Heat & Glo LifeStyle WS-250, WS-150 User Manual

Models:

Installers Guide

WS-150

WS-250

This manual contains instructions for:

Installation Operation Maintenance

- PLEASE READ ALL OF THE OWNERS MANUAL AND SAFETY NOTES -

IMPORTANT SAFETY NOTES:

1. When installing your stove, particular attention

should be paid to fire protection. If this unit is not

properly installed, a house fire may result. For

your safety, follow the installation instructions and

contact local building or fire officials about restrictions and installation inspection requirements in

your area.

2. Never use gasoline or similar liquids to start a fire

in this unit. Keep all such liquids well away from

stove.

3. During operation, if any part of the stove starts to

glow, the stove is in an overfired condition. Close

the air controls completely until the glowing has

stopped. OVERFIRING VOIDS WARRANTY.

4. Cool ashes should be disposed of carefully, using

a metal container.

5. Do not burn wet or green wood. Store wood in dry

location.

6. Do not burn garbage, treated wood, or wood with

salt (driftwood, etc.). Burning materials other than

wood (including charcoal) under adverse conditions

may generate carbon monoxide in the home, resulting in illness or possible death.

7. Do not permit creosote or soot to accumulate excessively in the chimney or inside the firebox.

8. Check your chimney system thoroughly when installing into an existing metal or masonry chimney. Seek

professional advice if in doubt about its condition.

9. Do not connect this unit to a chimney flue already

serving another appliance.

10. Comply with all minimum clearances to combustibles

as shown in this manual for this appliance.

11. Build fire on brick firebox floor. Do not use grates,

andirons or other methods to support fuel.

12. HOT WHILE IN OPERATION. Keep children, pets,

clothing and furniture away. Contact can cause skin

burns.

13. Do not connect to any air distribution duct or system.

14. RISK OF FIRE! Do not operate with stove door open.

15. For further information refer to NFPA 211 (U.S.) or

CAN/CSA-B365 (Canada).

16. WARNING: WHEN ASSEMBLING APPLIANCE, USE

ONLY HEAT-N-GLO PRODUCTS MANUFACTURED

COMPONENTS. USE OF ANY OTHER COMPONENTS WILL VOID YOUR WARRANTY AND COULD

PRESENT A SERIOUS SAFETY HAZARD.

17. WARNING: DO NOT OPERATE YOUR WS-150 or

WS-250 STOVE BEFORE FULLY ASSEMBLING ALL

COMPONENTS.

Printed in U.S.A. Copyright 2000,

Heat-N-Glo, a division of Hearth Technologies Inc.

20802 Kensington Blvd., Lakeville, MN 55044

Please contact your Heat-N-Glo dealer with any

questions or concerns. For the number of your

nearest Heat-N-Glo dealer, please call 952-985-6000.

1

396-980D 7/00

FOR FUTURE REFERENCE

ATTACH YOUR SALES RECEIPT HERE

Serial No.:

Date Purchased:

- NOTES -

Dealership Where Purchased:

Dealer Phone No.:

2

TABLE OF CONTENTS

DIMENSIONS .......................................................................................................... 4

CLEARANCES TO COMBUSTIBLES ..................................................................... 6

SAFETY LISTING .................................................................................................... 7

INSTALLATION MATERIALS NEEDED ................................................................... 7

VENTING SYSTEM ................................................................................................. 7

CHIMNEY CONNECTOR ........................................................................................ 8

CHIMNEY HEIGHT/DRAFT ..................................................................................... 8

CONNECTION TO A MASONRY CHIMNEY ............................................................ 8

INSTALLATION USING MASONRY OR BRICK CHIMNEY ...................................... 11

CONNECTION TO A METAL PREFABRICATED CHIMNEY .................................... 13

DOOR INSTALLATION ............................................................................................ 14

MOBILE HOME INSTALLATION .............................................................................. 15

LEG KIT INSTALLATION.......................................................................................... 15

OUTSIDE AIR KIT ................................................................................................... 16

OPTIONAL BLOWER ............................................................................................. 17

ASH REMOVAL SYSTEM ........................................................................................ 18

OPERATING INSTRUCTIONS ................................................................................ 19

Burning process ......................................................................................... 19

Primary and secondary air systems ........................................................... 19

Wood selection and storage ....................................................................... 20

Overfiring .................................................................................................... 20

Building a fire .............................................................................................. 20

Burning guidelines ...................................................................................... 21

MAINTENANCE ....................................................................................................... 22

Creosote ..................................................................................................... 22

Care and cleaning of glass ......................................................................... 22

Chimney cleaning ....................................................................................... 22

Ash removal ................................................................................................ 22

Firebrick ...................................................................................................... 22

GLASS REPLACEMENT......................................................................................... 23

DOOR HANDLE ASSEMBLY .................................................................................. 23

BAFFLE REMOVAL AND INSTALLATION ................................................................ 24

BRICK INSTALLATION ............................................................................................ 25

ACCESSORIES AND SERVICE PARTS ................................................................ 26

WARRANTY ............................................................................................................ 27

3

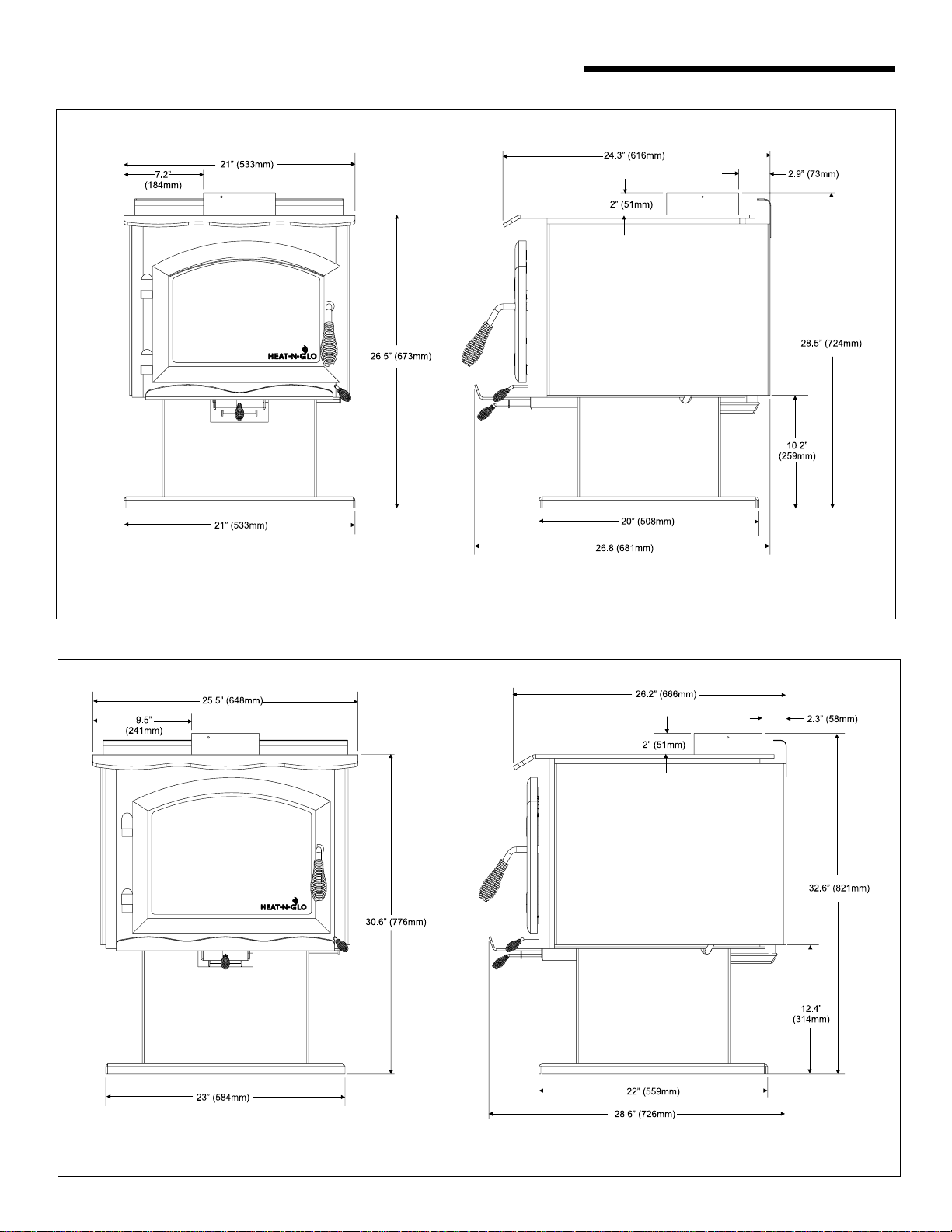

DIMENSIONS OF MODELS WS-150 AND WS-250

WITH PEDESTAL

FIGURE 1. WS-150 with Pedestal

FIGURE 2. WS-250 with Pedestal

4

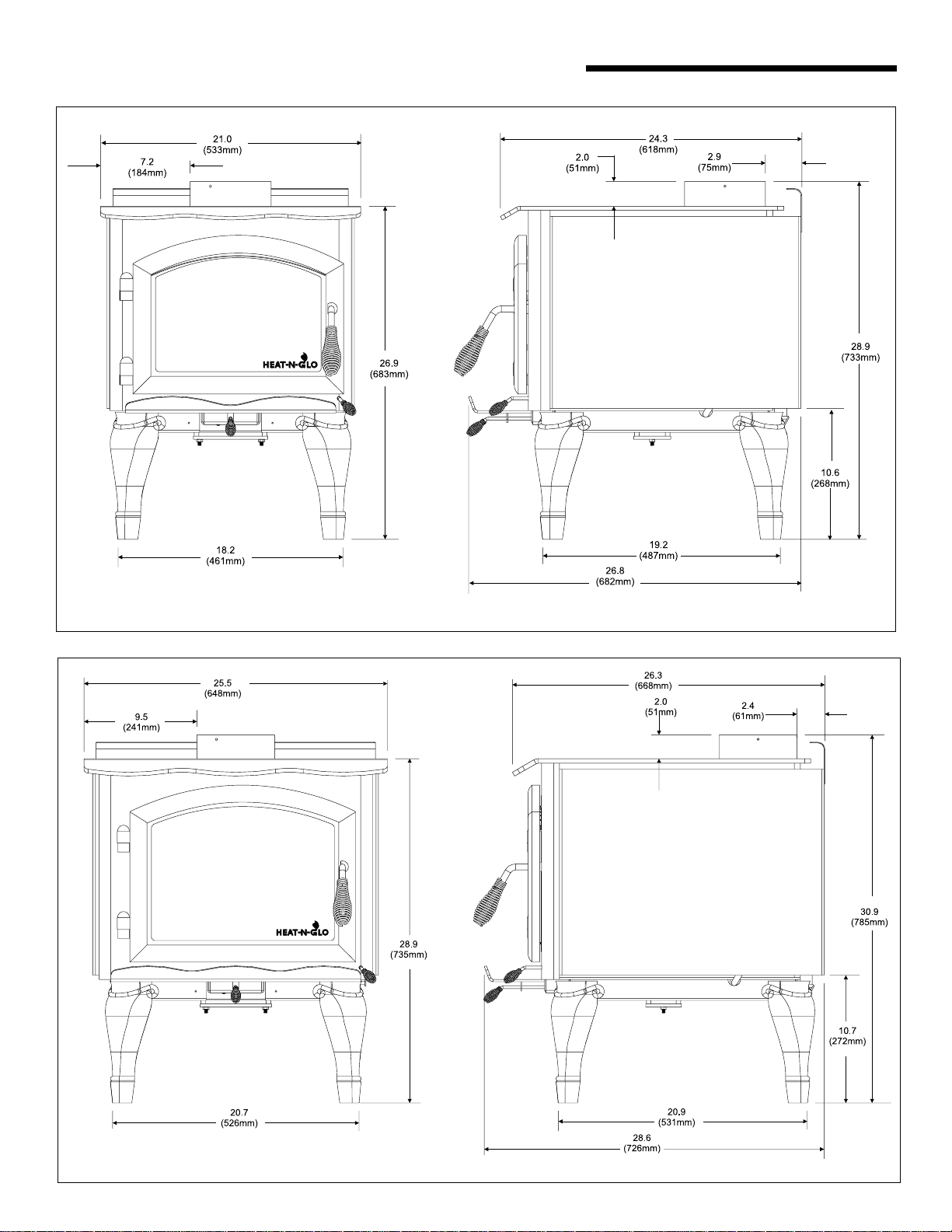

DIMENSIONS OF MODELS WS-150 AND WS-250

WITH LEGS

FIGURE 3. WS-150 with Legs

FIGURE 4. WS-250 with Legs

5

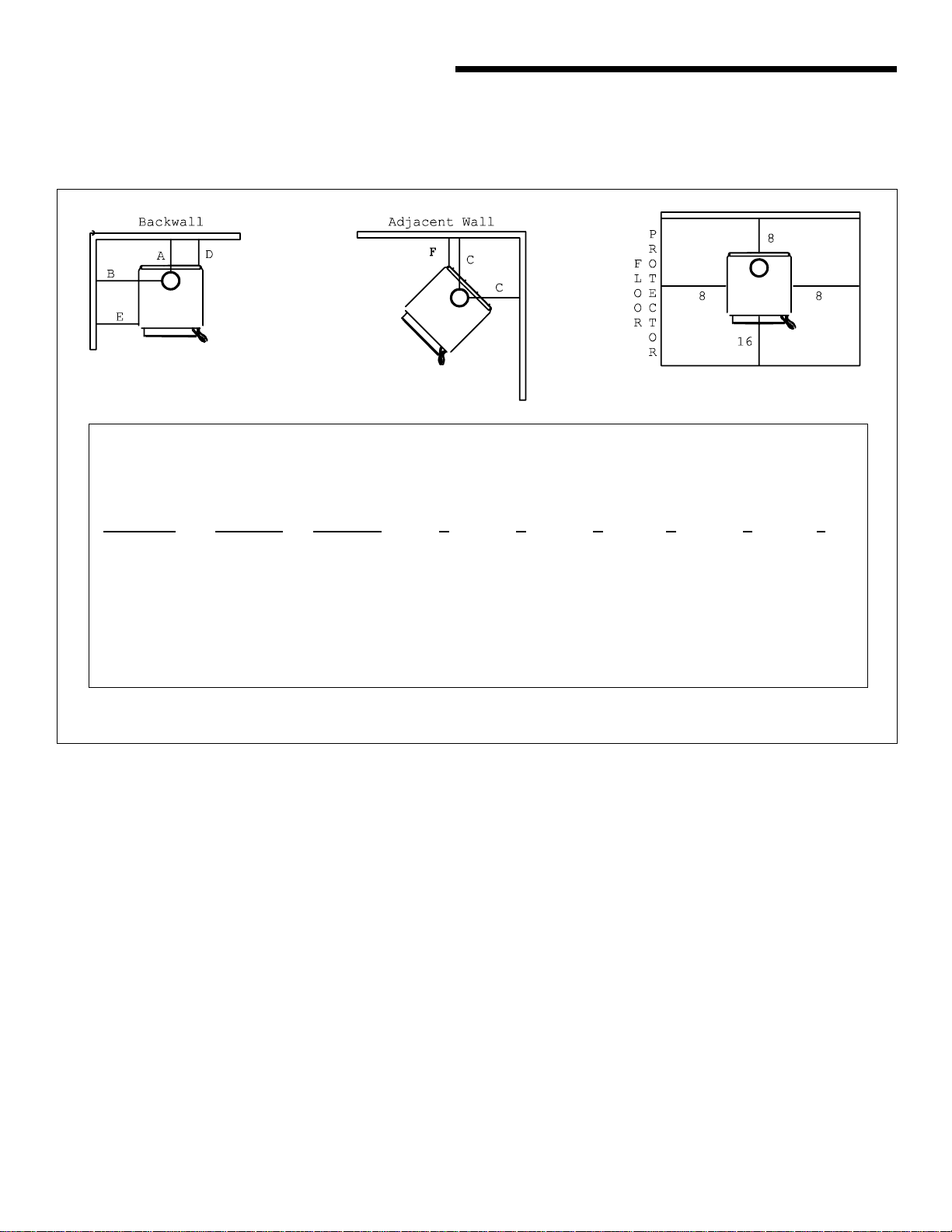

CLEARANCES TO COMBUSTIBLES

Floor protector must be 3/8 (10mm) thick minimum

noncombustible material or equivalent, extending

beneath heater and to the front/sides/rear as indicated

in the Floor Protection (See Figure 5).

Minimum clearances to Combustible Materials

(in inches and millimeters)

Installation Clearance Connector A B C D E F

Chimney &

Residential Standard Note 1 14" 26" 18" 12" 18" 10"

(356) (661) (457) (305) (457) (254)

Residential/ Reduced Note 2 12" 26" 16" 10" 18" 8"

Mobile Home (305) (661) (406) (254) (457) (203)

Alcove Standard Note 2 & 3 12" 26" N/A 10" 18" 8"

(305) (661) N/A (254) (457) (203)

FIGURE 5. Clearance to Combustibles (UL AND ULC)

Note 1: 6" (152mm) diameter single wall, minimum

24 MSG black or blued steel connector pipe with a

listed factory-built type HT chimney suitable for use

with solid fuels or a masonry chimney.

Note 2: 6" (152mm) diameter double wall air cooled

connector pipe with listed factory-built type HT chimney or a masonry chimney. (Mobile home venting system must be equipped with a rain cap and spark arrestor.) For installations with a preexisting class A

chimney system, a listed stainless steel chimney liner

should be installed, or the existing chimney examined by a chimney sweep for acceptable further use.

Note 3: Alcove specifications: Maximum depth of alcove shall be no more than 48" (1219mm). For additional alcove information and clearances, refer to

clearances to combustibles above.

NOTE: Unit is approved for use with listed double wall

air-insulated chimney connector or elbows.

When locating your stove consider safety, convenience, traffic flow, and the fact that the stove will need

a chimney and chimney connector.

NFPA 211: Use a noncombustible material with 1

(25mm) ventilated air space to reduce clearances.

However, this is not to exceed 50% of WS-150s (or

WS-250s) specified clearances.

NOTE: Must follow NFPA 211 spacing and materials

to qualify. It is also subject to local jurisdiction.

AVOID FIRE: Maintain the designated clearances to

combustibles. Insulation must not touch the chimney.

You must maintain the designated air space clearance around the chimney. This space around a chimney is necessary to allow natural heat removal from

the area. Insulation in this space will cause a heat

buildup, which may ignite wood framing.

6

SAFETY LISTING

The WS-150 AND WS-250 are approved for mobile

home installations with outside combustion air in the

U.S. (See page 14 for further details). For residential

installations in Canada without an outside combustion air kit, a source of fresh air into the room must be

provided.

detector manufacturers placement and installation instructions, and be sure to maintain regularly.

2. A conveniently located Class A fire extinguisher

to contend with small fires resulting from burning

embers.

3. A practiced evacuation plan, consisting of at least

two escape routes.

INSTALLATION MATERIALS NEEDED

FOR YOUR SAFETY

CHIMNEY CONNECTOR (also known as flue pipe

or stove pipe): The chimney connector joins the stove

to the chimney (see page 11). It should be 6" (152mm)

minimum diameter 24 MSG black or blued steel, or

an approved air-insulated double wall venting pipe.

THIMBLE: A manufactured or site-constructed

device installed in combustible walls through

which the chimney connector passes to the chimney (see pages 11-12). It is intended to keep the

walls from igniting.

CHIMNEY SYSTEMS

A. APPROVED MASONRY (see specifications on

pages 12-13) with at least 5/8" (16mm) fire clay

lining joined with refractory cement or other listed

system suitable for use with wood stoves.

B. PREFABRICATED 6" (152mm) listed high tem-

perature (UL 103HT or ULC 629M) chimney. Components required by manufacturers for installation such as the chimney support base, firestop

(as appropriate), attic insulation shield, insulated

tee, etc., are necessary to assure a safe chimney installation. Use only components manufactured for the chimney. Chimney installation should

meet NFPA 211 standards.

4. A plan to deal with a chimney fire as follows: In

the event of a chimney fire:

A. Notify fire department

B. Prepare occupants for immediate evacuation.

C. Close all openings into the stove.

D. While awaiting fire department, watch for ig-

nition of adjacent combustibles from overheated stove pipe, hot embers or sparks

from the chimney.

VENTING SYSTEM

The venting system consists of a chimney connector

and a chimney. These get extremely hot during use.

In the event of a creosote fire, temperatures inside

the chimney may exceed 2000°F (1100°C). To protect against the possibility of a house fire, the chimney connector and chimney must be properly installed

and maintained. An approved thimble must be used

when a connection is made through a combustible

wall to a chimney. A chimney support package must

be used when a connection is made through the ceiling to a prefabricated chimney. These accessories

are absolutely necessary to provide safe clearances

to combustible wall and ceiling material. Follow venting manufacturers clearances when installing venting system.

FIRE SAFETY: To provide reasonable fire safety, the

following should be given serious consideration:

1. Install at least one smoke detector on each floor

of your home to ensure your safety. They should

be located away from the heating appliance and

close to the sleeping areas. Follow the smoke

This stove may be connected to a lined masonry

chimney or a listed high temperature prefabricated

approved metal chimney. Do not connect it to a chimney serving another appliance. To do so will affect the

safe operation of both appliances.

7

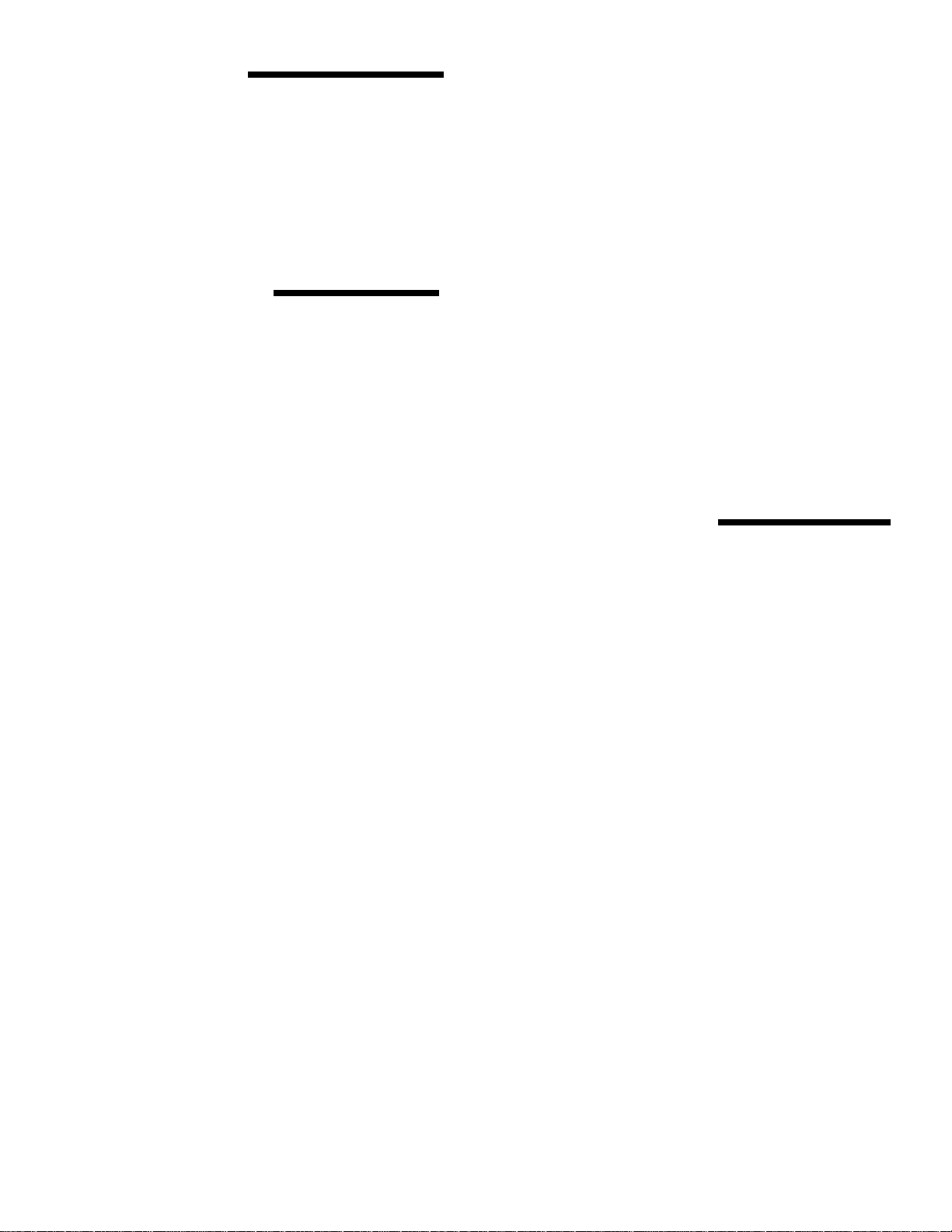

CHIMNEY CONNECTOR

The chimney connector must be 6" (152mm) diameter with a minimum thickness of 24 gauge. Do not

use aluminum or galvanized steel. They cannot properly withstand the extreme temperatures of a wood

fire. Do not use chimney connector pipe as a chimney. You must connect your stove to a chimney comparable to those illustrated in this manual.

Chimney connector sections must be attached to the

stove and to each other with the crimped end toward

the stove (see Figure 6). This allows creosote to run

into the stove and not onto the outside of the pipe.

Attach the chimney connector to the flue collar with

three sheet metal screws. All joints should also be

secured with three sheet metal screws. Otherwise,

in the event of a creosote fire, the connector may vibrate apart.

measured from the top of the stove. The further your

stack height or diameter varies from this configuration,

the probability of performance problems increases.

In addition, exterior conditions such as roof line,

surrounding trees, prevailing winds and nearby hills

can influence stove performance.

CONNECTION TO A MASONRY

CHIMNEY

1. CHIMNEY:

Should the stove be connected to a masonry

chimney, the chimney should be examined for cracks,

loose mortar, or other signs of deterioration and

blockage. The stove should not be installed until it is

determined that the chimney is safe for use. Since

an oversized flue contributes to the accumulation of

creosote, the size of the flue should be checked to

determine that it is not too large for the stove. The

chimney should also be checked to insure it meets

the minimum standards of the National Fire Protection

Association (NFPA) Standard 211. Following is a list

of the more critical minimum requirements for a

properly constructed chimney.

FIGURE 6

For proper operation, the chimney connector should

be as short as possible. Horizontal lengths of chimney

connector should have a minimum upward slope from

the stove of at least ¼" per foot.

CHIMNEY HEIGHT/DRAFT

To insure that the stove burns properly, the chimney

draft (static pressure) should be approximately 0.1"

water column (W.C.) during a high burn and .04" W.C.

during a low burn, measured 6" (152mm) above the

top of the stove after one hour of operation at each

burn setting.

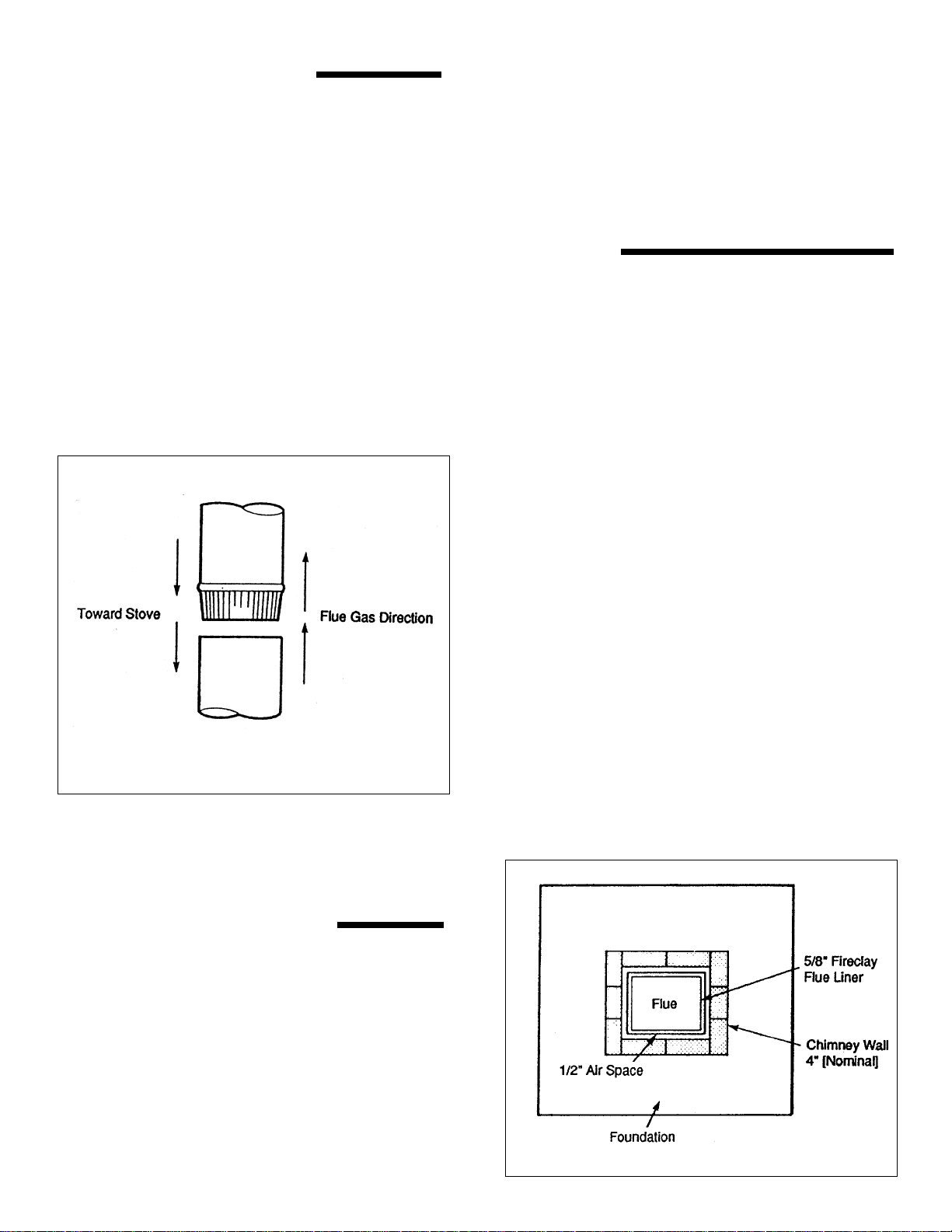

The masonry wall of the chimney, if brick or modular

block, must be a minimum of 4" (102mm) thick. A

mountain or rubble stone wall must be at least 12"

(305mm) thick.

The chimney must have a fire clay flue liner (or

equivalent) with a minimum thickness of 5/8" (16mm)

and must be installed with refractory mortar. There

must be at least ½ " (13mm) air space between the

flue liner and the chimney wall (see Figure 7). An

equivalent liner must be a listed chimney liner system

or other approved material.

NOTE: These are guidelines only, and may vary

somewhat for individual installations.

This stove was designed for and tested on a 6"

(152mm) chimney, 12'-14' (3.66-4.27m) high,

FIGURE 7

8

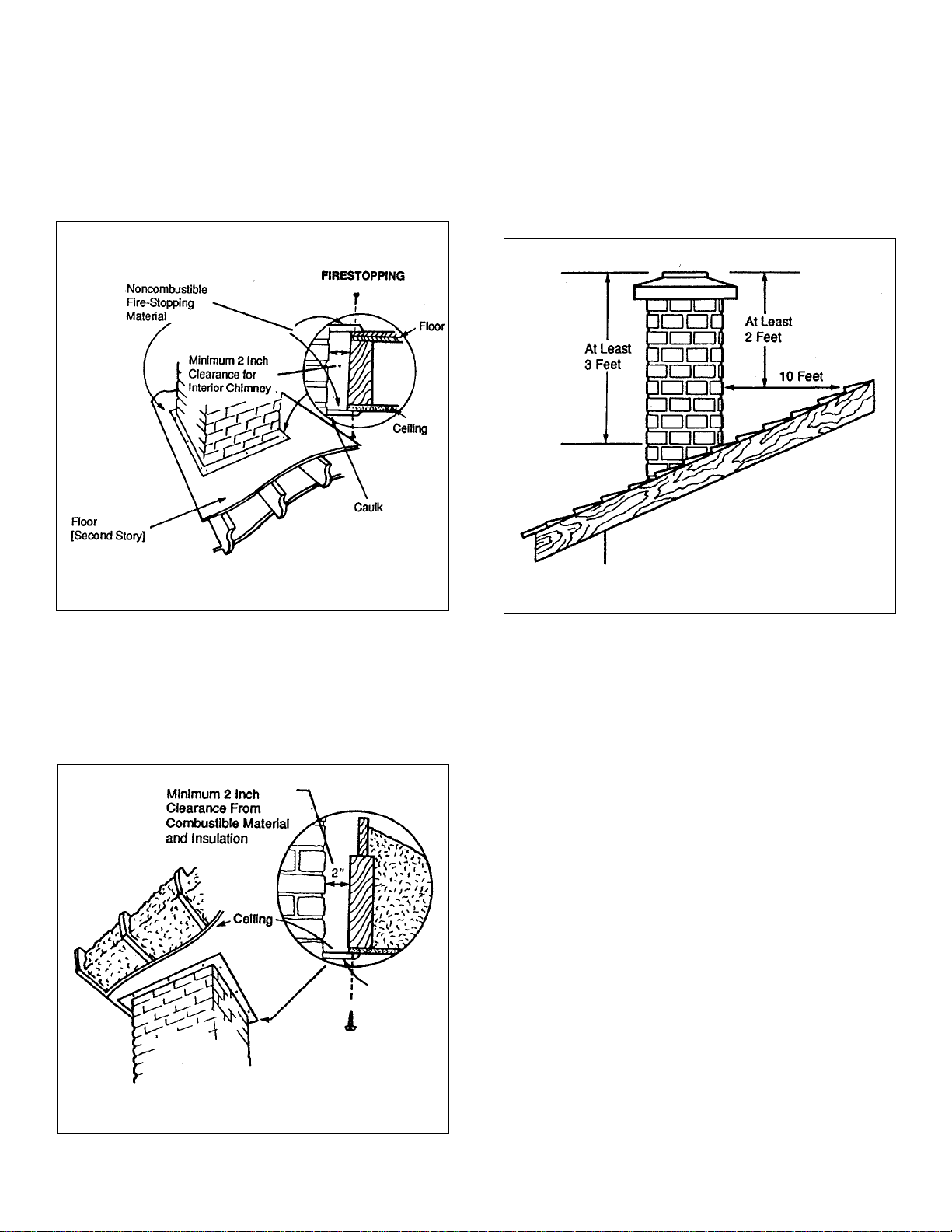

A chimney inside the house must have at least 2"

(50mm) of clearance to the combustible structure.

A chimney outside the house must have at least 1"

(25mm) clearance to the combustible structure.

Firestops must be installed in the spaces where

the chimney passes through floors and/or ceiling

(Figure 8).

Minimum 1

Clearance for

Exterior Chimney

to Sheathing

A chimney must be the required height above the

roof or other obstruction for safety and proper draft

operation. The chimney must be a minimum of 3'

(914mm) higher than the highest point where it

passes through the roof, and at least 2' (610mm)

higher than the highest part of the roof or structure

that is within 10' (3048mm) of the chimney, measured horizontally (Figure 10).

FIGURE 8

Remember that insulation must not contact the

chimney. There must be air space around the

chimney. Insulation must be 2" (50mm) or more from

the chimney (Figure 9).

Noncombustible

Fire-Stopping

Material

FIGURE 10

FIGURE 9

9

Loading...

Loading...