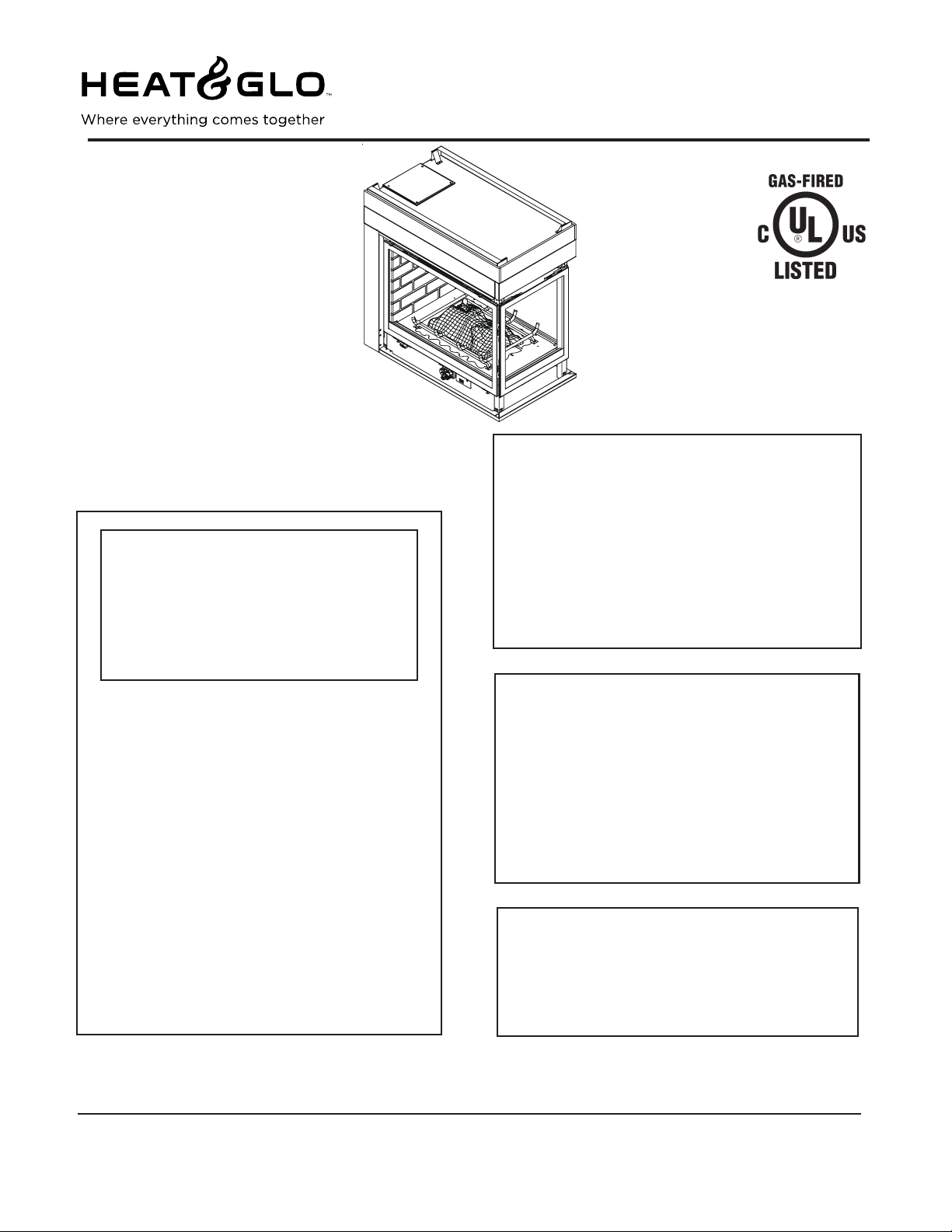

Heat & Glo LifeStyle LCOR-HV-IPI, ST-HV-IPI, PIER-HV-IPI, RCOR-HV-IPI User Manual

Models:

Pier-HV-IPI

ST-HV-IPI

LCOR-HV-IPI

RCOR-HV-IPI

READ THIS MANUAL BEFORE INSTALLING OR

OPERA TING THIS APPLIANCE. THIS INSTALLERS

GUIDE MUST BE LEFT WITH APPLIANCE FOR

FUTURE REFERENCE.

WARNING: IF THE INFORMATION

IN THESE INSTRUCTIONS IS NOT

FOLLOWED EXACTL Y, A FIRE OR

EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE, PERSONAL INJUR Y, OR DEA TH.

Owner’s Manual

Installation and Operation

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION,

SERVICE OR MAINTENANCE CAN

CAUSE INJURY OR PROPERTY DAMAGE. REFER TO THIS MANUAL. FOR

ASSIST ANCE OR ADDITIONAL INFORMATION CONSULT A QUALIFIED INST ALLER, SERVICE AGENCY , OR THE

GAS SUPPLIER.

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

- What to do if you smell gas

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call

the fire department.

- Installation and service must be performed by a

qualified installer, service agency, or the gas

supplier.

Printed in U.S.A. Copyright 2006

Heat & Glo, a brand of Hearth & Home T echnologies Inc.

20802 Kensington Boulevard, Lakeville, MN 55044

This product may be covered by one or more of the following patents: (United States) 4593510, 4686807, 4766876, 4793322, 481 1534, 5000162, 5016609, 5076254, 51 13843, 5191877, 5218953, 5263471,

5328356, 5341794, 5347983, 5429495, 5452708, 5542407, 5601073, 5613487, 5647340, 5688568, 5762062, 5775408, 5890485, 5931661, 5941237, 5947112, 5996575, 6006743, 6019099, 6048195, 6053165,

6145502, 6170481, 6237588, 6296474, 6374822, 6413079, 6439226, 6484712, 6543698, 6550687, 6601579, 6672860, 6688302B2, 6715724B2, 6729551, 6736133, 6748940, 6748942, 6769426, 6774802,

6796302, 6840261, 6848441, 6863064, 6866205, 6869278, 6875012, 6880275, 6908039, 6919884, D320652, D445174, D462436; (Canada) 1297749, 2195264, 2225408, 2313972; (Australia) 780250,

780403, 1418504 or other U.S. and foreign patents pending.

1.This appliance may be installed in an aftermarket, permanently located, manufactured (mobile) home, where not prohibited

by local codes.

2. This appliance is only for use with the type

of gas indicated on the rating plate. This

appliance is not convertible for use with

other gases, unless a certified kit is used.

In the Commonwealth of Massachusetts:

• installation must be performed by a licensed

plumber or gas fitter;

See Table of Contents for location of additional

Commonwealth of Massachusetts requirements.

Please contact your Heat & Glo dealer with any

questions or concerns. For the location of your nearest

Heat & Glo dealer, please visit www .heatnglo.com.

Heat & Glo • PIER-HV-IPI, ST -HV -IPI, L&R-COR-HV -IPI • 2005-900 Rev . K • 1 1/06

1

Safety and Warning Information

READ and UNDERSTAND all instructions carefully

!

before starting the installation. FAILURE TO

FOLLOW these installation instructions may result

in a possible fire hazard and will void the warranty.

Prior to the first firing of the fireplace, READ the

!

Using Your Fireplace section of the Owners Guide.

DO NOT USE this appliance if any part has been

!

under water. Immediately CALL a qualified service

technician to inspect the unit and to replace any part

of the control system and any gas control which has

been under water.

THIS UNIT IS NOT FOR USE WITH SOLID FUEL.

!

Installation and repair should be PERFORMED by a

qualified service person. The appliance and venting

!

system should be INSPECTED before initial use

and at least annually by a professional service

person. More frequent cleaning may be required

due to excessive lint from carpeting, bedding

material, etc. It is IMPERATIVE that the unit’s

control compartment, burners, and circulating air

passageways

adequate combustion and ventilation air.

BE KEPT CLEAN to provide for

These units MUST use one of the vent systems

described in the Installing the Fireplace section of

!

the Installers Guide. NO OTHER vent systems or

components MAY BE USED.

This gas fireplace and vent assembly MUST be

!

vented directly to the outside and MUST NEVER be

attached to a chimney serving a separate solid fuel

burning appliance. Each gas appliance MUST USE

a separate vent system. Common vent systems are

PROHIBITED.

INSPECT the external vent cap on a regular basis to

!

make sure that no debris is interfering with the air

flow.

The glass door assembly MUST be in place and

!

sealed, and the trim door assembly MUST be in

place on the fireplace before the unit can be placed

into safe operation.

DO NOT OPERATE this appliance with the glass

!

door removed, cracked, or broken. Replacement of

the glass door should be performed by a licensed

or qualified service person. DO NOT strike or slam

the glass door.

Always KEEP the appliance clear and free from

!

combustible materials, gasoline, and other

flammable vapors and liquids.

NEVER OBSTRUCT the flow of combustion and

!

ventilation air. Keep the front of the appliance

CLEAR of all obstacles and materials for servicing

and proper operations.

Due to the high temperature, the appliance should

be LOCATED out of traffic areas and away from

!

furniture and draperies. Clothing or flammable

material SHOULD NOT BE PLACED on or near the

appliance.

Children and adults should be ALERTED to the

!

hazards of high surface temperature and should

ST AY AW AY to avoid burns or clothing ignition.

Y oung children should be CAREFULL Y SUPERVISED

when they are in the same room as the appliance.

The glass door assembly SHALL ONLY be

!

replaced as a complete unit, as supplied by the gas

fireplace manufacturer. NO SUBSTITUTE material

may be used.

DO NOT USE abrasive cleaners on the glass door

!

assembly. DO NOT ATTEMPT to clean the glass

door when it is hot.

Turn off the gas before servicing this appliance. It is

recommended that a qualified service technician

!

perform an appliance check-up at the beginning of

each heating season.

Any safety screen or guard removed for servicing

!

must be replaced before operating this appliance.

DO NOT place furniture or any other combustible

!

household objects within 36 inches of the fireplace

front.

Heat & Glo • PIER-HV-IPI, ST -HV -IPI, L&R-COR-HV -IPI • 2005-900 Rev . K • 1 1/062

Table of Contents

Safety and Warning Information.................................................. 2

Í

Service Parts List ......................................................................... 4

Approvals and Codes ................................................................13

Appliance Certification ................................................................................. 13

Installation Codes ........................................................................................ 13

High Altitude Installations............................................................................. 13

Í

Requirements for the Commonwealth of Massachusetts .............................. 14

Getting Started............................................................................ 15

Introducing the Heat & Glo Gas Fireplaces .................................................. 15

Pre-install Preparation ................................................................................. 15

Installing the Fireplace ............................................................... 19

Step 1. Locating the Fireplace .................................................................... 19

Step 2. Framing the Fireplace..................................................................... 20

Step 3. Inst alling the Vent System .............................................................. 23

A. Vent System Approvals ......................................................... 23

B. Installing V ent Components ................................................... 30

Î

C. Vent Termination.................................................................... 32

Step 4. Positioning, Leveling, and Securing the Fireplace ........................... 35

Step 5. The Gas Control System ................................................................ 35

Step 6. The Gas Supply Line ...................................................................... 36

Step 7. Gas Pressure Requirements........................................................... 36

Î

Step 8. Wiring the Fireplace........................................................................ 37

Step 9. Finishing......................................................................................... 40

Step 10. Installing Trim, Logs & Ember Material .......................................... 41

Installing the Trim .......................................................................... 41

Positioning the Logs...................................................................... 41

Shutter Settings ............................................................................ 41

Glass Specifications...................................................................... 41

Preparing Electric Ember Bed and Lava Rock ............................... 41

Placing the Ember Material ........................................................... 43

Ember Light Bulb Replacement ..................................................... 43

Step 11. Before Lighting the Fireplace........................................................ 44

Step 12. Lighting the Fireplace ................................................................... 44

After the Installation ..................................................................................... 44

Maintaining and Servicing Your Fireplace................................ 45

Î = Contains updated information.

Heat & Glo • PIER-HV-IPI, ST -HV -IPI, L&R-COR-HV -IPI • 2005-900 Rev . K • 1 1/06

3

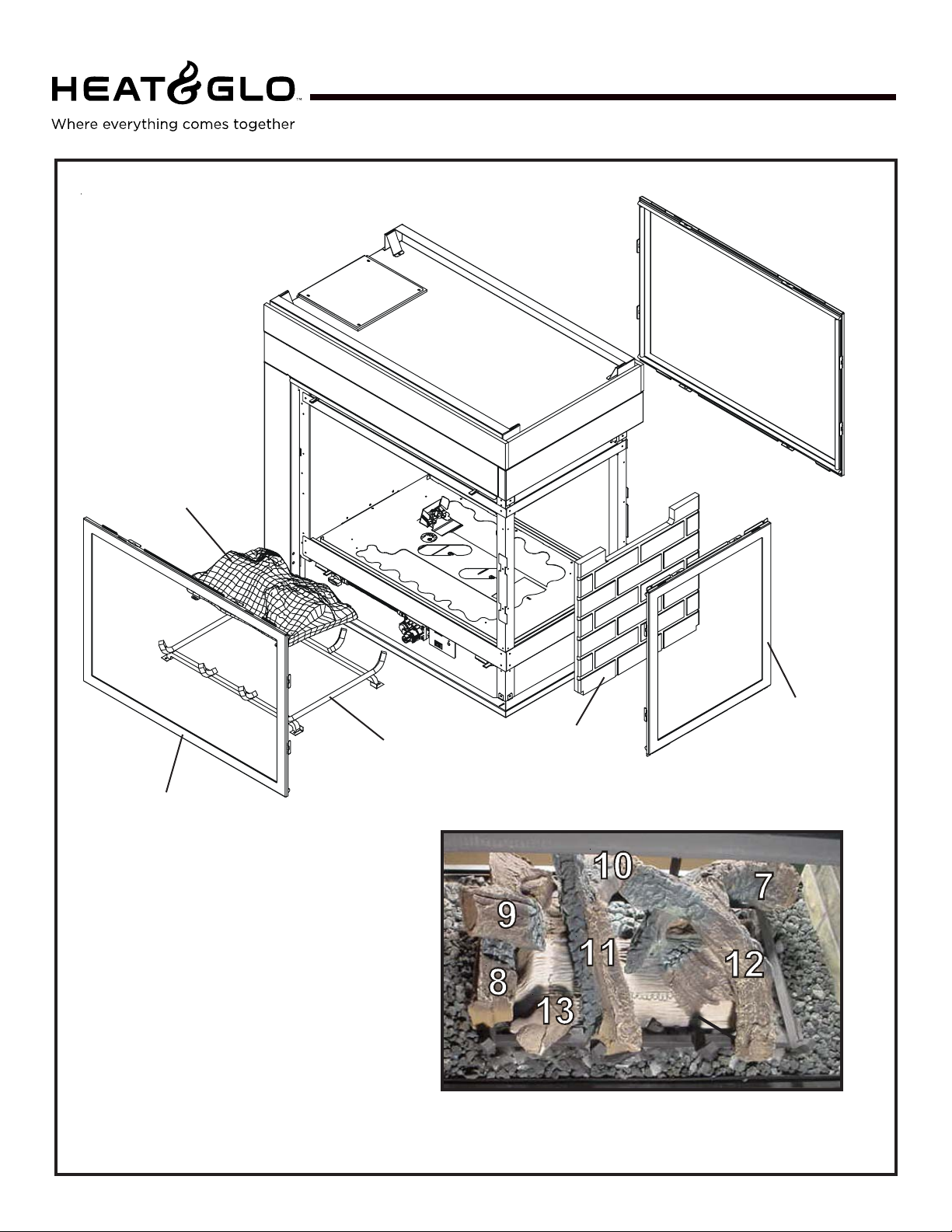

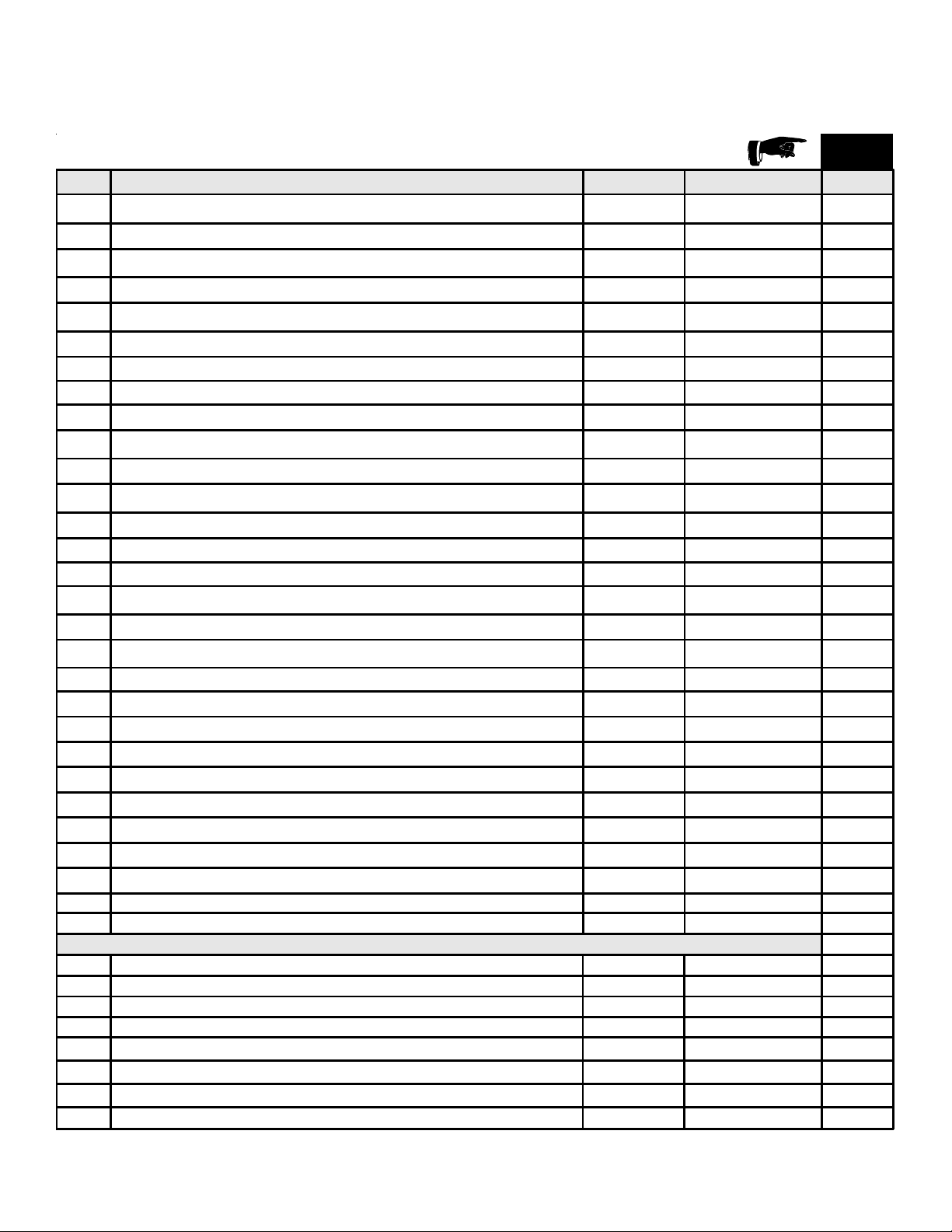

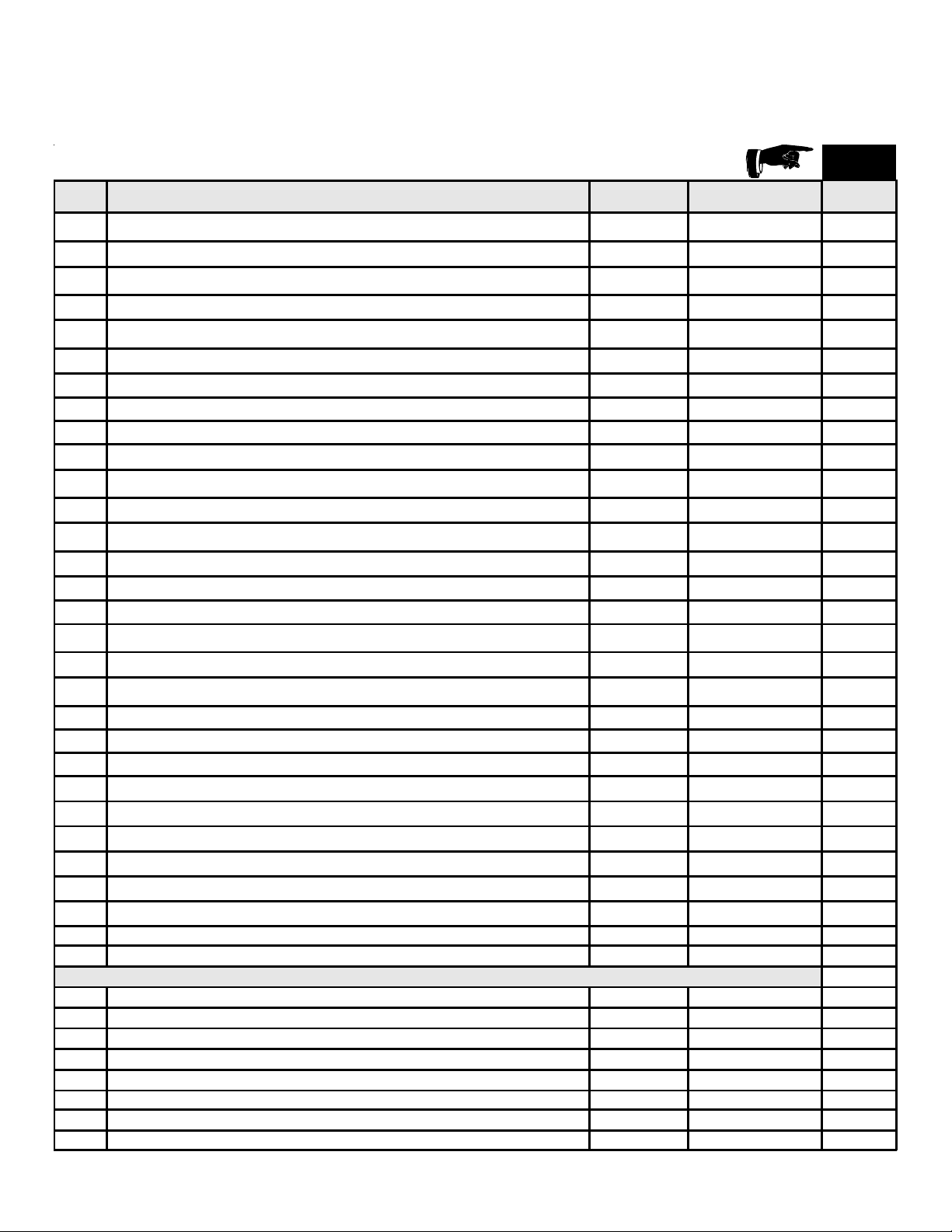

Service Parts

Pier-HV-IPI

(NG, LP) Exploded Parts Diagram

3

Beginning Manufacturing Date: 6-03

Ending Manufacturing Date: ______

1

4

2

6 Log Assembly

5

Grate

Bar

Heat & Glo • PIER-HV-IPI, ST -HV -IPI, L&R-COR-HV -IPI • 2005-900 Rev . K • 1 1/064

Service Parts List (NG, LP)

PIER-HV-IPI

IMPORT ANT: THIS IS DA TED INFORMA TION. The most current information is located on your dealers VIP site. When ordering,

supply serial and model numbers to ensure correct service parts.

AVAILAB LE

TO S HIP IN 24

HOURS

ITEM DESCRIPTION SERIAL # PART NUMBER

Burner Orifice NG (#33DMS) 582-833 Y

Burner Orifice LP (#50DMS) 582-850 Y

1 End Glass A sse mbly GLA - MS Y

2 Glass Door Assembly GLA-6TROC Y

3 Burner Assembly 2005-006 Y

4 Log Grate 2005-012

5Side Refractory SRV2005-730

6 Log Set Assembly LOGS-MSR Y

7 Log 1 SRV2005-701

8 Log 2 SRV2005-700

9 Log 3 SRV2005-702

10 Log 4 SRV2005-703

Î

11 Log 5 SRV2005-704

12 Log 6 SRV2005-705

13 Log 7 SRV703-703

Lava Rock Bag 2005-790

Flue Restrictor 385-128

Teco-Sil, 5 lb. bag 700-790

Ember Mesh Assembly 2006-008 Y

Junction Box 4021-013 Y

Non-Combustible Board (side) 2006-136

Non-Combustible Board (end) 2006-137

3V Adaptor Plug 593-593A Y

Battery Pack 593-594A Y

Fiberglass Rope 060-455

Glass Latch Support Assembly 386-122A Y

Min eral Wool 050-721

Conversion Kit NG NGK-MS Y

Conversion Kit LP LPK-MS Y

ACCESSORIES

Fan Kit GFK-160A

Remote Control Kit RC-SMART-HNG

Remo te C o ntro l Ki t SMART-STAT-HNG

Remote Control - Multi-functional RCT-MLT-HNG

Wall Switch, Multi-functional WSK-MLT

Plug Adapator Kit (for WSK-MLT) PLUG-ADP

Louvers with Mesh MS-LOUVERS

Louvers with Mesh - End Panel MS-LOUVERS-EP

Heat & Glo • PIER-HV-IPI, ST -HV -IPI, L&R-COR-HV -IPI • 2005-900 Rev . K • 1 1/06

5

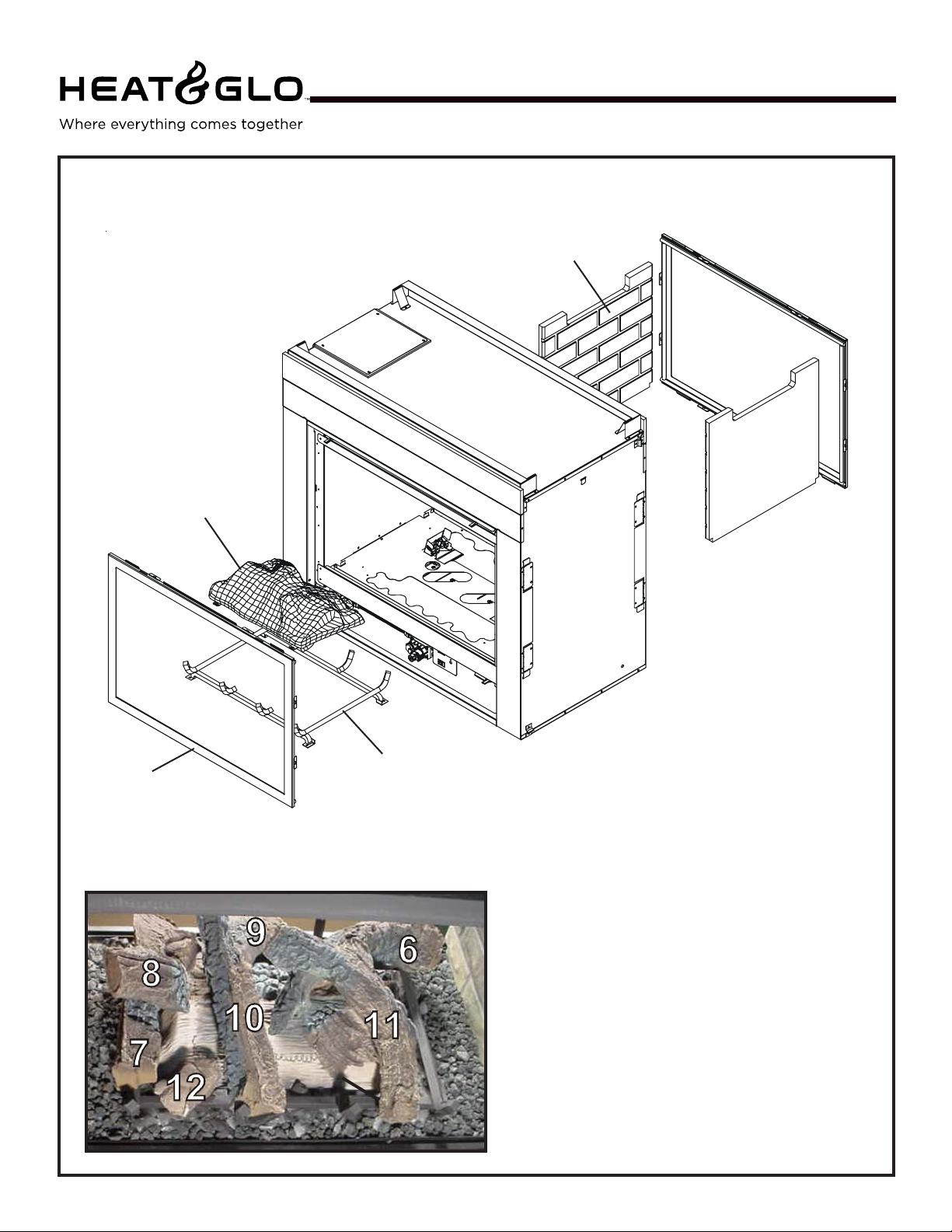

Service Parts

ST-HV -IPI

(NG , LP) Exploded Parts Diagram

4

2

Beginning Manufacturing Date: 6-03

Ending Manufacturing Date: ______

1

5 Log Assembly

3

Grate

Bar

Heat & Glo • PIER-HV-IPI, ST -HV -IPI, L&R-COR-HV -IPI • 2005-900 Rev . K • 1 1/066

Service Parts List (NG, LP)

ST-HV-IPI

IMPORT ANT: THIS IS DA TED INFORMA TION. The most current information is located on your dealers VIP site. When ordering,

supply serial and model numbers to ensure correct service parts.

ITEM DESCRIPTION SERIAL # PAR T NU M BER

Burner Ori fice NG (#32DMS) 582-832 Y

Burner Ori fice LP (#50DMS) 582-850 Y

1 Glass Door Assembly GLA-6TROC Y

2 Burne r As se mb l y 2005-006 Y

3 Log Grate 2005-012

4 Side Refracto ry SRV2005-730

5 Log Set Assembly LOGS-MSR Y

6Log 1 SRV2005-701

7Log 2 SRV2005-700

8Log 3 SRV2005-702

9Log 4 SRV2005-703

AVAILABLE TO

S HIP IN 2 4

HOURS

Î

10 Log 5 SRV2005-704

11 Log 6 SRV2005-705

12 Log 7 SRV703-703

Lava Rock Bag 2005-790

Flue Restrictor 385-128

Te c o-S il, 5 lb. bag 700-790

Hood, black SRV60-143-BK

Ember Mesh Assembly 2005-008 Y

Non-Combustible Board 2005-172

Junction Box 4021-013 Y

Fiberglass Rope 060 -455

Glass Latch Support Assembly 386-122A Y

Minera l W o o l 050-721

3V Adaptor Plug 593-593A Y

Battery Pack 593-594A Y

Conversion Kit NG NGK-MS Y

Conversion Kit LP LPK-MS Y

ACCESSORIES

Fan Kit GFK-160A

Remote Control Kit RC-SMART-HNG

Remo te C ontrol K it SMART-STAT-HNG

Remote Control - Multi-functional RCT-MLT-HNG

Wall Switch, Multi- functional WSK-MLT

Plug Adapator Kit (for WSK-MLT) PLUG-ADP

Louvers with Mesh MS-LOUVERS

Louvers with Mesh - End Panel MS-LOUVERS-EP

Heat & Glo • PIER-HV-IPI, ST -HV -IPI, L&R-COR-HV -IPI • 2005-900 Rev . K • 1 1/06

7

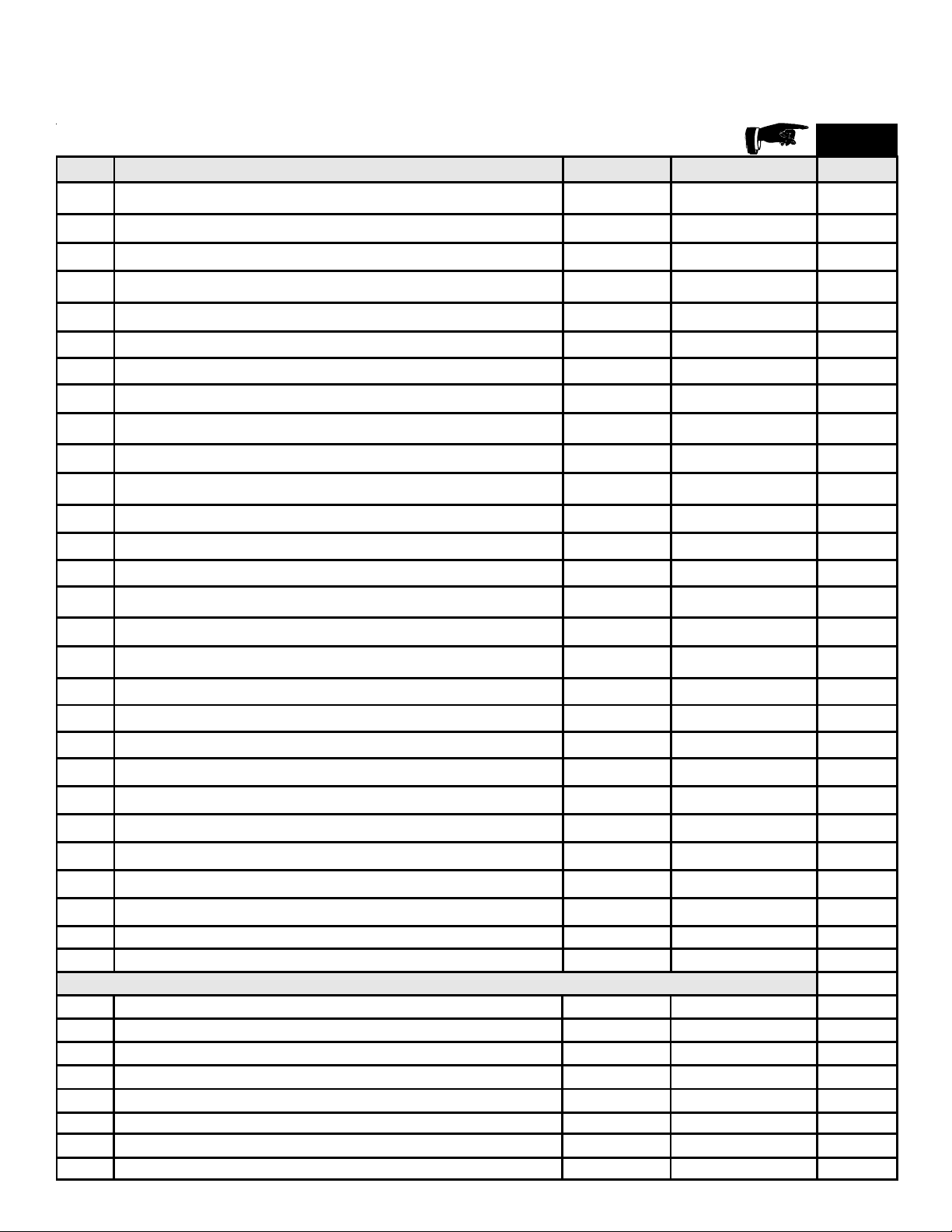

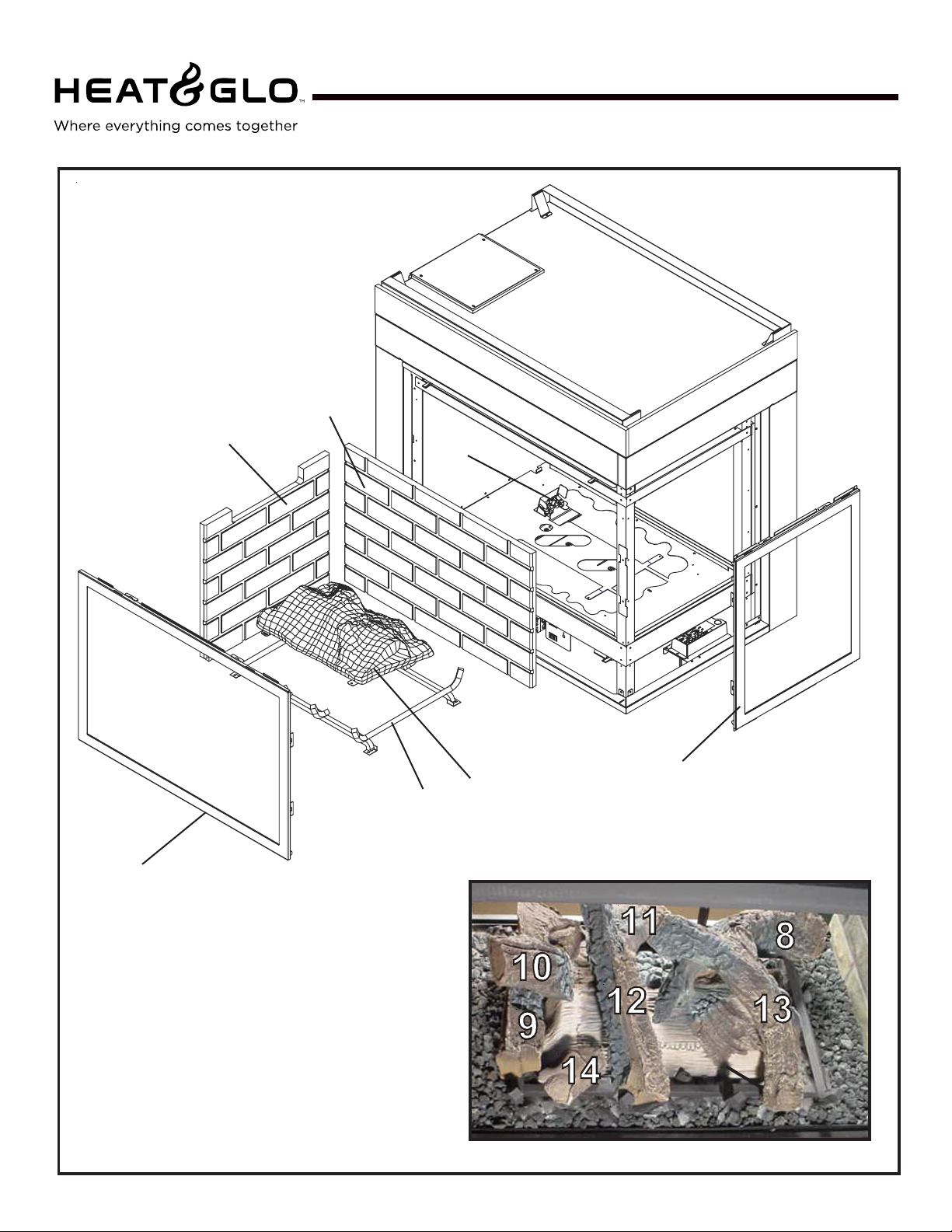

Service Parts

LCOR-HV-IPI

(NG , LP) Exploded Parts Diagram

1

6

2

Beginning Manufacturing Date: 6-03

Ending Manufacturing Date: ______

7 Log Assembly

3

4

5

15

15

Part number list on following page.

Heat & Glo • PIER-HV-IPI, ST -HV -IPI, L&R-COR-HV -IPI • 2005-900 Rev . K • 1 1/068

Service Parts List (NG, LP)

LCOR-HV -IPI

IMPORT ANT: THIS IS DA TED INFORMA TION. The most current information is located on your dealers VIP site. When ordering,

supply serial and model numbers to ensure correct service parts.

AVAILABLE TO

SHIP IN 24

HOURS

ITEM COMMON PARTS SERIAL # PART N UMBER

Burner Orifice NG (#32DMS) 582-832 Y

Burner Orifice LP (#50DMS) 582-850 Y

1End Glass Assembly GLA-MS Y

2 Glass Door Asse mbly GLA-6TROC Y

3Burner Assembly 2005-006 Y

4 Log Grate 2005-012

5 Si d e Refra c tory SRV2005-730

6 Refractory, Back SRV2005-731

7 Log Set Assembly LOGS-MSR Y

8Log 1 SRV2005-701

9Log 2 SRV2005-700

10 Log 3 SRV2005-702

Î

11 Log 4 SRV2005-703

12 Log 5 SRV2005-704

13 Log 6 SRV2005-705

14 Log 7 SRV703-703

Lava Rock Bag 2005-790

Flue Restrictor 385-128

Teco-Sil, 5 lb. bag 700-790

Ember Mesh Assembly 2006-008

Non-Combustible Board (side) 2006-136

Non-Combustible Board (end) 2008-114

Junction Box 4021-013

Fiberglass Rope 060-455

Glass Latch Support Assembly 386-122A Y

Mineral Wool 050-721

3V Adaptor Plug 593-593A Y

Battery Pack 593-594A Y

Conversion Kit NG NGK-MS Y

Conversion Kit LP LPK-MS Y

ACCESSORIES

Fan Kit GFK-160A

Remo t e Control Kit RC-SMART -HNG

Remo t e Control Kit SMART-STAT-HNG

Remote Control - Multi-functional RCT-MLT-HNG

Wall Switch, Multi-functional WSK-MLT

Plu g Adapator Kit (for WSK-MLT) PLUG-ADP

Louvers with Mesh MS-LOUVERS

Louvers with Mesh - End Pan el MS-LOUVERS-EP

Heat & Glo • PIER-HV-IPI, ST -HV -IPI, L&R-COR-HV -IPI • 2005-900 Rev . K • 1 1/06

9

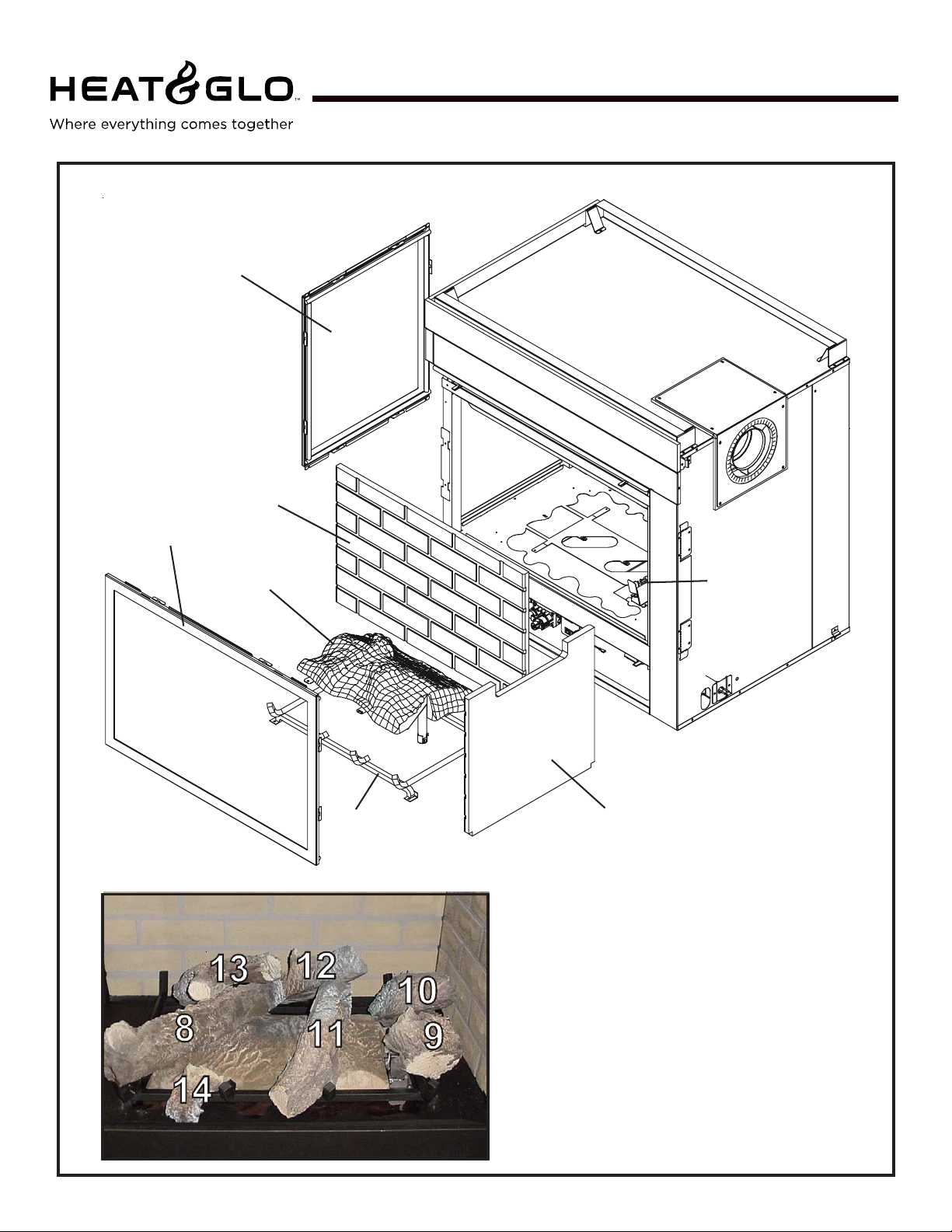

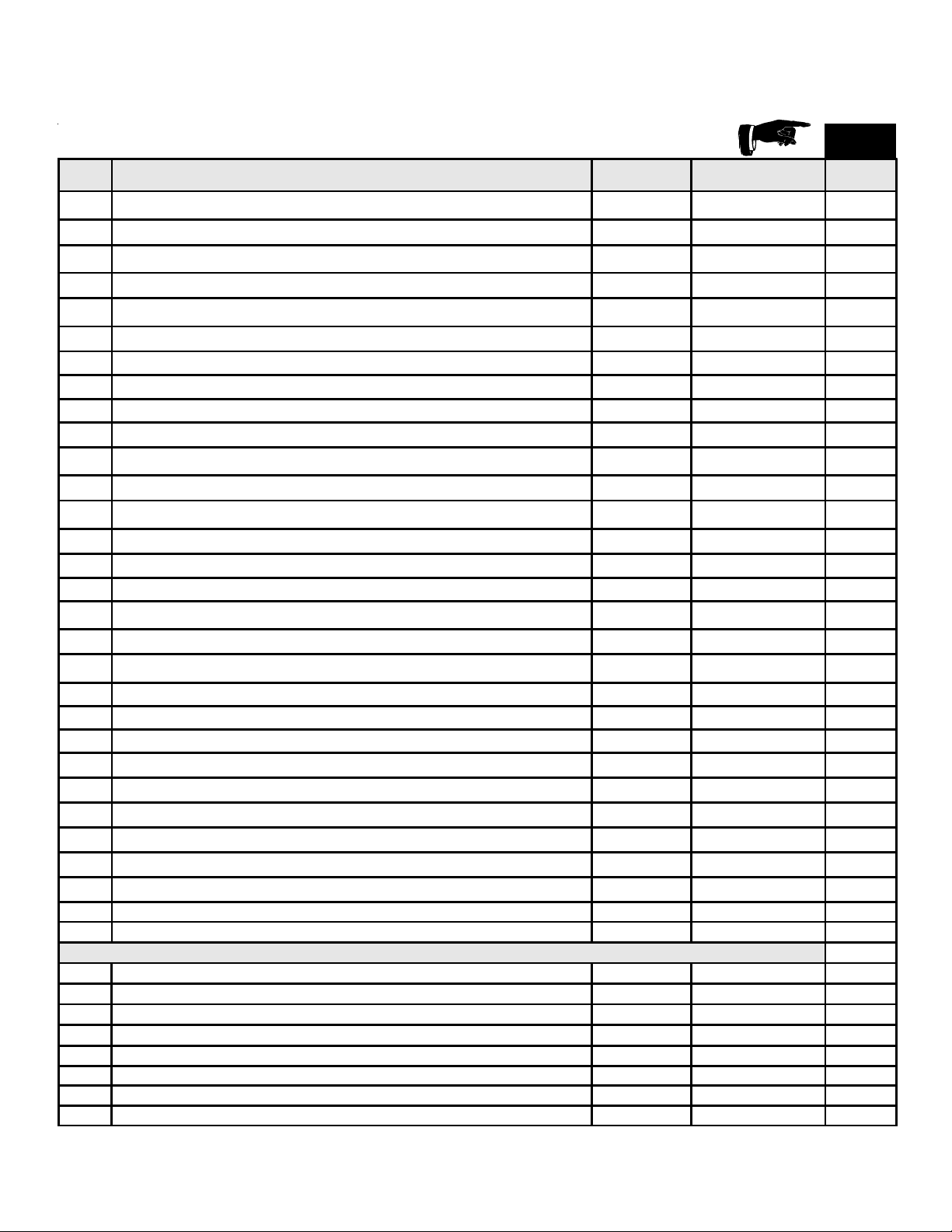

Service Parts

RCOR-HV-IPI

(NG , LP) Exploded Parts Diagram

6

5

15

Beginning Manufacturing Date: 6-03

Ending Manufacturing Date: ______

2

Part number list on following page.

Heat & Glo • PIER-HV-IPI, ST -HV -IPI, L&R-COR-HV -IPI • 2005-900 Rev . K • 1 1/0610

4

3

7 Log Assembly

1

Grate

Bar

Service Parts List (NG, LP)

RCOR-HV-IPI

IMPORT ANT: THIS IS DA TED INFORMA TION. The most current information is located on your dealers VIP site. When ordering,

supply serial and model numbers to ensure correct service parts.

AVAILABLE

TO SHIP IN 24

HOURS

ITEM COMMON PARTS SERIAL # PART NUMBER

Burner Orifice NG (#32DMS) 582-832 Y

Burner Orifice LP (#50DMS) 582-850 Y

1End Glass Assembly GLA-MS Y

2 Glass Door Assembly GLA-6TROC Y

3 Burner Assembly 2005-006 Y

4 Log Grate 2005-012

5 Si de Refractory SRV2005-730

6 Refractory, Back SRV2005-731

7 Log Set Assembly LOGS-MSR Y

8 Log 1 SRV2005-701

9 Log 2 SRV2005-700

10 Log 3 SRV2005-702

11 Log 4 SRV2005-703

Î

12 Log 5 SRV2005-704

13 Log 6 SRV2005-705

14 Log 7 SRV703-703

Lava Rock Bag 2005-790

Flue Restrictor 385-128

Teco-Sil, 5 lb. bag 700-790

Ember Mesh Assembly 2006-008 Y

Non-Combustible Board (side) 2006-136

Non-Combustible Board (end) 2008-114

Junctio n Box 4021-013 Y

3V Adaptor Plug 593-593A Y

Battery Pack 593-594A Y

Fiberglass Rope 060-455

Glass Latch Support Assembly 386-122A Y

Mineral Wool 050-721

Conversion Kit NG NGK-MS Y

Conversion Kit LP LPK-MS Y

ACCESSORIES

Fan Kit GFK-160A

Remote Control K it RC-SMART-HNG

Remote Control K it SMART-STAT-HNG

Remote Control - Multi-functional RCT-MLT-HNG

Wall Switch, Multi-functional WSK-MLT

Plug Adapator Kit (for WSK-MLT) PLUG-ADP

Louvers wit h Mesh MS-LOUVERS

Louvers with Mesh - End Panel MS-LOUVERS-EP

Heat & Glo • PIER-HV-IPI, ST -HV -IPI, L&R-COR-HV -IPI • 2005-900 Rev . K • 1 1/06

11

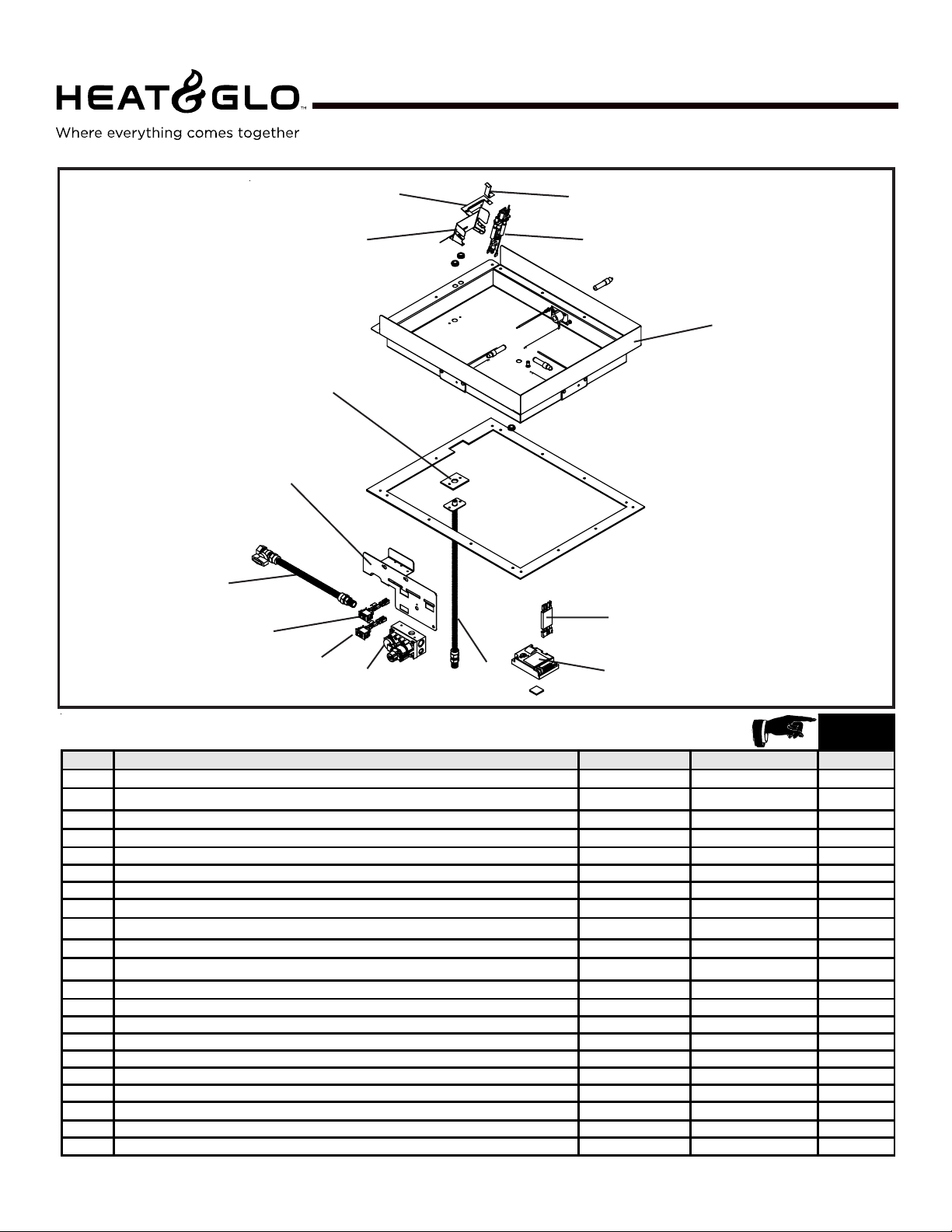

PIER-HV -IPI, ST-HV -IPI

11

Service Parts

(NG , LP) Exploded Parts Diagram

13

9

10

L&RCOR-HV -IPI

Beginning Manufacturing Date: 6-03

Ending Manufacturing Date: ______

14

8

7

12

6

1

2

ITEM DESCRIPTION SERIAL # PART NUMBER

1 ON/OFF Rocker Switch 060-511 Y

2ON/OFF Wire Assembly 060-521A Y

3Valve NG 750-500 Y

3Valve LP 750-501 Y

4 Flexible Gas Connector 2005-009 Y

5Module 593-592 Y

6Wire Assembly 593-590A Y

7 E mbe r B o x Asse mb ly 2005-114 Y

8 Pi lot Assembly NG 385-510A Y

8 Pilot Assembly LP 385-511A Y

9 Pilot Bracket 2005-118

10 Gask e t Orific e 2005-166

11 Valve B racket 2005-120

12 Flex Ball Valve Assembly 302-320A Y

13 Pilot Assembly Support 385-120

14 G r ound Str ap 385-512

Regulato r, NG NGK-DXV Y

Regulator, LP LPK-DXV Y

Pilot Tube 446-301 Y

Orifi c e Spud NG 446-505 Y

Orifice Spud LP 446-517 Y

NOTE: Replacement bulbs to be supplied by homeowner. Recommended replacements: Sylvania Mini Candelabra 75 watt s.

3

4

5

AVAIL ABLE TO

SH IP IN 24

HOURS

Heat & Glo • PIER-HV-IPI, ST -HV -IPI, L&R-COR-HV -IPI • 2005-900 Rev . K • 1 1/0612

1

Approvals and

Codes

Appliance Certification

The Heat & Glo fireplace models discussed in this Installers

Guide have been tested to certification standards and listed

by the applicable laboratories.

Certification

MODELS: PIER-HV-IPI, ST -HV -IPI,

LCOR-HV-IPI, RCOR-HV -IPI

LABORA TORY: Underwriters Laboratories

TYPE: Direct Vent Gas Fireplace Heater

ST ANDARD: ANSI Z21.88•CGA2.22•UL307B

Installation Codes

The fireplace installation must conform to local codes. Before

installing the fireplace, consult the local building code

agency to ensure that you are in compliance with all

applicable codes, including permits and inspections.

In the absence of local codes, the fireplace installation must

conform to the National Fuel Gas Code ANSI Z223.1 (in the

United States) or the CAN/CGA-B149 Installation Codes

(in Canada). The appliance must be electrically grounded

in accordance with local codes or, in the absence of local

codes with the National Electric Code ANSI/NFPA No. 70

(in the United States), or to the CSA C22.1 Canadian Electric

Code (in Canada).

High Altitude Installations

U.L. Listed gas appliances are tested and approved without requiring changes for elevations from 0 to 2,000 feet in

the U. S. A. and in Canada.

When installing this appliance at an elevation above 2,000

feet, it may be necessary to decrease the input rating by

changing the existing burner orifice to a smaller size. Input

rate should be reduced by 4% for each 1000 feet above a

2000 foot elevation in the U.S.A. or 10% for elevations

between 2000 and 4500 feet in Canada. If the heating value

of the gas has been reduced, these rules do not apply . To

identify the proper orifice size, check with the local gas

utility.

If installing this appliance at an elevation above 4,500 feet

(in Canada), check with local authorities.

These models may be installed in a bedroom or bed-sitting

room in the U.S.A. and Canada.

Heat & Glo Quality Systems

registered by SGS ICS

Heat & Glo • PIER-HV-IPI, ST -HV -IPI, L&R-COR-HV -IPI • 2005-900 Rev . K • 1 1/06

13

NOTE: The following requirements reference various

Massachusetts and national codes not contained in

this document.

G. Requirements for the Commonwealth of

Massachusetts

For all side wall horizontally vented gas fueled equipment

installed in every dwelling, building or structure used in

whole or in part for residential purposes, including those

owned or operated by the Commonwealth and where the

side wall exhaust vent termination is less than seven (7)

feet above finished grade in the area of the venting, including but not limited to decks and porches, the following requirements shall be satisfied:

Installation of Carbon Monoxide Detectors

At the time of installation of the side wall horizontal vented

gas fueled equipment, the installing plumber or gasfitter

shall observe that a hard wired carbon monoxide detector

with an alarm and battery back-up is installed on the floor

level where the gas equipment is to be installed. In addition, the installing plumber or gasfitter shall observe that a

battery operated or hard wired carbon monoxide detector

with an alarm is installed on each additional level of the

dwelling, building or structure served by the side wall horizontal vented gas fueled equipment. It shall be the responsibility of the property owner to secure the services of qualified licensed professionals for the installation of hard wired

carbon monoxide detectors.

In the event that the side wall horizontally vented gas fueled equipment is installed in a crawl space or an attic, the

hard wired carbon monoxide detector with alarm and battery back-up may be installed on the next adjacent floor

level.

In the event that the requirements of this subdivision can

not be met at the time of completion of installation, the

owner shall have a period of thirty (30) days to comply with

the above requirements; provided, however, that during said

thirty (30) day period, a battery operated carbon monoxide

detector with an alarm shall be installed.

Approved Carbon Monoxide Detectors

Each carbon monoxide detector as required in accordance

with the above provisions shall comply with NFP A 720 and

be ANSI/UL 2034 listed and IAS certified.

Inspection

The state or local gas inspector of the side wall horizontally

vented gas fueled equipment shall not approve the installation unless, upon inspection, the inspector observes carbon

monoxide detectors and signage installed in accordance with

the provisions of 248 CMR 5.08(2)(a)1 through 4.

Exemptions

The following equipment is exempt from 248 CMR 5.08(2)(a)1

through 4:

• The equipment listed in Chapter 10 entitled “Equipment

Not Required To Be Vented” in the most current edition

of NFP A 54 as adopted by the Board; and

• Product Approved side wall horizont ally vented gas fueled equipment installed in a room or structure separate from the dwelling, building or structure used in whole

or in part for residential purposes.

MANUFACTURER REQUIREMENTS

Gas Equipment Venting System Provided

When the manufacturer of Product Approved side wall horizontally vented gas equipment provides a venting system

design or venting system components with the equipment,

the instructions provided by the manufacturer for installation of the equipment and the venting system shall include:

• Detailed instructions for the installation of the venting

system design or the venting system components; and

• A complete parts list for the venting system design or

venting system.

Gas Equipment Venting System NOT Provided

When the manufacturer of a Product Approved side wall

horizontally vented gas fueled equipment does not provide

the parts for venting the flue gases, but identifies “special

venting systems”, the following requirements shall be satisfied by the manufacturer:

• The referenced “special venting system” instructions shall

be included with the appliance or equipment installation

instructions; and

• The “special venting systems” shall be Product Approved

by the Board, and the instructions for that system shall

include a parts list and detailed installation instructions.

Signage

A metal or plastic identification plate shall be permanently

mounted to the exterior of the building at a minimum height

of eight (8) feet above grade directly in line with the exhaust vent terminal for the horizontally vented gas fueled

heating appliance or equipment. The sign shall read, in

print size no less than one-half (1/2) inch in size, “GAS

VENT DIRECTLY BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS”.

Heat & Glo • PIER-HV-IPI, ST -HV -IPI, L&R-COR-HV -IPI • 2005-900 Rev . K • 1 1/0614

A copy of all installation instructions for all Product Approved side wall horizontally vented gas fueled equipment,

all venting instructions, all parts lists for venting instructions, and/or all venting design instructions shall remain

with the appliance or equipment at the completion of the

installation.

See Gas Connection section for additional Commonwealth of Massachusetts requirements.

Loading...

Loading...