Page 1

Page 2

HEATHCOMPANYPHONEDIRECTORY

The

foilomna telephone

Kit

orders

and

Cle4n

............................................

Replacemem

TBChhicd

Assistance

RC,

Aud'b,

hateur

Radio

Test Equipment.

CIOC~,

Weather

Television

Aubmme,

SBardty.

&nerd

numbers

are

aired lines lo

delW

inlormation

Pam..

...............................

and

E&onic

...................................

Slmbe

In8humenlP

........................................

Mame.

Wliances,

Prduck..

......................

hgans .................

Lighfs,

Cdcuiatoro,

........................

........................

the

depanmem lirted:

(616) 982541 1

(616) 8823661

(616) 982.3~1

(616) 982.3310

(616) 882-3286

(616) 982.3315

(616) 982-3307

(515) 9825496

YOUR

HEATHKIT

90-DAY

FULL

WARRANTY

Page 3

Assembly

and

Operation

of

the

Introduction

Parts List

Step-by-step Assembly

Installation and Applications

In Case of Difficulty

Specifications

Warranty

Customer Service

.............................

...............................

.........................

.........................

.............................

........................

.....................

TABLE OF CONTENl'S

......................

Inside front cover

Inside rear cover

1

2

4

9

13

14

COAXIAL SWITCH

MODEL

HD-1234

BENTON

The Model HD-1234 Coaxial Switch

receiver to any one of several antennas or RF loads, while grounding the unused

connectors.

The Coaxial Switch can be used in conjunction with the

Wattmeter for off-theair

antenna for normal transmission and reception.

A

mounting bracket is provided to permit you to conveniently hang the switch

on the side of an equipment enclosure, onto a desk, or on a wall. The switch

may be used handily without the mounting bracket in any application which

suits the needs of your transmission system.

HEATH

HARBOR. MICHIGAN

COMPANY

INTRODUCTION

is

tuneup, and can then be immediately switched to an

49022

designed to switch one RF source or

Heathkit RF Load

Page 4

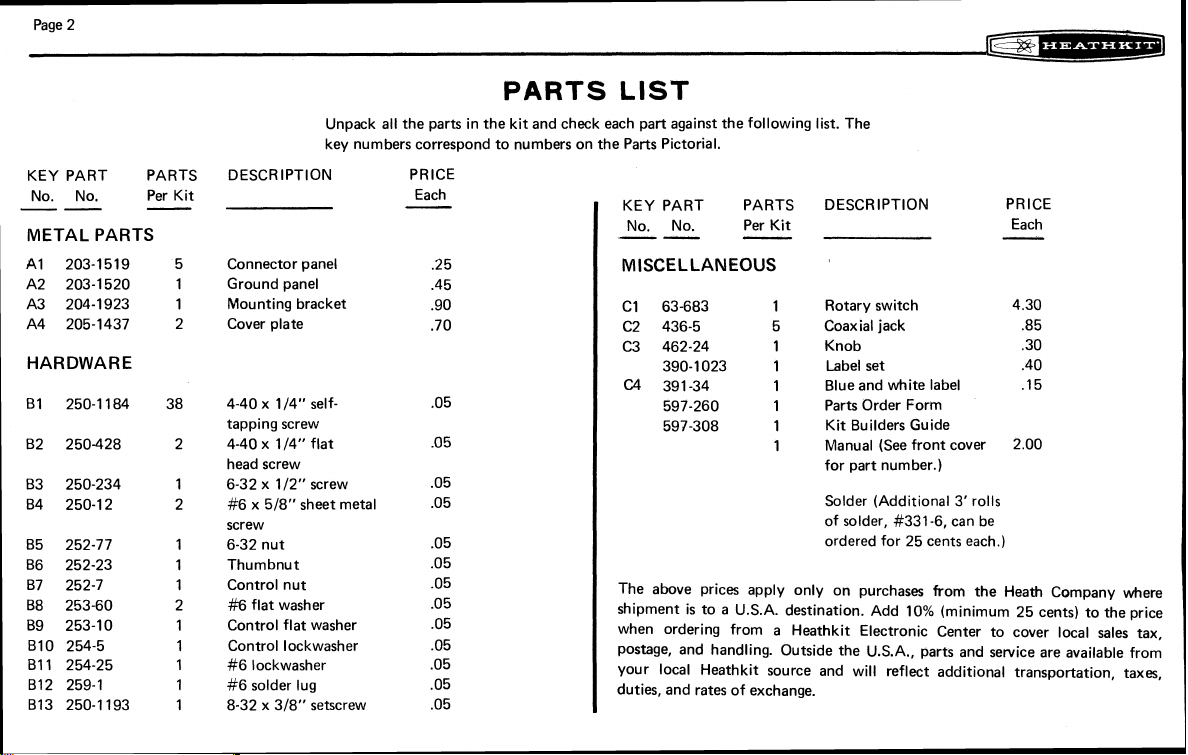

Page 2

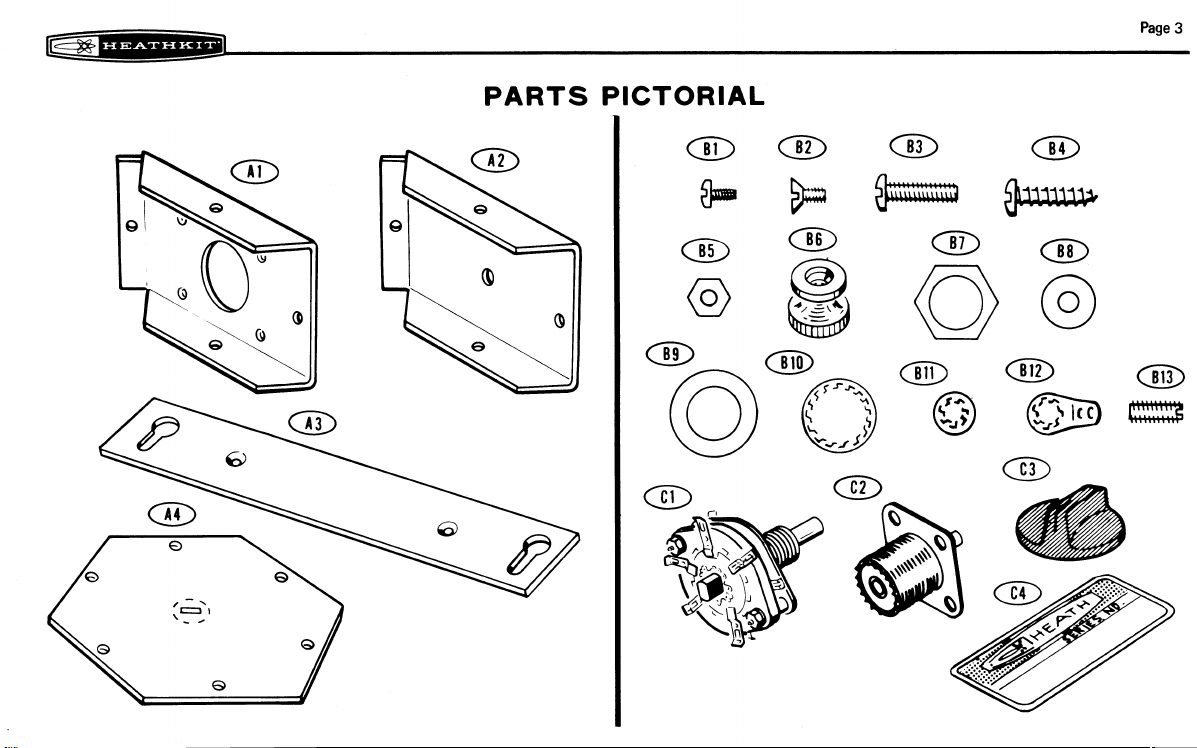

KEY PART PARTS

No. No. Per Kit

--

-

METAL PARTS

HARDWARE

Unpack all the parts in the kit and check each part against the following list. The

key numbers correspond to numbers on the Parts Pictorial.

DESCRIPTION PRICE

Connector panel .25

Ground panel .45

Mounting bracket .90

Cover plate .70

4-40 x

114" self- .05

tapping screw

114" flat .05

4-40 x

head screw

112" screw .05

6-32 x

#6 x 518" sheet metal .05

screw

6-32 nut .05

Thumbnut .05

Control nut

#6

flat washer .05

Control flat washer .05

Control lockwasher .05

#6 lockwasher .05

#6 solder lug .05

318" setscrew .05

8-32 x

-

Each

.05

PARTS

LIST

KEY PART PARTS DESCRIPTION PRICE

No. No.

--

Per Kit

-

MISCELLANEOUS

C1 63-683

C2

436-5

C3

462-24 1 Knob

390-1023 1 Label set .40

(24

391-34 1 Blue and white label .15

597-260 1 Parts Order Form

597-308 1 Kit Builders Guide

The above prices apply only on purchases from the Heath Company where

shipment is to a

when ordering from a Heathkit Electronic Center to cover local sales tax,

postage, and handling. Outside the U.S.A., parts and service are available from

your local

duties, and rates of exchange.

Heathkit source and will reflect additional transportation, taxes,

1 Rotary switch 4 30

5 Coaxial jack

1

Manual (See front cover 2.00

for part number.)

Solder

(Add~t~onal

of solder,

ordered for 25 cents each.)

U.S.A. destination. Add 10% (minimum 25 cents) to the prlce

#331-6, can be

3'

rolls

Each

-

.85

.30

Page 5

PARTS PICTORIAL

Page

3

Page 6

Page 4

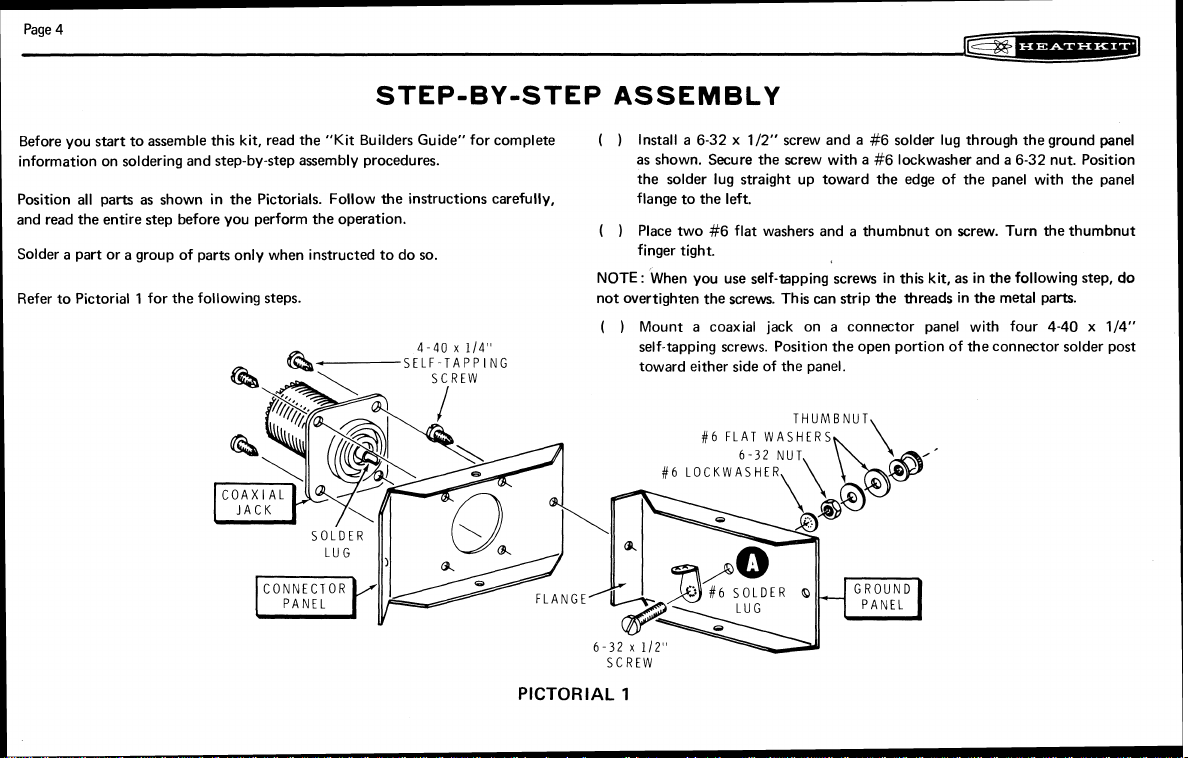

STEP-BY-STEP ASSEMBLY

Before you start to assemble this kit, read the "Kit Builders Guide" for complete

information on soldering and step-by-step assembly procedures.

Position all parts as shown in the Pictorials. Follow the instructions carefully, flange to the left.

and read the entire step before you perform the operation.

a

part or a group of parts only when instructed to do so.

Solder

Refer to Pictorial 1 for the following steps.

4-40

x

SELF

114"

TAPPING

PICTORIAL

Install a 6-32 x 112" screw and a #6 solder lug through the ground panel

( )

as shown. Secure the screw with a

the solder lug straight up toward the edge of the panel with the panel

Place two

(

)

finger tight.

NOTE

:

not overtighten the screws. This

( )

Mount a coaxial jack on a connector panel

self-tapping screws. Position the open portion of

toward either side of the panel.

SCREW

#6

flat washers and a thumbnut on screw. Turn the thurnbnut

When you use self-tapping screws in this kit, as in the following step,

#6

FLAT

1

can

strip the threads in the metal parts.

WASHERS

#6 lockwasher and a 6-32 nut. Position

do

with four 4-40 x 114"

the connector solder post

Page 7

In the same manner, mount the four remaining coaxial jacks onto four

(

)

connector panels with 4-40 x

Add a small amount of solder to pre-tin each connector solder post.

)

(

2

Refer to Pictorial

NOTE:

In the following steps, you will .fasten connector panels and the ground

together. Be sure the flange end of each panel fits

panel

for the following steps.

114'' self-tapping screws.

we the panel to

which it is attached. Tighten each screw as it is installed; then loosen it

The screws will be tightened later.

Connect the ground panel to one of the connector panels with a 4-40 x

(

)

114" self-tapping screw as shown in Pictorials 1 and

2.

114 turn.

Page

5

)

Similarly, attach a connector panel to the other end of the ground panel

(

with a 4-40 x 114" self-tapping screw.

In the same manner, attach the remaining three connector panels to those

( )

previously assembled. Use four 4-40 x 1 /4" self-tapping screws.

)

Secure one of the cover plates to the connector and ground panels with six

(

114" self-tapping screws. Position the cover plate so the embossed

4-40 x

lettering is visible on the outside and so the embossed

G

is adjacent to the

ground connector as shown. Note the position of the solder lug.

)

Tighten the six cover screws. Then tighten the six screws that connect the

(

six connector and ground panels.

Turn the assembly so the cover plate is up. Bend the plug out of the center

( )

of the cover plate with the blade of a screwdriver.

SELF-TAPPING

PICTORIAL

2

CONNEClOR

NOTE. FLANGE

IhSI

DE

Page 8

Page 6

0

6

PICTORIAL

LOCKWASHER

CONNECTOR

FLAT WASHER

3

UND

Refer to Detail

NOTE:

that there is one long contact lug on the switch wafer at

notch in the rotary center portion of the switch.

Grasp the switch shaft with a pair of pliers and turn the switch rotor until

(

)

the long contact lug and the rotor notch are positioned together as shown

in the Detail. Do not turn the rotor again until the knob has been secured

to the switch shaft.

Carefully bend each of the lugs so

(

)

surface.

Refer to the Pictorial and carefully insert the rotary switch into the switch

(

)

housing assembly; the switch lug will easily drop through the corner

openings in the assembly. Rotate the switch and position the long contact

lug near the ground lug inside the housing as shown.

Place the control flat washer and the control nut on the switch shaft; do

)

(

not tighten the nut.

Reach inside the housing and turn the body of the switch until the long

(

)

contact lug is directly under the ground lug as shown in Detail

that one single lug on the front of the switch wafer will be under the

connector center conductor at

be in a position above and below each of the remaining four connector

center conductors.

Hold the switch firmly in this position and tighten the control nut.

(

)

3A

and to Pictorial 3 for the following steps.

Carefully study the rear of the rotary switch

it

is flat and straight out from the

D.

The remaining pairs of switch lugs will

as

shown in Detail

B,

and also there is a

3A.

3A

Note

Note

(

)

Bend the ground lug downward with the blade of a screwdriver until

touches the long switch lug. Solder the two lugs together.

it

Page 9

re*:w---=*-

Page

7

GROUND

(

I

Bend the remaining rotary switch lugs until they all touch the center

conductors of the coaxial jacks. Solder all five of the coaxial center

conductors to their respective switch lugs. NOTE: Be sure that both the

top and bottom switch lugs are securely soldered. Use enough solder to

sure the job is well done, but avoid an excess that will short the inner

conductor and switch lugs to the housing assembly.

4

Refer to Pictorial

for the following steps.

i'6~

Detail

3A

be

PICTORIAL

,

Secure

the

8-32

remaining

x

(

assembly with six 4-40 x

embossed markings are toward the outside of the housing.

Start an

( )

cover

plate

114''

318''

setscrew in the tapped hole of the knob.

4

to

the

self-tapping screws. Turn the cover so the

rear

of

the

switch

housing

Page 10

Page

8

rek*---=*:-~J

Refer to Pictorial 5 for the following steps.

(

)

4-40

x

114"

FLAT HEAD

SCREW

/

BRACKET

Place the knob on the switch shaft so the pointer is toward

the setscrew in the knob securely. You may now rotate the switch as

desired.

NOTE: You may wish to hang the Coaxial Switch on a wall or on an equipment

enclosure. A mounting bracket has been furnished for this purpose. Any two of

the opposite screws holding the rear cover plate may be removed to install the

mounting bracket in the following step. If you do not wish to use the mounting

bracket, skip the next step and also the third step (which tell you to install the

mounting bracket).

Note the numbers on the top cover and remove the two screws opposite

)

(

( )

( )

"2"

and the "C".

the

Place the blue and white label on the rear cover so the stamped numbers

are positioned

the label in this manner will permit you to read these numbers after the

mounting bracket is installed. NOTE: The Model Number and Production

Series Number of your kit are shown on this label. Refer to these numbers

in any communications you have with the Heath Company about this kit.

Install the mounting bracket on the rear cover plate with two

flat head screws as shown in the Pictorial.

as

close to two adjacent screw heads

as

@

.

Tighten

possible. Positioning

4-40

x

114"

- -

SETSCREW

This completes the "Step-by-step Assembly" of your Coaxial Switch. You will

be

instructed to apply the decals from your label set during the "Installation and

Applications" section which follows.

Page 11

C~=*:*-.L=*~@

INSTALLATION AND APPLICATION

NOTE: There are many ways that your Coaxial Switch may be installed and

there are various applications for its use. One method for installing the Switch is

outlined below, and two methods for its use will be covered. Your individual

needs will dictate your specific application.

INSTALLATION

Refer to Figure 1 for the following steps.

Page

9

Place the Switch against the wall or panel where

( )

the tip of each keyhole slot in the mounting bracket on the selected

surface.

( )

Drill 3/32" holes at the marked locations.

)

Turn the two

(

of the shank is showing. Hang the mounting bracket onto the two screws;

then tighten the screws securely.

(

)

Loosen the thumbnut on the ground connection screw. Place the

earth-ground lead between the two flat washers; then tighten the

thumbnut securely.

k6

x 518" sheet metal screws into the holes until only 1/8"

it

is to be installed. Mark

BAR

Figure

1

Page 12

Page

10

APPLICATIONS

Refer to Figure 2 for the following steps.

TO

D

I

POLE

ANTEIUhA

c-=-*---&J

Primary Method

Connect a dummy load to connector

)

(

a reflected power meter, if one is used) to the C (common) connector.

Then connect from one to three antennas to connectors

#4.

Connect the transceiver (through

#1

Alternate Method (requires two Coaxial switches)

Refer to Figure

(

)

Connect the C (common) connectors of two coaxial switches together

with a length of

units to connectors

up to three antennas to connectors

switch.

1'

(

i

select the appropriate decals in your label set. Remove those selected, one

at

embossed circles on the front panel of the switch assembly, Position them

so they are vertically aligned as you look at them.

be omitted if desired.

3

for

the following steps.

RG-8/U coaxial cable. Connect up to three transceiver

#1

through

#3

on one Coaxial Switch. Then connect

#I

through

hen you have chosen the arrangement that best suits your requirements,

a time, from the paper backing and press each into place over the

#3

of the other coaxial

NOTE:

This step may

through

#3.

TO

TRI

AhTtNhA

-BAND

-LOAIIAL

CABLE

1

Figure

TO

CAhTEhNA

DUMMY

LOAD

TO

TRANSCEIVER

[THROUGH

REFL.

2

Page 13

Page

11

TRAhSCEI VER

LJ

RECEl VER

m

TO

OR

DUh\MY

-=COAXIAL CABLE

-

=

G

R 0 U

Figure

N D W I R

3

E

TO TRIBAhD

ANTENNA

TO INVERTED

===+

CAN~ENNA

LOAD

This scan is not authorized to

boupht hs scanned manual on eBay, then

bought

it

Please file a complaint with eBay and demand a refund.

&om is a hef who sold you stolen

Dl

POLE

TO

ANTEkI'.A

be

sold on eBay. If you

the

vendor you

property.

ANTENNA

-V

Page 14

Page

12

@$b=**--4*5--3

OPERATION

Refer to Schematic Diagram, Figure

When the switch knob

output connectors are grounded except the C connector. WARNING: DO NOT

OPERATE THE TRANSMITTER INTO THE COAXIAL SWITCH WHEN THE

POINTER IS AT THE

of

either

these positions, the transmitter is connected to an open circuit.

is

@

4.

rotated to either the @ or the @ positions, all

OR THE @ POSITION. When the Switch

is

in

ROTARY

SWITCH

m

REAR WAFER ,FRONT WAFER

I

t

I

Figure

4

I

I

Page 15

@@*:*---=*:.+a

IN

CASE

OF DIFFICULTY

Page

13

There are only two possible difficulties that can be found in the Coaxial Switch,

with the exception of parts failure. These would be either an open circuit or a they are properly grounded, or are connected through from input to output as

shorted circuit when the opposite should be the case.

In either event, remove the rear cover from the switch assembly and carefully

inspect each solder connection. Be sure that no solder has run from any of the

center conductors to the metal parts of the assembly. If a circuit is known to be

open, try moving the switch lugs where they touch the coaxial jack center

conductors. Be sure both the upper and lower switch lugs not only make contact

with these center conductors, but that they are well soldered and immovable.

Finally, check each of the coaxial jacks with an ohmmeter and make sure that

they should be.

It is suggested, if there still appears to be a problem, that you reheat each solder

connection and melt a small additional amount of solder onto each connection.

Then recheck the Switch for proper continuity with an ohmmeter once again.

Page 16

Page

14

SPECIFICATIONS

IF

%

w**:*d

Standing Wave Ratio (to 250 MHz)

Power Capability

The Heath Company reserves the right to discontinue instruments and to change

specifications at any time without incurring any obligation to incorporate new

features in instruments previously sold.

....................

............

1.1

:1

maximum.

1000 watts (2000 watts PEP) maximum

Page 17

L

EXPEDITED PARTS ORDER

(FOR REPAIR PARTS ONLY)

NAME

FORM

PLEASE DO NOT WRITE IN

1

THIS SPACE

ADDRESS

CITY

I

KIT MODEL PURCHASE DATE INVOICE NUMBER LOCATION PURCHASED

I

QTY.

-

r

I

INSTRUCTIONS:

(MINIMUM

AUTHORIZE PERMISSION FOR C.0 D. SHIPMENT (MINIMUM ORDER SHIPPED

C.0.D IS

MICHIGAN RESIDENTS ADD

HEATH

PART

NUMBER

INCLUDE CHECK OR MONEY ORDER FOR TOTAL PARTS ORDERED ADD

$0.25)

$10.00).

FOR INSURANCE, POSTAGE AND HANDLING.

STATE

4%

SALES TAX

ZIP

DESCRIPTION OF PART

rn

THlS FORM IS FOR U.S. CUSTOMERS ONLY. OVERSEAS CUSTOMERS SEE YOUR DISTRIBUTOR.

10%

SEND

HEATH COMPANY

BENTON HARBOR,

I

MICHIGAN

ATTN PARTS REPLACEMENT

TOTAL

PRICE

C.O.D. AUTHORIZATION

DESIRED METHOD

EDITORS INITIALS

SIGNED

49022

I

OF SHIPMENT

Page 18

Page 19

Page 20

Schlumberger

lii9

LIMO

IN

USA

*

Loading...

Loading...