Heath Company Heathkit H9 Assembly Manual

,,'"..'t'.

.:.,r

::,

.

'

H

MANUAL

for the

VIDEO

ASSEMBLY

TERMINAL

Model

H9

5e5-1se6-05

\,

\

HEATH

COMPANY

.

BENTON

HARBOR,

MICHIGAN

HEATH

The following

Kit

orders

Credit.

ReplacementParts..

8:00 A.M. to 12

RZC, Audio,

Amateur

Test Equipment,

Home

Television

Aircraft,

Appliances

Computers

telephone numbers

and delivery information

Technical Asslstance

P.M. and 1:00

and Electronic

Radio

Weather Instruments

Clocks

Marine, Security,

and General Products

COMPANY PHONE DIRECTORY

are direct lines

Phone Numbers

P.M. to 4:30 P.M.,

Organs .

and

Scanners, Automotive,

to the

departments listed:

(616)

......

......(616)982-3561

(616)

..

EST, Weekdays

(616)

....

(616)

(616)

(616)

(616)

. . .. .

(616)

...

982-3411

982-9571

Only

982-3310

982-3296

e82-3315

982-3307

982-3496

982-3309

YOUR HEATHKIT

you

If

ae not satisfied with our sewice

Services, Heath Company, Benton Harbor, Michigan

attention.

Our attorney, who happens to be

phrases

in

order to comply with the new

period

For a

either in materials

telephoning us at

We wmrant that during

and used in accordance with

If

a defective

fault

Electronic

You will receive

drop us a

Our wananty does not cover and we ile not responsible

incomect

advertised. Our warranty does not include reimbursement

This

our

limitation

gives you

of ninety

part

yours,

we will

of

Center

line

or

assembly, misuse, fire, or by unauthorized modifications to or uses of our

warranty covers only Heathkit

products.

We are not responsible

incidental or consequential damages, so the above limitation or exclusion

of

specific

days after

[90)

workmanship. You can obtain

or

SB2-3571.

[616]

first ninety

the

in

or error

(units

free

give

legal rights,

design

service

of Schlumberger Products Corporation), or

consultation on any

us a call. Sorry, we cannot

warranty

-

quite

a kitbuilder himself,

wananty regulations. Fine. Here they are:

purchase,

And

we'll

(90)

days after

printed instructions, will meet

our

has

caused

it free

and

proof

upon

problem you

products

and

for

incidental or consequential darnages.

you

may also have

90

or otherwise - or

49022. He

Heath Company

parts

pay

shipping chmges

purchase,

your

Heathkit

purchase

of

might encounter

accept collect

is

not extended to

other

HEATH

BENTON HARBOR, MI. 49022

DAY LIMITED

products,

with our

will make certain

insists

that we describe our

will replace

from

directly

our

product

and

delivery

calls.

for

damage caused

for

customer assembly or set-up

rights which

COMPANY

or

Heath Companyby

get

to

those

products,

published

to malfunction during the wailanty

at

any

our authorized overseas distributors.

of

in the

allied

equipment

vary from

WARRANTY

write directly to our Director of Custoner

your problems

repair free of chmge any

parts

when correctly assembled, calibrated,

specifications.

your

expense to the Heath

assembly

by the use

or components used in conjunction

Some states do not allow the exclusion or

state

receive immediate,

warranty using all the necessary

parts

miting us at the address below or by

you

to

- anywhere

your

or use of

corrosive

of

products

may

for

time.

not apply

to

state.

that are defective

in the world.

period

factory,

Heathkit

solder,

purposes

you.

to

defective tools,

other than as

This waranty

ffirdtffbTbTbllThtllK

personal

adiusted

through no

Heathkit

any

product.

legal

|ust

with

d5

o<J

-ir

.fJ

=-

Prices

and specifications

subject to

change without notice.

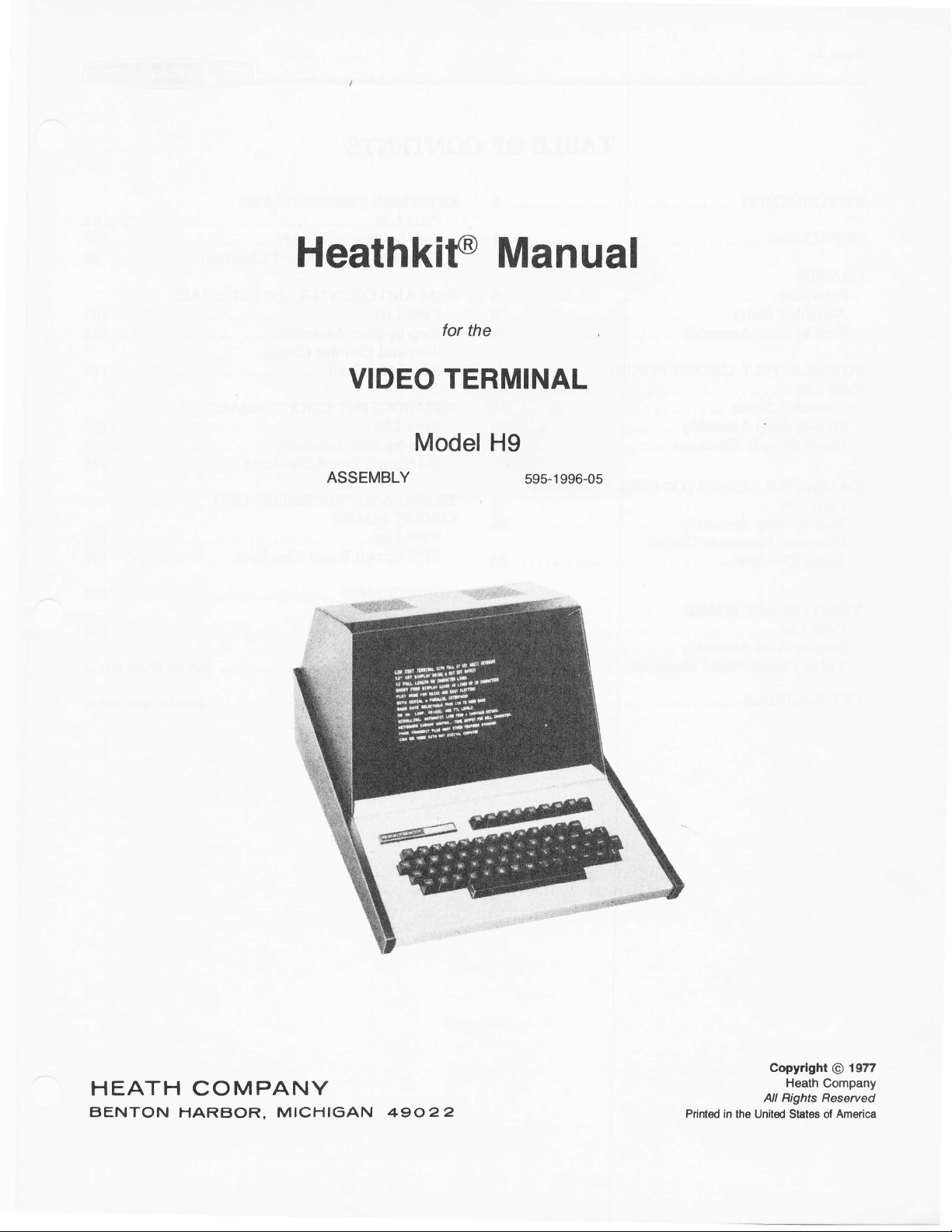

Heathkit@

for the

Manual

VIDEO TERMINAL

Model H9

ASSEMBLY

5e5-1ee6-05

HEATH COMPANY

BENTON

HARBOR,

MICHIGAN

49o

22

Printed

Copyrlght

Heath

Nl Rights Reserved

in the

Uniled States of

1977

@

Company

America

Pase.

@

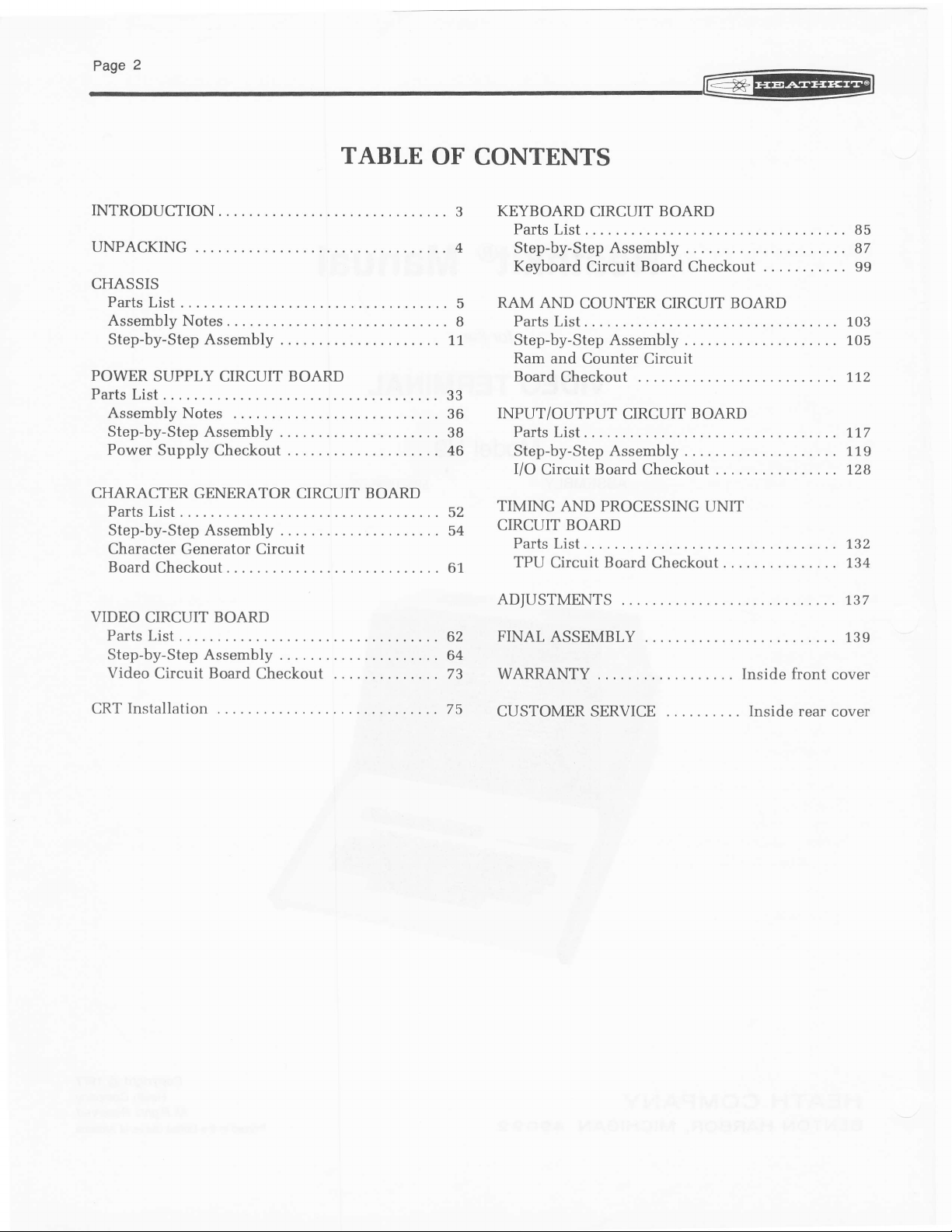

INTRODUCTION.

UNPACKING

CHASSIS

Partslist

Assembly

Step-by-StepAssembly

POWER

Parts List

Assembly

Step-by-Step Assembly

Power

CHARACTER GENERATOR

Parts

List

Step-by-Step Assembly

Character Generator Circuit

Board

VIDEO

CIRCUIT

Parts

List

Step-by-Step

Video

.. ..

Notes

SUPPLY

Supply

Checkout

Circuit Board

CIRCUIT

Notes .

Checkout

BOARD

Assembly

BOARD

Checkout

TABLE

CIRCUIT

BOARD

OF

.....5

... . . 8

...71,

33

36

38

46

52

54

61

62

64

73

CONTENTS

KEYBOARD

Partslist

Step-by-Step Assembly ...

Keyboard

RAM AND

Partslist

Step-by-Step Assembly .. 105

Ram

Board

INPUT/OUTPUT

Partslist

Step-by-StepAssembly ..119

I/O

Circuit Board

TIMING

CIRCUIT

Partslist

TPU

ADIUSTMENTS .

FINAL

WARRANTY

CIRCUIT

Circuit

COUNTER CIRCUIT

and Counter Circuit

Checkout .. 1.12

AND PROCESSING

BOARD

Circuit

ASSEMBLY

Board

.... .. Inside front

BOARD

Board

CIRCUIT

Checkout

Checkout

Checkout . .... 99

BOARD

BOARD

UNIT

....85

87

...103

...1.17

.. . . 728

...732

... 734

't37

...

....... 139

cover

CRT Installation

.

75

CUSTOMER SERVICE ....

Inside rear

cover

L@

-

INTRODUCTION

Page3

The Heathkit

information

mation into

72"

ort a

capable of displaying 960

rows

with 80 characters

A sixty-seven

compose

bility

of

This message or

tions.

ted through

TTL,

or

through the

punch.

The Video Terminal

computer in dedicated, stand-alone

in

time-sharing systems.

with a digital computer

such as Basic, Assembler, etc.,

machine language. The Video Terminal is also

(up

faster

mechanical teleprinter systems. You can select any

rate

data

Model H9

coming from a computer or enter

a computer.

(diagonal)

key ASCII keyboard

and edit

64 different

the standard serial

mA

20

current

parallel I/O interface to a

to 9600 baud) than the standard electro-

between 110 and

Video

The information is displayed

cathode

directly

characters and

program

loop) to a digital computer

can

Terminal can display

ray

characters at

per

row.

onto

be used with any digital

It lets

in higher-level

9600

(CRT)

tube

one

permits you

the CRT with

24 different

can then

I/O interface

applications, or

you

communicate

rather

baud.

infor-

which is

in 12

time

a capa-

func-

be transmit-

[EIA,

paper

than

tape

languages,

just

in

much

to

or

important features

Other

o

Automatic

a

Cursor

o

Erase

.

Erase

o

Short form

characters).

o

Automatic line

o

Plot

o

Built-in

These features,

cabinet, make the Video Terminal a

peripheral

controls.

to end of line.

page.

mode.

speaker

along

your

to

include:

scrolling.

(four

12-line

carryover.

(audible

with

computer system.

bellJ.

the attractively-styled

columns

very versatile

of

2O

TJNPACKING

Inside

"PKS 1-6,"

remove

parts

ray

Remove

cathode ray

called for in

cathode

so in a

sonal

When

find a Pack Index

the shipping

and a

the box

will

tube is separate

the

ray

step. Improper

injury

you

stamped PKS 1-6,

be considered the "final

box stamped

tube

a Parts List.

tube carton

or tube

open the box stamped PKS 1-6,

carton there is a box

number

in its

carton and

until

unpacking

damage.

Sheet

loose

of

pack."

own shipping

PKS

1-6-

set it

WARNING:

you

are instructed

can result

in the top

all the

of

stamped

parts.

After

remaining

The

cathode

carton.

Remove

aside until

Do not

open the

in

you

the box. This

you

it is

to

per-

will

the

do

sheet shows

ent compartments

as "packs." You will be directed

"packs"

be

removed from the boxes or

until they are specifically called for by a

the

Manual.

Each

assembly

"Parts

tions.

be instructed

be directed,

parts

from

how

it is needed.

as

List"

and "Step-by-Step

At

the beginning

to open

in

the final

box has

the

which are referred to

section

one of the

some Parts Lists,

pack.

been

CAUTION:

of the Manual

of each

divided into differ-

in

to

open each

No

their

compartments

contains

Assembly" instruc-

"Parts

List,"

packs.

You

to remove

Manual

the

of these

parts

should

Parts List in

its

own

you

will

will also

certain

r@

-

CHASSIS

Page5

Unpack the following

check each

key numbers

sis Parts

part

Any

with a

envelope

step.

NOTE:

your

than

used

way if

Some

aging number.

and do not appear

only

packaging

all

cated.

To

order a replacement part,

PART

with

this kit

Order Form

part

against

correspond

Pictorial

that is

part

after it is identified

You should

work area.

until later in

placed

parts

NUMBER.

(Illustration

packaged

number

are marked with a "77L-" or

or at

is not

on

place

Many

the assembly

your

on

These

numbers are

material until all

Use the Parts

the rear

available, refer

parts

from

the final

following

the

to the numbers

Booklet,

in

individual

an

it should

the

of

work area.

in

the

of this Manual. If

placed

be

until it is

parts

in a location

parts

these

and will be in

used for

Manual Parts List. Save

parts

always

Form furnished

Order

to "Replacement

PARTS

pack

and

Parts List. The

on the

Pages 1 and 2).

called

"172-"

have been lo-

include

Chas-

envelope

back in

will

packaging

the

for

in a

other

not

be

your

pack-

the

a Parts

LIST

Parts"

the front

Parts Price

Each

ponent

number

of these

ever has to

the

numbers

inside

cover. For

circuit

Number

for

numbers,

same

part

will

In

At

ponent

In

In

In

rear

the

List."

component in

only that

be replaced,

in

appeal

the Parts

the

some illustrations.

the

the

cover.

prices,

(R2,

which

each section

beginning

is installed.

Schematic.

sections at the

C4,

one

is

List.

refer

this kit

Q1,

part

are

to help

Warranty

Your

to the separate

has a

etc.). This is a

in the kit. The purpose

especially

you

of the

of each

step where

rear

of

is inside

"Heath

Circuit

specific

useful if

easily identify

Manual. These

the

Manual.

Com-

part

a

a com-

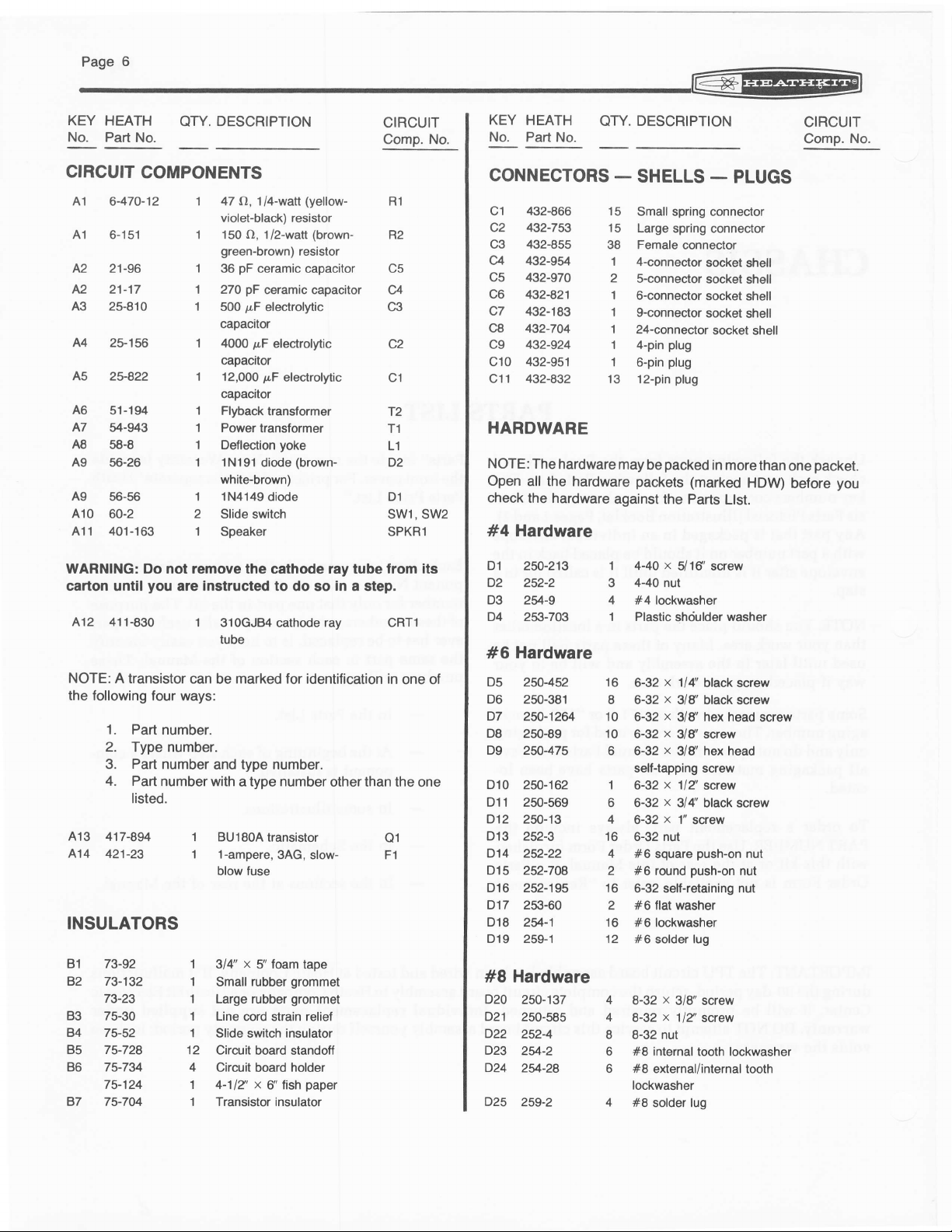

IMPORTANT: The TPU

during the 90-day

Center.

warranty. DO

voids

It will be

the warranty.

period,

NOT

promptly

attempt

circuit

board assembly has been wired and tested at

return the complete circuit board assembly to

repaired and

to service this circuit board assembly

returned. Individual replacement

yourself

Heath

during

Heath

Company.

Company or

parts

are not

the warranty

If it malfunctions

a Heathkit Electronic

supplied under

period;

to do so

Paseo

KEY

HEATH

No.

Part No.

DESCRIPTION

QTY.

CIRCUIT

Comp. No.

KEY

No.

HEATH

Part

No.

DESCRIPTION

QTY.

@

CIRCUIT

Comp. No.

CIRCUIT

A1

A1 6-15'l

A2

M 21-17

A3 25-810

A4

A5

A6

A7

A8

A9 56-26

A9

A10

All 401-163

COMPONENTS

6470-12

2't-96

25-156

25-822

51-194

g-943

58-8

56-56

60-2

1

1

1

1

'l

1

1

1

2

1

A,

47

1|4-watl

violet-black) resistor

O,

150

green-brown)

pF

36

ceramic capacitor

pF

270

pF

500

capacitor

pF

4000

capacitor

12,@O

capacitor

Flyback

Power transformer

Deflection

1N191

white-brown)

1N4149 diode

Slide switch

Speaker

(yellow-

1/2-waft

ceramic capacitor

electrolytic

y"F

diode

(brown-

resistor

electrolytic

electrolytic

transformer

yoke

(brown-

WARNING: Do not remove the cathode ray tube

carton

A1z

NOTE: A

the following

you

until

41 1-830

instructed

are

1 310GJB4

tube

to do so

cathode

ray

in

a step.

transistor can be marked for identification in

four ways:

1. Part number.

2. Type number.

3. Part number

4. Part

number with a type number

and type number.

other than the

listed.

A13

414

417-894

421-23

1 BU180A

transistor

1 l-ampere,3AG,

slow- Fl

blow fuse

INSULATORS

81 73-92

82

73-132

73-23

83 75-30

84 75-52

85 75-728

86 75-734

75-124

87 75-704

1

314' x 5" foam

1

1

1 Line

'l

'12

4

1 4-112'

rubber

Small

Large rubber

cord strain relief

Slide switch insulator

Circuit board standoff

Circuit board holder

x

grommet

grommel

d'fish

tape

paper

1 Transistor insulator

R'l

c5

@

c3

c2

c1

T2

T1

L1

D2

D1

SW1, SW2

SPKRl

from its

CRTl

one of

one

01

CONNECTORS

c1 432-866

_

15

c2 432-753 15

c3 432-855

u 432-9il

c5

432-970

c6 432-821

c7

432-183

432-924

c9

432-951

c10

38

1

2

1

1

|

1

c1l 432-832 13

HARDWARE

NOTE:

The

hardware

Open

all the hardware

check

the hardware

against

#4 Hardware

D1 250-213 1

D2 252-2 3

D3

2U-9

4

D4 253-703 1

Hardware

#6

D5

250-4s2 16

D6 250-381

D7

250-1264 10

D8

250-89 10

D9 2fi-475

D10 2fi-162

D11 250-569

D12 250-13

D13 252-3

I

6

1

6

4

16

D14 252-22 4

D15 252-708

2

D16 252-195 16

D17 253-60

D18

2*-1 16

D19

259-1 12

2

#8 Hardware

D20

250-137 4

D21

250-585 4

D22

D23

D24

D25

2524

2V-2

2*-28

259-2

8

6

6

SHELLS

Small spring connector

Large spring connector

Female

4-conneclor

s-connector

6-connector

g-connector

24-connector

4-pin

6-pin

12-pin

may

be

packets

connector

socket

socket shell

socket

socket

plug

plug

plug

packed

(marked

-

socket

in

the Parts

x

4-40

5/16'screw

440

nut

#4 lockwasher

Plastic

shciulder

x

114'

6-32

6-32 x 3/8'

6-32

6-32 x 3/8'screw

6-32 x 318'

self-tapping screw

6-32 x 1/Z

6-32 x 3l4i

6-32

5-32 nut

#6 square

#6 round

6-32 self-retaining nut

#6 flat washer

#6 lockwasher

#6

solder

8-32

8-32

8-32 nut

#8 internal

#8

externaUinternal tooth

lockwasher

#8

solder lug

black screw

black screw

x

hex head

3/8'

hex

screw

black screw

x

1"

screw

push-on

push-on

lug

x

3/8" screw

x

1/2'screw

tooth lockwasher

PLUGS

shell

shell

shell

shell

more than

HDW)

Ltst.

washer

screw

head

nut

nut

packet.

one

before

you

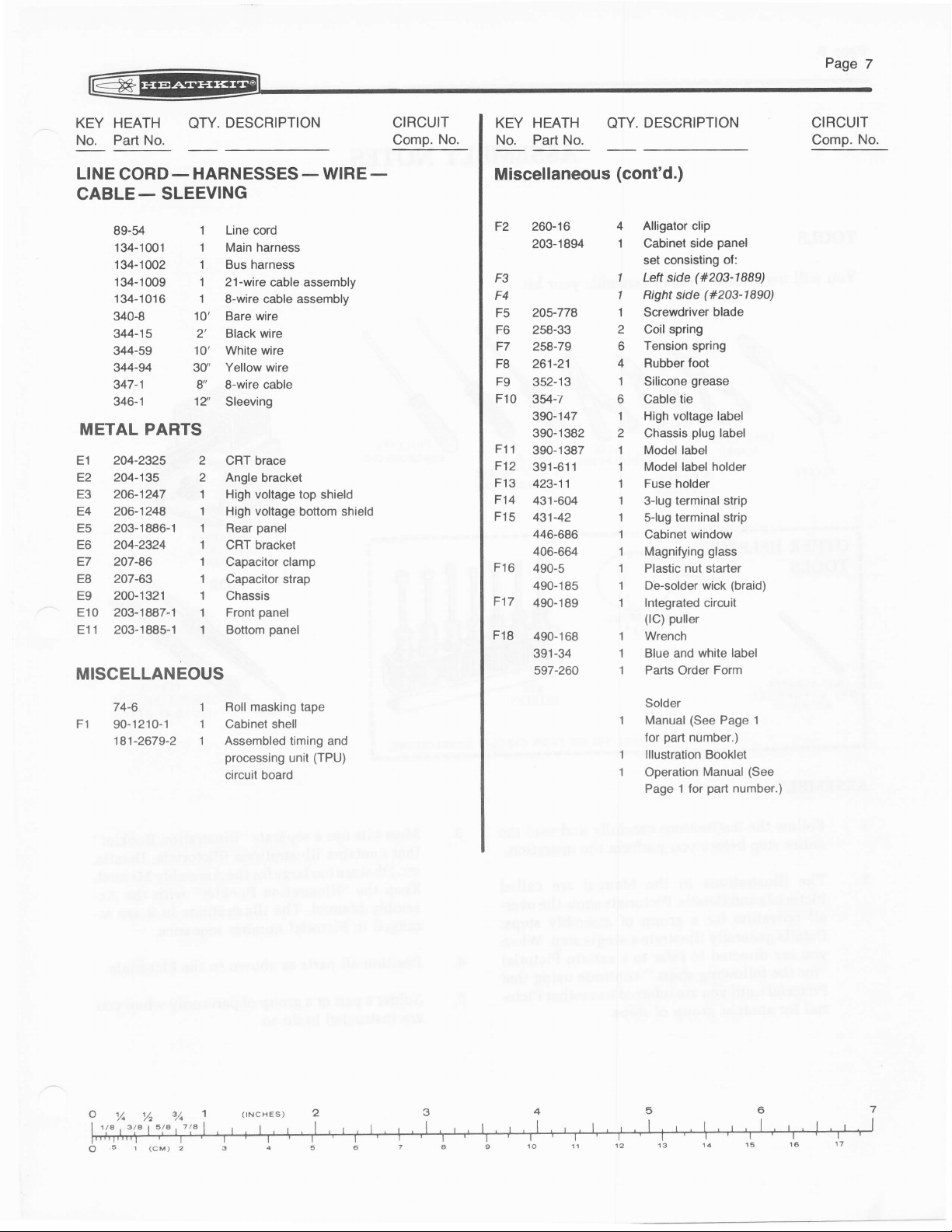

KEY

No.

HEATH

Part No.

DESCRIPTION

QTY.

CIRCUIT

No.

Comp.

KEY HEATH OTY. DESCRIPTION

No. Part

No.

CIRCUIT

Comp.

No.

LINE

CORD

CABLE-

89-54

134-1001 1

134-1002 1

134-1009 1

134-1016 1

340-8

344-15 z',

344-59

344-94 3g'

347-1 8',

346-1 12',

HARNESSES - WIRE

-

SLEEVING

1

10',

10',

METAL PARTS

E1 204-2325 2

204-135 2

E2

E3 206-1247 1

E4 206-1248 1

E5 203-1886-1

E6 204-2324 1

E7 207-86 1

E8 207-63 1

E9 200-1321 1

E10 203-1887-1 1

203-1885-1

E11

|

1

MISCELLANEOUS

Line cord

Main harness

Bus harness

2'l

-wire

8-wire

Bare wire

Black wire

White wire

Yellow

8-wire cable

Sleeving

brace

CRT

Angle bracket

High voltage top

High voltage bottom shield

panel

Rear

CRT bracket

Capacitor clamp

Capacitor strap

Chassis

Front

Bottom

cable

cable

wire

panel

panel

assembly

assembly

shield

1

(cont'd.)

4

Alligator

1

Cabinet

consisting of:

set

Left side

1

Right side

't

Screwdriver

2

6

4

1

6

1

2

'l

1

1

1

I

1

1

1

'1

1

1

1

spring

Coil

Tension spring

Rubber

Silicone

Cable tie

voltage

High

Chassis

Model label

Model label holder

Fuse holder

terminal strip

3-lug

s-lug terminal strip

Cabinet window

Magnitying

Plastic nut starter

De-solder wick

Integrated circuit

puller

(lC)

Wrench

Blue and white

Parts

Order

clip

panel

side

(#203-1889)

(#203-1890)

blade

foot

grease

label

plug

label

glass

(braid)

label

Form

-

Miscellaneous

F2 260-16

203-1894

F3

F4

205-778

F5

F6 258-33

258'79

F7

F8 261-21

F9

352-13

F10

3y-7

390-147

390-1382

F11

390-1387

F12

391-61

F13

423jt1

F14

431-604

F15

431-42

446-686

406-664

Fl6

490-5

490-1

85

F17

490-189

Fl8

490-168

391-34

597-260

F1

74-6

90-'t2't0-1

181-2679-2

I

Roll masking tape

Cabinet shell

1

Assembled timing and

1

processing

circuit board

unit

(TPU)

Solder

1

Manual

for

1

lllustration

1

Operation

Page 1 for

part

(See

Page

number.)

Booklet

Manual

part

number.)

1

(See

Pases

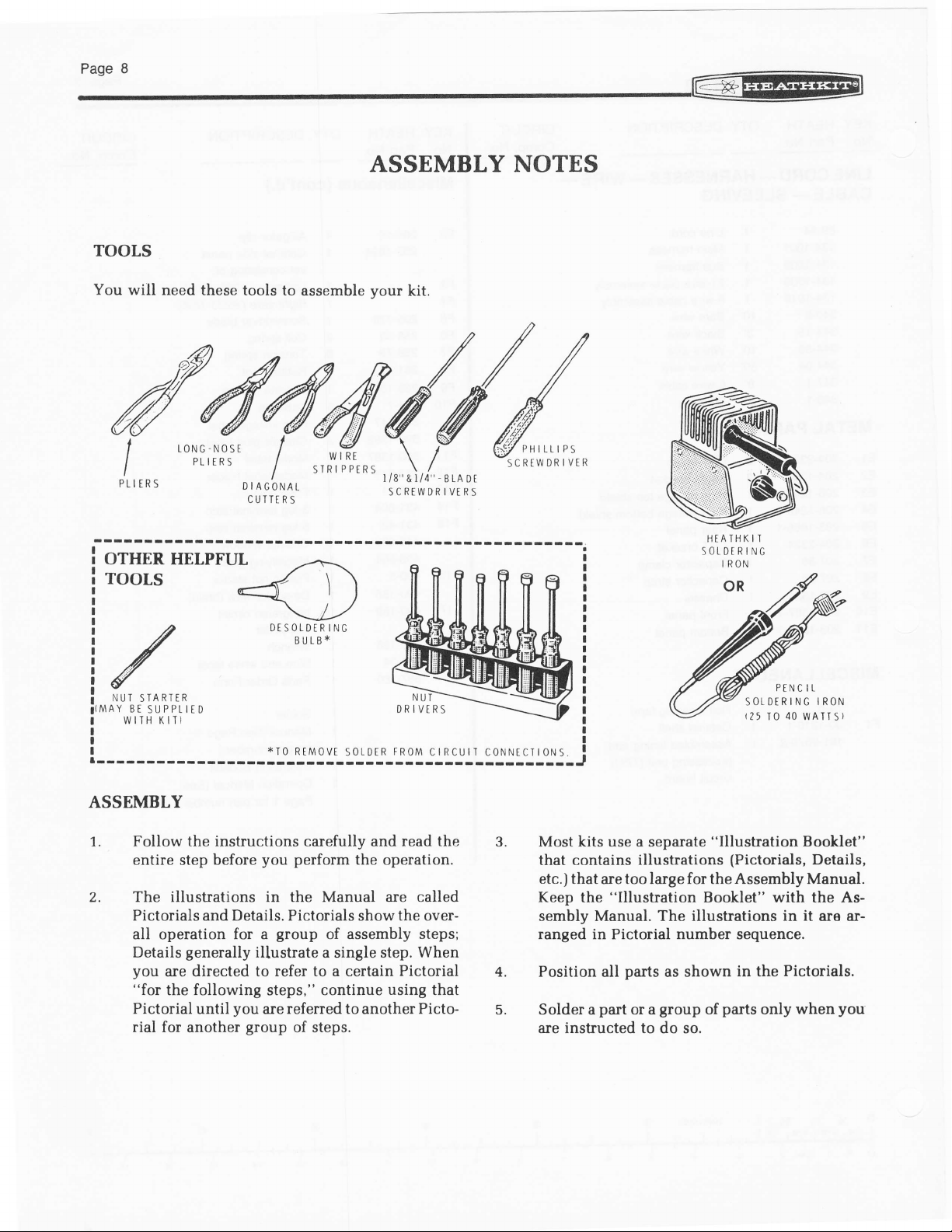

TOOLS

@

ASSEMBLY NOTES

You will

need these tools to

I

I

I

PLIERS

LONG.NOSE

PL IT R

OTHER HELPFUL

root,s

ilur

!

1{MAY

I

sTARTtR

Bt

SUPPtItD

WIIH

KIT}

assemble

I

S

I

I

DIAGONAT

CUTTTRS

--+.

4 \ )

\,

DiSOLDTRING

EIJLBT

WIRT

STRIPPIRS

kit.

vour

@

l

l/8"&r/4'

SCRTWD

I

4''-BLADT

DRIVTRS

PHILLIPS

SCREWDRIVTR

PtNC

10

40

tr

wATTS)

SOTDERING

125

IRON

ASSEMBLY

Follow the

entire

The

2.

illustrations

Pictorials

all operation for a

Details

you

are directed to

"for

the following steps," continue

Pictorial until

rial for

instructions

step before

Details. Pictorials

and

generally

you

another

Sroup

*I0

RtM0vt

carefully

you perform

in the

group

Manual

of assembly

illustrate a

s0LDtR

single

FR0M

ctRcutT c0NNEcTt0NS

and read the

the operation.

are called

the

show

over-

steps;

step. When

refer to a certain Pictorial

using

that

are referred to another Picto-

of steps.

I

-----J

3.1,

Most kits use a

that contains

etc.)

that are too large for the Assembly Manual.

Keep

the

sembly Manual. The

separate

illustrations

"Illustration

"Illustration

Booklet" with the As-

illustrations in it

ranged in Pictorial number sequence.

part

parts

group

or a

to do so.

as shown

of

4.

J.

Position all

Solder a

instructed

are

(Pictorials,

in the

parts

Pictorials.

only when

Booklet"

Details,

are ar-

you

r@

-

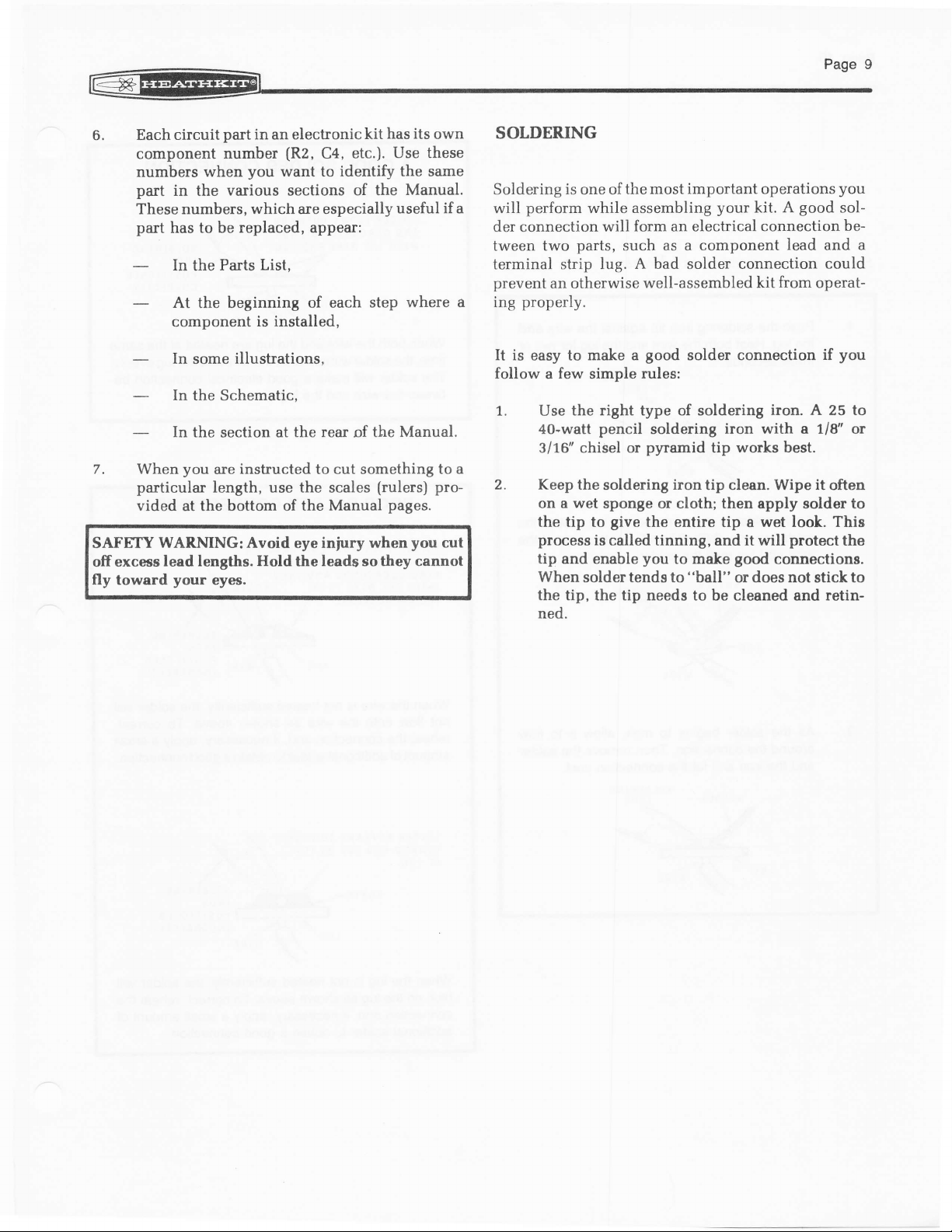

Page9

part

Each circuit

6,

component

numbers

part

These numbers, which are especially

part

7.

When

particular

vided

SAFETY WARNING: Avoid eye iniury when

excess

off

fly toward

when

in the various sections

has to

In

the

At

the beginning

component

In some illustrations.

In the

In the

you

at the bottom

lead lengths. Hold the leads so they cannot

your

in an electronic

number

be replaced, appear:

Parts

Schematic,

section at

are instructed to cut something to a

length,

eyes.

(R2,

C4, etc.).

you

want to identify the same

List,

of each step

is installed,

the rear

the

use

scales

of the Manual

has

kit

Use these

of the

useful if a

the

of

(rulers) pro-

pages.

its own

Manual.

where a

Manual.

you

cut

SOLDERING

Soldering

will

der connection

tween two

terminal strip

prevent

ing

It is

follow a few

1. Use

2. Keep the

is

perform

an otherwise

properly.

easy to

the right type of soldering

40-watt

3/16" chisel or

wet

on a

the tip to

process

tip

and

When

the tip, the tip needs to be

ned.

the

one of

assembling

while

form

will

parts,

such as

lug. A bad solder connection

make a

simple

pencil

soldering

sponge or cloth; then

give

is called tinning,

enable

solder tends to

good

and

could

operat-

if

25

etick

retin-

you

sol-

you

the

most important operations

your

kit. A

an electrical

a component

well-assembled kit

good

solder connection

rules:

soldering

pyramid

the entire tip a wet look. This

you

tip

iron

tip clean. Wipe it often

make

to

"ball"

connection

lead

from

iron. A

iron with a 1/8" or

works best.

apply solder to

protect

it will

and

good

connections.

or does not

cleaned and

be-

a

to

to

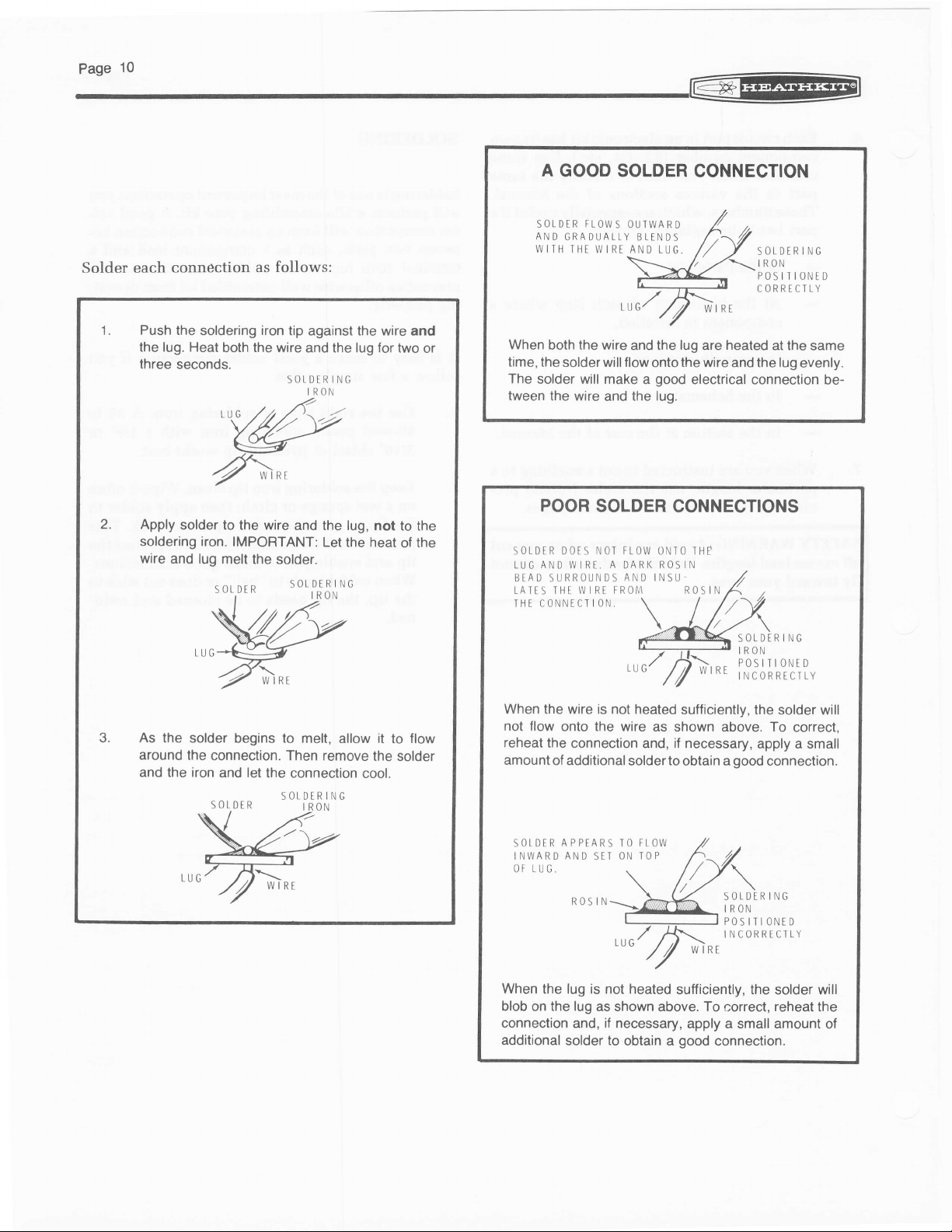

Paselo

A

GOOD SOLDER

@

CONNECTION

Solder each

1.

Push the

the lug.

three

2.

Apply

soldering iron.

wire

connection

soldering

Heat

both

seconds.

solder to

IMPORTANT:

lug

and

melt

follows:

as

iron

tip

against

the

wire and the lug lor two

SOTDERING

IRON

wire

the

and the lug,

Let

the solder.

the

wire and

not to the

the heat

or

of the

SOtDER

AND

WITH

When

time,

The

solder will make

tween

SOTDER

LUG

BEAD SURROUNDS

TATIS

THI CONNECTION

FLOWS

GRADUALLY

THT WIRI AND

both the wire

the solder will flow

the wire

POOR

ANO

THt

and

SOLDER

DOTS NOI

WIRT. A DARK

W I RI FROM

OUIWARD

BLENDS

LUG.

,ur/

and the

onto

good

a

the lug.

FLOW

oNTo rHe

ROSIN

AND

INSU

SOLDERING

IRON

POSITIONiD

CORRTCILY

lug

heated

are

the

wire and the lug

at the same

evenly.

electrical connection

CONNECTIONS

ROSIN

SOLDERING

IRON

POSITIONED

wlRE

iuConnEcriv

be-

3.

As

the

solder begins to melt,

around

the

connection. Then remove

and the iron

and

let

the

connection cool.

SOLDtRING

allow it

the solder

to

flow

When the wire is

not

flow

onto the wire as

reheat

the

amount

When

blob

of additional solder to

INWARD

LUG.

APPTARS

SOtDIR

OF

the lug is not heated

the lug

on

not heated

sufficiently, the

shown above.

connection and, if necessary,

obtain a

FLOW

SIT

IO

ON TOP

AND

ROS IN

sufficiently, the solder will

as shown above. To

connection and, if necessary,

additional

solder

to

obtain a

good

solder will

To

correct,

apply a small

good

connection.

ING

R

s0tD

IRON

POSITIONED

INCORRECTLY

correct,

reheat

the

apply a small amount

connection.

of

@

t"n"tt

STANDOFF

INSULATOR

STEP.BY.STEP

NUT

DR IVER

o*

ll

pusH

oowni

?

, r*$'Jl,(,*

CARTFULLY

WORK

INSULATOR

INTO

/

HOLE

ASSEMBLY

@o

druu

r'rur

iz

LocKWAsHER

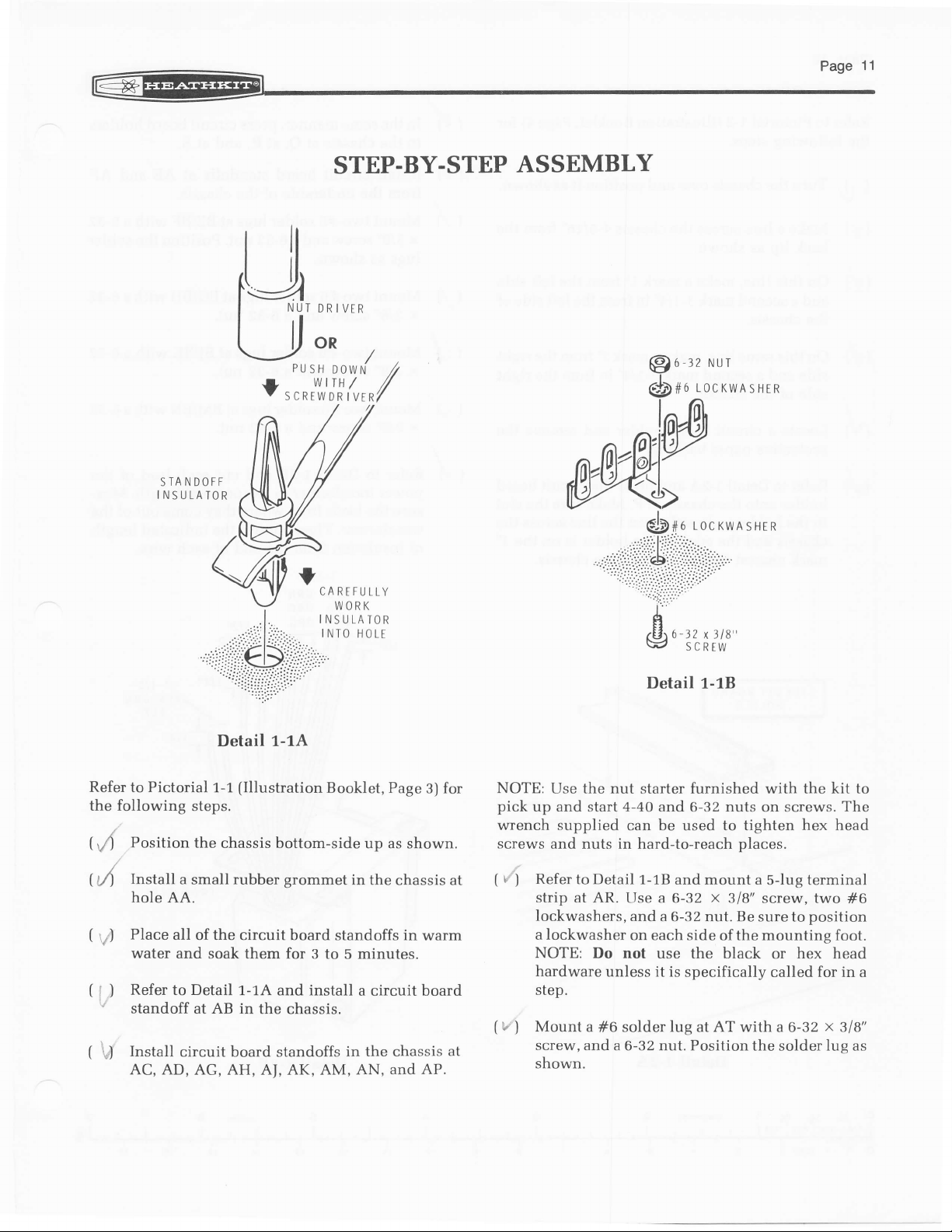

Refer

Pictorial

to

the following

(rA

Position

(A

Install

hole AA.

(

Place all

rf)

water

(

Refer

)

I

''

(

U

to

standoff at AB in

Install

AC, AD, AG,

Detail

1-1

1-1A

(Illustration

Booklet, Page

steps.

the chassis bottom-side

a small

rubber grommet

of the circuit board

and soak them for 3

Detail

1-1A

and

to 5 minutes.

install

the chassis.

circuit board

AH,

standoffs

AJ, AK,

AM,

for

3)

up as shown.

in the

chassis at

standoffs in warm

a

circuit

in the chassis

AN,

board

at

and AP.

Detail t-tB

NOTE:

pick

wrench supplied

screws and nuts in hard-to-reach

( ,/)

(i"

Use the nut starter furnished with the kit to

up and

Refer

strip at AR.

lockwashers,

a lockwasher

NOTE:

hardware

step.

Mount a

)

screw, and

shown.

4-40 and

start

can be used to tighten

to Detail

1-18 and mount a

Use a 6-32 x 318'

and

on each

Do not use

unless it is

#6 solder

a 6-32 nut. Position the

6-32

a 6-32 nut. Be sure to

side of the mounting foot.

the

specifically called for in

lug

at

black

AT

nuts

on screws.

places.

5-lug terminal

screw, two

or

with a 6-32

solder

The

hex head

position

hex

head

x

3lB"

lug

#6

a

as

Refer

the

f

(

r"

(',

(U)

\/)

(

(;,

Pictorial 1-2

to

following

Turn

fJ

)

)

)

the chassis

Make a line across the chassis 4-511,6'from the

back lip

On this line, make

and a second mark

the

chassis.

this

On

side

side

Locate

protective paper

Refer to Detail

holder onto the chassis

in the holder is

chassis and the

mark nearest the left

same

and a second mark 3-1/4" in

of the chassis.

a circuit board holder

CIRCUIT

HOLDER

(Illustration

steps.

over and

as shown.

line,

backing.

1-2A and

directly over the line across

edge of the

BOARD

Booklet,

position

a mark 1" from the left

3-1,14'in from the left

make a mark 1" from

from the rieht

and

press

the circuit board

P.

at

Make sure the

holder is

edge of the

Page

it as

shown.

side of

the right

remove

on

chassis.

for

4)

side

the

slot

the

the 1."

(

In

4

to

(

Install

4

from

(

,

Mount

)

x

lugs

(,/)

Mount

'

x

('l

Mount

x

(

Mounttwo#6

d'

x

(

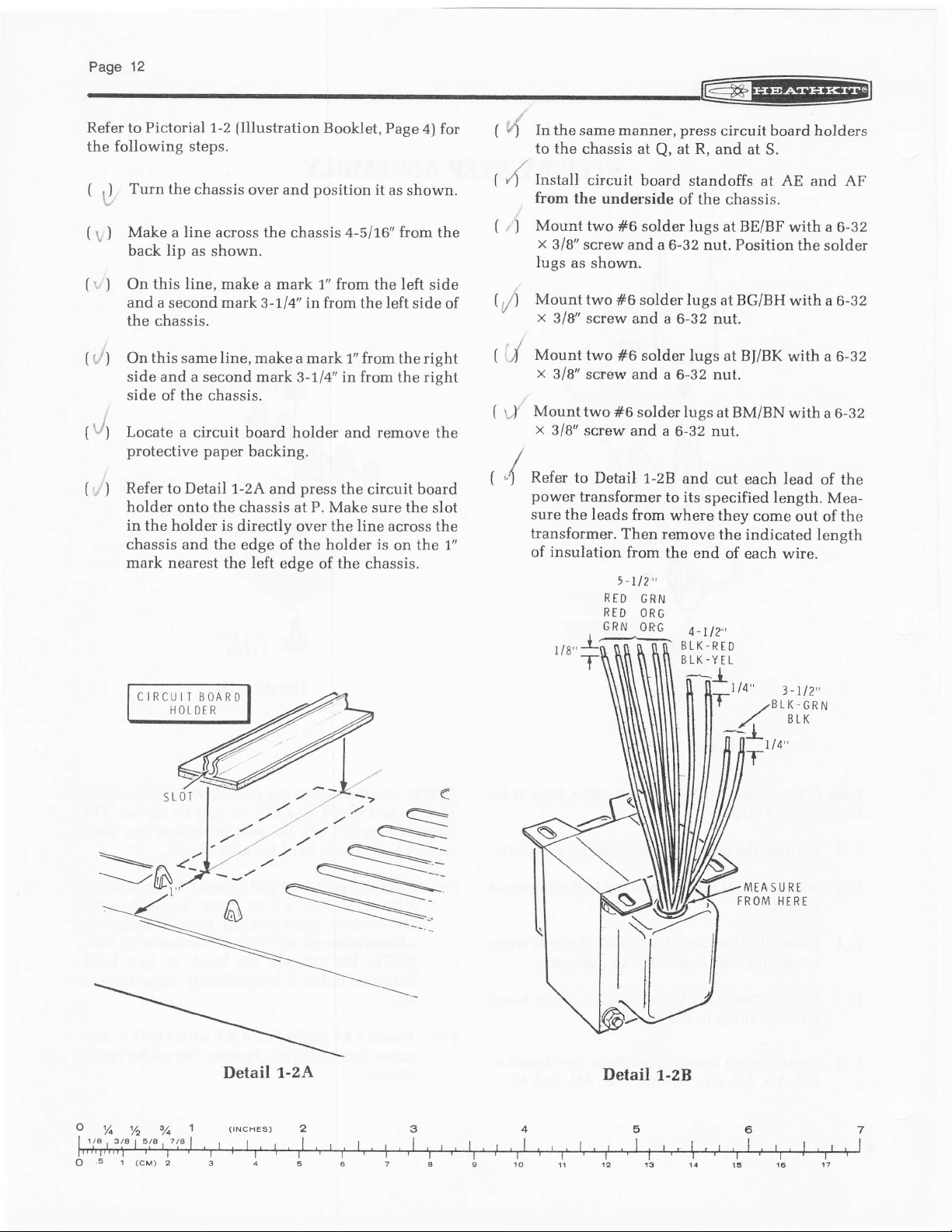

Refer

4

power

sure the

transformer.

of insulation

the same manner,

the chassis

circuit

the underside

two

3/8"

screw and a

as

two

3/8'screw

two

318"

screw and

318"

screw and

to

transformer

at

Q,

board standoffs at AE and

solder

#6

shown.

solder lugs

#6

and a 6-32 nut.

solder lugs

#6

a 6-32 nut.

solderlugsatBM/BNwitha6-32

a

Detail 1-28

leads from

Then remove

from

-112',

5

RID

GRN

RTD

ORG

6RN

0RG

6-32 nut. Position

to

where

the end

press

circuit board holders

at R,

and at S.

of the chassis.

lugs at BE/BF

BG/BH

at

at BI/gf

6-32 nut.

and

cut each lead

its

specified length.

they

come

the indicated

of

each wire.

4_rlT,

BLK-RED

BLK-YEL

l-

|14"

/"[r3^'

Ll4"

AF

with a 6-32

the solder

with a 6-32

with a 6-32

of the

Mea-

out of the

length

3-rl2',

Detail

1-2A

nr

Nt[.

-/

Detail

1-28

5

MEASURE

FROM HERE

S tOTS

LARGI SPRING

CONNECTOR

INSET

IX

S

CONNECTOR

SOCKTT

RED

PUSH

IN ON

TAB OF

SPRING CLIP

CRIMP OVER BARE

OF LEAD

TND

@:_

COOLED,

(

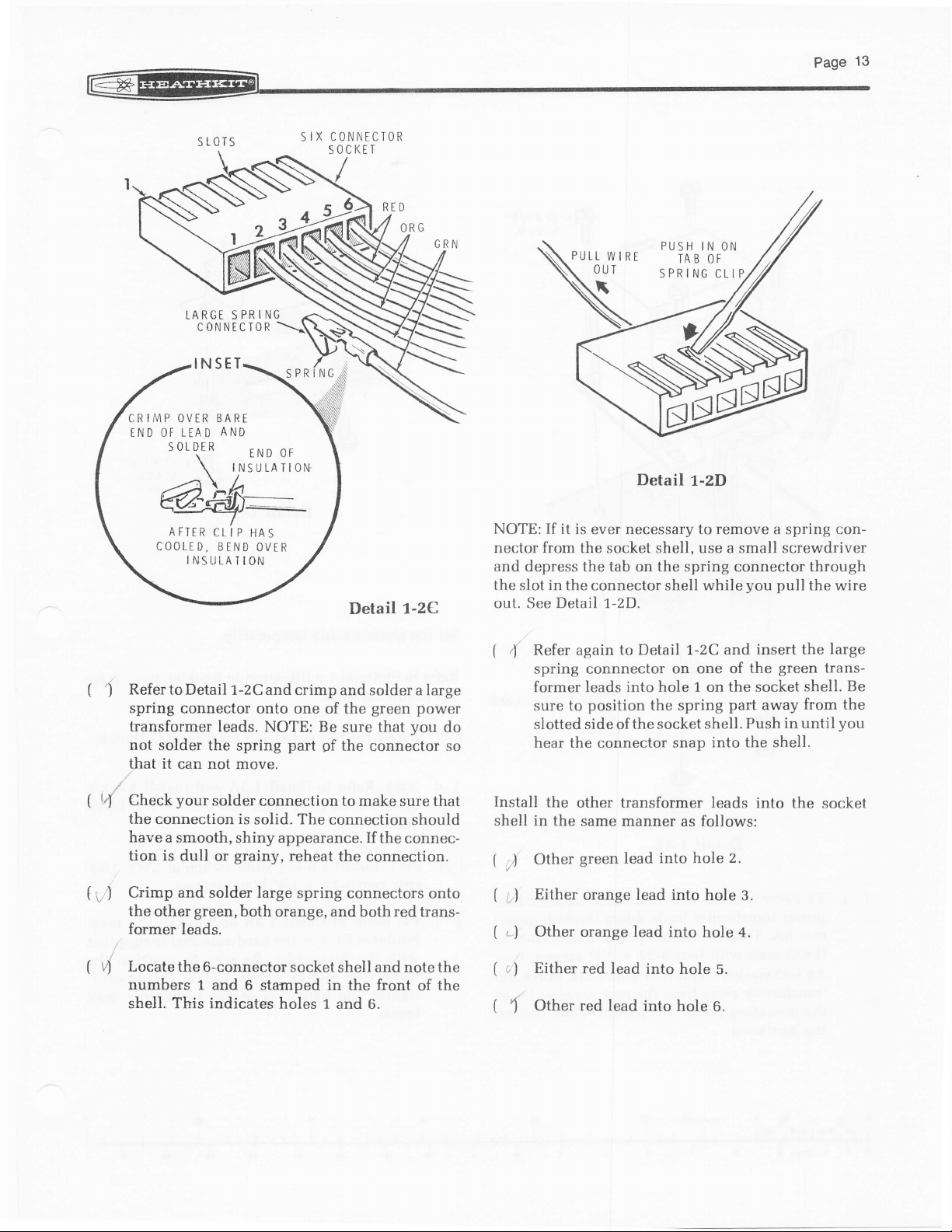

Refer

1

spring

transformer

not

solder the

that it

( Vl

Check

the connection is

have

is

tion

SOLDER

AFTER

AND

END OF

INSULATION

\

CLIP

HAS

BEND

INSULATION

OVIR

to Detail 1-2C and

connector onto one

leads. NOTE:

spring

can not move.

your

solder

connection to make sure that

solid.

a smooth,

dull

shiny appearance. If

grainy,

or

Detail

r-2C

crimp and solder a large

green power

the

of

Be sure that

part

9f

The

connection

the

you

connector

should

the connec-

reheat

the

connection.

do

so

'BEE

Detail

NOTE:

nector from the socket shell, use a small screwdriver

and

the

out. See Detail 1-2D.

(

Install

shell in the

(

If it

is ever necessary to

depress the tab on the spring connector through

in

slot

the connector shell while

Refer again to

4

spring

former leads

sure to

slotted side of the socket

hear the connector snap

Other

,)

connnector on one of

position

the

other transformer

same manner

green lead

Detail 1-2C and

into hole 1 on the socket

1-2D

remove

the spring

shell. Push

into the shell.

leads into

as follows:

into hole

you pull

insert the

the

part

2.

away

a spring con-

the wire

large

green

transshell. Be

from the

in until

the socket

you

Crimp and solder Iarge

tyl

other

green,

the

former leads.

( ,,4

Locate

the 6-connector socket

numbers 1

shell. This indicates

spring

both

orange, and both red trans-

connectors onto

shell and note the

and 6 stamped in the front

holes 1 and

6.

of

the

(

Either

i.l

(

,

Other orange lead

)

(

;)

Either

(

Other

\

orange lead into

into hole

red lead

red

into hole

lead into

hole

hole 3.

4.

5.

6.

Page

14

K;fi

^M

8-32

SCREW

x

318"

Detail

1-3A

6-32

BLACK

SCREW

x

ll4"

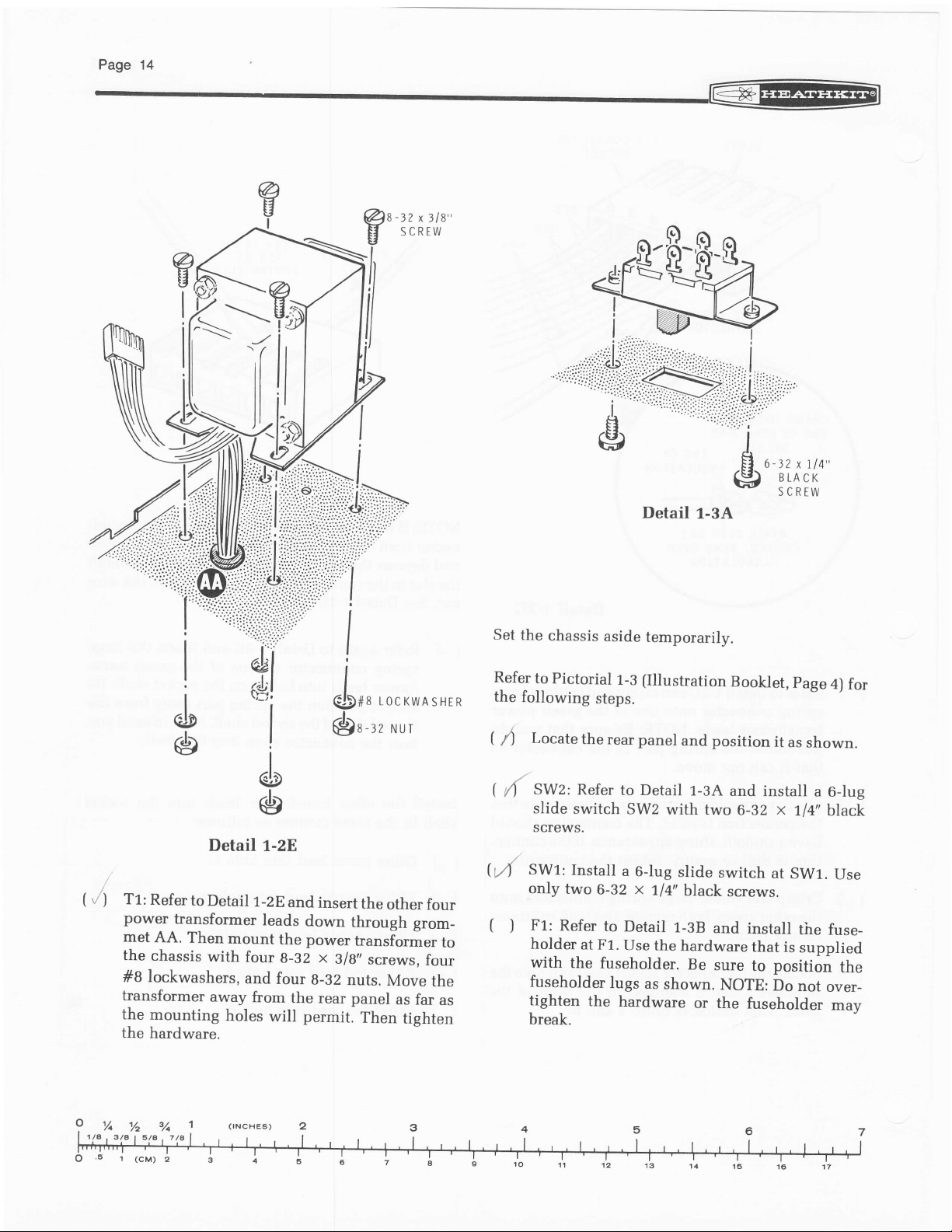

(

/)

T1:

Refer

power

met

AA.

the

chassis

#B lockwashers,

transformer

the

mounting

the

hardware.

.t

o

Detail 1-28

to

Detail

transformer

Then

mount

with

four

and

away

holes

1-2E

and

leads

down

the power

g-32

four

from

the rear panel

permit.

will

@)a-lz

insert

x

3/g,,

g-32

Nur

the

other

through

transformer

nuts.

Then

grom_

screws,

Move

as far

tighten

four

to

four

the

as

Set

Refer

the

(

I

1 4f

h,4

(

)

the

chassis

to

Pictorial

following

Locate

slide

screws.

SW1:

only

F1:

holder

with

fuseholder

tighten

break.

SWz:

two

Refer

Refer

switch

Install

the

the rear panel

at F1.

aside

temporarily.

1-3 (Illustration

steps.

to Detail

SW2

a

6-lug

x

6-32

to

fuseholder.

the

1/+"

Detail

Use

the hardware

lugs

as

hardware

and

1-3A

with

two 6-32

slide

black

1-3B

Be

shown.

or the

Booklet,

position

and

switch

screws.

and

install

that

sure

to

NOTE:

fuseholder

page

it

as

install

x

1/4" black

at

SW1.

the fuse-

is

supplied

position

Do

not

4)

for

shown.

a 6-lug

Use

the

over_

mav

3/A

6r(cv)z

3/t

%

7lA

I

(rNcHES)

1

@

t"n"tu

NUT

RUBBTR

WA SHER

Detail 1-38

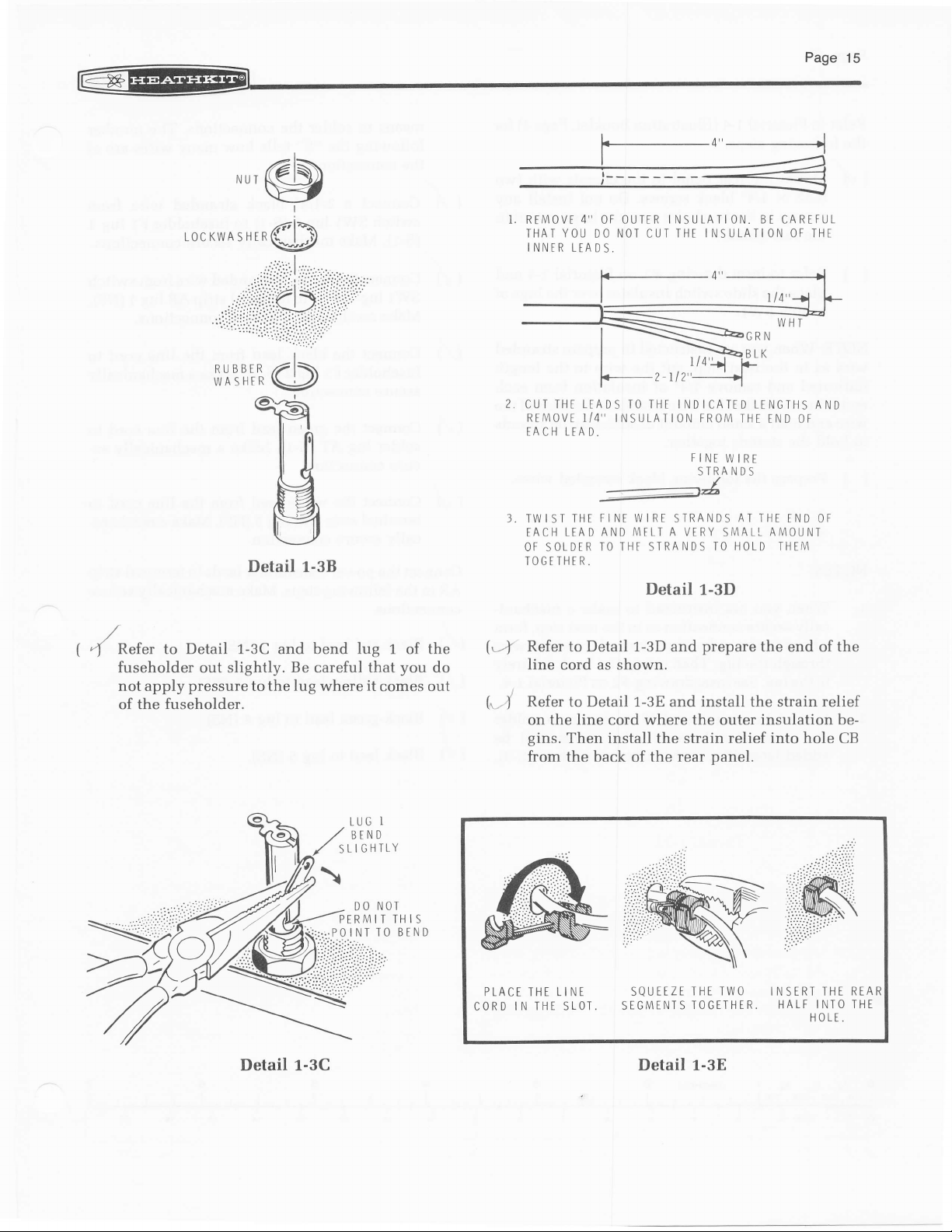

Xefer to Detail 1-3C and bend

{

fuseholder

not apply

of the

out slightly.

pressure

fuseholder.

to the lug where

Be

careful that

lug

1 of the

it

comes out

you

do

REIVI OVE

IHAI YOU

INNER LEADS.

CUT IHT

RTMOVE I/4" INSULATION

TACH LFA

3, TW I ST

EACH LEAD

OF SOTDER

TOGETHER.

(4

Refer

4"

OF OUTER

DO

LEADS

D.

FI

THE

AND

TO THF STRA

Detail 1-3D

to

NOT

NE W I RE STRANDS

I

NSULATION. BE CARFFL-

IHE I NSULATI ON OF IHE

CUT

TO THE INDICAIED LENGTHS

MFLT A

Detail

FROM

THE END OF

FINT

WIRE

S TRA N D

VERY

NDS TO HOLD THEM

S

AT

THE TND

SMAL!.

1-3D

prepare

and

the end of the

line cord as shown.

(..1

Refer to Detail 1-3E and install the strain relief

on the line cord where the outer

gins.

Then install the strain relief into

from

the back of the rear

panel.

insulation be-

AND

OF

AMOUNT

hole

CB

Detail t-eC

I

LUG

BEND

.IGHTLY

NOT

I TH

TO BEND

IS

PLACT

CORD

THT

I N THE

LINE

SLOT,

SQUEEZE

SEGMENTS

THE TWO

TOGETHER.

Detail L-3E

INSERT THE

HALF I NTO

HOLE.

REAR

THE

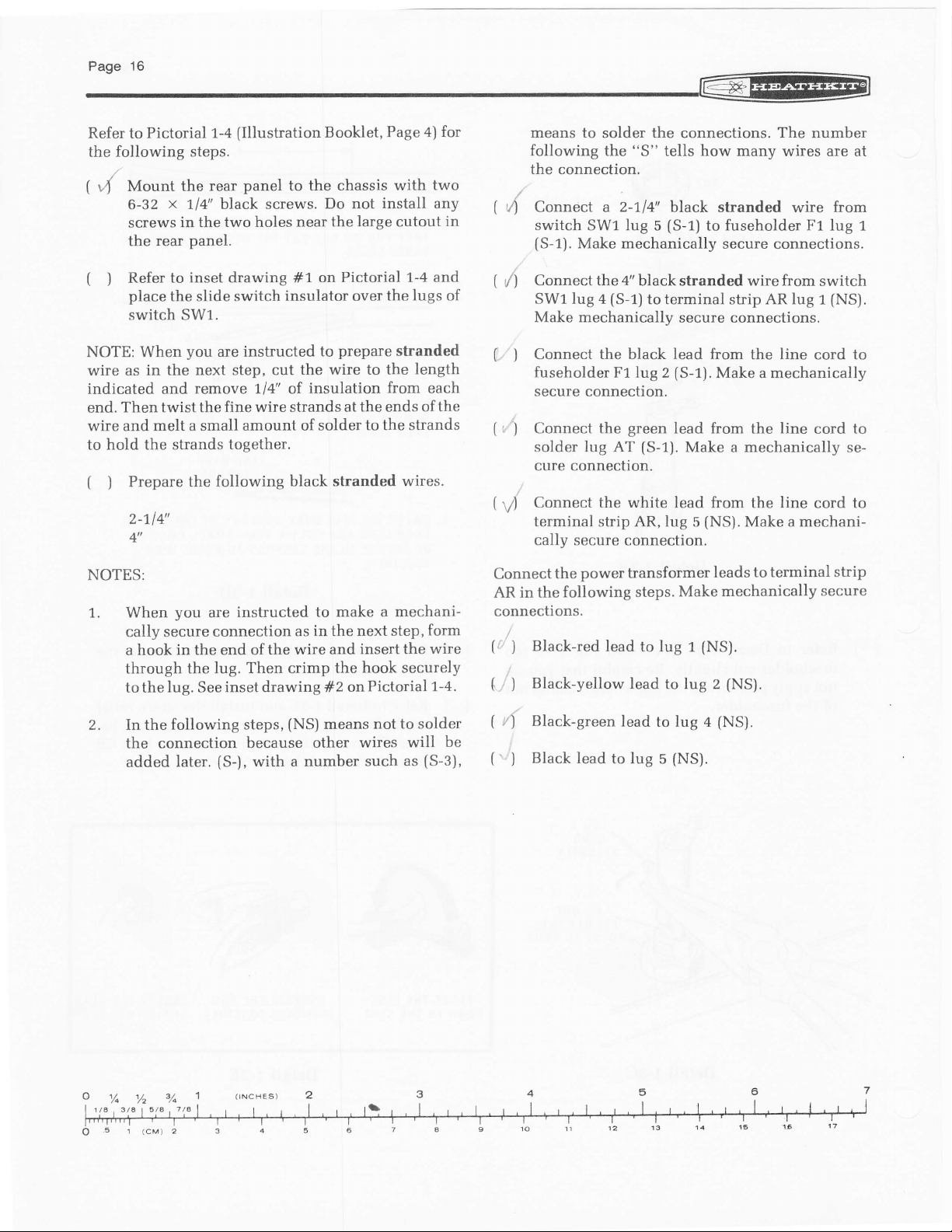

Refer to Pictorial

following steps.

the

(

Mount the

,4

x

6-32

screws

the

1/4" black screws.

in the

panel.

rear

(Illustration

1-4

panel

rear

two holes

Booklet,

to the

chassis with

Do not

near the large cutout

Page

install any

4)

two

for

in

means to

following the

the connection.

(

Connect a 2-114x

'/)

switch

(S-1).

Make mechanically

solder the connections. The number

"S"

SW1 lug 5

how many

tells

black stranded wire from

(S-1)

fuseholder F1

to

secure connections.

wires are at

lug

1

(

Refer to

I

place

switch SW1.

NOTE: When

wire

as

indicated and

Then twist the

end.

wire and melt a small

hold the strands

to

(

Prepare

)

2_\14'

4"

NOTES:

1,. When

cally secure

hook in the end of

a

through the lug. Then

to the

2. In the following

the

added

inset drawing #1. on

the slide switch

you

are instructed

in the

next step, cut the

remove 714' of

fine wire strands at

together.

the following black

you

are

connection

lug.

connection

later.

inset drawing #2

See

{S-),

insulator over

to

insulation

amount of

instructed to

the wire and

steps,

because other

with

solder to the strands

in

as

crimp the

(NS)

means

a number

stranded

length

from

each

of

form

wire

(S-3),

and

Pictorial 1-4

the lugs of

prepare

wire to the

the

ends

stranded wires.

make a mechani-

next step,

the

insert the

hook securely

Pictorial t-4.

on

not to solder

wires will

such as

the

be

(

Connect

t/)

SW1 lug 4

Make mechanically

(

Connect the black lead from

)

fuseholder

secure connection.

')

(,

Connect the

solder

cure connection.

(

Connect the white

r,/)

terminal

cally secure

Connect

AR in the

connections.

(r

,

(

(

rJ

('

the

following

Black-red

)

Black-yellow

)

Black-green

Black lead

)

4"

the

black stranded wire from

(S-1)

to terminal strip AR lug r

F1 lug 2

green

lug

power

(S-1).

AT

strip AR,lug 5

connection.

transformer

steps.

lead

to

lead

lead

to lug s

secure connections.

line

the

(S-1).

Make a mechanically

lead from

Make a mechanically

lead from the

(NS).

leads

Make mechanically

(NS).

lug

1

to lug 2

to lug a

(NS).

(NS).

(NS).

line

the

line

Make a mechani-

to terminal

switch

(NS).

cord to

cord to

se-

to

cord

strip

secure

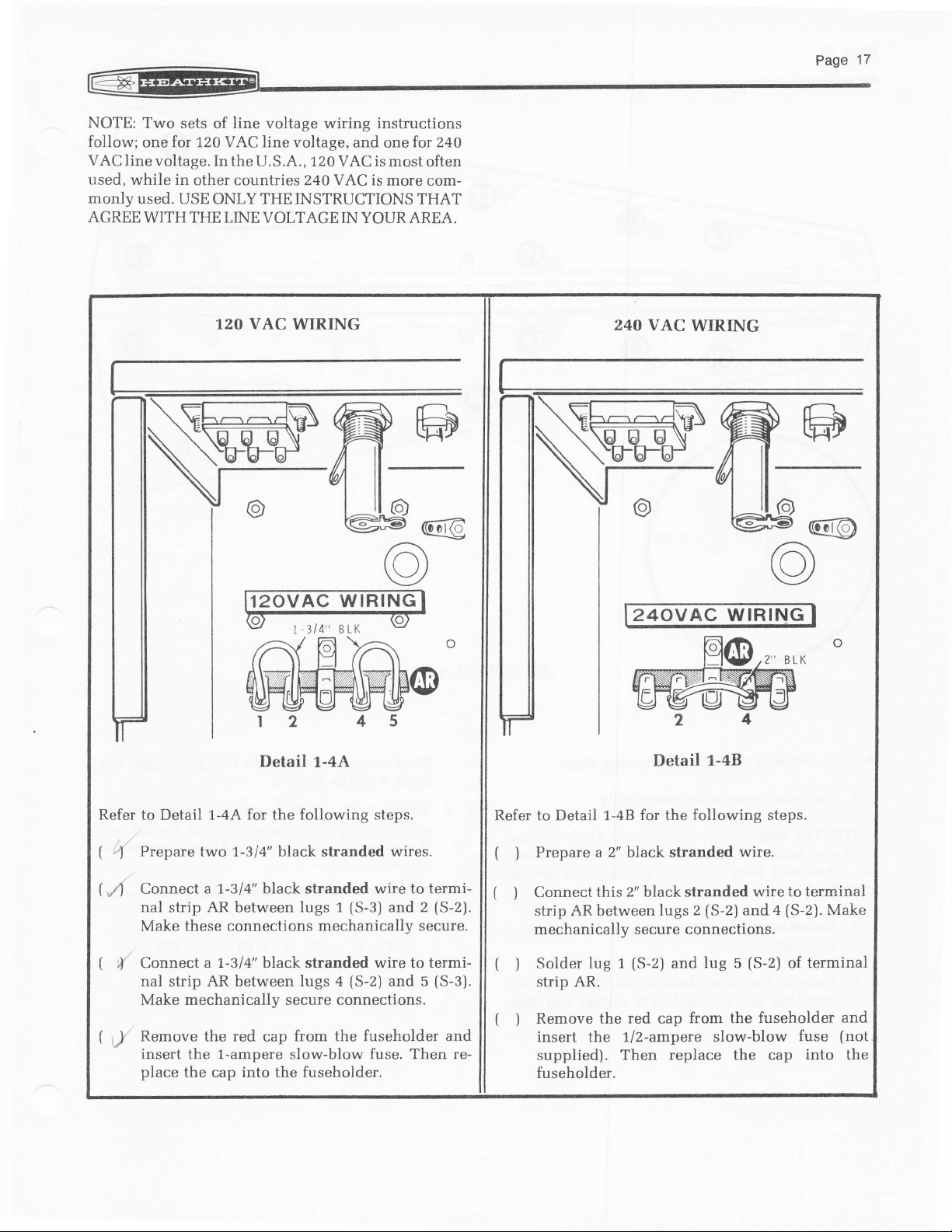

NOTE:

follow;

VAC

used,

monly

AGREE

Two sets

one

line voltage. In

while in

used. USE ONLY THE INSTRUCTIONS

WITH THE

line voltage

of

wiring

for 120 VAC line voltage,

the U.S.A., 120 VAC is

other countries 24OVAC is

LINE VOLTAGE IN YOUR AREA.

instructions

and one

most often

more com-

for 240

THAT

120 VAC

Detail r-+A

WIRING

24O

VAC

WIRING

24oV A,C W|RING

Detail

1-48

Refer to Detail 1-4A for the

(

"f

(

A

Prepare

Connect

two 1,-314" black stranded wires.

a 1.-314" black stranded wire to termi-

nal strip AR between lugs 1

(

J'

Make these

Connect a

nal

strip

connections

7-314'black

AR between lugs 4

following steps.

(S-3)

mechanically secure.

stranded

wire to termi-

(S-2)

Make mechanically secure connections.

(

,,)'

Remove

the

red

from the fuseholder and

cap

insert the 1-ampere slow-blow fuse. Then replace

the cap into the

fuseholder.

and 2

and 5

(S-2).

(S-3).

Refer to Detail 1-48

Prepare a 2" black stranded

t )

Connect

f )

strip

mechanically

(

Solder

)

strip

(

Remove the

)

this 2" black stranded

AR between lugs

secure

(S-2)

lug 1

AR.

red

for

following steps.

the

connections.

and

from the

cap

insert the 1/2-ampere slow-blow

supplied). Then

replace the cap

fuseholder.

(S-2)

2

lug

wire.

wire to terminal

(S-2).

a

and

(S-2)

5

terminal

of

fuseholder and

fuse

into

Make

(not

the

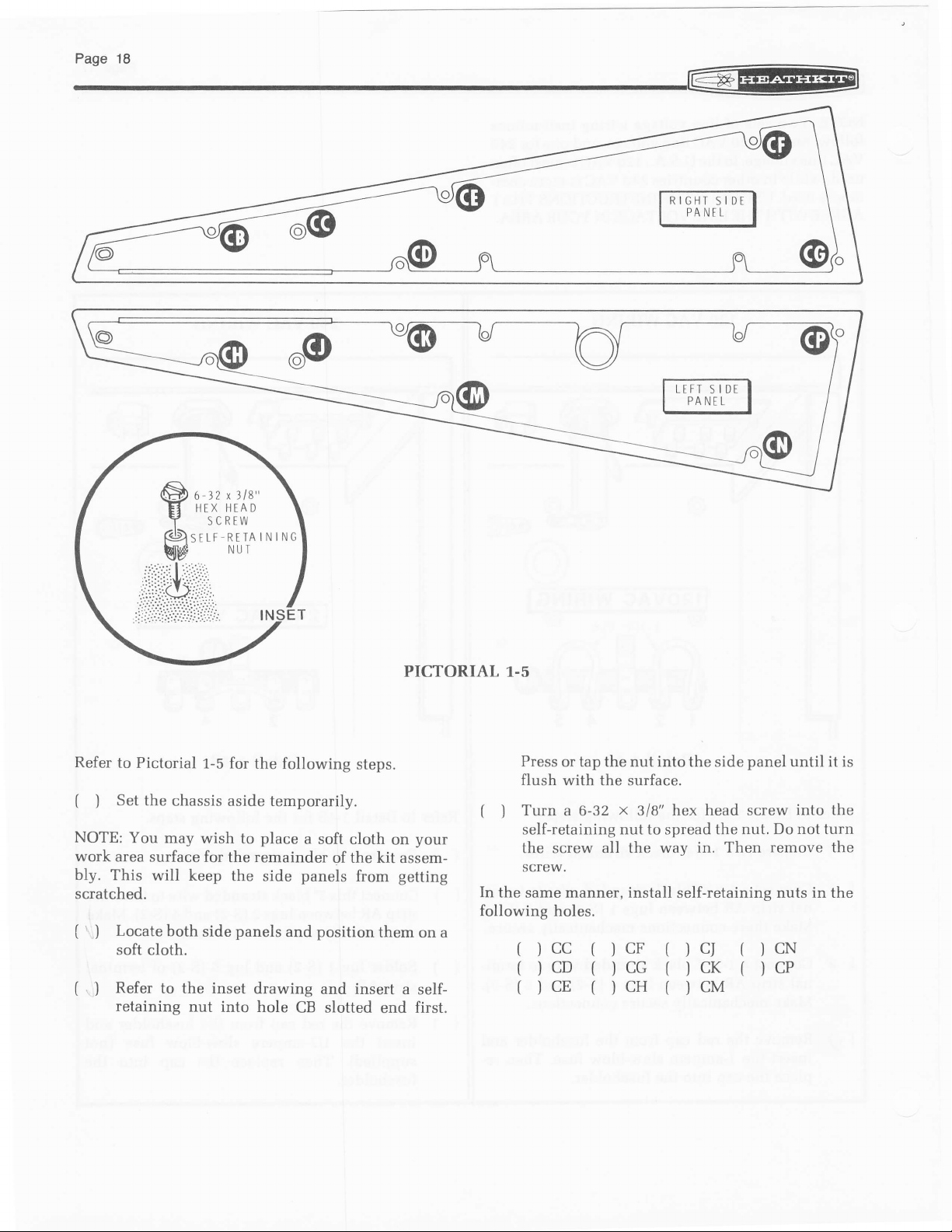

PICTORIAL 1.5

Refer

to Pictorial

(

Set the

)

NOTE;

work

bly.

scratched.

(

( .

This

'

)

l

You may

area

Locate

soft

Refer

retaining

1-5

for the following

chassis aside temporarily.

wish

surface for

will keep

both

side

cloth.

to the inset

nut

place

to

remainder

the

the

side

panels

drawing

into hole

panels

and

CB slotted

steps.

a soft

cloth

of the kit

from

position

and insert

on

assem-

getting

them

a self-

end

your

on a

first.

Press

or tap the nut into the side

flush with the surface.

Turn a 6-32 x 3/8" hex

t )

self-retaining nut to spread the nut.

the screw all the

screw.

In the

same manner, install self-retaining nuts in the

following holes.

CC

CD

CE

wav in. Then

CF

CG

CH

cI

cK

CM

panel

head screw

(

(

until it is

into the

Do not turn

remove the

)cN

)cP

@

6-jL

ry?-'ry

\

0

.g

6-32 x

I]EX

SCRTW

318"

HTA

Page

19

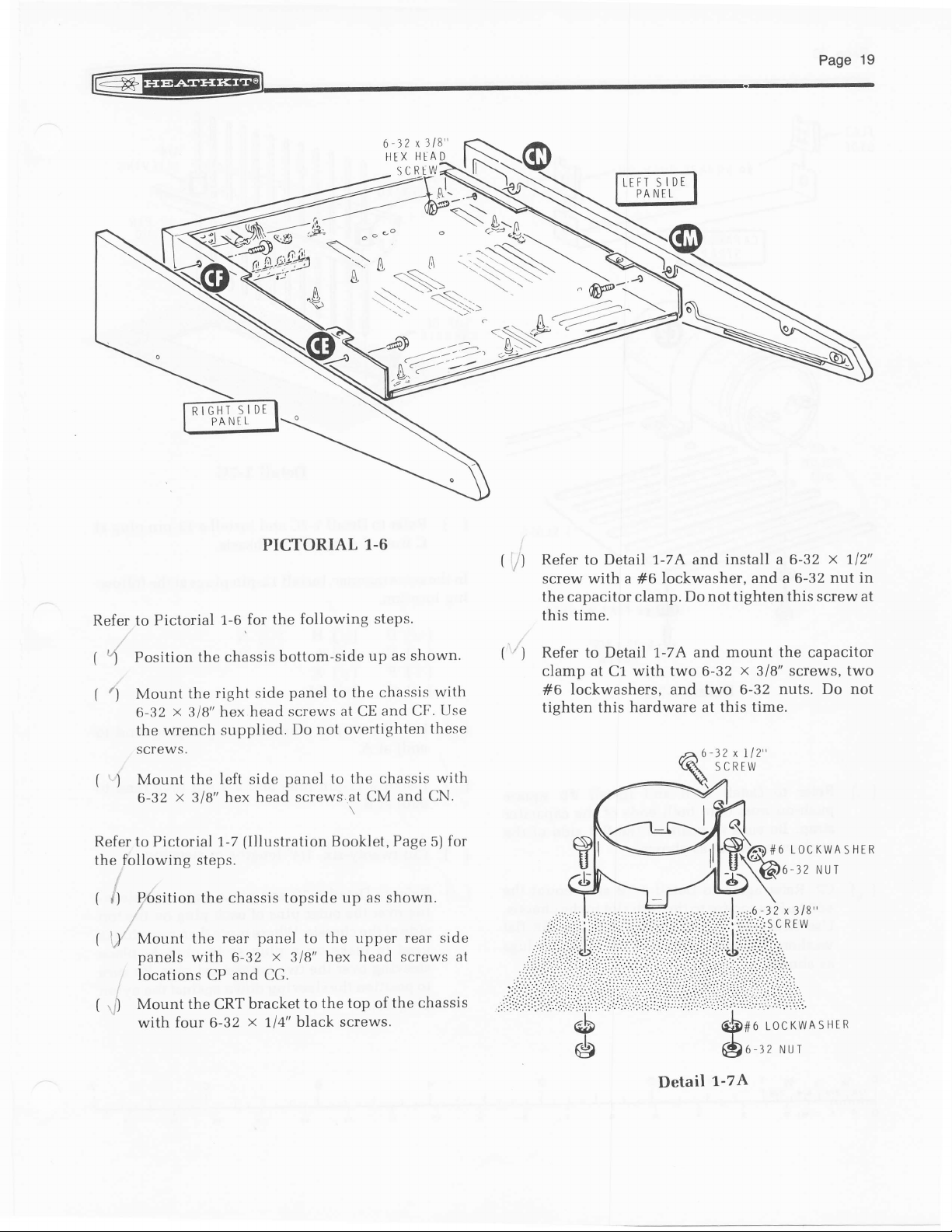

Refer to

(

\

(

(

Refer to Pictorial 1-7

the following steps.

f

(

Pictorial

Position the

t)

Mount

6-32 x 3/B"

wrench

the

SCTE\^/S.

Mount

)

6-32

P7bsition

it

i/

Mount the

panels

locations CP and CG.

1-6,for

chassis

right side

the

hex head

supplied.

the left side

x

hex

3/8"

the chassis topside up

rear

with

PICTORIAL

the

bottom-side

panel

screws

Do

panel

head screws

(lllustration

panel

x

6-32

3/8"

1.6

following

not overtighten

to the upper

hex head screws at

steps.

up as shown.

chassis

to the

at

and CF.

CE

the chassis

to

at CM

Booklet, Page

and UN.

as shown.

rear side

with

Use

these

with

for

5)

('

Refer to Detail 1-7A and

t)

(

')

with a

screw

the capacitor clamp.

this time.

Refer to Detail 1-7A and

clamp at C1 with two 6-32

lockwashers, and two 6-32 nuts.

#6

tighten

#6

this hardware at this

install a 6-32

lockwasher. and

Do not tighten this screw

mount the

a 6-32 nut

x

318" screws, two

time.

LOCKWASHER

-32

x

112"

in

at

capacitor

Do not

NUT

(

Mount the CRT bracket

';J

with four 6-32

x

to

black screws.

1/4"

the top of

the chassis

Detail

1-74

LOCKWASHER

#6

6-32 NUI

Pase2o

@

FLAT

IDE

S

6

g

fl

fl

SQUARE

#6

PUSH.ON

FLAT

IDE

S

rl4"

SLEEVING

il

ilt-

'lll-

ill-

-tl

il

Detail

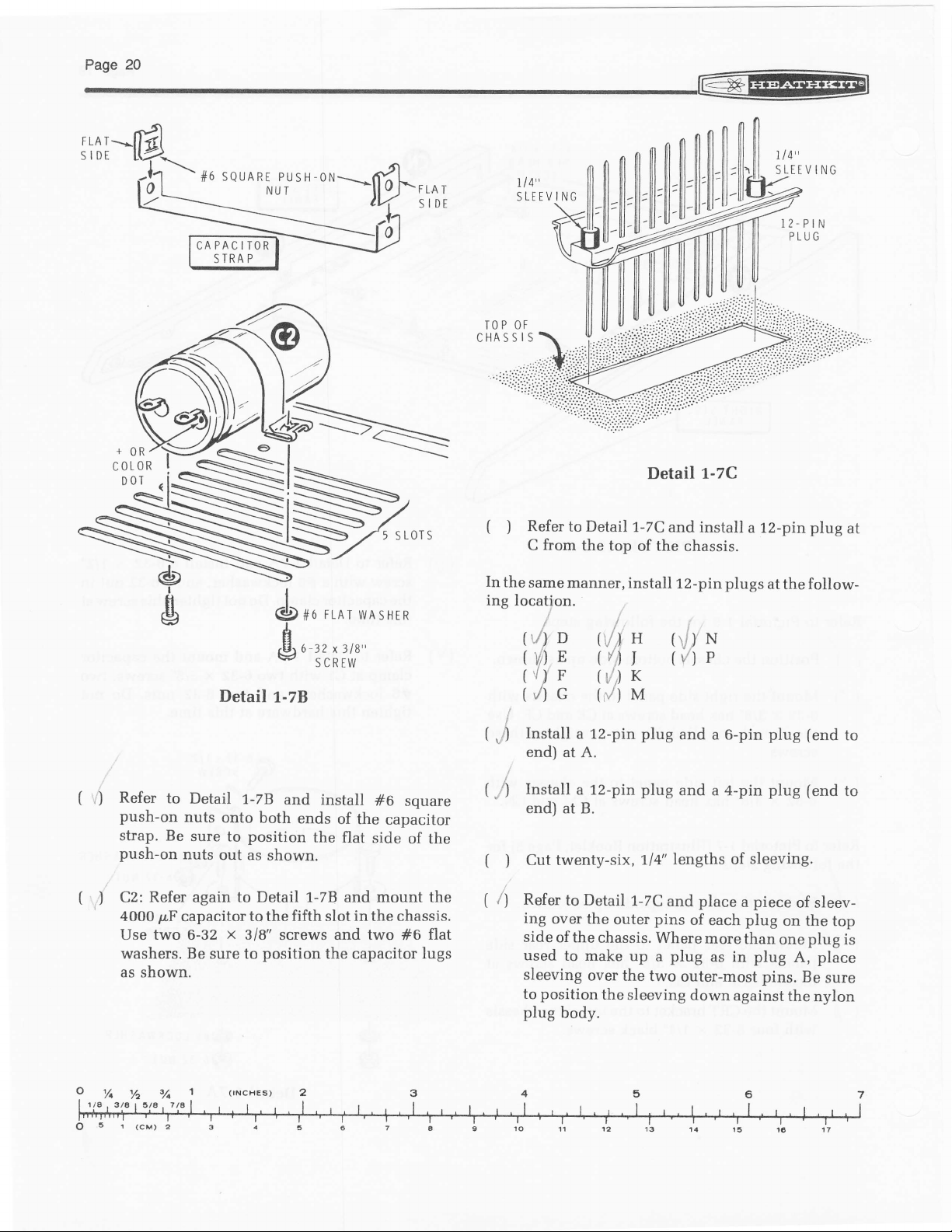

(

Refer

)

In

I

FLAT

6ou

wA'HER

the

ing location.

$'rt*;*'

Detail

t-zB

i

(

",')

to Detail

from

C

same

manner, install

//r

(t/)

D

(vfln

v/

F

t

(/)

G

Install

end) at

a

the top

A.

1-7C

of the chassis.

('l)

H

(/lI

(r'',)

r

(,/)

M

12-pin plug

t-zC

and install

12-pin plugs

(rlJ'

N

(/)P

and

a 6-pin

1l 4"

SLEEVING

l2-PtN

PLUG

12-pin

a

at the follow-

plug

fend

plug

at

to

(

Refer

r)

push-on

strap. Be

push-on

()

C2: Refer again to Detail 1-7B and mount the

4000

Use

washers. Be

as

to

Detail

nuts

onto

sure

to

nuts

out as

pcF

capacitor

two 6-32 x 3/8"

sure to

shown.

1-7B

and

both

position

shown.

to the

screws

position

ends

the

fifth

install

of the

flat

in

slot

and two

the

capacitor

#6

souare

capacitor

side

of the

the chassis.

flat

#6

lugs

(

Install

,l)

end) at B.

(

Cut twenty-six,1l4"

)

(

Refer

i

ing

side

used

sleeving

to

plug

a 12-pin plug

to

over the

of the

to make

position

body.

Detail

1-7C

and

pins

outer

chassis. Where

up a plug

over the

the

two

sleeving

and a 4-pin

place

of

each

more

as in

down

of

a

plug

than

against

lengths

outer-most

plug (end

sleeving.

piece

of sleev-

on the

plug

one

plug

A, place

pins.

Be

the

to

top

is

sure

nylon

r@

-

OF

NtI

LABET

MBER

SHTET

Page.1

S

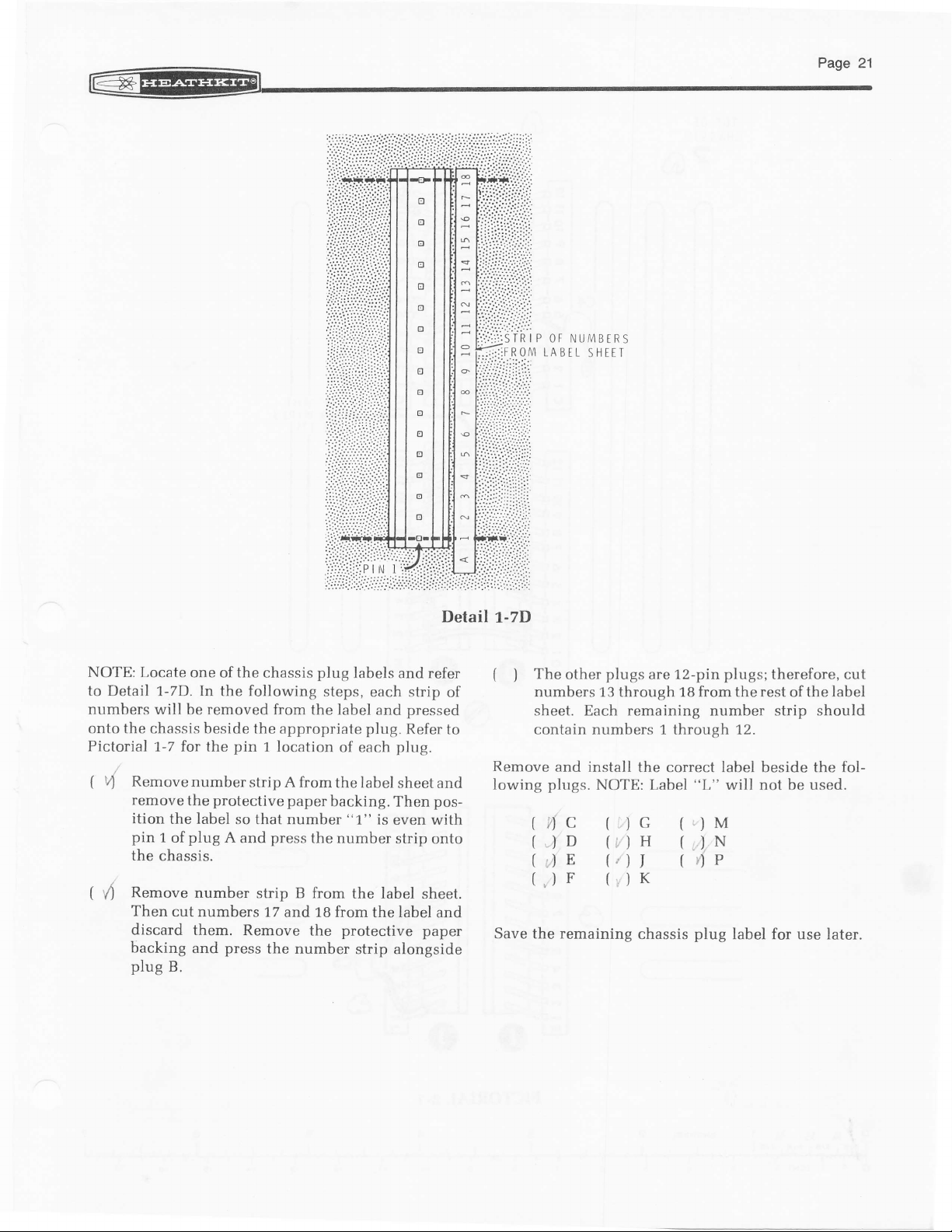

NOTE: Locate

to Detail

numbers will

onto the

Pictorial

(

v)

RemovenumberstripAfromthelabel

remove

ition

pin

the

(

\4

Remove

Then

discard them,

backing

plug

one

the

of

chassis

In

1-7D.

chassis beside the

1.-7 for the

the label

1 of

chassis.

cut numbers

B.

the following

removed

be

pin

protective

the

so that number

plug

A

and

number

Remove the protective paper

press

and

1 location

press

strip B from

1,7 and 18 from

the number

plug

from the label

appropriate

paper

the

labels and refer

steps,

each strip

pressed

and

plug.

Refer

of each

backing. Then

"l."

number

plug.

sheetand

is even with

strip onto

the label

the label and

strip alongside

Detail

of

to

pos-

sheet.

1-7D

(

The

)

numbers 13 through 1B from the rest

sheet. Each remaining

contain numbers 1 through 12.

Remove

lowing

and install

plugs.

fic

,.)

r)E

,)F

Save the remaining

plugs

other

NOTE: Label "L" will

D

are 12-pin

the correct label beside the fol-

(.)

G

(,,).

H

(

T

K

chassis

4P

plug

plugs;

therefore, cut

the label

of

number strip should

be used.

not

M

N

label for use later.

Page

22

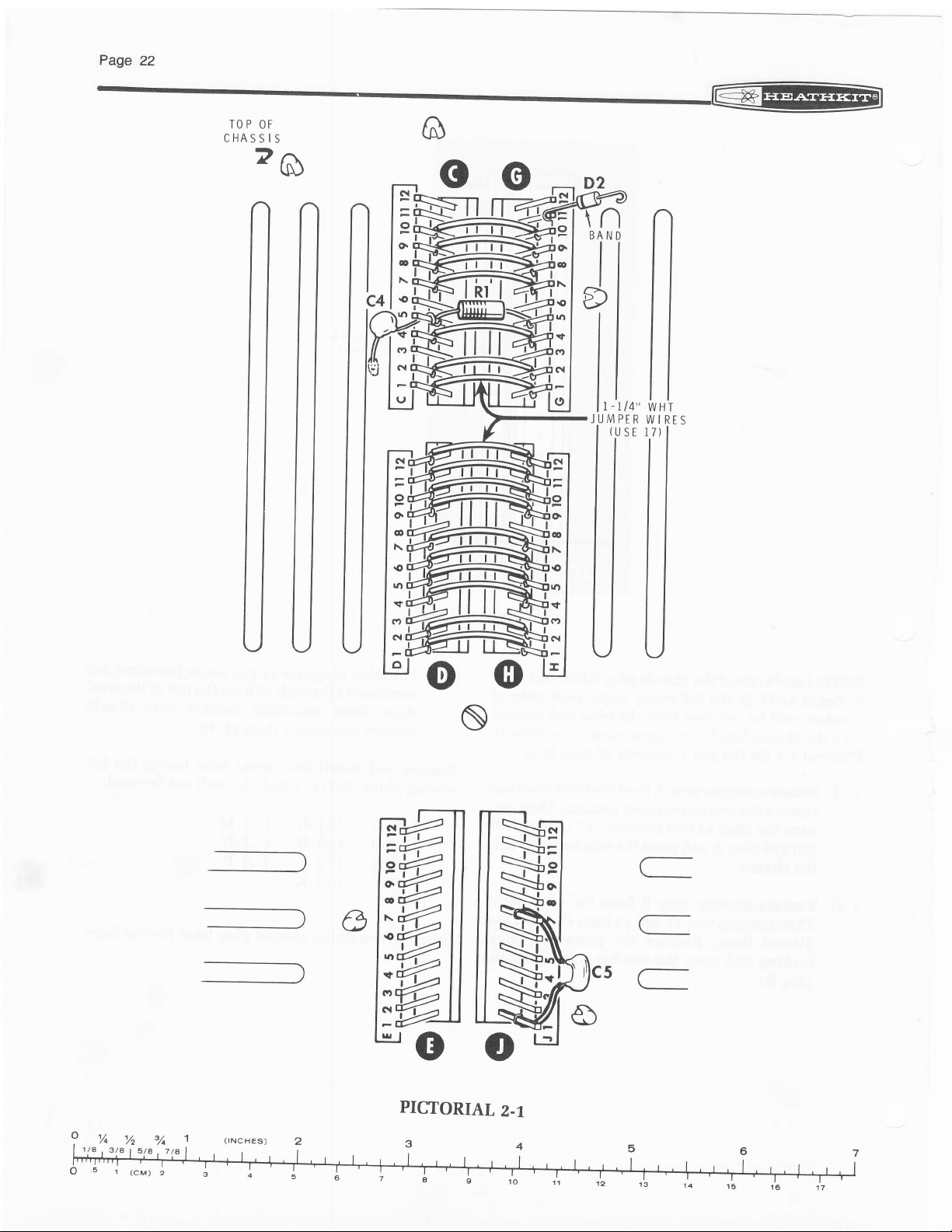

TOP OF

CHASSIS

z6

ff

lIl

llll

@

c

o@

ff

_lo

-----\

o

or

O

C

C

5C

i-r/4"

JUMPFR

(

r'1

((-,Y

|umper

lrmper

wire between

between

wire

pins

pins

10.

11.

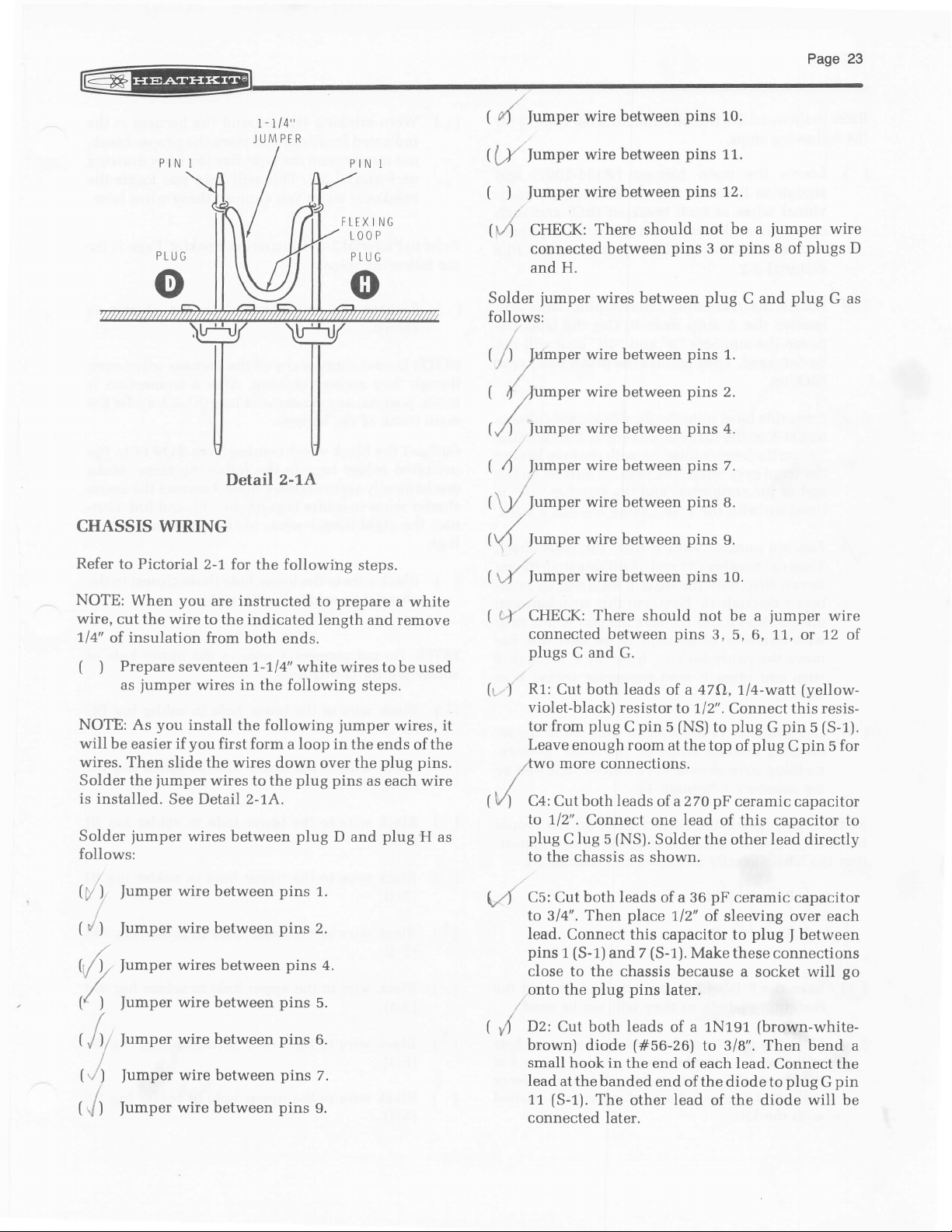

CHASSIS WIRING

Refer

to Pictorial

NOTE:

wire,

714"

(

NOTE:

will

wires.

Solder the

is installed.

Solder

follows:

When

cut the wire

insulation

of

Prepareseventeen

)

jumper

as

As

be easier if

Then

jumper

jumper

2-'1, for

you

to the indicated

from

wires in

you

install the following

you

the

slide

See Detail 2-1A.

wires between

Detail

are instructed

first form

wires to the

z-tA

the following

both

ends.

7-714'

whitewirestobeused

the following

a loop in the

wires down

plug pins

plug

steps.

prepare

to

length and remove

jumper

over

D and

steps.

wires, it

ends of the

plug

the

as

each

plug

a white

pins.

wire

H

as

(

)

|umper

/

CHECK:

$A

connected

and H.

Solder

follows:

(

/) l,umper

(

{

7Yu

(,/)

fumper

(

4

fumper

(!),/

/umper

(\/)

|umper

(UJa

Jumper

(

L+'/

CHECK: There

connected between

plugs

(s

R1:

)

violet-black)

tor

Leave

lwo

C4: Cutbothleads

tVl

to

plug

to

wire

jumper

p"r

C and G.

Cut both leads

from

enough room at

more

712".

lug

C

the chassis as shown.

between

There should

between

wires between

wire between

wire between

wire

between

wire between

wire between

wire between

wire

between

resistor

plug C pin 5 (NS)

connections.

Connect one lead

(NS).

5

pins

not be a

pins

3 or

plug

pins

pins

pins

pins

pins

pins

pins

should not be a

pins

47O,1/4-watt

of a

Io 712".

the top of

of aZ7OpF ceramiccapacitor

Solder the other lead

12.

jumper

pins

8

C and

1.

2.

4.

7.

8.

g.

10.

jumper

3, 5, 6, 1.1,

Connect this resis-

plug

to

of this capacitor to

pin

G

plug C pin

plugs

of

plug

wire

12

or

(yellow-

(S-1).

5

directly

wire

G as

5 for

D

of

w\

r/t

(r/

),,

r/t

I

(,/)i

('/)

(J

fumper

fumper

fumper

fumper

fumper

fumper

|umper

wire between

wire

between

wires between

wire between

wire between

wire between

wire between

pins

pins

pins

pins

pins

pins

pins

1.

2.

5.

6.

g.

7.

4.

C5: Cut both leads of a 36

\r4

to

lead.

pins

close to

onto the

.

(

D2:

r/)

brown)

small hook in

lead

11

connected

Then

314'.

Connect

(S-1)

1

and 7

the chassis because a

plug pins

Cut both leads of a 1N191

diode

at the banded

(S-1).

The

later.

place

112" of

this

capacitor to

(S-1).

later.

(#56-26)

the end

end of the

lead

other

pF

ceramic capacitor

sleeving over each

plug

Make

these connections

to 3/8". Then bend a

of each lead.

diode to

the

of

between

)

socket will

(brown-white-

Connect the

plug G pin

will be

diode

go

Refer

to

Pictorial

the

following

(

Locate

)

straighten

vidual

connector

nector

Pictorial

(

vJ Locate

remove

tween

be

damaged.

backine.

(

Yress

7f

tors

"

1. "

the large gray

end

lined

(rl

Remove

-

Then

have

bers 1 through

the numbers

with

move the paper

strip and

shown.

(

Cut numbers

4

maining

maining

the numbers

2-2

steps.

the

main harness

it

out as

wires

at

socket

socket

the

this

at A

has

2-2.

the remaining

the

A

numbers

Then

label

the

on

on the label

wire,

of the

connector)

up

with the

number

numbers

cut

a strip with

9 and 10.

numbers

10 through

press

13 through

number

strip

should have

1 through

(Illustration

shown. Position

each breakout

as shown.

its

slots up

chassis

strip from

"9"

remove

onto

harness.

is

lined

the

up with

(the

it.

and

double

Be

sure

letter

and the

hole

having

strip B from

17

and 18

the letter

16. Next,

B followed

cut this strip between

Save the

16 for later

backing

it

from

onto connector

18 from

strips

on the

12.

Booklet, Page

(#134-1OO1l

(BO)

BE SURE

or dovrn

plug

Cut the

"10"

so it

the protective

socket

that the

the hole

A

will be

number

the black

the label

off this strip

part

6) for

the indi-

and

each

each

con-

iust

label

label

will not

paper

connecnumber

having

on the

"10"

wire.

sheet.

so

by

num-

of this strip

use. Re-

the B

through

socket B

all

of the re-

sheet. Each re-

a letter followed

and

like

and

be-

is

you

as

by

{\t

Refer

the following

(

NOTE:

though

made, position

main

Connect

indicated

mechanically

shorter

nect

lugs.

(

NOTE:

9

solder lug BE

(V)

[.

Wrap masking

indicated

out numbers

Pictorial

on

breakouts

to Pictorial

Position

)

shown.

Do

not shorten

they

appear

trunk

of the harness.

the

black wires

solder lugs

wires

to solder

the

eight

Black

)

wire to the

chassis)

Do

not connect a wire in

Black

wire

(s-1).

Black

)

wire to the

(s-1).

tape around the harness

locations

and mark the

on the tape.

2-2. This will help

when

2-3

connect these wires later.

vou

(Illustration

steps.

the main

harness

any

of the harness

too long. After

any

excess

wire length

coming from

in the following

secure

connections.

lugs BE, BG,

longer

wires

lower hole

in

solder lug

at this time.

the lower

to

upper hole

proper

See the inset

you

drawing

locate

Booklet, Page 7)

on the

chassis as

wires

a

connection is

back under

BO#I4

steps.

Connect the

BI, and BM.

to the

BE

other four

(hole

(S-1).

solder

closest to

the upper hole

hole in solder lug BG

in

solder lug BG

the

at

break-

the

for

even

the

to

the

Make

seven

Con-

the

of

Remove

harness

tion

and install

connector

the labels

/l/'

(WE

(4..J

(q

K

Save the F label

[

\,z

,femaining

(

Mark the remaining

V

with

their

proper

the

point

ball

with

the kit.

the

correct label

sockets as follows.

exactly as

(v

/v

(il

0"')

labels,

shown in Pictorial

N

P

for

use

as

they will not be

harness

"S"

number

end

as shown. Use a felt

pen

and

and a numb

the

masking

on the

Be

sure to

later

and

discard the

used.

connector sockets

et 1..7 , or 8 at

tip marker

furnished

tape

proper

posi-

2-2.

or

(

(

(

{'

(')

()

-)

'..'

',')

1,

I

)

)

Black wire

(s-1).

Black

wire to the upper

(s-1).

Black

wire

ts-1).

Black

wire to the

(s-1).

Black

wire to

(s-1).

Black

wire to the

(s-1).

to the lower hole in

hole in solder lug BJ

to the lower hole in

upper

hole in

the lower hole in

upper

hole in

lug

BJ

BM

solder lug

solder

solder lug BM

solder lug

solder

lug

BF

BF

LI'

(

nlack wire to the

(S-t1'

lower hole in solder

lug BH

Connect the wires

harness to switch

coming

as follows:

SW2

from BO#r7 of

the

main

(

Black wire to the upper

\/)

hole in solder

(s-1).

i/)

(

Black wire to the lower hole in solder

ts-1).

( .)

Black wire to the upper hole

(s-1).

(

Black wire to

)

(s-1).

(

Black

I

wire to the upper hole in solder

(s-1).

(

CHECK: Solder lug BE

)

connected

(

,, ) Prepare

(

Refer

)

large

the ends

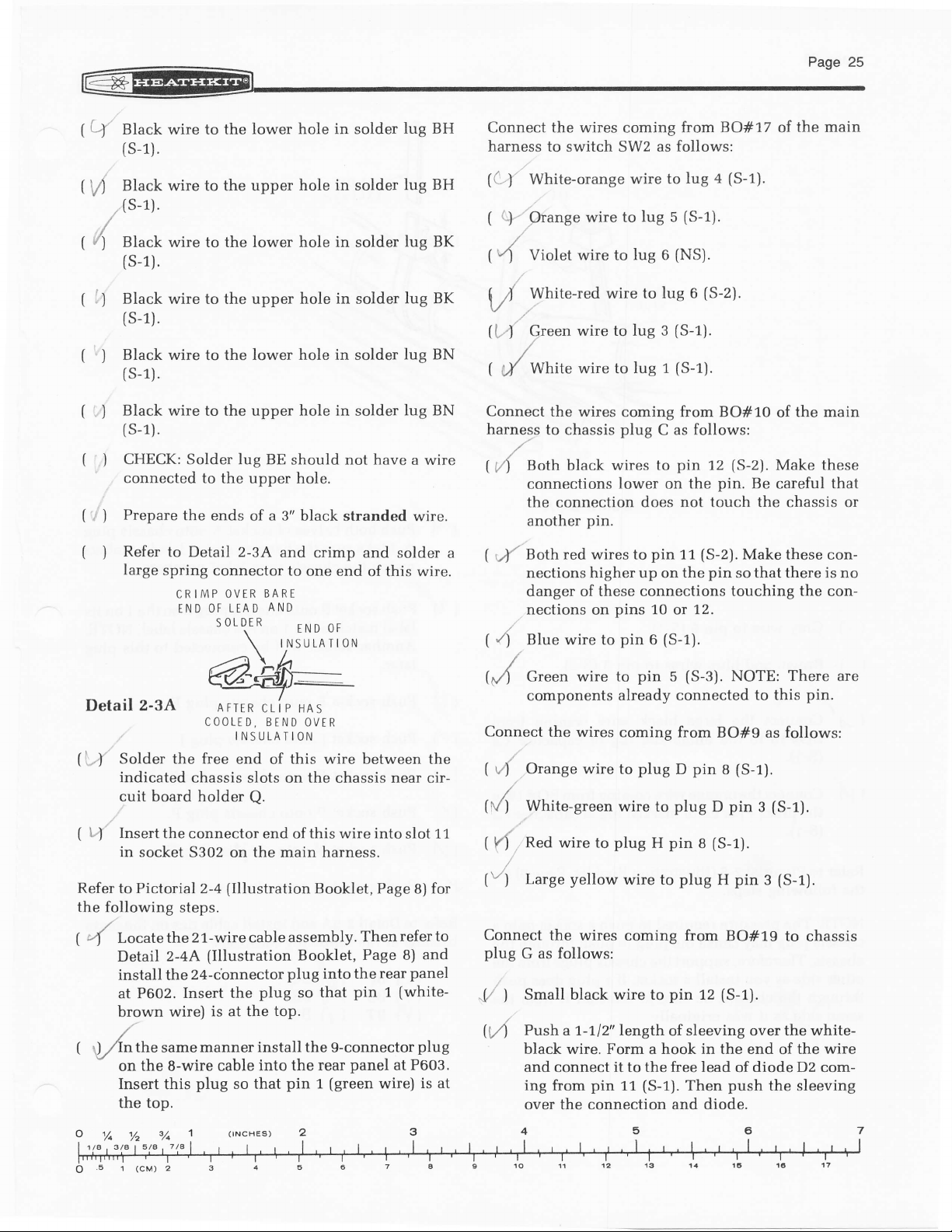

to Detail 2-3A

spring

CRIMP

END

to the upper hole.

lower hole in solder

the

should not have a wire

of a 3" black stranded

and

crimp and solder

connector to

OVIR BARE

OF LEAD

SOLNR

\

one end

AND

END

INSULATION

in

OF

solder

BH

lug

lug BK

lug BK

lug BN

lug BN

wire.

of this wire.

a

((

White-orange

)'

i;.'

brange

1

(4

Violet

White-red wire to

\ /

Green

U..1

(

White wire to lug

;/

Connect

harness

(?4

Both black

wire to

wire to lug 6

wire to lug 3

the wires

to chassis

connections

the connection does

pin.

red wires to

1

,r(

another

Aoth

nections higher up on

danger

of

nections on

/)

(

Blue wire to

a

lug 5

lug

(S-1).

{S-1).

wire to

(NS).

(S-2).

lug 6

(S-1).

(S-1).

1

coming from BO#10

plug

wires to

lower on the

as follows:

C

pin

12

(S-2).

pin.

the main

of

Make these

Be

careful

that

not touch the chassis or

11

the

(S-2).

Make these con-

pin

that

so

there

is

no

pin

these connections touching the con-

pins

10

12.

or

(S-1).

pin

6

Detail 2-3A

Solder the free

{i...}'

indicated

cuit board holder

l'".'}

Insert

t

Refer to Pictorial

the

following

(

4

(

t)

,Anthe

the connector end of this wire into

in socket

steps.

Locate

Detail

install the

at P602.

brown

on the 8-wire cable

Insert

the top.

the

2-aA

Insert the

wire)

same

this

a-M_

AFTER

COOLED, BEND

chassis slots on the chassis near cir-

5302 on the main harness.

2-4

21-wire cable assembly.

(Illustration Booklet,

24-cbnnector

is at the

manner install the

plug

CLI P HAS

INSULATION

end of this wire between the

Q.

flllustration

so that

OVER

plug

plug

so

top.

into the

pin

slot 11

Booklet, Page

refer to

Then

Page 8)

rear

the

into

(white-

pin

panel

wire)

1

at P603.

that

9-connector

rear

(green

1

8)

panel

plug

for

and

is at

Green

0,4

components

Connect

(

,"ri'

(V)

(

!d

(")

Connect

plug

"l/'

U/1

the wires

Orange wire

White-green

Red wire

yellow

Large

the wires

follows:

G as

Small black wire to

)

Push a 7-1.12" \errgth

wire to

pin

5

already connected

coming from

plug D pin

to

plug D pin

pin

H

to

to

plug

wire to

wire

coming from BO#19

pin

of sleeving over

black wire. Form a hook in the end

and connect it to the free lead

L1

(S-1).

and diode.

ing from

pin

over the connection

(S-3).

NOTE: There

to this

BO#9 as follows:

(S-1).

S

(S-1).

s

plug

Then

12

pin

H

(S-1).

of

push

diode D2

pin.

(S-1).

3

(S-1).

3

to

chassis

the white-

the wire

of

com-

the sleeving

are

o

Pase26

SLOT

t|]

OFF

CUT

EXCESS.,-

IIJ-

7

@

(

(

(,.

I

)

J

Gray wire

Brown

Connect

BO#19

pin 6 (S-1).

to

and blue wires to

the large

to the

(s-1).

(

Connect the

,' )

the

plus (+)

orange wire

or color marked

(s-1).

Refer to Pictorial 2-5

the following

NOTE:

chassis

chassis. Therefore,

other side

through

same

The

side as it

pressure

plug

as

the

steps.

may

cause the

support

you

install

chassis,

was

Detail

pin 3 (S-2).

black wire

unmarked lug

coming from

(Illustration

required

be

originally.

to

plug

the chassis

a socket.

sure to reinstall it from

of

lug

of capacitor

Booklet, Page

push

a socket

push

to

plugs

plug

If a

2-5A

coming from

capacitor

B

through

does

C2

O# 1 9 to

C2

for

9)

onto a

the

from

the

push

the

t,/

(

Push

1

A.

match the

( tl

Push

label

Another

later.

tl

Push socket

, ,/,

tvl

Push

f \ ' )

Push

(/')

Push socket P

.1

r

Push

Push

{')

Refer

to Detail

harness

'r)

/,)

\i')

both halves

Make

sure the harness

chassis

socket B

matches

socket

socket K

socket N

socket

at the following

ne

BS

BT

onto chassis

the 1

socket will be

E onto

onto chassis

I

onto chassis

onto chassis

onto chassis

M

onto chassis

2-5A

and install

nq

rl

'r7

BR

su

I{)

of socket A

socket

plug

label

plug

the

on

locations:

chassis label.

connected

chassis

plug

cable ties

onto chassis

label

numbers.

B

so the 1

to this

plug

E.

I.

plug

K.

plug

P.

plug

N.

plug

M.

on the main

plug

numbers

its

on

NOTE:

plug

L@

-

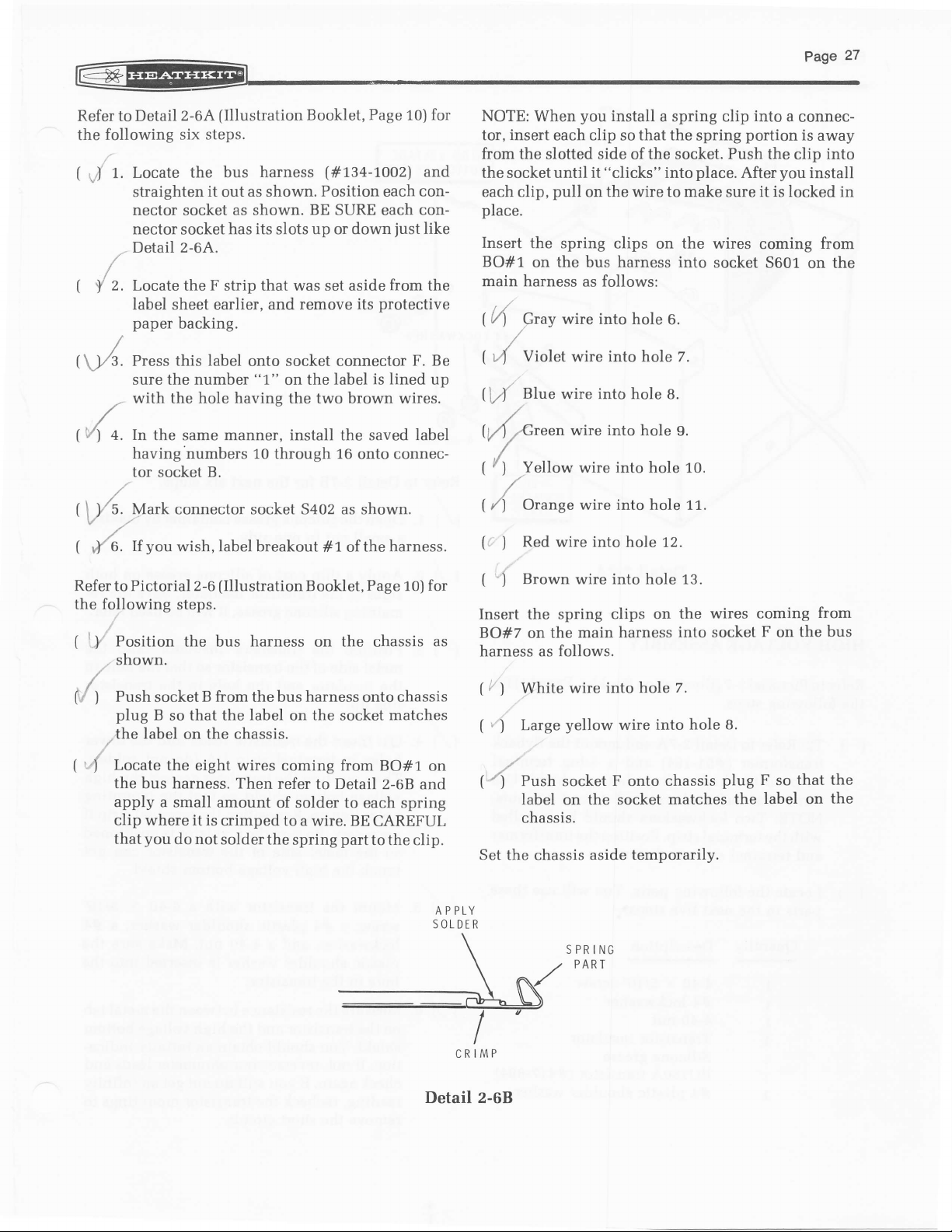

(Illustration

Refer to Detail

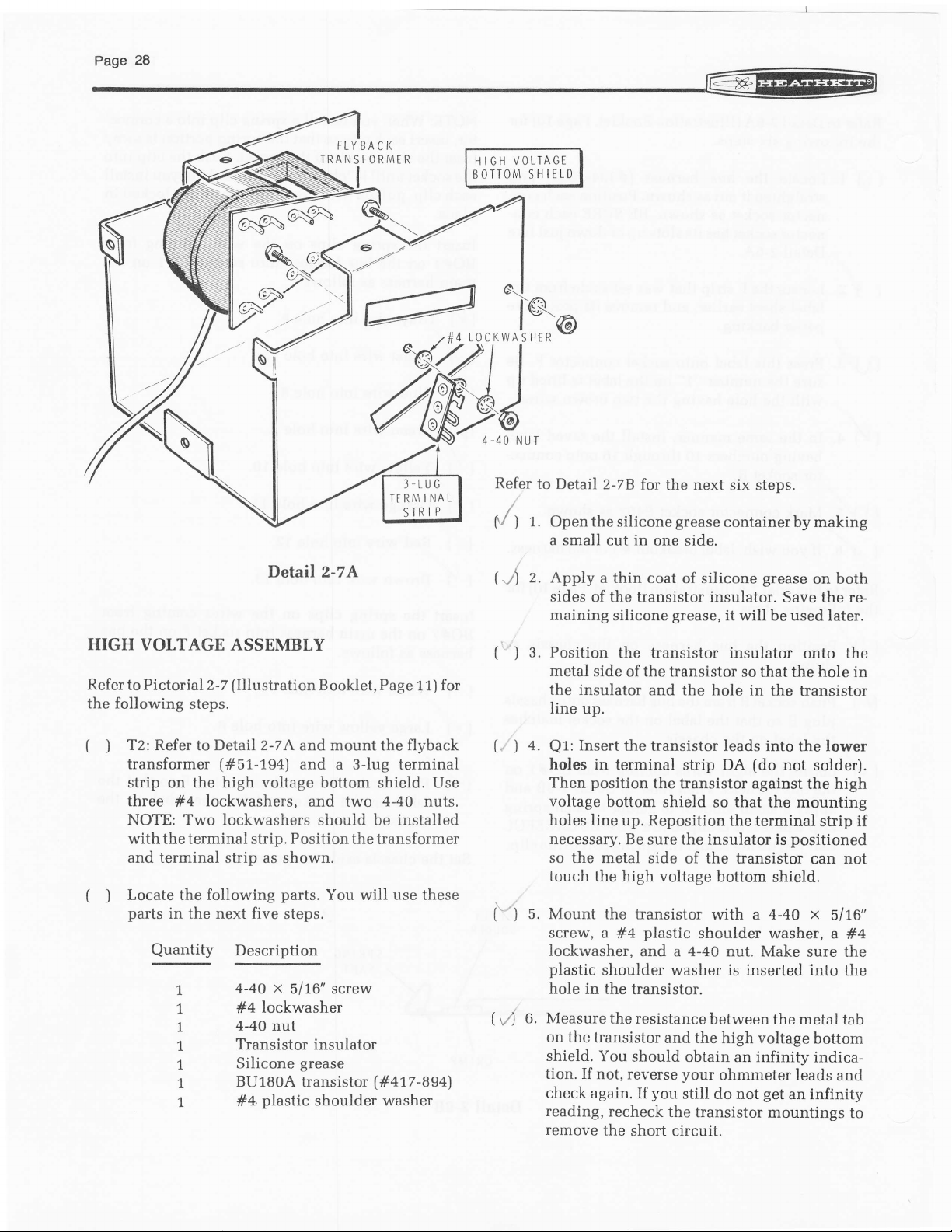

following six

the

(

t

t|/s.

(q

Locate the

t.

vi

straighten

nector socket as shown.

nector

,.Detail2-6A.

z. Locate the F strip that was set aside

t'

label sheet

paper

Press this

sure the number

with the hole having the two brown wires.

-

s. In

having'numbers 10

tor socket B.

2-6A

steps.

harness

bus

it

as

out

shown.

socket

backing.

the same manner, install the saved label

has its slots up or down

earlier,

label

and remove

onto socket connector

"1"

on

through 16 onto connec-

.-

Booklet, Page 10) for

(#734-1^o1z)

Position each

BE

SURE each

its

the label

is lined

and

concon-

just

like

from

the

protective

F. Be

up

NOTE:

tor, insert each clip

from

the slotted side of the socket.

the socket until it "clicks" into

each clip,

place.

Insert

BO#7

main

the spring clips

on the bus harness into

harness

Gray

6

Violet

,n

Blue

V

t(

17)r,'Green

/)

Yellow wire into hole 10.

you

When

pull

the wire to make

on

as follows:

wire into

wire into hole 7.

into

wire

wire into hole 9.

install

that the

so

hole 6.

hole 8.

a spring clip

on the wires

into

spring

place.

portion

Push

After

it

sure

coming

socket 5601

a

connec-

the

clip

you

is

locked in

Page2'

is

away

into

install

from

on the

(

.V

(

Refer

the following

(

(/

(,-4

Mark connector socket 5402

| V5.

you

If

,tr6.

to Pictorial 2-6

r)

Position

. shown.

PushsocketBfromthebusharnessontochassis

)

plug

the label

Locate

the bus harness. Then

apply a small

clip where it is

that

wish,label breakout

(Illustration

steps.

the bus

B

so that the

on the

the

you

do

eight wires coming from

not

harness

label

chassis.

amount