Heath Consultants Gasurveyor 500 User Manual

Heath

Gasurveyor 3-500

User’s Manual

Issue 4

20/07/04

Part Number: 42129

GMI welcomes comments on all our publications.

Your comments can be of great value in helping us

to improve our customer publications. Please send

any comments that you have to our Sales

Department at GMI. Contact details are provided

inside the back cover of this handbook.

Instrument Service / Repair contact details are also

provided inside the back cover of this handbook.

COPYRIGHT

This User Handbook is copyright of Gas Measurement Instruments Ltd (GMI) and

the information contained within, is for use only with the Gasurveyor 3-500

instrument. Reproduction, in whole or in part, including utilisation in machines

capable of reproduction or retrieval without written permission of Gas Measurement

Instruments Ltd is prohibited. Reverse engineering is not permitted.

LIABILITY

Every care has been taken in the preparation of this document, but GMI Ltd do not

accept any responsibility for errors or omissions and their consequences. Information

in this document is subject to change without notice. This document does not constitute

a specification or basis for a contract. Your statutory rights under law are not affected.

MODIFICATION NOTICES

GMI aim to notify customers of relevant changes in the product operation and maintain

this manual up to date. In view of the policy of continuous product improvement

there may be operational differences between the latest product and this manual.

This Handbook is an important part of the Gasurveyor 3-500 product. Please note

the following points:

• It should be kept with the instrument for the life of the product.

• Amendments should be attached.

• This Handbook should be passed on to any subsequent owner/user of the

instrument.

• Although every care is taken in the preparation of this Handbook it does not

constitute a specification for the instrument.

SOFTWARE

Software supplied on EPROM or similar device for use in a particular product, may

only be used in that product and may not be copied without the written permission of

Gas Measurement Instruments Ltd. Reproduction or disassembly of such embodied

programmes or algorithms is prohibited. Ownership of such software is not

transferable and GMI Ltd does not warrant that the operation of the software will be

error free or that the software will meet the customer’s requirements.

DISPOSAL ADVICE

When no longer in use, dispose of the instrument carefully and with respect for the

environment. GMI will dispose of the instrument without charge if returned to the

factory.

i

GASURVEYOR 3-500 USER HANDBOOK

SAFETY

• The instrument must be regularly serviced and calibrated by fully trained

personnel in a safe area.

• Batteries: Alkaline batteries or *Rechargeable battery pack must be

exchanged (*and recharged) in a safe area and fitted correctly before use.

Never use damaged batteries or expose to extreme heat.

See Section 4 : OPERATOR MAINTENANCE.

• Only GMI replacement parts should be used.

• If the instrument detects gas, follow your own organisation’s procedures and

operational guidelines.

• The combustion chamber is a flameproof assembly and must not be opened

in the presence of a flammable atmosphere.

• Gasurveyor 3-500 instruments are certified as EEx iad IIC T4

(-20oC< Tamb < 50oC). BAS01ATEX2292 II 2 G.

UL Class 1 Groups A, B, C and D.

• This equipment is designed and manufactured to protect against other

hazards as defined in paragraph 1.2.7 of Annex II of the ATEX Directive

94/9/EC

Any right of claim relating to product liability or consequential damage to any third

party against GMI is removed if the warnings are not observed.

AREAS OF USE

Exposure to certain chemicals can result in a loss of sensitivity of the flammable

sensor. Where such environments are known or suspected it is recommended that

more frequent response checks are carried out. The chemical compounds that can

cause loss of sensitivity include Silicones, Lead, Halogens and Sulphur. Do not

use instrument in potentially hazardous atmospheres containing greater than 21%

Oxygen. The enclosure material is polypropylene and must not be exposed to

environments which are liable to result in mechanical or thermal degradation or to

damage caused by contact with aggressive substances. Additional protection may

be required in environments where the instrument enclosure is liable to damage.

STORAGE, HANDLING AND TRANSIT

The batteries in the rechargeable pack contain considerable energy and care should

be taken in their handling and disposal. Battery packs should be removed if the

instrument is stored for longer than 3 months. The instrument is designed to handle

harsh environments. The sensing elements are sealed to IP54 and the rest of the

instrument to IP64. If not subject to misuse or malicious damage, the instrument

will provide many years of reliable service. The instrument contains electrochemical

sensors with a life of 2 years. Under conditions of prolonged storage the sensors

should be removed. The sensor contains potentially corrosive liquid and care should

be taken when handling or disposing of the sensor, particularly when a leak is

suspected.

ii

REVISION RECORD

Date Pages Description Of Change

Issue 1 All New Handbook

21.09.00

Issue 2 All Handbook revised to

25.05.01 reflect updated

Issue 3 All Handbook revised to

17.07.03 include effect of CR 2291

Issue 4 All To include Appendix C

20/07/04 (translations)

instrument options and

features

iii

GASURVEYOR 3-500 USER HANDBOOK

iv

CONTENTS

COPYRIGHT ................................................................. i

LIABILITY ...................................................................... i

MODIFICATION NOTICES ........................................... i

SOFTWARE .................................................................. i

DISPOSAL ADVICE ...................................................... i

SAFETY ........................................................................ ii

AREAS OF USE ........................................................... ii

STORAGE, HANDLING AND TRANSIT ...................... ii

REVISION RECORD ..................................... iii

INTRODUCTION ........................................... 1

GENERAL INFORMATION ........................... 3

Ranges of Operation .................................................... 3

LEL, 0 to 100% .......................................................... 3

Volume Gas, 0 to 100 % ............................................ 4

LEL Displayed as % Volume Equivalent ................... 5

Alarms ........................................................................... 5

Alarm Functions ......................................................... 6

Construction .................................................................. 7

v

GASURVEYOR 3-500 USER HANDBOOK

Batteries ........................................................................ 7

Disposable Alkaline (LR20) Dry Cell Batteries .......... 7

Rechargeable (NiCd) Battery Pack ........................... 8

Filters ............................................................................ 8

Liquid Crystal Display (LCD) ........................................ 9

Before Use Checks ....................................................... 9

OPERATING INSTRUCTIONS.................... 11

Modes of Operation .................................................... 11

Switching On ............................................................ 12

Calibration Date Features ........................................ 13

Switching Off the Instrument Pump ......................... 13

Switching On in Purge Mode ................................... 14

Switching Off ............................................................ 14

Summary of Button Operation .................................... 15

Operator Messages / Fault Flags ............................... 15

OPERATOR MAINTENANCE ..................... 19

Rechargeable Battery Pack ........................................ 19

Standard Charger ..................................................... 19

Flatbed Charger ....................................................... 20

Smart Charger .......................................................... 20

Replacing the Battery Pack ..................................... 21

Recharging the Battery Pack ................................... 22

vi

CONTENTS

Replacing Alkaline (LR20) Dry Cell Batteries ............ 22

Filter Replacement ..................................................... 24

CALIBRATION ............................................ 27

Calibration Validity ...................................................... 28

ACCESSORIES........................................... 29

ADDITIONAL INFORMATION ..................... 33

Training ....................................................................... 33

World Wide Web ......................................................... 33

TYPICAL OPERATING PARAMETERS .....A-1

Size ........................................................................ A-2

Weight .................................................................... A-2

Operating Temperature .......................................... A-2

Humidity ................................................................. A-2

Construction ........................................................... A-2

Display .................................................................... A-2

Sampling System ................................................... A-2

Power Source ......................................................... A-3

vii

GASURVEYOR 3-500 USER HANDBOOK

FIELD CALIBRATION ................................ B-1

Selectable Ranges in FCM ....................................... B-3

Entering FCM ............................................................ B-3

Zeroing the Instrument ............................................. B-4

Field Calibration Procedure ...................................... B-5

Quitting FCM ............................................................. B-9

Quit And Save Changes ........................................ B-9

Quit Without Saving Changes ................................ B-9

OPERATING INSTRUCTIONS.................. C-1

English ..................................................................... C-2

Français (French) .................................................... C-6

Deutsch (German) ................................................. C-10

Svensk (Swedish) .................................................. C-14

Dansk (Danish) ...................................................... C-18

Nederlands (Dutch) ............................................... C-22

INDEX ............................................................ I

viii

1

INTRODUCTION

The Gasurveyor 3-500 is a two button flammable gas leak

location and purge instrument, designed to measure Lower

Explosive Level (LEL) and Volume flammable gas. The

instrument is designed to the latest standards and is

certified for use in Hazardous Areas.

The Gasurveyor 3-500 contains the following ranges:

$ LEL, 0 to 100%

$ Volume gas, 0 to 100%

As the Gasurveyor 3-500 has a wide variety of available

user selected options, it is not possible to provide an

operator handbook specific to each possible variation,

therefore, what we have provided in the following pages

is the standard default of how the instrument would

1

GASURVEYOR 3-500 USER HANDBOOK

generally be configured, with the possible options detailed

in italic text.

GMI recommend that you take the time to study your

instrument and, where practical and with advice from your

company’s Purchasing / Management departments,

highlight your particular instrument configuration.

The main default features of the instrument are:

$ Rugged carbon loaded polypropylene case, sealed

to IP54 rating and suitable for outdoor use.

$ Two button operation allowing the user access to

all features.

$ LCD with backlighting which displays the current

gas readings (in both digital and analogue forms)

together with operational and status information.

$ Audible and Visual alarm options, if selected, are

pre-set to specific gas concentration levels.

$ Directly interfaces with the GMI Auto Test Cali-

bration Units.

2

2

GENERAL INFORMATION

Ranges of Operation

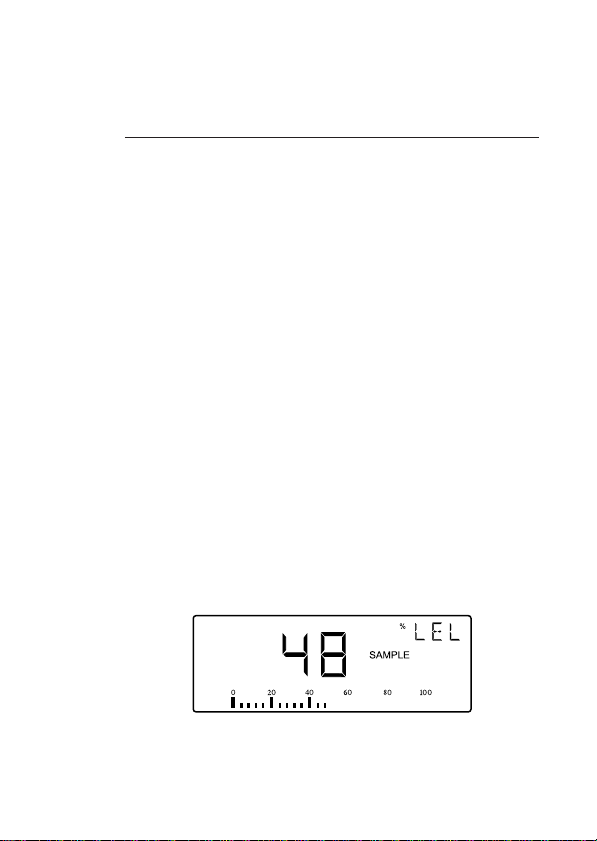

LEL, 0 to 100%

The LEL range indicates the explosibility of the flammable

gas in the sample. This is displayed as a percentage of the

lower explosive limit (LEL) of the gas. For methane 100%

LEL corresponds to 5% Volume methane in Air.

The instrument range is displayed in the top right corner

of the display as % LEL. From 0 to 10% LEL the digital

display resolves to 0.1% LEL. From 10 to 100% LEL the

digital display resolves to 1% LEL. The analogue bar

graph follows in 4% steps. An example of the LEL display

is shown in Figure 2.1. Autoranging will automatically

switch the range to Volume Gas when 100% LEL is

reached.

The detection principle for this range is a catalytic reaction.

Figure 2.1 LEL Range

3

GASURVEYOR 3-500 USER HANDBOOK

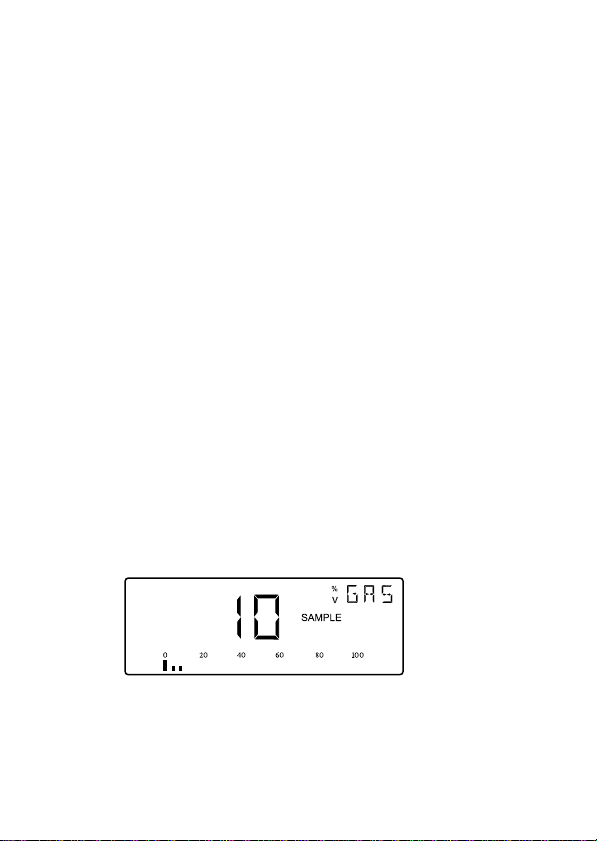

Volume Gas, 0 to 100 %

This range displays the total volume of a specific

flammable gas with respect to air. The calibration gas is

shown on the service label and for the purpose of this

handbook is assumed to be methane. Instruments

calibrated for methane in air should only be used for

measuring such mixtures. To change the calibration gas,

e.g. from methane to propane, the instrument must be

recalibrated by suitably trained personnel.

On the Volume Gas range the instrument range is

displayed in the top right corner of the LCD as GAS. The

digital display resolves the signal to 1% GAS with the

analogue bar graph following in steps of 4%. Figure 2.2

shows the Volume Gas display. The detection principle

for the Volume Gas range is thermal conductivity.

When using PURGE mode to measure flammable gas in

air or Nitrogen, or a combination of both background

gases, the Gasurveyor 3-500 will use the thermal

conductivity Volume gas range only.

The digital display will resolve the signal to 1% Gas, with

the analogue bar graph following in steps of 4%.

Figure 2.2 Volume Gas Range

4

GENERAL INFORMATION

LEL Displayed as % Volume Equivalent

The LEL Displayed as a % Volume Equivalent is available

for methane in air calibrated instruments only.

In this mode, the range is displayed in the top right hand

corner of the display, as % Gas. From 0 to 100% LEL

Equivalent, the digital display resolves to 0.1% Gas.

Note: If you are using the Gasurveyor 3-500 instrument

for purge operations using the Volume Gas range, ensure

that LEL Displayed as a % Volume Equivalent range

option, is not selected as a user option.

Alarms

The Gasurveyor 3-500, by default, has both audible and

visual alarms off when operating.

The audible alarm is rated up to 85 dB(A). The visual

alarm is a red LED indicator which protrudes from the

instrument top plate, allowing viewing from any angle

above the top plate.

The instrument, where selected, can have alarm levels

for the Flammable LEL pre-set.

The Gasurveyor 3-500 has the facility to have two (2)

instantaneous alarm levels for the flammable LEL range

in the instrument. These are described as LOW and HIGH,

although generally only the high alarm would be active.

When both instantaneous alarms are set, the LOW audible

and visual alarm cycle will be activated for 0.5 seconds

on and 0.5 seconds off. The HIGH audible and visual

alarm cycle will be activated for 0.25 seconds on and

0.25 seconds off.

5

GASURVEYOR 3-500 USER HANDBOOK

The option is to have the instantaneous alarms activated.

It is the responsibility of the user to ensure that the alarm

levels, where set in the instrument, are appropriate for

the safe operation and legal requirements for the country

/ industry in which the unit is being used.

Alarm Functions

The Gasurveyor 3-500, by default, has the alarm function

on the flammable range disabled.

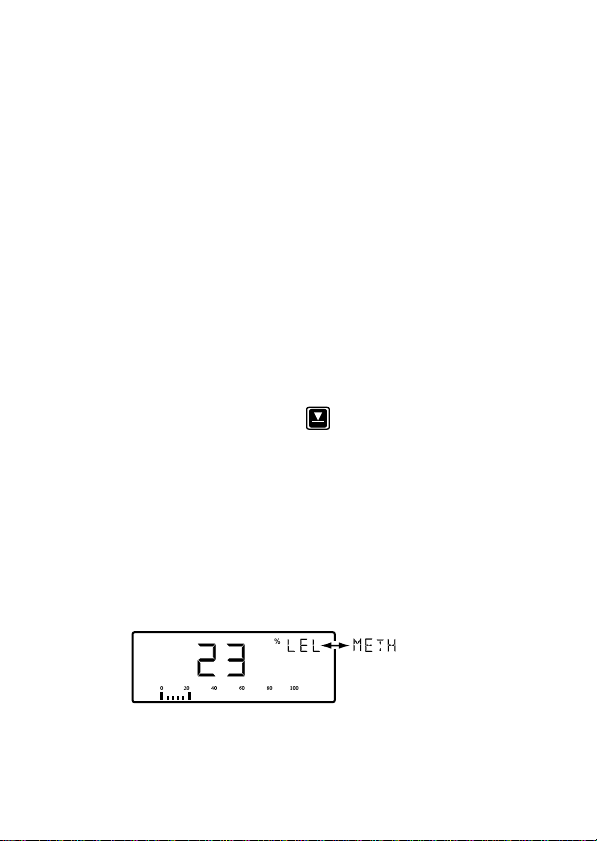

Where the alarm function is enabled, the instrument has

the facility to have either latching or non-latching alarms.

Latching means that when the alarm level is exceeded,

the LED will flash (visual) and the sounder will pulse

rapidly (audible). Latching alarms are cleared manually,

by a double press of Button Two , after the detected

gas level has fallen below the alarm limit.

Each alarm has to be acknowledged individually, e.g. If

both LOW (10%) and HIGH (20%) instantaneous alarms

have been set, then both would have to be acknowledged

individually if LEL is greater than 20%. If the audible

and/or visual indicators are set to off then the display

alarm function would need to be acknowledged in the

same way. Alarm display example is shown in Figure 2.3.

Figure 2.3 LEL Alarm Display Example

6

GENERAL INFORMATION

Non-Latching means that the alarms clear automatically

when the gas level falls below the alarm limit.

For both latching and non-latching alarms, it is possible

for both audible and visual indicators to be either On or

OFF independent of each other.

Construction

The instrument is housed in a tough, impact resistant,

moulded case made of carbon loaded polypropylene.

The top panel is protected by a stainless steel top plate

covering a toughened glass LCD cover.

The battery pack is sealed and attached to the main

instrument body by means of 2 stainless steel hexagonal

screws.

The instrument is sealed against dust and water to IP54

standard. The sensors are protected from dust and water

by membrane and cotton filters.

Batteries

Disposable Alkaline (LR20) Dry Cell Batteries

Alkaline batteries provide approximately 15 hours

operational life at ambient temperature of 20

When the batteries are low or exhausted it is necessary to

fit 4 new batteries. Do not mix old and new batteries.

An indication of the battery condition is displayed after

power on and during warm-up, with status shown as either

OK or LO. If LO condition is displayed, a maximum

battery operational life of 120 minutes remains. During

o

C (68oF).

7

GASURVEYOR 3-500 USER HANDBOOK

operation the ‘BAT’ alarm flag is displayed when

approximately 60 minutes of operating time remains at

normal temperature. The instrument may continue to be

used until it switches off automatically.

Rechargeable (NiCd) Battery Pack

The GMI rechargeable battery pack provides

approximately nine hours operational life, from fully

charged, at ambient temperature of 20

o

C (68oF). An

indication of the battery condition is displayed after power

on and during warm-up, with status shown as either OK

or LO. If LO condition is displayed, a maximum battery

operational life of 90 minutes remains. During operation

the ‘BAT’ flag is displayed when approximately 30

minutes operating time is left at normal temperatures. The

instrument will then turn off.

There are three GMI Battery Chargers: a Standard Charger, a Flatbed Charger and a Smart Charger. The Smart Charger has both slow and fast charge options as well as a serial link for communications with the instrument. See Rechargeable Battery Pack in Section 4

OPERATOR MAINTENANCE.

Filters

A number of different filter types are available from GMI.

The minimum requirement is a cotton particulate filter

and a hydrophobic filter which are incorporated in the

probe handle assembly, supplied with the instrument.

Filters must be checked at frequent intervals and where

appropriate changed to ensure a clean sample path. If water

8

GENERAL INFORMATION

is drawn into the instrument any filter which has been

contaminated must be cleaned or replaced. See Filter

Replacement in Section 4 OPERATOR MAINTENANCE.

Liquid Crystal Display (LCD)

The LCD shows the current gas readings in both analogue

and digital form together with operational and status

information. The display is protected by a toughened glass

cover. Backlighting is provided to enable the display to

be seen under low ambient light conditions.

Before Use Checks

The following checks should be carried out before using

the instrument on site:

$ The instrument is clean and in good condition.

$ The batteries have sufficient power left in them

for the intended use of the instrument.

$ The filters are clean and in good condition.

$ The sample line and any accessories are in good

condition and leak free.

$ All gas ranges are operational and zeroed correctly.

$ The calibration is still valid.

9

GASURVEYOR 3-500 USER HANDBOOK

10

3

OPERATING INSTRUCTIONS

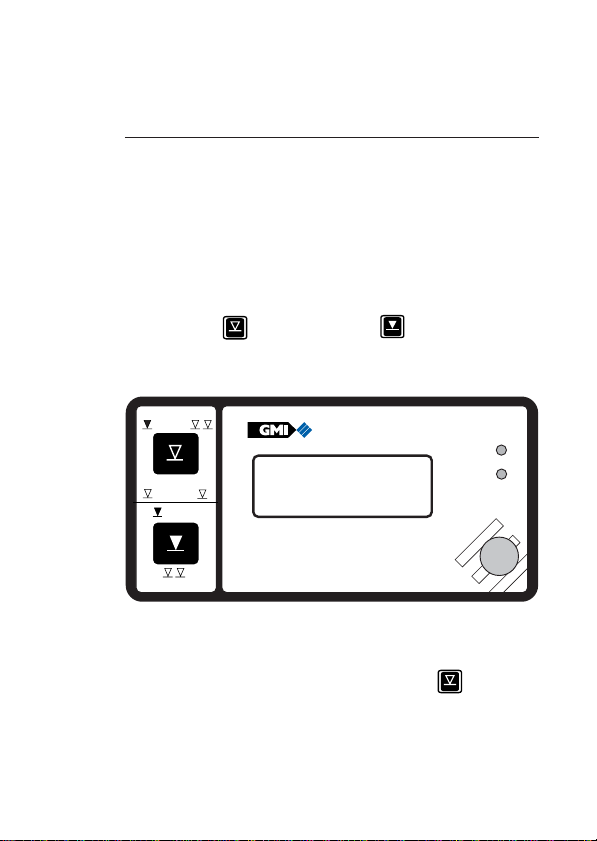

Modes of Operation

The instrument has two modes of operation which are

accessed by switching the instrument ON with either

Button One or Button Two . See Figure 3.1

below.

ON

OFF

INST.

ON OFF

PUMP

PURGE

ALARM ACK.

GASURVEYOR 3-500

Figure 3.1 Instrument Front Plate

Mode 1. Switching ON with Button One provides

two gas ranges:

a) LEL autoranging to Volume Gas.

11

GASURVEYOR 3-500 USER HANDBOOK

Audible/visual alarms can operate in this mode.

Mode 2. Switching ON with Button Two

provides access to only 0-100% Vol Gas range for

purge applications. No audible/visual alarms are

available in this mode.

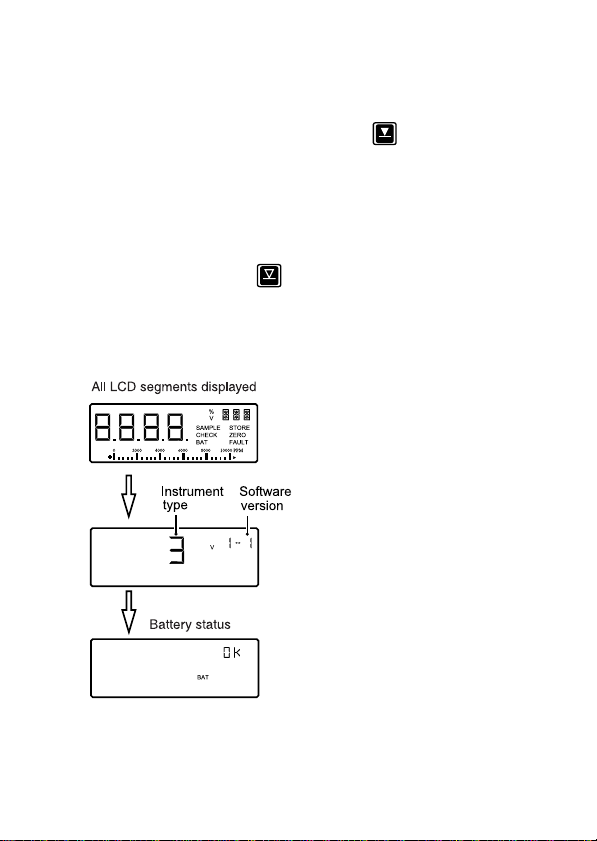

Switching On

Press and hold Button One

to turn the instrument on.

This initiates the instruments warm up cycle and switches

on the pump. Figure 3.2 displays the warm up cycle for

the Gasurveyor 3-500.

12

Note: Battery status is displayed

as either OK or LO at start-up.

Figure 3.2 Warm Up

OPERATION

Calibration Date Features

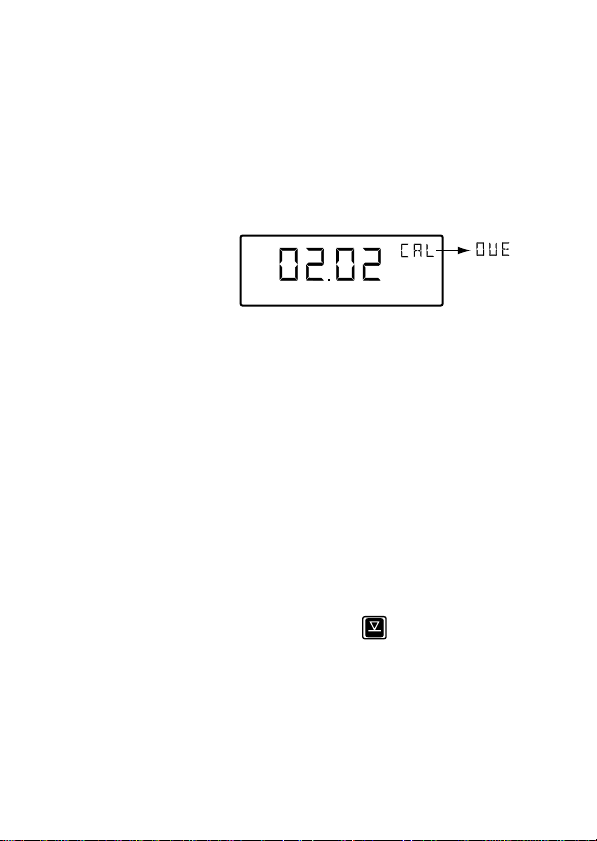

At the end of warm-up and before the Gasurveyor 3-500

instrument is ready for measuring, the instrument will

indicate on the display when the next calibration is due.

This will be displayed as month and year, as shown in

Figure 3.3:

Calibration Due

February 2002

(Alternate flash)

Figure 3.3 Calibration Date

The re-calibration interval pre-set for all Gasurveyor

3-500 instruments is twelve (12) months.

This period can be altered as an option, however, you

should ensure that the instrument is always within its

calibration period prior to use.

An option which ensures that an ‘out of calibration

instrument’ is not used, is the automatic switch-off when

overdue.

Switching Off the Instrument Pump

A single press of Button One

, when the pump is

running, turns the pump off and stops sampling. Pressing

button one again turns the pump back on.

13

GASURVEYOR 3-500 USER HANDBOOK

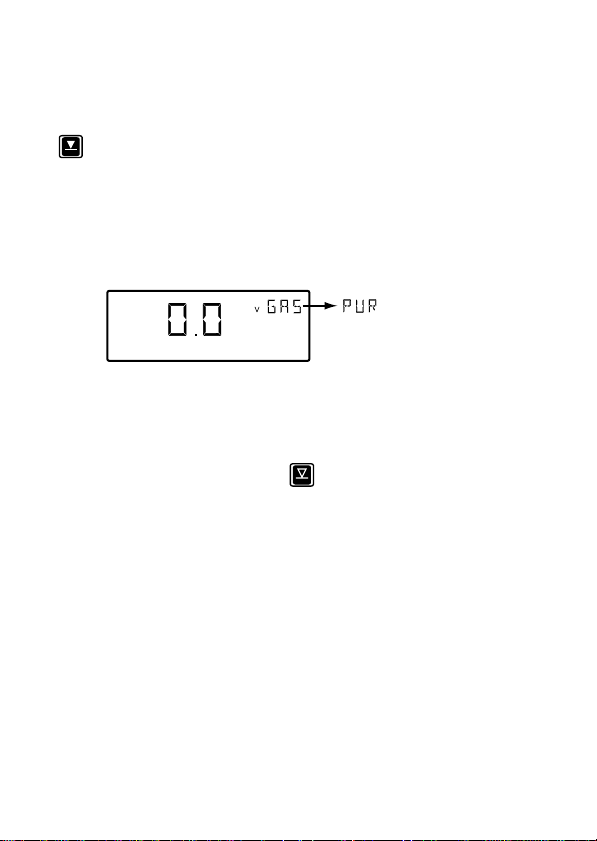

Switching On in Purge Mode

To switch on in Purge mode, press and hold Button Two

. The Gasurveyor 3-500 will initiate the warm-up

sequence as explained previously. This mode uses the

thermal conductivity Volume gas range only since inert

Nitrogen atmospheres are likely to be present. When in

purge mode, the PURGE flag is activated on the display,

as shown in Figure 3.4.

(Alternate flash)

Figure 3.4 Purge Mode

Switching Off

A double press of Button One

turns the instrument

off.

14

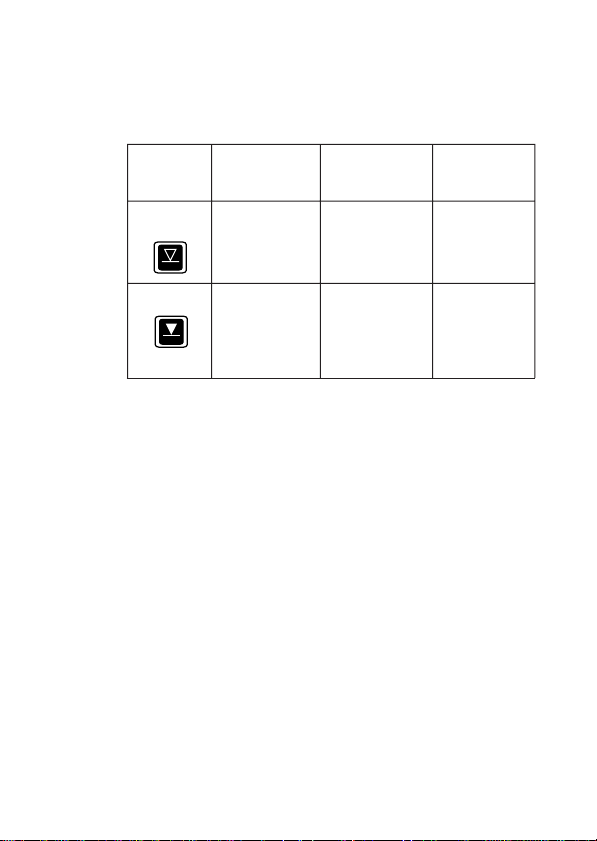

Summary of Button Operation

OPERATION

ffOsehctiwS

tnemurtsnI

in Purge mode

Press and

Hold

OnsehctiwS

tnemurtsnI

OnsehctiwS

Instrument

Measure

Mode

Button 1

Button 2

Single Press

Toggles Pump

On / Off

(during operation)

_

Double

Press

Acknowledge

Alarm

Operator Messages / Fault Flags

Various messages can appear on the LCD screen to

indicate instrument status.

‘SAMPLE’

This indicates that the pump is running and the instrument

is sampling.

‘OFF’

This indicates that the instrument is about to switch off.

This command can be cancelled by a single press of any

button.

15

GASURVEYOR 3-500 USER HANDBOOK

‘SAMPLE FAULT’

This indicates a problem with the instrument’s flow due

to the sample path being blocked, water ingress, a blocked

filter or pump failure.

In Measure and Purge mode, the pump stops

automatically. The sample line, filters etc. should be

checked for water ingress or blockage and Button One

should then be pressed to restart the pump.

‘CHECK ZERO’

This indicates that there may have been a zero shift due

to the presence of gas. Switch off the instrument and

switch on again in fresh air.

‘ZERO FAULT’

This indicates that the zero is outwith its calibration limits.

Switch the instrument off and then on again in fresh air.

If the fault does not clear, return the instrument for

servicing.

‘BAT’

This indicates that the batteries will soon require

replacement. At this point there will be approximately 60

minutes operation left in a set of alkaline batteries,

although this figure will vary depending on battery

manufacturer, temperature conditions, usage etc. With

rechargeable batteries the ‘BAT’ flag indicates

approximately 30 minutes operation left.

As the battery power continues to fall, the LCD flashes a

‘BAT FAULT’ message. Subsequently the LCD displays

16

OPERATION

‘OFF’ and the instrument automatically switches off. The

batteries should be replaced immediately.

‘BAT FAULT’

This indicates that the batteries require replacing.

‘1’

This message which can also appear after power on,

indicates that a calibration data error has been detected.

The instrument should be returned for servicing.

17

Loading...

Loading...