Page 1

Î

INSTALLATION AND OPERATION INSTRUCTIONS

MODEL: ATS-AU-D

AUSTRALIAN GAS ASSOCIATION APPROVED

AGA Approval Number 5543

WARNING

HOT SURFACES!

Glass and other surfaces are hot during operation AND cool down.

Hot glass will cause burns.

• DO NOT touch glass until it is cooled

• NEVER allow children to touch glass

• Keep children away

• CAREFULLY SUPERVISE children in same room as fi replace.

• Alert children and adults to hazards of high temperatures.

High temperatures may ignite clothing or other fl ammable materials.

• Keep clothing, furniture, draperies and other fl ammable materials away.

This appliance has been supplied with an integral barrier to prevent direct contact with the

fi xed glass panel. DO NOT operate the appliance with the barrier removed.

THIS MANUAL MUST BE USED FOR INSTALLATION AND RETAINED

BY HOMEOWNER FOR OPERATION AND MAINTENANCE.

Î

This product may be covered by one or more of the following patents: (United States) 4593510, 4686807, 4766876, 4793322, 4811534, 5000162, 5016609, 5076254, 5113843,

5191877, 5218953, 5263471, 5328356, 5341794, 5347983, 5429495, 5452708, 5542407, 5601073, 5613487, 5647340, 5688568, 5762062, 5775408, 5890485, 5931661, 5941237,

5947112, 5996575, 6006743, 6019099, 6048195, 6053165, 6145502, 6170481, 6237588, 6296474, 6374822, 6413079, 6439226, 6484712, 6543698, 6550687, 6601579, 6672860,

6688302B2, 6715724B2, 6729551, 6736133, 6748940, 6748942, 6769426, 6774802, 6796302, 6840261, 6848441, 6863064, 6866205, 6869278, 6875012, 6880275, 6908039,

6919884, D320652, D445174, D462436; (Canada) 1297749, 2195264, 2225408, 2313972; (Australia) 780250, 780403, 1418504 or other U.S. and foreign patents pending.

HEAT & GLO, a brand of Hearth & Home Technologies Inc.

7571 215th Street West, Lakeville, MN 55044, USA, www.heatnglo.com

1Heat & Glo • ATS-AU-D • 327-900 Rev. F • 6/09

Page 2

Î

INSTALLATION AND OPERATION INSTRUCTIONS

PLEASE READ THIS MANUAL BEFORE INSTALLING AND USING THIS

APPLIANCE.

MODEL A TS-AU-D IS AUSTRALIAN GAS ASSOCIATION APPROVED FOR

NATURAL GAS OR PROPANE AS A BALANCED FLUE HEATER.

Refer to the appliance data plates for gas consumptions and pressures.

Installation of this appliance should only be carried out by an authorized person

in accordance with the manufacturers instructions. All relevant codes and regulations laid down by the gas piping authorities, municipal building regulations,

electrical wiring regulations and the requirements of the AGA Gas Installation

Code must be observed.

This appliance and its components are tested and safe when installed in accordance with this Installation Manual. Report to your dealer any parts damaged

in shipment, specifi cally check glass condition. The gas logs and fl ue system

components are in separate packages. Read all instructions before starting

installation and follow these instructions carefully during installation to ensure

maximum benefi t and safety. Failure to follow them will void your warranty and

may present a fi re hazard.

The Heat & Glo, a brand of Hearth T echnologies, Inc. warranty will be voided by,

and Heat & Glo disclaims any responsibility for the following actions:

• Installation of any damaged heater or fl ue system component

• Modifi cation of the heater or balanced fl ue system Installation other than as

instructed by Heat & Glo

• Improper positioning of the gas logs or the glass door

• Installation and/or use of any component part not manufactured or approved

by Heat & Glo, not withstanding any independent testing laboratory or other

party approval of such component part or accessory.

IMPORTANT: Read all instructions carefully before starting installation. Failure to follow these installa-

tion instructions may result in a possible fi re hazard and will void the warranty.

Heat & Glo, a brand of Hearth & Home Technologies, Inc.

Î

7571 215th Street West, Lakeville, MN 55044

Copyright 2009 • Printed in U.S.A.

2 Heat & Glo • ATS-AU-D • 327-900 Rev. F • 6/09

Page 3

TABLE OF CONTENTS

1.0 Installation Instructions .....................................................................................8

1.1 Introduction ................................................................................................8

1.2 Flue System ..............................................................................................8

1.2.1 Flue System Approvals ....................................................................8

1.2.2 Connecting the Flue Pipe ................................................................9

1.3 Connecting the Gas Supply .......................................................................9

1.4 Fan ..........................................................................................................10

1.5 Surround Installation ................................................................................10

1.6 Finishing ..................................................................................................14

1.7 Log Installation ........................................................................................14

1.8 Installer Testing .......................................................................................14

2.0 Operating Instructions ....................................................................................15

2.1 Safety and Lighting Information ...............................................................16

2.2 Safety Information ...................................................................................16

2.3 Lighting Instructions .................................................................................17

2.4 Fan Operation ..........................................................................................18

3.0 Servicing and Maintenance ............................................................................18

3.1 Removal of Covers for Servicing .............................................................19

3.2 Removal of Components for Service ....................................................... 19

3.3 Parts Replacement ..................................................................................19

3.4 Adjustments and Replacement Parts ......................................................19

3.5 Troubleshooting .......................................................................................20

4.0 Replacement Parts .........................................................................................22

Limited Lifetime Warranty ...............................................................................25

Î = Contains updated information.

3Heat & Glo • ATS-AU-D • 327-900 Rev. F • 6/09

Page 4

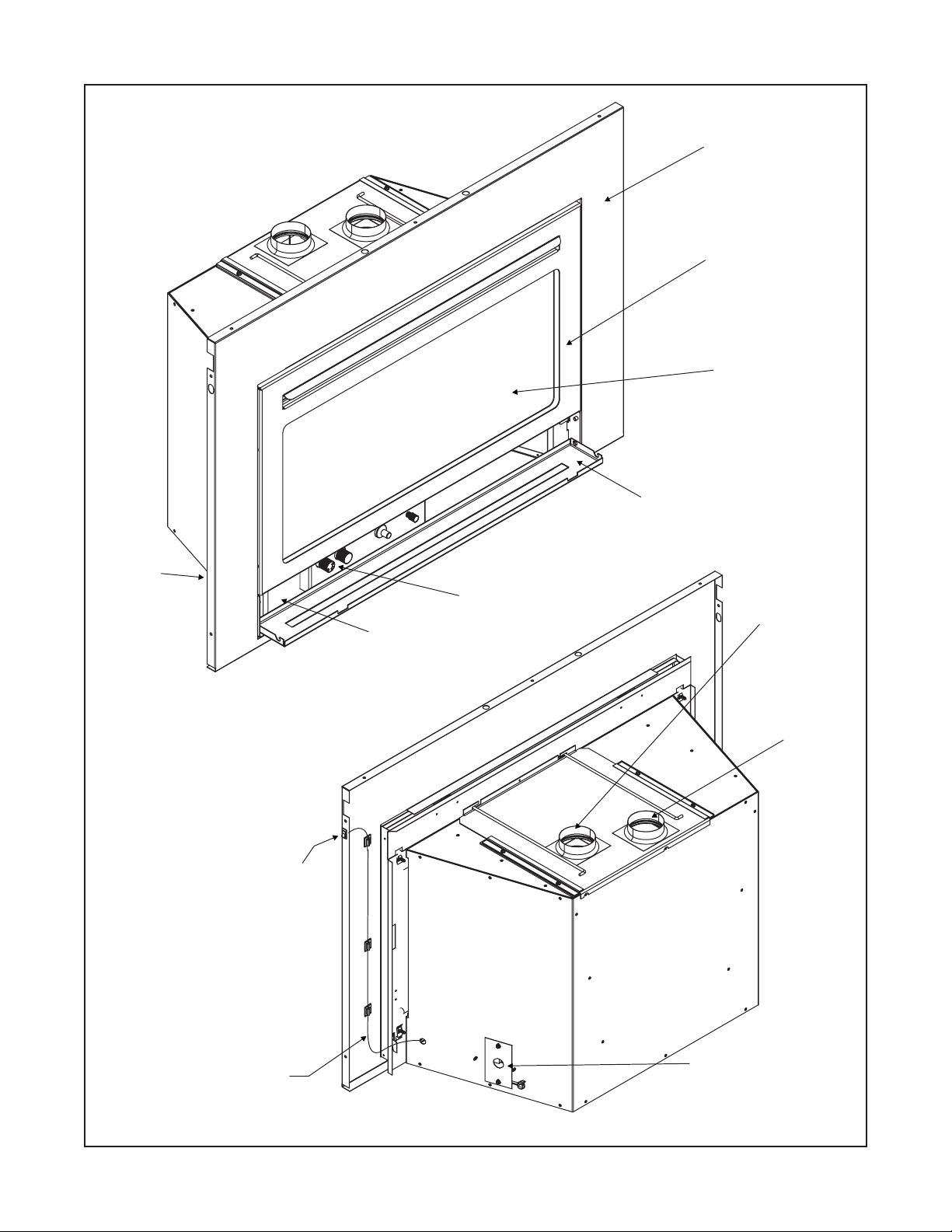

GAS LINE

ACCESS

DATA BADGE

& LABELS

GAS

CONTROL

VALVE

LOWER

GRILLE

SURROUND

DRESS

GUARD

GLASS

ASSEMBLY

EXHAUST FLUE

COLLAR

FIGURE 1

ON/OFF

SWITCH

LOW VOLTAGE

WIRES

ELECTRICAL

JUNCTION BOX

ACCESS

INLET FLUE

COLLAR

4 Heat & Glo • ATS-AU-D • 327-900 Rev. F • 6/09

Page 5

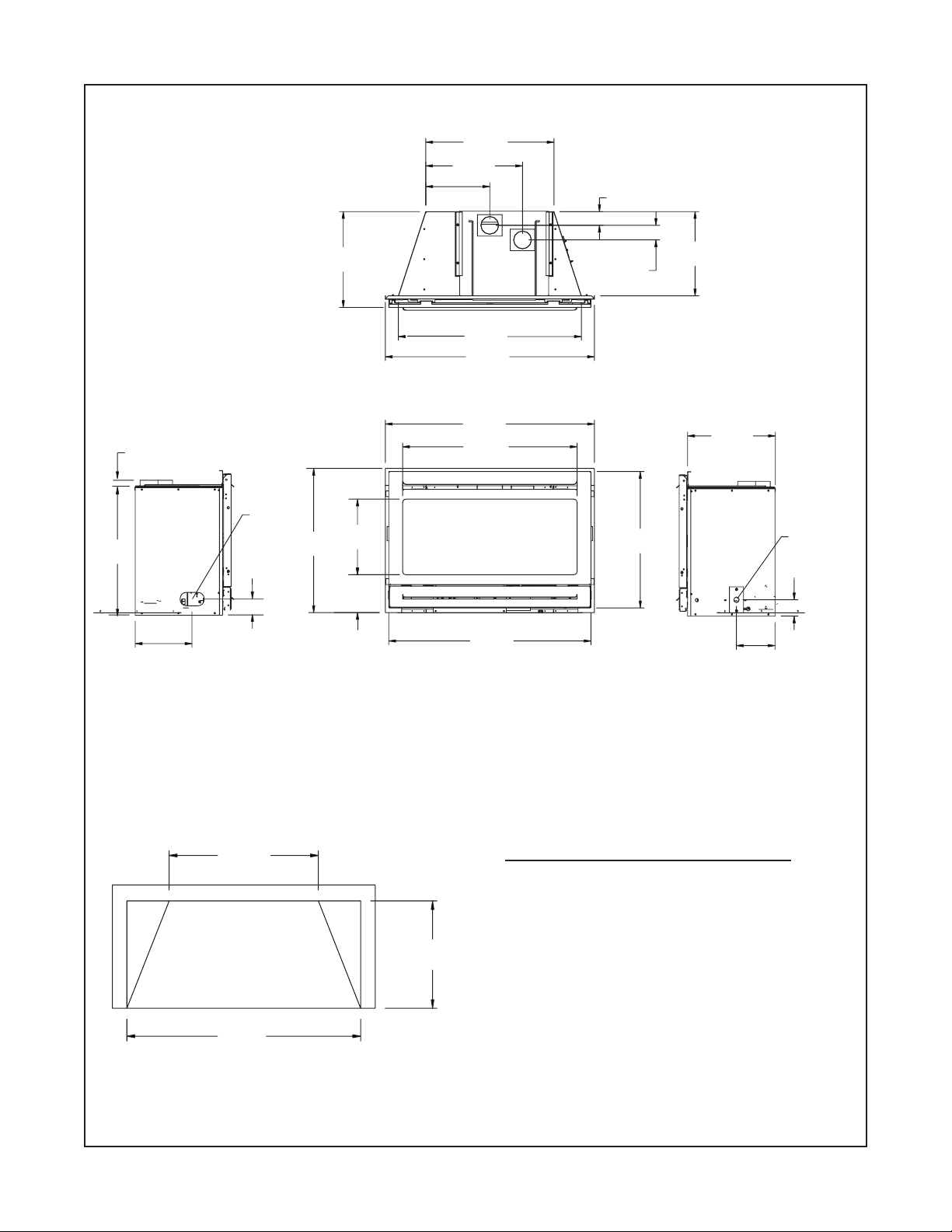

256 mm

512 mm

387 mm

55 mm

514 mm

24 mm

227 mm

GAS LINE

ACCESS

64 mm

575 mm

383 mm

302 mm

151 mm

731 mm

835 mm

835 mm

697 mm

808 mm

58 mm

544 mm

336 mm

154 mm

351 mm

ELECTRICAL

ACCESS

65 mm

TOP VIEW

MASONRY OF FACTORY-BUILT FIREPLACE

521 mm

816 mm

FIGURE 2

MINIMUM FIREPLACE OPENING

WIDTH: 32-1/8" (816 mm)

DEPTH: 13-1/2" (343 mm)

HEIGHT: 20-1/2" (521 mm)

343 mm

NOTE: If exhaust collar on insert and fi replace

damper do not line up, add 4 inches (102 mm) to

minimum fi replace opening height to accommodate

bends in vent pipe.

5Heat & Glo • ATS-AU-D • 327-900 Rev. F • 6/09

Page 6

MODEL FLUE TERMINATION APPROVAL

ATS-AU-D LINK-DV30B VERTICAL TERMINATION CAP

TABLE 1

TERMINATION CAP

EXHAUST

AIR FLUE PIPE

WARNING: THE EXHAUST PIPE MUST

ONLY BE CONNECTED TO THE EXHAUST STARTING COLLAR OF THE

UNIT AND THE CENTER COLLAR OF

THE TERMINA TION CAP.

THE INLET AIR PIPE MUST ONLY BE

CONNECTED TO THE INLET AIR COLLAR OF THE UNIT AND ATTACHED

TO THE INLET AIR COLLAR OF THE

TERMINATION CAP.

V = 3.0 m (10 FT.) MINIMUM

10 m (40 FT.) MAXIMUM

INLET AIR

FLUE PIPE

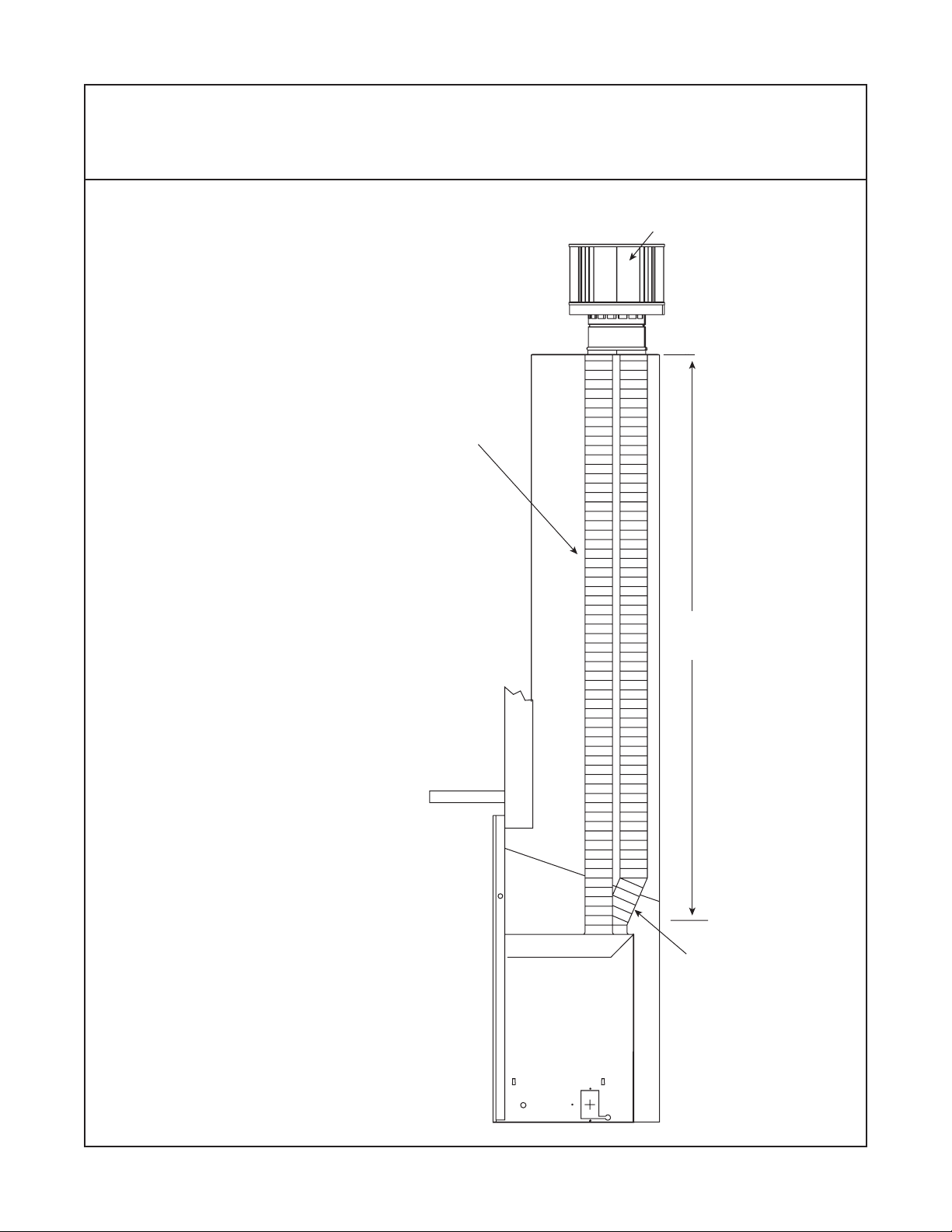

FIGURE 3

6 Heat & Glo • ATS-AU-D • 327-900 Rev. F • 6/09

Page 7

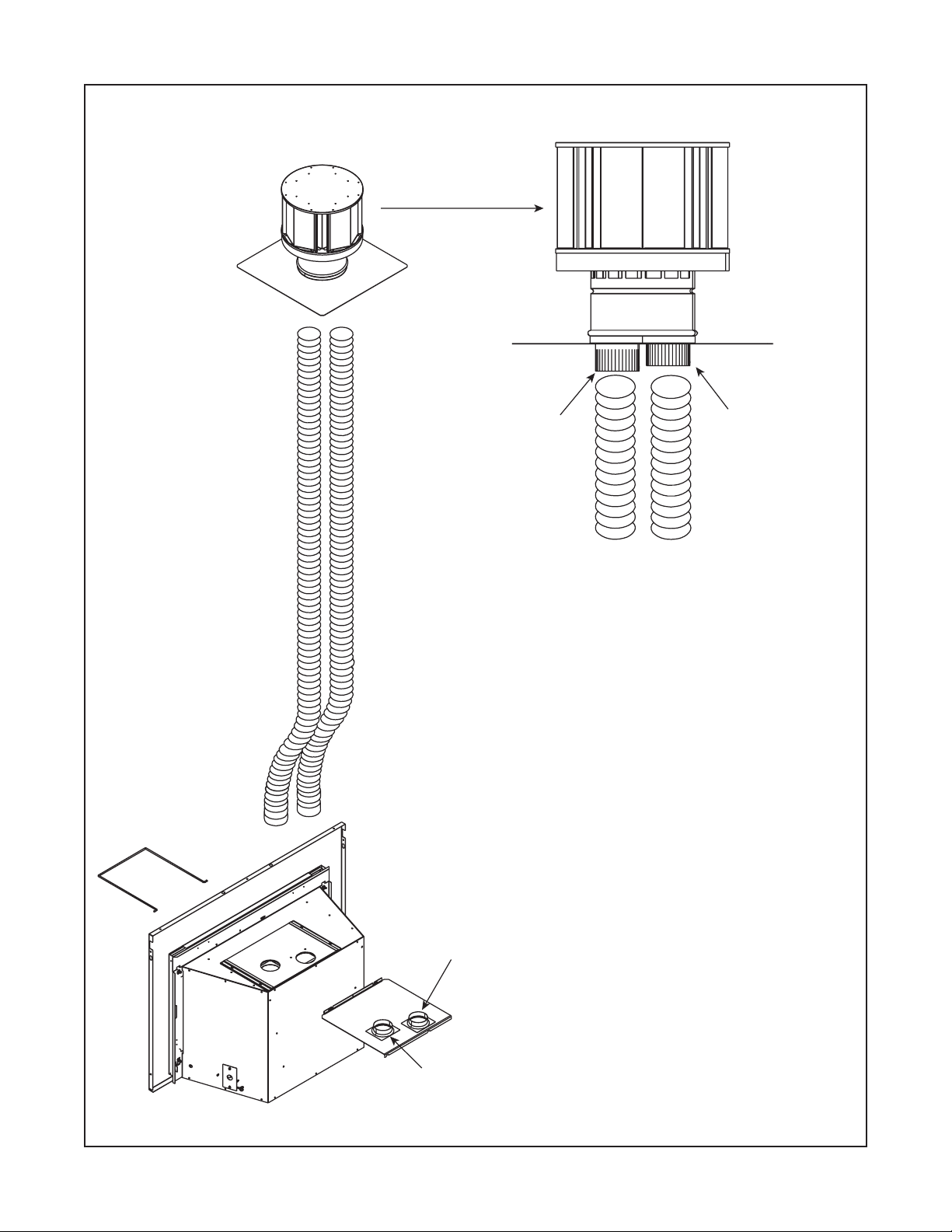

TERMINATION CAP

EXHAUST

COLLAR

INLET AIR

COLLAR

FIGURE 4

INLET AIR

STARTING

COLLAR

EXHAUST

STARTING

COLLAR

7Heat & Glo • ATS-AU-D • 327-900 Rev. F • 6/09

Page 8

1.0 INSTALLATION INSTRUCTIONS

1.1 INTRODUCTION

This model is designed to operate with all combustion

air being siphoned from the outside of the building and

all exhaust gases expelled to the outside of the building. This model is designed to be installed in a masonry

fi replace or factory built fi replace. These units CAN-

NOT be recessed inside combustible construction.

Minimum dimensions of the masonry or factory-built

fi replace into which these models can be installed, are

32 1/8-inches (816 mm) width x 13 1/2 -inches (343

mm) depth x 20 1/2 inches (521 mm) height.

WARNING: THIS UNIT IS NOT FOR USE WITH

SOLID FUEL.

This unit MUST use the fl ue termination described in

the fl ueing section of the manual.

The control system for this model is a millivolt type.

It consists of a gas control valve/variable regulator, a

standing pilot/thermopile/thermocouple, a piezo ignitor,

and an ON/OFF switch. The controls are located behind the lower grille. Access to the controls is gained

by rotating the grille up. ON/OFF switch is located on

the front surround. See Figures 1 and 7.

Minimum inlet gas supply pressure for purpose of input

adjustment is 4.5 inches w.c. (1.13 kPa) for natural gas

and 11 inches w.c. (2.75 kPa) for propane. Manifold

(outlet) pressures should be set at 3.2 inches w.c. (.80

kPa) for natural gas models and 9.6 inches w.c. (2.40

kPa) for propane models.

In planning the installation for the insert it is necessary to determine where the unit is to be installed, and

whether optional accessories (wall switch, thermostat,

or remote control) are desired. Gas supply piping

should also be planned. Model ATS-AU-D has a factory installed fan.

This model is designed to be installed in a masonry or

factory-built fi replace. The separate 3.3 inch (84 mm)

combustion air and exhaust pipes must be run up

through the chimney and terminated vertically. Horizontal fl ue terminations MUST NOT be done.

Before starting installation of fl ue kits, the installer

should read the Gas Fireplace Instructions and the Flue

Kit Instructions to ensure that a proper fl ue installation

is completed.

Consult your local Building Codes before beginning

the installation.

WARNING: THIS GAS FIREPLACE AND FLUE

ASSEMBLY MUST BE FLUED DIRECTLY TO THE

OUTSIDE AND MUST NEVER BE ATTACHED TO

A CHIMNEY SERVING A SEPARATE SOLID FUEL

BURNING APPLIANCE. EACH GAS APPLIANCE

MUST USE A SEPARATE FLUE SYSTEM.

CAUTION: Prior to connecting the fl ue system to

the unit, read sections:

1.3 Connecting the Gas Supply

1.4 Fan

1.2 FLUE SYSTEM

1.2.1 FLUE SYSTEM APPROVALS

Table 1 and Figures 3-5 show the fl ue termination

caps and systems approved for use with this model.

Approved fl ue system terminations are labeled for

identifi cation. 3.3 inch (84mm) diameter listed fl exible

aluminum or stainless steel gas fl ue is used for both

the incoming combustion air and exhaust fl ue pipes.

NO OTHER FLUEING SYSTEMS OR COMPONENTS

MAY BE USED. Detailed installation instructions are

included with each fl ue termination kit and should be

used in conjunction with this manual.

HORIZONTAL FLUEING

The fl ue system on this model CANNOT be terminated

horizontally.

VERTICAL FLUEING

The fl ue pipes MUST be connected to the proper col-

lars on the unit AND the exhaust fl ue pipe MUST be

connected to the termination cap or the unit will not

operate. The combustion air fl ue pipe MUST be con-

nected to the termination cap.

NOTE: The minimum vertical rise (exhaust fl ue) is

10 feet (3M) and the maximum vertical rise is 40 feet

(10M). These dimensions are measured from the starting collars of the unit to the end of the last section of

fl ue pipe (See dimension V in Figure 3).

A vertical fl ue termination system installed on this

model will include one (1) length of 3.3 inch (84 mm)

fl exible fl ue pipe for the combustion air, one (1) length

of 3.3 inch (84 mm) fl exible fl ue pipe for the exhaust,

one (1) LINK-DV30B Vertical Termination Kit.

8 Heat & Glo • ATS-AU-D • 327-900 Rev. F • 6/09

Page 9

1.2.2 CONNECTING THE FLUE PIPE

NOTE: The damper of the masonry or factory-built

chimney may have to be removed to allow installation of the fl exible-fl ue pipe.

Install the 3.3 inch (84mm) fl exible fl ue pipes down

through the chimney. Slide the starting collar bracket

towards the back of the unit. See Figure 4. Attach and

secure the bottom ends of the fl ex pipes to the starting

collar bracket with 3 plated sheetmetal screws on each

collar. Slide the gas insert into place, and position any

excess fl ex fl ue pipe back up into the chimney . Use the

handle to slide the starting collar plate forward. Hold

the collar bracket from sliding backwards by inserting a

screw through the unit front and into the collar plate.

Attach the pipe-to-cap adaptor to the termination cap

and to the top of the fl exible fl ue pipe and set the cap in

place at the top of the chimney. See Figures 3 and 4.

CAUTION: To avoid downdrafts and/or cold air

problems, it is recommended to seal off the area

between the termination cap and the top of the

solid-fuel chimney opening into which the fl ue cap

has been installed.

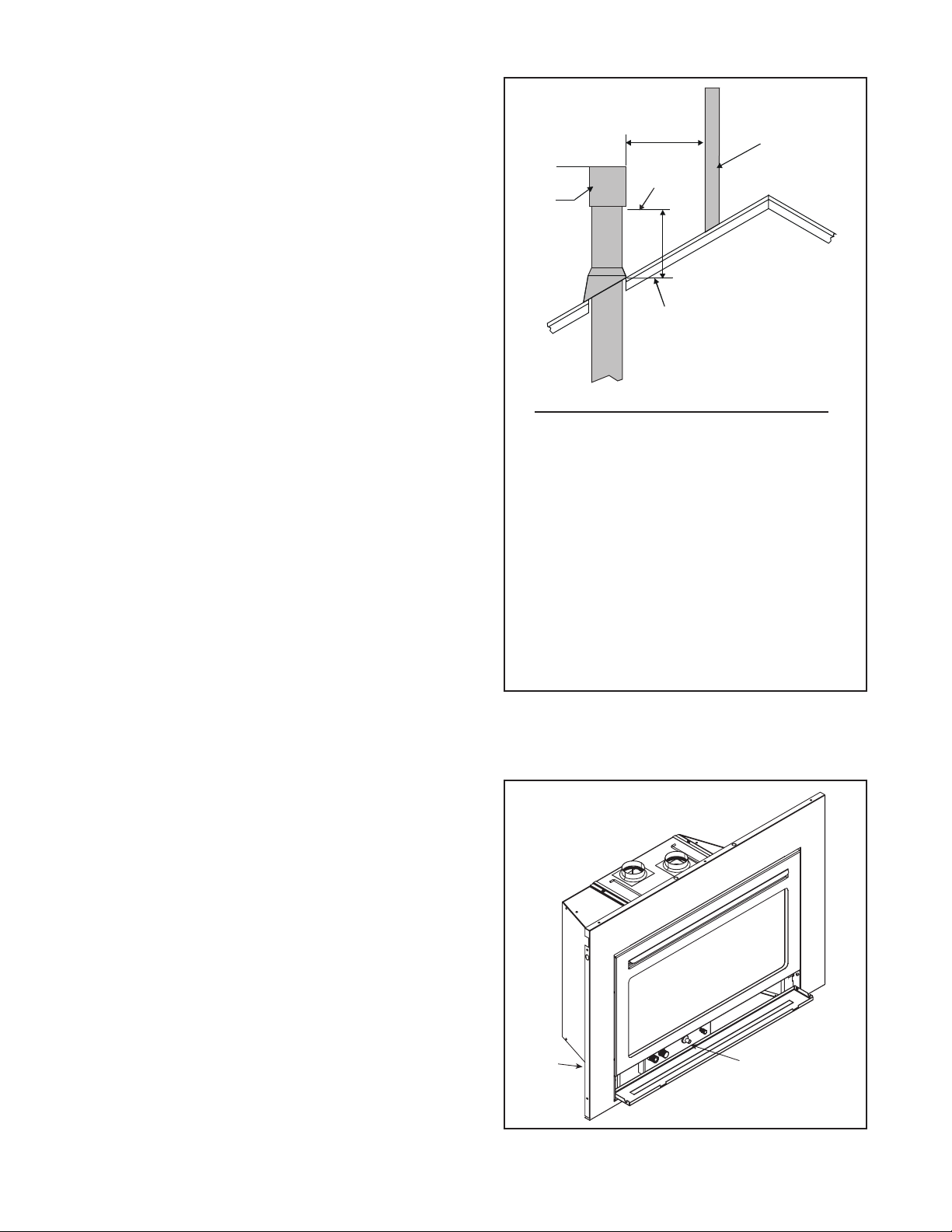

WARNING: A 12-inch (305 mm) minimum chim-

ney and/or fl ue height above the roof top is neces-

sary in the interest of safety. See Figure 5.

NOTE: THIS ALSO PERT AINS T O VERTICAL FLUE

SYSTEMS INSTALLED ON THE OUTSIDE OF THE

BUILDING.

1.3 CONNECTING THE GAS SUPPLY

The gas is introduced to the appliance on the left hand

side. See Figure 6. After the gas pipe installation is

complete, check all gas connections carefully for

leaks with a soap solution. DO NOT USE AN OPEN

FLAME.

610 mm

LOWEST

DISCHARGE

TERMINATION

CAP

Angle H (Min.) M

0°-26.6° ........................................................0.30*

26.6°-30.3° ........................................................0.38*

30.3°-33.7° ........................................................0.46*

33.7°-36.9° ........................................................0.61*

36.9°-39.8° ........................................................0.76

39.8°-42.5° ........................................................0.99

42.5°-45.0° ........................................................1.22

45.0°-49.4° ........................................................1.52

49.4°-53.1° ........................................................1.83

53.1°-56.3° ........................................................2.13

56.3°-59.0° ........................................................2.29

59.0°-60.3° ........................................................2.44

Figure 5 Minimum Height from Roof to Lowest

Discharge Opening

OPENING

H (MIN.) - MINIMUM HEIGHT FROM ROOF

TO LOWEST DISCHARGE OPENING

*.91 M minimum in snow regions

VERTICAL

WALL

FIGURE 5 specifi es minimum fl ue heights for various

pitched roofs.

NOTE: THE GAS SUPPLY LINE SHOULD BE

PURGED OF ANY TRAPPED AIR PRIOR TO THE

FIRST FIRING OF THE UNIT.

GAS LINE

ACCESS

FIGURE 6

GAS CONTROL

VALVE

9Heat & Glo • ATS-AU-D • 327-900 Rev. F • 6/09

Page 10

SURROUND

WITHOUT TRIM

FIREBOX

SURROUND

ON/OFF

SWITCH

DRESS GUARD

FIGURE 7

1.4 FAN

Model ATS-AU-D has a factory installed Fan, Junction

Box, variable speed Rheostat Control Switch, and

Temperature Sensor Switch for the fan. The fan, temperature sensor switch, and junction box are located

behind the lower grille. T o provide the 240 V AC needed

at the Junction Box, simply plug the 3-prong grounded

cord into a 3-prong grounded 240 V AC wall outlet. This

cord exits the unit at the lower right hand corner.

1.5 INSTALLING THE SURROUND

NOTE: REMOVE FRONT TRIM DOOR AND GLASS

DOOR ASSEMBLIES FROM THE INSERT BEFORE

SURROUND INSTALLATION.

1. Find the coiled low voltage wires and ON/OFF switch

attached to outer right side of the insert. See Figure 7.

2. Disconnect the ON/OFF switch from the low voltage

wire leads, and insert the short wires of the ON/OFF

switch through the hole at the upper right corner

of the surround and push the back of the switch

through the hole - it will be retained in the hole.

LOW VOLTAGE WIRES

3. Run the low voltage lead wires up the back of the

right side of the surround and secure them with

the three wire ties found there. Reconnect the low

voltage wires to the short wires of the ON/OFF

switch.

4. Remove and retain the four surround attachment

screws at the corners of the face of the unit. See

Figure 7.

5. Slide the surround against the face of the unit,

aligning the holes in upper and lower, right and left

corners and secure the surround to the unit with

the attachment screws.

NOTE: PLACE THE THREE INSULATION PIECES

INTO THE CAVITIES AT THE BACK OF THE SURROUND BEFORE POSITIONING THE INSERT INTO

THE FACT ORY-BUILT OR MASONRY FIREPLACE.

THIS INSULATION WILL HELP SEAL FOR COLD

AIR LEAKS.

10 Heat & Glo • ATS-AU-D • 327-900 Rev. F • 6/09

Page 11

Log Assembly: 327-700A

Model: A TS-AU-D

Remove dress guard and glass door from heater.

Carefully remove logs from cardboard.

CAUTION: Logs are fragile!

LOG PLACEMENT

INSTRUCTIONS

1

4

3

6

2

5

Photo A

LOG #1 (SRV327-701): Place log #1 in the back of the heater , locating it's slot on the right over the protruding

tab. The left end of the log is positioned by the two bend up tabs shown in Photo A.

11Heat & Glo • ATS-AU-D • 327-900 Rev. F • 6/09

Page 12

LOG #2 (SRV327-702): Position log #2 by locating its slot over the tab on the front left of the burner. The

slot of the left side of log #2 fi ts over the bar grate. Push the left side back onto it so it rests against the step.

LOG #3 (SRV327-703): Position log #3 by locating its slot over the tab on the right front of the burner . The

slot on the right side of log #3 fi ts over the bar grate.

LOG #4 (SRV327-704): Place the bottom left corner of log #4 behind log #2 and rest its top right corner

on log #1.

12 Heat & Glo • ATS-AU-D • 327-900 Rev. F • 6/09

Page 13

LOG #5 (SRV327-705): Rest log #5 in the cutouts on both log #1 and log #2 as shown.

LOG #6 (SRV438-724): Position the "Y" end of log #6 into the cutout on log #4 and its opposite end into

the groove on log #2.

13Heat & Glo • ATS-AU-D • 327-900 Rev. F • 6/09

Page 14

1.6 FINISHING

Figure 8 shows the minimum vertical and corresponding maximum horizontal dimensions of mantels or other

combustible projections above the gas heater.

1.7 LOG INSTALLATION

Carefully remove the log package from the fi replace

and the logs from their package. Handle logs gen-

tly.

Place the logs in the fi replace by following the steps

shown on pages 11-13.

Replace the glass door and trim door previously removed prior to lighting the unit. Be certain the gas logs

are properly positioned.

1.8 INSTALLER TESTING

The space heater must be tested and be operating

according to manufacturer's specifi cations prior to the

installer leaving the site. Note: The tips of the fl ames

should never hit the top of the fi rebox after the unit has

warmed up. Please contact your dealer or a qualifi ed

service person to replace injector or adjust valve.

Upon completing the gas line connection, a small

amount of air will be in the lines. When fi rst lighting

the pilot light, it will take a few minutes for the lines

to purge themselves of this air. Once the purging is

complete, the pilot and burner will light and operate as

indicated in the Lighting Instructions.

Subsequent lights of the appliance will not require

such purging.

MANTEL

12" (305 mm)

TOP OF

12" (305 mm)

MAXIMUM

MINIMUM

UNIT

CAUTION: DURING THE INITIAL PURGING

AND SUBSEQUENT LIGHTINGS, NEVER ALLOW

THE GAS VALVE CONTROL KNOB TO REMAIN

DEPRESSED IN THE "PILOT" POSITION WITHOUT

PUSHING THE RED IGNITOR BUTTON AT LEAST

ONCE EVERY SECOND.

Follow the Safety Information and Lighting Instructions

pages of this manual to light the appliance.

T o obtain proper operation, it is imperative that the pilot

and main burner fl ame characteristics are steady, not

lifting or fl oating. Typically, the top 3/8-inch (10 mm)

of the pilot generator should be engulfed in the pilot

fl ame. (Figure 9).

3/8 in. (10 mm)

FIGURE 9

FIGURE 8

Proper gas log positioning is shown on pages 11-13.

Follow Section 3.5 TROUBLESHOOTING for adjusting

the appliance to operate properly.

14 Heat & Glo • ATS-AU-D • 327-900 Rev. F • 6/09

Page 15

THERMOCOUPLE

FIGURE 10

2.0 OPERATING INSTRUCTIONS

3/16” PIGGYBACK CONNECTOR

GAS VALVE

OPTIONAL WALL SWITCH,

THERMOSTAT OR REMOTE

WHITE T2

RED TI

THERMOPILE

WARNING

HOT SURFACES!

Glass and other surfaces are hot during

operation AND cool down.

Hot glass will cause burns.

• DO NOT touch glass until it is cooled

• NEVER allow children to touch glass

• Keep children away

• CAREFULLY SUPERVISE children in same room as

fi replace.

• Alert children and adults to hazards of high temperatures.

High temperatures may ignite clothing or other

fl ammable materials.

• Keep clothing, furniture, draperies and other fl ammable

materials away.

This appliance has been supplied with an integral barrier

to prevent direct contact with the fi xed glass panel. DO

NOT operate the appliance with the barrier removed.

The control system for these models is a millivolt type. It

consists of a gas control valve/variable regulator, a standing pilot assembly, a thermopile, a piezo ignitor, and an

ON/OFF rocker switch. The controls are located in the

lower compartment behind the lower grille. Access to

this compartment is gained by rotating the grille up. See

Figure 1.

WARNING:

DO NOT CONNECT 240 VAC TO THE

GAS CONTROL V AL VE OR CONTROL WIRING SYSTEM

OF THIS UNIT.

The gas control system is wired so the thermopile, when

heated with the pilot light, will provide approximately 350

to 500 millivolts. This activates the gas control valve. See

Figure 11 for appliance wiring diagram.

When lit for the fi rst time, the appliance will emit a slight

odor for an hour or two. This is due to paint and lubricants

used in the manufacturing process. Additionally, for the

fi rst few minutes after each lighting, vapor may condense

and fog the glass and the fl ames may be blue. After a

few minutes this moisture will disappear and within 15-30

minutes the fl ames should become yellow.

Following this initial burn, turn off the fi replace and allow

the glass to cool completely. Remove the glass using the

appropriate removal instructions. Clean the glass with any

common household glass cleaner and soft cloth. Cleaning the glass after the initial burn will prevent the fi lm from

becoming baked onto the glass. After this initial cleaning it

should only be necessary to clean the glass occasionally as

required. Never scrape or rub glass with any abrasive

materials or cleaners.

The heater may produce a noise, caused from metal expansion and contraction as it heats up and cools down.

This noise is similar to one that a furnace heat duct may

produce and does not affect the operation or longevity of

the heater.

15Heat & Glo • ATS-AU-D • 327-900 Rev. F • 6/09

Page 16

OPERATING CAUTIONS

• THIS APPLIANCE MAY EXHIBIT A SLIGHT CARBON DEPOSITION.

• DO NOT PLACE ARTICLES ON OR AGAINST THIS

APPLIANCE.

• DO NOT USE OR STORE FLAMMABLE MATERIALS NEAR THIS APPLIANCE.

• DO NOT SPRA Y AEROSOLS IN THE VICINITY OF

THIS APPLIANCE WHILE IT IS IN OPERATION.

• THE DRESS GUARD IS FITTED TO THIS APPLIANCE TO REDUCE THE RISK OF FIRE OR

INJURY FROM BURNS AND NO PART OF IT

SHOULD BE PERMANENTLY REMOVED. FOR

PROTECTION OF YOUNG CHILDREN OR THE

INFIRM, A SECONDARY GUARD IS REQUIRED.

• THE GLASS DOOR ASSEMBLY MUST BE IN

PLACE AND SEALED AND THE FIXED MESH

DRESS GUARD MUST BE IN PLACE ON THE

HEATER BEFORE THE UNIT CAN BE PLACED

INTO SAFE OPERATION.

• DO NOT USE THIS APPLIANCE IF ANY P ART HAS

BEEN UNDER WATER. IMMEDIATELY CALL A

QUALIFIED SERVICE TECHNICIAN TO INSPECT

THE UNIT AND TO REPLACE ANY PART OF THE

CONTROL SYSTEM AND ANY GAS CONTROL

WHICH HAS BEEN UNDERWATER.

• DO NOT OPERATE THIS APPLIANCE WITH THE

GLASS DOOR REMOVED, CRACKED, OR BROKEN. REPLACEMENT OF THE GLASS DOOR

SHOULD BE DONE BY A LICENSED OR QUALIFIED PERSON. DO NOT STRIKE OR SLAM THE

GLASS DOOR.

• THE GLASS DOOR ASSEMBL Y SHALL ONL Y BE

REPLACED AS A COMPLETE UNIT AS SUPPLIED

BY THE GAS HEATER MANUFACTURER. NO

SUBSTITUTE MATERIALS MAY BE USED.

2.1 SAFETY AND LIGHTING INFORMATION

Follow Section 2.2 SAFETY INFORMATION and 2.3

LIGHTING INSTRUCTIONS to light the appliance.

By design, the fl ame pattern will not be identical from

unit to unit. Additionally, fl ame pattern may vary de-

pending on installation type and weather conditions.

NOTE: THE TIPS OF THE FLAMES SHOULD NEVER

HIT THE TOP OF THE FIREBOX.

2.2 SAFETY INFORMATION

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING: IF YOU DO NOT FOLLOW THESE INSTRUCTIONS EXACTLY, A FIRE OR EXPLO-

SION MAY RESULT CAUSING PROPERTY DAMAGE, PERSONAL INJURY, OR LOSS OF LIFE.

A. This appliance has a pilot. When lighting the pilot,

follow these instructions exactly.

B. BEFORE LIGHTING smell all around the appli-

ance area for gas. Be sure to smell next to the

fl oor because some gas is heavier than air and

will settle on the fl oor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

16 Heat & Glo • ATS-AU-D • 327-900 Rev. F • 6/09

C. Use only your hand to push in or turn the gas

control knob. Never use tools. If the knob will not

push in or turn by hand, don’t try to repair it. Call a

qualifi ed service technician. Forced or attempted

repair may result in a fi re or explosion.

D. Do not use this appliance if any part has been

under water. Immediately call a qualifi ed service

technician to inspect the appliance and to replace

any part of the gas control system which has been

under water.

Page 17

2.3 LIGHTING INSTRUCTIONS

LIGHTING INSTRUCTIONS

PILOT BURNER

1. "STOP!" Read the safety information on

previous page.

2. To access controls, open the bottom grille.

3. Turn the valve control knob to the "OFF"

position. To do this, you must turn the knob

clockwise to the "Pilot" position, and

then press in and continue turning clockwise

to the "OFF" position.

GAS CONTROL VALVE

NOTE: Knob cannot be turned from "PILOT"

to "OFF" unless knob is pushed in slightly . Do

not force.

4. WAIT FIVE (5) MINUTES TO CLEAR OUT

ANY GAS. Then smell for gas, including near

the fl oor. If you then smell gas, STOP! Follow

"B" in the safety information above. If you

don't smell gas, go to the next step.

5. The pilot should not require accessing for

lighting purposes. The pilot is located inside

the combustion chamber. If it is necessary

to access the pilot, follow the instructions in

Section 3.1 and 3.3 for glass door removal

and replacement.

THERMOCOUPLE THERMOPILE

6. To put the control in the pilot position, turn the

control knob counter-clockwise

"Pilot" position.

7. To light the pilot depress the control knob and

then depress the red piezo button until it makes a

clicking sound. It may be necessary to repeat this

step. If the pilot does not light after 10 seconds,

go back to step 3. The control knob should be

held down for a MINUTE after pilot ignition.

• If the control knob does not pop out when

released, STOP-shut off the gas supply to the

heater control valve, and IMMEDIATELY call

your service technician or gas supplier.

• If the pilot will not stay lit after two tries, turn

the control knob to the "OFF" position and call

your service technician or gas supplier.

8. After the pilot has been lit, the burner can be

turned on by turning the knob counter-clockwise

to the "ON" position. Flip the ON/OFF

switch to the "ON" position.

9. Close the bottom grille.

to the

1. Turn ON/OFF switch to "OFF".

2. Open the bottom grille.

TO TURN OFF GAS APPLIANCE

3. Turn the valve control knob clockwise

to the "Pilot" position, then depress knob and continue

turning to "OFF" position.

4. Close the bottom grille.

17Heat & Glo • ATS-AU-D • 327-900 Rev. F • 6/09

Page 18

FAN

JUNCTION BOX

TEMPERATURE

SENSOR SWITCH

SPEED CONTROL

FAN SPEED

CONTROL

FIGURE 11

JUNCTION BOX DETAIL

YELLOW/GRN

BLK

TEMP. SENSOR

SWITCH

JUNCTION BOX

BLUE

BRN

GRD

BLK

BLK

BLUE

BLK

BLK

BLUE

BRN

YELLOW/GRN

FAN WIRING DIAGRAM

BLK

BLUE

YW/GR

BRN

YELLOW/GREEN

BLUE

BROWN

FAN

2.4 FAN OPERATION

The accessory fan is wired in series with a speed control switch and a temperature sensor switch. Set the

speed control to an "ON" position and light the heater.

The temperature sensor switch will automatically start

the fan when the switch warms up—and stop the fan

when it cools down. Y ou can manually stop the fan by

turning the speed control switch to "OFF". See Figure

11 for fan wiring diagram.

3.0 SERVICING AND MAINTENANCE

A. HEATER SERVICING: Frequency of heater servic-

C. The appliance and fl ue system should be inspected

before initial use and at least annually by a qualifi ed

fi eld service person.

D. Inspect the external fl ue cap on a regular basis to

make sure that no debris is interfering with the air

fl ow.

E. Keep the control compartment, logs, and burner

area surround the logs clean by vacuuming or

brushing at least twice a year.

CAUTION: THE LOGS GET VERY HOT - HANDLE

ONLY WHEN COOL.

ing will depend upon use and type of installation.

B. IMPORTANT: TURN OFF GAS BEFORE SERVIC-

ING APPLIANCE. IT IS RECOMMENDED THA T A

COMPETENT SERVICE TECHNICIAN PERFORM

SERVICE CHECK-UPS AT THE BEGINNING OF

EACH HEATING SEASON.

18 Heat & Glo • ATS-AU-D • 327-900 Rev. F • 6/09

Page 19

WARNING: DO NOT USE ABRASIVE CLEAN-

ERS ON THE GLASS DOOR ASSEMBLY. DO NOT

ATTEMPT TO CLEAN THE GLASS DOOR WHEN

IT IS HOT.

F . The glass door should be cleaned using a house-

hold glass cleaner. DO NOT handle or attempt to

clean the glass when it is HOT.

G. In order to properly clean the burner and pilot

assembly , turn of f the gas to the unit and remove

the logs exposing the burner and pilot assembly.

Clean all foreign materials from top of burner.

Check to make sure that the burner orifi ce is

clean.

Visually inspect the pilot periodically. Brush or blow

away any dust or linen accumulations. If the pilot orifi ce

is plugged, disassembly may be required to remove

any foreign materials from the orifi ce or tubing.

To obtain proper operation, it is imperative that the

pilot and main burner fl ame characteristics are steady ,

not lifting or fl oating. Typically, the top 3/8-inch (9.5m)

of the pilot generator should be engulfed in the pilot

fl ame (Figure 9).

3.1 REMOVAL OF COVERS FOR SERVICING

1. Control Compartment Grille

• Rotate the bottom grille down to access the gas

controls.

2. Dress Guard and Glass Door

• Pull the bottom of the dress guard out to disengage its retaining clips. Lift the guard up and

forward to remove. Replace the dress guard

when servicing is complete.

• Rotate the bottom grille down. Release the two

spring latches, at the bottom of the glass door,

releasing the glass frame. Carefully rotate the

glass door out at its bottom and lower the top

clips to clear their retainers.

3.2 REMOVAL OF COMPONENTS FOR

SERVICE

1. Burner

• Carefully remove the log set. Next, unscrew the two

fasteners holding the grate. The grate and base pan

can now removed.

• Unscrew the brackets at both ends of the burner and

slide the burner to the right away from the burner

orifi ce.

2. Pilot Assembly/Ignition System

• Remove the log set, log grate, and base pan.

• Disconnect the gas supply tube from the underside

of the pilot burner.

• Disconnect the electrode wire from the piezo ignitor

(found adjacent to the gas control valve).

• Unscrew the pilot assembly bracket and remove.

NOTE: When removing the pilot assembly , carefully

pull the electrode wire up through the grommeted

hole in the base pan.

3.3 PARTS REPLACEMENT

1. Fan

• Unplug the power cord.

• Remove the electrical cover plate from the lower

right hand side of the heater. Loosen the retaining

screws on the wire connector to disconnect the

fan wires. Disconnect earth wire from junction box

stud.

• Slide the fan out the front of the lower controls

compartment.

2. Fan Speed Control

• Disconnect the wires from the fan speed control

switch, pull off the knob, and remove the nut holding

the speed control to the bracket.

3. Temperature Sensor

• Disconnect the wires from the fan temperature sensor switch and remove the nut holding the switch

bracket onto the side of the fi rebox.

4. Glass Panel

• To replace the glass door, insert the top two tabs

into the receiving slots. Push glass against unit and

latch the spring latches onto the bottom two tabs of

the glass frames.

3.4 ADJUSTMENTS AND REPLACE-

MENT PARTS

Adjustments and replacement parts for this appliance

should only be done by a qualifi ed service person. A

wiring diagram for the appliance is shown in SECTION

2.0 OPERA TING INSTRUCTIONS. A replacement part

table is shown in SECTION 4.0 of this manual.

19Heat & Glo • ATS-AU-D • 327-900 Rev. F • 6/09

Page 20

3.6 TROUBLESHOOTING

ATS-AU-D

With proper installation and maintenance, your new Gas Heater should provide years of trouble-free service. If you do experience a

problem, refer to the Trouble Shooting Guide below. This guide will assist a qualifi ed service person in the diagnosis of problems and

the corrective action to be taken.

Electronic Ignition System

Symptom Possible Causes Corrective Actions

1. Spark Ignitor will not light pilot after repeated triggering of

red button.

2.

Pilot will not stay lit after

carefully following lighting

instructions.

3. Pilot burning, no gas burner,

valve knob "ON", "on-off"

switch "ON".

4. Frequent pilot outage prob-

lem.

a. Defective ignitor (no spark at

electrode).

b. Defective pilot.

c. No gas or low gas pressure.

d. No L.P. in tank. Check L.P. (propane) tank. Refi ll the fuel tank.

a. Defective thermocouple.

b. Defective valve. If thermocouple is producing more than 15 millivolts, replace faulty valve.

a. ON-OFF" switch or wires

defective.

b. Thermopile may not be gener-

ating suffi cient millivoltage.

c. Defective valve.

d. Plugged burner orifi ce. Check burner orifi ce for stoppage and remove.

e. Wall switch, or wires defective.

a. Pilot fl ame may be too high

or too low, or blowing (high),

causing pilot safety to drop out.

Check for spark at electrode and pilot; if no spark and electrode wire is

properly connected, replace ignitor.

Using a match, light pilot. If pilot lights, turn off pilot and trigger the red

button again. If pilot lights, an improper gas/air mixture caused the bad

lighting and a longer purge period is recommended.

Check unit's shut-off valve and remote shut-off valves from heater . Usually

there is a valve near the main. There can be more than one (1) valve

between the heater and main.

Low pressure can be caused by a variety of situations such as a bent line,

too narrow diameter of pipe or even low line pressure. Check for kinked

lines. If none, consult with plumber or gas supplier.

Check that pilot fl ame impinges on thermocouple. Clean and/ or adjust

pilot for maximum fl ame impingement.

Ensure that the thermocouple connection at the gas valve is fully inserted

and tight (hand tight plus 1/4 turn).

Disconnect the thermocouple from the valve, place one millivolt meter lead

wire on the tip of the thermocouple and the other meter lead wire on the

thermocouple copper lead. Start the pilot and hold the valve knob in. If the

millivolt reading is less than 15 mv, replace the thermocouple.

Check "on-off" switch and wires for proper connections. Place jumper wires

across terminals at switch-if burner comes on, replace defective switch. If

OK, place jumper wires across switch wires at gas valve-if burner comes

on, wires are faulty or connections are bad.

If the pilot fl ame is not close enough physically to the thermopile, adjust

the pilot fl ame.

Be sure the wire connections from the thermopile at the gas valve terminals

are tight and the thermopile is fully inserted into the pilot bracket.

Check the thermopile with a millivolt meter. Take the reading at TH-TP

& TP terminals of the gas valve. The meter should read 325 millivolts

minimum, while holding the valve knob depressed in the pilot position,

with the pilot lit, and the ON/OFF switch in the OFF position. Replace the

faulty thermopile if the reading is below the specifi ed minimum.

With the pilot in the ON position, disconnect the thermopile leads from

the valve. Take a reading at the thermopile leads. The reading should be

325 millivolts minimum. Replace the thermopile if the reading is below the

minimum.

Turn valve knob to “ON”. Place ON/OFF switch to “ON”. Check with

millivolt meter at thermopile terminals. Millivolt meter should read greater

than 100 m.v. If the reading is okay and the burner does not come on,

replace the gas valve.

Follow corrective action in A.1 above; check switch and wiring. Replace

where defective.

Clean and adjust pilot fl ame for maximum fl ame impingement on the

thermocouple. Follow lighting instruction carefully.

20 Heat & Glo • ATS-AU-D • 327-900 Rev. F • 6/09

Page 21

5. The pilot and main burner

extinguish while in operation.

6. Glass soots.

5.

Flame burns blue and lifts off

burner.

a. No L.P. in tank. Check L.P. (Propane) tank. Refi ll fuel tank.

b. Inner fl ue pipe leaking exhaust

gases back into system.

c. Glass too loose and air tight,

gasket leaks in corners after

usage.

d. Horizontal fl ue improperly

pitched.

e. Bad thermopile or thermo-

couple.

f. Improper fl ue cap installation. Check for proper installation and freedom from debris or blockage.

a. Flame impingement on logs. Adjust the log set so that the fl ame does not excessively impinge on it.

b. Improper venturi setting. Adjust the air shutter at the base of the burner.

c. Debris around venturi.

a. Insuffi cient oxygen being

supplied

Check for leaks.

Be certain glass assembly is installed correctly and tighten corner.

The horizontal fl ue cap should slope down only enough to prevent any

water from entering the unit. The maximum downward slope is 1/4 inch.

Replace if necessary.

Inspect the opening at the base of the burner. It is imperative that NO

material be placed in this opening.

Check to make sure fl ue cap is installed properly and free of debris. Make

sure that fl ue system joints are tight and have no leaks.

Check to make sure that no material has been placed at the burner base.

Be sure glass is tightened properly on unit, particularly on top corners.

21Heat & Glo • ATS-AU-D • 327-900 Rev. F • 6/09

Page 22

4.0 REPLACEMENT PARTS

Î

14

13

12

Service Parts

Service Parts Diagram

8

10

9

11

ATS-AU-D

Beginning Manufacturing Date: 3/05

Ending Manufacturing Date: ______

7

19

15

17

16

Log Set Assembly

2

6

20

18

4

1

5

3

Part number list on following page.

22 Heat & Glo • ATS-AU-D • 327-900 Rev. F • 6/09

Page 23

Service Parts List ATS-AU-D

IMPORTANT: THIS IS DATED INFORMATION. When requesting service or replacement parts for your appliance please provide model

number and serial number. All parts listed in this manual may be ordered from an authorized dealer.

ITEM DESCRIPTION SERIAL # PART NUMBER

Log Set Assembly LOGS-ATS-D

Log #1 SRV327-701

1

Log #2 SRV327-702

2

Log #3 SRV327-703

3

Log #4 SRV327-704

4

Log #5 SRV327-705

5

Log #6 SRV438-724

6

Burner Assembly N 327-176A

7

Burner Assembly P 327-175A

Grate 327-360A

8

Heat Shield 327-150

9

10

11

12

13

14

15

16

17

18

19

20

Base Pan 327-124

Flame Control Knob 571-531

Pilot Control Knob 571-530

Valve Cover 327-119

Glass Door Assembly GLA-349

Piezo Ignitor 291-513

Rheostat Knob 100-512

Rheostat Assembly 220V 491-510A

Blower Assembly 100-505A

Junction Box 491-250A

Cover Plate 060-219

Dress Guard DF-ATS-D

Glass Latch Assembly 386-122A

Pilot Orifi ce N (.0181) 060-517

Pilot Orifi ce P (.0121) 060-505

Mineral Wool 050-721

Temp Sensor 046-530

Touch-Up Paint TUP-GBK-12

Additional service part numbers appear on following page.

23Heat & Glo • ATS-AU-D • 327-900 Rev. F • 6/09

Page 24

Î

Valve Assembly

Service Parts

Valve Assembly Parts List

ATS-AU-D

Beginning Manufacturing Date: 3/05

Ending Manufacturing Date: ______

1

2

3

4

5

6

7

IMPORTANT: THIS IS DATED INFORMATION. When requesting service or replacement parts for your appliance please provide model

number and serial number. All parts listed in this manual may be ordered from an authorized dealer.

ITEM DESCRIPTION SERIAL # PART NUMBER

Pilot Assembly N 485-510A

1

Pilot Assembly P 485-511A

Pilot Bracket 571-164

2

Orifi ce Bracket 438-223

3

Orifi ce N (#34A) 067-800

4

Orifi ce P (#51A) 079-803

Valve Bracket 571-152

5

Gas Shutoff Assembly 302-320A

6

Valve N 060-522

7

Valve P 060-523

Flexible Gas Connector 477-301A

8

Wire Asembly 2020-059

24 Heat & Glo • ATS-AU-D • 327-900 Rev. F • 6/09

8

Page 25

Î

Limited Lifetime Warranty

25Heat & Glo • ATS-AU-D • 327-900 Rev. F • 6/09

Page 26

26 Heat & Glo • ATS-AU-D • 327-900 Rev. F • 6/09

Page 27

For Service or Replacement Parts Contact:

Melbourne

Jetmaster

444 Swan Street

Richmond 3121

(03) 9429-5573

Perth

Fireplace Corner

277 Lord Street

East Perth 6000

(08) 9228-2600

Sydney

Jetmaster

10 Martin Avenue

Arncliff 2205

(02) 9597-7222

27Heat & Glo • ATS-AU-D • 327-900 Rev. F • 6/09

Loading...

Loading...