Heatcraft Refrigeration Products H-IM-UC User Manual

Installation and

Operations Manual

H-IM-UC August 2008 Part No. 25008201

Replaces None. Information formerly included in H-IM-64L

Unit Coolers

Table of Contents

General Safety Information .................................................................. 2

Inspection ................................................................................................2

Warranty Statement ............................................................................... 2

Placement .............................................................................................3-4

Defrost Troubleshooting ....................................................................... 4

Condensate Drain Lines ........................................................................5

Field Wiring .............................................................................................. 5

H-IM-UC-0808 | Version 000

Check Out and Start Up ......................................................................... 5

Operational Check Out .......................................................................... 6

Evaporator Superheat ...........................................................................6

Expansion Valve Selection .................................................................... 7

Evaporator Troubleshooting ................................................................8

InterLink Replacement Parts ................................................................ 8

Installation and Operations Manual

General Safety Information

1. Installation and maintenance to be performed only

by qualied personnel who are familiar with this type

of equipment

2. Some units are pressurized with dry air or inert gas.

All units must be evacuated before charging the system

with refrigerant.

WARNING: Refrigerant can be harmful if it is inhaled. Refrigerant must be used and recovered responsibly.

Failure to follow this warning may result in personal injury or death.

Inspection

Responsibility should be assigned to a dependable individual at the

job site to receive material. Each shipment should be carefully checked

against the bill of lading. The shipping receipt should not be signed

until all items listed on the bill of lading have been accounted. Check

carefully for concealed damage. Any shortage or damages should

be reported to the delivering carrier. Damaged material becomes the

delivering carrier’s responsibility, and should not be returned to the

manufacturer unless prior approval is given to do so. When uncrating,

care should be taken to prevent damage. Heavy equipment should be

left on its shipping base until it has been moved to the nal location.

Check the serial tag information with invoice. Report any discrepancies

to your Heatcraft Refrigeration Products Sales Representative.

Warranty Statement

Seller warrants to its direct purchasers that products, including Service

Parts, manufactured by SELLER shall be of a merchantable quality, free

of defects in material or workmanship, under normal use and service

for a period of one (1) year from date of original installation, or

eighteen (18) months from date of shipmen

rst occurs. Any product covered by this order found to Seller’s

satisfaction to be defective upon examination at Seller’s factory will

at SELLER’s option, be repaired or replaced and returned to Buyer

via lowest common carrier, or SELLER may at its option grant Buyer

a credit for the purchase price of the defective article. Upon return

of a defective product to SELLER’s plant, freight prepaid, by Buyer,

correction of such defect by repair or replacement, and return freight

via lowest common carrier, shall constitute full performance by SELLER

of its obligations hereunder.

SELLER shall have no liability for expenses incurred for repairs made by

Buyer except by prior, written authorization. Every claim on account

of breach of warranty shall be made to SELLER in writing within the

warranty period specied above – otherwise such claim shall be

deemed waived. Seller shall have no warranty obligation whatsoever

if its products have been subjected to alteration, misuse, negligence,

free chemicals in system, corrosive atmosphere, accident, or if

operation is contrary to SELLER’s or manufacturer’s recommendations,

or if the serial number has been altered, defaced, or removed.

Seller makes no express warranties except as noted above. All implied

warranties are limited to the duration of the Express Warranty. Liability

for incidental and consequential damages is excluded.

The forgoing is in lieu of all other warranties, express or implied,

notwithstanding the provisions of the uniform commercial code, the

Magnuson-Moss Warranty - Federal Trade Commission Improvement

Act, or any other statutory or common law, federal or state.

t by SELLER, whichever

3. Make sure that all eld wiring conforms to the requirements

of the equipment and all applicable national and local codes.

4. Avoid contact with sharp edges and coil surfaces.

They are a potential injury hazard.

5. Make sure all power sources are disconnected before any

service work is done on units.

SELLER makes no warranty, express or implied, of tness for any

particular purpose, or of any nature whatsoever, with respect

to products manufactures or sold by seller hereunder, except as

specically set forth above and on the face hereof. It is expressly

understood and agreed that SELLER shall not be liable to buyer,

or any customer of buyer, for direct or indirect, special, incidental,

consequential or penal damages, or for any expenses incurred by

reason of the use or misuse by buyer or third parties of said products.

To the extent said products may be considered "consumer products,"

As dened in Sec. 101 of the Magnuson-Moss Warranty - Federal

Trade Commission Improvement Act, SELLER makes no warranty of

any kind, express or implied, to "consumers," except as specically set

forth above and on the face hereof.

The following conditions should be adhered to when installing

this unit to maintain the manufacturers warranty:

(a) System piping must be in accordance with good

refrigeration practices.

(b) Inert gas must be charged into the piping during

brazing.

(c) The power supply to the unit must meet the

following conditions:

A. Three phase voltages must be +/ 10% of nameplate ratings. Single

phase must be within +10% or

-5% of nameplate ratings.

B. Phase imbalance cannot exceed 2%.

(d) All control and safety switch circuits must be

properly connected according to the wiring diagram.

(e) The factory installed wiring and piping must not be

changed without written factory approval.

(f) All equipment is installed in accordance with

Heatcraft Refrigeration Products specied minimum

clearances.

© 2008 Heatcraft Refrigeration Products LLC

2

Unit Coolers

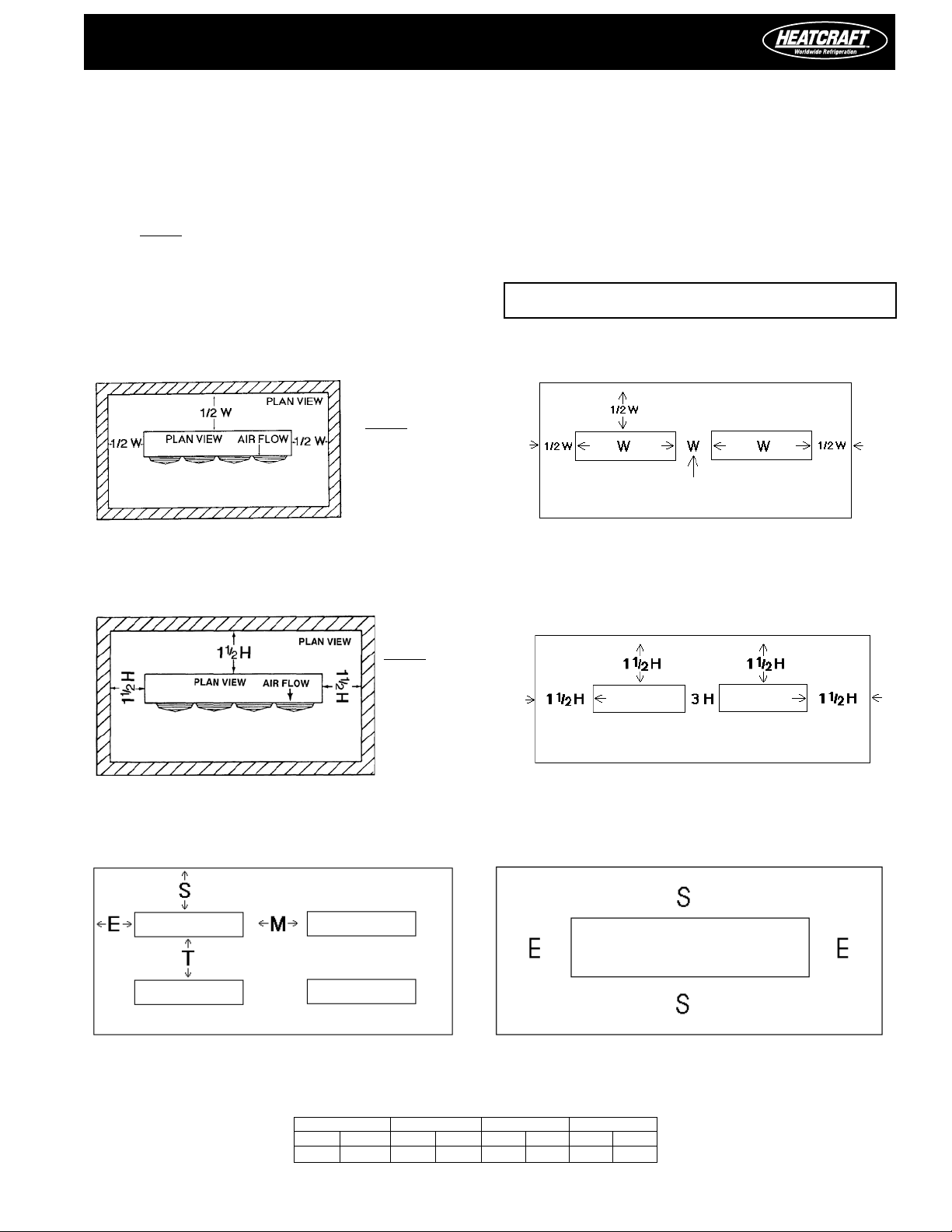

Recommended Unit Cooler Placement

Some general rules for evaporator placement which must be

followed are:

1. The air pattern must cover the entire room.

2.

NEVER locate evaporators over doors.

3. Location of aisles, racks, etc. must be known.

4. Location relative to compressors for minimum pipe runs.

5. Location of condensate drains for minimum run.

Minimum Unit Clearances

Figure 1. Medium Prole and Large Unit Coolers

NOTE:

W = Total width

of evaporator

coil surface.

The size and shape of the storage will generally determine the

type and number of evaporators to be used and their location.

The following are some typical examples:

NOTE: Leave space equal to unit height between bottom of unit

and product. Do not stack product in front of fans.

One evaporator

Figure 2. Low Prole Unit Coolers

One evaporator

Figure 3. Center Mount Unit Coolers

Two evaporators

NOTE:

H = Total height

of evaporator

coil surface.

Two evaporators

Recommended Maximum - Minimum Dimensions for

Center Mount Unit Cooler Installations.

E S M T

Max. Min. Max. Min. Max. Min. Max. Min.

25' 2' 20' 3' 40' 3' 40' 6'

3

Loading...

Loading...