Heath Consultants GT Series User Manual

User Handbook

1

USER HANDBOOK

Issue 2

30/05/06

Part Number: 67112

GMI welcomes comments on all our publications.

Your comments can be of great value in helping us

to improve our customer publications. Please send

any comments that you have to our Sales

Department at GMI. Contact details are provided

inside the back cover of this handbook.

Instrument Service / Repair contact details are also

provided inside the back cover of this handbook.

Copyright

2

Gas Measurement Instruments Ltd 2005

©

COPYRIGHT

COPYRIGHT

This User Handbook is copyright of Gas Measurement Instruments Ltd (GMI) and

the information contained within, is for use only with GT series instruments.

Reproduction, in whole or in part, including utilisation in machines capable of

reproduction or retrieval without written permission of Gas Measurement Instruments

Ltd is prohibited. Reverse engineering is not permitted.

LIABILITY

Every care has been taken in the preparation of this document, but GMI Ltd do not

accept any responsibility for errors or omissions and their consequences. Information

in this document is subject to change without notice. This document does not constitute

a specification or basis for a contract. Your statutory rights under law are not affected.

MODIFICATION NOTICES

GMI aim to notify customers of relevant changes in the product operation and maintain

this manual up to date. In view of the policy of continuous product improvement there

may be operational differences between the latest product and this manual.

This Handbook is an important part of the GT series product. Please note the

following points:

It should be kept with the instrument for the life of the product.

Amendments should be attached.

This Handbook should be passed on to any subsequent owner/user of the

instrument.

Although every care is taken in the preparation of this Handbook it does not

constitute a specification for the instrument.

SOFTWARE

Software supplied on EPROM or similar device for use in a particular product, may

only be used in that product and may not be copied without the written permission of

Gas Measurement Instruments Ltd. Reproduction or disassembly of such embodied

programmes or algorithms is prohibited. Ownership of such software is not

transferable and GMI Ltd does not warrant that the operation of the software will be

error free or that the software will meet the customers requirements.

DISPOSAL ADVICE

When no longer in use, dispose of the instrument carefully and with respect for the

environment. GMI will dispose of the instrument without charge if returned to the

factory.

i

USER HANDBOOK

SAFETY

The instrument must be regularly serviced and calibrated by fully trained

personnel in a safe area.

Batteries: Alkaline or *Rechargeable batteries must be exchanged (*and

recharged) in a safe area and fitted correctly before use.

Never use damaged batteries or expose to extreme heat.

See Chapter 12 : OPERATOR MAINTENANCE.

Only GMI replacement parts should be used.

If the instrument detects gas, follow your own organisations procedures

and operational guidelines.

The combustion chamber is a flameproof assembly and must not be opened

in the presence of a flammable atmosphere.

GT series instruments are certified as ATEX II 2 G EEx iad IIB T3

(-20oC < Tamb < 50oC). UL Class 1 Groups C and D.

This equipment is designed and manufactured to protect against other

hazards as defined in paragraph 1.2.7 of Annex II of the ATEX Directive

94/9/EC

Any right of claim relating to product liability or consequential damage to any third

party against GMI is removed if the warnings are not observed.

WARNING: To prevent ignition of flammable or combustible atmospheres, remove

batteries before servicing.

WARNING: To prevent ignition of flammable or combustible atmospheres, read,

understand and adhere to the manufacturers live maintenance procedures.

WARNING: To reduce the risk of ignition of a flammable or explosive atmosphere,

batteries must be changed only in a location known to be non-hazardous.

WARNING: To reduce the risk of explosion, do not mix old batteries with used

batteries or mix batteries from different manufacturers.

WARNING: Never attempt to recharge non rechargeable cells.

CAUTION: Not for use in oxygen enriched atmospheres.

CAUTION: Replace batteries only with approved batteries:

NiMH GP350

Alkaline Duracell, Energizer, Rayovac.

ii

COPYRIGHT

AREAS OF USE

Exposure to certain chemicals can result in a loss of sensitivity of the flammable

sensor. Where such environments are known or suspected it is recommended

that more frequent response checks are carried out. The chemical compounds

that can cause loss of sensitivity include Silicones, Lead, Halogens and

Sulphur. Do not use instrument in potentially hazardous atmospheres containing

greater than 21% Oxygen. The enclosure material is polypropylene and must not

be exposed to environments which are liable to result in mechanical or thermal

degradation or to damage caused by contact with aggressive substances.

Additional protection may be required in environments where the instrument

enclosure is liable to damage.

STORAGE, HANDLING AND TRANSIT

Rechargeable batteries contain considerable energy and care should be taken in

their handling and disposal. Batteries should be removed if the instrument is stored

for longer than 3 months. The instrument is designed to handle harsh environments.

The sensing elements are sealed to IP54 and the rest of the instrument to IP64. If

not subject to misuse or malicious damage, the instrument will provide many years

of reliable service. The instrument contains electrochemical sensors with a life of

2 years. Under conditions of prolonged storage the sensors should be removed.

The sensor contains potentially corrosive liquid and care should be taken when

handling or disposing of the sensor, particularly when a leak is suspected.

WARRANTY

The GT series instrument has a warranty against faulty goods or workmanship

of 5 years. Consumable and Mechanical parts are not included in this. These are

covered under GMI standard warranty conditions. For details, please contact GMI

Ltd (UK).

iii

USER HANDBOOK

iv

REVISION RECORD

Date Issue Description Of Change

07/09/2005 1 New Handbook

30/05/2006 2 To incorporate effect of

CR 4223, CR 4229, CR

4279 and various other

instrument configuration

updates.

v

USER HANDBOOK

vi

CONTENTS

CONTENTS

COPYRIGHT ................................................................... i

LIABILITY ....................................................................... i

MODIFICATION NOTICES ................................................ i

SOFTWARE ................................................................... i

DISPOSAL ADVICE ........................................................ i

SAFETY ......................................................................... ii

AREAS OF USE ............................................................ iii

STORAGE, HANDLING AND TRANSIT ......................... iii

WARRANTY ................................................................. iii

REVISION RECORD ....................................... v

INTRODUCTION .......................................... 1-1

1.1 INSTRUMENT RANGES .................................... 1-3

GENERAL FEATURES ............................... 2-1

2.2 MODES OF OPERATION ................................... 2-2

OPERATING PROCEDURE ........................ 3-1

3.1 SWITCH THE INSTRUMENT ON ........................ 3-2

3.2 INSTRUMENT IDENTIFICATION ......................... 3-3

vii

USER HANDBOOK

3.3 BATTERY STATUS ........................................... 3-3

3.4 TIME AND DATE ................................................ 3-4

3.5 CALIBRATION DUE DATE ................................. 3-4

3.6 SERVICE DUE DATE ....................................... 3-10

3.7 SWITCH THE INSTRUMENT OFF OR RE-ENTER

THE MODE MENU ................................................... 3-17

LEAK TEST MODE ..................................... 4-1

LEAK TEST RANGES .............................................. 4-1

4.2 LEAK TEST FEATURES .................................... 4-1

4.3 LEAK TEST DISPLAYS .....................................4-2

4.4 LEAK TEST BUTTON OPERATION ................... 4-6

4.5 DESCRIPTION OF LEAK TEST BUTTON OPERA-

TION ......................................................................... 4-7

4.6 LEAK TEST TICKER (GEIGER) FUNCTION ..... 4-11

4.7 LEAK TEST ALARMS ..................................... 4-12

4.8 LEAK TEST LOGGING .................................... 4-12

CONFINED SPACE MODE ......................... 5-1

5.1 CSM RANGES .................................................. 5-1

5.2 CSM FEATURES ............................................... 5-1

5.3 CSM DISPLAYS ................................................ 5-2

5.4 CSM BUTTON OPERATION .............................. 5-4

5.5 DESCRIPTION OF CSM BUTTON OPERATION .. 5-5

5.6 CSM PUMP ........................................................ 5-8

5.7 CSM ALARMS .................................................. 5-8

viii

CONTENTS

5.8 CSM LOGGING ................................................. 5-8

5.9 CSM CONFIDENCE SIGNAL ............................. 5-9

BARHOLE TESTING MODE ....................... 6-1

6.1 BARHOLE RANGES ......................................... 6-1

6.2 BARHOLE FEATURES ...................................... 6-1

6.3 BARHOLE DISPLAYS ....................................... 6-2

6.4 VIEW BARHOLE RESULTS .............................. 6-8

6.5 BARHOLE OPERATION .................................. 6-10

6.6 DESCRIPTION OF BARHOLE BUTTON OPERA-

TION ....................................................................... 6-10

6.7 BARHOLE ALARMS .......................................6-12

CO (CARBON MONOXIDE) MODE ............. 7-1

7.1 CO RANGES ..................................................... 7-1

7.2 CO FEATURES .................................................. 7-1

7.3 CO MENU ..........................................................7-2

7.4 CO DISPLAYS .................................................. 7- 3

7.5 CO BUTTON OPERATION .................................7-6

7.6 DESCRIPTION OF CO BUTTON OPERATION .... 7-6

7.7 CO ALARMS .....................................................7-8

7.8 CO LOGGING ................................................... 7-8

PURGE MODE ........................................... 8-1

8.1 PURGE RANGES .............................................. 8-1

ix

USER HANDBOOK

8.2 PURGE FEATURES ........................................... 8-1

8.3 PURGE DISPLAYS ............................................8-2

8.4 PURGE BUTTON OPERATION .......................... 8-3

8.5 DESCRIPTION OF PURGE BUTTON OPERATION ..

................................................................................. 8- 4

8.6 PURGE ALARMS .............................................. 8-5

SNIFFER MODE ......................................... 9-1

9.1 SNIFFER RANGES ............................................ 9-1

9.2 SNIFFER FEATURES ......................................... 9-1

9.3 SNIFFER DISPLAYS ......................................... 9-1

9.4 SNIFFER BUTTON OPERATION ........................ 9-3

9.5 DESCRIPTION OF SNIFFER BUTTON OPERATION

................................................................................. 9- 3

9.6 SNIFFER TICKER (GEIGER) INDICATION .......... 9-6

PRESSURE MODE .................................. 10-1

10.1 PRESSURE RANGES ....................................10-1

10.2 PRESSURE FEATURES .................................10-1

10.3 PRESSURE DISPLAYS ................................ 10-2

10.4 PREPARE INSTRUMENT (PRESSURE MODE)1 0- 3

10.5 PRESSURE BUTTON OPERATION ................10-4

10.6 DESCRIPTION OF PRESSURE BUTTON OPERA-

TION ....................................................................... 10-4

10.7 PRESSURE ALARMS .................................... 10-5

x

CONTENTS

ALARMS .................................................... 11-1

11.1 GAS ALARMS .............................................. 11-1

11.2 FLAMMABLE (LEL) ALARMS ....................... 11-1

11.3 OXYGEN (O2) ALARMS ............................... 11-1

11.4 TOXIC GAS (e.g. CO) ALARMS ................... 11-1

11.5 ALARM TYPES ............................................. 11-9

11.6 FAULT ALARMS ......................................... 11-13

OPERATOR MAINTENANCE .................... 12-1

12.1 CLEANING .................................................... 12-1

12.2 FILTER REPLACEMENT................................ 12-1

12.2.1 Probe Filter ................................................ 12-2

12.2.2 Chemical Filter (Accessory) .................... 12-5

12.2.3 Cotton Filter (Accessory) ...................... 12-10

12.3 BATTERY REPLACEMENT ........................ 12-13

12.3.1 Remove and Replace Batteries ............. 12-15

12.3.2 Charging (Rechargeable) Batteries ....... 12-19

CALIBRATION ........................................... 13-1

13.1 CALIBRATION VALIDITY .............................. 13-2

ACCESSORIES ........................................ 14-1

xi

USER HANDBOOK

ADDITIONAL INFORMATION ..................... 15-1

Training .................................................................... 15-1

World Wide Web ...................................................... 15-1

TYPICAL OPERATING PARAMETERS ....... A-1

Dimensions (excl. probe) ....................................... A-2

Weight (incl. probe & batteries) ............................. A -2

Temperature Limits ................................................. A- 2

Humidity .................................................................. A-2

Construction / Protection Rating ............................ A- 2

Display .................................................................... A-2

Sampling System.................................................... A-2

Power Source ........................................................ A-2

INDEX ............................................................. I

xii

INTRODUCTION

1

INTRODUCTION

The GMI GT series instruments are designed to be

multifunction, multi-application gas detectors to suit all the

needs of a Gas Industry Service Technician.

Fig. 1.1 GT series Instrument

1-1

USER HANDBOOK

In the following procedure, the five instrument buttons

shown in Fig 1.2 are referred to as detailed below:

Up

Centre

Down

LH

Fig. 1.2 Button References

Button Text Reference

LH (INVERT): LH button

Centre (RANGE): Centre button

RH (PUMP): RH button

Up: UP button

Down: DOWN button

RH

1-2

INTRODUCTION

The bottom line of the instrument display may indicate

button press options. For example, to select Yes from

the following screen option, you would press the RH

button. To select No, the LH button would be pressed.

Fig 1.3 Option Select

The principle of selecting any one of three options on the

bottom line of the instrument display, by pressing either

LH, CENTRE or RH buttons, is used throughout the

operation of this instrument.

1.1 INSTRUMENT RANGES

The detection ranges, available but which may not all be

included in the version of GT selected by your company,

are:

0-10,000 ppm Flammable (Sniffer Range)

0-100% LEL Flammable

(Option to display as %Gas)

0-100% VOL Flammable

0-25% O

2

0-2000 PPM CO

0-100 PPM H

S

2

0 to 60 in. Water Gauge (0 to 150mBar)

1-3

USER HANDBOOK

1-4

GENERAL FEATURES

2

GENERAL FEATURES

An integral pump draws the required sample over

all of the sensors

The pump flow is monitored by means of a pres-

sure transducer

Datalogging is available for some applications

A Bleep sounds for each button press

A green LED indicates Power ON

To simplify use in its many applications, the instrument

utilises a menu system similar to a (cell) mobile phone, as

shown in Fig 2.1.

Fig. 2.1 Mode Menu

The bottom line of the LCD can also be used to indicate

press and hold button functions available.

2-1

USER HANDBOOK

By simple selection of the application you need, the

appropriate gas(es) are shown on the display and only

the necessary button functions and alarms are activated.

Note: Your company may have decided to have its

instruments configured only for certain of the

aforementioned applications.

2.2 MODES OF OPERATION

Leak Test

This mode is for the technician to investigate odour or

leak complaints and to pinpoint the leak.

Refer to Chapter 4 for Leak Test mode operation.

Confined Space

Used for confined space pre-entry testing and for personal

monitoring in areas such as basements etc.

Refer to Chapter 5 for Confined Space mode operation.

Barhole

Used to locate underground leaks. This can be timed or

non-timed. Your company may have selected only one of

these options.

Refer to Chapter 6 for Barhole mode operation.

CO

The CO (Carbon Monoxide) mode allows the user to make

either CO Direct, Differential CO, or Air Free CO readings

(if an O

chosen only certain of these options.

cell is fitted). Note: Your company may have

2

Refer to Chapter 7 for CO mode operation.

2-2

GENERAL FEATURES

Purge

This mode is used in gas and air purging applications.

Refer to Chapter 8 for Purge mode operation.

Sniffer

This mode is used to find small fitting leaks. Very fast

detection rates are achieved using the semiconductor

sensor in the probe.

Refer to Chapter 9 for Sniffer mode operation.

Pressure

In this mode, the instrument can be used as a manometer

to measure appliance and regulator pressure and to check

the system for leaks.

Refer to Chapter 10 for Pressure mode operation.

2-3

USER HANDBOOK

2-4

OPERATING PROCEDURE

OPERATING PROCEDURE

Check the following:

The instrument is clean and in good condition.

The batteries are in good condition, fully charged

and fitted correctly.

The hydrophobic filter is clean and in good condi-

tion.

The sample line and any other accessories used

are in good condition.

The clear bulb at probe end is screwed tightly.

Switch instrument ON in fresh air.

The battery indication provides sufficient

capacity for the operation.

The instrument is within the calibration period you

have decided is necessary for your application.

All applicable ranges are operational.

There are no fault indications.

Attach optional accessories, as required.

The instrument displays a sample / flow fault when

inlet is blocked (with a finger for example). If fault

is not displayed, check tightness of all fittings.

After use, allow the instrument to run for 1 2

minutes in fresh air before switching the instrument OFF.

3

3-1

USER HANDBOOK

Each time you use the instrument, carry out the following

procedure:

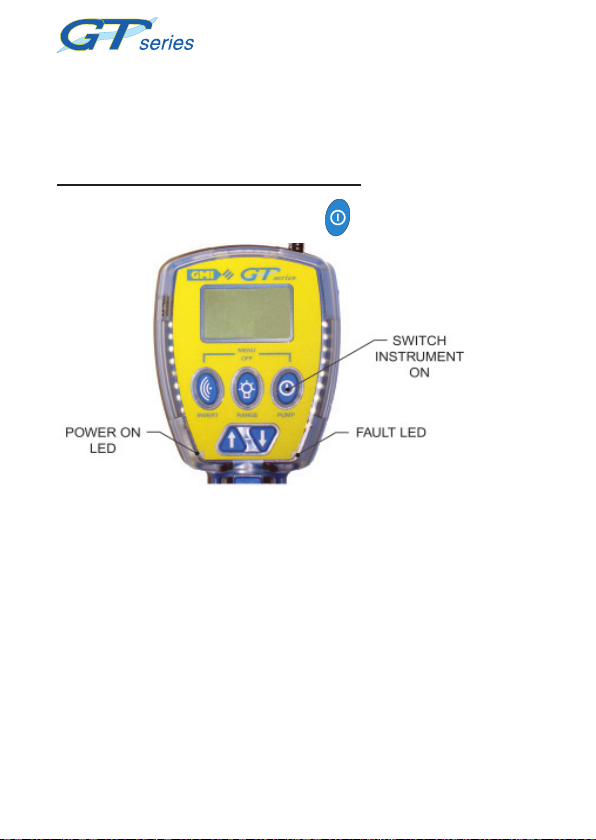

3.1 SWITCH THE INSTRUMENT ON

To switch the instrument ON in fresh air:

Press and hold the RH button

, for one second.

Fig. 3.1 Switch ON

The instrument begins its warm-up routine, which lasts

approximately 30 seconds. During the warm-up cycle, a

countdown timer appears in the top right hand corner of

the display.

The Power ON LED illuminates when the instrument is

switched ON and also during operation. The display

backlight illuminates and remains ON during warm-up.

When the warm-up cycle is complete, the screen light

automatically switches OFF.

The Fault LED illuminates briefly, for approximately five

(5) seconds, during the warm-up cycle.

3-2

OPERATING PROCEDURE

100%

75%

50%

25%

3.2 INSTRUMENT IDENTIFICATION

During the warm-up cycle, the instrument display identifies

the model, serial number, software version and battery

status information as shown in Fig. 3.2:

Fig. 3.2 Instrument Identification

3.3 BATTERY STATUS

This feature provides the user with a battery capacity

level indicator that displays instrument battery power

remaining, as shown in Fig. 3.3.

Fig. 3.3 Battery Capacity

This battery symbol will be indicated for approximately

five (5) seconds during the warm-up cycle, then on the

top of the display during normal operation.

3-3

USER HANDBOOK

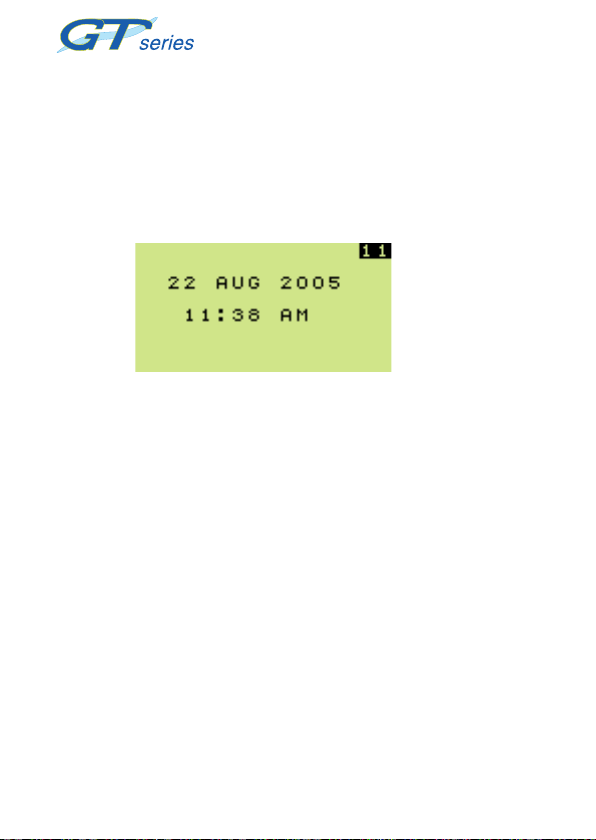

3.4 TIME AND DATE

The time and date from the instruments built-in clock is

displayed on the screen during warm-up, as shown in

Fig. 3.4.

If datalogging is being used, the time and date is set from

this clock. This may be important when viewing the logged

data.

Fig. 3.4 Time and Date

3.5 CALIBRATION DUE DATE

The CAL DUE date can be set by the workshop and is set

to 365 days by default. The date can be set from 1 to 400

days.

The CAL DUE is reset when the instrument is successfully

calibrated.

The CAL DUE feature has five (5) configurable options:

1. Cal Due Date message is not displayed.

3-4

OPERATING PROCEDURE

2. Cal Due Date and overdue date messages are

displayed.

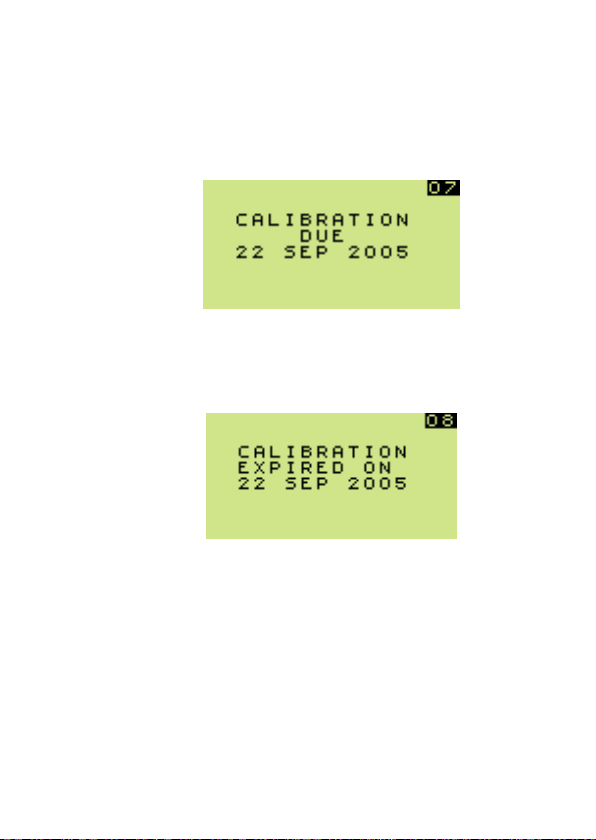

Calibration due date is displayed, as shown in Fig.

3.5.

Fig. 3.5 Calibration Due Date

The screen, shown in Fig. 3.6, is displayed when

the Calibration date has expired. i.e. overdue.

Fig. 3.6 Calibration Overdue

After approximately five (5) seconds, the

instrument warm-up continues.

3-5

USER HANDBOOK

3. Cal Due Date message is displayed with user

acknowledge if overdue (Default).

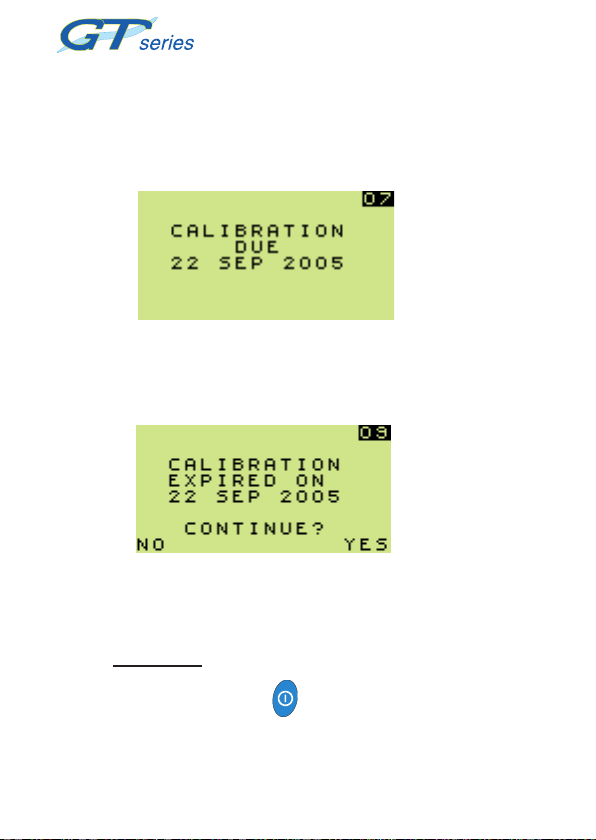

Calibration due date is displayed as shown in Fig.

3.7.

Fig. 3.7 Calibration Due Date

The screen, shown in Fig. 3.8, is displayed when

the Calibration date has expired. i.e. overdue.

Fig. 3.8 Calibration Overdue

The user must acknowledge that Calibration has

expired.

To continue:

Press and hold YES for instrument warm-up

to continue.

3-6

OPERATING PROCEDURE

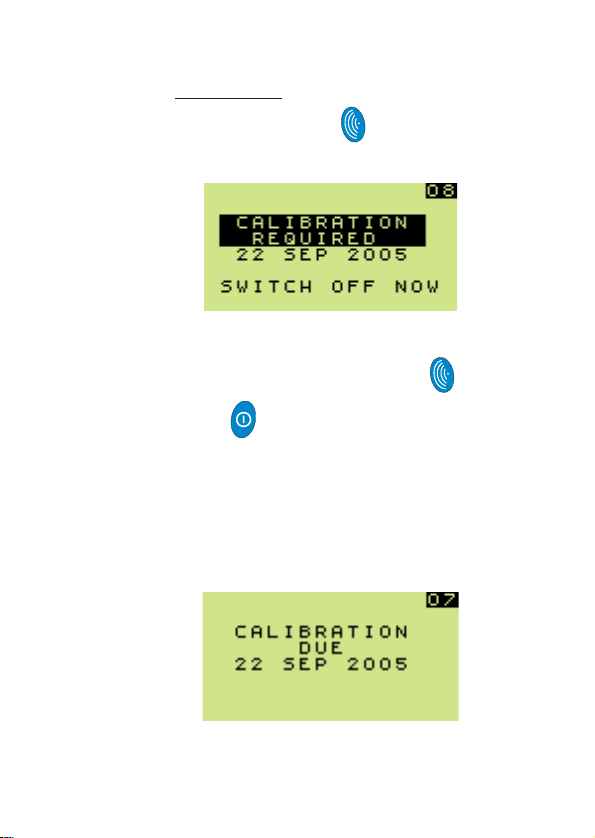

To switch OFF:

Press and hold NO . The screen, shown in

Fig. 3.9, is displayed.

Fig. 3.9 Switch OFF

Press and hold both the LH button and the RH

button

switch-off sequence.

4. Cal Due Date message is displayed with user

acknowledge for extended period option, if

overdue.

Calibration Due Date message is displayed, as

shown in Fig. 3.10.

simultaneously to proceed with the

Fig. 3.10 Calibration Due Date

3-7

USER HANDBOOK

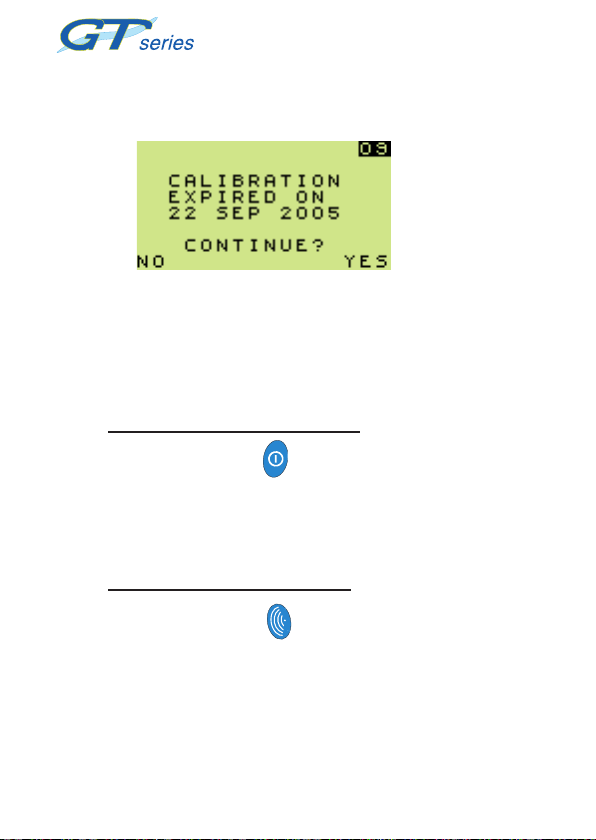

If overdue but within the extended period, the

screen, shown in Fig. 3.11, is displayed.

Fig. 3.11 Calibration Overdue

The user must acknowledge that Calibration has

expired.

Note: The extended period can be set from 1 to

To accept extended period option:

up continues.

Note: When the extended period option expires,

To reject extended period option:

31 days

Press and hold YES and the instrument warm-

the user will be forced to switch the

instrument OFF.

Press and hold NO . The screen, shown in

Fig. 3.12, is displayed.

3-8

Loading...

Loading...