Page 1

OWNERS MANUAL AND

INSTALLATION INSTRUCTIONS

BCBR36

B-VENT GAS APPLIANCE

WARNING: If the information in this manual

is not followed exactly, a fire or explosion may

result causing property damage, personal injury or loss of life.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

What to do if you smell gas

Do not try to light any appliance.

Do not touch any electrical switch; do not use

any phone in your building.

Immediately call your gas supplier from a

neighbors phone. Follow the gas suppliers

instructions.

If you cannot reach your gas supplier, call the

fire department.

Installation and service must be performed by a

qualified installer, service agency or the gas

supplier.

CAUTION:

Do not expose the appliance to

the elements (such as rain, etc.).

WARNING!

Installation and service must be performed by a qualified installer, service agency or the gas supplier. Improper installation,

adjustment, alteration, service or maintenance can cause injury or property damage. Refer to this manual. For assistance or

additional information, consult a qualified installer, service agency or the gas supplier.

06-03 35020 Rev G 1

This manual must be used for installation of the

BCBR36 Gas Appliance and retained by the

homeowner for operation and maintenance

instructions.

Page 2

BCBR36 B-VENT GAS APPLIANCE

Please retain this manual for future use.

TABLE OF CONTENTS

Design and Installation Considerations for B-Vents .................................................................................................... 3

A. Appliance Specifications ............................................................................................................................................... 4

B. Location and Clearances .............................................................................................................................................. 5

C. Framing ......................................................................................................................................................................... 6

D. Setting the Appliance .................................................................................................................................................... 6

E. Venting .......................................................................................................................................................................... 7

F. Utilities ......................................................................................................................................................................... 10

G. Finishing ...................................................................................................................................................................... 14

H. Appliance Preparation ................................................................................................................................................. 14

I. Lighting Instructions .................................................................................................................................................... 16

J. Seasonal Checklist ...................................................................................................................................................... 17

K. Start-up Issues ............................................................................................................................................................ 18

L. Maintenance Instructions ............................................................................................................................................ 19

M. Log Removal/Replacement ......................................................................................................................................... 21

N. Optional Components ................................................................................................................................................. 22

O. Replacement Parts ...................................................................................................................................................... 23

Index ............................................................................................................................................................................ 27

Limited Lifetime Warranty ........................................................................................................................................... 28

WARNING!

DO NOT use this appliance if any part has been under water. Immediately call a qualified service technician to

inspect the appliance and to replace any part of the control system and any gas control which has been under

water.

SAFETY PRECAUTIONS

1. Please read these installation instructions completely before beginning installation procedures. Failure to follow them

could cause an appliance malfunction resulting in serious injury and/or property damage.

2. Installation and repair should be done by a qualified service person. This appliance should also be inspected annually

by a qualified service person. More frequent inspections/cleaning may be required due to excessive lint from carpeting,

bedding materials, etc. It is imperative that the control compartment, burners and circulating air passageways of the

appliance be kept clean.

3. This is a vented decorative gas appliance. Do not burn wood or other material in this appliance.

4. NEVER leave children unattended when there is a fire burning in the appliance.

5. This appliance must be vented with a 5 B-vent system and must terminate above the roof line. Venting must not be

connected to a chimney flue servicing a solid fuel burning appliance.

6. Use only the fuel gas specified on the rating label of this gas appliance.

7. The appliance area shall be kept clear and free from combustible materials, gasoline and other flammable vapors and

liquids.

8. While servicing this appliance, always shut off all electricity and gas to the appliance. This will prevent possible

electrical shock or burns. Also, make sure the appliance is completely cooled before servicing.

9. Do not use this appliance if any part has been under water. Immediately call a qualified service technician to inspect

the appliance and to replace any part of the control system and any gas control which has been under water.

10. Be sure to provide adequate clearances around the air openings into the combustion chamber and adequate

accessibility clearances for servicing and proper operation.

11. Provisions shall be made to provide adequate combustion and ventilation air. The flow of combustion and ventilation

air should not be obstructed.

2 35020 Rev G 06-03

Page 3

BCBR36 B-VENT GAS APPLIANCE

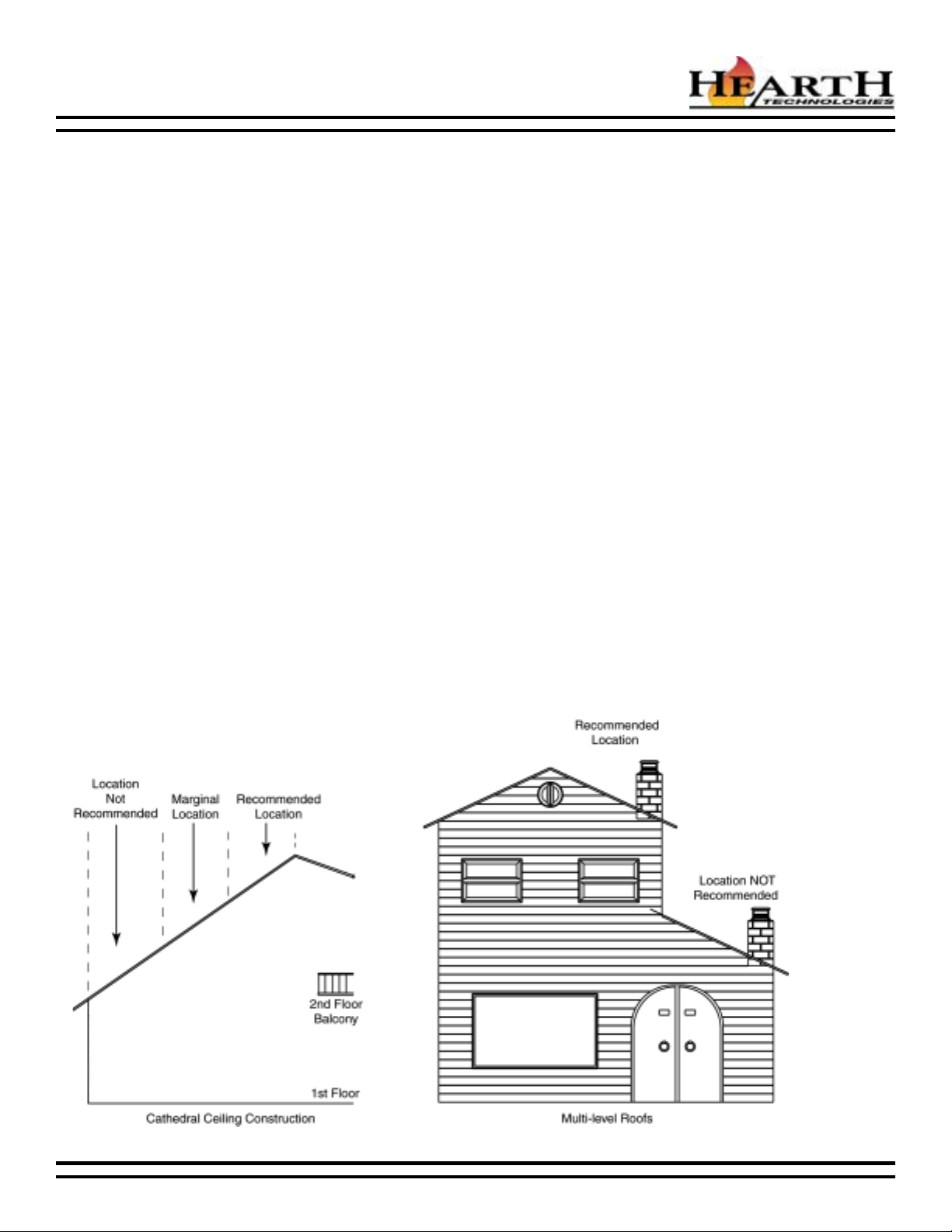

DESIGN AND INSTALLATION CONSIDERATIONS FOR B-VENTS

When selecting a location for your B-Vent appliance, it is important to evaluate a number of considerations. Modern

construction techniques can create conditions that may not allow your vent to draft properly. This may result in spillage

from your B-Vent appliance, as well as cause other combustion appliances to operate incorrectly.

Tightly sealed construction is important for energy efficiency. Unfortunately, a great deal of effort has been directed to

tightening up sidewall construction, while considerably less attention has been paid to tightening upper portions of the

warm air envelope (insulated ceilings). This has increased the Stack Effect, a condition that increases the negative

pressure generated by the structure. This negative pressure will directly affect the drafting performance of a B-Vent

appliance vent. To minimize the negative pressure generated by stack effect, make certain that all ductwork installed in

the attic spaces is sealed airtight. Minimize the number of recessed light fixtures installed in the insulated ceiling and use

sealed recessed light fixtures. Finally, make certain the whole house fans and attic access panels are tightly sealed.

These are important design considerations that must be observed during the design and construction stage of the home.

If you desire to put an appliance in your basement, we recommend that you consider a direct vent gas appliance. Basements

always have a significant negative air pressure that causes the B-Vent system to be more susceptible to spillage and cold

flue backdrafting. Since direct vent gas appliances are sealed, they are not affected by the negative pressure that exists

in basements.

Finally, a B-Vent appliance performs best when the vent (roof termination) is located on the upper half of the roof, especially

when cathedral ceilings are present. Vents that are located on the lower half of the roof realize what is known as lazy flue

and will not draft as well as a vent that is located in the upper portion of the roof. The reason for this is that the stack effect

generated by the overall height of the living spaces inside the house will exceed the draft generated by the vent system.

If you desire to place an appliance in a location where the termination cap would be located on the lower half of a roof;

such as on an outside wall at the base of a cathedral ceiling, we recommend that you consider using a direct vent gas

appliance. This will ensure an appliance that operates correctly.

These properties do not affect just your B-Vent appliance. They can cause any woodburning fireplace as well as any

conventionally vented (B-Vent) gas appliance to operate improperly. Careful planning at this stage of your project will

ensure satisfaction with the operation of your appliance once it is completed.

06-03 35020 Rev G 3

Page 4

BCBR36 B-VENT GAS APPLIANCE

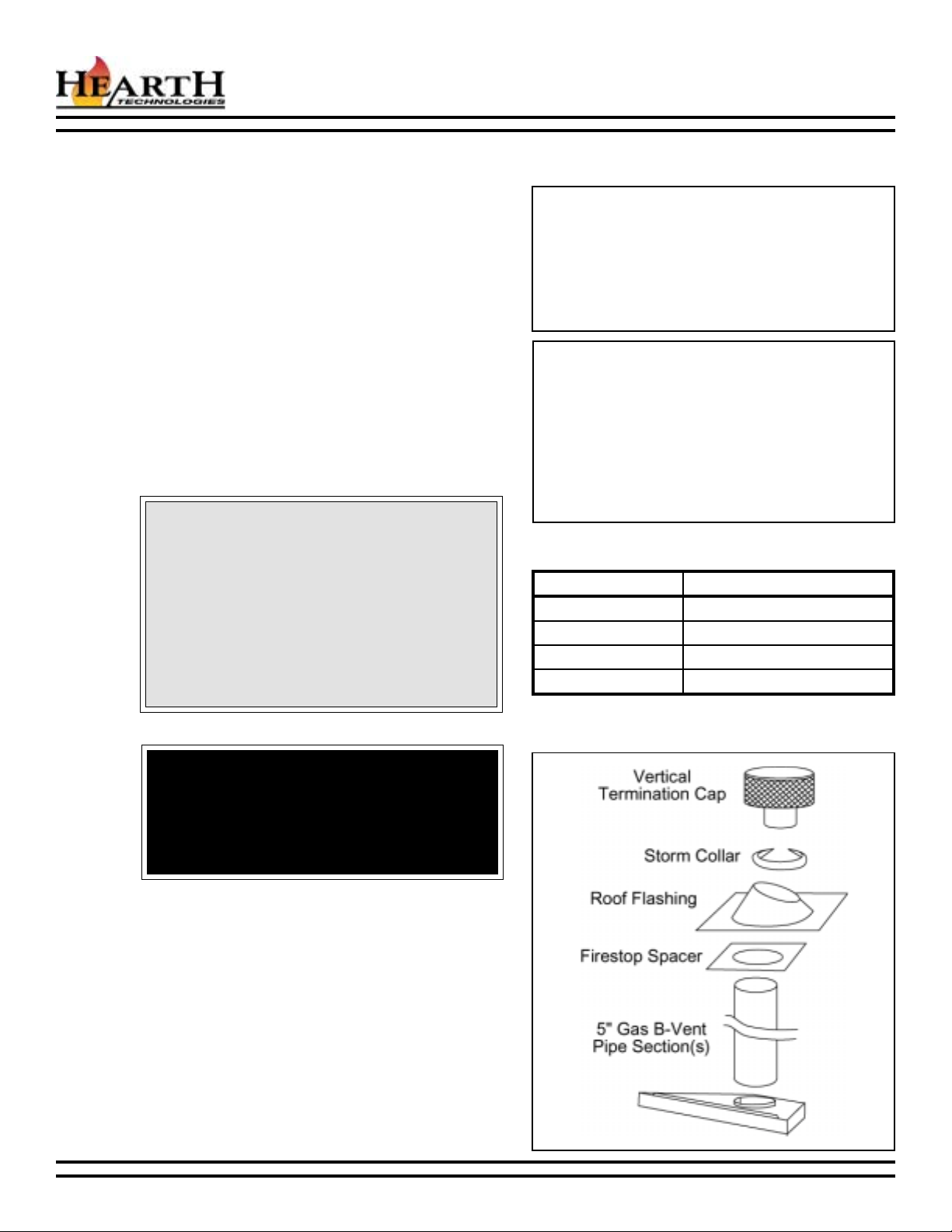

A. APPLIANCE SPECIFICATIONS

U.S. and Canada Certification

The BCBR36 Gas Appliance has been tested in accordance

with the standards ANSI Z21.50-2000 and CSA 2.22-2000,

and has been listed by Underwriters Laboratories Inc. for

installation and operation as described in this manual. All

components are UL, AGA, CGA, or CSA safety certified.

Local Codes

This installation must conform with local codes. In the

absence of local codes comply with the National Fuel Gas

Code ANSI Z223.1-latest edition in the U.S.A., and the

CAN/CGA B149 Installation Codes in Canada.

If you need assistance during installation, please contact

your local dealer or the Technical Services Department,

Hearth & Home Technologies, 1915 W. Saunders Street,

Mt. Pleasant, Iowa 52641, 1-800-843-2848.

We strongly recommend that you DO NOT install BVent Gas Appliances in strong negative air locations,

such as a basement or a public facility. Living rooms

with cathedral ceilings could be susceptible to a

negative air situation, but such installations can be

overcome through raising the termination,

depending on specific installations. This appliance

uses room air for normal operation and could have

problems establishing a positive draft in a negative

air location. In lieu, we recommend a Direct Vent Gas

Appliance.

Note: Minimum and maximum clearances must be main-

tained at all times. Illustrations throughout these instructions reflect typical installations and are for design purposes only. Actual installation may vary slightly due to

individual design preferences.

The illustrations and diagrams used throughout these

installation instructions are not drawn to scale.

Tools and building supplies normally required for

installation:

Saw Wall-finishing materials

Pliers Framing material

Hammer Appliance surround

Phillips screwdriver Caulking material

Tape measure Safety gloves

Plumb line Electric drill/bits

Level Framing Square

BCBR36 Nomenclature

#golataCnoitpircseD

CBeciohCsredliuB

BtneV-B

RtnaidaR

63ecnailppA"63

WARNING!

This appliance is tested and listed for use only with

the optional accessories listed in these instructions. Use of optional accessories not specifically

tested for this appliance could void the warranty

and/or result in a safety hazard.

Typical Installation Components

4 35020 Rev G 06-03

Page 5

BCBR36 B-VENT GAS APPLIANCE

B. LOCATION AND CLEARANCES

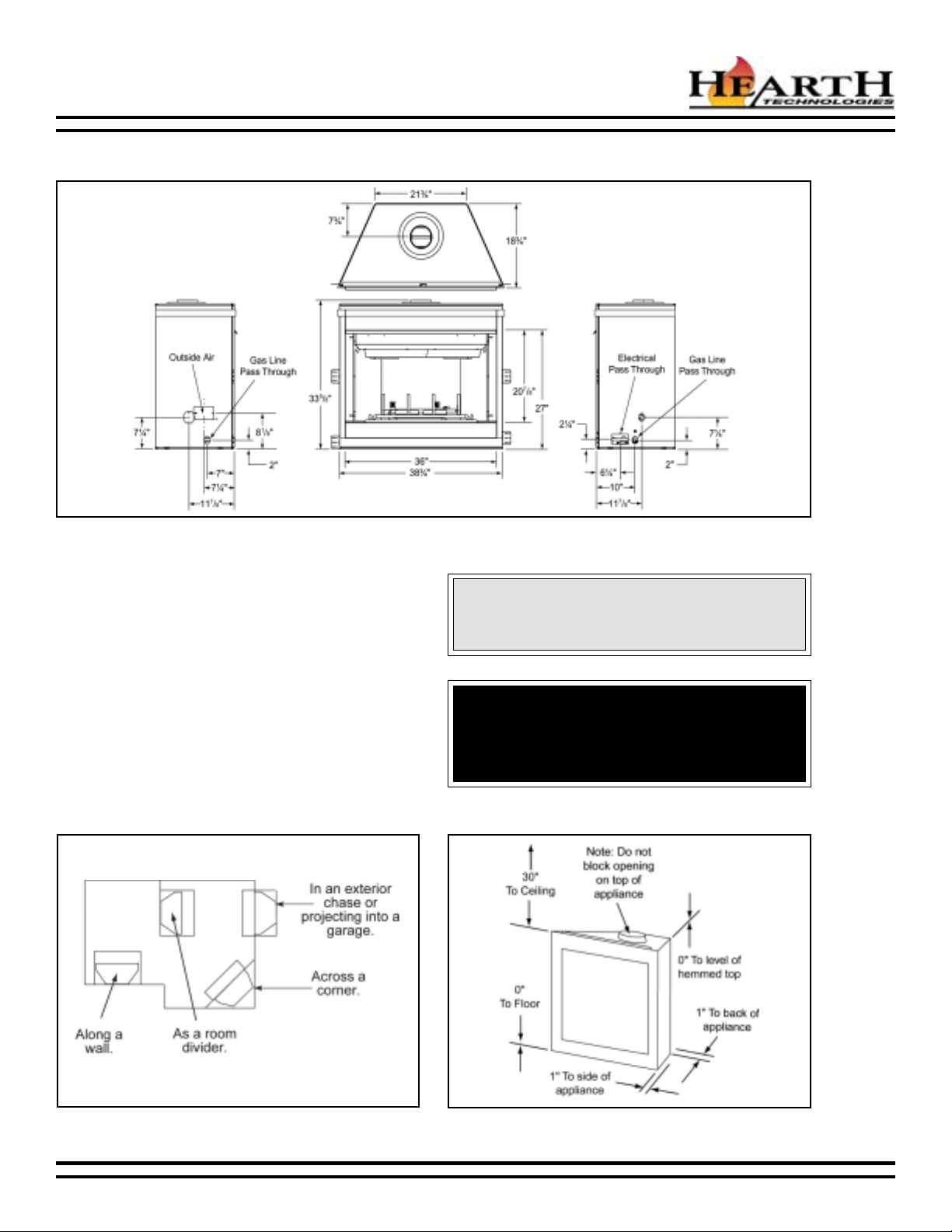

Appliance Dimensions

1. Appliance Locations and Space Requirements

Figure 1 illustrates a variety of ways the appliance may

be located in a room. The BCBR36 may be installed

directly on the floor or raised on a hearth. These

appliances are certified for installation in a bedroom

or bed/sitting room in the U.S. and Canada, provided

that the bedroom or bathroom has a volume of at least

1150 cubic feet.

2. Clearances

Figure 2 shows all clearances that must be maintained

around the appliance.

CAUTION:

Do not expose the appliance to the elements (such

as rain, etc.).

WARNING!

Due to high temperatures, the appliance should be

located out of traffic and away from furniture and

draperies.

Figure 1 - Appliance Locations

Appliance Clearances to Combustible Materials

06-03 35020 Rev G 5

Figure 2

Page 6

BCBR36 B-VENT GAS APPLIANCE

C. FRAMING

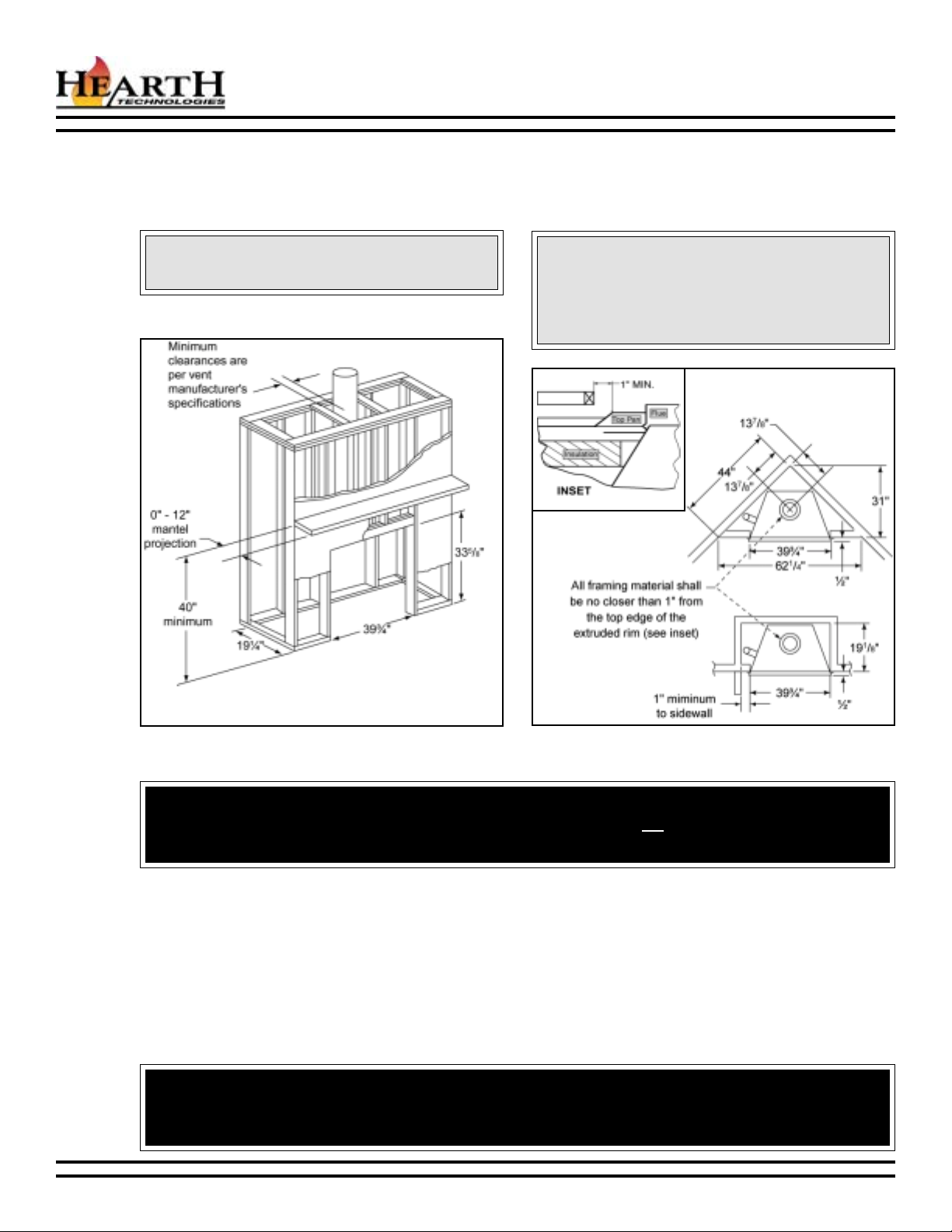

Figure 3 shows typical framing of this appliance using combustible materials and the minimum mantel heights. All required

clearances to combustibles must be adhered to. Figure 4 shows rough framing dimensions.

CAUTION:

Wear gloves and safety glasses for protection.

Header and mantel

heights are measured

from the base of the

appliance.

Figure 3 - Framing

CAUTION:

Provide adequate clearances around the air openings into the combustion chamber and adequate

accessibility clearances for servicing and proper

operation.

Figure 4 - Rough Framing Dimensions

WARNING!

To prevent contact with sagging or loose insulation, the appliance must not be installed against vapor barriers or exposed insulation.

D. SETTING THE APPLIANCE

This appliance may be placed on a smooth combustible or noncombustible continuous, flat surface. When the appliance

is installed directly on carpeting, tile, or a combustible material other than wood flooring, the appliance shall be

installed on a metal or wood panel extending the full width and depth of the appliance. Slide the appliance into

position and level the appliance from side-to-side and front-to-back. Shim with noncombustible material as necessary.

Secure the appliance by bending out the nailing flanges on each side of the appliance and nail to framing. The nailing

flanges have been positioned ½ back from the front of the appliance to allow the addition of drywall.

WARNING!

This appliance may only use an approved B-Vent chimney system. It must not be connected to a chimney flue

servicing a separate solid fuel or gas fuel burning appliance.

6 35020 Rev G 06-03

Page 7

BCBR36 B-VENT GAS APPLIANCE

E. VENTING

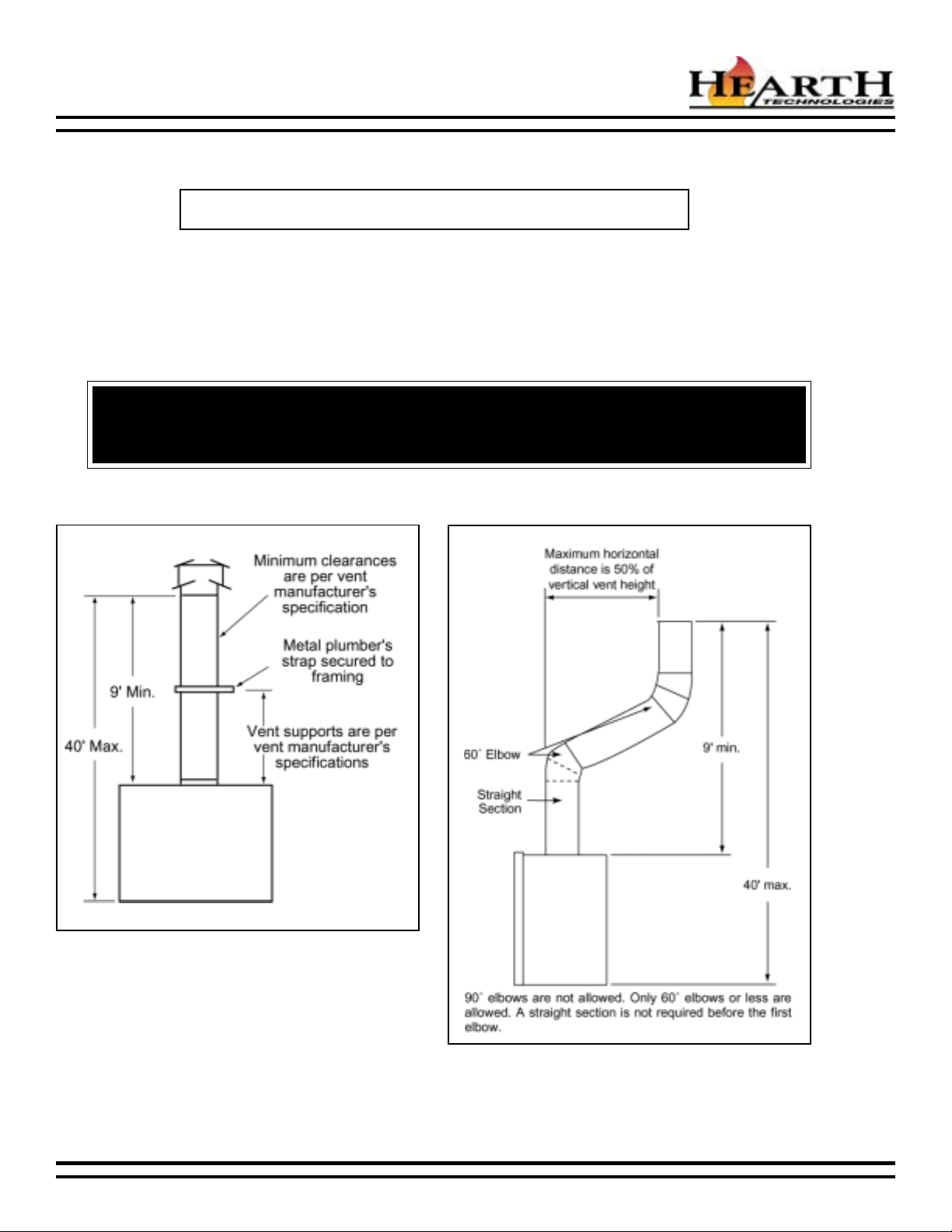

Note: This appliance requires a 5 B-vent for operation. Never down-size pipe.

1. Clearances

Vent clearances are per vent manufacturers specifications.

2. Vent Lengths

Various venting configurations are shown in Figures 5 and 6 from which maximum vent runs can be determined.

WARNING - RISK OF FIRE!

Always maintain minimum clearances or greater around the vent system. Do not pack air spaces with

insulation or other material.

Figure 5

Vertical Termination Vent Lengths

Figure 6

Venting off the Top of the Appliance

06-03 35020 Rev G 7

Page 8

BCBR36 B-VENT GAS APPLIANCE

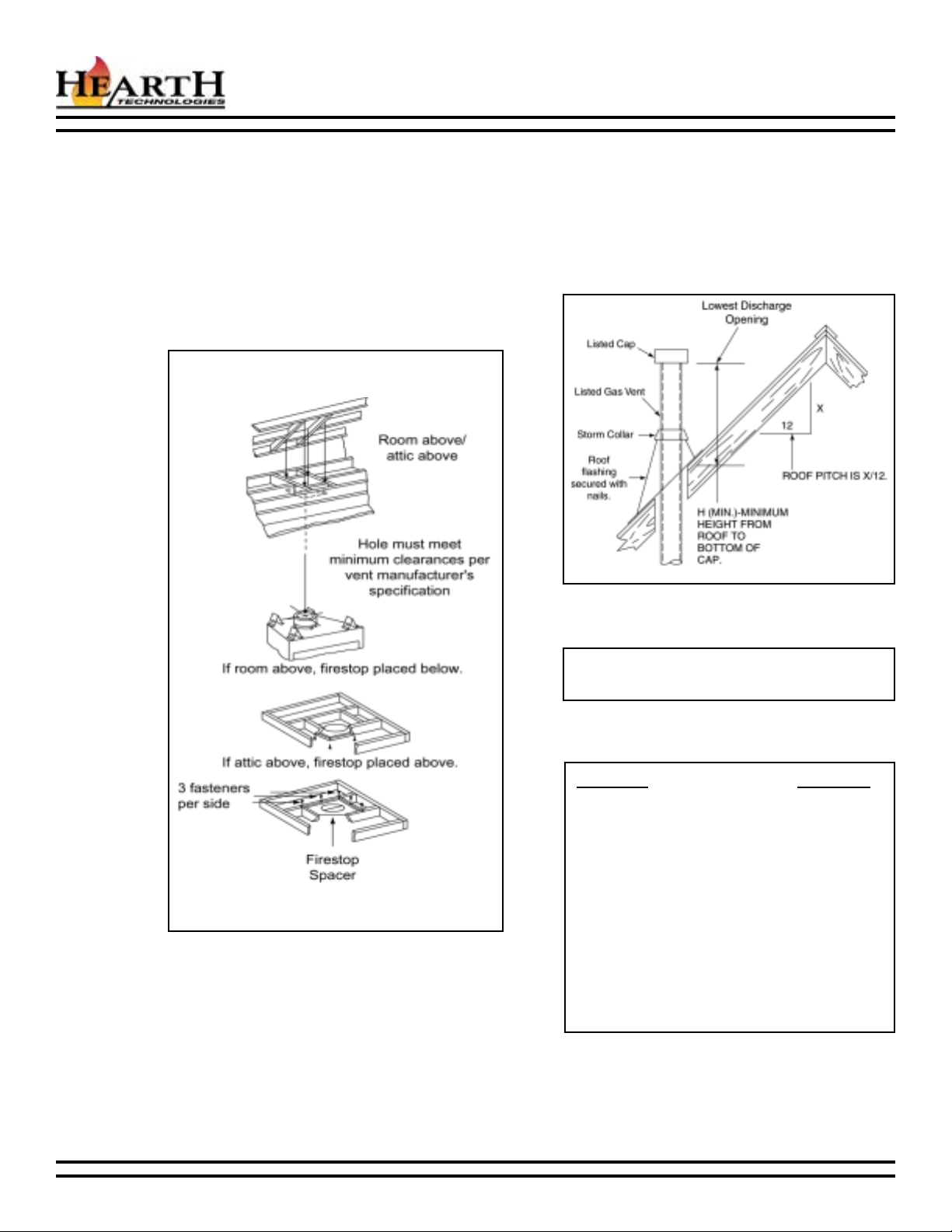

3. Firestop Spacer/Vent Installation

Frame an opening and install a firestop spacer

whenever the vent penetrates a ceiling/floor area, as

shown in Figure 7. Frame the opening with the same

sized lumber as used in the ceiling/floor joists. Unless

the flue is offset, the hole should be directly above the

appliance. DO NOT pack insulation around the vent.

Assemble vent sections as per manufacturers

specifications.

4. Chase/Termination Installation

Figure 8 and Table 1 specify minimum vent heights for

various pitched roofs.

These vent heights are necessary for safety and do

not ensure draft-free operation. Trees, buildings,

adjoining roof lines, adverse conditions, etc. may create

a need for a taller vent should down drafting occur.

Figure 8

Vent Height for Vertical Termination

Figure 7

Installing the Firestop Spacer

Note: To ensure proper operation, verify all venting

and the termination are unobstructed.

Roof Pitch H (Min.) Ft.

Flat to 6/12 ................................................ 1.0

6/12 to 7/12 ............................................... 1.25

Over 7/12 to 8/12 ...................................... 1.5

Over 8/12 to 9/12 ...................................... 2.0

Over 9/12 to 10/12 .................................... 2.5

Over 10/12 to 11/12 .................................. 3.25

Over 11/12 to 12/12 .................................. 4.0

Over 12/12 to 14/12 .................................. 5.0

Over 14/12 to 16/12 .................................. 6.0

Over 16/12 to 18/12 .................................. 7.0

Over 18/12 to 20/12 .................................. 7.5

Over 20/12 to 21/12 .................................. 8.0

Table 1

Vent Height

8 35020 Rev G 06-03

Page 9

BCBR36 B-VENT GAS APPLIANCE

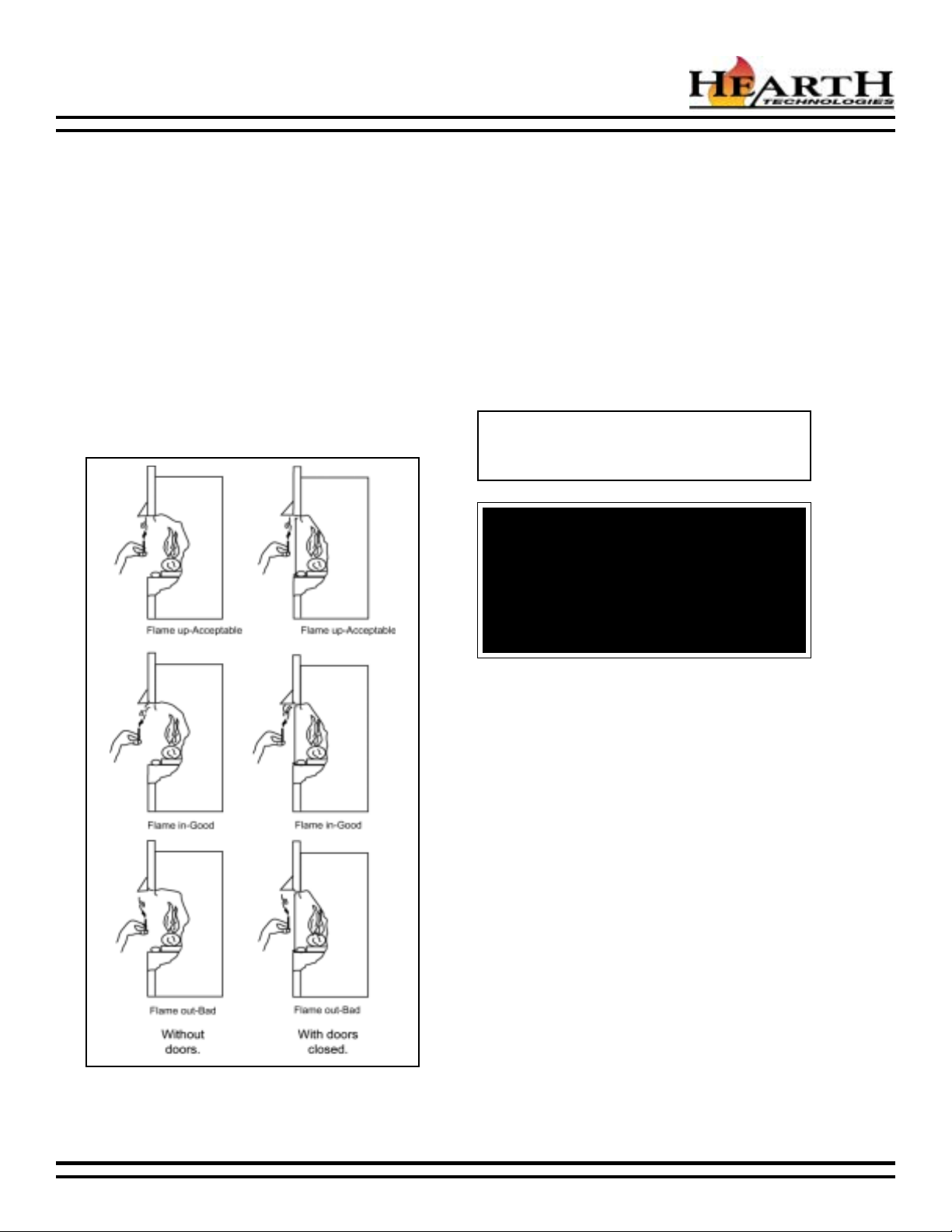

5. Checking the Vent System

Test the venting system periodically to assure proper

operation. This can be done with a match while the

appliance is operating.

Hold a lighted match at the top edge of the appliance

opening. If the flames and smoke remain upright,

ventilation is acceptable. If the flames and smoke are

drawn into the appliance, this means ventilation is

good. If the flames and smoke are forced away from

the appliance, this may indicate a ventilation blockage

or down draft resulting in gas spillage into your home.

If this occurs, turn off the appliance and do not burn it

until it has been inspected by a qualified service

person.

If you have installed optional doors, close the doors

and conduct the test following the same instructions

above. See Figure 9.

6. Outside Air Kit Installation

An outside air kit is available as an optional feature

with this appliance. An outside air kit helps to decrease

the amount of room air taken, by utilizing outside air

for combustion. It is strongly recommended that it be

installed. An outside air kit can be installed only on the

left side.

It is recommended to utilize the shortest duct run to

optimize the performance of the outside air kit. The

outside air kit inlet thimble should be positioned at least

four feet above the ground level, in a manner that will

not allow snow, leaves, etc. to block the inlet.

To install the outside air kit, refer to the installation

instructions provided with the kit.

Note: The outside air kit can terminate at any level

with the exception that it must terminate at least one

foot below the vent termination cap.

WARNING!

Exhaust products of gasoline engines are hazardous. The outside air must not be taken from

a garage space, attic spaces, basements, or

above the roofing where other heating appliances, fans, or chimneys exhaust or utilize air.

Figure 9

Testing Ventilation

06-03 35020 Rev G 9

Page 10

BCBR36 B-VENT GAS APPLIANCE

F. UTILITIES

1. High Altitude Installation

For U.S. installation, appliances are tested and approved for elevations from 0-2000 feet. When installing this appliance

at an elevation above 2000 feet, National Fuel Gas Codes require a decrease of the input rating by changing the

existing burner orifice to a smaller size. Input should be reduced 4% for each 1000 feet above sea level. Check with

the local gas utility for proper orifice size identification. The correct orifice is available from your Hearth & Home

Technologies distributor.

For Canada, appliances are certified for elevations from 0-4500 feet. When installing this appliance at an elevation

between 0-4500 feet in Canada, the input rating does not need to be reduced. When installing this appliance at an

elevation above 4500 feet in Canada, check with local authorities.

2. Gas Line Connection

The appliance is provided with a stainless steel flexible connector and a listed (and Commonwealth of Massachusetts

approved) T-handle manual shutoff valve.

You may plumb this appliance from either the right or left side of the appliance. The incoming gas line should be piped

into the valve compartment and connected to the 1/2 FIP connection provided on the manual shutoff valve. See

Figure 10 to connect the gas line. Optional: Seal around the gas line to prevent cold air leakage.

All connections must be tightened and checked for leaks with a soap and water solution or a leak detector.

Bleed the gas line to extract any air that may have been trapped inside the pipe.

Note: Have the gas supply line installed in accordance with building codes by a qualified installer approved and/or

licensed as required by the locality. In the Commonwealth of Massachusetts, installation must be performed by a

licensed plumber or gas fitter.

Note: This appliance and its manual shutoff valve must be disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of 1/2 psi (3.5 kPa). The appliance must be isolated from the

gas supply piping system by closing its manual shutoff valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 psi (3.5 kPa).

Figure 10 - Gas Line

10 35020 Rev G 06-03

Page 11

BCBR36 B-VENT GAS APPLIANCE

WARNING!

This valve has been preset at the factory. Altering

settings may result in fire hazard or bodily injury.

3. Gas Pressure

On the intermittent pilot gas control valve, a pressure tap is included on the front face of the valve. Pressure taps are

immediately upstream of the gas supply connection and accessible for test gauge connection. See Table 2.

4. Gas Conversions

Natural or propane gas conversions necessary to meet the application need to be made by a qualified technician

using Hearth & Home Technologies specified and approved parts.

In the event your appliance must be converted to use propane, you must use a DCKP conversion kit. To be converted

to use natural gas, you must use a DCKN conversion kit.

63RBCB

)GN(erusserPylppuSsaGtelnI.c.w.ni).xam(0.7-).nim(5.4

)GN(sserPdlofinaMlamitpO.c.w.ni5.3

)PL(erusserPylppuSsaGtelnI.c.w.ni).xam(0.41-).nim(0.11

)PL(erusserPdlofnaMmumitpO.c.w.ni01

Table 2

63RBCB

)GN(etaRtupnI.rh/UTB000,32

)PL(etaRtupnI.rh/UTB000,32

)PL(eziSecifirOmm24.1/650.

)GN(eziSecifirOmm62.2/980.

Table 3

06-03 35020 Rev G 11

Page 12

BCBR36 B-VENT GAS APPLIANCE

5. Ignition System

This appliance is equipped with an intermittent pilot control valve which operates on a 3 volt system. See wiring

diagram, Figure 11.

The appliance is supplied with a battery pack and a 3 volt AC transformer, which requires the installation of the

supplied JK9 Junction Box Kit. It is highly recommended that the JK9 be installed at this time to avoid reconstruction.

The battery pack requires two D cell batteries (not included). Batteries cannot be placed in the battery pack while

using the 3 volt AC transformer. Conversely, the transformer must be unplugged if the battery pack is used.

Note: This appliance must be electrically wired and grounded in accordance

with local codes or, in the absence of local codes, with National Electric Code

ANSI/NFPA 70-latest edition or the Canadian Electric Code, CSA C22l.1.

Battery polarity must be correct or control module

damage will occur.

5.

CAUTION:

Figure 11 - Intermittent Pilot Ignition Wiring Diagram

12 35020 Rev G 06-03

Page 13

BCBR36 B-VENT GAS APPLIANCE

6. JK9 Junction Box Installation

Your appliance is supplied with a JK9 Junction Box. To operate the appliance with the supplied 3V AC transformer

and/or remote control option, it is recommended that the junction box be installed and wired at this time to avoid

reconstruction.

a. Refer to installation instructions included with the JK9 Junction Box.

b. Wire the junction box per the diagram in Figure11.

c. Prior to attaching the junction box to the appliance, the heat shield supplied with your appliance must be installed.

Insert the top flange of the heat shield through the electrical knockout hole from the inside (Figure12), then insert

the JK9 through the hole and attach with three screws. See Figure 13.

Figure 12 - Attaching the Heat Shield

Figure 13 - Attaching the Junction Box

06-03 35020 Rev G 13

Page 14

G. FINISHING

1. Combustible Finishing Material

Material made of or surfaced with wood, compressed

paper, plant fibers, plastics, or any material capable

of igniting and burning, whether flame proofed or not,

plastered or unplastered (this includes drywall).

2. Noncombustible Finishing Material

Material which will not ignite and burn. Such materials

are those consisting entirely of steel, iron, brick, tile,

concrete, slate, glass or plasters, or any combination

thereof, or have a UL fire rating of zero (0).

3. High Temperature Sealant Material

Sealants that will withstand high temperatures: General

Electric RTV103 (Black) or equivalent. Rutland, Inc.

Appliance Mortar #63, or equivalent.

A high temperature sealant, 1/8 wide minimum bead,

must be used to close off gaps between the appliance

and facing to prevent cold air leaks. See Figure 14.

A combustible mantel may be installed. Please refer

to Figure 3, page 6.

BCBR36 B-VENT GAS APPLIANCE

Figure 14

WARNING!

Air slots on this appliance cannot, in any way, be

covered as it may create a fire hazard.

H. APPLIANCE PREPARATION

1. Appliance Preparation

The log set should look similar to that in Figure 26, page 21. Remove the control access panel from its shipping location

(Figure 15) by removing the two screws holding it in place. Replace the two screws. Put the control access panel in place

by sliding one end on the appliance bottom by means of slots in the control access panel. Slide the other end onto the

appliance bottom. See Figure 16.

Figure 15 - Control Access Panel Shipping Location

Figure 16 - Control Access Panel Installation/

Removal

14 35020 Rev G 06-03

Page 15

BCBR36 B-VENT GAS APPLIANCE

2. Placing the Lava Rock and Vermiculite

Place lava rock on top of control access panel, in front of, under and around burner. When placing vermiculite,

sprinkle it evenly over the area covered by the lava rock. See Figures 17-18.

It is not necessary to use all the lava rock and vermiculite. Save the remainder for future use.

3. Placing the Rock Wool

Place approximately 1/2 diameter pieces of rock wool under the front log, on the lower portion of the burner tube.

Place the rock wool the full length of the burner. Do not pack the wool tightly against the burner. This appliance is

supplied with one bag of rock wool. It is not necessary to use all the wool. Save the remaining amount for future use.

See Figure 19.

Figure 17

Placing the Lava Rock

Figure 18

Placing the Vermiculite

Figure 19

Placing the Rock Wool

06-03 35020 Rev G 15

Page 16

BCBR36 B-VENT GAS APPLIANCE

I. LIGHTING INSTRUCTIONS

WARNING!

If you do not follow these instructions exactly, a fire or explosion may result causing property damage,

personal injury or loss of life.

A. This appliance is equipped with an ignition device which automatically lights the pilot. Do not try to light the pilot

by hand.

B. BEFORE LIGHTING smell all around the appliance area for gas. Be sure to smell next to the floor because some

gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Do not touch any electric switch; do not use any phone in your building.

Immediately call your gas supplier from a neighbors phone. Follow the suppliers instructions.

If you cannot reach your gas supplier, call the fire department.

C. Use only your hand to close the gas line. Never use tools. If the knob will not push in or turn by hand, dont try to

repair it; call a qualified service technician. Force or attempted repair may result in a fire or explosion.

D. Do not use this appliance if any part has been under water. Immediately call a qualified service technician to

inspect the appliance and to replace any part of the control system and any gas control which as been under

water.

INTERMITTENT PILOT IGNITION LIGHTING INSTRUCTIONS

1. Turn wall switch to the OFF position.

2. This appliance is equipped with an ignition device which automatically lights the pilot. Do not try to light the pilot

by hand.

3. Wait five minutes to clear out any gas. If you then smell gas, STOP! Follow B in the safety information above on

this label. If you do not smell gas, go on to the next step.

4. Turn the wall switch to the ON position.

5. If the appliance will not operate, follow the instructions TO TURN OFF THE GAS TO THE APPLIANCE and call

your service technician or gas supplier.

6. If using the battery pack and the appliance will not operate, check the batteries for sufficient charge and replace

if necessary.

TO TURN OFF THE GAS TO THE APPLIANCE

1. Turn off the wall switch.

2. Open control access panel. Turn manual shutoff

valve to the CLOSED position. Do NOT force.

3. Close control access panel.

16 35020 Rev G 06-03

Page 17

BCBR36 B-VENT GAS APPLIANCE

J. SEASONAL CHECKLIST

WARNING!

Children and adults should be alerted to the hazards of high surface temperatures and should stay away to

avoid burns or clothing ignition. Young children should be carefully supervised when they are in the same

room as the appliance.

CAUTION:

Any safety screen or guard removed for servicing an appliance must be replaced prior to operating this

appliance.

Clothing or other flammable material should not be placed on or near the appliance.

Installation and repair should be done by a qualified service person. The appliance should be inspected

before use and at least annually by a qualified service person. More frequent cleaning may be required

due to excessive lint from carpeting, bedding material, etc. It is imperative that control compartments,

burners and circulating air passageways of the appliance be kept clean.

Before operating this appliance, have a qualified technician:

1. Review proper placement of logs, rock wool and vermiculite (pages 15 and 21).

2. Check wiring (page 12).

3. Check air shutter adjustment (page 19).

4. Ensure there are no gas leaks (page 10).

5. Ensure the flow of combustion and ventilation air is not obstructed.

WARNING!

Keep the area near the appliance clear and free from combustible materials, gasoline and other flammable vapors and liquids.

06-03 35020 Rev G 17

Page 18

BCBR36 B-VENT GAS APPLIANCE

1. Intermittent Pilot ignition Operation

a. Lighting the Appliance During Regular Use

Turn the wall switch to ON.

b. Shutdown During Regular Use

Turn the wall switch to OFF.

c. To Shut Down the Appliance for a Long Period

of Time

Turn all wall switches to OFF.

Turn the gas line to CLOSED.

d. To relight the appliance, see page 16.

2. Fuel Conversion Instructions

a. Do not burn wood or other material in this

appliance.

b. Natural or propane gas conversions necessary to

meet the application need to be made by a

qualified technician using Hearth & Home

Technologies specified and approved parts.

c. In the event you must convert your appliance to

propane, refer to Section F, #4. Gas Conversions

(page 11).

3. Operating the Outside Air Kit

The outside air kit is supplied as an optional feature

with this appliance. The outside air kit helps decrease

the amount of room air taken by utilizing outside air for

combustion. It is strongly recommended that it be

installed.

To operate the outside air kit, before starting the

appliance: Grasp the small, black handle located on

the left side of the appliance. See Figure 20. Lift the

handle and move it to the left. When through burning

the appliance, grasp the handle and move it to the right

to close the outside air door.

CAUTION:

The air kit handle may get hot while burning the

appliance. Use care when operating the handle.

WARNING!

Do not use this appliance if any part has been under water. Immediately call a qualified service technician to inspect the appliance and to replace any

part of the control system and any gas control which

has been under water.

K. START-UP ISSUES

EUSSISNOITULOS

.1ehtnonoitasnednoC

sroodssalg

.2semalfeulB.2otnigeblliwsemalfehtdnanoitarepolamronfotluserasisihT

.3ecnailppaehtmorfrodO.3ehtrofrodonaesaeleryamecnailppasiht,detarepotsrifnehW

.4ehtnomliF

sroodssalg

.1sA.snoitairaverutarepmetdnanoitsubmocsagfotluserasisihT

.4.sgoldnatniapehtfossecorpgnirucehtfotluserlamronasisihT

Figure 20 - Operating the Outside Air Kit and

Circulating Air Passageway

.raepasiddluohsnoitasnednocsiht,smrawecnailppaeht

.nrubotdewollasiecnailppaehtsawolley

dnatniapehtfognirucehtybdesuacsisihT.sruohlarevestsrif

.gnirutcafunammorfgniniamerslioynafoffogninrubeht

gninrublaitinifosruoh6-4nihtiwdenaelcebdluohssroodssalG

A.ssecorpgnirutcafunamehtmorfslioybtfelstisopedevomerot

.yrassecenebyamossarBsahcusrenaelcevisarba-non

WARNING!

Never use gasoline, gasoline-type lantern fuel, kerosene, charcoal lighter fluid or similar liquids in

this appliance. Keep any flammable liquids a safe distance from the appliance.

18 35020 Rev G 06-03

Page 19

BCBR36 B-VENT GAS APPLIANCE

L. MAINTENANCE INSTRUCTIONS

1. Cleaning the Burner and Control Compartment

Keep the burner and control compartment clean by

brushing and vacuuming at least once a year. Always

turn off the wall switch (or remote control) and gas valve

before cleaning.

2. Checking the Vent System

Inspect the flame of the burner periodically, making

sure the flames are steady, not lifting or floating. The

flame color should be blue with yellow tips. The sensor

tip should be covered with flame. See Figure 21.

If the vent configuration is installed incorrectly, the vent

may cause the flames inside the appliance to lift or

ghost, a dangerous situation. Inspect the flames after

installation to ensure proper performance. See

Figure22. If the vent configuration is correct, yet the

flames are lifting or ghosting, shut off gas to the

appliance and contact a qualified service technician.

Air Shutter Adjustment

To reduce the possibility of soot, we have equipped

your appliance with an adjustable air shutter. See

Figure 23. Your air shutter is provided in the closed

position for natural gas and 1/8 open for propane.

Figure 21 - Intermittent Pilot Ignition Assembly

Note: The look of the flames and embers may differ

based on the type of fuel and venting assembly that

is required.

3. Proper Operation of Optional Glass Doors

While operating your appliance, you should either have

the doors completely open or completely closed, but

never partially open. See Figure 24.

Figure 22 - Flame Patterns

Figure 23 - Air Shutter

Figure 24 - Correct Operation of Doors

06-03 35020 Rev G 19

Page 20

4. High Limit Safety Switch

This appliance is equipped with an auto reset high limit

switch which will shut down the appliance if it becomes

too hot. If this happens, turn the appliance off and shut

off the gas supply. Do not attempt to operate the

appliance until it has been examined by a qualified

service technician. See Figure 25 for limit switch

location.

5. Glass Breakage/Cleaning

It is recommended to wear gloves while handling or

removing glass. DO NOT REMOVE GLASS WHEN

IT IS HOT!

a. Clean glass after initial 4-6 hours burning time.

This is to remove any film that develops from oils

and log burn. After initial cleaning, clean as

needed.

b. Handle glass panel with care to avoid striking or

scratching it on hard objects.

c. To clean the glass, use a nonabrasive, mild

cleaning solution (i.e. Brasso). Apply an adequate

amount to the glass and wipe off per

manufacturers instructions. Contact your local

stove shop or fireplace accessories store for

further recommendations.

d. In the event of glass breakage, carefully remove

the glass frame. This will allow the removal of all

glass fragments and sheet metal edge protection

strips. Vacuum all remaining glass pieces with a

shop vac. DO NOT VACUUM IF PIECES ARE

HOT! Replace glass doors only with a Hearth &

Home Technologies glass door assembly ordered

through your local distributor/dealer. Never use

substitute material. Only fully tempered soda lime

safety glass may be used on this appliance.

BCBR36 B-VENT GAS APPLIANCE

WARNING!

Gas appliances equipped with doors should be operated only with doors fully open or doors fully

closed. If doors are left partially open, gas and flame

may be drawn out of the firebox opening, creating

risks of both fire and spillage.

Figure 25 - Limit Switch Location

Note: When cleaning the glass, NEVER use

abrasive materials. NEVER clean glass when it

is hot. Keep pets and children a safe distance

away.

20 35020 Rev G 06-03

Page 21

BCBR36 B-VENT GAS APPLIANCE

M. LOG REMOVAL/REPLACEMENT

1. Remove the lava rock from the appliance and save.

2. The top log is simply placed and located by indents in

the front log.

3. For removal of the front grate/log assembly remove

two screws (one per side) from the hearth pan. Pull

the grate/log assembly forward. See Figure26. Pull

forward on the assembly to remove it from the

appliance and set it aside, being careful not to damage

any of the logs. See Figure 27.

4. To remove the back log, remove two screws and

carefully lift off. See Figure 28.

5. Reverse the order to reinstall the logs.

Figure 26

Unscrewing the Log/Grate Assembly

from the Hearth Pan

Figure 27

Log Removal

06-03 35020 Rev G 21

Figure 28

Back Log Removal

Page 22

AK22 - Air Kit

BCBR36 B-VENT GAS APPLIANCE

N. OPTIONAL COMPONENTS

RC-SMART-HTL

Remote Control

RC-BATT-HTL

Battery-Operated Remote

Control

(Standing Pilot)

RCT-MLT-HTL

Multi-Function

Remove Control

SMART-STAT-HTL

Remote Control with

Thermostat Control

SMART-BATT-HTL

Battery-Operated Remote

Control

with Thermostat Control

DCKN Propane to

Natural Gas

Conversion Kit

DM1036

DM1036B

DM1036S

Bifold Doors

DCKP Natural to

Propane Gas

Conversion Kit

WSK-21

Wall Switch Kit

WSK-21-W

Wall Switch Kit (White)

BCRK36

Refractory

22 35020 Rev G 06-03

Page 23

BCBR36 B-VENT GAS APPLIANCE

O. REPLACEMENT PARTS

Replacement parts are available from your distributor/dealer.

Gas Log Assembly

Valve Assembly

METI#TRAPNOITPIRCSED.YTQ

164943goLtnorF1

284943goLpoT1

374943goLkcaB1

33341looWkcoR1

11982kcoRavaL1

64782etilucimreV1

456843ylbmessAetarG1

564041GN980.ecifirO1

54831PL650.ecifirO1

681241pilCdroC1

762341xelF-09rotcennoCssarB1

869651eniLsaGxelF"011

979651evlaVffO/nO1

0142571woblEssarB1

1108491epaTcitengaM1

2119432paCtsuD1

3161843hctiwStimiL1

4159333etalPevlaV1

51295-395lortnoCnoitingI1

61A495-395kcaPyrettaB1

71500-1204saGlarutaN-.yssAtoliPMI1

600-1204PL-.yssAtoliPMI1

A095-395ssenraHeriW1

81A395-395gulProtpadAV31

91005-395saGlarutaN-evlaV1

105-395PL-evlaV1

0223043ebuTrenruB1

1296843MF06ULB1H.yssAeriW1

2273943MF06KLB1H.yssAeriW1

20682hctiwSllaW.yssAeriW1

Visit our Website at

06-03 35020 Rev G 23

www.fireplaces.com for a dealer/distributor near you!

Page 24

BCBR36 B-VENT GAS APPLIANCE

HOMEOWNERS NOTES

24 35020 Rev G 06-03

Page 25

BCBR36 B-VENT GAS APPLIANCE

HOMEOWNERS NOTES

06-03 35020 Rev G 25

Page 26

BCBR36 B-VENT GAS APPLIANCE

HOMEOWNERS NOTES

26 35020 Rev G 06-03

Page 27

BCBR36 B-VENT GAS APPLIANCE

Index

A

Air Kit 22

Installation 9

Operation 18

Air Shutter 19

Air Shutter Adjustment 19

Appliance Preparation 14

B

Bifold Doors 22

BTUs 11

Building Codes 4

C

Certification 4

Chase Installation 8

Checklist 17

Cleaning

Burner & Control Compartment

19

Clearances 4, 5, 6, 7

Codes 4

Building 4

Electric 12

Gas 4

Combustible Finishing Material 14

Combustible Material 6

Conversion Kits 11, 22

E

Electric Codes 12

F

Finishing 14

Firestop Spacer 8

Flame

Patterns 19

Flames

Blue 18

Framing 6, 8

Fuel Conversion Instructions

11, 18

G

Gas Codes 4

Gas Conversions 11, 18

Gas Line Connection 10

Gas Pressure 11

Glass

Cleaning 20

Condensation 18

Film 18

Glass Doors 19

H

Heat Shield 13

High Altitude Installation 10

High Limit Safety Switch 20

High Surface Temperatures 17

I

Input Rate 11

Inspection 17

Insulation 7, 8

Intermittent Pilot Ignition 19

Operation 18

J

Junction Box 13

L

Lava Rock 15

Lighting Instructions 16

Location and Clearances 5

Log/Grate Assembly 21, 23

Logs

Removal/Replacement 21

M

Maintenance 19

Mantel 14

Minimum Heights 6

N

Nailing Flanges 6

Natural Gas 18

O

Odor 18

Outside Air Kit 22

Installation 9

Operation 18

P

Propane Gas 18

R

Refractory 22

Remote Control 22

Rock Wool 15

S

Sealant Material 14

Space Requirements 5

Start-up Issues 18

T

Termination Installation 8

Testing

Vent System 9

Typical Installation 4

U

Utilities 10

V

Vent Lengths 7

Vent System

Checking 19

Vermiculite 15

Vertical Termination 8

W

Water 18

Website 23

Wiring Diagram 12

06-03 35020 Rev G 27

Page 28

Gas Appliance (Fireplace)

LimiLifetime Warranty

HEARTH & HOME TECHNOLOGIES INC. (HHT) extends the following warranty for Hearth Technologies Inc. gas appliances installed in the United States of America or Canada (the Appliance). Dealers and employees of HHT have no authority

to make any warranty or authorize any remedies in addition to or inconsistent with the terms of this warranty.

Limited Lifetime Warranty

HHT warrants the Appliance for component failure due to a manufacturing defect of any of the following components: combustion chamber, burner pan, and logs. The Limited Lifetime Warranty specified above is subject to the conditions, exclusions and

limitations listed below, is for the period the Appliance is owned by the original homeowner only, and is nontransferable.

1 Year Limited Warranty

HHT warrants the Appliance to be free from failure of any of the following components for a period of one year after installation: valve, flexible gas line connector, glass panel, fan, direct vent chimney components, factory paint, gasket, piezo ignitor,

thermopile, thermocouple, junction box, pilot assembly, shutoff valve, high limit switch, refractory liners, transformer, and

control box. If the HHT Appliance is found to be defective in either material or workmanship within one year of the date of

original installation, HHT will provide replacement parts at no charge and pay reasonable labor and freight costs, and is for the

period of one year following the date of original installation of the Appliance.

Conditions, Exclusions, & Limitations of Liability

A. Both the Limited Lifetime and 1 Year Limited Warranties supplied by HHT apply only while the Appliance is in its location

of original installation. HHTs obligation under this warranty does not extend to damages resulting from (1) installation,

operation or maintenance of the Appliance not in accordance with the Installation Instructions, Operating Instructions, and

the Listing Agent Identification Label furnished with the Appliance; (2) installation which does not comply with local

building codes; (3) shipping, improper handling, improper operation, abuse, misuse, accident or unworkmanlike repairs;

(4) environmental conditions, inadequate ventilation or drafting caused by tight sealing construction of the structure, air

handling devices such as exhaust fans or forced air furnaces, or other causes; (5) use of fuels other than those specified

in the Operating Instructions; (6) installation or use of components not supplied with the Appliance or any other components not expressly authorized and approved by HHT; and/or (7) modification of the Appliance not expressly authorized

and approved by HHT in writing. This warranty is limited to only the component parts manufactured or supplied by HHT.

B. HHTs liability under both the Limited Lifetime Warranty and the 1 Year Limited Warranty is limited to the replacement and

repair of defective components or workmanship during the applicable period. HHT may fully discharge all of its obligations under such warranties by repairing the defective component(s) or at HHTs discretion, providing replacement parts

at no charge and paying reasonable labor and freight costs.

C. EXCEPT TO THE EXTENT PROVIDED BY LAW, HHT MAKES NO EXPRESS WARRANTIES OTHER THAN THE

WARRANTY SPECIFIED HEREIN. THE DURATION OF ANY IMPLIED WARRANTY IS LIMITED TO DURATION OF

THE WARRANTY SPECIFIED ABOVE.

D. Some states do not allow exclusions or limitations of incidental or consequential damages, so those limitations may not

apply to you. This warranty gives you specific rights; you may also have other rights which vary from state to state.

How to Obtain Service

To obtain service under this warranty you must:

1. Send written notice of the claimed condition to the Technical Service Department, Hearth & Home Technologies, 1915 W.

Saunders Street, Mt. Pleasant, Iowa 52641-1563. You may also register your claim online at www.heatilator.com/

contact.asp.

2. Provide proof of purchase, model number, serial number, and manufacturing date code to HHT.

3. Provide HHT reasonable opportunity to investigate the claim, including reasonable opportunity to inspect the Appliance

prior to any repair or replacement work and before the Appliance or any component of the Appliance has been removed

from the place of original installation.

4. Obtain HHTs consent to any warranty work before the work is done.

Additional Information:. If you would like information on current HHT products or want to locate a dealer in your area, call

1-800-843-2848.

28 35020 Rev G 06-03

Loading...

Loading...