Exclusive Distributor

HI FLOW® Sampler

For Natural Gas

Leak Rate Measure m ent

Instruction 0055-9017

Operation and Maintenance

Rev. 6 – March 2012

Product Leadership • Training • Service • Reliability

WARRANTY

Bacharach, Inc. warrants to Buyer that at the time of delivery this Product will be free from defects in material and manufacture and will conform substantially to Bacharach Inc.’s applicable specifications. Bacharach’s liability and Buyer’s remedy under

this warranty are limited to the repair or replacement, at Bacharach’s option, of this Product or parts thereof returned to Seller

at the factory of manufacture and shown to Bacharach Inc.’s reasonable satisfaction to have been defective; provided that

written notice of the defect shall have been given by Buyer to Bacharach Inc. within one (1) year after the date of delivery of

this Product by Bacharach, Inc.

Bacharach, Inc. warrants to Buyer that it will convey good title to this Product. Bacharach’s liability and Buyer’s remedy under

this warranty of title are limited to the removal of any title defects or, at the election of Bacharach, to the replacement of this

Product or parts thereof that are defective in title.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND ARE GIVEN AND ACCEPTED IN LIEU OF (I) ANY AND ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE: AND (II) ANY OBLIGATION, LIABILITY, RIGHT, CLAIM OR REMEDY IN CONTRACT OR TORT,

WHETHER OR NOT ARISING FROM BACHARACH’S NEGLIGENCE, ACTUAL OR IMPLIED. The remedies of the Buyer shall be limited

to those provided herein to the exclusion of any and all other remedies including, without limitation incidental or consequential

damages. No agreement varying or extending the foregoing warranties, remedies or this limitation will be binding upon

Bacharach, Inc. unless in writing, signed by a duly authorized officer of Bacharach.

Register Your Warranty by Visiting

www.mybacharach.com

NOTICE

Product improvements and enhancements are continuous; therefore the specifications and information contained

in this document may change without notice.

Bacharach, Inc. shall not be liable for errors contained herein or for incidental or consequential damages in

connection with the furnishing, performance, or use of this material.

No part of this document may be photocopied, reproduced, or translated to another language without the prior

written consent of Bacharach, Inc.

Patent # 5,563,335 and 6,489,787.

Copyright © 2012, Bacharach, Inc., all rights reserved.

®

BACHARACH

trade names, service marks and logos referenced herein belong to their respective owners.

and HI FLOW® are registered trademarks of Bacharach, Inc. All other trademarks,

Hi Flow Sampler Table of Contents

Table of Contents

1 Introduction ..................................................................................................................... 5

1.1 General Description and Use ................................................................................................................... 5

1.2 Material Supplied ..................................................................................................................................... 6

1.3 Why Use the Hi Flow Sampler? .............................................................................................................. 6

1.4 Control Unit Description .......................................................................................................................... 7

1.5 Top Panel Connections and Controls ....................................................................................................... 7

1.6 Technical Data .......................................................................................................................................... 8

2 Operation......................................................................................................................... 9

2.1 Operating Precautions ............................................................................................................................. 9

2.2 Battery Connection .................................................................................................................................. 9

2.3 Sampling Hose and Attachment Connections ........................................................................................ 10

2.4 Grounding .............................................................................................................................................. 10

2.5 Attachments ........................................................................................................................................... 11

2.5.1 Flange Strap (34", 80", and 137") .............................................................................................. 11

2.5.2 Beveled Nozzle Tool (6.5" and 24") ........................................................................................... 12

2.5.3 Capture Bag ............................................................................................................................... 12

2.5.4 Bellows Tool .............................................................................................................................. 13

2.5.5 Aluminum Crevice Tool ............................................................................................................. 13

2.6 Turning ON the Hi Flow Sampler .......................................................................................................... 13

2.7 Turning OFF the Hi Flow Sampler ......................................................................................................... 14

2.8 Selecting the Basic or Expanded Menu Mode ....................................................................................... 14

2.8.1 Basic Main Mode ....................................................................................................................... 15

2.8.2 Expanded Main Mode ............................................................................................................... 16

2.9 Menu System ......................................................................................................................................... 17

2.10 Battery Status ......................................................................................................................................... 18

2.11 Calibration Menu ................................................................................................................................... 19

2.12 Set Flow Units – LPM or CFM ................................................................................................................. 19

2.13 Menu Mode – Basic or Expanded .......................................................................................................... 19

2.14 Operating Mode – Automatic or Manual ............................................................................................... 19

2.14.1 Automatic 2-Stage Measurement Mode ................................................................................... 20

2.14.2 Manual Measurement Mode .................................................................................................... 21

2.14.2.1 Manual 2-Stage Mode................................................................................... 21

2.14.2.2 Manual 1-Stage Mode................................................................................... 21

2.15 Access Records ....................................................................................................................................... 22

2.15.1 Send Records ............................................................................................................................. 22

2.15.2 View Records ............................................................................................................................. 24

2.15.3 Erase Records ............................................................................................................................ 24

2.16 Importing Saved Data into a Spreadsheet ............................................................................................. 25

2.17 Access Test IDs ....................................................................................................................................... 27

2.17.1 Select Test IDs ............................................................................................................................ 27

2.17.2 Edit Test IDs ............................................................................................................................... 28

2.17.3 Send Test IDs ............................................................................................................................. 28

2.17.4 Erase Test IDs............................................................................................................................. 30

2.18 Making a Leak Rate Measurement ........................................................................................................ 31

2.18.1 Leak Rate Measurement – Basic Menu Mode ........................................................................... 31

2.18.2 Leak Rate Measurement – Automatic 2-Stage Mode................................................................ 32

2.18.3 Leak Rate Measurement – Manual 2-Stage Mode .................................................................... 34

2.18.4 Leak Rate Measurement – Manual 1-Stage Mode .................................................................... 35

2.19 Message Line .......................................................................................................................................... 37

3 Calibration ..................................................................................................................... 39

3.1 View Calibration Dates ........................................................................................................................... 39

Instruction 0055-9017 3

Table of Contents Hi Flow Sampler

3.2 Gas Calibration Equipment Setup ......................................................................................................... 39

3.3 Check Calibration Procedure ................................................................................................................. 40

3.4 Gas Calibration Procedure ..................................................................................................................... 41

3.5 Calibration Amplifier Gain Check .......................................................................................................... 43

3.6 Erase Calibration Procedure .................................................................................................................. 43

4 Maintenance .................................................................................................................. 44

4.1 Electrostatic Discharge Precautions ...................................................................................................... 44

4.2 Charging the Battery Pack ..................................................................................................................... 44

4.3 Removing the Cover .............................................................................................................................. 45

4.4 Replacing the Internal Filters ................................................................................................................ 46

4.4.1 Leak-Gas Filter .......................................................................................................................... 46

4.4.2 Leak-Gas Sensor Filter ............................................................................................................... 47

4.4.3 Background-Gas Sensor Filter ................................................................................................... 47

4.5 Gas Sensor Replacement ....................................................................................................................... 48

4.6 Pump Replacement ............................................................................................................................... 49

4.7 Flow Rate Verification ........................................................................................................................... 50

4.8 Setting Date and Time ........................................................................................................................... 53

4.9 Resetting the Microprocessor ............................................................................................................... 54

5 Troubleshooting ............................................................................................................. 55

5.1 Instrument Repair ................................................................................................................................. 55

5.2 Troubleshooting Guide .......................................................................................................................... 55

5.3 Error Codes in Saved Test Records ........................................................................................................ 57

6 Parts & Service ............................................................................................................... 59

6.1 Replacement Parts ................................................................................................................................ 59

6.2 Optional Accessories ............................................................................................................................. 59

6.3 Service Centers ...................................................................................................................................... 60

7 Declaration of Conformity .............................................................................................. 61

∇ ∇ ∇

4 Instruction 0055-9017

Introduction Hi Flow Sampler

1 Introduction

1.1 General Description and Use

WARNING: The High Flow

its intended purpose or beyond the scope of its specifications. Failure to follow this

warning can result in personal injury or damage to the equipment. For details on

appropriate use, refer to the general description, application, and operation discussions

in this manual.

The Hi Flow

Sampler is a portable, intrinsically safe, battery-powered instrument

designed to determine the rate of gas leakage around various pipe fittings, valve

packings, and compressor seals found in natural gas transmission, storage, processing,

gas gathering, production, offshore, and distribution facilities.

A component’s leak rate is measured by sampling at a high flow rate so as to capture all

the gas leaking from the component along with a certain amount of surrounding air. By

accurately measuring the flow rate of the sampling stream and the natural gas

concentration within that stream, the gas leak rate can be calculated using Equation 1.

The instrument automatically compensates for the different specific gravity values of air

and natural gas, thus assuring accurate flow rate calculations.

Leak = Flow x (Gas

sample

where:

Leak = rate of gas leakage from source (cfm)

Flow = sample flow rate (cfm)

Gas

Gas

background

= concentration of gas from leak source (%)

sample

= background gas concentration (%)

To ensure that the instrument is capturing all the gas that is escaping from the

component, two measurements are performed at two different flow rates. The first

measurement is taken at the highest possible flow rate, followed by a second

measurement at a flow rate that is approximately 70–80% of the first. If the two

calculated leak rates are within 10% of each other, then it can be assumed that all gas

has been captured during the test.

For those mathematicians who are wondering how both calculations can be the same

with different flow rates, note that the measured CH

higher due to less air being drawn in with the sample, thus balancing out the lower flow

rate.

The instrument is packaged inside a backpack, thus leaving the operator’s hands free for

climbing ladders or descending into a confined space.

The instrument is controlled by a handheld Control Unit consisting of an LCD and a 4-key

touch pad, which is attached to the main unit via a 6 foot coiled cord. The Control Unit

comes with two magnets which can be easily attached to a steel pipe, regulator box or

compressor for easy viewing. Alternately, the Control Unit can be used in conjunction

with the neck strap accessory.

The gas sample is drawn into the unit through a flexible 1.5 inch I.D. hose. Various

attachments connected to the end of the sampling hose provide the means of capturing

all the gas that is leaking from the component under test.

Sampler is not to be used in any application that is beyond

– Gas

background

) x 10–2 Eq. 1

level at the lower flow rate will be

4

Instruction 0055-9017 5

Hi Flow Sampler Introduction

The main unit consists of an intrinsically safe, high-flow blower that pulls air from

around the component being tested through a flexible hose and into a gas manifold

located inside the unit. The sample is first passed through a venturi restrictor where the

measured pressure differential is used to calculate the sample’s actual flow rate. Next, a

portion of the sample is drawn from the manifold and directed to a combustibles sensor

that measures the sample’s CH

concentration in the range of 0.05 to 100% gas by

4

volume. A second identical combustibles sensor channel measures the background CH

level within the vicinity of the leaking component. The final element in the sampling

system is a blower that exhausts the gas sample back into the atmosphere away from

the sampling area.

The measured flow rate and the measured CH

levels (both leak and background levels)

4

are used to calculate the leak rate of the component being tested, with all measured

and calculated values being displayed on the hand-held control unit.

1.2 Material Supplied

• High Flow Sampler Unit

• Backpack

• 6 Foot, 1.5 Inch Hose Assembly

• Battery Pack (Qty. 2)

• Battery Charger w/ Power Supply

• Control Unit with LCD and 4-button keypad

• Assortment of Attachments (for complete capture of the gas leak)

• Flange Strap 34", 80", and 137"

• Capture Bag 36" x 36"

• Beveled Nozzle 6.5" and 24"

• Bag Nozzle

• Bellows Tool

• Claw Tool

4

1.3 Why Use the Hi Flow Sampler?

• Allows ranking of gas leaks in leak-rate order

• Allows users to determine if the potential savings in lost gas by repairing a leak

• Allows users to determine payback periods for particularly expensive repairs

• Allows more cost-effective use of your maintenance budget

• Identifies problem areas

• Determines baseline leakage conditions

• EPA Best Management Practice Tool for Directed Inspection and Maintenance

Programs at Natural Gas Facilities

• Provides permanent record of leakage and repair

• Approved Measurement tool in conjunction with United Nations Framework

Convention on Climate Change Methodology 0023, Leak Reduction at Natural Gas

Facilities

• Pays for itself in recovered gas

6 Instruction 0055-9017

Introduction Hi Flow Sampler

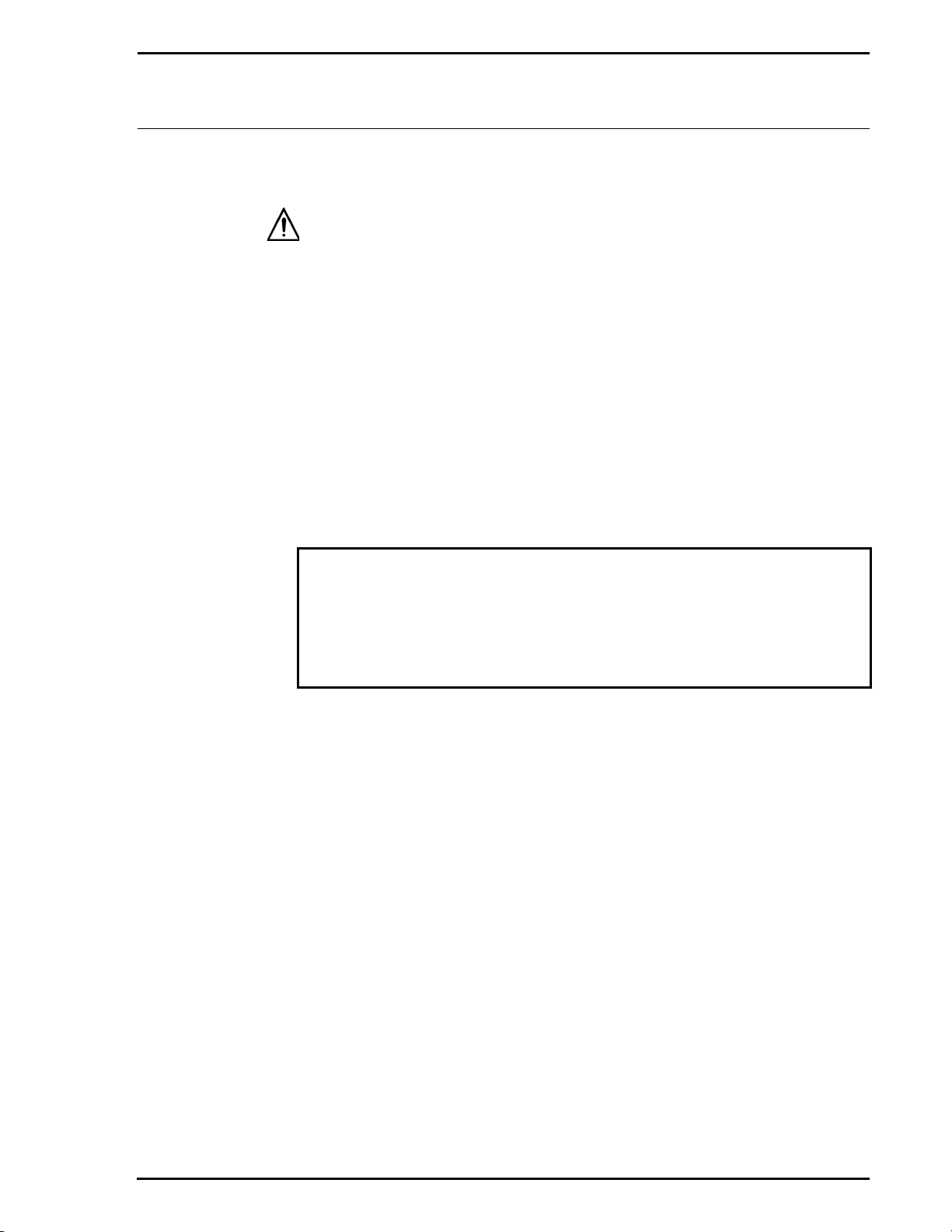

1.4 Control Unit Description

The control unit consists of an 8 line by 20 character LCD and the four pushbuttons.

Figure 1-1. Control Unit

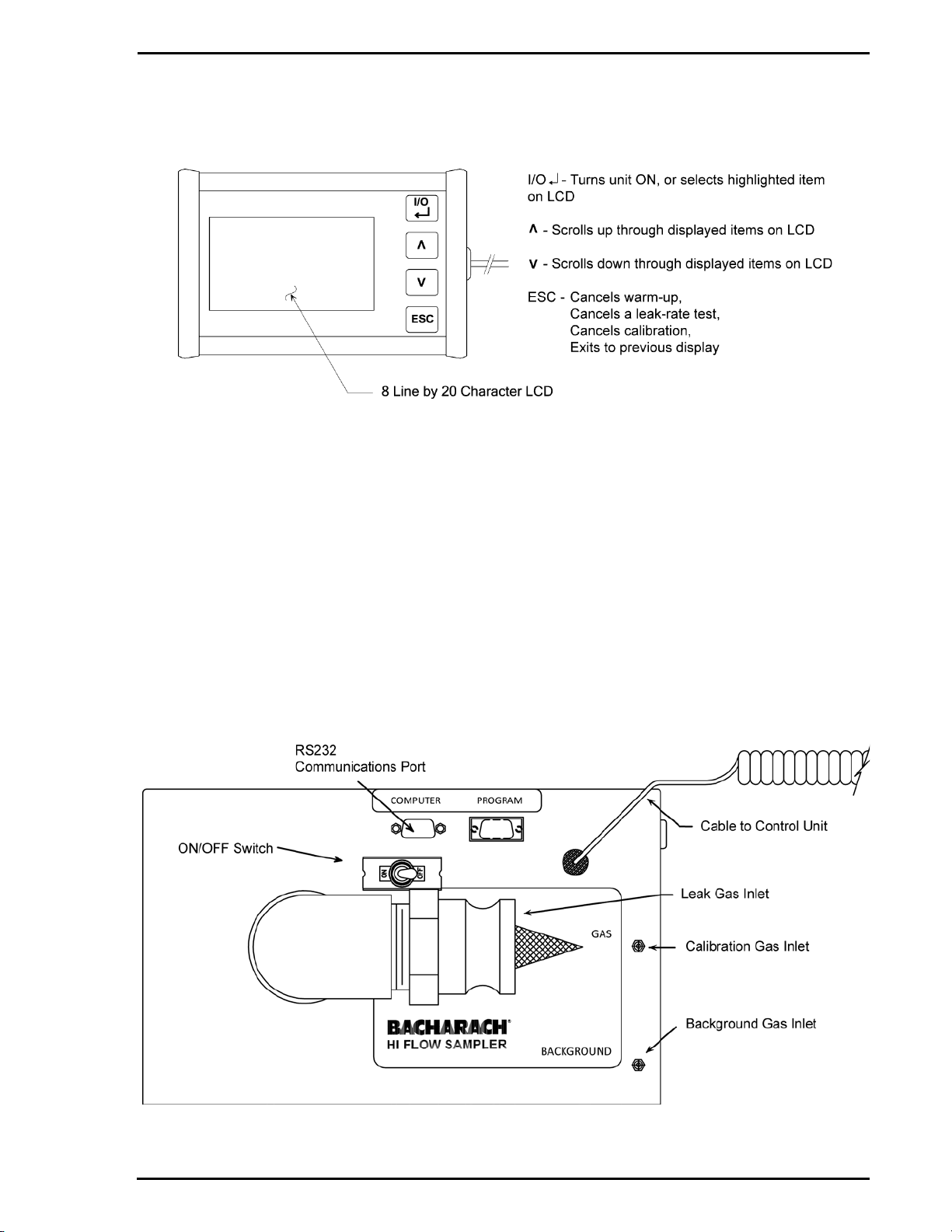

1.5 Top Panel Connections and Controls

The top panel contains the following items.

ON/OFF Switch Turns unit ON and OFF.

Computer Port RS232 communications port for downloading stored test data to an

external computer.

Leak Gas Inlet Main hose connection used to collect gas from leak source.

GAS Inlet Calibration gas connection.

Background

Inlet Gas hose connection used to sample background levels of CH

.

4

Figure 1-2. Top Panel Connections

Instruction 0055-9017 7

Hi Flow Sampler Introduction

• Leak concentration in ppm or % by volume

∧

∨

• Battery voltage

• Sample gas concentration

Maximum .................................... 10.5 SCFM (297 LPM) at full battery charge

Detection Method ....................... Catalytic oxidation / Thermal conductivity

Accuracy ...................................... ±5% of reading or 0.02 % methane, whichever is greater

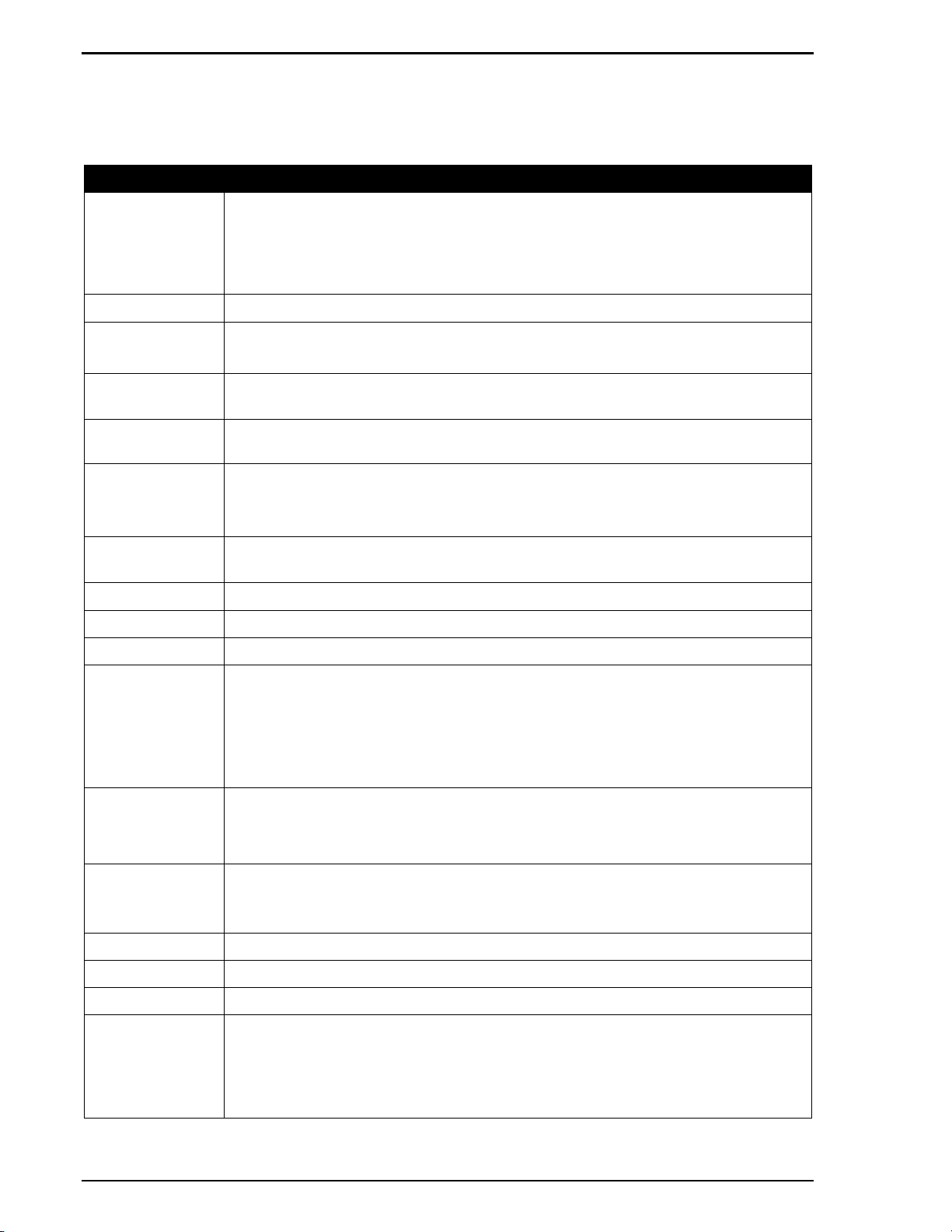

1.6 Technical Data

TABLE 1-1. TECHNICAL SPECIFICATIONS

Specification Description

Information

Displayed

Display 8 line by 20 character LCD

Pushbutton

Controls

Communication Three DB9 connectors providing serial data transfer at 115200 baud to a personal

Measured Values

Calculated Values Leak concentration corrected for background gas level

Measurable Leak

Rate

Accuracy

Temperature Operating: 0 to 50 °C (32 to 122 °F) Storage: –40 to 60 °C (–40 to 140 °F)

Humidity 5 to 95% RH (non-condensing)

• Date and Time

• Battery voltage

• Leak rate in cfm

• Sampling flow rate in cfm

I/O ↵ (Enter)

(Up Arrow)

computer, or other peripheral device

• Sampling flow rate

Leak rate

Percent difference between leak rate measurements #1 and #2

0.05 to 8.00 SCFM (1.42 to 226 LPM)

0.05 to 6.00 SCFM (1.42 to 170 LPM)

Calculated Leak Rate: ±10% of reading

• Background gas concentration in ppm or % by

volume

• Percent difference between leak rate

measurements #1 and #2

(Down Arrow)

ESC (Escape)

• Background gas concentration

Sampling Flow

Rate

Natural Gas Sensor

Battery Voltage ............... 4.8 V, max.

Memory Stores up to 1000 individual test parameters

Dimensions 18L x 12W x 7H inches (457 x 305 x178 mm)

Weight 20 lbs (0.9 kg)

Agency Approvals Designed to be intrinsically safe for use in hazardous locations Class I, Division 1, Groups

8 Instruction 0055-9017

Operating Flow Points ................. Initial flow ≈ 10 SCFM (283 LPM). Second flow ≈ 8

SCFM (226 LPM). (The second flow rate is 25% of the

initial flow)

Measurement Method ................ Differential pressure across restriction

Accuracy ...................................... ±5% of reading

Range: Catalytic oxidation.......... 0 to 5% by volume methane

Range: Thermal conductivity ..... 5 to 100% by volume methane

Type .......... Intrinsically Safe NiMH rechargeable pack

Recharge Time ... 8 to 10 hrs

A, B, C & D in North America. CAN/CSA-C22.2 No. 157 – (June 1992). ANSI (June 27,

2002)/UL913-2002. Intrinsically Safe Apparatus and Associated Apparatus for use in

Class I, Division 1, Hazardous (Classified) Locations. CE Mark – See section 8 for

Declaration of Conformity statement.

Run Time ... >4.5 hours continuous operation @ 20 °C

(68 °F)

∇ ∇ ∇

Hi Flow Sampler Operation

2 Operation

2.1 Operating Precautions

To ensure that the gas sensors are properly zeroed at startup, the Hi Flow

must be turned ON in clean air (free of combustible gases or vapors).

Calibrate the instrument about every 30 days to assure its accuracy. The frequency of

calibration, however, may change depending on how often the instrument is used and

the amount of gas that was sampled. Create a maintenance log to keep track of when an

instrument was calibrated, and then use this log to help develop a calibration schedule.

For example, an instrument that fails its calibration after only being calibrated a single

time should be calibrated more often.

IMPORTANT: Avoid sampling leaded gasoline vapors, or gases or vapors that contain

silicones or sulfur compounds. Tetraethyl lead, silicones, and sulfur compounds can form

contaminating compounds on the sensor element (poison the sensor), with resulting loss

in sensitivity.

Always purge the instrument with clean air after testing. This removes combustibles

from the sensor chambers and prolongs the life of the sensors.

Sampler

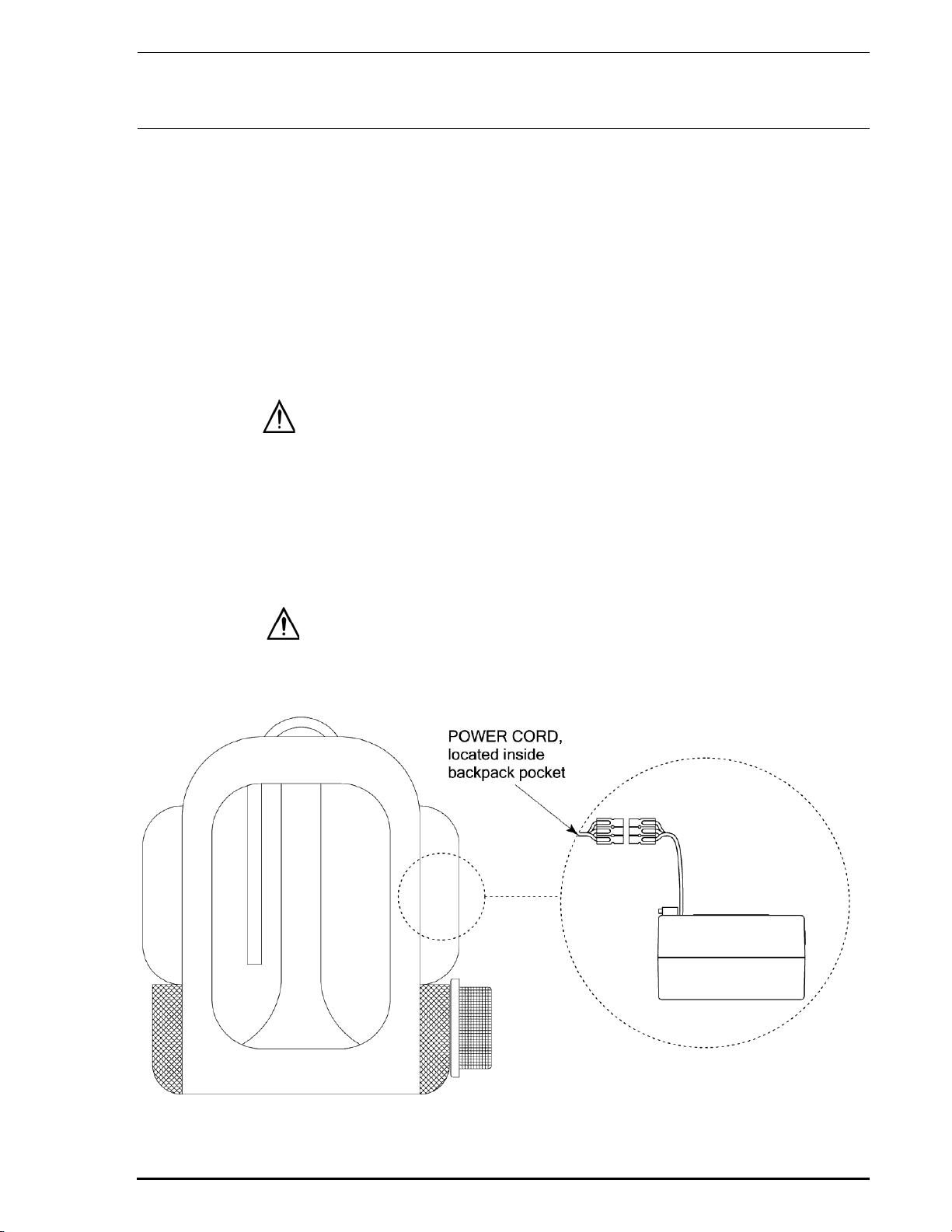

2.2 Battery Connection

WARNING: Explosion hazard! DO NOT connect or disconnect the battery in an unsafe

atmosphere.

The instrument’s power cord is located inside the backpack’s right-side pocket. Insert a

battery pack into this pocket and connect it to the power cord.

Figure 2-1. Battery Pack Connection

Instruction 0055-9017 9

Operation Hi Flow Sampler

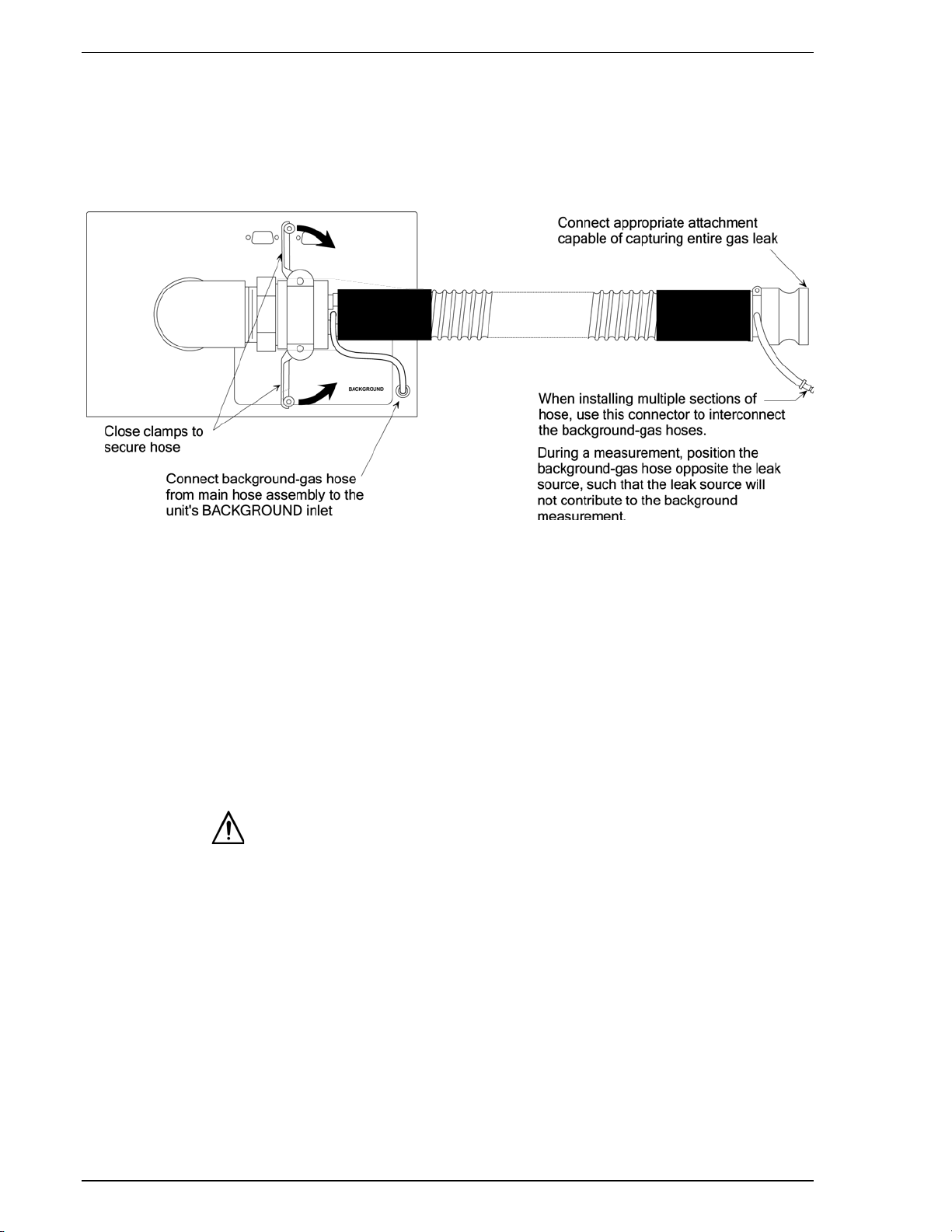

2.3 Sampling Hose and Attachment Connections

Connect the sampling hose to the instrument’s leak-gas inlet by clamping the hose to

the inlet as shown in Figure 2-2. Also connect the background gas sampling hose to the

unit’s BACKGROUND inlet.

Figure 2-2. Hose and Attachment Connections

The standard sampling hose is 6 foot long. If a longer length is needed, the optional 12

foot hose (P/N 0055-0287) can be ordered, or additional sections of hose can be added

by simply clamping them together along with connecting together the background-gas

hose.

Choose an attachment (refer to Section 2.5 Attachments) that will capture the entire

leak and attach it to the end of the hose.

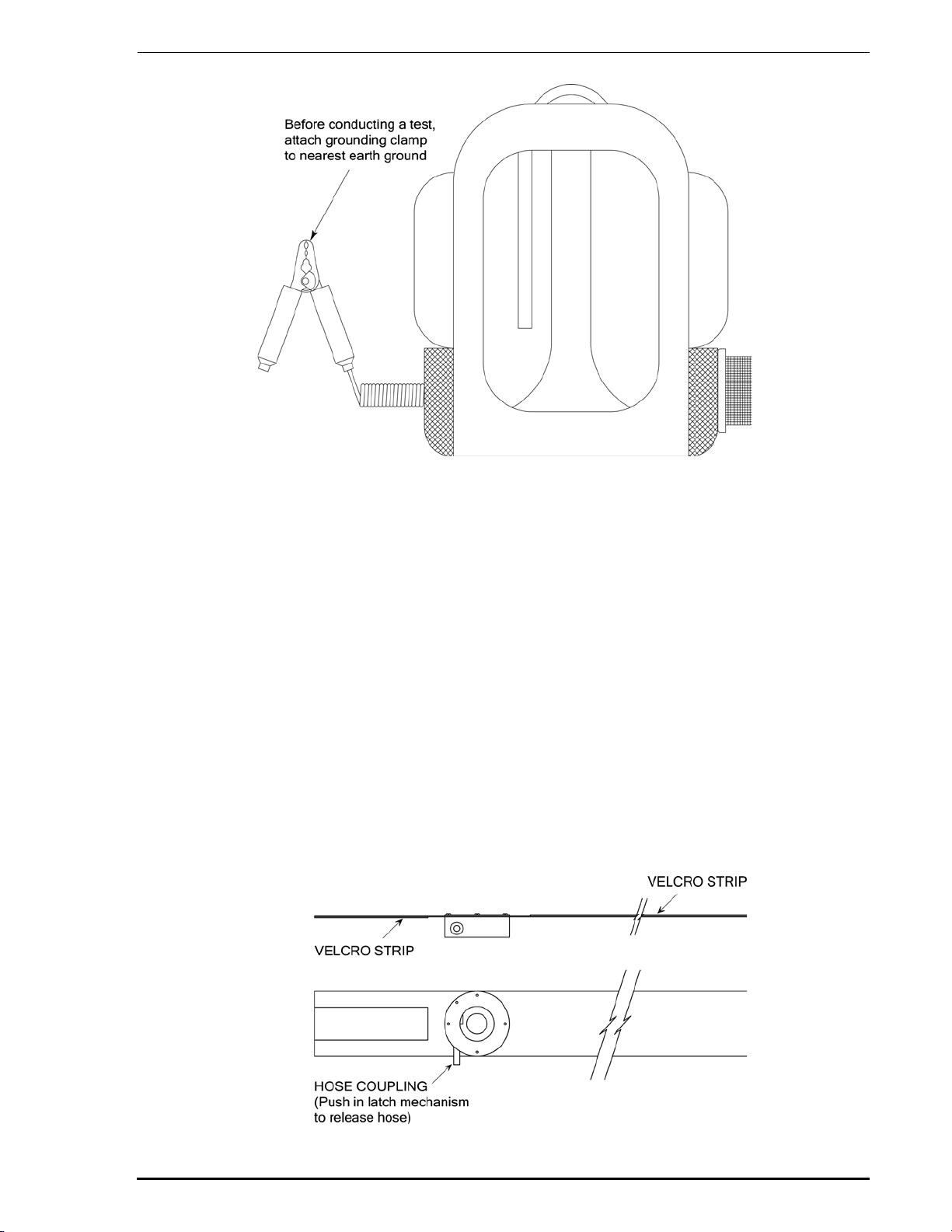

2.4 Grounding

WARNING: To prevent the possibility of a static discharge, the Hi Flow

be grounded while conducting a leak test.

Attach the unit’s grounding clamp to the nearest earth ground.

Tip: When not in use, the grounding clamp can be stored by attaching it to one of the

shoulder straps.

Sampler should

10 Instruction 0055-9017

Hi Flow Sampler Operation

Figure 2-3. Grounding Clamp

2.5 Attachments

A variety of attachments are available for the Hi Flow

capturing the entire gas leak. Choose the appropriate attachment for the type of

component being tested from the ones listed below, and then connect it to the end of

the instrument’s main sampling hose.

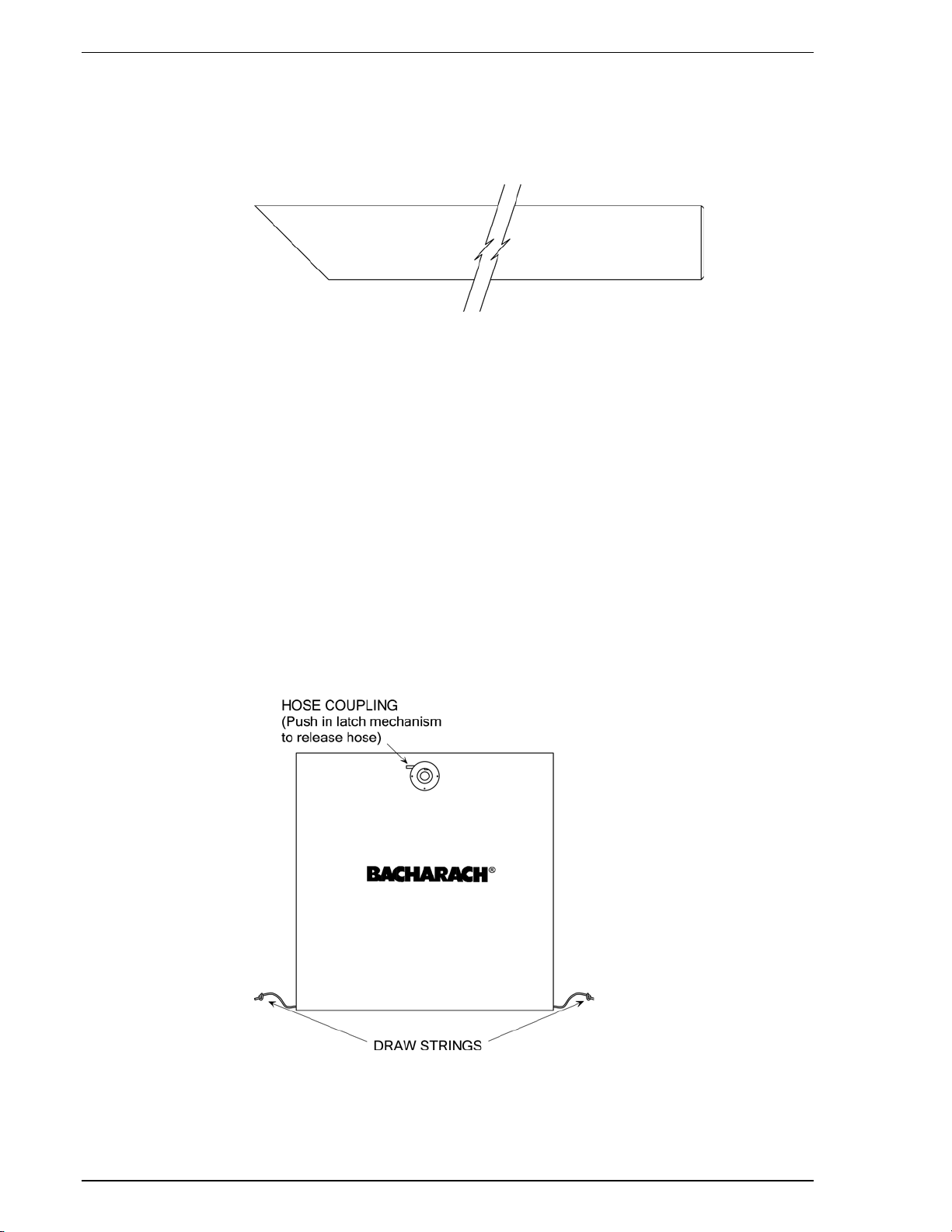

2.5.1 Flange St ra p ( 3 4", 80", and 137")

Flange leaks can be captured by wrapping this attachment around the edge of the

flange, and securing in place using the two Velcro strips.

Attach the Hi Flow

the end of the hose into the attachment’s hose coupling. A click should be heard when

the hose has been successfully connected. Release the hose by pushing in the coupling’s

release mechanism.

Sampler’s main sampling hose to the flange strap by simply pushing

Sampler that simplify the task of

Figure 2-4. Flange Strap

Instruction 0055-9017 11

Operation Hi Flow Sampler

2.5.2 Bevele d Nozzle Tool (6.5" and 24")

For simple pin-hole type leaks, position this attachment directly over the leak source.

Figure 2-5. Beveled Nozzle Tool

2.5.3 Capture Ba g

This reusable capture bag measures 36" x 36" and can be used to completely surround a

component that may have multiple leak sources, or contains a leak source that is

difficult to pinpoint or reach.

Attach the Hi Flow

of the hose into the bag’s hose coupling. A click should be heard when the hose has

been successfully connected. Release the hose by pushing in the coupling’s release

mechanism.

Use the draw strings to close up the end of the bag. DO NOT, however, completely close

off the bag – allow air to flow into the bag so as to replace the volume of gas and air

being removed during the test.

Sampler’s main sampling hose to the bag by simply pushing the end

Figure 2-6. Capture Bag

12 Instruction 0055-9017

Hi Flow Sampler Operation

2.5.4 Bell ow s Tool

This tool is useful in capturing leaks in valve stems and small fittings.

Figure 2-7. Bellows Tool

2.5.5 Alumi num Crev ice Tool

Use this tool when the leak source is spread out over a narrow area, such as a crack in a

pipe, square flanges, and cylinder heads.

Figure 2-8. Aluminum Crevice Tool

2.6 Turning ON the Hi Flow Sampler

With the Hi Flow

or vapors), turn ON the instrument by flipping the ON/OFF switch to its ON position.

WARNING: Turning ON the instrument in air contaminated with combustible gas will

cause false readings to occur. Use one of Bacharach’s portable gas detection instruments

to sample the surrounding area for levels of combustible gas before turning ON the

instrument.

An initial banner screen is first displayed for 3 seconds that shows the instrument’s

name, software version, and the software’s Month, Day, Year, and Time of creation.

Instruction 0055-9017 13

Sampler located in an area containing clean air (no combustible gases

Operation Hi Flow Sampler

keys to view additional

After the banner screen is displayed, the sensors are automatically zeroed to ambient

conditions. Zeroing time is dependent on the temperature of the sensors, and whether

there is residual gas present inside the sensor chambers. If a sensor fails to zero, a

message appears at the bottom of the LCD describing the cause of the failure. Refer to

Section 6 Troubleshooting for possible causes and remedies for this failure.

After the sensors are zeroed, either the instrument’s Basic or Expanded Main Screen

appears (refer to Section 2.8). The example below shows the Basic Main Screen.

The arrow symbols on the left indicate that

there are more items to view above and/or

below the current display.

Press the ∧ and ∨

items.

2.7 Turning OFF the Hi Flow Sampler

Turn OFF the unit by flipping the ON/OFF switch to its OFF position.

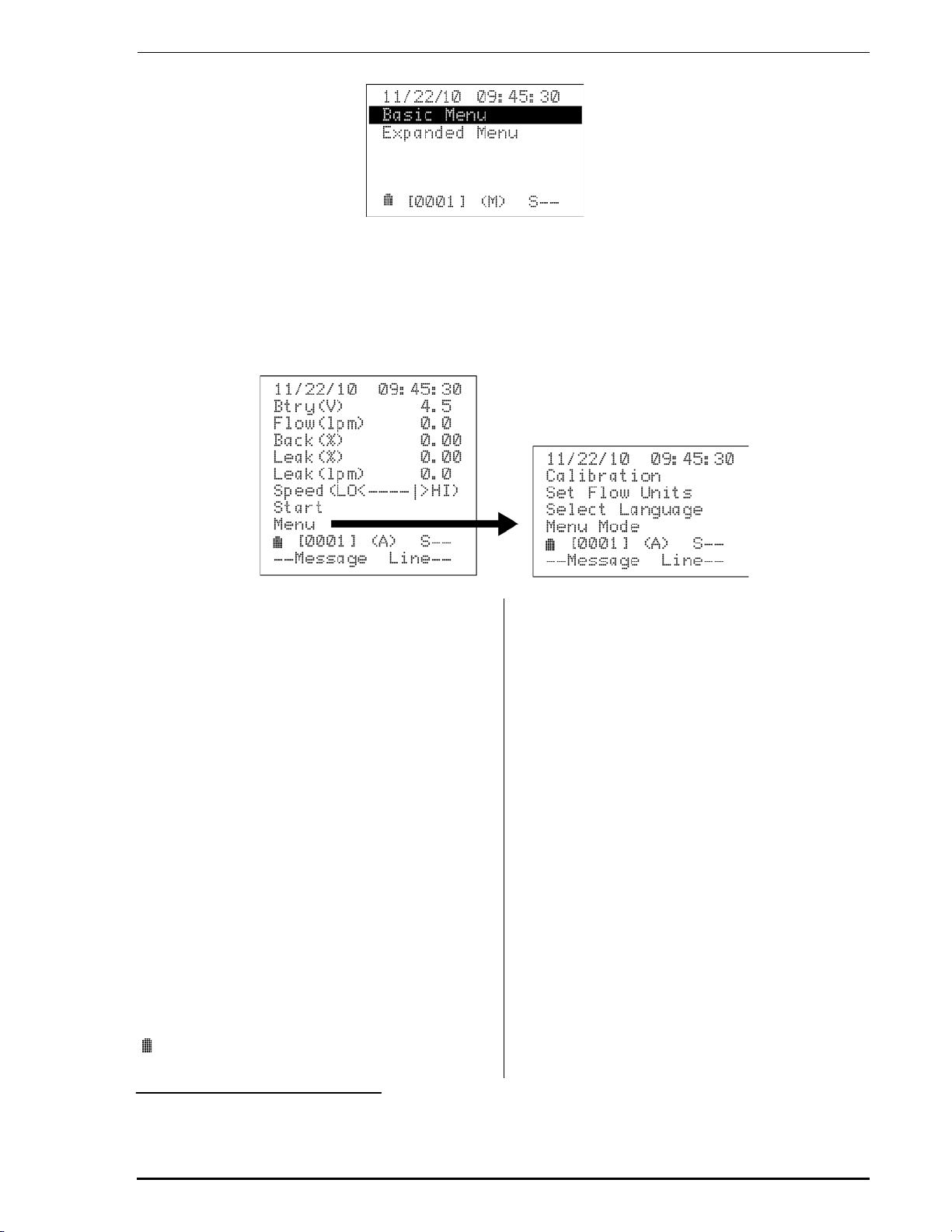

2.8 Selecting the Basic or Expanded Menu Mode

Select the Basic or Expanded Menu Mode as follows:

1. From either the Basic or Expanded Main Screen, select Menu > Menu Mode.

2. Highlight the desired menu mode, and then press the I/O ↵ key to select that

mode.

14 Instruction 0055-9017

Hi Flow Sampler Operation

Date and Time: Date displayed as mm/dd/yy, while

[0001]: Current Test ID number

3. Press ESC to return to the Main Screen.

Refer to Sections 2.8.1 and 2.8.2 for detailed descriptions of the information contained

in the Basic and Expanded Main Screens.

2.8.1 Basic Main Mode

time is displayed in a 12-hour format. The date and

time are set per Section

Btry (V): Battery voltage

Flow (lpm): Sample flow rate in either liters/min or

cu.ft./min.

4.8.

(A) or (M): Automatic or Manual mode (refer to Section

2.14)

S--: Standby

-1-: Measurement #1 (maximum flow rate)

--2: Measurement #2 (reduced flow rate)

Back (%): Measured background gas level in either

percent-by-volume or ppm.

Leak (%): Measured natural gas leak concentration at

the current sample flow rate in either percent-byvolume or ppm.

Leak (lpm): Calculated leak rate in either liters/min or

cu.ft./min.*

Speed (LO<––––|>HI): Blower speed indicator.

Start / Stop: Select to Start and Stop a test**

Menu: Select to display the first of several submenus

(refer to Section 2.9)**

: Battery status icon (refer to Section 2.10)

* “Not Avail.” is displayed when a value cannot be calculated from available information.

** Selections are made by using the ∧∨ keys to highlight the desired function, and then pressing the I/O ↵ key to

activate that function.

Instruction 0055-9017 15

Message Line: Various messages appear during

operation describing the current function being

performed, or errors that have occurred (refer to

Section2.19: Message Line on page 37).

Calibration: Allows user to perform various calibration

functions, including calibrate, verify, view calibration

dates, view amplifier gain values, or erase calibration.

Set Flow Units: Select to set flow rate display to either

lpm (liters per minute), or cfm (cubic feet per minute).

Select Language: Select to set menu language to

English or Russian.

Menu Mode: Select to set menu to basic mode or

expanded mode.

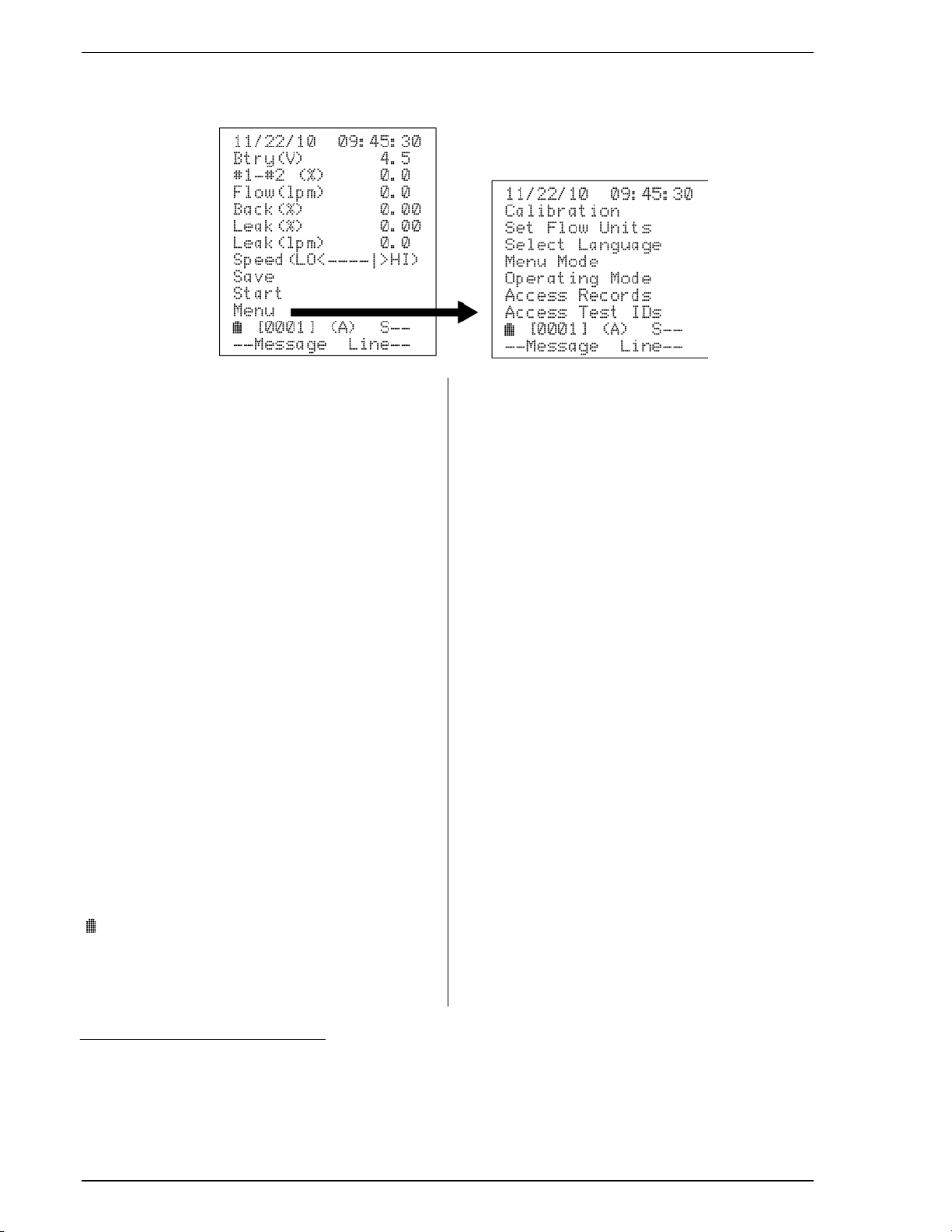

Operation Hi Flow Sampler

Date and Time: Date displayed as mm/dd/yy, while

(A) or (M): Automatic or Manual mode (refer to Section

2.8.2 Expanded Main Mode

time is displayed in a 12-hour format. The date and

time are set per Section

Btry(V): Battery voltage

#1 – #2(%): Difference between test measurements #1

and #2 in percent*

Flow(lpm): Sample flow rate in either liters/min or

cu.ft./min.

Back(%): Measured background gas level in either

percent-by-volume or ppm

Leak(%): Measured natural gas leak concentration at

the current sample flow rate in either percent-byvolume or ppm

Leak(lpm): Calculated leak rate in either liters/min or

cu.ft./min.*

Speed (LO<––––|>HI): Blower speed indicator.

Save: Select to save all current measurement

parameters in memory**

4.8.

2.14)

S--: Standby

-1-: Measurement #1 (maximum flow rate)

--2: Measurement #2 (reduced flow rate)

Message Line: Various messages appear during

operation describing the current function being

performed, or errors that have occurred (refer to

Section2.19: Message Line on page 37).

Calibration: Allows user to perform various calibration

functions, including calibrate, verify, view calibration

dates, view amplifier gain values, or erase calibration.

Set Flow Units: Select to set flow rate display to either

lpm (liters per minute), or cfm (cubic feet per minute).

Select Language: Select to set menu language to

English or Russian.

Menu Mode: Select to set menu to basic mode or

expanded mode.

Start / Stop: Select to Start and Stop a test**

Menu: Select to display the first of several submenus

(refer to Section 2.9)**

: Battery status icon (refer to Section 2.10)

[0001]: Current Test ID number

* “Not Avail.” is displayed when a value cannot be calculated from available information.

** Selections are made by using the ∧∨ keys to highlight the desired function, and then pressing the I/O ↵ key to

activate that function.

16 Instruction 0055-9017

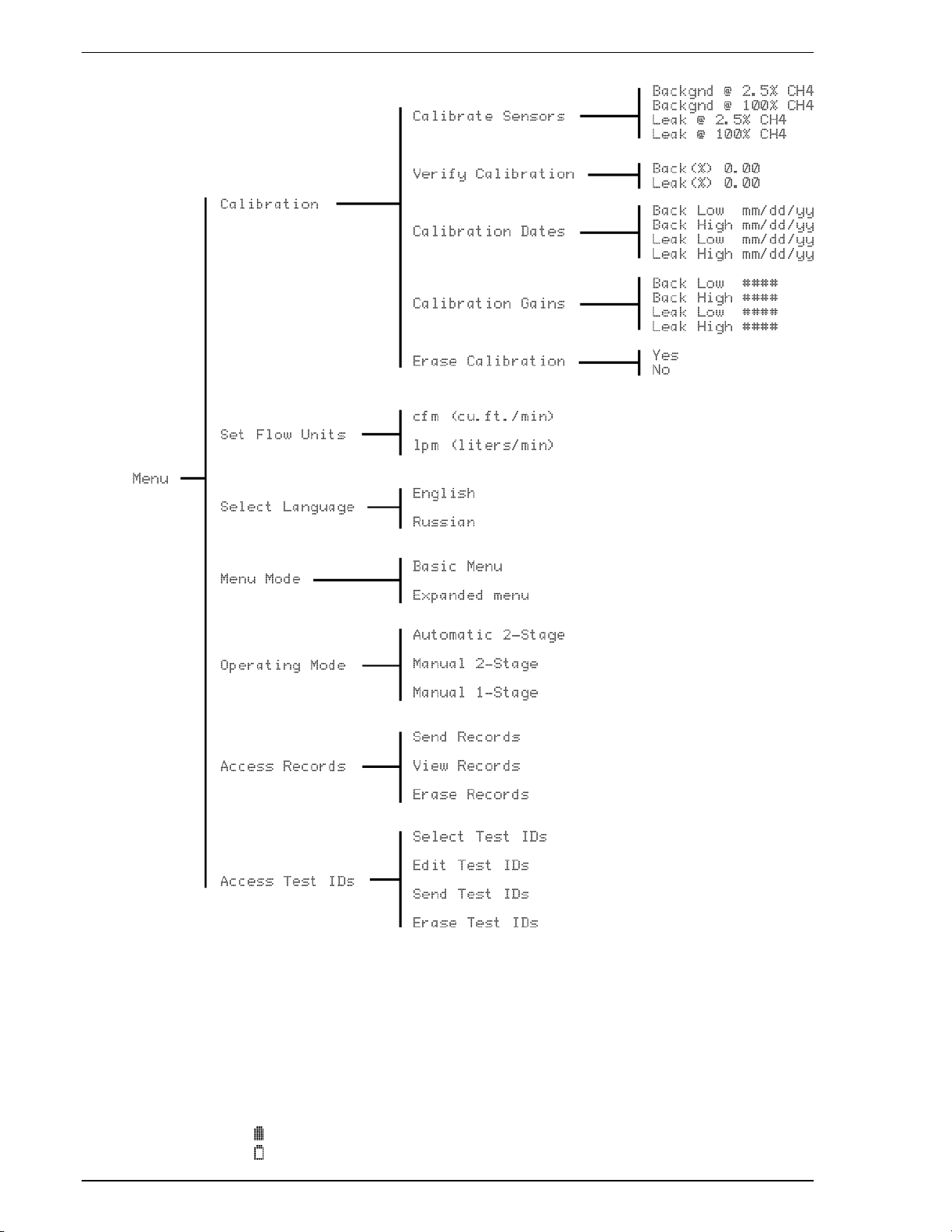

Operating Mode: Select to set operating mode to

automatic or manual mode.

Access Records: Select to send (to a PC), view (on LCD),

or erase all saved records.

Access Test IDs: Create a new Test ID, edit an old one,

send the Test IDs to a computer, or erase all existing

Test IDs.

Hi Flow Sampler Operation

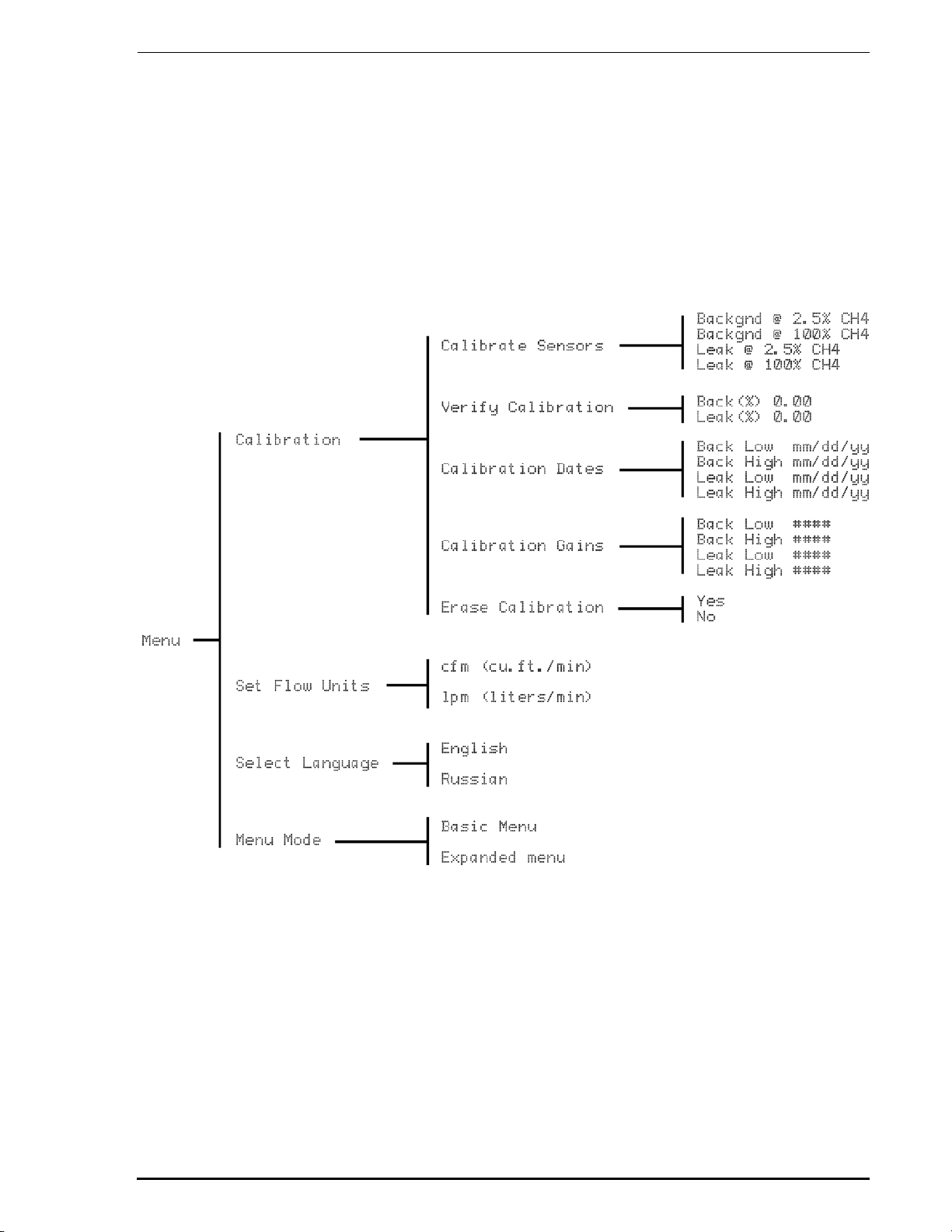

2.9 Menu System

Selecting Menu from either the Basic or Expanded Main Screen provides the user access

to a system of submenus as shown in Figures 2-9 and 2-10.

The items that are listed in the submenus depend on whether the instrument is in its

Basic or Expanded menu mode.

The functions listed are described in their associated sections of this manual.

Figure 2-9. Basic Menu System

Instruction 0055-9017 17

Operation Hi Flow Sampler

Figure 2-10. Expanded Menu System

2.10 Battery Status

Battery status is displayed as a single battery icon shown in the lower-left hand portion

of the LCD. Since the voltage curve of the battery pack drops off rapidly towards the end

of its charge, the Battery status icon is useful only in showing when the battery pack is

nearing depletion. It does not show the pack’s remaining percentage-of-charge. It does

not show the pack’s remaining percentage of charge.

4.0 volts and above

Shutdown imminent, less than 5 minutes of operating time remain

18 Instruction 0055-9017

Hi Flow Sampler Operation

2.11 Calibration Menu

Selecting Calibration from the Menu System allows the user to either:

1) calibrate the sensors

2) verify calibration

3) view dates on which calibrations were performed

4) view amplifier gain values (in hexadecimal) of each sensor circuit, or

5) erase calibration.

A detailed description of each calibration function is provided in Section 3 Calibration.

2.12 Set Flow Units – LPM or CFM

Selecting Set Flow Units from the Menu System allows the user to select whether the

flow rate is displayed in either lpm (liters per minute), or cfm (cubic feet per minute).

Select the desired flow rate unit of measure as follows.

1. From the Main Screen, select Menu > Set Flow Units.

2. Highlight the desired units of measure and then press the I/O ↵ key.

2.13 Menu Mode – Basic or Expanded

3. Press ESC to return to the Main Screen.

Selecting Menu Mode from the Menu System allows the user to select whether only the

most basic amount of information is displayed on the Main Screen (Basic Menu mode),

or if all available information is displayed (Expanded Menu mode).

Refer to Section 2.8 Selecting the Basic or Expanded Menu Mode for detailed

information on how to select the desired menu mode, and learn about what type of

information is displayed in each mode.

2.14 Operating Mode – Automatic or M anual

Note: The Operating Mode can only be selected if operating in the Expanded Menu

Mode. Refer to Section 2.8.

Selecting Operating Mode from the Expanded Menu System allows the user to set the

instrument’s operating mode to either Automatic or Manual.

Instruction 0055-9017 19

Loading...

Loading...