Page 1

Assembly and Operation of

the Heathkit Transistor Tester

Model IM-36

595-861-03

Heath Company

Benton Harbor,

Michigan 49022

Copyright © 1967

----------------------------------This electronic edition of the Heathkit IM-36 Transistor

Tester manual was prepared, by Gary Edwards, garyedwa@hwy.com.au

November 2004.

It has been partially retyped, and partially scanned to obtain the graphics.

The document was prepared in Word 2000, and converted to *.pdf with Acrobat 5.0

The layout is slightly different than the original, which was altered primarily to

economise on space (or number of pages), however apart from the alterations to the

layout and some minor formatting changes it contains all of the information from the

original document.

, 3rd

Table of Contents

Introduction 2

Parts List 3

Step-by-step Assembly

Switch Pre-wiring 5

Control Panel Parts Mounting and Initial Wiring 13

Battery Housing Assembly and Wiring 23

Knob Installation 28

Battery Installation 29

Initial Tests and Adjustments. 30

Operational Check 33

Final Assembly 34

Operation 35

Reference Material 41

In Case of Difficulty 41

Troubleshooting Chart 42

Specifications 43

Factory Repair Service 43

Circuit Description 44

Replacement Parts Price List 47

Schematic (fold-out from page) 47

Introduction

The Heathkit Model IM-36 Transistor Tester is a professional quality instrument for

shop, laboratory, or remote on-the-job testing of transistors and diodes.

Page 2

Direct readings of DC Beta (gain) from 0 to 400 and accurate measurements of

currents and leakage in transistors permit testing under simulated operating conditions.

These conditions are set up by switch-selecting the voltages and currents that are

applied to the transistor elements to duplicate published characteristics.

Four lever switches permit eight different tests and measurements, which result in a

comparative quality figure (beta, gain) rather than the simple good-bad test made by

many other transistor testers.

The self-contained power supply, that consists of seven readily obtainable standard Dcell batteries, makes the instrument fully portable. Since no battery current is drawn

unless a transistor is being tested, long battery life is assured.

External voltage sources for higher values of bias, collector, or leak voltages, can be

connected to convenient binding posts for higher voltage transistor testing.

Diodes can be tested for forward and reverse characteristics under appropriate current

conditions.

By following the step-by-step assembly, test, and operating instructions in the manual,

you can build, test, and use this instrument in a few hours.

The attractively styled cabinet, functionally designed control panel, and efficient

circuitry, combine to give you a transistor tester that you will use with confidence for

many years.

Refer to the "Kit Builders Guide" for complete information on unpacking, parts

identification, tools, wiring, soldering, and step-by-step assembly procedures.

Parts List

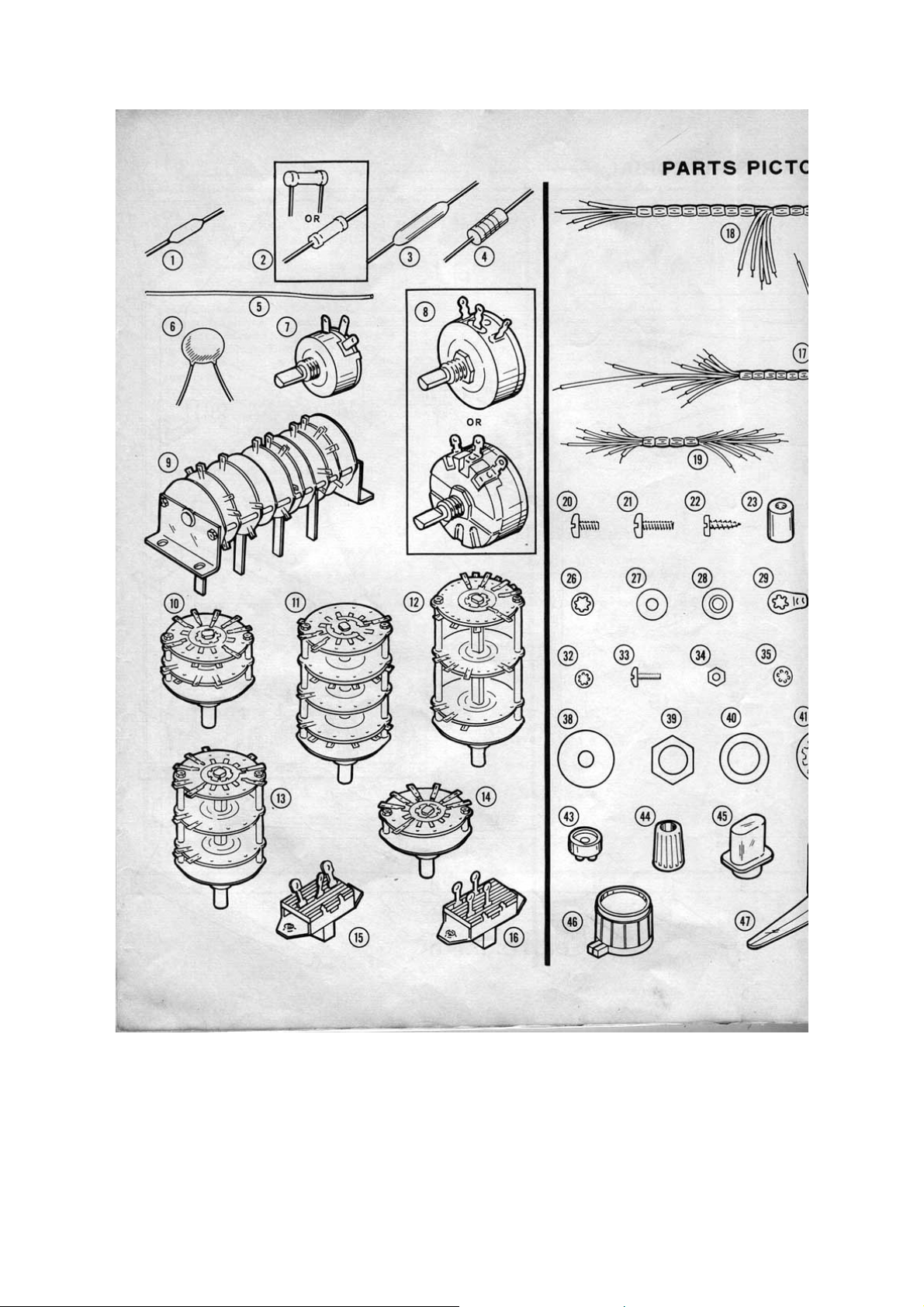

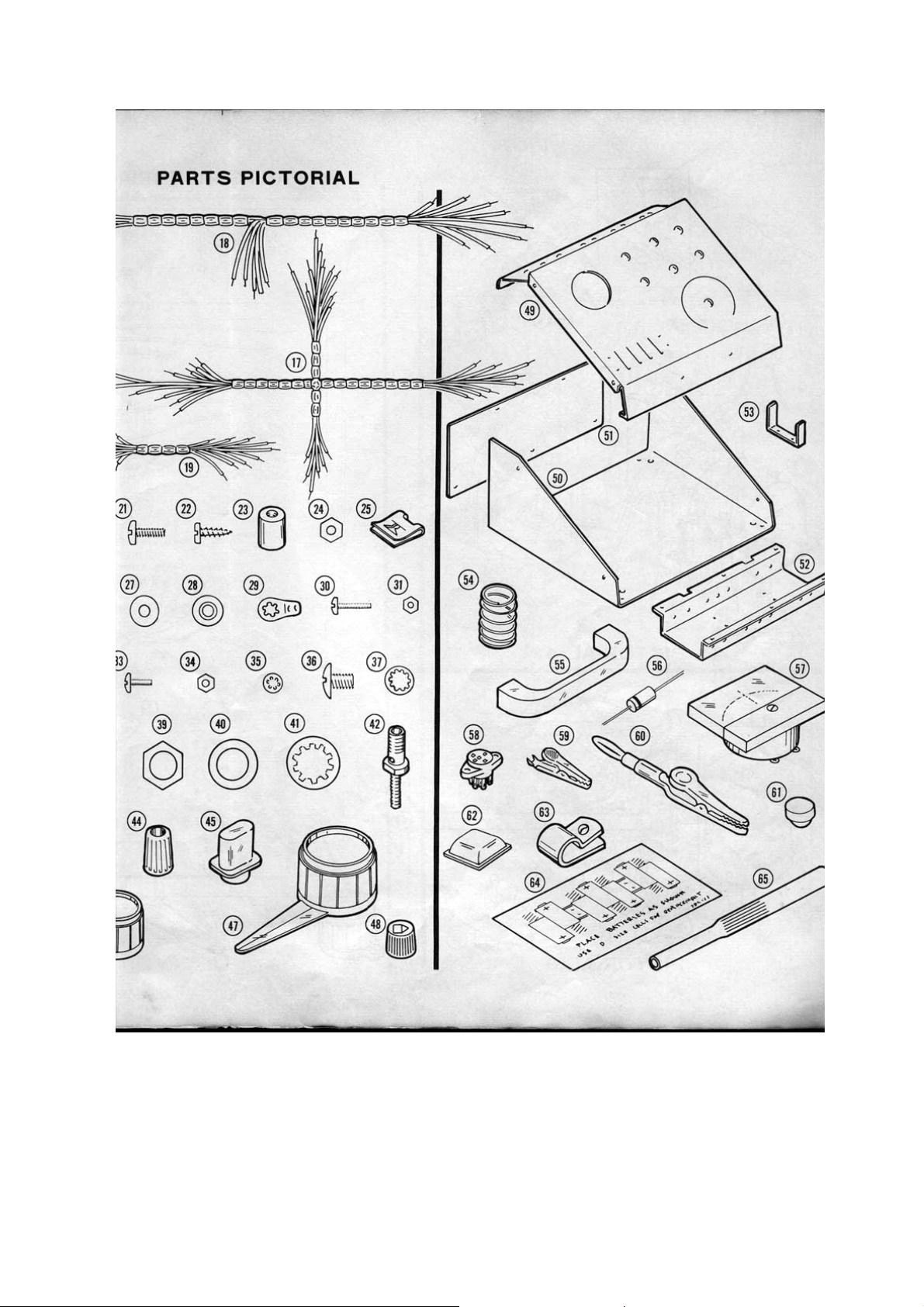

Note: the numbers in parenthesis in the Parts List are keyed to the numbers on the

Parts Pictorial (Fold-out from Page 5).

To order replacement parts, refer to the "Replacement parts Price List" on Page 47 and

use the Parts Order Form furnished with this kit.

Note: Precision resistors may be marked in Ω, KΩ, or MΩ. (KΩ equals 1000Ω, MΩ

equals 1,000,000Ω).

Part No.

Resistors

Precision 1%, 0.5 watt.

(1) 2-148 1 0.09Ω

2-148 1 0.9Ω

2-229 1 2Ω

(2) 2-19 1 9Ω

2-230 2 18Ω

2-24 1 90Ω

Parts Per

Kit

Description

Page 3

Parts Per

Part No. Kit Description

2-231 2 180Ω

2-29 1 900Ω

2-232 1 1800Ω (1.8kΩ)

2-233 1 2020Ω (2.02kΩ)

2-35 1 9000Ω (9kΩ)

2-189 1 18KΩ

2-156 1 145KΩ

2-157 1 350KΩ

2-14 1 1MΩ

2-158 1 3.5MΩ

2-17 1 10MΩ

2 watt.

(3) 2-15-2 1 2Ω 1%

(4) 3-5-2 1 2.2Ω 10% (red-red-gold-silver)

Other Resistances.

(5) 340-12-1 1 0.01Ω resistance wire.

Capacitors

(6) 21-48 2 0.05 uf Disc.

Controls

(7) 11-75 1 20KΩ 2 Watt

(8) 11-79 1 100Ω 4 Watt

Switches

(9) 62-14 1 3-position 6 wafer 4 lever

(10) 63-440 1 3-position 2-wafer rotary

(11) 63-441 1 10-position 4-wafer rotary

(12) 63-442 1 6-position 3-wafer rotary

(13) 63-443 1 10-position 3-wafer rotary

(14) 63-444 1 6-position 1-wafer rotary

(15) 60-4 1 SPDT Slide

(16) 60-5 1 DPST slide

Wire Harnesses and Wire

(17) 134-138 1 Main wire harness

(18) 134-152 1 Battery pack wire harness

(19) 134-153 1 Small wire harness

344-6 1 Red wire

344-59 1 White wire

Hardware #6

(20) 250-56 10 6-32 x ¼" screw

(21) 250-89 24 6-32 x 3/8" screw

Page 4

Parts Per

Part No. Kit Description

(22) 250-8 7 #6 x 3/8" sheet metal screw

(23) 255-23 2 6-32 threaded spacer

(24) 252-3 40 6-32 nut

(25) 252-22 8 6-2 speednut

(26) 254-1 15 #6 lockwasher

(27) 253-1 7 #6 fibre flat washer

(28) 253-2 14 #6 fibre shoulder washer

(29) 259-1 23 #6 solder lug

Other Hardware

(30) 250-175 2 2-56 x 3/8" screw

(31) 252-51 2 2-56 nut

(32) 254-7 2 #3 lockwasher

4-40 Hardware

(33) 250-52 4 4-40 x ¼" screw

(34) 252-2 4 4-40 nut

(35) 254-9 4 #4 lockwasher

(36) 250-107 2 10-24 x ¼" screw

(37) 254-3 2 #10 lockwasher

(38) 253-6 7 #10 flat fibre washer

Control Hardware

(39) 252-7 7 Control nut

(40) 253-10 7 Control flat washer

(41) 254-4 7 Control lockwasher

Binding Post and Knob Parts

(42) 427-3 9 Binding Post Base

(43) 75-17 18 Binding Post base insulator

(44) 100-16-2 6 Black Binding Post Cap

100-16-18 3 Red Binding Post Cap

(45) 462-97 4 Lever Switch Knob

(46) 462-245 6 Small Round Knob

(47) 462-253 1 Large Pointer Knob

(48) 455-50 7 Knob bushing

Metal Parts

(49) 203-740-1 1 Panel

(50) 90-502-2 1 Cabinet Shell

(51) 205-307-2 1 Rear Cover

(52) 214-14 1 Battery Housing

(53) 204-413 2 Battery Spacing bracket

(54) 258-43 7 Battery Contact Spring

(55) 211-14 1 Handle

Miscellaneous

(56) 56-10 2 Silicon Diode

Page 5

Parts Per

Part No. Kit Description

(57) 407-122 1 Meter (10-0-10 uA)

(58) 434-116 1 Transistor Socket

(59) 260-16 1 Alligator clip

(60) 438-14 2 Alligator clip with adaptor

(61) 261-4 4 Rubber Foot

(62) 261-28 4 Plastic Foot

(63) 207-18 2 3/8" cable clamp

(64) 390-114 1 Battery label

391-34 1 Blue & white identification label

(65) 490-5 1 Nut starter

597-308 1 Kit Builders Guide

597-260 1 Parts Order Form

1 Manual (See front cover for part

number.

Solder.

Note: Seven D-cell flashlight batteries (not furnished) will be required for operation of

the completed Transistor Tester. You may want to purchase these batteries now to

have them ready when you finish assembling the kit.

Step-By-Step Assembly

Before you start to assemble the Transistor Tester, read the Kit Builders Guide for

complete information on wiring, soldering, and step-by-step assembly procedures.

As you perform a step in the Step-by-step assembly, first read the step completely

through. Then perform the operation as directed. Position each part as wire as shown

on the pictorial that accompanies the series of steps. The details provide specific

information for individual steps.

Switch Pre-wiring

The assembly of this kit will begin with the pre-wiring of the switches. Before you begin

to pre-wire a switch, compare its physical construction with its pictorial so you can

identify the contacts and lug positions. Note that each contact position has a number,

even if it does not have a lug.

To hold the switch firmly while you connect the wires, you may find it convenient to

temporarily mount the switch in one of the 3/8" holes in the control panel. Place a

towel or soft cloth on your work surface to avoid scratches, and mount the control on

the inside of the panel.

Polarity Switch (#63-440)

Note: When wiring some of the parts in this kit, you will be instructed to prepare

lengths of wire ahead of time, as in the following steps. To prepare a wire, cut it to the

indicated length and remove ¼" of insulation from each end. The wires are listed in the

order in which they will be used.

Page 6

Page 7

Page 8

Page 9

Page 10

( ) Prepare the following lengths of wire:

Wire Colour Length

Red 3-¼"

White 4–¼"

White 4–¼"

White 6–¼"

White 8–¼"

* Red 3-½"

* Red 2-¼"

* Red 2-¾"

* Remove ¼" of insulation from one end and ¾" of insulation from the other end of

these three red wires.

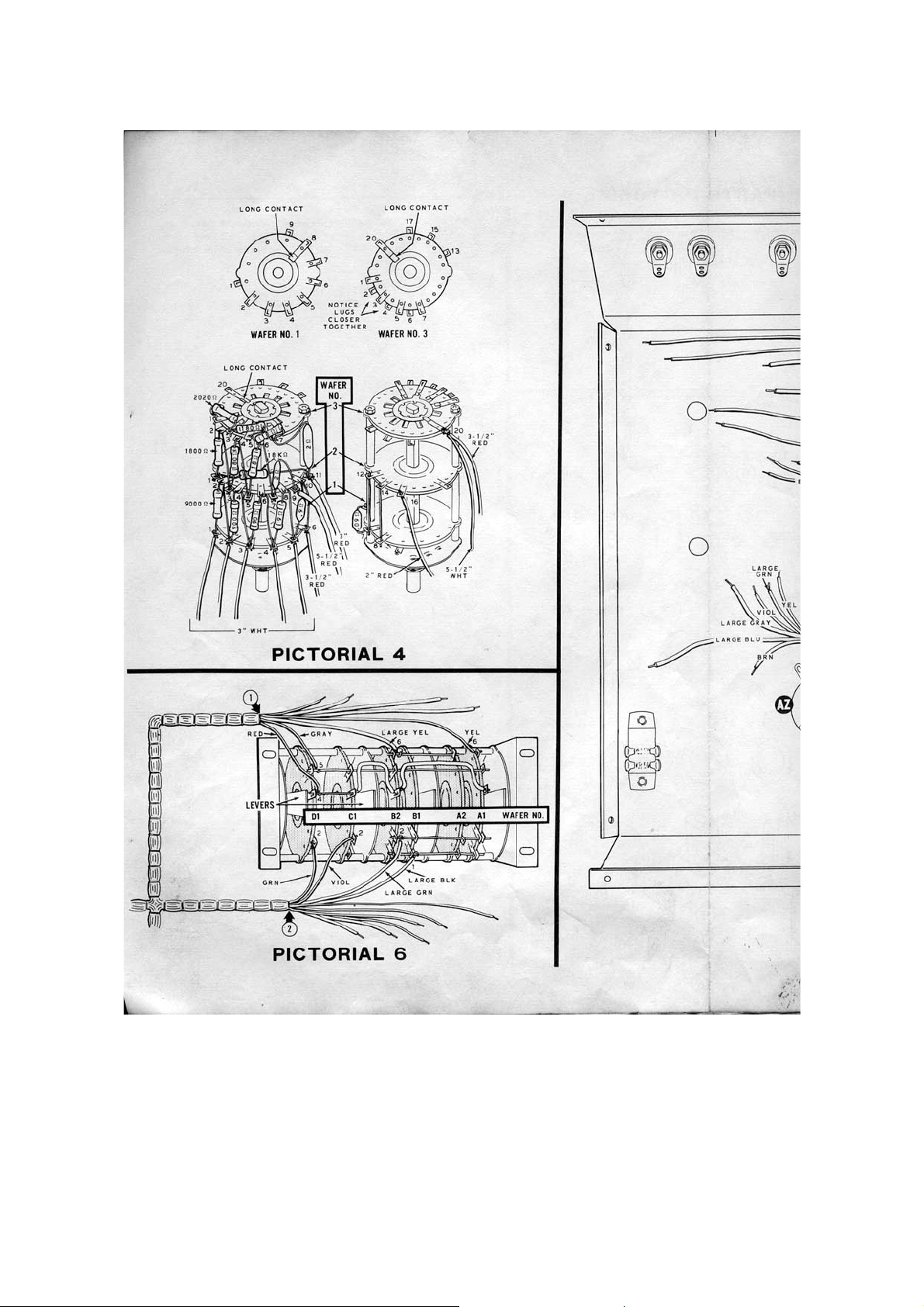

Refer to Pictorial 1 for the following steps.

( ) Locate the 3-position 2-wafer Polarity switch (#63-440) and compare its wafer

and lug positions with those numbered in the Pictorial. Note that the long contact

on wafer 2 is identified as lug 3.

Note: Only the switch wafer and lug number will be called out in the following steps.

As you connect a wire to a lug, pass the end of the wire through the lug. Then crimp

the end of the wire around the lug to hold it in place until you are instructed to solder

the connection, be sure to solder the connection, be sure to solder both lugs and the

wire.

Connect one end of each of the prepared wires to the 3-position 2-wafer Polarity switch

as follows.

Page 11

( ) 3-¼" red to wafer 1 lug 1 (S-1).

( ) 4-¼" white to wafer 1 lug 4 (S-1).

( ) 4-¼" white to wafer 1 lug 6 (S-1).

( ) 6-¼" white to wafer 2 lug 1 (S-1).

( ) 8-½" white to wafer 2 lug 11 (S-1).

( ) 3-½" red, short end to wafer 1 lug 3 (S-1).

( ) 2-¼" red, short end to wafer 2 lug 2 (S-1).

( ) 2-¾" red, short end to wafer 2 lug 4 (S-1).

This completes the pre-wiring of the Polarity switch. Set the switch aside until it is

called for later.

Collector Voltage Switch (#63-441)

( ) Prepare the following lengths of white wire:

1-¼", 1-¾", 2", 2-½", 2-¾"

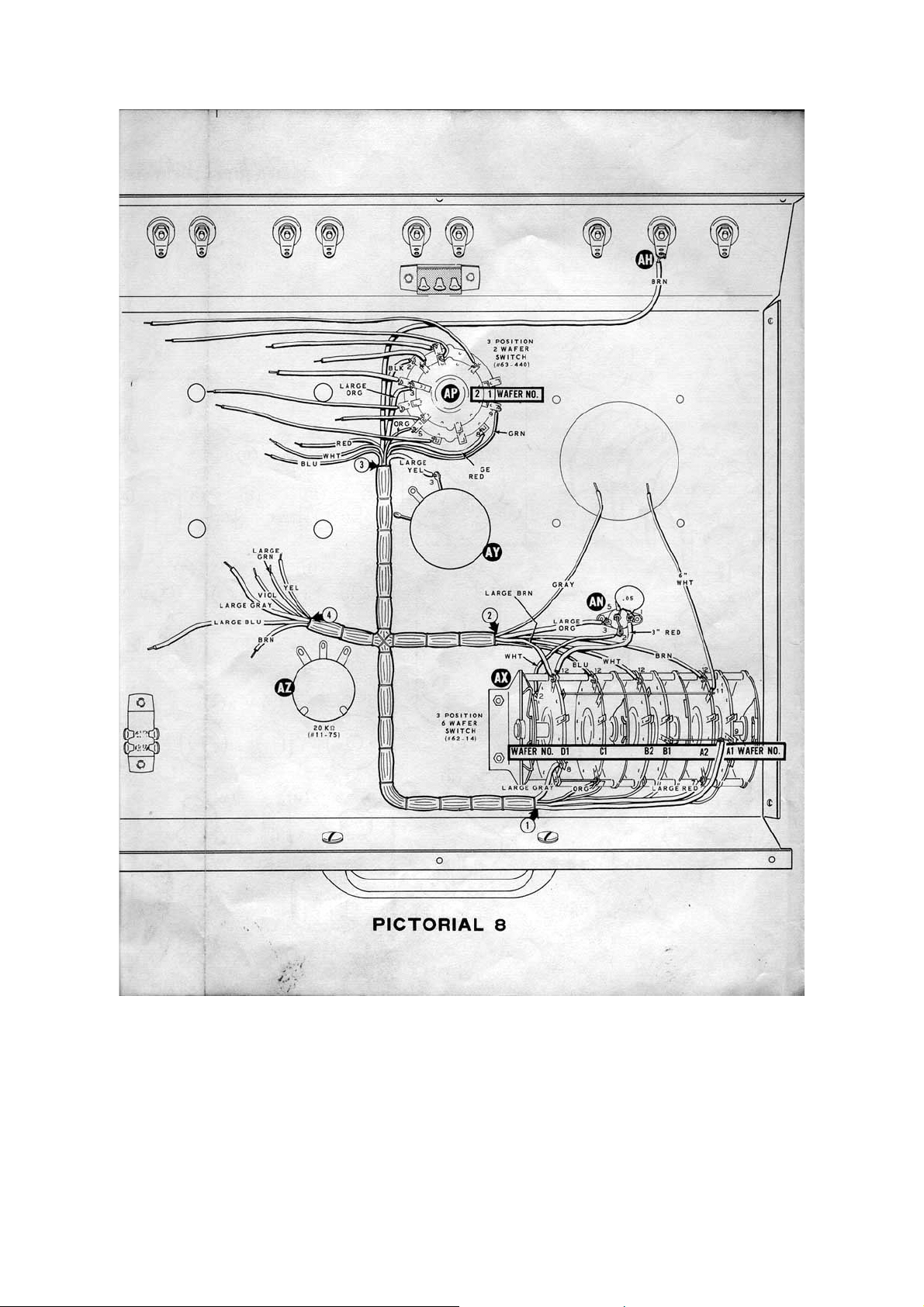

Refer to Pictorial 2 for the following steps:

( ) Locate the 10 position 4 wafer Collector voltage switch (#63-441). Compare the

lug positions with those shown in Pictorial 2. Note that the long contact on wafer

4 is lug 7.

Connect the prepared wires from wafer 3 to wafer 1 in the following steps:

Wire From Wafer 3 To Wafer 1

( ) 1-¼" Lug 4 (NS) Lug 4 (NS)

Page 12

( ) 1-¾" Lug 3 (NS) Lug 5 (NS)

( ) 2-¾" Lug 2 (NS) Lug 6 (NS)

( ) 2" Lug 5 (NS) Lug 3 (NS)

( ) 2-½" Lug 6 (NS) Lug 2 (NS)

( ) Strip the insulation from a 1-½" length of white wire. Then cut this bare wire into

two ¾" lengths.

Connect the two ¾" bare wires as follows:

( ) From wafer 1 lug 1 (NS) to wafer 2 lug 1 (S-1).

( ) From wafer 4 lug 3 (NS) to wafer 4 lug 2 (S-1).

( ) Locate the small wire harness (#134-153) and note the end that has the shortest

red, white and blue wires.

Wires from the end of the wire harness just identified will be connected to the

Collector Voltage switch in the following steps. Wires at the other end of the

harness will be connected later.

( ) Bend the four longest wires back away from the five short wires. This will help

avoid accidentally burning any wires while soldering.

Connect the following harness wires to wafer 1 of the switch.

( ) Black to lug 2 (S-2).

( ) White to lug 3 (S-2).

( ) Blue to lug 4 (S-2).

( ) Red to lug 5 (S-2).

( ) Brown to lug 6 (S-2).

Connect the following harness wires to wafer 4 of the switch.

( ) Violet to lug 12 (S-1).

( ) Grey to lug 1 (S-1).

( ) Yellow to lug 3 (S-2).

( ) Green to lug 7 (S-1).

( ) Carefully examine the lugs of the switch. All lugs on wafers 1, 2 and 4 that have

wires attached should have been soldered, except lug 1 on wafer 1. Lugs 2, 3,

4, 5 and 6 of wafer 3 have wires that are not soldered.

This completes the pre-wiring of the Collector Voltage switch. Set the switch aside until

it is called for later.

Page 13

Leak Voltage Switch (#63-443)

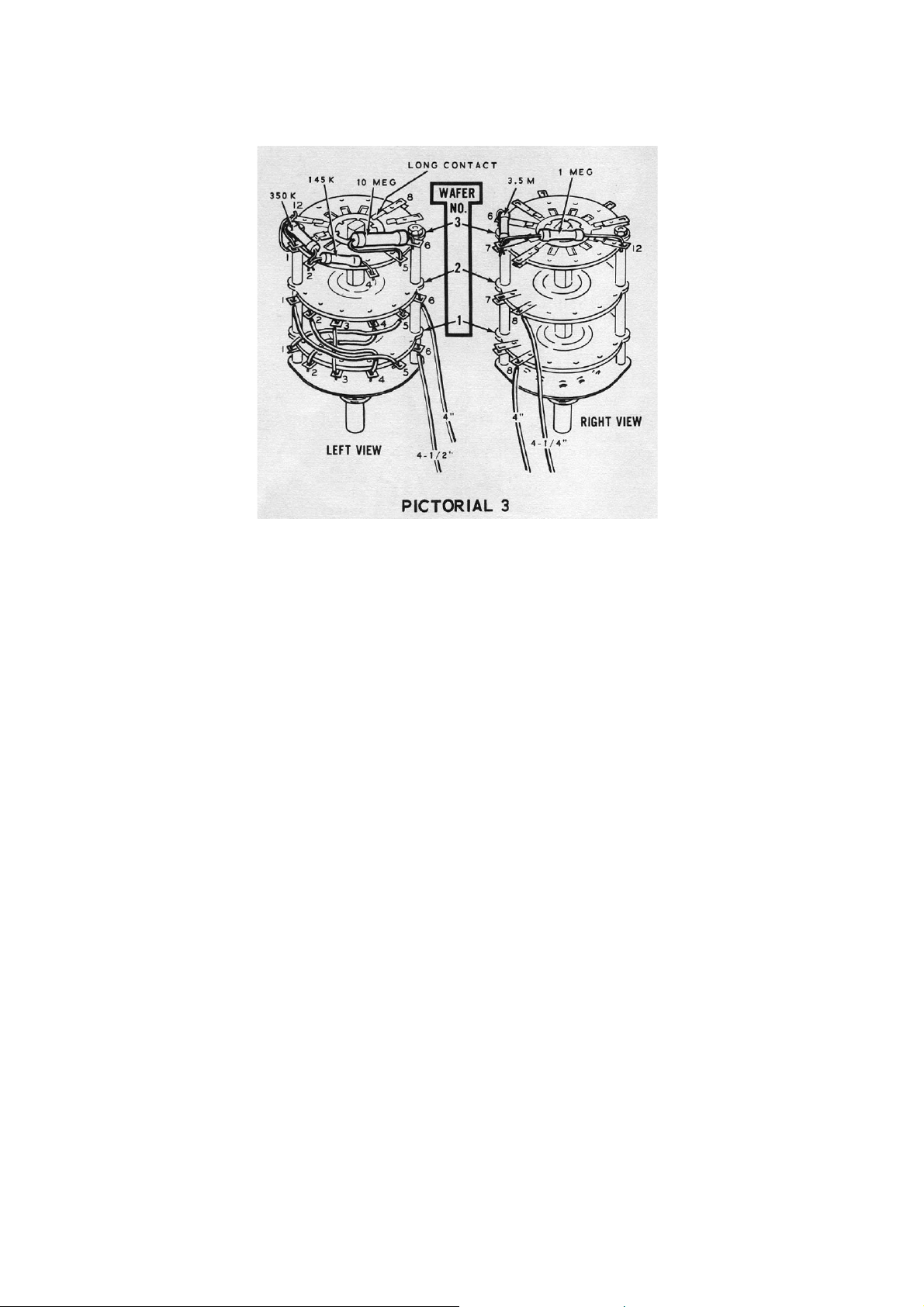

Refer to Pictorial 3 for the following steps.

( ) Locate the 10-position 3-wafer Leak Voltage switch (#63-443). Compare the

switch with Pictorial 3 so that you can identify the lug numbers. Notice that lug 8

is the long contact on wafer 3.

Note: When you connect a precision resistor, as in the following steps, do not handle

the resistor body with pliers or other tools. Preshape the resistor leads so its body can

be positioned as show in the Pictorial; then cut of the excess lead lengths after the

resistor is installed.

The following 1% precision resistors will be connected to the lugs on wafer 3 of the

Leak Voltage switch. Position each resistor as shown in Pictorial 3.

( ) 145KΩ from lug 4 (NS) to lug 2 (NS)

( ) 10 MΩ from lug 5 (S-1) to lug 6 (NS)

( ) 3.5 MΩ from lug 6 (NS) to lug 7 (NS).

( ) 1 MΩ from lug 7 (NS) to lug 12 (NS)

Note: Where a wire passes through one lug then goes to another point, as in the

following step, it will count as two wires in the soldering instruction (S-2) one entering

and one leaving.

( ) Pass one lead of the 350KΩ precision resistor through lug 1 (NS) to lug 12 (NS).

Shape the lead away from the switch spacer. Then connect the other lead of this

resistor to lug 2 (NS). Now solder lug 1 (NS).

( ) Prepare the following lengths of wire.

7/8 ", 1-¾", 2 x 1-½", 2-½"

Page 14

Connect these prepared wires from lugs on wafer 1 to lugs on wafer 2 as follows.

( ) 1-¾" 1 (NS) 5 (S-1)

( ) 1-½" 2 (NS) 4 (S-1)

( ) 1-½" 4 (NS) 2 (S-1)

( ) 2-½" 5 (NS) 1 (S-1)

( ) 7/8" 3 (NS) 3 (S-1)

( ) Prepare the following lengths of wire:

2 x 4", and 2 x 4-½"

Connect only one end of each of these prepared wires to lugs on the switch as follows.

( ) 4-½" to wafer 1 lug 6 (S-1).

( ) 4" to wafer 2 lug 6 (S-1).

( ) 4" to wafer 1 lug 8 (S-1).

( ) 4-¼" to wafer 2 lug 8 (S-1).

(There appears to be a small error here, no 4-¼" length was prepared)

This completes the wiring of the Leak Voltage switch. Set the switch aside until it is

called for later.

Wire From Wafer 1 Lug To Wafer 2 lug

Collector Current Switch (#63-442)

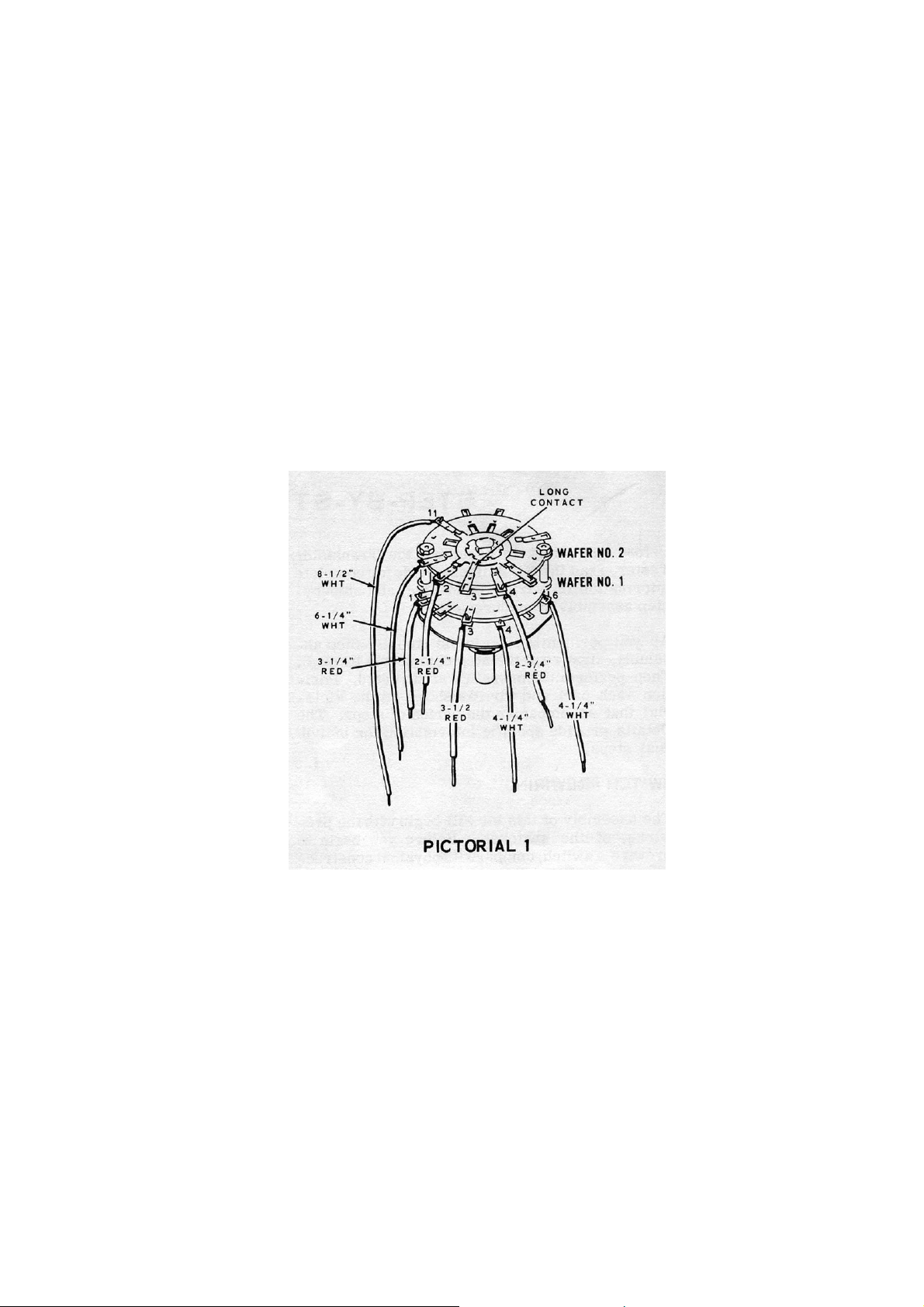

Refer to Pictorial 4 (fold-out from page 6) for the following steps.

( ) Locate the 6-position 3-wafer Collector Current switch (#63-442) and compare its

contacts and lugs with those shown in Pictorial 4. Notice that some lugs on

wafers 2 and 3 are closer together than the lugs on wafer 1. The long contact on

wafer 3 is lug 20.

Caution: Use extra care in making connections to the closely spaced lugs on the

switch. Bend wires over the end of the lug. Trim excess lead lengths close to the lug.

Be careful not to bend or break a lug. Where there is a front and rear lug at a position

on a wafer, pass the wire through both lugs. Then be sure to solder both lugs and the

wire when you are instructed to solder.

Note: The 1% precision resistors may be marked in Ω, KΩ, or MΩ (KΩ = 1000Ω, MΩ

= 1,000,000Ω). For example: 1800Ω = 1.8KΩ, 2020Ω = 2.02KΩ, Examine each

resistor carefully to be sure you install the correct value each time. As you install a

resistor on the switch, pre-shape the leads so the resistor body can be positioned as

shown in Pictorial 4.

Read each step completely through first; then perform the operation described in the

step. Connect both leads of each resistor before you solder either lead.

In the following steps, you will connect 1% precision resistors to lugs on the wafers of

the Collector Current switch.

Page 15

( ) Connect the 18KΩ resistor from lug 1 (NS) to lug 11 (NS) on wafer 2. Position

the resistor away from the movable parts of the switch.

( ) Pass one end of the 1800Ω (1.8KΩ) through lug 2 on wafer 3 (S-2) to lug 3 on

wafer 2 (NS). Connect the other end of this resistor to lug 1 on wafer 2 (S-2).

( ) Pass one lead of a 180Ω resistor through lug 4 on wafer 3 (S-2) to lug 5 on wafer

2 (NS). Connect the other lead to lug 3 on wafer 2 (S-2).

( ) Pass one lead of an 18Ω resistor through lug 6 on wafer 3 (S-2) to lug 7 on wafer

2 (NS). Connect the other lead to lug 5 on wafer 2 (S-2).

( ) Connect the 2Ω 0.5 watt precision resistor from lug 7 on wafer 2 (NS) to lug 9 on

wafer 2 (NS).

( ) Connect the 2Ω 2 watt precision resistor from lug 11 on wafer 2 (NS) to lug 7 on

wafer 3 (NS).

( ) Connect the remaining 18Ω precision resistor from lug 7 (S-2) to lug 5 (NS) on

wafer 3.

( ) Connect the remaining 180Ω precision resistor from lug 5 (S-2) to lug 3 (NS) on

wafer 3.

( ) Connect the 2020Ω (2.02 KΩ) resistor from lug 3 (S-2) to lug 1 (S-1) on wafer 3.

( ) Connect the 0.09Ω resistor from lug 6 (NS) to lug 7 (NS) on wafer 1.

( ) Pass one lead of the 0.9Ω resistor through lug 10 on wafer 2 (S-2) to lug 6 on

wafer 1 (NS). Connect the other lead to lug 5 on wafer 1 (NS).

( ) Pass one lead of the 9Ω resistor through lug 8 on wafer 2 (S-2) to lug 5 on wafer

1 (NS). Connect the other lead to lug 4 on wafer 1 (NS).

( ) Pass one lead of the 90Ω resistor through lug 6 on wafer 2 (S-2) to lug 4 on

wafer 1 (NS). Connect the other lead to lug 3 on wafer 1 (NS).

( ) Connect the 900Ω resistor from lug 4 on wafer 2 (NS) to lug 2 on wafer 1 (NS).

( ) Remove the insulation from a 1-½" white wire. Then connect this wire from lug 4

on wafer 2 (S-2) to lug 3 on wafer 1 (NS).

( ) Pass one lead of the 9000Ω (9KΩ) resistor through lug 2 on wafer 2 (S-2) to lug

2 on wafer 1 (NS). Connect the other lead to lug 1 on wafer 1 (NS).

( ) Remove the insulation from a 2-¾" length of red wire. Then cut this bare wire

into two 1-3/8" lengths.

In the next two steps, you will connect the heavy bare wires you have just prepared.

( ) 1-3/8" bare wire from lug 7 on wafer 1 (S-2) to lug 12 on wafer 2 (S-1).

( ) 1-3/8" bare wire from lug 8 on wafer 1 (S-1) to lug 14 on wafer 2 (NS).

Page 16

( ) Remove ¼" of insulation from each end of a 2" red wire. Then, connect one end

of this wire to lug 16 on wager 2 (S-1). The other end will be connected later.

( ) Prepare the following lengths of red wire.

3", 2 x 3-½", 5-½"

Connect one end of each of these prepared wires in the following steps.

( ) 3-½" to lug 6 on wafer 1 (S-3).

( ) 5-½" to lug 9 on wafer 2 (S-2).

( ) 3" to lug 11 on wafer 2 (S-3).

( ) 3-½" to lug 20 on wafer 3 (NS).

( ) Prepare a 5-½" white wire, then connect one end of this wire to lug 20 on wafer 3

(S-2).

( ) Prepare five 3" lengths of white wire.

In the following steps you will connect one end of each of these prepared 3" wires to

lugs on wafer 1.

( ) Lug 1 (NS).

( ) Lug 2 (S-3).

( ) Lug 3 (S-3).

( ) Lug 4 (S-3).

( ) Lug 5 (S-3).

This completes the pre-wiring of the Collector Current Switch. Set the switch aside

until it is called for later.

Lever Switch (#62-14)

Refer to Pictorial 5 for the following steps.

( ) Locate the 3-position 6-wafer 4-lever switch (#62-14) and compare its sections,

wafers, and lugs with those shown in Pictorial 5.

Note: the lever switch contains four separate switch sections, marked A, B, C, and D in

Pictorial 5. Sections A and B each have two wafers, while sections C and D each have

one wafer. To identify the wafers and lugs on the lever switch, a letter-number

combination will be used as follows: The letter will identify the section and the first

number will identify the wafer in that section. The number that follows the dash will

indicate the lug. For example A2-11 would refer to section A, wafer 2, lug 11.

( ) Cut the following lengths of red wire (10), then remove the insulation from each

of them. (These will be the bare wires used in the steps that follow.)

Page 17

2 x ¾", 1", 1-¼", 1-1/8", 2 x 1-½", 2-3/8", 2 x 2-¾",

Note: You will connect the bare wires to lugs on the lever switch in the following steps.

Pass the wire through the lugs in the order given; then solder only the lugs indicated.

Where two lugs appear at a position on a wafer, and you are instructed to solder, be

sure to solder both of the lugs and the wire. Be sure none of the bare wires touch any

metal parts.

Position the lever switch as shown in the upper part of Pictorial 5. Then connect the

prepared bare wires as follows:

( ) 1" from B2-6 (S-1) to A2-6 (S-1).

( ) 2-¾" through lug 5 on all wafers. Solder all but D1-5 (NS).

( ) ¾" from D1-4 (S-1) to C1-4 (NS).

( ) 1-½" through B2-2 (S-1), B1-2 (S2), A2-2 (S-2), A1-2 (S-1).

( ) 1-½" through B2-1 (NS), B1-1 (S-2), A2-1 (S-2), A1-1 (S-1).

( ) Connect the 2.2Ω 2 watt (red-red-gold-silver) resistor from C1-1 (S-1) to B2-1 (S-

2). Position the resistor as shown.

( ) Remove ¼" of insulation from each end of a 2" length of red wire. Then connect

this wire from C1-4 (S-2) to B2-4 (NS). Shape and position the wire as shown.

Page 18

( ) Remove ¼" of insulation from each end of a 2-½" length of red wire. Then

connect this wire from B2-4 (S-2) to A1-4 (S-1).

( ) Remove ¼" of insulation from each end of a 2-½" length of white wire. Then

connect one end of this wire to D1-2 (NS). The other end will be connected later.

Position the switch as shown in the lower part of Pictorial 5. Then connect the rest of

the prepared bare wires as follows.

( ) 1-1/8" from B2-7 (S-1) to A2-7 (NS).

( ) ¾" from D1-7 (S-1) to C1-7 (NS).

( ) 1-¼" from B1-9 (S-1) to A1-9 (NS).

( ) 2-¾" through lug 10 on al wafers. Solder all of the lugs.

( ) 2-3/8" through lug 11 on all wafers. Solder all but A2-11 (NS).

( ) Connect a 2-7/8" red wire from A1-8 (S-1) to D1-8 (NS).

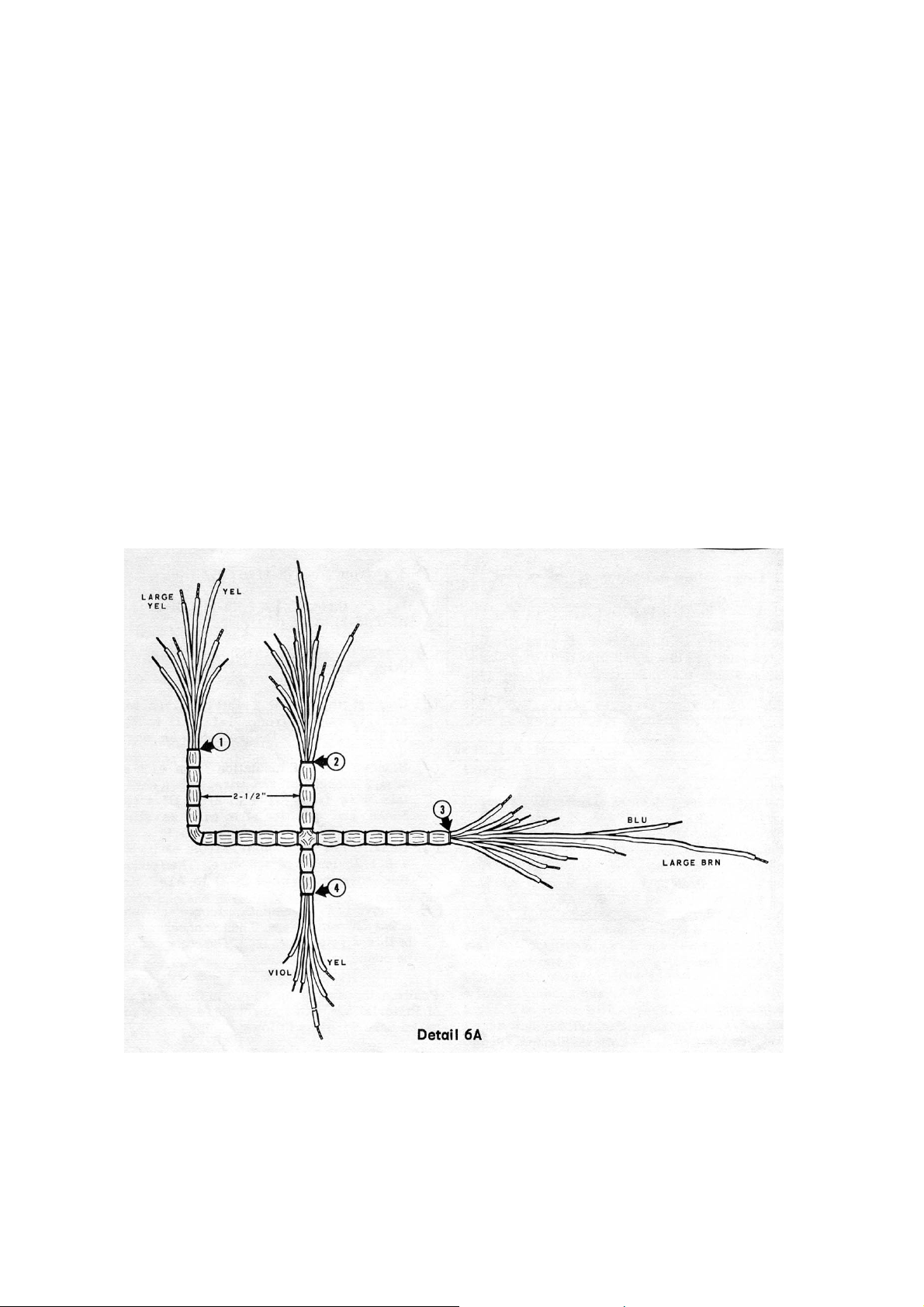

Refer to Pictorial 6 (fold-out from Page 6) for the following steps.

( ) Locate the main wire harness (#134-138). Form the harness as shown in Detail

6A. Note that the breakout #1 has a large yellow and small yellow wire, and

breakout #3 has a long large brown wire.

Page 19

( ) Position the wire harness and the lever switch as shown in Pictorial 6.

Note: In the following steps, you will connect the harness wires to the lever switch.

Some of the switch lugs were left unsoldered to accept the small wires from the

harness. When you connect the large wires, form a hook in the end of the wire; then

wrap the hook around the bare wire near the specified lug and solder the connection.

Small wires are called out by their colors, while large wires are labelled "large". For

example, "yellow" and "large yellow."

Connect the wires from breakout #2 as follows:

( ) Green to D1-2 (S-2).

( ) Violet to C1-2 (S-1).

( ) Large green to B2-2 (S-1).

( ) Large black to B1-1 (S-1).

Connect the wires from breakout #1 as follows:

( ) Gray to D1-5 (S-2).

( ) Red to D1-4 (S-2). Note that this lug was soldered previously. Heat the

connection; then insert the red wire and resolder.

( ) Large yellow to B2-6 (S-1).

( ) Yellow to A1-6 (S-1).

The remainder of the harness wires will be connected after the lever switch is installed.

Carefully examine the connections on the lever side of the switch. Every lug should

be connected and soldered. Be sure that no bare wires touch any metal parts. Set the

lever switch aside temporarily.

Control Panel Parts and Initial Wiring.

Most of the parts in the Transistor Tester will be mounted and wired on the control

panel. The operations in this part of the manual are divided into three sections as

follows:

1. Initial parts mounting.

2. Switch mounting and wiring

3. Other parts mounting and wiring.

Initial Parts Mounting.

Refer to Pictorial & (fold-out from page 15) for the following steps.

( ) Locate the control panel and position it as shown. Place a towel or soft cloth on

your work surface to avoid scratching the panel.

Page 20

Note: the Heath Company has provided a plastic nut starter with this kit. Use this nut

starter to hold and start 2-56, 4-40, and 6-32 nuts on screws. Refer to page 3 of the Kit

Builders Guide for further information.

( ) Install a binding post base at AA. Use a

binding post base, two binding post

insulators, a #6 lockwasher, a #6 solder

lug, and two 6-32 nuts as shown in Detail

7A.

( ) In a like manner, install binding posts at

AB, AC, AD, AE, AF, AG, AH, and AJ.

( ) Install red binding post caps on the binding

posts at AA, AC, and AE. Each of these

binding posts is marked ( + ) on the top of

the panel. Turn each cap all the way onto

its base.

( ) Install black binding post caps on the

remaining six binding posts. Turn each cap

all the way onto its base.

Note: If you wish to keep the binding posts from

falling off when they are loosened, perform the

following step at each of the binding posts that

were just installed.

( ) Insert the tip of a ¼" shaft Philips screwdriver into the open end of the binding

post cap. Then tap the handle of the screwdriver sharply with a small hammer or

tool. Support the binding post so the hammer blow does not crack this insulator

or bend the panel.

( ) Refer to detail 7B and install the SPDT

slide switch (#604) at AK. Use two 6-32 x

¼" screws and position the switch as show

in Pictorial 7.

( ) In the same manner, install the DPST slide

switch (#60-5) at AL with two 6-32 x ¼"

screws.

( ) Install the handle on the front apron of the

control panel. Use two 10-24 x ¼" screws

and #10 lockwashers.

( ) Refer to Detail 7C and install the transistor

socket at AN. Use 2-56 x 3/8" screws, #3

lockwashers, and 2-56 nuts as shown. Be

sure to position the socket so lug 1 is

toward the edge of the panel.

( ) This completes the initial control panel

Page 21

parts mounting. Other parts will be mounted and wired in the following sections.

Switch Mounting and Wiring.

he pre-wired switches will be mounted and wired in this section. Handle the switches

T

carefully to avoid damaging the wafers or contacts.

osition the wires as shown in the Pictorials, and be sure you do not pinch any wires

P

under mounting hardware

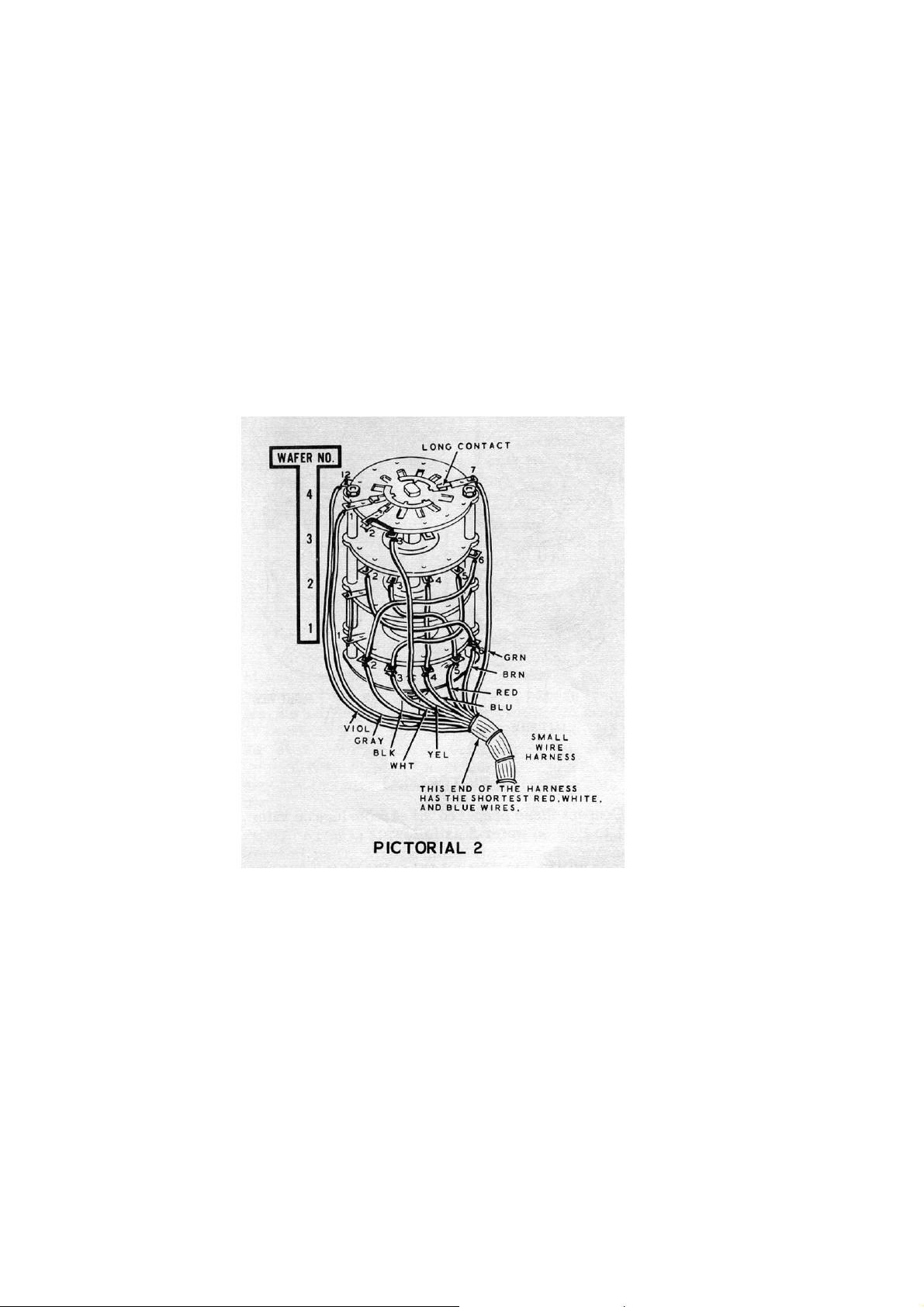

efer to Pictorial 8 (fold-out from page 6) for the following steps.

R

) Mount the pre-wired lever switch at AX as shown in Detail 8A. Use 4-40 x ¼"

(

screws, #4 lockwashers, and 4-40 nuts. First mount the switch loosely; then turn

the panel over and be sure the switch levers are centred in their slots. Finally,

tighten the hardware.

) Connect the white wire that comes from lever switch D1-2 to lug 2 of transistor

(

socket AN (NS).

) Connect a 3" red wire from lever switch D1-12 (NS) to lug 1 of transistor socket

(

AN (NS)

Page 22

( ) Connect one lead of a 0.05 uF disc capacitor through lug 5 (S-2) to lug 2 (S-2) of

transistor socket AN. Connect the other lead of this capacitor to lug 1 (S-2) of

the same socket.

( ) Prepare a 6" white wire and connect one end to lever switch A2-11 (S-2). The

other end will be connected later.

onnect the wires from breakout #2 of the wire harness as follows:

C

) Large brown to D1-12 (S-2).

(

) Blue to C1-12 (S-1).

(

) White to B2-12 (S-1).

(

) Brown to A2-12 (S-1).

(

) Large orange to lug 3 of transistor socket AN (S-1).

(

he grey wire from breakout #2 will be connected later.

T

onnect the wires from breakout #1 to the lever switch as follows:

C

) Orange to C1-7 (S-2).

(

) Large Grey to D1-8 (S-2).

(

Page 23

( ) Large red to A2-7 (S-2).

) Larger blue to A1-9 (S-2).

(

ll wires from breakouts #1 and #2 should now be connected and soldered except one

A

grey wire from breakout #2. This wire will be connected later.

res from breakout #3 of the main wire harness will be connected to the Polarity

Wi

switch, before the switch is mounted, in the following steps.

) Locate the pre-wired 3-position 2-wafer Polarity switch (#63-440). Be sure to

(

correctly identify the wafers and lugs. Wafer 1 is nearest the knob end of the

shaft and lug 3 is the long contact on wafer 2. See detail 8B.

onnect the wires from breakout #3 to the lugs on wafer

C

1 as follows:

) Large black to lug 2 (S-1).

(

) Orange to lug 5 (S-1).

(

) Large red to lug 8 (S-1).

(

) Green to lug 9 (NS).

(

) Connect the large orange wire to lug 3 on wafer 2 (NS).

(

Page 24

( ) Refer to detail 8C and mount the Polarity switch at

AP on the front panel. Use a control lockwasher,

control flat washer, and a control nut. Position the

switch and its wires as shown in Pictorial 8.

) Install the 100Ω control (#11-79) at AY as shown

(

in Detail 8D. Use a control lockwasher, a control

flat washer, and a control nut. Position the control

as shown in pictorial 8.

) In a like manner, install the 20KΩ control (#11-75)

(

at AZ.

) Connect the large yellow wire from wire harness

(

breakout #3 to lug 3 of control AY (S-1).

) Connect the long brown wire from breakout #3 to

(

the solder lug at AH (NS). Route this wire along

the bend in the panel as shown in the Pictorial.

efer to Pictorial 9 (fold-out from page 16) for the

R

following steps.

) Mount the pre-wired 10-position 4-wafer Collector

(

voltage switch (#63-441) at AR. Use a control

lockwasher, a control flat washer, and a control nut

as shown in detail 9A. Position the switch and its

wires as shown in Pictorial. Be sure you do not

pinch any wires under the mounting hardware.

) Note: Throughout the remainder of the step-by-

(

step assembly instructions, switches will be

identified by a letter number combination. For

example, the term AP2-11 would refer to switch

AP, wafer 2, lug 11.

) Connect the white wire from AP2-11 to solder

(

lug AA (NS).

) Connect the white wire from AP2-1 to solder lug

(

AB (NS).

) Connect the red wire from AP1-1 to AR1-1 (S-2).

(

) Connect the red wire that comes from AP1-3

(

through AR2-12 (S-2) to AR3-12 (S-1)

) Connect the red wire that comes from AP2-4

(

through AR1-11 (NS) to AR2-11 (S-1).

) Prepare the following lengths of wire.

(

2-¼" red, 2-½" red, 3" red, 5" red, 5" white, 8"

white, 8-½" red

Page 25

( ) red wire from AR1-11 (S-3) to solder lug AD (S-1).

( ) Connect the red wire that comes from AP2-2 through AR2-10 (NS)

( ) nect a 3" red wire from AR2-10 (S-3) to solder lug AC (S-1).

( ) Connect a 2-½" red wire from AP1-10 (S-1) to lug 2 of switch AK

( ) Connect a 5" red wire from AP1-9 (NS) to solder lug AG (NSD).

( ) Connect a one end of a 5" white wire to AP1-9 (S-3). The o

( ) red wire from AP2-3 (NS) to solder lug AJ (S-1).

( ) Connect one end of an 8" white wire to AP2-3 (S-3). The oth

( ) F disc capacitor from solder lug AG (S-2) to solder lug AH (S-2).

( ) Remove the insulation from a 1" red wire. Then connect this bare wire from

Refer

( ) Mount the pre-wired 10-position 3-wa

Connect the free ends of the wires from the switches as follows:

( ) White from AS1-8 to solder lug AA (S-2).

Connect a 2-¼"

to AR3-10 (S-

1).

Con

(S-1).

ther end will be

connected later.

Connect an 8-½"

er end will be

connected later.

Connect a 0.05 u

solder lug AE (S-1) to lug 1 of switch AK (S-1).

to Pictorial 10 for the following steps.

fer Leak Voltage switch (#63-443) on the

control panel at AS. Use a control lockwasher, control flat washer, and a control

nut. Position the switch as shown in Pictorial 10. Be sure you do not pinch any

wires under the mounting hardware.

Page 26

( ) White from AS2-8 to solder lug AB (S2).

( )

(

(

(

In

the ven length; then remove ¼" of ins

w

( ) Connect a 3" whiter wire from AR1-7 (S-2) to AP2-7 (NS).

( )

(

T

the llowing steps. Connect the ends of these wires to lugs on wafer

fo

( ) Black to AS1-5 (S-2).

(

(

(

(

C

White from AP1-6 to AS1-7 (S-1).

) White from AP1-4 to AS2-7 (S-1).

) White from AS2-6 to AR1-7 (NS).

) White from AS1-6 to AR3-7 (NS).

the next three steps, the length and colour of each wire is called out. Cut the wire to

gi ulation from each end before connecting the

ire.

Connect a 2-¼" white wire from AR3-7 (S-2) to AP2-5 (NS).

) Connect a 5" red wire from solder lug AF (S-1) to AP1-7 (NS).

he wires from the small wire harness that comes from switch AR will be connected in

fo 1 of switch AS as

llows.

) White to AS1-4 (S-2).

) Blue to AS1-3 (S-2).

) Red to AS1-2 (S-2).

) Brown to AS1 (S-2).

onnect the following small harness wires to wafer 3 of switch AS:

Page 27

( ) Yellow to AS3-7 (S-3).

) Grey to AS3-6 (S-3).

(

) Green to AS3-2 (S-3).

(

) Violet to AS3-12 (S-3).

(

) Position the wires from the small wire harness as shown in Pictorial 10.

(

) Connect the white wire that comes from AP2-3 to AS3-4 (S-2).

(

) Carefully examine the lugs on switch AS. Every lug except lug 8 (long contact)

(

on wafer 3 should have been connected and soldered.

Other Parts Mounting and Wirin

g.

Refer to Pictorial 11 for the following steps.

) Install the 6-position 1-wafer Base Current switch (#63-442) at AT. Use a control

(

a control nut. Position the switch as shown

( )

lockwasher, a control flatwasher, and

in the Pictorial.

In a like manner, install the pre-wired 6-position 3-wafer Collector Current switch

(#63-442) at A

hardware.

U. Be careful not to pinch any wires under the mounting

Page 28

In t following steps you will connect the wires that come from lugs on wafer 1 of

he

switch

(

( ) White from AU1-2 to AT-2 (S-1).

( ) White from AU1-3 to AT-3 (S-1).

( ) White from AU1-4 to AT-4 (S-1).

( ) White from AU1-5 to AT-5 (S-1).

( ) Red from AU1-6 to AT-6 (S-1).

( ) Remove an extra ¼" of insulation

(

( ) Connect the red wire that comes from AU2-16 to lug 1 of control AY (S-1).

( ) wire that comes from AU2-11 to lug 1 of control AZ (NS).

( ) Connect the white wire that comes from AU3-20 to lug 3 of control AZ (S-1)

( ) Connect the white wire that comes from AP1-9 to AU2-20 (S-1).

( ) Remove ½" of insulation from one end, and ¼" of insulation from the other end,

Refer to Pictorial 12 (fold-out from page 27 for the following steps.)

Conne

( ) Blue to AS3-8 (S-1).

( ) White to AR4-4 (S-1).

( ) Red to AU1-1 (S-3).

Connect the wires from b

fo

(

( ) La

( ) Violet to AU2-10 (S-3

AU to corresponding lugs on switch AT.

) White from AU1-1 to AT-1 (S-1).

from the end of the red wire coming from AU2-

9. Then pass this end of the wire through lug 2 (S-2) to lug 1 (S-1) of switch AL.

) Connect the red wire that comes from AU3-20 to lug 2 of control AY (S-1). Move

the harness and other wires aside and be careful not to burn any wires with your

soldering iron.

Connect the red

.

of a 4" red wire. Pass the ½" bare end through lug 4 (S-2) to lug 3 (S-1) of switch

AL. Then connect the other end of this wire to lug 1 of control AZ

ct the remaining wires from breakout #3 of the wire harness as follows:

reakout #4 as

llows:

) Yellow to AU1-9 (S-1.)

rge Green to AU2-14 (S-2).

). Note that

AU2-10 was already soldered.

Reheat the lug and connect th

Then resolder.)

e wire.

(S-2).

Page 29

Large grey to AT-8 (S-1). ( )

( ) Large blue to the wire betw

( ) Carefully unpack the meter from the box and remove the sh

between the meter terminals.

( ) nt the meter on the front of the panel. Use the

( ) e lead of a silicon

( )

( ) " white wire from AP2-10 (S-1) to lug 1 of the meter (NS).

( ) Connect a 6" white wire from AP2-9 (S-1) to lug 2 of the meter (S-4).

( ) Connect the grey wire from breakout #2 of the wire harness to lug 1 o

( ) the length of resistance wire (#340-12-1) and shape it as shown in detail

T ompletes the Control

w

AT, or AU or on controls AY or AZ.

Refer to Detail 12A and mou

lockwasher and nuts that are supplied with the meter. Be careful not to

overtighten the nuts or you might pull the screw studs from the meter case.

Note: Refer to Detail 12B in the following steps to identify the cathode en

e silicon diodes.

th

Connect the cathod

diode to lug 1 of the meter (NS).

Connect the other end to lug 2 (NS).

Connect the cathode end of the

remaining silicon diode to lug 2 of the

meter (NS). Connect the other end to

lug 1 (NS).

Connect a 5

(S-4).

Locate

12C. then connect one end of this wire to the bare wire near AU1-7 (S-1).

Connect the other end of the resistance wire to the bare wire near D1-10 (S-1).

Do not cut this wire.

his c Panel Parts Mounting and Wiring. Check to see that all

ire ends are connected. There should be no unsoldered connections on switches AS,

een lugs 1 and 2 of switch AL (S-1).

orting wire from

ds of

f the meter

Page 30

Tip and shake the Control Panel to dislodge any bits of solder or wire clippings that

may have fallen unnoticed into the wiring.

Set the control panel aside temporarily and proceed to the Battery Housing Assembly

and Wiring instructions that follow.

Battery Housing Assembly and Wiring.

Refer to Pictorial 13 for the following steps.

( ) Locate the battery housing and position it

as shown in this Pictorial.

( ) Mount a battery contact spring a 1. Use a

6-32 x 3/8" screw, a #10 flat fibre washer,

a #6 fibre shoulder washer, a #6 solder

lug, and a 6-32 nut. See Detail 13A

( ) In a like manner, install battery contact

springs at 3, 5, 7, 9, 11, 13.

( ) Refer to detail 13B and install a 6-32 x

3/8" screw, #6 fibre shoulder washer, #6

fibre flat washer, #6 solder lug, and 6-32

nut at 2.

( ) In a like manner install similar hardware at 4,6, 8, 10, 12 and 14.

( ) Install 6-32 threaded spacers at BA and BB. Use 6-32 x ¼" screws and #6

lockwashers as shown in detail 13C.

( ) Install a battery spacer bracket at BC as show in detail 13D. Use a 6-32 x ¼"

hardware in one mounting hole and 6-32 x 3/8" hardware with a 3/8" cable clamp

in the other mounting hole.

Page 31

( ) In a like manner, install the other

battery spacer bracket and cable clam

at BD.

( ) Install 6-32 speednuts at each of the

holes on the battery housing flange as

shown in Pictorial 13. Be sure that the

flat side of each speednut faces

upward.

Position the battery housing as shown in

Pictorial 14 for the following steps.

( ) Locate the battery pack wire harness

and pass the four wires of breakout #3

through both cable clamps as shown

in the pictorial.

( ) Prepare the following lengths of bare

wire. To prepare the bare wire, first

cut the indicated lengths of red wire.

Then remove all the insulation from

each length.

3 x 1-¾", and 2 x 2-¼"

Connect these bare wires to the solder lugs

on the battery pack as follows:

( ) 2-¼" from lug 2 (NS) to lug 3 (S-1).

( ) 1-¾" from lug 4 (S-1) to lug 5 (NS).

( ) 1-¾" from lug 8 (S-1) to lug 9 (NS).

( ) 1-¾" from lug 10 (NS) to lug 11 (S-1).

( ) 2-¼" from lug 12 (S-1) to lug 13 (NS).

Connect the wires from breakout #3 of the

battery pack harness to the lugs on the

battery housing as follows:

( ) Yellow to lug 1 (S-1).

( ) Red to lug 2 (S-2).

( ) Brown to lug 9 (S-2).

( ) Orange to lug 10 (S-2).

Connect the wires from breakout #2 of the bottom pack harness to the lugs on the

battery housing as follows:

( ) Black to lug 5 (S-2).

Page 32

( ) Violet to lug 6 (S-1).

( ) Green to lug 7 (S-1).

( ) Grey to lug 13 (S-2).

( ) Blue to lug 14 (S-1).

This completes the assembly and wiring of the battery housing. Proceed to the Final

Wiring instructions that follow.

Page 33

Final Wiring

In the final wiring of your Transistor Tester, the battery pack harness wires will be

connected to switches AP and AR. Since there are already several wires connected to

these switches, you must be very careful not to accidentally burn any wires with your

soldering iron. Move aside any wires that are close.

Prefer to pictorial 15 and connect the wires from the battery pack harness as follows:

( ) Connect the blue wire to lug 3 of switch AK (S-1).

( ) Green to AP1-7 (S-2).

( ) Yellow to AP2-7 (S-2).

( ) Violet to AP2-5 (S-2).

( ) Brown to AR3-2 (S-2).

( ) Red to AR3-3 (S-2).

( ) Orange to AR3-4 (S-2).

( ) Grey to AR3-6 (S-2).

( ) Black to AR3-5 (S-2).

( ) Locate the alligator clip (#260-16)

and connect one end of the 4" red

wire as shown in detail 15A.

Lay the alligator clip aside it will be

used later.

Refer to Pictorial 16 for the following

steps.

( ) Mount the battery housing to the top

edge of the control panel as shown

in the Pictorial. Use three 6-32 x

3/8" screws.

( ) Peel away the paper backing from

the battery placement label. Then

press the label firmly into place in

the battery housing as shown in

Pictorial 16.

This completes the final wiring of your

Transistor Tester. Tip and shake the

assembly to dislodge any bits of solder or

wire ends that may have fallen unnoticed

into the wiring.

Page 34

Carefully examine all connections to be sure that they are properly made and soldered.

Now proceed to the knob installation steps that follow.

Knob Installation

The knobs supplied with this kit use knob bushings that provide positive action without

the use of setscrews.

In the following steps, you will install a knob on each switch and control shaft as shown

in detail 17A. Perform these steps carefully, since it is difficult to remove a knob from a

bushing once it is fully inserted.

Refer to Pictorial 17 for the locations of the switch and control shafts.

( ) Place a knob bushing on each of the switch and control shafts; the spring tab on

the bushing should face outward.

( ) Turn each control and switch shaft to its full counter-clockwise position.

Page 35

( ) Press a knob firmly onto only the BIAS control bushing with the pointer at the 7

o'clock position.

( ) With the bushing installed on it, remove the BIAS knob. Then press the knob

bushing firmly into the knob with the handle of a screwdriver.

Page 36

Page 37

( ) Reinstall the BIAS knob.

Note: The Gain control knob will not be installed until after the adjustments have been

made in a later section.

( ) Install a knob lightly on each of the switch shafts with the pointer at the full

counter-clockwise position.

( ) Turn each knob clockwise to see if the pointer lines up with each switch marking.

( ) If the pointers line up properly, press the knobs firmly onto the bushings and then

remove the knobs with their bushings. Press the bushings firmly into the knobs

with a screwdriver handle, then reinstall the knobs. If a pointer does not line up

properly, perform the next three steps.

Note: It is not necessary to perform the next three steps if the pointer lines up properly

at each switch marking.

1. ( ) Turn the knob pointer to a mid-position marking on the panel.

2. ( ) Remove the knob from the bushing and turn it slightly to line up the pointer with

the mid position marking.

3. ( ) Press the knob slightly onto the knob bushing. Then turn the knob to each

switch position and recheck the pointer alignment. If more than a slight error is

noticed at either end position, repeat these three steps.

Page 38

( ) When the pointer lines up properly with the switch positions, remove the knob

and bushing together and press the bushing firmly into the knob with a

screwdriver handle. Then replace the knob on the shaft.

( ) Install the four lever knobs on the lever shafts A, B, C, and D.

Battery Installation.

Note: Before you install batteries in the Transistor Tester, be sure the Polarity switch

is in the Transit / Off position.

( ) Refer to Pictorial 18 and install seven D-cell batteries in the battery housing. As

you install each battery, press the negative ( - ) end firmly against the battery

contact spring. Then slip the positive ( + ) end into place against the positive

contact screw head.

Batteries can be replaced in the same manner should they become weak through

extended use. After the Transistor Tester is fully assembled, it will only be necessary

to remove the rear cover to expose the batteries.

Initial Tests and Adjustments

The tests you will perform in this section of the Manual will verify that the Transistor

Tester was properly assembled and wired. The adjustments will calibrate the Gain

control knob for accurate gain measurements. See Figure 1 (fold-out from page 28) for

location of these switches and controls.

If the Indicated results are not obtained in any of these tests, refer to the In Case of

Difficulty section on Page 41

Initial Tests.

( ) Set the Polarity switch in the Transit/Off position.

( ) Set all other rotary switches and controls at their full counter-clockwise positions.

Page 39

Polarity Switch

( ) Pick up and shake the Transistor Tester from side to side to make the meter

pointer swing both side of zero. The pointer movement should be well damped

(hard to swing from zero) when the Polarity switch is set at Off.

( ) Repeat the above step with the Polarity switch set at NPN, and then at PNP.

The meter should swing much more freely now.

( ) Set the polarity switch at PNP.

Collector Voltage and Leak Voltage Switches

Note: The meter scales are marked 15-0-15 and 50-0-50. Voltage will be read on one

of the two scales, as indicate by the position of the Collector Voltage or Leak Voltage

switch. In the first position (1.5) of either switch, voltage reads on the 15-0-15 scale by

moving the decimal point one place to the left. In the next two switch positions (3 and

4.5), the 50-0-50 scale is used with the decimal moved one place to the left. For the

next three switch positions, voltage is read directly on the 15 scale.

( ) Raise lever switch B to the Collector Voltage position. The meter pointer

should deflect to the right and indicate 1.5 volts, or slightly higher if fresh

batteries were installed.

( ) Change the Polarity switch to NPN and repeat the previous step. The pointer

should deflect to the left and indicate 1.5 volts.

( ) Turn the Collector Voltage switch to 3, 4, 5, 6, 7.5 and 9 repeating the

preceding two steps at each position. The meter should indicate the same

voltage as marked for each position of the switch.

( ) Repeat the preceding three steps, using the Leak Voltage switch and raising

lever switch C to the Leak Voltage position.

Note: The meter will not deflect when lever switches B or C are raised if the

corresponding Collector Voltage or Leak Voltage switch is in any Ext position during

these tests.

Bias Control

( ) Temporarily connect a wire between the Emitter and Base binding posts.

( ) Set the switches and controls as follows:

Polarity Switch to PNP

Collector Current switch to 150 ma.

Leak Current switch to 15 ma.

Gain switch to Low.

Bias switch to Int.

Bias Control to Full counter-clockwise

( ) Raise lever switch A to Base Current and advance the Bias control about 1/3

rotation. The meter pointer should deflect about two divisions to the right on the

Page 40

0-15 scale. While holding lever switch A up, change the Bias switch to Ext and

the meter should return to zero.

Collector Current Lever Switch B

( ) Remove the shorting wire from between the Emitter and Base binding posts.

Then connect the wire between the Collector and Emitter binding posts.

( ) Set the following switches to the position indicated:

Polarity to PNP

Collector Voltage to Int 1.5.

Collector Current to 15 a.

( ) Press lever switch B to the Collector Current position. The meter should deflect

slightly.

( ) Change the Collector Current switch to 1.5 a and again press lever B. The

pointer should now deflect to full scale.

Short Test Lever Switch C.

( ) Leave the shorting wire connected between the Collector and Emitter binding

posts. Leave the switches set as for the previous test.

( ) Press lever switch C to Short Test. The meter should deflect.

( ) Remove the shorting wire from the binding post and again press lever switch C.

The meter should remain at zero.

Collector to Base Leak Switch D.

( ) Connect a shorting wire between the Base and Collector binding posts.

( ) Set the Leak Voltage switch to Int. 1.5 and the Leak Current switch to 1.5 a.

( ) Press the lever switch D to Collector to Base Leak – I

. The meter should

CBO

deflect slightly beyond full scale.

Gain Switch, High-Low.

( ) Connect a shorting wire between the Base and Emitter binding posts.

( ) Set the switches and controls as follows:

Polarity Switch

PNP

Collector Current switch 15 ma.

Gain switch Low

Bias Control Fully counter-clockwise

Bias Switch

Gain Control

Int.

½ rotation

( ) Press lever switch A to Gain and adjust the Bias control until the meter pointer

deflects slightly to the left of zero.

Page 41

( ) While holding lever switch A down, change the Gain switch to High. The pointer

deflection should now be slightly greater.

If the proper results were obtained in all of the Initial Tests, proceed with the

adjustment section that follows.

Adjustments

Meter Zero Adjustment.

( ) Turn the Polarity switch to the Transit/Off position.

( ) Lightly tap the meter face with your finger and note whether the pointer is directly

over zero.

( ) Turn the screw on the meter face slowly in either direction, while tapping the

meter face with a finger, to place the pointer directly over zero.

Gain Control Adjustment.

( ) Connect a shorting wire between the Emitter and Base binding posts.

( ) Set the switches and controls as follows.

Polarity Switch

Collector Voltage switch 1.5

Collector Current switch 15 ma

Gain switch Low

Bias Control Fully counter-clockwise

Gain Control

( ) Temporarily install the large pointer knob lightly on the Gain control knob

bushing, with the pointer over 0/200. Then turn the knob clockwise to 20.

( ) Press lever A to Gain and turn the Bias control clockwise until the meter

indicates 5 to the left on the 15 scale.

( ) Turn the Gain control fully counter-clockwise. Then hold down lever switch A and

slowly turn the gain control clockwise until the meter pointer just starts to deflect.

( ) Note whether the Gain control pointer is directly over the 0/200 mark on the dial.

If not, carefully remove the knob from the knob bushing and reinstall it. Be sure

you do not turn the shaft, and that the 0/200 mark is where the meter pointer just

starts to deflect.

( ) Press the knob firmly onto the bushing.

Note: If the zero position of the Gain control knob pointer is the starting point of meter

pointer deflection, proceed to the Operational Check instructions. Otherwise perform

the following steps.

PNP

Fully counter-clockwise

Page 42

( ) Remove the Gain control knob from its shaft, then loosen the control nut on the

panel.

( ) Replace the knob on the control shaft.

( ) While holding down lever switch A, turn the Gain control knob until the meter

pointer just starts to deflect.

( ) Reach under the control panel and carefully turn the body of the Gain control

until the knob pointer is directly over zero.

( ) While holding the body of the Gain control firmly against the inside of the panel,

remove the knob and tighten the control nut.

( ) Replace the Gain control knob and recheck the zero position with the meter

deflection. Repeat the previous five steps if necessary.

This completes the test and adjustments of the Transistor Tester.

Operational Check.

This section of the manual will give you an additional check to be sure your Transistor

Tester is operating properly before you install it in the cabinet.

Two or three transistor that are known to be good will be required for this check.

( ) Insert the leads of a test transistor on the panel. Use the three binding posts at

the top left-hand side if the transistor leads do not fit the socket. See Figure 2.

( ) Set the control and switches as follows:

Bias control Full counter-clockwise

Bias switch Int.

Polarity switch To type of transistor (PNP

or NPN)

Collector Voltage switch 1.5 volts Int.

Leak Voltage switch 9 volts Int.

Collector Current switch 15 ma

Leak Current switch 1.5 ma

Gain switch Low.

( ) Press lever switch C to Short Test. If the transistor is not shorted, the meter

pointer will not deflect from zero. If the pointer does deflect, try another

transistor.

( ) Press lever switch B to Collector Current and slowly advance the Bias control.

Notice that the meter indicates higher collector current as the bias is increased if

the transistor is good. Now adjust the Bias control until the meter indicates 5 ma

of collector current.

( ) Check the collector voltage by raising lever switch B to Collector Voltage. The

meter should read approximately 1.5 volts.

Page 43

( ) Press lever switch A to Gain and rotate the Gain control until the meter indicates

zero. The knob pointer will read upscale to 30 or more depending on the

particular transistor being tested.

( ) Raise lever switch A to Base Current. The base current range is set with the

Leak Current switch. This setting must not be less than 1/10 of the Collector

Current switch setting. Otherwise, the base current would be reduced.

( ) Raise lever switch C to Leak Voltage. The meter should indicate 9 volts.

( ) Raise lever switch D to Collector To Emitter Leak - I

and note the leakage

CBO

indicated on the meter. If the meter pointer goes off scale, increase the Leak

Current switch setting.

( ) Press lever switch D to Collector To Base Leak - I

and read the leakage on

CBO

the meter. Change the setting of the Leak Current switch, if necessary. Note

that l

is much smaller than I

CBO

CEO

.

( ) Place the Polarity switch in the Transit/Off position. The preceding steps

provided an operational cheek of your Transistor Tester. The procedure and

result should have been typical for a good transistor of the type tested. Detailed

information on complete use of the Tester will be found in the Operation section.

Now that you are sure the Tester will operate properly, proceed to the Final Assembly

instructions that follow.

Final Assembly.

Page 44

Refer to Pictorial 19 for the following steps.

( ) Install a rubber foot in each of the four mounting holes in the bottom of the

cabinet shell. Use a small screwdriver to pull the small end of the foot through

the hole.

( ) Install the unit in the cabinet shell, using three #6 sheet metal screws and two

6-32 x 1/4" screws on the bottom of the cabinet. Tighten securely.

( ) Insert four #6 x 3/8" sheet metal screws in the sides of the cabinet. Do not

tighten.

( ) Install a plastic foot in each corner of the back plate. First remove the protective

backing from the foot, and then press the foot firmly into position.

( ) Install the back plate, using five 6-32 x 3/8" screws. Do not tighten.

( ) Make sure the back plate is flush with the top panel and tighten the five screws

on the back of the unit.

( ) Now tighten the two screws on each side of the cabinet.

( ) Carefully peel away the backing paper from the blue and white identification

label. Then press the label onto the bottom of the cabinet shell. Be sure to refer

to the numbers on this label in any communications you have with the Heath

Company about this kit.

Your Transistor Tester can now be put into service.

Operation

Although you made a "rough test" of a transistor while performing the Operational

Check, you will need a thorough understanding of your Transistor Tester, and a

knowledge of how to interpret its meter readings to accurately test the quality of

transistors. Read the following pages carefully.

This Tester measures the DC Beta (gain) characteristic of transistors, a characteristic

that will even vary between transistors of the same type. This DC Beta test will give

you the actual operating characteristics of a transistor, and not merely give you a "bad"

or a "good" rating.

Refer to Figure 1 (fold-out from Page 28) for the location and description of the

controls, switches, and connections on the Transistor Tester.

Note: When carrying or moving the Tester, the Polarity switch should be in the Transit/

Off position to damp movement of the meter pointer.

General Transistor Testing

A transistor specification sheet or rating chart will be required for testing transistors to

manufacturers specifications. This data is contained in most standard transistor

manuals. (See Reference Material, Page 41.) If you do not have data for a particular

Page 45

transistor, refer ahead to the procedure titled "Testing Transistors With Unknown

Ratings."

Caution: Do not test FET or SCR types with this Transistor Tester. Field effect

transistors (FET) or silicon controlled rectifiers (SCR) require special equipment for

testing.

Set up the conditions for the transistor to be tested by setting the following switches to

the desired parameters, as listed in the specification sheet or manual:

Collector Voltage;

Leak Voltage;

Collector Current;

Leak Current;

Polarity (NPN or PNP).

Set the BIAS control fully counter-clockwise. Then insert the transistor leads into the

socket, or connect the leads to the proper terminal posts. Refer to a basing chart to

identify the emitter, base, and collector leads and be sure to connect the transistor

leads properly.

Note: The following tests are momentary. Do not hold a lever switch up or down longer

than necessary to obtain a meter reading. Never move more than one lever switch at a

time.

Press lever switch C for Short Test. A shorted transistor will cause a reading of 4 or

more on the 15 scale of the meter.

Raise lever switch D to the Collector To Emitter Leak - I

position. Read the

CEO

leakage current on the meter. Change the Leak Current switch position if the meter

reads off scale.

Press lever switch D to the Collector to Base Leak - I

leakage on the meter. Note that l

is much lower than l

CBO

CEO

position and read the

CBO

.

Press lever switch B to Collector Current and adjust the Bias control for proper

collector current.

Raise lever switch B to Collector Voltage and read the meter to see that proper

voltage is applied.

Press lever switch A to Gain and adjust the Gain control until the meter reads zero.

Read the gain indicated by the pointer on the Gain control knob.

Note: Two Gain control ranges are provided. The 0-200 outer range is used when the

Gain switch is in the Low position. The 200-400 inner range is used when the Gain

switch is in the High position. The Bias control must be readjusted to provide correct

collector current when using either the High or Low positions of the Gain switch.

Testing Transistors With Unknown Ratings

Set the switches and control as follows for each of the tests in this section.

Polarity Switch

- PNP.

Page 46

Collector Voltage Switch

Collector Current Switch

Leak Voltage Switch

Bias Control

- 1.5 int.

- 15 ma.

- 9 int.

- full counter-clockwise.

Insert the transistor leads in the transistor socket, or connect them to the proper

binding posts at the top of the panel.

Short Test

Press lever switch C to Short Test. The meter will indicate 4 or more on the 15 scale if

the transistor is shorted. Do not make any further tests on a shorted transistor.

Testing for PNP or NPN

Press lever switch B to Collector Current, if the meter pointer does not deflect,

advance the bias control to see if a collector current is obtained. If the meter pointer

now deflects to the right, the transistor is a PNP type. Leave the polarity switch at

PNP.

If the meter pointer does deflect with the bias control fully counter-clockwise when lever

switch B is pressed, the transistor is probably an NPN type. Turn the bias control

clockwise while holding down lever switch B. If the meter pointer moves toward zero

as the bias control is advanced, it confirms that the transistor is an NPN type. Then

change the polarity switch to NPN and the collector current should increase normally

as the bias control is advanced.

Testing Small Transistors

After you have determined whether the transistor is NPN or PNP, be sure the Polarity

switch is set accordingly.

Press lever switch B to Collector Current and advance the bias control, if the collector

current increases as the bias control is advanced, the transistor is conducting.

As a final cheek, press lever switch D to I

than 25 µa. Raise lever switch D to I

higher than l

CBO

.

CEO

. Leakage current should not be more

CBO

and note that this leakage current is much

Testing power transistors

Change the collector current switch to 1.5 a. Press lever switch B to Collector

Current and advance the bias control. If the collector current increases as the bias

control is advanced, the transistor can be assumed to be good. As a final cheek, press

lever switch D to l

. The leakage current should not be over 5 ma.

CBO

Matching Transistors for Gain and Leakage

Set up test as for transistor testing. Using identical bias control and leak voltage switch

settings, insert each transistor to be checked into the transistor socket and determine

gain and leakage. Then separate them into common groups.

Production Go No-Go Tests

PNP Transistors

Page 47

Set up the specified test conditions. Check for shorts; then check for leakage. Each

transistor must show less than the maximum allowable leakage for the particular

production application.

For checking gain, set up the proper bias condition and set the gain control for

minimum allowable gain. With the gain lever pressed, each transistor having a gain

higher than the minimum allowable (preset) will deflect the meter to the right. Any

transistor having less gain will deflect the meter to the left.

NPN Transistors

Use the same procedure as described above, except NPN transistors having a gain

higher than the minimum allowable will deflect the meter to the left. NPN transistors

having less gain will deflect the meter to the right.

DC Current gain (h

)

fe

Note: the base current switch setting should not be more than one range lower than

the collector current switch setting. If this is not done, the meter resistance will reduce

the original collector current setting.

DC current gain is defined as collector current (Ic) divided by base current (I

); that is,

B

= h = ; alpha =

dc fe

β

Ic

Bd

I +

dc

β

c

β

1

DC current gain, beta and alpha, is read directly from the calibrated dial under the gain

control pointer. This gain may be found using the instructions under general transistor

testing.

AC Current Gain (h

AC current gain equals

)

fe

Ic

+

+

C

E constant

B

I

Ic1 - Ic2

or

I1 - I2

BB

at the same EC.

AC current gain is defined as: the change in collector current divided by the change in

base current that produced the change in collector current, with collector voltage held

constant.

Set the Polarity, Collector Voltage, Collector Current, and Leak Current switches to

the desired positions, depending on the type of transistor to be checked.

Press the Collector Current lever and adjust the bias control to the desired collector

current (Ic1). Raise the base current lever and read base current (I

1) on the meter.

B

Now press the collector current lever and adjust the bias to a lower collector current,

say 25%. This is Ic2. Raise the base current lever and read I

2 in the meter.

B

Using the values determined above, calculate the ac current gain.

Page 48

DC Transconductance (g

)

fe

DC transconductance is defined as collector current (Ic) divided by base voltage (E

Ic

FE

that is

g =

.

E

B

);

B

To find gFE, set up a given bias condition and, with an external voltmeter, measure

base to emitter voltage at the external transistor terminals. Then use the above

formula.

AC Transconductance (g

FE

)

AC transconductance is defined as a change in base voltage (∆ E

) that will produce a

B

change in collector current (∆ lc), with collector voltage (Ec) held constant; that is,

g = Ec constant, or Ec constant

BBB

E E 1- E 2

∆

Ic Ic1- Ic2

∆

FE

To find g

, set up a given bias condition, press the Collector Current lever and adjust

FE

the Bias control. Read collector current Ic1 on the meter. With an external voltmeter

measure base to emitter voltage E

the collector current lever, reduce the bias, and read Ic2 on the meter. Read E

1 at the external transistor terminals. Now press

B

2 on an

B

external voltmeter.

Calculate g

FE

by

Ic1 - Ic2

=

E1 - E2

BB

DC Base Resistance (R

)

B

DC base resistance is defined as base voltage (E

B

R =

) divided by base current (IB); that is,

B

E

B

.

B

I

Set up a given bias condition, press the Collector Current lever, and adjust the Bias

control. Raise the Base Current lever and read IB on the meter. With a voltmeter

connected between the Base and Emitter transistor terminals, read base voltage E

.

B

AC Base Resistance

AC base resistance is defined as the change in base voltage (E

change in base current (I

) with collector voltage (Ec) held constant; that is,

B

) divided by the

B

E

B

Ec constant.

B

I∆∆

To find AC base resistance, set up a given bias condition, press the Collector Current

lever and adjust the bias control. Raise the Base Current lever and read IB1. With a

voltmeter connected between Base and Emitter external transistor terminals, read

base voltage E

the base current lever and read I

1. Now press the collector current lever and reduce the bias. Raise

B

2. Read EB2 on external voltmeter.

B

Using the values just found, calculate ac base resistance as follows:

Page 49

BB

E1 - E2

BB

I1 - I2

DC Collector Resistance

DC collector resistance is defined as collector voltage Ec divided by collector current Ic;

that is,

Rc =

.

Ec

Ic

To find DC collector resistance, set up a given bias condition, press the Collector

Current lever and adjust the Bias control. Read collector current Ic. Raise the

Collector Voltage lever and read collector voltage Ec.

AC collector resistance

AC collector resistance is defined as a change in collector voltage (Ec) divided by the

change in collector current (lc) with the base current (I

Ec

∆

∆

B

I constant.

Ic

) held constant; that is,

B

To find AC collector resistance, set up a low collector voltage condition. Press the

Collector Current lever and adjust the Bias control. Read collector current Ic2. Now

raise the Collector Voltage lever to read collector voltage Ec2.

Increase the Collector Voltage switch setting, use the same bias setting as above,

and read Ec1. Now push the collector current lever and read Ic1.

Using the values just found, calculate AC collector resistance as follows:

Ec1 - Ec2

Ic1 - Ic2

Transistor Leakage Tests

I

= collector to base leakage with the emitter open.

CBO

Adjust the Leak Voltage switch to the specified voltage, and set the Leak Current

switch to the proper meter range. Press the I

directly.

I

= collector to emitter leakage with the base open.

CEO

Adjust the Leak Voltage switch to the specified voltage, and set the Leak Current

switch to the proper meter range. Raise the I

directly.

I

= collector to emitter leakage with base shorted to the emitter.

CES

Connect a shorting wire between the Base and Emitter binding posts. Then read I

on the meter, using the same procedure as outlined above for l

I

= collector to emitter leakage with a specified resistance connected between the

CER

base and emitter.

lever and read leakage current

CBO

lever and read leakage current

CEO

.

CEO

CES

Page 50

Connect the specified resistance between Base and Emitter binding posts. Then read

I

on the meter, using the procedure outlined for l

CER

CEO

.

I

, I

CERV

collector to emitter leakage with specified reverse bias battery and resistance

CEX

in series between the base and emitter.

Connect the specified reverse battery and resistance between the Base and Emitter

binding posts. Now read I

for I

CEO

.

CERV

or I

on the meter, using the procedure outlined above

CEX

Diode Testing

Reverse Current

Set the Leak Voltage switch to the proper value and set the Leak Current switch to

the proper meter range. Place the Polarity switch in the Diode Rev position. Press

the Short lever to see if the diode is shorted. If the diode is not shorted, raise the

diode lever and read the reverse (leakage) current on the meter.

Forward Current

Warning: Always connect a resistor in series with the diode before checking forward

current. Without a series resistor, too much current will flow, possibly damaging the

diode.

Example: A silicon diode normally drops approximately 0.7 volt. If the 1.5 volt supply

is used, a series resistor must be used to drop the other 0.8 volt.

I = 500 ma

E = 0.8 V

E 0.8

Rs = = = 1.6

Ω

I 0.5

Here a 2Ω resistor will prevent excessive

current from damaging the diode under test.

The series resistor may be left connected

when checking Reverse Current. The series

resistance is normally a very small resistance

compared to the high reverse-current

resistance of the diode.

Connect the diode to be tested and the predetermined series resistor to the external

transistor terminals, cathode to the Emitter and diode anode to the Collector (diode

terminals). Set the Leak Voltage switch to the proper value and the Leak Current

switch to the proper meter range. Place the Polarity switch in the Diode Fwd position.

Raise the Diode lever and read forward current on the meter.

Other types of diodes may also be tested as just described.

External bias voltage terminals

The external bias terminals should be used when continuous power transistor testing is

required. The external bias supply may be a battery or any high-current, low-voltage

unit, such as a battery eliminator.

Page 51

Connect the external bias (DC power) supply leads to the external bias terminals; the

positive lead to positive ( + ) terminal and the negative lead to negative ( - ) terminal.

Set the Bias switch to the Ext position. The internal bias control is used to set the

desired amount of bias. Note: a maximum of 5 volts may be applied to these

terminals.

External Collector Voltage Terminals

The external collector voltage terminals should be used when continuous power

transistor testing is required. The external collector voltage power supply may be any

high-current unit, such as a battery eliminator.

Connect the external DC power supply to external Collector Voltage terminals; the

positive lead from the power supply connects to the positive ( + ) terminal and the

negative lead to the negative ( - ) terminal.

Adjust the Collector Voltage switch to the desired Ext voltage range. Now set the

power supply for the desired collector voltage. Note: a maximum of 50 volts may be

applied to these terminals.

External Leak Voltage Terminals

The external Leak Voltage terminals must be used when higher leak voltages are

required than are available from the internal battery supply. The external leak voltage

power supply may be any high-voltage supply such as a laboratory dc power supply.

Connect the external dc power supply leads to the external Leak Voltage terminals,

the positive lead to the positive ( + ) terminal and the negative lead to the negative ( - )

terminal.

Adjust the Leak Voltage switch to the proper Ext voltage range. Now set the power

supply for the desired Leak Voltage. Note: a maximum of 150 volts may be applied to

these terminals.

Checking Current Ranges

Ext. Transistor Terminals

Connect an external DC ammeter between the

Collector and Emitter external terminals. The

positive ( + ) side goes to the emitter with the polarity

switch in the PNP position. Connect resistance Rx in

series with the ammeter as shown in figure 4.

Before calculating the size of resistor Rx decide on the

current range to be checked, and what voltage it will

be checked at.

For example:

Current range to be checked - 150 milliamperes.

E 1.5

Rx = = = 10

Ω

I 0.15

Collector voltage used -1.5 volts.

In this case, a 10Ω resistor is used as Rx to limit the current to 150 milliamperes.

Page 52

Set the Polarity switch to PNP and set the Collector Voltage switch to 1.5 volts. Now