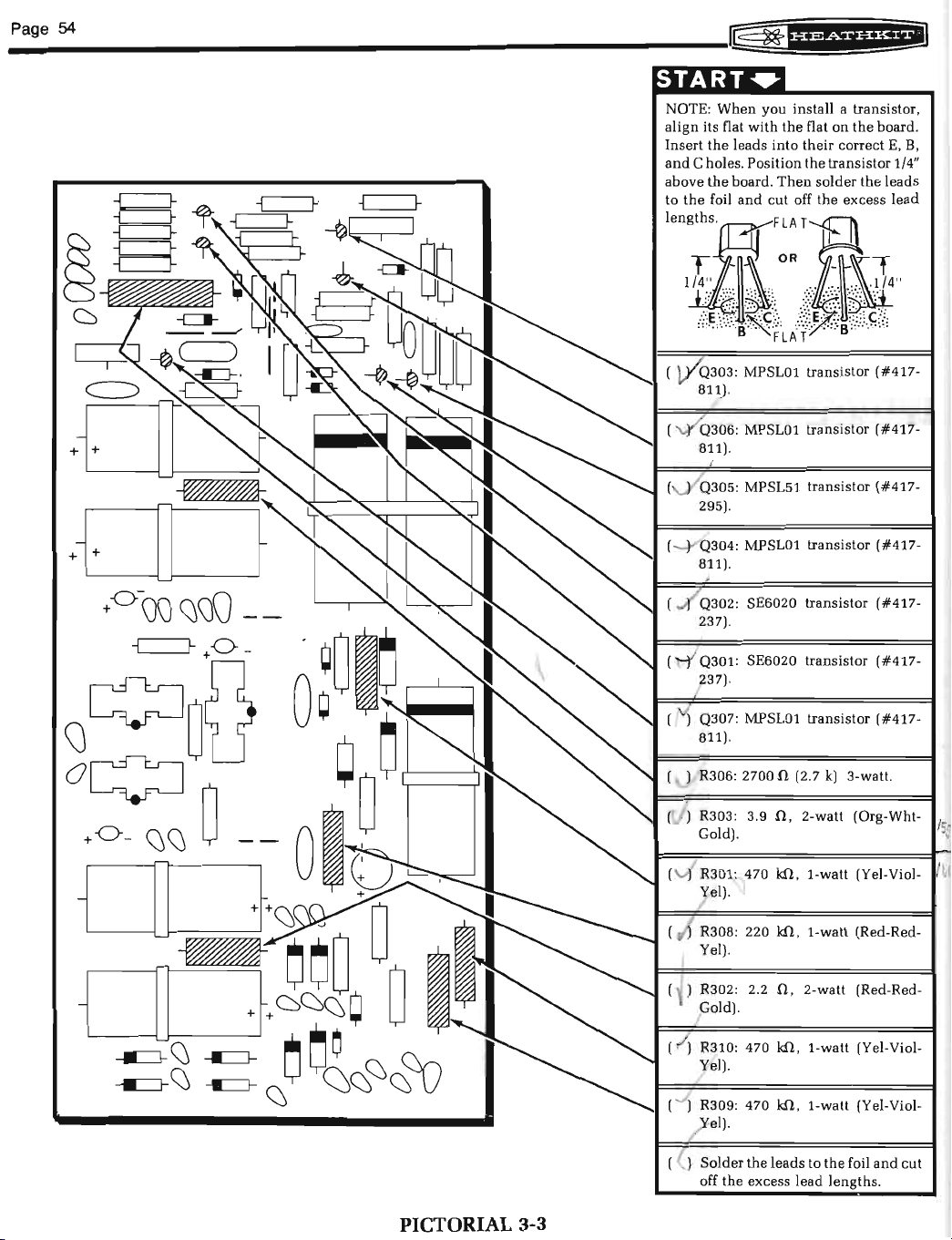

you install a

the

flat

on

their

correct

the

Then

cut

off

transistor

nine

steps,

board

E,

excess

. Insert

B,

and

the

align

leads

lead

the

transistor 1/4"

solder

the

IDENTIFICATION

DRAWING

in

C

The

in

this

steps

area of

performed

the

circuit

in

this

NUMBER

Pictorial are

board.

PART

CONTINUEO

NOTE:

In

the

following four steps, in-

stall

each

of

the

transistors as follows:

1. Refer to

2.

3.

Turn

4.

der

off the excess

the

below

and

C leads of

Insert

the

the

corresponding

holes

in

the

Position

mately 1/

board

.

the

the

leads

illustration

identify

the

transistor leads

circuit

the

transistor approxi-

4"

above

circuit

to

example

theE

transistor.

board over, sol-

the

lead

, B,

E,

B,

board.

the

circuit

foil,

and

lengths.

WI

and

and

into

C

cut

DE

t;:~

( )

Q103A:

(#417-801) .

[

VJ

Q107A:

(#417-235).

-/)'

Q106A:

(

(#417-235) .

Q109A: 2N4121

[#417-235).

Q108A: 2N4121

(#417-235).

Q111A:

( V

(#417-293).

112A:. 2N5770

#417-293).

( vl Q114: SE6020

237).

.

;&l

MPSA20

2N4121

2N4121

2N5770

SE6020

transistor

transistor

transistor

transistor

transistor

transistor

transistor

transistor

transistor

(#417-

(#417-

-II

CJjE

B E

WI

DE

[

")

Q104A:

[#

(

+

,17-260).

2N4248

transistor

transistor

PICTORIAL 1-9

[

(

Page 23

IDENTIFICATION

DRAWING

Page

21

Q105B: 2N4258

(#417-

260).

transistor

transistor

The steps

in thi s area of the circ

performe

d in thi s Pi ctorial are

uit

NUMBER

board.

CONTINUE

AR

T

P

NOTE:

When

each

of

its flat

the

leads

holes.

abo

ve

to th

e foil

lengths

Q103B: MPSA

(#417-801).

you

the

following

with

the

into

their

Position

the

board. Then sol

and

.

(~06B:

(#417-235).

(

~

109B:

(#417-235).

Q111

B:

(#417-293).

v

install a transistor

nine

steps, align

flat

on

the

board. Insert

correct

the

cut

2N4121

2N4121

2N5770

E, B,

transistor 1/4"

der

off

the

excess

20

transistor

transistor

transistor

transistor

transistor

the

and

leads

lead

in

C

PICTORIAL 1-10

~

112B

(#417

(

'1"'

Q108

(#417-235).

Q117: MPSA20

801).

V Q118: MPSA20

801).

:

-293) .

B:

2N5770

2N41

transistor

21

transistor

transistor

transistor

(#417-

(#417

-

Page 24

Page 22

The

steps perform

in

this area of the

ed

in this Pictorial are

circuit

board.

NUMBER

PART

C109B: .

C105B: 330

NOTE: When you install electrolytic

capacitors, always

(

+)

mark

positive (

match

OR

capacitor

the

circuit board.

01

C105A: 330

C107 A: .005

off

the

excess

ClOBA: .002

on

the

+)

mark

the

minus

with

JJ.F

ceramic.

pF

pF

JA.F

lead

JA.F

match

capacitor

on

the

minus

ceramic.

ceramic.

ceramic.

lengths

ceramic.

the

the

circuit

(-)

mark

(-)

.

positive

with

the

board

on

the

mark on

IDENTIFICATION

DRAWING

I I !

@7/2> I

N

1o~Do

\)I

~8

I I

I

( V)"

Solder

off

the

the

leads to

excess

lead

the

foil

lengths

and

.

cut

PICTORIAL 1-11

Page 25

Page

23

(

_,{

C116A:

56

( v ) CllBB: 56

C117B:

33

pF

pF

pF

ceramic.

ceramic.

ceramic.

IDENTIFICATION

DRAWING

PART

NUMBER

The

steps performed

thi

in

s area of

in

the

circuit board.

this Pictori al are

Solder

the

leads

to

ILF

pF

ceramic.

ILF

ILF

ILF

leads

the

lengths

ceramic.

ceramic.

ceramic

ceramic.

to

the

( )

9

ff

the

excess lead

( ) C128: .0011J.F ceramic.

(

./

C129: .001

(

t.{

C121: 100

C131: .0033

( ) C135: .005

(

~ C136: .005

( ) C124: .02

(~older

off

ILF ceramic.

the

the

excess lead lengths.

foil

.

foil

and

.

and

cut

cut

PICTORIAL 1-12

Page 26

Page 24

The

steps performed

in

this area of

in

the

circuit board.

this Pictorial are

IDENTIFICATION

DRAWING

PART

NUMBER

NOTE: When you install a

capacitor, place a 1/4" plastic

over

the

screw

and

insert

its

the

circuit board slots.

into

sides of

the

install each

must

be soldered.

C106A: 80-400

77).

C106B: 80-400

77).

18A: 100

C118B: 100

end

trimmer

leaves to

JLF

JLF

end

Solder

the

foil as you

. All

the

pF

trimmer

pF

trimmer

electrolytic.

electrolytic.

trimmer

spacer

leaves

both

leaves

(#31-

(#31

\:)I

1

~~~--

:==:_...:::::!._~~===;-__J

~--

~~

-

----+-----

~

==~

C119A: 100

C126: 250

C133: 10

Solder

off

Solder

off

ILF

JLF

the

leads to

the

excess lead lengths.

JLF

: 10

4:

10

JLF

7: 250

JLF

2: 10

JLF

the leads to

the

excess

JLF

electrolytic.

electrolytic.

electrolytic.

the

electrolytic.

electrolytic.

electrolytic.

electrolytic.

the

lead

lengths.

foil

foil

and

and

cut

cut

•If-

PICTORIAL 1-13

Page 27

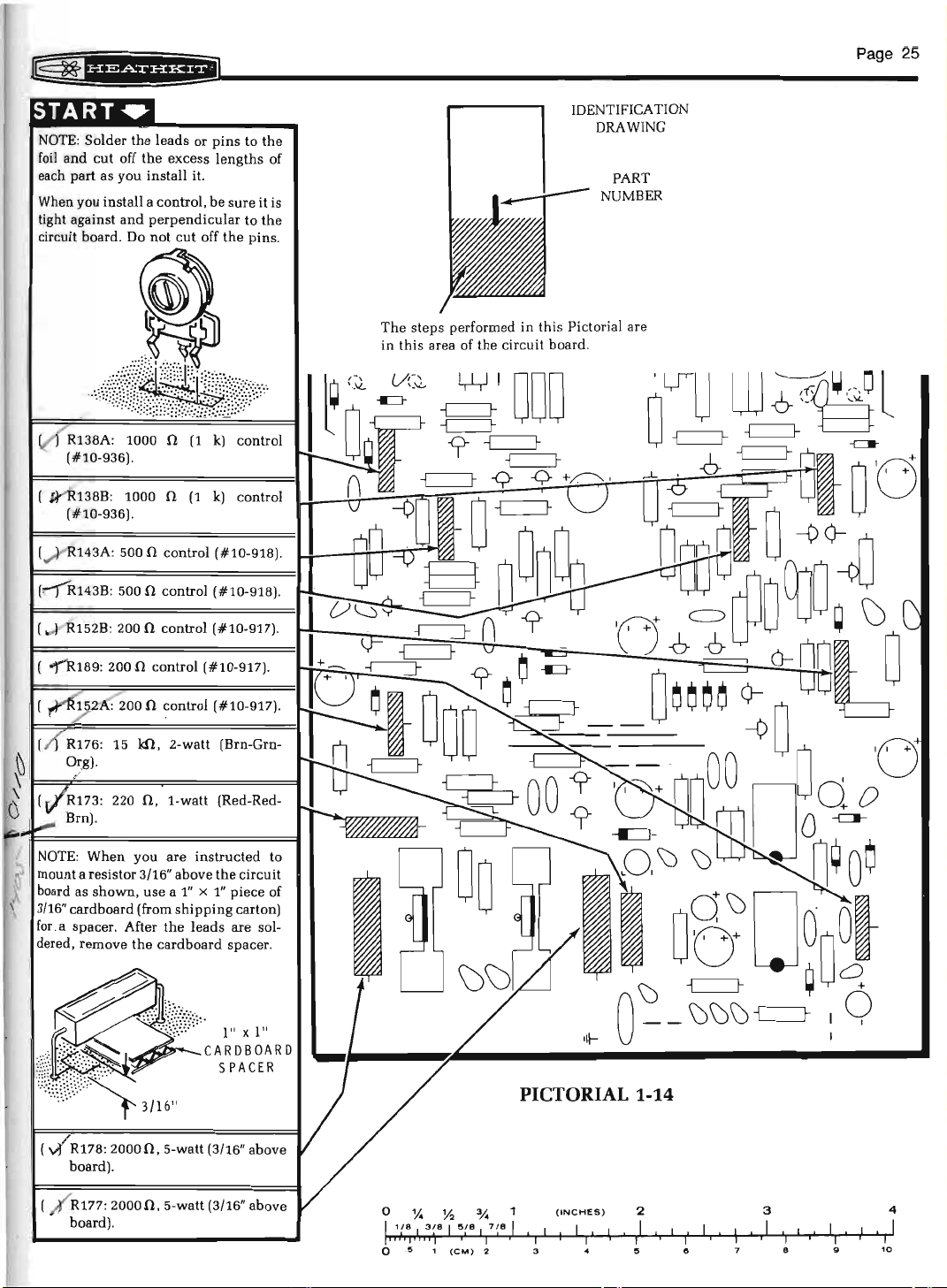

NOTE

foil

: Solder

and

cut

off

the

the

leads or

excess

pins

lengths

each part as you install it.

When you install a control, be

tight against

circuit board. Do

(

~

and

138B

:

1000 0

perpendicular

not

cut

off

(1

k)

(#10-936).

(

.,....l

143A: 500 0 control (#10-918) .

sure

the

control

to

to

pins

the

it

the

of

is

Page

25

IDENTIFICATION

DRAWING

PART

NUMBER

.

The

steps performed in this Pictorial are

in

thi

s area of

the

circuit board.

(!"'")R.143B: 500 0 control (#10-918).

152B: 200

0 control (#10-917) .

200

0 control (#10-917).

15

kn

, 2-watt (Brn-Grn-

220 0 , 1-watt (Red-Red-

you are

instructed

mount a resistor 3/16" above

board as

3/

for

dered , remove

shown, use a 1" x 1"

16"

card

board (from

. a

spacer

. After

the

cardboard

~

or--

shipping

the

leads

the

CARDBOARD

circuit

piece of

carton)

are sol-

spacer

X 1"

1"

SPACER

to

.

•II-

PICTORIAL 1-14

R178:

board) .

R177:

board).

20000

, 5-watt (3/16" above

20000

, 5-watt (3/16" above

0

I

0

I I

1(8

fl

y.

I

j I I I

.5

%

!S(B

3~8

I

I

')

1

(CM)

"4

1;8

I

I

2 3 5

(INCHES)

1

I I

I

I

I I I I

I I

I

4

I

I

I

I

10

I I

I

I

3

I I

I

I

I

I

I

8

"

2

I

I

"

Page 28

Page

26

Refer

toPictorial1-15

the

following steps.

NOTE:

circuit

pin 1 end

the

(

( ) Q101B: Install a 5566

(

When

(I

circuit board. See

~

Q101A: Install a 5566

location Q101A .

location Q101B.

-1

Q102A: Install a 5566

location Q102A.

C)

of

in

you

the

the

(Illustration Booklet, Page

install a transistor

following steps,

transistor

or

Detail1-15A.

( j Q102B: Install a 5566

/ location Q102B.

( ) U102: Install a

I U102.

7472Ic:;

or

integrated

be

sure

to

match

IC

to

the

index

transistor ( #417

transistor

transistor

transistor ( #417

(#443-4)

(#417-902)

(#417-902) at

at

3)

for

the

mark

on

-902)

at

at

-902)

ar

location

2.

Fit

the

pins

of

into

control

down

turn

the

end

these

against

If

they

the

switch

all

the

foil.

rotary

you

step, cut

length

their

switch

and

time,

and

switch

3. Carefully

only

spect

are

tight

board.

push

solder

to

the

(

'-')

/ SW2A - R3A: In

other

(#63-1316) at its location

the

When

next

end

.

NOTE:

in

indicated

each

each

switch

board

holes

pins

are

in

tight

against

the

circuit

pins

of each wafer

pins

the

printed

are not,

remaining

switch

are

reheat

tight

against

the

same

with

instructed

the

specified color

remove 1/4" of

wafer,

place.

the

board

to

make

switch

manner,

5000 0

on

to

one

until

all

Then

circuit

over

to

sure

side

of

the

connection

the

and

(5

the

circuit

prepare

insulation

wafer at a

the

push

board.

and

the

foil. In-

all

the

the

board.

control

install

k)

control

board.

wires, as

wire

switch

the

solder

pins

circuit

and

Then

pins

the

to

the

from

(

~

U101:

U101.

(

SW2B-

/

rotary

1316)

circuit

1. Carefully

with

Install a 7400

switch

at

board

their

IC

R3B: Refer to

with

5000 0

its

location

as follows:

align

the

pins

holes

in

the

SMALL

(#443-1) at

Detail1

on

the

of

circuit

5B

(5

k)

printed

the

front wafer

board.

location

and

mount

control

side

(#63-

of

the

(A)

DOT

a

·~~~~

ulf)~

PIN1 PIN1

~

PIN

Detail1-15A

Prepare

are

RIDGE

listed

the

in

3"

2"

NOTCH ___

~~

PIN

1

following

the

3"

2-1/4"

0{1

pIN

1

~

order

.

brown

they

--

~

wires.

The

will be used.

<

~~

wires

Page 29

Page

27

I§~

f§fifi*U*FP

NOTES:

1.

When

board, always

after

in

2.

solder

later.

means

number

wires are

3.

When you

sure

directly above

capacitors, as

justed later.

j

Connect a 3"

( )

(S-1)

tion

the

spacer

you

connect a wire

cut

the

connection

the

following steps, (NS)

because

"S-"

to

other

with a number,

solder

following

at

the

connection.

wire

to

no

wires or

components

the

these

Brn

wire

to

switch

on

wire

the

SW2A

between

switch.

off

the

excess

is soldered.

wires

the

connection.

the

"S"

tells

the

rotary

screws

in

trimmers

from

circuit

wafer A lug

the

shaft

to

the

circuit

lead

length

means

will

such

not

be

added

as (S-3),

how

switches,

are

positioned

the

trimmer

must

be

board

hole

9 (NS). Posi-

and

indicated

to

The

many

be

ad-

A

C

v(

Connect a 2"

A2 (S-1) to

(J Place a 1/2"

0 , 1/2-watt (Org-Org-Blk)

33

/)['

R2A:

tween

switch

length

Connect

wafer A

(S-1).

(

~

R106A: Connect a 33

5%

resistor from

in

the

circuit

B

lug

9 (S-1).

(

~

onnect

CC

Position

indicated

V )

Connect

hole

(S-1).

the

~

33

(~B:

tween

~

S-1).

(

v('

R106B: Connect a 33

5%

on

B

(

~

a

3"

(S-1) to

switch

the

spacer

a 2-1/4" Brn

B2

(S-1) to

Position

indicated

/2"

length

0,

1/2-watt (Org-Org-Blk)

Connect

wafer A lug

resistor from

the

circuit

lug

9 (S-1).

t

the

circuit

Brn

wire

from circuit

SW2A wafer A lug 8 (S-1).

of sleeving

on

5%

this

lug

the

board

Brn

wire

resistor to

9 (NS)

0,

indicated

(S-1) to

switch

and

wafer B

1/2-watt (Org-Org-Blk)

resistor

switch

from circuit

SW2B wafer A

wire

between

on

switch

the

wire

spacer

of sleeving

the

on

the

shaft

switch.

wire

from

SW2B wafer A

between

the

the

switch.

on

each

5%

this

the

board

board

resistor ! o

9~')

0,

indicated

(S-1) to

aside

switch

and

wafer B

1/2-watt (Org-Org-Blk)

resistor

switch

temporarily

board

hole

each

lead

of a

resistor.

SW2A be-

lug

outline

SW2A wafer

board

lug

circuit

hole

9 (NS).

and

board

the

lug

shaft

and

lead

of a

resistor.

SW2B be-

lug

outline

SW2B wafer

.

8

8

8

Q .5 1

(C

M ) 2

'II

7

I

17

(INCHES)

'I

I I

II,

3

2

. I '

I

·,

I

I '

s

"

3

' I .

'I

4

, I ,

I I

8

' I

I I'

I

10

9

I, ' I'

11

5

'• I I

12 13

6

I I

I ' I

I''

,.

I '

I

1tl

1S

Page 30

Page

28

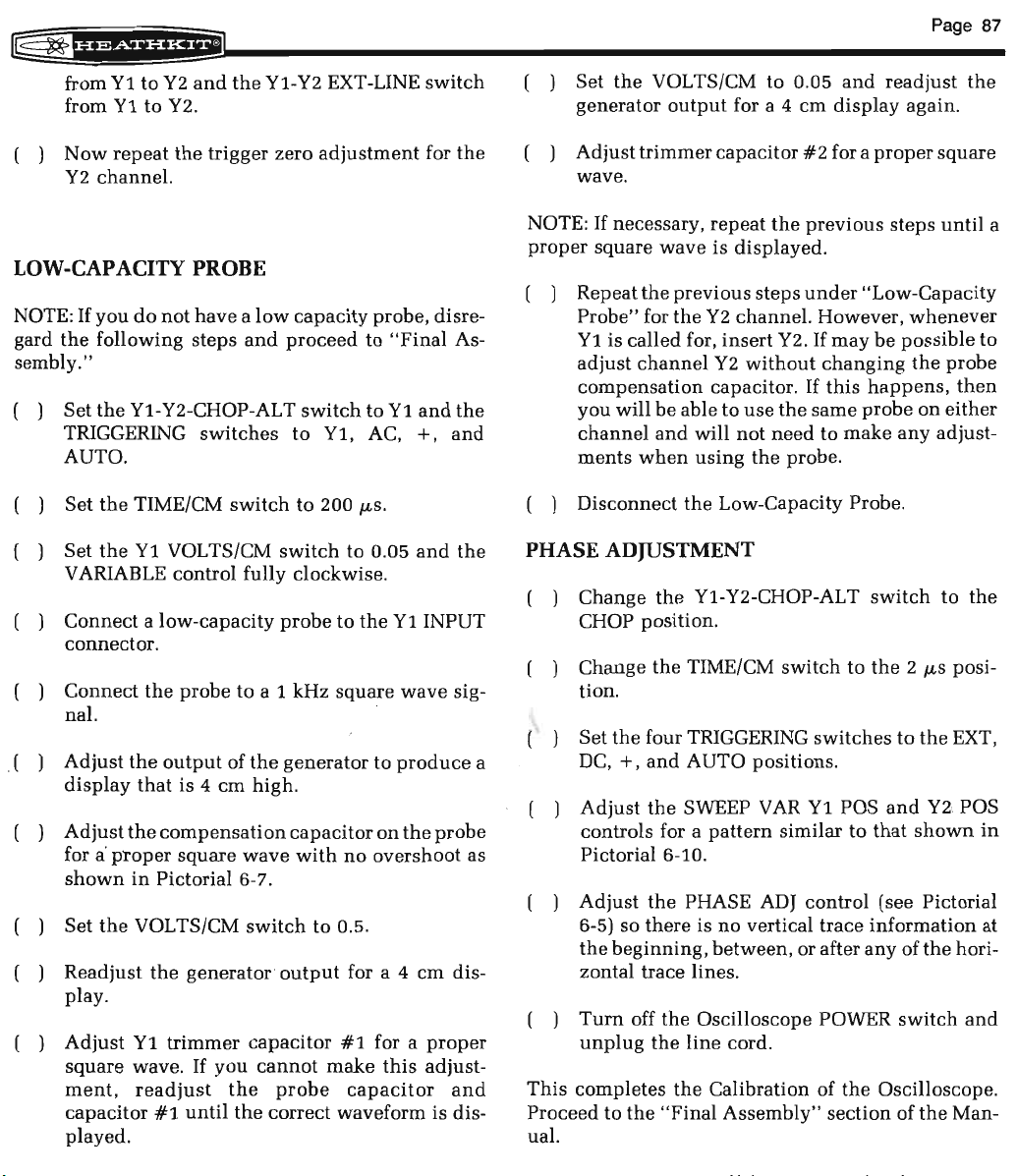

Refer to Pictorial 1-16 for

~

(

Locate

shown.

the

switch

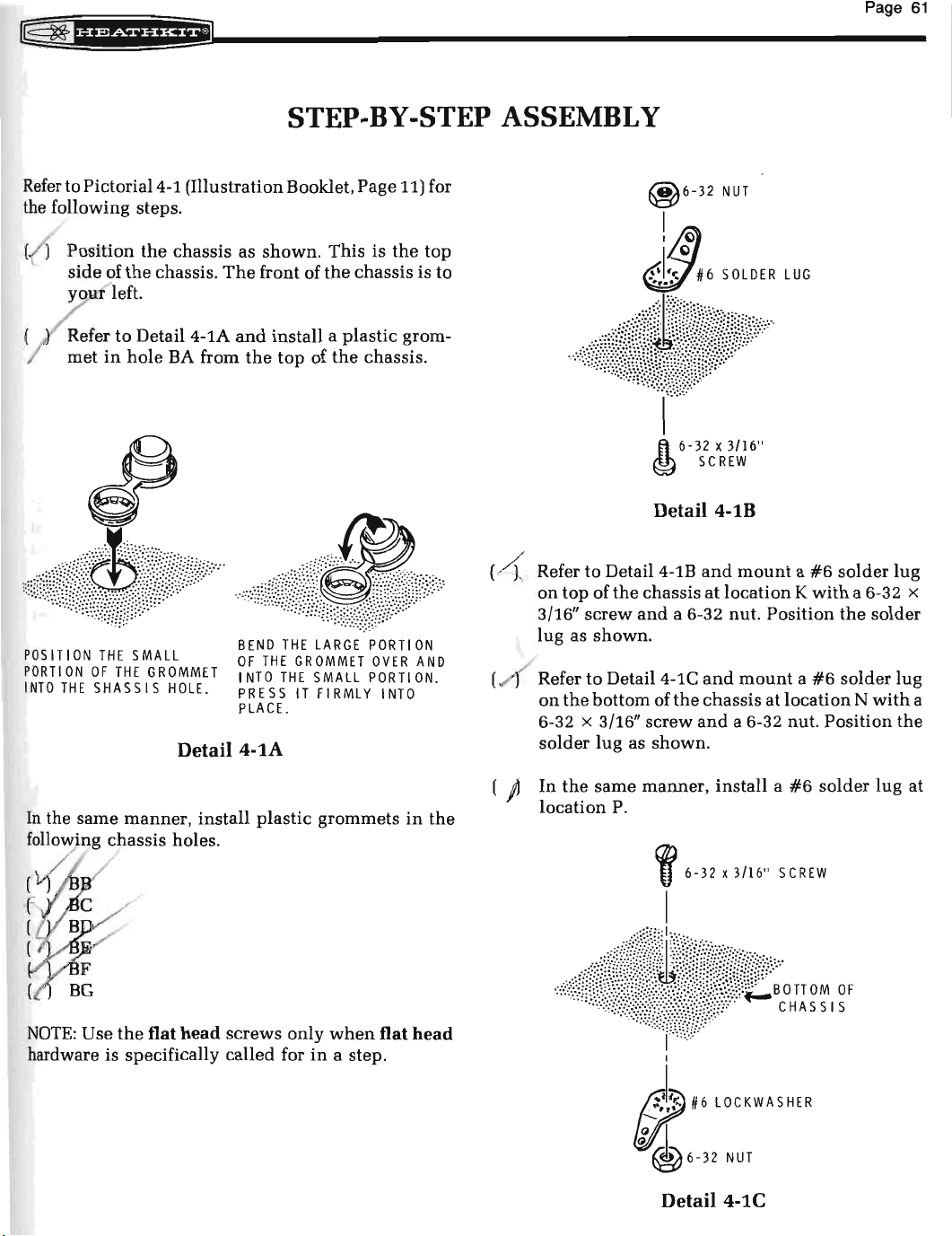

I SW1A: Install a DP3T

location

x 1/4"

stalled

( .;{ SW1B:

3-position

switch

NOTE:

refers

use

hardware,"

screw,

Refer

number

install

nished

start

The

to

to

mount

one

to

the

with

them

SW1A

flat head screws.

either

In

the

slide

bracket.

term

"hardware"

the

screws,

parts.

for example,

or

more

the

Detail called

of

lockwashers

hardware. Use

the

kit

on

screws.

in

the

way.

same

switch

nuts,

The

#4

lockwashers

to

to

pick

the

following steps.

bracket

3-position

switch

The

manner,

at

location

in

the

and

lockwashers

phrase

means

out

in

use

the

up

to

the

and

plastic

#4

and

position