Page 1

Models:

CFX-IN

CFX-Grand

WARNING: IF THE INFORMATION

IN THESE INSTRUCTIONS IS NOT

FOLLOWED EXACTLY, A FIRE OR

EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE, PERSONAL INJURY, OR DEATH.

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

- What to do if you smell gas

Do not try to light any appliance.

Do not touch any electrical switch.

Do not use any phone in your building.

Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

If you cannot reach your gas supplier, call

the fire department.

- Installation and service must be performed by a

qualified installer, service agency, or the gas

supplier.

Installers Guide

Underwriters

Laboratories Listed

READ THIS MANUAL BEFORE INSTALLING OR

OPERATING THIS APPLIANCE. THIS INSTALLERS

GUIDE MUST BE LEFT WITH APPLIANCE FOR

FUTURE REFERENCE.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION,

SERVICE OR MAINTENANCE CAN

CAUSE INJURY OR PROPERTY DAMAGE. REFER TO THIS MANUAL. FOR

ASSISTANCE OR ADDITIONAL INFORMATION CONSULT A QUALIFIED INSTALLER, SERVICE AGENCY, OR THE

GAS SUPPLIER.

1. This appliance may be installed in an aftermarket, permanently located, manufactured

(mobile) home, where not prohibited by local codes.

2. This appliance is only for use with the type

of gas indicated on the rating plate. This

appliance is not convertible for use with

other gases, unless a certified kit is used.

Printed in U.S.A. Copyright 2001,

Heat-N-Glo, a division of Hearth Technologies Inc.

20802 Kensington Boulevard, Lakeville, MN 55044

This product is covered by one or more of the following patents: (United States) 4,112,913; 4,408,594; 4,422,426; 4,424,792; 4,520,791; 4,793,322;

4,852,548; 4,875,464; 5,000,162; 5,016,609; 5,076,254 5,191,877; 5,218,953; 5,328,356; 5,429,495; 5,452,708; 5,542,407; 5,613,487; (Australia)

543790; 586383; (Canada) 1,123,296; 1,297,746; 2,195,264; (Mexico) 97-0457; (New Zealand) 200265; or other U.S. and foreign patents pending.

Please contact your Heat-N-Glo dealer with any

questions or concerns. For the number of your

nearest Heat-N-Glo dealer, please call 952-985-6000.

1

568-900E 3/01

Page 2

SAFETY AND WARNING INFORMATION

READ and UNDERSTAND all instructions carefully

!

before starting the installation. FAILURE TO

FOLLOW these installation instructions may result

in a possible fire hazard and will void the warranty.

Prior to the first firing of the fireplace, READ the

!

Using Your Fireplace section of the Owners Guide.

DO NOT USE this appliance if any part has been

!

under water. Immediately CALL a qualified service

technician to inspect the unit and to replace any part

of the control system and any gas control which has

been under water.

THIS UNIT IS NOT FOR USE WITH SOLID FUEL.

!

Installation and repair should be PERFORMED by a

qualified service person. The appliance and venting

!

system should be INSPECTED before initial use

and at least annually by a professional service

person. More frequent cleaning may be required

due to excessive lint from carpeting, bedding

material, etc. It is IMPERATIVE that the units

control compartment, burners, and circulating air

passageways BE KEPT CLEAN to provide for

adequate combustion and ventilation air.

These units MUST use one of the vent systems

described in the Installing the Fireplace section of

!

the Installers Guide. NO OTHER vent systems or

components MAY BE USED.

This gas fireplace and vent assembly MUST be

!

vented directly to the outside and MUST NEVER be

attached to a chimney serving a separate solid fuel

burning appliance. Each gas appliance MUST USE

a separate vent system. Common vent systems are

PROHIBITED.

INSPECT the external vent cap on a regular basis to

!

make sure that no debris is interfering with the air

flow.

The glass door assembly MUST be in place and

!

sealed, and the trim door assembly MUST be in

place on the fireplace before the unit can be placed

into safe operation.

DO NOT OPERATE this appliance with the glass

!

door removed, cracked, or broken. Replacement of

the glass door should be performed by a licensed

or qualified service person. DO NOT strike or slam

the glass door.

Always KEEP the appliance clear and free from

!

combustible materials, gasoline, and other

flammable vapors and liquids.

NEVER OBSTRUCT the flow of combustion and

!

ventilation air. Keep the front of the appliance

CLEAR of all obstacles and materials for servicing

and proper operations.

Due to the high temperature, the appliance should

be LOCATED out of traffic areas and away from

!

furniture and draperies. Clothing or flammable

material SHOULD NOT BE PLACED on or near the

appliance.

Children and adults should be ALERTED to the

!

hazards of high surface temperature and should

STAY AWAY to avoid burns or clothing ignition.

Young children should be CAREFULLY SUPERVISED

when they are in the same room as the appliance.

The glass door assembly SHALL ONLY be

!

replaced as a complete unit, as supplied by the gas

fireplace manufacturer. NO SUBSTITUTE material

may be used.

DO NOT USE abrasive cleaners on the glass door

!

assembly. DO NOT ATTEMPT to clean the glass

door when it is hot.

Turn off the gas before servicing this appliance. It is

recommended that a qualified service technician

!

perform an appliance check-up at the beginning of

each heating season.

Any safety screen or guard removed for servicing

!

must be replaced before operating this appliance.

DO NOT place furniture or any other combustible

!

household objects within 36 inches of the fireplace

front.

2

Page 3

TABLE OF CONTENTS

u

Safety and Warning Information ................................................ 2

u

u

Service Parts Lists ..................................................................... 4

Section 1: Approvals and Codes ............................................... 8

Appliance Certification................................................................... 8

u

Installation Codes .......................................................................... 8

High Altitude Installations ............................................................... 8

Section 2: Getting Started ......................................................... 9

Introducing the Heat-N-Glo Gas Appliances .................................. 9

Pre-installation Preparation ........................................................... 9

Venting and Installation .................................................................. 9

u

Section 3: Installing the Insert ................................................. 11

u

Step 1 Installing the Vent System............................................. 11

Step 2 Positioning, Leveling, and Securing the Insert ............. 15

Step 3 The Gas Control Systems ........................................... 15

Step 4 The Gas Supply Line ................................................... 15

u

Step 5 Gas Pressure Requirements ...................................... 16

Step 6 Wiring the Appliance .................................................... 16

u

Step 7 Installing Logs and Ember Material .............................. 17

Positioning the Logs .................................................... 17

Placing the Ember Material .......................................... 17

Step 8 Installing Trim Surround ............................................... 17

Step 9 Before Lighting the Appliance ...................................... 18

u

Step 10 Lighting the Appliance .................................................. 18

After the Installation ..................................................................... 18

Section 4: Maintaining and Servicing Your Appliance ........ 19

u

u = Contains updated information.

3

Page 4

Service Parts

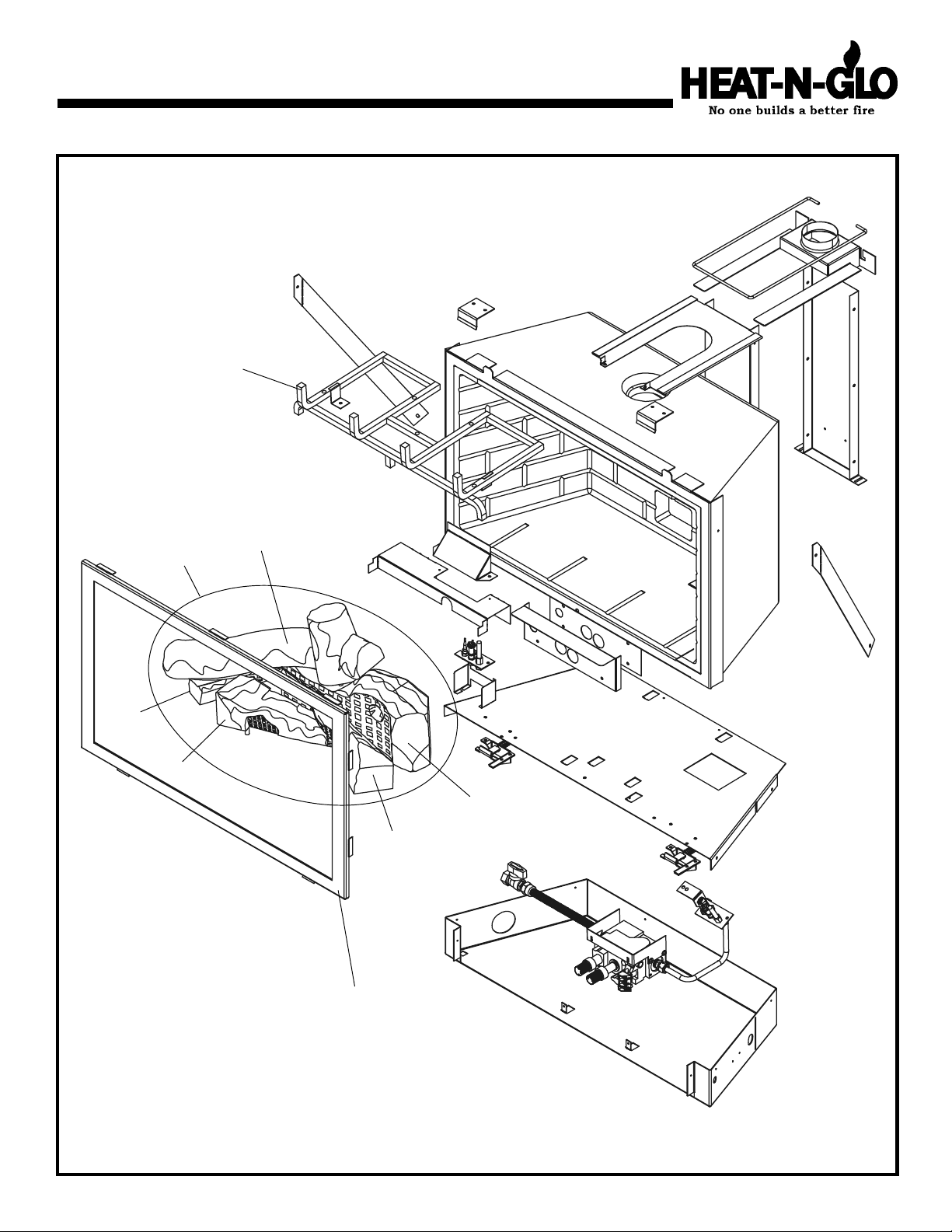

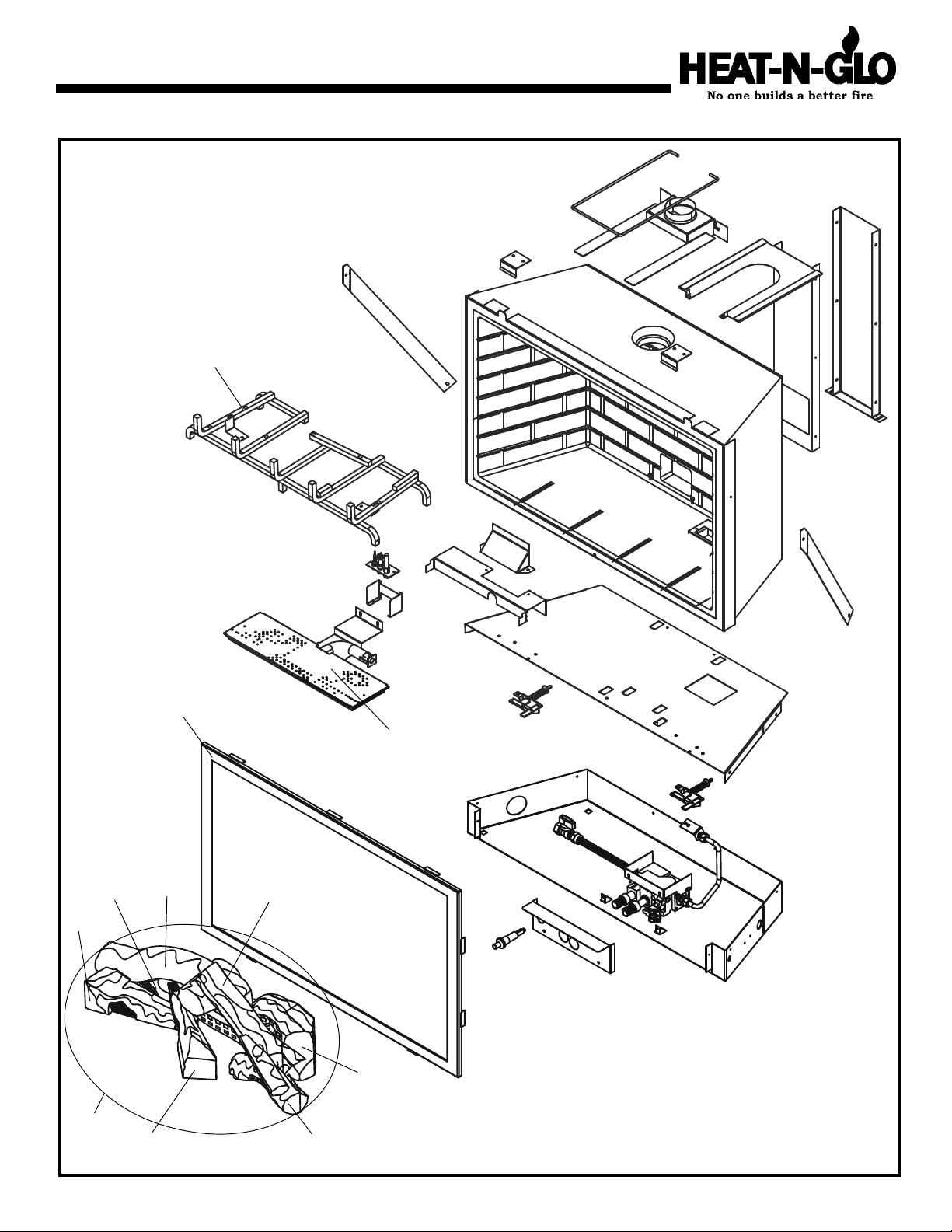

CFX-IN (NG, LP) Exploded Parts Diagram / CFX-IN (GN, PL) Vue éclatée des pièces

2

3

8

5

6

4

7

1

Part number list on following page.

*

La liste des numéros de pièce se trouve à la page suivante.

*

4

Page 5

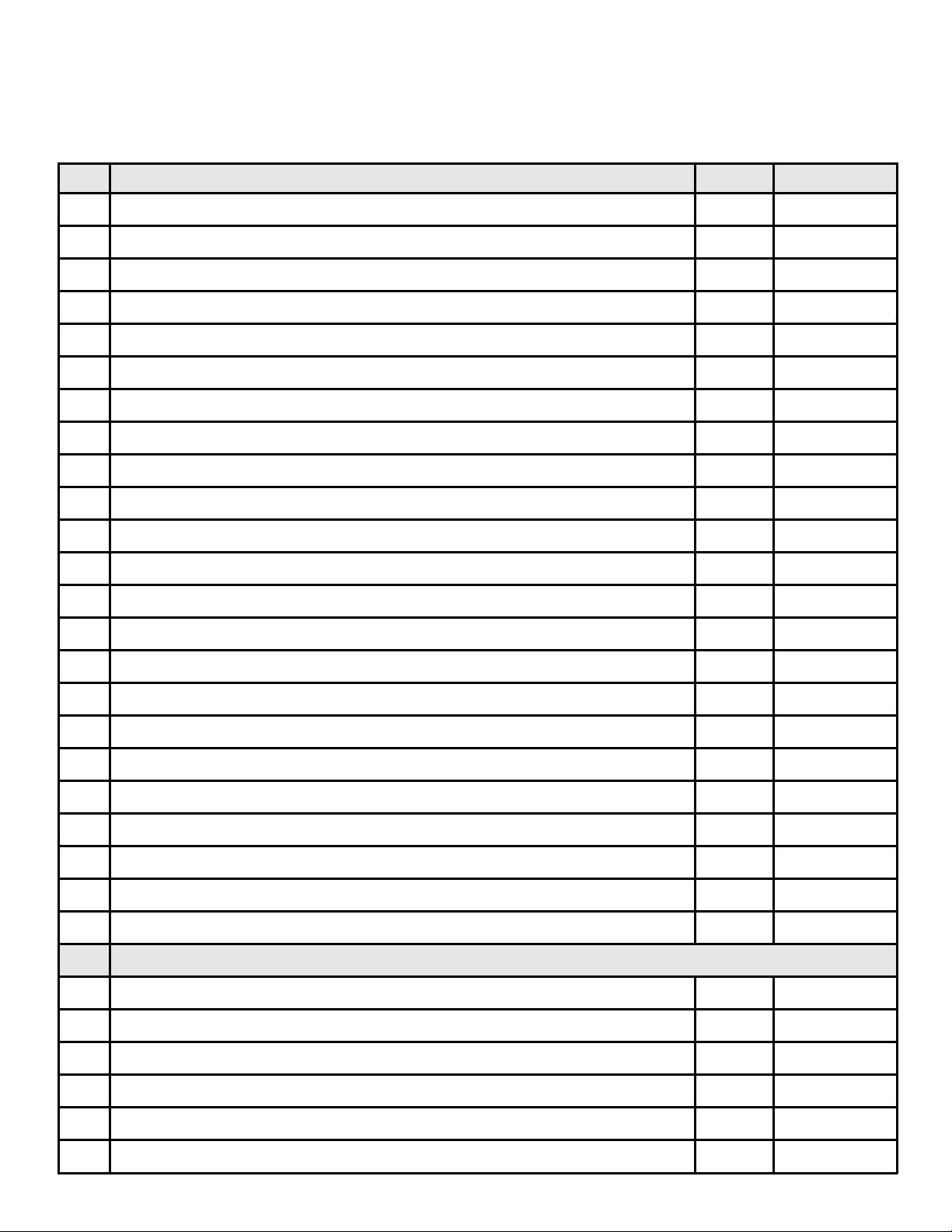

CFX-IN (NG, LP) Service Parts List / CFX-IN (GN, PL) Liste des pièces de rechange

IMPORTANT: THIS IS DATED INFORMATION. The most current information is located on your dealers VIP site. When ordering, supply serial and model numbers to ensure correct service parts. / IMPORTANT : L'information fournie dans cette brochure

n'est valide que pendant une courte période. Les sites VIP des distributeurs disposent des renseignements les plus récents.

Lors d'une commande, veuillez fournir les numéros de série et de modèles pour un remplacement adéquat des pièces.

ITE M /

PIÈCE

STANDING PILOT / VEILLEUSE

SERIAL # /

N° DE SÉRIE

PART N UMBE R

/ N° DE PIÈCE

ON /OFF Roc ker Switch / Interrupteur à bascule marche/arrêt 680-528

Piezo Ignitor / Allumage Piézo 418-513

Burner Tube / Tube de brûleur 477-301A

Burner Orifice NG (#32B) / Orifice de brûleur GN (#32B) 573-800

Burner Orifice LP (#49B) / Orifice de brûleur PL (#49B ) 047-801

1 Glass Door Assembly, Ceramic / Porte en verre GLA-CFXIN

Burner NG / Brûleur GN 573-326A

Burner LP / Brûleur PL 573-325A

2 Log Grate / Grille de Bûche 573-360A

3 Log Set Assembly / Jeu de Bûches LOGS-CFXIN

4 Log 1 / Bûche 1 SRV573-701

5 Log 2 / Bûche 2 S RV573-703

6 Log 3 / Bûche 3 S RV573-704

7 Log 4 / Bûche 4 S RV573-705

8Log 5 / Bûche 5 SRV573-702

Valve N G / Va lve GN 571-500

Valve LP / Valve PL 571-501

Pilot Assembly NG / Module de veilleuse GN 571-510A

Pilot Assembly LP / Module de veilleuse PL 571-511A

Pilot Orifice NG / Orifice de veilleuse GN 571-516

Pilot Orifice LP / Orifice de vei lleuse PL 571-517

Thermocouple / Thermocouple 57 1-511

Thermopile / Thermopile 060-512

ACCESSORIES / AC CE SSOIRES

Remote Co ntrol Kit / Commande à di s tance RC-SMA RT

Remote C ontrol Kit / Commande à distance SMART-STAT

Wall Switch Kit, Off-white / Module d'interrupteur mural, B lanc Cassé WSK-21

Wall Switch Kit, White / Module d'interrupteur mural, Blanc WSK-21-W

Conversion Kit NG / Module de conversion GN NGK-CFXIN

Conversion Kit LP / Module de conversion PL LPK-CFXIN

5

Page 6

Service Parts

CFX-GRAND (NG, LP) Exploded Parts Diagram / CFX-GRAND (GN, PL) Vue éclatée des pièces

3

1

2

10

6

11

7

5

4

8

9

Part number list on following page.

*

La liste des numéros de pièce se trouve à la page

*

suivante.

6

Page 7

CFX-GRAND (NG, LP) Service Parts List / CFX-GRAND (GN, PL) Liste des pièces de rechange

IMPORTANT: THIS IS DATED INFORMATION. The most current information is located on your dealers VIP site. When ordering,

supply serial and model numbers to ensure correct service parts. / IMPORTANT : L'information fournie dans cette brochure n'est

valide que pendant une courte période. Les sites VIP des distributeurs disposent des renseignements les plus récents. Lors

d'une commande, veuillez fournir les numéros de série et de modèles pour un remplacement adéquat des pièces.

ITE M /

PIÈCE

STANDING PILOT / VEILLEUSE

SERIAL # /

N° DE S ÉRIE

PART NUMBER

/ N° DE PIÈCE

ON/OFF Rocker Switch / Interrupteur à bascule marche/arrêt 680-528

Piezo Ignitor / Allumage Piézo 418-513

Burner Tube / Tube de brûleur 477-301A

Burner Orifice NG (#31B) / Orifice de brûleur GN (#31B) 455-800

Burner Orifice LP (#49B) / Orifice de brûleur PL (#49B) 047-801

1 Glass Door Assembly, Ceramic / Porte en verre GLA-CFXG

2 Burner NG / Brûleur GN 568-326A

2 Burner LP / Brûleur P L 568-325A

3 Log Grate / Grille de Bûche 568 -360A

4 Log Se t Assembly / Jeu de Bûches LOGS-CFXG

5 Log 1 / Bûche 1 SRV573-701

6 Log 2 / Bûche 2 SRV568-705

7 Log 3 / Bûche 3 SRV573-704

8 Log 4 / Bûche 4 SRV573-705

9 Log 5 / Bûche 5 SRV568 -705

10 Log 6 / Bûche 6 S RV573-702

11 Log 7 / B ûche 7 SRV568 -706

Valve NG / Valve GN 571-500

Valve LP / Valve PL 571-501

Pilot Assembly NG / Module de veilleuse GN 571-510A

Pilot Assembly LP / Module de veilleuse PL 571-511A

Pilot Orifice NG / Orifice de veilleuse GN 571-516

Pilot Orifice LP / Orifice de veilleuse PL 571-517

Thermocouple / Thermocouple 571-511

Thermopile / Thermopile 060-512

ACCESSORIES / ACCESSOIRES

Remote Contro l Kit / Commande à distance RC-SMART

Remote Contro l Kit / Commande à distance SMART-STAT

Wall S w i tc h Ki t, Off- whi te / M o d ule d'inter rup teur mura l, Bla nc Cas s é WSK - 21

Wall Switch Ki t, White / Module d'interrupteur mural, Blanc WSK-21-W

Conversion Kit NG / Module de conversion GN NGK-CFX G

Conversion Kit LP / Module de conversion PL LPK-CFX G

7

Page 8

1

Approvals and

Codes

Appliance Certification

The Heat-N-Glo appliance models discussed in this

Installers Guide have been tested to certification standards

and listed by the applicable laboratories.

Certification

MODELS: CFX-IN, CFX-GRAND

LABORATORY: Underwriters Laboratories

TYPE: Direct Vent Gas Fireplace Heaters

STANDARD: ANSI Z21.88CSA2.33UL307B

Installation Codes

The appliance installation must conform to local codes.

Before installing the appliance, consult the local building

code agency to ensure that you are in compliance with all

applicable codes, including permits and inspections.

In the absence of local codes, the fireplace installation must

conform to the National Fuel Gas Code ANSI Z223.1 (in the

United States) or the CAN/CGA-B149 Installation Codes

(in Canada). The appliance must be electrically grounded

in accordance with local codes or, in the absence of local

codes with the National Electric Code ANSI/NFPA No. 70

(in the United States), or to the CSA C22.1 Canadian Electric

Code (in Canada).

High Altitude Installations

U.L. Listed gas appliances are tested and approved for

elevations from 0 to 2,000 feet in the U.S.A. and from 0 to

4,500 feet in Canada.

When installing this appliance at an elevation above 2,000

feet (in the United States), it may be necessary to decrease

the input rating by changing the existing burner orifice to a

smaller size. Input should be reduced four percent (4%) for

each 1,000 feet above sea level, unless the heating value of

the gas has been reduced, in which case this general rule

will not apply. To identify the proper orifice size, check with

the local gas utility.

When installing this appliance at an elevation between 2,000

and 4,500 feet (in Canada), the input rating must be reduced

by ten percent (10%).

When installing this appliance at an elevation above 4,500

feet (in Canada), check with local authorities.

Consult your local gas utility for assistance in determining

the proper orifice for your location.

These models may be installed in a bedroom or bed-sitting

room in the U.S.A. and Canada.

Heat-N-Glo Quality

Systems registered

by SGS ICS

8

Page 9

2

Getting Started

Introducing the Heat-N-Glo Gas Appliances

Heat-N-Glo direct vent gas appliances are designed to

operate with all combustion air siphoned from outside of

the building and all exhaust gases expelled to the outside.

The information contained in this Installers Guide, unless

noted otherwise, applies to all models and gas control

systems. Gas appliance diagrams, including the dimensions,

are shown in this section.

Pre-install Preparation

This gas insert fireplace and its components are tested

and safe when installed in accordance with this Installers

Guide. Report to your dealer any parts damaged in shipment,

particularly the condition of the glass. Do not install any

unit with damaged, incomplete, or substitute parts.

The vent system components and trim surrounds are shipped

in separate packages. The gas logs are packaged

separately and must be field installed.

Read all of the instructions before starting the

installation. Follow these instructions carefully during

the installation to ensure maximum safety and benefit.

Failure to follow these instructions will void the

owners warranty and may present a fire hazard.

The Heat-N-Glo Warranty will be voided by, and Heat-N-Glo

disclaims any responsibility for, the following actions:

Installation of any damaged fireplace or vent system

component.

Modification of the fireplace or direct vent system.

Installation other than as instructed by Heat-N-Glo.

Improper positioning of the gas logs or the glass door.

Installation and/or use of any component part not manu-

factured and approved by Heat-N-Glo, not withstanding

any independent testing laboratory or other party approval

of such component part or accessory.

ANY SUCH ACTION MAY POSSIBLY CAUSE A FIRE

HAZARD.

VENTING AND INSTALLATION

1. Heat -N-Glo gas inserts are designed for recessed in-

stallations into solid fuel Masonry or Factory Built Non

Combustible fireplaces that have been installed in accordance with the National, Provincial, State and local

building codes.

2. Minimum fireplace opening requirements are shown in

Figures 1 and 2 of this installation manual. The firebrick

(refractory) can be removed from a factory built fireplace

in order to gain minimum gas insert opening requirements.

WARNING: Under no circumstances is cutting

!

of sheet metal surfaces allowed for installation.

If the factory built fireplace has no gas ac-

!

cess holes provided, an access hole of 1 diameter (25mm) or less may be drilled through the

lower sides or bottom of the combustion chamber in a proper workmanship like manner.

3. To assure top performance, safety and efficiency, inserts

must be installed with an approved flue liner as per CAN/

CGA B-149 or National Fuel Code ANSI Z223 and these

instructions.

WARNING: A HEARTH OR HEARTH EXTEN-

!

SION (IF PRESENT) MUST COMPLY WITH EITHER OF THE FOLLOWING: 1) THE SOLID-FUEL

BURNING FIREPLACE MANUFACTURERS SPECIFICATION, OR 2) LOCAL BUILDING CODES REQUIRED BY AUTHORITY HAVING JURISDICTION.

WARNING: THE SOLID FUEL FIREPLACE HAS

!

BEEN CONVERTED FOR USE WITH GAS

ONLY AND CANNOT BE USED FOR BURNING

WOOD OR SOLID FUELS UNLESS ALL ORIGINAL

PARTS HAVE BEEN REPLACED AND THE FIREPLACE HAS BEEN REAPPROVED BY THE AUTHORITY HAVING JURISDICTION.

4. The solid fuel fireplaces flue damper must be fully locked

in the open position or removed for installation.

5. The chimney must be cleaned and in good working order

and constructed of noncombustible materials.

6. Make sure that all chimney cleanouts fit properly so air

cannot leak into the chimney.

7. Install the insert without the trim surround and make all

gas, venting, and electrical connections.

WARNING: Modification of any sheetmetal or

!

fiber surfaces is strictly PROHIBITED in the

installation of this appliance.

8. Install decorative trim surround. Please refer to instructions included with the trim surround.

Ensure there are no obstructions to side air

!

passages by the decorative trim once it is installed on insert.

When planning a fireplace insert installation, its necessary

to determine:

The vent system configuration to be used.

Gas supply piping.

Whether optional accessoriesdevices such as a wall

switch or remote controlare desired.

9

Page 10

9 7/8 (251mm)

13 3/4

(349mm)

19 3/4 (502mm)

1 5/8 (42mm)

3 3/4 (95mm)

GAS LINE

ACCESS

1 1/2

(39mm)

8 1/4

(210mm)

MINIMUM FIREPLACE SIZE

FRONT WIDTH : 30 (762mm)

REAR WIDTH : 20 1/4 (514mm)

DEPTH : 14 1/4 (362mm)

HEIGHT : 23 1/2 (597mm)

*

NOTE: If exhaust collar on insert and fireplace damper

*

do not line up, add 4 inches (102mm) to minimum

fireplace height for bends in vent pipe.

Figure 1. Diagram of the CFX-IN

21 3/8

(543mm)

12 1/8 (308mm)

29 (736mm)

14 1/4”

(362mm)

24 1/4 (616mm)

Ø 2 3/4 ( 70mm)

23 3/8

(593mm)

ELECTRICAL ACCESS

20 1/4” (514mm)

30” (762mm)

1 5/8 (42mm)

13 7/8

(352mm)

GAS LINE

ACCESS

25 3/16

(640mm)

1 1/2

(40mm)

8 3/16

(208mm)

MINIMUM FIREPLACE SIZE

FRONT WIDTH : 34 3/4 (883mm)

REAR WIDTH : 25 1/4 (641mm)

DEPTH : 14 1/4 (362mm)

HEIGHT : 26 3/4 (679mm)

*

NOTE: If exhaust collar on insert and fireplace damper

*

do not line up, add 4 inches (102mm) to minimum

fireplace height for bends in vent pipe.

33 3/4 (857mm)

14 1/4” (362mm)

3 3/4 (95mm)

Ø 2 7/8 (73mm)

26 13/16

(681mm)

ELECTRICAL ACCESS

25 1/4” (641mm)

34 3/4” (883mm)

Figure 2. Diagram of the CFX-GRAND

10

Page 11

3

Installing the Insert

Step 1. Installing the Vent System

Vent System Installation Precautions

Before starting installation of vent kits, the installer should

read these instructions and the Vent Kit Instructions to

ensure that a proper vent installation is completed.

Consult your local building codes before beginning the

installation.

WARNING: THIS GAS INSERT AND VENT AS-

!

SEMBLY MUST BE VENTED DIRECTLY TO THE

OUTSIDE AND MUST NEVER BE ATTACHED TO A

CHIMNEY SERVING A SEPARATE SOLID FUEL

BURNING APPLIANCE. EACH GAS APPLIANCE

MUST USE A SEPARATE VENT SYSTEM. COMMON

VENT SYSTEMS ARE PROHIBITED.

Vent System Approvals

Models: Vent System

CFX-IN LINK-DV30, LINK- DV4-30

CFX-GRAND LINK-DV30, LINK-DV4-30

Table 1

Table 1 and Figures 4 through 6 show the vent termination

caps and systems approved for the use with these models.

Approved vent system terminations are labeled for identification. 3-inch diameter listed flexible aluminum and stainless steel gas vent is used for both the incoming combustion air and exhaust vent pipes. NO OTHER VENTING SYSTEMS OR COMPONENTS MAY BE USED. Detailed installation instructions are included with each vent termination kit and should be used in conjunction with this manual.

Horizontal Venting

The vent system on this model CANNOT be terminated

horizontally.

Vertical Venting

The vent pipes MUST be connected to the proper collars

on the unit AND the exhaust vent pipe MUST be connected

to the termination cap or the unit will not operate. The combustion air vent pipe CAN be connected to the termination

cap (LINK -DV30) or it can terminate inside the chimney

(LINK-DV4-30). The bottom opening of the chimney must

be sealed around the vent pipes if the combustion air vent

is NOT connected to the termination cap. See Figures 4, 5

and 6.

NOTE: The minimum vertical rise (exhaust vent) is 14 feet

and the maximum vertical rise is 40 feet. These dimensions

are measured from the starting collars of the unit to the end

of the last section of vent pipe. See dimension V in Figure 4.

A vertical vent termination system installed on this model

will include one (1) length of 3-inch flexible vent pipe for the

combustion air, one (1) length of 3-inch flexible vent pipe for

the exhaust air, one (1) pipe-to-cap adaptor, and one (1)

SLK-991DA or SLK-980D Vertical Termination Cap.

NOTE: The damper of the masonry chimney may need to

be removed to allow installation of the flexible-vent pipe.

This fireplace has been altered to accommodate an

insert and should be inspected by a qualified person

prior to re-use as a conventional fireplace.

NOTE: The above label, located in the instruction package,

must be affixed to the existing fireplace prior to installation.

For zero clearance factory built woodburning fireplaces, the

use of kit LINK-ZC-ADP in place of the standard square

flashing will allow you to mount the adaptor and cap on

metal pipe. Additionally, the use of kit FLASH-DAMP will

seal off the damper opening when terminating the inlet air

vent pipe just above the damper. These 2 kits are

recommended for zero clearance, factory built woodburning

fireplaces.

Connecting the Vent Pipe

Install the 3 flexible vent pipe(s) down through the chimney.

Secure the end of the flexible vent pipe for exhaust to the

provided 3 section of stainless steel flexible vent pipe. A 3

collar is factory installed on one end for mating the two

ends of flexible pipe. Slide the gas insert into place, and

position any excess flexible vent pipe back up into the

chimney.

WARNING: THE 3 SECTION OF STAINLESS

!

STEEL FLEXIBLE PIPE MUST BE ATTACHED

DIRECTLY TO THE EXHAUST COLLAR OF THE UNIT.

Using the provided T-handle pull down tool, reach through

exhaust opening in exhaust collar by its center pin. Pull

down until exhaust collar extends through exhaust opening.

The collar should slip fit through the molded in 3 inch opening.

Carefully readjust liners to align if necessary.

Secure in place by sliding retainer pin through the provided

holes in the exhaust collar. See Figure 5.

Attach either 4 or 30 section of intake liner to the intake

collar assembly on top of the fireplace using 3 screws. This

assembly may be removed from the unit to aid installation.

Slide insert into position, while pulling intake collar assembly

towards the front of the unit. This assembly will be secured

in place when the pull handle can be locked into position at

locking tabs.

11

Page 12

WARNING: DO NOT FORCE

!

COLLAR ATTACHMENT INTO

PLACE. THE FIREPLACE IS MADE

OF A FRAGILE MATERIAL, AND

MAY BREAK. READJUST FLEXIBLE VENT PIPES IF NECESSARY.

Attach the pipe-to-cap adaptor to the

termination cap and to the top of the

flexible vent pipe and set the cap in place

at the top of the chimney. See Figures 4,

5 and 6.

CAUTION: TO AVOID DOWNDRAFTS

AND/OR COLD AIR PROBLEMS, IT IS

RECOMMENDED TO SEAL OFF THE

AREA BETWEEN THE TERMINATION

CAP AND THE TOP OF THE SOLIDFUEL CHIMNEY OPENING INTO

WHICH THE VENT CAP HAS BEEN INSTALLED.

WHEN USING THE LINK-DV4-3O VENT

SYSTEM, IT IS REQUIRED TO SEAL

AROUND THE FLEXIBLE VENT PIPES

IN THE DAMPER AREA. SEE FIGURE

5. USE FIBERGLASS INSULATION OR

OTHER SUITABLE NON-COMBUSTIBLE MATERIAL.

WARNING: MAJOR U.S.

!

BUILDING CODES SPECIFY

MINIMUM CHIMNEY AND/OR VENT

HEIGHT ABOVE THE ROOF TOP.

THESE MINIMUM HEIGHTS ARE

NECESSARY IN THE INTEREST OF

SAFETY. SEE THE FOLLOWING

DIAGRAM FOR MINIMUM HEIGHTS,

PROVIDED THE TERMINATION CAP

IS AT LEAST 2-FEET FROM A VERTICAL WALL AND 2-FEET BELOW

A HORIZONTAL OVERHANG.

HORIZONTAL OVERHANG

TERMINATION CAP

2 FT.

MIN.

2 FT. MIN.

LOWEST

DISCHARGE

OPENING

X

12

ROOF PITCH IS X/ 12

H (MIN.) - MINIMUM HEIGHT FROM ROOF

TO LOWEST DISCHARGE OPENING

Roof Pitch H (min.) ft.

flat to 6/12 1.0

6/12 to 7/12 1.25

over 7/12 to 8/12 1.5

over 8/12 to 9/12 2.0

over 9/12 to 10/12 2.5

over 10/12 to 11/12 3.25

over 11/12 to 12/12 4.0

over 12/12 to 14/12 5.0

over 14/12 to 16/12 6.0

over 16/12 to 18/12 7.0

over 18/12 to 20/12 7.5

over 20/12 to 21/12 8.0

Figure 3. Minimum Height from Roof to Lowest

Discharge Opening

VERTICAL WALL

NOTE: This also pertains to vertical vent

systems installed on the outside of the

building.

12

Page 13

TERMINATION

CAP

ADAPTOR

EXHAUS T CO LLA R

INLET AIR COLLAR

EXHAUST

VENT PIPE

V= 14 FT. MINIMUM

40FT. MAXIMUM

3 INCH COLLAR

(Factory installed to

stainless steel section)

WARNING: DO NOT

BLOCK P IPE END WITH

INSULATION OR ANY OTHER

SEALING MATERIAL

This option shows both exhaust and inlet

air vent pipes attached to the adaptor.

Figure 4.

WARNING: THE EXHAUST VENT PIPE MUST

!

ONLY BE CONNECTED TO THE EXHAUST

STARTING COLLAR OF THE UNIT AND THE

CENTER COLLAR OF THE TERMINATION CAP.

A 3 FOOT SECTION OF STAINLESS STEEL

!

FLEXIBLE LINER MUST BE ATTACHED

DIRECTLY TO THE EXHAUST COLLAR ON THE

FIREBOX.

STAINLESS STEEL

PIPE - 3 FT. MIN.

REQUIRED (INCLUDED)

LOCKING TABS

INLET AIR

VENT PIPE

COLLAR ATT A CH MENT

BRACKET

THE INLET AIR PIPE MUST ONLY BE

!

CONNECTED TO THE INLET AIR COLLAR OF

THE UNIT AND EITHER ATTACHED TO THE

INLET AIR COLLAR OF THE TERMINATION CAP

OR TERMINATED IN THE CHIMNEY.

13

Page 14

GASKET

EXHAUST COLLAR

T-HANDLE

RETAINER PIN

Figure 5. Stainless adapter for exhaust (required).

3 INCH

STAINLESS STEEL

FLEXIBLE VENT

O

(45 ELBOW)

3 INCH COLLAR

The retainer pin secures the collar

attachment bracket to the fireplace from

inside the combustion chamber.

NOTE: Inspect for exhaust collar gasket

to insure positive exhaust seal.

3 INCH

COLLAR

TERMINATION

CAP

ADAPTOR

INLET AIR VENT COLLAR

(LINK-DV30 SHOWN)

EXHAUST VENT PIPE SUPPLIED

WITH TERMINATION KIT

INLET AIR VENT PIPE

ST AINLESS STEEL

ADAPTER FOR EXHAUST

(MUST BE INSTALLED)

O

45 ELBOW EXHAUST

COLLAR MAY BE ORIENTED

TO EITHER SIDE OF INTAKE

TO AID INSTALLAT ION

(RIGHT ORIENTATION SHOWN)

USE T-HANDLE TO PULL

DOWN ONTO UNIT EXHAUST

COLLAR AND PIN IN PLACE

WITH RETAINER PIN

Note: Inspect for exhaust

collar gasket to insure

positive exhaust seal.

Figure 6. Typical configuration of vent liners.

14

Page 15

Step 2. Positioning, Leveling, and

Securing the Insert

Place the insert into position.

Level the insert from side to side and from front to back.

Use the leveling legs included with the manual

bag if necessary to set each corner of the base.

Step 4. The Gas Supply Line

NOTE: Have the gas supply line installed in accordance

with local building codes by a qualified installer

approved and/or licensed as required by the locality.

NOTE: Before the first firing of the fireplace, the gas

supply line should be purged of any trapped air.

Step 3. The Gas Control System

WARNING: THIS UNIT IS NOT FOR USE WITH

!

SOLID FUEL.

These models use a standing pilot ignition type of gas control system.

Standing Pilot Ignition System

This system includes millivolt control valve, standing pilot,

thermopile/thermocouple flame sensor, and piezo ignitor.

WARNING: 110-120 VAC MUST NEVER BE

!

CONNECTED TO A CONTROL VALVE IN A

MILLIVOLT SYSTEM.

STANDING PILOT

NOTE: Consult local building codes to properly size

the gas supply line leading to the 1/2 inch (13 mm)

hook-up at the unit.

This gas fireplace is designed to accept a 1/2 inch

(13 mm) gas supply line. To install the gas supply line:

A listed (and State of Massachusetts approved) 1/2 inch

(13mm) tee-handle manual shut-off valve and a listed

flexible gas connector are connected to the 1/2 inch

(13mm) inlet of the control valve. NOTE: If substituting

for these components, please consult local codes for

compliance.

Locate the gas line access hole in the outer casing of

the fireplace.

Open the lower grille, insert the gas supply line through

the gas line hole, and connect it to the shut-off valve.

When attaching the pipe, support the control so that the

lines are not bent or torn.

After the gas line installation is complete, use a soap

solution to carefully check all gas connections for leaks.

Figure 7. Gas Controls System

WARNING: DO NOT USE AN OPEN FLAME

!

TO CHECK FOR GAS LEAKS.

GAS

SHUT-OFF

Figure 8. Gas Supply Line (CFX-IN shown)

FLEXIBLE

GAS LINE

CONTROLS

15

Page 16

Step 5. Gas Pressure Requirements

Pressure requirements for these gas appliances are shown

in the table below.

Pressure Natural Gas Propane

Minimum 5.0 inches 11.0 inches

Inlet Pressure w.c. w.c.

Maximum Inlet 14.0 inches 14.0 inches

Gas Pressure w.c. w.c.

Manifold 3.5 inches 10.0 inches

Pressure w.c. w.c.

A one-eighth (1/8) inch (3 mm) N.P.T. plugged tapping is

provided on the inlet and outlet side of the gas control for a

test gauge connection to measure the manifold pressure.

Use a small flat blade screwdriver to crack open the screw

in the center of the tap. Position a rubber hose over the tap

to obtain the pressure reading.

The fireplace and its individual shut-off valve must be

disconnected from the gas supply piping system during

any pressure testing of the system at test pressures in

excess of one-half (1/2) psig (3.5 kPa).

The fireplace must be isolated from the gas supply piping

system by closing its individual shut-off valve during any

pressure testing of the gas supply piping system at test

pressures equal to or less than one-half (1/2) psig (3.5 kPa).

Step 6. Wiring the Fireplace

NOTE: Electrical wiring must be installed by a licensed

electrician.

CAUTION: DISCONNECT REMOTE CONTROLS IF ABSENT FOR EXTENDED TIME PERIODS. THIS WILL PREVENT ACCIDENTAL APPLIANCE OPERATION.

For Standing Pilot Ignition Wiring

Appliance Requirements

This appliance DOES NOT require 110-120 VAC to operate.

WARNING: DO NOT CONNECT 110-120 VAC

!

TO THE GAS CONTROL VALVE OR THE APPLIANCE WILL MALFUNCTION AND THE

VALVE WILL BE DESTROYED.

Wall Switch

Position the wall switch in the desired position on a wall.

Run a maximum of 25 feet (7.8 m) or less length of 18

A.W.G. minimum wire and connect it to the fireplace valve

pigtails.

WARNING: DO NOT CONNECT 110-120 VAC

!

TO THE WALL SWITCH OR THE CONTROL

VALVE WILL BE DESTROYED.

CAUTION: LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING CONTROLS. WIRING ERRORS

CAN CAUSE IMPROPER AND DANGEROUS OPERATION.

VERIFY PROPER OPERATION AFTER SERVICING.

THERMOCOUPLE

WHITE T2

GAS

VALVE

RED T1

Figure 9. Standing Pilot Ignition Wiring Diagram

THERMOPILE

ON

OFF

ROCKER

SWITCH

OPTIONAL WALL SWITCH

THERMOSTAT OR REMOTE

16

Page 17

Step 7. Installing Logs and Ember Material

Positioning the Logs

The logs for models CFX-IN and CFX-Grand have been

packaged separately. Refer to the installation instructions

that accompany this manual. Save the log instructions

with this manual.

If sooting occurs, the logs might need to be repositioned

slightly to avoid excessive flame impingement.

Placing the Ember Material

Three separate bags of ember material are shipped with

this gas appliance. The bag labeled Golden Ember (GE-

93) is flame colorant material. The bags labeled Glowing

Ember (050-721) is standard glowing ember material.

To place the ember material:

Remove the glass door from the unit (see Figure 10).

Place a dime size piece of glowing ember material near

port holes in burner top, sides and front (see Figure 11).

BURNER PAN

EMBER MATERIAL

(TOP SURFACE ,

SIDES AND FRONT)

Figure 11. Placement of the Ember Material

Space ember pieces about a 1/2 inch apart.

PULL TO OPEN

Figure 10.

Glass Assembly (CFX-IN shown)

Step 8. Installing Trim

Surrounds

Combustible materials MUST

NEVER overlap onto the front

face.

1. Find the coiled low voltage wires

and ON/OFF switch attached to

outer right side of the insert. See

Figure 12, (Model CFX-IN shown).

Never press embers into burner ports.

Cover the top of the burner with a single layer of ember

material. Then sprinkle GE-93 (Golden Ember) on top of

the burner.

Save the remaining ember materials for use during fire-

place servicing. The embers provided are sufficient for 2

to 4 applications.

Replace the glass door.

Re-install and latch the glass door.

LOCATING TABS

FIREBOX

LOCATING SLOTS

2. Disconnect the ON/OFF switch

from the low voltage wire leads,

and insert the ON/OFF switch

through the hole at the upper

right corner of the surround - it

will be retained in the hole.

Figure 12.

17

SURROUND

WITH TRIM

ON/OFF

SWITCH

Page 18

3. Reconnect the low voltage wires to the ON/OFF switch.

Step 9. Before Lighting the Appliance

4. Attach surround assembly by hooking the support bracket on the locating tabs on top of the gas insert fireplace

(see Figure 12.) Once the surround assembly is on the

locating tabs, ensure the bottom hooks are resting on

the locating pins at the base. Reposition the fireplace if

necessary. Refer to surround instructions provided with

the decorative surround.

NOTE: PLACE THE THREE INSULATION PIECES INTO

THE CAVITIES AT THE BACK OF THE SURROUND BEFORE POSITIONING THE INSERT INTO THE FACTORYBUILT OR MASONRY FIREPLACE. THIS INSULATION

WILL HELP SEAL FOR COLD AIR LEAKS.

12” MAX.

MANTEL

12” MIN.

Before lighting the appliance, be sure to do the following:

Remove all paperwork from underneath the fireplace.

Review safety warnings and cautions

Read the Safety and Warning Information section at

the beginning of this Installers Guide.

Double-check for gas leaks

Before lighting the appliance, double-check the unit for

possible gas leaks.

Double-check vent terminations for obstructions.

Before lighting the appliance, double-check the unit for

possible obstructions that could be blocking the vent terminations.

Double-check for faulty components

Any component that is found to be faulty MUST BE re-

placed with an approved component. Tampering with the

appliance components is DANGEROUS and voids all warranties.

A small amount of air will be in the gas supply lines. When

first lighting the appliance, it will take a few minutes for the

lines to purge themselves of this air. Once the purging is

complete, the appliance will light and will operate normally.

Subsequent lightings of the fireplace will not require this

purging of air from the gas supply lines, unless the gas

valve has been turned to the OFF position, in which

case the air would have to be purged.

TOP OF

UNIT

Figure 13

Figure 13 shows the minimum vertical and corresponding

maximum horizontal dimensions of mantels or other combustible projections above the gas fireplace.

NOTE: The fireplace should be run 3 to 4 hours on the initial

start-up. Turn it off and let it cool completely. Remove and

clean the glass. Replace the glass and run the fireplace for

an additional 8 hours. This will help to cure the chemicals

used in the paint and logs.

Step 10. Lighting the Appliance

Youve reviewed all safety warnings, youve checked the

appliance for gas leaks, you know the vent system is

unobstructed, and youve checked for faulty components.

Now youre ready to light the appliance.

WARNING: PLEASE REFER TO THE USERS

!

MANUAL FOR ALL CAUTIONS, SAFETY, AND

WARNING INFORMATION PERTAINING TO THE

LIGHTING AND OPERATION OF THE APPLIANCE.

After the Installation

LEAVE THIS INSTALLATION MANUAL WITH

!

THE APPLIANCE FOR FUTURE REFERENCE.

18

Page 19

Maintaining and Servicing Your Appliance

4

Appliance Maintenance

Although the frequency of servicing and maintenance will

depend on use and the type of installation, you should have

a qualified service technician perform an appliance checkup at the beginning of each heating season. See the table

below for specific guidelines regarding each fireplace maintenance task.

IMPORTANT: TURN OFF THE GAS BEFORE SERVICING

YOUR FIREPLACE.

Replacing old ember material

Frequency: Once annually, during the checkup.

By: Qualified service technician.

Task: Brush away loose ember material near the burner.

Replace old ember material with new dime-size and shape

pieces of Golden Ember (DE-93) and Glowing Ember (050-

721). New ember material should be placed alternately on

top of the burner - a layer of Golden Ember, a layer of

Glowing Ember, and so on. Save the remaining ember

material and repeat this procedure at your next servicing.

For more information, see Placing Ember Material.

Cleaning Burner and Controls

Frequency: Once annually.

By: Qualified service technician.

Task: Brush or vacuum the control compartment, fireplace

logs and burner areas surrounding the logs.

MAKE SURE THE FLAMES

ARE STEADYNOT

LIFTING OR FLOATING.

Figure 14. Burner Flame Patterns

Checking Vent System

Frequency: Before initial use and at least annually

thereafter, more frequently if possible.

By: Qualified service technician/Home owner.

Task: Inspect the external vent cap on a regular basis to

ensure that no debris is interfering with the flow of air. Inspect

entire vent system for proper function.

Checking Flame Patterns, Flame Height

Frequency: Periodically.

By: Qualified service technician/Home owner.

Task: Make a visual check of your fireplaces flame patterns.

Make sure the flames are steady - not lifting or floating.

See Figure 14. The thermopile/thermocouple (standing pilot)

tips should be covered with flame. See Figure 7.

Cleaning Glass Door

Frequency: After the first 3 to 4 hours of use. As neces-

sary after initial cleaning.

By: Home owner.

Task: Remove and clean glass after the first 3 to 4 hours of

use. After the initial cleaning, clean as necessary, particularly after adding new ember (flame colorant) material. Film

deposits on the inside of the glass door should be cleaned

off using a household glass cleaner. NOTE: DO NOT handle

or attempt to clean the door when it is hot and DO

NOT use abrasive cleaners.

19

Loading...

Loading...