Heath Consultants DP User Manual

DETECTO-PAK 4

Users Manual

®

Proprietary Notice

The contents of this manual are proprietary to Heath Consultants

Incorporated. Reproduction of this manual, in whole or in part, is

prohibited without the express written consent of Heath Consultants

Incorporated.

Heath Consultants Incorporated operates under a continual product

improvement program and reserves the right to make improvements

and/or changes without prior notication.

This manual supersedes all previous manuals for the Heath

Detecto-Pak 4.

HPN Manual: 100786-0 Rev D

HPN DP 4 Complete Unit: 100659-0

©COPYRIGHT 1995, Heath Consultants Incorporated

Detecto-Pak® 4

Users Manual

Heath Consultants Incorporated

Houston, TX

713-844-1300

Fax: 713-844-1309

1-800-HEATH-US

www.heathus.com

Safety, Leadership, Innovation, Performance

Then, Now and Tomorrow

TABLE OF CONTENTS

INTRODUCTION ……..............................…………………………………. .ii

FUNCTION ….............................…………………………………………… iii

WARNINGS ...........................................……………………………………. .iv

CHAPTER ONE PROCEDURES

I. DETECTO-PAK 4 PROCEDURES…………........................……… 1

CHAPTER TWO FUEL CYLINDERS

II. FUEL MOTHER TANKS, FUEL CYLINDERS …......................…. 6

CHAPTER THREE CALIBRATION CYLINDERS

III. CALIBRATION MOTHER TANKS, CALIBRATION

CYLINDERS …....................................................................................... 10

CHAPTER FOUR NiMH BATTERY

IV. NICKEL METAL HYDRIDE (NiMH) BATTERY ………..............…. 13

CHAPTER FIVE OPERATION

V. OPERATING THE DETECTO-PAK 4 ….........................…………… 16

CHAPTER SIX CALIBRATION

VI. CALIBRATION …….............................……………………………….. 23

CHAPTER SEVEN APPLICATIONS

VII. APPLICATIONS FOR THE DETECTO-PAK 4 ………...........…… 28

CHAPTER EIGHT MAINTENANCE

VIII. MAINTENANCEINFORMATION …………....……………………. 30

CHAPTER NINE SERVICE INFORMATION

IX. SERVICE INFORMATION ……………………………………......... I

GLOSSARY ……………………………………………………………… IV

INDEX ……………………………….………………………………..….. VI

i

INTRODUCTION

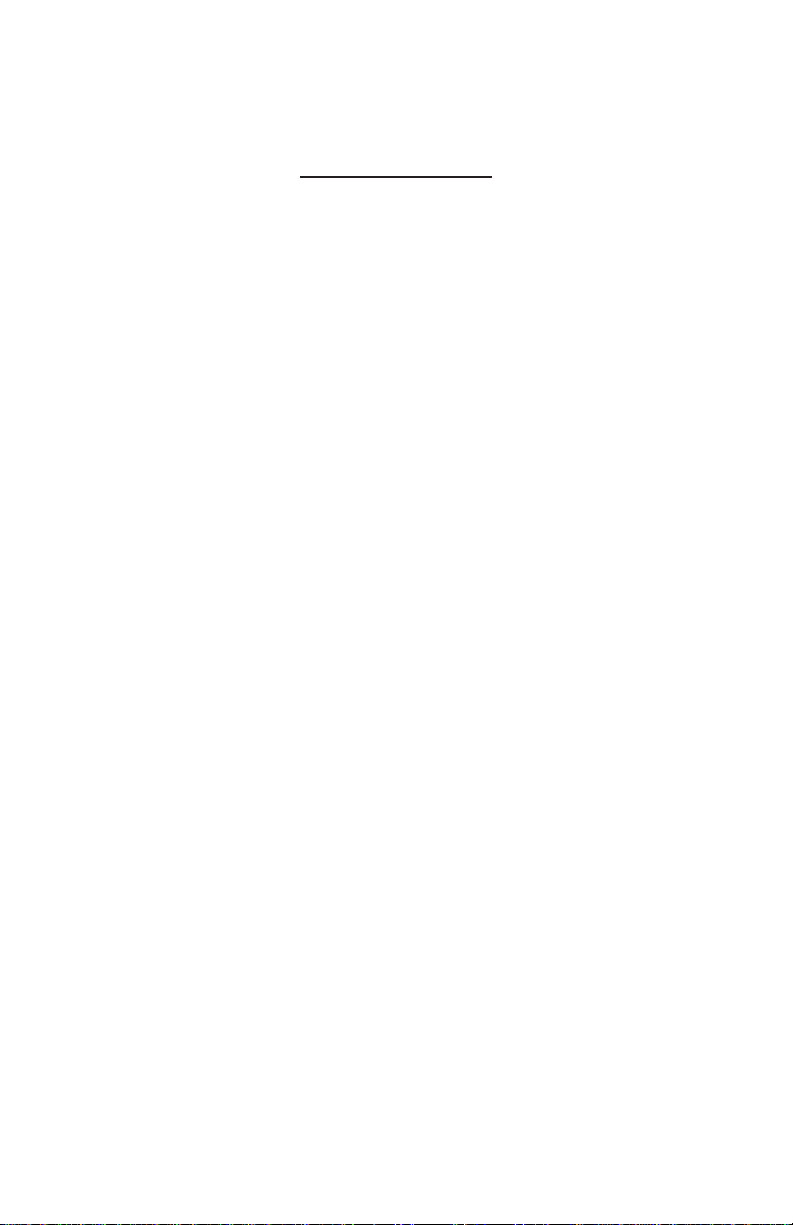

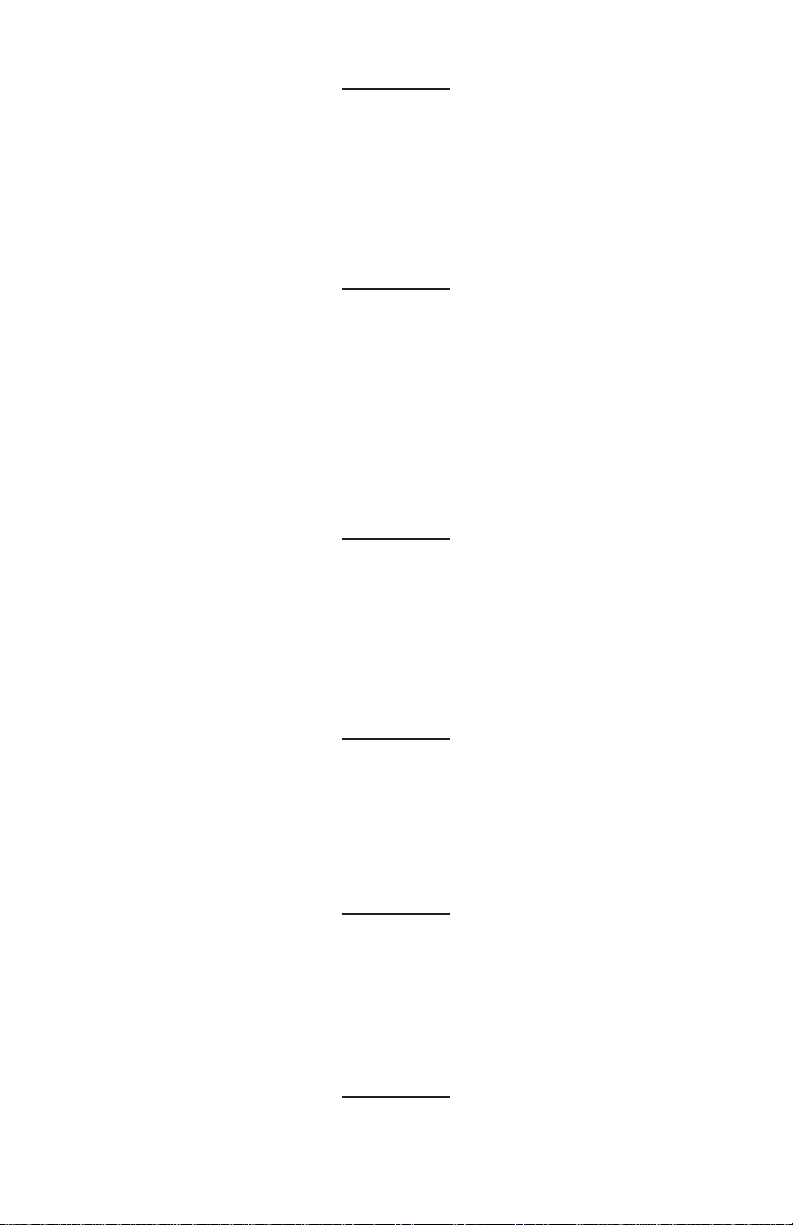

The HEATH Detecto-Pak 4 Flame Ionization Hydrocarbon Detector

is designed to withstand normal eld use and provide sensitive

indication of the presence of hydrocarbon vapors.

This instruction manual is divided into nine chapters. Each chapter

is designed to assure that the operator will obtain the best use of

the Detecto-Pak 4. Chapter One, Detecto-Pak 4 features, should be

required reading for all operating personnel prior to using the DetectoPak 4. Chapter Five, Operating the Detecto-Pak 4, outlines the steps

necessary to make the instrument operational. Other chapters cover

topics such as troubleshooting procedures, periodic maintenance,

applications, etc.

ii

FUNCTION

The Heath Detecto-Pak 4 Flame Ionization Hydrocarbon Detector

is designed to detect and measure the presence of hydrocarbons

(calibrated for methane). The instrument has ve sensitivity ranges:

10, 50, 100, 1,000 (1K), and 10,000 (10K) ppm (1% gas).

This instruction manual describes the operation of the instrument and

provides limited maintenance information. Heath rmly believes the

Detecto-Pak 4, when properly maintained, will provide reliability and

ease of operation for many years.

iii

WARNING

EXPLOSIVE GAS MIXTURES CAN CAUSE SERIOUS INJURY

OR DEATH. INHALATION OF VAPORS CAN CAUSE HEALTH

IMPAIRMENT.

WARNING

IT IS ESSENTIAL THAT USERS OF THIS INSTRUMENT READ,

UNDERSTAND, AND FOLLOW THE INSTRUCTIONS FOR

OPERATION AND MAINTENANCE AND THE PRECAUTIONS

CONTAINED IN THIS MANUAL TO ENSURE THE

INSTRUMENT IS USED IN A PROPER AND SAFE MANNER.

WARNING

DO NOT ATTEMPT TO REPAIR THE INTERNAL FUEL

REGULATOR. DISASSEMBLY COULD CAUSE DAMAGE TO

THE DETECTO-PAK 4.

WARNING

DO NOT ATTEMPT TO REPAIR THE FUEL OR CALIBRATION

CYLINDER/VALVE ASSEMBLY.

WARNING

THE BATTERY MUST BE CHANGED OR CHARGED IN AN

AREA KNOWN TO BE NONFLAMMABLE TO REDUCE THE

RISK OF IGNITING A FLAMMABLE ATMOSPHERE.

WARNING

iv

CHAPTER ONE

I. DETECTO-PAK 4 FEATURES

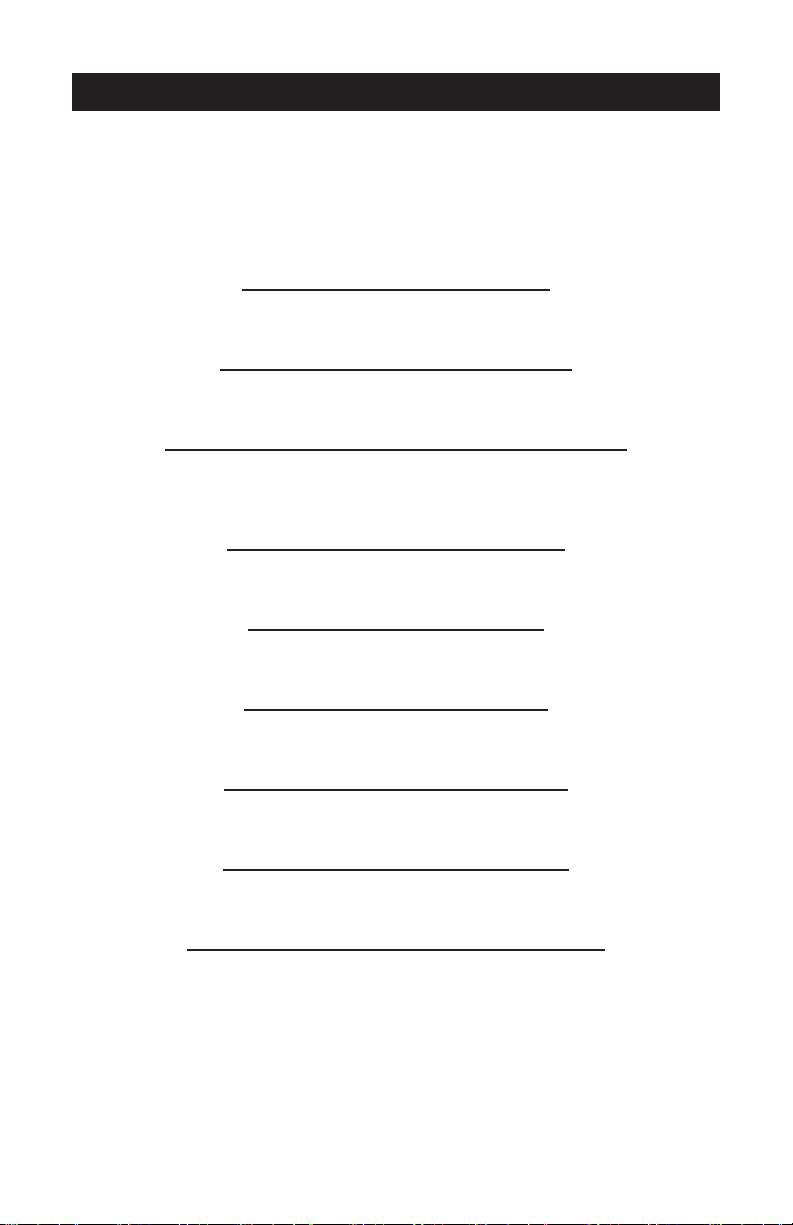

This Chapter describes the features of the Detecto-Pak 4. Please refer

to Figure 1 for illustration of individual parts.

DETECTO-PAK 4 COMPLETE

(Part No. 100659-0, 110 VAC) (Part No. 100659-2, 220 VAC)

(Part No. 100659-1, 110 VAC High Alt.) (Part No. 100659-3, 220 VAC High Alt.)

(Part No. 100659-4, 0-100K)

(Figure 1)

1. Instrument Only

(Part No. 100581-0, 100581-1)

2. Probe, Sample

(Part No. 0111006)

3. Battery Charger (Auto)

(Part No. 100258-0, 110 HVAC)

4. Filters, (Pkg/10)

(Part No. 0110163)

100786-0 Rev. D 05/09

5. Fuel Cylinder (2 included)

(Part No. 0618303)

6. Gauge Adapter

(Part No. 0618302)

7. Carrying Strap W/Pad

(Part No. 100472-0)

8. Fuel Transller

(Part No. 0514937)

1

PROCEDURES

1. INSTRUMENT

Sensitivity Ranges: 0-10, 0-50, 0-100, 0-1,000 (1K), and

0-10,000 (10K) ppm

Audible Alarm, continuous: Continuous alarm indicates ame is out.

Audible Alarm, pulsating: Pulsating alarm indicates signal level above

approximately 35 to 45% full meter scale.

Fuel Cylinder Pressure

Indicator: Gauge 0 - 3,000 psig

Fuel Regulator, Internal:

22 - 42 psig; factory set for 30 cc/min fuel

ow with 1,000 psig in fuel cylinder.

Fuel Cylinder Holder:

cylinder. See opening at end of instrument.

Weight of Instrument: 7 lbs. (3.2 kg), Operating

2. PROBE, Sample

Adjustable Length: 25 to 41 inches (63 to 104 cm)

Weight: 12 oz. (.340 kg)

3. BATTERY CHARGER

Automatic Reduction: 16 hours to full charge

Power: 110 VAC, 60 Hz

Output: 14.5 VDC at 60ma

Inlet Pressure, 0 - 1,750 psig; Outlet Pressure,

Holder located inside instrument to carry fuel

4. FILTRATION

Replaceable Filters: Part No. 0110163, Pkg/100 or

Part No. 0110683, Pkg/500

100786-0 Rev. D 05/09

2

PROCEDURES

5. FUEL CYLINDERS

Color: Black, DOT Rated 3E1800

Volume: 100 cubic centimeters (approximate)

Maximum Working Pressure: 1,750 psig

Weight: 1 lb. (.453 kg)

6. GAUGE ADAPTER

Gauge Adapter is used to indicate outlet pressure setting of internal regulator.

Weight: 5.6 oz. (.159 kg)

7. CARRYING STRAP WITH PAD

Strap: Strap facilitates carrying instrument over

shoulder with cushioning pad.

Weight: 6.4 oz. (.181 kg)

8. FUEL TRANSFILLER (Part No. 0514937)

Fuel Transller is used for relling fuel cylinders.

Pressure Indicator: Gauge 0 - 3,000 psig

Restrictor, INTERNAL: Restrictor prevents pressure surge when

lling cylinders.

Purge Valve: Purge Valve relieves pressure when lling

cylinder is complete.

Weight: 15.5 oz. (.439 kg)

9. CARRYING CASE, System

Dimensions: 24 x 19 x 8.5 inches (60 x 48 x 21 cm)

Weight: Empty 15 lbs. (6.8 kg)

Filled 29 lbs. (13.2 kg)

Total weight in shipping carton:31 lbs. (14.1 kg)

100786-0 Rev. D 05/09

3

ADDITIONAL FEATURES (not shown)

• Instruction Manual

• “O” Rings for fuel cylinder valve:

Dimensions .145 ID x .070 CS inches

Material: Buna-N

• “O” Ring Lubricant:

Lubricant supplied for “O” Rings for fuel cylinder valves.

• Sample Intake Rate:

Pump, 2,000 cc per minute, (2 SLPM) nominal

• Ignition Type:

Glow Coil

PROCEDURES

• Battery Indicator:

Needle indication (three color) on instrument ppm meter shows battery

status.

• Power Supply:

Internal, rechargeable NiMH Battery, 12 VDC, 1500 mah

• Fuel Consumption:

30 cc per minute, 40% Hydrogen - 60% Nitrogen at 22-42 psig

• Daily Operating Life:

Life is eight hours with fully- charged battery and two fuel cylinders lled

to 1,750 psig.

100786-0 Rev. D 05/09

4

PROCEDURES

OPTIONAL ACCESSORIES

Calibration Kit This Calibration Kit is available to eld calibrate the

With Gas: Detecto-Pak 4 to ensure proper sensitivity levels, and comes

complete with Calibration Gas Cylinder.

(Part No. 0123309-0).

Calibration Gas: Calibration cylinder lled to approx. 1500 + 200 psig of 100

+ 10 ppm methane, balance air, to use with above calibration

kit.

(Part No. 0123071)

Calibration Cylinder

Transller: Item used to rell above calibration gas cylinder, same as

Item 8 above, except for CGA 590 inlet and CGA 170 outlet

ttings.

(Part No. 0124601)

Pressure Indicator: Gauge 0 - 3,000 psig.

Restrictor, Internal: Restrictor prevents pressure surge when lling cylinders.

Purge Valve: Valve relieves pressure when lling of cylinder is

complete.

100786-0 Rev. D 05/09

5

CHAPTER TWO

II. FUEL MOTHER TANKS/FUEL CYLINDERS:

This Chapter discusses, in detail, the proper steps to take in transferring fuel to

the fuel cylinder.

Recommendations for ordering fuel mother tanks, along with proper storage, are

also discussed in detail.

A. FUEL GAS MIXTURE

The fuel gas is a certied mixture of 40% hydrogen/60% nitrogen +/- 2%

with less than .5 ppm of hydrocarbon.

B. TRANSFILLING FUEL CYLINDERS

Heath assumes no liability in relling of fuel cylinders. If you wish to rell

your own fuel cylinders, caution must be exercised during the relling

process. It is also recommended that all safety precautions be used in

the handling of high-pressure, compressed ammable gases during the

relling process.

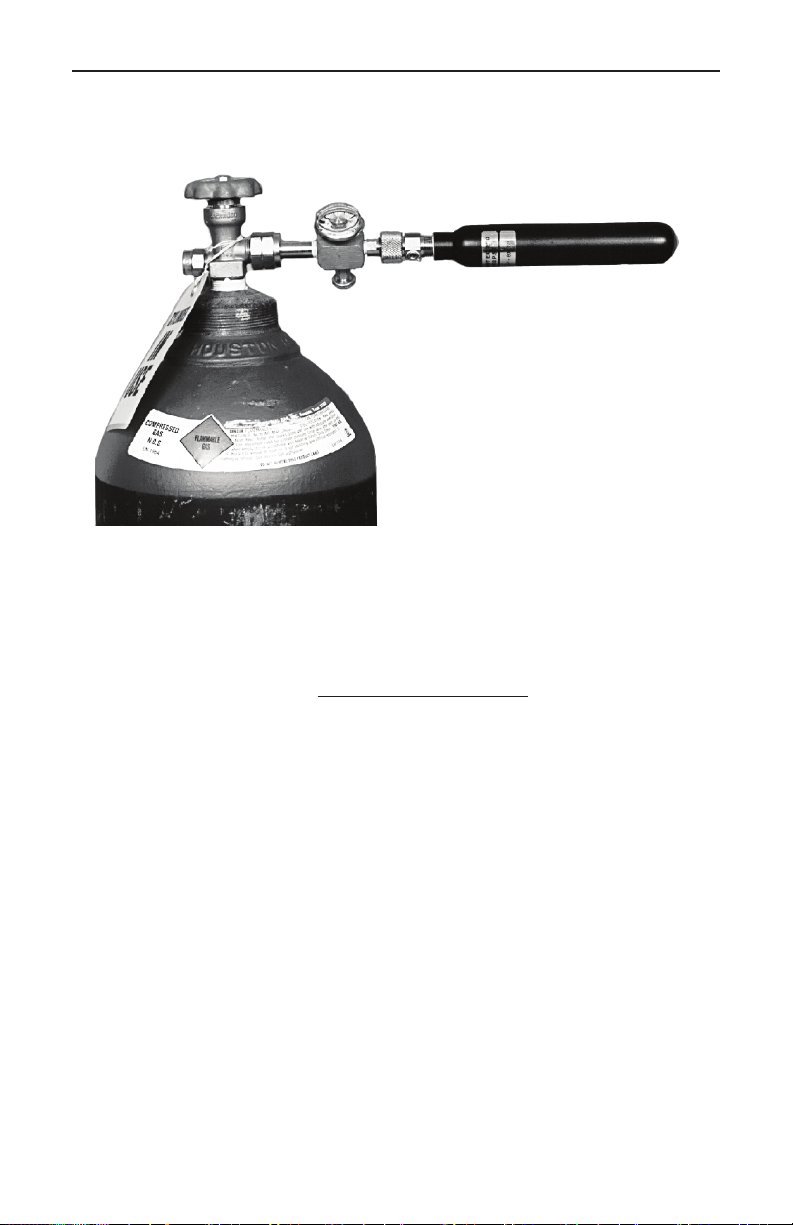

To rell the fuel cylinders, connect the fuel transller to a fuel mother

tank, then attach a non-contaminated fuel cylinder to the transller. See

(Figure 2) this Section and **NOTE**, Paragraph C, of this Section.

100786-0 Rev. D 05/09

6

FUEL CYLINDERS

Fuel Cylinder

Transfiller

Mother Tank

MOTHER TANK, TRANSFILLER & FUEL CYLINDER

CONNECTED FOR TRANFILLING

(Figure 2)

1. Remove the safety cap or caps from the fuel mother tank.

100786-0 Rev. D 05/09

2. Very slowly, open valve on the fuel mother tank a very small

amount (crack). Then close it immediately. This will clean (blow)

any contaminants out of the valve.

3. Firmly secure the hex nut on the transller to the fuel mother tank

valve outlet using an appropriate wrench. (Note: notches in hex nut

body indicate the nut threads are “Reverse Cut” threads.)

4. Finger tighten knurled nut on transller to valve outlet on fuel

cylinder.

5. Close bleed off valve on transfiller by turning it completely

clockwise.

6. Slowly open fuel mother tank valve counterclockwise until the

pressure gauge on the transller continues to rise, or approximately

one-half of a turn open.

7. Observe transller pressure gauge and turn off fuel mother tank valve

at 1750 psig or when the pressure gauge stops rising below 1750 psig

7

FUEL CYLINDERS

level (determined by fuel mother tank internal pressure). DO NOT

EXCEED 1750 psig pressure in the fuel cylinder.

8. Open bleed off valve on transfiller to eliminate pressure in

transller.

9. Loosen knurled nut with nger pressure and remove fuel cylinder.

10. Remove transller from fuel mother tank, replace safety cap or caps,

and safely store fuel mother tank. For storing and transporting of

these fuel mother tanks/fuel cylinders, see Paragraphs D. and E. of

this Section.

C. ORDERING FUEL MOTHER TANKS

When ordering a mother tank of fuel, it is recommended that a certied

mix of 40% hydrogen/60% nitrogen +/- 2% with less than .5 ppm of

hydrocarbon be requested.

The following companies can supply the proper fuel mixtures in fuel

mother tanks. This list is not intended as an endorsement, and other

suppliers may be available. If you are unable to locate a fuel source, please

contact your nearest Heath representative.

**NOTE**

When ordering, it is extremely important to specify CERTIFIED. This

helps ensure quality gas. Not ordering CERTIFIED gas increases the risk

of not securing a 40% H2 (hydrogen)/60% N2 (nitrogen) mix of less than

(0.5) ppm hydrocarbon background. See Chapter Eight, Section VIII, - A,

Item 2b for example of negative effect.

SUPPLIERS OF FUEL GAS MIXTURES:

AIRCO SCIENTIFIC GAS PRODUCTS

LINDE MATHESON GAS PRODUCTS

ALPHAGAZ SCOTT SPECIALTY GASES

LIQUID CARBONIC AIR PRODUCTS

MG INDUSTRIES

100786-0 Rev. D 05/09

8

Loading...

Loading...