Heath Consultants Aqua-Scop User Manual

AQUA-SCOPE

User Manual

®

Proprietary Notice

The contents of this manual are proprietary to Heath Consultants

Incorporated. Reproduction of this manual, in whole or in part, is

prohibited without the express written consent of Heath Consultants

Incorporated.

Heath Consultants Incorporated operates under a continual product

improvement program and reserves the right to make improvements

and/or changes without prior notication.

This manual supersedes all previous manuals for the Heath AquaScope.

HPN 2913769

Revision B

©COPYRIGHT 2001, Heath Consultants Incorporated

AQUA-SCOPE

User Manual

®

Heath Consultants Incorporated

Houston, TX

713-844-1300

Fax: 713-844-1309

1-800-HEATH-US

www.heathus.com

Heath....Safety, Leadership, Innovation, Performance

Then, Now and Tomorrow

INTRODUCTION

Economy and hygiene demand the most expedient way to locate and

repair water pipeline damage. More extensive water leaks can also

result in considerable danger to trafc by causing street ooding.

The best method to locate and pinpoint leaks in water pipelines is

by means of electro-acoustical detection. The sounds made by water

escaping from a water leak spread as spherical background waves in

the ground. The sounds are also transmitted by the (metallic) pipeline

itself. The use of suitable detecting devices enables us to determine the

exact location of a leak by listening to the escaping water from a small

hole in the water pipeline. The sounds made from such leaks provide

a good condition for electro-acoustical water leak detection.

FUNCTION

The Heath Consultants Incorporated AQUA-SCOPE® System is

an advanced state-of-the-art electro-acoustical water leak locator

designed to provide the operator with the means for efcient locating

and pinpointing of water pipeline leaks.

The instrument amplier/receiver unit provides a wide range of clarity,

simplicity, and ease of control. The ground and hand microphones

have good wind immunity for outdoor use. A removable handle and

extension rods are handy for compact storage.

1

TABLE OF CONTENTS

INTRODUCTION...........................................................................1

FUNCTION ........................................................................................1

TABLE OF CONTENTS .....................................................................2

CHAPTER I

I. AQUA-SCOPE SYSTEM, COMPLETE:

AQUA-SCOPE Basic System (Figure 1) ..................................4

II. AQUA-SCOPE SYSTEM, COMPLETE W/OPTIONAL

ACCESSORIES:

AQUA-SCOPE System with Optional

Accessories (Figure 2) .............................................................5

A. Amplier Module (Figure 3) ........................................6

B. Ground Microphone (Figure 4) .....................................7

C. Direct Contact Microphone (Figure 5)............................9

D. Headphones (Figure 6) ...............................................10

E. Meter Module (Figure 7) .............................................11

F. Resonant Plate (Figure 8) ............................................12

G. Plunger Bar (Figure 9) ................................................13

CHAPTER TWO

III. PRINCIPLES OF SOUND:

A. Engineering References ............................................14

B. Relating Sound Principles

to Leakage Detection .................................................17

2

CHAPTER THREE

IV. AQUA-SCOPE OPERATION:

A. Application ................................................................ 19

B. Leakage Detection with the

Direct Contact Microphone ......................................... 19

C. Pinpointing with the Ground Microphone .................... 22

D. Exercises with the Direct

Contact/Ground Microphones .................................... 25

E. Graphical and Numerical Determination

of the Point of Leakage ........................................... 26

F. Practical Examples ............................................... 29

G. Alternate Methods of Leakage Detection ..................... 31

CHAPTER FOUR

V. SERVICE INFORMATION:

A. Warranty and Warranty Repair .................................... 33

Customer Assistance, Manufacturing and

Service Locations ....................................................Back Cover

3

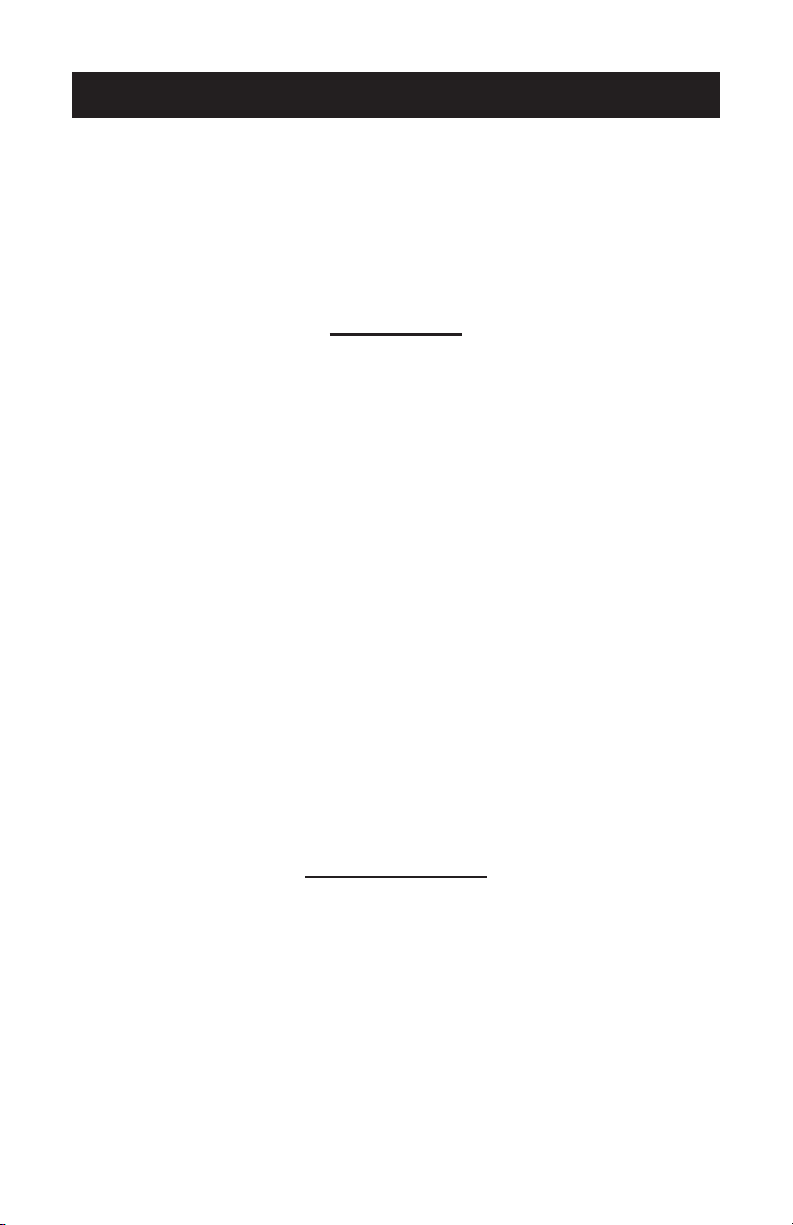

CHAPTER ONE

I. AQUA-SCOPE SYSTEM, COMPLETE:

7

3

5

1

4

2

6

(Figure 1)

AQUA-SCOPE Basic System (part No. 2903768)

1. Direct Contact 5. Ground Microphone

Microphone w/ext w/Handle

(Part No. 2916428) (Part No. 2916427)

2. Amplier Module 6. Microphone Cables (2)

(Part No. 2916426) (Part No. 2916411)

3. Headphones 7. Carrying Case

(Part No. 2911352) (Part No. 2913767)

5

4. Instruction Manual

(Part No. 2913769)

4

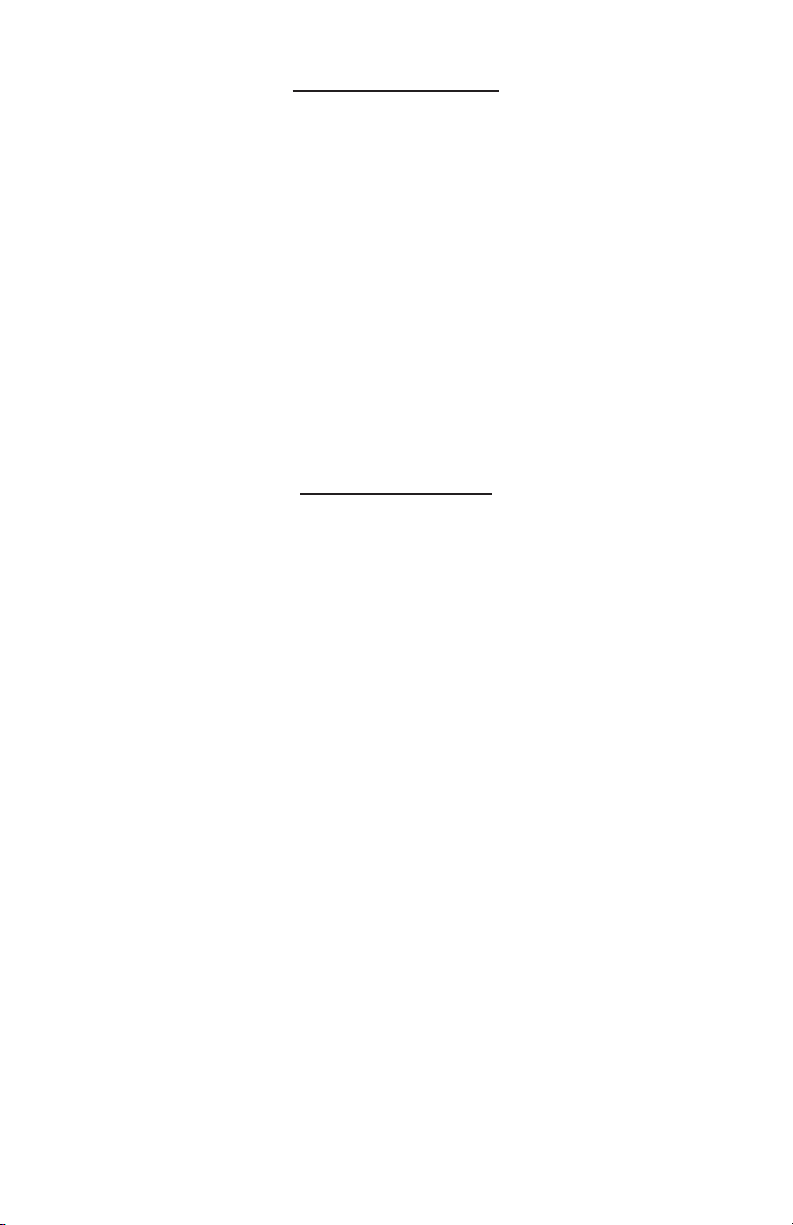

II. AQUA-SCOPE SYSTEM, COMPLETE W/ OPTIONAL

ACCESSORIES:

9

8

10

(Figure 2)

AQUA-SCOPE System with Optional Accessories

8. Meter Module w/ Battery 12. Good Vibrations VHS

Charger (110 VAC) Video Training Present (Part No. 2923754) tation (Not Shown)

(Part No. 7106653)

9. Resonant Plate 13. Meter Module

with 18” Spike w/ Battery Charger

(Part No. 2921326) (220 VAC) (Not Shown)

(Part No. 2923698)

10. Magnetic Tip used with 14. Ear Pad Cover used

The Direct Contact w/ Headset (Not Shown)

Microphone (Part No. 2927414)

(Part No. 2923776)

11. Plunger Bar w/ Insulated

Handle (Not Shown)

5

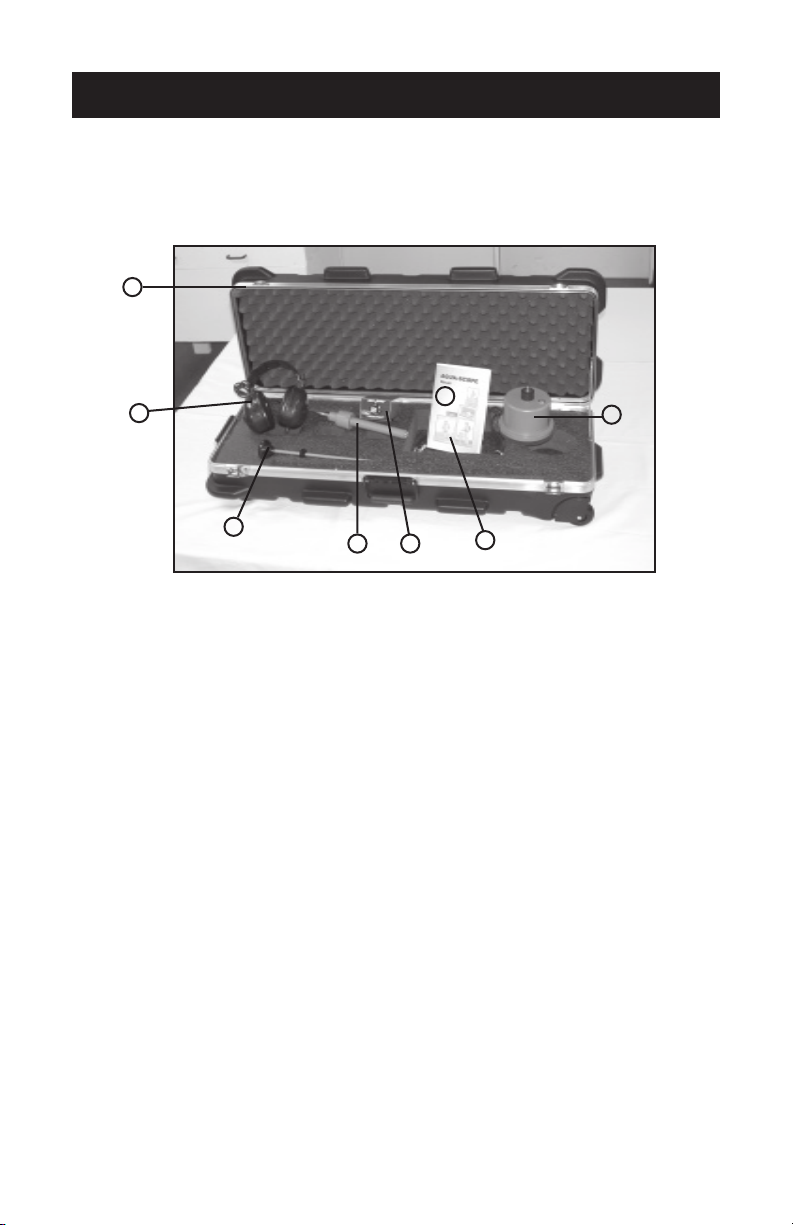

A. Amplier Module (Part No. 2916426)

(Figure 3)

1. General Specications:

Weight: 1.37 lbs. (620 grams) including batteries.

Size: 5” deep x 3.7” wide x .4” thick (12.7 x 9.40

x 6.096 cm) including all projecting knobs,

clips, and jacks.

Batteries: Requires 2 alkaline 9-volt batteries. Eveready

522, Mallory MN1604 or any NEDA 1604A

type is recommended.

Battery Life: Approximately 30 hours.

Amplier

Gain: Approximately 3 x 105 volts/volt maximum.

Storage

Temperature: Limited to the specications on the batteries

used.

Figure 3 depicts in two views the Amplier Module with all hardware,

in put/output jacks, and controls. Battery access is gained by removing

the Battery Access Plate, exposing the two nine volt batteries, which

power the instrument. The battery adjacent to the input jack should

be removed rst. The second battery may require lateral movement

toward the input jack end to clear the opening. Replacement and insertion should be performed in the opposite sequence. Be careful not to

cross thread the access plate retaining screw when securing the battery

access plate.

6

The push button “LISTEN” control switch should only be depressed

after the ground microphone has been rmly placed on a solid surface

and one to two seconds Sensor Settle Time elapsed. When using the

direct contact microphone, be certain that the tip is in rm contact with

the pipe, valve box, etc., before depressing the “LISTEN” control

switch.

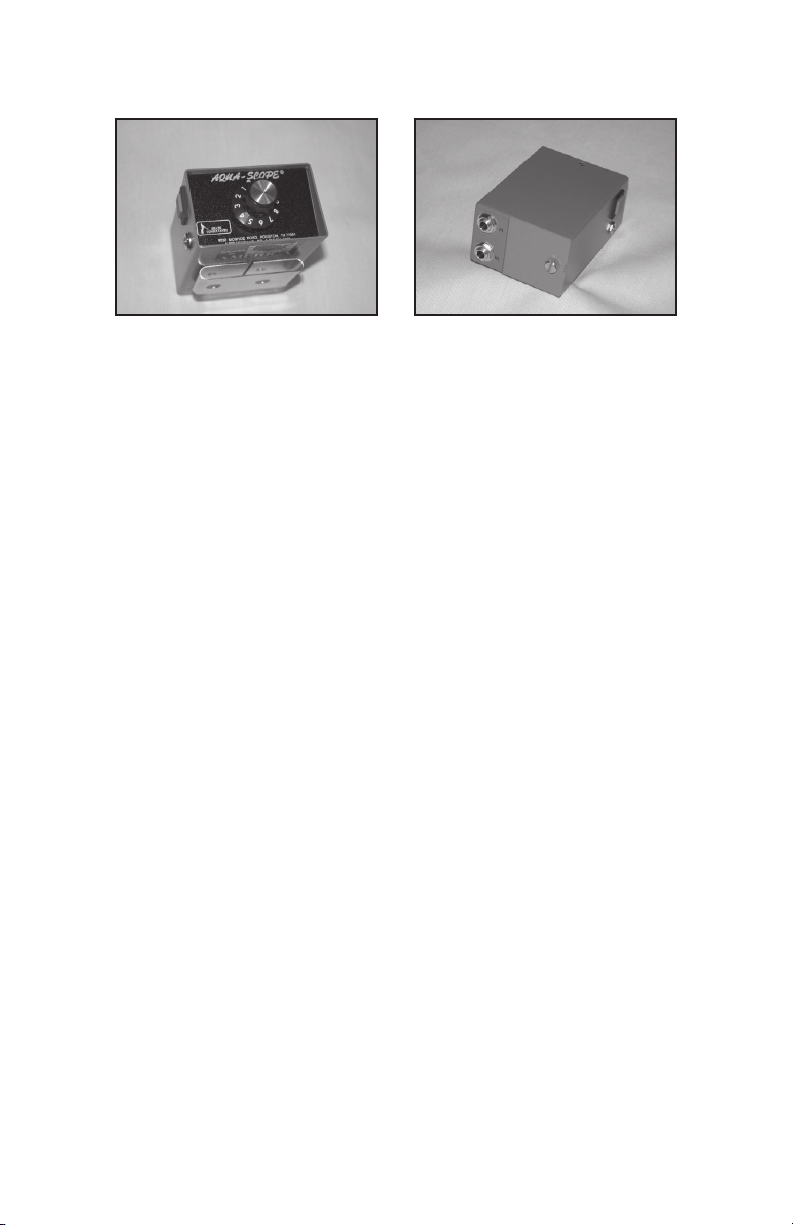

B. Ground Microphone (Part No. 2916427)

(Figure 4)

1. General Specications:

Construction: Acoustically suspended variable

reluctance sensor

Impedance: 380 Ohm DC resistance

Frequency

Response: 10 - 300 Hertz

Weight: Approximately 2 Lbs. 5 Oz.

(1049 grams)

7

Figure 4 illustrates the Ground Microphone with the Ground Microphone

Handle. The shock insulator minimizes sound coupling through the handle.

The foam rubber sound seal restricts ambient noises, which may be present in the work area. The internal sensor is suspended and magnetically

shielded to improve the signal to background noise ratio. The 1/4” plug

mates with the 1/4” jack labeled “M” on the Amplier Module via one of

the two Microphone Cables.

8

C. Direct Contact Microphone (Part No. 2916428)

(Figure 5)

1. General Specications:

Construction: Cold rolled steel case. Stainless steel

sensor shaft, probe tip, and extension

rods. Rods are 5/16” diameter. All

threaded sections are #10-32 thread.

Poured in place, the urethane core

suspends the sensor shaft in the body

for acoustical isolation. Each Direct

Contact extension is 24” long.

Sensor: Piezo-Ceramic, resonant at

approximately 3000 Hz.

Frequency

Response: Approximately 300-6000 Hertz.

The Direct Contact Microphone, microphone tip, optional magnet,

and two extensions are depicted in Figure 5. All threaded joints are

stainless steel on the Direct Contact Microphone; probe tip, and the

extensions. The 1/4” plug mates with the 1/4” jack labeled “M” on

the Amplier Module via one of the two Microphone Cables.

9

Loading...

Loading...