Page 1

F

MODIFICATION KIT

Evert

66

R.

Culpeppur

Newport

G*

News,

Ave.

Va

23608

SB-104 SINGLE SIDE BAND TRANSCEIVER

MODEL

SBM-104-2

The purpose of the Modification Kit is to update your

SB-104 Transceiver to reflect all the latest Heathkit

engineering improvements. When the changes are

completed, your Transceiver will be identical to the

-Heathkit SB-104A Transceiver.

-

b

*.*

-%*

~hehkeach part against th; follotving list. Any part

that is packed in an individual envelope with the part

on

number

.A

after you identify it until it is called for in a step. The

.

-

*

c

it should be placed back in the envelope

ers correspond to the numbers on the Parts

F

KEY

No.

-

HEATH

part

No.

QTY.

DESCRIPTION CIRCUIT

cs-

PARTS

"

3

Comp. No.

LIST

To order a replacement part, always include the

PART NUMBER. Use a Parts Order Form, or, if one is

not available, refer to "Replacement Parts" inside the

rear cover of your Transceiver Manual. For prices,

refer to the separate "Heath Parts Price List."

NOTE: The circuit component numbers refer to the

component numbers in the

.

Schematic.

-

SB-104A Manual and

2

A1

.1*!2

*,\

.

wing resistomhave a tolerance of

btherwise.

50h

\

is

10%

is

indicated by a fourth color

indicated by a fourth color band of gold.

4

100

(brown-black-brown)

a,

5

%

1 180

brown)

1

390

1

1000

1

3300

3 5600

1

6800 0,So/,

1

12 k0 (brown-red-orange)

1

22 k0 (red-red-orange)

(brown-gray-

(orange-wh~te-brown)

a

(brown-black-red)

0

(orange-orange-red)

SL

(green-blue-red)

(blue-gray-red)

BENTON HARBOR, MICHIGAN

...

10%

unless

R343,

W,

R619, R621

R13

RS14

R684

R321

R612, R677,

R679

R322

R329

R625

HEATH

COMPANY

..-

49022

/dl

Page 2

Page

2

KEY

HEATH QTY. DESCRIPTION CIRCUIT'

No. Part No.

-

I

-

22

n

(red-red-black) R22

n

(yellow-videt-black) R23, R1237

47

n

(brown-black-brown) R1253

100

n

(brown-green-brown) R21, R1206

150

470 (yellow-videt-brown) R1203

n,

5% (videtgreen- R254

750

brown)

1200 (brown-red-red) R1201

n

(orangeorange-red) R1231

3300

15 kn (browngreen-orange) R407, R507

22 kn (red-red-orange) R1251,

33 kn (orangeorange R209

orange)

kn (brown-black-yellow) R568

100

180 kn (brown-gray-yellow) R566, R567

330 kn (orangeorange R564

yellow)

MR.

(browngreengreen) R207

1.5

.. ,.

Comp. No.

R1254

R1252

KEY

HEATH QTY. DESCRIPTION

No. Part No.

-

Mlca

(cont'd.)

81 20-106 1

B1 20-116 1

B1 20-128 2 470

-

390

so0

Ceramic

~w=---~.--a~

CIRCUIT

Cornp. No.

pF

PF

pF

I

I

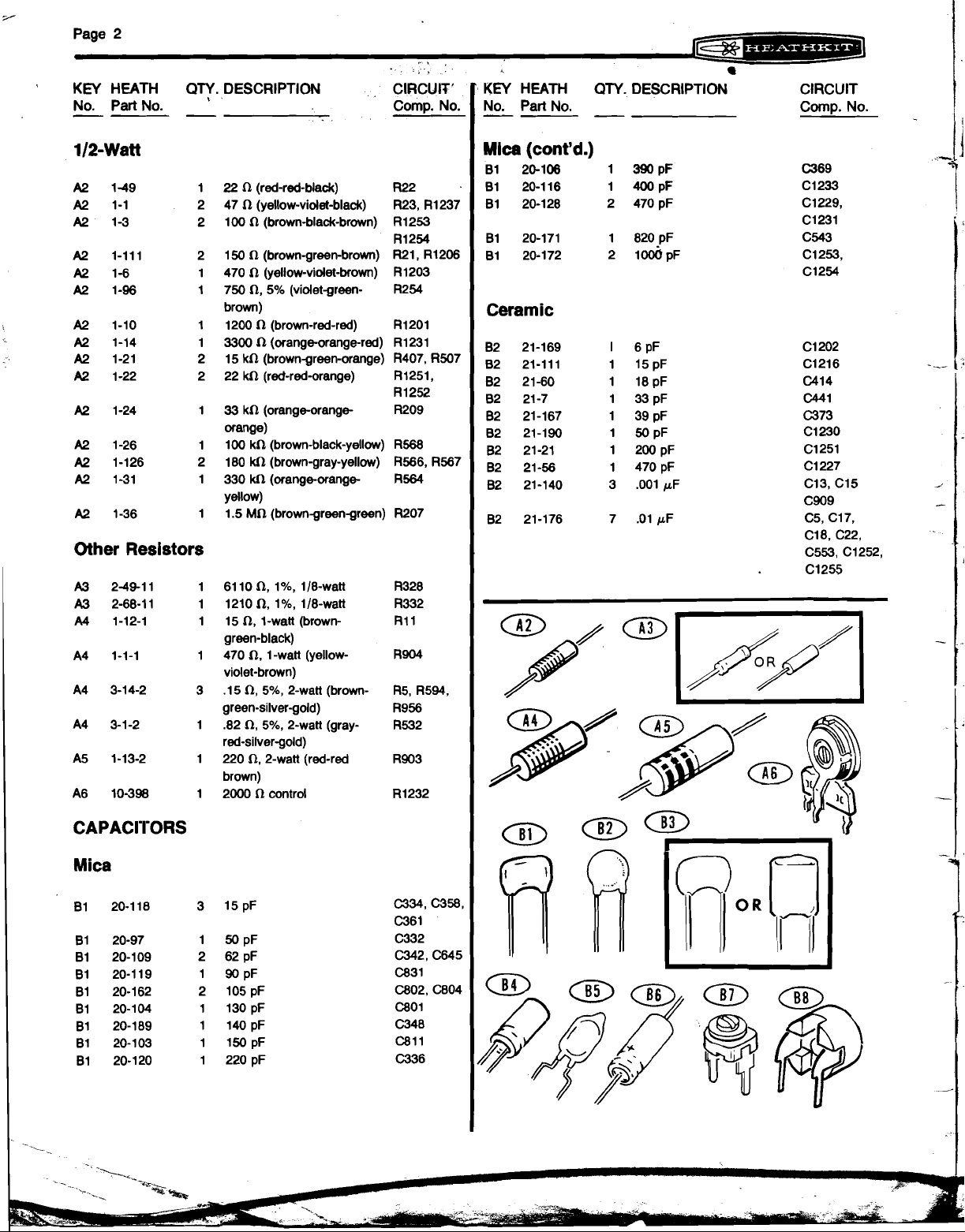

Other Resistors

CAPACI'I'ORS

Mica

6110 n,I%, 118-watt

n,

1210

15

green-black)

470

violet-brown)

.15 n,

green-silver-gold)

.82

red-silver-gold)

220

brown)

2000

1% 118-watt

n,

I-watt (brown-

n.

1-watt (yellow-

5%,

2-watt (brown-

n,

5%

2-watt (gray-

a,

2-watt (red-red

fl

control

Page 3

Page

3

KEY HEATH QTY. DESCRIPTION KEY HEATH QTY. DESCRIPTION CIRCUIT

No. Part No. Comp. No. INo. Part No.

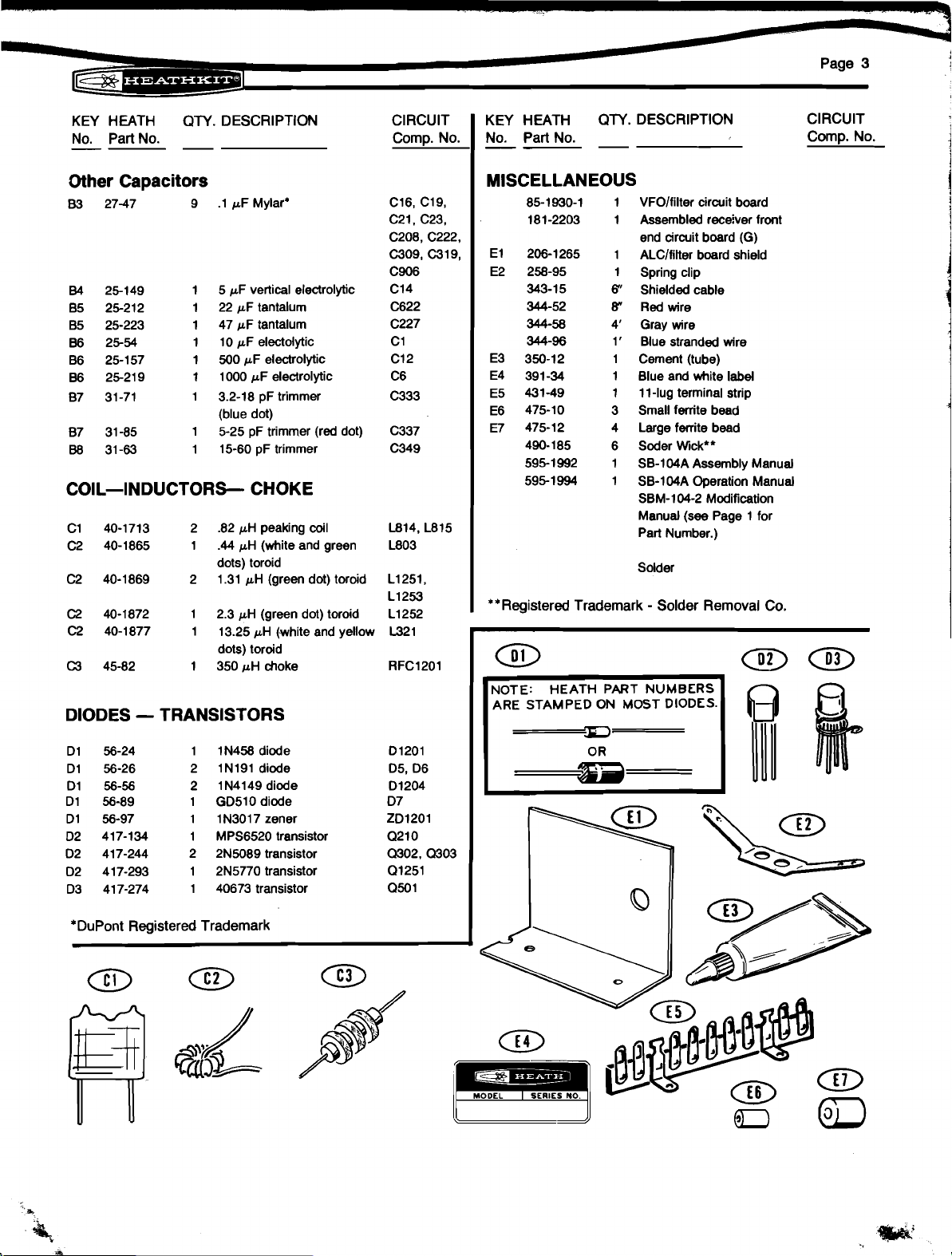

Other Capacitors

83

27-47 9

.I

pF

Mylar*

pF

vertical electrolytic

5

pF

tantalum

22

47

pF

tantalum

10

pF

electolytic

pF

electrolytic

500

1000

pF

electrolytic

3.2-18

pF

trimmer

(blue dot)

pF

5-25

15-60

trimmer (red dot)

pF

trimmer

COIL-INDUCTORS CHOKE

pH

C1 40-1713 2 .82

C2 40-1865 1

C2 40-1869 2 1.31

C2

40-1872 1 2.3

C2 40-1877 1 13.25

C3

45-82 1 350

peaking coil

.44

pH

(white and green

dots) toroid

pH

(green dot) toroid

pH

(green dot) toroid

pH

dots) toroid

pH

choke

(.white and yellow

cRculT

-

MISCELLANEOUS

85-1 930-1 1 VFOlfilter circuit board

181 -2203 1 Assembled receiver front

El 206-1265 1 ALClfiRer board shield

E2 258-95 1 Spring clip

343-15

344-52

344-58

344-96 1' Blue stranded wire

E3 350-12 1 Cement (tube)

E4 391-34 1 Blue and white

E5 431-49 1 1 1-lug terminal strip

E6 475-10 3 Small ferrite bead

E7 475-12

490- 185 6 Soder W~ck"

595-1992 1 SB-104A Assembly Manual

595-1994 1 SB-104A Operation Manual

**Registered Trademark -Solder Removal Co.

end circuit board (G)

6"

Shielded cable

8"

Red wire

4' Gray wire

label

4 Large ferrite bead

SBM-104-2 Modification

Manual (see Page 1 for

Part Number.)

Solder

Comp. No.

DIODES -TRANSISTORS

IN458 diode

IN191 diode

1 N4149 diode

GD510 diode

1 N3017 Zener

MPS6520 transistor

2N5089 transistor

2N5770 transistor

40673 transistor

*DuPont Registered Trademark

ARE STAMPED

ON

MOST DIODES.

Page 4

Page

4

p S L = . - - * = . - 5 + 9 J

MODIFICATION PROCEDURE

This modification kit contains all of the current mod-

ifications for your SB-104 transceiver.

To make a modification, check each component in the

following step-by-step assembly with the component

installed in your kit. If the component in your kit is

different from the one in this Manual, remove it from

your kit and install the new one at the location shown.

If

the component shown in the Manual is the same as

the one installed in your kit, disregard it and proceed

to the next step. Be careful when you remove a com-

ponent from a circuit board, or damage to the circuit

foil will occur.

When you make a chassis connection, the indicated

number of wires at the connection are shown in the

solder instructions. For example, when you connect a

wire to a solder lug where two wires are already

connected, the solder instructions will read

may be necessary to remove any excess solder from a

connection to make room for the new wire or component lead. Make sure you apply enough heat to the

connection so that solder flows to each wire or component lead.

Do not make any connections, or install any components or circuit boards, until you are instructed to do

so in a step.

When assembly or disassembly is required in a step,

refer to your

proper procedure.

SB-104A Assembly Manual for the

(S-3). It

Page 5

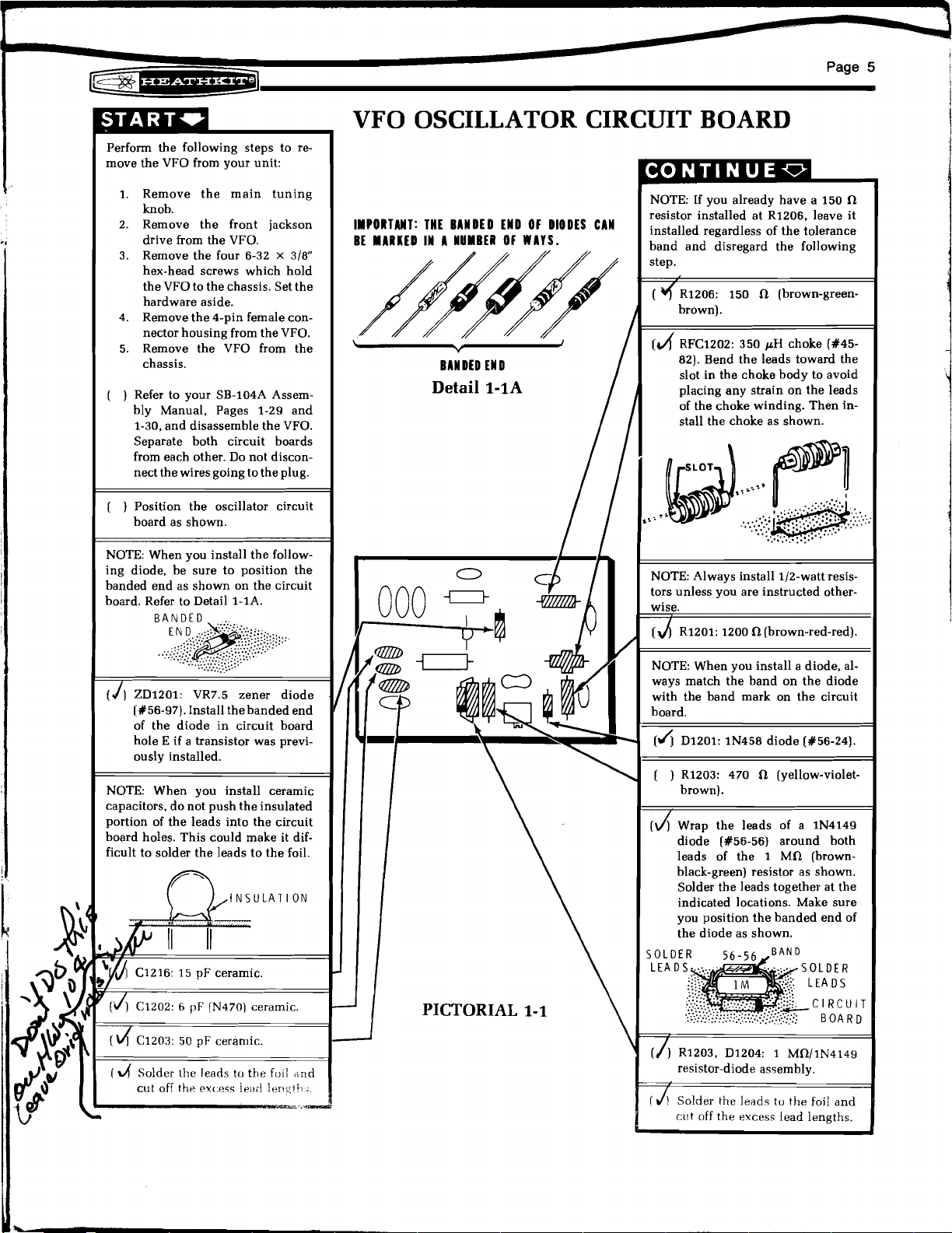

Perform the following steps to remove the VFO from your unit:

1. Remove the main tuning

2.

Remove the front jackson

drive from the VFO.

3.

Remove the four

hardware aside.

6-32 x 318"

VFO OSCILLATOR CIRCUIT BOARD

esistor installed at R1206, leave it

BANDED END

Detail

1-1A

i

1

1

of the diode in circuit board

E

if a transistor was previ-

hole

INSULATION

PICTORIAL

around both

1-1

Page 6

Page

6

(

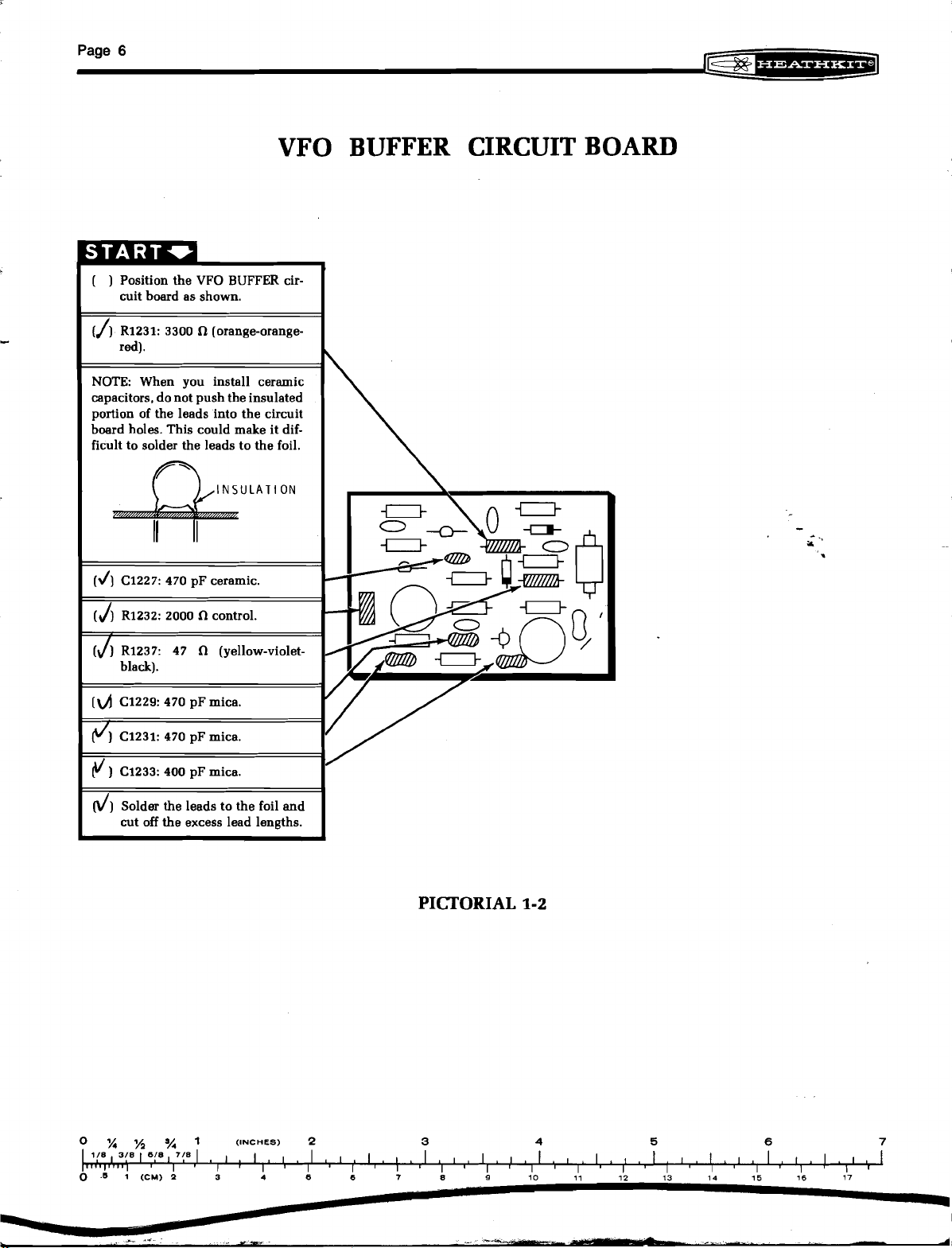

( )

Position the VFO BUFFER cir-

I

cuit board as shown.

(/)

R1231: 3300 (orange-orange-

red).

NOTE: When you install ceramic

capacitors, do not push the insulated

portion of the leads into the circuit

board holes. This could make it dif-

ficult to solder the leads to the foil.

VFO BUFFER CIRCUIT BOARD

I

I

@%

b=*==-*=*-aii

:

47 0 (yellow-violet-

)

C1233: 400 pF mica.

)

Solder the leads to the foil and

cut off the excess lead lengths.

PICTORIAL

1-2

Page 7

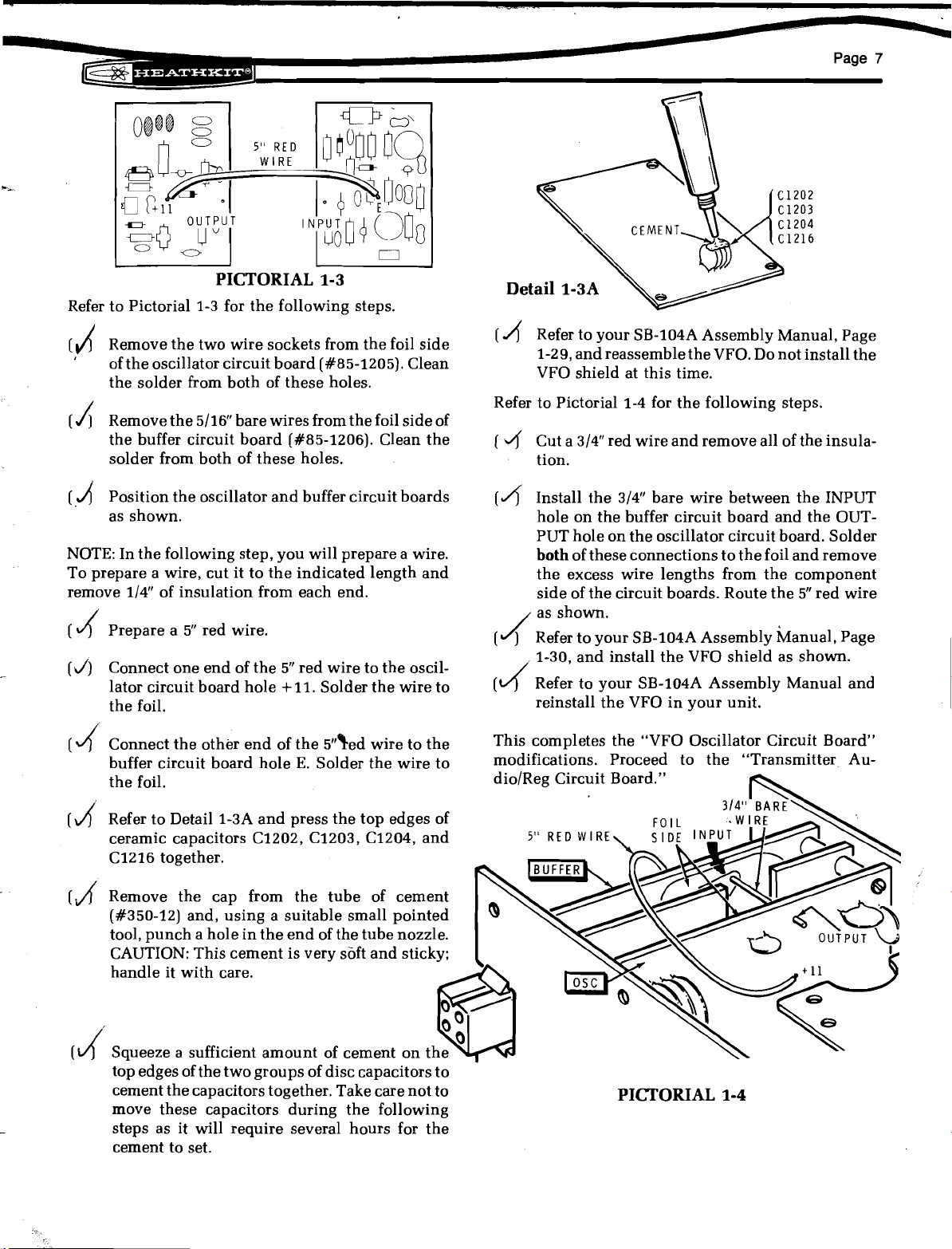

(

/r

()/J

Remove the two wire sockets from the foil side

of the oscillator circuit board (#85-1205). Clean

the solder from both of these holes.

(4

Remove the 5/16'' bare wires from the foil side of

the buffer circuit board (#85-1206). Clean the

solder from both of these holes.

(/r

Position the oscillator and buffer circuit boards

as shown.

NOTE: In the following step, you will prepare a wire.

To prepare a wire, cut it to the indicated length and

remove

(

4

-

(J)

114" of insulation from each end.

Prepare a 5" red wire.

Connect one end of the 5" red wire to the oscil-

lator circuit board hole +11. Solder the wire to

the foil.

Refer to your SB-lO4A Assembly Manual, Page

1-29, and reassemble the VFO. Do not install the

VFO shield at this time.

Refer to Pictorial 1-4 for the following steps.

(

i/j

Cut a 314" red wire and remove all of the insulation.

(4

Install the 314" bare wire between the INPUT

hole on the buffer circuit board and the OUTPUT hole on the oscillator circuit board. Solder

both

of these connections to the foil and remove

the excess wire lengths from the component

side of the circuit boards. Route the 5" red wire

J

as

(

)

Refer to your SB-104A Assembly Manual, Page

1-30, and install the VFO shield as shown.

Refer to your SB-104A Assembly Manual and

(4'

reinstall the VFO in your unit.

Connect the other end

buffer circuit board hole

the foil. dio/Reg Circuit Board."

Refer to Detail 1-3A and press the top edges of

ceramic capacitors C1202, C1203, C1204, and

C1216 together.

Remove the cap from the tube of cement

(#350-12) and, using a suitable small pointed

tool, punch a hole in the end of the tube nozzle.

CAUTION: This cement is very soft and sticky;

handle it with care.

Squeeze a sufficient amount of cement on t

top edges of the two groups of disc capacitors to

cement the capacitors together. Take care not to

move these capacitors during the following

steps as it will require several hours for the

cement to set.

of

the 5"yed wire to the

E.

Solder the wire to modifications. Proceed to the "Transmitter Au-

This completes the "VFO Oscillator Circuit Board"

5"

RED WIRE

@

-

PICTORIAL

1-4

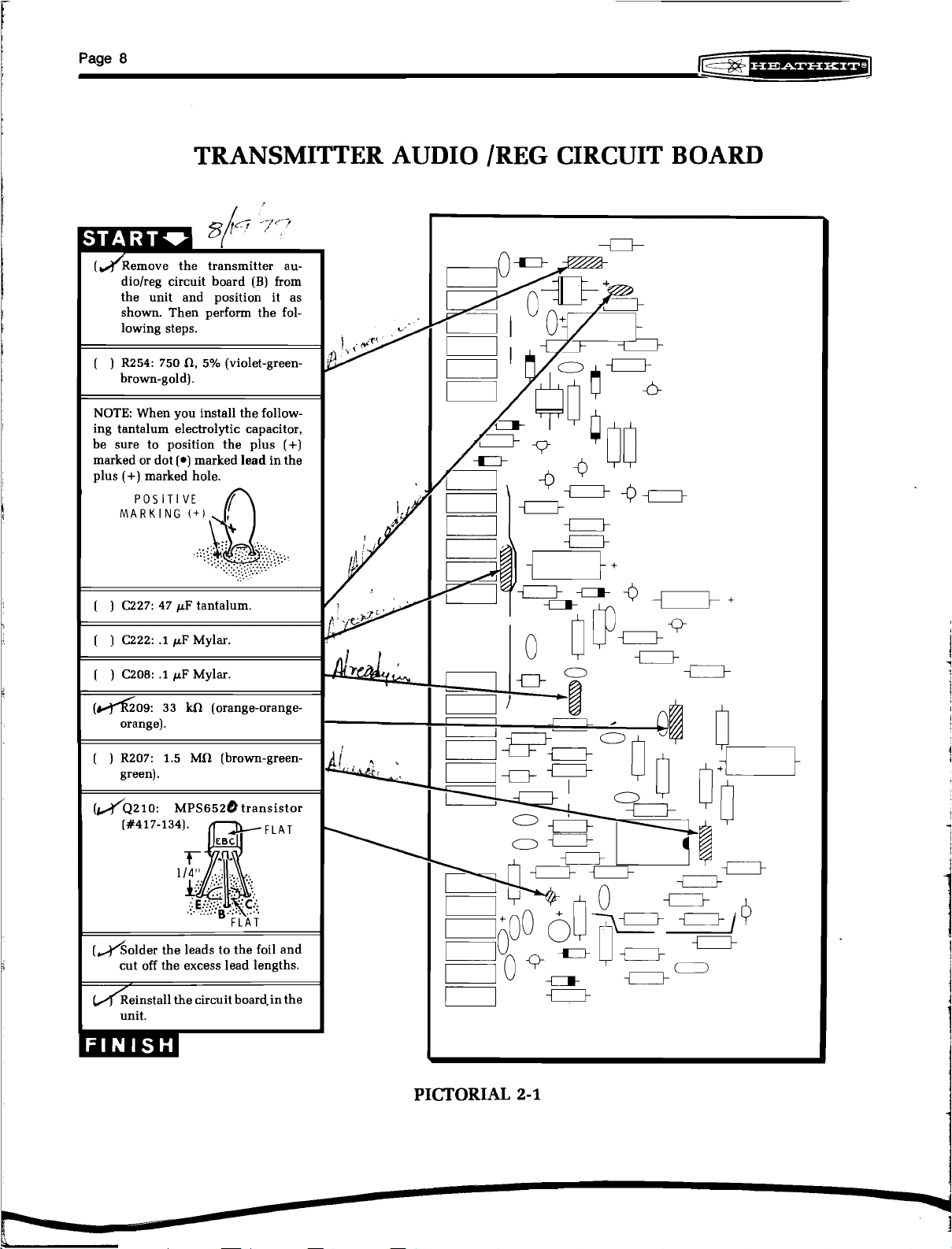

Page 8

Page

8

TRANSMITTER AUDIO /REG CIRCUIT BOARD

ing tantalum electrolytic capacitor,

be sure to position the plus

marked or dot

(+)

plus

(0)

marked

marked hole.

lead

(+)

in the

ircuit board-in the

PICTORIAL

2-1

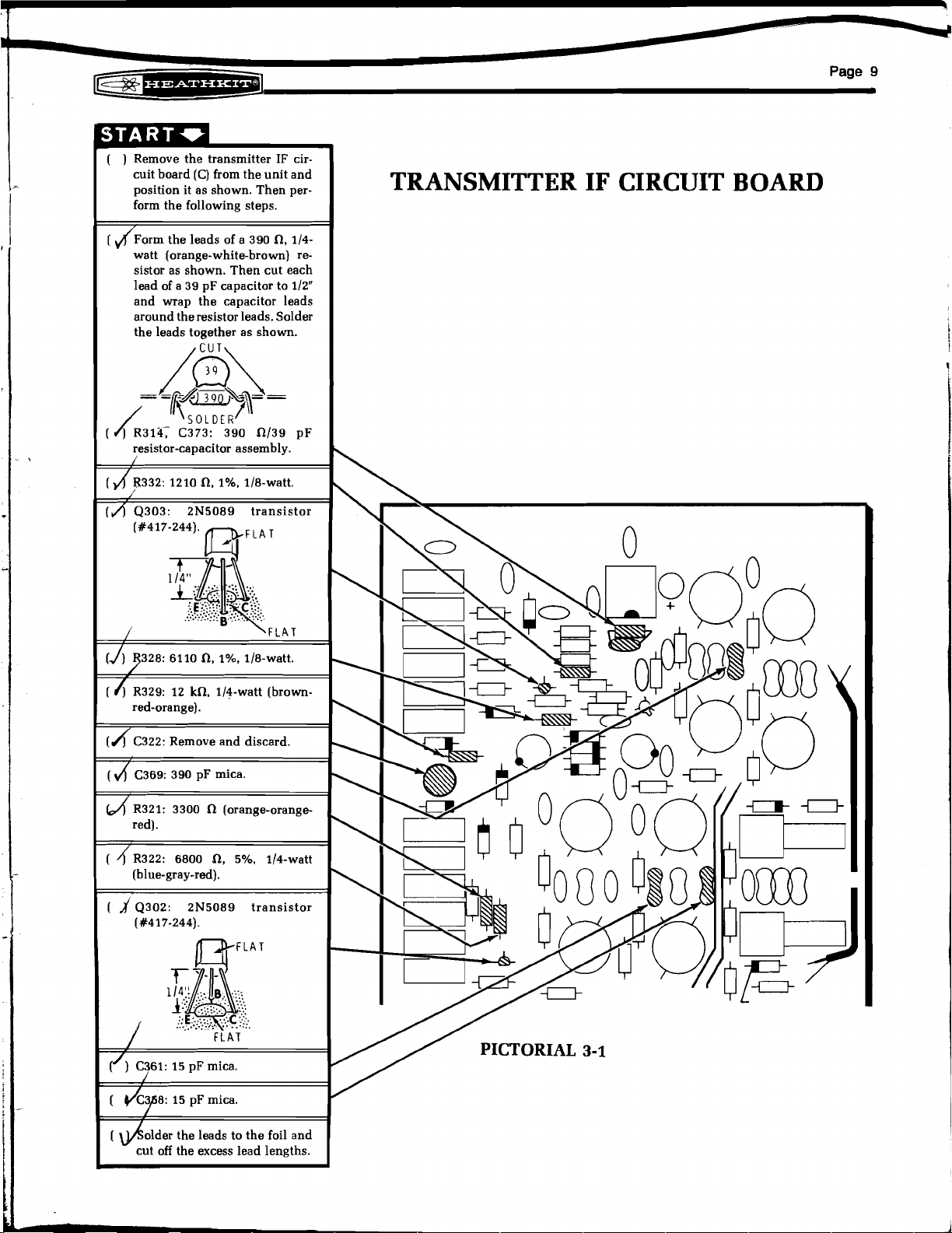

Page 9

LG

b=*==-=*=*'%j

)

Remove the transmitter

(

cuit board (C) from the unit and

position it as shown. Then per-

form the following steps.

[

d~ormthe leads of a 390

watt (orange-white-brown) re-

sistor as shown. Then cut each

lead of a 39 pF capacitor to 112"

and wrap the capacitor leads

around the resistor leads. Solder

the leads together as shown.

/CUT\

(4

R314: C373: 390 a139 pF

resistor-capacitor assembly.

/

[A

4303: 2N5089 transistor

IF

n.

cir-

114-

TRANSMITTER IF CIRCUIT BOARD

Page

9

/

(

/j

R329: 12 kn. 114-watt (brown-

red-orange).

(/J

C322: Remove and discard.

C369: 390 pF mica.

R321: 3300 (orange-orangered).

(

R322: 6800 n, 5%. 114-watt

(blue-gray-red).

(

i'

4302: 2N5089 transistor

(#417-244).

BFLAT

/

I

1

(/)

C361: 15 pF mica.

/

t

(

Jcye: 15 p~ mica.

FLAT

older the leads to the foil and

cut off the excess lead lengths.

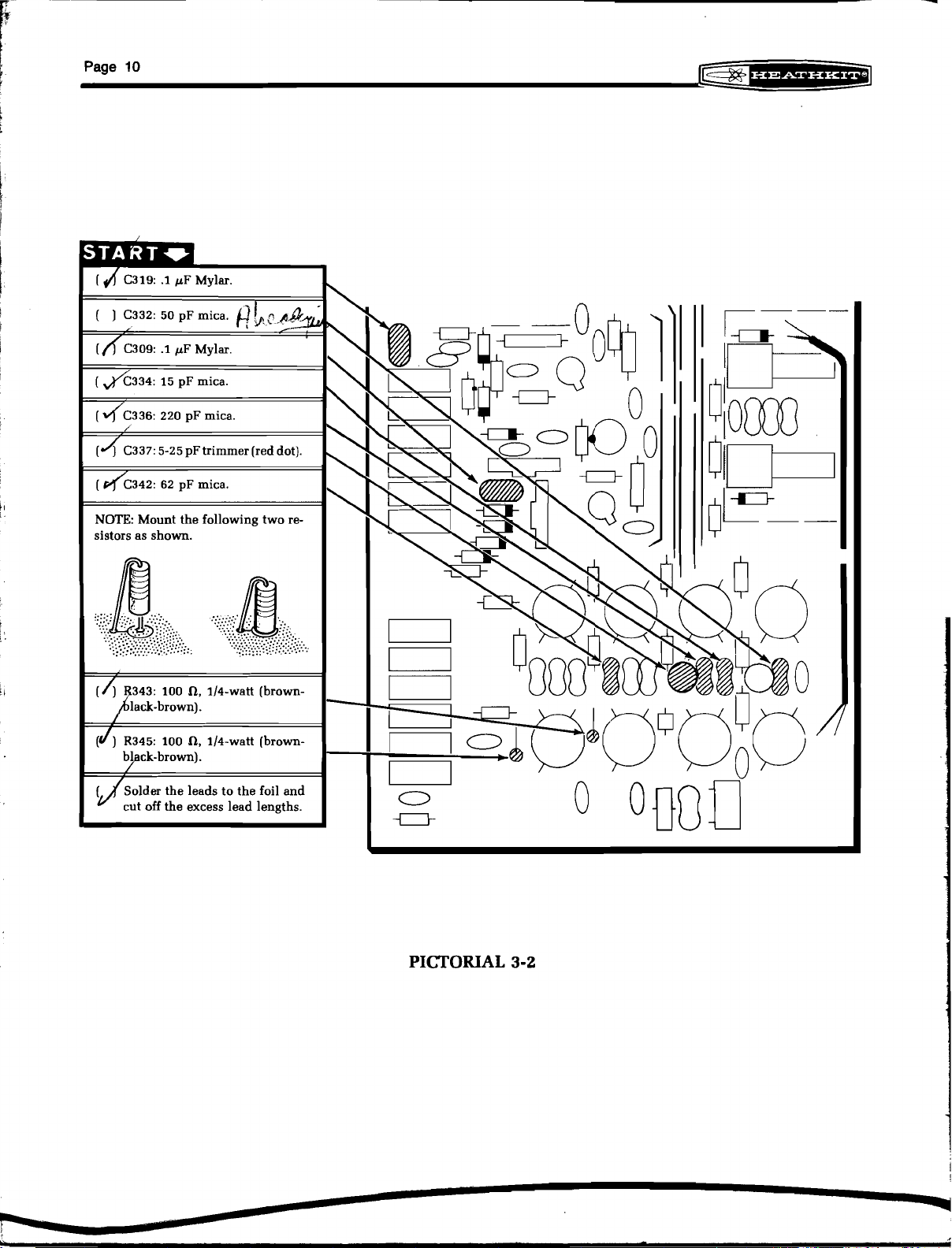

Page 10

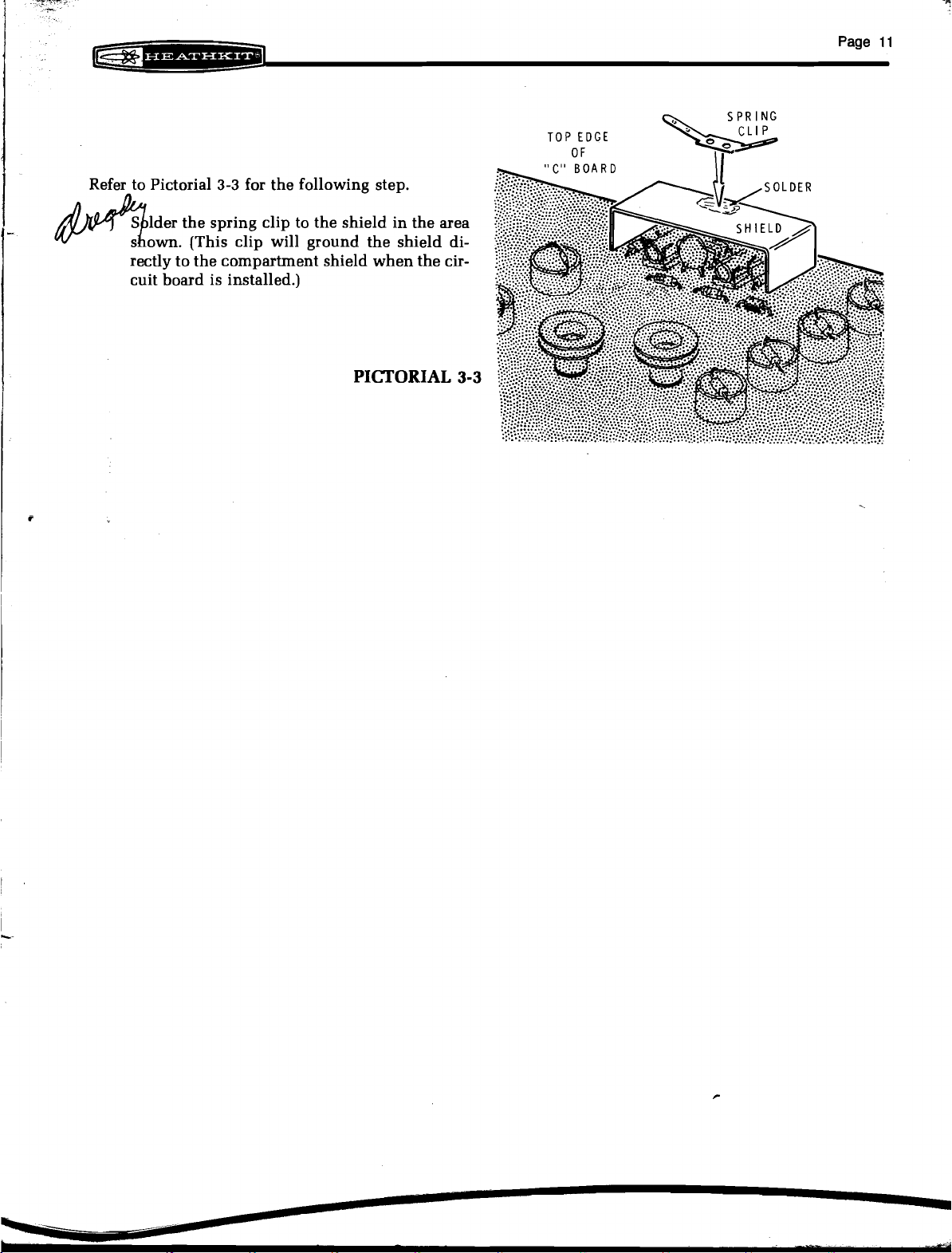

Page 11

TOP EDGE

0

F

SPRING

Page

11

Refer to Pictorial

3-3

for the following step.

lder the spring clip to the shield in the area

wn.

(This clip will ground the shield di-

rectly to the compartment shield when the cir-

cuit board is installed.)

PICTORIAL

3-3

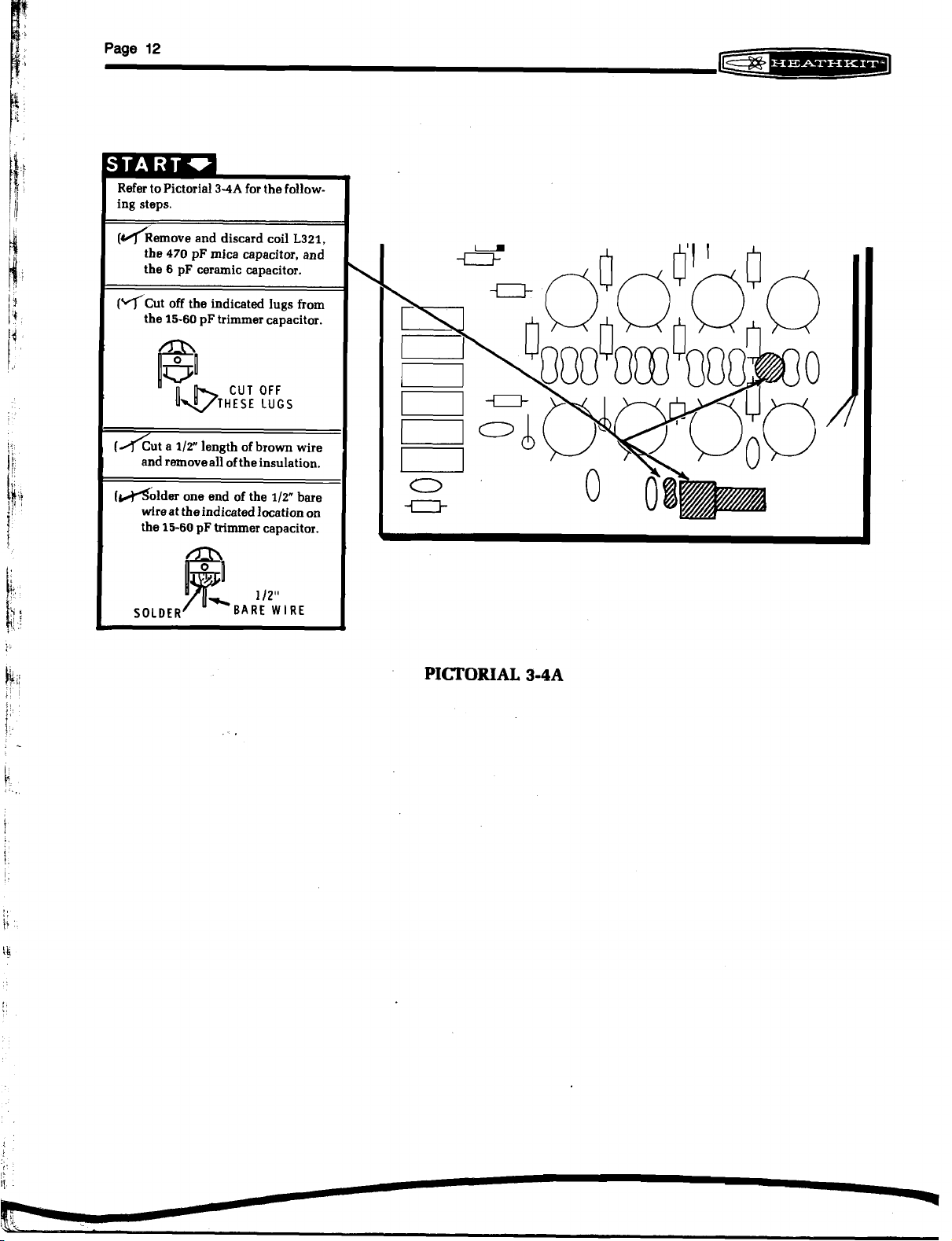

Page 12

Page

12

giiJ-dj

Refer to Pictorial

ing steps.

the 470 pF mica capacitor, and

the 6 pF ceramic capacitor.

the 15-60 pF trimmer capacitor.

(dut a 112" length of brown wire

and removeall of the insulation.

(Mblder

wireat the indicated location on

the 15-60 pF trimmer capacitor.

SOLDER

34A

for the follow-

CUT

OFF

one end of the 112" bare

BARE

W lRE

I

I

PICTORIAL

3-4A

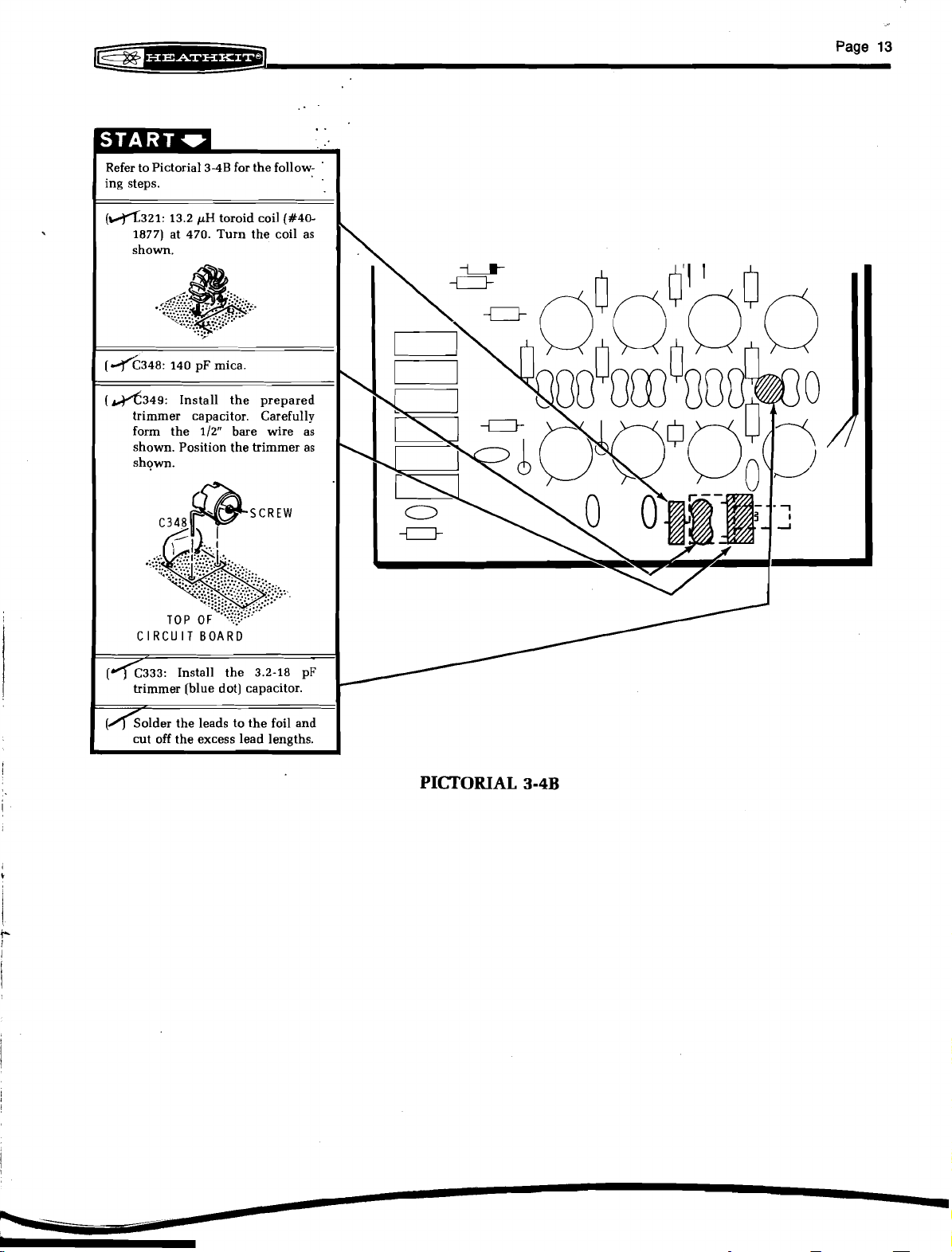

Page 13

dl1nja.re3 .xo)pede3 ~aurur!q

.z/r

aql urxoj

se aqm axeq

11n:,tr1:,

atrvoa

Page 14

Page

14

HFOlPREMIXER CIRCUIT BOARD

PICTORIAL

4-1

Page 15

Page

15

1

CARRIER GENERATORIXTAL FILTER CIRCUIT BOARD

PICTORIAL

5-1

Page 16

Page

16

NOTE:

If you have the optional

filter installed, perform the following steps.

(4~679:5600 R (green-blue-red).

(4~677:5600 R (green-blue-red).

[&'R684: 1000 R (brown-black-

red).

&w*Q

CW

(Lufnstall the circuit board in your

unit.

PICTORIAL

I

5-2

Page 17

r-1

RECEIVER IFIAUDIO CIRCUIT BOARD

I

SHORTING

SPRING

Page

17

circuit board

and ~osition

board. Insert the transistor leads

(see Detail

holes on the circuit board. Solder each lead to the foil and cut

(F)

from the unit

it

as shown.

6-1A)

into the correct

Page 18

Page

18

'm

I I

POWER AMPLIFIER CIRCUIT BOARD

(

/position the circuit board as shown.

318"

NOTE:

your unit, you will have either wires and ferrite beads

or

Depending on which PA circuit board is in

.51

R

resistors installed at holes A and B.

14"

Detail

. .

7-1

Refer to Pictorial

(i)

Remove the power amplifier circuit board from

your unit and remove the heat sink. Set the heat

sink aside. Be careful not to get any of the

ma1 compound on your clothing, since it is difficult to remove.

for the following steps.

7-1A

ther-

(4'

Remove each wire and ferrite bead, or both

R

(green-brown-gold-gold) resistors, from the

circuit board at holes A and B. Discard the wires

and ferrite beads, or resistors.

(d

Refer to Detail

2-watt (brown-green-silver-gold) resistors as

shown.

(/(

Install one prepared resistor on the circuit

board at hole A and the other prepared resistor

at hole

locations and cut off the excess lead lengths

from the foil side of the circuit board.

B.

7-1A

and prepare two

Solder each resistor at the indicated

.15

R.

.51

5%

PICTORIAL 7-1

Page 19

&#J===--,-==-@di

Page

19

Refer to Pictorial

)

Turn the power amplifier circuit board over

8-1

for the following steps.

(foil side up) and unsolder the wire at hole

(

)

Decrease the turns of wire, through the two

brass tubes, by one turn (five to four).

(

)

Route the wire back to hole Mand cut off the

excess wire length at that point. Discard the

excess wire,

0

0

-6

5/4

1

(INCHES)

I.I,l.I1l,I.I.I,I,I.l,l.l

1 (CM) 2 3 4 0 6 7

' I ~ I ~ I ~ I ~ I ~ I ~

2

PICTORIAL

(J]

AA.

(J)

I/

(

(

d

3

B

0

8-1

Prepare the free end of the wire and apply a

small amount of solder to the wire strands to

hold them together. Solder the wire to hole

Unsolder the wire at hole

AB

and repeat the

three previous steps.

/

)

Reinstall the heat sink on the circuit board.

)

Install the circuit board in your unit.

4

.l,l.l.l.l,I,I.I.I.I,

10 11 12 13 14 10 16 17

5

6

AA.

7

Page 20

Page 21

c-35

ALCIOUTPUT CIRCUIT BOARD

board

(K)

position it as shown.

Cut the wire from the top wafer

(

switch SWlC between lugs 12

an? 14.

/

ut a

and remove the insulation.

from your unit and

318"

length of gray wire

I

DETAIL 10-1A

Page

21

I

d~eferto Detail 10-IA and solder

318"

bare wire between wafer

the

PICTORIAL

10-1

Page 22

SZB?

,r

(

)

JO

aj!q d~eqs e asn

OMJ

aql le ~!oj aqlln3 pue

apelq rozeJ pa8pa-a18u!s

.suo!le~o~paleznpu!

:st81

aql Japlos

pea1 1!03 paa~n~

01

1!o3 pa~eda~d

1!0j aqlol

aql JaploS au~oqs se pnoq 1!n3~!3 aql jo ap!s

aql daa>~ .~!oj puno~8 aql

$1 leql os poj aql jo a8pa ap!su! aqlol asop peal

-u! 8u!mp s!sseq~ aql ql!~ aJapalu! lou saop

lsu!e%e 1q8!l dpoq 1!03 aql uo!~!sod .uo!leIlels

.pJeoq 1!n3~!3 aql

06

)

(

:r~83

sso~~e

\!OD

aql JaploS

vr87

pa~eda~d

aql uo!l!sod

~olpede:, e3!u1 ~d

gn3q3 aql jo ap!s 1!0j aq u~og

dpoq ~opede~ .u~oqsse p~eoq

.pJeoq l!n3~!3 aql lsu!e8e lq8!l

Page 23

L@@J=**--=*+El

VFOIFILTER CIRCUIT BOARD

Page

23

Position the VFOIfilter circuit boardp

(#85-1930-1) as shown and complete

the following steps.

NOTE: To prepare a length of wire,

cut it to the indicated length and remove 114'' of insulation from each

end.

(\n/prepare a 1-314'' gray wire. Re-

move an extra 114" of insulation

from either end of the wire.

Then insert the

end in hole

wire to the foil. The free end of

this wire will be connected later.

/

(4

L1253: Toroid coil (#40-1869).

C1254: 1000 pF mica.

114" stripped

D

and solder the

.

.

1

6~1255:

(drepare a 1-314" red wire. Then

1

(61253: 100

(

,&€1252:

(

d51: 22 k0 (red-red-orange).

(

Molder the leads to the foil and

(

4~1251: 2N5770 transistor

.O1

@F ceramic.

insert one end of this wire in

hole C and solder the wire to the

foil.will be The free end later. connected of this wire

0.

(brown-black-

brown).

.O1

@F ceramic.

cut off the excess lead lengths.

(#417-293). First lineup the flat

on the transistor with the outline of the flat on the circuit

board. Then insert the transistor

leads into their corresponding

holes indicated by E, B, and C.

Solder the leads to the foil and

cut off the excess lead lengths.

I

I

I

(4

L1252: Toroid coil (#40-1872).

(J)

C1253: 1000 pF mica.

)

L1251: Toroid coil (#40-1869).

(

(4

R1254: 100 R (brown-black-

brown).

(

1~1252:22

(9

C1251: 200 pF ceramic.

(

/)"solder the leads to the foil and

cut off the excess lead lengths.

(

]

Squeeze a little cement into the

centers of the three toroid coils

to affix them to the circuit

board.

kR

(red-red-orange).

Prepare a 6" shielded cable. Re-

(

move 314" of outer insulation

and 114" of inner insulation

from both ends of the cable.

(

XConnect the inner lead of the 6"

shielded cable to hole

shield lead to hole B. Solder

both leads to the foil and cut off

the excess lead lengths. The free

end will be connected later.

Proceed to "Installation of the New

VFOIFilter Circuit Board."

A

and the

I

Page 24

1

*ax

PI

01

IBU

T-ZT

1syol3!d

'3

saIOq le pmoq

su!d'pa

'~3

aql aoj

'A

'3

'a

'8a

'~a

'3

-u~oqsse s!sseq~ aql uo!l!sod

pue

pue '6a

.sdals

%U!MOIIOJ

'H

'OTC~

Y

x

aql aAomax

le pnoq

qn=a!= aalI!j/odA am uo saa? 6818 x!s aq In3

-!ma) )e saa? ~ea~am pmos!p pue anomax x!s

/

Y

€3

suld leu

g#

OM$

aql pue s~ams

'nv

pue

>nr

.A1!naodmal

-m

pm

PIO

Iepw laaqs peaq-xaq ,8/s

l!n3q3 aq moq saa~eds ,,8/~

ap!se aaeMpnq aql $as

-!maal moq saqM alqe3 paplays aql aap~osun

'pnoq l!n3~!3 J~~I!J/O~IA aql Pn3s!

Page 25

Page 26

Page

26

@%+-ii

i

CABLE

#3

PICTORIAL

13-1

Page 27

gg-T-2

CIRCUIT BOARD

I

I

#6

x518"

HEX HEAD

HEET METAL

SCREW

I

Page

27

Refer to Pictorial 13-1 for the following steps.

(

u)/~efer to Detail 13-1A and install the new circuit

board on the chassis. Use the two hex-head

sheet metal screws and the two 118" spacers that

you previously removed at AK and AM.

(A

Connect the free end of the 1-314'' red wire

ing from circuit board hole C to terminal pin Dl

(S-3).

Install a small ferrite bead on the free end of the

4''

[

1-314" gray wire coming from circuit board hole

D. Connect the wire with the ferrite bead to

terminal pin D4 [S-11.

Detail

corn-

13-1A

(

df

Disconnect the shield wire on shielded cable

#3 at terminal pin G3 and install a small ferrite

bead on the shield. Reconnect the shield to terminal pin G3 (NS). NOTE: It may be necessary

to remove an extra 114" of outer insulation from

the shielded cable to make the shield longer.

(Aonnect the inner lead of the shielded cable

coming from the VFOIfilter circuit board to

terminal pin G4 (S-3). Then install a ferrite bead

on the shield lead and connect the lead to terminal pin G3 (S-4). Dress shielded cable #3 as

shown.

This completes the "Installation of the New

ter Circuit Board." Proceed to "Chassis Changes."

VFOIFil-

Page 28

Page 29

Page

29

CHASSIS

discard the .33 R resistor con-

(

dconnect the positive

trolytic capacitor to transistor

Connect the other lead to phone jack

C14: Connect the positive

(4

vertical electrolytic capacitor to terminal strip

BE

lug 3 (S-4). Connect the other lead to lug

(

+Tf

your unit has a .1pF ceramic capacitor instal-

led between terminal pins C2 and C4, remove it.

-6:

Connect a .1 pF Mylar capacitor between

terminal pins C2 (S-3) and C4 (S-2).

(+)

lead of a 1000 pF elec-

42

(+)

lead of a 5 pF

lug B (S-2).

J2

lug

1

4

CHANGES

(

kC1: Connect the positive

electrolytic capacitor to terminal pin C7 (S-2).

Connect the other lead to solder lug AH (S-5).

(

4R22: Connect a

tween terminal pin D4 (S-2) and solder lug AL

(S-3).

(

d"

C19: Connect a

terminal pin Dl5 (S-3) and solder lug AN (S-2).

(

d"

C18: Connect a

tween terminal pin F8 (S-21 and the indicated

solder lug at AP (S-2).

(dC13: Connect a .001 pF ceramic capacitor be-

tween terminal pins F13 (S-3) and F15 (S-3).

J

(

)

R23: Connect a

tor between terminal pin G4 (S-3) and solder lug

AT (S-5).

C21: Connect a

terminal pins GI9 (S-2) and G21 (S-2).

Remove and discard the .lpF ceramic capacitor

(

/

between terminal pin K5 and solder lug

(/)

C15: Connect a .001 pF ceramic capacitor at

relay RY between lugs 10 (S-2) and ITS-3).

22

R

.1

pF Mylar capacitor between

.O1

47

R

.I

pF Mylar capacitor between

(+)

lead of a 10 pF

(red-red-black) resistor be-

WF ceramic capacitor be-

(yellow-violet-black) resis-

BJ.

(

&&4:

Connect a

terminal pin C6 (S-2) and solder lug AH (S-4).

Do not allow the lead of this capacitor, that is

connected to terminal pin C6, to touch the leads

of the .01 pF ceramic capacitor.

.1

pF Mylar capacitor between

(

/

)

C12: Connect the positive

electrolytic capacitor to terminal pin

Connect the other lead to phono socket CA lug

(S-3).

(+)

lead of a 500 pF

J1

(S-5).

2

Page 30

Page

30

ce

b=**-*=*=*]

Refer to Pictorial 14-2 for the following steps.

(

y)i

Unsolder the 3-314" gray wire at terminal pinK5

and slide the four large ferrite beads over the

wire as shown.

NOTE:

ferrite bead. Then, when you install the gray wire,

push the beads down against the chassis so the cement will hold them to the chassis.

(v)/

In the next step, apply a drop of cement to each

the

3-314" gray wire with the ferrite

byads to terminal pin K5 (S-1).

Connect a

RY between lugs 13 (S-3) and 14 (S-2).

Unsolder the end of the 5" orange wire at relay

RY lug

nal Jl), and reconnect the wire to terminal

(S-3).

.O1

pF ceramic capacitor at relay

11

(the other end is connected to termi-

H6

/

Unsolder the end of the 4" orange wire at termi-

(

)

nal

Jl

(the other end is connected to terminal

K3), and reconnect the wire to relay RY lug

(S-2).

Cut the ends of the two heavy orange wires,

(J)

coming from

(4)

Prepare the ends of two heavy orange wires and

reconnect them to terminal F19 (S-2). Shorten

the wires as necessary.

Refer to Pictorial 15-1 for the following steps.

(J)

Prepare a 10" gray wire.

Connect one end of the 10" gray wire to terminal

(J)

pin F7 (S-21, and route the other end through

grommet

BA.

BO

#5, at terminal

J1.

11

Page 31

c--=*~*g

i

Remove and discard the red wire connected

between terminal pins G2 and G13.

PICTORIAL 15-1

CONTROL

Page

31

Route the heavy orange wire coming from ter-

minal pin B2 to terminal pin G2. Cut the heavy

orange wire at the G2 junction and prepare the

two wire ends. Make sure you allow eqough

slack at both ends of the wire before you cut it.

Connect both orange wires to terminal pin G2

(S-2).

Refer to Detail

shown. Then connect the free end of the 10"

gray wire coming from grommet BA to rear

panel access socket CY pin 3 (S-1). Be careful

not to burn any insulation on the adjacent

wires.

15-1A and position the chassis as

Refer to Pictorial 16-1 for the following steps.

he two gray wires at control R2 lug

ove and discard the short gray wire con-

d to the control ground lug.

e the free end of the remaining gray wire

d connect it to the control

6.

Detail

repare a 5" gray wire.

PANEL

one end of the 5" gray wire to terminal

lug 3 (S-3). Connect the other end to

15-1A

Page 32

Page

p

32

c a J = ' * " *

CUT

=*:-4l]

I

SHIELD

WAFER

LI

ARD

Detail 16-3A

CW CRYSTAL WIDE AND NARROW MODIFICATIONS

Refer to Pictorial 16-3 for the following steps.

NOTE: When you complete the following modifica-

tions, the SSB filter will be enabled when

switch is out, and the CW filter will be enabled when

the90

(/f

Hz

switch is in.

Remove and discard the gray jumper wire between terminal pins E9 and E17.

the*^

Hz

PICTORIAL 16-2

Refer to Pictorial 16-2 for the following steps.

(A'

Position the chassis as shown.

/

(

i/

R11: Remove the 15 a,112-watt (brown-greenblack) resistor from S1 wafer A lugs

a,

Install a 15

1-watt resistor in its place.

1

and 3.

[

$'

Remove the white-orange wire at terminal pin

E9 and connect it to terminal pin El7 (S-2).

(A

Refer to Detail 16-3A and prepare the 11-lug

terminal strip as shown. Use diagonal cutters to

cut through the terminal strip insulator. Save

the indicated sections.

(

4

Remove the hex-head screw at chassis hole AM

and install the prepared 3-lug terminal strip as

shown.

1

(4

Install a IN4149 diode (#56-56) at terminal

strip AM between lugs

nect the banded end at lug 3.

(

4

Cut a 1-518" gray wire and remove all the insulation.

(J;/

Connect the 1-518" gray wire between terminal

strip AM lug 3 (S-2) and terminal pin El0 (S-2).

,--.

(

)

Remove the white-black wire from switch E lug

[

,

j

4 and connect it to switch ilug 6 (5-11.

2

(NS) and 3 (NS). Con-

Page 33

C-&---=*=@l

(

4

Remove the gray wire from switch E lug

move 314" of insulation from the wire end. You

will connect it later.

(

r)/~emove the jumper wire between switch E lug

and switch F lug

fl

Remove the two red wires from switch E lug

and reconnect them to switch F lug 2 (S-2).

(

4

Prepare two 1" gray wires.

(

/Connect one 1" wire to switch E between lugs

(S-1) and 6 (NS).

(~"~onnectthe remaining 1" wire to switch E be-

tween lugs

(

vf

Prepare a 7-112" gray wire.

(&,Connect one end of the 7-112" gray wire to

switch

minal strip AM lug

E

lug 6 (S-2) and the other end to ter-

5.

2

(S-1) and 5 (NS).

2

(S-2).

6.

Re-

1

Page

33

6

1

NOTE: When a wire passes through a connection and

then goes to another point, as in the next step, it will

count as two wires in the solder instructions (S-2),

one entering and one leaving the connection.

(

Lh/

Connect the gray wire, with the 314" prepared

end, to switch

4-w).

lug

(vj"Prepare the following gray wires:

(d

Connect one end of the 5"gray wire to switch

lug 3 (S-1) and the other end to terminal pin B14

(S-4).

(/connect one end of the 9-114" gray wire to

switch

nal pin E9 (S-2).

This completes the "CW Crystal Wide and Narrow

Modification." Proceed to "RFDetector Installation."

E

F

through lug 5(S-2) to switch E

cs-1)

E

lug 5(S-2) and the other end to termi-

PICI'ORIAL

16-3

;.

::

5

Page 34

Page

34

cm=*-+-*=*:*g

RF DETECTOR INSTALLATION

Re r to Pictorial 16-4 for the following steps.

Position the chassis as shown.

)

l

(d

Remove the 180 I1(brown-gray-brown)resistor

across the meter terminals.

Refer to Pictorial 16-5 for the following steps.

Position the chassis as shown.

4f'

(

(

d

Prepare a 2" gray wire. Remove an extra 114" of

insulation &omone end of the wire (112") total.

(

d

Connectthe 112"stripped end of the 2" gray wire

to switch B through lug 5(S-2)to switch A lug 6

(S-1). Connect the other end to switch C lug

(NS)

1

(d

Connect a 180

between switch Clug 5 (S-2)and switch

(NS)

(d

Prepare a 2-112" gray wire.

I1

(brown-gray-brown)resistor

,

PICTORIAL

5

D

lug 5

16-4

GRAY GRAY

S

0

Q

-

8

-

(L+

Connect one end of the 2-112" gray wire to

D

switch

E

lug 4 (S-2).

lug 5 (S-2)and the other end to switch

PICTORIAL

16-5

Page 35

Page

35

PICTORIAL 16-6

Refer to Pictorial 16-6 for the following steps.

(vfiosition the chassis as shown.

(

l.-+"?~isconnect the white-red wire at control Rls

lug

5

and prepare the end.

(

$/Refer to Detail 16-6A and connect the white-red

wire to switch

C

lug 2 (S-I).

S

69

/

WHT -RED

WIRE

Detail

16-6A

Page 36

Page

36

'fl~zGl

Refer to Pictorial

(

]

Remove the jumper wire at switch

2

lugs

(

)

Unsolder the red wire at switch D lug 5 and

reconnect it to lug

and

16-7

for the following steps.

5.

2

(S-2).

GRAY

PICTORIAL

D,

\\

[

16-7

)

Prepare a

Connect one end of the 2"gray wire to switch

)

lug

(S-3).

5

(S-1)

2"

gray wire.

and the other end to switch E lug

D

2

a

a

1/4

0

.6 1 (cu)

~ a

3/4

, 1 , (INCHES), ,

l ' l ' l ' l ' l ' l ' l ~ l ' ~ ~ ~ ~ ~ ' ~

a

3

2

1

, ~

4

6

6

3

1

7 a

,

,

B

4

I

I . l . I , I . l ~ I , I . 1 , r . I ~ ; I

10

9 9

5

12

13

14 16 16 17

6

7

Page 37

PICTORIAL 17-1

Page

37

Refer to Pictorial 17-1 for the following steps.

(

\/:

Remove both 1kfl (brown-black-red) resistor

leads at terminal pins GI3 and G15.

,

(

d'

Remove the 2" gray wire at terminal pin G24.

(

d'

Remove both leads of the shielded cable from

terminal strip AE lugs 2 and 3.

PICTORIAL 17-2

(JRemove and discard the 8.65 MHz trap (termi-

nal strip AE) from the chassis. Save the screw

but do not reinstall it at this time.

Refer to Pictorial 17-2 for the following steps.

Position the prepared 4-lug terminal strip as

(L:)

shown.

pF

a .01

lugs

1

(NS) and 2 (NS).

(d

Connect a 150 fl (brown-green-brown) resistor

between lugs 2 (NS) and 3 (NS).

Connect a

(NS] and 4 (NS).

(/connect the banded end of a IN191 diode

(#56-26) to lug 2 (NS) and the other end to lug 3

(NS).

(dconnect the banded end of a lNl9l diode

(#56-26) to lug 4 (NS) and the other end to lug 2

IS-4).

.1

pF

ceramic capacitor between

Mylar capacitor between lugs 3

the banded end of a 6D510 diode

(#56-89) to lug 3 (S-4) and the other end to lug 4

(NS).

Page 38

Page

p-

38

b=*---=*-&$jJ

1

PICTORIAL

Refer to Pictorial

(

J~emove the white-red wire from terminal pin

G5. (S-2).

(

hut a

tion.

Connect the

G5 [S-1)

17-3

for the following steps.

1-114"

gray wire and remove all the insula-

1-11'''

bare wire from terminal pin

to solder lug AT

(S-6).

/

(,/f

Reconnect the shield lead from the shielded

cable to terminal pin

inner lead to terminal pin

cable and prepare' the end as necessary.

(

d'

Mount the wired 4-lug terminal strip to chassis

hole AE with the screw you removed earlier.

/

(d

Connect the white-red wire, which you removed from terminal pin

AE

lug

4 (s-4).

NOTE: pull the white-red wire

through the wire harness if it is not long

enough.

,G23 [S-2).

G24 (S-1).

G5,

to terminal strip

Connect the

Cut the

17-3

6"

Prepare a

[

d~onnectone end to terminal strip AE lug

length of blue stranded wire.

I

NOTE: You will use the free end of the blue stranded

wire as a probe during the "Alignment" section. In

the following step, ''tack'' solder the connection since

the wire will be moved later.

(

vf

Connect the free end of the

wire to terminal pin

(

K~urn

the chassis over and install the new re-

ceiver front end circuit board

G5 (S-2).

6ff

blue stranded

(G)

in your unit.

This completes the "Chassis Changes." Proceed to

Pictorial

18-1.

s/,

1

0

1/4

I ' I ' l ' l ' l l l l ~ l ~ ~ I g ~ l l ~ ~ l

0

.s

1 (CM) 2 3 4

(INCHES)

2

5

6 10

3

4

11

5

12 13 14

6

15

16 17

7

Page 39

&

~=---~=*~d

Page

39

u

&e&

&3

u

o

\

END

OF

SWITCH SHAFT

I

I

II I

I

1

I

I

I

/'

Refer toPictoria1 18-1 for the following steps.

Position the chassis as shown.

(

d~oosenthe collar setscrew on the Band switch

shaft. Pull the shaft out so the end is in front of

the converter as shown.

(

Aemove the ALC circuit board from the chassis.

(

fiemove the driver circuit board from the right

side panel.

(/Remove the right side panel from the chassis.

Remove the converter hardware at BG and BH.

(li(

Position the ALClfilter circuit board shield

under the converter as shown. Then reinstall

the converter hardware at BG and BH.

(

d'

Reinstall the ALC circuit board and Band

switch shaft. Tighten the setscrewon the collar.

(

fleinstall the right side panel and the driver

circuit board on the chassis.

PICTORIAL

18-1

"

w

I

I

\

.s,

L//Mark your new Operation Manual so you per-

form the following adjustments after the "Low

Power Transmitter Check" but before the "CW

Check."

This completes the SBM-104-2 modifications. Proceed to the SB-104A Operation Manual VFO Adjustment section and perform the balance of the "Alignment Procedure."

Page 40

Page

40

t ~ ~ ~ = m

/

Fifteen Meter Power Adjustment

Unplug circuit board C from compartment CC.

(1

)

Then plug your extender board into compartment CC.

0)

Plug circuit board C into the extender board.

(

J

)

Set the BAND switch to 21.0.

(

)

Depress the ON, ALC, and USB buttons. Be sure

the HI button is released.

(J

)

Refer to the inset drawing on Pictorial 19-1 and

preset trimmer capacitor C349 to maximum

capacity (silver portion positioned as shown).

Tune the Transceiver to 21.250.

(

/

)

( J )

Rotate the MIClCW LEVEL control fully

clockwise.

Push the TUNE button and adjust trimmer C333

[I

1

.

.

on circuit board C for maximum meter indica-

tion. Use the MIC/CW LEVEL control to keep

the meter near midscale.

PICTORIAL

(

(

Twenty Meter Power Adjustment

(

(

(

(,)

(

(I/

( v )

19-1

Check the meter indications at 21.0 and 21.450.

4

If the two indications are not the same, readjust

trimmer (2333 a small amount until the indica-

tions are the same.

Release the TUNE and On buttons.

d')

Set the BAND switch to 14.0.

)

Depress the

i)

the HI button is released.

/)

Tune to 14.12.

Rotate the MICICW LEVEL control fully

clockwise.

1)

Push the TUNE button and adjust trimmer C337

on circuit board C for a maximum meter indica-

tion. Use the MIClCW LEVEL control to keep

the meter near midscale.

Release the TUNE button.

)

Depress the PWR and TUNE buttons.

ON,

ALC, and USB buttons. Be sure

Check the meter indications at 14.0 and 14.350.

(

Release the TUNE button.

(

d

)

Depress the PWR and TUNE buttons. tions are the same.

(

J)

j)

If

the two indications are not the same, readjust

trimmer

C337

a small amount until the indica-

Page 41

Page

41

a--=q

PICTORIAL

Release the TUNE and ON buttons.

(

i

( )

Unplug the circuit board C from the extender

board. midrange.

Remove the extender board.

(

-

1

NOTE: When you install the circuit board in the next

step, push down each end of the spring clip mounted meter.

to the coil shield until the board is completely seated.

[

Plug circuit board C into its compartment. Visually check to make sure the peaking coils do

not touch the metal shield. If necessary, bend

them over enough to clear the shield.

Ten Meter IFlPredriver Filters

(

4

Make sure your dummy load is connected to the

ANT socket.

NOTE: The coil adjustments in the following steps

should not require tuning the coil slugs more than 114

turn from the factory setting. Be sure to correctly

identify each coil before inserting the alignment tool.

Be sure the meter drops to 0 when the LEVEL control

is fully counterclockwise.

(4

Depress the ALC and ON buttons.

19-2

NOTE: During the following coil adjustments, the

ALC indication will vary with the setting of the

MlCICW LEVEL control. Keep the meter reading at

(4

Depress the TUNE button.

(

4

Adjust coil L310 for a peak indication on the

(

4

Release the TUNE button.

(

4

Turn the BAND switch to 29.0 and tune the

Transceiver to 29 100.

(4'

Depress the TUNE button.

(

4'

Adjust coil L319 for a peak indication on the

meter.

(

4

Release the TUNE button.

(4

Turn the BAND switch to 29.5 and tune the

Transceiver to 29 600.

(A

Depress the TUNE button.

(4

Adjust coils L309 and L320 for a peak indication on the meter. Repeat the adjustment until

no higher reading can be obtained.

Refer to Pictorial 19-2 for the following steps.

(

4

Turn the>BAND switch to 28.0.

I

4

Tune the Transceiver to 28 100.

(4

Repeat the foregoing series of steps two or three

times until you are sure the maximum reading

has been obtained.

(4

Release the TUNE and ON buttons.

Loading...

Loading...