Heat & Glo 704-902 User Manual

Para obtener un ejemplar en Español de este

Manual del propietario, visite www.heatnglo.com.

Model:

Bravo

Pour demander un exemplaire en français de ce Manuel

du propriétaire, visitez www.heatnglo.com.

Owner’s Manual

Installation and Operation

CAUTION

DO NOT DISCARD THIS MANUAL

• Important operating

and maintenance

instructions included.

WARNING: If the information in these

instructions is not followed exactly, a fi re

or explosion may result causing property

damage, personal injury, or death.

• Do not store or use gasoline or other fl am-

mable vapors and liquids in the vicinity of

this or any other appliance.

• What to do if you smell gas

- Do not try to light any appliance.

- Do not touch any electrical switch. Do not

use any phone in your building.

- Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s instructions.

- If you cannot reach your gas supplier, call

the fi re department.

• Installation and service must be performed

by a qualifi ed installer, service agency , or the

gas supplier.

This appliance may be installed as an OEM installation in

manufactured home (USA only) or mobile home and must be

installed in accordance with the manufacturer’s instructions and

the manufactured home construction and safety standard, Title

24 CFR, Part 3280 or Standard for Installation in Mobile Homes,

CAN/CSA Z240MH.

This appliance is only for use with the type(s) of gas indicated

on the rating plate.

• Read, understand and follow

these instructions for safe

installation and operation.

DO NOT

DISCARD

• Leave this manual with

party responsible for use

and operation.

WARNING

HOT SURFACES!

Glass and other surfaces are hot during

operation AND cool down.

Hot glass will cause burns.

• Do not touch glass until it is cooled

• NEVER allow children to touch glass

• Keep children away

• CAREFULLY SUPERVISE children in same room as

fi replace.

• Alert children and adults to hazards of high temperatures.

High temperatures may ignite clothing or other fl ammable

materials.

• Keep clothing, furniture, draperies and other fl ammable

materials away.

This appliance has been supplied with an integral barrier

to prevent direct contact with the fi xed glass panel. DO

NOT operate the appliance with the barrier removed.

Contact your dealer or Hearth & Home Technologies if the

barrier is not present or help is needed to properly install one.

In the Commonwealth of Massachusetts installation must be

performed by a licensed plumber or gas fi tter.

See Table of Contents for location of additional Commonwealth

of Massachusetts requirements.

Installation and service of this appliance should be

performed by qualifi ed personnel. Hearth & Home

Technologies suggests NFI certifi ed or factory trained

professionals, or technicians supervised by an NFI

certifi ed professional.

Heat & Glo • Bravo • 704-902 Rev. F • 10/08 1

Read this manual before installing or operating this appliance.

Please retain this owner’s manual for future reference.

Congratulations

Congratulations on selecting a Heat & Glo gas appliance

—an elegant and clean alternative to wood burning

appliances. The Heat & Glo gas appliance you have

selected is designed to provide the utmost in safety,

reliability, and effi ciency.

As the owner of a new appliance, you’ll want to read and

carefully follow all of the instructions contained in this

Owner’s Manual. Pay special attention to all Cautions

and Warnings.

Homeowner Reference Information

This Owner’s Manual should be retained for future

reference. We suggest that you keep it with your other

important documents and product manuals.

The information contained in this Owner’s Manual, unless

noted otherwise, applies to all models and gas control

systems.

Your new Heat & Glo gas appliance will give you years of

durable use and trouble-free enjoyment. Welcome to the

Heat & Glo family of appliance products!

We recommend that you record the following

pertinent information about your appliance.

Model Name: ___________________________________________ Date purchased/installed: __________________

Serial Number: __________________________________________ Location on appliance: ____________________

Dealership purchased from: _______________________________ Dealer Phone: __________________________

Notes: _______________________________________________________________________________________

_____________________________________________________________________________________________

Listing Label Information/Location

This product may be covered by one or more of the following patents: (Nos produits sont couverts par un ou plusieurs des brevets suivants): (United States)

4593510,4686807, 4766876, 4793322, 4811534, 5000162, 5016609, 5076254, 5113843, 5191877, 5218953, 5263471, 5328356,5341794,5347983, 5429495,

5452708,5542407, 5601073, 5613487, 5647340, 5688568, 5762062, 5775408, 5890485,5931661,5941237, 594711 2,5996575, 6006743, 6019099, 6048195,

6053165, 6145502, 6170481, 6237588, 6296474, 6374822, 6413079, 6439226, 6484712, 6543698, 6550687, 6601579, 6672860, 6688302B2, 6715724B2,

6729551, 6736133, 6748940, 6748942, D320652, D445174, D462436; (Canada)1297749, 2195264, 2225408; or other U.S. and foreign patents pending (ou

autresbrevetsamericainsetetrangersenattente).

Type of Gas

Not for use with solid fuel .

(Ne doit pas entre utilise avec un combustible solide).

Ty pe of Gas (Sorte De Gaz) :

NATURA L GAS

Gas and Electric

Information

Minimum Permissible Gas Supply for Purpos es of Input Adjustment .

Approved Minimum (De Gaz) Acceptabl e 0. 0 in w. c. (Po. Col. d’eau)

Maximum Pressure (Pression) 0. 0 in w. c. (Po. Col. d’eau)

Maximum Manifold Pressure (Pression) 0. 0 in w. c. (Po. Col. d’eau)

Minimum Manifold Pressure (Pression) 0. 0 in w. c. (Po. Col. d’eau)

To tal Electrical Requirements: 000V ac, 00Hz., less than 00 Ampere s

AL TI TUDE : 0-0000 FT . 0000-0000FT .

MAX. INPU T BTUH: 00,000 00,000

MIN. INPU T BTUH: 00,000 00,000

ORIFICE SIZE: #XXXXX #XXXXX

The model information regarding your specifi c appliance can be found on

the rating plate usually located in the control area of the appliance.

He at & Gl o, a of Hearth & Ho me Te chnologies, Inc.

20802 Kensington Boulevard, Lakeville, MN 5504 4

This appliance must be installed in accordance with local codes, if any; if not, follow ANSI Z223.1

in the USA or CAN/CG A B149 installation codes. (Installer l’ appa re il selon les codes ou regl emen ts

lo caux ou , en l’absence de tels reglements, selon les codes d’in stallation CAN/CGA-B149.)

bran d

ANSI Z21X X-XXXX · CS A 2.XX-MXX · UL307B

IN CANADA

Mode l:

(Modele):

Serial

(Serie):

XXXXXXXX

XXXXXXXX

MADE IN US A

Model Number

Serial Number

Heat & Glo • Bravo • 704-902 Rev. F • 10/082

Table of Contents

1 Listing and Code Approvals

A. Appliance Certifi cation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

B. Glass Specifi cations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

C. BTU Specifi cations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

D. High Altitude Installations . . . . . . . . . . . . . . . . . . . . . . . . . . 4

E. Non-Combustible Materials Specifi cation. . . . . . . . . . . . . . 4

F. Combustible Materials Specifi cation . . . . . . . . . . . . . . . . . 4

G. Electrical Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

H. Requirements for the Commonwealth of Massachusetts . . 5

2 Getting Started

A. Design and Installation Considerations . . . . . . . . . . . . . . . 6

B. Tools and Supplies Needed . . . . . . . . . . . . . . . . . . . . . . . . 6

C. Inspect Appliance and Components . . . . . . . . . . . . . . . . . . 6

3 Framing and Clearances

A. Selecting Appliance Location . . . . . . . . . . . . . . . . . . . . . . . 7

B. Constructing the Appliance Chase . . . . . . . . . . . . . . . . . . . 8

C. Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

D. Mantel Projections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Termination Locations

A. Vent Termination Minimum Clearances . . . . . . . . . . . . . . 10

5 Vent Information and Diagrams

A. Vent Table Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

B. Use of Elbows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

C. Measuring Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

D. Vent Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6 Vent Clearances and Framing

A. Pipe Clearances to Combustibles . . . . . . . . . . . . . . . . . . 18

B. Wall Penetration Framing . . . . . . . . . . . . . . . . . . . . . . . . 18

C. Vertical Penetration Framing . . . . . . . . . . . . . . . . . . . . . . 19

7 Appliance Preparation

A. Securing and Leveling the Appliance . . . . . . . . . . . . . . . 20

8 Installing Vent Pipe

A. Assembly of Vent Sections (DVP Pipe) . . . . . . . . . . . . . . 21

B. Disassembly of Vent Sections . . . . . . . . . . . . . . . . . . . . . 23

C. Installing Heat Shield and Horizontal Termination Cap . . 24

D. Installing Roof Flashing and Vertical Termination Cap . . . 25

10 Electrical Information

A. Recommendation for Wire . . . . . . . . . . . . . . . . . . . . . . . . 29

B. Connecting to the Appliance. . . . . . . . . . . . . . . . . . . . . . . 29

C. Intellifi re Ignition System Wiring . . . . . . . . . . . . . . . . . . . 29

D. Wall Switch (Required) . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

E. Junction Box Installation. . . . . . . . . . . . . . . . . . . . . . . . . . 31

11 Finishing

A. Mantel Projections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

B. Facing Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

C. Finishing Styles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

12 Appliance Setup

A. Remove Shipping Materials . . . . . . . . . . . . . . . . . . . . . . . 36

B. Clean the Appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

C. Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

D. Lava Rock and Ember Placement . . . . . . . . . . . . . . . . . . 36

E. Positioning the Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

F. Glass Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

G. Grilles and Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

H. Air Shutter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

13 Operating Instructions

A. Before Lighting Appliance. . . . . . . . . . . . . . . . . . . . . . . . . 41

B. Lighting Appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

C. After Appliance is Lit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

D. Frequently Asked Questions . . . . . . . . . . . . . . . . . . . . . . 43

14 Troubleshooting

A. Intellifi re Ignition System . . . . . . . . . . . . . . . . . . . . . . . . . 44

15 Maintaining and Servicing Appliance

A. Maintenance Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

16 Reference Materials

A. Appliance Dimension Diagram . . . . . . . . . . . . . . . . . . . . . 48

B. Vent Components Diagrams . . . . . . . . . . . . . . . . . . . . . . 49

C. Service Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

D. Limited Lifetime Warranty . . . . . . . . . . . . . . . . . . . . . . . . . 56

E. Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

9 Gas Information

A. Fuel Conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

B. Gas Pressures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

C. Gas Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Heat & Glo • Bravo • 704-902 Rev. F • 10/08 3

1

1

Listing and Code Approvals

A. Appliance Certifi cation

MODELS: Bravo

LABORATORY: Underwriters Laboratories, Inc. (UL)

TYPE: Direct Vent Gas Appliance Heater

STANDARD: ANSI Z21.88-2000 • CSA2.33-M2000 • UL307B

This product is listed to ANSI standards for “Vented Gas

Appliance Heaters” and applicable sections of “Gas Burning Heating Appliances for Manufactured Homes and

Recreational Vehicles”, and “Gas Fired Appliances for Use

at High Altitudes”.

NOT INTENDED FOR USE AS A PRIMARY HEAT SOURCE.

This appliance is tested and approved as either supplemental

room heat or as a decorative appliance. It should not be factored as primary heat in residential heating calculations.

This model may be installed in a bedroom or bed-sitting

room in the USA and Canada.

B. Glass Specifi cations

Hearth & Home T echnologies appliances manufactured with

tempered glass may be installed in hazardous locations

such as bathtub enclosures as defi ned by the Consumer

Product Safety Commission (CPSC). The tempered glass

has been tested and certifi ed to the requirements of ANSI

Z97.1 and CPSC 16 CFR 1202 (Safety Glazing Certifi cation

Council SGCC# 1595 and 1597. Architectural T esting, Inc.

Reports 02-31919.01 and 02-31917.01).

This statement is in compliance with CPSC 16 CFR

Section 1201.5 “Certifi cation and labeling requirements”

which refers to 15 U.S. Code (USC) 2063 stating “…Such

certifi cate shall accompany the product or shall otherwise

be furnished to any distributor or retailer to whom the

product is delivered.”

Some local building codes require the use of tempered

glass with permanent marking in such locations. Glass

meeting this requirement is available from the factory.

Please contact your dealer or distributor to order.

Note: This installation must conform with local codes. In the

absence of local codes you must comply with the National

Fuel Gas Code, ANSI Z223.1-latest edition in the U.S.A.

and the CAN/CGA B149 Installation Codes in Canada.

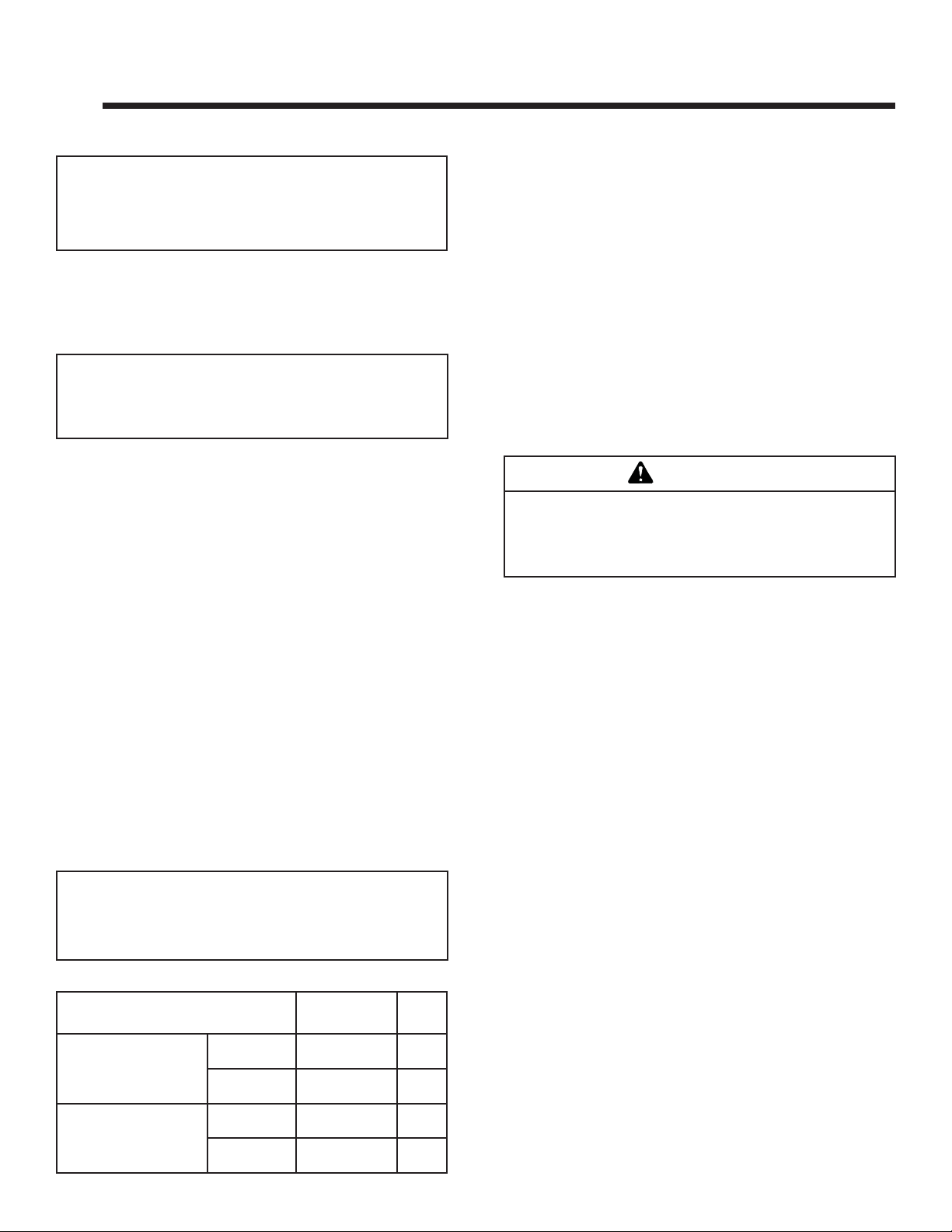

C. BTU Specifi cations

Orifi ce

Size

(DMS)

Bravo (NG)

Bravo (LP)

Models

(U.S. or Canada)

US

(0-2000 FT)

CANADA

(2000-4500 FT)

US

(0-2000 FT)

CANADA

(2000-4500 FT)

Maximum

Input BTUH

23,000 42

20,700 43

23,000 53

20,700 54

D. High Altitude Installations

U.L. Listed gas appliances are tested and approved without

requiring changes for elevations from 0 to 2000 feet in the

U.S.A. and Canada.

When installing this appliance at an elevation above 2000

feet, it may be necessary to decrease the input rating by

changing the existing burner orifi ce to a smaller size. Input

rate should be reduced by 4% for each 1000 feet above

a 2000 foot elevation in the U.S.A., or 10% for elevations

between 2000 and 4500 feet in Canada. If the heating

value of the gas has been reduced, these rules do not

apply. To identify the proper orifi ce size, check with the

local gas utility.

If installing this appliance at an elevation above 4500 feet

(in Canada), check with local authorities.

WARNING

Do NOT use this appliance if any part has been under water.

Immediately call a qualifi ed service technician to inspect

the appliance and to replace any part of the control system

and any gas control which has been under water.

E. Non-Combustible Materials Specifi cation

Material which will not ignite and burn. Such materials are

those consisting entirely of steel, iron, brick, tile, concrete,

slate, glass or plasters, or any combination thereof.

Materials that are reported as passing ASTM E 136,

Standard Test Method for Behavior of Materials in a

Vertical Tube Furnace at 750oC, shall be considered

non-combustible materials.

F. Combustible Materials Specifi cation

Materials made of or surfaced with wood, compressed

paper, plant fi bers, plastics, or other material that can ig-

nite and burn, whether fl ame proofed or not, or whether

plastered or unplastered shall be considered combustible

materials.

G. Electrical Codes

NOTICE: This appliance must be electrically wired and

grounded in accordance with local codes or, in the absence

of local codes, with National Electric Code ANSI/NFPA

70-latest edition or the Canadian Electric Code CSA

C22.1.

• A 110-120 VAC circuit for this product must be protected

with ground-fault circuit-interrupter protection, in compliance

with the applicable electrical codes, when it is installed in

locations such as in bathrooms or near sinks.

Heat & Glo • Bravo • 704-902 Rev. F • 10/084

Note: The following requirements reference various

Massachuset ts and national codes not contained in this

document.

H. Requirements for the Commonwealth of

Massachusetts

For all side wall horizontally vented gas fueled equipment

installed in every dwelling, building or structure used in

whole or in part for residential purposes, including those

owned or operated by the Commonwealth and where the

side wall exhaust vent termination is less than seven (7)

feet above fi nished grade in the area of the venting, in-

cluding but not limited to decks and porches, the following

requirements shall be satisfi ed:

Installation of Carbon Monoxide Detectors

At the time of installation of the side wall horizontal vented

gas fueled equipment, the installing plumber or gas fi tter

shall observe that a hard wired carbon monoxide detector

with an alarm and battery back-up is installed on the fl oor

level where the gas equipment is to be installed. In addition, the installing plumber or gas fi tter shall observe that

a battery operated or hard wired carbon monoxide detector with an alarm is installed on each additional level of

the dwelling, building or structure served by the side wall

horizontal vented gas fueled equipment. It shall be the

responsibility of the property owner to secure the services

of qualifi ed licensed professionals for the installation of

hard wired carbon monoxide detectors.

In the event that the side wall horizontally vented gas fueled equipment is installed in a crawl space or an attic,

the hard wired carbon monoxide detector with alarm and

battery back-up may be installed on the next adjacent

fl oor level.

In the event that the requirements of this subdivision can

not be met at the time of completion of installation, the

owner shall have a period of thirty (30) days to comply

with the above requirements; provided, however, that during said thirty (30) day period, a battery operated carbon

monoxide detector with an alarm shall be installed.

Approved Carbon Monoxide Detectors

Each carbon monoxide detector as required in accordance with the above provisions shall comply with NFPA

720 and be ANSI/UL 2034 listed and IAS certifi ed.

Signage

A metal or plastic identifi cation plate shall be permanent-

ly mounted to the exterior of the building at a minimum

height of eight (8) feet above grade directly in line with the

exhaust vent terminal for the horizontally vented gas fueled heating appliance or equipment. The sign shall read,

in print size no less than one-half (1/2) inch in size, “GAS

VENT DIRECTLY BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS”.

Inspection

The state or local gas inspector of the side wall horizontally vented gas fueled equipment shall not approve the

installation unless, upon inspection, the inspector observes carbon monoxide detectors and signage installed

in accordance with the provisions of 248 CMR 5.08(2)(a)1

through 4.

Exemptions

The following equipment is exempt from 248 CMR

5.08(2)(a)1 through 4:

• The equipment listed in Chapter 10 entitled “Equipment

Not Required To Be Vented” in the most current edition

of NFPA 54 as adopted by the Board; and

• Product Approved side wall horizontally vented gas fu-

eled equipment installed in a room or structure separate

from the dwelling, building or structure used in whole or

in part for residential purposes.

MANUFACTURER REQUIREMENTS

Gas Equipment Venting System Provided

When the manufacturer of Product Approved side wall

horizontally vented gas equipment provides a venting

system design or venting system components with the

equipment, the instructions provided by the manufacturer

for installation of the equipment and the venting system

shall include:

• Detailed instructions for the installation of the venting

system design or the venting system components; and

• A complete parts list for the venting system design or

venting system.

Gas Equipment Venting System NOT Provided

When the manufacturer of a Product Approved side wall

horizontally vented gas fueled equipment does not provide

the parts for venting the fl ue gases, but identifi es “special

venting systems”, the following requirements shall be satisfi ed by the manufacturer:

• The referenced “special venting system” instructions

shall be included with the appliance or equipment installation instructions; and

• The “special venting systems” shall be Product Ap-

proved by the Board, and the instructions for that system shall include a parts list and detailed installation

instructions.

A copy of all installation instructions for all Product Approved side wall horizontally vented gas fueled equipment, all venting instructions, all parts lists for venting

instructions, and/or all venting design instructions shall

remain with the appliance or equipment at the completion

of the installation.

See Gas Connection section for additional Commonwealth of Massachusetts requirements.

Heat & Glo • Bravo • 704-902 Rev. F • 10/08 5

2

2

Getting Started

A. Design and Installation Considerations

Heat & Glo direct vent gas appliances are designed to

operate with all combustion air siphoned from outside of

the building and all exhaust gases expelled to the outside.

No additional outside air source is required.

CAUTION

Check building codes prior to installation.

• Installation MUST comply with local, regional, state and

national codes and regulations.

• Consult local building, fi re offi cials or authorities having jurisdic-

tion about restrictions, installation inspection, and permits.

When planning an appliance installation, it’s necessary to

determine the following information before installing:

• Where the appliance is to be installed.

• The vent system confi guration to be used.

• Gas supply piping.

• Electrical wiring.

• Framing and fi nishing details.

• Whether optional accessories—devices such as a wall

switch, or remote control—are desired.

C. Inspect Appliance and Components

WARNING

Inspect appliance and components for damage.

Damaged parts may impair safe operation.

• Do NOT install damaged components.

• Do NOT install incomplete components.

• Do NOT install substitute components.

Report damaged parts to dealer.

• Carefully remove the appliance and components from

the packaging.

• The vent system components and trim doors are shipped

in separate packages.

• The gas logs may be packaged separately and must be

fi eld installed.

• Report to your dealer any parts damaged in shipment,

particularly the condition of the glass.

• Read all of the instructions before starting the installation. Follow these instructions carefully during the

installation to ensure maximum safety and benefi t.

WARNING

WARNING

Keep appliance dry.

• Mold or rust may cause odors.

• Water may damage controls.

B. Tools and Supplies Needed

Before beginning the installation be sure that the following

tools and building supplies are available.

Reciprocating saw Framing material

Pliers Hi temp caulking material

Hammer Gloves

Phillips screwdriver Framing square

Flat blade screwdriver Electric drill and bits (1/4 in.)

Plumb line Safety glasses

Level 1/2 - 3/4 inch length, #6 or #8 Self-drilling screws

Manometer Voltmeter

Tape measure Noncorrosive leak check solution

• Installation and use of any damaged appliance or vent

system component.

• Modifi cation of the appliance or vent system.

• Installation other than as instructed by Hearth & Home

Technologies.

• Improper positioning of the gas logs or the glass door.

• Installation and/or use of any component part not approved

by Hearth & Home Technologies.

Any such action may cause a fi re hazard.

Hearth & Home Technologies disclaims any

responsibility for, and the warranty will be voided

by, the following actions:

Heat & Glo • Bravo • 704-902 Rev. F • 10/086

3

3

Framing and Clearances

Note:

• Illustrations reflect typical installations and are FOR

DESIGN PURPOSES ONLY.

• Illustrations/diagrams are not drawn to scale.

• Actual installation may vary due to individual design

preference.

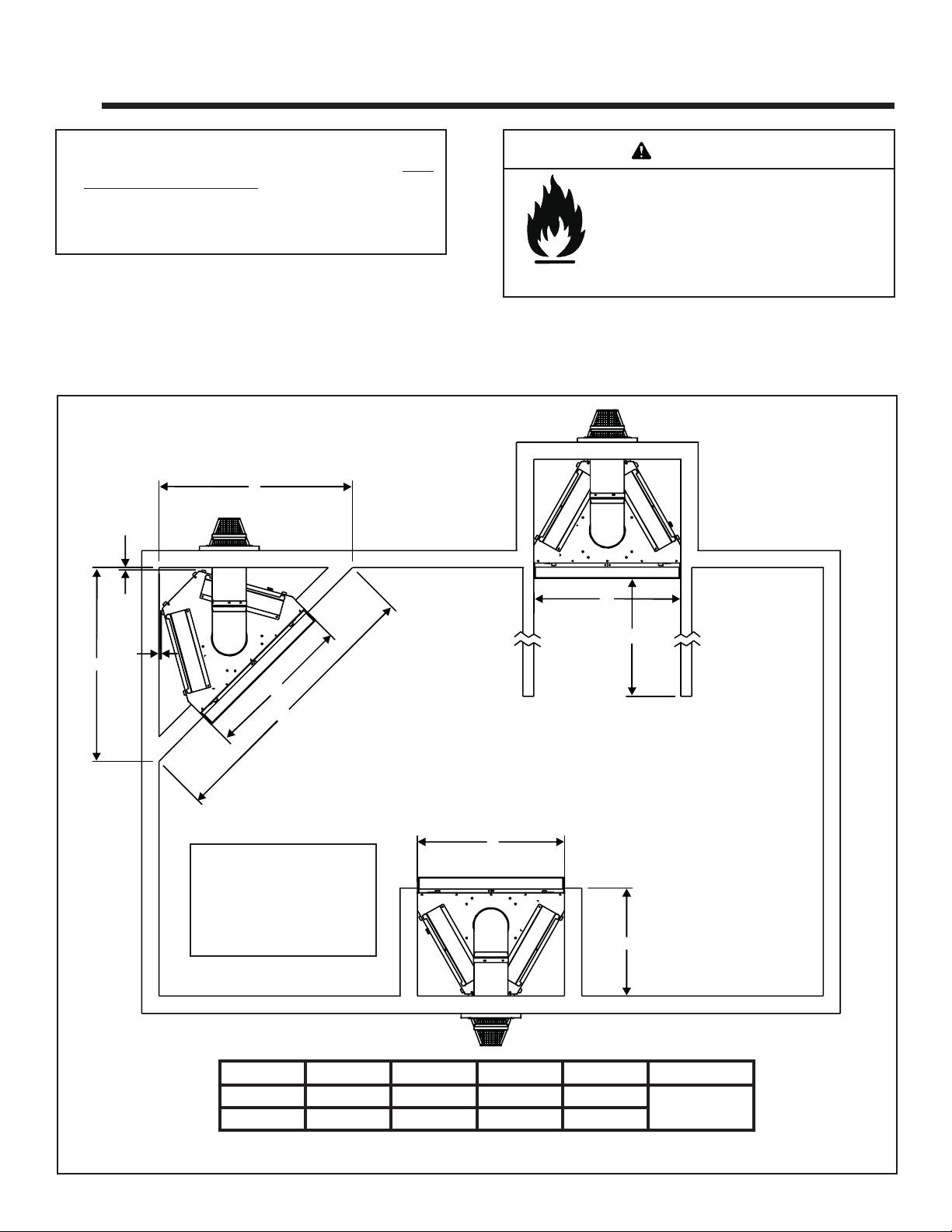

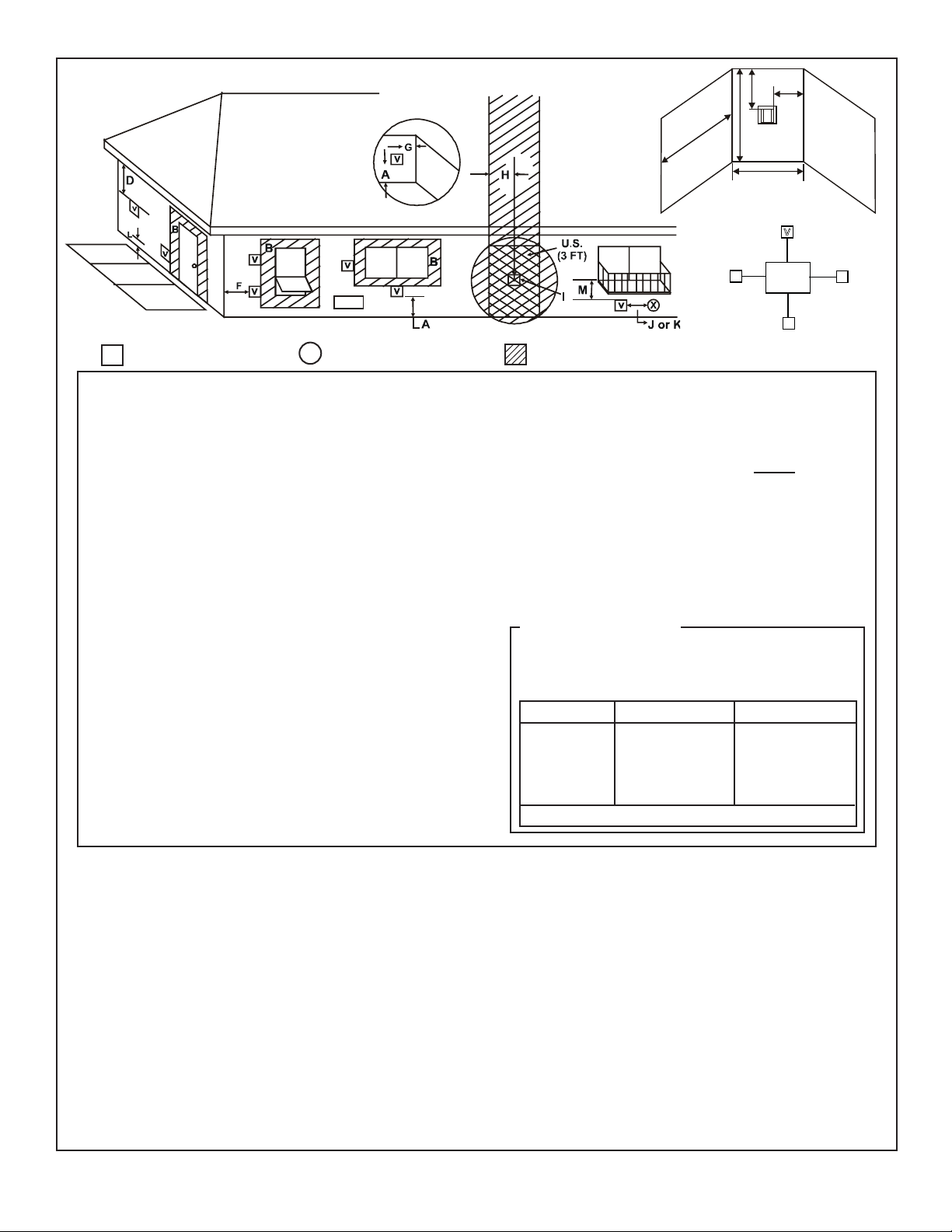

A. Selecting Appliance Location

When selecting a location for your appliance it is important to

consider the required clearances to walls (see fi gure 3.1).

A

½

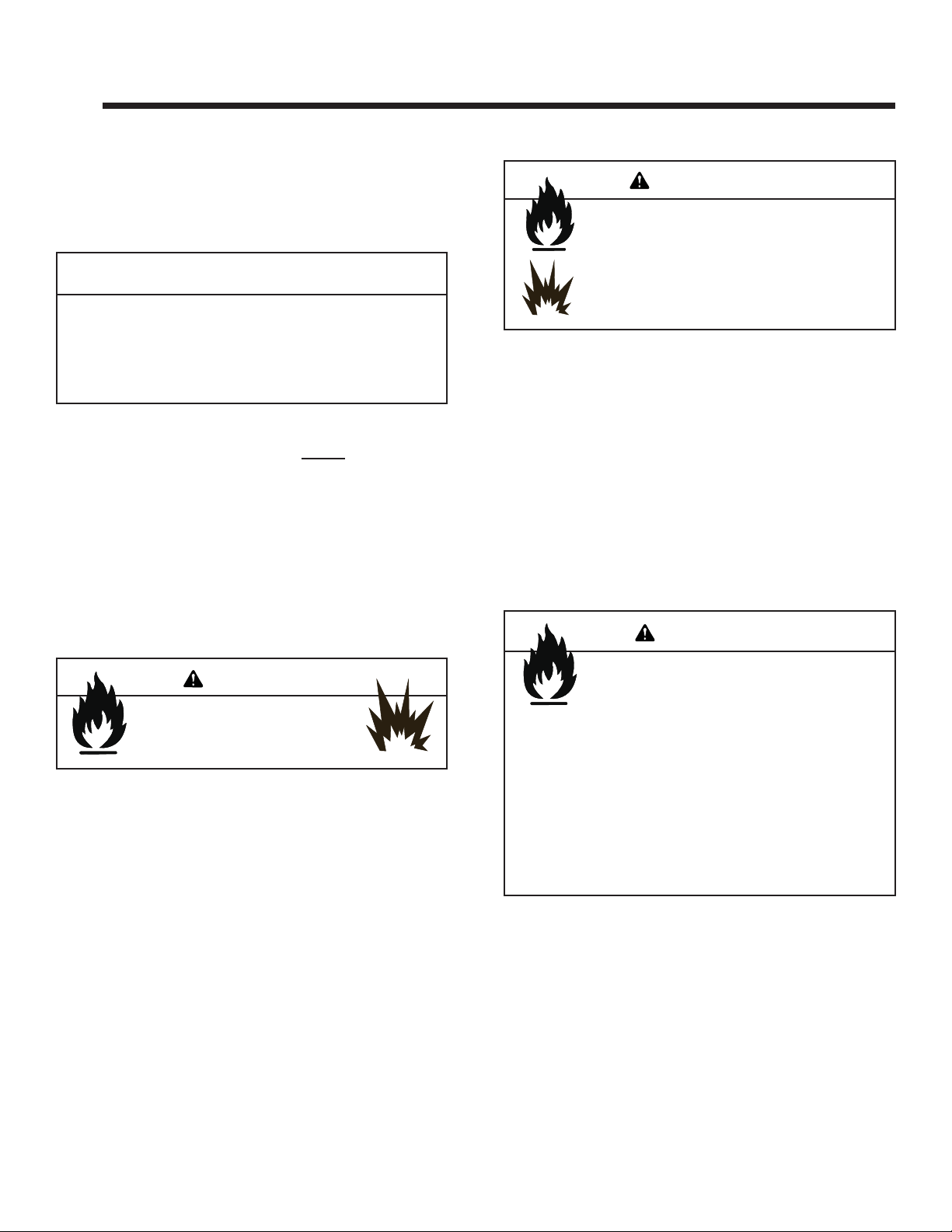

WARNING

Fire Risk

Provide adequate clearance:

• Around air openings

• To combustibles

• For service access

Locate appliance away from traffi c areas.

Note: For actual appliance dimensions refer to Section 16.

B

E

½

A

B

C

In addition to these framing dimensions, also reference the following sections:

• Clearances and Mantel Projections (Section 3.C and 3.D)

• Vent Clearances and Framing (Section 6).

B

Note: These dimensions

are for fl ush wall fi nishing

method. For a recessed

arch fi nishing method refer

to Option B in Finishing

(Section 11).

ABCD E

Inches 45-1/8 34-3/8 63-7/8 25-1/4

Millimeters 1146 873 1622 641

D

No maximum

Figure 3.1 Appliance Locations

Heat & Glo • Bravo • 704-902 Rev. F • 10/08 7

B. Constructing the Appliance Chase

A chase is a vertical boxlike structure built to enclose the

gas appliance and/or its vent system. Vertical vents that run

on the outside of a building may be, but are not required

to be, installed inside a chase.

Construction of the chase may vary with the type of building.

These instructions are not substitutes for the requirements

of local building codes. Local building codes MUST be

checked.

Chases should be constructed in the manner of all outside

walls of the home to prevent cold air drafting problems.

The chase should not break the outside building envelope

in any manner.

Walls, ceiling, base plate and cantilever fl oor of the chase

should be insulated. Vapor and air infi ltration barriers

should be installed in the chase as per regional codes for

the rest of the home. Additionally, in regions where cold

air infi ltration may be an issue, the inside surfaces may be

sheetrocked and taped for maximum air tightness.

T o further prevent drafts, the wall shield and ceiling fi restops

should be caulked with high temperature caulk to seal gaps.

Gas line holes and other openings should be caulked with

high temp caulk or stuffed with unfaced insulation. If the

appliance is being installed on a cement slab, a layer of

plywood may be placed underneath to prevent conducting

cold up into the room.

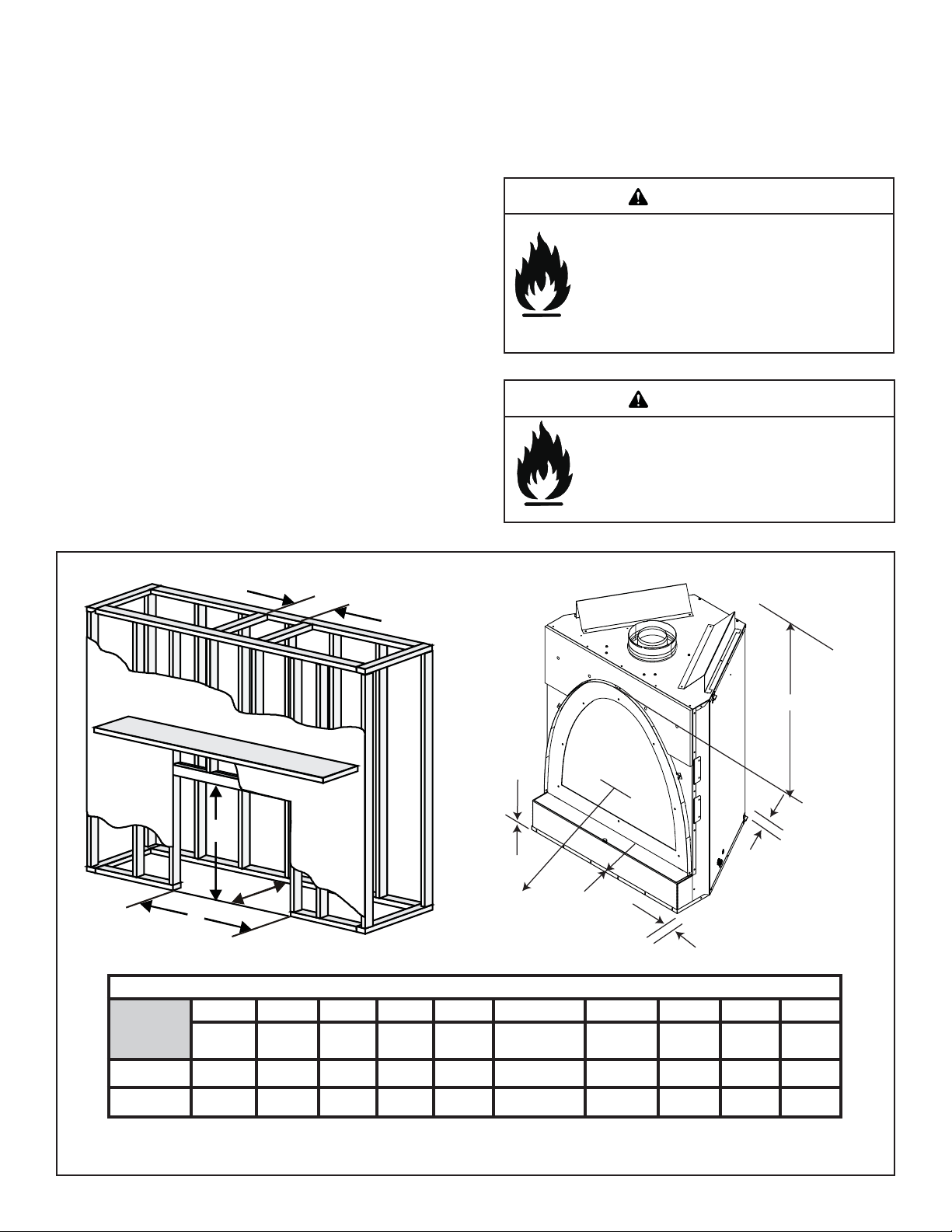

C. Clearances

WARNING

Fire Risk.

Odor Risk.

• Install appliance on hard metal or wood surfaces

extending full width and depth of appliance.

• Do NOT install appliance directly on carpeting,

vinyl, tile or any combustible material other than

wood.

WARNING

Fire Risk.

• Construct chase to all clearance specifi cations

in manual.

• Locate and install appliance to all clearance

specifi cations in manual.

A

E

F

B

H

C

*

J

G

I

D

Clearance to Combustibles

A B C* D E F G H IJ

Rough

Opening

(Vent Pipe)

Inches 10 44 25-1/4 35-3/8 34-7/8 0 0 1/2 1/2 36

Rough

Opening

(Height)

Rough

Opening

(Depth)

Rough

Opening

(Width)

Clearance

to Ceiling

Combustible

Floor

Combustible

Flooring

Behind

Appliance

Sides of

Appliance

Front of

Appliance

FROM

TOP OF

FINISHING

STRIP TO

CEILING

Millimeters 25 1118 641 699 886 0 0 13 13 914

*For additional framing options and dimensions, see Section 11, Finishing.

Figure 3.2 Clearances to Combustibles

Heat & Glo • Bravo • 704-902 Rev. F • 10/088

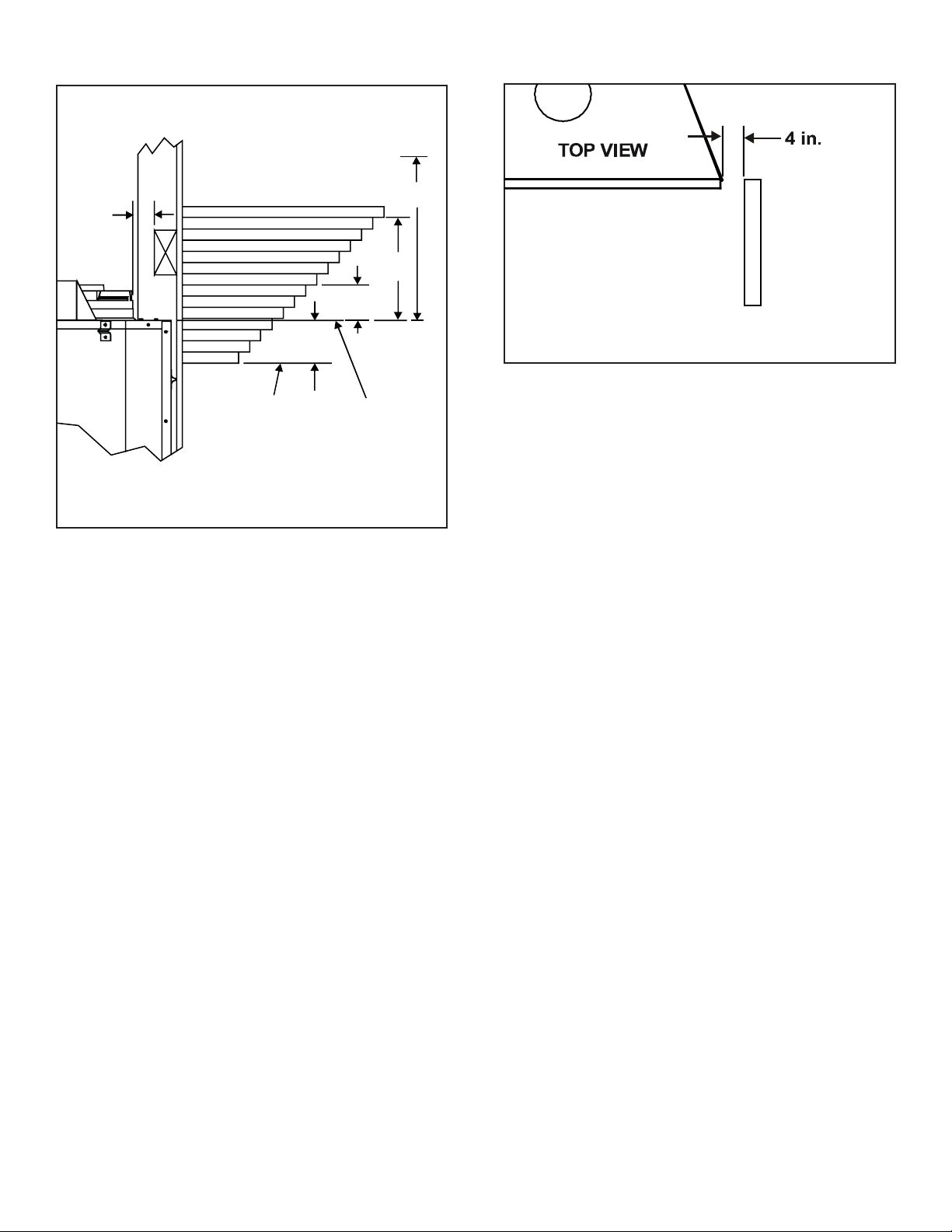

D. Mantel Projections

Note: All

measurements

in inches.

1 INCH

MINIMUM

TO

VENT PIPE

10

9

8

7

6

5

TOP OF

FINISHING STRIP

11

12

37/8

16

15

14

13

31/8

Figure 3.3 Clearances to Mantels or Combustibles

above Appliance

18

17

TOP OF

UNIT

CEILING

91/8

MIN.

31

Figure 3.4 Clearances to Mantel Legs or Wall Projections

(Acceptable on both sides of opening.)

Heat & Glo • Bravo • 704-902 Rev. F • 10/08 9

4

4

Termination Locations

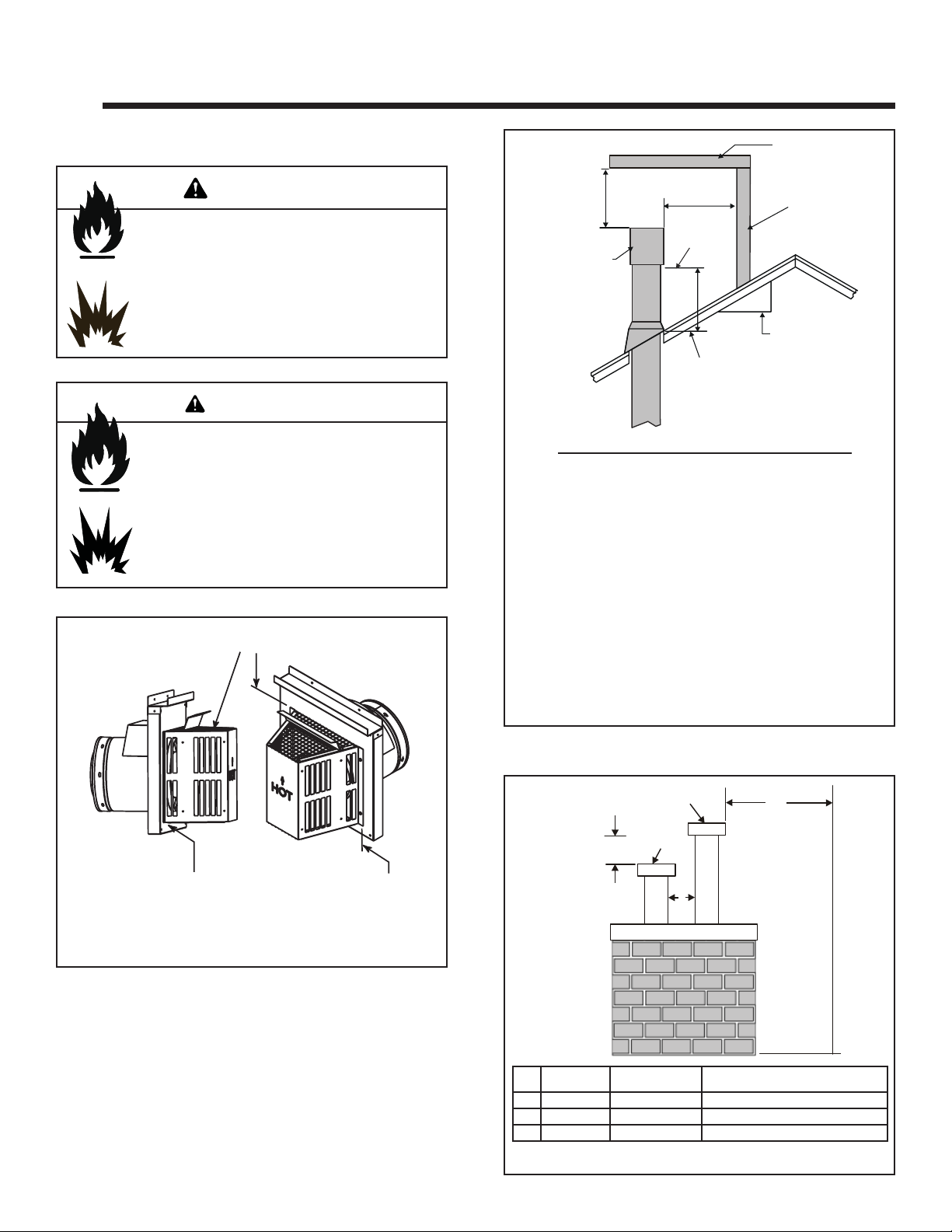

A. Vent Termination Minimum Clearances

WARNING

Fire Risk.

Explosion Risk.

Inspect external vent cap regularly.

• Ensure no debris blocks cap.

• Combustible materials blocking cap may

ignite.

• Restricted air fl ow affects burner operation.

WARNING

Fire Risk.

Explosion Risk.

Maintain vent clearance to combustibles as

specifi ed.

• Do not pack air space with insulation or other

materials.

Failure to keep insulation or other materials

away from vent pipe may cause fi re.

Measure vertical clearances from this surface.

HORIZONTAL

OVERHANG

2 FT.

MIN.

GAS DIRECT VENT

TERMINATION CAP

Roof Pitch H (Min.) Ft.

Flat to 6/12...........................................................1.0*

Over 6/12 to 7/12 .................................................1.25*

Over 7/12 to 8/12 .................................................1.5*

Over 8/12 to 9/12 .................................................2.0*

Over 9/12 to 10/12 ...............................................2.5

Over 10/12 to 11/12 .............................................3.25

Over 11/12 to 12/12 .............................................4.0

Over 12/12 to 14/12 .............................................5.0

Over 14/12 to 16/12 .............................................6.0

Over 16/12 to 18/12 .............................................7.0

Over 18/12 to 20/12 .............................................7.5

Over 20/12 to 21/12 .............................................8.0

20 INCHES MIN.

LOWEST

DISCHARGE

OPENING

H (MIN.) - MINIMUM HEIGHT FROM ROOF

TO LOWEST DISCHARGE OPENING

X

12

ROOF PITCH

VERTICAL

WALL

IS X/ 12

* 3 foot minimum in snow regions

Figure 4.2 Minimum height from roof to lowest discharge

opening

Measure horizontal clearances from this surface.

(See Figure 4.4 for specifi c clearances)

Figure 4.1

Figure 4.2 specifi es minimum vent heights for various

pitched roofs.

GAS, WOOD OR FUEL

OIL TERMINATION

GAS

TERMINATION

C

A

Gas

Termination

A 6 in. 20 in. min. Horizontal distance between terminations

B 20 in. 24 in. min. Distance to perpendicular wall

C 18 in. 18 in. Vertical distance between terminations

Figure 4.3 Multiple Vertical Termination

Wood & Fuel Oil

Termination

B

Comments

Heat & Glo • Bravo • 704-902 Rev. F • 10/0810

R

(See Note 2)

M

N

P

Q

V

T

Electrical

Service

V

S

V

D*

S

V

= VENT TERMINAL

V

A = 12 inches ...............clearances above grade, veranda,

(See Note 1)

X

= AIR SUPPLY INLET

porch, deck or balcony

B = 12 inches ...............clearances to window or door

that may be opened, or to permanently closed window. (Glass)

D* = 18 inches ...............vertical clearance to unventilated

soffi t or to ventilated soffi t located

above the terminal

*30 inches ..............for vinyl clad soffi ts and below

electrical service

F = 9 inches ................clearance to outside corner

G = 6 inches .................clearance to inside corner

H = 3 ft. (Canada) ........not to be installed above a gas

meter/regulator assembly within 3

feet (90cm) horizontally from the

center-line of the regulator

I = 3 ft. .......................clearance to gas service regulator

vent outlet

J = 9 inches (U.S.A.)

12 inches (Canada) clearance to non-mechanical

air supply inlet to building or the

combustion air inlet to any other

appliance

= AREA WHERE TERMINAL IS NOT PERMITTED

K = 3 ft. (U.S.A.)

6 ft. (Canada) ...........clearance to a mechanical

(powered) air supply inlet

L** = 7 ft. ..........................clearance above paved

(See Note 1)

sidewalk or a paved driveway

located on public property

M*** = 18 inches.................clearance under veranda, porch,

deck, balcony or overhang

42 inches ................vinyl

S = 6 inches ...................clearance from sides of elec-

(See Note 5)

trical service

T = 12 inches ..................clearance above electrical

(See Note 5)

service

Alcove Applications

N = 6 inches ..................non-vinyl sidewalls

12 inches ................vinyl sidewalls

P = 8 ft.

Q

MIN

1 cap 3 feet 2 x Q

2 caps 6 feet 1 x Q

3 caps 9 feet 2/3 x Q

4 caps 12 feet 1/2 x Q

Q

= # termination caps x 3 R

MIN

= (2 / # termination caps) x Q

MAX

R

MAX

ACTUAL

ACTUAL

ACTUAL

ACTUAL

ACTUAL

** a vent shall not terminate directly above a sidewalk or paved driveway

which is located between two single family dwellings and serves both

dwellings.

*** only permitted if veranda, porch, deck or balcony is fully open on a

minimum of 2 sides beneath the fl oor, or meets Note 2.

Note 1: On private property where termination is less than 7 feet above a

sidewalk, driveway, deck, porch, veranda or balcony, use of a listed cap

shield is suggested. (See vents components page)

Note 2: Termination in an alcove space (spaces open only on one side

and with an overhang) are permitted with the dimensions specifi ed for

vinyl or non-vinyl siding and soffi ts. 1. There must be 3 feet minimum

between termination caps. 2. All mechanical air intakes within 10 feet

of a termination cap must be a minimum of 3 feet below the termination

cap. 3. All gravity air intakes within 3 feet of a termination cap must be a

minimum of 1 foot below the termination cap.

Figure 4.4 Minimum Clearances for Termination

Note 3: Local codes or regulations may require different

clearances.

Note 4: Termination caps may be hot. Consider their proximity to

doors or other traffi c areas.

Note 5: Location of the vent termination must not interfere with

access to the electrical service.

WARNING: In the U.S: V ent system termination is NOT permitted in

screened porches. Y ou must follow side wall, overhang and ground

clearances as stated in the instructions.

In Canada: Vent system termination is NOT permitted in screened

porches. Vent system termination is permitted in porch areas with

two or more sides open. You must follow all side walls, overhang

and ground clearances as stated in the instructions.

Hearth & Home Technologies assumes no responsibility for the

improper performance of the appliance when the venting system

does not meet these requirements.

CAUTION: IF EXTERIOR WALLS ARE FINISHED WITH VINYL SIDING, IT IS SUGGESTED THAT A VINYL PROTECTOR KIT BE INSTALLED.

Heat & Glo • Bravo • 704-902 Rev. F • 10/08 11

5

5

Vent Information and Diagrams

A. Vent Table Key

The abbreviations listed in this vent table key are used in

the vent diagrams.

Symbol Description

V

First section (closest to appliance of vertical length

1

Vertica l

V

H

H

Second section of vertical length

2

First section (closest to appliance) of horizontal length

1

Second section of horizontal length

2

WARNING

Fire Hazard.

Explosion Risk.

Asphyxiation Risk.

Do NOT connect this gas appliance to a

chimney fl ue serving a separate solid-fuel or

gas burning appliance.

• Vent this appliance directly outside.

• Use separate vent system for this appliance.

May impair safe operation of this appliance or

other appliances connected to the fl ue.

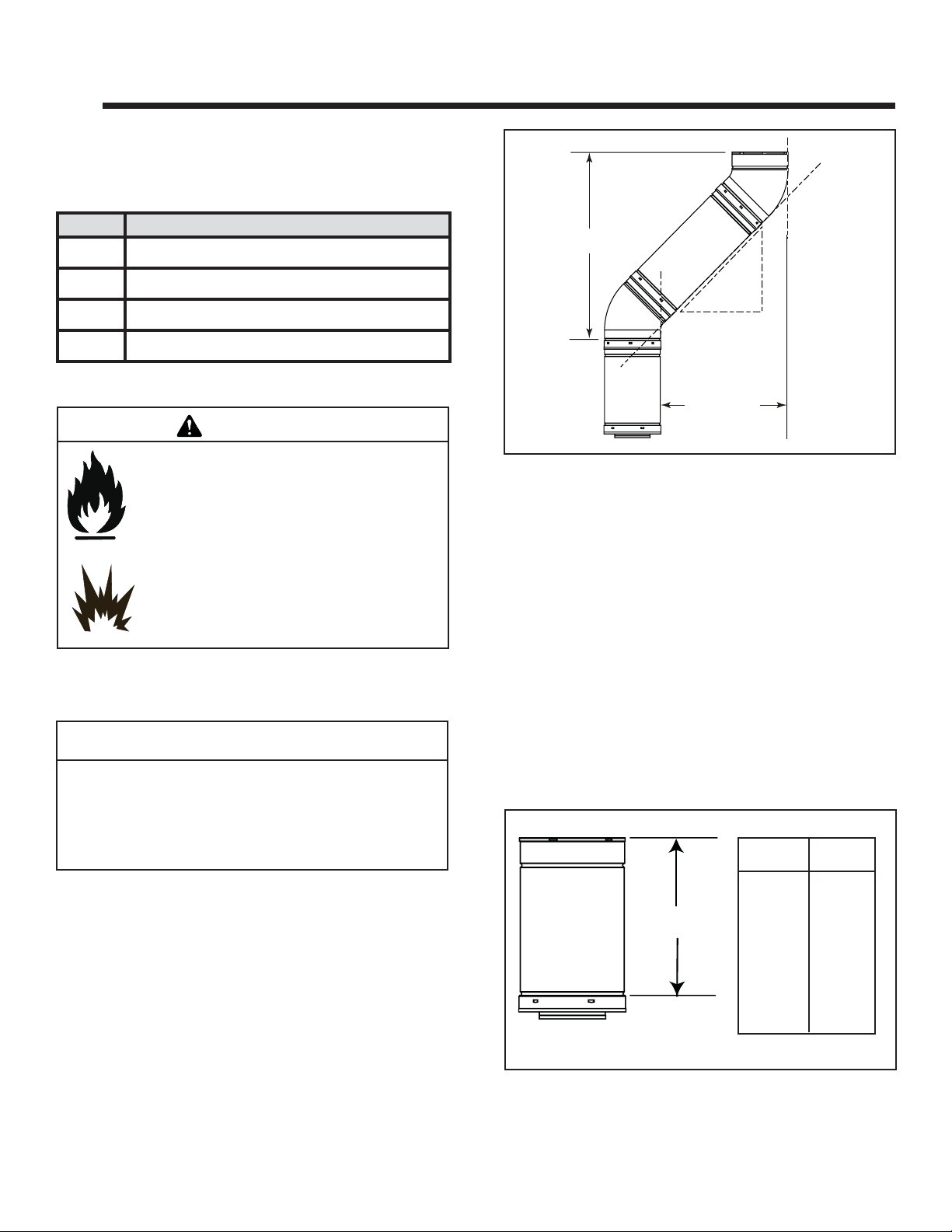

B. Use of Elbows

CAUTION

ALL vent confi guration specifi cations MUST be followed.

• This product is tested and listed to these

specifi cations.

• Appliance performance will suffer if specifi cations are

not followed.

Diagonal runs have both vertical and horizontal vent aspects when calculating the effects. Use the rise for the

vertical aspect and the run for the horizontal aspect (see

Figure 5.1).

Two 450 elbows may be used in place of one 900 elbow. On

450 runs, one foot of diagonal is equal to 8.5 inches horizontal run and 8.5 inches vertical run. A length of straight

pipe is allowed between two 450 elbows (see Figure 5.1).

12 in.

8-1/2 in.

Horizontal

Figure 5.1

8-1/2 in.

C. Measuring Standards

Vertical and horizontal measurements listed in the vent

diagrams were made using the following standards.

1. Pipe measurements are shown using the effective length

of pipe (see Figure 5.2).

2. Measurements are made from the appliance outer wrap,

not from the standoffs.

3. Horizontal terminations are measured to the outside

mounting surface (fl ange of termination cap) (see Figure

4.1).

4. Vertical terminations are measured to bottom of termination cap.

5. Horizontal pipe installed level with no rise.

Length/

Inches

Effective

Height/Length

Figure 5.2 DVP Pipe Effective Length

Pipe

DVP4 4

DVP6 6

DVP12 12

DVP24 24

DVP36 36

DVP48 48

DVP6A 3 to 6

DVP12A 3 to 12

DVP12MI 3 to 12

DVP24MI 3 to 24

Heat & Glo • Bravo • 704-902 Rev. F • 10/0812

D. Vent Diagrams

Fire Risk. Explosion Risk.

Do NOT pack insulation or other combustibles between ceiling fi restops.

• ALWAYS maintain specifi ed clearances around venting and fi restop systems.

• Install wall shield and ceiling fi restops as specifi ed.

Failure to keep insulation or other material away from vent pipe may cause fi re.

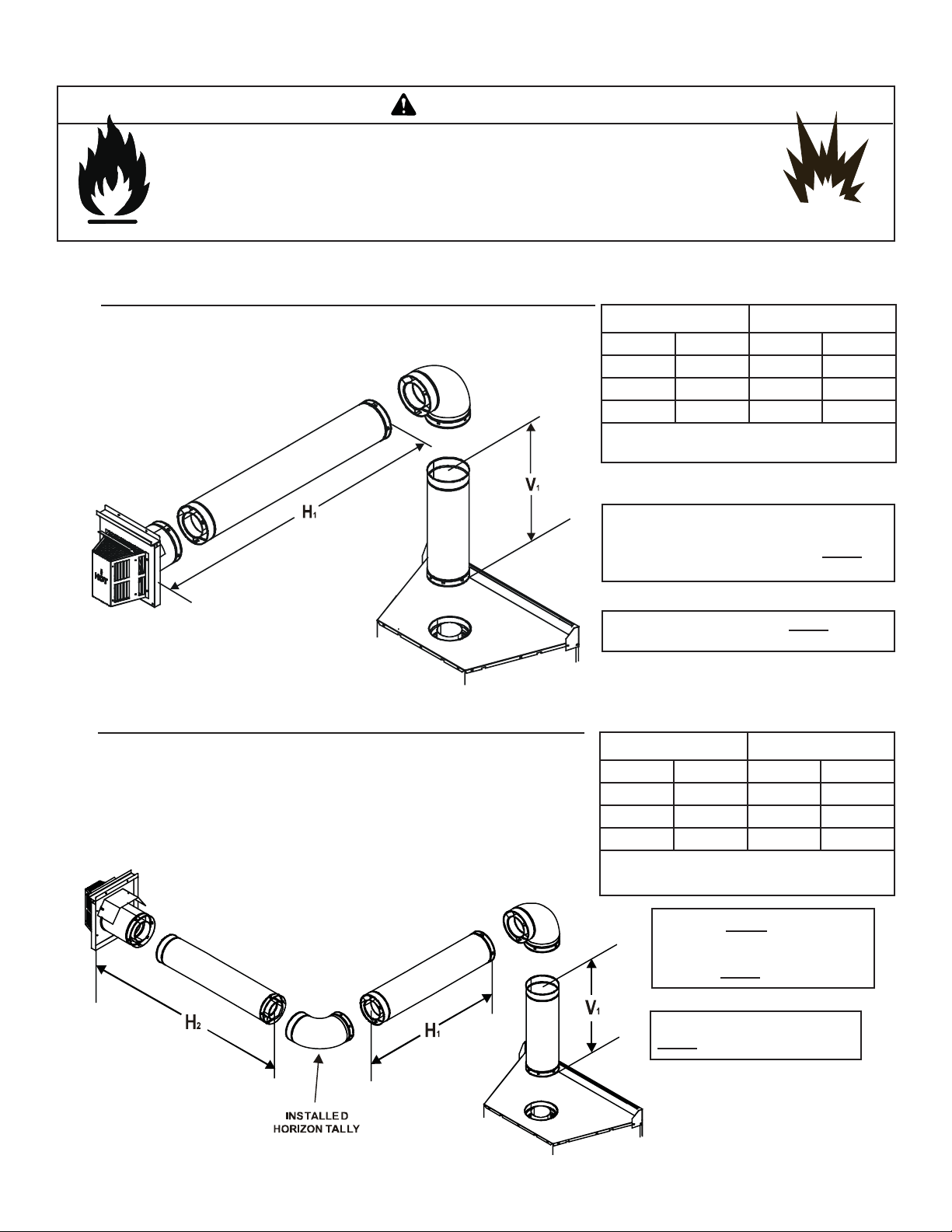

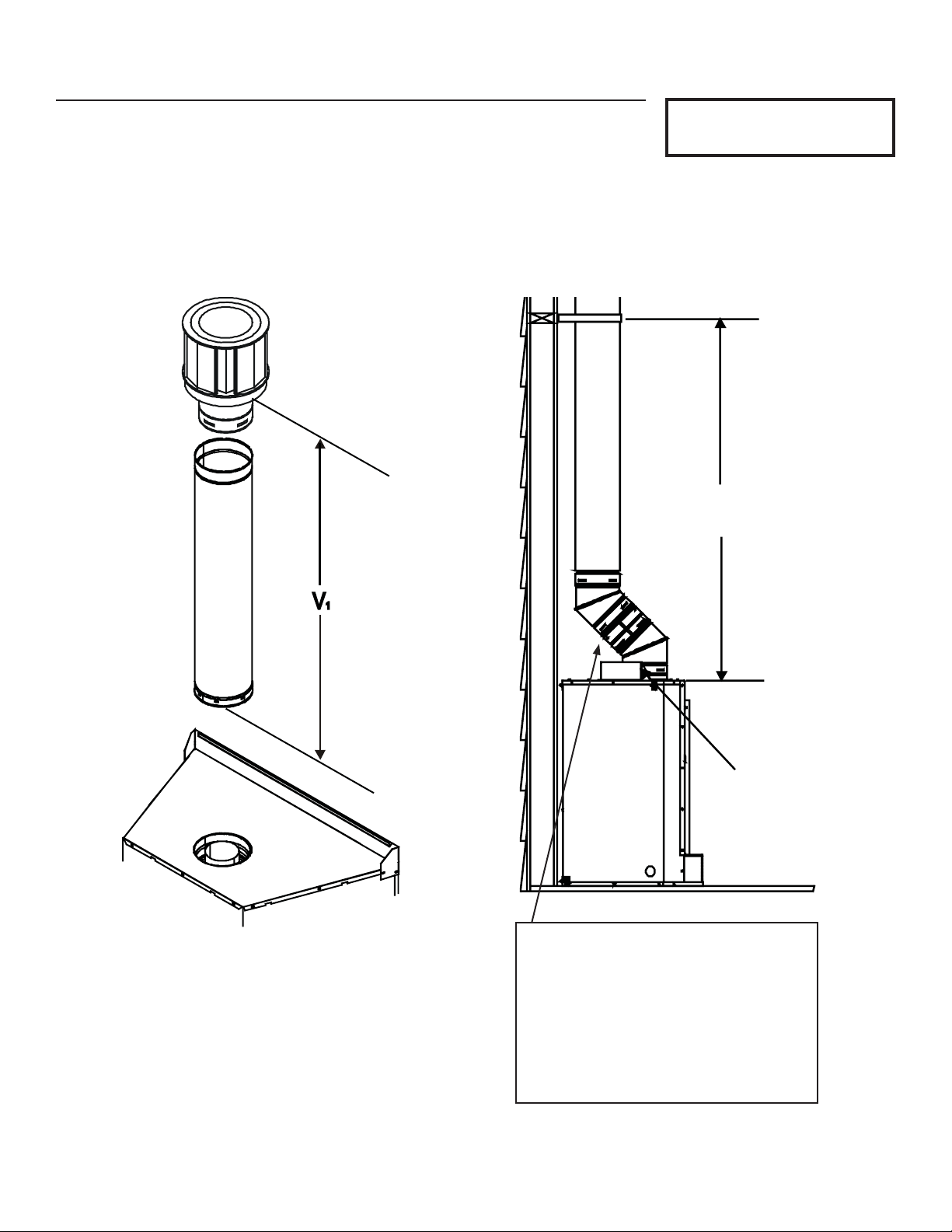

1. Top Vent - Horizontal Termination

One Elbow

WARNING

V1 Minimum H1 Maximum

3 ft. 0.9 m 2 ft. 0.6 m

4 ft. 1.2 m 4 ft. 1.2 m

5 ft. 1.5 m 6 ft. 1.8 m

12 ft. 3.7m 20 ft. 6.1 m

+ H1 = 40 ft. (12.2 m) Maximum

V

1

H1 = 20 ft. (6.1 m) Maximum

Note: When installing the TAOS surround

and venting with one elbow, a straight section of venting (30 in. minimum) MUST be

attached directly to starting collars on unit.

Figure 5.3

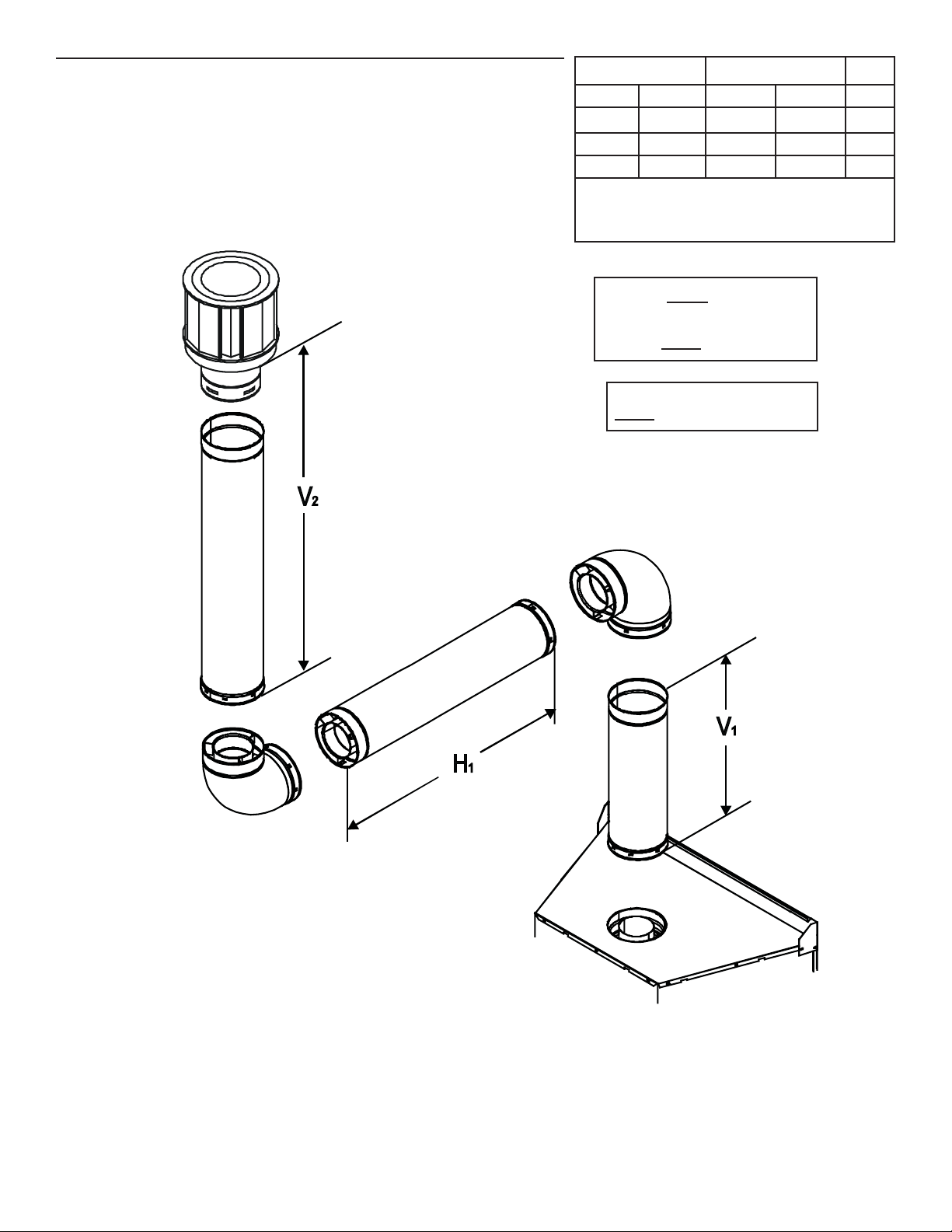

Two Elbows

Note: The fi rst elbow used MUST always

be DVP90ST.

V1 Minimum H1 + H2 Maximum

3 ft. 0.9 m 2 ft. 0.6 m

4 ft. 1.2 m 4 ft. 1.2 m

5 ft. 1.5 m 6 ft. 1.8 m

12 ft. 3.7 m 20 ft. 6.1 m

V1 + H1 + H2 = 40 ft. (12.2 m) Maximum

H1 + H2 = 20 ft. (6.1 m) Maximum

Note:

V

MUST be a minimum

of 3 feet unless using the TAOS

surround. For TAOS surround, V

minimum MUST be 30 in.

Note: The first elbow used

MUST always be DVP90ST.

1

1

Figure 5.4

Heat & Glo • Bravo • 704-902 Rev. F • 10/08 13

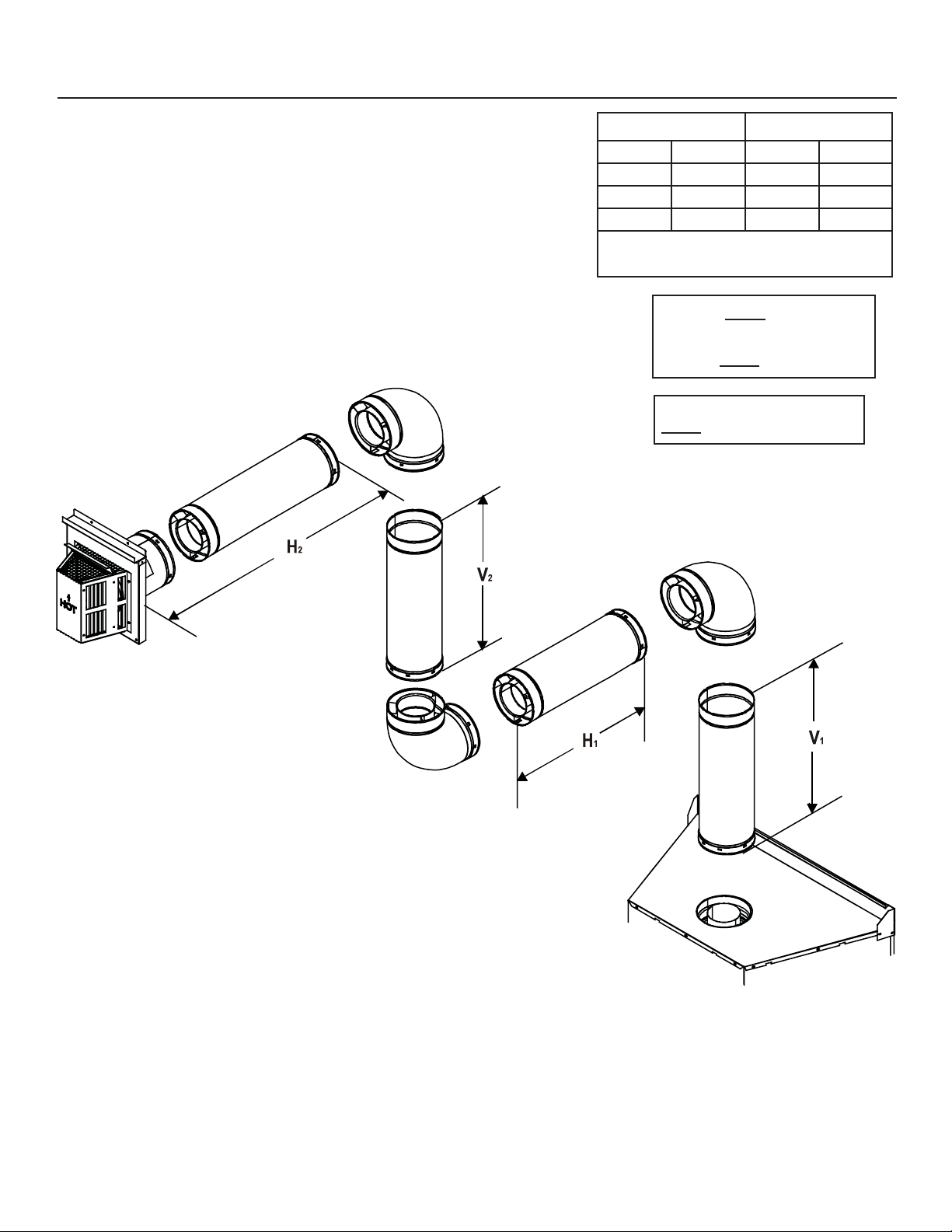

1. Top Vent - Horizontal Termination - (continued)

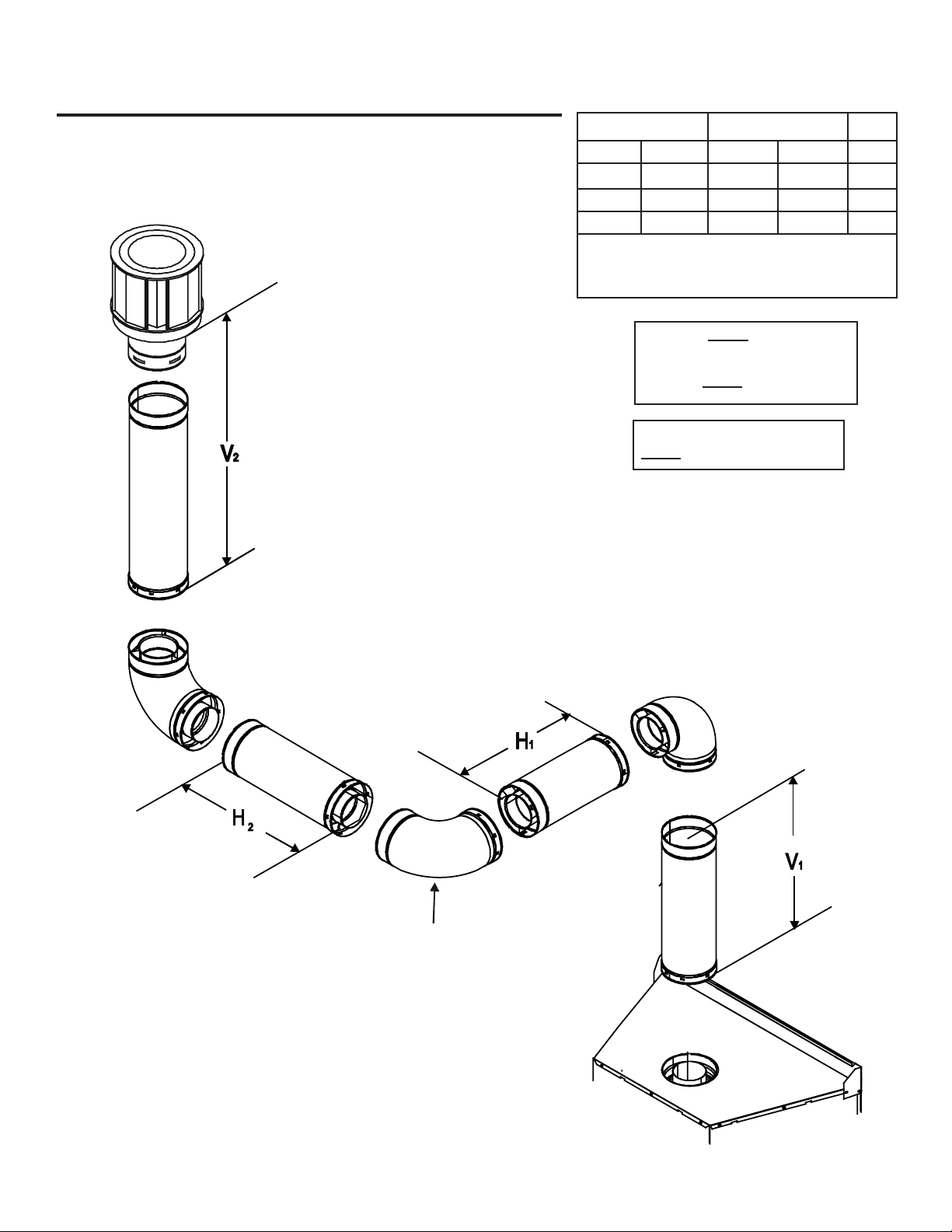

Three Elbows

V1 + V

Minimum H1 + H2 Maximum

2

3 ft. 0.9 m 2 ft. 0.6 m

4 ft. 1.2 m 4 ft. 1.2 m

5 ft. 1.5 m 6 ft. 1.8 m

12 ft. 3.7 m 20 ft. 6.1 m

V1 + V2 + H1 + H2 = 40 ft. (12.2 m) Maximum

H1 + H2 = 20 ft. (6.1 m) Maximum

Note: V1 MUST be a minimum

of 3 feet unless using the TAOS

surround. For TAOS surround, V

minimum MUST be 30 in.

1

Note: The first elbow used

MUST always be DVP90ST.

Figure 5.5

Heat & Glo • Bravo • 704-902 Rev. F • 10/0814

2. Top Vent - Vertical Termination

No Elbow

V1 = 46 ft. Max. (14.0 m)

8 F T.

(2.4mm)

Figure 5.6

FLUE

OUTLET

Note: A 45° elbow may be attached

directly to starting collars on unit only

if used in conjunction with a return 45°

elbow AND terminating vertical with V =

8 feet MINIMUM.

A straight section of pipe can be used

between the two 45° elbows.

Heat & Glo • Bravo • 704-902 Rev. F • 10/08 15

Two Elbows

V1 Minimum H1 Maximum V

3 ft. 0.9 m 2 ft. 0.6 m *

4 ft. 1.2 m 4 ft. 1.2 m *

5 ft. 1.5 m 6 ft. 1.8 m *

12 ft. 3.7 m 20 ft. 6.1 m *

V

+ V2 + H1 = 40 ft (12.2 m) Maximum

1

*No specifi c restrictions on this value EXCEPT

V1 + V2 + H

Note:

of 3 feet unless using the TAOS

surround. For TAOS surround, V

minimum MUST be 30 in.

Note: The first elbow used

MUST always be DVP90ST.

cannot exceed 40 ft (12.2 m)

1

V

MUST be a minimum

1

1

2

Figure 5.7

Heat & Glo • Bravo • 704-902 Rev. F • 10/0816

2. Top Vent - Vertical Termination - (continued)

Three Elbows

V1 H

+ H

1

2

3 ft. 0.9 m 2 ft. 0.6 m *

4 ft. 1.2 m 4 ft. 1.2 m *

5 ft. 1.5 m 6 ft. 1.8 m *

12 ft 3.7 m 20 ft. 6.1 m *

+ H2 = 20 ft (6.1 m) Maximum

H

*No specifi c restrictions on this value EXCEPT

1

V1 + V2 + H1 + H

= 40 ft (12.2 m) Maximum

2

Note: V1 MUST be a minimum

of 3 feet unless using the TAOS

surround. For TAOS surround, V

minimum MUST be 30 in.

1

Note: The first elbow used

MUST always be DVP90ST.

V

2

Figure 5.8

INSTA LLE D

HORIZONTALLY

Heat & Glo • Bravo • 704-902 Rev. F • 10/08 17

6

6

Vent Clearances and Framing

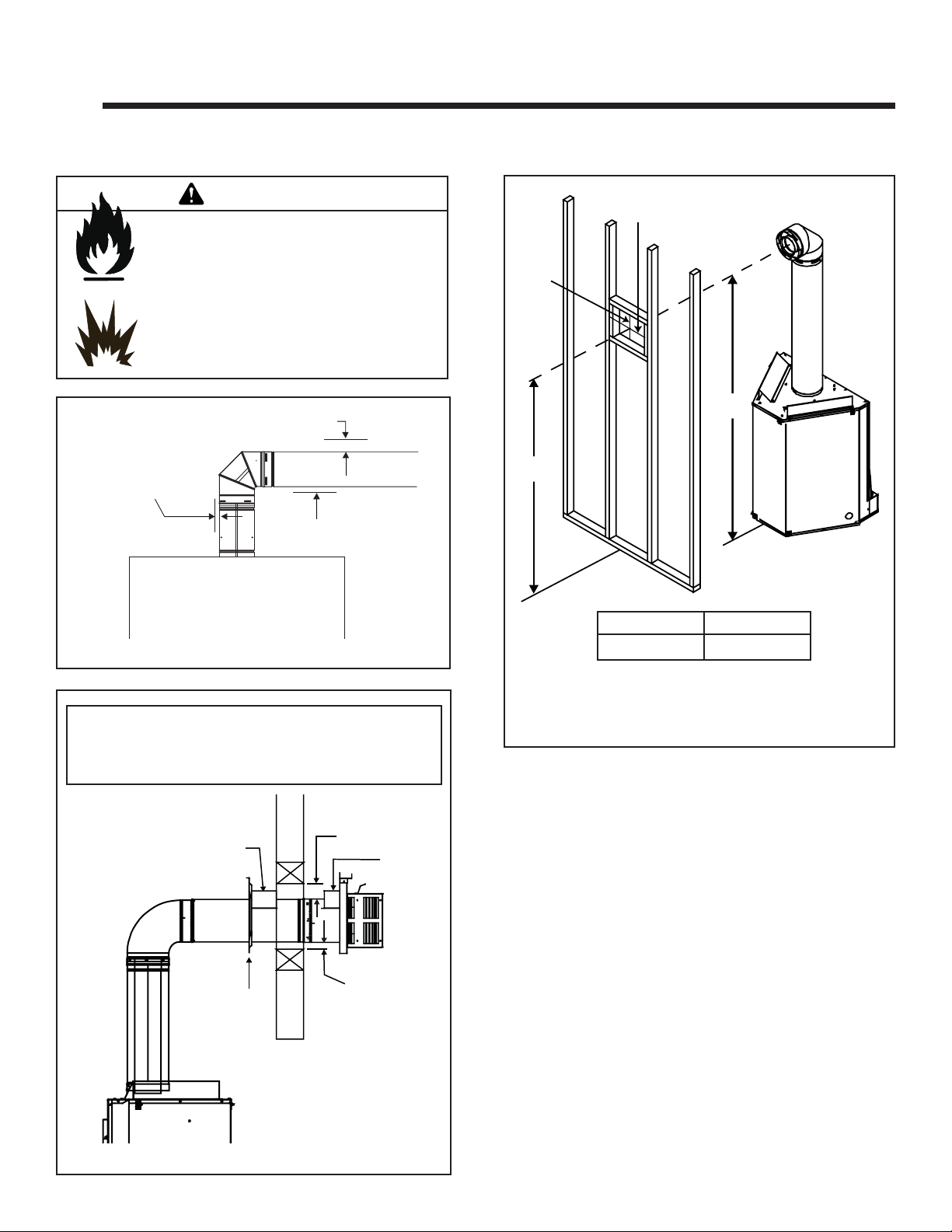

A. Pipe Clearances to Combustibles

WARNING

Fire Risk.

Explosion Risk.

Maintain vent clearance to combustibles as

specifi ed.

• Do not pack air space with insulation or

other materials.

Failure to keep insulation or other materials

away from vent pipe may cause fi re.

3 in. TOP

CLEARANCE

1 in. CLEARANCE

AROUND VERTICAL

SECTIONS

1 in. SIDE AND

BOTTOM CLEARANCE

B. Wall Penetration Framing

10 in.

12 in.

B

A

Figure 6.1 Pipe Clearances

Note: Heat shields MUST overlap by a minimum of 1-1/2 in. (38 mm).

The heat shield is designed to be used on a wall 4 in. to 7-1/4 in. (102

mm to 184 mm) thick. If wall thickness is less than 4 in. (102 mm) the

existing heat shields must be fi eld trimmed. If wall thickness is greater than

7-1/4 in. (184 mm) a DVP-HSM-B will be required.

3in.TOP

HEAT

SHIELD

SHIELD

FIRESTO P

WALL

WALL

CLEARANC E

HEAT

SHIELD

1in.CLEARANCE

BOTTOM & SIDES

A* B

87-3/4 in. 86-3/4 in.

* Shows center of vent framing hole for top venting. The

center of the hole is one (1) inch (25.4mm) above the

center of the horizontal vent pipe.

Figure 6.3 Exterior Wall Hole

Combustible Wall Penetration

Frame a hole in a combustible wall for an interior wall

shield fi restop, (Figure 6.2) whenever a wall is penetrated.

Use same size framing materials as those used in the wall

construction. The wall shield fi restop maintains minimum

clearances and prevents cold air infi ltration.

Non-Combustible Wall Penetration

If the hole being penetrated is surrounded by noncombustible materials such as concrete, a hole with diameter one

inch greater than the pipe is acceptable.

Whenever a non-combustible wall is penetrated, the wall

shield fi restop is only required on one side and no heat

shield is necessary.

If your local inspector requires the wall shield fi restop on

both sides, then both wall shield fi restops must have a heat

shield attached to them.

Figure 6.2 Horizontal Venting Clearances to Combustible Materials

Heat & Glo • Bravo • 704-902 Rev. F • 10/0818

Loading...

Loading...