Heat & Glo LifeStyle ST-38HV-AU User Manual

INSTALLATION AND OPERATION

INSTRUCTIONS

MODEL: ST -38HV-AU

AUSTRALIAN GAS ASSOCIATION APPROVED

APPROV AL NUMBER 6027

THIS MANUAL MUST BE USED FOR INST ALLATION AND RETAINED

BY HOMEOWNER FOR OPERA TION AND MAINTENANCE.

HEAT & GLO, a brand of Hearth & Home Technologies Inc.

20802 Kensington Blvd., Lakeville, MN 55044, USA • (952) 985-6000

This product may be covered by one or more of the following patents: (United States) 4593510, 4686807, 4766876, 4793322, 481 1534, 5000162, 5016609, 5076254, 51 13843, 5191877, 5218953, 5263471,

5328356, 5341794, 5347983, 5429495, 5452708, 5542407, 5601073, 5613487, 5647340, 5688568, 5762062, 5775408, 5890485, 5931661, 5941237, 5947112, 5996575, 6006743, 6019099, 6048195,

6053165, 6145502, 6170481, 6237588, 6296474, 6374822, 6413079, 6439226, 6484712, 6543698, 6550687, 6601579, 6672860, 6688302B2, 6715724B2, 6729551, 6736133, 6748940, 6748942, 6769426,

6774802, 6796302, 6840261, 6848441, 6863064, 6866205, 6869278, 6875012, 6880275, 6908039, 6919884, D320652, D445174, D462436; (Canada) 1297749, 2195264, 2225408, 2313972; (Australia)

780250, 780403, 1418504 or other U.S. and foreign patents pending.

675-900D 1 1/05

1

INSTALLA TION AND OPERA TION INSTRUCTIONS

PLEASE READ THIS MANUAL BEFORE INSTALLING AND

USING THIS APPLIANCE.

MODEL ST-38HV-AU

IS AUSTRALIAN GAS ASSOCIA TION

APPROVED FOR NATURAL GAS OR

PROPANE AS A BALANCED FLUE

HEATER.

Refer to the appliance data plates for gas

consumptions and pressures.

Installation of this appliance should only be

carried out by an authorized person in accordance with the manufacturers instructions. All

relevant codes and regulations laid down by

the gas fitting authorities, municipal building

regulations, electrical wiring regulations, and

the requirements of the AGA Gas Inst allation

Code must be observed.

This appliance and its components are tested

and safe when installed in accordance with

this Installation Manual. Report to your dealer

any parts damaged in shipment, specifically

check glass condition. Read all instructions

before starting installation and follow these in-

structions carefully during installation to ensure

maximum benefit and safety . Failure to follow

them will void your warranty and may present

a fire hazard.

The Heat & Glo warranty will be voided by , and

Heat & Glo disclaims any responsibility for the

following actions:

• Installation of any damaged heater or flue

system component

• Modification of the heater or balanced flue

system installation other than as instructed

by Heat & Glo.

• Improper positioning of the gas logs or the

glass door

• Installation and/or use of any component

part not manufactured or approved by Heat

& Glo , not withstanding any independent

testing laboratory or other party approval

of such component part or accessory .

IMPORTANT: Read all instructions carefully before starting installation.

Failure to follow these installation instructions may result in a possible fire

hazard and will void the warranty . Save this manual for future reference.

Heat & Glo, a brand of Hearth & Home Technologies, Inc.

20802 Kensington Blvd., Lakeville, MN 55044, USA

Copyright 2005 • Printed in U.S.A.

2

Heat & Glo

Quality Systems

registered by SGS ICS

TABLE OF CONTENTS

1.0 INSTALLATION INSTRUCTIONS. ................................................................... 4

1.1 Locating the Heater ..................................................................................... 5

1.2 Framing the Heater ..................................................................................... 6

1.3 Flue System Approvals and Inst allation ........................................................ 8

1.4 Connecting the Gas Supply ......................................................................... 17

1.5 Fan ............................................................................................................. 17

1.5.1 Installing the Electrical Service to the Junction Box.................................... 19

1.6 Mantel Clearances ...................................................................................... 19

1.7 Log Installation ............................................................................................ 19

1.8 Installer T esting ............................................................................................ 23

2.0 OPERATING INSTRUCTIONS......................................................................... 23

2.1 Safety and Lighting Information.................................................................... 24

2.2 Safety Information........................................................................................ 25

2.3 Lighting Instructions ..................................................................................... 25

2.4 Fan Operation ............................................................................................. 26

3.0 SERVICING AND MAINTENANCE. ................................................................. 26

3.1 Removal of Covers for Servicing ................................................................. 27

3.2 Removal of Components for Service ........................................................... 27

3.3 Parts Replacement...................................................................................... 27

3.4 Adjustments and Replacement Parts ........................................................... 27

3.5 Troubleshooting........................................................................................... 28

4.0 REPLACEMENT PARTS. ................................................................................ 32

Î

Limited Warranty ............................................................................................... 34

Î = Contains updated information.

3

1.0 INSTALLATION INSTRUCTIONS

When planning a heater installation, it’s

necessary to determine:

• Where the unit is to be installed.

• The vent system configuration to be used.

• Gas supply piping.

• Electrical supply wiring.

• Framing and finishing details.

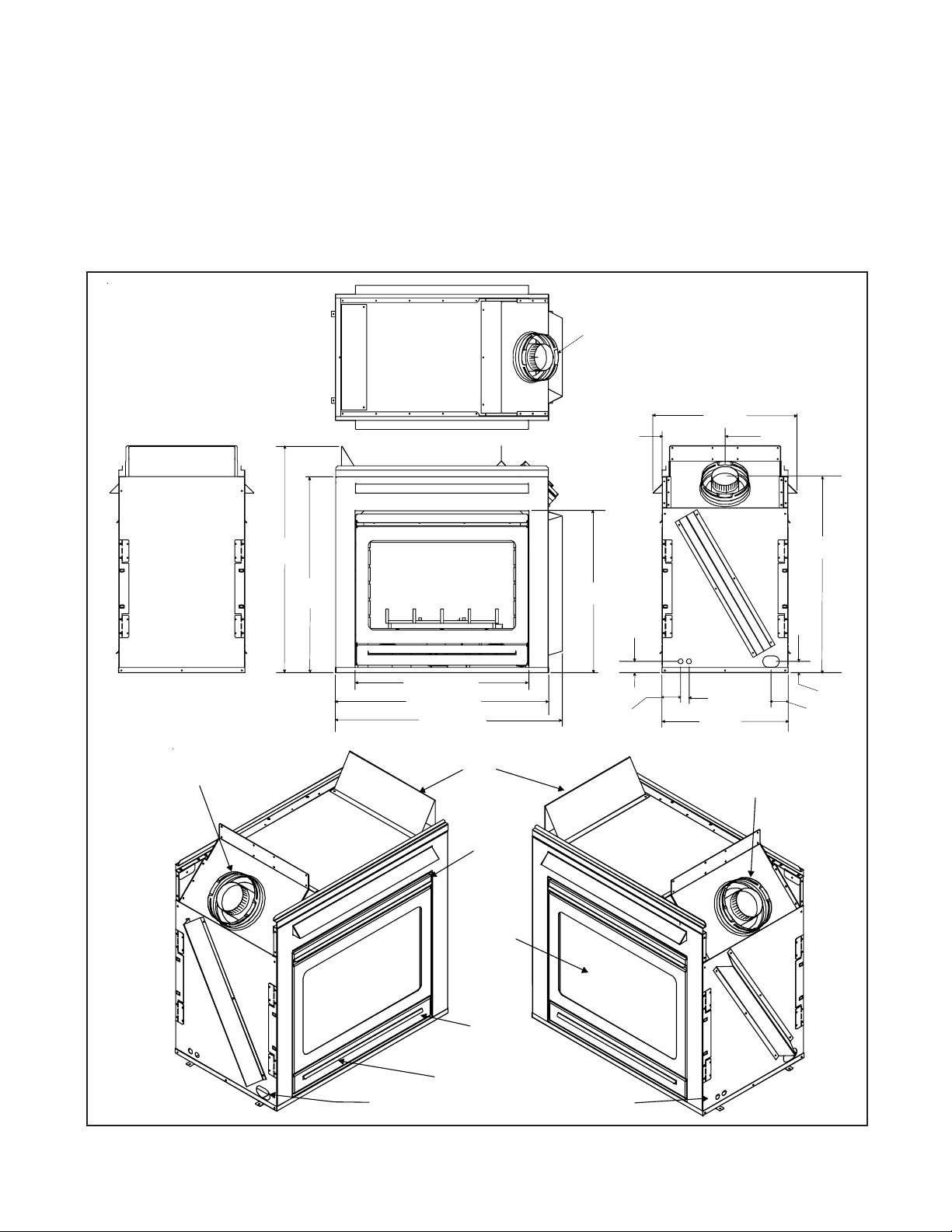

40 5/8

(1032mm)

• Whether optional accessories—devices such

as wall switch, or remote control—are desired.

If the heater is to be installed on carpeting or tile,

or on any combustible material other than wood

flooring, the heater should be installed on a metal

or wood panel that extends the full width and depth

of the heater .

Ø 8 5/8

(219mm)

25 7/8

11 5/16

(287mm)

(657mm)

35 5/16

(897mm)

FLUE COLLAR

35 1/8

(892mm)

31 3/16 (792mm)

38 1/4 (972mm)

40 3/4 (1034mm)

TOP STANDOFFS

TOP

GRILL

GLASS

DOOR

BOTTOM

GRILL

29 1/8

(740mm)

2

(52mm)

3 3/8

(85mm)

1 1/2

(38mm)

22 11/16

(576mm)

FLUE COLLAR

(52mm)

3 1/16

(79mm)

2

Figure 1. Diagram of ST-38HV -AU

GAS LINE

ACCESS

GAS CONTROLS

& LABELS

4

ELECTRICAL

ACCESS

1.1 Locating the Heater

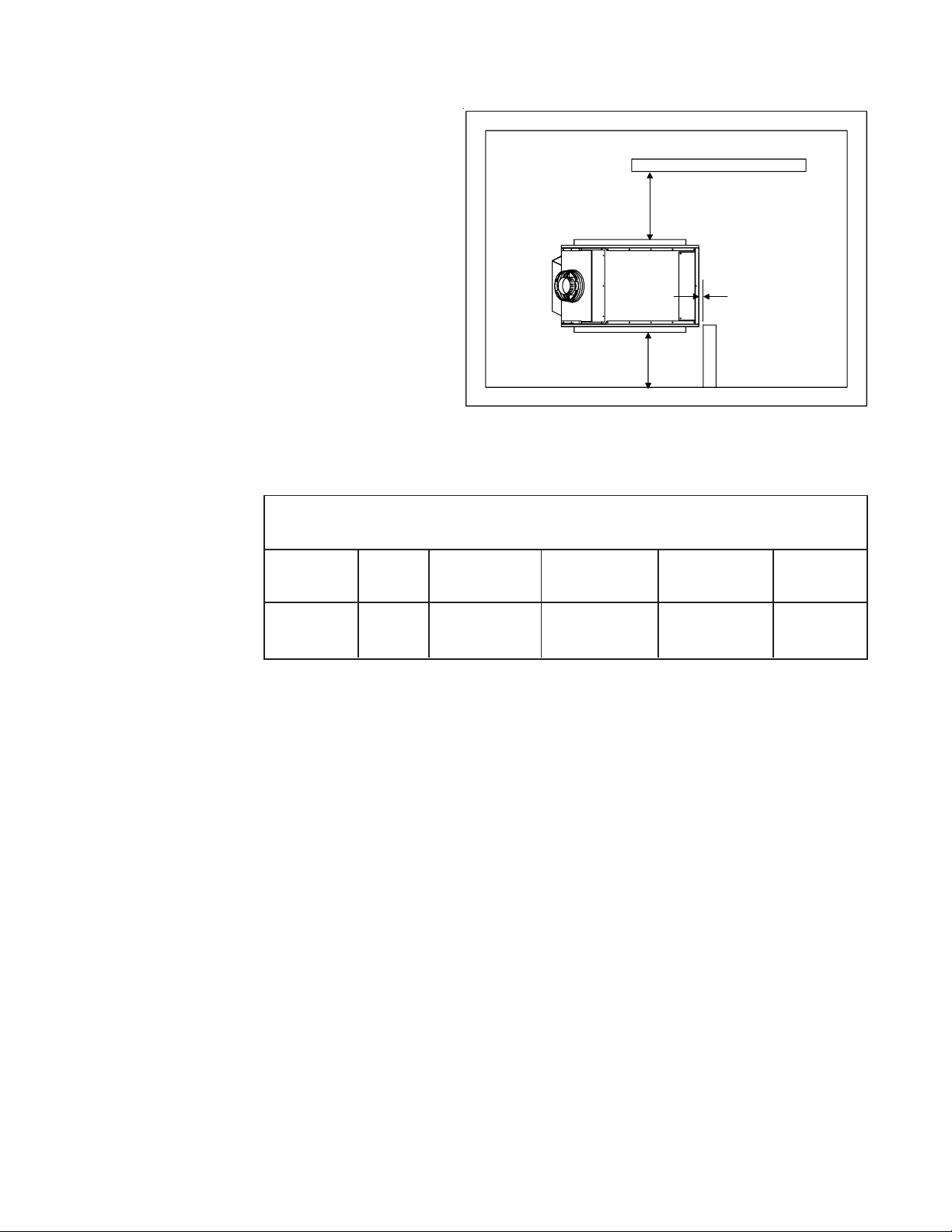

The diagram (See figure 2) shows space and

clearance requirements for locating a heater

within a room.

Clearance Requirements

The top, back, and sides of the heater are

defined by stand-offs.

The minimum clearance to a perpendicular

wall extending past the face of the heater is

one inch (25mm). The metal ends of the heater

may NOT be recessed into combustible

construction.

Minimum Clearances from the Heater to

Glass Exhaust Side Opposite Side Top of

Front Floor of Heater of Heater Heater Ceiling

36 inches 0 2-1/2 inch 0 5-1/2 inches 36 inches

(914 mm) (64 mm) (127 mm) (914 mm)

36” (914mm)

1” (25mm)

36” (914mm)

Figure 2. Heater Dimensions, Locations,

and Space Requirements

Combustible Materials

NOTE: The clearance to the ceiling is measured from the top of the unit excluding

standoffs.

5

Minimum Clearances from the Flue Pipe to

Combustible Materials

For Vertical

For Horizontal Sections Sections At Wall Firestop s

Top Bottom Sides Top Bottom Sides

3 inches 1 inch 1 inch 1 inch 2-1/2 inches 1/2 inch 1 inch

(75mm) (25mm) (25mm) (25mm) (64mm) (13mm) (25mm)

For minimum clearances, see the direct vent

termination clearance diagrams on page 7.

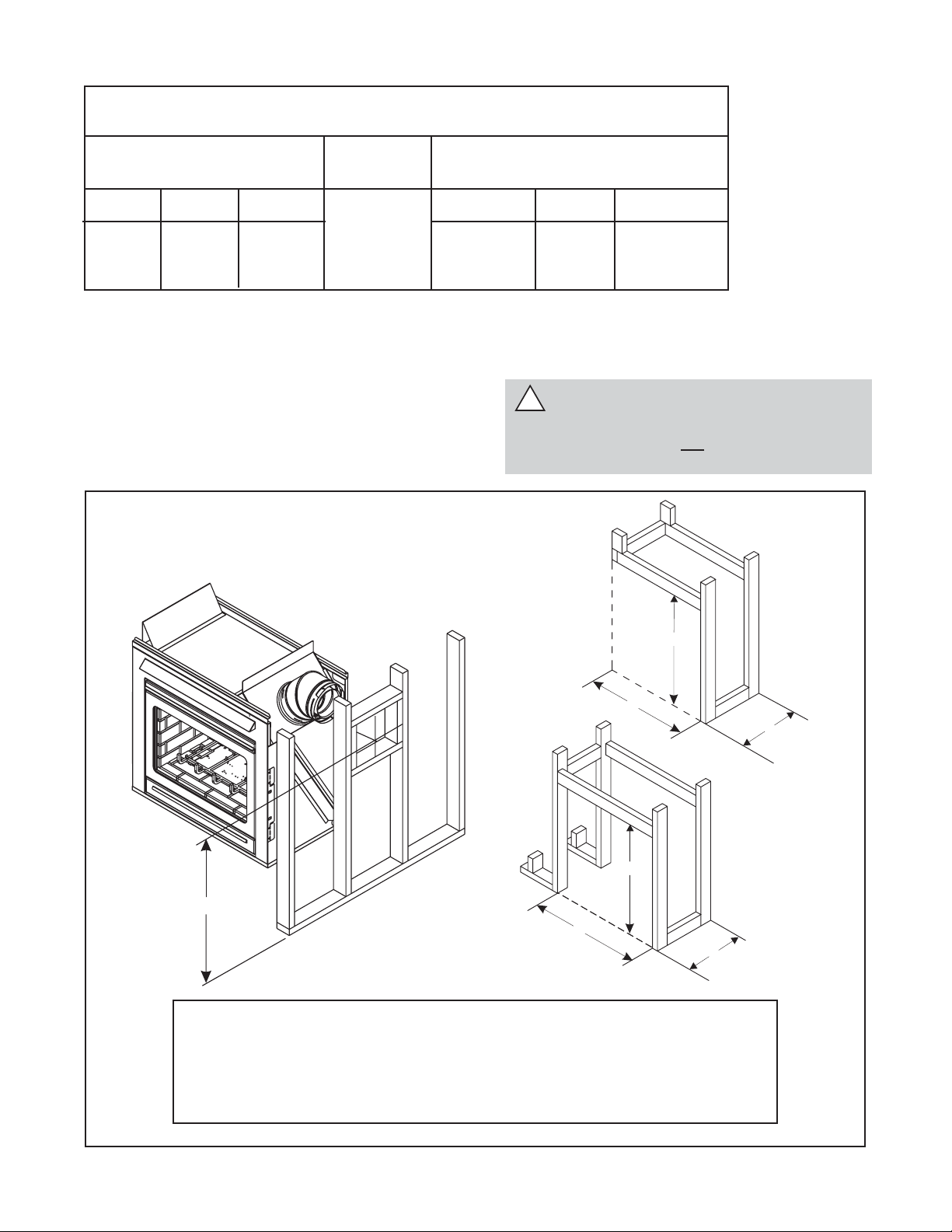

1.2 Framing the Heater

Framing can be built before or after the heater is

set in place. Framing should be positioned to

accommodate wall coverings and heater facing

material. The diagram below shows framing

reference dimensions.

Shows center of 12" x 12” (305mm x 305mm) flue framing

holes. The center of the hole is 25mm above the center

of the horizontal flue pipe. Framing should be constructed

of 2" x 4" (51mm x 102mm) lumber or heavier.

CAUTION: MEASURE HEATER DIMENSIONS

AND VERIFY FRAMING METHODS AND WALL

COVERING DET AILS, BEFORE FRAMING CONSTRUCTION BEGINS.

WARNING: FRAMING DIMENSIONS AS-

!

SUME USE OF 1/2 INCH THICK WALL

COVERING MA TERIALS ON EXTERIOR OF

FRAMING ONL Y AND NO SHEETROCK ON INTERIOR OF FRAMING .

B

A

C

D

Model: ST-38HV-AU A B C D

450 Elbow (Horizontal) Flue 41" 43 1/4" 21 9/16" 37 1/8"

450 Elbow (Vertical) Flue 42 3/4" 40 3/4" 21 9/16"

Figure 3. Framing Dimensions

B

A

C

(1041mm) (1099mm) (548mm) (943mm)

(1086mm) (1035mm) (548mm)

-

6

a

j

OPENABLE

WINDOW

n

f

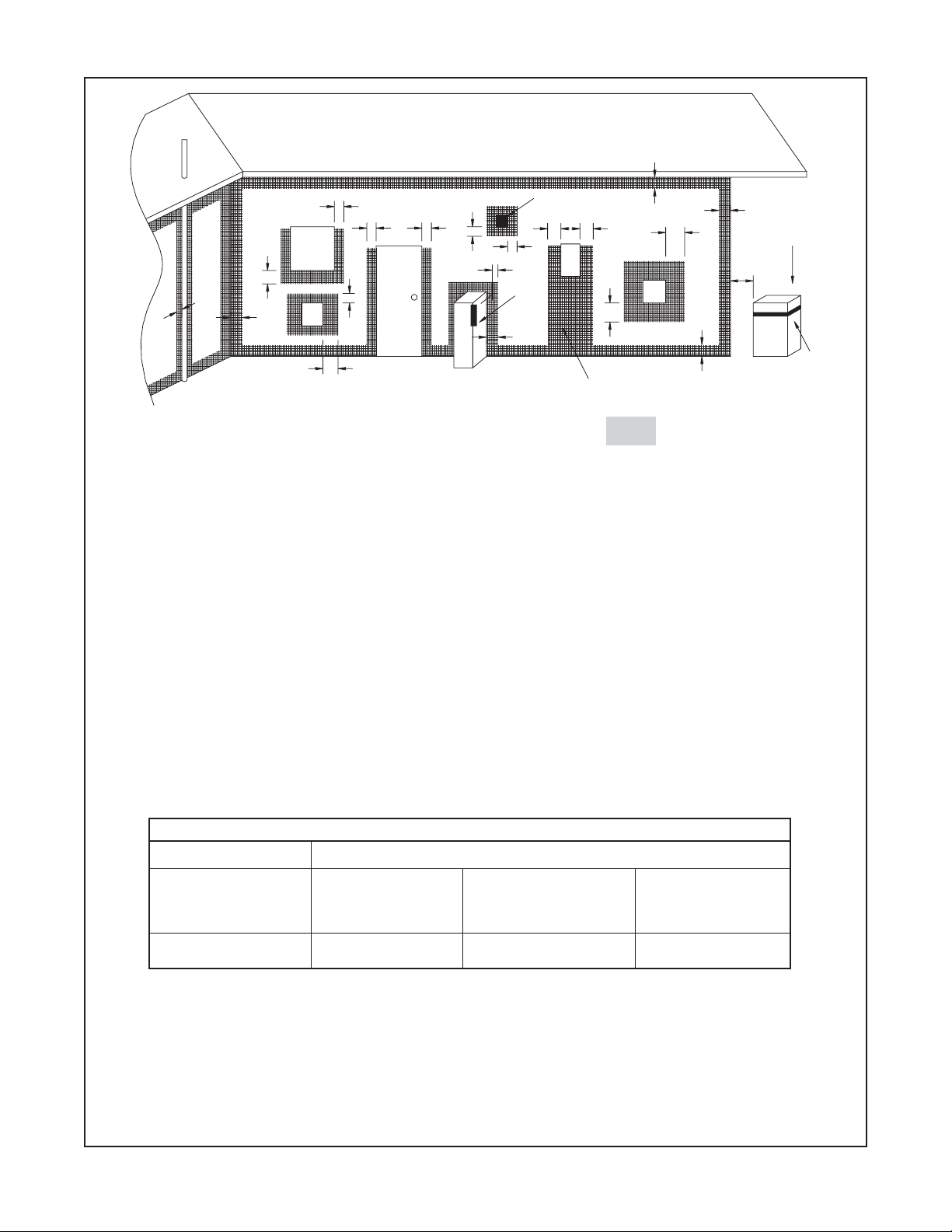

T = Flue terminal M = Gas meter Shading indicates prohibited

I = Mechanical air inlet P = Electricity meter areas for flue terminals

c

I

j

DOOR

k

k

or fuse box

h

j

h

t

e

e

h

d

c

SEE NOTE 3

P

g

t

g

SEE NOTE 2

M

d

b

t

a - Below eaves, balconies or other projections: MIN. CLEARANCE(mm)

Appliances up to 50 MJ/h input ........................................................................................... 300

Appliances over 50 MJ/h input ............................................................................................ 500

b - From the ground or above a balcony...................................................................................... 300

c - From a return wall or external corner ..................................................................................... 500

d - From a gas meter (M) ...........................................................................................................1000

e - From an electricity meter or fuse box (P) ............................................................................... 500

f - From a drain or soil pipe ......................................................................................................... 150

g - Horizontally from any building structure (unless appliance approved

for closer installation) or obstruction facing a terminal......................................................... 500

h - From any other flue terminal, cowl, or combustion air intake ............................................... 500

j - Horizontally from an openable window, door, non-mechanical air

inlet, or any other opening into a building, with the exception of

sub-floor ventilation:

Appliances up to 150 MJ/h input ......................................................................................... 500

Appliances over 150 MJ/h input ........................................................................................ 1500

k - From a mechanical air inlet, including a spa blower .........................................................1500

n - Vertically below an openable window, non-mechanical air

inlet or any other opening into a building, with the exception of

sub-floor ventilation .............................................................................................See table below

CLEARANCES

Space Heaters All other Appliances

Up to 50 MJ/h

Input

150

NOTES: 1. All distances are measured vertically or horizontally along the wall to a point

in line with the nearest part of the terminal.

2. Prohibited area below electricity meter or fuse box extends to ground level.

3. See clause 5.13.6.6 for restrictions on a flue terminal under a roofed area.

4. See Appendix J, Figure J1(a) and J2(a) for clearances required from a flue

terminal to a LP Gas cylinder. A flue terminal is considered to be a source of ignition.

MINIMUM CLEARANCES REQUIRED FOR BALANCED FLUE TERMINALS

Figure 4

Up to 50 MJ/h

Input

500

Over 50 MJ/h and

up to 150 MJ/h Input

1000

OR THE FLUE TERMINALS OF OUTDOOR APPLIANCES

7

Over 1 50 MJ/h

Input

1500

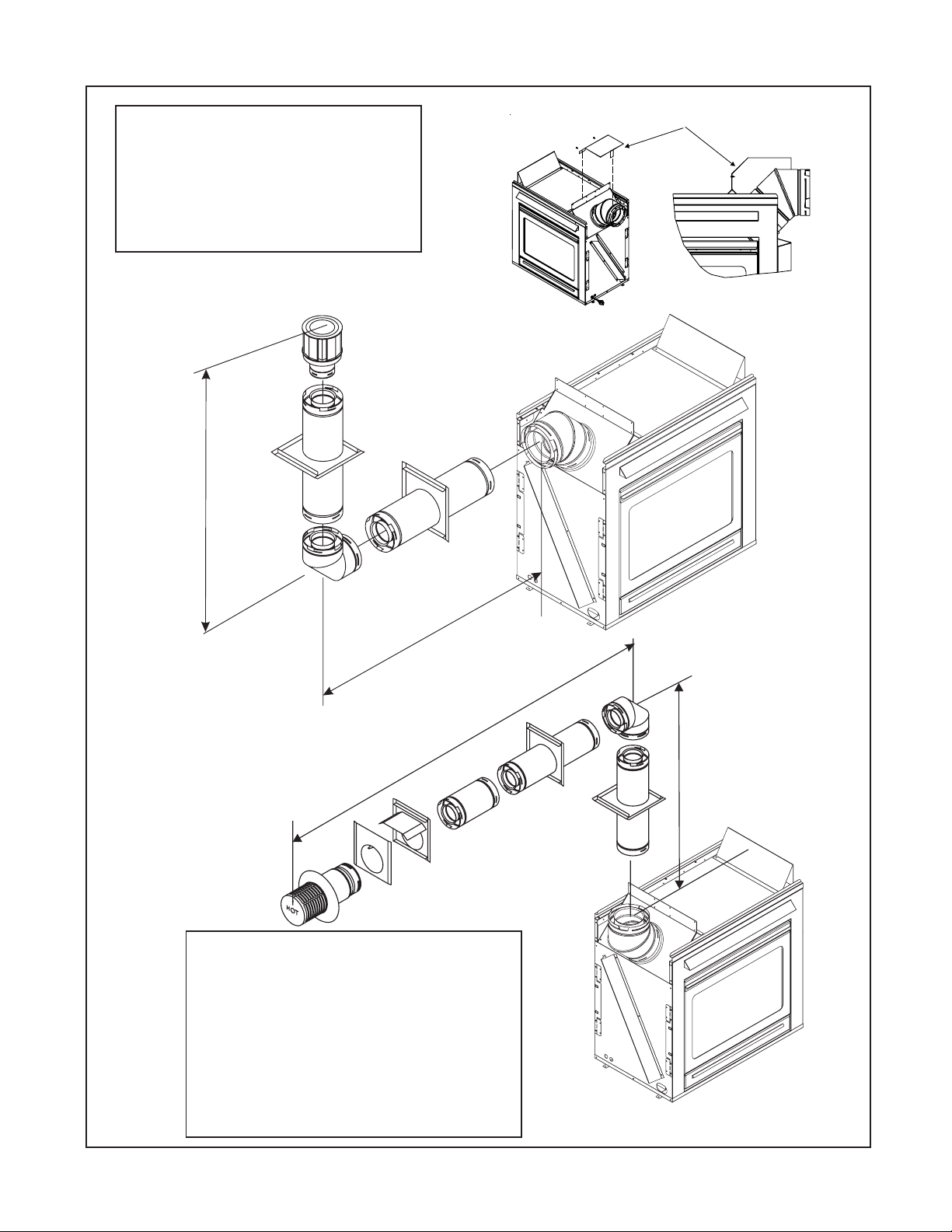

MODEL FLUE TERMINA TION APPROV ALS

ST-38HV-AU DVK-01DA, DVK-01TR

DVK-03DA DVK-TVCD

TABLE 1

1.3 FLUE SYSTEM APPROVALS AND

INST ALLATIONS

This model is approved to use D-Series flue pipe

components. A DVK-01DA, DVK-03DA or DVK-01TR

Termination Cap must be used to terminate vent systems in a horizontal position. DVK-TVCD vertical Termination Caps must be used to terminate vent systems

in a vertical position.

Figures 6 through 10 show the flue systems approved

for use with these models. Approved flue system components are labeled for identification. NO OTHER FLUE

SYSTEMS OR COMPONENTS MAY BE USED. Detailed installation instructions are included with each

flue termination kit and should be used in conjunction

with this manual.

W ARNING: THIS GAS APPLIANCE AND FLUE AS-

SEMBL Y MUST BE FLUED DIRECTLY TO THE OUTSIDE AND MUST NEVER BE ATT ACHED TO A CHIMNEY SERVING A SEP ARA TE SOLID FUEL BURNING

APPLIANCE. EACH GAS APPLIANCE MUST USE A

SEP ARATE FLUE SYSTEM-COMMON FLUE SYSTEMS

ARE PROHIBITED.

CAUTION: UNDER NO CONDITION SHOULD COM-

BUSTIBLE MATERIAL BE CLOSER THAN 3 INCHES

(2 1/2 INCHES A T WALL FIRESTOPS) FROM THE TOP

OF THE 8 5/8-INCH PIPE OR 1-INCH TO THE SIDES

AND THE BOTTOM FOR HORIZONT AL SECTIONS OF

THIS FLUE SYSTEM. VERTICAL SECTIONS OF THIS

SYSTEM REQUIRE A MINIMUM OF 1-INCH CLEARANCE TO COMBUSTIBLE MA TERIALS ALL AROUND

THE 8 5/8 - INCH PIPE.

For alternative installations, other than depicted, contact your dealer for further information.

ELBOWS

The flue systems installed on this gas heater may also

include one (1), two (2), or three (3) 90 - degree elbow

assemblies, in addition to the 45 - degree elbow required at the unit.

Figures 7 through 10 and their corresponding tables show

examples of vent configurations using elbows. The relationships of vertical rise to horizontal run in vent configurations using elbows MUST be strictly adhered to.

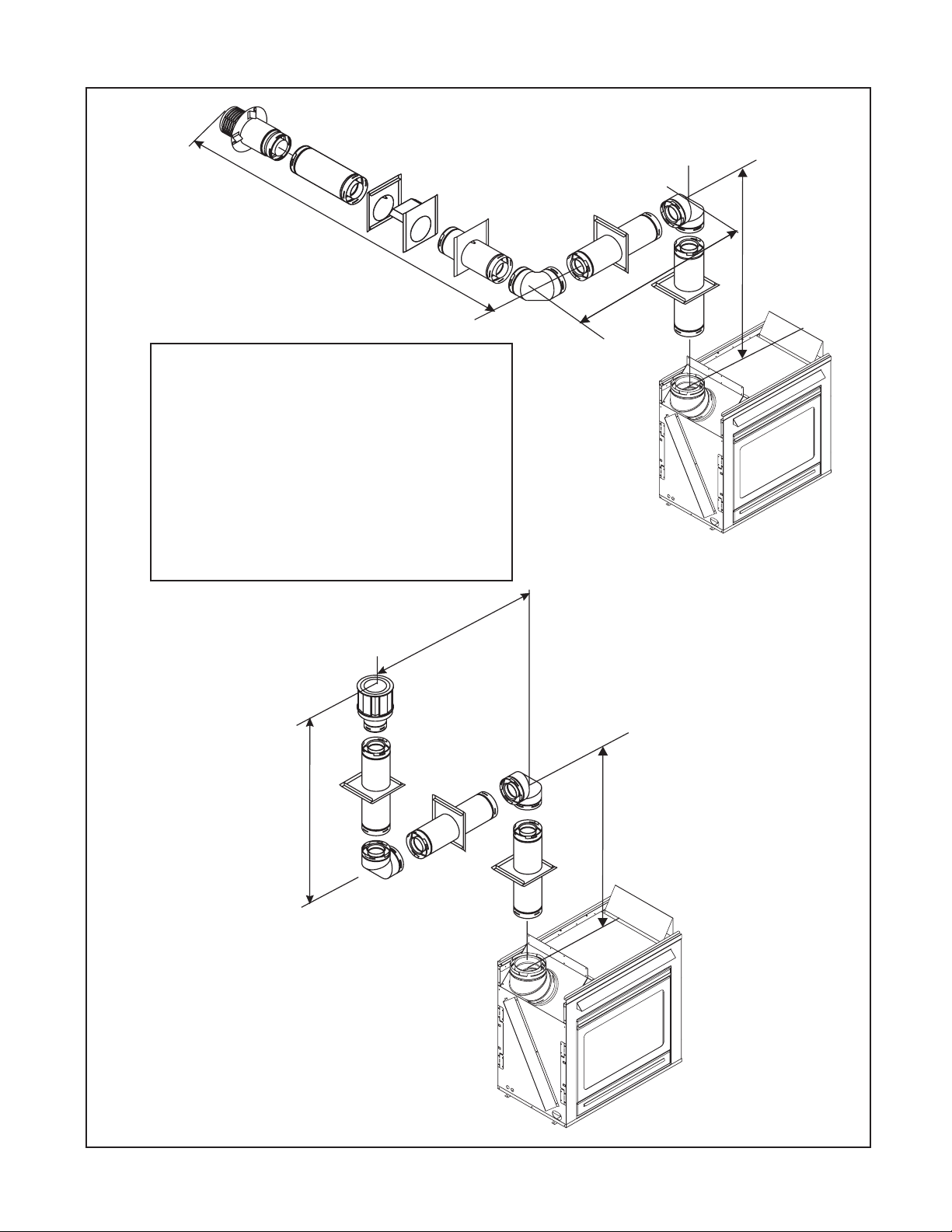

ONE (1) 90-DEGREE ELBOW

Figure 7 shows an installation using one (1) 90-degree

elbow. Dimension V is listed as MINIMUM vertical di-

mensions and dimension H is listed as corresponding

MAXIMUM horizontal dimensions.

TWO (2) 90-DEGREE ELBOWS

Figure 8 shows examples of possible installations using two (2) 90-degree elbows. Dimension V is listed as

MINIMUM vertical dimensions, dimension H is listed

as MAXIMUM beginning horizontal dimensions, and

dimension H+H1 is listed as corresponding TOTAL

MAXIMUM horizontal dimensions.

THREE (3) 90-DEGREE ELBOWS

Figures 9 and 10 show examples of possible installations using three (3) 90-degree elbows. Dimensions V

are listed MINIMUM first vertical dimensions and dimensions H are listed as beginning MAXIMUM horizontal dimensions. Dimensions H+H1 and H+H1+H2 are

listed as TOTAL MAXIMUM horizontal dimensions.

Dimensions V+V1 are listed as TOT AL MAXIMUM vertical dimensions.

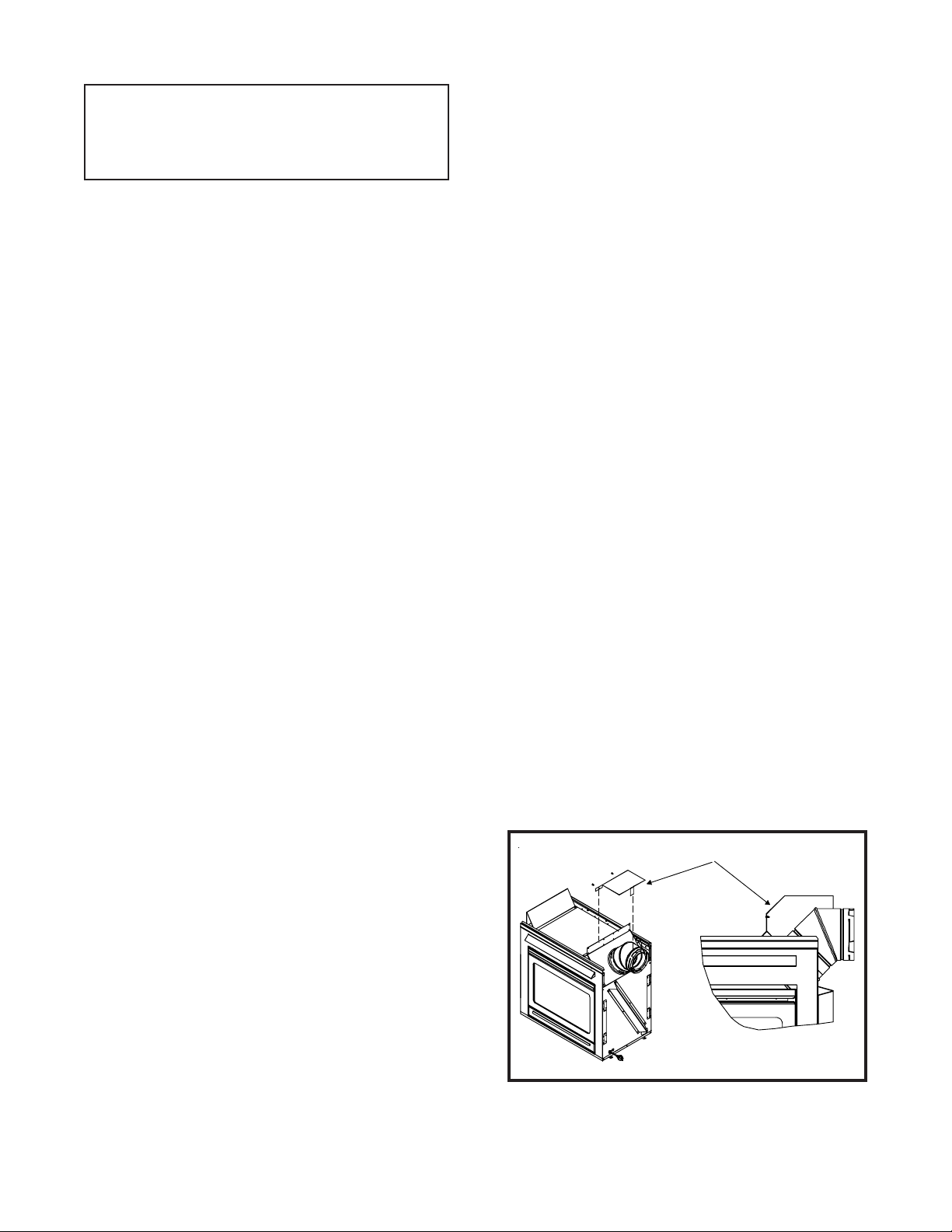

NOTE: When the 450 elbow is attached horizontally,

the supplied heat shield must be installed (see Figure 5).

HEAT SHIELD

Refer to Figure 4 for required clearances to flue terminals.

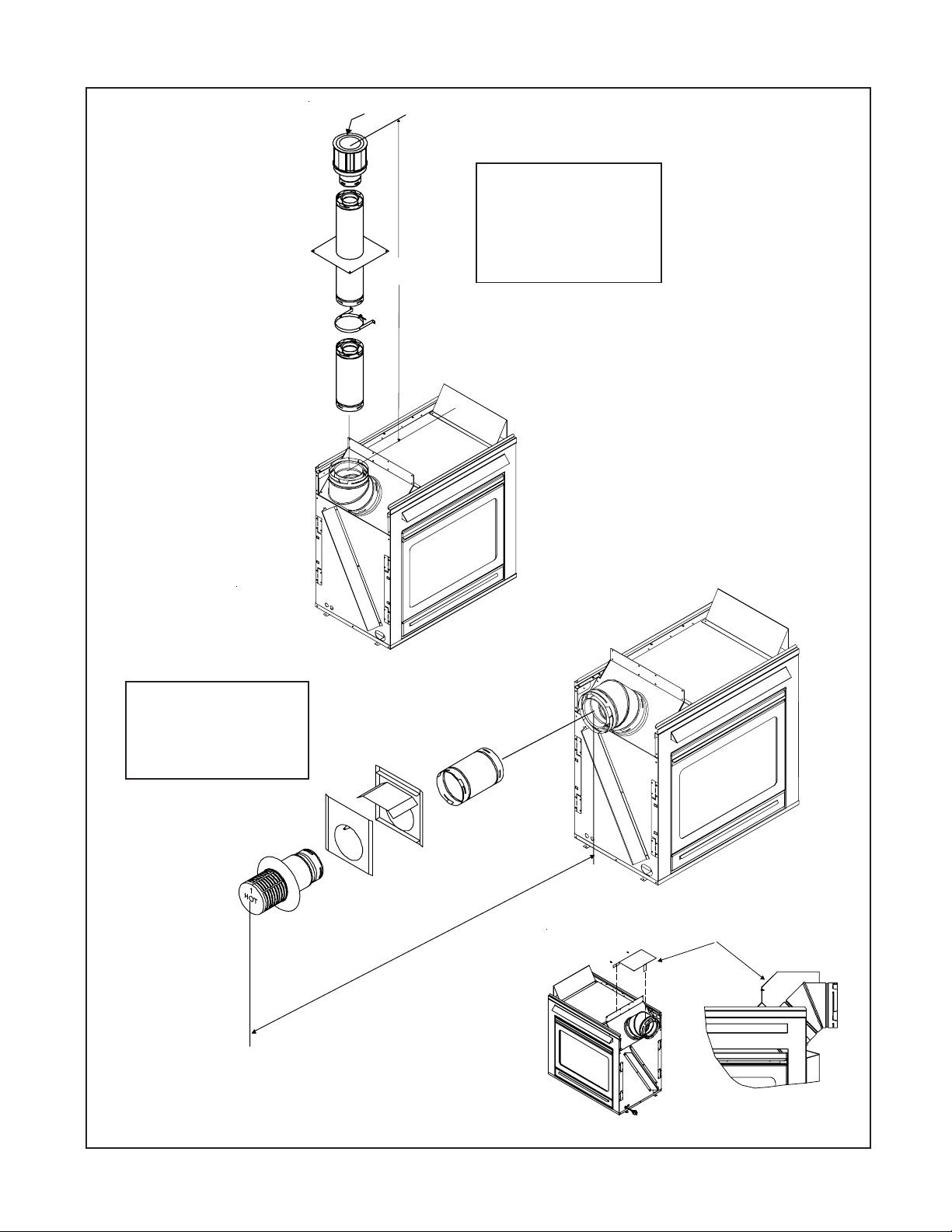

STRAIGHT OUT HORIZONTAL FLUE

SYSTEM

Figure 6 shows straight out horizontal flue systems and

straight up vertical flue systems approved for use on

this model.

Figure 5

8

CAP

STRAIGHT UP

VERTICAL FLUEING

V (FT.)

STRAIGHT OUT

HORIZONT AL FLUEING

H

Max. Run

24" (610 mm)

V

40' MAX. (12.4 M)

Figure 6

H

NOTE: When the 450 elbow is attached

horizontally, the supplied heat shield

must be installed.

9

HEAT SHIELD

FLUEING WITH ONE (1) 90° ELBOW

V (FT.) H (FT.)

4.5' MIN. (1.37m) 3' MAX. (.914m)

6' MIN. (1.86m) 4' MAX. (1.22m)

8' MIN. (2.4m) 5' MAX. (1.5m)

32' MAX. (9.75m) 5' MAX. (1.5m)

V + H = 37’ MAX. (11.3m)

NOTE: When the 450 elbow is attached horizontally , th e

supplied heat shield must be installed.

V

HEAT SHIELD

H

H

FLUEING WITH ONE (1) 90° ELBOW

V (FT.) H (FT .)

1' MIN. (305mm) 2' MAX. (610mm)

2' MIN. (610mm) 4' MAX. (1.22m)

3' MIN. (914mm) 6' MAX. (1.86m)

4' MIN. (1.22m) 8' MAX. (2.44m)

5’ MIN. (1.5m) 10’ MAX. (3.05m)

6’ MIN. (1.86m) 12’ MAX. (3.6m)

7’ MIN. (2.13m) 14' MAX. (4.27m)

32' MAX. (9.75m) 14' MAX. (4.27m)

V + H = 37’ MAX. (11.3m)

V

Figure 6

10

H

11

FLUEING WITH TWO (2) 90° ELBOWS

V (FT. ) H + H1 (FT.)

1' MIN. (305mm) 2' MAX. (610mm)

2' MIN. (610mm) 4' MAX. (1.22m)

3' MIN. (914mm) 6' MAX. (1.86m)

4' MIN. (1.22m) 8' MAX. (2.44m)

5’ MIN. (1.5m) 10’ MAX. (3.04m)

6’ MIN. (1.86m) 12’ MAX. (3.6m)

7’ MIN. (2.13m) 14' MAX. (4.27m)

14' MAX. (4.27m)

V + H = 37’ MAX. (11.3m)

H

H

V

Figure 8

V

11

V

11

Loading...

Loading...